Page 1

Page 2

CPK

Page 3

Contents

Point no. Description Page no.

1 General 1

1.1 Handling 1

2 Installation (on site) 1

2.1 Foundation 1

2.2 Base frame and Pump 1

2.3 Alignment of pump and driver 1

2.4 Connecting the piping 1

2.4.1 Auxiliary connections 2

2.4.2 Vacuum balance line 2

2.5 Coupling guard 2

2.6 Measuring Instruments 2

2.7 Final check 2

3 Commissioning, Start-up/Shutdown 2

3.1 Preliminary remarks regarding

commissioning 2

3.1.1 Lubricants 2

3.1.2 Shaft seal 2

3.1.2.1 Stuffing box 3

3.1.2.2 Shaft seal 3

3.1.2.3 Cooling to casing cover 3

3.1.2.4 Packing the stuffing box 3

3.1.2.5 Packing material 4

3.1.2.6 Sealing liquid 4

3.1.3 Alternate packing arrangement available 4

3.1.4 Checking the direction of rotation 4

3.2 Start-up 4

3.3 Shut down 4

4 Maintenance and lubrication 4

4.1 Supervision of operation 4

4.2 Bearings and lubrication 5

4.2.1 Lubricant quantities 5

4.2.2 Oil changes 5

4.2.3 Procedure 5

4.3 Preservation 5

5 Special instructions 5

5.1 General precautions 5

5.2 Dismantling 5

5.2.1 Soft-packed stuffing box 5

5.2.2 Mechanical seal stuffing box 6

5.3 Reassembly 6

5.3.1 Reassembly of stuffing box packing 6

5.3.2 Reassembly of mechanical seal 7

5.4 Cooling / heating 7

5.5 Spares 8

5.5.1 Ordering spare parts 8

CPK

6 Interchangeability of pump components 9

7 Recommended stock of spare parts

for 2 years of operation 10

8 Faults 10

8.1 Faults, causes and suggested remedies 10

8.2 Cause-Remedy 10

9 Sectional drawing & part list 12

9.1 Sectional drawing of CPK Y pumps 13

Annexure I 14

Annexure II 16

Annexure III 16

Annexure IV 17

Page 4

CPK

1. General

Your centrifugal pumps will give you completely trouble free

and satisfactory service on condition that it is installed with

due care and properly maintained. It is absolutely essential

that the instructions contained in this manual be scrupulously

observed and that the pumps are not operated under conditions

which differ from those specified under our ‘Operating

Conditions’. This operating instruction manual does not take

any account of any safety regulation which may apply to the

installation site, and the Site Engineer or Site Operator is

responsible for notifying our erection staff of any such

regulations and seeing that they are complied with.

The pump type size, main operating data and works order

number are stamped on the name plate affixed to the pump.

Please make sure to quote this information every time you

write to us in respect of queries, repeat orders and particularly

when ordering spare parts.

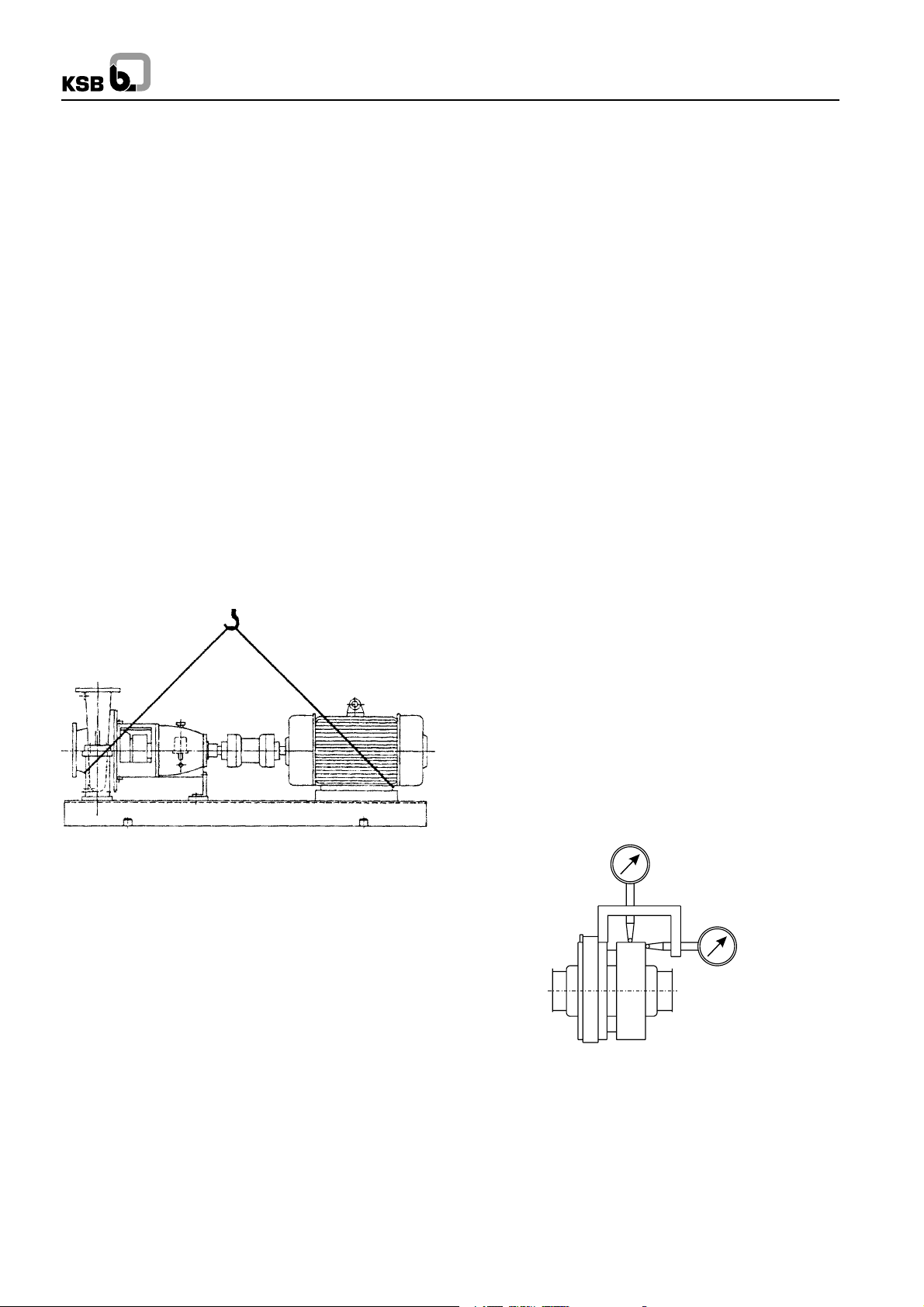

1.1 Handling

The Pump set should be properly handled and slung for

transport. Do not thread the ropes through the eye bolt on the

motor. (See Fig. 1)

During handling do not remove the rubber blankings provided

on the suction and discharge nozzles.

Fig. 1 : Pump and driver mounted on a combined baseplate

6. Grout the foundation bolts and the packer plate (if

applicable) by using quick setting non-shrink cement,

ACC make “Shrinkkomp” or FORSORC make

“Conbextra-GP2” or equivalent.

7. Allow curing time of 24 to 72 hours depending upon the

grout used.

8. Remove bolts which are holding packer plates with the

base frame (if applicable).

9. Carry out final levelling by inserting shims (S.S. Shims

preferred) between packer plates and base frame (if

applicable).

10. Tighten the foundation bolts and recheck the levelling.

Correct it, if necessary.

11. Grout the complete base frame, including hollow portion,

if any, using conventional grouting mix i.e. portland

cement, sand and aggregate in proportion 1:2:4 and

gravel size not exceeding 20 mm.

12. Plaster the foundation and apply suitable oil resistant

paint.

For figures refer Annexure I.

2.3 Alignment of pump and driver

Accurate coupling alignment requires a coupling alignment

jig. This can be manufactured from 20 x 20 mm steel flat. The

jig should be attached to the shafts. See Fig. 2.

The coupling can be considered correctly aligned with the aid

of the jigs illustrated if the difference measured does not

exceed 0.1 mm both in the radial and axial directions,

measurements being taken in 4 planes at 900 intervals.

Alignment should be checked when the pump is hot

(applicable for pump handling hot fluids), In case any deviation

is found, please check the pipe lines and or realign the pump.

The coupling alignment check should be repeated after the

piping has been connected to the pump to ensure stress free

piping. Prior to alignment, individual concentricity of coupling

should be checked. It should be within 0.03 mm. If not,

corrective action should be taken. The coupling should be

dynamically balanced in accordance with VDI 2060 (ISO

1940)/G6.3 for motor driven pumps and G2.5 for turbine driven

pumps.

2. Installation (on site)

2.1 Foundation

Make sure that the concrete foundation has set firmly before

placing the base frame along with the pump set or pump on

it. The surface of the foundation should be truly horizontal and

perfectly flat. The foundation bolts should be suspended in

the baseplate.

2.2 Base Frame and Pump

Procedure

1. Bolt the Pump on the base frame.

2. Bolt the packer plates on the bottom pads of the base

frame, if applicable.

3. Place the unit on the foundation.

4. Suspend the foundation bolts in the pockets provided on

the foundation block.

5. Level the pump on the delivery flanges or feet within 0.2

mm per mtr., using jacking bolts provided on the corners

of the base frame.

Fig. 2 : Alignment of coupling

2.4 Connecting the piping

Never use the pump itself as an anchor point for the piping.

Suction lift lines should be laid with a rising slope towards the

pump and suction head line with a downward slope towards

the pump. The pipelines should be anchored in close proximity

to the pump and should be connected to the latter without

transmitting any stress or strain, nor should the weight of the

piping be loaded on to the pump. The nominal sizes of the

1

Page 5

pipelines should be at least equal to the nominal sizes of the

V

B

C

E

R

ZA

Pump

pump nozzle. In case the suction pipeline size is bigger, the

connection should be done by means of an eccentric reducer,

in order to avoid air pockets. We recommended the

incorporation of check valves or non return valves and

isolating valves in the system, depending on the type of

installation and pump. Any thermal expansion of the piping

(due to high temperatures) must be compensated by suitable

means, so as not to impose any additional load on the pump.

CPK

A Main isolating valve R Check valve

B Vacuum balance line V Vessel under vacuum

C Isolating valve Z Intermediate flange

E Vacuum-tight isolating valve

Fig. 5 Suction line and vacuum balance line

Fig. 3

Fig. 4

2.4.1 Auxiliary Connections

The auxiliary connections required for your pump (cooling,

heating, sealing liquid, flushing liquid etc. as the case may

be) are indicated in the installation drawing and on the piping

diagram in respect of size and location.

2.4.2 Vacuum Balance Line

If the pump has to pump a liquid out of a vessel under vacuum,

it is advisable to install a vacuum balance line. This line should

have a nominal size of 25 mm at least. It should be arranged

to lead back into the vacuum vessel at a point above the

highest permissible liquid level. An additional line starting at

the pump discharge nozzle facilitates venting of the pump

before start up. The vacuum-tight isolating valve E in this

connecting line should be closed after the venting procedure

& should remain closed while the pump is running. The main

isolating valve C in the vacuum balance line must remain

open at all times when the pump is running and should be

closed when the pump is shutdown. Refer Fig. 5.

2.5 Coupling Guard

In compliance with the accident prevention regulations, the

pump may only be operated if it is fitted with a coupling guard.

If the customer states specifically that coupling guard is not to

be supplied by KSB, it must be provided by the pump operator.

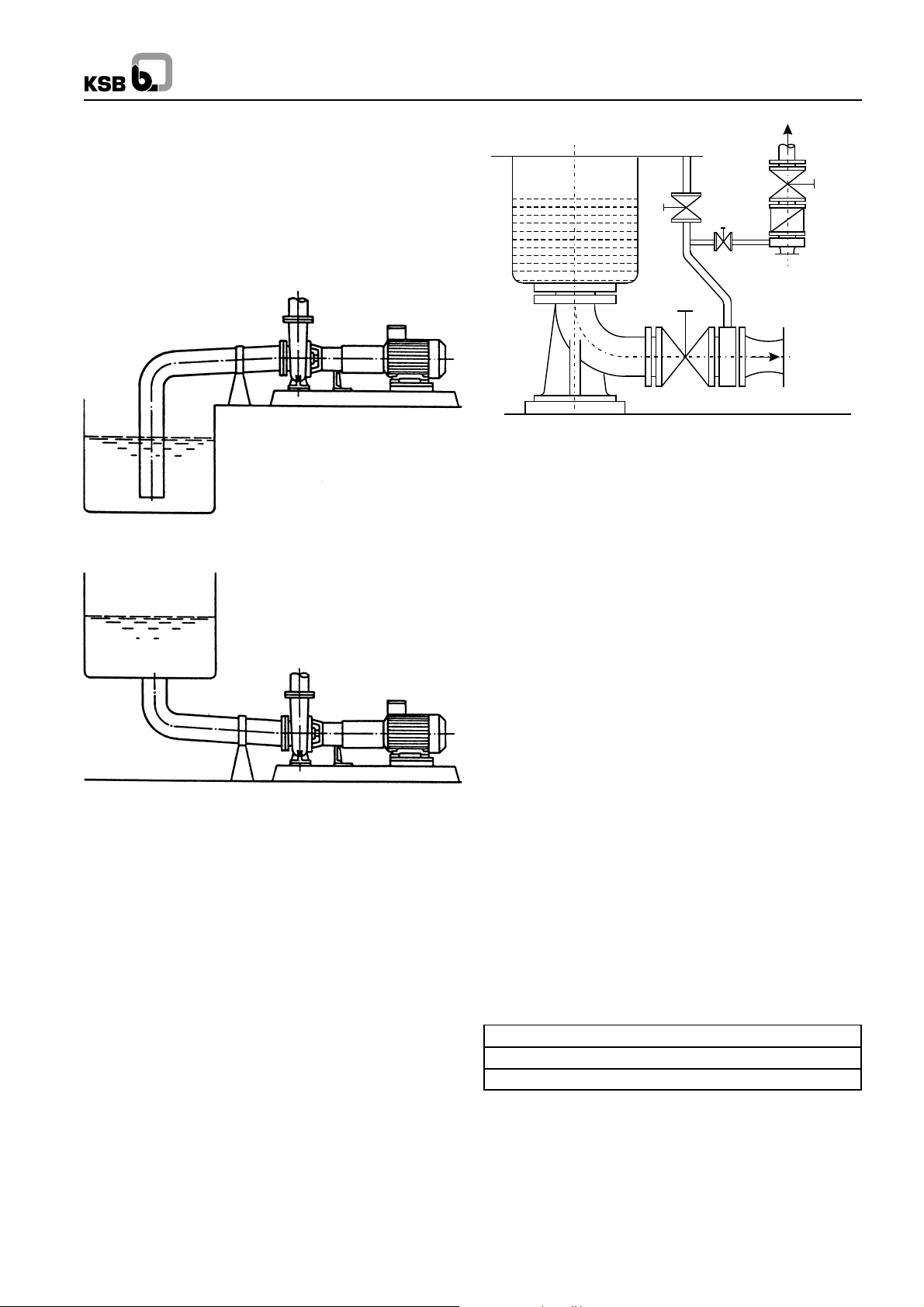

2.6 Measuring Instruments

Each pump should be equipped with two pressure gauges,

one at the suction nozzle and the other at the discharge nozzle.

Their measuring range should be suitable for the prevalent

pressure conditions, and they should be provided with a stop

cock or stop valve. If the suction conditions demand (e.g.

suction lift operation), the gauge on the suction nozzle should

be pressure vacuum gauge.

2.7 Final check

Check the alignment once more as described in section 2.3. It

must be possible to rotate the pump rotor freely without

additional effort by hand at the coupling.

3. Commissioning, Start-up/Shutdown

3.1 Preliminary remarks regarding commissioning

3.1.1 Lubricants

The bearing bracket should be filled with oil of any one of the

following types and specifications :

Indian Oil : Servosystem 46

Hindustan Petroleum : Enklo 46

Bharat Petroleum : Bharat Hydrol 46

If some other make of oil is used the properties of the oil should

be as follows.

Kinematic viscosity : 46 +4mm2/s at 40 0C

Flash point : +175 0C

Solidification point : 15 0C

Applicable temperature : Higher than permissible bearing

temperature

for 10 0C contact KSB

2

Page 6

CPK

Oil level in bearing

bracket and connection elbow

Drain

plug

Vent or filler

plug

cooling (pH =~ 7). The maximum pressure of cooling water is

10 bar. The cooling water quantities are specified in lpm for

∆t = 150C in Table No. 1.

Inlet temp. : 100C to 300C

Outlet temp. : 450C max.

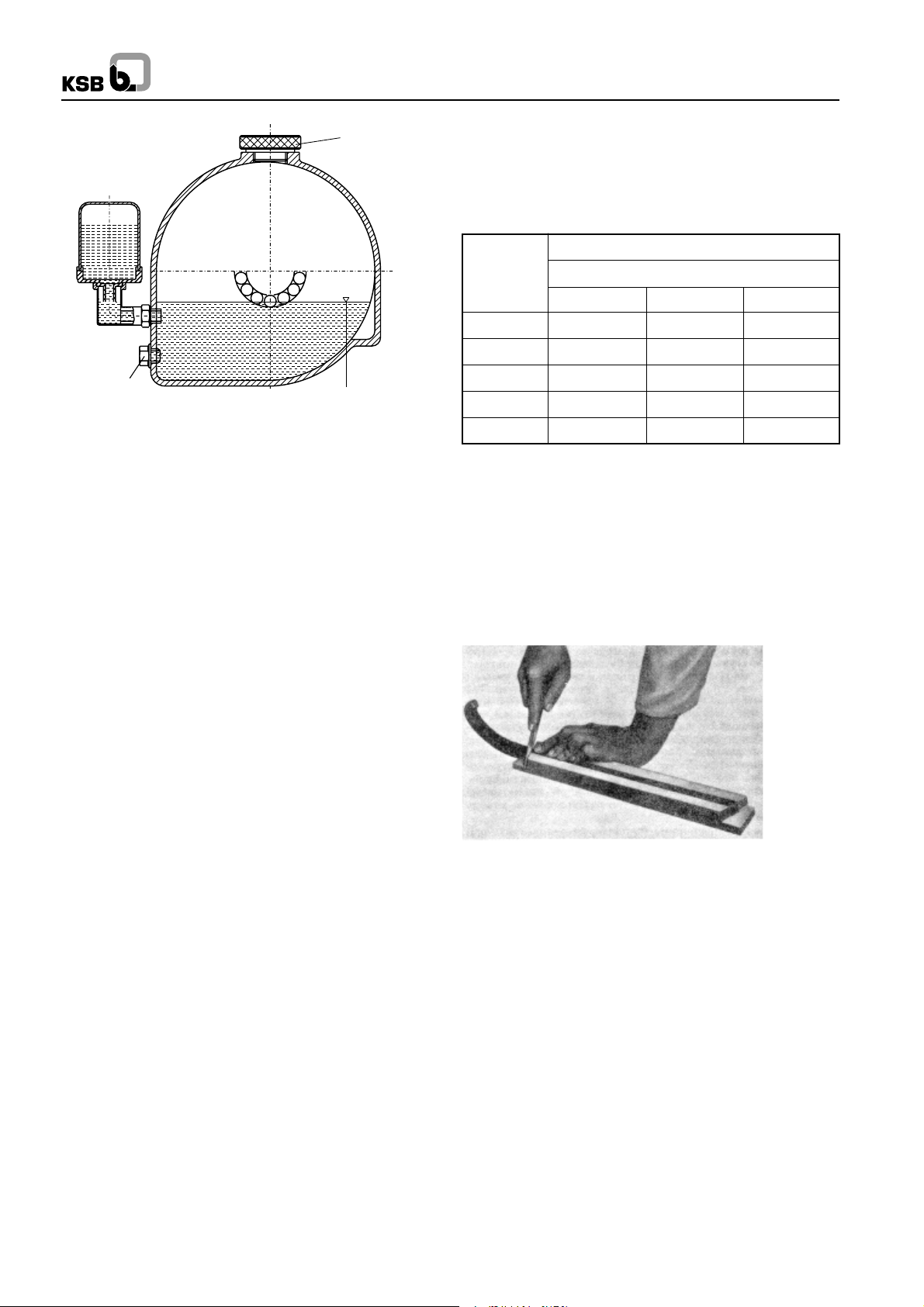

Fig. 6 : Oil fill

Procedure

Unscrew vent plug. Pour in oil through the vent plug aperture

after removing the reservoir of the constant level oiler, until oil

appears in the vertical portion of the connection elbow of the

constant level oiler (see fig. 6).

Then fill the reservoir of the constant level oiler with oil and fit

it back into operating position. Screw vent plug in again. After

a short time has elapsed, check whether the oil level in the

reservoir has sunk. The reservoir should always remain filled.

If the vent plug is inaccessible or difficult to reach e.g. the oil

can be filled into the bearing bracket through the connection

elbow of the constant level oiler.

Bearing

Bracket

P 25/62 5 6 8

P 35/80 6 8 9

P 45/120 9 11 12

P 55/140 12 14 15

P 65/160s 15 17 18

Quantity of cooling water in LPM

Temperature of pumping liquid

Up to 1500C 1500 to 2500C above 2500C

3.1.2.4 Packing the Stuffing Box

Caution :

The pump is despatched from our Works with the stuffing box

packed.

Before repacking, thoroughly clean stuffing box gland (452),

packing compartment and shaft protection sleeve (524).

Cut the packing rings to correct length and ends at 45º. Ensure

that the packing rings ends come into contact with one another

on fitment. (See Fig. 7)

Caution :

The oil level should always be situated below the level of the

vent slot arranged at the top edge of the connection elbow

and this slot should always be perfectly dry. Do not tighten the

elbow by applying force on the reservoir use lock nut for this

purpose.

3.1.2.1. Stuffing Box

The shaft is sealed at its exit through the casing by soft packed

stuffing box or a mechanical seal. Change over from gland

packing execution and vice verca is possible by using

conversion kit. For details refer KSB.

3.1.2.2 Shaft Seal

Soft-packed stuffing box reduce the flow of leakage liquid at

the clearance gap between casing cover and shaft protection

sleeve when the pressure inside the pump is higher than

atmospheric. Conversely, on pumps which operate on suction

lift pressure, the soft-packed stuffing box prevents the ingress

of air into the pump. Sealing is effected by means of soft

packings arranged in a number of rings in the annular space

between the casing cover (161) and the shaft protection sleeve

(524) and lightly compressed by the stuffing box gland (452).

Refer Fig. 8.

3.1.2.3 Cooling of Casing Cover

The casing cover jacket of soft packed stuffing boxes must be

cooled if the temperature of pumped fluid exceeds 900C.

Clean, clear and non aggressive water is recommended for

Fig. 7 : Cutting the packing rings to length.

If the packing rings are either too long or too short, the stuffing

box will not be able to perform its function properly. In the case

of asbestos-graphite packing material, the rubbing faces of

the individual rings should be lightly coated with Molykote

before insertion in the packing compartment. The first packing

ring is then inserted and pushed home into the compartment

with aid of the stuffing box gland (452).

The following packing rings are then inserted into the packing

compartment one by one, making sure that the butt joint of

each ring is offset by 900 approx. in relation to the butt joint of

the preceding ring. The individual rings are pushed home

into the packing compartment with the aid of the stuffing box

gland (452). The packing rings should only be pressed lightly

against one another. They should be inserted in the packing

compartment in such a way that a clear gap of 6 to 8 mm is left

at the outer end of the compartment for the positive guidance

of the stuffing box gland (452).

The inserted packing rings should then be compressed

moderately with the aid of the stuffing box gland (452) and the

nuts (920.03). Then the nuts (920.03) should be slackened

3

Page 7

CPK

again by one to two complete turns, and thereafter tightened

lightly by hand. The correct and even seating of the stuffing

box gland (452) should be checked when the pump is

subjected to suction pressure, by inserting a feeler gauge

between the stuffing box gland (452) and the shaft protection

sleeve (524).

In the case of the special stuffing boxes, a lantern ring is also

inserted in the packing compartment, at the centre of the

compartment (between the packing rings). In these cases,

an information plate is affixed to the casing cover (161),

showing the position of the lantern ring. The lantern ring must

register beneath the drilled hole in the casing cover (161), to

enable the sealing liquid to enter. The pressure of the liquid

should be 1 to 4 bar above the pressure existing in the packing

compartment of the stuffing box.

The packing of the stuffing box should be carried out with

great care, to avoid an excessively high radial pressing force

of the packing rings against the shaft protection sleeve, which

might damage the latter. If the shaft protection sleeve is scored

or grooved, even a new packing cannot be expected to last

very long in service.

A newly packed stuffing box should leak profusely at first. If

this leakage does not cease of its own after a relatively short

period of operation, the nuts on the stuffing box (452) gland

should be tightened slowly and evenly while the pump is

running, until the stuffing box only drips slightly. Make sure

that the stuffing box gland (452) is tightened evenly and not

askew, as otherwise the shaft protection sleeve (524) might

be damaged.

If the newly packed stuffing box starts to emit smoke when the

pump is started up for the first time, the pump should be

switched off. If the smoking persists after the pump has been

started up again and operated several times in succession,

the nuts on the gland should be slackened slightly, or the

stuffing box should be inspected if necessary.

3.1.2.5 Packing Material

When selecting the packing material, make sure it is

compatible with the fluid pumped (consult the manufacturer

in case of doubt).

must be opened fully and the unimpeded flow through these

lines must be verified. Open the isolating valve in the vacuum

balance line (if applicable to your installation) and close the

vacuum tight isolating valve ‘E”. (see Z fig.5).

3.1.4 Checking the direction of rotation

The direction of rotation must correspond to the arrow on the

pump. This can be checked by switching on the driver for a

short instant and switching it off again immediately. Mount the

coupling guard after checking the direction of rotation.

3.2 Start up

Always make sure that the isolating valve in the discharge

line is closed when the pump is switched on. Only after the

pump has attained full operating speed should the discharge

valve be opened gradually and the operating point conditions

adjusted by means of this valve.

Caution :

After the operating temperature has been attained and/or in

the event of leakage, tighten the Bearing bracket lantern to

casing connection bolts after switching off the pumping set. If

the leakage persists, check/change the gasket.

3.3 Shut down

Close isolating valve in the discharge line. If non-return valve

or a check valve has been incorporated in the discharge line,

the isolating valve can remain open so far as there is a back

pressure present in the line. Switch off driver. Observe the

pumping set running down smoothly and quietly to a standstill.

In the event of a prolonged shutdown, the isolating valve in

the suction lift line should be closed.

The shaft seal of pumps which are connected to a supply

vessel under vacuum must be fed with flushing liquid even

when the pump is switched off. In the event of frost and/or of

prolonged shutdowns, the pump and the cooling

compartments (if applicable) must be drained or otherwise

protected against freezing using suitable antifreeze solution.

4. Maintenance and lubrication

Packing material which has been kept in store for a certain

period has a longer service life than standard fresh packing

material from the packing manufacturer. Packing material fitted

in the pump while despatching are :-

CPK G/GC : Style 1003

E/EC : Style 1003

C : Style 1003

CPK EY : Graphoil

3.1.2.6 Sealing liquid

In case of soft packed pumps working under vacuum, handling

impure liquids, sealing liquid is required to be fed through

lantern ring connection. For this the GA drawing of the pump

should be referred to.

3.1.3 Alternate packing arrangements available

The pump suction lift line must be vented and primed with the

fluid pumped before start up. This valve in the suction lift line

must be fully open. All auxiliary connections provided on your

pump (e.g. flushing liquid, sealing liquid, cooling liquid etc.)

4.1 Supervision of operation

The pump should run quietly and free from vibration at all

times. The pump must never be allowed to run dry. Avoid any

prolonged running against a closed discharge valve.

The bearing temperature may be allowed to attain up to 500C

above room temperature but should not exceed 800C.

Make sure the oil level is adequate (see section 3.1.1). The

isolating valves in the auxiliary feed lines must always remain

open when the pump is running.

The soft packed stuffing box (if your pump has one) should

drip slightly during operation. The stuffing box gland should

only be tightened lightly.

Any standby pumps in the pumping installation should be

operated once a week for a short instant, by switching on and

switching off again, so as to maintain them in good condition

for instant start-up in case of emergency. The correct

functioning of the auxiliary connections should be kept under

observation. When signs of wear become apparent on the

4

Page 8

CPK

flexible coupling elements in the course of time, these element

should be replaced by new ones in good time. Otherwise

unbalance vibration will increase leading to failure of coupling.

It is necessary to maintain a log book on hourly basis, where

the suction and discharge pressure, flow rate, bearing

temperatures (pump end and motor end), motor current and

voltage should be noted.

4.2 Bearings and lubrication

4.2.1 Lubricant quantities

The anti-friction bearings are oil lubricated; Required lubricant

fills for different. brg. bkts are as under :-

Standard Bearing Assembly

Bearing Deep groove ball bearings Oil fill in

bracket 321.01/02 DIN 625/C3 bearing litres

clearance

P25/65 6305 C3 0.2

P35/80 6307 C3 0.5

P45/120 6409 C3 0.5

P55/140 6411 C3 1.5

Heavy duty bearing assembly

Bearing Cylindrical roller Angular contact Oil fill

Bracket bearing 322 ball bearing 320 in litres

P25/62s NU305 C3 7206BG 0.2

P35/80s NU307 C3 7307BG 0.5

P45/120s NU311 C3 7311B.TVP.UA80 0.5

P55/140s NU313 C3 7313B.TVP.UA80 1.5

P65/160s NU413 7315B.TVP.UA80 1.8

Table No. 2 Arrangement of bearings & quantity of oil.

4.2.2 Oil change

The first oil change should be carried out after 300 hours of

operation approx. and subsequent oil changes once every

3000 hours of operation approx. In case of newly replaced

bearings, the oil should be changed after 200 hours of running

and thereafter every 1000 working hours.

4.2.3 Procedure

Unscrew oil drain plug beneath the constant level oiler and

drain off the old oil. When the bearing bracket is empty, replace

the oil drain plug and fill in fresh oil in accordance with

section 3.1.1.

4.3 Preservation

If the pump is taken out of service for a prolonged period, it is

advisable to dismantle it completely. Proceed as described

in section 5.2 “Dismantling”. All components should be

thoroughly cleaned, dried and all bright components coated

with grease. Thereafter the pump should be reassembled.

All apertures on the pump should be plugged with wooden

cover plates fitted with O rings. A sachet filled with silicagel

(silicagel absorbs moisture) should be attached to the inside

faces of the oil soaked wooden cover plates on the suction

and discharge nozzles (i.e. inside the nozzles).

The packing should be removed from the stuffing box

compartment and it should be sealed by oil-soaked wooden

half tubes, each provided with two O-rings, in order to prevent

the penetration of moisture (not applicable to pumps fitted

with mechanical seals).

Caution :

Use acid free oils and greases only, when preserving the

pump.

5 Special Instructions

5.1 General Precautions

Before commencing dismantling .

Make sure that the pump will not be accidentally switched on.

The isolating valves in the suction and discharge line must be

closed.

The volute casing must have cooled down to ambient

temperature. The volute casing must be drained and

pressureless.

Always refer to the relevant sectional drawing when

dismantling and reassembling the pump.

5.2 Dismantling

5.2.1 Soft-packed stuffing box

Refer fig. 8.

1. Drain the oil in accordance with section 3.1.1.

2. Remove the coupling guard.

3. Disconnect coupling spacer, or if no spacer is fitted

remove the driver.

4. Disconnect and remove the auxiliary connections on

your pump.

5. Loop a rope tightly around the top stay of brg bkt. lantern.

6. Unscrew hex head bolt (901.02) and the base frame

fixing bolts of support foot (183) and remove the support

foot.

7. Unscrew hex nuts (920.01) and pull the complete

bearing bracket together with casing cover, shaft,

impeller and bearing bracket lantern out of the volute

casing. Use jack bolts for assistance in doing this having

first cleaned the threads. Take care not to damage

gasket (411.03).

8. Unscrew impeller nut (922) with its Heli-coil insert (right

handed screw thread), remove gasket (411.31) and

washer (551.13), pull off impeller (230), remove key

(940.01).

9. Remove stuffing box gland (452) together with stuffing

box pressure ring (454) after having unscrewed hex

nuts (920.02).

10. Remove Casing cover 161 remove gaskets (411.10) &

O-ring (412.01). Next remove stuffing box packing 461

& lantern ring (458). Then remove neck ring after

unscrewing screws (900).

11. Pull shaft protection sleeve (524) together with gasket

(411.32) & washer (551.32) and splash ring (507) off

the shaft.

12. Unscrew hex nuts (920.02) and remove bearing

bracket lantern, (344).

13. After having unscrewed allen head screw in the

coupling hub, pull the coupling half of the pump shaft

5

Page 9

CPK

with the aid of an extractor device and remove key

(940.02).

14. After having unscrewed Allen head screws (914.01/

02) in coupling hub dismantle bearing covers 360.01

and 360.02 at pump and drive ends together with flat

gaskets (400.01/02), oil seals (421.01/02) / Lantern

rings (423.01/02) as applicable.

14.1 Standard bearing assembly :

14.1.1 Carefully remove the shaft (210) together with deep

groov ball bearing (321.02) out of the bearing bracket.

14.1.2 Heat up the deep groove ball bearings and pull them

off the shaft.

14.2 Heavy duty bearing assembly :

14.2.1 Carefully remove the shaft (210) together with angular

contact ball bearings (320) and inner race of cyl. roller

bearing (322) towards the drive end of the pump.

14.2.3 Remove roller cage of cyl roller brg (322) from the

bearing bracket. Then remove spacer ring (504.2) &

circlip.

14.2.4 Bend back lock washer (931); unscrew bearing nut

(923) (righthanded screw thread) remove lock washer.

14.2.5 Heat up angular contact ball bearings (320) and the

inner race of cylindrical roller bearing (322) and pull

them off the shaft. Remove spacer ring (504.01) (applies

only to bearing bracket size 25/62s).

14.2.6 Clean all the components and examine them for signs

of wear. Touch up the damaged components or replace

them by new ones, if necessary.

5.2.2 Mechanical seal stuffing box :

1. Unscrew hex nuts (920.2) and pushback mechanical

seal cover (471) until it abuts against splash ring (507).

2. Dismantle casing cover 161 together with O - ring 412.1

3. Pull the complete mechanical seal together with shaft

protection sleeve 524, mechanical seal cover 471, and

splash ring 507 off the shaft.

5.3 Reassembly

The pump should be reassembled in accordance with the

rules of sound engineering practice. The fits of individual

components should be coated with graphite or other suitable

lubricants before assembly and the same applies to screwed

connections.

O-rings and radial shaft seal rings should be examined for

signs of damage and replaced by new ones, if necessary.

Flat gasket should in principal be replaced by new ones and

make sure that the thickness of the new gasket is exactly the

same as that of the old one.

Reassembly proceeds in reverse sequence to dismantling.

The following points should be carefully observed.

Use only the bearing types and sizes specified in section

4.2.1. The antifriction bearings 320/321.01/02 and inner race

of antifriction bearing 322 (when applicable) should be

preheated in an oil bath to 800C approx. before being slipped

on to the shaft until they abut against the shaft shoulder.

Caution :

1. For heavy duty bearing bracket, the antifriction bearings

320 must be mounted in O-arrangements (see sectional

drawing) Remember the spacer rings 504.01/02 for

normal/heavy brg bkts.

2. When the bearings 320 have been mounted, the

bearing nut 923 without the lock washer 931, must be

screwed on firmly with the aid of a hook spanner. (Do

not use a hammer).

3. The bearing nut must be removed again, the lock

washer inserted and the bearing nut screwed on firmly

again with the hook spanner (Do not use a hammer).

Bend lock washer forward to lock the nut.

4. Take care not to damage the oil seal rings 421.01/02

(when applicable) when mounting bearing covers

360.01/02.

5. The impeller nut should be tightened firmly. The

impeller nut should be tightened a new some 20 to 30

minutes after the initial tightening. Refer Annexure II

for details of metallic washer fitment in impeller.

6. After assembly into the volute casing which has

remained in situ in the piping the coupling alignment

should be checked (see section 2.3).

7. Fill in oil in accordance with section 3.1.1.

5.3.1 Reassembly of stuffing box packing

Assembly recommendations (when pump is dismantled)

Clamp casing cover 161 in a vice, or keep it on an assembly

table and slip in neck ring 456. Then insert the first packing

ring with its butt joint lying in the horizontal plane.

Hold the packing ring tight and slip the shaft protection sleeve

into the packing compartment from the pump end, chamfered

end first. Open out the internal diameter of the packing ring

slightly with the aid of the shaft protection sleeve by sliding

the latter to and fro. Then pull out the shaft protection sleeve

and insert the second packing ring with its butt joint offset 90

in relation to the butt joint of the first packing ring. Repeat the

opening out process with aid of the shaft protection sleeve.

Then insert lantern ring 458 (if fitted to your pump). Then insert

the remaining packing rings in succession with their butt joints

offset, and repeating the opening out process for each ring.

When the last packing ring has been inserted the shaft

protection sleeve should be left in the packing compartment.

Insert stuffing box ring 454 in such a way that its joint face is at

right angles to the stuffing box gland. Slip stuffing box gland

452 and tighten it lightly only by hand, by means of two hex

nuts 920.02.

Mount the completely packed casing cover together with the

shaft protection sleeve into the pump.

Caution :

The stuffing box should drip slightly when the pump is running.

Any sealing and cooling liquid connections which are in use

must be checked in respect of unimpeded fluid flow from time

to time.

When the stuffing box gland has been tightened repeatedly

(during use) until it abuts, it is time to repack the pump

completely with new packing.

0

6

Page 10

Fig. 8 Stuffing box dimensions

CPK

5.4 Cooling / Heating

Clean, clear and non-aggressive water is recommended for

cooling. Recommended pH value is 7.

Cooling to stuffing box :

Please follow the instruction given in point no. 3.1.2.3.

Sealing liquid / cooling of stuffing box gland :

For stuffing box with packings, clean solid free liquid at a

pressure of 1 bar above the pressure in stuffing box and at a

flow rate of 2-3 lpm is recommended.

Pressure (maximum) : 6 bar

Recommended temperature : 10 0C to 30 0C.

Bearing Dimensions of Cross Packing

bracket Packing compart- Section rings

ment in mm. packing

Ø di Ø da L

P25/62 35 51 53 8 x 8 4 rings and

P35/80 45 65 64 10 x 10 1 lantern

P45/120 55 75 64 10 x 10 ring or

P55/140 70 95 79 12.5 x 12.5 6 rings w/o

P65/160s 80 105 79 12.5 x 12.5 lantern ring

Table No. 3

See section 5.4.3 for corelation between pump and bearing

bracket sizes.

in mm.

5.3.2 Reassembly of Mechanical seal

Mount the mechanical seal as described in the instructions of

seal manufacturer. The following points should be observed

when mounting the mechanical seal :

Extreme care and cleanliness during assembly are the

essential prerequisites for the trouble free operation of the

mechanical seal.

The guard protecting the sealing faces should only be

removed only at the time of its fitment before assembly.

Cooling to bearing bracket :

No cooling shall be given to the bearing bracket up to a working

temperature of 200 0C.

For working temperature > 200 0C, use following data :

Cooling water qty. : 3 lpm.

Pressure (max.) : 10 bar

Recommended temperature : 10 0C to 30 0C.

Cooling to Pedestal

In case of centre feet mounted CPK Pumps, cooling to pedestal

is recommended for working temperature above 250 0C. The

cooling can be arranged in parallel or in sereis with the bearing

bracket.

Cooling water qty. :

In series with the bearing bracket (e.g. API Plan G) : 5 lpm.

In parallel with the bearing bracket (e.g. API plan G1) : 3 lpm

Pressure (max.) : 6 bar

Recommended temperature : 10 0C to 30 0C

Heating

The space between casing cover and bearing bracket can

also be used for heating by hot water, steam or any other

suitable heat transfer media.

Maximum temperature : 183 0C

Maximum Pressure : 10 bar.

When the stationary seal ring has been inserted, check its

plane parallelism in relation to the casing cover. The surface

of the shaft protection sleeve must be absolutely clean and

smooth and mounting edge of the sleeve must be chamfered.

When slipping the rotating assembly of the seal on to the

shaft protection sleeve take suitable steps to protect the

surface of the shaft protection sleeve against damage.

Before final mounting in the pump, the rubbing faces of the

mechanical seal should be wetted with a drop or two of silicon

oil. In the case of pumps equipped with a double acting

mechanical seal, the mechanical seal compartment must be

properly vented and pressurized to the correct pressure

specified in the installation drawing (it should remain under

pressure even when the pump is stopped).

The supply of quench liquid must remain turned on even when

the pump is stopped.

Fig. 9 : Stufing box arrangement of CPK Y Pumps.

7

Page 11

Bearing Dimensions of Cross Packing

bracket Packing compart- Section rings

ment in mm. packing

Ø da Ø di L

P25/62 35 51 53 8 x 8

P35/80 45 65 64 10 x 10

P45/120 55 75 64 10 x 10 6 nos.

P55/140 70 95 79 12.5 x 12.5

P65/160 80 105 - 12.5 x 12.5

in mm.

5.5 Spares

5.5.1 Ordering spare parts

Please quote the following information when ordering

spares

Part Name :

Pump type : CPK in this case with appropriate size

Part No. :

Serial No. :

Works Order No. :

The above details are stamped on the name plate.

CPK

8

Page 12

6 Interchangeability of pump components

CPK

Bearing

bracket

P25/62

P35/80

Pump

size

Angular contact ball brg. (set)

322 Cylindrical Roller bearing

330 Bearing bracket

344 Bearing bracket lantern

433 Mechanical seal

452 Stuffing box gland

456 Stuffing box pressure ring

457 Neck ring

458 Lantern ring

461 Stuffing box packing

471 Seal cover

502 Wearing ring

507 Splash ring

524 Shaft Protection sleeve

161 Casing Cover

183 Support foot

210 Shaft

320

Part No. Designation

32-125 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

32-160 2 2 1 1 1 1 1 2 1 1 1 1 1 1 1 1 1 1 1 1

40-160 2 2 1 1 1 1 1 2 1 1 1 1 1 1 1 2 1 1 1 1

50-160 2 3 1 1 1 1 1 2 1 1 1 1 1 1 1 3 1 1 1 1

32-200 3 3 1 1 1 1 1 3 1 1 1 1 1 1 1 1 1 1 1 1

40-200 3 3 1 1 1 1 1 3 1 1 1 1 1 1 1 2 1 1 1 1

50-200 3 3 1 1 1 1 1 3 1 1 1 1 1 1 1 3 1 1 1 1

80-160 4 5 2 2 2 2 2 4 2 2 2 2 2 2 2 10 2 2 2 2

65-200 5 5 2 2 2 2 2 5 2 2 2 2 2 2 2 8 2 2 2 2

80-200 5 5 2 2 2 2 2 5 2 2 2 2 2 2 2 10 2 2 2 2

100-200 5 6 2 2 2 2 2 5 2 2 2 2 2 2 2 12 2 2 2 2

32-250 6 5 2 2 2 2 2 6 2 2 2 2 2 2 2 6 2 2 2 2

40-250 6 5 2 2 2 2 2 6 2 2 2 2 2 2 2 5 2 2 2 2

50-250 6 5 2 2 2 2 2 6 2 2 2 2 2 2 2 4 2 2 2 2

65-250 6 6 2 2 2 2 2 6 2 2 2 2 2 2 2 8 2 2 2 2

80-250 6 7 2 2 2 2 2 6 2 2 2 2 2 2 2 11 2 2 2 2

40-315 7 6 2 2 2 2 2 7 2 2 2 2 2 2 2 5 2 2 2 2

50-315 7 7 2 2 2 2 2 7 2 2 2 2 2 2 2 7 2 2 2 2

321.1/2 Deep groove ball bearing

648 Drip plate

922 Impeller nut

100-250 8 8 3 3 3 3 3 6 3 3 3 3 3 3 3 13 3 3 2 3

125-250 8 9 3 3 3 3 3 6 3 3 3 3 3 3 3 15 3 3 2 3

150-250 8 10 3 3 3 3 3 6 3 3 3 3 3 3 3 16 3 3 2 3

65-315 9 8 3 3 3 3 3 7 3 3 3 3 3 3 3 9 3 3 2 3

P45/120

P55/140

P65/160s

Note : Part nos. 102 impeller & 230 Volute casing respectively cannot be used in other pump sizes.

80-315 9 9 3 3 3 3 3 7 3 3 3 3 3 3 3 12 3 3 2 3

100-315 9 9 3 3 3 3 3 7 3 3 3 3 3 3 3 14 3 3 2 3

125-315 9 10 3 3 3 3 3 7 3 3 3 3 3 3 3 16 3 3 2 3

80-400 10 10 3 3 3 3 3 8 3 3 3 3 3 3 3 12 3 3 2 3

100-400 10 10 3 3 3 3 3 8 3 3 3 3 3 3 3 14 3 3 2 3

125-400 10 11 3 3 3 3 3 8 3 3 3 3 3 3 3 15 3 3 2 3

200-250 11 13 4 4 4 4 4 9 4 4 4 4 4 4 4 17 4 4 3 4

150-315 12 12 4 4 4 4 4 10 4 4 4 4 4 4 4 18 4 4 3 4

200-315 12 13 4 4 4 4 4 10 4 4 4 4 4 4 4 19 4 4 3 4

250-315 12 16 5 4 4 4 4 10 4 4 4 4 4 4 4 21 4 4 3 4

150-400 13 12 4 4 4 4 4 11 4 4 4 4 4 4 4 18 4 4 3 4

200-400 13 13 4 4 4 4 4 11 4 4 4 4 4 4 4 20 4 4 3 4

200-500 16 17 6 5 5 5 12 5 5 5 5 5 20 5 5 3 5

250-400 15 17 6 5 5 5 11 5 5 5 5 5 22 5 5 3 5

250-500 16 15 6 5 5 5 12 5 5 5 5 5 23 5 5 3 5

9

Page 13

7 Recommended stock of spare parts for 2 years of operation

Part No. Designation Number of pumps (including stand by pumps)

2 3 4 5 6 8 10 and more

No. of spare parts

210 Shaft 1 1 2 2 2 3 30%

230 Impeller 1 1 2 2 2 3 30%

320 Angular contact ball bearings (set) 1 1 2 2 2 4 50%

CPK

321.01/02

322 Cylindrical roller bearing 1 1 2 2 3 4 30%

330 Bearing bracket - - - 1 1 1 2 per 10 nos.

433 Mechanical seal Refer works

454 Stuffing box pressure ring 1 1 2 2 2 3 30%

456 Neck ring 1 1 2 2 2 3 30%

458 Lantern ring 1 1 2 2 2 3 30%

461 Stuffing box packing (set) 2 2 3 3 3 4 40%

502 Casing wear ring 2 2 2 3 3 4 50%

503 Impeller Wear ring 2 2 2 3 3 4 50%

524 Shaft protection sleeve 2 2 2 3 3 4 50%

Deep groov ball bearing 1 1 2 2 2 4 50%

Gaskets (set) and O ring 4 6 8 8 9 12 150%

8. Faults

8.1 Faults, causes and suggested remedies.

Faults Code Number

Cause-remedy

Pump delivers insufficient 1,2,3,4,5,6,7,8,9,

liquid 10,11,18,28

Driver is overloaded 12,13,14,15,23,27,28

Excessively high pump 15

discharge pressure

Excessively high bearing 22,23,24,25,26

temperature

Leakage at the pump 29

Excessively leakage at 17,18,19,20,21,22,23,33

shaft seal

The pump runs rough 3,6,11,12,22,23,30,31,32

Excessive temperature 3,6,32

rise inside the pump

8.2 Cause-Remedy

1. The pump delivers against an excessively high

discharge pressure

- open discharge valve further until the duty point

conditions have been attained (adjusted)

2. Excessively high back pressure

- fit an over size impeller

- increase rotational speed

(applies to turbine or I.C. engine driven pumps)

3. The pump and/or piping are incompletely vented or

primed.

- vent or prime the pump and system completely.

4. Suction line or impeller clogged.

- Remove deposits in the pump and/or piping.

5. Formation of air pockets in piping.

- Alter piping layout

10

1)

2)

Page 14

CPK

- If necessary fit a vent valve.

6. NPSH available is too low (on positive suction head

installation)

- Check liquid level in suction vessel.

- Open isolating valve in suction line fully.

- Install a different suction line if necessary, if the

friction losses in the suction line are excessive.

- Check the suction line strainer.

7. Excessively high suction lift

- Clean out suction strainer basket and suction piping.

- Check liquid level in the pit.

- Alter the suction line.

8. Entrainment of air through the stuffing box.

- Sealing liquid passages are clogged; clean them

out if necessary, arrange a sealing liquid supply

from an outside source, or increase sealing liquid

pressure.

- Fit a new shaft seal.

9. Reverse rotation.

- Change over two of the phase leads of the power

supply cable.

10. Rotational speed is too low

2) 3)

- Increase rotational speed

- Increase voltage of power supply

11. Excessive wear of the pump internals

- Replace worn components by new ones.

12. Pump back pressure is lower than specified in the

purchase order.

- Adjust duty point accurately by means of the isolating

valve in the discharge line.

- In case of persistent overloading, trim the impeller

if necessary

13. Specific gravity or viscosity of the fluid pumped is

higher than that specified in the purchase order

2)

2)

14. Stuffing box gland tightened excessively or askew

- Adjust the gland as required.

15. Excessive rotational speed

- Reduce speed (applies to turbine or I.C. engine

driven pumps

2) 3)

16. Worn shaft seal

- Check condition of shaft seal and renew it if

necessary.

- Check flushing liquid or sealing liquid pressure.

17. Grooving score marks or roughness on shaft protection

sleeve surface.

- Fit a new shaft protection sleeve

18. Lack of cooling liquid or fouled and clogged liquid

compartment.

- Increase the flow of cooling liquid

- Clean out the cooling compartment

- Clean the cooling liquid itself.

19. Stuffing box gland, and cover or seal cover incorrectly

tightened, wrong type of packing material used.

- Remedy the fault.

20. The pump runs rough

- Correct the suction conditions

- Check alignment of pumping set and realign if

necessary

- Re-balance the pump rotor dynamically

- Increase the suction pressure at pump suction

nozzle.

21. Pumping set misaligned

- Check alignment at coupling and realign the set if

necessary

22. The pump is warped

- Check piping connections and pump fixing bolts.

23. Excessive axial thrust

2)

- Clean out balance holes in impeller

- Fit new casing wear ring.

24. Too much or too little lubricant or unsuitable lubricant

quality.

- Top up lubricant, reduce quantity of lubricant or change

lubricant quality.

25. The prescribed coupling gap has not been maintained

- Restore correct coupling gap in accordance with

the data on the foundation drawing.

26. Operating voltage is too low.

- Rectify.

27. The motor is running on two phases only.

- Replace the defective fuses.

- Check the cable connections.

28. The connecting bolts are slack.

- Tighten the bolts.

- Fit new gaskets.

29. The rotor is out of balance

- Clean the rotor

- Re-balance the rotor dynamically

30. Defective bearings

- Fit new bearings.

31. Insufficient rate of flow

- Increase the minimum rate of flow.

32. Faults in the circulation liquid supply

- Increase the cross section of the circulation liquid

line.

1) The pump should be made pressurless before attempting to remedy faults

concerning parts exposed to pressure

2) Please refer to KSB

3) This fault can be also be remedied by altering the impeller diameter.

11

Page 15

9. Sectional drawing & Part list

CPK

Part No. Description

102 Volute casing

161 Casing cover

183 Support foot

210 Shaft

230 Impeller

321.01/02 Deep groove ball bearings

330 Bearing bracket

344 Bearing bracket lantern

360.01/02 Bearing covers

400.01/02 Flat gasket

411.10/11 Flat gasket - hex. head plug

411.31/32 Flat gasket - impeller nut / impeller

411.46 Flat gasket - drain plug

412.01 O ring

421.01/02 Oil seals

457 Neck ring

502.01 Wearing ring - casing

Part No. Description

503.01 Wearing ring impeller

507.01 Splash ring

524 Shaft protection sleeve

551.31/32 Washer

554 Spring washer

562.02 Cylindrical pin

638 Constant level oiler

901.02 Hex. bolt

901.31 Hex. bolt

902.01/04 Stud

903.01/46 Hex. head plug

913 Vent plug

914.01/02 Allen head screw

916.18 Allen head plug

920.01/04 Hex. head nut

922.01 Impeller nut

940.01/02 Key

12

Page 16

CPK

9.1 Sectional drawing of CPK Y Pumps.

Typical arrangement showing CPK Y Pump with heavy bearing bracket. In case you need more details about the pump

available with you; please contact our Authorised Dealer or KSB office.

Part no. Description Part no. Description

102 Volute casing

502.01 Wearing ring - Casing

904.01 Allen grub plug - Casing wearing ring

903.01 Hex. Hd. Plug - Casing drain

902.01 / 920.01 Stud / Hex. Nut - volute casing

411.10 Gasket - Volute casing

161 Casing Cover

411.11 Gasket - Casing cover

230 Impeller

503.01 Impeller Ring

904.02 Allen grub plug - Impeller ring

922.01 Impeller nut

551.31 / 551.32 Washer - Impeller

411.31 / 411.32 Gasket - Impeller

210 Shaft

940.01 / 940.02 Key

524 Shaft protection sleeve

344 Bearing bracket lantern

902.04 / 920.04 Stud / Hex. Nut - Brg. Bkt / Brg. Bkt.

Lantern

183 Support foot

901.02 Hex. Hd. Bolt - Support foot

554 Spring Washer - Support foot

330 Bearing bracket

322.01 Cylindrical roller bearing

320.02 Angular contact bearing

932.01 / 932.02 Circlip

504.01 / 504.02 Adjusting Disc

931.01 Lock Washer

923 Withdrawl nut

400.01 / 400.02 Gasket - Bearing cover

360.01 / 360.02 Bearing cover

914.01 / 914.02 Socket Hd. Cap Screw - Bearing cover

423.01 / 423.02 Labyrinth ring

507.01 / 507.02 Splash ring

913 Vent plug

638 Constant lever oiler

903.46 / 411.46 Hex. Hd. Plug / Gasket - oil drain

13

Page 17

Annexure I : Arrangement For Base frame Grouting

A. Grouting details for base frame without Packer plates.

CPK

B. Grouting details for foundation bolts.

14

Page 18

C. Grouting details for base frame with Packer plates.

CPK

D. Grouting details for foundation bolts

15

Page 19

CPK

Annexure II : Metallic washer fitment for impeller, impeller nut and shaft protection sleeve

(wherever applicable)

Metal to metal fit of impeller nut (922), impeller (230) and shaft protection sleeve (524) against the shaft shoulder is done as

shown in the sketch and as described in the procedure given below :

This is achieved without reworking of standard parts. However recheck cavity dimensions as shown below and rework only if

required.

Procedure

Spacer washer (551.32) and gasket (411.32) are inserted between shaft protection sleeve (524) and impeller (230). Then the

spacer washer (551.31) and gasket (411.31) are placed between the impeller (230) and impeller nut (922) and finally impeller

nut (922) is tightened.

To calculate g1 & g2 use following formula

1. g1 + F = N + Wf

2. g2 + B = S + Wb

Where wf : front washer thickness

wb : back washer thickness

g1 : front gasket cavity thickness

g2 : back gasket cavity thickness

F : Impeller front length

B : Impeller back length

S : Sleeve length

Bearing

Bracket

Washer thickness Gasket thickness

(mm) (mm)

551.31 551.32 411.31 411.32

P 25/62 1.1 1 1.5 1.5

P 35/80s 2.1 1 1.5 1.5

P 45/120s 2.1 1 1.5 1.5

P 55/140s 2.1 1 1.5 1.5

P 65/160s 3.1 1 1.5 1.5

P 80/200s 5 1 1.5 1.5

Part No. Part Name

210 Shaft

230 Impeller

411.31/32 Graphite gaskets

524 Shaft protection sleeve

551.31/32 Spacer washers

922 Impeller nut

940 Key

Note :

1. When bearing brackets P 55/140s & above; are used,

check if the washer 551.31 rests on the supporting face of

the impeller. If not, rework length of the key.

2. For bearing brackets P 55/140s & above; part no. 551.32

will be in two halves.

Annexure III : Wearing Ring Clearances

Pump size Group 1 Group 3*

up to DN 65 0.4

DN 80-150 0.5

DN 250 & above 0.65

DN 200 0.55

+ 0.1

+ 0.1

+ 0.15

+ 0.1

The clearances are in mm and identical on the suction & discharge side.

* For all CPK C pumps and for CPK E pumps with

temperature > 2800C.

0.6

0.65

0.75

0.65

+ 0.1

+ 0.1

+ 0.15

+ 0.15

16

Page 20

CPK

Annexure IV - Environment Protection - Pruduct Disposal after useful life

Products manufactured by KSB Pumps are designed with utmost care for environmental protection. Innovative designs and

wide product range takes care of specific customer requirements reducing material and electrical energy consumption.

Product materials are recyclable. Our customers are educated with environment friendly methods of disposing product ingredients

at the end of their useful life. Please find herewith methods of disposing used pump ingredients.

Environment Protection measures during product disposal

Sr. Product Ingredients Disposal Methods

1. Pumps Paint : Pump body, Base frame Sludge to be disposed through authorised re processor

Non ferrous parts :

a) Impellers, Diffusers

b) Bushes

c) Stage sleeves

d) Thrust plate To be disposed through authorized re-processor

e) Wearing ring

f) Coupling Guard

g) Brg. Guard

Rubber / Plastic Parts :

a) Cover for NRV

b) Plastic cap To be disposed through authorized re-processor

c) Nozzle blanking

d) Cooling Fan

2. Motor Paint : Motor body, Rotor Sludge to be disposed through authorised re-processor

Non ferrous parts :

a) Support bushes

b) Copper sticks and stampings To be disposed through authorized re-processor

c) Balancing rings

d) Winding wire with varnish

Rubber / Plastic Parts :

a) Oil seal

b) Sand guard To be disposed through authorized re-processor

c) Notch keys, slot insulators

d) Overhang protection pipe

17

Page 21

CPK

Page 22

Loading...

Loading...