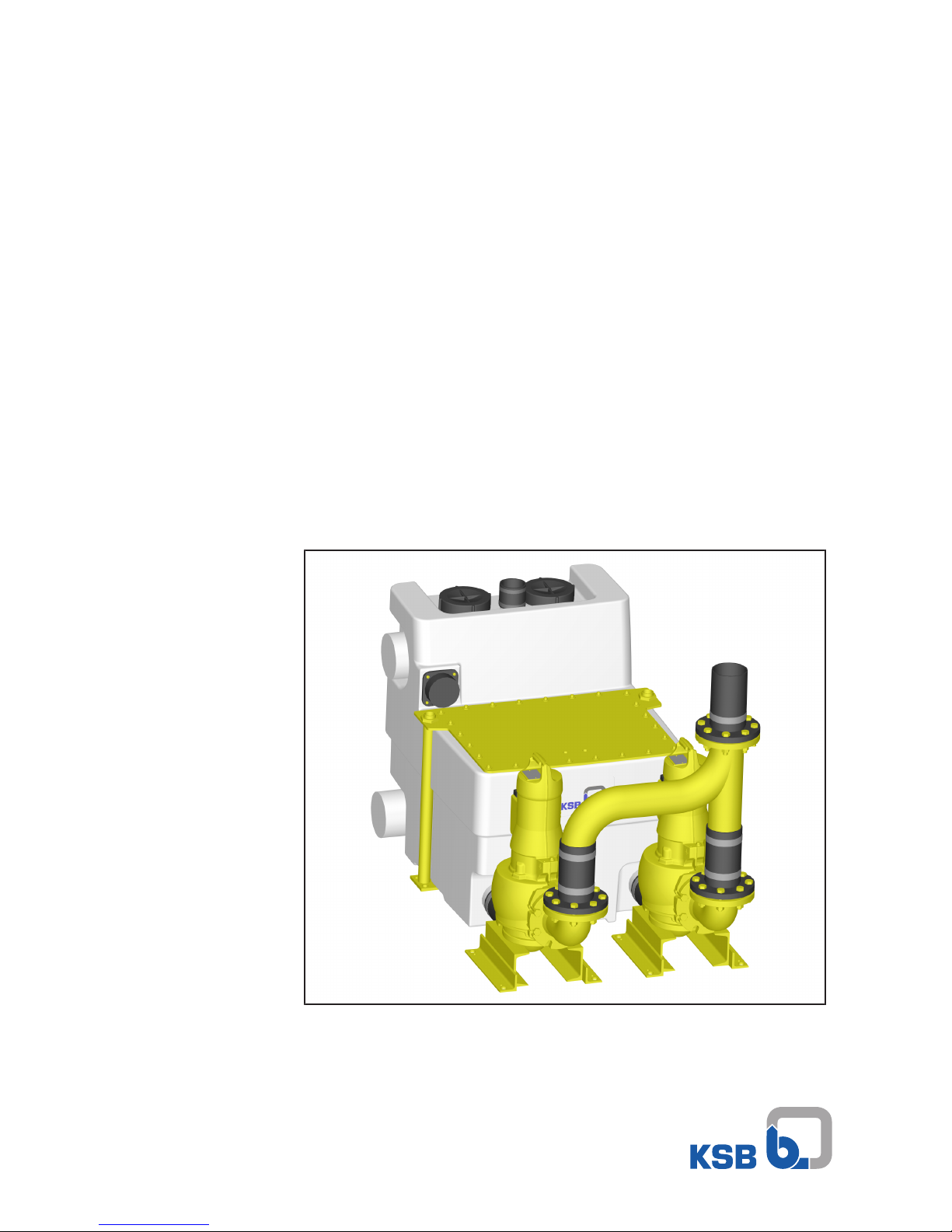

KSB Compacta UZ14.450D, Compacta UZ11.450D, Compacta UZ11.900D, Compacta UZ10.900D, Compacta UZ12.900D Installation & Operating Manual

...Page 1

Sewage Lifting Unit

Compacta UZ, ZF, ZK

UZ - with Amarex N/KRT

ZF, ZK - with Sewabloc

From series S-V/1

From series 2013w01

Installation/Operating Manual

Page 2

Legal information/Copyright

Installation/Operating Manual Compacta UZ, ZF, ZK

Original operating manual

All rights reserved. The contents provided herein must neither be distributed, copied, reproduced,

edited or processed for any other purpose, nor otherwise transmitted, published or made available to a

third party without the manufacturer's express written consent.

Subject to technical modification without prior notice.

© KSB SE & Co. KGaA, Frankenthal 23/07/2018

Page 3

Contents

3 of 64

Compacta UZ, ZF, ZK

Contents

Glossary .................................................................................................................................................. 5

1 General.................................................................................................................................................... 6

1.1 Principles ...........................................................................................................................................................6

1.2 Installation of partly completed machinery....................................................................................................6

1.3 Target group.....................................................................................................................................................6

1.4 Other applicable documents............................................................................................................................6

1.5 Symbols .............................................................................................................................................................6

2 Safety...................................................................................................................................................... 7

2.1 Key to safety symbols/markings.......................................................................................................................7

2.2 General..............................................................................................................................................................7

2.3 Intended use .....................................................................................................................................................8

2.4 Personnel qualification and training...............................................................................................................8

2.5 Consequences and risks caused by non-compliance with this manual .........................................................8

2.6 Safety awareness ..............................................................................................................................................8

2.7 Safety instructions for the operator/user........................................................................................................9

2.8 Safety information for maintenance, inspection and installation ................................................................9

2.9 Unauthorised modes of operation..................................................................................................................9

3 Transport/Temporary Storage/Disposal............................................................................................. 10

3.1 Checking the condition upon delivery..........................................................................................................10

3.2 Transport.........................................................................................................................................................10

3.3 Storage/preservation......................................................................................................................................12

3.4 Return to supplier...........................................................................................................................................13

3.5 Disposal ...........................................................................................................................................................13

4 Description............................................................................................................................................ 14

4.1 General description ........................................................................................................................................14

4.2 Designation.....................................................................................................................................................14

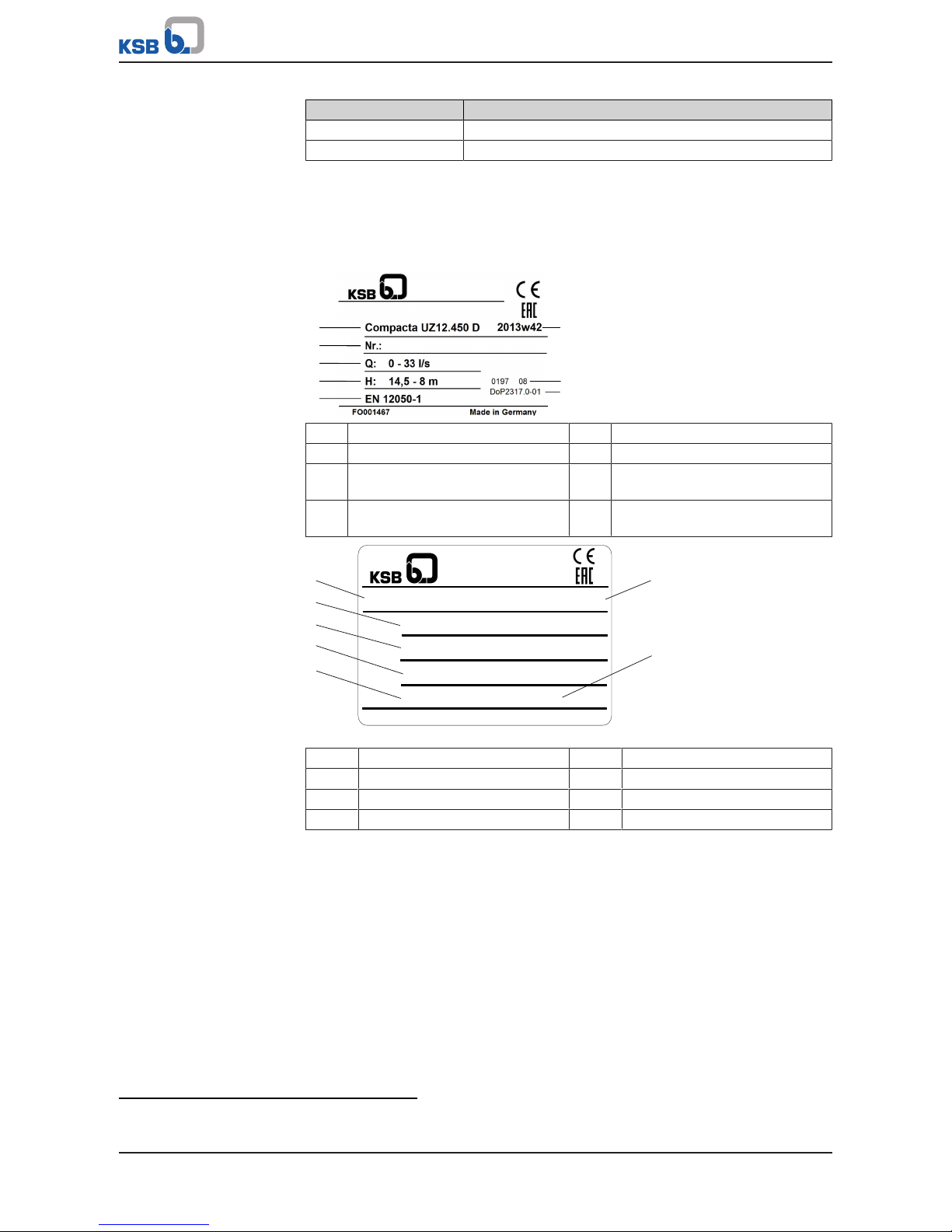

4.3 Name plates ....................................................................................................................................................15

4.4 Design details..................................................................................................................................................15

4.5 Configuration and function...........................................................................................................................16

4.6 Technical data of the control unit.................................................................................................................18

4.6.1 Electrical data.....................................................................................................................................18

4.6.2 Technical specifications for sensors ..................................................................................................18

4.7 Fluids handled.................................................................................................................................................19

4.8 Collecting tank................................................................................................................................................19

4.9 Noise characteristics .......................................................................................................................................20

4.10 Scope of supply...............................................................................................................................................20

4.11 Dimensions and weights ................................................................................................................................20

5 Installation at Site................................................................................................................................ 21

5.1 Safety regulations...........................................................................................................................................21

5.2 Checks to be carried out prior to installation...............................................................................................21

5.3 Installing the lifting unit................................................................................................................................22

5.3.1 Setting up the tank(s)........................................................................................................................22

5.3.2 Setting up the pump..........................................................................................................................22

5.4 Connecting the piping ...................................................................................................................................23

5.5 Cellar drainage ...............................................................................................................................................24

5.6 Connection to power supply..........................................................................................................................25

5.7 Checking the direction of rotation................................................................................................................26

6 Commissioning/Start-up/Shutdown................................................................................................... 27

6.1 Commissioning/Start-up.................................................................................................................................27

6.1.1 Prerequisites for commissioning/start-up .........................................................................................27

6.2 Operating limits..............................................................................................................................................27

Page 4

Contents

4 of 64

Compacta UZ, ZF, ZK

6.2.1 Operating limits per operating mode ..............................................................................................27

6.2.2 Supply voltage....................................................................................................................................28

6.3 Commissioning/start-up of control unit........................................................................................................28

6.3.1 Lifting unit with LevelControl Basic 2...............................................................................................29

6.4 Shutdown........................................................................................................................................................30

7 Operation.............................................................................................................................................. 32

7.1 Control panel..................................................................................................................................................32

7.1.1 Indicators............................................................................................................................................32

7.1.2 Display ................................................................................................................................................33

7.1.3 Navigation keys..................................................................................................................................33

7.2 Manual-0-automatic selector switch .............................................................................................................34

7.3 Control panel..................................................................................................................................................34

7.3.1 Displaying measured value parameters............................................................................................34

7.3.2 Setting parameters ............................................................................................................................35

7.3.3 Acknowledging alerts and warnings ................................................................................................36

7.3.4 Displaying the alerts list ....................................................................................................................37

7.3.5 Replacing the rechargeable battery .................................................................................................37

8 Servicing/Maintenance........................................................................................................................ 38

8.1 General information/Safety regulations .......................................................................................................38

8.2 Servicing/inspection........................................................................................................................................38

8.2.1 Inspection contract ...........................................................................................................................39

8.2.2 Measuring the insulation resistance of the motor ..........................................................................39

8.2.3 Oil check/Oil change ..........................................................................................................................39

8.2.4 Emergency operation with one pump..............................................................................................39

8.3 Dismantling the pump ...................................................................................................................................40

8.4 Reassembly......................................................................................................................................................40

8.4.1 General instructions...........................................................................................................................40

8.4.2 Pump reassembly ...............................................................................................................................41

8.5 Tightening torques.........................................................................................................................................41

8.6 Disposal/recycling of the lifting unit .............................................................................................................41

8.7 Checklist for commissioning/inspection ➀ and maintenance ➁ ..................................................................41

9 Trouble-shooting.................................................................................................................................. 43

10 Related Documents.............................................................................................................................. 45

10.1 General assembly drawing/exploded view and list of components............................................................45

10.1.1 General assembly drawing of the lifting unit ..................................................................................45

10.1.2 Exploded view of collecting tank......................................................................................................47

10.2 Connection examples .....................................................................................................................................48

10.2.1 Compacta UZ10.450 - UZ15.450 ........................................................................................................48

10.2.2 Compacta UZ10.900 - UZ15.900 ........................................................................................................49

10.2.3 Compacta UZ20.450 - ZK56.450 ........................................................................................................50

10.2.4 Compacta UZ20.900 - ZK56.900 ........................................................................................................50

10.3 Dimensions......................................................................................................................................................52

10.4 Wiring diagrams .............................................................................................................................................53

10.4.1 LevelControl Basic 2 Type BC - dual-pump unit - DOL starting - up to 4kW - with motor

protection switch - for Compacta UZ................................................................................................53

10.4.2 LevelControl Basic 2 Type BS - dual-pump unit - DOL starting - 5.5kW and above - with motor

protection switch - for Compacta UZ................................................................................................54

10.4.3 LevelControl Basic 2 Type BS - dual-pump unit - star/delta starting - 5.5kW and above - with

motor protection switch - for Compacta UZ ....................................................................................55

10.4.4 LevelControl Basic 2 Type BS - for Compacta ZF and Compacta ZK................................................56

11 EU Declaration of Conformity............................................................................................................. 57

12 Declaration of Performance as per Regulation (EU) No. 305/2011, Annex III.................................. 58

13 Certificate of Decontamination........................................................................................................... 59

Index ..................................................................................................................................................... 60

Page 5

Glossary

5 of 64

Compacta UZ, ZF, ZK

Glossary

Certificate of decontamination

A certificate of decontamination is enclosed by the

customer when returning the product to the

manufacturer to certify that the product has been

properly drained to eliminate any environmental

and health hazards arising from components in

contact with the fluid handled.

DIN1986-3 and -30

German standard which stipulates technical rules

for the operation, maintenance and servicing of

drainage systems in buildings and on premises

Discharge line

Pipe for transporting waste water to a level above

the flood level into the sewer system

DOL starting

For low power ratings (usually up to 4kW), the

three-phase motor is connected directly to the

mains voltage.

Effective volume

Volume in the collection tank between start and

stop level that can be lifted

EN 12 056-4

European standard governing the selection,

operation and maintenance of sewage lifting units

within buildings and sites.

Flood level

Maximum backflow level of waste water in a

drainage system

Inlet line

Pipe used for draining waste water from sanitary

installations into the lifting unit

Nominal diameter DN

Identifier (inside diameter) used for characterising

mating components such as pipes, pipe

connections and fittings

Separator

Device for physically separating the two phases of

a two-phase flow, e.g. for separating solid

particles or liquid drops from flowing gases.

Sewage lifting unit

Device for collecting and automatically lifting

waste water with or without faeces above the

flood level

Stormwater

Water from natural precipitation which has not

been contaminated by any form of use

Vent line

Pipe provided to limit pressure fluctuations within

the sewage lifting unit. The vent line is led

through the roof.

Waste water

Water which has been changed by some type of

use, e.g. domestic waste water

Working space

The space required for performing work on the

unit

Page 6

1 General

6 of 64

Compacta UZ, ZF, ZK

1 General

1.1 Principles

This operating manual is valid for the type series and variants indicated on the front

cover.

The manual describes the proper and safe use of this equipment in all phases of

operation.

The name plate indicates the type series, the main operating data and the serial

number. The serial number uniquely describes the product and is used as

identification in all further business processes.

In the event of damage, immediately contact your nearest KSB Service centre to

maintain the right to claim under warranty.

1.2 Installation of partly completed machinery

To install partly completed machinery supplied by KSB refer to the sub-sections under

Servicing/Maintenance.

1.3 Target group

This operating manual is aimed at the target group of trained and qualified specialist

technical personnel.

1.4 Other applicable documents

Table1: Overview of other applicable documents

Document Contents

Sub-supplier product literature Operating manuals and other product literature

of accessories and integrated machinery

components,

operating manual of waste water pump

1.5 Symbols

Table2: Symbols used in this manual

Symbol Description

✓ Conditions which need to be fulfilled before proceeding with the

step-by-step instructions

⊳ Safety instructions

⇨

Result of an action

⇨ Cross-references

1.

2.

Step-by-step instructions

Note

Recommendations and important information on how to handle

the product

Page 7

2 Safety

7 of 64

Compacta UZ, ZF, ZK

2 Safety

!

DANGER

All the information contained in this section refers to hazardous situations.

In addition to the present general safety information the action-related safety

information given in the other sections must be observed.

2.1 Key to safety symbols/markings

Table3: Definition of safety symbols/markings

Symbol Description

!

DANGER

DANGER

This signal word indicates a high-risk hazard which, if not avoided,

will result in death or serious injury.

!

WARNING

WARNING

This signal word indicates a medium-risk hazard which, if not

avoided, could result in death or serious injury.

CAUTION

CAUTION

This signal word indicates a hazard which, if not avoided, could

result in damage to the machine and its functions.

Explosion protection

This symbol identifies information about avoiding explosions in

potentially explosive atmospheres in accordance with EU Directive

2014/34/EU (ATEX).

General hazard

In conjunction with one of the signal words this symbol indicates a

hazard which will or could result in death or serious injury.

Electrical hazard

In conjunction with one of the signal words this symbol indicates a

hazard involving electrical voltage and identifies information about

protection against electrical voltage.

Machine damage

In conjunction with the signal word CAUTION this symbol indicates

a hazard for the machine and its functions.

2.2 General

This operating manual contains general installation, operating and maintenance

instructions that must be observed to ensure safe operation of the system and

prevent personal injury and damage to property.

The safety information in all sections of this manual must be complied with.

The operating manual must be read and understood by the responsible specialist

personnel/operators prior to installation and commissioning.

The contents of this operating manual must be available to the specialist personnel

at the site at all times.

Information attached directly to the product must always be complied with and kept

in a perfectly legible condition at all times. This applies to, for example:

▪ Arrow indicating the direction of rotation

▪ Markings for connections

▪ Name plate

The operator is responsible for ensuring compliance with all local regulations not

taken into account in this operating manual.

Page 8

2 Safety

8 of 64

Compacta UZ, ZF, ZK

2.3 Intended use

▪ The lifting unit must not be used in potentially explosive atmospheres.

▪ The lifting unit must only be operated within the operating limits described in

the other applicable documents.

▪ Only operate lifting units which are in perfect technical condition.

▪ Do not operate partially assembled lifting units.

▪ Only use the lifting unit to handle the fluids described in the product literature

of the respective design variant.

▪ Never operate the lifting unit without the fluid to be handled

▪ Observe the minimum flow rates indicated in the data sheet or product literature

(to prevent overheating, bearing damage, etc).

▪ Observe the minimum flow rate and maximum flow rate indicated in the data

sheet or product literature (to prevent overheating, mechanical seal damage,

cavitation damage, bearing damage, etc).

▪ Do not throttle the flow rate on the inlet side of the lifting unit (to prevent

cavitation damage)

▪ Consult the manufacturer about any use or mode of operation not described in

the data sheet or product literature.

▪ Never exceed the permissible application and operating limits specified in the

data sheet or product literature regarding pressure, temperature, etc.

▪ Observe all safety information and instructions in this manual.

2.4 Personnel qualification and training

All personnel involved must be fully qualified to install, operate, maintain and

inspect the equipment this manual refers to.

The responsibilities, competence and supervision of all personnel involved in

installation, operation, maintenance and inspection must be clearly defined by the

operator.

Deficits in knowledge must be rectified by means of training and instruction

provided by sufficiently trained specialist personnel. If required, the operator can

commission the manufacturer/supplier to train the personnel.

Training on the lifting unit must always be supervised by technical specialist

personnel.

2.5 Consequences and risks caused by non-compliance with this manual

▪ Non-compliance with these operating instructions will lead to forfeiture of

warranty cover and of any and all rights to claims for damages.

▪ Non-compliance can, for example, have the following consequences:

– Hazards to persons due to electrical, thermal, mechanical and chemical

effects and explosions

– Failure of important product functions

– Failure of prescribed maintenance and servicing practices

– Hazard to the environment due to leakage of hazardous substances

2.6 Safety awareness

In addition to the safety information contained in this manual and the intended use,

the following safety regulations shall be complied with:

▪ Accident prevention, health regulations and safety regulations

▪ Explosion protection regulations

▪ Safety regulations for handling hazardous substances

▪ Applicable standards, directives and laws

Page 9

2 Safety

9 of 64

Compacta UZ, ZF, ZK

2.7 Safety instructions for the operator/user

▪ Fit protective equipment (e.g. contact guards) supplied by the operator for hot,

cold or moving parts, and check that the equipment functions properly.

▪ Do not remove any protective equipment (e.g. contact guards) during operation.

▪ Provide the personnel with protective equipment and make sure it is used.

▪ Contain leakages (e.g. at the shaft seal) of hazardous fluids handled (e.g.

explosive, toxic, hot) so as to avoid any danger to persons and the environment.

Adhere to all relevant laws.

▪ Eliminate all electrical hazards. (In this respect refer to the applicable national

safety regulations and/or regulations issued by the local energy supply

companies.)

2.8 Safety information for maintenance, inspection and installation

▪ Modifications or alterations of the lifting unit require the manufacturer's prior

consent.

▪ Use only original spare parts or parts authorised by the manufacturer. The use of

other parts can invalidate any liability of the manufacturer for resulting damage.

▪ The operator ensures that maintenance, inspection and installation is performed

by authorised, qualified specialist personnel who are thoroughly familiar with

the manual.

▪ Carry out work on the lifting unit during standstill only.

▪ The pump casing must have cooled down to ambient temperature.

▪ Pump pressure must have been released and the pump must have been drained.

▪ When taking the lifting unit out of service always adhere to the procedure

described in the manual.

▪ Decontaminate lifting units which handle fluids posing a health hazard.

(ðSection8.1,Page38)

▪ As soon as the work has been completed, re-install and re-activate any safety-

relevant devices and protective devices. Before returning the product to service,

observe all instructions on commissioning.

▪ Make sure the lifting unit cannot be accessed by unauthorised persons (e.g.

children).

2.9 Unauthorised modes of operation

Always observe the limits stated in the product literature.

The warranty relating to the operating reliability and safety of the lifting unit

supplied is only valid if the equipment is used in accordance with its intended use.

(ðSection2.3,Page8)

Page 10

3 Transport/Temporary Storage/Disposal

10 of 64

Compacta UZ, ZF, ZK

3 Transport/Temporary Storage/Disposal

3.1 Checking the condition upon delivery

1. On transfer of goods, check each packaging unit for damage.

2. In the event of in-transit damage, assess the exact damage, document it and

notify KSB or the supplying dealer and the insurer about the damage in writing

immediately.

3.2 Transport

DANGER

Lifting unit falling off the pallet

Risk of injury from falling lifting unit!

▷ Always transport the lifting unit in a horizontal position.

▷ Give due attention to the weight data, centre of gravity and fastening points.

▷ Never suspend the lifting unit by its power cable.

▷ Use suitable and permitted transport equipment, e.g. crane, forklift or pallet

truck.

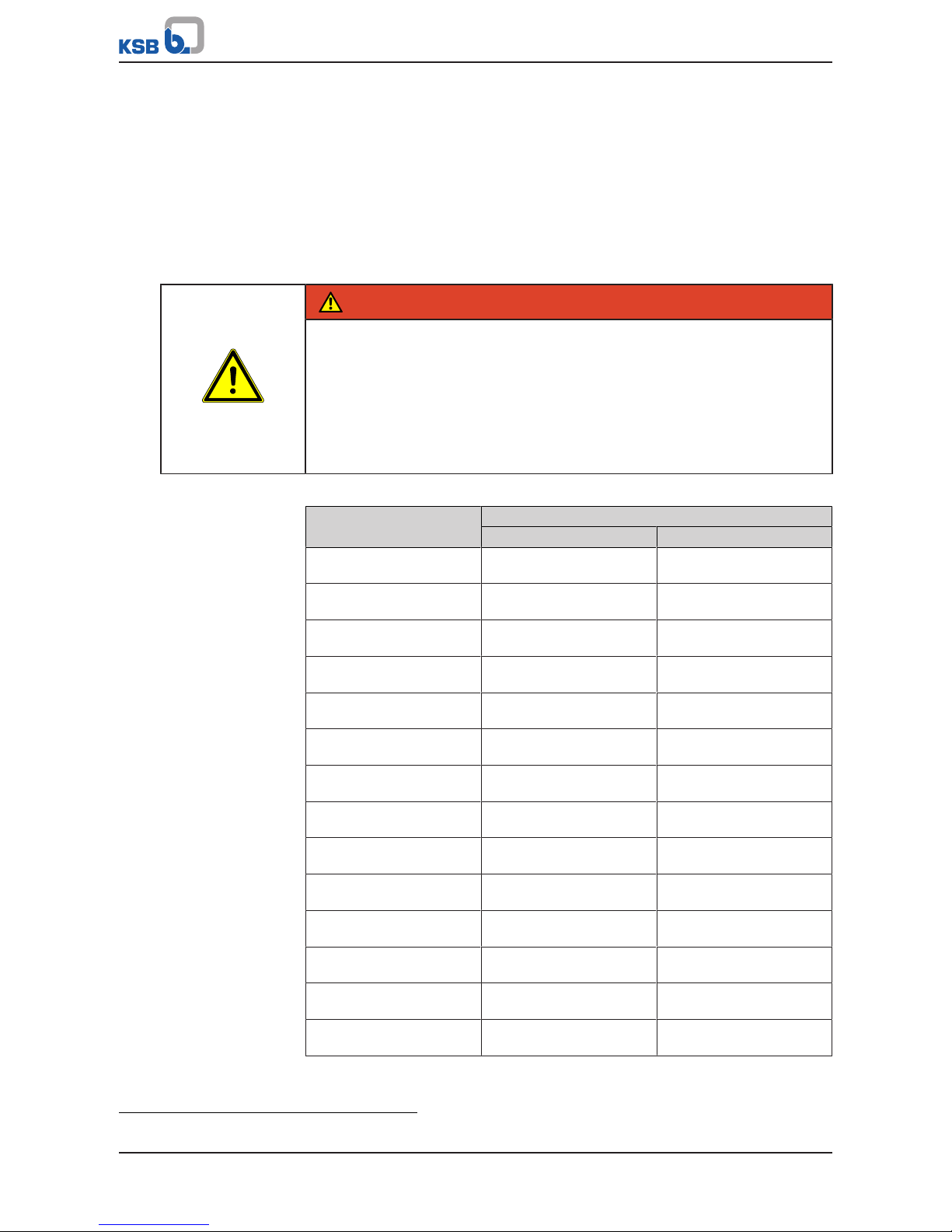

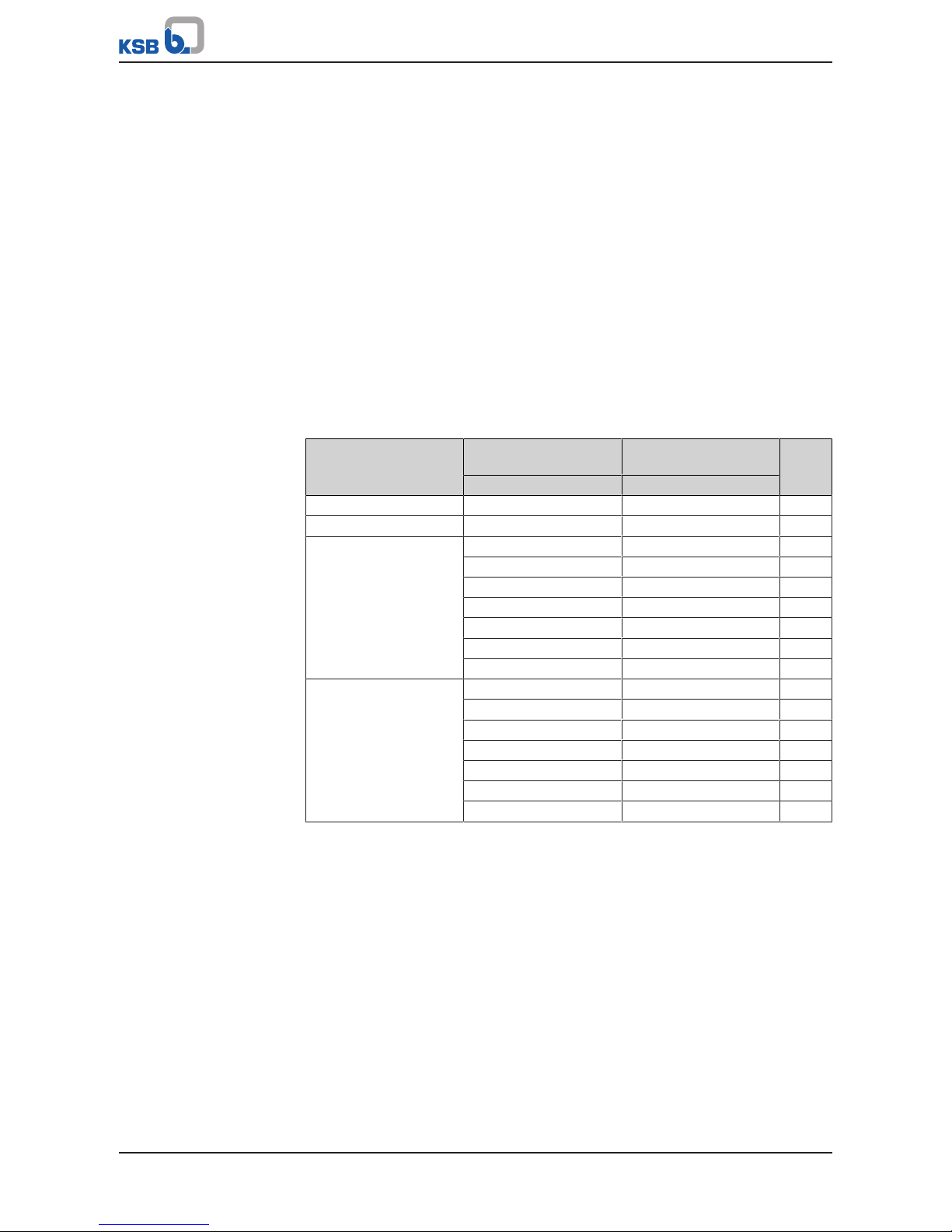

Table4: Weight Compacta UZ - Amarex N/KRT [kg]

Sizes Weight

Per pump Lifting unit

1)

UZ10.450D

UZ10.900D

85

85

305

380

UZ11.450D

UZ11.900D

87

87

315

390

UZ12.450D

UZ12.900D

142

142

400

485

UZ13.450D

UZ13.900D

153

153

420

505

UZ14.450D

UZ14.900D

180

180

470

555

UZ15.450D

UZ15.900D

180

180

470

555

UZ20.450D

UZ20.900D

165

165

465

540

UZ21.450D

UZ21.900D

175

175

485

560

UZ22.450D

UZ22.900D

213

213

561

646

UZ23.450D

UZ23.900D

213

213

564

646

UZ24.450D

UZ24.900D

213

213

561

646

UZ25.450D

UZ25.900D

213

213

561

646

UZ26.450D

UZ26.900D

213

213

561

646

UZ27.450D

UZ27.900D

180

180

495

570

1) Weight of the lifting unit without water fill

Page 11

3 Transport/Temporary Storage/Disposal

11 of 64

Compacta UZ, ZF, ZK

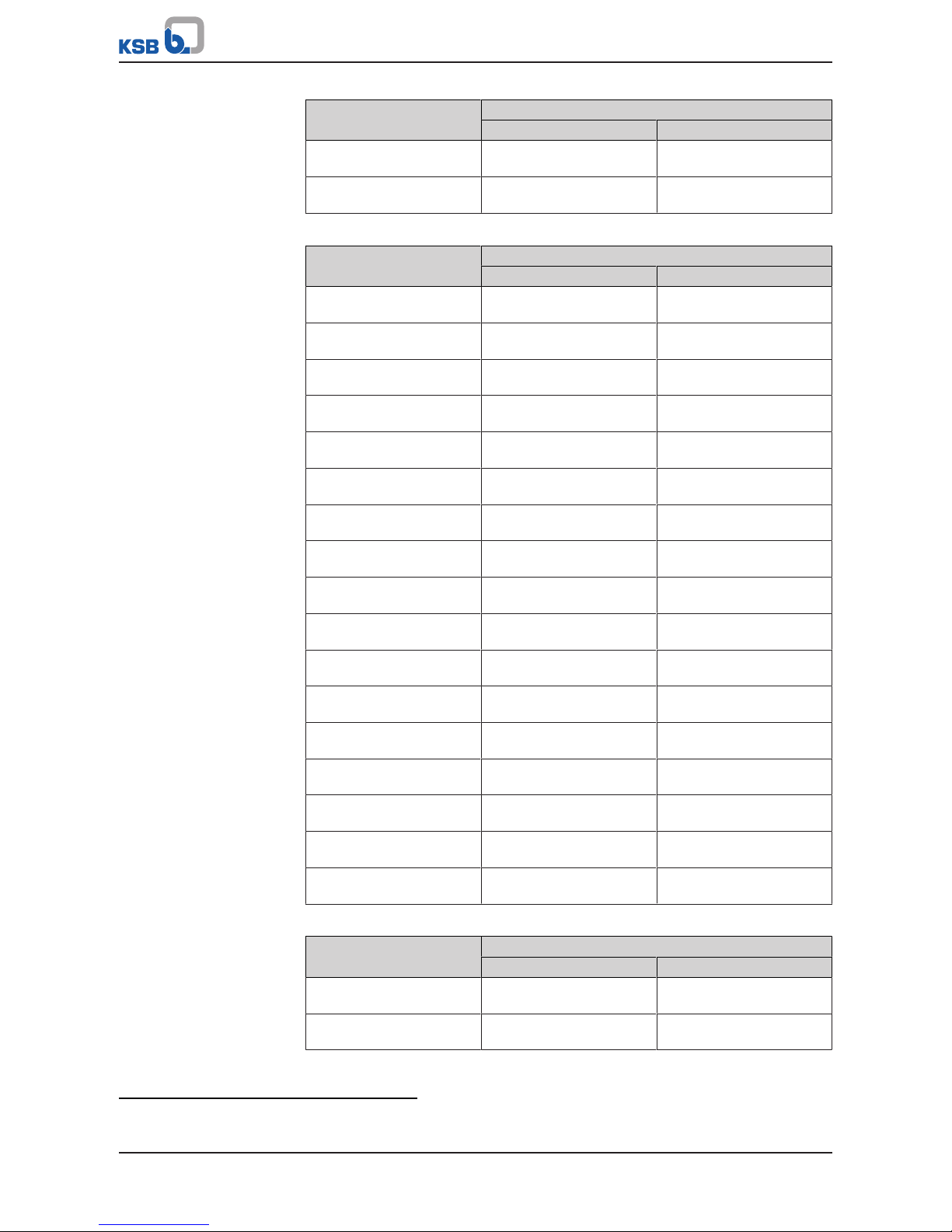

Sizes Weight

Per pump Lifting unit

1)

UZ28.450D

UZ28.900D

180

180

495

570

UZ29.450D

UZ29.900D

180

180

495

570

Table5: Weight Compacta ZF - Sewabloc [kg]

Sizes Weight

Per pump Lifting unit

2)

ZF30.450D

ZF30.900D

195

195

525

600

ZF31.450D

ZF31.900D

204

204

543

618

ZF32.450D

ZF32.900D

204

204

543

618

ZF33.450D

ZF33.900D

275

275

695

770

ZF34.450D

ZF34.900D

335

335

695

770

ZF35.450D

ZF35.900D

335

335

695

770

ZF36.450D

ZF36.900D

335

335

695

770

ZF40.450D

ZF40.900D

117

117

369

444

ZF41.450D

ZF41.900D

121

121

377

452

ZF42.450D

ZF42.900D

134

134

403

478

ZF43.450D

ZF43.900D

141

141

417

492

ZF44.450D

ZF44.900D

141

141

417

492

ZF45.450D

ZF45.900D

170

170

475

550

ZF46.450D

ZF46.900D

182

182

499

574

ZF47.450D

ZF47.900D

121

121

377

452

ZF48.450D

ZF48.900D

130

130

395

470

ZF49.450D

ZF49.900D

135

135

405

480

Table6: Weight Compacta ZK - Sewabloc [kg]

Sizes Weight

Per pump Lifting unit

3)

ZK50.450D

ZK50.900D

128

128

391

466

ZK51.450D

ZK51.900D

128

128

391

466

2) Weight of the lifting unit without water fill

3) Weight of the lifting unit without water fill

Page 12

3 Transport/Temporary Storage/Disposal

12 of 64

Compacta UZ, ZF, ZK

Sizes Weight

Per pump Lifting unit

3)

ZK52.450D

ZK52.900D

135

135

405

480

ZK53.450D

ZK53.900D

135

135

405

480

ZK54.450D

ZK54.900D

135

135

405

480

ZK55.450D

ZK55.900D

141

141

417

492

ZK56.450D

ZK56.900D

141

141

417

492

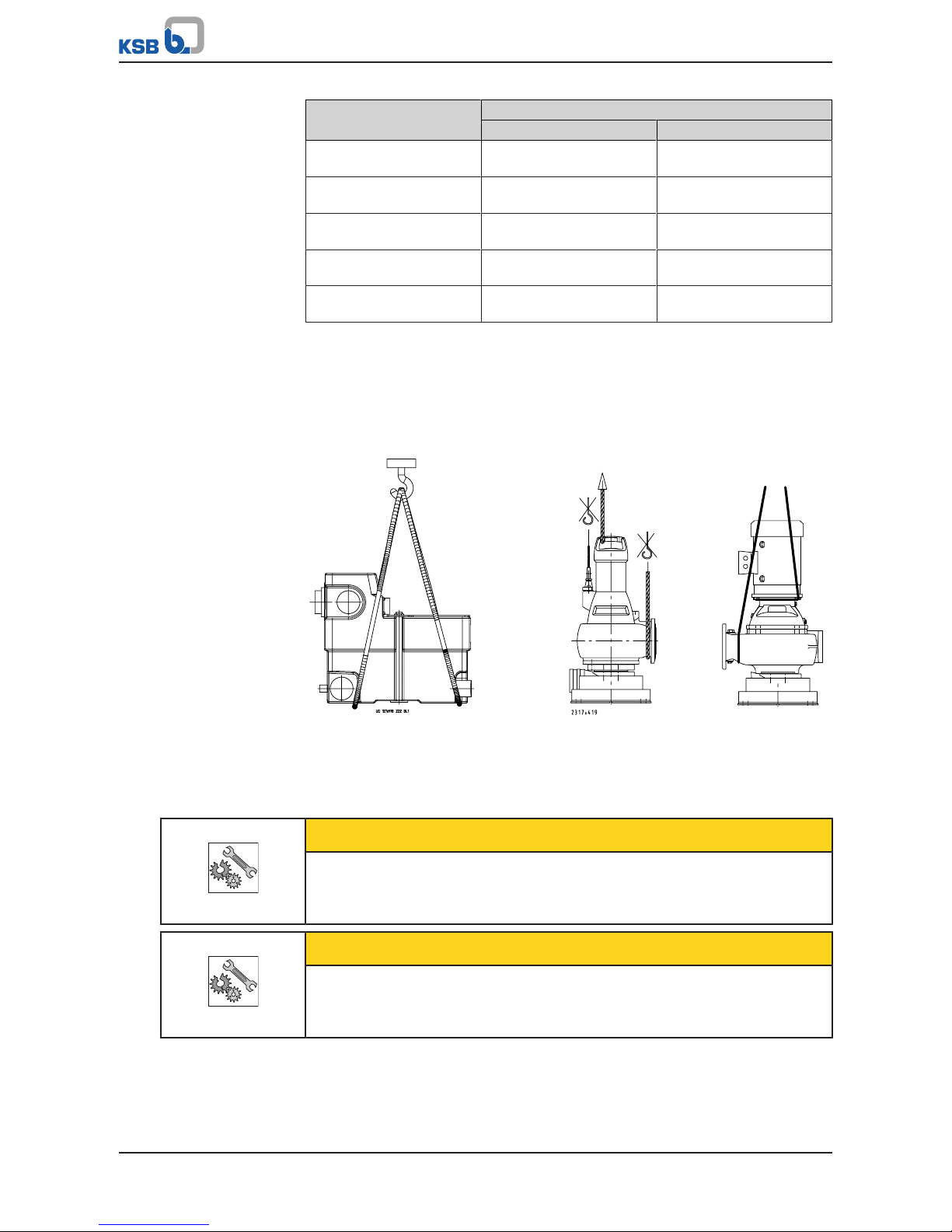

ü The lifting unit has been checked for in-transit damage.

1. Select suitable transport equipment (in acc. with weights table).

2. Transport the tank/pump to the place of installation.

3. Remove the transport fixtures.

4. Use suitable lifting equipment to place the tank/pump down at the place of

installation (as shown).

Fig.1: Transporting the tank - Amarex/KRT - Sewabloc

3.3 Storage/preservation

If commissioning is to take place some time after delivery, we recommend that the

following measures be taken for storing the lifting unit:

CAUTION

Damage during storage due to frost, humidity, dirt, UV radiation or vermin

Corrosion/contamination of the lifting unit!

▷ Store the lifting unit in a frost-proof, roofed area.

CAUTION

Wet, contaminated or damaged openings and connections

Leakage or damage of the lifting unit!

▷ Only open the openings of the lifting unit at the time of installation.

Store the lifting unit in a dry, protected room where the atmospheric humidity is as

constant as possible.

Page 13

3 Transport/Temporary Storage/Disposal

13 of 64

Compacta UZ, ZF, ZK

3.4 Return to supplier

1. Drain the lifting unit as described in the manual.

2. Always flush and clean the lifting unit, particularly if it has been used for

handling noxious, explosive, hot or other hazardous fluids.

3. If the unit has handled fluids whose residues could lead to corrosion damage in

the presence of atmospheric humidity or could ignite upon contact with oxygen,

the unit must also be neutralised and blown through with anhydrous inert gas

to ensure drying.

4. Always complete and enclose a certificate of decontamination when returning

the lifting unit. (ðSection13,Page59)

Always indicate any safety and decontamination measures taken.

NOTE

If required, a blank certificate of decontamination can be downloaded from the

following web site: www.ksb.com/certificate_of_decontamination

3.5 Disposal

WARNING

Fluids handled, consumables and supplies which are hot and/or pose a health

hazard

Hazard to persons and the environment!

▷ Collect and properly dispose of flushing fluid and any fluid residues.

▷ Wear safety clothing and a protective mask if required.

▷ Observe all legal regulations on the disposal of fluids posing a health hazard.

1. Dismantle the lifting unit.

Collect greases and other lubricants during dismantling.

2. Separate and sort the pump materials, e.g. by:

- Metals

- Plastics

- Electronic waste

- Greases and other lubricants

3. Dispose of materials in accordance with local regulations or in another

controlled manner.

Page 14

4 Description

14 of 64

Compacta UZ, ZF, ZK

4 Description

4.1 General description

Floodable sewage lifting unit

▪ The sewage lifting unit consists of either one or two collecting tanks, two pump

sets and the unit control system.

NOTE

The flow velocity in the discharge line must not be less than 0.7m/s and not higher

than 2.3 m/s.

NOTE

The effective volume of the lifting unit must be greater than the volumetric

content of the discharge line up to the backflow loop.

4.2 Designation

Example: Compacta UZ X 12.450 D

Table7: Designation key

Code Description

Compacta Type series

UZ Type of lifting unit

U Floodable AmarexKRT submersible motor pump,

Fimpeller

Z Dual-pump unit

F Dry-installed Sewabloc volute casing pump,

Fimpeller

K Dry-installed Sewabloc volute casing pump,

Kimpeller

X Special design

12 Hydraulics code

450 Total volume of collecting tank [litres]

450,

900

D Three-phase motor

Control unit

Example: BC 2 400 D V N A 100 B 2

Table8: Designation key

Code Description

BC Type

BC Basic Compact

2 Number of pumps

400 Electrical voltage, e.g. 400V, resulting in the number of

wires (e.g. 400V, 4wires or 5wires)

D Starting method

D DOL starting

V Sensor 0-5V

N Without ATEX function

A Installation option with rechargeable battery

100 Rated current x 10 (e.g. 10A)

Page 15

4 Description

15 of 64

Compacta UZ, ZF, ZK

Code Description

B Pump variant

2 Country-specific version

4.3 Name plates

Examples:

Pump For the pump name plate refer to the installation/operating manual of the waste

water pump.

Tank

1

2

3

4

5

6

7

8

Johann-Klein-Straße 9

Deutschland

67227 Frankenthal

KSB SE & Co. KGaA

1 Type series, size 2 Serial No.

3 Maximum flow rate 4 Maximum head

5 Principles of construction and

testing

6 Year/week of construction

7 Notified body / year of

introduction

8 Declaration of performance

reference No.

Control unit

1

2

3

4

5

6

7

ZNI 1448xa

2014w07

BD706005

BC2400DFNO100

IP 54

Made in Germany

Ue: 3/N/PE/AC 400 V 50 HZ

Ie: 6,3 - 10,0 A

LevelControl Basic 2

Johann-Klein-Straße 9

Deutschland

67227 Frankenthal

KSB SE & Co. KGaA

Fig.2: Example of name plate

1 Designation 2 Product code

3 Nominal voltage 4 Nominal current

5 Circuit diagram number 6 Year/week of construction

7 Enclosure

4.4 Design details

Lifting unit

Design

▪ Sewage lifting unit to EN12050-1

▪ Ready-to-connect dual-pump station

▪ Gas and water-proof plastic collecting tank, sensors and control unit

– UZ, ZF, ZK900 battery design with two collecting tanks

Compacta UZ:

▪ Floodable sewage lifting unit

4)

▪ Two vertically installed submersible waste water pumps

4) Max. flooding height: 2 metres, max. flooding period: 7 days (does not apply to control unit). The lifting unit must be

cleaned and serviced after it has been flooded.

Page 16

4 Description

16 of 64

Compacta UZ, ZF, ZK

Compacta ZF, ZK:

▪ Two dry-installed vertical waste water volute casing pumps

Drive

▪ Surface-cooled

▪ Three-phase motor

▪ Thermal class F

▪ Electrical voltage 400V (three-phase motor)

▪ Frequency 50 Hz

▪ DOL starting (from 5.5kW star-delta starting)

Compacta UZ:

▪ Submersible motor made by KSB, IP68 enclosure

▪ Monitoring by temperature switches in the winding

Compacta ZF, ZK:

▪ Standardised motor made by KSB, IP55 enclosure

▪ Monitoring via three PTC thermistors

Impeller type

▪ Free-flow impeller

▪ Various application-oriented impeller types

Bearings

▪ Grease-packed, maintenance-free rolling element bearings

Shaft seal

▪ Two bi-directional mechanical seals with oil reservoir filled with environmentally

friendly oil

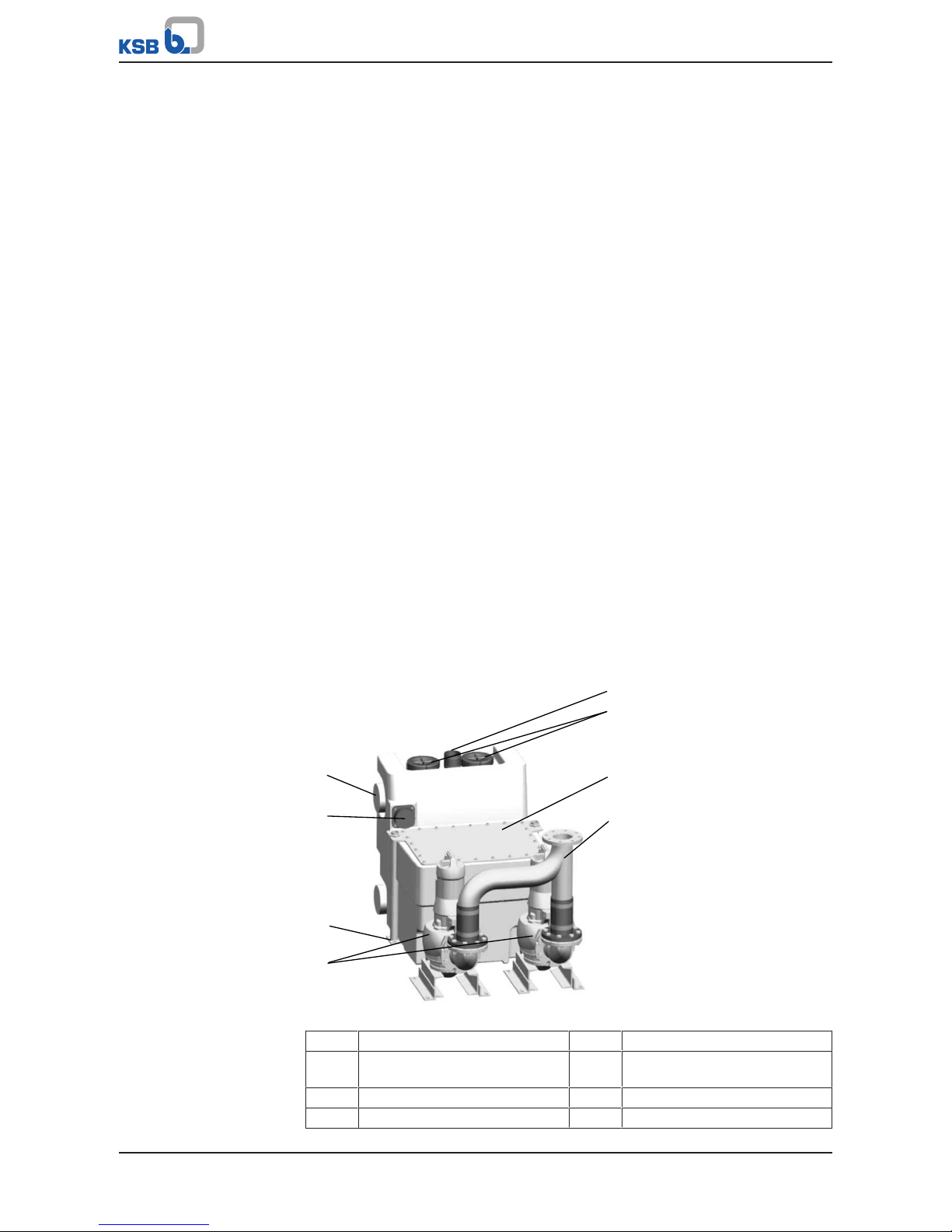

4.5 Configuration and function

1

3

7

8

2

4

6

5

Fig.3: Compacta

1 Inlet 2 Level sensor

3 Transport and

float protection

4 Pump

5 Vent connection 6 Hand hole cover

7 Tank 8 Discharge line

Page 17

4 Description

17 of 64

Compacta UZ, ZF, ZK

Design The lifting unit is provided with several horizontal inlet nozzles(1). The pump(4)

pumps the fluid handled into the vertical discharge line(8).

Function The fluid to be handled flows into the lifting unit through horizontal inlet nozzles(1)

and is collected in a gas-, odour- and water-tight plastic tank(7). When the level

sensor detects a defined fill level, the fluid is automatically pumped off to a level

above the flood level and towards the public sewer by either one or two pumps(4).

Sealing Two bi-directional mechanical seals supplied with environmentally-friendly oil.

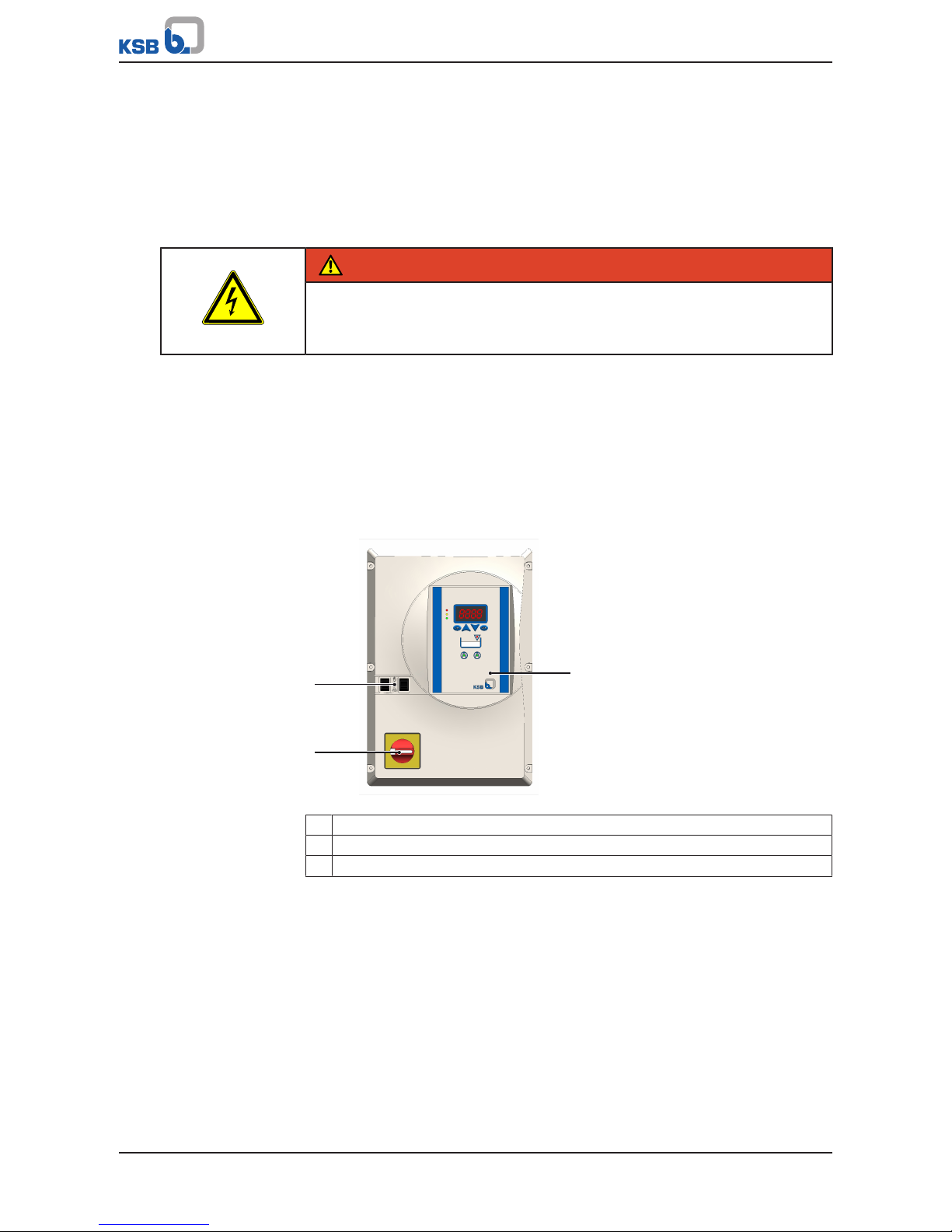

Control unit

DANGER

Flooding of control unit

Danger of death from electric shock!

▷ Operate the control unit in flood-proof rooms only.

LevelControl Basic 2

Type BasicCompact (BC)

▪ Pump control and monitoring unit in compact plastic housing

▪ For either one or two pumps

▪ With display

▪ Level detection via:

– Level sensor 0-5V

▪ DOL starting

2

3

1

Fig.4: Type Basic Compact (BC)

1 Control panel

2 Master switch (optional)

3 Manual-0-automatic switch

LevelControl Basic 2

Type Basic Control Cabinet (BS)

▪ Pump control and monitoring unit in sheet steel housing

▪ For either one or two pumps

▪ With display

▪ Level detection via:

– Level sensor 0-5V

▪ DOL starting or star/delta starting

Page 18

4 Description

18 of 64

Compacta UZ, ZF, ZK

1

2

3

Fig.5: Type Basic Control Cabinet (BS)

1 Master switch

2 Control panel

3 Manual-0-automatic switch

NOTE

The control units are not explosion-proof, and therefore must only be operated

outside potentially explosive atmospheres.

The control unit is always located outside the potentially explosive atmosphere and

may only be installed in a flood-proof room.

4.6 Technical data of the control unit

4.6.1 Electrical data

NOTE

The rated current must not be exceeded.

Higher currents and power ratings are available on request.

Table9: Electrical data of the LevelControl Basic 2 control unit

Characteristic Value

Rated operating voltage 3 ~ 400 V AC +10 % -15 %

Mains frequency 50 Hz ± 2%

Enclosure 400V: IP54

Rated insulation voltage 500V AC

Rated current per motor

(standard models)

Type

BS:

1.6A / 2.5A / 4A / 6.3A / 10A / 14A / 18A / 23A /

25A / 40A / 63A

4.6.2 Technical specifications for sensors

Analog level sensor

▪ Input voltage 0-5V

Motor protection sensors

▪ Max. 2 bimetal switches (thermal circuit breaker) for each pump, 24V, motor

monitoring, PTC data analysis for Compacta ZF, ZK

▪ Max. 1 moisture monitor for each Amarex N/KRT pump

Process inputs

▪ 1 x external alarm input, 24V, via volt-free contact

▪ 1 x remote acknowledgement, 24V, via volt-free contact

Page 19

4 Description

19 of 64

Compacta UZ, ZF, ZK

Process outputs

▪ 1 x volt-free signalling output (250V, 1A, changeover contact)

▪ 1 x signalling output (12.6 to 13.2V), e.g. for connecting a horn, alarm

combination or alarm strobe light (12V connection)

Rechargeable battery

Connection for rechargeable battery, for mains-independent power supply of:

▪ Electronics

▪ Sensors

▪ Alarm equipment

Battery life/charging time

Battery life:

▪ Approx. 10 hours when supplying the integrated piezo buzzer 85dB(A),

electronics, and sensors

▪ Approx. 4 hours when supplying external alarm equipment (e.g. horn, alarm

combination, or alarm strobe light)

Charging time

▪ Approx. 11 hours (if battery is fully discharged)

4.7 Fluids handled

WARNING

Pumping of impermissible fluids

Hazardous to persons and the environment!

▷ Only discharge permissible fluids into the public sewer system.

▷ Check the suitability of pump/system materials.

Permissible

fluids

According to DIN1986-3 the following fluids can be discharged into sewer systems:

Water contaminated by domestic use, human and - as far as required and permitted animal faeces together with the necessary flushing water as well as stormwater in

case no other way of disposal is possible.

5)

Impermissible

fluids

Substances / water which must not be discharged into the sewer system are, amongst

others:

Solid matter, fibres, tar, sand, cement, ash, coarse paper, paper towels, cardboard,

debris, garbage, offal, grease, oil.

Waste water from installations situated above the flood level (EN12056-1).

Waste water containing hazardous substances (DIN1986-100), e.g. greasy waste

water from large-scale catering kitchens.

For drainage of greasy water a grease separator to DIN4040-1 must be fitted.

4.8 Collecting tank

The collecting tank is designed for unpressurised operation; that means the waste

water is stored in the tank in unpressurised condition and is then pumped into the

sewer system.

Size Total volume

Effective volume

Litres Litres

UZ450 450 290

UZ900 900 580

5) Other types of waste water, e.g. industrial waste water, must not be discharged into the local sewer system without prior

treatment.

Page 20

4 Description

20 of 64

Compacta UZ, ZF, ZK

4.9 Noise characteristics

The sound pressure level depends on the local conditions and the duty point. It is

≤70dB(A).

4.10 Scope of supply

Depending on the model, the following items are included in the scope of supply:

Sewage lifting unit consisting of:

▪ Either one or two gas-, odour- and water-tight collecting tanks made of impact-

resistant plastic material, with two waste water pumps

▪ Flexible hose connections and hose clips

▪ Automatic level transmitter

▪ Electronic control unit

4.11 Dimensions and weights

available For dimensions and weights please refer to the outline drawing of the lifting unit.

Control unit Table10: Dimensions and weights

LevelControl Maximum current Size

H × B × T

[kg]

[A] [mm]

Basic 1 10 135 × 171 × 107 3

Basic 2 BC 10 400 × 281 × 135 3

Basic 2 BS1 10 400 × 300 × 155 10

14 600 × 400 × 200 14

18 600 × 400 × 200 14

23 600 × 400 × 200 14

25 600 × 400 × 200 14

40 800 × 600 × 200 18

63 800 × 600 × 200 18

Basic 2 BS2 10 400 × 300 × 155 16

14 800 × 600 × 200 19

18 800 × 600 × 200 19

23 800 × 600 × 200 19

25 800 × 600 × 200 19

40 800 × 600 × 200 24

63 800 × 600 × 200 26

Page 21

5 Installation at Site

21 of 64

Compacta UZ, ZF, ZK

5 Installation at Site

The "Installation at Site" section describes the conditions which must be fulfilled for

assembling the complete sewage lifting unit in accordance with the instructions and

without compromising the safety and health of persons.

5.1 Safety regulations

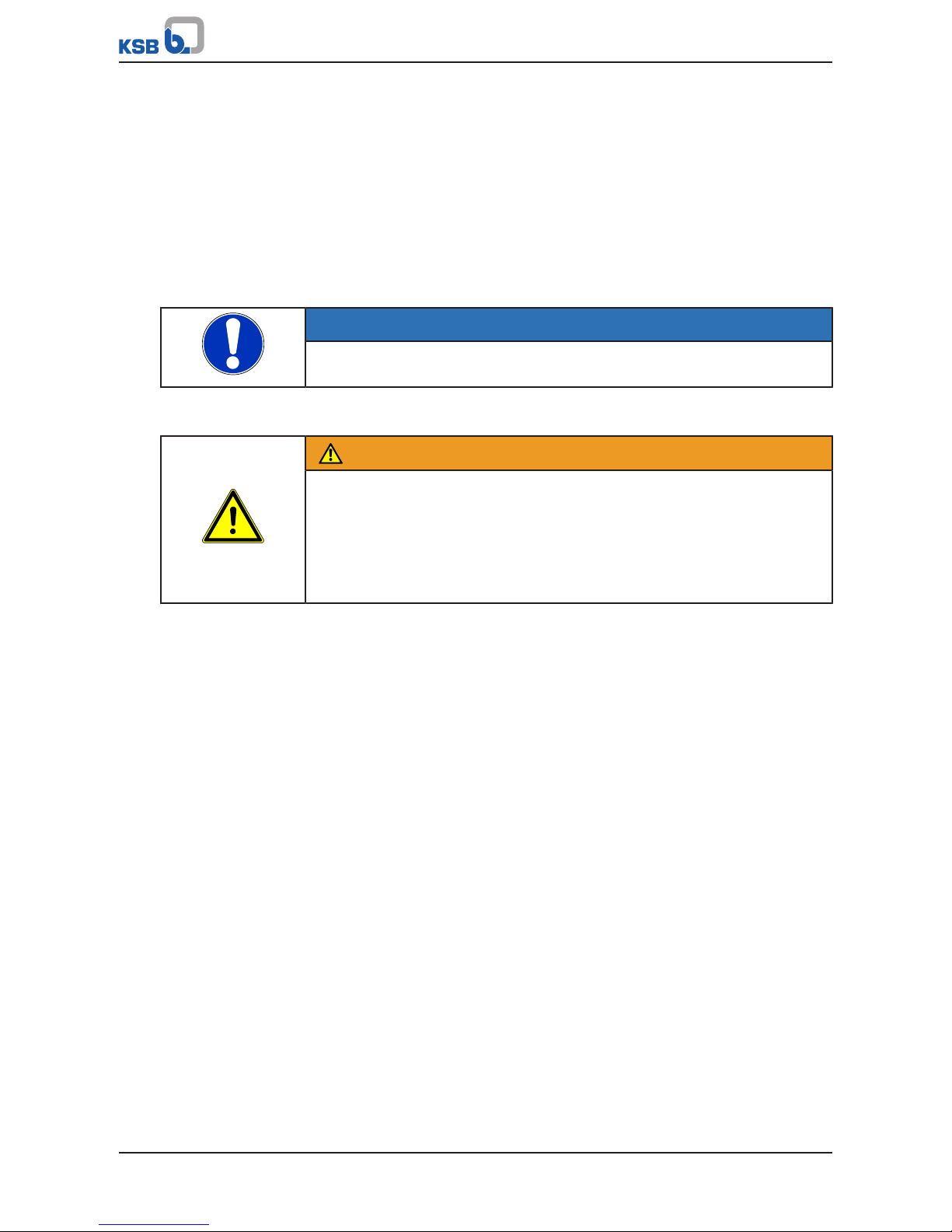

DANGER

Improper installation

Explosion hazard!

▷ Never use sewage lifting units in potentially explosive atmospheres.

WARNING

Hot motor surface

Risk of injury!

▷ Allow the motor to cool down to ambient temperature.

CAUTION

Incorrect connection of the three-phase motor

Damage to the lifting unit!

▷ Always use a 3-pole mechanically interlocked K-type automatic circuit breaker

for external protection.

CAUTION

Incorrect installation of connections and signalling devices

A failure of the lifting unit can cause damage to property by flooding due to the

risk of backflow from the sewage system.

▷ Fit operator-supplied mains-independent alarm equipment (e.g. alarm

switchgear).

▷ Take suitable measures at the site to prevent overflow/flooding (e.g. a swing

check valve in the floor drain, or similar).

5.2 Checks to be carried out prior to installation

Place of installation

WARNING

Installation on mounting surfaces which are unsecured and cannot support the

load

Personal injury and damage to property!

▷ Use a concrete of compressive strength class C12/15 which meets the

requirements of exposure class X0 to EN206-1.

▷ The mounting surface must have set and must be completely horizontal and

even.

▷ Observe the weights indicated.

Check structural requirements.

All structural work required must have been prepared in accordance with the

dimensions stated in the outline drawings/connection examples.

(ðSection10.2,Page48)

Page 22

5 Installation at Site

22 of 64

Compacta UZ, ZF, ZK

5.3 Installing the lifting unit

5.3.1 Setting up the tank(s)

NOTE

Lifting units should not be installed next to sleeping or living quarters.

WARNING

Insufficient ventilation

Personal injury and damage to property!

▷ Provide proper aeration and ventilation.

▷ For room drainage, a pump sump must be provided.

ü The name plate data has been compared against the purchase order and the site

data (e.g. supply voltage, frequency, pump operating data, etc).

ü The fluid to be handled is an approved fluid. (ðSection4.7,Page19)

ü The installation room is frost-proof.

ü All structural work required has been prepared in accordance with the

dimensions stated in the connection example and in EN12056.

ü The installation room is of sufficient size - see connection example.

(ðSection10.2,Page48)

ü The installation room is adequately lit.

ü Alarm messages are always recognised in time by the operator (use an external

alarm transmitter, if required).

1. Place the tank on a level floor and align with the help of a spirit level.

2. Place pads 99-3.2 under the foot areas of tank 591.

NOTE

The anti-vibration mounts of the lifting unit provide adequate insulation against

solid-borne noise.

3. Use the transport/float protection fixtures supplied to secure the tank firmly to

the floor.

Battery design with two collecting tanks UZ, ZF, ZK 900

Connect the two tanks with each other via the two DN150 connection nozzles (1x

connection level 100mm and 1x connection level 700mm), using flexible hose

connections.

5.3.2 Setting up the pump

1. Place pads 99-3.2 under the foot points of the pumps.

2. Connect the pump inlet to the collecting tank by means of the flexible

connection supplied (flexible tube 719.6 with internal pipe 710.2 and pipe clamps

733.21).

3. Align the pumps using a spirit level.

4. Fasten pump foot 182 to the foundation using screws and plug fixings 90-3.

NOTE

For the individual discharge pipes of the pumps to be connected to a common

discharge line via a Y-pipe, the distances between the pump centrelines given in the

installation examples must absolutely be complied with. (ðSection10.2,Page48)

Page 23

5 Installation at Site

23 of 64

Compacta UZ, ZF, ZK

NOTE

In battery design (two tanks), each pump is assigned to a tank.

5.4 Connecting the piping

DANGER

Impermissible loads acting on the system nozzles

Danger to life from leakage of hot, toxic, corrosive or flammable fluids!

▷ Do not use the lifting unit as an anchorage point for the piping.

▷ Anchor the pipes immediately upstream of the lifting unit and connect them

without transmitting any stresses or strains.

▷ Observe the permissible forces and moments at the lifting unit.

(ðSection8.5,Page41)

▷ Take appropriate measures to compensate thermal expansion of the piping.

NOTE

The installation of check and shut-off elements is mandatory. However, such

elements must not obstruct proper drainage or hinder disassembly of the lifting

unit.

Discharge line

CAUTION

Incorrect installation of discharge line

Leaks and flooding of installation room!

▷ Run the discharge line above the flood level before leading it into the sewer.

▷ Do not connect the discharge line to the downpipe.

▷ Do not connect any additional sanitary installations to the discharge line.

NOTE

To prevent any backflow from the collecting main, run the discharge line in the

form of a pipe loop whose invert at its highest point must be above the locally

defined flood level (e.g. street level).

A gate valve must be installed downstream of the check valve.

Inlet line

A gate valve must be fitted so that the inlet line can be shut off temporarily during

repair work or servicing.

Compacta units have variable inlet nozzle levels.

ü Piping weights have been supported at the site.

ü All tank nozzles are closed.

1. Determine which connection nozzles will be used.

2. Open the nozzles required (▼A) by sawing off the nozzle faces (approx.10mm).

Page 24

5 Installation at Site

24 of 64

Compacta UZ, ZF, ZK

A

A

Fig.6: Opening the nozzles

Vent line

for the collecting tank

Sewage lifting units to EN12050-1 must be vented through the roof.

The vent line must not be connected to the inlet-side vent line of a grease separator.

Connect the DN70 vent line to the vertical vent nozzle by means of the flexible hose

connection, making sure that the connection is odour-proof.

If changes of direction are unavoidable, the pipe should be laid with a minimum

gradient of 1:50.

NOTE

Lifting units featuring two collecting tanks require just one vent line.

Pump vent lines

Vent lines 70-1 must be fitted between the collecting tank and connection elbow

72-1.1 of each pump. (ðSection10.1.1,Page45)

The parts required are included in the scope of supply.

CAUTION

Air collecting in the upper section of the pump casing (on UZ10.450 to UZ11.900)

Specified performance data are not achieved!

▷ Connect the vent line directly to the pump casing (see B5.1 in general assembly

drawing). (ðSection10.1.1,Page45)

Drainage nozzle for hand diaphragm pump

NOTE

We recommend connecting a hand diaphragm pump (available as accessory) to

allow complete drainage of the tank for servicing work.

Fit this pump, using the flexible hose connection supplied, after having opened the

DN 40 nozzle.

5.5 Cellar drainage

Automatic

drainage

If the installation room is to be drained automatically, particularly if there is a risk of

flooding or seepage water, we recommend installing one of our Ama-Drainer

submersible waste water pumps.

This pump must be selected in accordance with the local conditions:

(Head H [m] = H

Static

+ H

Losses

).

The sump in the floor of the installation room should measure at least 500 x 500 x

500 mm.

Manual

drainage

If manual drainage is preferred, a hand diaphragm pump can be ordered as

accessory. In this case, the required sump dimensions are 300 x 300 x 500 mm.

Page 25

5 Installation at Site

25 of 64

Compacta UZ, ZF, ZK

CAUTION

Discharge line for cellar drainage connected to the discharge line of the lifting unit

Flooding of installation room!

▷ Run the separate discharge line for cellar drainage above the flood level before

leading it into the sewer.

▷ Never connect the discharge line for cellar drainage to the discharge line of the

lifting unit.

▷ Install a swing check valve.

5.6 Connection to power supply

DANGER

Electrical connection work by unqualified personnel

Risk of fatal injury due to electric shock!

▷ Always have the electrical connections installed by a trained and qualified

electrician.

▷ Observe regulations IEC 60364 and, for explosion-proof models, EN60079.

WARNING

Incorrect connection to the mains

Damage to the mains network, short circuit!

▷ Observe the technical specifications of the local energy supply companies.

Connection to power supply must be effected in accordance with the operating

manual supplied and the wiring diagrams of the waste water pump.

LevelControl Basic 2

Fig.7: LevelControl Basic 2

1. Check that the operating voltage indicated on the control unit is suitable.

2. Connect the mains cable to the control unit with a suitable cable gland.

3. Connect the mains cable to the terminal at the master switch; a terminal for the

earth conductor is provided.

4. Prior to switching on the unit, check that all protective equipment works

properly.

Page 26

5 Installation at Site

26 of 64

Compacta UZ, ZF, ZK

5.7 Checking the direction of rotation

WARNING

Hands or objects inside the pump casing / inside the lifting unit

Risk of injuries, damage to the pump / lifting unit!

▷ Never hold your hands or any other objects into the pump.

▷ Check that the pump and the tank are free from foreign objects.

CAUTION

Wrong direction of rotation

The lifting unit does not reach its duty point!

▷ Check the direction of rotation.

The direction of rotation must be checked during commissioning or when the unit is

returned to service.

For checking the direction of rotation of the pump refer to the installation/operating

manual of the waste water pump.

Page 27

6 Commissioning/Start-up/Shutdown

27 of 64

Compacta UZ, ZF, ZK

6 Commissioning/Start-up/Shutdown

6.1 Commissioning/Start-up

6.1.1 Prerequisites for commissioning/start-up

Before commissioning/start-up of the lifting unit make sure that the following

requirements are met:

▪ The lifting unit has been properly connected to the electric power supply and is

equipped with all protection devices.

▪ All relevant VDE standards and/or regulations applicable in the country of use are

complied with.

6.2 Operating limits

DANGER

Non-compliance with operating limits for pressure and temperature

Hot or toxic fluid could escape!

Explosion hazard!

▷ Comply with the operating data indicated in the technical product literature.

▷ Avoid prolonged operation against a closed shut-off element.

▷ Never operate the lifting unit at temperatures exceeding those specified in the

technical product literature or on the name plate.

▷ Dry running must be prevented by all means.

Observe the following parameters and values during operation:

Parameter Value

Maximum permissible fluid temperature 40°C

for max. 5 minutes up to 65°C

Max. ambient temperature 40°C (air)

6.2.1 Operating limits per operating mode

Table11: Operating modes

Operation Type

UZ intermittent duty S3 to VDE

ZF, ZK continuous duty S1

6.2.1.1 Application limits for S3 duty

Compacta UZ - Hydraulics code 10 to 29

6)

The units are designed for S3 duty (intermittent duty). The max. permissible inflow

must always be smaller than the capacity of one pump.

▪ Intermittent duty S3

▪ The units are designed for the ratio of Q

Z

7)

:Q

P

8)

=0.9 not to be exceeded.

6) For continuous inflow or repeated inflow over longer periods of time the maximum permissible frequency of starts must be

observed!

7) Maximum possible inflow in m³/h

8) Duty point of a pump in m³/h

Page 28

6 Commissioning/Start-up/Shutdown

28 of 64

Compacta UZ, ZF, ZK

Table12: Frequency of starts

Motor rating

[kW]

Maximum No. of starts per pump

[Starts/hour]

3,7 - 7,5 30

> 7,5 15

6.2.1.2 Application limits for S1 duty

Compacta ZF, ZK - Hydraulics code 30 to 56

▪ Continuous duty S1

Table13: Frequency of starts

Motor rating

[kW]

Maximum No. of starts per pump

[Starts/hour]

≤ 11 25

≤ 37 20

6.2.2 Supply voltage

CAUTION

Wrong supply voltage

Damage to the lifting unit!

▷ The maximum permissible deviation in supply voltage is 10% of the rated

voltage indicated on the name plate.

6.3 Commissioning/start-up of control unit

Verify that all safety regulations and instructions are complied with and that the

technical specifications of the lifting unit are suitable for operation.

Commissioning:

The lifting unit is fully installed and all transport locks, e.g. at the sensor, have been

removed.

NOTE

The control unit parameters have been set at the factory. The parameters need not

be changed for commissioning.

Page 29

6 Commissioning/Start-up/Shutdown

29 of 64

Compacta UZ, ZF, ZK

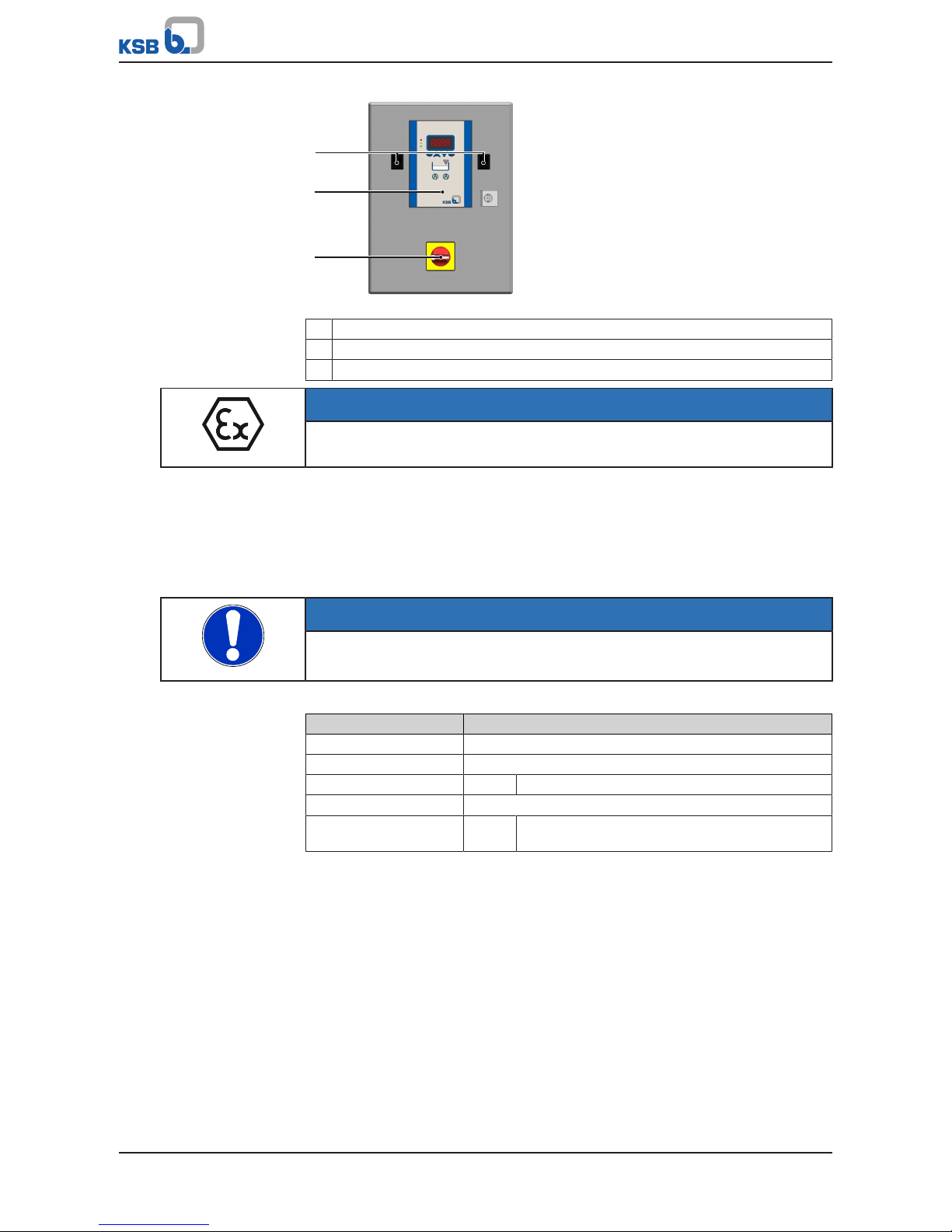

6.3.1 Lifting unit with LevelControl Basic 2

DANGER

Live voltage

Danger to life!

▷ Only open the device after it has been de-energised.

Setting the motor protection switch

Set the motor protection switch to the rated motor current indicated on the pump

name plate and switch on the motor protection switch.

Connecting the rechargeable battery

To enable the mains-independent alert, connect the rechargeable battery in the

control unit.

Fig.8: Battery of LevelControl Basic BC

Fig.9: Battery of LevelControl Basic BS

Checking the direction of rotation

Rotary field of mains

connection

1. If an A12 alert signals that the rotary field of the mains supply is incorrect,

correct the rotary field by interchanging two phases at the mains connection.

Direction of rotation of the

pump

ü The pump has been removed from the system.

1. Check the direction of rotation or determine the direction of rotation by

another, suitable measurement method.

ð If the pump is running in the wrong direction of rotation, correct by

interchanging two phases at the motor power cable.

Functional test and leak testing

Test-run the lifting unit for several fill and pump-off cycles and check the proper

function and leak-free operation of the lifting unit, using the checklist provided.

(ðSection8.7,Page41)

Page 30

6 Commissioning/Start-up/Shutdown

30 of 64

Compacta UZ, ZF, ZK

NOTE

A sensor fault may be displayed when the lifting unit has not been filled yet. It will

disappear after the lifting unit has been filled.

The manual-0-automatic switch must be set to "Automatic".

6.3.1.1 Using additional functions

6.3.1.1.1 Functional check run

For pumps with long idle periods, a functional check run can be activated at

parameter 3-7-1. The functional check run is carried out weekly for a duration of

three seconds.

6.3.1.1.2 External alarm input

Ext

A NO contact can be connected to LevelControl Basic 2 as external alarm. If the

contact is activated, alert A10 is displayed and the pumps are stopped.

6.3.1.1.3 Fault signalling contact

Alarm

For fault signalling, a relay contact is available as changeover contact. The NC contact

is closed in the event of a fault.

6.3.1.1.4 External acknowledgement input

Ack

A push-button for external acknowledgement can be connected to the Ack terminals.

6.3.1.1.5 Output for horn or signal light

A horn or signal light 12VDC, max.200mA, can be connected.

6.4 Shutdown

1. Pump off the tank contents.

2. Shut off the inlet and discharge lines.

3. Interrupt power supply and secure against unintentional start-up.

DANGER

Power supply not disconnected

Danger to life!

▷ Disconnect all electrical connections from the power supply and secure against

unintentional start-up.

4. Drain the tank completely by hand (e.g. by means of the hand diaphragm

pump).

5. After prolonged standstill:

Remove and clean the waste water pump.

Spray the hydraulic section with oil for preservation.

6. Unscrew handhole cover 160.

7. Clean the tank.

Page 31

6 Commissioning/Start-up/Shutdown

31 of 64

Compacta UZ, ZF, ZK

WARNING

Fluids handled and supplies posing a health hazard

Hazard to persons and the environment!

▷ Decontaminate lifting units which handle fluids posing a health hazard.

Wear safety clothing and a protective mask, if required.

▷ Observe all legal regulations on the disposal of fluids posing a health hazard.

Page 32

7 Operation

32 of 64

Compacta UZ, ZF, ZK

7 Operation

DANGER

Unintentional starting of pumps

Risk of injury: Limbs can be pulled into or crushed by machinery!

▷ Make sure that nobody is within the immediate, hazardous vicinity of the

pumps.

▷ Make sure that all piping is properly installed and that the fluid handled cannot

escape.

NOTE

This section provides information about a control unit for two pumps. The control

unit for one pump is operated in the same way. Pump-specific steps shall only be

carried out once in this case.

The control unit can be operated via:

▪ Control panel (ðSection7.1,Page32)

▪ Manual-0-automatic selector switch (ðSection7.2,Page34)

▪ Service interface (connector inside control unit)

7.1 Control panel

ESC OK

1

2

3

4

5

Fig.10: Control panel

1 Display (7 segment, 5 character)

2 Traffic light LEDs

3 Navigation keys

4 "High water" LED

5 LED for pump operating status (for each pump)

7.1.1 Indicators

Traffic light LEDs

The "traffic light" LEDs provide information about the operating status of the

control unit.

Page 33

7 Operation

33 of 64

Compacta UZ, ZF, ZK

Table14: Traffic light LEDs

LED Description

Green Readiness for operation

Yellow Warning (one or more warnings)

Red Alert (one or more alerts)

LED for pump operating status

This LED indicates the operating status of the pumps:

Table15: LED for pump operating status

LED Description

Green Pump ready for operation

Flashing green Pump running

Yellow Pump OFF (manual-0-automatic selector switch set to "0")

Flashing yellow Pump running in manual mode

Manual-0-automatic selector switch set to "manual" (nonlocking button)

Red Pump blocked by alert or no enable signal

"High water" LED

If a high water alert is output, the red LED lights up. The pumps are started with high

priority (except if sensor of ATEX-compliant models is defective). Alerts with a higher

priority overwrite the high water alert.

7.1.2 Display

The following information is displayed:

Fig.11: Display

1 Parameter

2 Parameter/measured value

3 Alert

7.1.3 Navigation keys

For navigating through the menus and confirming settings:

Table16: Control unit: navigation keys

Key Description

Arrow keys (up/down):

▪ Move up/down in the menu options.

▪ Increase/decrease a numerical value

Esc

Escape key:

▪ Cancel entry without saving it.

▪ When entering numbers: Go to the previous digit.

▪ Move up one menu level.

OK

OK key:

▪ Confirm settings.

▪ Confirm a menu selection.

▪ When entering numbers: Go to the next digit.

Page 34

7 Operation

34 of 64

Compacta UZ, ZF, ZK

7.2 Manual-0-automatic selector switch

Each pump can be operated as follows by means of a manual-0-automatic selector

switch:

Table17: Switch positions of manual-0-automatic selector switch

Switch position Function

Function allowing the pump to be operated manually for a

short period

Switch locks in place.

The pump is switched off.

Switch locks in place.

The pump is started/stopped by the control unit as a

function of demand.

7.3 Control panel

7.3.1 Displaying measured value parameters

Fig.12: Displaying measured value parameters

1. Press ESC (several times, if necessary) to call up the measured value parameters.

2. Use the arrow keys to select the required parameter number.

ð The relevant measured value is displayed automatically after 1.5 seconds.

3. Use the arrow keys to select the next parameter number.

The following measured value parameters can be displayed:

Table18: Menu structure

Parameter Description

1.1.1 Level (Analog) Fill level if analog sensors are used

[mm]

1.1.3 Mains Voltage Mains voltage [V]

1.2.1 Operating Hours Pump 1 Operating hours of pump 1 [h]

1.2.2 Start Count Pump 1 Number of starts of pump 1

1.3.1 Operating Hours Pump 2 Operating hours of pump 2 [h]

1.3.2 Start Count Pump 2 Number of starts of pump 2

2.1.1 Pending Messages Pending messages (displayed in fault

mode only)

Page 35

7 Operation

35 of 64

Compacta UZ, ZF, ZK

7.3.2 Setting parameters

NOTE

The parameters that you can call up depend on the operating mode and

measurement method. Only parameters that are relevant to the current operating

mode and measurement method are displayed.

Fig.13: Setting parameters

1. Press and hold the ESC key and press OK.

ð The first parameter number (P 3-3-2) is displayed.

OK

2. Use the arrow keys to select the required parameter number.

3. Confirm the parameter number with OK.

ð The parameter value is displayed immediately.

4. Set the parameter value using the arrow keys:

ð In multi-digit entries, the digit to be entered flashes.

ð To move one digit to the right or left, press OK or ESC and make the

required entry.

OK

5. To confirm the entry press OK: The parameter value will be saved.

ð The parameter number is displayed.

Esc

6. To cancel the entry press ESC: The parameter value remains unchanged.

ð The parameter number is displayed.

Esc

7. Return to the measured values by pressing ESC.

Table19: Menu structure

Parameter Description

3.1.2.1 Tank Commissioning of lifting units Setting the tank type

(may be disabled)

3.1.2.2 Inlet Level Commissioning of lifting units Setting the unit to the lowest open

inlet nozzle

Page 36

7 Operation

36 of 64

Compacta UZ, ZF, ZK

Parameter Description

3.3.4.1 Pumps OFF Level Pumps OFF [mm]

3.3.4.2 Base Load ON Level Base Load ON [mm]

3.3.4.3 Peak Load ON Level Peak Load ON [mm]

3.3.4.4 High Water Level High Water [mm]

3.3.5.3 Stop Delay Setting the stop delay [1/10 s]

4.1.1 Firmware version Firmware version

7.3.3 Acknowledging alerts and warnings

Fig.14: Acknowledging alerts and warnings

Alerts with auto-acknowledgement are deactivated and acknowledged automatically

as soon as the cause of the alert has been rectified. Such alerts (incl. horn/buzzer) can

also be acknowledged manually.

Alerts with manual acknowledgement must be acknowledged at the control panel or

via the remote acknowledgement input.

1. If it is active, exit the screen for setting parameters by pressing ESC .

ð The alert with the highest priority is displayed.

2. Acknowledge the alert with OK .

ð Horn/buzzer is deactivated.

ð If the alert is still present, it is entered in the alerts list (2-1-1).

ð The next alert (if any) is displayed.

3. Rectify the cause of the fault:

ð If necessary, call up the parameter settings by pressing OK or ESC .

Table20: Alerts and warnings

No. Prio. Type Acknowledgement Description Action

A1 1 Alert Manual Motor protection pump 1 Pump 1 OFF

A2 2 Alert Manual Motor protection pump 2 Pump 2 OFF

A3 3 Alert Auto Motor 1 temperature too high Pump 1 OFF

A4 4 Alert Auto Motor 2 temperature too high Pump 2 OFF

A5 5 Alert Auto Power supply failure Both pumps OFF

A6 6 Alert Auto Phase error (phase failure) Both pumps OFF

A7 7 Alert Manual Leakage motor 1 (Amarex N/KRT) Pump 1 OFF

A8 8 Alert Manual Leakage motor 2 (Amarex N/KRT) Pump 2 OFF

Page 37

7 Operation

37 of 64

Compacta UZ, ZF, ZK

No. Prio. Type Acknowledgement Description Action

A9 9 Alert Auto High water alert Both pumps ON

A10 10 Alert Auto External alert Both pumps OFF (can be

changed via the KSB

Service Tool)

A11 11 Alert Auto Sensor fault No changes

A12 12 Warning Auto Incorrect rotary field of mains supply

(phase sequence)

No changes

A13 13 Warning Auto Undervoltage (- 15 % of rated

voltage 230V or 400V)

No changes

A14 14 Warning Auto Overvoltage (+ 15 % of rated

voltage 230V or 400V)

No changes

A15 15 Warning Auto Flat battery No changes

A16 16 Warning Auto Service interval system (deactivated

by default)

No changes

NOTE

The service interval is deactivated by default and can be set via the KSB Service

Tool.

7.3.4 Displaying the alerts list

Alerts that have been acknowledged but are still present are stored in the alerts list

(2-1-1) and can be called up.

1. If no measured value number (P 1-X-X) is displayed, press ESC (more than once if

necessary).

2. Use the arrow keys to select the alerts list (P 2-1-1).

ð The most recent entry is displayed automatically after 1.5seconds.

ð The next entry is displayed after another 1.5 seconds.

3. To return to the screen in which you can select a measured value, press ESC.

7.3.5 Replacing the rechargeable battery

NOTE

The rechargeable batteries must be replaced every five years to ensure that the

device operates reliably in battery mode.

Use original KSB spare parts only.

1. Switch off the power supply.

2. Open the control unit.

3. Disconnect the battery.

4. Undo the battery clamp.

5. Replace the batteries.

6. Reattach the battery clamp.

7. Re-establish the connections for the battery.

8. Close the device properly.

9. Switch the power supply back on.

Page 38

8 Servicing/Maintenance

38 of 64

Compacta UZ, ZF, ZK

8 Servicing/Maintenance

8.1 General information/Safety regulations

WARNING

Improper lifting/moving of heavy assemblies or components

Personal injury and damage to property!

▷ Use suitable transport devices, lifting equipment and lifting tackle to move

heavy assemblies or components.

WARNING

Work on the lifting unit by unqualified personnel

Risk of personal injury!

▷ Always have repair and maintenance work performed by specially trained,

qualified personnel.

Observe the general safety instructions and information.

For dismantling and reassembly observe the exploded views and general assembly

drawings.

After maintenance/repair, make sure that hand hole cover 160 is screwed on tightly.

In the event of damage you can always contact our service staff.

DANGER

Insufficient preparation of work at the lifting unit

Risk of personal injury!

▷ Properly shut down the lifting unit and secure it against unintentional start-up.

▷ Close the shut-off elements in the suction and discharge line.

▷ Drain the lifting unit.

▷ Close any auxiliary connections.

▷ Allow the lifting unit to cool down to ambient temperature.

WARNING

Fluids handled and supplies posing a health hazard

Hazard to persons and the environment!

▷ Decontaminate lifting units which handle fluids posing a health hazard.

Wear safety clothing and a protective mask, if required.

▷ Observe all legal regulations on the disposal of fluids posing a health hazard.

8.2 Servicing/inspection

Supervision of operation

Lifting unit

EN12056-4 stipulates that drainage systems must be serviced and maintained so as to

ensure that waste water can be properly discharged and changes detected and

remedied at an early stage.