Page 1

Drinking Water Pump

Calio-Therm S NC/NCV

Installation/Operating Manual

Page 2

Legal information/Copyright

Installation/Operating Manual Calio-Therm S NC/NCV

Original operating manual

All rights reserved. The contents provided herein must neither be distributed, copied, reproduced,

edited or processed for any other purpose, nor otherwise transmitted, published or made available to a

third party without the manufacturer's express written consent.

Subject to technical modification without prior notice.

© KSB SE & Co. KGaA, Frankenthal 23/03/2018

Page 3

Contents

Contents

Glossary .................................................................................................................................................. 5

1 General.................................................................................................................................................... 6

1.1 Principles ...........................................................................................................................................................6

1.2 Target group.....................................................................................................................................................6

1.3 Symbols .............................................................................................................................................................6

2 Safety...................................................................................................................................................... 7

2.1 Key to safety symbols/markings.......................................................................................................................7

2.2 General..............................................................................................................................................................7

2.3 Intended use .....................................................................................................................................................7

2.4 Personnel qualification and training...............................................................................................................8

2.5 Consequences and risks caused by non-compliance with this manual .........................................................8

2.6 Safety awareness ..............................................................................................................................................8

2.7 Safety information for the operator/user.......................................................................................................8

2.8 Safety information for maintenance, inspection and installation ................................................................9

2.9 Unauthorised modes of operation..................................................................................................................9

3 Transport/Temporary Storage/Disposal............................................................................................. 10

3.1 Checking the condition upon delivery..........................................................................................................10

3.2 Transport.........................................................................................................................................................10

3.3 Storage/preservation......................................................................................................................................10

3.4 Return to supplier...........................................................................................................................................10

3.5 Disposal ...........................................................................................................................................................11

4 Description of the Pump (Set)............................................................................................................. 12

4.1 General description ........................................................................................................................................12

4.2 Designation.....................................................................................................................................................12

4.3 Name plate......................................................................................................................................................12

4.4 Design details..................................................................................................................................................13

4.5 Configuration and function...........................................................................................................................13

4.6 Noise characteristics .......................................................................................................................................14

4.7 Scope of supply...............................................................................................................................................14

4.8 Dimensions and weight..................................................................................................................................14

5 Installation at Site................................................................................................................................ 15

5.1 Safety regulations...........................................................................................................................................15

5.2 Checks to be carried out prior to installation...............................................................................................15

5.3 Installing the pump set ..................................................................................................................................15

5.4 Connecting the piping ...................................................................................................................................16

5.5 Casing/insulation ............................................................................................................................................17

5.6 Electrical connection ......................................................................................................................................17

6 Commissioning/Start-up/Shutdown................................................................................................... 20

6.1 Commissioning/Start-up.................................................................................................................................20

6.1.1 Prerequisites for commissioning/start-up ......................................................................................... 20

6.1.2 Priming and venting the pump.........................................................................................................20

6.1.3 Start-up............................................................................................................................................... 21

6.1.4 Operation ...........................................................................................................................................21

6.2 Shutdown........................................................................................................................................................22

6.3 Operating limits..............................................................................................................................................22

6.3.1 Ambient temperature........................................................................................................................23

6.4 Shutdown/storage/preservation ....................................................................................................................23

6.4.1 Measures to be taken for shutdown ................................................................................................23

6.5 Returning to service .......................................................................................................................................23

7 Servicing/Maintenance........................................................................................................................ 24

7.1 Maintenance/inspection.................................................................................................................................24

7.2 Drainage/cleaning ..........................................................................................................................................24

Calio-Therm S NC/NCV

3 of 32

Page 4

Contents

7.3 Removing the pump set from the piping .....................................................................................................24

7.3.1 Removing the complete pump set from the piping ........................................................................24

8 Trouble-shooting.................................................................................................................................. 26

9 EU Declaration of Conformity............................................................................................................. 27

Index ..................................................................................................................................................... 28

4 of 32

Calio-Therm S NC/NCV

Page 5

Glossary

Glossary

Discharge line

The pipeline which is connected to the discharge

nozzle

Pump

Machine without drive, additional components or

accessories

Pump set

Complete pump set consisting of pump, drive,

additional components and accessories

Suction lift line/suction head line

The pipeline which is connected to the suction

nozzle

Calio-Therm S NC/NCV

5 of 32

Page 6

1 General

1 General

1.1 Principles

This operating manual is valid for the type series and variants indicated on the front

cover.

The manual describes the proper and safe use of this equipment in all phases of

operation.

The name plate indicates the type series and size as well as the main operating data.

They uniquely identify the pump (set) and serve as identification for all further

business processes.

In the event of damage, immediately contact your nearest KSB Service centre to

maintain the right to claim under warranty.

1.2 Target group

This operating manual is aimed at the target group of trained and qualified specialist

technical personnel. (ðSection2.4,Page8)

1.3 Symbols

Table1: Symbols used in this manual

Symbol Description

✓ Conditions which need to be fulfilled before proceeding with the

step-by-step instructions

⊳ Safety instructions

⇨ Result of an action

⇨ Cross-references

1.

2.

Step-by-step instructions

Note

Recommendations and important information on how to handle

the product

6 of 32

Calio-Therm S NC/NCV

Page 7

2 Safety

!

DANGER

!

DANGER

!

WARNING

CAUTION

2 Safety

All the information contained in this section refers to hazardous situations.

In addition to the present general safety information the action-related safety

information given in the other sections must be observed.

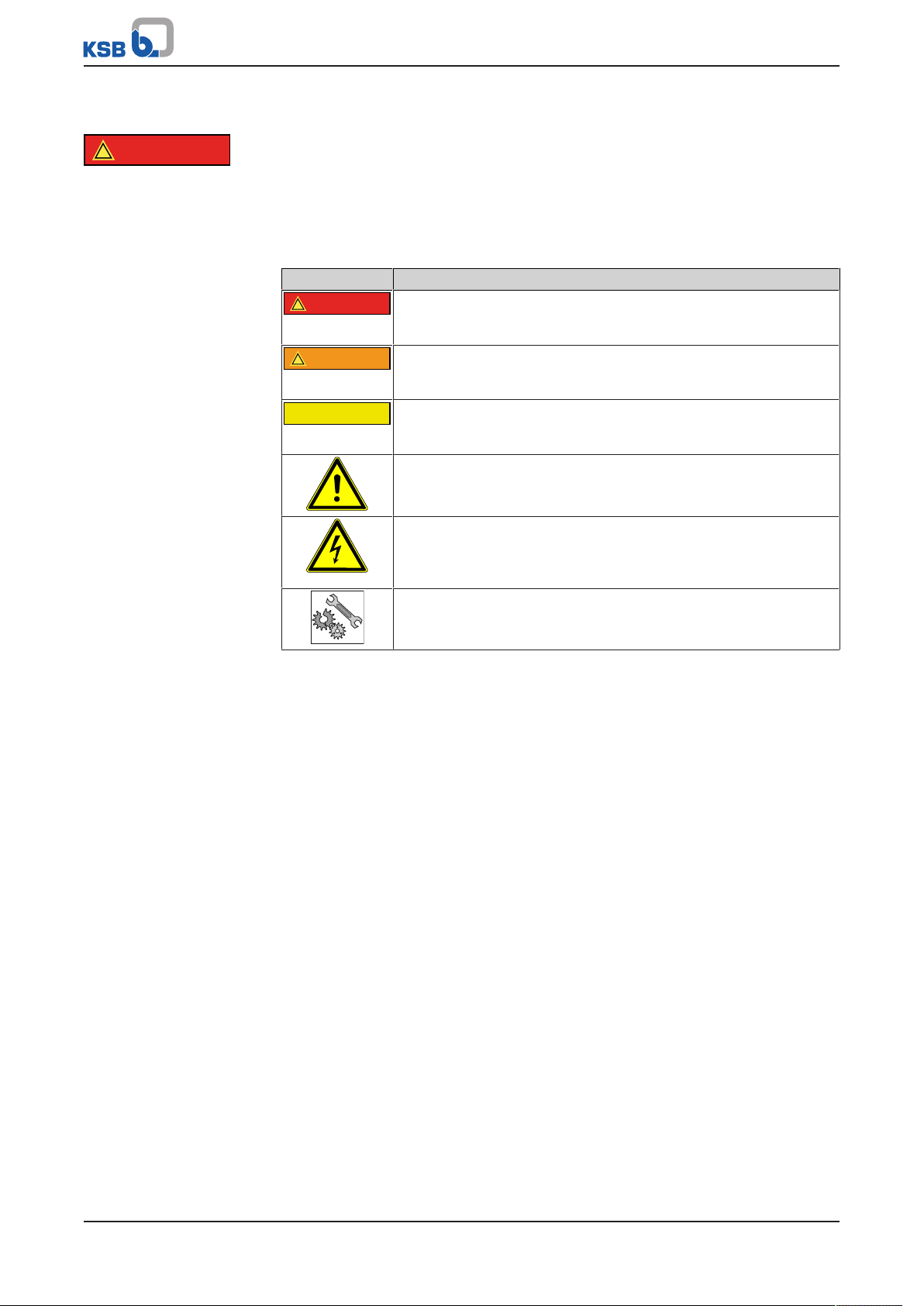

2.1 Key to safety symbols/markings

Table2: Definition of safety symbols/markings

Symbol Description

DANGER

This signal word indicates a high-risk hazard which, if not avoided,

will result in death or serious injury.

WARNING

This signal word indicates a medium-risk hazard which, if not

avoided, could result in death or serious injury.

CAUTION

This signal word indicates a hazard which, if not avoided, could

result in damage to the machine and its functions.

General hazard

In conjunction with one of the signal words this symbol indicates a

hazard which will or could result in death or serious injury.

Electrical hazard

In conjunction with one of the signal words this symbol indicates a

hazard involving electrical voltage and identifies information about

protection against electrical voltage.

Machine damage

In conjunction with the signal word CAUTION this symbol indicates

a hazard for the machine and its functions.

2.2 General

This operating manual contains general installation, operating and maintenance

instructions that must be observed to ensure safe operation of the system and

prevent personal injury and damage to property.

The safety information in all sections of this manual must be complied with.

The operating manual must be read and understood by the responsible specialist

personnel/operators prior to installation and commissioning.

The contents of this operating manual must be available to the specialist personnel

at the site at all times.

Information attached directly to the product must always be complied with and kept

in a perfectly legible condition at all times. This applies to, for example:

▪ Flow direction arrow

▪ Markings for connections

▪ Name plate

The operator is responsible for ensuring compliance with all local regulations not

taken into account in this operating manual.

2.3 Intended use

▪ The pump (set) must only be operated in the fields of application and within the

use limits specified in the other applicable documents.

▪ Only operate pumps/pump sets which are in perfect technical condition.

▪ Do not operate the pump (set) in partially assembled condition.

▪ Only use the pump to handle the fluids described in the data sheet or product

literature of the pump model or variant.

▪ Never operate the pump without the fluid to be handled.

Calio-Therm S NC/NCV

7 of 32

Page 8

2 Safety

▪ Observe the minimum flow rate and maximum flow rate indicated in the data

sheet or product literature (e.g. to prevent overheating, cavitation damage,

bearing damage).

▪ Do not throttle the flow rate on the suction side of the pump (to prevent

cavitation damage).

▪ Consult the manufacturer about any use or mode of operation not described in

the data sheet or product literature.

2.4 Personnel qualification and training

All personnel involved must be fully qualified to transport, install, operate, maintain

and inspect the machinery this manual refers to.

The responsibilities, competence and supervision of all personnel involved in

transport, installation, operation, maintenance and inspection must be clearly

defined by the operator.

Deficits in knowledge must be rectified by means of training and instruction

provided by sufficiently trained specialist personnel. If required, the operator can

commission the manufacturer/supplier to train the personnel.

Training on the pump (set) must always be supervised by technical specialist

personnel.

2.5 Consequences and risks caused by non-compliance with this manual

▪ Non-compliance with these operating instructions will lead to forfeiture of

warranty cover and of any and all rights to claims for damages.

▪ Non-compliance can, for example, have the following consequences:

– Hazards to persons due to electrical, thermal, mechanical and chemical

effects and explosions

– Failure of important product functions

– Failure of prescribed maintenance and servicing practices

– Hazard to the environment due to leakage of hazardous substances

2.6 Safety awareness

In addition to the safety information contained in this manual and the intended use,

the following safety regulations shall be complied with:

▪ Accident prevention, health regulations and safety regulations

▪ Explosion protection regulations

▪ Safety regulations for handling hazardous substances

▪ Applicable standards, directives and laws

2.7 Safety information for the operator/user

▪ Fit protective equipment (e.g. contact guards) supplied by the operator for hot,

cold or moving parts, and check that the equipment functions properly.

▪ Do not remove any protective equipment (e.g. contact guards) during operation.

▪ Contain leakages (e.g. at the shaft seal) of hazardous fluids handled (e.g.

explosive, toxic, hot) so as to avoid any danger to persons and the environment.

Adhere to all relevant laws.

▪ Eliminate all electrical hazards. (In this respect refer to the applicable national

safety regulations and/or regulations issued by the local energy supply

companies.)

▪ If shutting down the pump does not increase potential risk, fit an emergency-

stop control device in the immediate vicinity of the pump (set) during pump set

installation.

8 of 32

Calio-Therm S NC/NCV

Page 9

2 Safety

2.8 Safety information for maintenance, inspection and installation

▪ Modifications or alterations of the pump (set) are only permitted with the

manufacturer's prior consent.

▪ Use only original spare parts or parts/components authorised by the

manufacturer. The use of other parts/components can invalidate any liability of

the manufacturer for resulting damage.

▪ The operator ensures that maintenance, inspection and installation is performed

by authorised, qualified specialist personnel who are thoroughly familiar with

the manual.

▪ Only carry out work on the pump (set) during standstill of the pump.

▪ Only perform work on the pump set when it has been disconnected from the

power supply (de-energised).

▪ The pump (set) must have cooled down to ambient temperature.

▪ Pump pressure must have been released and the pump must have been drained.

▪ When taking the pump set out of service always adhere to the procedure

described in the manual. (ðSection6.4,Page23)

▪ Decontaminate pumps which handle fluids posing a health hazard.

▪ As soon as the work has been completed, re-install and re-activate any safety-

relevant devices and protective devices. Before returning the product to service,

observe all instructions on commissioning. (ðSection6.1,Page20)

2.9 Unauthorised modes of operation

Never operate the pump (set) outside the limits stated in the data sheet and in this

manual.

The warranty relating to the operating reliability and safety of the supplied pump

(set) is only valid if the equipment is used in accordance with its intended use.

Calio-Therm S NC/NCV

9 of 32

Page 10

3 Transport/Temporary Storage/Disposal

3 Transport/Temporary Storage/Disposal

3.1 Checking the condition upon delivery

1. On transfer of goods, check each packaging unit for damage.

2. In the event of in-transit damage, assess the exact damage, document it and

notify KSB or the supplying dealer and the insurer about the damage in writing

immediately.

3.2 Transport

CAUTION

Improper pump transport

Damage to the pump!

▷ Never suspend the pump/pump set from the power cable.

▷ Prevent the pump (set) from getting knocked or dropped.

3.3 Storage/preservation

If commissioning is to take place some time after delivery, we recommend that the

following measures be taken for pump (set) storage.

CAUTION

Damage during storage due to humidity, dirt, or vermin

Corrosion/contamination of the pump (set)!

▷ For outdoor storage cover the packed or unpacked pump (set) and accessories

with waterproof material.

CAUTION

Wet, contaminated or damaged openings and connections

Leakage or damage to the pump!

▷ Clean and cover pump openings and connections as required prior to putting

the pump into storage.

Store the pump (set) in a dry, protected room where the atmospheric humidity is as

constant as possible.

If properly stored indoors, the equipment is protected for a maximum of 12months.

For storing a pump (set) which has already been operated, observe the instructions

in (ðSection6.4.1,Page23) .

3.4 Return to supplier

1. Drain the pump as per operating instructions.

2. Flush and clean the pump, particularly if it has been used for handling noxious,

explosive, hot or other hazardous fluids.

3. If the pump has handled fluids whose residues could lead to corrosion damage

in the presence of atmospheric humidity or could ignite upon contact with

oxygen also neutralise the pump and blow through with anhydrous inert gas to

ensure drying.

4. Always complete and enclose a certificate of decontamination when returning

the pump.

Indicate any safety measures and decontamination measures taken.

10 of 32

Calio-Therm S NC/NCV

Page 11

3 Transport/Temporary Storage/Disposal

3.5 Disposal

WARNING

Fluids handled, consumables and supplies which are hot and/or pose a health

hazard

Hazard to persons and the environment!

▷ Collect and properly dispose of flushing fluid and any fluid residues.

▷ Wear safety clothing and a protective mask if required.

▷ Observe all legal regulations on the disposal of fluids posing a health hazard.

1. Dismantle the pump (set).

Collect greases and other lubricants during dismantling.

2. Separate and sort the pump materials, e.g. by:

- Metals

- Plastics

- Electronic waste

- Greases and other lubricants

3. Dispose of materials in accordance with local regulations or in another

controlled manner.

Calio-Therm S NC/NCV

11 of 32

Page 12

4 Description of the Pump (Set)

1

2

3

4

Calio-Therm S NCV S

1~230V 50/60 Hz Max 0,04 A

Class F IP42 PN10 TF60

Material Nr. 29 134 813

ProdNr.

CE

2016w35-0867

Made in Germany

Johann-Klein-Straße 9

Deutschland

67227 Frankenthal

KSB SE & Co. KGaA

4 Description of the Pump (Set)

4.1 General description

▪ Non-self-priming in-line pump

▪ Pump for handling drinking water of up to 65°C

4.2 Designation

Example: Calio-Therm S NCV S

Table3: Designation key

Code Description

Calio-ThermS Type series

NCV Design

NC Fixed speed

NCV Fixed speed with integrated non-return valve and shut-

off valve (ball valve)

S Connection variants

S With plug-type connection

K With integrated power cable (2m length) and

shockproof plug (plug typeF)

Key to the series code

4.3 Name plate

Fig.1: Name plate (example)

1 Size 2 Voltage, frequency, max. input

power, thermal class, enclosure,

max. operating pressure,

temperature class

3 Material number 4 Series code

Example: 2016w35-0867

Table4: Key to the series code

Code Description

2016 Year 2016

w35 Week

0867 Consecutive number

12 of 32

Calio-Therm S NC/NCV

Page 13

4 Description of the Pump (Set)

1 2 3 4 5 6 7 8 9

10

11

4.4 Design details

▪ Maintenance-free glandless pump

▪ Screw-ended

▪ 3 speed levels

Operating modes

▪ Operation at fixed speed level

Manual functions

▪ Setting the speed level

Drive

▪ Short-circuit-proof electric motor

▪ 230V, 50Hz/60Hz

▪ IP42 enclosure

▪ Thermal class F

▪ Temperature class TF60

▪ Interference emission EN55014-1:2006+ A1:2009+ A2:2011, EN61000-3-2:2006+

A1:2009+ A2:2009, EN61000-3-3:2008

▪ Interference immunity EN55014-2:1997+ A1:2001+ A2:2008

Bearings

▪ Product-lubricated

4.5 Configuration and function

Fig.2: Sectional drawing of the pump

1 Pump casing 2 Check valve (only with 1 ¼")

3 Rotor 4 Union nut

Calio-Therm S NC/NCV

13 of 32

Page 14

Design

Function

4 Description of the Pump (Set)

5 Rotor 6 Motor housing

7 Electronics 8 Casing cover

9 LED display panel with pushbutton 10 Power connection

11 Ball check valve (only with 1 ¼")

The pump is designed with a radial fluid inlet and a radial outlet arranged on the

same axis. The impeller is rigidly connected to the motor shaft.

The motor housing is equipped with a terminal box. Mechanical sealing is not

required as the rotating assembly is completely isolated from the stator winding. The

rotating assembly is lubricated and cooled by the fluid pumped. The advanced

lubricating system and precision-balanced impeller ensure smooth running and a

long service life.

The fluid enters the pump via the suction nozzle and is accelerated outward in a

cylindrical flow by the rotating impeller, which is driven by the motor shaft. In the

flow passage of the pump casing the kinetic energy of the fluid is converted into

pressure energy. The fluid is pumped to the discharge nozzle, where it leaves the

pump.

4.6 Noise characteristics

Table5: Noise characteristics [dBA]

Sound pressure level

All 45 max.

4.7 Scope of supply

Depending on the model, the following items are included in the scope of supply:

▪ Pump set

▪ Installation/operating manual

▪ Plastic caps

▪ Plug-type connection or integrated connection cable

▪ Insulation shells

4.8 Dimensions and weight

For dimensions and weights please refer to the type series booklet of the pump (set).

14 of 32

Calio-Therm S NC/NCV

Page 15

5 Installation at Site

✔ ✔✔ ✘ ✘✘

✔ ✔✔ ✘ ✘✘

5 Installation at Site

5.1 Safety regulations

DANGER

Installation in potentially explosive atmospheres

Explosion hazard!

▷ Never install the pump in potentially explosive atmospheres.

▷ Observe the information given in the data sheet and on the name plates of the

pump system.

5.2 Checks to be carried out prior to installation

Before beginning with the installation check the following:

▪ The pump set can be operated on the power supply network according to the

data on the name plate.

▪ The fluid to be handled matches the description of suitable fluids.

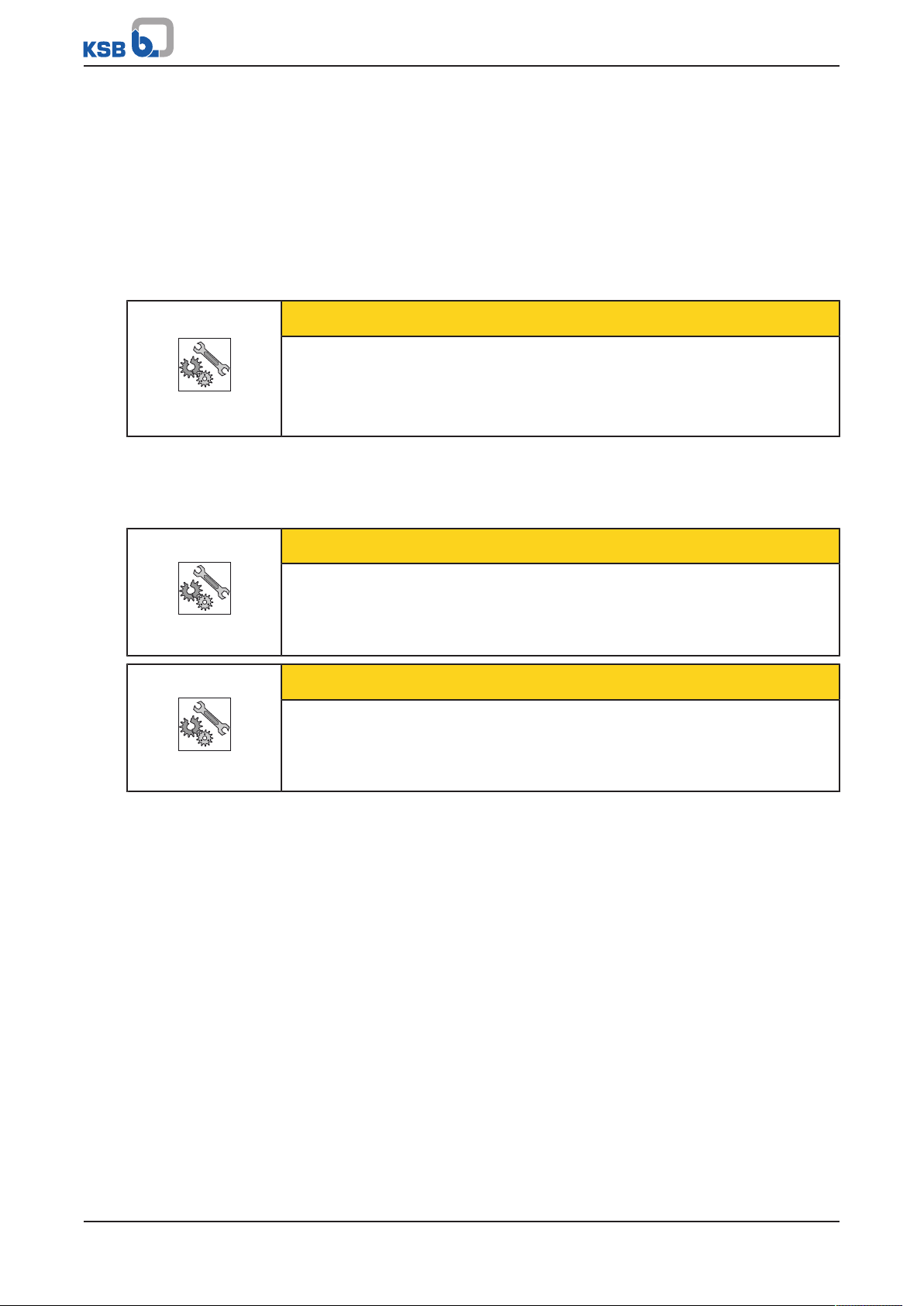

5.3 Installing the pump set

Install the pump set in an easily accessible place.

CAUTION

Ingress of fluid into the motor

Damage to the pump set!

▷ Install the pump set with the pump shaft in a horizontal position. Connect the

piping without transmitting any stresses and strains.

NOTE

We recommend installing shut-off valves upstream and downstream of the pump.

Make sure that no leaking water can drip into the pump motor or terminal box.

Table6: Permissible installation positions

Sizes

Calio-Therm S NC

Calio-Therm S NCV

An arrow on the pump casing indicates the direction of flow.

The plug-type connection/ cable connection integrated in the pump can be fixed in

any position (e.g. pointing downward). To do so, loosen the product-integrated

union nut and move the pump head (connection housing including motor) into the

required position. Then tighten the union nut.

NOTE

The direction of flow of a vertically installed pump should be upwards.

Calio-Therm S NC/NCV

15 of 32

Page 16

5 Installation at Site

CAUTION

Air entering the pump

Damage to vertically installed pump sets whose direction of flow is downwards!

▷ Fit a vent valve at the highest point of the suction line.

NOTE

To prevent any impurities from collecting in the pump do not install the pump at

the lowest point of the system.

1. The circulator is usually installed in the piping directly upstream of the drinking

water storage tank. The water is pumped from the last tapping point via the

circulation line back to the storage tank.

2. Install a lift check valve on the pump's discharge side. It prevents backflow

through the pump when the tap is opened.

3. A shut-off valve is installed on the pump's suction side to facilitate maintenance.

Calio-Therm S NCV comes with a lift check valve and a shut-off option integrated

in the lower pump section.

4. Install the pump with the pump shaft in a horizontal position. Connect the

piping without transmitting any stresses and strains.

An arrow on the pump casing indicates the direction of flow.

CAUTION

Heat building up at motor housing and pump casing

Pump overheating!

▷ Never insulate the motor and electronic system housings.

5.4 Connecting the piping

WARNING

Impermissible loads acting on the pump nozzles

Risk of burns by leakage of hot fluids!

▷ Do not use the pump as an anchorage point for the piping.

▷ Anchor the pipes in close proximity to the pump and connect them without

transmitting any stresses or strains.

▷ Take appropriate measures to compensate for thermal expansion of the piping.

CAUTION

Contamination/dirt in the piping

Damage to the pump!

▷ Flush the piping prior to commissioning or replacing the pump. Remove any

foreign matter.

16 of 32

Calio-Therm S NC/NCV

Page 17

5 Installation at Site

NOTE

Installing check and shut-off elements in the system is recommended, depending on

the type of plant and pump. However, such elements must not obstruct proper

drainage or hinder disassembly of the pump.

ü Suction lift lines have been laid with a rising slope, suction head lines with a

downward slope towards the pump.

ü The nominal diameters of the pipes are equal to or greater than the nominal

diameters of the pump nozzles.

ü The pipelines have been anchored in close proximity to the pump and connected

without transmitting any stresses or strains.

1. Thoroughly clean, flush and blow through all vessels, pipelines and connections

(especially of new installations).

CAUTION

Welding beads, scale and other impurities in the piping

Damage to the pump!

▷ Free the piping from any impurities.

5.5 Casing/insulation

WARNING

The pump takes on same temperature as the fluid handled

Risk of burns!

▷ Insulate the volute casing.

▷ Fit protective equipment.

CAUTION

Heat building up at motor housing and pump casing

Pump overheating!

▷ Never insulate the motor and electronic system housings.

5.6 Electrical connection

DANGER

Electrical connection work by unqualified personnel

Risk of fatal injury due to electric shock!

▷ Always have the electrical connections installed by a trained and qualified

electrician.

▷ Observe regulations IEC 60364 and, for explosion-proof models, EN60079.

DANGER

Work performed on an energised terminal box

Danger of death from electric shock!

▷ Switch off the power supply at least 5 minutes prior to commencing work and

ensure that it cannot be switched on again unintentionally.

Calio-Therm S NC/NCV

17 of 32

Page 18

5 Installation at Site

24+/- 1.0

12+/- 1.0

1 2

WARNING

Incorrect connection to the mains

Damage to the mains network, short circuit!

▷ Observe the technical specifications of the local energy supply companies.

1. The pumps do not require any motor protection.

All pumps are designed for connection to 230VAC50/60Hz and delivered with a

plug-type connection (supplied but not fitted) or integrated power cable with mains

plug depending on the version.

The power cable needs to be wired to the supplied plug.

After the cable/plug assembly has been completed, connect the plug to the

corresponding jack at the pump (IP42).

Table7: Power cable

Cable Cable type

Outside diameter of the cable 5,5 - 10,0mm

Outside diameter of the core (including

insulation)

Cable cross-sections 0,75mm2 - 1,5mm2 massive or fine core cable

Connecting the cable at the pump

1. Verify the supply voltage at the site against the data on the name plate of the

pump.

2. Switch off the pump's power supply. Secure it against unintentional start-up.

Verify that the pump is de-energised.

3. Strip the power cable as shown in the diagram.

At the cable to be inserted into the plug, strip about 24mm of the sheath. Then

strip at least 12mm of the insulation at each strand (see illustration).

2,95mm max.

18 of 32

Fig.3: Stripping the cable

4. Remove the supplied plug-type connector from its packaging. Undo and remove

the screwed-on cable gland. Feed the stripped cable through the cable gland.

Fig.4: Plug-type connection

1 Strain relief device

2 Cable gland

Calio-Therm S NC/NCV

Page 19

5 Installation at Site

1

1 2

3

NOTE

When fitting the power cable to the plug-type connection make sure to insert the

strain relief device into the cable gland in the correct position. Only in its correct

installation position can the strain relief device function correctly in combination

with the cable gland.

Otherwise the strain relief device will be pressed onto the blue locking/unlocking

mechanism of the plug, which causes it to open and release the cores.

5. Insert the stripped cores/strands of the cable into the corresponding terminals L,

N and Earth (PE) of the plug. The markings are shown on the blue removal

mechanism (ring). The automatic locking mechanism locks the strand in place,

establishes contact and prevents the strand from sliding out of the plug.

A marking underneath the PE terminal helps identify the correct connection.

After the cable has been wired to the plug, screw the cable entry onto the plug

and tighten it.

Fig.5: Plug-type connection with marking

1 PE marking

Fig.6: Connections at the plug

1 Phase (230VAC) 2 Neutral (N)

3 Earth (embossed marking on the

ring) (PE)

6. After the cable/plug assembly has been completed, connect the plug to the jack

at the pump.

7. The cores/strands can be removed from the plug by pressing down the blue ring.

Calio-Therm S NC/NCV

19 of 32

Page 20

6 Commissioning/Start-up/Shutdown

6 Commissioning/Start-up/Shutdown

6.1 Commissioning/Start-up

6.1.1 Prerequisites for commissioning/start-up

Before commissioning/starting up the pump set, make sure that the following

conditions are met:

▪ The pump set has been properly connected to the power supply and is equipped

with all protection devices.

▪ The pump has been primed with the fluid to be handled. The pump has been

vented.

▪ Before commissioning/starting up the pump set, make sure that the system is free

of contamination and foreign objects.

6.1.2 Priming and venting the pump

CAUTION

Increased wear due to dry running

Damage to the pump set!

▷ Never operate the pump set without liquid fill.

▷ Never close the shut-off element in the suction line and/or supply line during

pump operation.

1. Fill the system with the fluid to be handled.

CAUTION

Operation without the fluid to be handled

Damage to the pump!

▷ Prime the pump with the fluid to be handled.

2. Vent the system thoroughly. To this end, loosen the union nut of the pump so

that air can escape from the pump.

3. Carefully open the inlet line until water escapes from the pump.

DANGER

Moisture in the electrical connection area

Short circuit in the pump!

▷ De-energise the pump.

4. Tighten the union nut hand tight with a suitable tool.

5. Start up the pump set.

6. Audible flow noises indicate that there is air in the piping.

Repeat the venting procedure, if necessary, to remove all air from the system.

20 of 32

Calio-Therm S NC/NCV

Page 21

6 Commissioning/Start-up/Shutdown

1 2

6.1.3 Start-up

DANGER

Non-compliance with the permissible pressure and temperature limits if the pump

is operated with the suction and discharge lines closed.

Hot fluids escaping!

▷ Never operate the pump with the shut-off elements in the suction line and/or

discharge line closed.

▷ Only start up the pump set against a slightly or completely open discharge-side

shut-off element.

DANGER

Excessive temperatures due to insufficient lubrication of shaft seal

Damage to the pump set!

▷ Never operate the pump set without liquid fill.

▷ Prime the pump as per operating instructions.

▷ Always operate the pump within the permissible operating range.

CAUTION

Abnormal noises, vibrations, temperatures or leakage

Damage to the pump!

▷ Switch off the pump (set) immediately.

▷ Eliminate the causes before returning the pump set to service.

ü The system piping has been cleaned.

ü Pump, suction line and inlet tank, if fitted, have been vented and primed with

the fluid to be handled.

ü The lines for priming and venting have been closed.

1. Fully open the shut-off element in the suction head/suction lift line.

2. Close or slightly open the shut-off element in the discharge line.

3. Start up the motor.

Position of shut-off valve of Calio-Therm S NCV

Fig.7: Position of shut-off valve of Calio-Therm S NCV

1 Open position 2 Closed position

6.1.4 Operation

The pump starts up when it is connected to the power supply.

The number of lit LEDs indicates the speed level at which the pump is operated

(operation at constant speed). 3 speed levels can be set via the pushbutton. The

pump can be optimally adjusted to the existing system by selecting the most suitable

characteristic curve. 3 flashing LEDs indicate a fault or error.

Calio-Therm S NC/NCV

21 of 32

Page 22

6 Commissioning/Start-up/Shutdown

3 2 1 4

Fig.8: Indication of speed level

1 Speed level 1 2 Speed level 2

3 Speed level 3 4 Pushbutton

6.2 Shutdown

ü The shut-off element in the suction line is and remains open.

1. Close the shut-off element in the discharge line.

2. Switch off the motor and make sure the pump set runs down smoothly to a

standstill.

NOTE

If the discharge line is equipped with a check valve, the shut-off element in the

discharge line may remain open, provided the site's requirements and regulations

are taken into account and observed.

For prolonged shutdown periods:

1. Close the shut-off element in the suction line.

CAUTION

Risk of freezing during prolonged pump shutdown periods

Damage to the pump!

▷ Drain the pump and the cooling/heating chambers (if any) or otherwise protect

them against freezing.

6.3 Operating limits

DANGER

Non-compliance with operating limits for pressure, temperature, fluid handled and

speed

Hot fluids escaping!

▷ Comply with the operating data indicated in the data sheet.

▷ Avoid prolonged operation against a closed shut-off element.

▷ Never operate the pump at product temperatures exceeding those specified in

the data sheet or on the name plate.

22 of 32

Calio-Therm S NC/NCV

Page 23

6 Commissioning/Start-up/Shutdown

6.3.1 Ambient temperature

CAUTION

Operation outside the permissible ambient temperature

Damage to the pump (set)!

▷ Observe the specified limits for permissible ambient temperatures.

Observe the following parameters and values during operation:

Table8: Permissible ambient temperatures

Permissible ambient temperature Value

Maximum 40 °C

Minimum 0 °C

6.4 Shutdown/storage/preservation

6.4.1 Measures to be taken for shutdown

The pump (set) remains installed

ü Sufficient fluid is supplied for the operation check run of the pump.

1. Start up the pump (set) regularly between once a month and once every three

months for approximately five minutes during prolonged shutdown periods.

This will prevent the formation of deposits within the pump and the pump

intake area.

The pump is removed from the pipe and stored

The pump has been properly drained and the safety instructions for dismantling the

pump have been observed.

Observe any additional instructions and information provided. (ðSection3,Page10)

6.5 Returning to service

For returning the pump to service observe the sections on commissioning/start-up

and the operating limits.

In addition, carry out all servicing/maintenance operations before returning the

pump (set) to service.

WARNING

Failure to re-install or re-activate protective devices

Risk of injuries by escaping fluid!

▷ As soon as the work is completed, re-install and/or re-activate any safety-

relevant and protective devices.

Calio-Therm S NC/NCV

23 of 32

Page 24

7 Servicing/Maintenance

7 Servicing/Maintenance

7.1 Maintenance/inspection

The circulators are almost maintenance-free.

If the pump has not been in operation for a prolonged period of time or if the

system is severely contaminated, the rotor can become blocked.

Remove the pump head (loosen the union nut and take off pump head) to access and

remove the impeller. After the pump head has been removed, tighten the union nut

to a tightening torque of 30Nm with a belt wrench.

Fig.9: Belt wrench for tightening the union nut

This allows unblocking the rotor and/or cleaning the pump.

NOTE

Any repairs on the pump must only be performed by one of our authorised service

partners.

In the event of a failure, please contact your heating system engineer.

7.2 Drainage/cleaning

WARNING

Fluids, consumables and supplies which are hot and/or pose a health hazard

Hazard to persons and the environment!

▷ Collect and properly dispose of flushing fluid and any residues of the fluid

handled.

▷ Wear safety clothing and a protective mask if required.

▷ Observe all legal regulations on the disposal of fluids posing a health hazard.

1. Always flush and clean the pump before transporting it to the workshop.

Provide a cleaning record for the pump.

7.3 Removing the pump set from the piping

7.3.1 Removing the complete pump set from the piping

DANGER

24 of 32

Electrical connection work by unqualified personnel

Risk of fatal injury due to electric shock!

▷ Always have the electrical connections installed by a trained and qualified

electrician.

▷ Observe regulations IEC 60364 and, for explosion-proof models, EN60079.

Calio-Therm S NC/NCV

Page 25

7 Servicing/Maintenance

DANGER

Strong magnetic field in the rotor area

Danger of death for persons with pacemaker!

▷ Keep a safety distance of at least 0.3 m.

DANGER

Pump acting as a generator when running in reverse

Danger to life from hazardous induction voltage at the motor terminals!

▷ Prevent the fluid from flowing back by closing the shut-off elements.

WARNING

Danger by strong magnetic field

Danger of crushing injuries when pulling out the rotor!

Due to the strong magnetic field the rotor can be suddenly pulled back into its

original position!

Danger of magnetic parts near the rotor being attracted!

▷ The rotor must generally only be removed from the motor housing by

authorised specialist personnel.

▷ Remove any magnetic parts from the vicinity of the rotor.

▷ Keep the assembly area clean.

▷ Keep a safety distance of at least 0.3m from electronic components.

CAUTION

Strong magnetic field in the rotor area

Interference with magnetic data carriers, electronic devices, components and

instruments!

Uncontrolled magnetic attraction forces between magnetic components, tools or

similar!

▷ Remove any magnetic parts from the vicinity of the rotor.

▷ Keep the assembly area clean.

CAUTION

Danger by strong magnetic field

Negative impact on or damage to electrical devices!

▷ The rotor must generally only be removed from the motor housing by

authorised specialist personnel.

ü The relevant notes and steps stated been observed/carried out.

ü The pump has cooled down to ambient temperature.

ü A container for collecting the fluid has been positioned underneath the pump

set.

1. De-energise the pump set (disconnect the motor) and ensure that it cannot be

re-energised unintentionally.

2. Close the shut-off elements.

3. Disconnect the discharge and suction nozzles from the piping.

4. Remove the complete pump set from the piping.

Calio-Therm S NC/NCV

25 of 32

Page 26

8 Trouble-shooting

8 Trouble-shooting

WARNING

Improper work to remedy faults

Risk of injury!

▷ For any work performed to remedy faults, observe the relevant information

given in this operating manual and/or in the product literature provided by the

accessories manufacturer.

If problems occur that are not described in the following table, consultation with the

KSB customer service is required.

Pump is running, but does not deliver

A

Pump does not start up or pump running irregularly

B

Pump running but not delivering water

C

Noises during pump operation

D

Table9: Trouble-shooting

A B C D Possible cause Remedy

✘ - - - Pump not connected to power supply Check the power supply and fuses or

reset the voltage (interrupt and re-establish

power supply).

✘ - - - Pump blocked (e.g. due to contamination) (ðSection7,Page24)

✘ - - - Defective motor Replace the pump.

- ✘ - - Impurities in the pump See section on maintenance.

- - ✘ - Air in the system Vent the system and the pump.

- - ✘ - Gate valve closed Open the gate valve.

- - - ✘ Excessive pump power output Select a lower speed level.

- - - ✘ System pressure too low Increase the system pressure by filling more water

into the boiler.

- - - ✘ Air in the system Vent the pump and piping.

1)

1) Release pump pressure before attempting to remedy faults on parts which are subjected to pressure.

26 of 32

Calio-Therm S NC/NCV

Page 27

9 EU Declaration of Conformity

9 EU Declaration of Conformity

Manufacturer: KSB SE & Co. KGaA

Johann-Klein-Straße 9

67227 Frankenthal (Germany)

The manufacturer herewith declares that the product:

Calio-Therm S NC / NCV

Serial number range: 2018w01 to 2019w52

▪ is in conformity with the provisions of the following Directives as amended from time to time:

– Electromagnetic Compatibility Directive 2014/30/EU

– Low-voltage Directive 2014/35/EU

The manufacturer also declares that

▪ the following harmonised international standards have been applied:

– DINEN 55014-1, EN 55014-2

– DINEN 60335-1, EN 60335-2-51

– DINEN 61000-3-2, EN 61000-3-3

The EU Declaration of Conformity was issued in/on:

Frankenthal, 1 February 2018

Joachim Schullerer

Head of Product Development Pump Systems and Drives

KSB SE & Co. KGaA

Johann-Klein-Straße 9

67227 Frankenthal

Calio-Therm S NC/NCV

27 of 32

Page 28

Index

Index

B

Bearings13

C

Commissioning20

D

Designation12

Disposal11

Drive13

E

Event of damage6

F

Faults

Causes and remedies26

Fields of application7

I

Intended use7

K

Key to safety symbols/markings7

W

Warnings7

Warranty claims6

M

Manual functions13

N

Name plate12

O

Operating limits22

Operating modes13

P

Piping17

Preservation10, 23

R

Return to supplier10

Returning to service23

S

Safety7

Safety awareness8

Scope of supply14

Shutdown23

Start-up21

Storage10, 23

28 of 32

Calio-Therm S NC/NCV

Page 29

Page 30

Page 31

Page 32

KSB SE & Co. KGaA

Johann-Klein-Straße 9 • 67227 Frankenthal (Germany)

Tel. +49 6233 86-0

www.ksb.com

1157.88/05-EN

Loading...

Loading...