kranzle quadro 799 TS-T operation manual

Operating manual

High pressure cleaners

quadro 599 TS T

150 bar / 2175 psi

quadro 799 TS T

180 bar / 2600 psi

quadro 899 TS T

150 bar / 2175 psi

- GB -

Read and conform safety instructions before use!

Keep instructions in a safe place for later use and

pass them on to any future user.

www.kraenzle.com

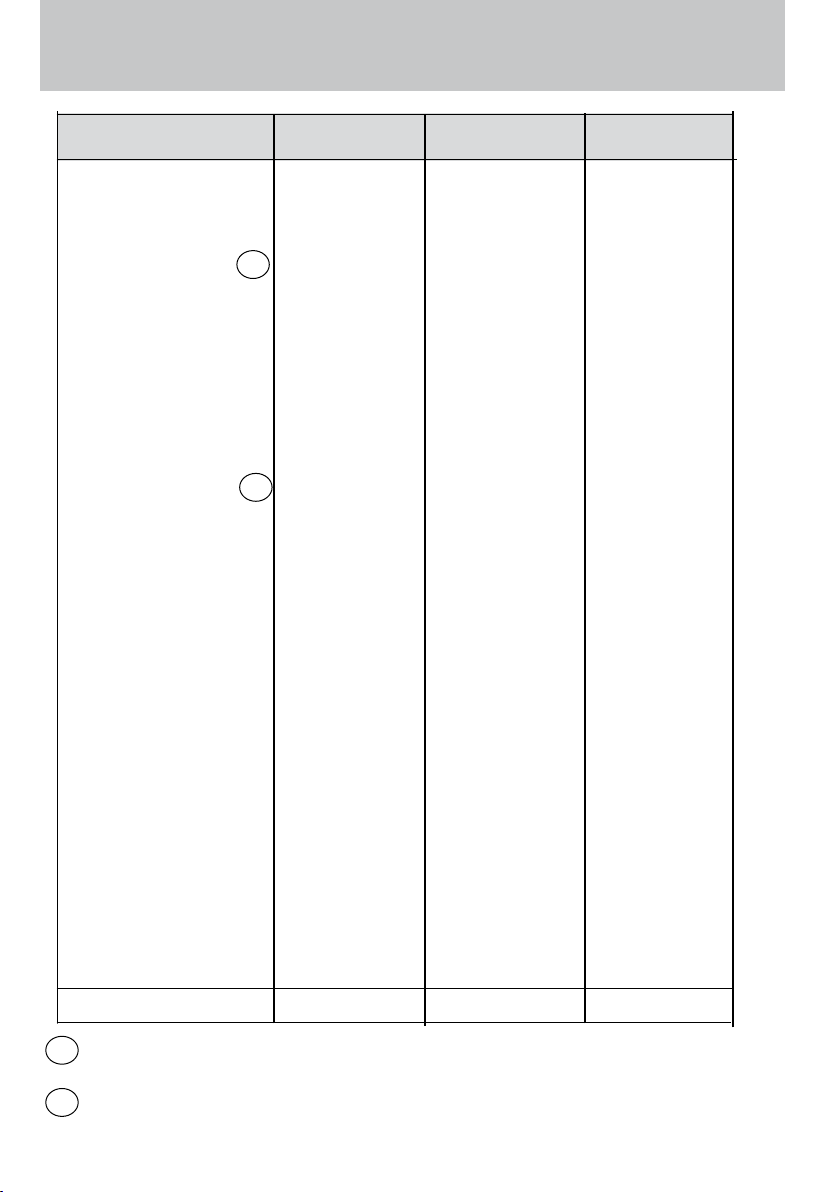

Technical data

Technical

data

Operating pressure,

steplessly adjust.

max. permissible

overpressure

Water output

at 0 bar

at nominal pressure

Nozzle size

(Flat jet)

(Dirt killer)

Volume

Water tank

max. inlet water

temp. to water tank

Direct suction height

Hose drum

High pressure hose

Electrical ratings

Motor speed adjust.

Connect.wattage Inp.

Output

Weight (incl. access.

with empty water tank)

Dimensions incl. handle

L x W x H in mm

Sound level acc. to DIN

45 635 (reg. working place)

with dirtkiller

Guaranteed sound level L

Vibrations at lance

Recoil at lance

Order n°

*1

*2

WA

10 - 150 bar

165 bar

10,0 l/min

9,5 l/min

25035

035

10 l

max. 60 °C

2,5 m

ja

20 m

230 V/50 Hz

14 A

1400 U/min

P1: 3,2 kW

P2: 2,3 kW

60 kg

780 x 395 x 870

88 dB (A)

90 dB (A)

88 dB (A)

ca. 20 N

2,0 m/s²

40.431

quadro 799 TSTquadro 599 TST quadro 899 TST

10 - 180 bar

200 bar

14,0 l/min

13,0 l/min

25045

045

10 l

max. 60 °C

2,5 m

ja

20 m

400 V/50 Hz

8,5 A

1400 U/min

P1: 5,5 kW

P2: 4,0 kW

60 kg

780 x 395 x 870

88 dB (A)

90 dB (A)

88 dB (A)

ca. 20 N

2,1 m/s²

40.432

780 x 395 x 870

10 - 150 bar

170 bar

15,0 l/min

14,5 l/min

25060

060

10 l

max. 60 °C

2,5 m

ja

15 m

400 V/50 Hz

8,5 A

1400 U/min

P1: 5,5 kW

P2: 4,0 kW

60 kg

88 dB (A)

90 dB (A)

88 dB (A)

ca. 22 N

2,1 m/s²

40.434

Permissible tolerance for gures ± 5 % in acc. with VDMA uniform sheet 24411

*1

Min. water quantity to be supplied to the high pressure cleaner!

(2 - 8 bar admission pressure)

Direct suction is possible through by-passing of water tank!

*2

(see page 5)

2

Description

Dear customer

We would like to congratulate you on your new high pressure cleaner with integrated water tank and to thank you for the purchase.

To ease your introduction to the use of the cleaner, we have provided the following

pages of explanations, tips and hints, which we ask you to read before using it for

the rst time.

The equipment will assist you professionally in all cleaning tasks, e.g.:

- facades

- agstones

- terraces

- vehicles of all types

- stables

- machines etc.

- barrels and containers

- channels

Contents Page

Technical data .................................................... 2

Construction and components ................................4

Water system ..........................................................5

Detergent / caring system .......................................5

Lance and spay gun ................................................5

High pressure hose and spray device .....................6

Unloader valve - safety valve ..................................6

Delayed motor cut-out .............................................7

Safety cut-out ..........................................................7

Setting up / Location ...............................................7

Electrical connection ...............................................8

Brake .......................................................................9

Brief operating instructions......................................9

This is what you’ve purchased ...............................10

Preparation for use.................................................11

External suction......................................................13

When using detergents ..........................................14

To shut down the pump / Frost protection ..............14

Safety notes „This is prohibited !“...........................15

Additional accessories ...........................................18

Small repairs ..........................................................20

Spare parts lists .....................................................22

Wiring diagram .......................................................42

General rules / oil change / guarantee ...................44

Declaration of conformity .......................................45

Inspection report ....................................................46

3

Description

10

2

1

9

8

7

4

quadro 599

230V/50Hz

quadro 799

quadro 899

400V/50Hz

5

3

6

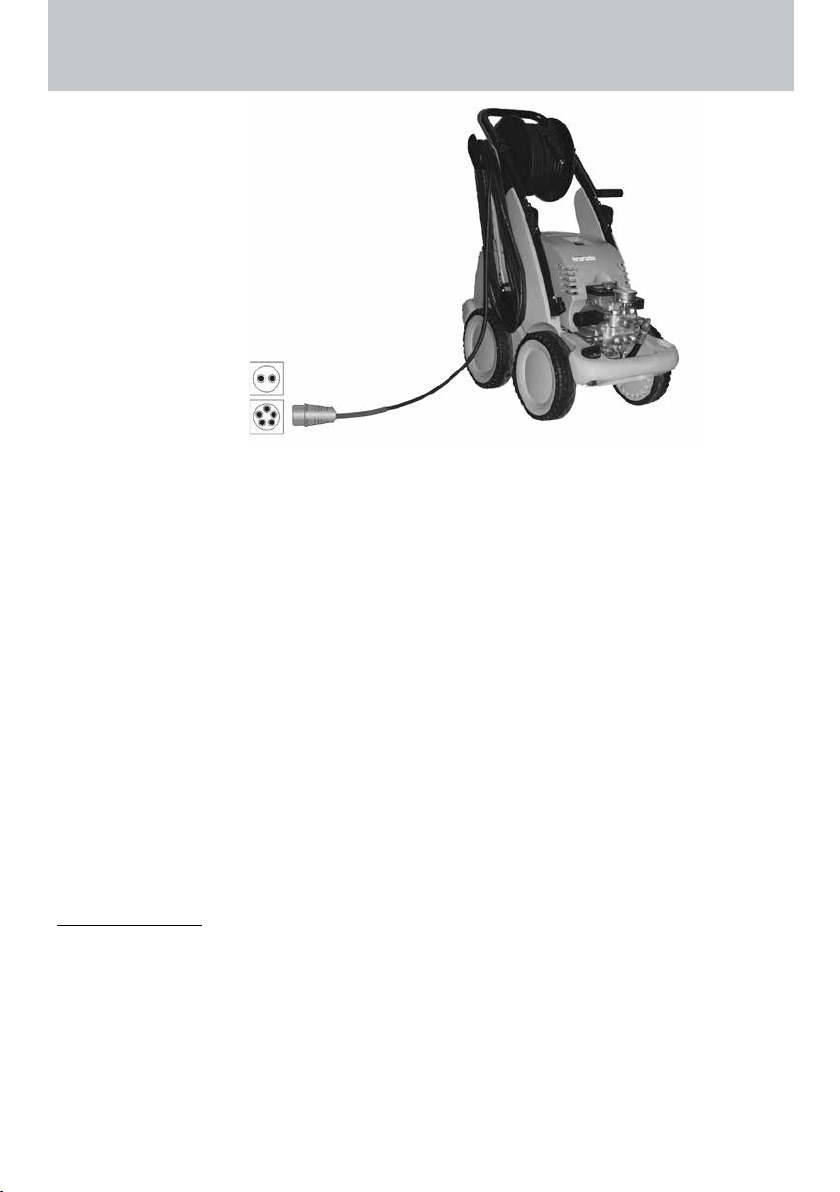

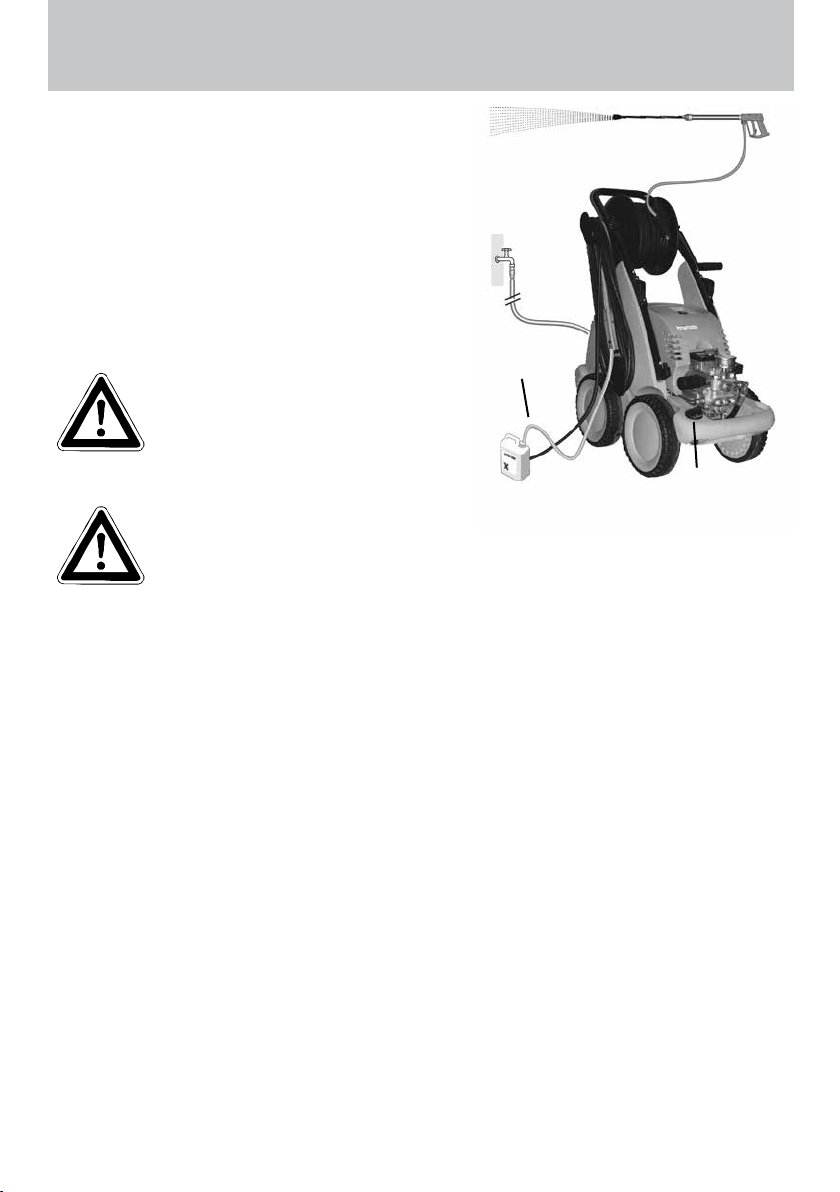

Connection principle

The KRÄNZLE quadro 599 TST , 799 TST and 899 TST- high pressure cleaners are

mobile machines with hose drum and 20m industrial hose.

The connection principle can be seen from the illustration.

Components

1 Water inlet connection with lter

2 Cover for water tank

3 High pressure pump

4 Press. gauge with glycerin lling

5 Unloader valve - safety valve

4

6 Detergent valve

7 High pressure hose

8 Spray gun

9 Interchangeable lance with at jet

nozzle and nozzle protection

10 Interchangeable lance with dirtkiller

Description

Water system

The water must be lead to the high pressure cleaner under pressure (2 – 8 bar

ad-mission pressure). A oat valve regulates the water inlet. Then, the water is

sucked by the high pressure pump from the water tank and supplied to the lance

under the set pressure. The high pressure jet is formed by the nozzle at the end of

the lance.

Detergent and caring system

The high pressure pump can also suck a detergent/caring

agent and mix it with the high pressure jet. The additive

is sucked through the pump and brought in with the set

pressure.

Insert the detergent hose into the detergent container and

open the detergent valve (6). The detergent must have

the ph-value 7-9 neutral.

The detergent discharges with the water at the high pressure nozzle.

Only open the dosing valve, if the chemistry sieve is

placed in a liquid. Sucked air leads to destruction of the

pump seals !!!

The rules concerning the environment, refuse and

ground water protection must be complied with!

6

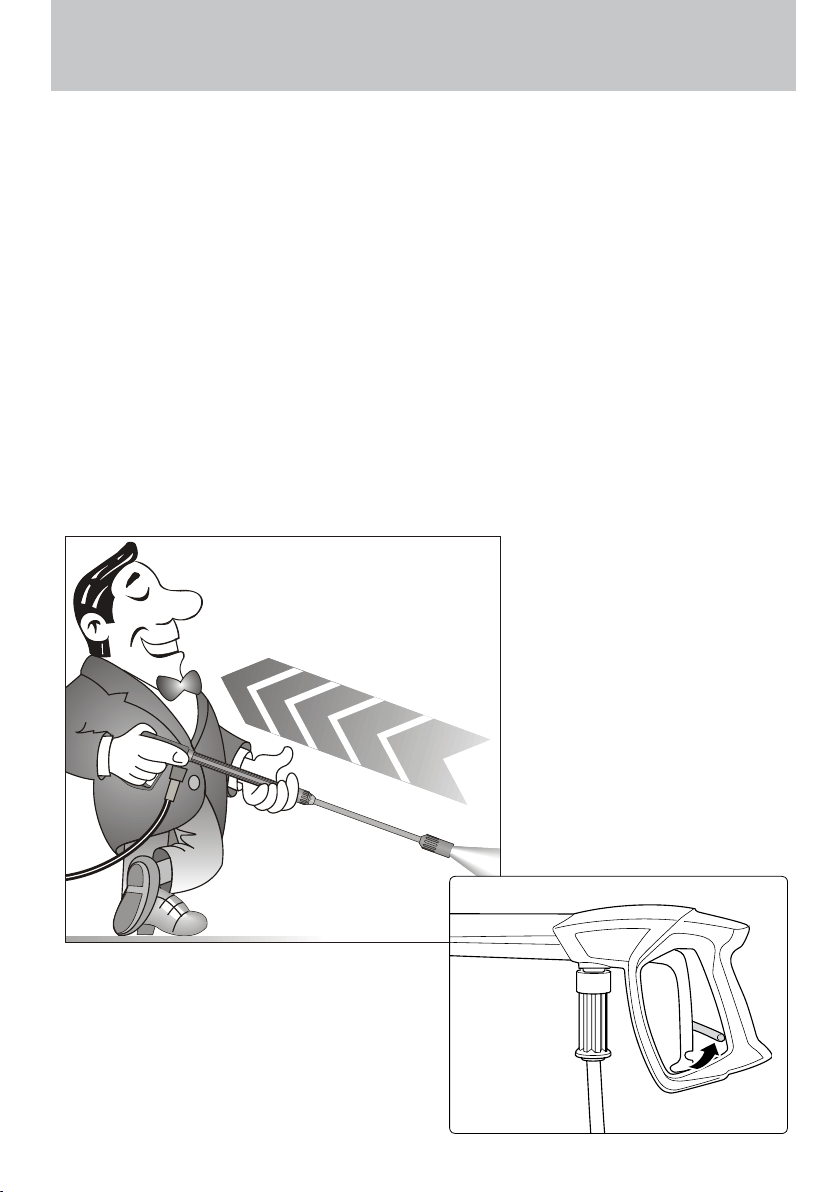

Lance with spray gun

The machine can only be operated when the safety trigger is squeezed.

When the lever is squeezed, the spray gun opens. The liquid is then pumped

to the nozzle. The spray pressure increases and quickly reaches the selected

operating pressure. For the deairing of the system open and close the gun quickly

a few times. When the trigger is released, the trigger gun closes and any further

spraying of liquid from the lance is stopped and the pressure gauge must show 0

bar.

The increase in pressure when the trigger gun is closed causes the unloader

valve-safety valve to open. The pump remains switched on and continues to pump

liquid through the pump at reduced pressure. When the spray gun is opened, the

unloader valve - safety valve closes and the pump ressumes spraying from the

lance with the selected operating pressure.

The spray gun is a safety device. Repairs should only

be performed by qualied persons. Should replacement

parts be required, use only components authorized by

the manufacturer.

5

Description

High pressure hose and spraying device

The high pressure hose and spraying device supplied with the machine are made

of high grade material. They are also optimized for the machine and marked as

required by the appropriate regulations.

If replacement parts are required, only such parts that are authorized

by the manufacturer and which bear the markings required by the

appropriate regulations may be used. The high pressure hose and

spraying device must be connected in a pressure-tight manner.

The high pressure hose may not be driven over, pulled excessively or

twisted. Hose lines are wear parts. Guarantee is accepted only for ma-

nufacturing errors, not for external damages.

High pressure hose lines and spraying equipment must not be repaired, but replaced by a new hose or spraying equipment.

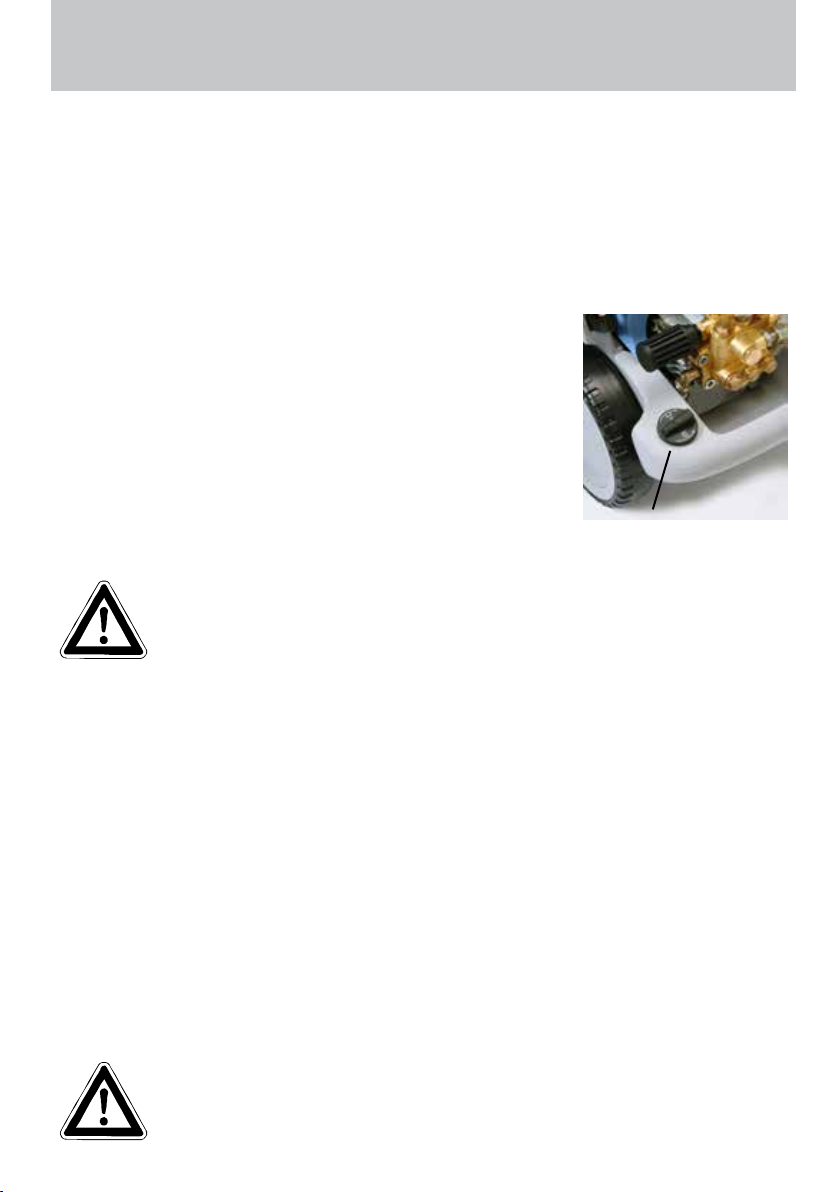

Unloader valve - safety valve

The unloader valve - safety valve protects the machine from a build up of excess

pressure, and is designed not to permit an excess pressure to be selected for

operation. The limit nut on the handle is sealed with a spray coating.

The operating pressure and spray rate can be steplessly

adjusted by turning the handle.

Replacements, repairs, new adjustments and sealing

should only be performed by qualied persons.

Take care that all screw connections are pressure-tight. A

leakage of gun, high-pressure hose or hose drum has to be

repaired at once. Leakages lead to an increased wear and

to the destruction of the delayed motor cut-out.

Operator’s task:

Prior to each usage of this liquid spraying device, the operator is obliged to check if all safety relevant parts are in

perfect working condition. (e.g. safty valves, high-pressure

hose, cables and connections, spraying devices, etc. )

6

Description

Delayed motor cut-out

Frequent, work-necessitated switching on and off of motors on

machines of this size puts a heavy load on the power network and

causes increased wear on internal electrical parts. Therefore the

motor of the new KRANZLE device only switches off 30 seconds after closing the

gun and then goes to stand still. By opening the gun, the device is started again.

Safety cut-out

If the device is accidentally not turned off after use or the pistol is not used for 20

minutes, the device automatically goes into the safety state via deactivating. By

operating the main switch again, the device is activated again.

Replacements and inspection work should only be performed by quali-

ed persons when the machine is disconnected from the

power supply, i.e. the plug pulled out from the electrical

socket.

Setting up

Location

Neither set up and operate the machine in rooms where there is a risk

of re or explosion nor put it into puddles. Do not use the machine under

water. The device must not stand in the spray area of the high pressure jet.

CAUTION !

Never suck in liquid containing solvents such as paint thinners, petrol,

oil or similar liquid matter. Pay attention to the instructions of

the manufacturers of the cleaning agents. The seals in the

machine are not resistant to solvents! The spray of solvents is inammable, explosive and poisonous.

CAUTION !

When running your high pressure cleaner with hot water of 60° C

raised temperatures occur. Do not touch the machine without

safety gloves!

7

Description

quadro 599

230V/50Hz

quadro 799

400V/50Hz

Electrical connection

The machine is supplied with an electrical power cord with plug.

The mains plug must be tted to a standard grounded socket with a 30mA residual current operated device. The socket must be protected with a 16A delay action

fuse on the mains side.

KRÄNZLE quadro 599 TST = 230 Volt / 50 Hz

KRÄNZLE quadro 799 TST = 400 Volt / 50 Hz

KRÄNZLE quadro 899 TST = 400 Volt / 50 Hz phase-sequence not signicant)

When using an extension cable, this must have a grounded lead which is properly

connected to the socket. The conductors in the extension cable must have a mini-

mum cross section of 1.5 mm². Plug connections must be of a spray-proof design

and may not be located on a wet oor.

CAUTION !

The use of extension cables which are too long may lead to malfunctions and start

up difculty. If the extension cable is longer than 10m it must have a min. cross

section of 2.5mm².

When using a cable drum, always keep the cable wound as far as possible.

8

Description

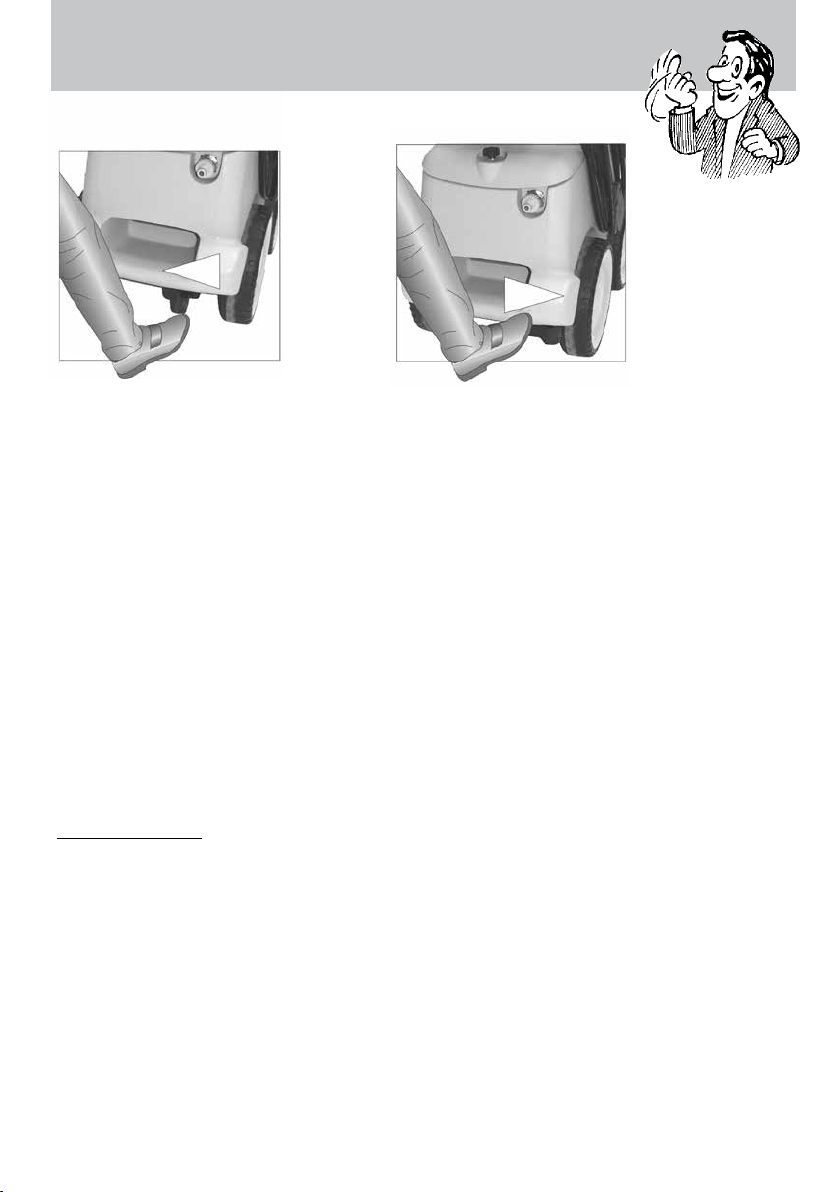

Brake

Brake appliedBrake not applied

Brief operating instructions:

1. Connect high pressure hose with spray gun.

2. Connect to suitable water supply.

3. Connect current

(quadro 599: 230V/50Hz AC;

quadro 799 , 899: 400V/50Hz three-phase current).

4. Switch on machine and start cleaning.

5. After having completed the cleaning process, put main switch in zero position and by opening the gun, reduce the pressure in the high pressure

hose.

Then, the high pressure hose can be rolled up.

- Only use clean water ! Protect from frost !

CAUTION !

Please pay attention to the regulations of your waterworks company.

Because of the water tank, the device can be connected to any drinking water line

without worries.

9

This is what you’ve purchased:

www.kraenzle.com

1. Dirtkiller

Lance with nozzle

protection and high

pressure nozzle

Flat jet 25°

2. Spray gun M2000

with insulated handle

and screw connection

3. KRÄNZLE - High pressure cleaners

quadro 599 TST and quadro 799 TST with hose drum and

20 m HP hose NW 6 with steel reinforcement

4. Operating manual

5. HP hose 20 m NW 6

with hose drum

6. Collapsible crank

for hose drum

(already installed)

7. Plug-in connection of

water inlet parts and

lter (already installed)

10

Preparation for use

To control the high pressure cleaner

put

1. the foot against the tilt bases and

2. then pull the device towards you.

1. Check oil level.

There are two

possibilities for checking the

oil level of the pump:

a) Oil must be visible in the viewing

window

b) The oil level must be between the two

markings on the oil dip stick.

To check the oil level, loosen the oil cover screw and take

out the oil dip stick. The oil level must be between the two

markings.

b

a

11

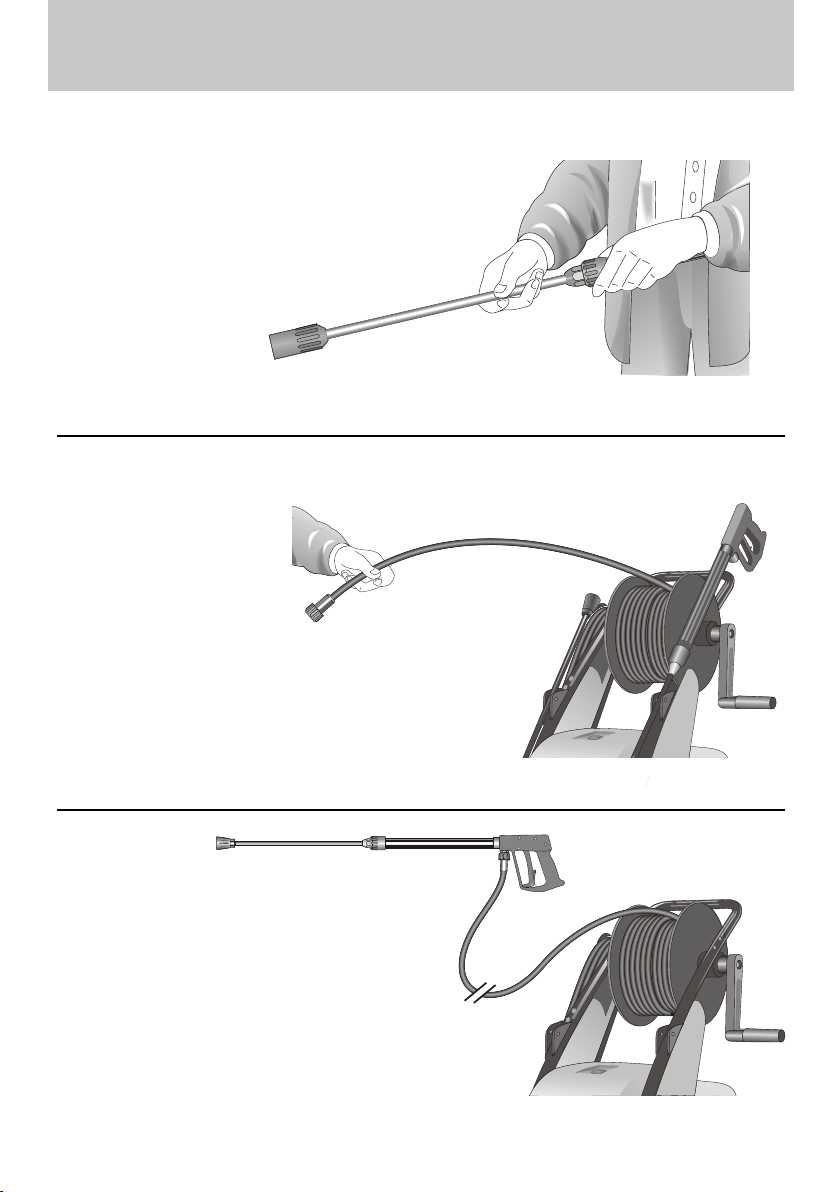

Preparation for use

2. Connect the high pressure lance

or dirtkiller to the spray gun.

3. Unroll hose without kinks and connect with handgun and pump. Use

max. 20 m HP hose.

4. Connection of high pressure

hose from device to lance.

12

Preparation for use

5. The machine must be connected to the water line

with cold water or up to 60° C warm water (see

page 2).

The hose cross section must be at least 3/4" =

16 mm (free passage). Filter 1 must always be

clean.

Please make sure that the lter is clean before

using your high pressure cleaner.

CAUTION !

When running your high pressure cleaner

with hot water of 60° C raised temperatures occur.

Do not touch the pump without safety gloves!

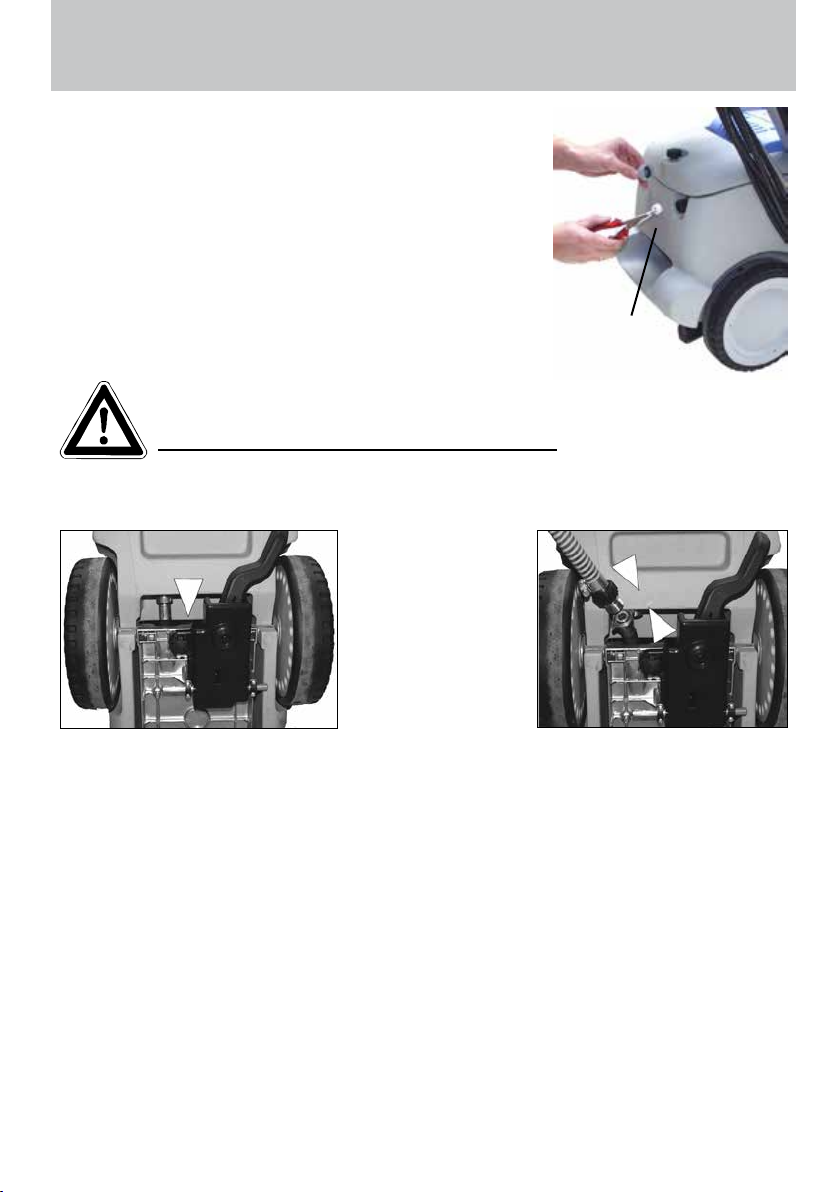

External suction

1

Undercarriage Undercarriage

If water is to be sucked from an external container for the high pressure cleaner,

the connection hose between the high pressure pump and the water tank must be

screwed off and the suction hose must be connected via a double nipple 3/4“ (Order

no.: 46.004) to the connection hose.

Make sure that the water is clean. Use the Kränzle suction hose with suction lter.

(Order no. 15.038 3)

Maximum suction height 2.5 m, maximum water

temperature for direct suction: 60°C

(see technical data on page 2)

13

To shut down the pump

When using detergents

Put chemistry sieve number 5 into the detergent container. Open the detergent valve (6),

then the detergent is sucked in. When closing

the detergent valve, the chemistry supply is

automatically closed. Allow detergent to act

and then wash off. (see page 5).

Note that you must always comply

with the instructions provided by

the manufacturer of the detergent

(e.g. safety clothing) and the water

protection regulations!

Only open the valve, if the chemistry

sieve is in a liquid. Sucked in air leads

to the destruction of the pump seals !!!

Damages to the pump caused by sucked in air are

not covered by the guarantee.

5

To shut down the pump:

1. Switch off the machine. Device switch to „0“ position.

2. Cut off the water supply.

3. Open the spray gun briey until the pressure is released.

4. Apply the safety catch on the spray gun.

5. Remove the water hose and spray gun.

6. Pull the plug from the socket.

7. Winter: store the pump in rooms above 0°C.

8. Clean the water lter.

6

14

Safety notes

Frost protection

Normally after operation, there is still some water in the device. Thus, you must take

special measures to protect the device from frost.

- Completely drain the device

For this purpose, separate the device from the water supply. Then, turn on the main

switch and open the gun. Now, the pump presses the remaining water from the

water tank and the pump. However, do not allow the device to operate without water

for longer than one minute.

- Fill the device with antifreeze agent

If the device is not operated for longer periods, especially over the winter, you

should pump an antifreeze agent through the device. For this purpose, ll the

anti-freeze agent into the water box and turn on the device. Wait with opened gun,

until the agent comes from the nozzle.

However, the best way to protect the device from frost is

to store it at a frost-free location.

As to the recoil see notice on page 2!

Apply the safety catch on the spray

gun after each use, in order to prevent

unintentional spraying!

15

Loading...

Loading...