Kroy Europe Ltd K6200 Series, K6300 Series User Manual

kroy

USER’S

MANUAL

K6200 (200DPI) & K6300 (300DPI)

THERMAL TRANSFER / DIRECT THERMAL

BAR CODE PRINTER

Version 1.0b: 12/09/11

1

Copyright Information

©2011 KROY & TSC Auto ID Technology Co., Ltd,

The copyright in this manual, the software and firmware in the printer

described therein are owned by TSC Auto ID Technology Co., Ltd, All

rights reserved.

CG Triumvirate is a trademark of Agfa Corporation. CG Triumvirate Bold

Condensed font is under license from the Monotype Corporation. Windows

is a registered trademark of Microsoft Corporation.

All other trademarks are the property of their respective owners.

Information in this document is subject to change without notice and does

not represent a commitment on the part of KROY or TSC Auto ID

Technology Co. No part of this manual may be reproduced or transmitted

in any form or by any means, for any purpose other than the purchaser’s

personal use, without the expressed written permission of KROY & TSC

Auto ID Technology Co.

2

Agency Compliance and Approvals

CE CLASS A

EN 55022:2006 +A1:2007

EN 55024:1998+A1:2001+A2:2003

EN 61000-4 SERIES REQULATIONS

FCC CFR Title 47 Part 15 Subpart B:2009-Section 15.107

and 15.109

ICES-003 Issue 4:2004 Class A

i

Contents

1. Introduction ............................................ 1

1.1 Product Introduction ............................................................................... 1

1.2 Product Features ..................................................................................... 2

1.2.1 Printer standard features .............................................................. 2

1.2.2 Printer optional features ............................................................... 4

1.3 General Specifications ............................................................................ 5

1.4 Print Specifications ...................................... 5

1.5 Ribbon Specifications .................................... 5

1.6 Media Specifications ..................................... 6

2. Operations Overview ..................................... 7

2.1 Unpacking and Inspection ...................................................................... 7

2.2 Printer Overview ...................................................................................... 8

2.2.1 Front View ...................................................................................... 8

2.2.2 Interior view .................................................................................... 9

2.2.3 Rear View ...................................................................................... 10

2.3 Operator Controls .................................................................................. 12

2.3.1 Front Panel Display ..................................................................... 12

2.3.2 LED Indicators ............................................................................. 12

2.3.3 Front Panel Keys ......................................................................... 13

2.4 Setting up the Printer ............................................................................ 13

2.5 Installation of Ribbon ............................................................................ 14

2.5.1 Loading Ribbon ........................................................................... 14

2.6 Installation of Media .............................................................................. 17

2.6.1 Loading Roll Labels ..................................................................... 17

2.6.2 Loading Fan-fold Labels ............................................................. 21

2.6.3 Loading Media in Peel-off Mode (Option) .................................. 22

2.6.4 Loading Media in Cutter Mode (Option) ..................................... 24

2.7 Print Head Pressure Adjustment Knob ................................................ 25

2.8 Using the Keyboard with PS/2 Interface .............................................. 26

3. Menu Function ......................................... 27

3.1 Setup Menu Overview ............................................................................ 28

3.1.1-1 Printer Setup (TSPL2) ............................................................... 29

3.1.1-2 Printer Setup (ZPL2) ................................................................. 36

3.1.2 Sensor ........................................................................................... 43

3.1.3 Serial Comm. ................................................................................ 51

ii

3.1.4 Ethernet ........................................................................................ 54

3.2 File Manager ........................................................................................... 57

3.2.1 File List ......................................................................................... 57

3.2.2 Avail. Memory ............................................................................... 58

3.2.3 Del. All Files .................................................................................. 58

3.3 Diagnostics ............................................................................................ 59

3.3.1 Print Config. ................................................................................. 59

3.3.2 Dump Mode .................................................................................. 60

3.3.3 Rotate Cutter ................................................................................ 61

3.4 Language ................................................................................................ 61

3.5 Service .................................................................................................... 62

3.5.1 Initialization .................................................................................. 62

3.5.2 Mileage Info. ................................................................................. 63

4. Diagnostic Tool ......................................... 64

4.1 Start the Diagnostic Tool ....................................................................... 64

4.2 Printer Function (Calibrate sensor, Ethernet setup, RTC setup………)

....................................................................................................................... 65

5 Setting Ethernet by Diagnostic Utility ........................ 66

5.1 Using USB interface to setup Ethernet interface ................................ 66

5.2 Using RS-232 interface to setup Ethernet interface ............................ 67

5.3 Using Ethernet interface to setup Ethernet interface ......................... 68

6. Troubleshooting ........................................ 70

6.1 Common Problems ................................................................................ 70

6.2 Mechanism Fine Adjustment to Avoid Ribbon Wrinkles .................... 74

7. Maintenance ........................................... 76

Revise History ........................................... 78

1. Introduction

1.1 Product Introduction

Thank you very much for purchasing the Kroy thermal transfer/thermal label printer.

The Kroy K6200/K6300 series have been designed for use within industrial and

manufacturing industries that require a robust and reliable printing solution. Equipped

with a die-cast aluminum chassis and metal cover with large clear media view window

the K6200/K6300 series more than meets the challenges of everyday use within these

environments.

With a back-lit graphic LCD display, the printer status can be easily monitored and

managed. The moveable sensor design can accept wide range of label media including

labels, tags, continuous materials, self-laminating cable and wire markers etc. All of the

most frequently used bar code formats are included. Fonts and bar codes can be printed

in any one of the four directions.

This printer has the high quality, high performance MONOTYPE IMAGING

®

True Type

font engine and one CG Triumvirate Bold Condensed smooth font built in as standard.

With flexible firmware design, operators can also download True Type Fonts from a PC

into the printer memory for printing labels. Besides the scalable font, it also provides a

choice of five different sizes of alphanumeric bitmap font, OCR-A and OCR-B fonts. By

integrating rich features, the K6200/K6300 series are the most cost effective and high

performance printers in their class!

To print label formats, please refer to the instructions provided with your labeling

software; if you need to write custom programs, please refer to the TSPL/TSPL2

programming manual that can be found on the accessories CD-ROM or on the Kroy

Europe website at http://www.kroyeurope.com

• Applications

o Compliance labeling for shipping and receiving

o Pallet labeling

o Inventory control labeling

o Drum labeling

o Warning labels

o Custom signage

o Brand marketing featuring graphics, logos and texts

o Multiple-up labels (two or three labels across)

2

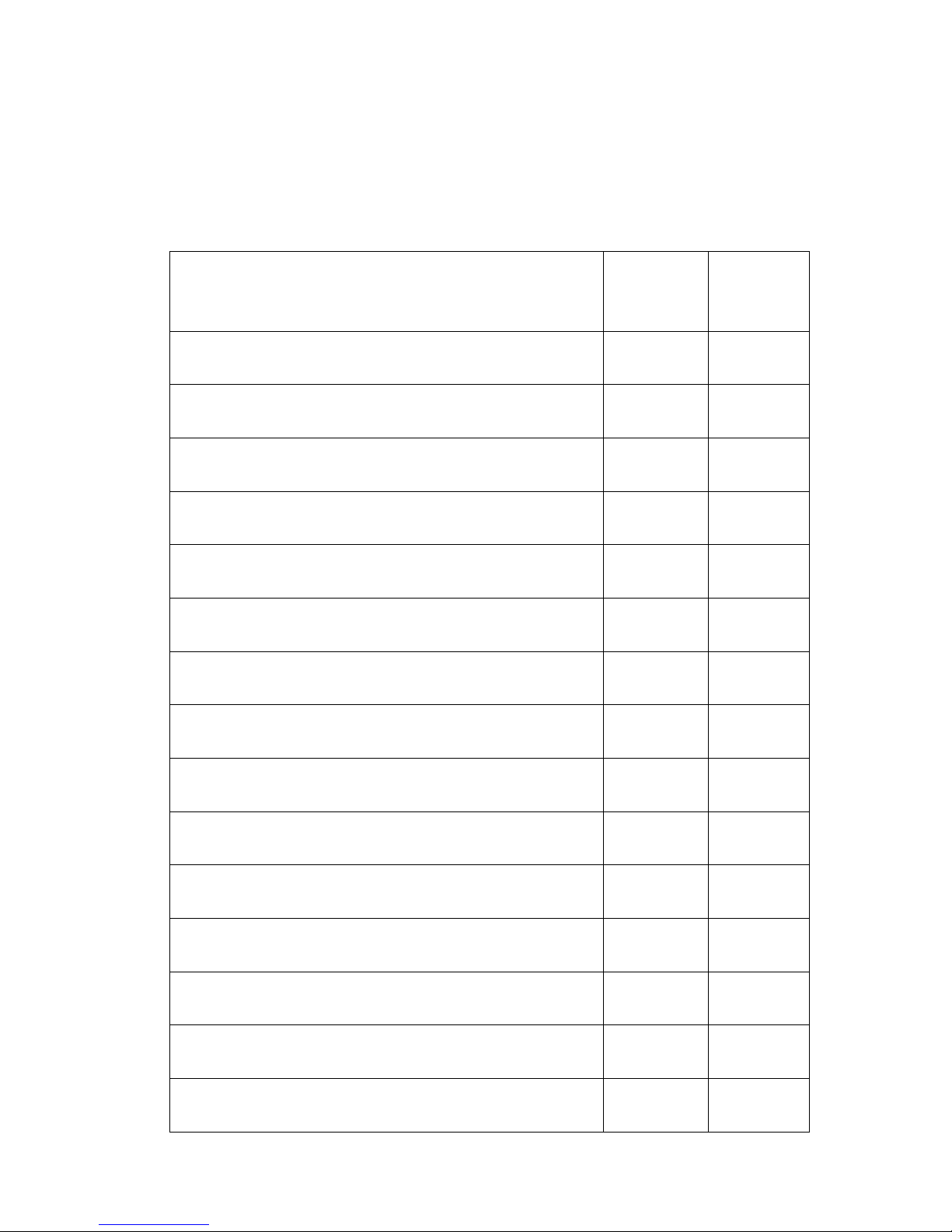

1.2 Product Features

1.2.1 Printer standard features

The printer offers the following standard features.

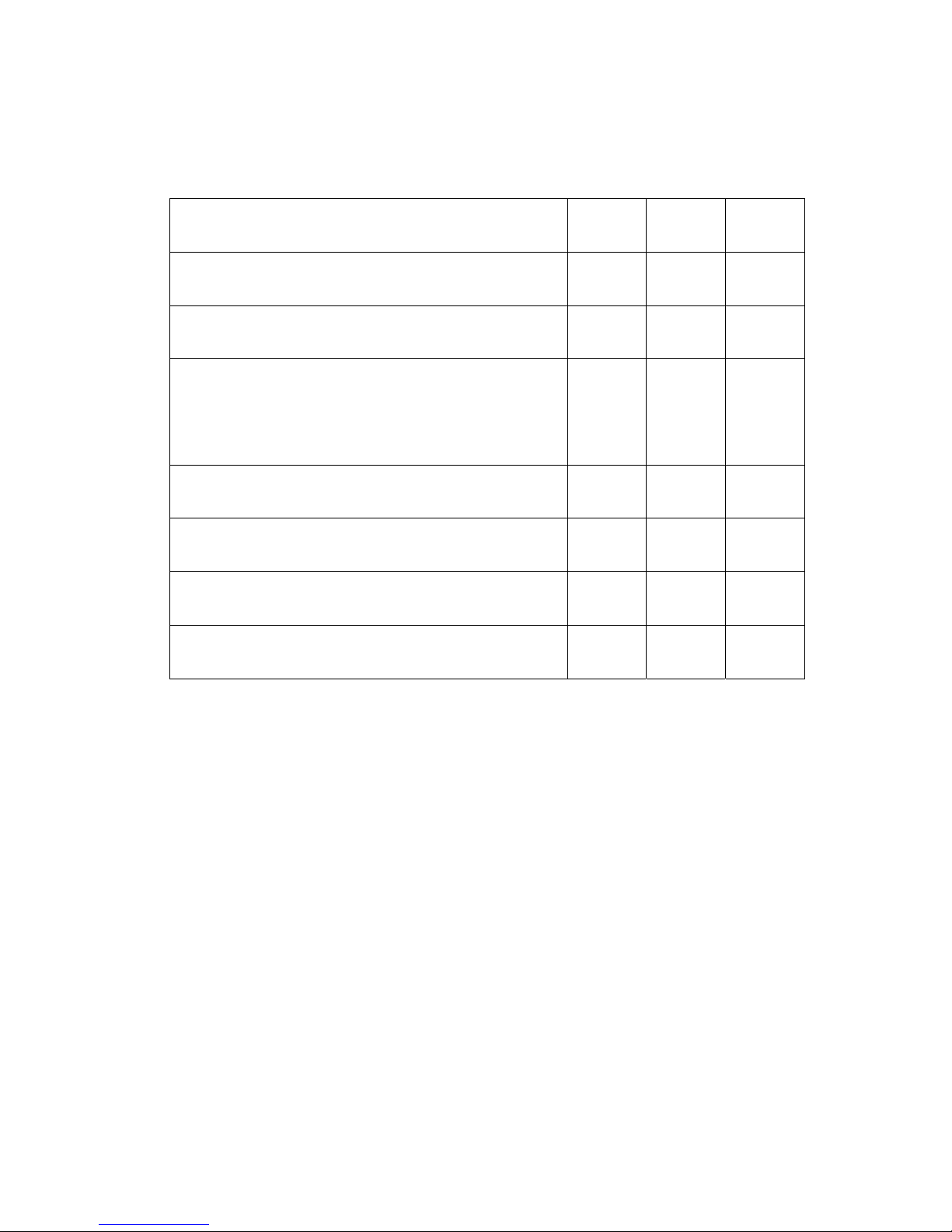

Product standard feature

K6200

200 dpi

models

K6300

300 dpi

models

Thermal transfer printing

○ ○

Direct thermal printing

○ ○

High quality die-cast aluminum design

○ ○

Metal cover with large clear media view window

○ ○

Moveable gap sensor (position adjustable from 2”~4”)

○ ○

Moveable black mark sensor position full web

adjustable

○ ○

Ribbon end sensor

○ ○

LCD display (graphic type, 128x64 pixel) with back

light

○ ○

Control panel with 6 operation buttons

○ ○

Control panel security (TCF)

○ ○

LED indicators

○ ○

Real time clock

○ ○

Internal Ethernet print server (10/100 Mbps) interface

○ ○

USB 2.0 (full speed) interface

○ ○

Serial RS-232C (2400-115200 bps) interface

○ ○

3

Centronics (SPP mode) interface

○ ○

PS/2 keyboard interface for stand-alone or data entry

at print site

○ ○

32 MB DRAM memory

○ ○

8 MB FLASH memory

○ ○

SD FLASH card memory expands storage to 4 GB

○ ○

Powerful 32 bit 200 MHz RISC processor

○ ○

Standard industry emulations right out of the box

including Eltron® and Zebra® language support

○ ○

Internal 8 alpha-numeric bitmap fonts

○ ○

Fonts and bar codes can be printed in any one of the

four directions (0, 90,180, 270 degree)

○ ○

Internal Monotype Imaging® true type font engine with

one CG Triumvirate Bold Condensed scalable font

○ ○

Downloadable fonts from PC to printer memory

○ ○

Downloadable firmware upgrades

○ ○

Text, bar code, graphics/image printing (Please refer

to the TSPL/TSPL2 programming manual for

supporting code page)

Support Bar Code Support image

1D bar code 2D bar code

BITMAP,

BMP,

PCX

Code 39,

Code 93,

Code128UCC,

Code128 subsets A.B.C,

Codabar,

Interleave 2 of 5, EAN-8,

EAN-13,

EAN-128,

UPC-A,

UPC-E,

EAN and UPC 2(5) digits

add-on,

MSI,

PLESSEY,

POSTNET,

China POST,

RSS-14,

Code 11

PDF-417,

Maxicode,

DataMatrix,

QR code,

Aztec

○ ○

4

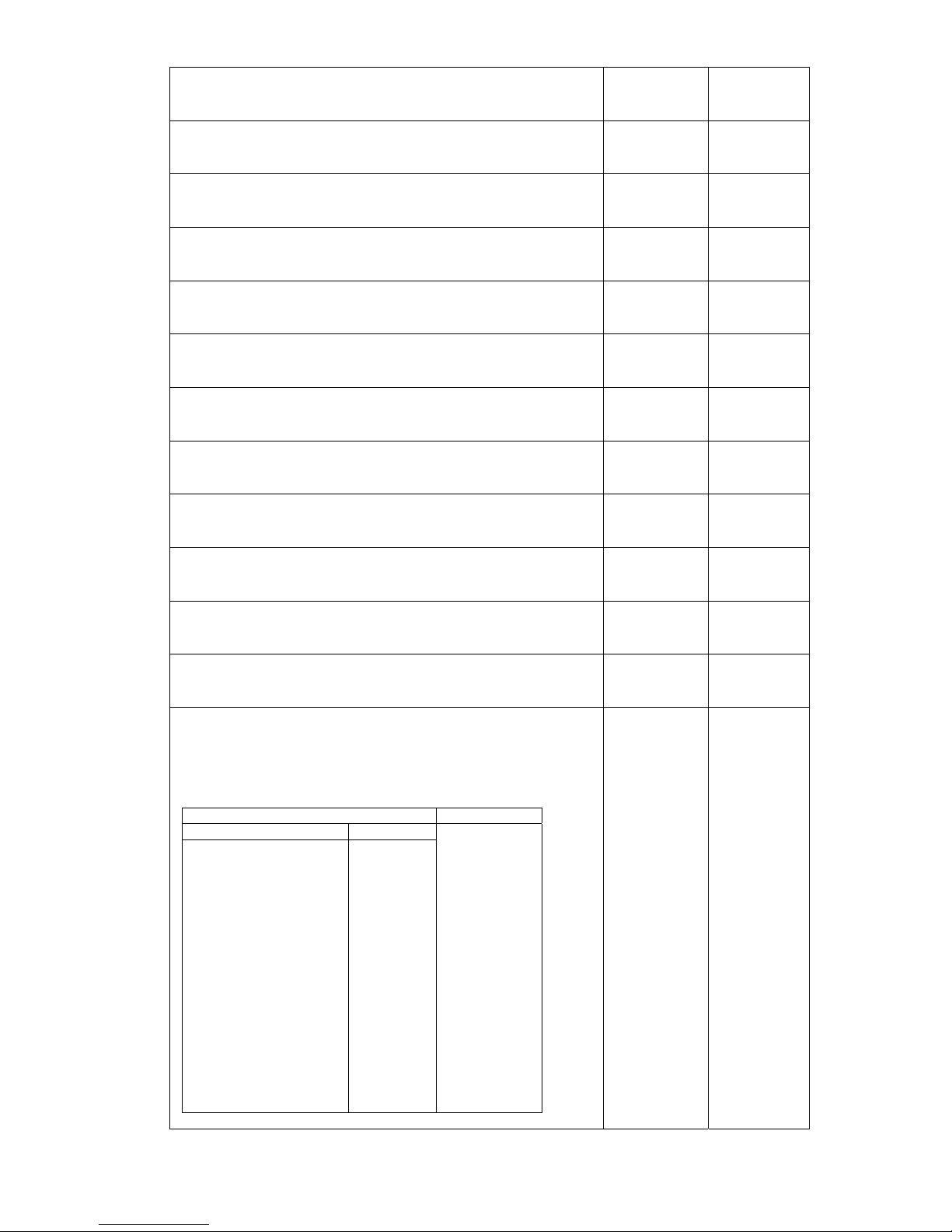

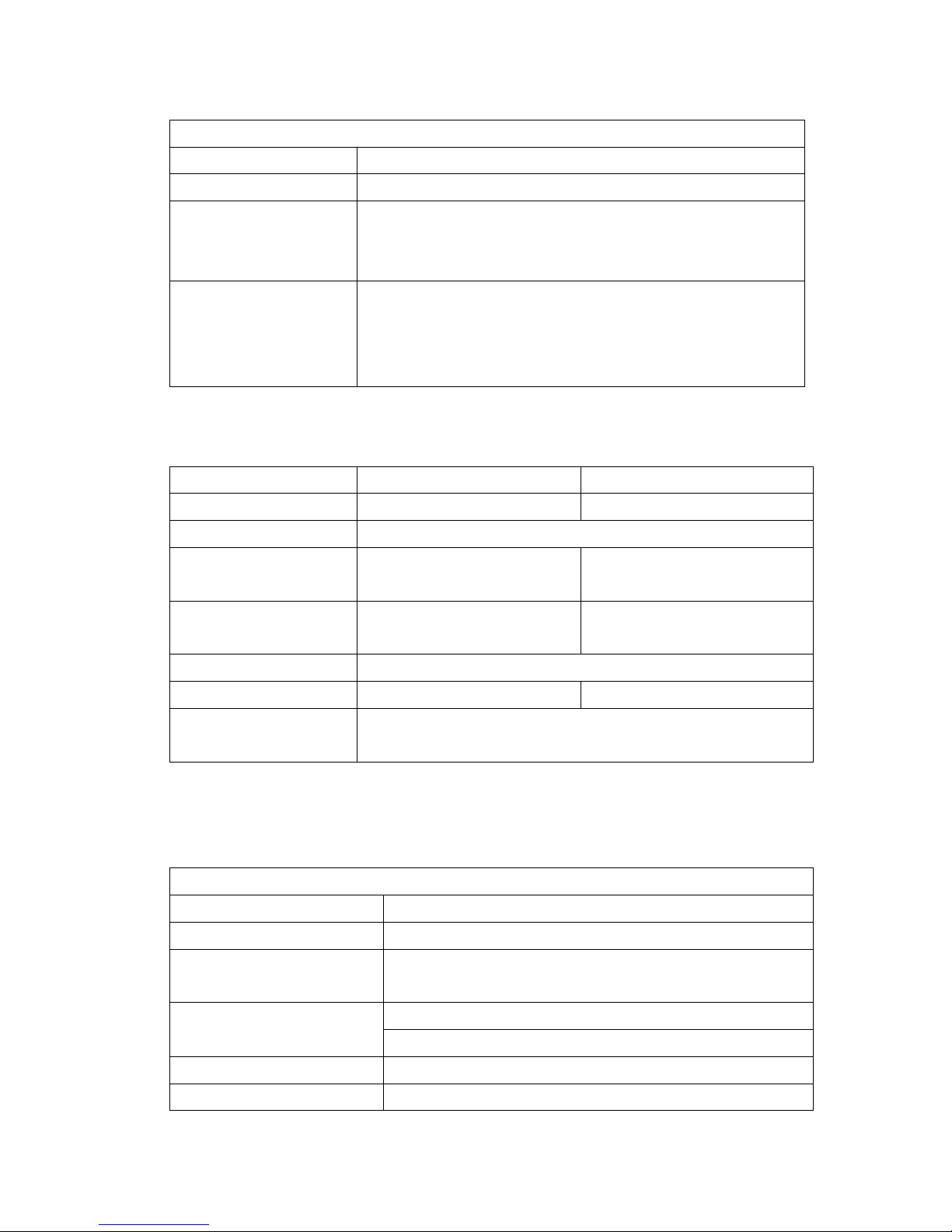

1.2.2 Printer optional features

The printer offers the following optional features.

Product option feature

User

options

Dealer

options

Factory

options

Applicator I/O interface

- -

○

Peel-off kit

(include internal rewind and peel-off module)

-

○

-

Heavy duty cutter module

(Max. paper width: 178 mm, Paper thickness:

Max 0.25 mm/ max. paper weight 250g/ m2,

1000000 cuts)

-

○

-

Bluetooth module (RS-232C interface)

○

- -

KP-200 Plus keyboard display unit

○

- -

KU-007 Plus programmable smart keyboard

display unit

○

- -

HCS-200 long rang CCD scanner

○

- -

5

1.3 General Specifications

General Specifications

Physical dimensions 355 mm (W) x 337 mm (H) x 510 mm (D)

Weight 23 kg (48.5 lb)

Electrical Internal switching power supply

Input: 90~230VAC, 47~63HZ

Output: 24V, 14.58A, 350W

Environmental

condition

Operation: 5 ~ 40˚C (41 ~ 104˚F), 25~85%

non-condensing

Storage: -40 ~ 60 ˚C (-40 ~ 140˚F), 10~90%

non-condensing

1.4 Print Specifications

Print Specifications K6200 - 200 dpi models K6300 - 300 dpi models

Print head resolution 203 dots/inch (8 dots/mm) 300 dots/inch (12 dots/mm)

Printing method Thermal transfer and direct thermal

Dot size

(width x length)

0.125 x 0.125 mm

(1 mm = 8 dots)

0.084 x 0.084 mm

(1 mm = 12 dots)

Print speed

(inches per second)

4, 5, 6, 7, 8 ips selectable

Up to 8 ips

4, 5, 6 ips selectable

Up to 6 ips

Max. print width 168 mm (6.61”)

Max. print length 5,080 mm (200”) 2,540 mm (100”)

Printout bias

Vertical: 1 mm max.

Horizontal: 1 mm max.

1.5 Ribbon Specifications

Ribbon Specifications

Ribbon outside diameter Max. 81 mm

Ribbon length 450 metres

Ribbon core inside

diameter

1 inch (25.4 mm)

Ribbon width

Max. 178 mm (7”)

Min. 50.8 mm (2.0”)

Ribbon wound type Ink coated outside wound, ink coated inside wound

Ribbon end type Transparency

6

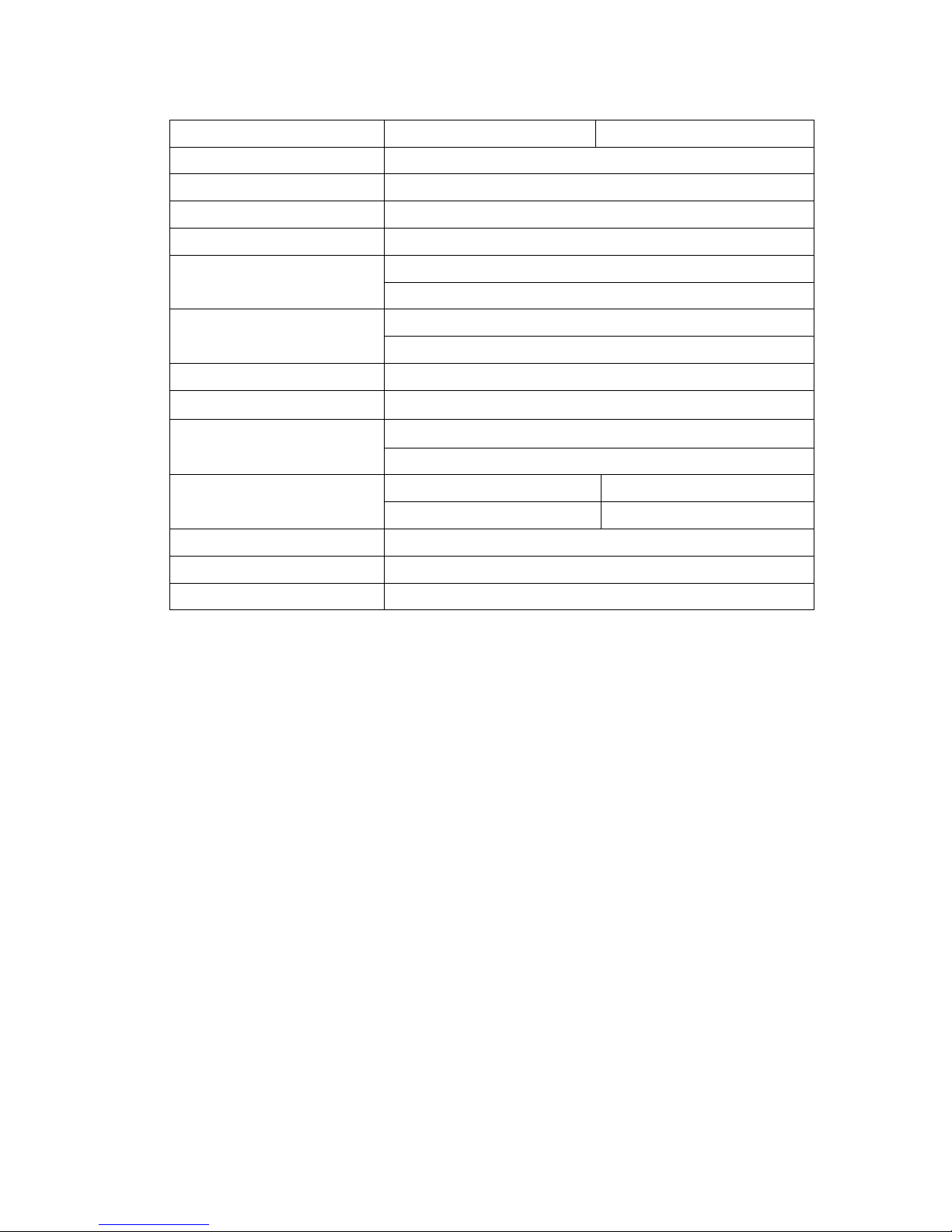

1.6 Media Specifications

Media Specifications K6200 - 200 dpi models K6300 - 300 dpi models

Label roll capacity 208.3 mm (8.2”)

Media alignment Edge alignment

Media type Continuous, die-cut, black mark, fan-fold, notch

Media wound type Printing face outside wound

Media width (label + liner)

Max. 172.7 mm (6.8”)

Min. 50.8 mm (2.0”)

Media thickness (label +

liner)

Max. 0.254 mm (10 mil)

Min. 0.06 mm (2.36 mil)

Media core diameter 76.2 mm (3”)

Label length Min. 10 mm (0.39”)

Label length (peeler

mode)

Max. 152.4 mm (6”)

Min. 24.5 mm (1”)

Label length (cutter

mode)

Max. 5,080 mm (200”) Max. 2,540 mm (100”)

Min. 24.5 mm (1”) Min. 24.5 mm (1”)

Gap height Min. 2 mm

Black mark height Min. 2 mm

Black mark width Min. 8 mm (0.31”)

7

2. Operations Overview

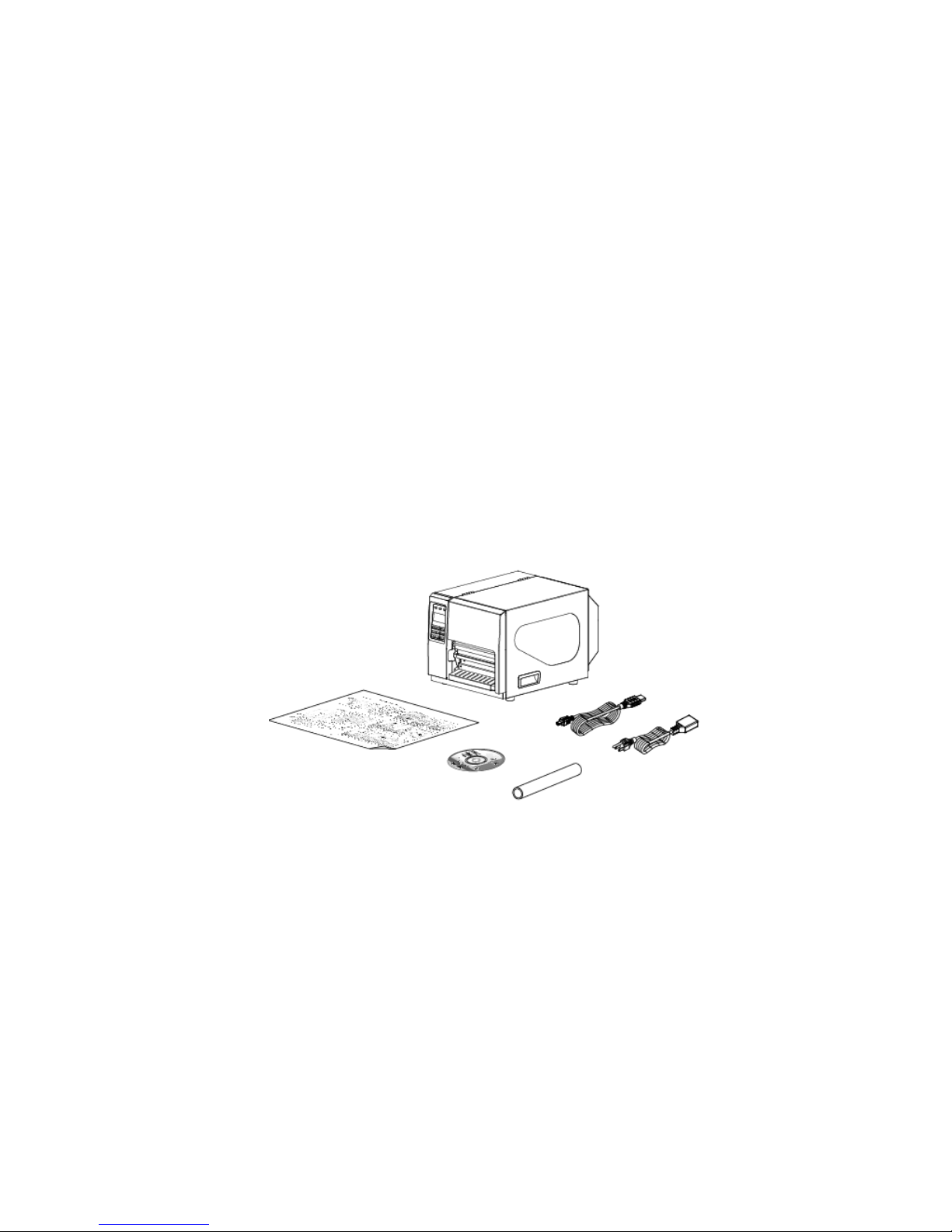

2.1 Unpacking and Inspection

This printer has been specially packaged to withstand damage during shipping.

Please carefully inspect the packaging and printer upon receiving the bar code printer.

Please retain the packaging materials in case you need to reship the printer.

Unpacking the printer, the following items are included in the carton.

One printer unit

One Windows labeling software/Windows driver CD disk

One quick installation guide

One power cord

One USB interface cable

One ribbon take up paper core

If any parts are missing, please contact the Customer Service Department of your

reseller or distributor. Alternatively please contact Kroy Europe Ltd

8

2.2 Printer Overview

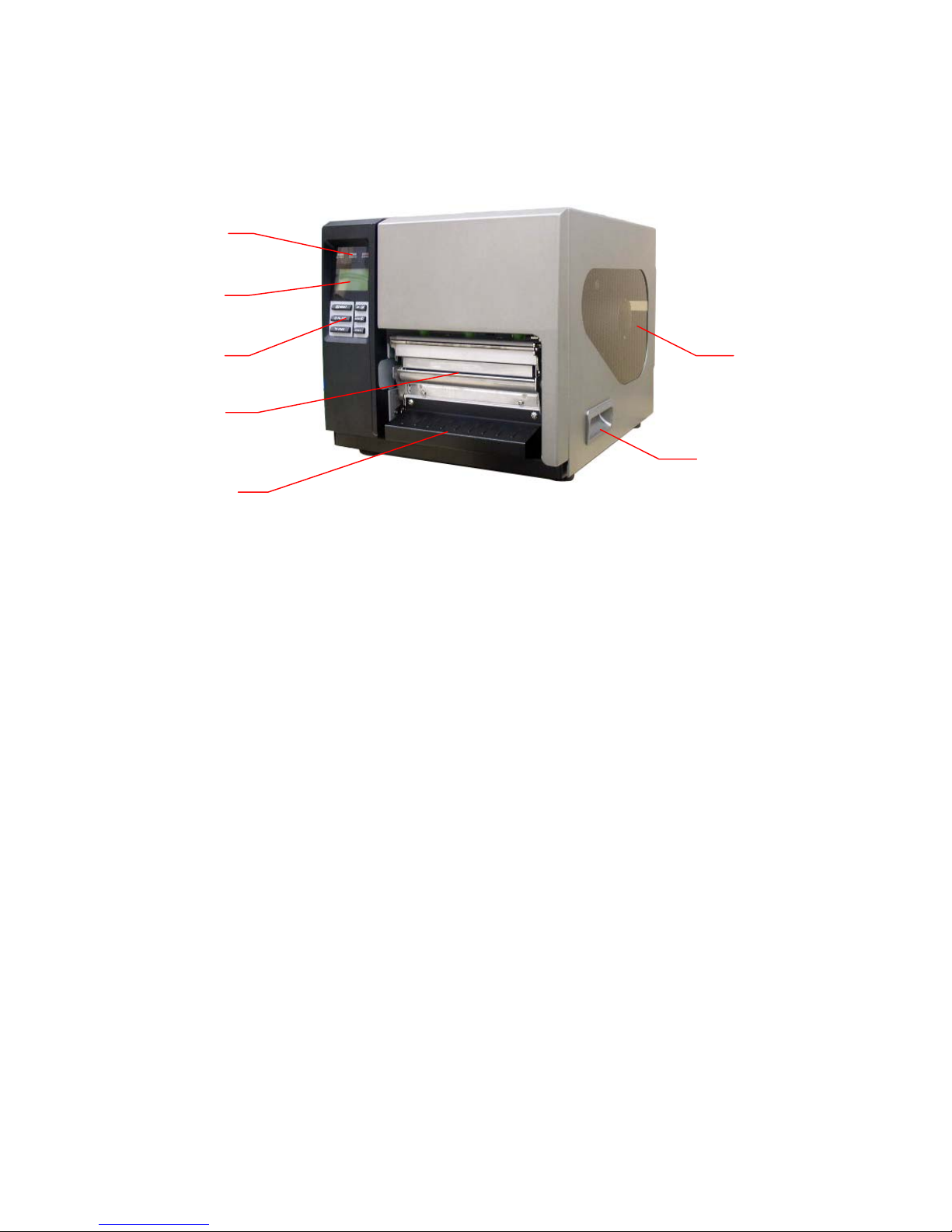

2.2.1 Front View

1. LED indicators

2. LCD display

3. Front panel buttons

4. Paper exit chute

5. Lower front cover

6. Media view window

7. Printer right side cover opener

1

2

3

4

7

5

6

9

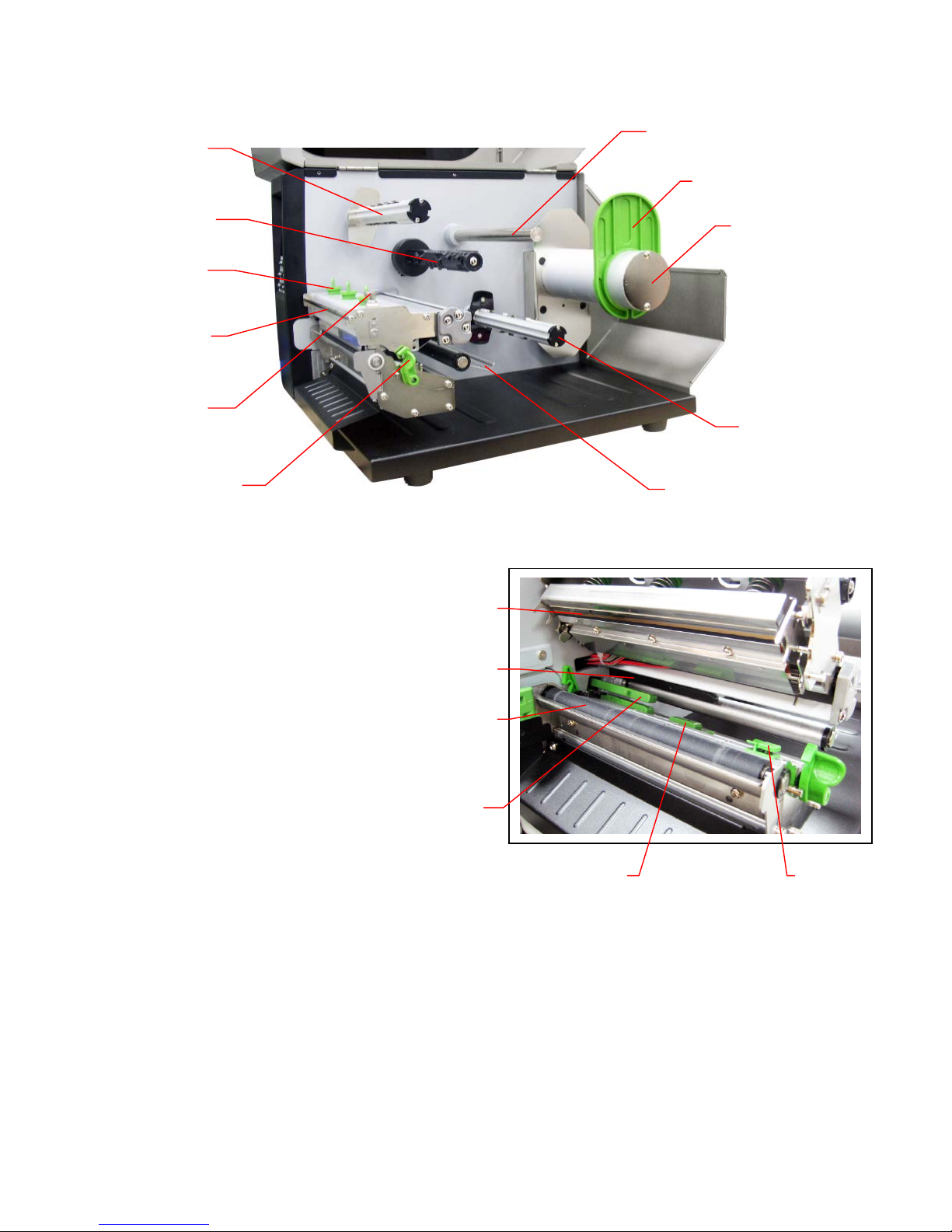

2.2.2 Interior view

1. Ribbon rewind spindle

2. Ribbon supply spindle

3. Print head pressure adjustment knob

4. Ribbon guide bar

5. Z axis mechanism adjustment knob

6. Print head release lever

7. Media guide bar

8. Label roll guard

9. Label supply spindle

10. Internal rewind spindle (Optional)

11. Damper

12. Print head

13. Ribbon sensor

14. Platen roller

15. Gap sensor

16. Black mark sensor

17. Label guide

5

9

7

10

6

11

4

3

1

2

14

13

17

15

16

12

8

10

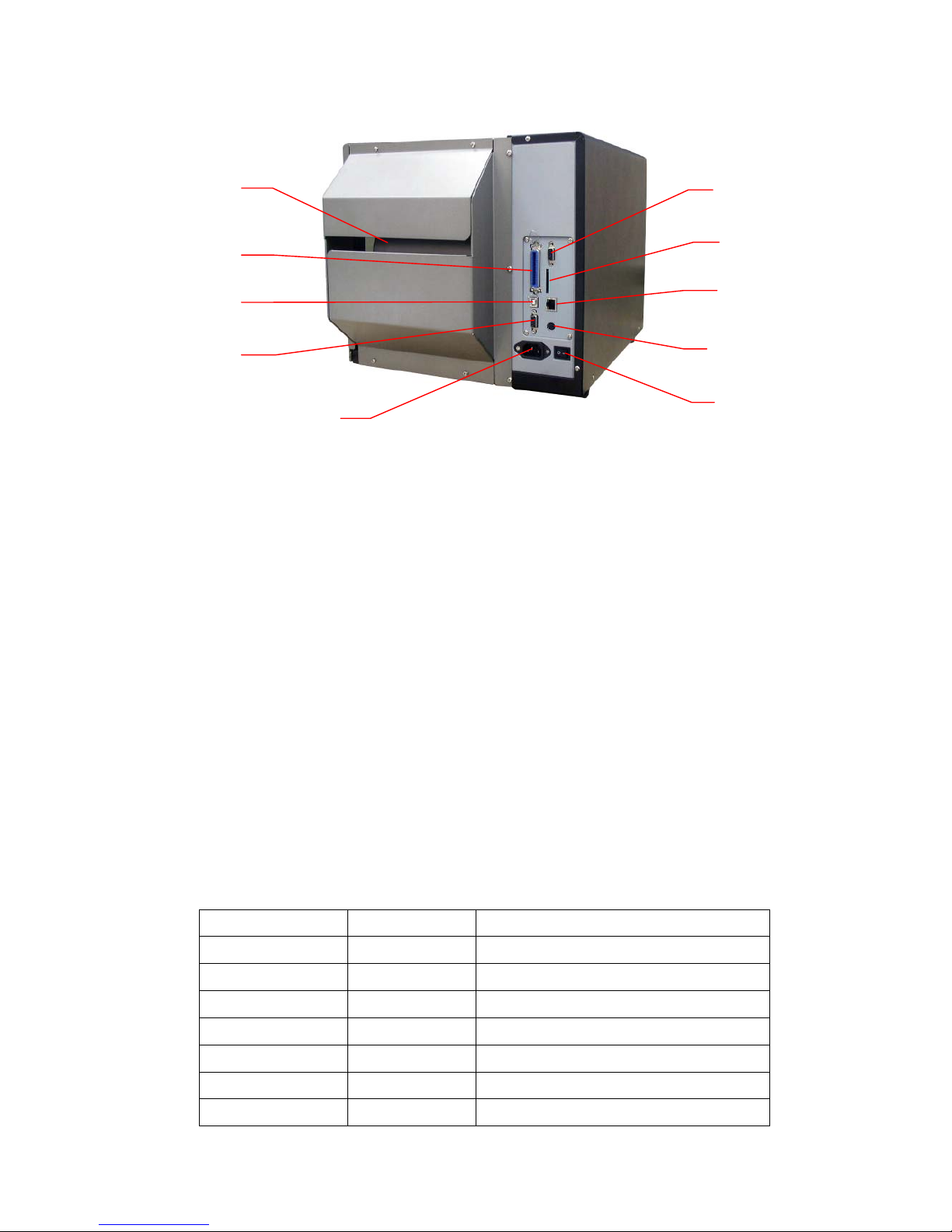

2.2.3 Rear View

1. Fan-fold paper entrance chute

2. Centronics interface (SPP mode)

3. USB interface (USB 2.0/ Full speed mode)

4. RS-232C interface (Max. 115,200 bps)

5. Power jack socket

6. GPIO interface (Factory option)

*7. SD card slot (Up to 4G)

8. Internal Ethernet interface (10/100 Mbps)

9. PS/2 keyboard interface

10. Power switch

Note:

The interface picture here is for reference only. Please refer to the product specification for

the interfaces availability.

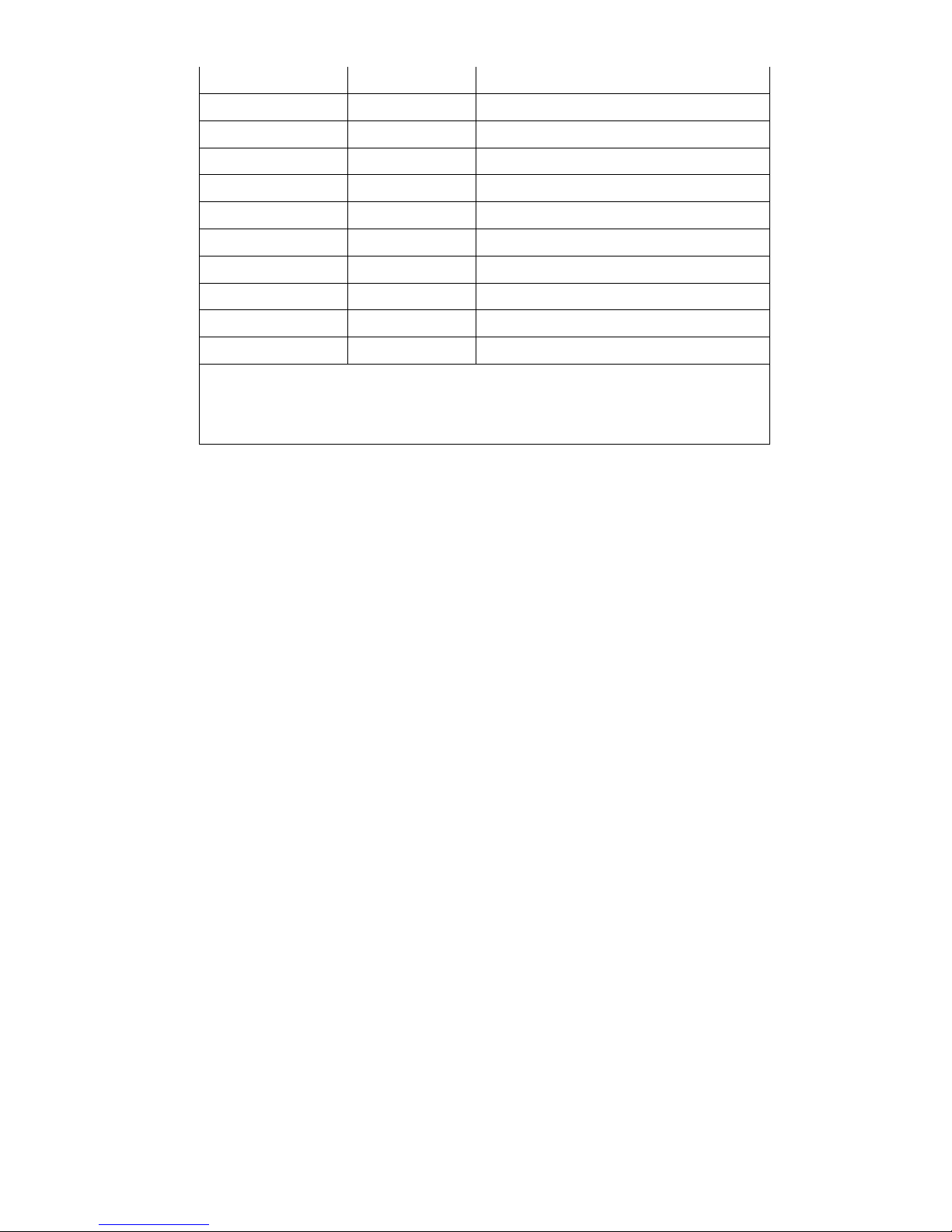

* Recommended SD card specification

SD card spec SD card capacity Approved SD card manufacturer

V1.0, V1.1 128 MB SanDisk, Transcend

V1.0, V1.1 256 MB SanDisk, Transcend, Panasonic

V1.0, V1.1 512 MB SanDisk, Transcend, Panasonic

V1.0, V1.1 1 GB SanDisk, Transcend, Panasonic

V2.0 SDHC CLASS 4 4 GB

V2.0 SDHC CLASS 6 4 GB SanDisk, Transcend, Panasonic

V1.0, V1.1 microSD 12 8 MB Transcend, Panasonic

1

3

5

4

2

10

6

7

8

9

11

V1.0, V1.1 microSD 25 6 MB Transcend, Panasonic

V1.0, V1.1 microSD 512 MB Panasoni c

V1.0, V1.1 microSD 1 G B Transcend, Panasonic

V2.0 SDHC CLASS 4 microSD 4 GB Panasonic

V2.0 SDHC CLASS 6 microSD 4 GB Transcend

V1.0, V1.1 miniSD 12 8 MB Transcend, Panasonic

V1.0, V1.1 miniSD 25 6 MB Transcend, Panasonic

V1.0, V1.1 miniSD 51 2 MB Transcend, Panasonic

V1.0, V1.1 miniSD 1 GB Transcend, Panasonic

V2.0 SDHC CLASS 4 miniSD 4 GB Transcend

V2.0 SDHC CLASS 6 miniSD 4 GB

- The DOS FAT file system is supported for the SD card.

- Folders/files stored in the SD card should be in the 8.3 filename format

- The mini SD/micro SD card adapter is required for SD card reader.

12

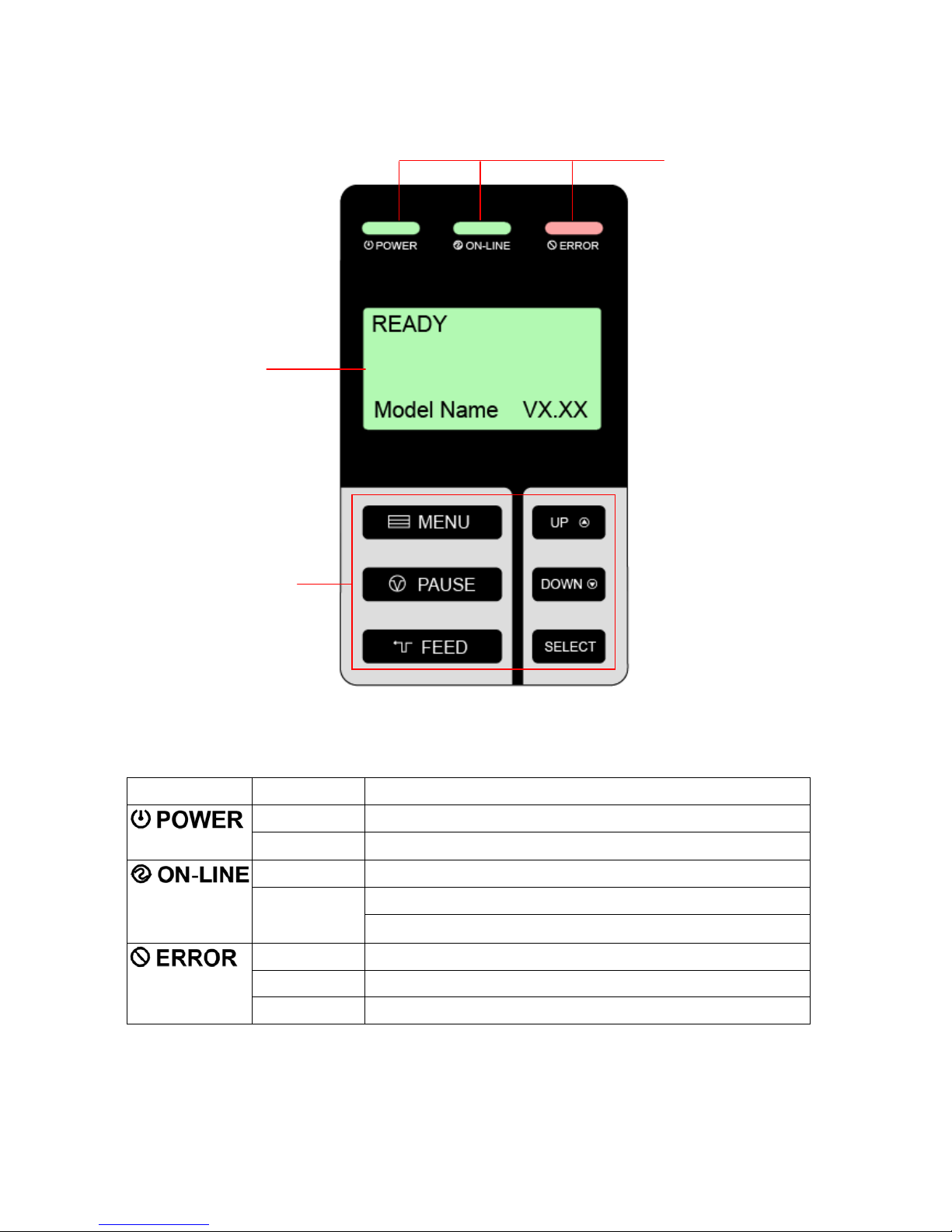

2.3 Operator Controls

2.3.1 Front Panel Display

2.3.2 LED Indicators

LED Status Indication

Off The printer power is turned off

On The printer power is turned on

On Printer is ready

Blinking

Pause

Downloading data into printer

Off Printer is ready

On “CARRIAGE OPEN” or “CUTTER ERROR”

Blinking “NO PAPER”, “PAPER JAM” or “NO RIBBON”

LCD display

LED indicators

Front panel buttons

13

2.3.3 Front Panel Keys

Keys Function

1. Enter the menu

2. Exit from a menu or cancel a setting and return to the previous menu

Pause/Resume the printing process

Advance one label

Scroll up the menu list

Scroll down the menu list

Enter/select cursor located option

2.4 Setting up the Printer

1. Place the printer on a flat, secure surface.

2. Make sure the power switch is off.

3. Connect the printer to the computer with the provided USB cable.

4. Plug the power cord into the AC power cord socket at the rear of the printer, and

then plug the power cord into a properly grounded power outlet.

Note:

Please switch OFF printer power switch prior to plug in the power cord to printer power jack.

14

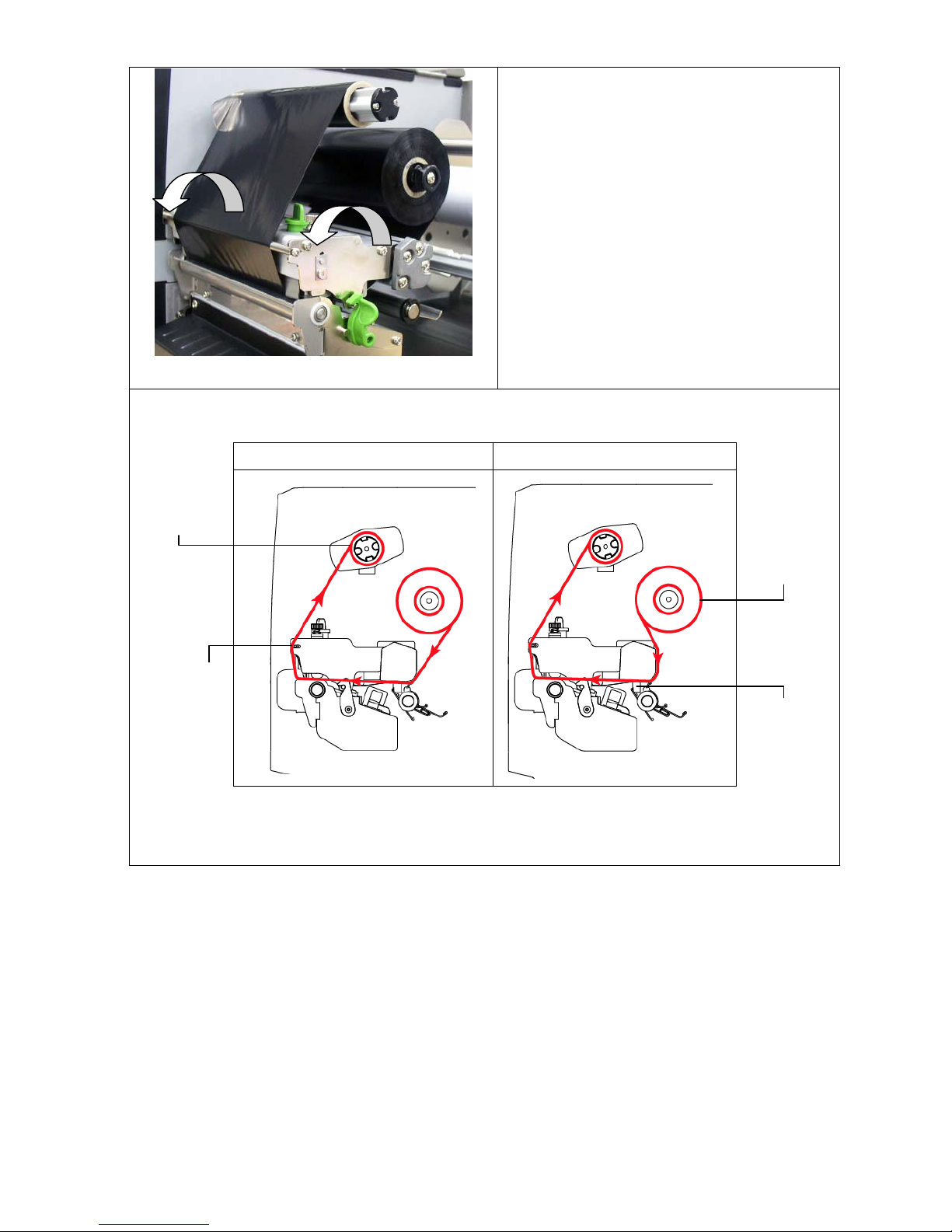

2.5 Installation of Ribbon

2.5.1 Loading Ribbon

1. Lift the handle to open the printer right

side cover.

2. Install the ribbon and paper core onto

the ribbon supply spindle and ribbon

rewind spindle.

3. Push the print head release lever to

open the print head mechanism.

15

4. Thread the ribbon through the ribbon

sensor slot and then through the open

space in between print head and

platen.

5. Stick the ribbon onto the paper core.

Keep the ribbon flat and avoid

creasing or wrinkling the ribbon.

6. Wind the ribbon clockwise about 3~5

circles onto the ribbon rewind spindle

until it is smooth and correctly

tensioned.

Ribbon sensor

Ribbon

16

7. Close the print head mechanism

making sure the latches are engaged

securely.

z Loading path for ribbon

Ink coated outside Ink coated inside

Ribbon

rewind

spindle

Ribbon

guide bar

Ribbon

supply

spindle

Ribbon

sensor

17

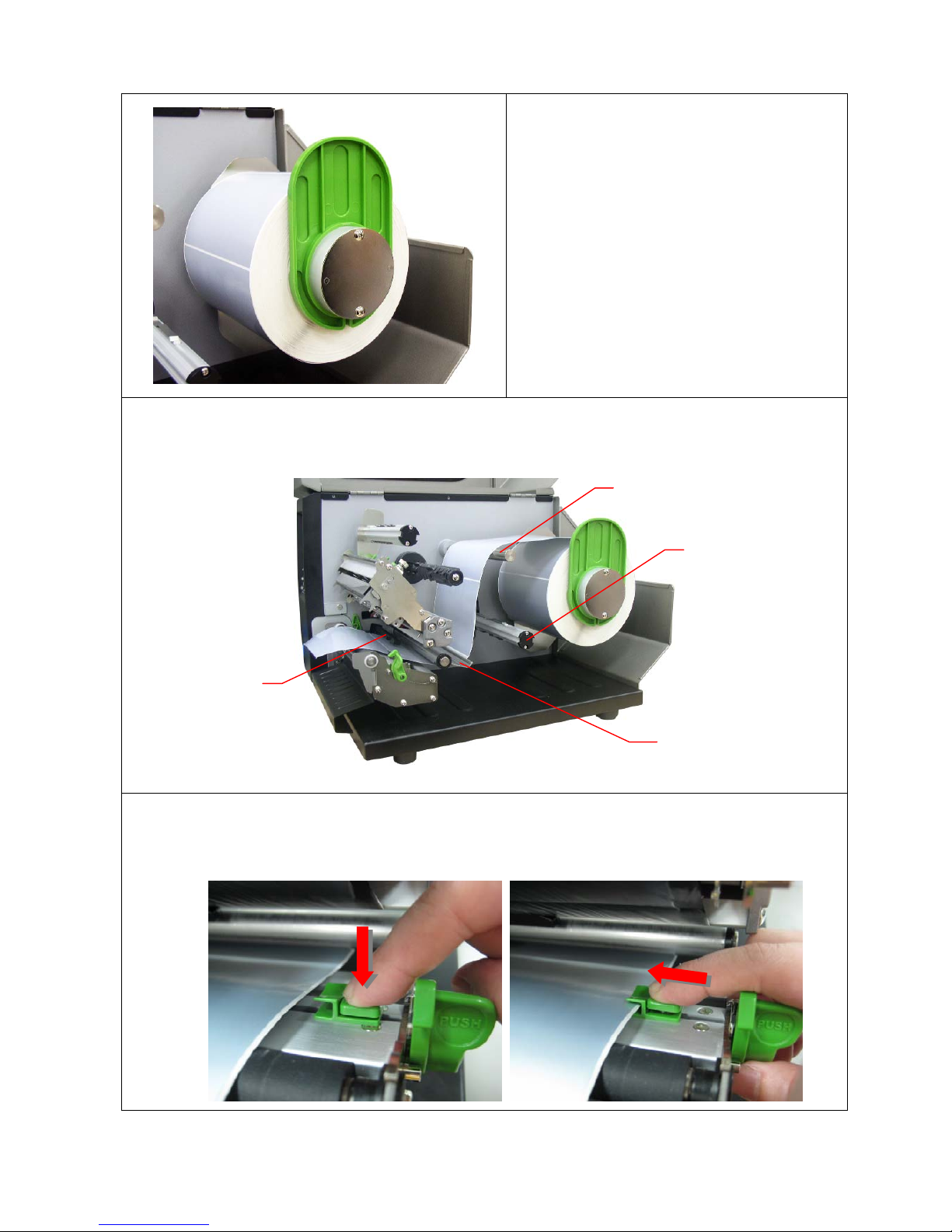

2.6 Installation of Media

2.6.1 Loading Roll Labels

1. Lift the handle to open the printer right

side cover.

2. Push the print head release lever to

open the print head mechanism.

3. Remove the label roll guard from the

label spindle.

18

4. Place the roll of media on the label

supply spindle and push it to the end

of label spindle. Install the label roll

guard gently to fit the width of label

roll.

5. Pull label roll leading edge forward through the media guide bar, damper, media sensor

and place the label leading edge onto the platen roller.

6. Adjust the label guide to fit the width of the label ensuring that the label fits under the

topmost lug of the guide.

Media guide bar

Damper

Media sensor

Internal rewind

spindle (Option)

19

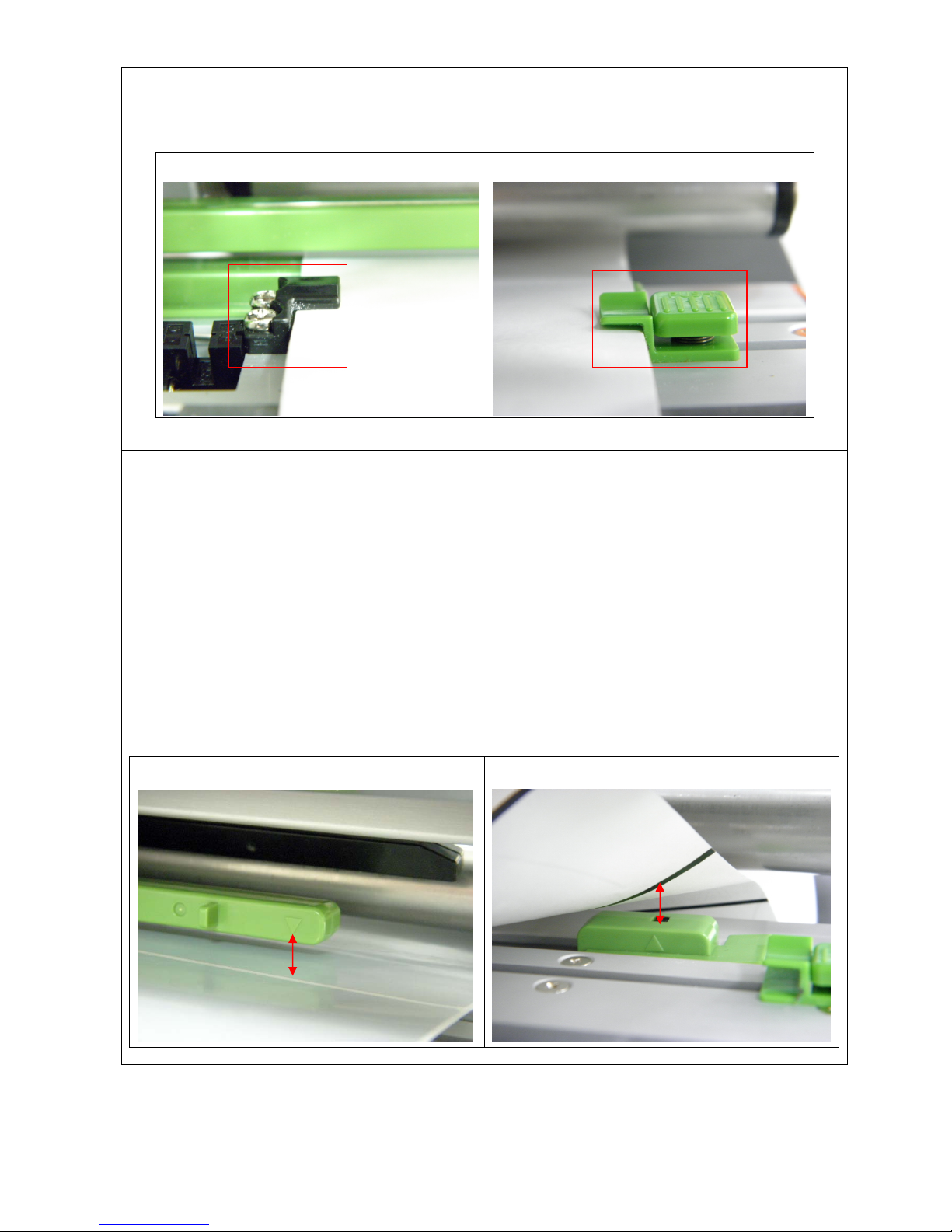

7. Make sure the label is in both label guides as indicated below.

Left label guide Right label guide (Adjustable)

8. Close the print head mechanism. Making sure the latches are engaged securely.

9. Using the front display panel to set the media sensor type and calibrate the selected

sensor. (Please refer to section 3.1.2)

Note:

• Please calibrate the gap/black mark sensor when changing media.

• The sensor location is marked by a triangle mark ▽ at the sensor housing.

• The media sensor position is moveable; please make sure the gap or black mark is at

the location where media gap/black mark will pass through for sensing.

Gap media Black mark media

20

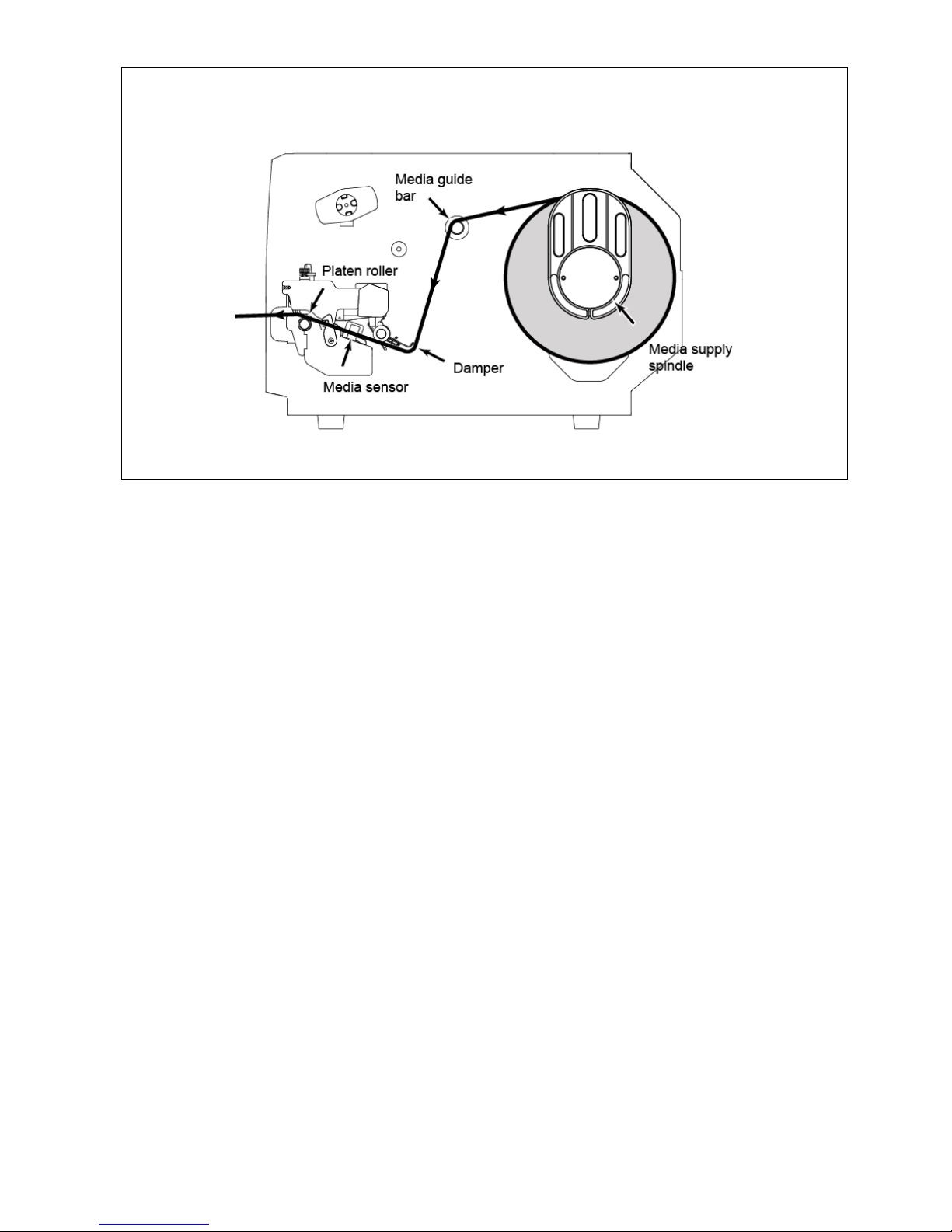

z Loading path for roll labels

21

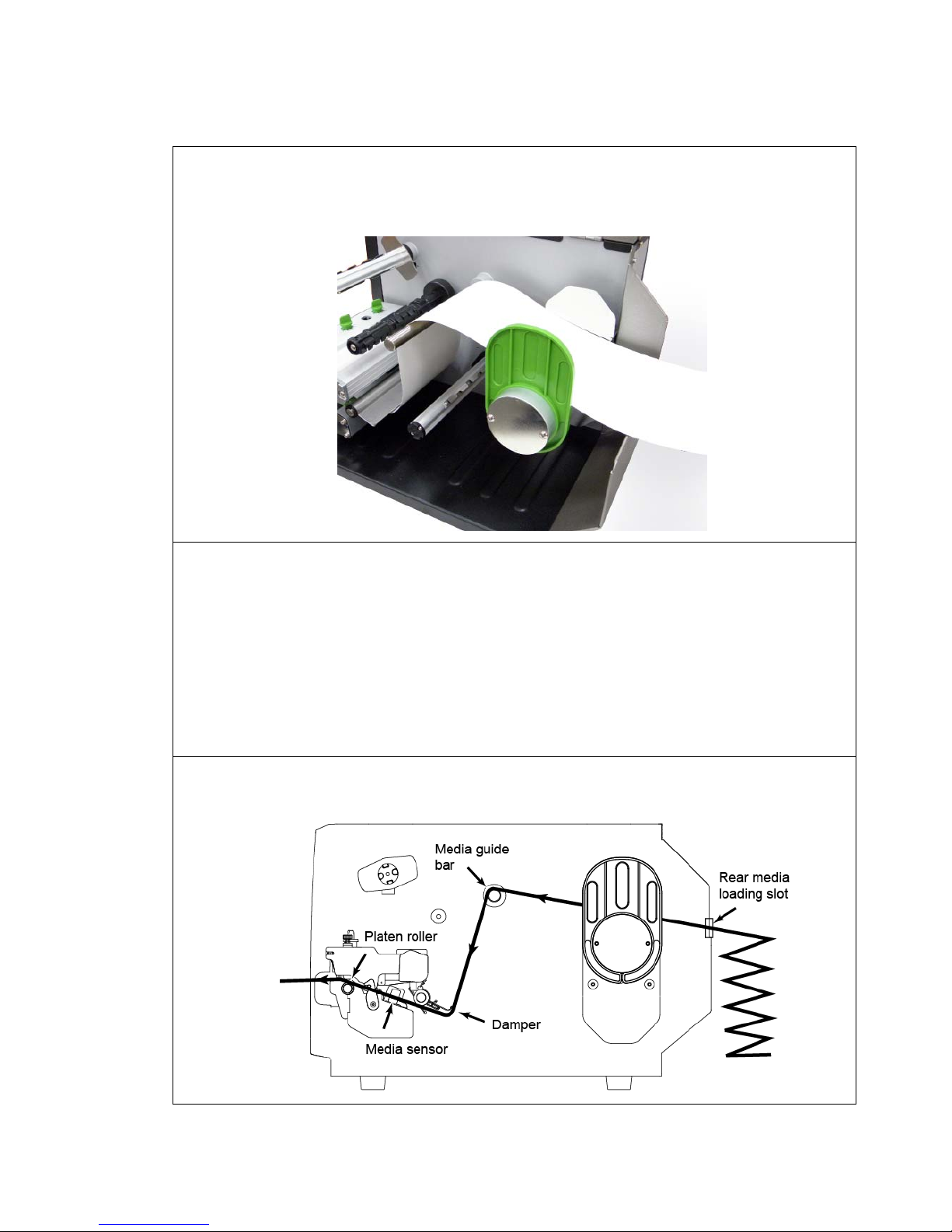

2.6.2 Loading Fan-fold Labels

Fan-fold media feeds through rear external label entrance chute.

1. Lift the handle to open the printer right side cover.

2. Push the print head release lever to open the print head mechanism.

3. Insert the fan-fold media through the rear external label entrance chute.

4. Pull fan-fold label leading edge forward through the media guide bar, damper,

media sensor and place the label leading edge onto the platen roller.

5. Adjust the label guide by sliding to fit the paper width.

6. Close the print head mechanism making sure the latches are engaged securely.

7. Set the media sensor type and calibrate the selected sensor. (Please refer to

section 3.1.2)

Note:

Please calibrate the gap/black mark sensor when changing media.

z Loading path for fan-fold labels

Loading...

Loading...