Page 1

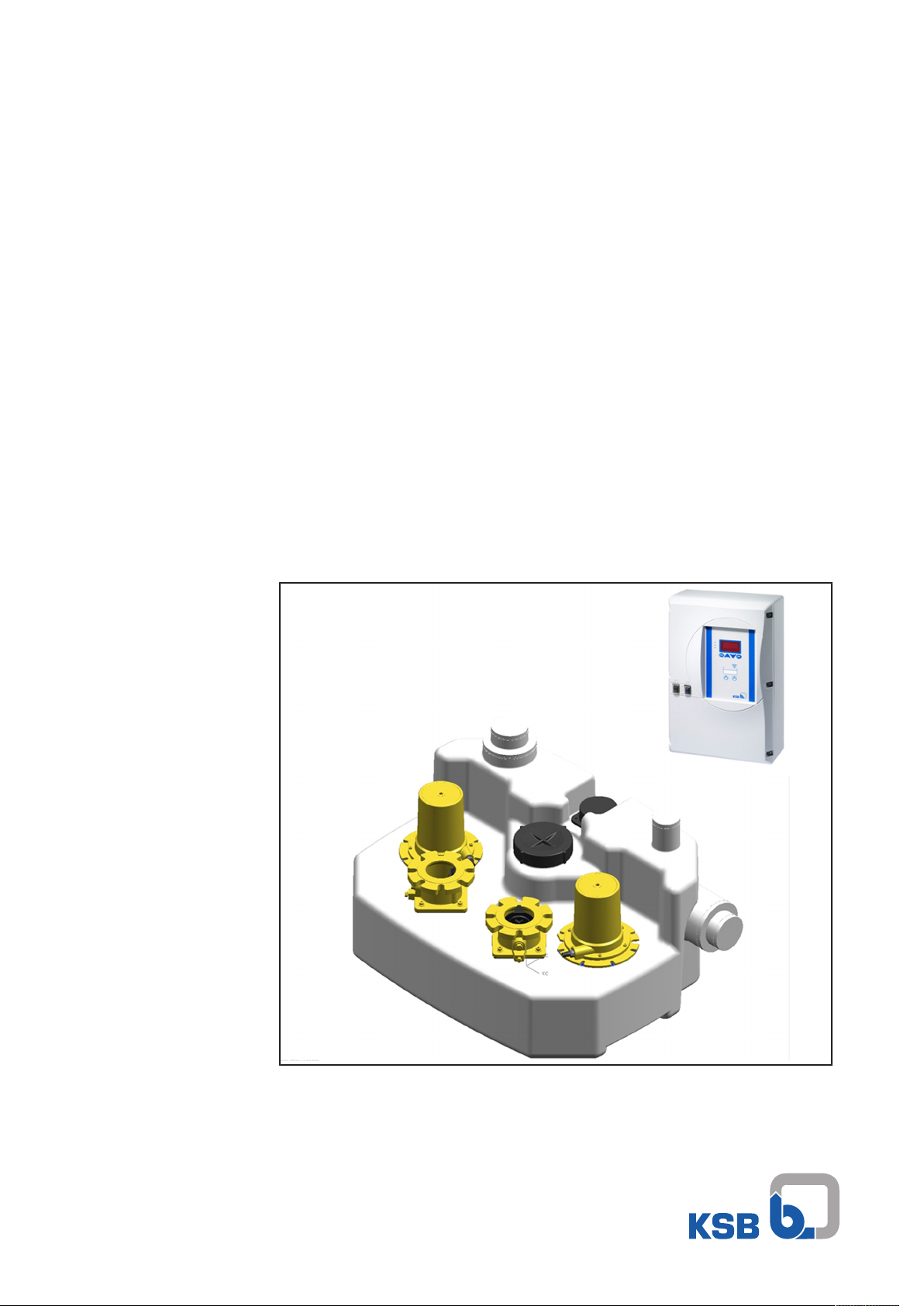

Floodable Sewage Lifting Unit

Compacta / mini-Compacta

Replacing the Control Unit

LevelControl Basic 2 BC

Supplementary Operating

Manual

Page 2

Legal information/Copyright

Supplementary Operating Manual Compacta / mini-Compacta

Original operating manual

All rights reserved. The contents provided herein must neither be distributed, copied, reproduced,

edited or processed for any other purpose, nor otherwise transmitted, published or made available to a

third party without the manufacturer's express written consent.

Subject to technical modification without prior notice.

© KSB SE & Co. KGaA, Frankenthal 24/01/2018

Page 3

Contents

Contents

1 General.................................................................................................................................................... 4

1.1 Principles ...........................................................................................................................................................4

1.2 Target group.....................................................................................................................................................4

1.3 Other applicable documents............................................................................................................................4

1.4 Symbols .............................................................................................................................................................4

2 Safety...................................................................................................................................................... 5

2.1 Key to safety symbols/markings.......................................................................................................................5

2.2 General..............................................................................................................................................................5

2.3 Intended use .....................................................................................................................................................5

2.4 Personnel qualification and training...............................................................................................................6

2.5 Consequences and risks caused by non-compliance with these operating instructions ..............................6

2.6 Safety awareness ..............................................................................................................................................6

2.7 Safety information for the operator/user.......................................................................................................6

2.8 Safety information for maintenance, inspection and installation work.......................................................6

2.9 Unauthorised modes of operation..................................................................................................................7

3 Replacing the LevelControl Basic 2 BC Control Unit............................................................................ 8

Compacta / mini-Compacta

3 of 12

Page 4

1 General

1 General

1.1 Principles

This supplementary operating manual is supplied as an integral part of the type

series and variants indicated on the front cover.

It supplements the installation/operating manual of the lifting unit type and variant

indicated on the front cover and specifically describes the operations required to

replace LevelControl Basic2 with a spare control unit.

1.2 Target group

This supplementary operating manual is aimed at the target group of trained and

qualified specialist technical personnel.

1.3 Other applicable documents

The other applicable documents are listed in the relevant installation/operating

manual of the pump (set).

1.4 Symbols

Table1: Symbols used in this manual

Symbol Description

✓ Conditions which need to be fulfilled before proceeding with the

step-by-step instructions

⊳ Safety instructions

⇨ Result of an action

⇨ Cross-references

1.

2.

Step-by-step instructions

Note

Recommendations and important information on how to handle

the product

4 of 12

Compacta / mini-Compacta

Page 5

2 Safety

!

DANGER

!

DANGER

!

WARNING

CAUTION

2 Safety

All the information contained in this section refers to hazardous situations.

In addition to the present general safety information the action-related safety

information given in the other sections must be observed.

2.1 Key to safety symbols/markings

Table2: Definition of safety symbols/markings

Symbol Description

DANGER

indicates a high-risk hazard which, if not avoided, will result in

death or serious injury.

WARNING

indicates a medium-risk hazard which, if not avoided, could result

in death or serious injury.

CAUTION

indicates a hazard which, if not avoided, could result in damage to

the machine and its functions.

General hazard

in conjunction with one of the signal words indicates a hazard

which will or could result in death or serious injury.

Electrical hazard

identifies information about protection against electrical voltage.

In conjunction with the signal word CAUTION, this symbol indicates

a hazard for the machine and its functions.

2.2 General

This supplementary operating manual contains additional applicable information.

General installation, operating and maintenance instructions that must be observed

to ensure safe operation and prevent personal injury and damage to property are

given in the installation/operating manual.

The safety information in all sections of this supplementary operating manual and in

the relevant installation/operating manual must be complied with.

The supplementary operating manual must be read and completely understood by

the responsible specialist personnel/operators.

The contents of this supplementary operating manual must be available to the

specialist personnel at the site at all times.

The operator is responsible for ensuring compliance with all local regulations which

are not taken into account in this supplementary operating manual.

2.3 Intended use

The lifting unit/control unit must only be operated within the operating limits

described in the other applicable documents.

▪ Only operate lifting units/control units which are in perfect technical condition.

▪ Do not operate partly assembled lifting units/control units.

▪ The lifting unit/control unit must only be operated with the fluids described in

the relevant installation/operating manual.

Prevention of foreseeable misuse

▪ Never exceed the permissible operating limits specified in the relevant

installation/operating manual.

▪ Observe all safety information and instructions in this supplementary operating

manual.

Compacta / mini-Compacta

5 of 12

Page 6

2 Safety

2.4 Personnel qualification and training

All personnel involved must be fully qualified to install, operate, maintain and

inspect the machinery this manual refers to.

The responsibilities, competence and supervision of all personnel involved in

installation, operation, maintenance and inspection must be clearly defined by the

operator.

Deficits in knowledge must be rectified by sufficiently trained specialist personnel

training and instructing the personnel who will carry out the respective tasks. If

required, the operator can commission the manufacturer/supplier to train the

personnel.

Training on the pump (set) must always be supervised by technical specialist

personnel.

2.5 Consequences and risks caused by non-compliance with these operating instructions

▪ Non-compliance with this supplementary operating manual will lead to

forfeiture of warranty cover and of any and all rights to claims for damages.

▪ Non-compliance can, for example, have the following consequences:

– Hazards to persons due to electrical, thermal, mechanical and chemical

effects and explosions

– Failure of important product functions

– Failure of prescribed maintenance and servicing practices

– Hazard to the environment due to leakage of hazardous substances

2.6 Safety awareness

In addition to the safety information contained in this manual and the intended use,

the following safety regulations shall be complied with:

▪ Accident prevention, health and safety regulations

▪ Explosion protection regulations

▪ Safety regulations for handling hazardous substances

▪ Applicable standards and laws

2.7 Safety information for the operator/user

▪ Fit protective equipment (e.g. contact guards) supplied by the operator for hot,

cold or moving parts, and check that the equipment functions properly.

▪ Do not remove any protective equipment (e.g. contact guards) during operation.

▪ Provide the personnel with protective equipment and make sure it is used.

▪ Contain leakages (e.g. at the shaft seal) of hazardous fluids handled (e.g.

explosive, toxic, hot) so as to avoid any danger to persons and the environment.

Adhere to all relevant laws.

▪ Eliminate all electrical hazards. (In this respect refer to the applicable national

safety regulations and/or regulations issued by the local energy supply

companies.)

▪ If shutting down the pump does not increase potential risk, fit an emergency-

stop control device in the immediate vicinity of the pump (set) during pump set

installation.

6 of 12

2.8 Safety information for maintenance, inspection and installation work

▪ When taking the pump set out of service always adhere to the procedure

described in the supplementary operating manual.

▪ As soon as the work is completed, re-install and/or re-activate any safety-relevant

and protective devices. Before returning the product to service, observe all

instructions on commissioning.

Compacta / mini-Compacta

Page 7

2 Safety

2.9 Unauthorised modes of operation

Never operate the lifting unit outside the limits stated in the data sheet and in the

lifting unit's installation/operating manual.

The warranty relating to the operating reliability and safety of the lifting unit

supplied is only valid if the equipment is used in accordance with its intended use.

Compacta / mini-Compacta

7 of 12

Page 8

3 Replacing the LevelControl Basic 2 BC Control Unit

3 Replacing the LevelControl Basic 2 BC Control Unit

DANGER

Incorrect connection of control unit

Danger to life!

▷ The control unit must be replaced by a trained electrician only.

Any personnel intending to replace the control unit must have read and

understood the operating manual of the lifting unit.

NOTE

Do not use these replacement instructions for customised units.

Marking on name plate:

UZX2.150D, X = customised unit.

Proceed as follows to replace the LevelControl Basic 2 control unit for miniCompacta/Compacta:

ü The lifting unit is not overfilled.

ü The lifting unit has been taken out of service for the replacement procedure.

1. Pull the mains plug of the control unit installed. If the control unit has been

connected without a plug: switch off the circuit breakers.

Take steps to ensure that the lifting unit cannot be inadvertently started!

2. Open the control unit cover and make sure the control unit is de-energised.

3. Disconnect the rechargeable battery.

4. Clearly mark all conductors as required, disconnect them at the control unit and

remove.

5. Remove the control unit and fit the spare control unit.

6. Run all conductors into the control unit again, connect them and verify correct

wiring in accordance with the wiring diagram shown in the operating manual.

7. Connect the rechargeable battery and close the control unit.

8. Set all manual-0-automatic selector switches to "0".

9. Check that the entire system can be operated safely.

10. Connect the lifting unit to the mains and switch it on.

11. Set the unit type as described below.

12. Follow the commissioning/start-up procedure described in section 6 of the

operating manual.

Also, comply with the instructions for setting the unit type as described below.

13. Set all manual-0-automatic selector switches to "automatic".

8 of 12

Setting the unit type

NOTE

Always set the unit type before setting the inlet nozzle level.

Compacta / mini-Compacta

Page 9

3 Replacing the LevelControl Basic 2 BC Control Unit

Esc

OK

Table3: Control unit: Navigation keys

Key Description

Arrow keys (up/down):

▪ Move up/down in the menu options.

▪ Increase/decrease a numerical value

Escape key:

▪ Cancel entry without saving it.

▪ When entering numbers: Go to the previous digit.

▪ Move up one menu level.

OK key:

▪ Confirm entries.

▪ Confirm a menu selection.

▪ When entering numbers: Go to the next digit.

1. Switch on LevelControl Basic 2.

2. Press the "ESC" and "OK" keys simultaneously: P3.1.2.1 is displayed.

3. Press "OK": The display of the lifting unit starts to flash.

4. Refer to the lifting unit's name plate for the unit type (e.g. UZ10.450D), look up

the relevant setting in the table shown below (e.g. 39 for UZ10.450D) and make

the appropriate setting (e.g. 39) using the "Up" and "Down" keys of the control

unit.

5. To confirm, press "OK".

6. Press "ESC" to exit parameterisation.

Table4: Setting the unit type

Unit Setting Unit Setting Unit Setting

U1.100 E 1 U5.300 D 18 UZ5.450 D 35

U1.100 D 2 UZ1.150 E 19 UZ3.900 D 36

U2.100 E 3 UZ1.150 D 20 UZ4.900 D 37

U2.100 D 4 UZ2.150 E 21 UZ5.900 D 38

U3.100 D 5 UZ2.150 D 22 UZ10.450 D 39

U4.100 D 6 UZ3.150 D 23 UZ11.450 D 40

U5.100 D 7 UZ4.150 D 24 UZ12.450 D 41

US1.100 E 8 UZ5.150 D 25 UZ13.450 D 42

US1.100 D 9 UZS1.150 E 26 UZ14.450 D 43

US2.100 E 10 UZS1.150 D 27 UZ15.450 D 44

US2.100 D 11 UZS2.150 E 28 UZ10.900 D 45

U1.150 E 12 UZS2.150 D 29 UZ11.900 D 46

U1.150 D 13 UZ3.300 D 30 UZ12.900 D 47

U2.150 E 14 UZ4.300 D 31 UZ13.900 D 48

U2.150 D 15 UZ5.300 D 32 UZ14.900 D 49

U3.300 D 16 UZ3.450 D 33 UZ15.900 D 50

U4.300 D 17 UZ4.450 D 34

Compacta / mini-Compacta

9 of 12

Page 10

3 Replacing the LevelControl Basic 2 BC Control Unit

Esc

OK

Setting the inlet nozzle level

Table5: Control unit: Navigation keys

Key Description

Arrow keys (up/down):

▪ Move up/down in the menu options.

▪ Increase/decrease a numerical value

Escape key:

▪ Cancel entry without saving it.

▪ When entering numbers: Go to the previous digit.

▪ Move up one menu level.

OK key:

▪ Confirm entries.

▪ Confirm a menu selection.

▪ When entering numbers: Go to the next digit.

1. Press the "ESC" and "OK" keys simultaneously: P3.1.2.1 is displayed.

2. Press "Up" key: P3.1.2.2 is displayed.

3. Press "OK".

4. Select the lowest inlet nozzle used from the table below and look up the

relevant setting (e.g. 1 for inlet nozzle level 180mm). Then make the appropriate

setting (e.g. 1) at the control unit, using the "Up" and "Down" keys.

5. To confirm the selected value press "OK".

6. Press "ESC" to exit parameterisation.

Table6: Setting the inlet nozzle level

Inlet

[mm]

180 1

250 2

320 3

700 4

Vertical 5

Setting

10 of 12

Compacta / mini-Compacta

Page 11

Page 12

KSB SE & Co. KGaA

Johann-Klein-Straße 9 • 67227 Frankenthal (Germany)

Tel. +49 6233 86-0

www.ksb.com

2317.8003/02-EN

Loading...

Loading...