KRUEGER CRFF-E, CRFF-E-ARS, CRFF-E-ARSM Maintenance Manual

INSTALLATION,

OPERATION &

MAINTENANCE

Fan Filter Units

CRFF-E, CRFF-E-ARS,

& CRFF-E-ARSM

ECM Motors

Revision: 02.01.17

Installation, Operation, & Maintenance for CRFF-E Series

Krueger | 1401 N Plano Rd | Richardson, TX 75081 | 972.680.9136 | kruegerinfo@krueger-hvac.com | www.krueger-hvac.com

Page: 2 of 26

Table of Contents

Critical Operations of the Fan Filter Unit...................................................................................................................3

Warnings.......................................................................................................................................................................3

Installation ....................................................................................................................................................................4

Unit Control Box ..........................................................................................................................................................5

Universal Control Card Set Up...................................................................................................................................6

Troubleshooting ........................................................................................................................................................11

Infrared Speed Controller .........................................................................................................................................12

Pre-filter Cleaning (foam) ..........................................................................................................................................13

Service: Removal and Replacement of CRFF-E filters...........................................................................................14

Service: Removal and Replacement of Roomside Replaceable Filters.................................................................15

Service: CRFF-E & CRFF-E-ARS Motor Removal and Installation........................................................................16

Service: CRFF-E-ARSM Motor Removal and Installation.......................................................................................17

Technical Note: TN1004 Changing Motors in the Field..........................................................................................18

Technical Note: TN1002 Design with VAV Boxes....................................................................................................18

Unit Wiring Diagrams.................................................................................................................................................20

Unit Replacement Parts List.......................................................................................................................................23

Drawing - CRFF-E Filter..............................................................................................................................................24

Drawing - CRFF-E-ARS & CRFF-E-ARSM Filter........................................................................................................25

Testing.........................................................................................................................................................................26

Krueger | 1401 N Plano Rd | Richardson, TX 75081 | 972.680.9136 | kruegerinfo@krueger-hvac.com | www.krueger-hvac.com

Installation, Operation, & Maintenance for CRFF-E Series

Page: 3 of 26

Critical Operation Conditions of the CRFF-E, CRFF-E-ARS and CRFF-E-ARSM

1. Touching of the HEPA filter could damage it, voiding the warranty on the filter. The screen is only to protect

against an accidental ‘touch’ of the filter. Never place a hand or tool on the filter. Never lay the filter face flat

down on a surface always have filter on its side or back to protect from damage

2. Prior to powering the unit, verify that the unit has been plugged into the correct voltage. The serial number label

on the top of the CRFF-E, CRFF-E-ARS and CRFF-E-ARSM unit has the required voltage.

3. For reorder purposes the CRFF-E, CRFF-E-ARS and CRFF-E-ARSM model number, configuration code and

serial number should be recorded. This information is located on the product and serial number labels, located

adjacent to the electrical box. If you cannot locate the FO# please contact Krueger for this information.

Read and Save These Instructions

!

To reduce the riskkof fire, electrical shock, or injury to persons, observe the following

1. Installation work and electrical wiring must be done by qualified person(s) in accordance with all applicable code

and standards, including fire-rated construction

2. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

3. If this unit is to be installed over a tub or shower, it must be marked as appropriate for the application.

4. Use this unit only in the manner intended by the manufacturer. If you have any questions, contact the

manufacturer:

5. Before servicing or cleaning unit, switch power off at service panel and lock service panel to prevent power from

being switched on accidentally.

Note: Units come set in manual mode from

the factory. Please review installation

requirements and set up with your end user

(See page 7 for complete set up instructions).

Krueger | 1401 N Plano Rd | Richardson, TX 75081 | 972.680.9136 | kruegerinfo@krueger-hvac.com | www.krueger-hvac.com

Installation, Operation, & Maintenance for CRFF-E Series

Page: 4 of 26

Installation

The CRFF-E Series Critical Room Fan Filter Units are completely assembled at the factory with the exception of the

optional ¼” (0.64 cm)-20 eyebolts, which can be used when hanging the unit from an overhead structure.

1. Carefully remove the unit from the shipping carton and inspect for any damage that may have occurred during

transportation. (See Figure 1)

Note: When ordering CRFF-ARS and CRFF-ARSM units, the HEPA filters may be shipped separately to be

installed into units after the fan box has been installed.

Recommendation: Review mode settings at this time as specified for installation (see page 7 for controls).

2. If using rigidly supported grid (usually 2” or wider), raise unit through ceiling and lower onto the gasketed grid. If

using a flexible grid (typically supported with wires) the unit must be secured to an overhead structure with

eyebolts, s-hooks and chain. Screw the four eyebolts into the nutserts on the lid assembly before lifting into an

overhead position (see Figure 2)

3. Have an electrician wire the unit to the appropriate voltage (115V, 220V, 277V AC), according to the wiring

diagram and all national and local electric codes. All units are equipped with a three position terminal block for

field connection. Verify correct single phase power, before energizing units.

4. Turn on the power using the two position rocker switch (ON/OFF) located on the electrical box. For the CRFFARS and CRFF-ARSM units, let the unit fur for a few hours to purge off particulate (if filters are shipped loose)

that may adhere to the inside of the unit before installing the filters. Do not run fan at full speed as this may cause

overload condition.

Note: Your fan filter may have been shipped separate. Controls have been shipped separately.

FIGURE 1 - UNBOXING FIGURE 2 - HANGAR SUPPORTS

EYEBOLT

FAN FILTER

UNIT

Krueger | 1401 N Plano Rd | Richardson, TX 75081 | 972.680.9136 | kruegerinfo@krueger-hvac.com | www.krueger-hvac.com

Installation, Operation, & Maintenance for CRFF-E Series

Page: 5 of 26

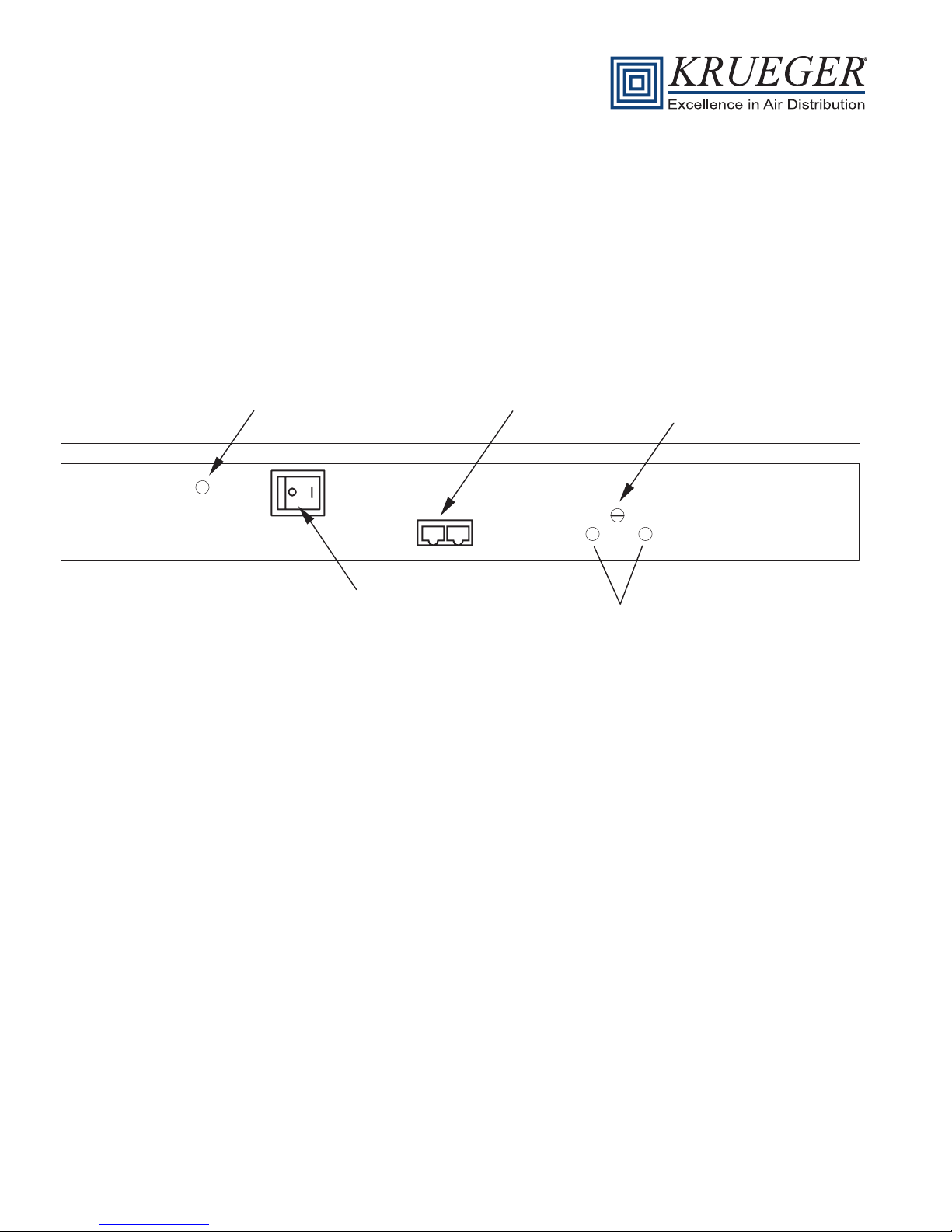

ON/OFF Switch - Speed/Airflow Adjustment

All CRFF-E series units are equipped with a two-position rocker switch (ON/OFF), which is located on the side of the

electrical box, on top of the unit. Unless otherwise specified, units are furnished with a Universal Control Card to

enable adjustment of airflow or set to preferred communication mode.

Note: The CAT5e/RJ45 network ports are non-directional (in or out). Be sure to examine your cabling to insure that

there is no cross-over wired cables.

Filter Indicator Light

Pressure Switch Adjuster

ON/OFF Switch

CAT 5e

Network Cable Connection

(RJ45 Connector)

RPM Test Probe Jack Comm.

Manual Speed Potentiometer

Filter Indicator Light Option

The pressure switch for the filter indicator light option is set at 0.60 in wc from the factory. The set point for the

pressure switch can be adjusted between 0.50 in wc and 3.00 in wc by turning the set screw, accessible for the front of

the control enclosure. Counterclockwise rotation will increase the set point differential for switching; clockwise rotation

will reduce the set point.

The process to adjust this for a specific application is detailed below:

1. Adjust fan to highest setting

2. Measure and note initial pressure differential between ceiling plenum and unit plenum (downstream of the fan

and upstream of the filter)

3. Restrict discharge airflow incrementally to increase differential pressure until measured value matches filter

loading requirements for the project

a. If no specific filter loading requirements are specified a general recommendation is to use twice the

pressure differential measured in step 2

4. With the unit discharge blocked, adjust the set point of the pressure switch

a. If the indicator light is illuminated, increase the set point of the pressure switch (CCW rotation) until the

light dims

b. If the indicator light is still dim, slowly decrease the set point of the pressure switch (CW rotation) until the

light illuminates

5. Remove obstruction(s) from the unit discharge

6. Adjust fan speed to operational set point

Krueger | 1401 N Plano Rd | Richardson, TX 75081 | 972.680.9136 | kruegerinfo@krueger-hvac.com | www.krueger-hvac.com

Installation, Operation, & Maintenance for CRFF-E Series

Page: 6 of 26

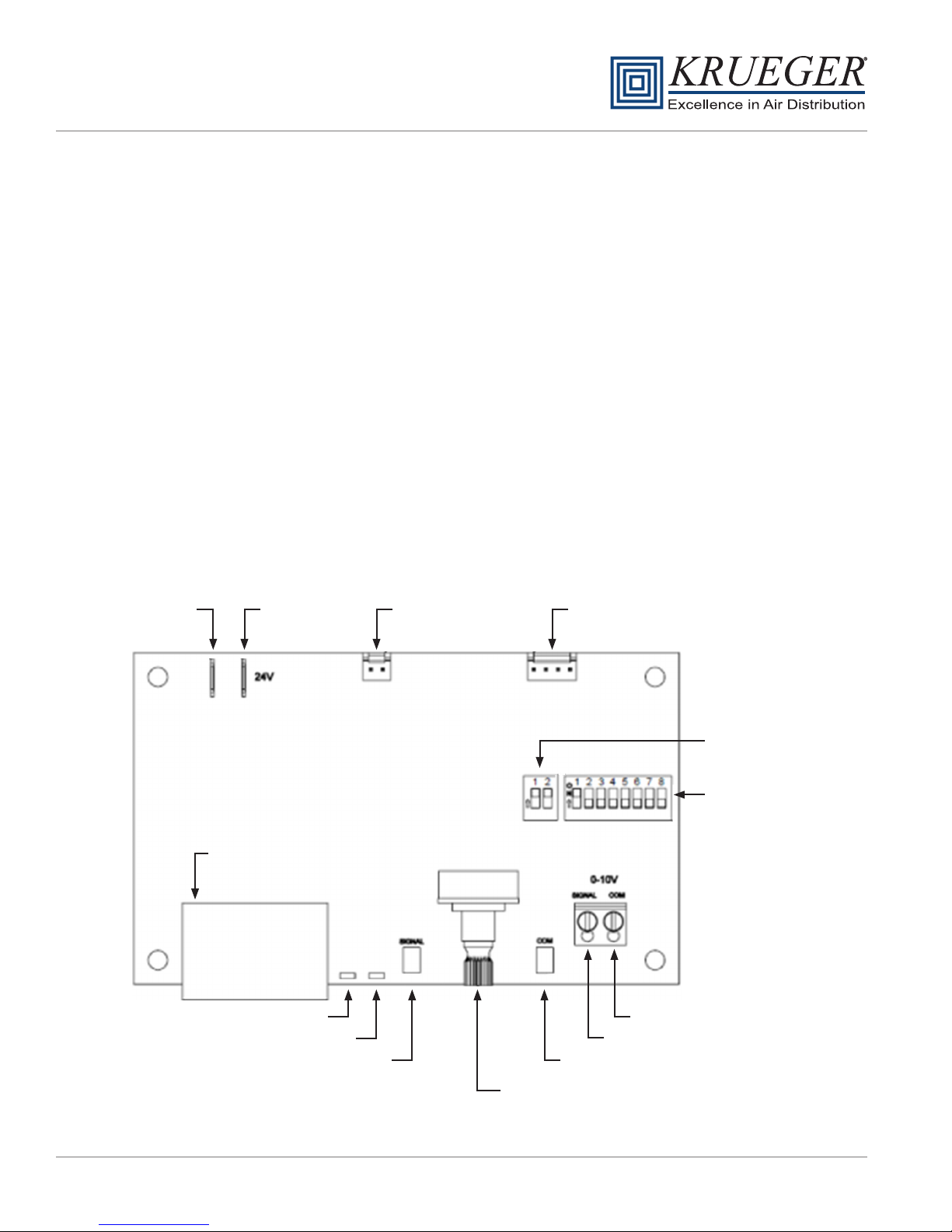

Universal Control Card Set Up (ENV1028)

CON4 UNIVERSAL CONTROL CARD - OVERVIEW

Krueger's ENV1028 Universal Control Card

provides MODBUS network and analog control

capabilities to a Krueger Fan Filter Unit equipped

with an electrically commutated motor. Three different

control modes provide installation versatility by allowing

the FFU to be controlled via MODBUS RTU network,

analog 0-10 VDC control signal, or by adjusting the

on-board potentiometer. The ENV1028 Universal

Control Card is fully compatible with all of Krueger’s

plug & play System Control Consoles using MODBUS

RTU. Additional details of the controls modes

are provided on page 7.

FIGURE 7: UNIVERSAL CARD OVERVIEW

COMMON INCOMING

POWER

24VAC

LED

CONNECTOR

FEATURES

+ Networkable Via MODBUS RTU

+ 0-10 VDC Analog Control

+ Manual Control Via Onboard Potentiometer

+ Simple Connections

- RJ45 For Networking Connection

- Screw Terminals For Analog Control

- Test Probe Jacks For DC mV Signal Output Of The Following:

- RPM

- Motor Control Set Point

+ LED Diagnostics

- Support for external LED (10mA) remote status notification via

2 Pin MTA connector

- On-board green LED for Board Status notification

- On-board red LED for Network Traffic

+ Powered from Network or Local Supply

CONTROL HARNESS

CONNECTOR

DUAL RJ-45 JACKS

FOR CAT5 CABLE

RED LED FOR NET ACTIVITY

GREEN LED FOR SYSTEM/RPM STATUS

CONTROL

DIP SWITCH

ADDRESSING

DIP SWITCH

ANALOG INPUT “COM”

ANALOG INPUT “SIGNAL”

RPM TEST PROBE JACK “COM”RPM TEST PROBE JACK “SIGNAL”

MANUAL SPEED POT

Krueger | 1401 N Plano Rd | Richardson, TX 75081 | 972.680.9136 | kruegerinfo@krueger-hvac.com | www.krueger-hvac.com

Installation, Operation, & Maintenance for CRFF-E Series

Page: 7 of 26

Control Modes

The ENV1028 operates in one of three selectable modes.

The Mode is selected using the control DIP switch; MANUAL

control (on-board potentiometer), ANALOG control

(Remote 0-10 VDC), NETWORK control (MODBUS RTU).

The ENV1028 is shipped from the factory in NETWORK

control mode.

Manual Control Mode

In Manual control mode, the motor speed is set using the

onboard potentiometer. Onboard potentiometer rotation is

CW to increase the motor output.

Analog Control Mode

In ANALOG control mode, the motor output is set using an

external 0-10 VDC demand signal.

Network Control Mode

In NETWORK control mode, the motor output is set using

MODBUS Register 2. Motor output is specified as a value

from 0 to 100 representing a percentage of motor torque

output. Each ENV1028 in a MODBUS network must be

set to a unique address. The address value is set in

binary using the eight DIP switches of switch band (S2).

A maximum of 200 ENV1028 devices is recommended

per local area network (LAN).

NetworkkControl Mode (cont)

If a Krueger ACC Control Console is the MODBUS

master, then addresses should be assigned within the

address range supported by the Control Console.

Address zero should not be used as it is reserved for

global commands. Address switch settings are only

checked by the ENV1028 at power-up. Power must be

cycled (OFF/ON) before any changes take effect.

Registers relevant to this mode:

• Register 1 “Start/Stop” (R/W)

– To enable motor, write a value of 1; To disable

motor, write a value of 0

• Register 2 “Motor Set Speed” (R/W)

– Motor Target speed value. Values may be written

from 0 to 100

• Register 6 “RPM” (R)

– Motor RPM. Read from the motor

• Register 12 “Actual Motor Speed Instruction” (R)

– Speed control signal applied to the motor by the

ENV1028. (R/W) = Read/Write, (R) = Read Only

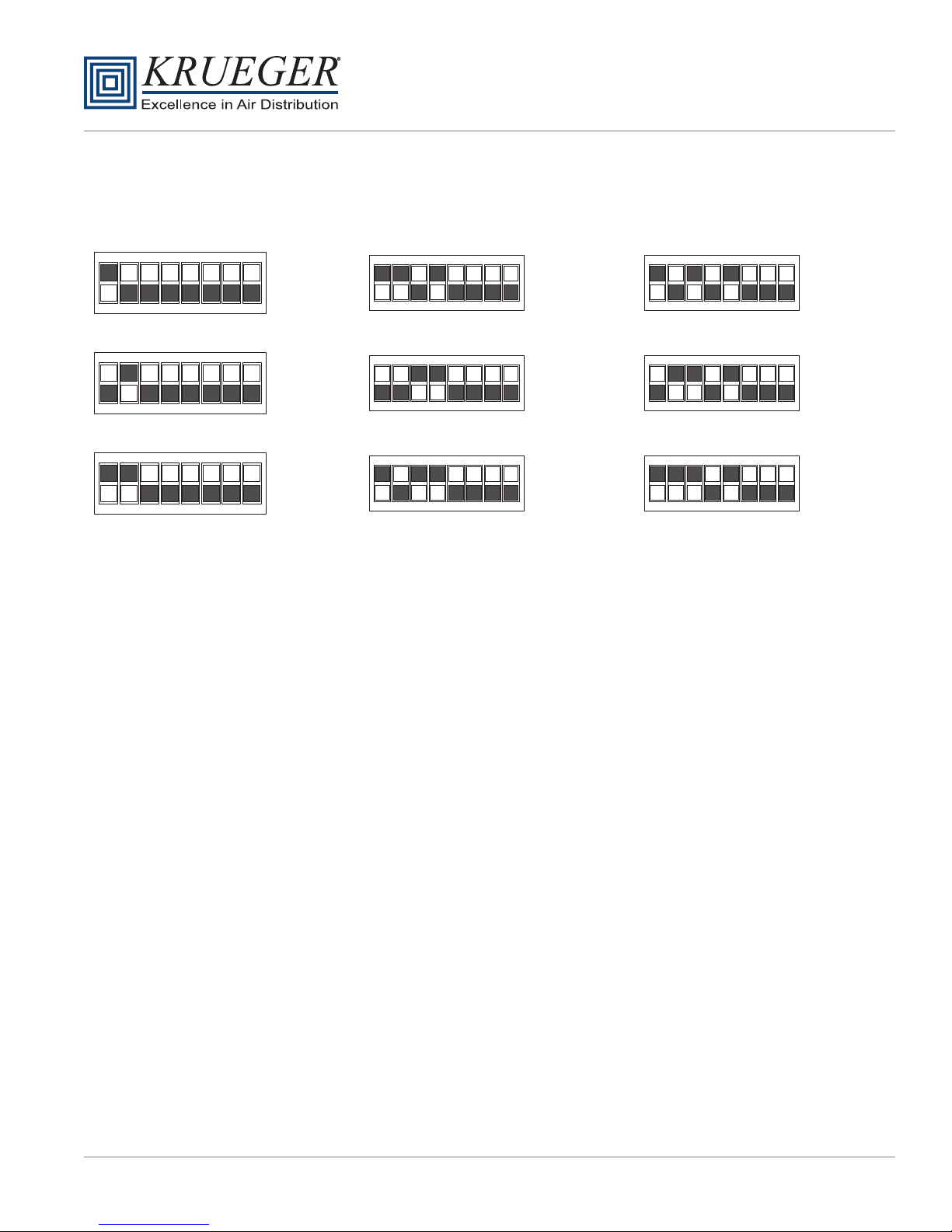

Manual Mode = 1 OFF 2 OFF

ON ADE02

O

N

1

2

Analog Mode = 1 ON 2 OFF

ON ADE02

O

N

1

2

21 3 4 5 6 7 8

21 3 4 5 6 7 8

Network Mode = 1 OFF 2 ON

ON ADE02

21 3 4 5 6 7 8

O

N

1

2

Network Mode = 1 ON 2 ON

ON ADE02

21 3 4 5 6 7 8

O

N

1

2

Note: Network mode can be configured using either DIP switch setting shown

above. DIP switch pictorials are for reference and may be labeled differently by

the manufacturer.

Krueger | 1401 N Plano Rd | Richardson, TX 75081 | 972.680.9136 | kruegerinfo@krueger-hvac.com | www.krueger-hvac.com

Control Modes (continued)

Installation, Operation, & Maintenance for CRFF-E Series

Page: 8 of 26

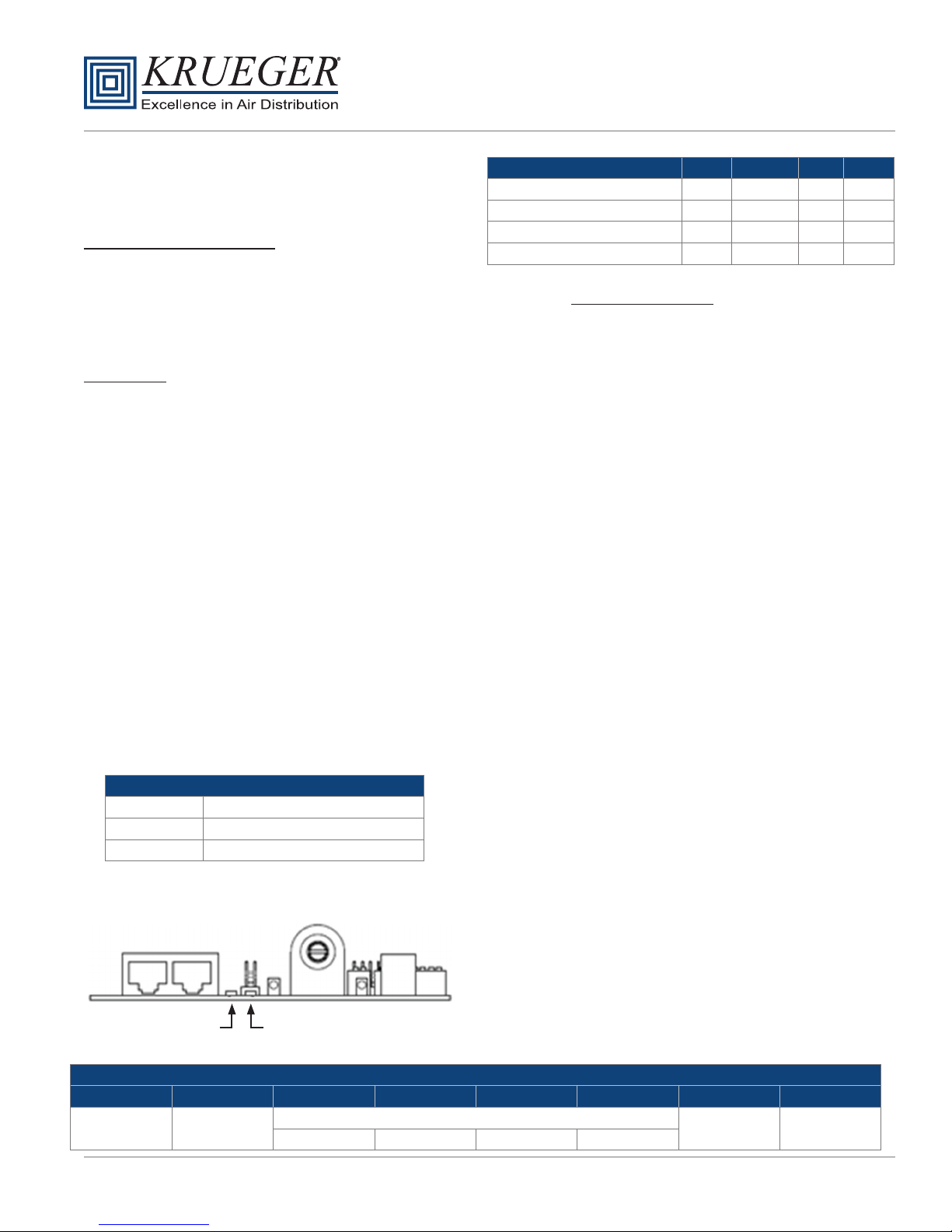

ON DIP

5 61 2 3 4 87

ON DIP

3 1 2 4 5 6 7 8

ON DIP

1 2 3 4 5 6 7 8

1

2

3

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

Example of binary S2 switch settings

DIP

11

DIP

12

DIP

13

ON

1 2 43 5 6 87

ON

21 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

DIP

DIP

DIP

21

22

23

Installation, Operation, & Maintenance for CRFF-E Series

Krueger | 1401 N Plano Rd | Richardson, TX 75081 | 972.680.9136 | kruegerinfo@krueger-hvac.com | www.krueger-hvac.com

Page: 9 of 26

Electrical Specification

Control and Interface Signals

External Speed 0-10V Input

• Input impedance 20k0hms.

Specificatio Min Typical Max Units

Input Voltage 22 24 42 VAC

Supply Frequency 50 50 / 60 60 Hz

Input Power Consumption n/a n/a 0.5 VA

Ambient Operating Temperature 0 25 50 C

• MIN ON-to-OFF threshold: 190mV*

• MAX OFF-to-ON threshold: 240mV*

External LED Output

• ON (-215mV) to 9.89V linearly scales 1 to 99% speed.

• 9.89V or more deadbands to 100% speed.

RPM Signal

• Signal Value: mVDC = RPM

• Ex: 900mV = 900RPM

• RPM Output Range: - 0, 5 to 2000 RPM (0, 5mV to 2000 mV DC)

• RPM Output Resolution: 5RPM (zero, 400 steps from 5 to 2000 RPM inclusive)

Test Probe Jack Points

The test probe jacks may be used to measure the motor

rpm or the PWM signal that is being output to the motor.

• In Manual or Analog Control Mode with an Address

setting of 1 or greater, the test probe jacks output

0-2000 mVDC representing motor RPM. By changing

the address DIP switches to 0, the test probe jacks will

output 0-1000 mVDC representing 0-100% demand

signal to the motor. The address may be changed

without interrupting power to the control card.

• In Network Control Mode, 0-2000 mVDC always

represents RPM.

Net LED Status Definitio

Green LED OFF

LED Flickering

Green LED ON

Power lost or no communications.

Network data traffic in progress

A/B network cables are swapped.

FIGURE 9: LED LIGHT LOCATIONS

LED Indicators

• Onboard Status LED:

The Onboard Status LED is software controlled

by the unit microcontroller. The Status LED is solid

ON when RPM reported by the motor is greater than

zero and OFF when RPM reported by the motor is

zero.

• External Status LED:

Support for an external Status LED (10mA currentcontrolled driver), via a 2-pin MTA connector, for

remote system status notification. The external Status

LED operates in the same manner as the Onboard

Status LED.

• Onboard Net LED:

The Onboard Net LED is driven directly by the receive

data signal. The NET LED shows all network traffic on

a 2-wire network. The NET LED is intended to

confirm low-level network connectivity,

independent of microcontroller or firmware

functionality. If A/B network wires are swapped, the

NET LED will be normally on, providing quick

diagnostics of this common condition.

• 10mA regulated.

• LED forward voltages up to 5V.

RED NETWORK LED GREEN STATUS LED

1 2 3 4 5 6 7 8

Bus Power

Pass Through

0V (GND)

RJ45 Network Cable Connections

RS-485

+ NC NC -

0V (GND)

Bus Power

Pass Through

Loading...

Loading...