Krystal Pure KR5, KR15, KR10 Owner's Manual

1

For Krystal Pure™ Reverse Osmosis Systems KR5 • KR10 • KR15

Para sistemas de ósmosis inversa

Owners Manual

Manual del propietario

Includes: Installation and Service Procedures, Specifications and Operation Guidelines.

Incluye: Procedimientos de instalación y servicio, Especificaciones y Guías de operación.

2

| Krystal Pure™ | Reverse Osmosis System Manual

INTRODUCTION 3

MANY USES AND BENEFITS OF REVERSE OSMOSIS WATER 3

TOOLS & MATERIALS RECOMMENDED FOR NORMAL INSTALLATION 3

CONTENTS OF PACKAGE 3

SPECIFICATIONS AND LIMITATIONS 4

WARNINGS 4

PHOTO OF R/O AND PARTS 5

INSTALLATION PROCEDURES 5

STEP 1 POSITION SYSTEM 5

STEP 2 FAUCET INSTALLATION 5

FIGURE 1 6

STEP 3 EASY TAP ADAPTER INSTALLATION 5

STEP 4 DRAIN SADDLE CLAMP INSTALLATION 6

FIGURE 2 7

STEP 5 STORAGE TANK PREPARATION 6

STEP 6 TUBING CONNECTIONS 7

STEP 7 SYSTEM START-UP PROCEDURES 7

STEP 8 REFRIGERATOR ICE MAKER HOOK UP 8

STEP 9 RECOMMENDED FILTER SERVICE LIFE 8

FILTER REPLACEMENT LIST 9

STEP 10 FILTER CHANGING PROCEDURES 9

STEP 11 RECOMMENDED SANITIZING PROCEDURE 9

STEP 12 SERVICE AND MAINTENANCE RECOMMENDATIONS 9

REPLACEMENT PARTS LIST 10

TROUBLESHOOTING GUIDE 10

KRYSTAL PURE™ R/O SCHEMATIC 12

PERFORMANCE DATA SHEET NSF/ANSI 58 14

MANUFACTURERS WARRANTY 15

WARRANTY REGISTRATION CARD 16

TABLE OF CONTENTS

3

Congratulations, you have purchased one of the highest quality Reverse Osmosis, “R/O” systems

available today. This unit combines a series of different filtration processes into one single module

that makes bottle-quality water right in your own home or office. This system has been engineered

with only the finest quality components and materials. The system works connected to most potable

city water supplies.

Obtain all materials and tools needed for installation before starting. Please read entire manual carefully before proceeding with installation. Failure to follow manual’s guidelines could cause personal

injury or property damage. Be sure to check household plumbing for signs of leaks, corrosion and

aging. Correct these problems before attempting to install your new R/O system.

1. Quality Drinking Water

2. Quality Ice Cubes

3. Car Batteries and Window Washer

4. Removing some carpet stains

5. Drinking water for pets

6. Watering plants

7. Some humidifiers

8. Washing windows

9. Making coffee, juice and teas

10. Use for cooking

11. Rinsing vegetables

12. Brushing teeth

13. Rinsing hair after washing

14. Steam irons

15. Office coolers

16. Bottled Water

❱ Filter Pac/R/O module

❱ Storage Tank

❱ Owner’s Manual

❱ Warranty Registration Card

❱ Standard air-gap faucet or optional colored

faucet.

❱ Water Quality Monitor (KR15 only)

❱ Parts Bag:

a. Easy Tap Adapter w/washer (plastic)

b. Drain Clamp (black plastic)

c. ¼” Coupler (plastic) for use w/air gap faucet

d. Faucet Adapter plastic (7/16” fip × 3/8” push)

e. Tank Ball Valve

f. Mounting Screws

1. Adjustable Wrench (2)

2. Phillips Screw Driver

3. 3/8” drill motor with a 3/8” drill bit

4. Teflon Tape

5. Safety Glasses

6. Step 2: Faucet Installation (optional) 1¼” hole

saw appropriate for sink material to be drilled

7. Step 8: Ice Line to refrigerator (optional) 3/8”

polyethylene or polypropylene tubing. 3/8”

× 3/8” × 3/8” plastic compression T-fitting

MANY USES AND BENEFITS OF REVERSE OSMOSIS WATER

INTRODUCTION

CONTENTS OF PACKAGE

TOOLS & MATERIALS RECOMMENDED FOR NORMAL INSTALLATION

4

| Krystal Pure™ | Reverse Osmosis System Manual

1. Only use with potable water supplies (Water

must be microbiologically safe).

2. Installation of R/O system must Comply with

state and local laws and regulations.

3. Check for leaks after installation or service

as system is reaching standard operating pressure and temperature. Check for leaks periodically thereafter. A system may be inadvertently moved or jarred while other items

are moved under the sink. If a fitting is accidentally loosened, a leak could result causing

damage to your cabinet.

4. Do not let system freeze. Allow to warm up

to room temperature before installing. Best to

be installed indoors with air temperature between 60° - 85° F.

5. Attach to cold water supply only.

6. Never drain R/O tank completely without

first turning off the refrigerator ice maker.

7. Air-gap faucet may cause a slight noise at first

but noise should diminish in about a week. If

noise continues, adjusting drain clamp may

help reduce noise. Also, install faucet so

air-gap faucet hole will drain into the sink if

drain line gets plugged from obstruction in

the drain line.

8. This reverse osmosis system contains a replaceable component critical to the efficiency of the system. Replacement of the reverse

osmosis component should be with one of

identical specifications, as defined by the

manufacturer, to assure the same efficiency

and contaminant reduction performance.

9. Failure to follow recommended service intervals or use of filters and parts other than

those recommended by the manufacturer

may void warranty.

10. Drain R/O tank completely at least twice a

year. If daily use averages less than a gallon

per day, drain every two weeks. (See page 3

for Many Uses).

11. We recommend having all porcelain/enamel-coated sinks professionally drilled.

12. Sanitizing most R/O systems on a yearly basis

is important for reducing bacteria build-up.

13. All membrane performance and life cycles

may be affected by severe water conditions.

Varying mineral content like hardness and

iron will require varying filter change intervals. Some customers choose pretreatment

options like water softening or iron reduction

systems to protect the entire home.

SPECIFICATIONS AND LIMITATIONS

INCOMING WATER SUPPLY

pH

3 min. to 11 max.

Water Pressure

40 PSI min. to 85 PSI max.

Total Dissolved Solids (TDS)

2000 PPM max.

Temperature Air and Water

40° F min. to 110° F max.

Hardness

Water Softener Recommended over 10 GPG

Iron Content <1 PPM max.

SYSTEM

System Dimensions 16” × 15.5” × 7”

Storage Tank Dimension 15.5” × 11”

Rejection Rate Up to 98% TDS*

Storage Capacity Up to 3.2 Gallons*

Production Capacity Membrane Rating 24 gallons per day*

*NOTE: These specifications are not the certified results and can vary greatly depending on feed water makeup,

i.e. pressure, temperature, TDS, and hardness. See Performance Data Sheet for the actual WQA Certified results

under standard test conditions on page 25. Regular maintenance and filter replacement are necessary for system’s

performance and longevity.

WARNINGS

5

STEP 1 POSITION SYSTEM

The R/O system needs both a water supply and

access to a drain. The R/O system is designed to

fit under most sinks. The kitchen sink is the most

common location for the R/O install. Remove all

system components from boxes and determine

the location for placement of the Filter Pac/R/O

module, tank, and faucet.

If you desire to hang the Filter Pac/R/O module,

use mounting screws, placing them to align with

holes in the bracket (make sure the cabinet wall

is thick enough to support the Filter Pac/R/O

module and that the mounting screws will not

pierce through the wall). Hang Filter Pac/R/O

module to assure sufficient space is allowed.

Remove Filter Pac/R/O module from the wall for

now and continue with install.

STEP 2 FAUCET INSTALLATION

1. Check for an extra hole in the sink. You must

drill a 1¼” hole for the faucet if the sink does

not have one.Determine Location of Faucet

Hole: Check underneath sink before drilling.

Make sure there are no obstructions. Drilling

a Stainless Steel Sink: Drill a 1¼” hole with a

hole saw or hole punch for an air-gap faucet.

Smooth out rough edges with a file if necessar y.Porcelain/Enamel-Coated Stainless

or Cast Iron Sink: The manufacturer recommends having this type of sink professionally

drilled because of possibility of chipping or

cracking. If you are attempting to drill, use extreme caution. Obtain the proper tools necessary to drill through the sink material. Follow

the drill manufacturers instructions for your

type of sink. Place an old towel under the

sink to catch any metal filings and to make

clean up easy. After drilling, clean up metal

filings quickly to avoid staining the porcelain.

2. Install Air-gap Faucet: Pre-assemble faucet

prior to installing on the sink. Place the white

spacer onto faucet stem flat side toward tubing and open end upward. Slide spacer up the

stem leaving enough room for the thickness of

the sink. Place the washer onto the stem and

thread on the 9/16” nut up to the spacer. Attach the plastic 3/8” faucet adapter fitting to

the base of the faucet stem (Do not over-tight-

en) (see A in Figure 1 page 6).

3. Guide the (2) tubes and the faucet stem through

the hole on the sink until the faucet rests on

top of the sink. Center the faucet over the hole.

Position the faucet so the air-gap hole and the

faucet lever point toward the sink basin (in case

drain tube plugs causing water to spill out of

the air-gap hole). Insert the slotted washer under the sink between the white spacer and the

base of the sink. Tighten the 9/16” nut securing

the white spacer tight against the sink (see B in

Figure 1 page 6). Faucet may require repositioning before final tightening. Remove short packing tubing from top of faucet and insert faucet

spout by pushing spout straight into the hole

until it seats.

STEP 3 EASY TAP ADAPTER INSTALLATION

Turn off cold water supply to the sink faucet

and relieve pressure by opening the cold water

faucet. (Repair any existing plumbing sink leaks

before continuing). Follow water supply from the

cold water supply valve, toward the sink faucet,

until you reach a coupling nut (may be at the

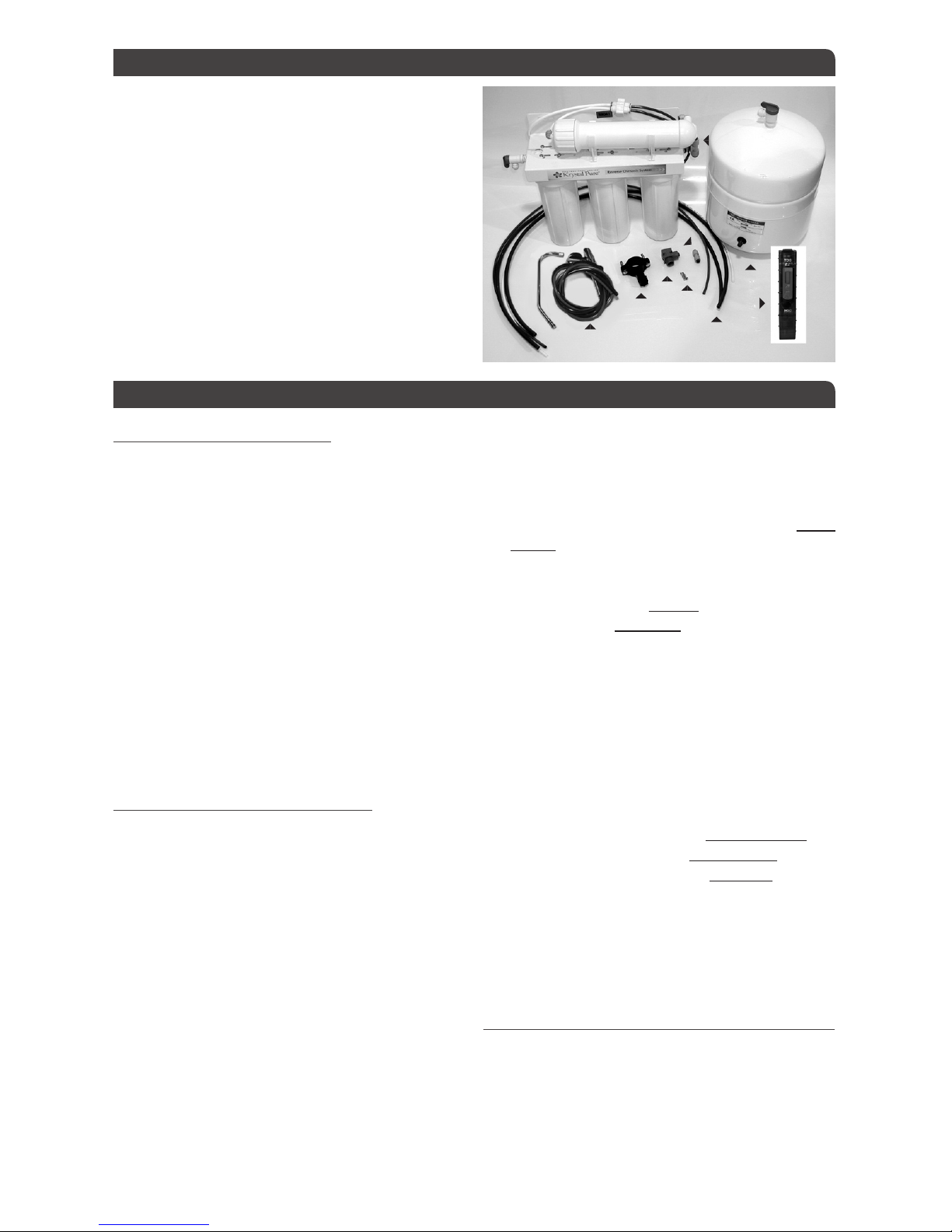

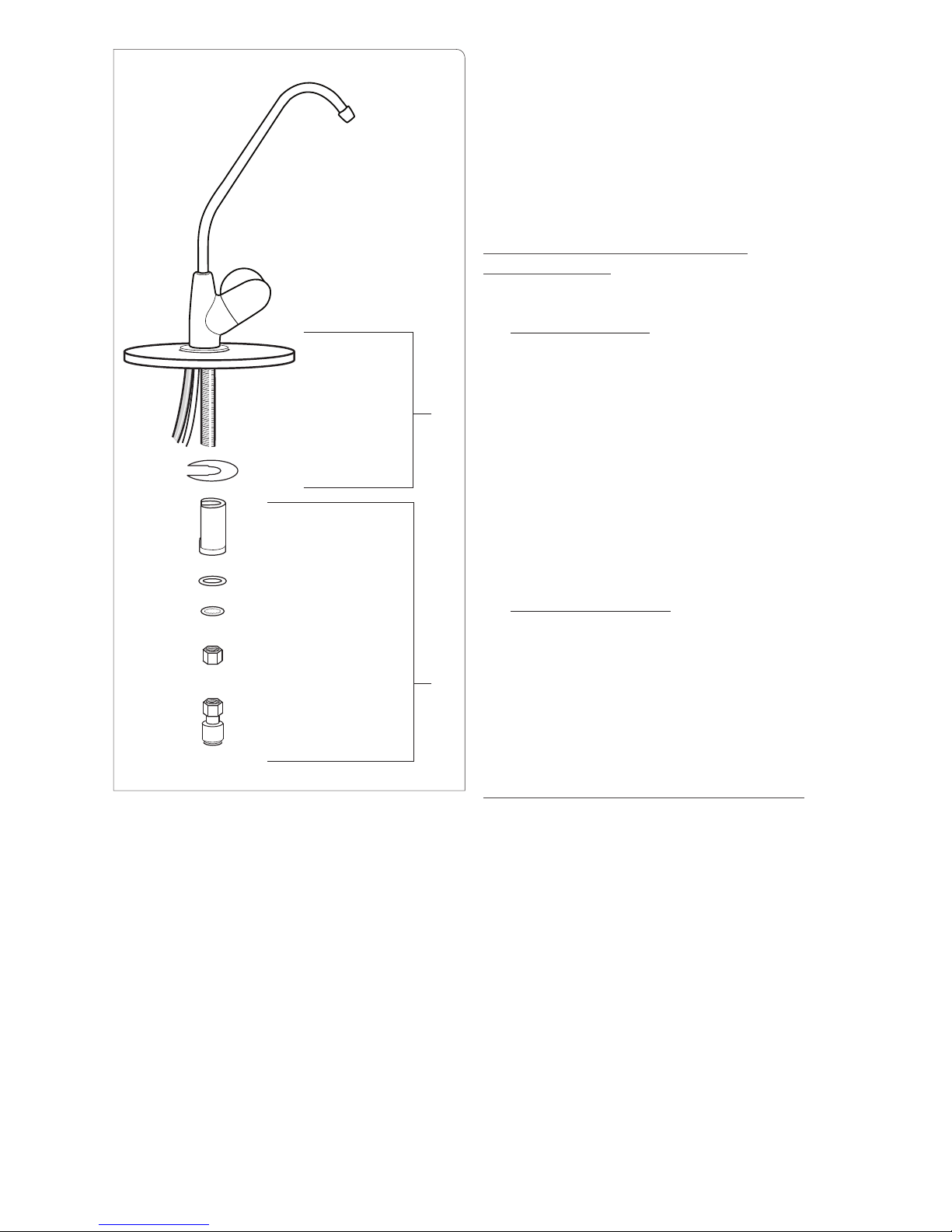

A. Faucet and tubing

B. Drain clamp

C. Easy Tap Adapter

D. Screws

E. Union Coupling

F. R/O tubing

G. Storage tank with ball valve

H. Filterpac Unit (image may vary from model

in box, KR5 will have two filter canisters)

I. Water Quality Monitor (included with KR15

model only)

PHOTO OF R/O AND PARTS

INSTALLATION PROCEDURES

A

B

C

D

F

G

I

E

H

6

| Krystal Pure™ | Reverse Osmosis System Manual

base of the faucet). Unscrew the coupling nut.

Place rubber washer into the plastic easy tap

faucet adapter and screw adapter onto location

of coupling nut. Hand-tighten, then tighten one

more complete turn with a wrench. Re-attach the

supply line to the adapter with the coupling nut.

Leave the cold water off.

CAUTION:

1. When tightening easy tap, make sure the tube

to which you are attaching the easy tap is not

twisted. Use two wrenches to hold existing

tube while tightening the easy tap adapter.

2. Examine existing cone shaped washer on water supply tube, adjust or replace if damaged

or worn (not included).

3. If self-piercing valve is used instead of easy

tap, attach to hard copper tubing only. Do not

over tighten screws (see instructions on piercing valve package, not included).

NOTE: Push-In style fittings are designed for ease of use.

Simply push the tubing in until it seats. Give a tug on it to

make sure it is secure. Insert red locking clip between fitting and collar. If you need to remove the tubing, remove

the red locking clip, hold the locking ring collar against the

fitting while pulling out the tubing. No inserts or nuts are

used with the Push-In style fittings.

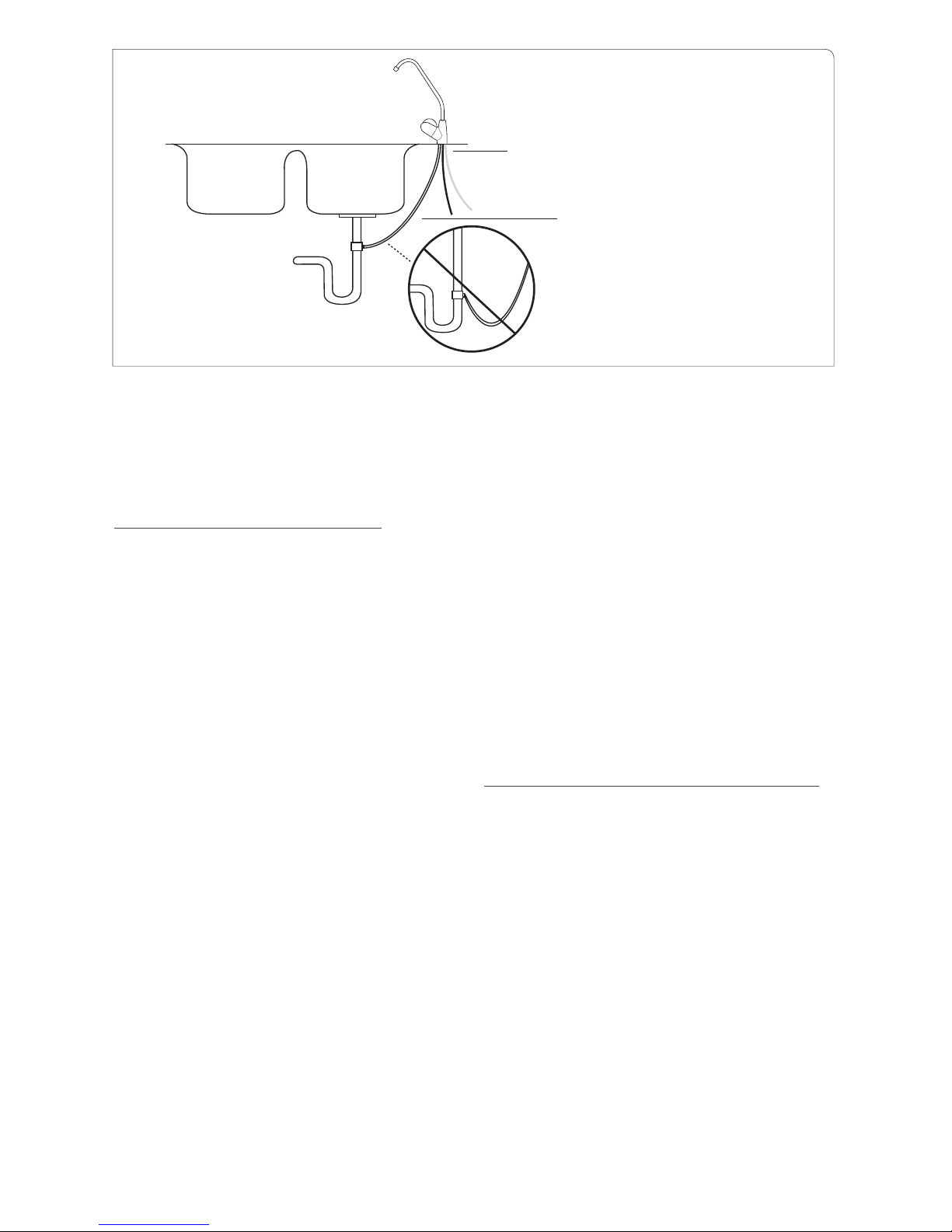

STEP 4 DRAIN SADDLE CLAMP

INSTALLATION

Location of Drain Clamp

1. Sink With Disposal: Select location to place

drain saddle clamp. Best choice is the vertical pipe as near the sink as possible making

certain that the drain clamp is above the horizontal garbage disposal waste pipe. When

connecting the black drain tube to drain saddle

clamp keep the tube run as straight as possible

and that there are no dips, loops, low spots or

kinks (See D in Figure 2 on page 7). Also, to

reduce noise, assure that R/O drain line enters

the vertical pipe from a direction other than the

direction of entry of the garbage disposal pipe.

Or

2. Sink Without Disposal: Best choice is the vertical pipe about 4” above the water level in

the trap.

To Install:

Drill a 3/8” hole through one side of the drainpipe. Align the hole in the drain clamp with the

hole in the drainpipe. Tighten down the drain

clamp snugly so it will not move on drainpipe.

STEP 5 STORAGE TANK PREPARATION

1. Wrap the threads on top of the tank with 6

wraps of Teflon tape (do not use any type of

pipe compounds).

2. Screw tank ball valve onto the top of the

tank (approximately 4 to 5 full turns, do not

over-tighten). Check for leaks once R/O is

pressurized and while tank is filling and again

when tank is full.

3. Tank is pre-charged with air pressure. Tank

can be laid on its side if necessary (tank will

hold approximately 2 to 3 gallons of R/O water depending on water pressure, tank positioning, and tank air pressure).

4. Tank pressure can be increased to improve water flow to the faucet or refrigerator. Air pressure can only be tested when tank is completely

FIGURE 1

countertop

A

B

F

slot washer

white spacer

washer

lock washer (optional)

9/16” nut

5/8” adapter fitting

× 3/8” tube adapter

fitting

faucet stem

7

empty of water. Air pressure of 5 PSI minimum,

12 PSI maximum is recommended. The higher

the air pressure the smaller the volume of water

the tank will hold. Pressure of 10-12 PSI may be

necessary to feed a line to the refrigerator. Over

pressurizing may ruin the tank.

STEP 6 TUBING CONNECTIONS

IMPORTANT: Fitting manufacturer requires fit-

tings to be re-checked after system reaches full

operating pressure and temperature, Re-tighten

and secure as necessary.

It is not recommended to shorten the length of

any tubes during installation (except black 3/8”

drain tube on air gap faucet). This will make future servicing easier.

1. ¼” White Supply Tube on Filter Pac/R/O module: Connect the supply (white) tube firmly

into the push-in port on the side of the easy

tap adapter installed on the cold water supply

line. OPTIONAL: If self-piercing valve is used,

connect to valve using brass nut, tubing support, ferrule, and plastic insert (not included).

2. ¼” Red Drain Tube on Filter Pac/R/O module

- Air-Gap faucet system: Use the coupler from

the parts bag to connect the ¼” red drain tube

from the faucet to the red tube from Filter Pac/

R/O Module (See C in Figure 2 above). Push

firmly so tubes will not pull out of coupler or

leak. IMPORTANT: 1/4” red tubing MUST be

connected using the provided coupler or else

unit WILL NOT work properly.

3. 3/8” Black Drain Tube from Faucet: Connect

this tube to the black 3/8” drain clamp. (See D

in Figure 2). Tighten firmly so tube will not pull

out of drain clamp. IMPORTANT: Do not leave

excessive slack in drain tubing. Shorten tubing

so that it flows directly to the drain with no

dips, loops, low spots, or kinks. If not installed

correctly, water will be forced out the side airgap hole of the faucet.

4. Post Filter Connection to Faucet: KR10: Connect the 3/8” blue tube on the front of the

post-filter bowl (labeled out) to the 3/8” pushin adapter fitting on the R/O faucet. KR15:

Connect the 3/8” blue tube on the back of the

post-filter bowl (labeled out) to the 3/8” pushin adapter fitting on the R/O faucet.

5. R/O Tank Connection: KR10: Connect the 3/8”

blue tube on the back of the post-filter bowl

(from the tee fitting) to the push-in ball valve

on top of the R/O storage tank. KR15: Connect

the 3/8” blue tube on the front of the post-filter

bowl (from the tee fitting) to the push-in ball

valve on top of the R/O storage tank.

STEP 7 SYSTEM START-UP PROCEDURES

Turn your sink cold water supply valve to the on

position while leaving the Filter Pac/R/O module and R/O tank ball valves in the off position

(horizontal, which is perpendicular to the valve).

Check for leaks and adjust as necessary.

1. Slowly turn Filter Pac/R/O module ball valve

to the on position (blue valve vertical, which

is in line with the valve). As water enters the

filter bowls and makes its way through the filters to the membrane element you will hear

air escaping through the drain. This is normal.

Open R/O faucet on the sink until the water

starts coming out. (Water flow will only be a

trickle and may take up to 20 minutes before

water starts to come out of the faucet spout on

some units). Shut R/O faucet off and check for

leaks and adjust as necessary.

FIGURE 2

Faucet supply from R/O system

NO DIPS IN LINE

C (Red line connects to R/O drain line)

D

8

| Krystal Pure™ | Reverse Osmosis System Manual

2. Open the tank ball valve by turning handle a ¼

turn toward the tubing. Let tank fill for 4 to 6

hours (if you are changing filters, your tank may

already be full, so you would not need to wait).

Then turn on R/O faucet and drain tank completely, (approx. 5 minutes). Shut R/O faucet

off, allow tank to refill, and drain again in 4 to

6 hours. The R/O system is shipped with a food

grade preservative and must be flushed out prior to use. DO NOT DRINK THE R/O WATER

UNTIL TANK HAS BEEN DRAINED TWICE.

3. Shut R/O faucet off and let system fill again.

R/O water is now ready for use.

IMPORTANT: Check carefully for small leaks every

few hours for the first few days to assure there are

no leaks. It is wise on any R/O system to inspect for

leaks since the system sits unseen underneath your

sink and a small leak may not be detected without close inspection. Check for leaks occasionally

thereafter and make adjustments as necessary

STEP 8 REFRIGERATOR ICE MAKER

HOOK UP

1. If there is not an ice-line from the R/O to the

refrigerator, you may choose to run an ice-line

so that your ice and water dispenser will have

filtered water. If the distance from the refrigerator to the R/O is more than 50 ft., we recommend 3/8” polypropylene or polyethylene

tubing for best results. DO NOT USE COPPER

(Be sure you have the recommended water

pressure to your ice maker according to the

refrigerator manufacturer’s specifications.) 3/8”

tubing, a supplemental storage tank, more R/O

air pressure, or different usage patterns, may be

required to supply adequate pressure!

2. Connect tube (not included) to appropriate refrigerator connection and to a plastic “T” fitting

(not included) spliced into the 3/8” blue tube

between the post filter and faucet. It is recommended to install a ball valve on the tube to the

refrigerator for service and start up purposes.

Keep ball valve off until start up procedures are

completed and R/O tank is completely full after

the second tank draining.

IMPORTANT: Never turn on icemaker before

R/O tank is full of water to avoid damaging refrigerator solenoid. If your refrigerator has a water

dispenser in the door, upon initial start-up you

will need to depress the water supply lever 2 to 3

minutes before the water will dispense.

STEP 9 RECOMMENDED FILTER

SERVICE LIFE

The types of filters listed below vary depending

on R/O system style. The manufacturer provides

very high capacity carbon filters and replacement intervals are based on our filters. Other

filters may not have the same capacity as original factory filters and may not last as long. Water

conditions vary greatly by region and can affect

filter change intervals. For filter change interval

recommendations, follow the guidelines below.

If in doubt, contact the manufacturer.

Sediment Pre-filter: These are the only filter(s)

that you can visually inspect. They are white

when new and will turn dark with dirt and sediment when changing is necessary. A water softener will extend the life of the filter(s). Inspect every 6 months or sooner in bad water conditions.

Carbon Pre-filter: These filters should be

changed at least once a year. Changing these filters is necessary to help insure membrane life and

water quality. Use of high capacity carbon block

filters is recommended. Granular carbon filters

are not recommended because they release excessive carbon fines at initial start-up, which can

reduce the life of the membrane element.

R/O Membrane: The R/O membrane element is

a replaceable component critical for effective reduction of TDS (Total Dissolved Solids). The R/O

membrane should be changed when TDS rejection

rate falls below 75%. The rejection rate should be

tested periodically to insure optimal performance.

The membrane typically lasts 2-5 years depending

on influent water quality and hardness. See performance indicator information listed below.*

Carbon Post-filter/Carbon M.A.P.™ Filter: These

filters need to be changed at least every 12

months to insure quality water. Do not wait until

taste is a problem.

*Performance indicator. The R/O system contains

a replaceable treatment component critical for effective reduction of TDS (Total Dissolved Solids).

The product water shall be tested periodically to

verify that the system is performing properly. Testing can be accomplished by contacting the service

company that installed your R/O system or an authorized dealer. If a service company is not available in your area a water sample may be sent to

AmeriFlow™ for a free TDS test of your R/O water.

Additionally a water quality monitor is available

for purchase from the manufacturer that will allow

the product water to be tested at home.

To send water samples for TDS testing to the manufacturer do the following. Using 2 clean containers put approximately ½ cup of tap water in one

9

container and ½ cup of R/O product water in the

other container. Send both samples to the manufacturer along with your contact information.

To order replacement filters or locate a source

in your area call the factory: AmeriFlow™ Water

Systems Inc. (602) 275-4188.

STEP 10 FILTER CHANGING PROCEDURES

Sediment and Carbon: Turn Filter Pac/R/O mod-

ule ball valve to off position. Turn tank ball valve

off. Turn on R/O faucet to help de-pressurize

system. Unscrew filter bowls by turning counter-clockwise. Remove old filters and discard.

Clean filter bowls if needed in warm, soapy water. Insert new filters into appropriate filter bowls.

Make sure O-ring at top of filter bowl is clean, lubricated and seated properly when tightening. If

changing the post filter, do so now following the

same procedure as the pre-filters. Follow Step 7:

System Start-Up Procedures. Check for leaks and

adjust as necessary.

R/O Membrane: Turn R/O tank and water supply

off. Turn on R/O faucet to help de-pressurize system. Disconnect white tube going into membrane

housing. Unscrew end cap of membrane housing. Have a towel and a bucket handy because

some water will pour out. Pull out old membrane

and clean membrane housing if necessary with

warm, soapy water. Insert new membrane in the

same direction as old membrane. Push firmly up

to properly seat R/O membrane. Replace end cap

and reconnect white tube to membrane housing.

Follow Step 7: System Start-Up Procedures. System should be sanitized each time the membrane

is changed. (See Recommended Sanitizing Procedures). Test TDS (Total Dissolved Solids) rejection rates and be sure the rates are over 75%. A

TDS monitor is optional on some models and included on others. If your unit did not come with

a monitor, you can order one or seek advice from

a local water treatment service company. A new

membrane should perform between 90-98% TDS

removal. Check for leaks and adjust as necessary.

STEP 11 RECOMMENDED SANITIZING

PROCEDURE

The manufacturer recommends having your system professionally sanitized once a year. The best

time to sanitize is when changing all the filters

and/or when changing the membrane.

1. Drain all water from R/O tank by turning on

R/O faucet until water stops flowing. Follow

Filter Changing Procedures (assuring ball

valve on tank and Filter Pac/R/O module

are in off position). Remove old pre-filters

and membrane from housings. Remove the

post-filter from the filter bowl canister.

2. Carefully put 2 capfuls of household bleach

into the empty filter bowl canisters. Re-install

filter bowls without filters. CAUTION: Be careful not to splash bleach on hands or surfaces.

3. Turn water supply on (open ball valve on

tank and R/O module) and let system fill for 4

minutes with tap water. Shut system off. Turn

R/O faucet on until water comes out and then

shut it off.

4. Let entire system sit for about 30 minutes

to sanitize. Then turn on R/O faucet and let

system drain until empty. Turn off water supply valves and empty water in filter bowls.

Re-install filter bowls. Turn the water supply

on again. Turn off faucet and let system refill with tap water as before. Drain again. Install new filters following the Step 10: Filter

Change Procedures. Follow Step 7: System

Start-Up Procedures.

STEP 12 SERVICE AND MAINTENANCE

RECOMMENDATIONS

All Reverse Osmosis systems require periodic

maintenance to insure the continuation of wa-

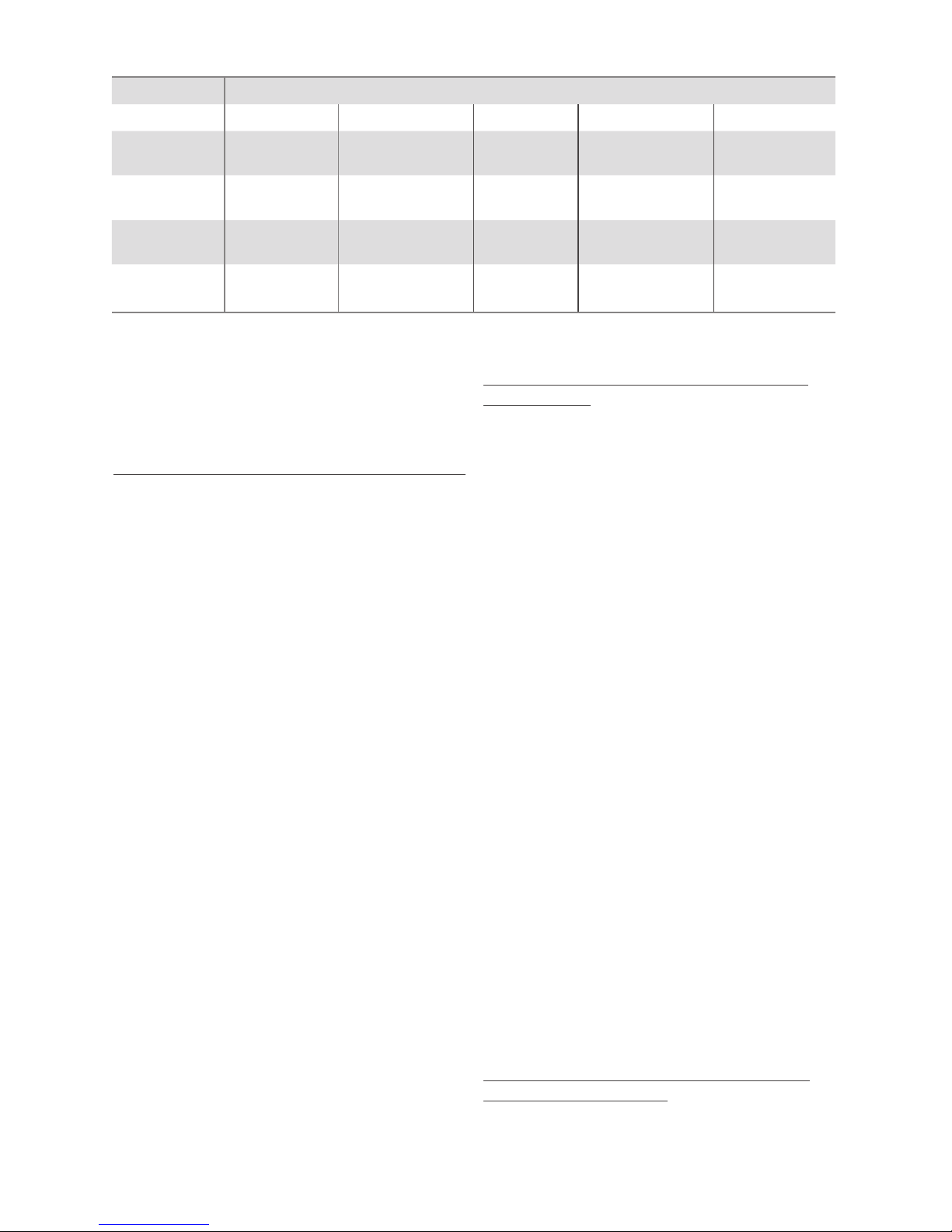

FILTER REPLACEMENT LIST

Part Numbers

R/O Model PRE SEDIMENT PRE CARBON MEMBRANE M.A.P.™ CARBON POST CARBON

KR5 N/A CB05 #135-1210-1 TFC-24 #138-

124-1

N/A CB #135-1210-2

KR10 P1 #136-1110-1 CB05 #135-1210-1 TFC-24 #138-

124-1

N/A CB #135-1210-2

KR15

N/A

CB05 #135-1210-1 TFC-24 #138-

124-1

CB-A #135-1210-2 CB #135-1210-2

Replacement

Frequency

6mo. - 1yr.

1 yr. 2-5 yrs. 1 yr. 1 yr.

10

| Krystal Pure™ | Reverse Osmosis System Manual

ter quality. Test TDS rejection rates at least every 6 months. Changing filters is important for

continuous good water quality. Filters need to

be replaced at recommended intervals as old filters may retain a considerable amount of debris

and contaminants. Failure to change filters, use

of lower quality filters, or improper sanitization

can dramatically reduce membrane life and water quality. DO NOT WAIT UNTIL YOUR WA-

TER TASTES BAD TO REPLACE YOUR FILTERS.

Remember most contaminants do not have a foul

taste except in extreme quantities. Testing the

check valve, flow restrictor, incoming water pressure, water hardness, and TDS levels periodically

are important to help extend membrane life and

overall water quality. Your local water professional can easily perform these tests. Failure to follow

proper maintenance instructions, use of filters

or parts other than those recommended by the

manufacturer, or use of an unauthorized service

agent may void your warranty.

REPLACEMENT PARTS LIST: KR5 • KR10 • KR15

Qty. Part No. Description Qty. Part No. Description

1 103-0504 Easy Tap Adapter 1 805-70-06 Fitting Union 3/8” JG Tee

1 419-1404-1 ¼” JG 90 Ball Valve 1 805-S10-06 Fitting ¼” mpt × 3/8” stem

1

805-S10-04

Fitting ¼” mpt × ¼” stem 2 805-40-06 Fitting ¼” mpt × 3/8” JG

Elbow

2

804-11-04

¼” Hex Nipple 1 125-124 R/O Faucet, Specify Color

1

419-1406

3/8” JG 90 Ball Valve, Storage

Tank

1 805-25-04 Faucet Adapter 3/8” ×

7/16” fpt

3

805-40-02

Fitting ¼” mpt × ¼” JG Elbow 1 805-15-04 ¼” Union JG

1

123-541

Water Conservation Shut-Off

Valve

1 124-462 Drain Saddle Clamp

1

128 - 00

R/O Membrane Housing 3 127-1101 Filter Bowl Canister

1

128 -R

O-ring, Membrane Housing 3 127-1R O-ring, Filter Bowl canister

2

805-40-04

Fitting 1/8” mpt × ¼” JG Elbow 6 805-LC-06 3/8” Locking Clip JG

1

121-1604-1

Check Valve Fitting 1/8” mpt ×

¼” JG Elbow

12 805-LC- 04 ¼” Locking Clip JG

1

129 -260

Flow Restrictor, 260 mL 2 122-321 Clips, Membrane

1

110-03181

3.2 Gallon Storage Tank 1 120 -131 Bracket

1

805-40042

Fitting 3/8” stem × ¼” JG

Elbow

TROUBLE SHOOTING GUIDE

PROBLEM CAUSE SOLUTION

Cloudy ice

cubes or milky

colored water.

Bad membrane. Replace Membrane and sanitize when below 75% rejec-

tion.

Water supply. High oxygen content.

Refrigerator. Some refrigerators freeze differently, leaving the ice cube

looking cloudy. Let cube dissolve in glass of water. If just

air, will float to surface and dissipate.

System is still new. This is normal and should clear up in two weeks

Loading...

Loading...