KSB BoosterControl Advanced Operating Manual

BoosterControl Advanced

Installation/Operating Manual

Legal information/Copyright

Installation/Operating Manual BoosterControl Advanced

Original operating manual

All rights reserved. The contents provided herein must neither be distributed, copied, reproduced,

edited or processed for any other purpose, nor otherwise transmitted, published or made available to a

third party without the manufacturer's express written consent.

Subject to technical modification without prior notice.

© KSB SE & Co. KGaA, Frankenthal 12/03/2018

Contents

3 of 88

BoosterControl Advanced

Contents

1 General.................................................................................................................................................... 5

1.1 Principles ...........................................................................................................................................................5

1.2 Target group.....................................................................................................................................................5

1.3 Other applicable documents............................................................................................................................5

1.4 Symbols .............................................................................................................................................................5

2 Safety...................................................................................................................................................... 6

2.1 Key to safety symbols/markings.......................................................................................................................6

2.2 General..............................................................................................................................................................6

2.3 Intended use .....................................................................................................................................................6

2.4 Personnel qualification and training...............................................................................................................7

2.5 Consequences and risks caused by non-compliance with this operating manual........................................ 7

2.6 Safety awareness ..............................................................................................................................................7

2.7 Safety information for the user/operator.......................................................................................................7

2.8 Safety information for maintenance, inspection and installation work.......................................................7

2.9 Unauthorised modes of operation..................................................................................................................8

2.10 Software Changes.............................................................................................................................................8

2.11 Electromagnetic compatibility.........................................................................................................................8

3 Transport/Temporary Storage/Disposal............................................................................................... 9

3.1 Checking the condition upon delivery............................................................................................................9

3.2 Transport...........................................................................................................................................................9

3.3 Storage..............................................................................................................................................................9

3.4 Disposal .............................................................................................................................................................9

4 Description............................................................................................................................................ 10

4.1 General description ........................................................................................................................................10

4.2 Designation.....................................................................................................................................................10

4.3 Name plate......................................................................................................................................................10

4.4 Functions.........................................................................................................................................................10

4.5 Technical data.................................................................................................................................................11

4.5.1 Parameterisable inputs/outputs ........................................................................................................12

4.6 Combination options......................................................................................................................................12

4.7 Options............................................................................................................................................................13

4.8 Software scope of supply...............................................................................................................................13

4.9 Dimensions and weight..................................................................................................................................13

5 Installation at Site................................................................................................................................ 14

5.1 Safety regulations...........................................................................................................................................14

5.2 Checking ambient conditions ........................................................................................................................14

5.3 Installing BoosterControl Advanced..............................................................................................................14

5.4 Electrical connection ......................................................................................................................................14

5.4.1 Electrical connections ........................................................................................................................14

5.4.2 Connection to power supply .............................................................................................................17

5.4.3 Connecting/bridging the motor protection device..........................................................................17

5.4.4 Connecting the pump contactors .....................................................................................................18

5.4.5 Connecting the pressure sensor ........................................................................................................18

5.4.6 Connecting the dry running protection device................................................................................18

5.4.7 Other connections required depending on the operating mode...................................................18

5.4.8 Making optional connections ...........................................................................................................19

6 Operation.............................................................................................................................................. 21

6.1 Control panel..................................................................................................................................................21

6.1.1 "Traffic light" LEDs ............................................................................................................................21

6.1.2 Graphical display................................................................................................................................ 21

6.1.3 Menu keys ..........................................................................................................................................22

6.1.4 Navigation keys.................................................................................................................................. 26

6.2 Operating the device via the service interface.............................................................................................27

Contents

4 of 88

BoosterControl Advanced

6.3 Operating the device via the control panel..................................................................................................27

6.3.1 Displaying and changing parameters ...............................................................................................27

6.4 General functions ...........................................................................................................................................28

6.4.1 Setting the physical units ..................................................................................................................28

6.4.2 Saving/loading customer settings .....................................................................................................28

6.4.3 Saving/loading factory settings.........................................................................................................29

6.4.4 Resetting to default settings............................................................................................................. 29

6.4.5 Enabling/disabling the password ...................................................................................................... 29

6.4.6 Displaying general information ........................................................................................................ 29

6.4.7 Displaying status information ........................................................................................................... 30

6.5 General information on parameterisation ...................................................................................................31

6.6 User login........................................................................................................................................................31

7 Quick Start Instructions ....................................................................................................................... 32

8 Commissioning/Start-up/Shutdown................................................................................................... 34

8.1 Ambient conditions for commissioning and operation ...............................................................................34

8.2 Commissioning................................................................................................................................................34

8.2.1 Starting up the system....................................................................................................................... 34

8.3 Setting BoosterControl Advanced.................................................................................................................34

8.3.1 Setting the display language ............................................................................................................34

8.3.2 Setting the time/date.........................................................................................................................34

8.4 Basic configurations of the pressure booster system ...................................................................................34

8.4.1 Cascade control ..................................................................................................................................36

8.4.2 Cascade control - with jockey pump.................................................................................................37

8.4.3 Control with one frequency inverter (per system)...........................................................................38

8.4.4 Control with one frequency inverter per pump (sequential starting/stopping of pumps) ........... 41

8.4.5 Control with one frequency inverter per pump (synchronous operation of pumps), multiple

pump operation .................................................................................................................................42

8.4.6 Setting the frequency inverter parameters......................................................................................44

8.5 Application functions.....................................................................................................................................45

8.5.1 Setting the parameters for dry running protection ........................................................................45

8.5.2 Setting an alternative setpoint .........................................................................................................45

8.5.3 Parameterisation of inlet tank function...........................................................................................46

8.5.4 Parameterising the accumulator function (frequency-controlled systems only) ...........................49

8.5.5 Water flow detection (WSD) ............................................................................................................. 49

8.5.6 Fire-fighting function ........................................................................................................................51

8.5.7 Emergency power function (limitation of number of pumps)........................................................51

8.5.8 Automatic setpoint reduction in case of inlet pressure drop (ASR) ..............................................52

8.5.9 Configuring the functional check run ..............................................................................................52

8.5.10 Dynamic pressure compensation (DFS).............................................................................................52

8.5.11 Setting freely parameterisable inputs ..............................................................................................53

8.5.12 Setting freely configurable outputs ................................................................................................53

8.5.13 Configuration example......................................................................................................................54

8.5.14 Setting alternative setpoint using a timer .......................................................................................54

9 Servicing/Inspection............................................................................................................................. 55

9.1 Safety regulations...........................................................................................................................................55

9.2 Servicing/Inspection........................................................................................................................................55

9.2.1 Supervision of operation ................................................................................................................... 55

10 Parameter list ....................................................................................................................................... 56

11 Trouble-shooting.................................................................................................................................. 78

11.1 Fault messages................................................................................................................................................78

12 Related documents .............................................................................................................................. 81

12.1 Checklist for commissioning and inspection.................................................................................................81

13 EU Declaration of Conformity............................................................................................................. 82

Index ..................................................................................................................................................... 83

1 General

5 of 88

BoosterControl Advanced

1 General

1.1 Principles

This manual is supplied as an integral part of the type series indicated on the front

cover. The manual describes the proper and safe use of this equipment in all phases

of operation.

The name plate indicates the type series, the main operating data and the serial

number. The serial number uniquely describes the product and is used as

identification in all further business processes.

In the event of damage, immediately contact your nearest KSB service centre to

maintain the right to claim under warranty.

1.2 Target group

This operating manual is aimed at the target group of trained and qualified specialist

technical personnel.

1.3 Other applicable documents

Table1: Overview of other applicable documents

Document Contents

Logic diagram Description of electrical connections and

performance data

For accessories and/or integrated machinery components, observe the relevant

manufacturer's product literature.

1.4 Symbols

Table2: Symbols used in this manual

Symbol Description

✓ Conditions which need to be fulfilled before proceeding with the

step-by-step instructions

⊳ Safety instructions

⇨ Result of an action

⇨ Cross-references

1.

2.

Step-by-step instructions

Note

Recommendations and important information on how to handle

the product

2 Safety

6 of 88

BoosterControl Advanced

2 Safety

!

DANGER

All the information contained in this section refers to hazardous situations.

In addition to the present general safety information the action-related safety

information given in the other sections must be observed.

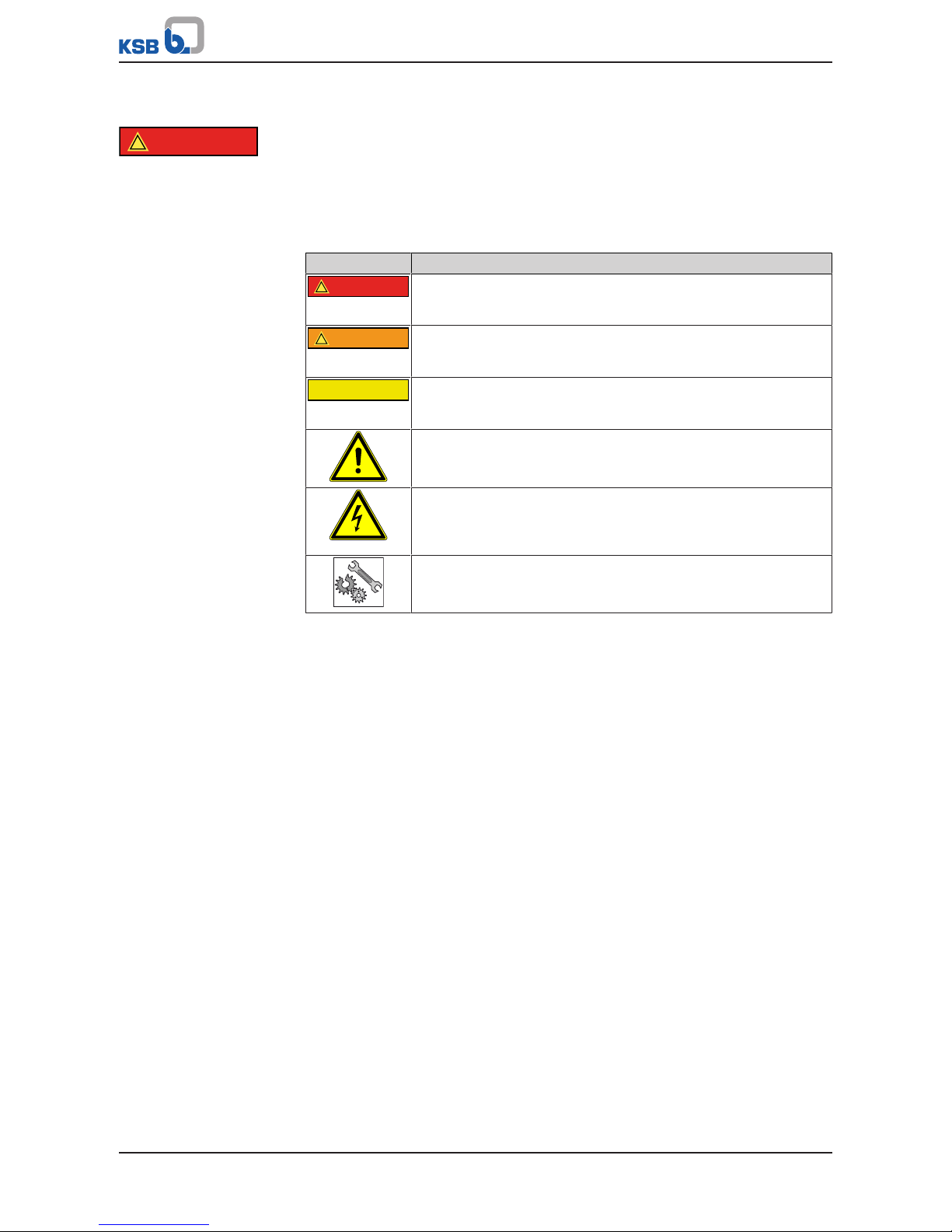

2.1 Key to safety symbols/markings

Table3: Definition of safety symbols/markings

Symbol Description

!

DANGER

DANGER

This signal word indicates a high-risk hazard which, if not avoided,

will result in death or serious injury.

!

WARNING

WARNING

This signal word indicates a medium-risk hazard which, if not

avoided, could result in death or serious injury.

CAUTION

CAUTION

This signal word indicates a hazard which, if not avoided, could

result in damage to the machine and its functions.

General hazard

In conjunction with one of the signal words this symbol indicates a

hazard which will or could result in death or serious injury.

Electrical hazard

In conjunction with one of the signal words this symbol indicates a

hazard involving electrical voltage and identifies information about

protection against electrical voltage.

Machine damage

In conjunction with the signal word CAUTION this symbol indicates

a hazard for the machine and its functions.

2.2 General

This operating manual contains general installation, operating and maintenance

instructions that must be observed to ensure safe operation of the system and

prevent personal injury and damage to property.

The safety information in all sections of this manual must be complied with.

The operating manual must be read and understood by the responsible specialist

personnel/operators prior to installation and commissioning.

The contents of this operating manual must be available to the specialist personnel

at the site at all times.

Information attached directly to the product must always be complied with and kept

in a perfectly legible condition at all times. This applies to, for example:

▪ Markings for connections

▪ Name plate

The operator is responsible for ensuring compliance with all local regulations not

taken into account in this operating manual.

2.3 Intended use

This product must not be operated beyond the values specified in the technical

product literature for the mains voltage, mains frequency, and ambient temperature,

or be used in any manner that is not compliant with the instructions provided in the

operating manual and in other, applicable documents.

The product must not be used in potentially explosive atmospheres.

2 Safety

7 of 88

BoosterControl Advanced

2.4 Personnel qualification and training

All personnel involved must be fully qualified to transport, install, operate, maintain

and inspect the product this manual refers to. The responsibilities, competence and

supervision of all personnel involved in installation, operation, maintenance and

inspection must be clearly defined by the operator.

Deficits in knowledge must be rectified by means of training and instruction

provided by sufficiently trained specialist personnel. If required, the operator can

commission the manufacturer/supplier to train the personnel.

Training on the product must always be supervised by specialist technical personnel.

2.5 Consequences and risks caused by non-compliance with this operating

manual

▪ Non-compliance with this operating manual will lead to forfeiture of warranty

cover and of any and all rights to claims for damages.

▪ Non-compliance can, for example, have the following consequences:

– Hazards to persons due to electrical, thermal, mechanical and chemical

effects and explosions

– Failure of important product functions

– Failure of prescribed maintenance and servicing practices

2.6 Safety awareness

In addition to the safety information contained in this manual and the intended use,

the following safety regulations shall be complied with:

▪ Accident prevention, health and safety regulations

▪ Explosion protection regulations

▪ Safety regulations for handling hazardous substances

▪ Applicable standards and legislation (e.g. EN50110-1)

2.7 Safety information for the user/operator

▪ Fit contact guards supplied by the operator for hot, cold or moving parts, and

check that the guards function properly.

▪ Do not remove any contact guards during operation.

▪ Provide the personnel with protective equipment and make sure it is used.

▪ Eliminate all electrical hazards. (In this respect, refer to the applicable national

safety regulations and/or regulations issued by the local energy supply

companies.)

2.8 Safety information for maintenance, inspection and installation work

▪ Modifications or alterations are only permitted with the manufacturer's prior

consent.

▪ Use only original spare parts or parts authorised by the manufacturer. The use of

other parts can invalidate any liability of the manufacturer for resulting damage.

▪ The operator ensures that all maintenance, inspection and installation work is

performed by authorised, qualified specialist personnel who are thoroughly

familiar with the manual.

▪ Any work on the product shall only be performed when it has been disconnected

from the power supply (de-energised).

▪ Carry out work on the product during standstill only.

▪ As soon as the work has been completed, re-install and/or re-activate any safety-

relevant and protective devices. Before returning the product to service, observe

all instructions on commissioning.

2 Safety

8 of 88

BoosterControl Advanced

2.9 Unauthorised modes of operation

Never operate the product outside the limits stated in the data sheet and in this

manual.

The warranty relating to the operating reliability and safety of the product supplied

is only valid if the product is used in accordance with its intended use.

2.10 Software Changes

The software has been specially created for this product and thoroughly tested.

It is impermissible to make any changes or additions to the software or parts of the

software. Software updates supplied by KSB are excluded from this rule.

2.11 Electromagnetic compatibility

EMC Directive 2004/108/EC ("Electromagnetic Compatibility") sets out the

requirements concerning the interference immunity and interference emissions of

electric and electronic equipment.

3 Transport/Temporary Storage/Disposal

9 of 88

BoosterControl Advanced

3 Transport/Temporary Storage/Disposal

3.1 Checking the condition upon delivery

1. On transfer of goods, check each packaging unit for damage.

2. In the event of in-transit damage, assess the exact damage, document it and

notify KSB or the supplying dealer (as applicable) and the insurer about the

damage in writing immediately.

3.2 Transport

▪ Transport the device in its original packaging.

▪ Observe the transport instructions on the original packaging.

▪ Keep the original packaging for future transport and storage.

3.3 Storage

If the ambient conditions for storage are met, the function of the control unit is

safeguarded even after a prolonged period of storage.

CAUTION

Damage during storage by humidity, dirt or vermin

Corrosion/contamination of the control unit!

▷ For outdoor storage cover the (packed or unpacked) control unit and

accessories with water-proof material.

Table4: Ambient conditions for storage

Ambient condition Value

Relative humidity 85% max. (non-condensing)

Ambient temperature -10°C to + 70°C

▪ Store the control unit in dry, vibration-free conditions and, if possible, in its

original packaging.

▪ Store the control unit in a dry room where the level of atmospheric humidity is as

constant as possible.

▪ Prevent excessive fluctuations in atmospheric humidity (see table on ambient

conditions for storage).

3.4 Disposal

The product is classified as special waste due to several installed components:

1. Dismantle the product.

2. Separate and sort the materials

e.g. by:

- Aluminium

- Plastic cover (recyclable plastic)

3. Dispose of materials in accordance with local regulations or in another

controlled manner.

PCBs, power electronics, capacitors and electronic components are all special

waste.

The requirements pertaining to RoHs 2002/95/EC are fulfilled.

4 Description

10 of 88

BoosterControl Advanced

4 Description

4.1 General description

▪ Control unit for pressure booster systems

With BoosterControl Advanced, up to 3 or 6 pump sets can be started, stopped and

controlled as a function of pressure.

4.2 Designation

Example: BCA 6

Table5: Key to the designation

Code Description

BCA BoosterControl Advanced

6 Number of pumps that can be connected

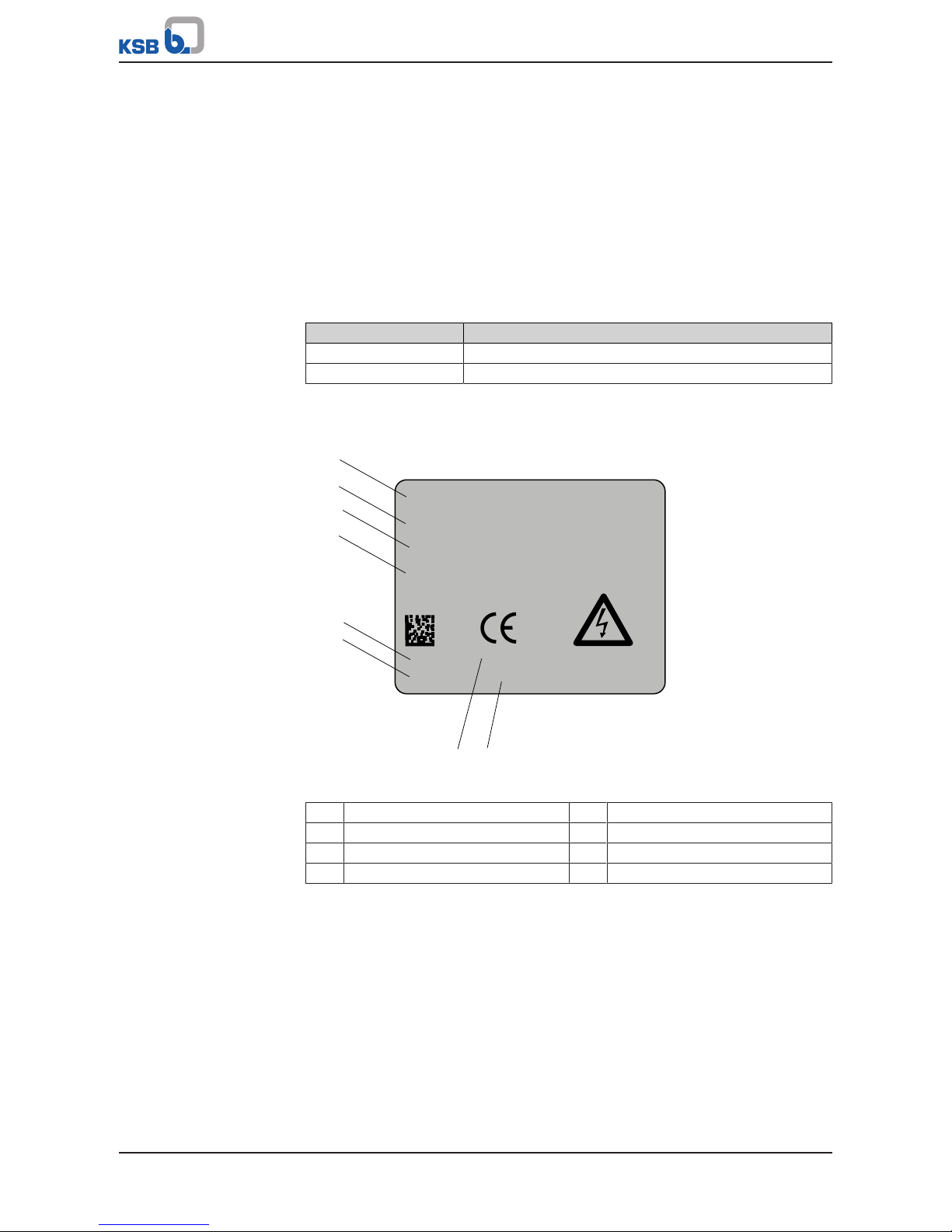

4.3 Name plate

BoosterControl 1.5 - 3P

P/N 01464675

S/N 010201211290018

Date 29-11-2012

Made in EU

230VAC

50/60Hz

IP20

15W

Warning!!!

High voltage

1

2

3

4

5

6

7 8

Fig.1: Name plate (example)

1 Type series, size 2 Ident. number

3 Series number 4 Year of construction

5 Input voltage 6 Mains frequency

7 Enclosure 8 Power input

4.4 Functions

Control system

Control of up to 3 or 6 pump sets as a function of pressure

The following functions, among others, are possible:

▪ Even distribution of operating hours among the pumps connected

▪ Automatic pump changeover

– as a function of operating hours

– in the case of a pump fault

▪ Pump starting and stopping in line with demand

▪ Functional check run

▪ Control of an inlet tank valve (for corresponding system configuration)

4 Description

11 of 88

BoosterControl Advanced

▪ Inlet tank control (for corresponding system configuration)

▪ Energy-saving operation

▪ Dynamic pressure setpoint compensation

▪ Base-load or peak-load pump operation (jockey function)

Monitoring

Monitoring of external conditions via digital and analog inputs

The following monitoring functions can be used:

▪ General fault message

▪ Individual fault messages (lack of water)

▪ Thermal monitoring of pump motors

▪ Sensor fault/broken wire

▪ Fault/warning per pump

▪ Monitoring of service interval

▪ Dry running detection via pressure switch or pressure sensor

▪ Operational availability, indicated via LEDs and display

▪ Level monitoring

▪ Fire alert recognition (with corresponding system configuration)

▪ Monitoring of the inlet tank valve (with corresponding system configuration)

▪ Water flow detection (water flow detector), including temperature monitoring

▪ Dry running protection

You can also assign up to 3inputs with freely configurable statuses or signals as an

option.

Communication

Communication with field bus systems via the following interfaces:

▪ Profibus

▪ Modbus RTU– RS485

Bus communication with frequency inverters is possible for the following

manufacturers:

▪ KSB PumpDrive

▪ Danfoss VLT 2800

▪ Danfoss Microdrive FC 51

▪ Danfoss Aquadrive FC 200

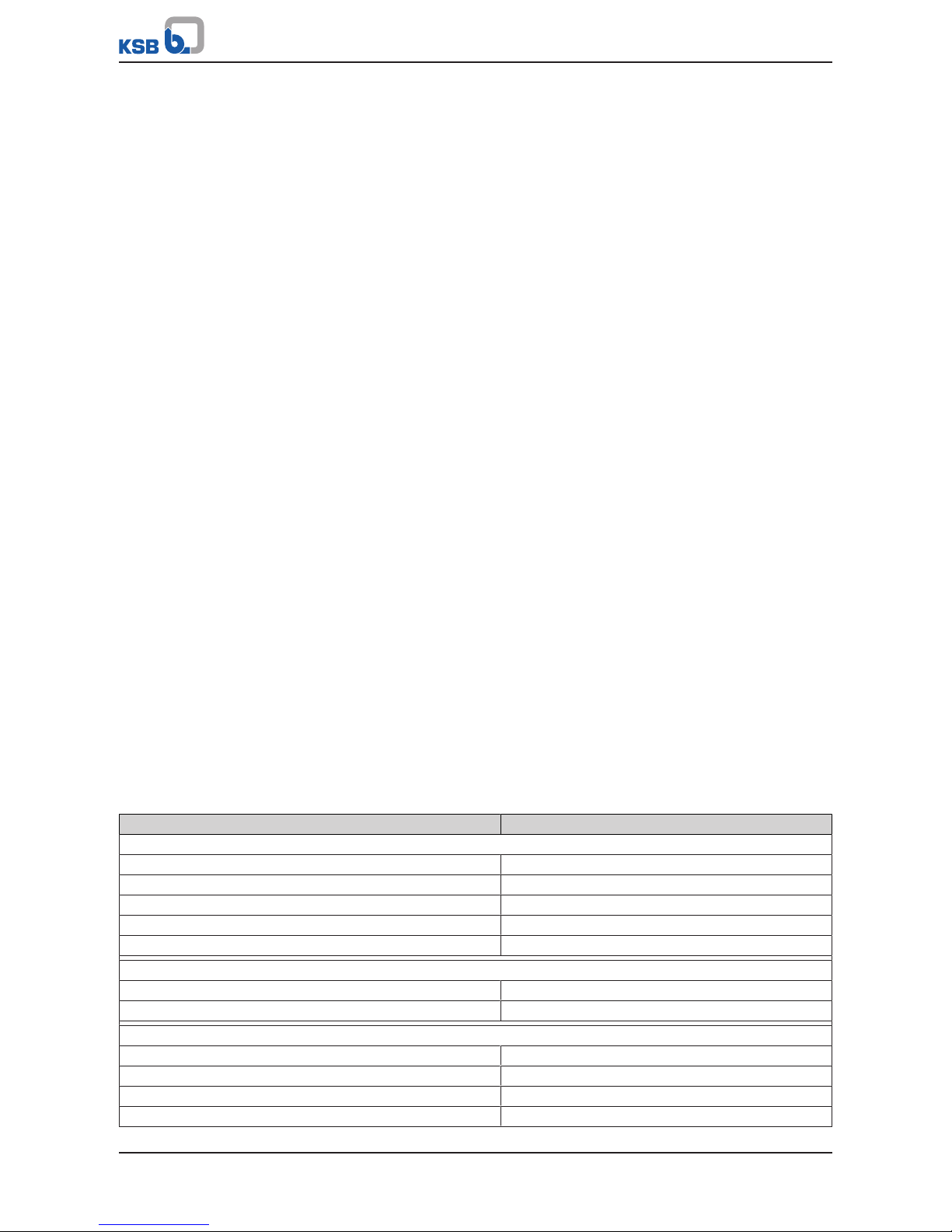

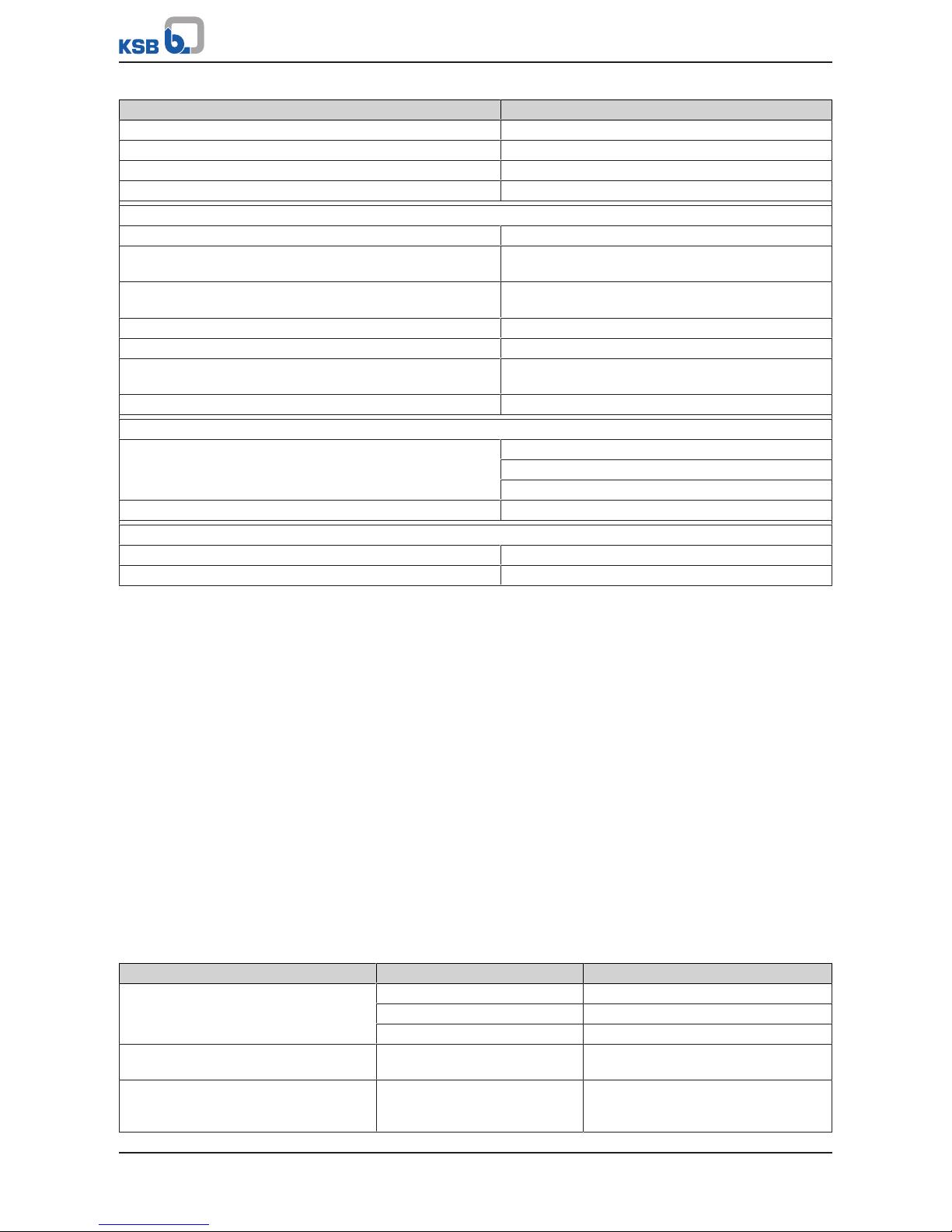

4.5 Technical data

Table6: Technical data

Characteristic Value

Power supply

Rated voltage 1~ 230 V AC ±10 %

Mains frequency 50/60 Hz

Rated insulation voltage 500 V AC

Standby current input ~ 35 mA

Standby power 7,5 W

Enclosure

Housing IP20

For control cabinet installation IP55

Digital inputs

Motor protection 24 V DC

Pressure switch 24 V DC

Water flow detector 24 V DC

Fault reporting relay of frequency inverter 24 V DC

4 Description

12 of 88

BoosterControl Advanced

Characteristic Value

Fault reporting relay of inlet tank valve 24 V DC

External OFF switch 24 V DC

Fire alert 24 V DC

Parameterisable digital inputs 24 V DC

Digital outputs

Contactor control per pump 250 V AC, 8 A

External warning Volt-free switching contact

NO/NC function

External alert Volt-free switching contact

NO/NC function

Starting the floating frequency inverter 24 V DC

Starting frequency inverter 1 - 6 24 V DC

Inlet tank valve 24 V DC or 0/4-20mA

Input impedance 200 ohms

Parameterisable digital outputs 250 V AC, 8 A

Analog inputs

2 pressure sensors 4-20 mA, input impedance 200 Ω

< 3.5 mA: broken wire detection

> 20.5 mA: short circuit detection

Temperature sensor PT1000

Analog outputs

Proportional inlet tank valve 0-20 mA

Setpoint transmitter for frequency inverter 0-20 mA

4.5.1 Parameterisable inputs/outputs

It is possible to freely program up to 3inputs/outputs.

The number of outputs (P4, P5, P6) varies in accordance with the operating mode set

in addition to the actual number of pumps connected.

Example:

In a system with 4 pumps, only 2 freely parameterisable outputs can be made

available for technical reasons. The pump output relays are used for this purpose.

The required function is assigned by setting the respective parameters.

Signals such as "dry running protection" can be transmitted as an output message,

for example.

4.6 Combination options

Not every frequency inverter can be used for every operating mode! Internal bus

communication forms the basis for this purpose.

The following combinations of frequency inverter and operating mode are

recommended by KSB:

Table7: Combinations of frequency inverters and operating modes

Cascade operating mode Power Frequency inverter

Floating frequency inverter ("V"

operating mode)

≤ 7,5 kW Danfoss MicroDrive (FC51)

11...18,5 kW Danfoss VLT 2800

22 kW Danfoss AquaDrive (FC200)

Motor-mounted frequency inverter per

pump ("VP" operating mode)

0,75 kW…22 kW KSB PumpDrive

Control cabinet-mounted frequency

inverter per pump ("Eco VP" operating

mode)

≤ 7,5 kW Danfoss MicroDrive (FC51)

4 Description

13 of 88

BoosterControl Advanced

4.7 Options

The following options are available:

Water flow detection

▪ Water flow detector as 4-20mA signal

▪ PT1000 temperature sensor

▪ Water flow detector as digital signal

▪ Expansion of digital signal inputs/outputs (freely parameterisable/assignable)

Field bus modules

▪ Profibus

▪ Modbus

4.8 Software scope of supply

The following software is provided or can be downloaded from the KSB web site at

www.ksb.com:

▪ KSB PC software "KSB ServiceTool PactWare for BoosterControl"

Also on request:

▪ USB RS232 connection cable

▪ WIBU key (dongle, a physical security device preventing unauthorised access to

data)

4.9 Dimensions and weight

Table8: Dimensions and weight

Characteristic Value

Dimensions (H x W x D) 306,5x187x72,5

Weight Approx. 1kg

5 Installation at Site

14 of 88

BoosterControl Advanced

5 Installation at Site

5.1 Safety regulations

DANGER

Incorrect installation

Danger to life!

▷ Install BoosterControl Advanced in a flood-proof location.

▷ Never use BoosterControl Advanced in potentially explosive atmospheres.

5.2 Checking ambient conditions

1. Check and safeguard ambient conditions. (ðSection8.1,Page34)

2. Contact the manufacturer if the device is to be used under ambient conditions

other than indicated.

3. Verify that the place of installation meets the following requirements:

- Sufficient space for installation/removal and proper ventilation

- No direct sunlight

- Protected against freezing

- Flood-proof

5.3 Installing BoosterControl Advanced

Install BoosterControl Advanced while referring to the outline drawing.

5.4 Electrical connection

DANGER

Incorrect electrical installation

Danger of death from electric shock!

▷ Any work on the electrical system shall be undertaken by a trained electrician

only (DINVDE 0105 - Part1/07.83).

▷ Before commencing any work on the electrical installations, de-energise the

system and make sure it cannot be re-started unintentionally. Ensure staff

safety by PELV1):

▷ Only motor protection devices with safe isolation to EN50178 (VDE0160) may

be connected directly.

CAUTION

Improper electrical connection

Damage to property

▷ All connections shall be made in accordance with the technical specifications

issued by the local energy supply companies.

▷ Check the type of current and voltage of the mains.

5.4.1 Electrical connections

All electrical connections of BoosterControl Advanced to the power relays or

contactors must always have circuit protection.

If more than two apparatuses are controlled in a control cabinet, always provide for

a separate control voltage supply in the control cabinet (as per EN60204).

1) PELV = Protective Extra Low Voltage. The inputs for the thermal circuit breakers (TCBs) are not galvanically isolated from

the PELV circuits of the control inputs, 24Vdigital outputs and service interface.

5 Installation at Site

15 of 88

BoosterControl Advanced

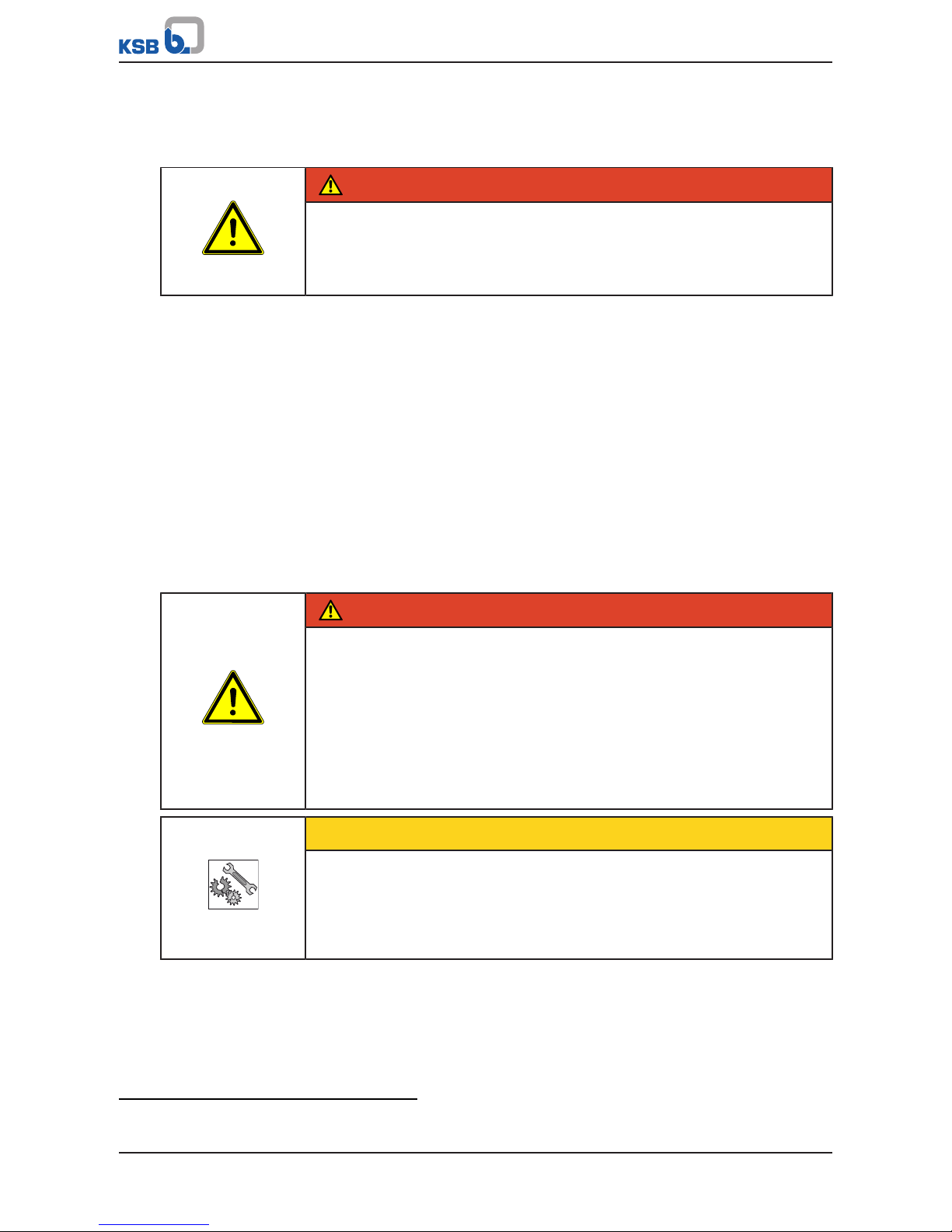

Electrical connections of mainboard (maximum of 3pumps)

15

1 2 3 4 5 6 7 8 9

10

17

16

14

13

12

11

Fig.2: Mainboard

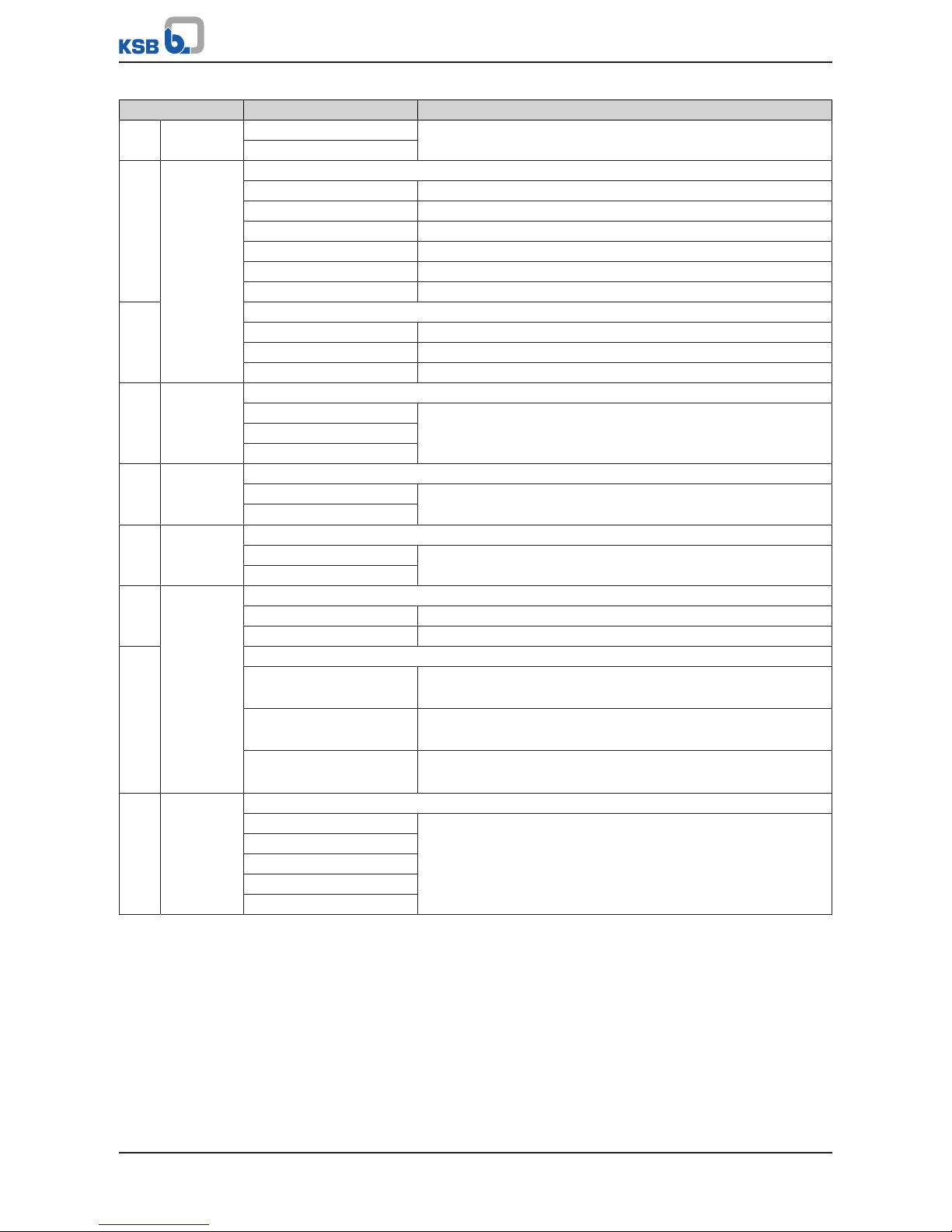

Table9: Connections on the mainboard

Terminal strip Terminal Description

1

J201

Power supply

L1 Power supply

Phase 1

L1 Power supply

Phase 1

N Power supply, neutral

PE PE power supply - earth

2 J601 Pump contactors and inlet tank valve

COM Pump contactors - earth

P1 Contactor of pump1

P2 Contactor of pump2

P3 Contactor of pump3

VALVE Inlet tank valve

3 J602 Activation of frequency inverters

F01 Start, frequency inverter 1

F02 Start, frequency inverter 2

F03 Start, frequency inverter 3

4 J605 B Output of alerts

URGENT Output for alerts

5 J605 A Output of warnings

NON URGENT Output for warnings

6 J604 Activation of frequency inverter

F0 START Start, floating frequency inverter

7 J404 Actual-value signal of pressure on discharge side

PT dis 24 V Pressure sensor, discharge side

PT dis +

PT dis -

8 J405 Actual-value signal of pressure on suction side

PT inl 24 V Pressure sensor, suction side

5 Installation at Site

16 of 88

BoosterControl Advanced

Terminal strip Terminal Description

8 J405 PT inl + Pressure sensor, suction side

PT inl -

9 J403 Digital inputs

RDP Pressure switch for dry running protection

TFO Fault reporting relay of frequency inverter

TVA Fault reporting relay of valve

OFF External OFF switch

FIRE Fire alert

COM Digital inputs - 24 V DC supply

10 Fault input, pump set

P1 Motor protection/thermal overload, pump 1

P2 Motor protection/thermal overload, pump 2

P3 Motor protection/thermal overload, pump 3

11 J302 Can bus (RS 485)

B RS485 bus for frequency inverter

A

GND

12 J501 Proportional valve for inlet tank

+ Proportional valve for inlet tank

-

13 J502 Setpoint signal, analog

+ Setpoint for floating frequency inverter

-

14 J401 Temperature sensor for water flow detection

PT1000 - Temperature sensor - earth

PT1000 + Temperature sensor - signal

15 Water flow detector for detecting water flow

WSD1 Water flow detector sensor 1

Parameterisable input 1

WSD2 Water flow detector sensor 2

Parameterisable input 2

WSD3 Water flow detector sensor 3

Parameterisable input 3

16 J301 CAN-Open

GND CAN bus

H

L

T-

T+

Connections on the expansion board (maximum of 6pumps)

The BoosterControl Advanced version for 6pumps is equipped with additional

terminals in the centre area at the rear of the control system (cannot be retrofitted;

factory-set).

Terminals P4 - P6 are used to connect the freely parameterisable outputs.

5 Installation at Site

17 of 88

BoosterControl Advanced

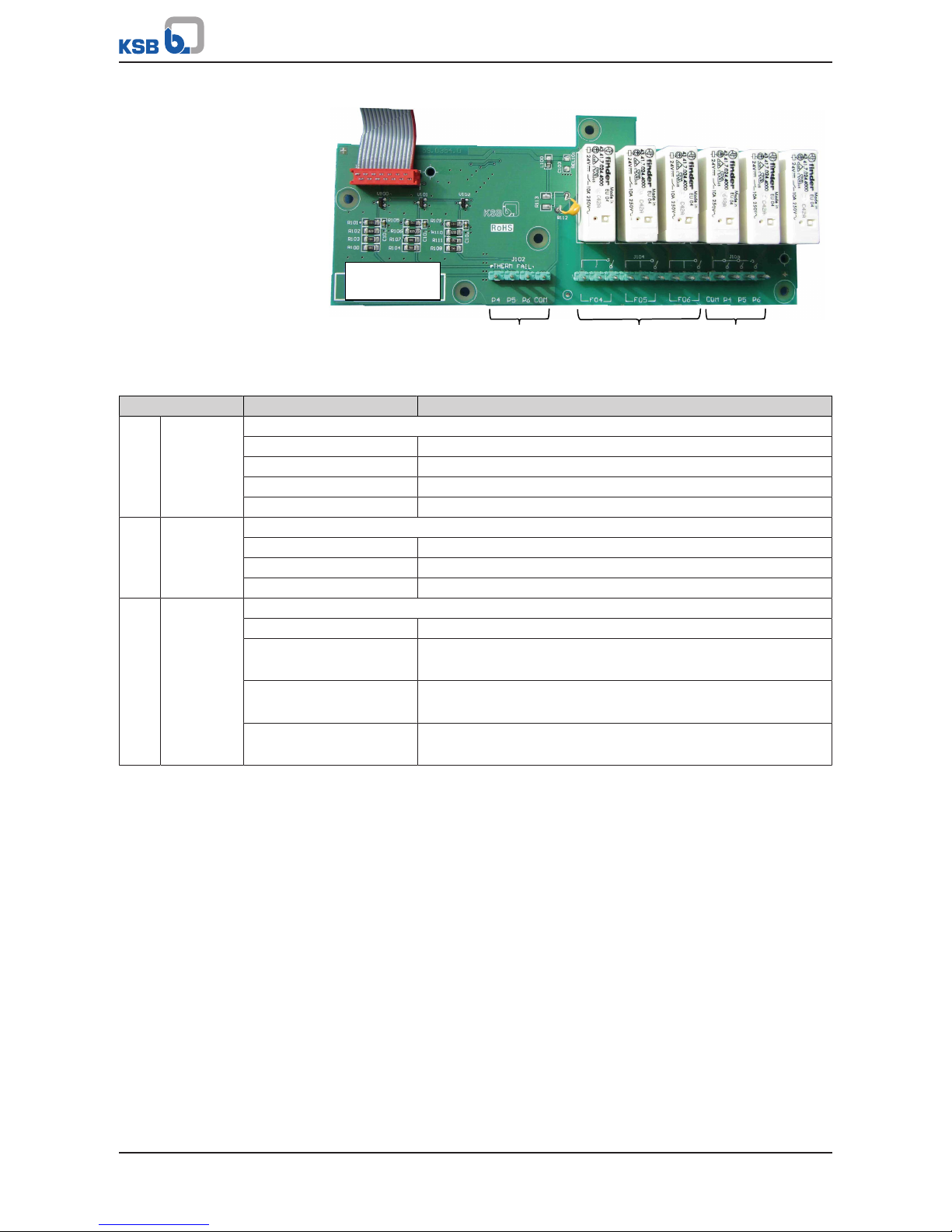

1 2 3

Fig.3: Expansion board

Table10: Additional connections on the expansion board for 6pumps with parameterisable outputs

Terminal strip Terminal Description

1 J102 Fault input, pump set

P4 Motor protection/thermal overload, pump 4

P5 Motor protection/thermal overload, pump 5

P6 Motor protection/thermal overload, pump 6

COM Digital inputs - 24 V DC supply

2 J104 Activation of frequency inverters 4 - 6

F04 Start, frequency inverter 4

F05 Start, frequency inverter 5

F06 Start, frequency inverter 6

3 J103 Pump contactors 4 - 6

COM Pump contactors - earth

P4 Contactor of pump4

Parameterisable output 1

P5 Contactor of pump5

Parameterisable output 2

P6 Contactor of pump6

Parameterisable output 3

5.4.2 Connection to power supply

1. Observe the terminal assignments on the printed circuit board.

(ðSection5.4.1,Page14)

2. Connect to power supply:

- Terminal strip J201, terminals L1, N and PE

5.4.3 Connecting/bridging the motor protection device

Connect motor protection device with safe isolation in acc. with EN50178.

Use the following terminals on the printed circuit board:

▪ Terminal strip J403, terminals P1, P2, P3 and COM

For more than 3pumps, also use the following terminals:

▪ Terminal strip J102, terminals P4 - P6 and COM

Connect/bridge the thermal circuit breaker.

5 Installation at Site

18 of 88

BoosterControl Advanced

Motors with thermal circuit breakers:

Motors with thermal circuit

breakers:

1. Ensure that the inputs/outputs are galvanically isolated from the thermal circuit

breaker inputs.

2. If thermal circuit breakers have not been safely isolated from the low-voltage

mains, decouple the signals using coupler modules.

3. Connect the thermal circuit breaker to BoosterControl Advanced.

Motors without thermal circuit breakers:

Motors without thermal

circuit breakers

1. Bridge the thermal circuit breaker connection on BoosterControl Advanced.

Observe terminal wiring diagram.

5.4.4 Connecting the pump contactors

The last two terminals can also be used as outputs for signal relays.

1. Observe the terminal assignments on the printed circuit board.

(ðSection5.4.1,Page14)

2. Connect to power supply:

- External 24 V to terminal strip J601, COM terminal

or

- 230 V from L1 terminal to terminal strip J601, COM terminal

3. Connect pump contactors:

- Terminal strip J601, terminals P1, P2, P3

4. For 6 pumps also use the following additional terminals:

- Terminal strip J103, terminals P4, P5, P6

5.4.5 Connecting the pressure sensor

1. Observe the terminal assignments on the printed circuit board.

(ðSection5.4.1,Page14)

2. If a 2-wire sensor is to be used:

- Terminal strip J404, terminals 24 V and +

3. If a 3-wire sensor is to be used:

- Terminal strip J404, terminals 24 V, + and -

5.4.6 Connecting the dry running protection device

Dry running protection can be effected by means of a pressure sensor or pressure

switch fitted on the suction side.

1. Connect the pressure sensor, if any:

- Terminal strip J405, terminals + and -

2. If available, connect pressure switch:

- Terminal strip J403, terminals RDP and COM

3. If no pressure switch is used, bridge the pressure switch terminal:

- Terminal strip J403, terminals RDP and COM

5.4.7 Other connections required depending on the operating mode

Cascade control

No further connections required.

Cascade operation with jockey pump

Ensure that the jockey pump is sized to act as a base-load pump and not as a peakload pump.

5 Installation at Site

19 of 88

BoosterControl Advanced

Floating frequency inverter

Only possible when the frequency inverter is integrated in the control cabinet.

1. Observe the logic diagram (see other applicable documents).

2. Connect frequency inverter start signal:

Terminal strip J604, terminal FO START

Fixed frequency inverter

1. Connect frequency inverter start signal to the frequency inverter of the pump to

be controlled:

- Terminal strip J604, terminal FO START, frequency inverter per pump

CAUTION

Use of different types of frequency inverter

Damage to property!

▷ Only use frequency inverters of the same type within a system!

1. Connect frequency inverter start signal:

- Terminal strip J602, terminals F01 - F03

2. For 6 pumps also use the following additional terminals:

- Terminal strip J104, terminals F04 - F06

5.4.8 Making optional connections

Some terminals must be bridged if not in use.

Bridge the following terminals if not in use:

▪ Fault reporting relay of frequency inverter: terminal strip J403, terminal TFR with

COM

▪ Fault reporting relay of valve: terminal strip J403, terminal TVA with COM

▪ External Off switch: terminal strip J403, terminal OFF with COM

▪ Fire alert: terminal strip J403, terminal FIRE with COM

The following connections can be made.

External signalling devices

The external signalling device can be powered via the BoosterControl Advanced

control unit if necessary.

1. Bridge the following connections to power the external signalling device:

Terminal strip J201, terminal L1, with terminal strip J605A or J605B, left pin

2. Connecting external signalling devices:

- For warnings, terminal strip J605A, NON URGENT terminal

- For alerts, terminal strip J605B, URGENT terminal

Water flow detection (WSD)

Up to 3water flow detectors can be connected.

1. Connect existing water flow detector:

- Terminal strip J401, terminals WS1, WS2 and WS3

2. Connect a PT1000 temperature sensor, if any:

- Terminal strip J401, terminals PT1000 - and PT1000 +

Additional information on function and configuration

5 Installation at Site

20 of 88

BoosterControl Advanced

Connections for inlet tank

ü Pump inlet pressure < 0.5bar

1. Connect pressure sensor for level monitoring:

- Observe logic diagram (refer to other applicable documents)

- Terminal strip J405, terminals +, - and 24 V

2. If a gate valve is to be used as an inlet tank valve, connect gate valve:

- Terminal strip J601, terminals VALVE and COM

3. If a proportional valve is to be used as an inlet tank valve, connect proportional

valve:

- Terminal strip J501, terminals + and -

4. If available, connect fault reporting relay of inlet tank valve:

- Terminal strip J403, terminals TVA and COM

Fault reporting relay of frequency inverter

1. Connect fault reporting relay:

- Terminal strip J403, terminals TFR and COM

External OFF switch

1. Connect external Off switch:

- Terminal strip J403, terminals OFF and COM

Fire alert

In case of a fire alert, BoosterControl Advanced starts all connected pumps at their

maximum speed.

A fire alert has absolute priority. The system cannot be stopped via the external OFF

switch.

1. Connect fire alert:

- Terminal strip J403, connect signal relay to FIRE and COM terminals

On BoosterControl Advanced, the last two terminals for pump contactors can be used

as outputs for signal relays.

1. Connect signal relay for BoosterControl Advanced version for up to 6pumps:

- Terminal strip J103, terminals P5, P6 and COM

6 Operation

21 of 88

BoosterControl Advanced

6 Operation

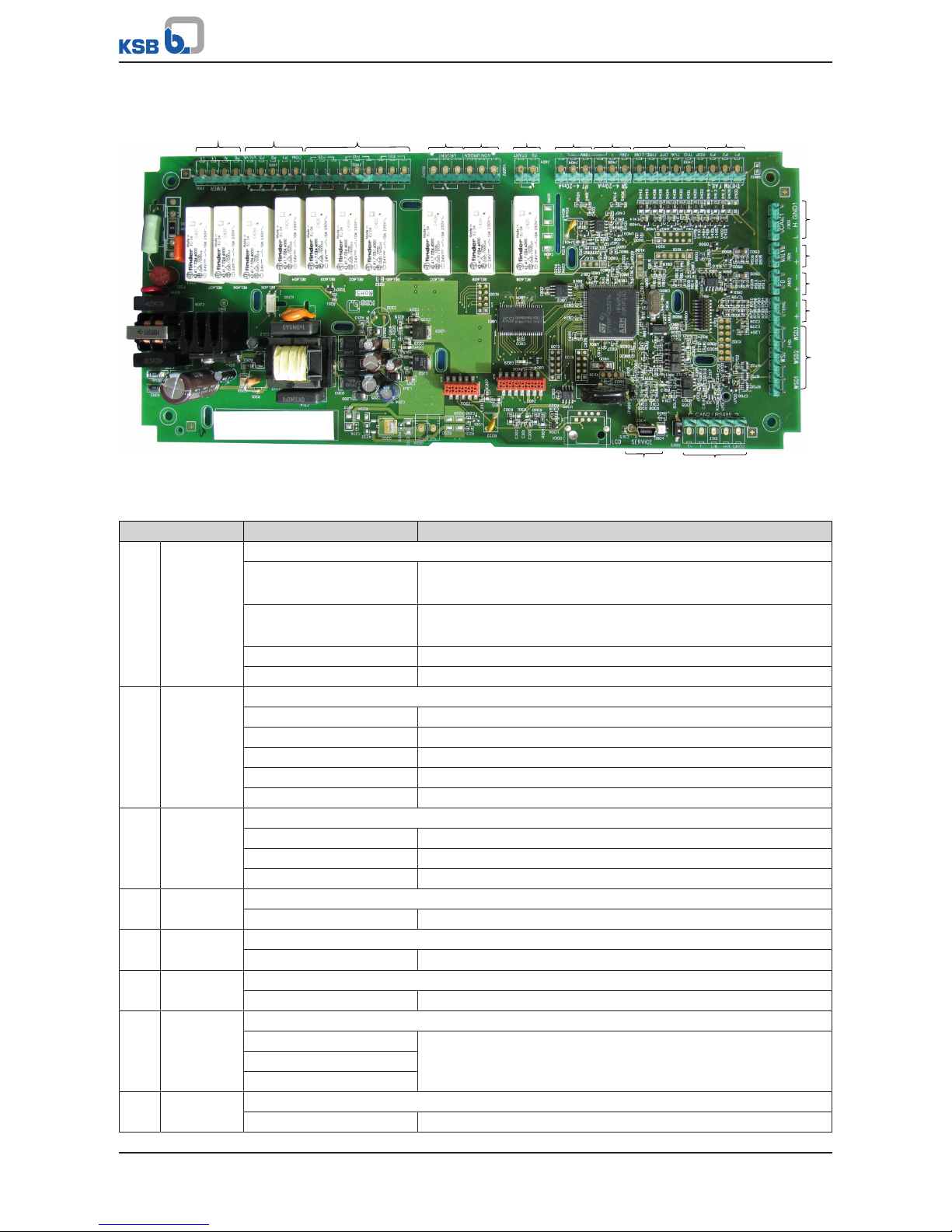

6.1 Control panel

1

2

3

4

5

Fig.4: Control panel

Table11: Description of control panel

Item Description Function

1 Graphical display Displays information on BoosterControl Advanced

operation

2 "Traffic light" LEDs The traffic light function provides information

about the pump system's operating status.

3 Menu keys Change to the elements of the first menu level

4 Navigation keys Navigation and parameter setting

5 Service interface Configuring and parameterising BoosterControl

Advanced using a PC/notebook

6.1.1 "Traffic light" LEDs

The "traffic light" LEDs provide information about the operating status of

BoosterControl Advanced.

Table12: LED description

LED Description

Red

One or several alerts are active

Amber

One or several warnings are active

Green

Steady light: trouble-free operation

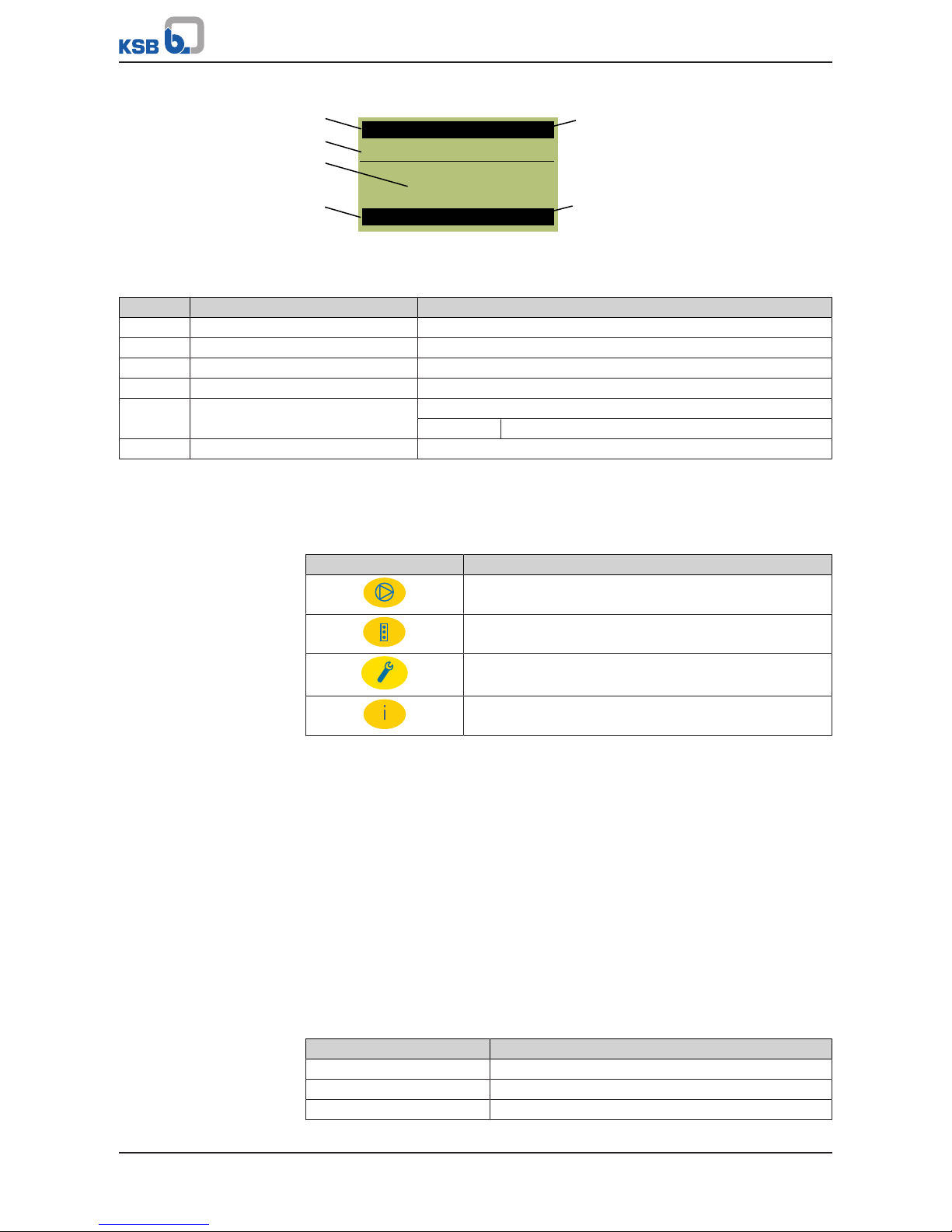

6.1.2 Graphical display

The graphical display breaks down into 6areas.

6 Operation

22 of 88

BoosterControl Advanced

3.52

12-06

bar

BC

12:37

3-5-1

Set point

Leakage

1

5

6

2

3

4

Fig.5: Graphical display (example)

Table13: Description of graphical display

Item Description Description

1 Parameter Shows the parameter selected

2 Parameter name Displays the name of the parameter selected

3 Current display Displays the current values for the parameter selected

4 Messages/alerts Displays current warning and fault messages

5 Model Displays model

BC = BoosterControl

6 Date/time Displays current date and time

6.1.3 Menu keys

You can use the menu keys to access the elements at the first menu level directly.

Table14: Assignment of menu keys

Key Menu

Operation

Diagnosis

Settings

Information

6.1.3.1 Menu: Operation

The Operation section contains all information required for operating the machine

and the process. This includes important process data (pressure, flow rate, etc.) as

well as current process states (input/output states).

The decision regarding which parameters are displayed on the main screen can be

influenced by a user who has the appropriate authorisation. The parameters to be

displayed on the main screen can be selected in the Settings menu.

6.1.3.1.1 Operating values in the start menu

A start menu can be called from the start screen following the boot procedure.

Press "OK" key when on the start screen.

The following parameters are displayed:

Table15: Parameters in start menu (depending on operating mode; here, Cascade

operating mode)

Parameter Value

3-2-1-1 PIN

3-5-1 Setpoint

3-5-3 Bandwidth

6 Operation

23 of 88

BoosterControl Advanced

Parameter Value

3-5-10 Delta p

3-5-11 High pressure alarm

3-5-13 Low pressure alarm

3-6-2 Minimum run time

3-6-5 Start delay

3-6-6 Stop delay

3-6-8 RDP delay

3-6-9 High/low alarm delay

6.1.3.2 Menu: Diagnosis

In the "Diagnosis" section, the user is provided with information about faults and

warnings that pertain to the pump set or process. This can be done with

BoosterControl Advanced in fault (system standstill) or warning (system operational)

status. The user can also find previous messages in the history.

Messages

All monitoring and protective functions trigger warnings or alerts. These are

signalled via the amber or red LED. A flashing message is output in the last line of

the control panel display. If more than one message is output, the last one is

displayed. Alerts have priority over warnings.

To display all warnings and alerts, choose the Diagnosis menu and then Active

Messages (2- 1-1). The general fault message is output via the relay outputs. .

Alert history

The alert history can be viewed under 2-1-2 after pressing the "Diagnosis" menu key.

The last 100 alerts are listed here. You can use the arrow keys and the OK key to

select an entry from the list. Information about when the alert has come and gone is

then displayed.

Acknowledging and resetting alerts

NOTE

Depending on the combination of settings, the system could conceivably restart

automatically after acknowledgement/reset or when the cause of failure has been

eliminated.

Acknowledgement

You can acknowledge the alert once the cause has been rectified. Alerts can be

acknowledged individually in the alerts list in the Diagnosis menu under (2-1-3).

Reset

All alerts are acknowledged at the same time during a reset. The reset can be carried

out via the control panel using the OK key (only possible in the start menu). You may

therefore have to press the ESC key several times to return to the start menu. The

reset can also be carried out via a digital input. Digital input 4 is defaulted for this

purpose.

Automatic reset

Alerts can also be reset automatically (3-9). Alerts and fault messages can be

configured to be reset automatically (3-9). This is only possible from the "Service"

access level.

6.1.3.2.1 Messages

All monitoring and protective functions trigger messages. BoosterControl Advanced

assigns a priority status to each message. The priority status of each message is

signalled via the amber or red LED.

If there are several messages, they are listed in order of priority.

Up to 100 messages are stored.

6 Operation

24 of 88

BoosterControl Advanced

To display current, active messages:

1. Select parameter 2-1-1.

To see more information about a message:

1. Select the message and press "OK" to confirm.

ð The status of the message is displayed (came, acknowledged, gone)

6.1.3.2.2 Displaying the alert history

The alert history is saved for future reference, even in the event of a power failure.

The alert history provides the user with a chronological log of alerts that have either

been acknowlegded or gone automatically.

1. To display the alert history:

Select parameter 2-1-2.

2. For more information on an alert:

- Select the required alert using the arrow keys.

- Press "OK" to display more information.

The following information is given for every message:

▪ Date

▪ Time

▪ Alert

▪ Status

6.1.3.2.3 Overview of warnings and alerts

Alerts, warnings and the set fault function can be assigned manually.

All warnings and alerts are listed for fault analysis.

6.1.3.3 Menu: Settings

General settings can be made or the settings for the process optimised in the Settings

section. All aspects that have to do with the operative function or availability of the

pump set can also be found here.

6.1.3.3.1 Display language

The following display languages can be toggled:

▪ German

▪ French

▪ English

▪ Dutch

▪ Turkish

Table16: Language parameter

Parameter Description Possible setting Access Factory setting

3-1-1-1 Display language German

French

English

Dutch

Turkish

Customer English

6.1.3.3.2 Access levels

Four access levels have been defined to prevent accidental or unauthorised access to

BoosterControl Advanced parameters:

6 Operation

25 of 88

BoosterControl Advanced

Table17: Access levels

Access level Description

Standard (no login) Access without password entry.

Customer Access level for the expert user with

access to all parameters required for

commissioning.

Service Access level for service personnel.

If a parameter's access level is not explicitly specified, the parameter is always

assigned the customer access level.

Table18: Access level parameter

Parameter Description Possible setting Access level required Factory

setting

3-2-1-1 Enter customer password for

access

0000...9999 Standard 0000

Enter service password for access 0000...9999 Service -

Change customer access level

password

0000...9999 Customer -

Password-protected access level

for customer parameter

Disabled

Enabled

Customer Disabled

Entering the password

Customer access level

You must enter the password under (3-2-1-1) Login to gain access. The password can

be changed under Customer Password after entering "7353" (factory password). If

password protection is deactivated via parameter 3-2-1-2, the customer access level

becomes the standard access level. This applies to the factory settings.

Service access level

You must enter a password under Service Login.

NOTE

If no keys are pressed for ten minutes, the system will automatically return to the

standard access level.

6.1.3.3.3 Displaying and changing parameters

The parameter numbers contain the navigation path, which helps you find a

particular parameter quickly and easily. The first digit of the parameter number

indicates the first menu level, which is called up directly via the four menu keys.

Table19: Assignment of menu keys

Key Menu

Operation

Diagnosis

Settings

Information

Subsequent steps are carried out via the navigation keys.

Example

Parameter 3-5-1 Setpoint

1. First digit of parameter number: 3-5-1

Press the "Settings" menu key.

ð 3-1 appears in the top left of the screen.

2. Second digit of parameter number: 3-5-1

Press the arrow key to change the display 3-1 on the screen (upper left) to 3-5.

6 Operation

26 of 88

BoosterControl Advanced

3. Press OK to confirm the selection.

ð 3-5-1 appears in the top left of the screen.

4. Press OK to confirm the selection.

ð You have called up the required parameter.

Changing the parameter value

1. Press OK.

ð The bar above the entry displays the value currently being entered.

2. Use the arrow keys to increase or decrease the value displayed.

3. Confirm the selected value by pressing OK.

ð The cursor moves to the next position (second position from the left).

4. Make the settings as described for the subsequent positions.

5. Press the OK key to save the new parameter value.

6.1.3.3.4 Access levels

Table20: Access levels

Access level Code displayed Properties

Standard - No login required

Restricted access to parameters

Customer C Login required

Access to main customer parameters

Service S Login required

Access to all service-relevant parameters

Factory F Login required

Access to all parameters

6.1.3.4 Menu: Information

All direct information about PumpDrive is provided in the Information section.

Important details regarding the firmware version are listed here.

6.1.4 Navigation keys

The navigation keys are used for navigating in the menus and for confirming

settings.

Table21: Assignment of navigation keys

Key Function

Arrow keys:

▪ Move up/down in the menu options.

▪ Increase/decrease a numerical value.

Esc

Escape key:

▪ Delete/reset entry

(the entry is not saved).

▪ Move up one menu level.

6 Operation

27 of 88

BoosterControl Advanced

Key Function

OK

OK key:

▪ Confirm settings.

▪ Confirm menu selection.

▪ Move to the next digit when entering numerals.

▪ Alert reset

?

Help key:

▪ Displays a help text for each selected menu option.

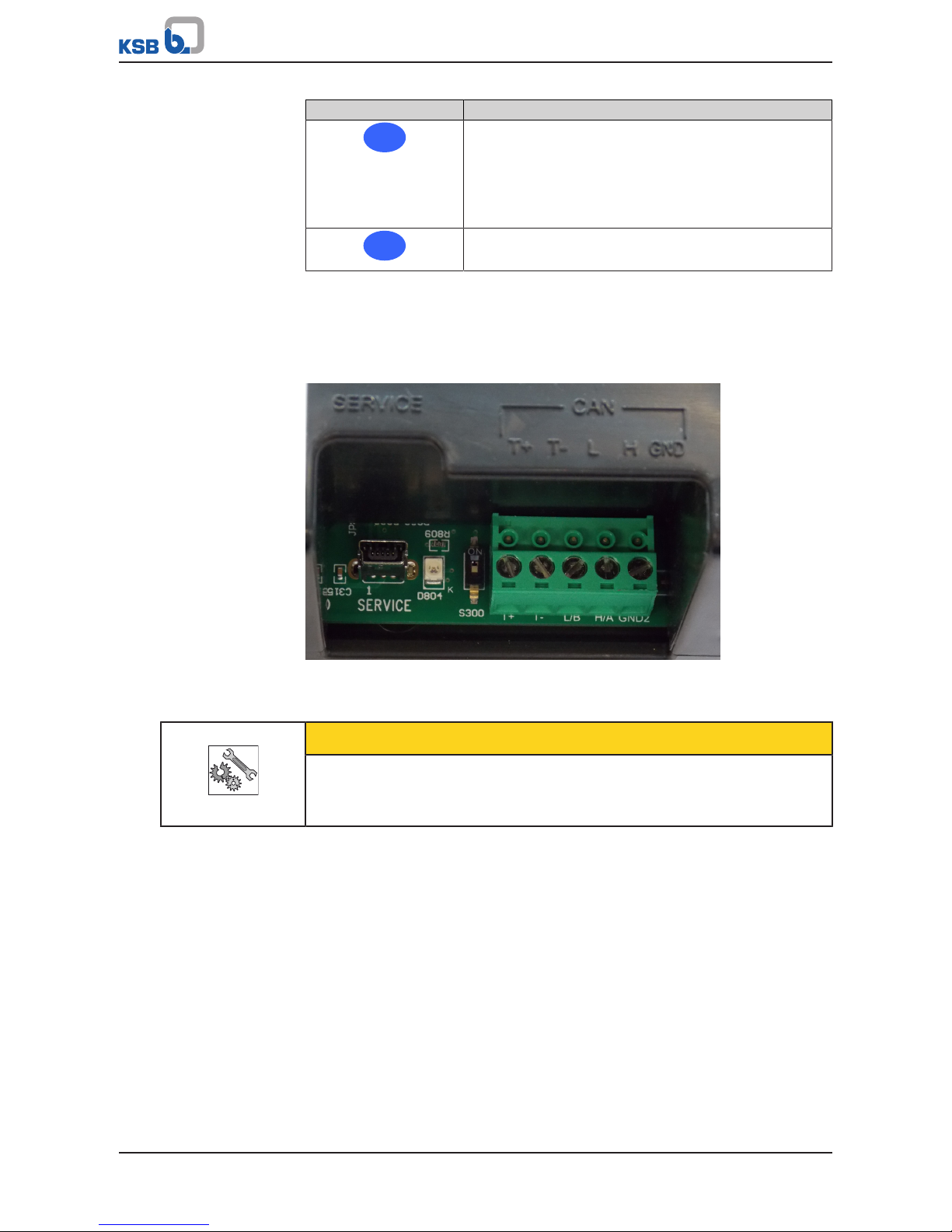

6.2 Operating the device via the service interface

Connection to the service interface can be established in two ways:

▪ Via a connector at the rear

▪ Via a connector on the control panel

Fig.6: Service interface at the rear

For details, please refer to the user manual of the "ServiceTool for BoosterControl"

Advanced.

CAUTION

Improper use of service interface

Damage to connected laptop/PC!

▷ Only use the connection cable offered by KSB (USB - RS232).

The service interface allows a PC/notebook to be connected via a special cable (USB RS232).

The following actions can be taken:

▪ Configuring and parameterising BoosterControl Advanced using the KSB service

software

▪ Software update

▪ Saving and documenting set parameters

The hardware protection (dongle) must be connected to enable the authorisation

level. Observe the service tool instructions.

6.3 Operating the device via the control panel

6.3.1 Displaying and changing parameters

The parameter number also serves as the navigation path.

The first digit of the parameter number indicates one of the following menus:

Loading...

Loading...