Page 1

INSTRUCTION MANUAL

DOMI, CLAS, DREX, S, BPU, CLASVORT, VX, VORTIX, CANAL, STONE, TRITUR, D4, D6

SUBMERSIBLE PUMPS

MIF-6100/02-I

01-09-05

1. RECEIPT

When you receive the equipment, check that the packaging

is in good conditions. If not, indicate this in writing on the

carrier’s delivery note. Unpack the equipment and verif y its

state. If there is damage, inform the dealer immediately.

2. SAFETY INSTRUCTIONS

In this manual, the important safety instructions are

specifically marked. These marks have the following

symbols:

Safety instructions whose lack of fulfilment could affect

the safety of people and installations.

Safety instructions to prevent electrical risks

(hydrocution, ...)

Safety instructions whose lack of fulfilment could

affect the equipment and its operation.

All the equipment supplied by BOMBAS ITUR are

properly protected to prevent possible accidents, but in

any case all the safety recommendations indicated o n

the pump, on all the documents supplied with it or in

applicable regulations, must be followed.

Failure to comply with these instructions exempts BOMBAS

ITUR S.A. from any responsibility.

The safety recommendations indicated are based on our

experience and on normal use of the equipment.

The installer/user is exclusively responsible for assessing

the individual risks that exist in each installation and for not

permitting its connection and start up without the

appropriate protections.

3. GENERAL COMMENTS

The user must not carry out operations that are not

permitted in this manual. Any operation or handling

must always be carried out with the appropriate means,

by duly qualified personnel and after having read an d

understood this manual.

Any installation, maintenance, repair or transport

operations must be carried out with the pump stopped

and safely disconnected.

The correct state of both the electrical system and

pipes must be verified on a regular basis. If their state

is not safe, the pump must be stopped and repaired.

This is especially important if the defects are located i n

electrical devices or cables.

When starting the equipment up, by activating the

switch or connecting it to a socket, make sure that this

is done on a dry floor, and never with wet hands and/or

without proper footwear.

Before starting the pump up, all its elements, especially

those that affect safety, must be correctly installed and

fastened. Never start the pump up when there are

people close to it.

Never use the power cable or the discharge tube as a

means of elevating or supporting the pump. A metal

cable or chain must be fitted, suitable for the weight,

attached to the handle or hooks prepared for this.

4. LOCATION

Access to the pump or installation must be sufficiently

restricted, so that nobody can inadvertently access it.

Safety elements must be placed that prevent the entry

of children or other risk people. Never remain in the

area where the pump is placed whilst it is in operation.

The pump, except those specifically designed for this,

must NOT be installed in places classified as hav ing a n

explosion risk.

if the pump is outdoors and there is a risk of frost,

it must be completely submerged and operating.

Never let the ice affect it, or let ice form on the inside.

If the pump is not going to be used for a long period of

time, it must be cleaned and stored in a dry and

ventilated place.

If the pump is in a well or pit, before carrying out any

operation, verify that there are no poisonous,

suffocating or explosive gases. If you are going to use

a blower or fan to evacuate the gases, verify that this

does not represent a risk of explosion. Whilst the pit is

open, place protections to prevent accidental falls.

If the bottom of the area where the pump is going

to be place is sandy or muddy, the pump must be

suspended using adequate means, or placed on a

sufficient base, to prevent it from sinking.

If the pumps are going to be used in swimming pools,

gardens or similar places, European Regulation 60335,

Section 2, protection class 1, must be complied with.

Check with a specialist.

5. LIQUID PUMPED

The pumps must never work dry.

The pumps referred to in this manual, have been

designed for use under the conditions indicated in the

catalogue, pump and applicable documents.

In any case, and as a general rule, the liquid pumped must

NOT be:

WARNING

WARNING

WARNING

WARNING

Page 2

MIF-6100/02-I

2

• Aggressive, corrosive, inflammable, toxic or explosive.

• Have a higher temperature than that indicated as

maximum for each model.

• Incompatible with the pump materials.

The presence of long or fibrous solids must be

avoided in all those pumps that have a grid,.

6. INSTALLATION

Both the user and the installer must strictly follow all

applicable safety standards, laws and regulations.

The prescriptions of DIN-1986 or applicable local

regulations must be followed in waste and faecal water

installations.

Place a control and isolating valve next to the pump in the

discharge pipe, and after it a retaining valve. Check that

the valves are suitable for the liquid to be pumped.

S-Series pumps must be suspended 10 cm from

the bottom at the least, and the liquid level must never

be less than 15 cm over the grid.

D4 and D6 series pumps must be suspended 15 0

cm from the bottom at the least and the liquid level

must never be less than 15 cm over the grid. These

pumps must not be installed in wells with sand, sludge

or abrasive particles in the water to be pumped.

The fluid entering the pump must be prevented

from entering directly onto the pump or the float.

If the pump is going to be activated automatically

with a float, the difference in heights between start and

stop must be sufficient so as not to produce

excessively continued starts. In any case the free

cable length must never be less than 10 cm.

7. ELECTRICAL INSTALLATION

The electrical connections must be carried out by

qualified personnel and meticulously observing all the

standards and recommendations to prevent accidents.

The earth tapping cables must be the first to be

connected and the last to be disconnected.

If an extension is going to be added to the cable, verify

that the type and section of the cable are suitable, and

that the splice is done correctly and hermetically.

The characteristics of the mains (voltage, frequency,

etc) must correspond to the values indicated on the

characteristics plate. A variation in voltage of up to 10

% is admissible.

An unbalance between phases of up to 5% is admissible. If

higher values are observed, check the values with the other

connection combinations of the cables (not varying the

rotation direction). If the highest value always occurs in th e

same phase of the line, the cause of the unbalance is

mainly in the mains.

The electrical installation must have:

• A suitable earth tap.

• An omnipole disconnection system (for all the

phases) with contact opening of at least 3 mm

separation.

• A high sensitivity differential switch (0.03 A).

• If the motor does not have thermal protection,

protection must be installed on the panel.

• The power cable must be at least type H07 RN-F

according to VDE 0250 (DIN-57282, DIN-57245).

The use of small-sized or low quality compo nents

in the electrical installation will provoke a rapid

deterioration in the contacts, with the subsequent

deterioration in the motor, due to unbalance in the

power supply.

In those single-phase pumps that do not

incorporate a capacitor, this must be installed on the

control panel.

Verify, if the pump works outdoors, that the

applicable electrical regulations and standards are

complied with. In some countries it may be necessary

to supply the pump through a transformer (220 V).

If the connection is made with a plug or similar,

the current tap must be safe and be located in a plac e

protected from flooding.

8. START-UP

Before starting the pump up, check that all the safet y and

protection elements are correctly installed and fastened.

Make the pump turn manually, to break any adherence.

Totally open the discharge valve. Submerge the pump and

place it in its operating position. Partially close the

discharge valve

(Only three-phase pump). Check that the direction of

rotation is correct. To do so, start the pump up for a few

seconds. Exchange two of the phases and start the pump

up again. The configuration, where the flow/pressure

supplied by the pump are greater, is the adequate one.

Start the pump up. Check that no incorrect operating

symptoms, such as excessive noises or vibrations, appear.

9. MAINTENANCE

From time to time check that both the float (if there is one)

and the grid and/or runner are clean. If they are not,

proceed to clean them. Any other type of maintenance

operation, especially those referring to the motor, must be

carried out by personnel from BOMBAS ITUR, or its

authorised technical services. For D4 and D6 series, this

maintenance is not necessary as these always work with

clean water.

If oil leaks are detected in the pump, stop it

immediately and notify the authorised technical service.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

Page 3

MIF-6100/02-I

3

This page has deliberately been left blank

Page 4

BOMBAS ITUR, S.A. (KSB Group)

P.O. Box 41 – 20800 ZARAUTZ (Gipuzkoa) Spain

Tel.: +34 943 899 899 – Fax +34 943 130 710

E-mail: postventa@itur.es – www.itur.es

MIF-6100/02-I

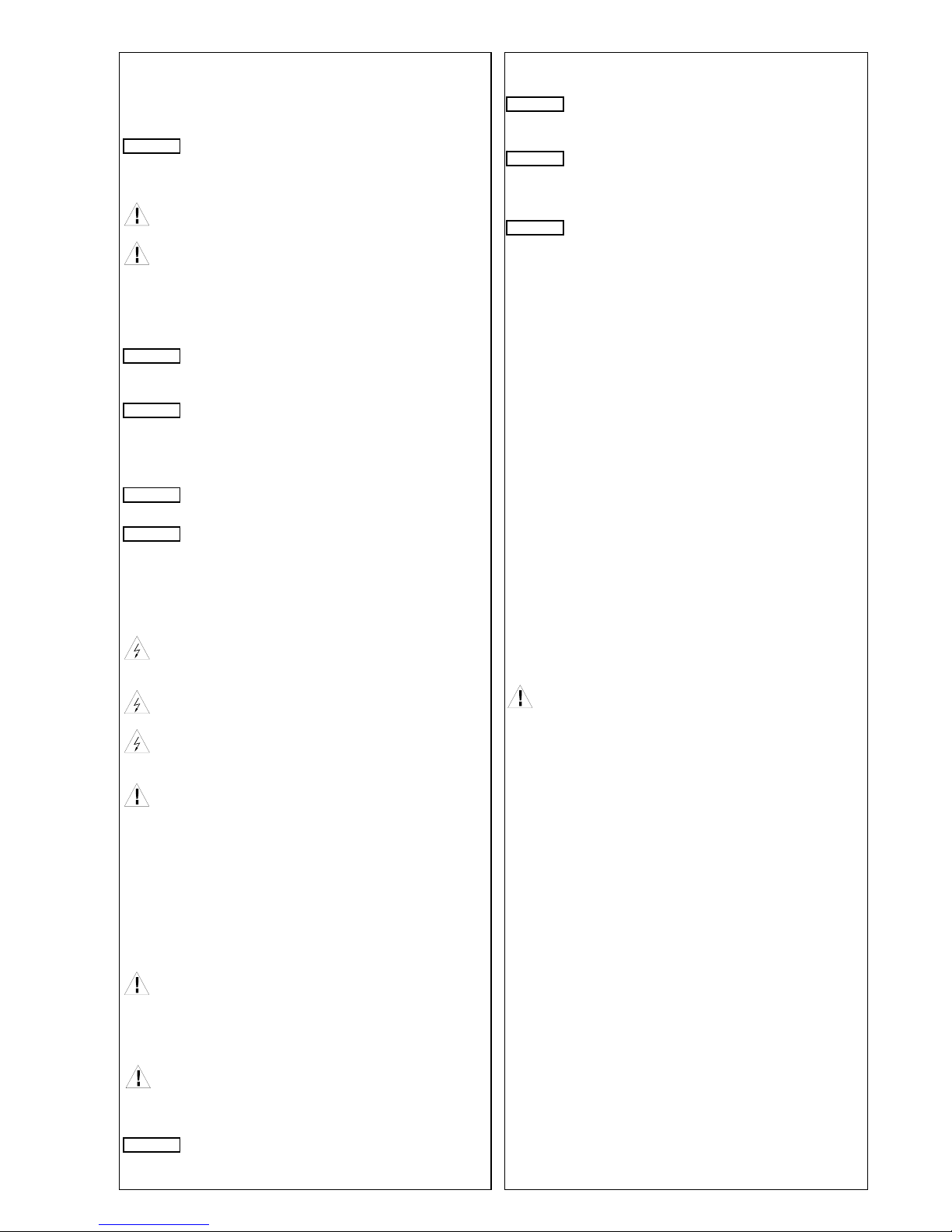

10. ANOMALIES IN THE OPERATION

1) The pump does not start.

2) The pump starts but does not give pressure.

3) The pump stops and starts continuously.

4) The pump starts but does not give flow volume

5) The motor heats up too much.

6) The rotor turns with difficulty.

7) Excessive noises or vibrations.

1 2 3 4 5 6 7 POSSIBLE CAUSES SOLUTIONS

X X

Pressure generated by the pump is less than that required by the

installation

Check head losses and geometric height

X X X

Inappropriate aspiration Improve aspiration. Check height of pump above floor, and state

of grid.

X X Density or viscosity of liquid Change pump for another suitable one

X X Insufficient pipe diameters Install pipes with larger diameter

X X X Air gets in Check regulation of levels in the well

X X X X Bearings wornº Go to an official technical service

X X X Pressure required less than that supposed Regulate discharge valve

X X X Bad priming Lift and submerge pump again

X X Pipe obstruction Clean pipes

X X X X X X Obstruction inside the pump Proceed to clean grid/r unner

X Incorrect direction of rotation Change motor connections

X X X X Badly regulated discharge valve Regulate correctly

X Supply, fuses the thermals disconnected Connect them reset them

X X Badly regulated float Regulate float

11. GUARANTEES

Failure to comply with the indications given in this manual means using the equipment incorrectly, from the technical and

safety viewpoint. Therefore this EXEMPTS BOMBAS ITUR FROM ANY RESPONSIBILITY IN THE CASE OF PERSONAL

ACCIDENTS OR MATERIAL DAMAGE, AND IT ALSO GIVES RISE TO THE LOSS OF ANY RIGHT TO CLAIM UNDER

GUARANTEE.

A one-year guarantee is established against any project or manufacturing defect. T ransport of the equipment to our fac ility or

to that of our agreed technical services is on the customer’s account as well as travelling expens es of our personnel to the

facility, if required.

Any handling of the equipment by the customer, without our written consent, means the loss of any right to claim under

guarantee.

"CE" DECLARATION OF APPROVAL

BOMBAS ITUR, S.A. herewith declares, on its own responsibility, that the above-mentioned products, which it

manufactures (if supplied with an engine), and to which this Declaration is related, meets that set down in European

Directives 98/37/CE, 89/336/CEE, 73/23/CEE on the laws of approximation of Member States with respect to machines.

Harmonised rules applied:

EN 292 Part 1 and EN 292 Part 2.

ZARAUTZ, 21/02/2006

Position: President

Name: Juan Antonio Uriarte

Loading...

Loading...