Page 1

Submersible Waste Water Pump

Ama-Drainer 4../5..

Installation/Operating Manual

Page 2

Legal information/Copyright

Installation/Operating Manual Ama-Drainer 4../5..

Original operating manual

All rights reserved. The contents provided herein must neither be distributed, copied, reproduced,

edited or processed for any other purpose, nor otherwise transmitted, published or made available to a

third party without the manufacturer's express written consent.

Subject to technical modification without prior notice.

© KSB SE & Co. KGaA, Frankenthal 12/03/2019

Page 3

Contents

Contents

Glossary .................................................................................................................................................. 5

1 General.................................................................................................................................................... 6

1.1 Principles ...........................................................................................................................................................6

1.2 Installation of partly completed machinery....................................................................................................6

1.3 Target group.....................................................................................................................................................6

1.4 Other applicable documents............................................................................................................................6

1.5 Symbols .............................................................................................................................................................6

1.6 Key to safety symbols/markings.......................................................................................................................7

2 Safety...................................................................................................................................................... 8

2.1 General..............................................................................................................................................................8

2.2 Intended use .....................................................................................................................................................8

2.2.1 Prevention of foreseeable misuse.......................................................................................................8

2.3 Personnel qualification and training...............................................................................................................8

2.4 Consequences and risks caused by non-compliance with this manual .........................................................9

2.5 Safety awareness ..............................................................................................................................................9

2.6 Safety information for the operator/user.......................................................................................................9

2.7 Safety information for maintenance, inspection and installation ................................................................9

2.8 Unauthorised modes of operation................................................................................................................10

3 Transport/Temporary Storage/Disposal............................................................................................. 11

3.1 Checking the condition upon delivery..........................................................................................................11

3.2 Transport.........................................................................................................................................................11

3.3 Storage/preservation......................................................................................................................................11

3.4 Return to supplier...........................................................................................................................................11

3.5 Disposal ...........................................................................................................................................................12

4 Description of the Pump (Set)............................................................................................................. 13

4.1 General description ........................................................................................................................................13

4.2 Designation.....................................................................................................................................................14

4.3 Name plate......................................................................................................................................................15

4.4 Design details..................................................................................................................................................15

4.5 Configuration and function...........................................................................................................................17

4.6 Scope of supply...............................................................................................................................................18

4.7 Noise characteristics .......................................................................................................................................18

4.8 Dimensions and weights ................................................................................................................................18

5 Installation at Site................................................................................................................................ 19

5.1 Safety regulations...........................................................................................................................................19

5.2 Checks to be carried out prior to installation...............................................................................................19

5.2.1 Checking the operating data ............................................................................................................19

5.2.2 Preparing the place of installation ...................................................................................................19

5.3 Installing the pump set ..................................................................................................................................20

5.4 Piping ..............................................................................................................................................................20

5.4.1 Connecting the piping.......................................................................................................................20

5.5 Electrical system..............................................................................................................................................21

5.5.1 Information for planning the control system ..................................................................................21

5.5.2 Setting the overload protection device............................................................................................22

5.5.3 Connecting the level control equipment .........................................................................................22

5.5.4 Connection to power supply .............................................................................................................23

5.6 Checking the direction of rotation................................................................................................................23

6 Commissioning/Start-up/Shutdown................................................................................................... 25

6.1 Commissioning/Start-up.................................................................................................................................25

6.1.1 Prerequisites for commissioning/start-up .........................................................................................25

6.1.2 Start-up/shutdown.............................................................................................................................25

Ama-Drainer 4../5..

3 of 60

Page 4

Contents

6.2 Operating limits..............................................................................................................................................26

6.2.1 Frequency of starts.............................................................................................................................26

6.2.2 Operation on the power supply network ........................................................................................26

6.2.3 Fluid handled .....................................................................................................................................27

6.3 Shutdown/storage/preservation ....................................................................................................................29

6.3.1 Measures to be taken for shutdown ................................................................................................29

6.4 Returning to service .......................................................................................................................................29

7 Servicing/Maintenance........................................................................................................................ 30

7.1 Safety regulations...........................................................................................................................................30

7.2 Servicing/inspection........................................................................................................................................30

7.3 Drainage/disposal ...........................................................................................................................................30

7.4 Dismantling the pump set..............................................................................................................................31

7.5 Reassembling the pump set...........................................................................................................................33

7.6 Tightening torques.........................................................................................................................................34

7.7 Recommended spare parts stock...................................................................................................................34

8 Trouble-shooting.................................................................................................................................. 35

9 Related Documents.............................................................................................................................. 37

9.1 General assembly drawing with list of components ....................................................................................37

9.1.1 General assembly drawing of Ama-Drainer .../10, .../10K, .../35......................................................37

9.1.2 General assembly drawing Ama-Drainer 522/11..............................................................................40

9.2 Dimensions and connections .........................................................................................................................42

9.2.1 Single pumps......................................................................................................................................42

9.2.2 Examples of transportable models ...................................................................................................45

9.2.3 Examples of stationary installation...................................................................................................47

9.2.4 Installation example of a dual-pump station...................................................................................49

9.3 Wiring diagrams .............................................................................................................................................50

9.3.1 Ama-Drainer SE..................................................................................................................................50

9.3.2 Ama-Drainer NE .................................................................................................................................51

9.3.3 Ama-Drainer SD .................................................................................................................................52

9.3.4 Ama-Drainer ND.................................................................................................................................53

10 EU Declaration of Conformity............................................................................................................. 54

11 EU Declaration of Conformity............................................................................................................. 55

12 Certificate of Decontamination........................................................................................................... 56

Index ..................................................................................................................................................... 57

4 of 60

Ama-Drainer 4../5..

Page 5

Glossary

Glossary

Backflow

Waste water flowing back from the sewer into the

connected drainage piping

Certificate of decontamination

A certificate of decontamination is enclosed by the

customer when returning the product to the

manufacturer to certify that the product has been

properly drained to eliminate any environmental

and health hazards arising from components in

contact with the fluid handled.

Close-coupled design

Motor directly fitted to the pump via a flange or a

drive lantern

Discharge line

Pipe for transporting waste water to a level above

the flood level into the sewer system

DOL starting

For low power ratings (usually up to 4kW), the

three-phase motor is connected directly to the

mains voltage.

submerged. They may be operated outside the

fluid for short periods of time, until the minimum

fluid level has been reached.

Waste water

Water consisting of a combination of water

discharged from households, industrial and other

businesses as well as surface water.

EN 12050-2

European Standard for waste water lifting units

which are used to dispose of faeces-free waste

water occurring below the flood level of buildings

and sites. It defines general requirements as well

as principles of construction and testing.

Flood level

Maximum backflow level of waste water in a

drainage system

Hydraulic system

The part of the pump in which the kinetic energy

is converted into pressure energy

Pump

Machine without drive, additional components or

accessories

Pump set

Complete pump set consisting of pump, drive,

additional components and accessories

Submersible motor pump

Submersible motor pumps are floodable, closecoupled units which are not self-priming. The

pumps are usually operated completely

Ama-Drainer 4../5..

5 of 60

Page 6

1 General

1 General

1.1 Principles

This operating manual is valid for the type series and variants indicated on the front

cover.

The operating manual describes the proper and safe use of this equipment in all

phases of operation.

The name plate indicates the type series, the main operating data and the serial

number. The serial number uniquely describes the product and is used as

identification in all further business processes.

In the event of damage, immediately contact your nearest KSB Service centre to

maintain the right to claim under warranty.

1.2 Installation of partly completed machinery

To install partly completed machinery supplied by KSB refer to the sub-sections under

Servicing/Maintenance.

1.3 Target group

This operating manual is aimed at the target group of trained and qualified specialist

technical personnel. (ðSection2.3,Page8)

1.4 Other applicable documents

Table1: Overview of other applicable documents

Document Contents

Sub-supplier product literature Operating manuals and other product literature

describing accessories and integrated machinery

components

For accessories and/or integrated machinery components observe the product

literature of the relevant manufacturer.

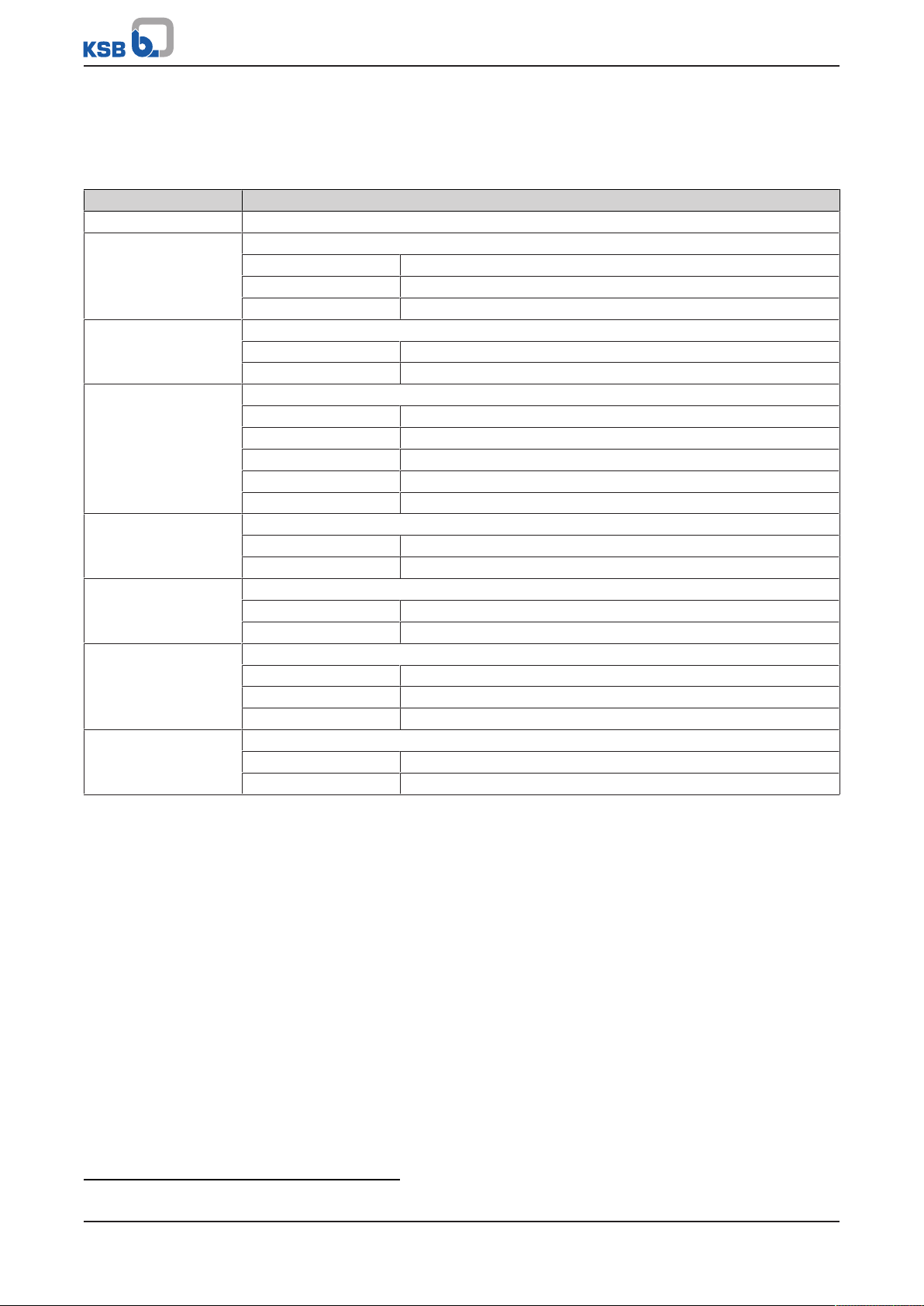

1.5 Symbols

Table2: Symbols used in this manual

Symbol Description

✓ Conditions which need to be fulfilled before proceeding with the

step-by-step instructions

⊳ Safety instructions

⇨

⇨ Cross-references

1.

2.

Result of an action

Step-by-step instructions

Note

Recommendations and important information on how to handle

the product

6 of 60

Ama-Drainer 4../5..

Page 7

1 General

!

DANGER

!

WARNING

CAUTION

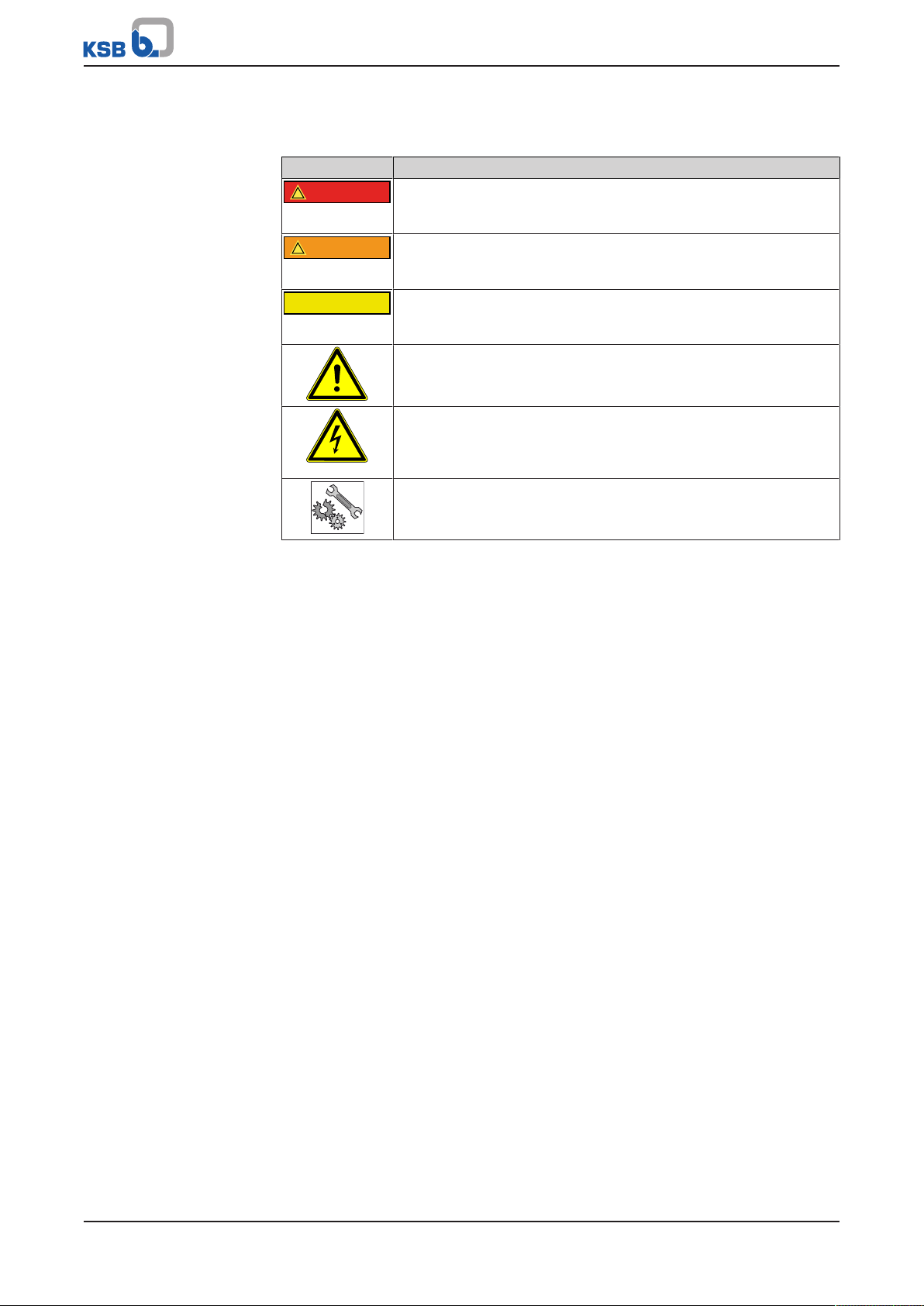

1.6 Key to safety symbols/markings

Table3: Definition of safety symbols/markings

Symbol Description

DANGER

This signal word indicates a high-risk hazard which, if not avoided,

will result in death or serious injury.

WARNING

This signal word indicates a medium-risk hazard which, if not

avoided, could result in death or serious injury.

CAUTION

This signal word indicates a hazard which, if not avoided, could

result in damage to the machine and its functions.

General hazard

In conjunction with one of the signal words this symbol indicates a

hazard which will or could result in death or serious injury.

Electrical hazard

In conjunction with one of the signal words this symbol indicates a

hazard involving electrical voltage and identifies information about

protection against electrical voltage.

Machine damage

In conjunction with the signal word CAUTION this symbol indicates

a hazard for the machine and its functions.

Ama-Drainer 4../5..

7 of 60

Page 8

2 Safety

!

DANGER

2 Safety

All the information contained in this section refers to hazardous situations.

In addition to the present general safety information the action-related safety

information given in the other sections must be observed.

2.1 General

▪ This operating manual contains general installation, operating and maintenance

instructions that must be observed to ensure safe operation of the system and

prevent personal injury and damage to property.

▪ Comply with all the safety instructions given in the individual sections of this

operating manual.

▪ The operating manual must be read and understood by the responsible specialist

personnel/operators prior to installation and commissioning.

▪ The contents of this operating manual must be available to the specialist

personnel at the site at all times.

▪ Information and markings attached directly to the product must always be

complied with and kept in a perfectly legible condition at all times. This applies

to, for example:

– Arrow indicating the direction of rotation

– Markings for connections

– Name plate

▪ The operator is responsible for ensuring compliance with all local regulations not

taken into account.

2.2 Intended use

▪ The pump (set) must only be operated in the fields of application and within the

use limits specified in the other applicable documents.

▪ Only operate pumps/pump sets which are in perfect technical condition.

▪ Do not operate the pump (set) in partially assembled condition.

▪ Only use the pump to handle the fluids described in the data sheet or product

literature of the pump model or variant.

▪ Never operate the pump without the fluid to be handled.

▪ Observe the minimum flow rates indicated in the data sheet or product literature

(to prevent overheating, bearing damage, etc).

▪ Observe the minimum flow rate and maximum flow rate indicated in the data

sheet or product literature (to prevent overheating, mechanical seal damage,

cavitation damage, bearing damage, etc).

▪ Do not throttle the flow rate on the suction side of the pump (to prevent

cavitation damage).

▪ Consult the manufacturer about any use or mode of operation not described in

the data sheet or product literature.

2.2.1 Prevention of foreseeable misuse

▪ Observe all safety information and instructions in this manual.

▪ Never exceed the permissible application and operating limits specified in the

data sheet or product literature regarding pressure, temperature, etc.

8 of 60

2.3 Personnel qualification and training

All personnel involved must be fully qualified to transport, install, operate, maintain

and inspect the machinery this manual refers to.

The responsibilities, competence and supervision of all personnel involved in

transport, installation, operation, maintenance and inspection must be clearly

defined by the operator.

Ama-Drainer 4../5..

Page 9

2 Safety

Deficits in knowledge must be rectified by means of training and instruction

provided by sufficiently trained specialist personnel. If required, the operator can

commission the manufacturer/supplier to train the personnel.

Training on the pump (set) must always be supervised by technical specialist

personnel.

2.4 Consequences and risks caused by non-compliance with this manual

▪ Non-compliance with these operating instructions will lead to forfeiture of

warranty cover and of any and all rights to claims for damages.

▪ Non-compliance can, for example, have the following consequences:

– Hazards to persons due to electrical, thermal, mechanical and chemical

effects and explosions

– Failure of important product functions

– Failure of prescribed maintenance and servicing practices

– Hazard to the environment due to leakage of hazardous substances

2.5 Safety awareness

In addition to the safety information contained in this operating manual and the

intended use, the following safety regulations shall be complied with:

▪ Accident prevention, health regulations and safety regulations

▪ Explosion protection regulations

▪ Safety regulations for handling hazardous substances

▪ Applicable standards, directives and laws

2.6 Safety information for the operator/user

▪ Fit protective equipment (e.g. contact guards) supplied by the operator for hot,

cold or moving parts, and check that the equipment functions properly.

▪ Do not remove any protective equipment (e.g. contact guards) during operation.

▪ Provide the personnel with protective equipment and make sure it is used.

▪ Contain leakages (e.g. at the shaft seal) of hazardous fluids handled (e.g.

explosive, toxic, hot) so as to avoid any danger to persons and the environment.

Adhere to all relevant laws.

▪ Eliminate all electrical hazards. (In this respect refer to the applicable national

safety regulations and/or regulations issued by the local energy supply

companies.)

▪ If shutting down the pump does not increase potential risk, fit an emergency-

stop control device in the immediate vicinity of the pump (set) during pump set

installation.

▪ Make sure the system cannot be accessed by unauthorised persons (e.g. children).

2.7 Safety information for maintenance, inspection and installation

▪ Modifications or alterations of the pump (set) are only permitted with the

manufacturer's prior consent.

▪ Use only original spare parts or parts/components authorised by the

manufacturer. The use of other parts/components can invalidate any liability of

the manufacturer for resulting damage.

▪ The operator ensures that maintenance, inspection and installation are

performed by authorised, qualified specialist personnel who are thoroughly

familiar with the manual.

▪ Only carry out work on the pump (set) during standstill of the pump.

▪ Only perform work on the pump set when it has been disconnected from the

power supply (de-energised).

▪ The pump (set) must have cooled down to ambient temperature.

Ama-Drainer 4../5..

9 of 60

Page 10

2 Safety

▪ Pump pressure must have been released and the pump must have been drained.

▪ When taking the pump set out of service always adhere to the procedure

described in the manual. (ðSection6.3,Page29)

▪ Decontaminate pumps which handle fluids posing a health hazard.

▪ As soon as the work has been completed, re-install and re-activate any safety-

relevant devices and protective devices. Before returning the product to service,

observe all instructions on commissioning. (ðSection6.1,Page25)

2.8 Unauthorised modes of operation

Never operate the pump (set) outside the limits stated in the data sheet and in this

manual.

The warranty relating to the operating reliability and safety of the supplied pump

(set) is only valid if the equipment is used in accordance with its intended use.

10 of 60

Ama-Drainer 4../5..

Page 11

3 Transport/Temporary Storage/Disposal

3 Transport/Temporary Storage/Disposal

3.1 Checking the condition upon delivery

1. On transfer of goods, check each packaging unit for damage.

2. In the event of in-transit damage, assess the exact damage, document it and

notify KSB or the supplying dealer and the insurer about the damage in writing

immediately.

3.2 Transport

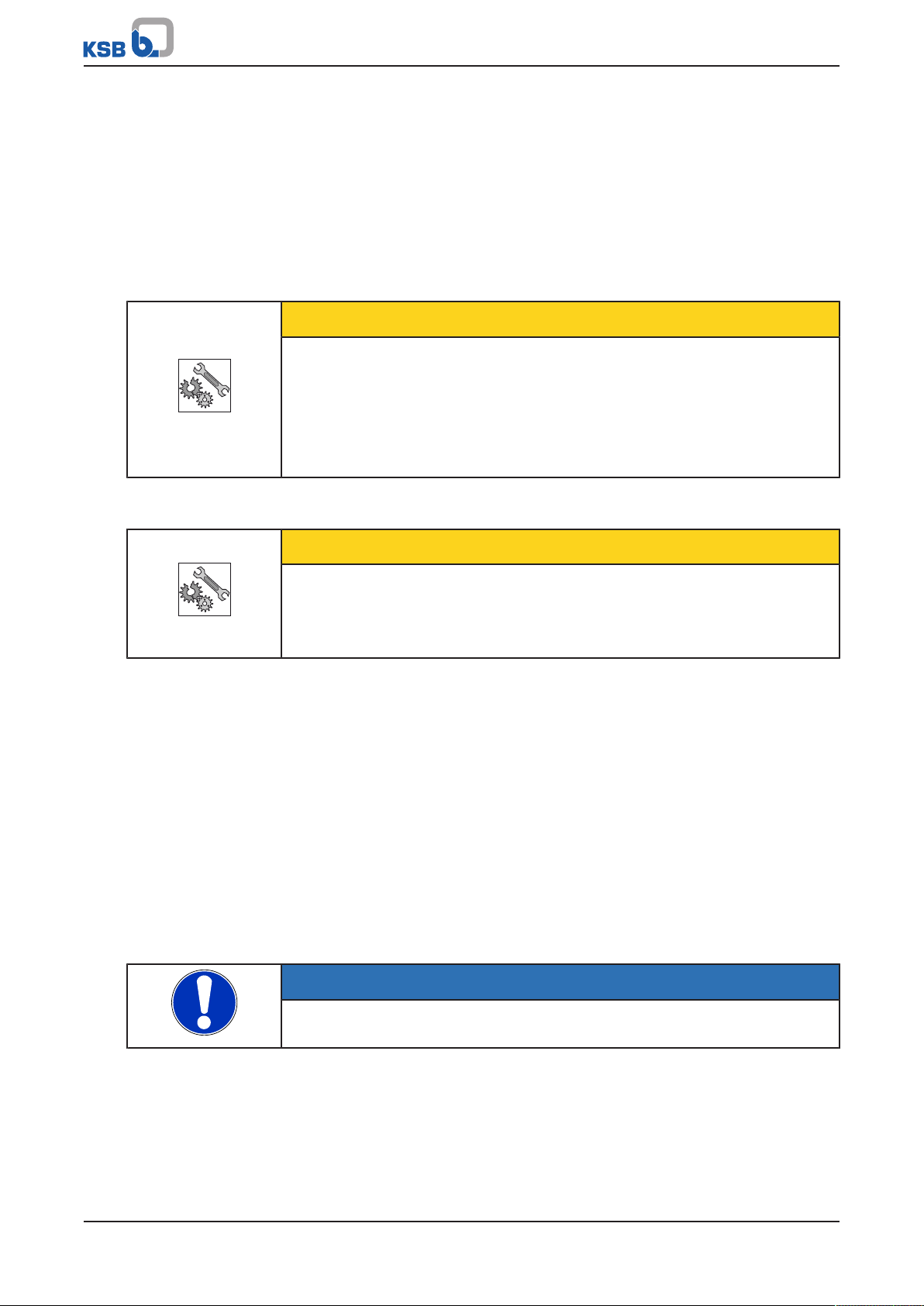

CAUTION

Improper pump transport

Damage to the pump!

▷ To transport the pump/pump set always use the handle provided.

▷ Never suspend the pump (set) from the float switch (type SE only) or the power

supply cable for transport.

▷ Prevent the pump (set) from getting knocked or dropped.

3.3 Storage/preservation

CAUTION

Damage during storage due to frost, humidity, dirt, UV radiation or vermin

Corrosion/contamination of the pump!

▷ Store the pump (set) in a dry, dark, frost-proof room not exposed to sunlight

where the atmospheric humidity is as constant as possible.

Store the pump (set) vertically in a dry, dark, frost-proof room not exposed to

sunlight. Under these conditions it does not need additional preservation.

3.4 Return to supplier

1. Drain the pump as per operating instructions.

2. Always flush and clean the pump, particularly if it has been used for handling

noxious, hot or other hazardous fluids.

3. If the fluids handled by the pump (set) leave residues which might lead to

corrosion when coming into contact with atmospheric humidity, or which might

ignite when coming into contact with oxygen, the pump set must be

neutralised, and anhydrous inert gas must be blown through the pump for

drying purposes.

4. Always complete and enclose a certificate of decontamination when returning

the pump (set). (ðSection12,Page56)

Always indicate any safety and decontamination measures taken.

NOTE

If required, a blank certificate of decontamination can be downloaded from the

following web site: www.ksb.com/certificate_of_decontamination

Ama-Drainer 4../5..

11 of 60

Page 12

3 Transport/Temporary Storage/Disposal

3.5 Disposal

WARNING

Fluids, consumables and supplies posing a health hazard

Hazard to persons and the environment!

▷ Collect and dispose of any preservatives, flushing liquids and fluid residues.

▷ Wear safety clothing and a protective mask, if required.

▷ Observe all legal regulations on the disposal of fluids posing a health hazard.

1. Dismantle the product.

Collect greases and other lubricants during dismantling.

2. Separate and sort the materials, e.g. by:

- Metals

- Plastics

- Electronic waste

- Greases and other lubricants

3. Dispose of materials in accordance with local regulations or in another

controlled manner.

Electrical or electronic equipment marked with the adjacent symbol must not be

disposed of in household waste at the end of its service life.

Contact your local waste disposal partner for returns.

If the used electrical or electronic equipment contains personal data, the user is

responsible for deleting it before the equipment is returned.

12 of 60

Ama-Drainer 4../5..

Page 13

4 Description of the Pump (Set)

4 Description of the Pump (Set)

4.1 General description

▪ Submersible waste water pump (see submersible motor pump)

Variant A (standard design)

▪ Chemically neutral waste water

▪ Slightly contaminated waste water (up to 40°C max.)

▪ Wash water (up to 90 °C max. for short periods t ≤ 3minutes)

Free passage 10/11mm:

▪ Solid particles with a particle size of up to 10 or 11mm

Free passage 35mm:

▪ Waste water containing long fibres and stringy material

▪ Solid particles with a particle size of up to 35mm

Variant C for aggressive fluids

In addition to standard variant:

▪ Swimming pool water

▪ Brackish water

▪ Seawater

▪ Water containing salt

▪ Aggressive fluids

▪ Condensate from heat recovery applications

1)

Variant R (for water containing oil / oil emulsions)

In addition to standard variant:

▪ Oil emulsions and cutting oils

▪ Waste water containing oil

1) Swimming pool water (0.4 to 1.4mg/l free chlorine, max.0.6mg/l combined chlorine, pH6.9 to 7.7, water hardness 10 to

30°dH, max. salt content 7g/l)

Ama-Drainer 4../5..

13 of 60

Page 14

4 Description of the Pump (Set)

4.2 Designation

Example: Ama-DrainerA422SD/10K

Table4: Designation key

Code Description

Ama-Drainer Type series

A Material variant

A Standard variant

C Variant for aggressive water

R Variant for water containing oil / oil emulsions

4 Nominal discharge nozzle diameter

4 ~ 40mm (G 11/2)

5 ~ 50mm (G 2)

22 Motor rating [kW x 10]

05 0.55kW

07 0.75 kW

11 1.1 kW

15 1.5 kW

22 2.2 kW

S Float switch

S With float switch

N Without float switch

D Motor

D Three-phase motor

E Single-phase alternating current

10 Free passage [mm]

10 10mm

11 11mm

35 35mm

K Cooling jacket

K With cooling jacket

2)

-

Without cooling jacket

2) Blank

14 of 60

Ama-Drainer 4../5..

Page 15

4 Description of the Pump (Set)

220-240 V ~ 50 Hz T40°C

AMA-DRAINER A 507 SE/10K

Made in Germany

0,75 kW 5,5 A classe F

2-25 m³/h

11,6-3,2 m IP 68 7m 14,7kg

EN12050-2 2016w16

Johann-Klein-Straße 9

Deutschland

67227 Frankenthal

KSB SE & Co. KGaA

1

2

5

4

3

6

10

9

12

11

8

13

15

14

7

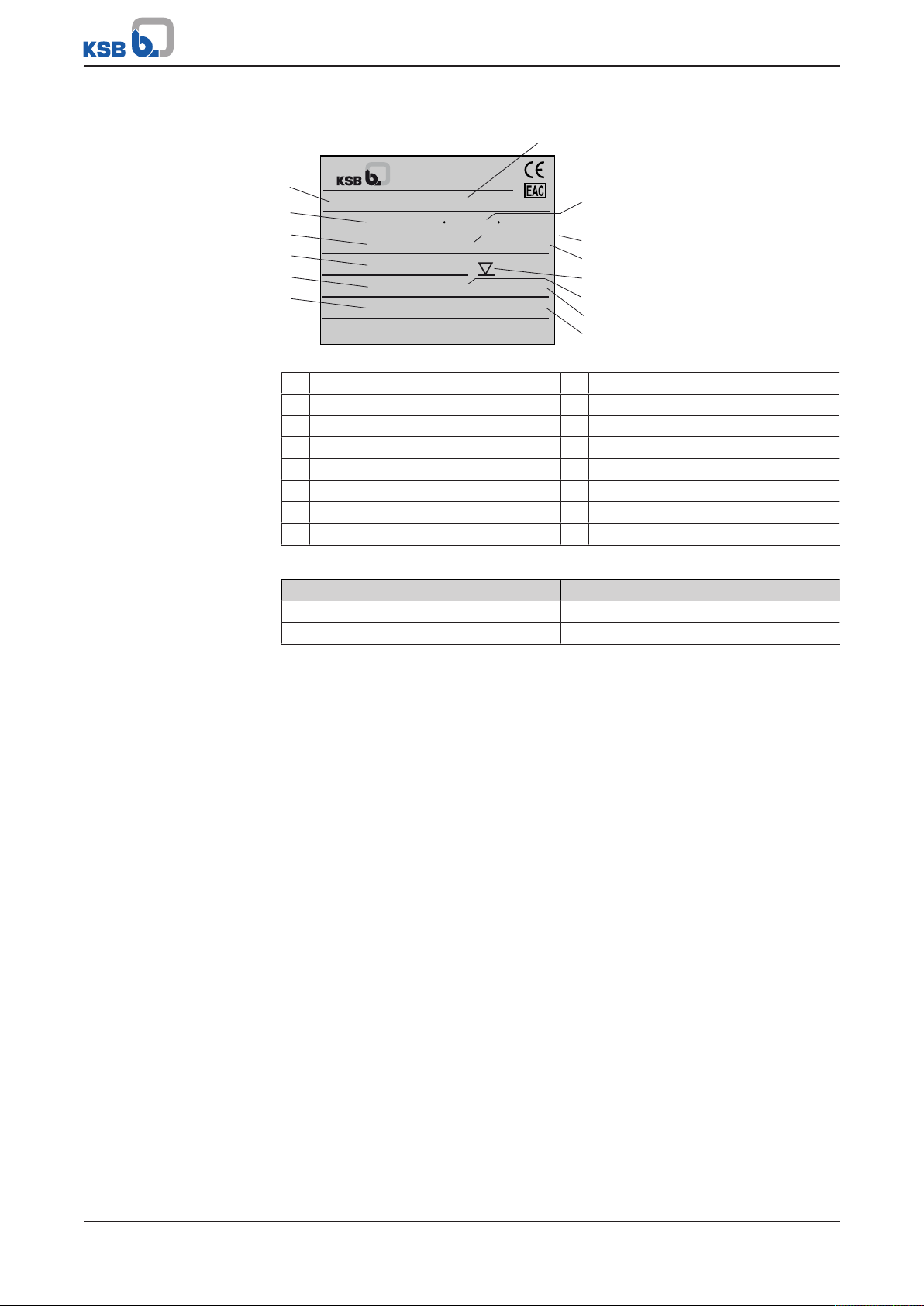

4.3 Name plate

Fig.1: Name plate (example)

1 Type series, size 9 Maximum fluid temperature

2 Rated voltage 10 Rated current

3 Rated pump power output 11 Thermal class of winding insulation

4 Flow rate (Q

5 Head (H

6 Principles of construction and testing 14 Total weight

7 Cable version (e.g. E= single-phase) 15 Year of production (serial number)

8 Rated frequency

min.

/ Q

min.

/ H

) 12 Maximum immersion depth

max.

) 13 Enclosure

max.

Table5: Key to the serial number

Code Description

2016 Calendar year

16 Calendar week

4.4 Design details

Design

▪ Fully floodable submersible motor pump

▪ Close-coupled design

▪ Single-stage

▪ To EN 12050-2

▪ Vertical discharge nozzle

▪ With or without level control

Installation

▪ Vertical installation

▪ Wet-installed transportable model

▪ Wet-installed stationary model

Drive

▪ Motor winding to IEC60038

▪ Motor design to EN60043T1/IEC34-1

▪ Thermal class F

▪ DOL starting

▪ Enclosure IP68 (permanently submerged) to EN60529/ IEC529

Ama-Drainer 4../5..

15 of 60

Page 16

4 Description of the Pump (Set)

Ama-Drainer NE/SE 10/35:

▪ AC motor

▪ Integrated temperature switch

▪ 10-metre power cable

▪ Shockproof plug

Ama-Drainer SD 10/11/35:

▪ Three-phase motor

▪ Integrated temperature switch

▪ 10-metre power cable

▪ CEE plug (3L+PE+N) with motor contactor and phase inverter

Ama-Drainer ND 10/11/35:

▪ Three-phase motor

▪ Integrated temperature switch

▪ 10-metre power cable with free cable end and protective cap

Shaft seal

▪ Pump end, 1 bi-directional mechanical seal

▪ Drive end: 1 shaft seal ring

▪ Liquid reservoir between the seals for cooling and lubrication

Impeller type

▪ Open multi-vane impeller

▪ Free-flow impeller

Bearings

▪ Maintenance-free

▪ Grease-packed rolling element bearings sealed for life

16 of 60

Ama-Drainer 4../5..

Page 17

4 Description of the Pump (Set)

1

3

2

4

5

6

7

8

9

10

11

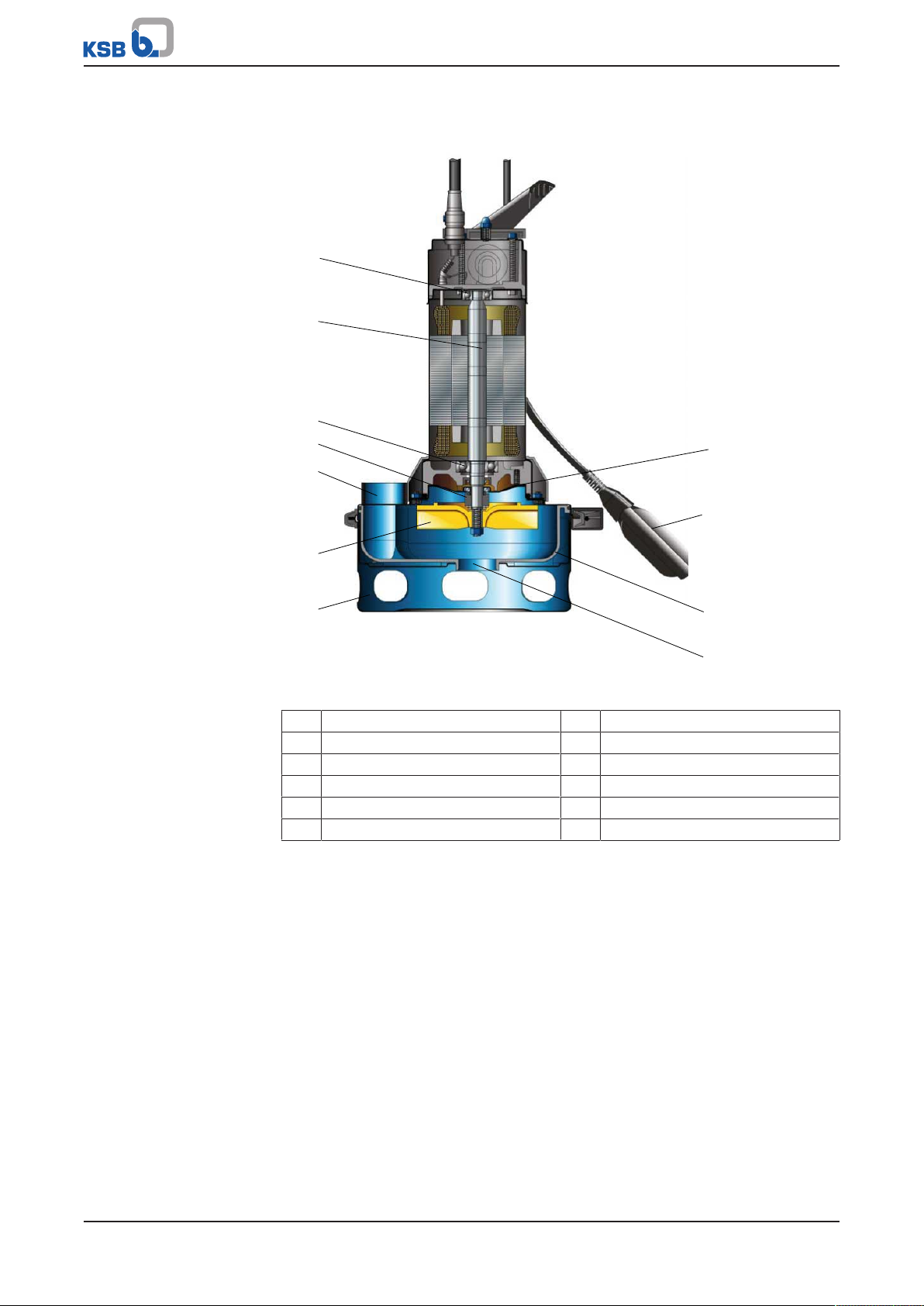

4.5 Configuration and function

Fig.2: Sectional drawing

1 Bearing, motor end 2 Shaft

3 Bearing, pump end 4 Shaft seal

5 Discharge nozzle 6 Impeller

7 Foot 8 Pump casing

9 Float switch 10 Volute casing

11 Suction nozzle

Design The pump is designed with a vertical fluid inlet and a vertical outlet. The hydraulic

Function The fluid enters the pump axially via the suction nozzle (11) and is accelerated

system sits on the extended motor shaft. The shaft runs in common bearings.

outward by the rotating impeller (6). In the flow passage of the volute casing (10) the

kinetic energy of the fluid is converted into pressure energy. The fluid is pumped to

the discharge nozzle (5), where it leaves the pump. At the rear side of the impeller,

the shaft (2) enters the pump casing (8) which houses the hydraulic system. The shaft

passage through the pump casing is sealed to atmosphere with a shaft seal (4). The

shaft runs in rolling element bearings (1) and (3).

Ama-Drainer 4../5..

17 of 60

Page 18

4 Description of the Pump (Set)

4.6 Scope of supply

Depending on the model, the following items are included in the scope of supply:

▪ Pump set

▪ Connection socket or discharge elbow with internal thread

▪ 10-metre power cable

For ... SE / ... SD:

▪ Float switch

Accessories

▪ Control units for proper operation of the pump sets

4.7 Noise characteristics

Sound pressure level < 70 dB(A)

4.8 Dimensions and weights

For dimensions and weights refer to the general arrangement drawing/outline

drawing or data sheet of the pump set.

18 of 60

Ama-Drainer 4../5..

Page 19

5 Installation at Site

5 Installation at Site

5.1 Safety regulations

DANGER

Unsuitable electrical installation

Danger to life!

▷ Make sure the electrical installation meets the VDE 0100 installation rules (i.e.

sockets with earthing terminals).

▷ Make sure the electric mains is equipped with a residual current device of

maximum 30 mA.

▷ Always have the electrical connections installed by a trained and qualified

electrician.

DANGER

Use in an outdoor area

Danger of death from electric shock!

▷ Any extension cords must match the quality of the supplied pump cable (10-

metre cable length).

▷ Do not expose electrical connections to any moisture.

DANGER

Continuous pump operation in swimming pools, garden ponds or similar

Danger of death from electric shock!

▷ Make sure that nobody is in the water while the pump is in operation.

▷ Only use the pump for draining swimming pools, garden ponds, etc. (It is

impermissible to use this pump as a recirculation pump, for example.)

5.2 Checks to be carried out prior to installation

Before beginning with the installation check the following:

▪ The pump set can be operated on the power supply network according to the

data on the name plate.

▪ The fluid to be handled matches the description of suitable fluids.

5.2.1 Checking the operating data

Before installing the pump set, verify that the name plate data matches the data

given in the purchase order and the site system data.

5.2.2 Preparing the place of installation

1. Check the structural requirements.

All structural work required must have been prepared in accordance with the

dimensions stated in the outline drawing/general arrangement drawing.

Ama-Drainer 4../5..

19 of 60

Page 20

5 Installation at Site

l x b

h

5.3 Installing the pump set

Fig.3: Dimensions for installation

Table6: Recommended installation dimensions

Type series l×b

Ama-Drainer 4..SE/10 500×500 500

Ama-Drainer 5..SD/10 K

Ama-Drainer 4..SD/35 550

Ama-Drainer 522/11

1. For transporting and lifting the pump observe the following notes.

(ðSection3.2,Page11)

2. If required, suspend the pump using a rope attached to the handle.

3. Place the pump on a solid surface.

4. Make sure that the float can move freely.

3)

[mm] [mm]

h

3)

5.4 Piping

5.4.1 Connecting the piping

DANGER

Impermissible loads acting on the pump nozzles

Danger to life from escaping hot, toxic, corrosive or flammable fluids!

▷ Do not use the pump as an anchorage point for the piping.

▷ Anchor the pipes in close proximity to the pump and connect them properly

without transmitting any stresses or strains.

▷ Observe the permissible forces and moments at the pump nozzles.

▷ Take appropriate measures to compensate for thermal expansion of the piping.

NOTE

Installing check and shut-off elements in the system is recommended, depending on

the type of plant and pump. However, such elements must not obstruct proper

drainage or hinder disassembly of the pump.

3) Minimum values

20 of 60

Ama-Drainer 4../5..

Page 21

5 Installation at Site

NOTE

The highest point of the discharge line must be above the flood level (usually street

level) to prevent any backflow from the sewage system.

Transportable models

1. Connect the discharge nozzle to a hose with a suitable adapter (e.g. Storz

coupling).

Stationary installation

▪ Ama-Drainer 405 ... 422

1. Connect the pump to the discharge line with a G 1 1/2 threaded socket.

Use a pipe with an inside diameter of 40mm.

▪ Ama-Drainer 505/10K ... 522/10K

1. Connect the pump to the discharge line with a G 2 threaded socket.

Use a pipe with an inside diameter of 50mm.

▪ Ama-Drainer 522/11

1. Connect the pump to the discharge line with a G 2 threaded socket.

Use a pipe with an inside diameter of 50mm.

This pump is also suitable for stationary installation in a sump with a duckfoot

bend and guide wire or guide rail arrangement.

5.5 Electrical system

5.5.1 Information for planning the control system

NOTE

When laying a cable between the control system and the pump set's connection

point, verify that the number of cores is sufficient for the sensors. A minimum crosssection of 1.5 mm² is required.

For the electrical connection of the pump set observe the wiring diagrams.

(ðSection9.3,Page50)

The pump set is supplied with power cables; it is wired for DOL starting.

The motors can be connected to low-voltage grids with nominal voltages and voltage

tolerances to IEC38 or other power supply networks/ power supply facilities with

maximum nominal voltage tolerances of ±10%.

Variants SD and ND:

▪ To ensure complete separation from the power supply network and to prevent

the pump set from running on two phases only, fit an external 3-pole mechanical

interlocking device (e.g. 3-pole circuit breaker).

▪ To ensure the pump set is switched off in the event of excessive temperatures

connect the bimetal switch integrated in the winding to the control circuit. This is

mandatory if:

– The CEE plug type Hyper has been removed.

– The pump set has a free cable end.

– The pump set is connected to a control unit (e.g. LevelControl)

– For any third-party products, observe the maximum load of the bimetal

switch: V

= 250VAC, I

CMAX

= 1.6AAC.

CMAX

Ama-Drainer 4../5..

21 of 60

Page 22

5 Installation at Site

5.5.2 Setting the overload protection device

1. Protect the pump set against overloading by a thermal time-lag overload

protection device in accordance with IEC60947 and local regulations.

2. Set the overload protection device to the rated current specified on the name

plate. (ðSection4.3,Page15)

5.5.3 Connecting the level control equipment

CAUTION

Fluid level below the specified minimum

Damage to the pump set by cavitation!

▷ Never allow the fluid level to drop below the specified minimum.

NOTE

The pump set is switched ON/OFF with the float switch at an UPWARD/

DOWNWARD slant of approximately 40° of the float housing (clearly audible

switching noise in the float housing).

Automatic operation of the pump set in a tank requires the use of level control

equipment.

Observe the minimum fluid level. (ðSection6.2.3.2,Page28)

The SE and SD variants are equipped with a float switch. Set the switching level on

site.

Conditions to be met when setting the switching levels

▪ Observe the minimum fluid level. (ðSection6.2.3.2,Page28)

▪ The pump set stops before the water level falls to the level of the pump foot's

suction openings.

▪ The pump set starts up before the water level reaches the upper edge of the

tank.

▪ The float switch must neither come to rest at the bottom nor hit against

anything at the top.

▪ The switching difference equals 40cm as a minimum.

When installing two pump sets and one control unit for dual-pump stations, arrange

the two float switches in a cascade. This configuration permits three switching

functions:

▪ Alternating start-up of the two pump sets for each switching cycle.

▪ Additional start-up of the stand-by pump at peak load.

▪ Start-up of the stand-by pump should the duty pump fail.

Setting the switching levels

1. Choose an appropriate height for attaching the float switch cable.

2. Attach the float switch cable to the discharge line, the lifting lug at the handle

or to another suitable point.

4)

4) On variantR the lifting lug at the handle cannot be used as an attachment point.

22 of 60

Ama-Drainer 4../5..

Page 23

5 Installation at Site

5.5.4 Connection to power supply

DANGER

Electrical connection work by unqualified personnel

Danger of death from electric shock!

▷ Always have the electrical connections installed by a trained and qualified

electrician.

▷ Observe regulations IEC60364.

DANGER

Operating a pump set that has not been fully connected

Explosion hazard!

Damage to the pump set!

▷ Never start up a pump set with power cables that have not been fully

connected or non-operational monitoring devices.

WARNING

Incorrect connection to the mains

Damage to the mains network, short circuit!

▷ Observe the technical specifications of the local energy supply companies.

CAUTION

Flow-induced motion

Damage to the power cable!

▷ Run the power cable upwards without slack.

CAUTION

Improper routing of power cable

Damage to the power cables!

▷ Never move the power cables at temperatures below - 25 ℃.

▷ Never kink or crush the power cables.

▷ Never lift the pump set by the power cables.

▷ Adjust the length of the power cables to the site requirements.

For the electrical connection observe the circuit diagrams (ðSection9.3,Page50)

in the Annex and the information for planning the control system .

The pump set is supplied complete with connection cables. Always use all cables

provided and connect all marked cores of the control cable.

1. Run the power cable upwards without slack and fasten it.

2. Only remove the protective caps from the power cable immediately before

connection.

3. If necessary, adjust the length of the power cable to the site requirements.

4. After shortening the cable, correctly re-affix the markings of the individual cores

at the cable end.

5.6 Checking the direction of rotation

Ama-Drainer SE and NE

The direction of rotation of pumps with single-phase AC motors need not be

checked.

Ama-Drainer 4../5..

23 of 60

Page 24

5 Installation at Site

Ama-Drainer SD and ND

WARNING

Hands inside the pump casing

Risk of injuries, damage to the pump!

▷ Always disconnect the pump set from the power supply and secure it against

unintentional start-up before inserting your hands or other objects into the

pump.

CAUTION

Pump set running dry

Increased vibrations!

Damage to mechanical seals and bearings!

▷ Never operate the pump set for more than 60seconds outside the fluid to be

handled.

CAUTION

Wrong direction of rotation

Damage to the pump!

▷ Follow the step-by-step instructions given for checking the direction of

rotation.

The power cable (CEE plug) has been connected in the factory so that the pump will

have the correct direction of rotation, provided that the mains' phase sequence

(building supply mains) is correct.

1. Start up the pump.

ð If the direction of rotation is correct, the pump should show a start reaction

in the direction indicated.

2. If the direction of rotation is incorrect, press in the phase inverter in the CEE

plug with an appropriate screwdriver and turn it by 180°.

24 of 60

3. If the pump set is connected via a control unit, interchange wires 1 and 2 of the

6-wire cable.

Ama-Drainer 4../5..

Page 25

6 Commissioning/Start-up/Shutdown

A

B

6 Commissioning/Start-up/Shutdown

6.1 Commissioning/Start-up

6.1.1 Prerequisites for commissioning/start-up

Before commissioning/starting up the pump set, make sure that the following

conditions are met:

▪ The operating data has been verified.

▪ The pump (set) has been installed and connected as described in this manual.

▪ The pump set has been properly connected to the power supply and is equipped

with all protection devices.

▪ The direction of rotation has been checked.

6.1.2 Start-up/shutdown

Type SE/SD

Fig.4: Start-up/switch-off level

A Start-up level B Switch-off level

The pump (set) has been properly connected to the electric power supply

The pump's automatic control system will start up when level "A" is reached and

switched off when level "B" is reached.

Type NE/ND

The pump (set) does not need to be started up or switched off.

It is operational as soon as it has been properly connected to the electric power

supply.

ü The pump (set) has been properly connected to the electric power supply.

1. Check that the pump operates in submerged condition.

NOTE

A small quantity of the fluid handled will spray out into the protective casing

through an internal vent bore and escape between the protective casing and the

pump casing.

Ama-Drainer 4../5..

25 of 60

Page 26

6 Commissioning/Start-up/Shutdown

X

X

Y

Y

Fig.5: Vent hole

6.2 Operating limits

6.2.1 Frequency of starts

CAUTION

Excessive frequency of starts

Risk of damage to the motor!

▷ Never exceed the specified frequency of starts.

To prevent high temperature increases in the motor and excessive loads on the

motor, seal elements and bearings, the frequency of starts shall not exceed 30 starts

per hour.

6.2.2 Operation on the power supply network

CAUTION

Wrong supply voltage

Damage to the pump (set)!

▷ The maximum permissible deviation in supply voltage is 10% of the rated

voltage indicated on the name plate.

▷ The maximum permissible voltage difference between the individual phases is

1%.

26 of 60

Ama-Drainer 4../5..

Page 27

6 Commissioning/Start-up/Shutdown

6.2.3 Fluid handled

6.2.3.1 Permissible fluids to be handled

WARNING

Pumping of impermissible fluids

Hazardous to persons and the environment!

▷ Only discharge permissible fluids into the public sewer system.

▷ Check the suitability of pump/system materials.

CAUTION

Unsuitable fluids

Damage to the pump!

▷ Never use the pump to handle corrosive, combustible or explosive fluids.

▷ Never use the pump to transport waste water from toilets and urinal systems.

▷ Do not use the pump for foodstuff applications.

Variant A (standard design)

▪ Chemically neutral waste water

▪ Slightly contaminated waste water (up to 40°C max.)

▪ Wash water (up to 90 °C max. for short periods t ≤ 3minutes)

Free passage 10/11mm:

▪ Solid particles with a particle size of up to 10 or 11mm

Free passage 35mm:

▪ Waste water containing long fibres and stringy material

▪ Solid particles with a particle size of up to 35mm

Variant C for aggressive fluids

In addition to standard variant:

▪ Swimming pool water

▪ Brackish water

▪ Seawater

▪ Water containing salt

▪ Aggressive fluids

▪ Condensate from heat recovery applications

Variant R (for water containing oil / oil emulsions)

In addition to standard variant:

▪ Oil emulsions and cutting oils

▪ Waste water containing oil

5)

5) Swimming pool water (0.4 to 1.4mg/l free chlorine, max.0.6mg/l combined chlorine, pH6.9 to 7.7, water hardness 10 to

30°dH, max. salt content 7g/l)

Ama-Drainer 4../5..

27 of 60

Page 28

6 Commissioning/Start-up/Shutdown

6.2.3.2 Minimum/maximum fluid level

Minimum level of fluid handled

CAUTION

Fluid level below the specified minimum

Damage to the pump set by cavitation!

▷ Never allow the fluid level to drop below the specified minimum.

The pump set is operational when the minimum fluid level is not lower than

dimension WT. This minimum fluid level must also be ensured during automatic

operation.

Table7: Minimum level of fluid handled

Type series W

Ama-Drainer .../10 60

Ama-Drainer .../11 120

Ama-Drainer .../35 120

T min.

[mm]

Maximum fluid level (see name plate)

Max. immersion depth: 7m

6.2.3.3 Temperature of the fluid handled

CAUTION

Incorrect temperature of the fluid handled

Damage to the pump (set)!

▷ Do not operate the pump (set) outside the specified temperature limits.

Never operate the pump at temperatures exceeding the ones stated below.

▪ Pump (set) in submerged condition:

– Maximum 40 ℃

– For a short time (up to 3 minutes) maximum 90 °C

▪ Pump (set) outside the fluid handled:

– For limited time (up to 10 minutes) maximum 40 ℃

– For a short time (up to 3 minutes) maximum 90 °C

6.2.3.4 Density of the fluid handled

The pump input power changes in proportion to the density of the fluid handled.

28 of 60

CAUTION

Excessive density of the fluid handled

Motor overload!

▷ Observe the information on fluid density in the data sheet.

▷ Make sure the motor has sufficient power reserves.

The pump (set) is suitable for handling chemically neutral waste water not containing

coarse substances, sand or faeces.

Ama-Drainer 4../5..

Page 29

6 Commissioning/Start-up/Shutdown

Table8: Particle size for slightly contaminated waste water

Type series Max. particle size

[mm]

Ama-Drainer /10 10

Ama-Drainer /11 11

Ama-Drainer /35 35

6.3 Shutdown/storage/preservation

6.3.1 Measures to be taken for shutdown

WARNING

Unintentional starting of the pump set

Risk of injury by moving components and shock currents!

▷ Ensure that the pump set cannot be started unintentionally.

▷ Always make sure the electrical connections are disconnected before carrying

out work on the pump set.

WARNING

Fluids handled, consumables and supplies which are hot and/or pose a health

hazard

Risk of injury!

▷ Observe all relevant laws.

▷ When draining the fluid take appropriate measures to protect persons and the

environment.

▷ Decontaminate pumps which handle fluids posing a health hazard.

1. Disconnect the pump from the power supply and protect it against start-up.

2. Wait until the pump has cooled down (10minutes), then remove it.

3. Properly flush the pump.

Point the water jet on the pump's discharge nozzle.

4. Leave the pump to dry.

5. Store the pump vertically in a dark, dry and frost-proof room.

6.4 Returning to service

For returning the pump to service observe the sections on commissioning/start-up

and the operating limits.

In addition, carry out all servicing/maintenance operations before returning the

pump (set) to service.

NOTE

On pumps/pump sets older than 5 years we recommend replacing all elastomer

seals.

Ama-Drainer 4../5..

29 of 60

Page 30

7 Servicing/Maintenance

7 Servicing/Maintenance

7.1 Safety regulations

DANGER

Power supply not disconnected

Danger to life!

▷ Pull the mains plug and secure the pump against unintentional start-up.

DANGER

Work on the pump set by unqualified personnel

Danger of death from electric shock!

▷ Have pump components modified and dismantled by authorised personnel

only.

WARNING

Insufficient stability

Risk of crushing hands and feet!

▷ During assembly/dismantling, secure the pump (set)/pump parts to prevent

tilting or tipping over.

WARNING

Fluids handled, consumables and supplies posing a health hazard

Hazard to persons and the environment!

▷ Clean the pump prior to any maintenance and installation work.

▷ Make sure persons cannot come into contact with the fluid handled.

7.2 Servicing/inspection

The pump is practically maintenance-free.

It will suffice to clean the pump once a year and carry out visual inspections of the

condition of the pump and supply line.

7.3 Drainage/disposal

WARNING

Fluids, consumables and supplies which are hot or pose a health hazard

Hazard to persons and the environment!

▷ Collect and properly dispose of flushing fluid and any residues of the fluid

handled.

▷ Wear safety clothing and a protective mask, if required.

▷ Observe all legal regulations on the disposal of fluids posing a health hazard.

30 of 60

The pump will be automatically drained when it is taken out of the fluid handled.

Always flush and clean the pump before transporting it to the workshop. Provide a

certificate of decontamination for the pump set.

Ama-Drainer 4../5..

Page 31

7 Servicing/Maintenance

7.4 Dismantling the pump set

WARNING

Hot surface

Risk of injury!

▷ Allow the pump set to cool down to ambient temperature.

1. Remove the cover from the clamp tie bar.

2. Undo screw 914.03 at the clamp tie bar.

3. Remove the clamp.

Ama-Drainer 4../5..

31 of 60

Page 32

7 Servicing/Maintenance

4. Pull out the volute casing.

5. Clean all dismantled parts and check them for signs of wear.

32 of 60

Ama-Drainer 4../5..

Page 33

7 Servicing/Maintenance

7.5 Reassembling the pump set

ü All parts have been cleaned and checked for wear.

ü Any damaged or worn parts have been replaced by original spare parts.

1. Fit the volute casing.

2. Fit the clamp tie bar.

Ama-Drainer 4../5..

33 of 60

Page 34

7 Servicing/Maintenance

3. Insert and tighten screw 914.03 at the clamp tie bar.

4. Fit the cover on the clamp tie bar.

7.6 Tightening torques

Table9: Tightening torques [Nm]

Part No. Description Tightening torque

[Nm]

914.03 Hexagon socket head cap

screw

6

7.7 Recommended spare parts stock

It is not necessary to keep spare parts on stock.

34 of 60

Ama-Drainer 4../5..

Page 35

8 Trouble-shooting

8 Trouble-shooting

WARNING

Improper work to remedy faults

Risk of injury!

▷ For any work performed to remedy faults, observe the relevant information

given in this instruction manual and/or in the product literature provided by the

accessories manufacturer.

NOTE

Before performing any work on the pump's internal parts during the warranty

period please always consult the manufacturer. Our after-sales service will be at

your disposal. Non-compliance will lead to forfeiture of any and all rights to claims

for damages.

If problems occur that are not described in the following table, consultation with the

KSB customer service is required.

A Pump is running, but does not deliver

B Insufficient flow rate

C Excessive current/power input

D Insufficient discharge head

E Vibrations and noise during pump operation

Table10: Trouble-shooting

A B C D E Possible cause Remedy

- ✘ - - - Pump delivers against an excessively high

pressure.

- ✘ - - - Gate valve in the discharge line is not fully

open.

- - ✘ - ✘ Pump running in off-design conditions (part

load / overload)

✘ - - - - Pump or piping are not completely vented. Clean vent hole 5 B in pump casing 101.

✘ - - - - Pump intake clogged by deposits Clean the intake, pump components and lift check

- ✘ - ✘ ✘ Supply line or impeller clogged Remove deposits in the pump and/or piping.

- - ✘ - ✘ Dirt/fibres in the clearance between the

casing wall and impeller; sluggish rotor.

- ✘ ✘ ✘ ✘ Wear of internal components Replace worn components by new ones.

✘ ✘ - ✘ - Defective riser (pipe and sealing element) Replace defective riser pipes and sealing elements.

- ✘ - ✘ ✘ Impermissible air or gas content in the fluid

handled

- ✘ ✘ ✘ ✘ Wrong direction of rotation If the pump set is running in the wrong direction

- - ✘ - - Operating voltage is too low. Check mains voltage.

✘ - - - - Motor is not running because of lack of

voltage.

✘ ✘ - ✘ - Motor is running on 2 phases only. Replace the defective fuse. Check the electrical

✘ - - - - Motor winding or electric cable are defective. Contact KSB's pump service.

Open the shut-off valve to re-adjust to duty point.

Fully open the gate valve.

Check the pump's operating data.

valve.

Check whether the impeller can be easily rotated;

clean the hydraulic system, if required.

Contact the manufacturer.

of rotation, check the electrical connection and the

control system, if necessary.

Check cable connections.

Check electrical installation, inform electric utility

company.

cable connections.

6)

6) The pump pressure must be released before attempting to remedy faults on parts which are subjected to pressure.

Disconnect the pump from the power supply and let it cool down before working on it.

Ama-Drainer 4../5..

35 of 60

Page 36

8 Trouble-shooting

A B C D E Possible cause Remedy

6)

- - ✘ - ✘ Defective radial bearing in the motor Contact the manufacturer.

- ✘ ✘ - - Pump clogged by sand, dirt in the pump

sump, insufficient inflow

✘ - - - - Temperature control device monitoring the

winding has tripped the pump as a result of

Clean the intake, strainer, pump components and

check valve; drain and clean the pump sump.

The motor will restart automatically once the

pump set has cooled down.

excessive winding temperatures.

36 of 60

Ama-Drainer 4../5..

Page 37

9 Related Documents

C2

A

B

102

03-40

(509)

(102)

(412.05)

(162)

(509)

(182)

(914.01)

433

932

102

(509)

(102)

(412.05)

101

(411)

(101)

(412.01)

162

(162)

(509)

182

(182)

(509)

81-59

(81-78)

(81-59)

826

(826)

(920)

13-16

683

818

(81-29.02)

1~99-20.01

(81-29.05)

(81-17.01)

(81-17.02)

(689)

433

(900)

(550.09)

(930)

1~99-20.02

433

551

433

(230)

(99-7.01)

230

(412.5)

(914.3)

(920.8)

(550.8)

(509)

(82-10)

99-20.03

(572)

(920.08)

(550.08)

(509)

(914.03)

(82-10)

572

(576)

(920.03)

(550.07)

576

(550.06)

(412.04)

(412.02)

99-9.02

(732)

(837)

99-20.01

837

(66-2)

(412.03)

(412.06)

66.2

(321.01)

(550.05)

(321.02)

99-9.02

(421)

(99-15)

(412.01)

(230)

(99-7.01)

230

(550.02)

(550.04)

(920.01)

(433)

(932)

433

(826.05)

(920.02)

826

(82-14)

(99-7.02)

(99-20.01)

82-14

(826.05)

(920.02)

826

(824)

(99-7.02)

(99-20.02)

824

81-45

826

81-45

(826.06)

(920.06)

(81-45)

(99-7.02)

(99-20.01)

C1

C3

C4

9 Related Documents

9.1 General assembly drawing with list of components

9.1.1 General assembly drawing of Ama-Drainer .../10, .../10K, .../35

Fig.6: General assembly drawing of Ama-Drainer .../10, .../10K, .../35

A Ama-Drainer A / R B Ama-Drainer C

C1 Ama-Drainer .../10, .../10K, ... /35 C2 Ama-Drainer SD

C3 Ama-Drainer .../35 C4 Ama-Drainer SE

Table11: List of components

Part No. Description Comprises:

03-40 Foot / suction cover assembly (for .../35) Suction cover 162

Foot 182

Intermediate ring 509

Ama-Drainer 4../5..

37 of 60

Page 38

9 Related Documents

Part No. Description Comprises:

101 Pump casing, complete Pump casing [101]

Joint ring 411

O-ring 412.01

Hexagon socket head cap screw 914.01

102 Volute casing Volute casing 102

O-ring 412.05

Intermediate ring 509

13-16 Protective casing Protective casing 13-16

162 Suction cover Suction cover 162

Intermediate ring 509

182 Pump foot Foot 182

Intermediate ring 509

230 Impeller, complete Impeller 230

Impeller installation kit 99-7.01

433 Mechanical seal, complete Mechanical seal (433)

Spacer disc 551 (for variant C only)

Circlip 932

572 Clamp, complete Clamp 572

Intermediate ring 509

Disc 550.08

Cover strip 82-10

Hexagon socket head cap screw 914.03

Nut 920.08

576 Handle, complete Handle 576

Disc 550.07

Nut 920.03

Plate 970

66-2 Cooling jacket, set of accessories Cooling jacket 66-2

O-ring 412.03/.06

683 Hood Hood 683

81-45 Float switch (single-phase units) Float switch (6A / 0.5m) 81-45

Float switch (10 A / 0.5m) 81-45

Repair kit for cable (single-phase) 99-20.01

Installation kit for hood 99-7.02

81-45 Float switch (three-phase units) Float switch (6A / 10m) 81-45

81-59 Stator, complete Stator [81-59]

Stator case 81-78

818 Pump rotor Pump rotor 818

82-14 Cable with plug (single-phase units) Cable with plug (3×1mm2, length 10m) 82-14

Repair kit for cable (single-phase) 99-20.01

Installation kit for hood 99-7.02

824 Cable (three-phase units) Cable (6×1mm2, length 10m) 824

Repair kit 99-20.02

Installation kit for hood 99-7.02

826 Cable gland Cable gland 826

Nut (M20x1.5) 920.05

837 Capacitor (single-phase units only) Capacitor 837

Capacitor holder 732

Repair kit for cable (single-phase) 99-20.01

38 of 60

Ama-Drainer 4../5..

Page 39

9 Related Documents

Part No. Description Comprises:

837 Capacitor (single-phase units only) Installation kit for hood 99-7.02

99-7.01 Impeller installation kit Adjusting washer 550.02

Disc 550.04

Nut 920.01

99-7.02 Installation kit for hood O-ring 412.02/.04

Disc 550.06

99-11 Bearing Deep groove ball bearing 321.01/.02

O-ring 412.01

Shaft seal ring 421

Disc 550.05

Lubricating oil 99-15

99-20.01/.02Cable repair kit Insulation tube 689

Disc 550.09

End connector 81-17.01/.02

Terminal 81-29.02

Screw 900

Serrated lock washer 930

99-20.03 Hydraulic system repair kit O-ring 412.05

Intermediate ring 509

Disc 550.08

Cover strip 82-10

Hexagon socket head cap screw 914.03

Nut 920.08

Ama-Drainer 4../5..

39 of 60

Page 40

9 Related Documents

A

B

824

(824)

99-20.02

99-9.02

(412.02)

(412.04)

(550.06)

(81-29.02)

(81-17.01)

(81-17.02)

(900)

(930)

(550.09)

(689)

683

818

81-59

13-16

(81-59)

(81-78)

144

182

(550.11)

(550.10)

(182)

(914.06)

(144)

(901.09)

(920.09)

433

(433)

(932)

433

(433)

(551)

(162)

(412.07*)

(914.05)

(100)

(914.01)

(412.01)

(410)

100

162

(550.02)

(550.04)

(920.01)

(99-7.01)

(230)

230

433

(433)

(932)

(321.01)

(321.02)

(421)

(412.01)

(99-15)

(550.05)

(576)

(920.03)

(550.07)

99-11

576

(826)

(571)

(901.10)

(920.10)

(920.05)

826

571

199-3

9.1.2 General assembly drawing Ama-Drainer 522/11

Fig.7: General assembly drawing of Ama-Drainer 522/11

A Ama-Drainer A / R B Ama-Drainer C

Table12: List of components

Part No. Description Comprises:

100 Casing, complete Casing 100

144 Discharge elbow, complete Discharge elbow 144

13-16 Protective casing Protective casing 13-16

162 Suction cover Suction cover 162

182 Pump foot Foot 182

Profile seal 410

O-ring 412.01

Hexagon socket head cap screw 914.01

Disc 550.10

Hexagon head bolt 901.09

Nut 920.09

O-ring 412.07

Hexagon socket head cap screw 914.05

Disc 550.11

Hexagon socket head cap screw 914.06

40 of 60

Ama-Drainer 4../5..

Page 41

9 Related Documents

Part No. Description Comprises:

199-3 Flange adapter

7)

Flange adapter (DN 50) 182.5

Profile seal 410.02

Disc 550.12

Stud 902.01

230 Impeller, complete Impeller 230

Impeller installation kit 99-7.01

433 Mechanical seal, complete Mechanical seal 433

Spacer disc 551 (for variant C only)

Circlip 932

571 Bracket, complete Bracket 571

Hexagon head bolt 901.10

Hexagon nut 920.10

576 Handle, complete Handle 576

Disc 550.07

Nut 920.03

683 Hood Hood 683

81-45 Float switch (three-phase units) Float switch (6A / 10m) 81-45

81-59 Stator, complete Stator 81-59

Stator case 81-78

818 Pump rotor Pump rotor 818

824 Cable (three-phase units) Cable (6×1mm2, length 10m) 824

Installation kit for hood 99-7.02

Repair kit 99-20.02

826 Cable gland Cable gland 826

Nut (M20×1.5) 920.05

99-7.01 Impeller installation kit Adjusting washer 550.02

Disc 550.04

Nut 920.01

99-7.02 Installation kit for hood O-ring 412.02/.04

Disc 550.06

99-11 Bearing Deep groove ball bearing 321.01/.02

O-ring 412.01

Shaft seal ring 421

Disc 550.05

Lubricating oil 99-15

99-20.02 Cable repair kit Insulation tube 689

Disc 550.09

End connector 81-17.01/.02

Terminal 81-29.02

Screw 900

Serrated lock washer 930

99-20.03 Hydraulic system repair kit O-ring 412.05

Intermediate ring 509

Disc 550.08

Cover strip 82-10

Hexagon socket head cap screw 914.03

Nut 920.08

7) Not shown in drawing

Ama-Drainer 4../5..

41 of 60

Page 42

9 Related Documents

P11

P10

X1

300

440

min 500 x 500

60

max 400

min 500

A

B

9.2 Dimensions and connections

9.2.1 Single pumps

9.2.1.1 Ama-Drainer 4..SE/10

Fig.8: Outline drawing Ama-Drainer 4..SE/10 without cooling jacket

A Start-up level

B Stop level

P 10 Swing check valve

P11 Gate valve

X1 Residual water level

42 of 60

Ama-Drainer 4../5..

Page 43

9 Related Documents

P11

P10

X1

300

440

min 500 x 500

60

max 400

min 500

A

B

P11

P10

X1

300

500

min 500 x 500

120

max 400

min 550

A

B

9.2.1.2 Ama-Drainer 5..SD/10 K

Fig.9: Outline drawing Ama-Drainer 5..SD/10 K with cooling jacket

A Start-up level

B Stop level

P 10 Swing check valve

P11 Gate valve

X1 Residual water level

9.2.1.3 Ama-Drainer 4..SD/35

Fig.10: Outline drawing Ama-Drainer 4..SD/35 without cooling jacket

A Start-up level

B Stop level

P 10 Swing check valve

Ama-Drainer 4../5..

43 of 60

Page 44

9 Related Documents

P11

P10

X1

340

480

min 500 x 500

120

max 400

min 550

A

B

P11 Gate valve

X1 Residual water level

9.2.1.4 Ama-Drainer 522/11

Fig.11: Outline drawing Ama-Drainer 522/11 without cooling jacket

A Start-up level

B Stop level

P 10 Swing check valve

P 11 Gate valve

X1 Residual water level

Ama-Drainer 4../5..

44 of 60

Page 45

9 Related Documents

P28

P24

P32

300

440

P28

P24

P32

300

440

9.2.2 Examples of transportable models

9.2.2.1 Ama-Drainer 4..NE/10

Fig.12: Outline drawing Ama-Drainer 4..NE/10 without cooling jacket

P 24 Storz rigid coupling

P 28 Plastic hose

P 32 Pipe extension

9.2.2.2 Ama-Drainer 5..NE/10 K

Fig.13: Outline drawing Ama-Drainer 5..NE/10 K with cooling jacket

P 24 Storz rigid coupling

P 28 Plastic hose

P 32 Pipe extension

Ama-Drainer 4../5..

45 of 60

Page 46

9 Related Documents

P28

P24

340

480

9.2.2.3 Ama-Drainer 522 ND/11

Fig.14: Outline drawing Ama-Drainer 522 ND/11 without cooling jacket

P 24 Storz rigid coupling

P 28 Plastic hose

46 of 60

Ama-Drainer 4../5..

Page 47

9 Related Documents

117 125

P 2

P 29

Ø 10

1

130

400

A A

125

180

51

432

120

60

105

200

120

117

270

117

80

120

100

79

B

B

A

A

DN 50 PN 16

ANSI 2“

P 5

436**

167*

≥ 1200 - 1500

≤ 1800

9.2.3 Examples of stationary installation

9.2.3.1 Ama-Drainer 522 ND/11 with guide hoop

Fig.15: Outline drawing Ama-Drainer 522 ND/11 with guide hoop

* When using flange adapter P 5: 217mm

** When using flange adapter P 5: 486mm

Table13: Overview of connections

Connection Description

1 Lowest stop level for automatic operation

P 2 Guide hoop arrangement

8)

P 5

P 29 Threaded flange

Flange adapter for stabilising the pump position during start-up

8) Not shown in drawing

Ama-Drainer 4../5..

47 of 60

Page 48

9 Related Documents

117 125

P 4

P 29

Ø 10

1

130

400

A A

125

180

51

432

120

60

105

200

120

117

270

117

80

120

100

79

B

B

A

DN 50 PN 16

ANSI 2“

A

85 85

13

70

Ø 10

125

P 5

436**

167*

9.2.3.2 Ama-Drainer 522 ND/11 with guide wire

9) Not shown in drawing

48 of 60

Fig.16: Outline drawing Ama-Drainer 522 ND/11 with guide wire

* When using flange adapter P 5: 217mm

** When using flange adapter P 5: 486mm

Table14: Overview of connections

Connection Description

1 Lowest stop level for automatic operation

P 4 Guide wire arrangement

9)

P 5

P 29 Threaded flange

Flange adapter for stabilising the pump position during start-up

Ama-Drainer 4../5..

Page 49

9 Related Documents

E 70

D

1

D

2

R

C BE

A

E 30/31

P 18

P 13

P 29

P 11

P 10

P 18

E 60.2

E 60

E 60.3

9.2.4 Installation example of a dual-pump station

Fig.17: Position of float switches in a dual-pump station

P 10 Swing check valve

P 11 Gate valve

P 13 Y-pipe

P 18 Cover plate

P 29 Threaded flange

E 5 AS 5 alarm switchgear

E 5/2 Horn

E 12 /

Control unit

E13

E 14 Float switch, normal water level

E 14/2 Float switch, high water level

E 14/3 Alarm contactor

R Flood level

Table15: Dimensions and weights

Size A B C D

1

D

2

E [kg]

[mm] [mm] [mm] [mm] [mm] [mm]

Ama-Drainer 4../10 275 190 130 1060 x 500 500 55 16

Ama-Drainer 4../35 275 190 130 1060 x 500 500 60 17

Ama-Drainer 5../10 K 300 210 130 1060 x 500 500 55 17

Ama-Drainer 522/11 300 210 130 1060 x 500 500 55 24

Ama-Drainer 4../5..

49 of 60

Page 50

9 Related Documents

L1

N

PE

bn

bn

bu

gn/ye

PE

gn/ye

bn

gn/ye

bn

bu

bu

bu

S2

U1

Z1 U2

wh

gn

rd

U1

U2

Z1

Z2

M

1~

3

21

22

F6

9.3 Wiring diagrams

9.3.1 Ama-Drainer SE

Fig.18: Wiring diagram Ama-Drainer SE

F6 Bimetal switch

M Motor

S2 Float switch

bu blue

bn brown

rd red

wh white

gn/ye green/yellow

gn green

50 of 60

Ama-Drainer 4../5..

Page 51

9 Related Documents

L1 N PE

bn

bu

gn/ye

bn

gn/ye

bn

bu

bu

U1

Z1 U2

wh

gn

rd

U1

U2

Z1

Z2

M

1~

3

21

22

F6

9.3.2 Ama-Drainer NE

Fig.19: Wiring diagram Ama-Drainer NE

F6 Bimetal switch

M Motor

bu blue

bn brown

rd red

wh white

gn/ye green/yellow

gn green

Ama-Drainer 4../5..

51 of 60

Page 52

9 Related Documents

M1

L1

K1

1

2

1

M

3

~

L2

3

4

2

L3

5

6

3

N

PE