Page 1

Operating Instructions

3300.810 / 06 - 85 G3

Submersible Motor Pumps (100 mm)

100 mm Submersible Motor Pumps

(50 Hz)

Page 2

Contents

Submersible motor pumps (100 mm)

Sr. no. Description Page no.

1 General 1

1.1 Safety of pumping unit 1

1.1.1 Checks & Safety of pumping unit 1

1.1.2 Instructions on unit (Printed matter) 1

1.1.3 For unauthorized spare part and modifications 1

1.1.4 For unauthorized modes of operation 1

1.1.5 Water characteristics 1

1.2 Description of Product 1

1.2.1 Designation (example) of pump 1

1.2.2 Designation (example) of motor 1

2 Installation 1

2.1 Installation and operational accessories 1

2.2 Motor preparations 1

2.2.1 Motor fill 1

2.2.2 Insulation resistance (IR) 2

2.2.3 Extended Cable connection 2

2.2.3.1 Selection of Cable 2

2.2.4 Coupling of pump and motor 2

2.3 Typical installation at site 3

2.3.1 Vertical installation 3

2.3.2 Horizontal Installation (e.g. in tank or pit) 3

2.3.3 Plastic / Flexible Rubber riser piping instead

of normal GI riser piping 3

2.3.4 Installation of water level guard 4

2.3.5 Protection against electric shock 4

2.3.6 Fixing the power supply cable to the riser pipe 4

2.3.7 Verification of power line with respect to

motor design 4

2.3.8 Trip circuit for over current 4

2.4 Starting mode 4

2.4.1 For single-phase motor 4

2.4.2 For three-phase motor 5

Sr. no. Description Page no.

8 Trouble shooting 8

8.1 Motor 8

8.2 Pump 9

9 Schematic Cross-sectional Drawings 10

9.1 Pump - CORA 100 (Radial flow) 10

9.2 Pump - CORA 18C (Mix flow) 11

9.3 Pump - CORA 2AH, 3AH & 3A (Radial flow) 12

9.4 Motor - UMA 100 13

9.5 Motor - UMA I 100 & UMA I (S) 100 14

9.6 Motor - UMT (S) 100 15

9.7 Motor - XUMA (S) 100 16

Annexure I - Environment Protection Product Disposal after useful life 17

3 Commissioning and start up 5

3.1 Verification of rated current 5

3.2 Switching ON of mains 5

3.3 Checking the direction of rotation 5

3.4 Discharge valve position during initial start-up 5

3.5 Operation against a closed discharge valve 5

3.6 Operation against a throttled discharge valve 5

3.7 Operating limits of pump 5

3.8 Switching frequency 5

3.9 Interruptions / Shutdown periods 6

4 UMT (S) 100 motors 6

4.1 The motor is hermetically sealed induction motor 6

4.2 Connecting the motor 6

4.2.1 Starter panel 6

5 Maintenance 7

5.1 Storage 7

6 Services 7

7 Recommended stock of spare parts for

2 years of continuous operation 7

Page 3

Submersible motor pumps (100 mm)

1 General

Submersible motor pumps by KSB have been developed in

accordance with state-of-the-art of design and manufacturing

technology with extreme care and rigid quality control. The manual

contains important information for reliable operation of pump.

The special feature of these submersible pumps is installation in

narrow deep wells to pump clean water for various applications

like water supply system, irrigation sprinkling systems, ground

water lowering, pressure boosting, fountains etc.

For any additional information or instructions please contact KSB’s

nearest office.

1.1 Safety of pumping unit

This operating manual contains fundamental installation,

operation and maintenance instructions. Hence this must be

clearly understood by concerned people, prior to installation. The

booklet must always be located for easy access at site.

1.1.1 Checks & Safety of pumping unit

Check for any transit damage. After unpacking inspect the pumpmotor for any signs of shaft deflection and for the damage of the

lead cable.

This operating manual does not take into account any safety

regulations those may apply. It’s a pump operator’s responsibility

that any such regulations are adhered to.

1.2 Description of Product

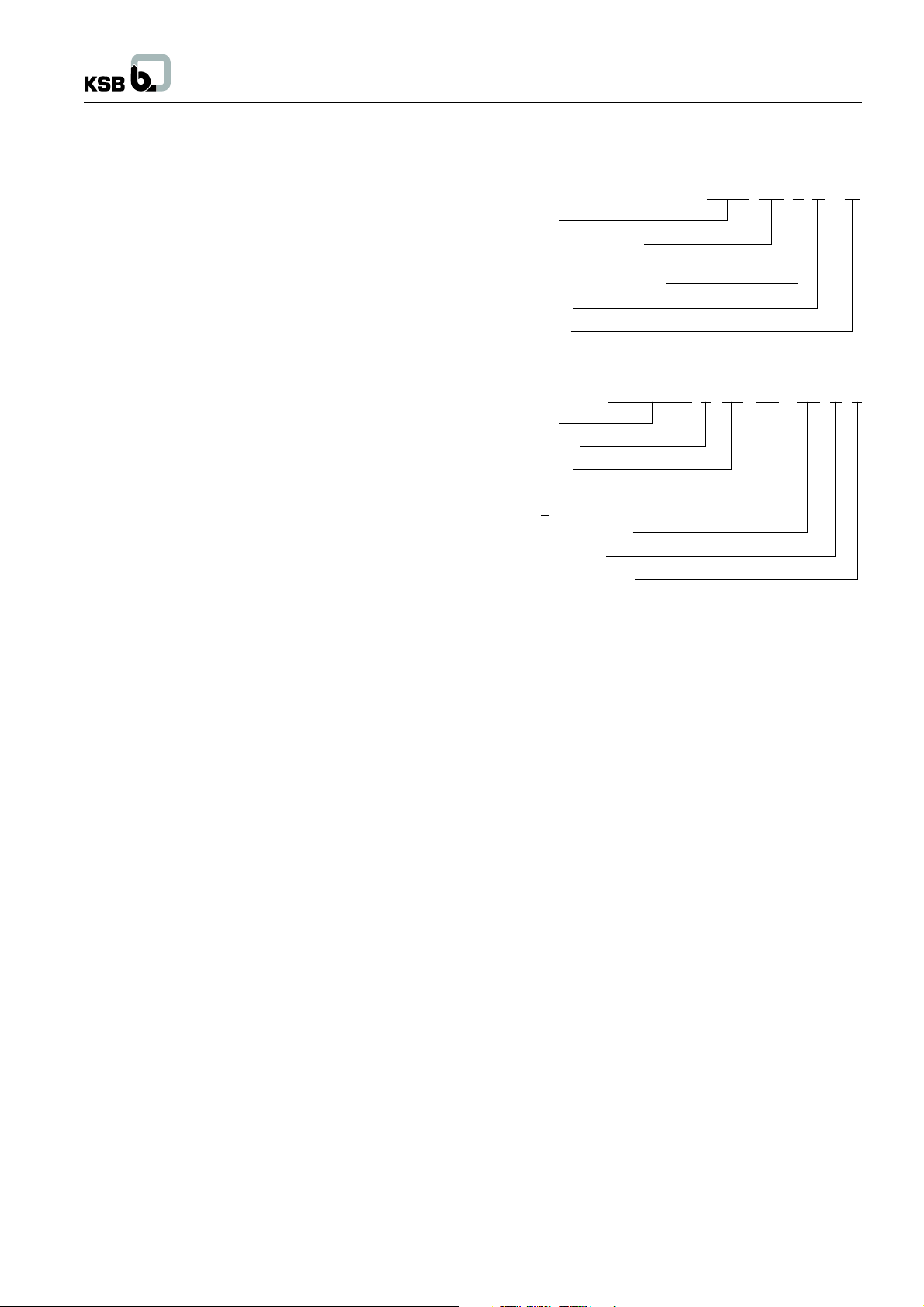

1.2.1 Designation (example) of pump

CORA 100 4 C / 7

Type series

Min. well diameter in mm

(100 mm ~ 4 inches)

Capacity for 50 Hz (in m3/hr.)

Design status

No. of stages

1.2.2 Designation (example) of motor

UMA / XUMA I (S) 100 - 0.8 / 2 1

Type series

Design variant

Single Phase

Min. well diameter in mm

(100 mm ~ 4 inches)

Electrical reference no.

No. of pair of poles

Winding wire insulation

1.1.2 Instructions on unit (Printed matter)

Follow the instructions attached on the motor / pump e.g.

- Arrow indicating the direction of rotation

- Various plugs for water connections viz. filling, venting, draining

etc. on motor

1.1.3 For unauthorized spare part and modifications

Modifications or alterations of the equipment supplied are strictly

not permitted. Original spare parts and accessories authorized

by the manufacturer ensure safety. The use of spurious parts

invalidates any liability of the manufacturer for consequential

damage.

1.1.4 For unauthorized modes of operation

The warranty related to the operation reliability and safety of the

unit supplied is valid only if the equipment is operated according

to designated parameters. The operating limits should not differ

from the limits specified on the nameplate.

1.1.5 Water characteristics

Submersible pumps are designed for handling clean or slightly

contaminated water with the following main characteristics : (As

per IS 8034 : 2002)

a) Turbidity : 50 ppm*, Max. (Silica scale)

b) Chlorides : 500 ppm*, Max.

c) Total Solids : 3000 ppm*, Max

d) pH value : 6.5 to 8.5

e) Temperature : 330 C, Max

f) Specific gravity : 1.004

g) Hardness : 300, Max (Drinking water)

* ppm – parts per million

2 Installation

2.1 Installation and operational accessories

The motor is supplied with a 3 meter long, 3 core waterproof

cable.

The following accessories are necessary for installation and

commissioning :

• A cable with vulcanizing rubber compound (which is normally

used for repairing the punctures in automobiles) and electric

insulation PVC tapes.

• Control panel

• 2 pairs of supporting or installation clamps for vertical

installation and 1 set of stands for horizontal installation.

• Overload trip unit, water level guard, single-phase preventor

(for 3 phase motor).

2.2 Motor preparations

2.2.1 Motor fill

For filling the motor with pure cold drinking water, follow the

procedure given below :

• Place the motor vertically up.

• Remove the two plugs provided at the top of the motor (Here

one plug is provided to escape the air and another for filling

the water).

• Fill the motor completely with pure water having no impurities

(Do not use distilled water).

• After filling the motor let it stand for 30 minutes and rotate the

rotor by hand to accelerate the escape of trapped air.

• At the same time pour more water to fill the loss of volume

caused by the escaped air bubbles.

• Refit the plugs.

• Check the motor completely for any leakages of water.

1

Page 4

Submersible motor pumps (100 mm)

Now motor is ready for operation.

If a unit has been in storage for more than 2 months, check for

the motor filling and for rotor freeness.

2.2.2 Insulation resistance (IR)

The insulation resistance value of the new motor with 500 V DC

megger is generally 20 Mega Ohms. For older motors if the value

observed to be less than 2 Mega Ohms, please contact KSB or

Authorized Dealer before switching on the motor.

2.2.3 Extended Cable connection

Only the proper cable connector ensures a perfect watertight

joint and provides a protection against mechanical damage to

the cable jointing. While connecting extra cable beyond standard

length along with the pump set, it is necessary to have a water

tightened cable joint.

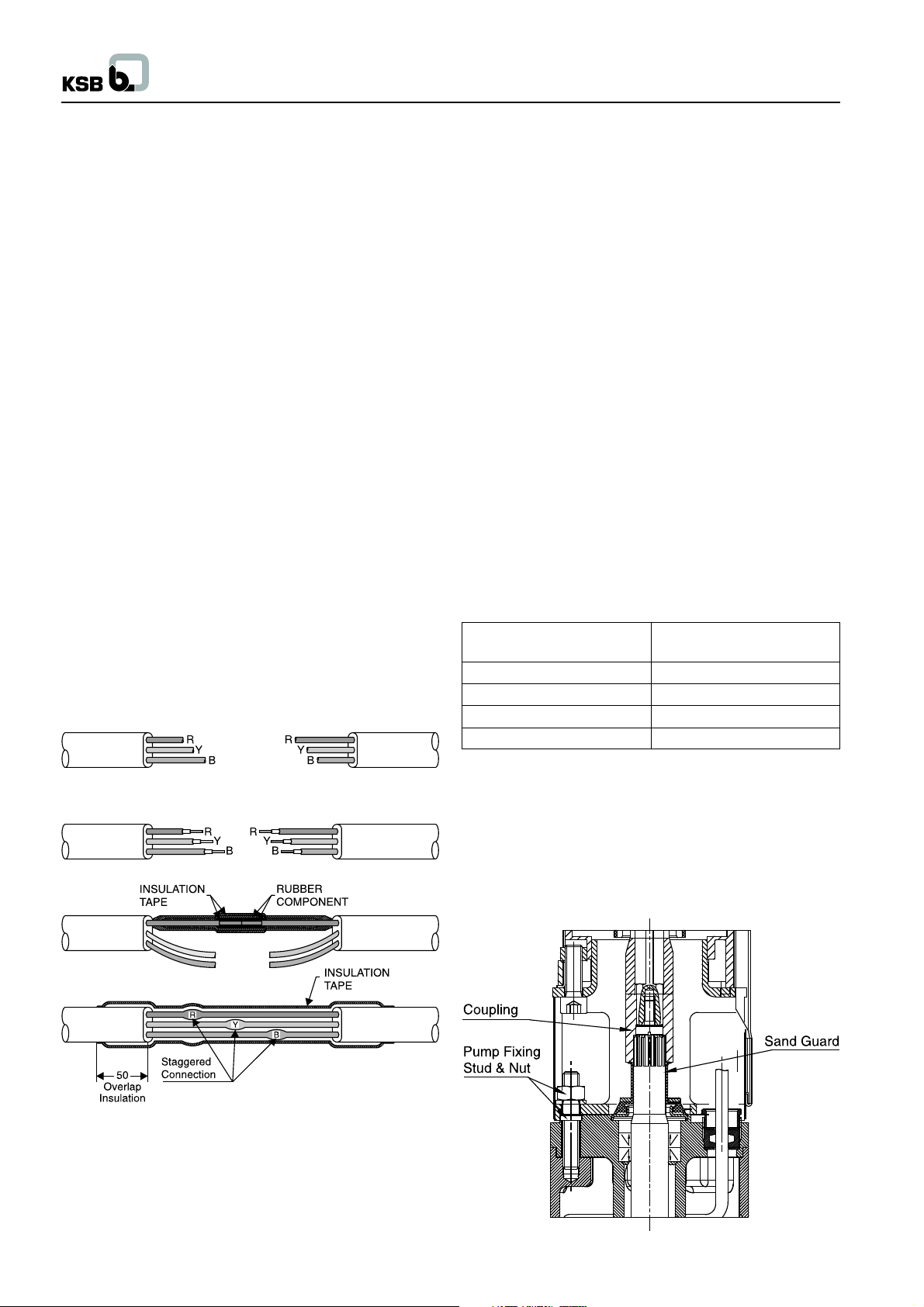

a. To connect the cables, cut off and strip the motor cable and

join it is staggered fashion where no 2 joints overlap each

other.

b. Colors of the leads, which are to be joined together must be

identical as per following sketch (Fig. 1).

c. Wrap vulcanizing rubber compound to each cable joint and

again wrap with electric insulation tape on the top of it.

d. To ensure proper insulation once again wrap with vulcanizing

rubber compound and electric insulation tape for each joint.

e. Finally wind the total cables with electric insulation tape.

f. Oil or grease should not have any contact with the tape.

g. Complete the taping over core insulation at each side.

Please see that each turn of the tape should have a 50% overlap

over the previous turn. The tape should be wound on to a

thickness at least equal to that of core insulation.

2.2.3.1 Selection of Cable

Voltage drop for extended cable should not be more than 3% of

rated voltage i.e.

Permissible voltage drop = Available voltage x 0.03

For Single phase :

Voltage drop = 2 x Cable Length in meters x Resistance / meter

for particular cable size x motor current

Allowed voltage drop is up to 7.0 volts (Considering available

voltage 230 volts).

e.g. For the cable length of 50 m and area of cross section 1.5

mm2, with rated current 3.5 A,

Voltage drop = 2 x 50 x 0.0121 x 3.5

= 4.24 volts (which is permissible)

For three phase :

Voltage drop = Cable Length in meters x Resistance / meter for

particular cable size x motor current

Allowed voltage drop is up to 12.5 volts (Considering available

voltage 415 volts).

e.g. For the cable length of 50 m and area of cross section 1.5

mm2, with rated current 2.4 A,

Voltage drop = 50 x 0.0121 x 2.4

= 1.45 volts (which is permissible)

Resistance / meter according to cross-section area :

Cross - section area Resistance in Ohm / m

(mm2) At 300C

1.5 0.0124

2.5 0.0075

4.0 0.0047

6.0 0.0031

Fig. no. 1

R = Red colored lead

Y = Yellow colored lead

B = Blue colored lead

2.2.4 Coupling of pump and motor

Couple the shaft to motor in vertical manner.

Before fitting the suction strainer the effortless rotation of the

coupled rotor should be checked at the sleeve coupling.

Please ensure that the top face of sand guard presses the bottom

face of the sleeve coupling to avoid the entry of sand inside the

coupling.

Fig. no. 2

2

Page 5

Submersible motor pumps (100 mm)

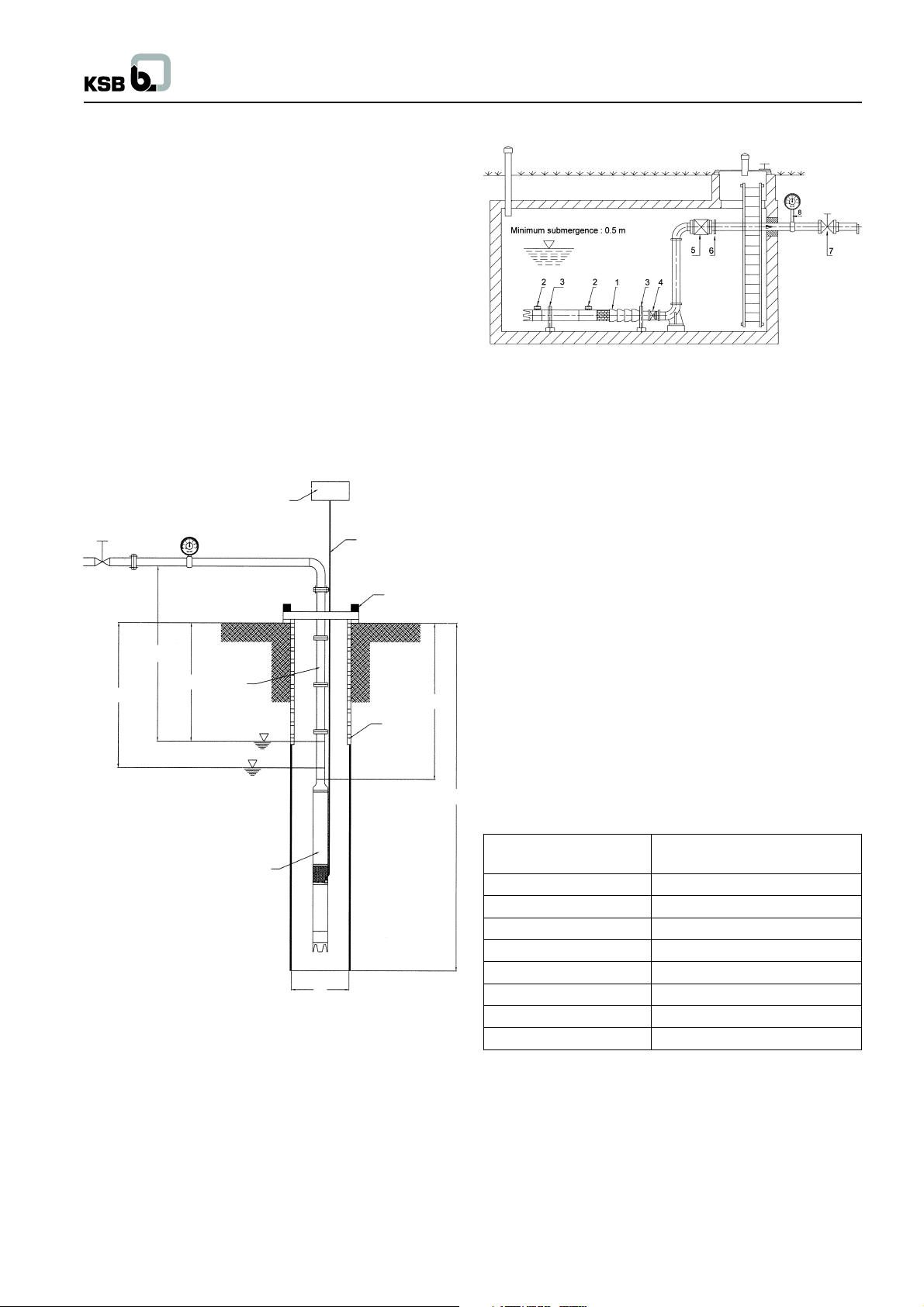

2.3 Typical installation at site

Use lifting device of capability of carrying the weight of pump

unit as well as the weight of pipe filled with water for installation.

2.3.1 Vertical installation

Before installing the unit in narrow deep wells, the well should be

tested for trueness of size over its entire length (e.g. by running

a dummy cylinder of diameter 98 mm and length about 2 m inside

the well). A slight inclination of the well is immaterial, whereas

any twists or bends can make installation difficult.

Installation depth should be selected such that the motor would

never run dry even when the water level is at its lowest mark

(i.e. draw down of bore well capacity).

The minimum water level should be 0.5 m above the top of the

non-return valve.

The pump should always be installed with the suction strainer

above the slotted casing pipe. The effect is that the pump draws

in the water free from loose sand.

6

H geo

8

H h

3

1

H t

5

2

H e

7

T

2.3.2 Horizontal Installation (e.g. in tank or pit)

Fig. no. 4

1. Submersible pump unit

2. Water reservior for Motor

3. Support

4. Expansion joint

Note : Generally the horizontal installation of submersible pump

unit is equipped with two storage tanks to increase the water

capacity.

1. Referring to the above figure (Fig. 4) for horizontal installation

only two supports are needed. One is placed at the extreme

end of the NRV while other is placed at the center of motor.

2. Install adapter pipe to the pump with 2 Water reservior and

the motor with proper fittings.

3. Ensure that the cast RCC foundation is incorporated with

the recommended foundation bolts of proper height.

4. To make up the correct center height of aligned pump - motor,

provide sufficient metallic packing in the RCC foundation

itself. To attain precise alignment, minor shims up to 2 mm

thick made of M.S. sheet may be used below the pump or

motor stand.

5. Such installed pump shall be either perfectly horizontal or

maximum of 5 degree inclination with motor down and pump

lifted up from the ground. Precise tightening of foundation

bolts has to be done at the final stage.

6. Surface of the motor should be cleaned periodically for

8

effective cooling.

5. Non-return valve

6. Flange adapter

7. Discharge valve

8. Pressure gauge

4

Fig. no. 3

1. Discharge valve

2. Supporting clamp

3. Raiser pipe

4. Submersible motor-Pump set

5. Power supply cable

6. Starter

7. Slotted Casing pipe

(Length up to rock level)

8. Pressure Gauge

D

D = Well diameter

TB = Well depth

He = Installation depth

Hh = Stationary water level

Ht = Operation water level

H

= Geostatic head

geo

Ht - Hh = Drawdown

Notes for installation :

The motor pump unit must be immersed minimum 0.5 m more

below the lowest operation water level Ht.

Pump type Max. no. of stages allowed

for horizontal installation

CORA 1C & CORA 2C 30

CORA 4C 23

CORA 7C 19

CORA 12C 8

CORA 18C 8

CORA 2AH 17

CORA 3AH 12

CORA 3A 15

It is important to ensure that pump does not sit on the base of the

well and there is no risk of sand or sludge deposition around the

motor. This would disrupt heat dissipation from the motor.

2.3.3 Plastic / Flexible Rubber riser piping instead

of normal GI riser piping

Consult the HDPE / rubber pipe suppliers for the capability of

pipes for withstanding the pressure. If the pump is to be fitted

with HDPE raising piping, it is to be firmly tied up with stainless

steel wire ropes of dia. 2-3 mm to the eyelets on the non return

3

Page 6

Submersible motor pumps (100 mm)

valve body and the vertical pipe line. This precaution will help

even in case of GI riser piping.

2.3.4 Installation of water level guard

Install a water level guard for dry running protection to avoid the

damage of pump unit in case of water level fluctuations.

2.3.5 Protection against electric shock

Submersible motors are provided with external earthing plug at

upper bearing body as a standard. A three-cored cable is led out

of the motor. The operator / user shall be responsible for proper

connection of the earthed conductor and of control unit at site.

2.3.6 Fixing the power supply cable to the riser pipe

During installation of pump into the bore well, power supply cable

should be fixed to the raiser pipe by means of cable clips at a

distance of approx. 3 m immediately after the flange or coupling

of the pipe.

2.3.7 Verification of power line with respect to

motor design

Verify the voltage and frequency of main supply with the data

given on the motor’s nameplate.

If it is not matching then consult with concerned electrical

authority.

Ensure that the main power supply is stable.

Typical examples of name plate :

Pump name plate :

KSB PUMPS LTD.

Type : CORA 100 1C/20

Sr. No. : -----

Q : 2.1 m3/hr Year : 2010

H : 48 mtrs kW : 0.75

N : 2800 rpm Ex. :

Motor name plate :

KSB PUMPS LTD.

Type : UMA I ( S ) 100 - 0.75 / 22

Sr. No. : ----

Voltage : 220 V Amp : 11.0

kW / HP : 0.75 / 1.0 Conn : ---

Speed : 2800 rpm Year : 2010

Run Capacitor : 36 uF 440 V Hz : 50 ± 3

Start Capacitor : 50 uF 230 V AC : 1 Ph

For operational values refer the nameplate attached to the pump

unit.

+ 6

- 15

2.3.8 Trip circuit for over current

A temperature compensated over current relay has to be provided

in the operational electrical circuit.

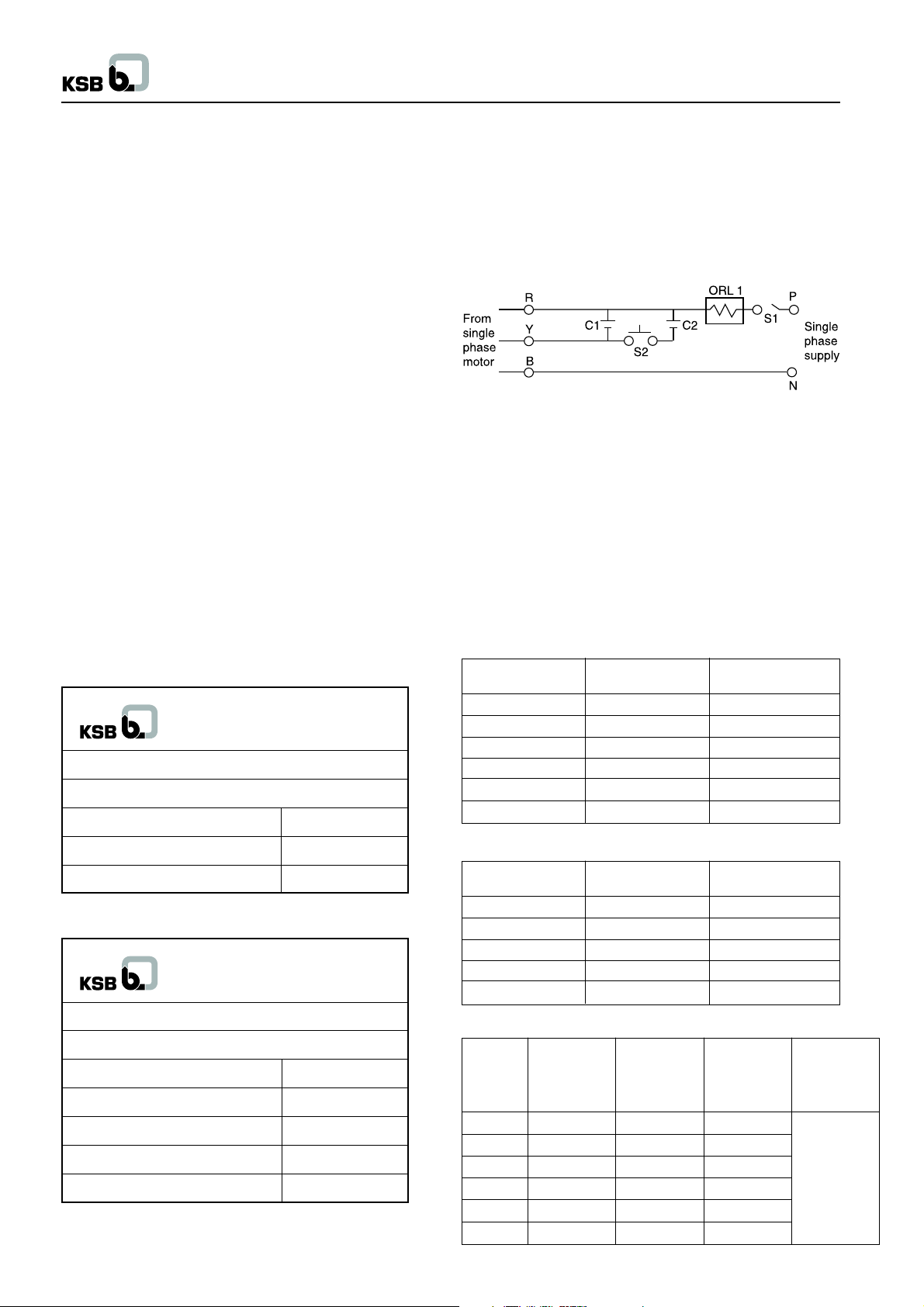

2.4 Starting mode

2.4.1 For single-phase motor

Single-phase motor connection diagram of starting method for

DOL is :

R : Red color wire C2 : Starting capacitor

B : Blue color wire C1 : Running capacitor

Y : Yellow color wire ORL 1 : Overload relay

S1 : On-off main switch P : Phase

S2 : Starting push button N : Neutral

Caution :

S2 - Starting push button should be pressed max. for 5 sec. In

case if the motor does not start, continuous operation of this

button may lead to burning the motor.

Capacitor details

C1 : Running capacitor : Polypropylene (440 V)

C2 : Starting capacitor : Electrolytic (230 V)

UMA I (S) 100

Motor capacity Run Capacitor Start Capacitor

kW

0.37 20 60

0.55 20 80-100

0.75 36 80-100

1.1 30 100-120

1.5 30 100-120

2.2 100 120-150

UMA (S) 100

Motor capacity Run Capacitor Start Capacitor

kW

0.5 25 100

0.8 25 100

1.25 36 120

1.5 50 120

2.2 50 200

XUMA (S) 100

Motor Run Start Run Start

Capacity Capacitor Capacitor Capacitor Capacitor

kW

0.37 20 60 - 80 30

0.55 30 80 - 100 30

0.75 36 80 - 100 50

1.1 50 100 - 120 50

1.5 50 100 - 120 100

2.2 100 120 - 150 120

µµ

µF

µµ

(> 180 Volt) (> 180 Volt) (< 180 Volt) (< 180 Volt)

µµ

µF

µµ

µµ

µF

µµ

µµ

µF

µµ

µµ

µF

µµ

µµ

µF

µµ

µµ

µF

µµ

µµ

µF

µµ

Value to be

enhance as

per actual

site

voltage

condition

4

Page 7

Submersible motor pumps (100 mm)

2.4.2 For three-phase motor

2. Using pressure gauge, check the discharge pressure in both

the direction of rotations. The higher value corresponds to

the correct direction of rotation. OR

3. By visual inspection see the flow rate in both cases. If water

comes out up to the short length through the raiser pipe, flow

rate is lower while if it comes farther, results in higher flow

rate. The higher flow indicates the correct direction of rotation.

For Single-phase motors

In case of single-phase AC motors the direction of rotation of the

motor itself corresponds to the correct direction of rotation of the

pump, irrespective of mode of connection to the power supply.

3.4 Discharge valve position during initial start-

up

During initial start-up the pump should run with the discharge

valve slightly open (approx. 1/3 of full opening). The water is

examined for sand content (The permissible sand contents for

warranty is 50 mg / liter) at this stage it is important that pump is

run continuously without stooping (if pump is stop, sand will settle

inside the pump and pump is block resulting in damage) till the

sand content in the water falls to an unnoticeable level OR Flush

the bore well completely before new pump installation.

3.5 Operation against a closed discharge valve

Pumps should not be allowed to run against a closed discharge

valve for longer than 5 minutes. This would cause the water in

the pump to warm up quickly and the heat would be transferred

to the motor, which causes a risk to the motor.

1. Submersible motor

2. Motor cable

3. Cable designation

4. Connected cable

5. Overload relay (thermal type)

6. Leads

7. Electro-magnetic switches

8. Fuses

L1, L2, L3 = Line supply

U, V, W = Leads

N = Neutral

S1, S2 = Push buttons

* Overload relay must be thermal type.

3 Commissioning and start up

3.1 Verification of rated current

Please refer to the motor nameplate for the values of rated current

required for relay setting.

3.2 Switching ON of mains

The pumping set should be switched on only if it is fully immersed

in the water.

3.3 Checking the direction of rotation

For three-phase motors

1. Let the pumping set run for a short time against a closed

discharge valve, in both the directions of rotation and check

the flow. Reversing of two points of connection, reverses

the direction of rotation. The higher flow rate gives the

direction of rotation. OR

3.6 Operation against a throttled discharge valve

If the pump set is to be operated against a throttled discharge

valve for a prolonged period of time, the minimum rate of flow

should be at least 10% of flow at the best efficiency point * (BEP)

of the characteristic curve, this must be observed in order to

reduce noisy operation and the overheating of the pump set.

* For best efficiency point (BEP) of the characteristic curve

consult with KSB dealer.

Actual start-up

• Check the power supply condition as per the name plate.

• Do proper earthling.

• Fix the pressure gauge before discharge valve.

• Set the relay as per current value given on name plate and

start the pump.

• Set the duty parameters as per value given on name plate by

control valve.

• Pump should run always on duty point specified on name plate

3.7 Operating limits of pump

Operational safety requirements stipulate that pump may only

be operated continuously within the flow rate and pump head

limits which are specified on nameplate. Otherwise ±10% of best

efficiency flow rate should be the pump operation range, provided

that motor is not overloaded. (For ensuring this the motor current

should not exceed as specified on name plate).

3.8 Switching frequency

In order to prevent the motor from heating up excessively due to

many switching cycles, a maximum of 15 starts per hour are

permitted with a minimum of 3 minutes interval as a shut down

period between two successive starts.

5

Page 8

Submersible motor pumps (100 mm)

3.9 Interruptions / Shutdown periods

In order to ensure a long motor service life, pumps should not be

allowed to remain idle in water for more than 8 to 10 days.

Otherwise fine deposits like lime, iron and other substances tend

to settle in the bearings and impeller gaps. This might block the

pump rotor. In case the situation is unavoidable, it is

recommended to run the pump for at least 10 to 15 minutes every

week. This will enable the pump to resume instant service at

any time.

4 UMT (S) 100 motors

Special attention on following points is required :

4.1 The motor is hermetically sealed induction

motor

It is pre-filled with liquid at works with rotor and bearings being

lubricated and cooled by the filled liquid. The motor is designed

for vertical and horizontal location in clean water, with a maximum

sand content of 50 g/m3. The maximum installation depth is 300

m.

4.2 Connecting the motor

4.2.1 Starter panel (Refer fig. 5)

Starter Panel

Recommended circuit diagram for UMT (S) motors (1 ø, 220 V, 50 Hz supply)

Legend :

Abbrevation Description

B R Y Motor terminals

P Phase

N Neutral

E Earth

C Common terminal

M Main winding

A Auxillary winding

OLR Overload relay

PB1 Start push button

PB2 Stop push button

IL Inter locks if any

T1 Start timer

K1 Contactor

C2 Start capacitor

C1 Run capacitor

(Electrolytic type)

(Polypropylene type)

Fig. no. 5

Capacitor values :

UMT (S) 100

Motor capacity Run Capacitor Start Capacitor

(kW) (C1)

0.37 16 100-120

0.55 20 100-120

0.75 26 100-120

1.1 36 100-120

1.5 40 100-120

µµ

µF (C2 )

µµ

µµ

µF

µµ

6

Page 9

Submersible motor pumps (100 mm)

5 Maintenance

5.1 Storage

Prior to delivery, submersible motors are generally preserved and stored up to 1 year.

Always store the motor in upright position protected from dust and frost.

6 Services

Do not attempt to open the motor / pump for repair that will render our warranty null & void.

Please take up with Authorised Service Center or to the concerned dealer.

Unauthorized repaires are not permitted since they cause poor performance and shorter life of the pumpset.

7 Recommended stock of spare parts for 2 years of continuous operation

Part No. Description

271 Sand Guard 1 2 3

384 Thrust Bearing Plate 1 2 3

412.01,02 O Ring 2 2 3

421 Oil Seal 2 3 4 sets

828 Cable Packing Ring 1 2 2 3

829 Cable Gland Ring 1 2 2 3

849 Coupling 1 1

912/913 Vent plug & Drain plug 1 1 1

932 Circlip 1 2 3

No. of pumps (including Standby Pumps)

2 3 4 5 6 8 10 or more

7

Page 10

8 Trouble shooting

8.1 Motor

Submersible motor pumps (100 mm)

Possible cause Remedies

Motor cannot be started

Motor fails, fuses have blown or motor has tripped

Overload protection is actuated after long operation

Repeated starting of the motor

Motor is not cut off (automatic control is not in

function). Applicable only to pressure booster pumps.

• Voltage is too low / no voltage Retighten loose connections, Contact

electrical supply authority.

• Motor winding or supply cable is damaged Repair / replace motor, cable

• Fuses or automatic switches are not suitable Replace fuse or switch

• Supply voltage is either too high or too low Change either supply or motor if wrong

than rated internal connections are made

• • Failure of a phase (single phasing in 3 Rectify loose connections. Replace fuses.

phase motor) Consult electrical authority.

• Switchgear positioned in too warmer place Protect switchgear from heat

• Control switch is not in function Repair / replace the control device

(level switch / level guard)

• • Leakage in the unit / faulty pressure gauge Trace leakage and seal it

• Extremely high momentary load Dismantle pump, clean & repair

(pump is silted up deeply etc.)

• Contaminated filter, excessive wear in Dismantle pump, clean & repair

pumping unit

• Incorrect co-ordination of pump & pressure Correct the co-ordination

tank (applied to booster pumps)

• Pump components are clogged. Pump should be repaired. To prevent such

incidents the pump-set should not be idle

for a long time. It should be operated at least

once in a week.

8

Page 11

8.2 Pump

Pump falls to deliver the water

Pump delivers insufficient flow of water

Pump does not develop required head / pressure

Pump has vibrations and noise

Submersible motor pumps (100 mm)

Possible Causes Remedies

• Power is not available Check the line

• Defective motor winding, cable and starters. Repair / replace the defective parts

• Coupling / motor shaft worn out. Take out pump-set for the repairing of damaged

Motor runs while pump remains stationary. coupling.

• Pump is silted up Clean out the suction casing, Impeller, Stage

casing and non return valve - (1)

• Pump set has broken away from the riser pipe Consult Installer

as a result of corrosion

• • Rotational speed is too low Check supply frequency and increase the

voltage up to tolerance limit as shown on

name plate

• Pump delivers against as excessive discharge Open discharge valve until the desired flow is

pressure. attained. Reduce no. of bends, increase the

pipe size.

• The pump delivers higher flow of water against Close discharge valve until the duty flow is

low discharge pressure. attained.

• Leakage in pipes Change the pipe.

• • • Excessive wear of pump internal Replace the worn-out components - (1)

• • • Closed raiser pipe Replace defective length of raiser pipe with new

gasket

• Discharge pipe coated with depositions Clean the pipe and remove the deposition or

(1) Consult KSB

Replace the pipe

• Installation causes heavy vibrations Consult Installer

• Abnormal drop in water level during operation / Make the use of compressor pumps to get the

Insufficient yield yield

9

Page 12

9 Schematic Cross-sectional Drawings

9.1 Pump - CORA 100 (Radial flow)

Submersible motor pumps (100 mm)

931 Washer

920 Nut Square

914.03 Screw (Chease head)

914.02 Screw (Allen head)

914.01 Screw (round head)

901 Hex. head bolt

751 Valve seat

849 Sleeve coupling

825 Cable protection pipe

759 Valve dish with ‘O’ ring & valve plate

751 Valve body

543 Spacer bush

529.02 Bearing sleeve (last)

529.01 Bearing sleeve (intermediate)

521 Stage sleeve

411 Gasket

382 Bearing body with bearing bush

232.02 Clockwise impeller (last) with wearing

ring (503), thrust bearing plate (384)

211 Pump shaft

143 Suction strainer

131 Inlet ring

109.02* Stage pipe last stage

109.01 Stage pipe

108.02 Stage casing (last stage)

108.01 Stage casing with stage bush (541*),

casing wearing ring (135*)

106 Suction casing

81-29 Cable clamp

10-6 Pump jacket

Part no. Description

10

Page 13

9.2 Pump - CORA 18C (Mix flow)

Submersible motor pumps (100 mm)

931 Washer

920 Nut

914.03 Screw (Chease head)

914.02 Screw (Allen head)

914.01 Screw (round head)

901 Bolt

849 Sleeve coupling

825 Cable protection pipe

759 Valve dish with ‘O’ ring

752 Valve seat

751 Valve body

529.02 Bearing sleeve (last)

529.01 Bearing sleeve (intermediate)

525 Spacer sleeve

521 Stage sleeve

500 End ring with wearing ring (502)

411 Gasket

384 Thrust bearing plate

382.03 Bearing body w/o bearing bush

382.02 Bearing body with bearing bush

382.01 Intermediate bearing body with brg. bush

230 Impeller

211 Pump shaft

143 Suction strainer

131 Inlet ring

112 Stage bowl

109 Stage pipe

106 Suction casing

81-29 Cable clamp

10-6 Pump jacket

Part no. Description

11

Page 14

9.3 Pump - CORA 2AH, 3AH & 3A (Radial flow)

Submersible motor pumps (100 mm)

931 Washer

920 Square nut

914.03 Screw (Chease head)

914.02 Screw (Allen head)

914.01 Screw (Round head)

901 Hex. head bolt

759 Valve dish with O-ring

752 Valve seat

751 Valve body

543 Spacer bush

529 Bearing sleeve

411 Gasket

384 Thrust ring

382 Intermediate bearing body with bush

232 Impeller

211 Pump shaft

143 Suction strainer

131 Inlet ring

108 Stage casing

106 Suction casing

81-29 Cable clamp

10-6 Pump jacket

Part No. Description

12

Page 15

9.4 Motor - UMA 100

Submersible motor pumps (100 mm)

914.05 Screw (Allen head)

914.04 Screw (Allen head)

914.03 Screw (Allen head)

914.02 Screw (Chease head)

914.01 Screw (Allen head)

904 Threaded pin

829 Cable pressure washer

828 Cable gland ring

818 Rotor

580 Sand cap guard

562 Cylindrical pin

550 Disc

421 Oil seal

392 Bearing segment carrier

389 Counter thrust bearing ring

387 Thrust bearing segement

384 Thrust bearing plate

382.02 Bearing body upper

382.01 Bearing body lower

342 Thrust bearing lantern

271 Sand guard

160 Cover

132.52 Intermediate part (Upper)

132.51 Intermediate part (Lower)

81-77 Balancing ring

81-74 Pressure Nut

81-59 Stator with winding

81-34 Finger pressure disc

59-12 Diaphragm

Part no. Description

13

Page 16

9.5 Motor - UMA I 100 & UMA I (S) 100

Submersible motor pumps (100 mm)

931 Washer

920.02 Hex. nut

920.01 Hex. domed cap nut

914.02 Slotted cheese head screw

914.01 Allen head bolt

904 Threaded pin

903.01,02 Plug (Water filling/drain)

902.02 Stud (M8 x 48)

902.01 Stud (M6 x 71)

829 Cable pressure washer

828 Cable gland ring

818 Rotor with balancing ring (81-77)

720 Double nipple

580 Sand guard cap

550 Washer

421 Oil seal

411.01, 02 Gasket

392 Bearing segment carrier with pin (560)

389 Counter thrust ring

387 Thrust bearing segment

384 Thrust plate assembly with disc (550)

382.02 Bearing body upper with bush (545.02)

382.01 Bearing body lower with bush (545.01)

354 Thrust bearing housing

271 Sand guard

160 Cover

132 Intermediate part

81-74 Pressure nut

81-59 Stator with press ring (81.34)

81-18 Cable shoe

59-33 Water reservior

59-12 Diaphragm

Part no. Description

14

Page 17

9.6 Motor - UMT (S) 100

Submersible motor pumps (100 mm)

920 Nut

914 Cheese head screw

904.52 Threaded pin

818 Rotor

817 Can

813 Stator packet

580 Sand cap guard

560.52 Thrust pin

550.53 Washer

550.52 Disc

550.51 Disc

545.52 Bearing bush (upper)

545.51 Bearing bush (lower)

421 Oil seal

412.53 O ring

412.52 O ring

412.51 O ring

387 Thrust bearing segment

384.52 Counter thrust bearing plate

384.51 Thrust bearing plate

382.52 Bearing body (upper)

382.51 Bearing body (lower)

271 Sand guard

160 Cover

81-96.53 Cable connector (female)

81-96.52 Cable connector (male)

81-78 Stator pipe

81-59 Stator

81-27.52 End disc (upper)

81-27.51 End disc (lower)

59-6 Ball

32-2 Ball retainer

Part no. Description

15

Page 18

9.7 Motor - XUMA (S) 100

Submersible motor pumps (100 mm)

932 Circlip

931 Washer

920.02 Hex. nut

920.01 Hex. domed cap nut

914.02 Slotted cheese head screw

914.01 Allen head bolt

904 Threaded pin

903.01,02 Plug (Water filling / Water drain)

902.02 Stud (M8x56.6)

902.01 Stud (M6x97)

829 Cable pressure washer

828 Cable gland ring

818 Rotor with balancing ring (81-77)

720 Double nipple

580 Sand guard cap

550 Washer

500.02 Ring - upper

500.01 Ring - lower

421 Oil seal

411.01,02 Gasket

392 Bearing segment carrier

389 Counter thrust ring

387 Thrust bearing segment

384 Thrust plate assembly with disc (550)

382.02 Beaing body upper with bush (545.02)

382.01 Bearing body lower with bush (545.01)

354 Thrust bearing housing

271 Sand guard

160 Cover

81-74 Pressure nut

81-59 Stator with inter part (132)

81-18 Cable shoe

59-33 Storage tank

59-12 Diaphragm

Part No. Description

16

Page 19

Submersible motor pumps (100 mm)

Annexure I - Environment Protection - Product Disposal after useful life

Products manufactured by KSB are designed with an extreme care for environmental protection. Innovative designs and wide

product ranges take care of customer’s requirements reducing material and electrical energy consumption. Product materials are

recyclable. Our customers are educated with environment friendly methods of disposing product ingredients at the end of product

useful life. Please find herewith methods of disposing used ingredients.

Environment Protection measures during product disposal

Sr. Product Ingredients Disposal Methods

1. Pumps Paint : Pump body, Base frame Sludge to be disposed through authorized re-processor

Non ferrous parts :

a) Impellers, Diffusers

b) Bushes

c) Stage sleeves

d) Thrust plate Sludge to be disposed through authorized re-processor

e) Wearing ring

f) Coupling Guard

g) Brg. Guard

Rubber / Plastic Parts :

a) Cover for NRV

b) Plastic cap Sludge to be disposed through authorized re-processor

c) Nozzle blanking

d) Cooling Fan

2. Motor Paint : Motor body, Rotor Sludge to be disposed through authorized re-processor

Non ferrous parts :

a) Support bushes

b) Copper sticks and stampings Sludge to be disposed through authorized re-processor

c) Balancing rings

d) Winding wire with varnish

Rubber / Plastic Parts :

a) Oil seal

b) Sand guard Sludge to be disposed through authorized re-processor

c) Notch keys, slot insulators

d) Overhang protection pipe

17

Page 20

Operating Instructions

Submersible motor pumps (100 mm)

Submersible Motor pumps (100 mm)

Mktg. Serv./06-15/25,000

Loading...

Loading...