K+R Performance Engineering, Inc.

PRO-CUBE

Ò

INSTALLATION AND OPERATING MANUAL

Congratulations on your purchase of the most advanced combination delay box/timer unit available for

today’s precision drag racing. The PRO-CUBE Ò has been designed to give you unprecedented control of

your reaction time and ET with a host of standard features, plus options for up to three general purpose

timers, all in one super-compact unit that can be mounted almost anywhere. The precision available with

these timers makes them perfect for controlling a variety of equipment including throttle stops, shifters, and

multi-stage nitrous systems. You should read and understand this entire manual, including the warranty

section beginning on page 8, before proceeding with installation.

STANDARD FEATURES

Cross-Over: Allows you to release the transbrake switch on a slower opponent’s top bulb on a full

open tree. The delay time is automatically calculated from dial-in and delay values you enter.

Second Hit: You can enter a separate delay for hitting the tree a second time. It’s the same as

having two delay boxes in one. This feature allows you to take two shots at the tree in long crossover situations. You will launch on the faster of the two reactions.

Bump-Down Ò: This powerful feature allows you to improve late reactions by subtracting delay time

after releasing the transbrake switch. You can program the amount of time to subtract, you can

bump-down any number of times, and you can use it for either one or both hits on the tree. In

addition, this feature can be used on Timer 1 during the run. If you have a throttle stop connected to

Timer 1, the Bump-Down feature will allow you to correct for track conditions such as tire spin by

reducing the stop time.

Flinch Protection Ò: Two different methods are provided for preventing red-light disqualification when you

release the transbrake switch before the tree starts.

Run Info: If you use either the second hit or the Bump-DownÒ feature, information will

automatically be displayed to indicate the difference in your reaction times for double-hits, as well as

the number of times you bumped-down your reactions and the number of times TIMER 1 was

bumped-down. This allows you to determine what your reaction(s) and E.T. would have been had

you not used these powerful features.

Transbrake Output: High current output for use on all types of transmission brake, foot brake, and clutch

release solenoids. Handles up to 25 amp load.

Line Lock Output: This output is activated and released simultaneously with the transbrake output but

includes a blocking diode to prevent back feed into the transbrake circuit. It can be used in front

wheel line lock applications or jumpered to the Pro-Stage ä or one of the timer outputs acting as a

“launch control” when connected to a compatible throttlestop. Handles up to 2 amp load.

Transbrake Lockout: A built-in timer prevents activation of the Transbrake and Line Lock outputs for a

programmed amount of time after the transbrake releases. This timer can be set from 0 to more than

an hour. Transbrake activation is automatically re-enabled when the timer completes.

Rev 08-99

Pro Cube

K+R Performance Engineering, Inc.

Pro-Stage ä: This special output controls a Pro-Stage ä compatible throttle stop during the

staging process. Developed by Frank Hawley, the patented Pro-Stage™ system1 allows you to

stage with your foot to the floor for both Pro tree and Full tree. Provides better driver concentration,

more consistency, and reduced wear and tear on the engine and converter.

Output Protection: All outputs are fully protected against shorts and severe overloads by advanced

electronic circuit breaker technology. Faulty outputs are indicated by flashing light on the front

panel, allowing fast diagnosis and correction of system problems.

OPTIONS

1 Timer: 4 stages (2 on/off cycles), first on/off cycle adjustable from 0.000 - 9.999 seconds, second

on/off cycle adjustable from 0.00 - 39.99 seconds. Bump-Down Ò can be used during the

run to make minor adjustments to your settings.

2 Timers: Timer 1 is same as above. Timer 2 has 2 stages (1 on/off cycle) adjustable from 0.00 - 39.99

seconds.

3 Timers: All 3 timers have 2 stages (1 on/off cycle each). Timer 1 adjustable from 0.000 - 9.999

seconds, timer 2 and 3 adjustable from 0.00 - 39.99 seconds.

SPECIFICATIONS

Overall Dimensions (H x W x D): 4.3" x 4.7" x 2.95"

Weight: 1.3 lbs

Power Supply Voltage: 10 - 18 Vdc

Power Supply Input Current (no outputs activated): 0.08 Amps

Output Current, Transbrake: 25 Amps for 1 minute

Output Current, Line Lock: 2 Amps continuous

Output Current, Timers and Pro-Stage ä: 10 Amps continuous

INSTALLATION

1. Mount the unit in a convenient location where you can easily read the display and reach the front

panel when strapped in the driver’s seat.

2. Refer to the wiring diagram for electrical connections.

3. IN ORDER TO DAMPEN VIBRATION, THE UNIT MUST BE MOUNTED USING THE THREE

RUBBER MOUNTS LOCATED ON THE BACK. SUFFICIENT CLEARANCE SHOULD BE

MAINTAINED ALL AROUND THE UNIT SO THAT IT DOESN’T VIBRATE AGAINST ANY

SURROUNDING METAL. NOTE: RUBBER MOUNTS ARE NOT REMOVEABLE.

4. FOR THRU-DASH INSTALLATIONS ALLOW CLEARANCE BETWEEN DASH AND UNIT AND

USE FIRM RUBBER MOLDING TO FILL THE GAP. THE UNIT MUST FIT SNUG IN OPENING.

5. ALWAYS COMPLETELY DISCONNECT THE UNIT BEFORE ANY WELDING IS DONE ON

THE CHASSIS.

1

Pro-Stage™ is protected by US Patents 5,839,419 and 5,855,196.

! Important

2

Pro Cube

what each output is doing.

wiring or equipment problems.

K+R Performance Engineering, Inc.

HOW TO SELECT AND CHANGE SETTINGS

Two three-position switches are used to select the various screens. These switches may be left in any

position while racing, they simply select what is being displayed. The table below shows the content of each

screen and the factory default settings for a fully equipped unit. Some screens may be blank (dashes)

depending on the number of timers installed in your particular unit. Use the adjusment (ADJ) switches just

below the displays to change settings. There is one switch for each digit in the display. Note: Changes to any

of the settings are automatically and permanently saved four seconds after making the change. The decimal

points in both displays will blink to indicate when the save operation is performed. If power is turned off or

the unit is reset within four seconds after making a change, those changes will not be saved.

Lighted LCD Displays

DIAL-IN TIMER ON OPP DIAL-IN TIMER OFF

Indicator lights show you exactly

A blinking light indicates

a shorted output to help you

quickly identify and correct

Reset Switch

Instantly cancels everything

and returns all outputs

to their original state.

Same as turning power off

and back on.

DLY

YOUR

DIAL-IN

10 0 0

10 0 0

DELAY 1 BUMP-DOWN

PRO-STAGE

TRANSBRAKE

TIMER 1

TIMER 2

TIMER 3

RESET

OPPONENT'S

DIAL-IN

12 0 0

TM

Select Dial-In, Tree type, or Delay;

Timer 1, 2, or 3 (as equipped) for adjustment.

Switch can be in any position while racing.

12 0 0

DELAY 2 TB LOCKOUT

R

ADJ

PRO-CUBE

K+R Performance Engineering

DIAL-IN

TREE

INTERFACE (DOUBLE HIT) MODE

in Fcd UAL

(2 TRIGGER SWITCHES)

407-267-2393

TIMER 1

TIMER 2

TIMER 3DELAY

DLY-CFG-TMR

CFGTMR

R

TIMER 1 ON

10 0 0

Center-Sprung Toggles

A separate switch for each

digit for fast, easy adjustment

of settings. Can be held up

or down for scrolling forward

or backward.

Select Transbrake Delay,

Unit Configuration,

or Timer settings

for display/adjustment.

Switch can be in any position

while racing.

TIMER 1 OFF

2 0 0 0

FULL/PRO TREE SELECT

(TIMER VERSIONS ONLY)

FULL LrEE

DELAY 1DELAY 2

10 0 0

-

10 0 0

TIMER 1

MODE

TIMER 2

MODE

n OFFn OFF

( NORMALLY OFF MODE )

BUMP-DOWN

AMOUNT

TRANSBRAKE

LOCKOUT DELAY

0 0 10 12 0

3

TIMER 1 ON

** TIMER 2 ON

3 0 0

TIMER 2 ON TIMER 2 OFF

** TIMER 3 ON

5 0 0

** APPLIES TO 3 TIMER VERSION ONLY **

TIMER 1 OFF

TIMER 2 OFF **

4 0 0

TIMER 3 OFF **

6 0 0

Pro Cube

DUAL TRIGGER MODE

NORMALLY OFF MODE

STAGE 4

K+R Performance Engineering, Inc.

INITIAL SETUP

Single vs Dual Trigger Interface Mode:

The PRO-CUBE Ò allows you to “hit” the tree twice and launch your vehicle on the quicker of two

reactions. If you want to take advantage of this double-hit capability, you have the option of using two

separate trigger (transbrake) switches or a single switch. If you choose not to use the double-hit capability,

you only need one transbrake trigger switch connected to the TRIGGER 1 terminal.

Select either Single or Dual trigger interface mode using any right-side ADJ switch.

The amount of cross-over time you have between the first and second hit will determine

whether it’s best to use one switch or two. Using Single Trigger mode to hit both top bulbs is

generally not recommended unless you’re at least 1.5 seconds faster than your opponent.

Hitting both top bulbs with two separate switches in Dual Trigger mode doesn’t require as

much cross-over time. In Dual Trigger mode, TRIGGER 1 is always used for the first hit, and TRIGGER 2

for the second hit. In Single Trigger mode, TRIGGER 2 is ignored.

Another important difference between these two modes involves the Flinch Protection Ò feature.

Simply stated, flinch protection can prevent you from red-lighting when you accidentally release the trigger

switch before the tree starts. If this occurs using Dual Trigger mode, just press the same trigger switch again

and the delay that was started unintentionally will be reset. The delay will be restarted when the trigger

switch is released. In Single Trigger mode, however, the delay is not reset by pressing the switch again. In

this mode a known red-light situation can only be prevented by pressing and holding the TRIGGER 1 switch

until the bottom of your tree. Your vehicle will launch instantly when the trigger switch is released.

Timer Output Configuration:

Except for the 3 timer version, Timer 1 is a 4-stage output that can be cycled on and off twice. If you

want to cycle this timer on and off just once, use either pair of settings and set the other pair to 0. In the 3

timer version all three timers have 2-stage outputs that can be cycled on and off once each.

For compatibility with all types of equipment, Timers 1 and 2 can be configured for either

“normally off” or “normally on” mode. Timer 3, however, is fixed in “normally off” mode for

most common equipment and cannot be changed. Configure the timers as required for your

equipment using the front panel switches.

Note that the first on/off cycle of Timer 1 is adjustable in 0.001 (one thousandth) second increments

for very precise control. Timers 2 and 3 and the second on/off cycle of Timer 1 are adjustable in 0.01 (one

hundredth) second increments for extended down-track range (up to 39.99 seconds). Note the decimal point

location while setting timer values.

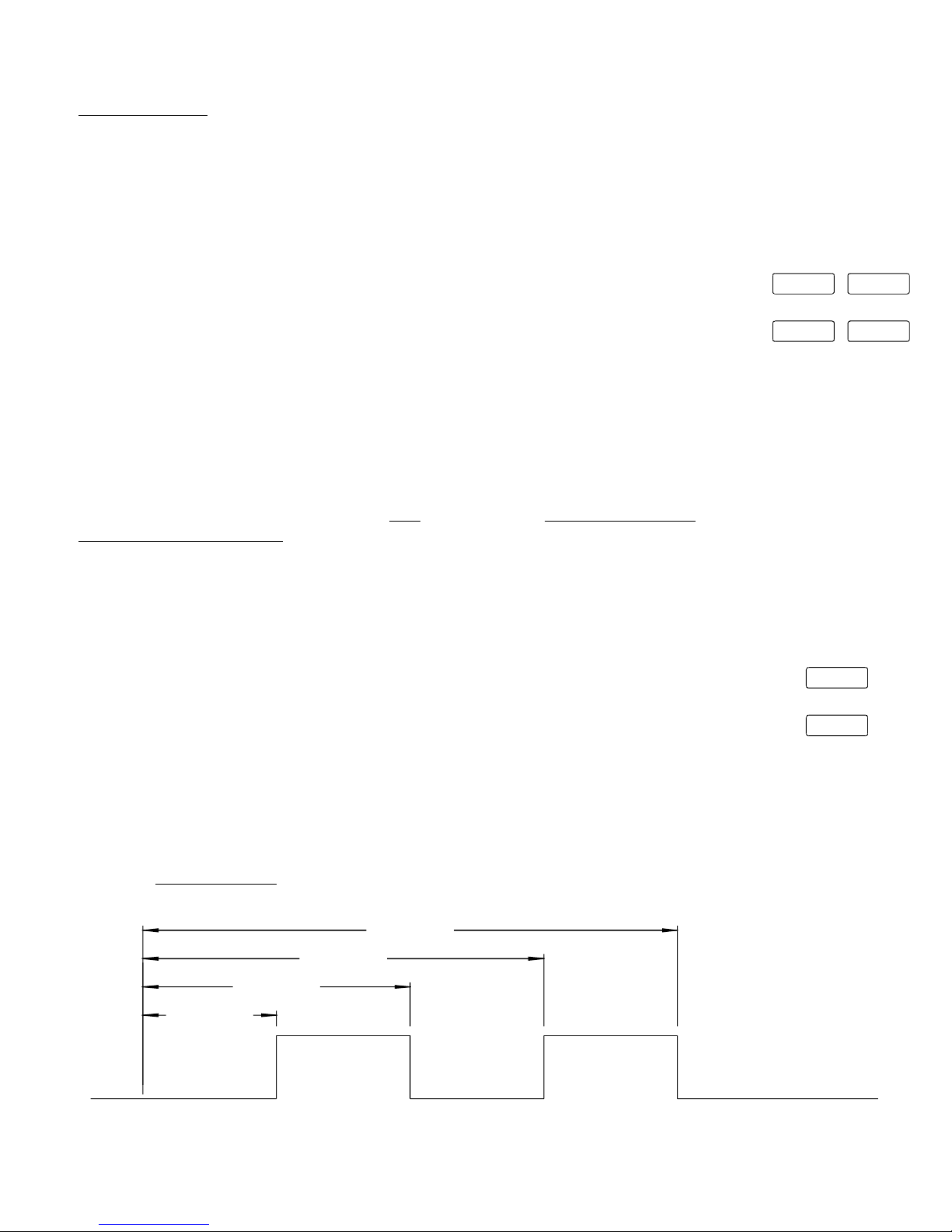

The diagram below illustrates a 4-stage pneumatic throttle stop application using Timer 1 in the

default “normally off” mode and factory settings for each stage. Note that the setting for each stage

represents time into the run, measured from launch.

in Fcd UAL

SINGLE TRIGGER MODE

in Fc

n OFF

NORMALLY ON MODE

n On

5 n 9 L

STAGE 3

STAGE 2

STAGE 1

1.000 SEC

WOT

(POWER REMOVED)

LAUNCH

2.000 SEC

3.00 SEC

THROTTLE

(POWER APPLIED)

CLOSED

4.00 SEC

WOTWOT

(POWER REMOVED)

4

THROTTLE

CLOSED

(POWER APPLIED)

WOT

(POWER REMOVED)

WOT = WIDE OPEN THROTTLE

Loading...

Loading...