Kronoterm WPG-07-1 HT, WPG-21-1 HT, WPG-10-1 HT, WPG-15-1 HT, WPG-18-1 HT Manual For Installation, Use And Maintenance

Page 1

Manual for Installation, Use and

Maintenance

For heat pumps earth-water and water-water

WPG-07-1 HT, WPG-10-1 HT

WPG-15-1 HT, WPG-18-1 HT

WPG-21-1 HT

The manual has to be handed over to the end user after installation.

ENG

Id.: 17-16-32-3048-01 | 7.2017

Page 2

Manual for Installation, Use and Maintenance of the earth-water and water-water heat pump

WPG-07-1 HT, WPG-10-1 HT, WPG-15-1 HT, WPG-18-1 HT, WPG-21-1 HT

Id: 17-16-32-3048-00 | 7.2017

Printed in Slovenia, copyright: Kronoterm d.o.o.

This document is copyrighted. Any use outside the provisions of the copyright law without the

permission of Kronoterm d.o.o. is illegal and punishable by law. All previous versions of this document

are void. We reserve the right to make changes and mistakes in print.

Page 3

1.

Important information 5

1.1 Symbols 5

1.2 General 6

1.3 Safety warnings and instructions 6

1.4 Obligations of the manufacturer 9

1.5 Obligations of the installer during installation 9

1.6 Obligations of the authorised contractor for commissioning at first commission. 9

1.7 Obligations of the user 9

1.8 Factory testing 10

2.

Transport and installation of the device 11

2.1 Transport 11

2.2 Installation of the device 11

2.3 Storing and warehousing of the device 11

2.4 Delivery package 11

2.5 Package and worn-out device management 12

3.

Installation of the device 13

3.1 General 13

Minimal clearance from the device 15

Levelling of the device 15

Removal of the lid. 16

Set up and connection of the external sensor. 17

3.2 Heating system of machine installations 17

The scheme of the heating system 18

Preparing the heating hydraulic system - secondary 20

Charging of the heating system 22

Heat source - primary 24

Underground water - primary 24

3.3 Electrical connection 25

Description of elements in the electrical cabinet 26

Schematic display of the control system - TT3000 27

Connection of the internal control unit – TT3000 28

Electrical connection of the power cable 30

3.4 Basic input-output module MD1 - WPG 33

Connection of the elements to the internal control unit TT3000 34

Main circulation pump connection 36

Connecting heating cycle 2 (direct cycle - optional) 37

Connection of heating cycle 2 (optional) 37

DHW connection (optional) 40

Connection of the device’s remote on/off (optional) 41

External switch of heating/cooling (optional) 41

Connecting the cooling valve (optional) 42

Connecting the relay of the additional source DOVOG- gas/oil DHW (optional) 42

3.5 Connection of the room temperature corrector KT-1 and KT-2 43

4.

Commissioning of the device 44

5.

Maintenance 44

Page 4

5.1 Cleaning the water filter 44

5.2 Monitoring the pressure in the heating system 44

5.3 Cleaning of the heat conductors 45

Cleaning of the heating system (water side) 45

5.4 Operation malfunctions 45

6.

Technical data 46

6.1 Dimensions of the device 46

6.2 Technical data 47

6.3 Operating envelope 52

Heating mode 52

Cooling mode 52

6.4 Noise 53

6.5 Legend of data label 55

Page 5

1. Important information

The manual describes the process of installation and maintenance of the device. The installation and

maintenance can only be performed by qualified personnel. Read the manual carefully before the

installation, this way you will be informed about the intended use, functionality and process of handling

the device.

The manual has to be handed over to the end user after installation.

In case the product shall be given to a third person for use, the manual has to be handed over

to them as well.

Definitions

An informed person is a person who reads this manual.

A qualified person has a certificate of expert qualifications.

An authorised commission contractor is trained by the manufacturer and authorised to perform

commission.

The authorised technician is trained and authorised by the manufacturer to perform

maintenance and servicing of the device.

The user uses the device according to its use.

The installer is a person professionally trained for performing hardware and/or electro-

installation work and mounting of the device.

Incorrect use of the device can lead to damage of the device, property or injury to the user. To reduce

risk the manual points out important information with the use of symbols.

1.1 Symbols

These symbols mark various risks for the user or the device.

DANGER:

Risk of situations which can lead to serious physical injuries.

WARNING: Risk of situations which can lead to minor physical injuries.

CAUTION: Risk of situations which can lead to damage or malfunction of

the device.

This symbol marks information for the user.

NOTE:

A notice which holds important information regarding requirements

of the manufacturer.

Page 6

1.2 General

NOTE

Read the instructions for use and installation before installation.

NOTE

Any remaking or replacement of original components of the device eliminates

the manufacturer’s guarantee for safe and functional operation. In the case

of undesignated and incorrect use of the device the manufacturer is not

responsible for the consequences and will not acknowledge claims for

damages in these cases. The user is solely responsible for injuries and

damages on the device itself or on other objects resulting from undesignated

and incorrect use of the device.

NOTE

The installation of the device has to be performed in accordance with the

manual; otherwise the manufacturer does not acknowledge the warranty.

NOTE

The device is designed for yearly use of 2000 hours. Choosing an inadequate

power of the device can lead to yearly operation of above 2000 hours which

will reduce the lifespan of the device.

NOTE

Devices with the rated current higher than 16 A are in accordance with IEC

61000-3-12.

NOTE

After connecting the device it is necessary to acquire the guarantee or consult

the operator of the distribution network that the impedance of the network is

lower than prescribed for the individual type of device in the technical data.

This way the device will operate within acceptable limits of disruptions.

Otherwise it is necessary to connect the device to the network using a soft

start device.

DANGER

Failure to comply with the manual and good practise while connecting the

device to the power supply can lead to serious injury or death.

WARNING

Connecting the device to the power source can only be performed by a

qualified installer.

1.3 Safety warnings and instructions

DANGER

It is prohibited to move, shift, clean or service the device while in operation.

WARNING

It is prohibited to play with the device. Children are not allowed to clean the

device without supervision.

Page 7

WARNING

The device can be operated independently only by informed persons who are

familiar with the safe operation of the device and understand possible hazards

of its operation. Children older than 8 and people with reduced physical and

mental capacities and with lack of experience and knowledge can only

operate the device under the supervision of an informed person.

WARNING

Before installation and any further adjustments to the device it is necessary to

consider the manual for safe use and maintenance.

WARNING

Installation has to be performed in accordance with national regulations on

electrical installations and with the instructions of the manufacturer. It has to

be performed by a professionally trained person.

CAUTION

The servicing and maintenance of the device can only be performed by a

person authorised by the manufacturer. In case of a malfunction, first contact

the installer who installed the device.

WARNING

It has to be made sure that the device does not endanger anybody. Access

to the device has to be denied to children and persons who are not informed

about the operation of the device.

WARNING

The device must never be cleaned with cleaning agents containing sand,

soda, acid or chlorides because these might damage the surface of the

device.

WARNING

The device contains fluorinated greenhouse gas. This is why tampering with

the device is only allowed to persons authorised for working with the

refrigerant as defined by the national legislation in force. While performing

works on the device, it is necessary to prevent the refrigerant to leak into the

atmosphere.

WARNING

It is necessary to consider all technical data and instructions in this manual as

well as all warnings and notes during planning, design, installation and use of

the device.

WARNING

Electrical installations have to be inspected in accordance with regulations on

the requirements for low voltage electrical installations in buildings by the

installer of electrical installations.

Page 8

DANGER

Connecting the devices power cable can be performed by a qualified

electrician. During the procedure the device must not be live.

WARNING

In case the power cable of the device is damaged it has to be immediately

replaced. The replacement can only be performed by the manufacturer and

authorised maintenance worker.

WARNING

Before opening the device disconnect all electrical circuits and make sure the

device is not live.

CAUTION

Putting any kinds of items on or next to the device is prohibited.

CAUTION

In case the device is placed on the ground which is more subject to the

transfer of vibrations than a classical concrete panel with a screed, it is

necessary to underlay the device with a suitably thick and quality anti-vibration

underlay.

CAUTION

The device must not be placed in a room where it cannot be removed. Later

walling or setting up of other obstacles next to the device is forbidden.

CAUTION

In three-phase versions of the device, it is necessary to ensure the correct

arrangement of phases when connecting it to the power supply.

CAUTION

For the correct operation of the device, the electrical distributor has to provide

electricity of adequate quality (SIST EN 50160). In normal conditions this is

within ± 10 % of the rated voltage The data about the state of the electrical

grid have to be acquired from the electrical distributor.

CAUTION

Operation of the device with a frequency converter is forbidden.

CAUTION

Connecting the device to the electrical network has to be performed in

accordance with the standards for connecting devices to the electrical

network. Connect the device to the electrical network via the power supply

cut-off which is installed into the electrical installation under the regulations in

force.

Page 9

1.4 Obligations of the manufacturer

The manufacturer guarantees that the device is in accordance with current European directives and

standards. The device is marked with the mark CE and it has all the necessary documentation.

We reserve the right to make changes to the manual without prior notice.

As manufacturer we do not take responsibility for the consequences arising from:

Non-compliance with the manual for the device.

Incorrect and/or inadequate maintenance of the device.

Non-compliance with the manual for the installation of the device.

1.5 Obligations of the installer during installation

The installer is responsible for installing the device in accordance with the following requirements:

To thoroughly study the instructions for use and installation accompanying the device before

installation.

To install the device in accordance with the instructions and national legislation, policies and

standards in force.

1.6 Obligations of the authorised contractor for commissioning at

first commission.

CAUTION

The first commission can only be performed by the contractor of commissions appointed by

the manufacturer in accordance with the instructions for commission.

The contractor for commissions is responsible for commissioning the device in accordance with the

following requirements:

Performs the first commission and with the installer of others section of heating system

eliminates all eventual irregularities found at the commission.

To train the user for operating the device and settings.

Alerts the user to regularly maintain the device for keeping the device functioning properly

throughout its entire lifespan.

Gives the user all the documentation accompanying the device.

1.7 Obligations of the user

For ensuring unobstructed and effective operation of the device the user has to follow the following

instructions:

To thoroughly study the instructions for use and installation accompanying the device before

use.

To have a qualified and authorised installer perform the installation of the device.

To have a contractor for commissions perform the commission.

Allow the authorised contractor for commissioning or ask him to thoroughly explain the

functioning and how to operate the device.

Ensure regular yearly inspections and maintenance of the device by the authorised

maintenance worker.

Store this manual in an appropriate dry place close to the device.

Page 10

1.8 Factory testing

For ensuring the high quality standard every device is tested in production for the following:

Tightness of the cooling cycle,

Water-tightness

Electrical safety and

Functionality.

Page 11

2. Transport and installation of the device

2.1 Transport

CAUTION

The device must be transported with transport devices.

Secure the device during transport to prevent damage.

Transport the device in vertical position.

It is prohibited to tilt the device above 45°. Otherwise, damage to the cooling system

may occur.

2.2 Installation of the device

2.3 Storing and warehousing of the device

The device has to be stored in a dry and clean place. The allowed storing temperature is between 10 °C

and 45 °C, for a short period (up to 24h) also up to 50 °C.

2.4 Delivery package

The heat pump (device) for internal installation (internal unit).

Installation instructions.

Instructions for use.

Temperature sensor for external air temperature PT1000.

Temperature sensor for DHW.

Temperature sensor of mixing-heating cycle 2.

CAUTION

Appropriate transport equipment must be used for installing the device. Safety regulations

and good practise have to be followed.

STANDARD

LABEL

Page 12

2.5 Package and worn-out device management

Sort the package according to cardboard, wood and foil and dispose of it in appropriate

containers.

After the lifespan of the device ends it has to be disposed of in accordance with the legislation

on waste electrical and electronic devices in force.

Refrigerant

The device holds the fluorinated greenhouse gas. You have to prevent leakage of the gas into the

atmosphere. During a maintenance procedure or removal of the device it has to be made sure that the

gas is removed in accordance with the current regulations on the use of substances harmful to the

ozone and fluorinated greenhouse gasses.

Page 13

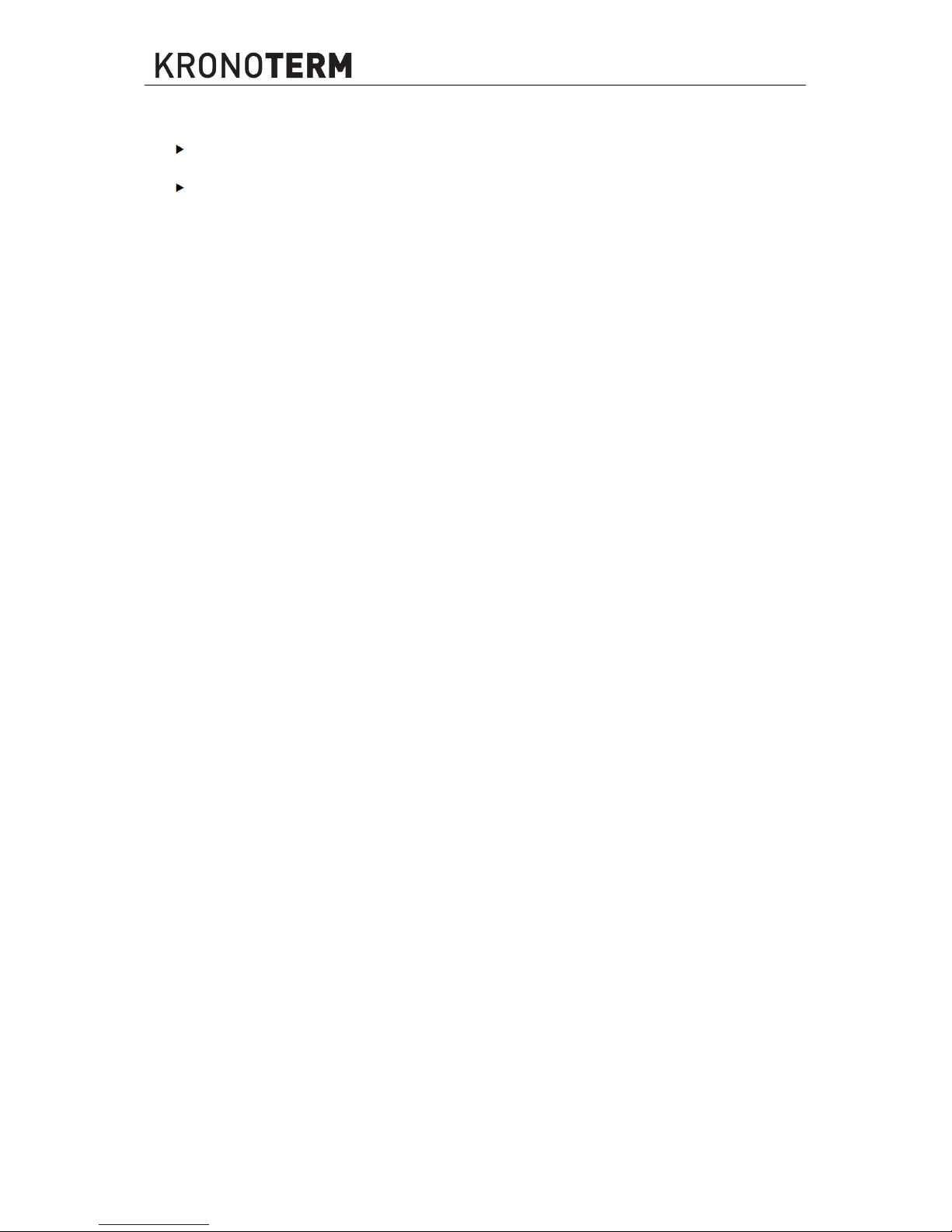

3. Installation of the device

3.1 General

Install the device in the utility room. The pipes connecting the device to the heating system are located

on the upper side of the device.

INSTALLATION of the device in case of using the heat of ground water

A

B

A

B

P1

P2

P3

P4

P5

P6

P7

P8

P10

P10

P11

P11

P15

P14

P13

P11

P9

C D

A

Supply pipe for heating

(heating)

C Supply pipe for heating - heat source

B

Return pipe for heating

(heating)

D Return pipe for heating - heat source

P1 Device with regulation P9 Temperature sensor for external temperature

P2 Heat exchanger P8

An adequate protection hose separate for power /

communication

P3 Electrical cabinet P9

Heat insulation with appropriate screen (for example

ALU harness)

P4 Water filter P10 Suitable protective pipe

P5 Power cable - internal device P11 Pipe heat insulation

P6

Power cable - submersible

pump

P13 Primary water connection

P7 Power cable - circulation pump P14 Secondary water connection

P8 Sensor communication cable P15 Magnetic separator of impurities

Page 14

INSTALLATION in case of using ground heat

P9

P7

P9

ABA

B

P2

P6

P4

P5

P3

P1

P8

P11

C D

A

Supply pipe for heating

(heating)

C Supply pipe for heating - heat source

B

Return pipe for heating

(heating)

D Return pipe for heating - heat source

P1 Device with regulation P6 Sensor communication cable

P2

Magnetic separator of

impurities

P7 Temperature sensor for external temperature

P3 Electrical cabinet P8 Suitable protective pipe

P4 Power cable - internal device P9 Pipe heat insulation

P5

Power cable - circulation

pump

P11 Water connection

Page 15

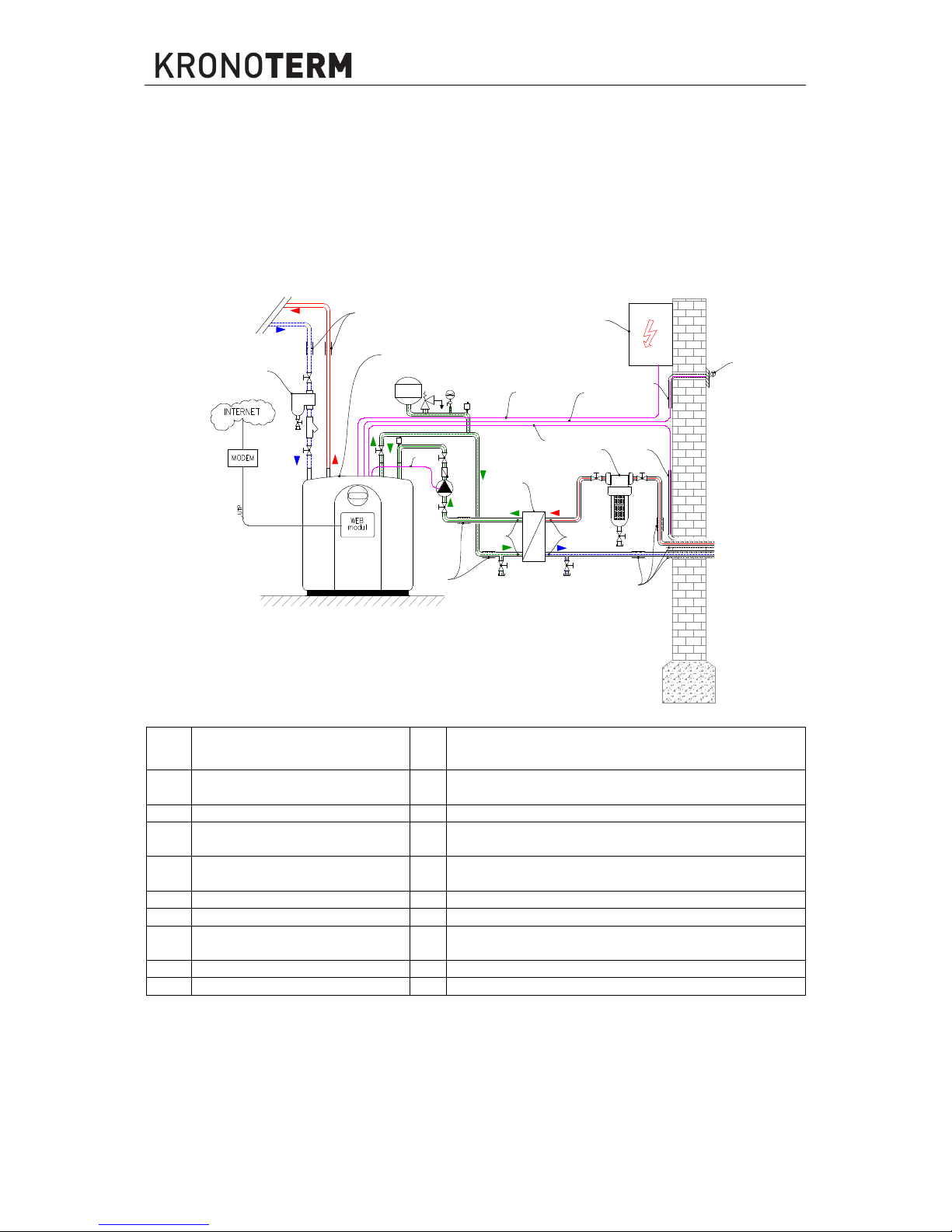

Minimal clearance from the device

Minimal clearances of the internal device from walls for seamless operation, maintenance and servicing.

min.400 mmmin.400 mm

min.1000 mm

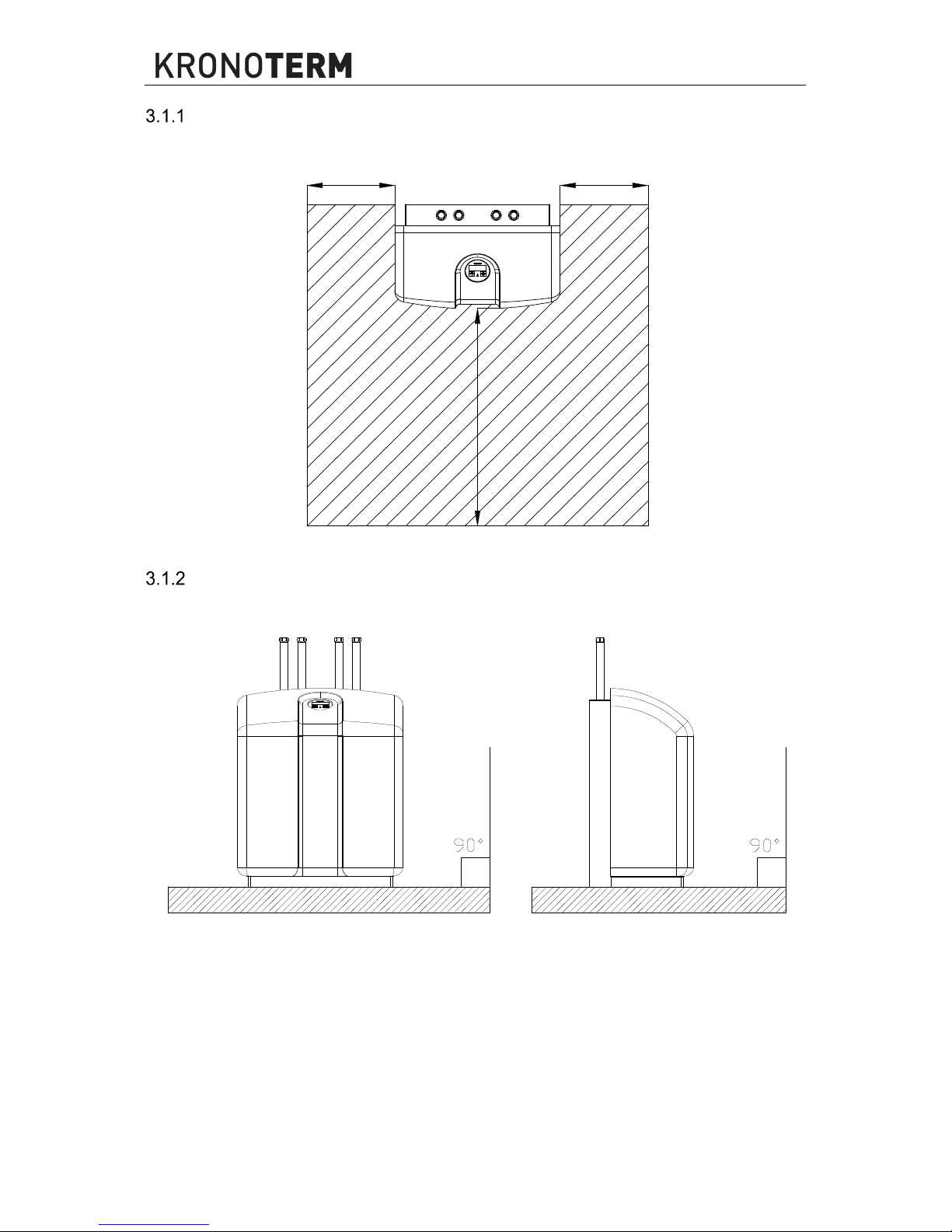

Levelling of the device

The internal device must be levelled in the horizontal position as shown on the diagrams below:

Page 16

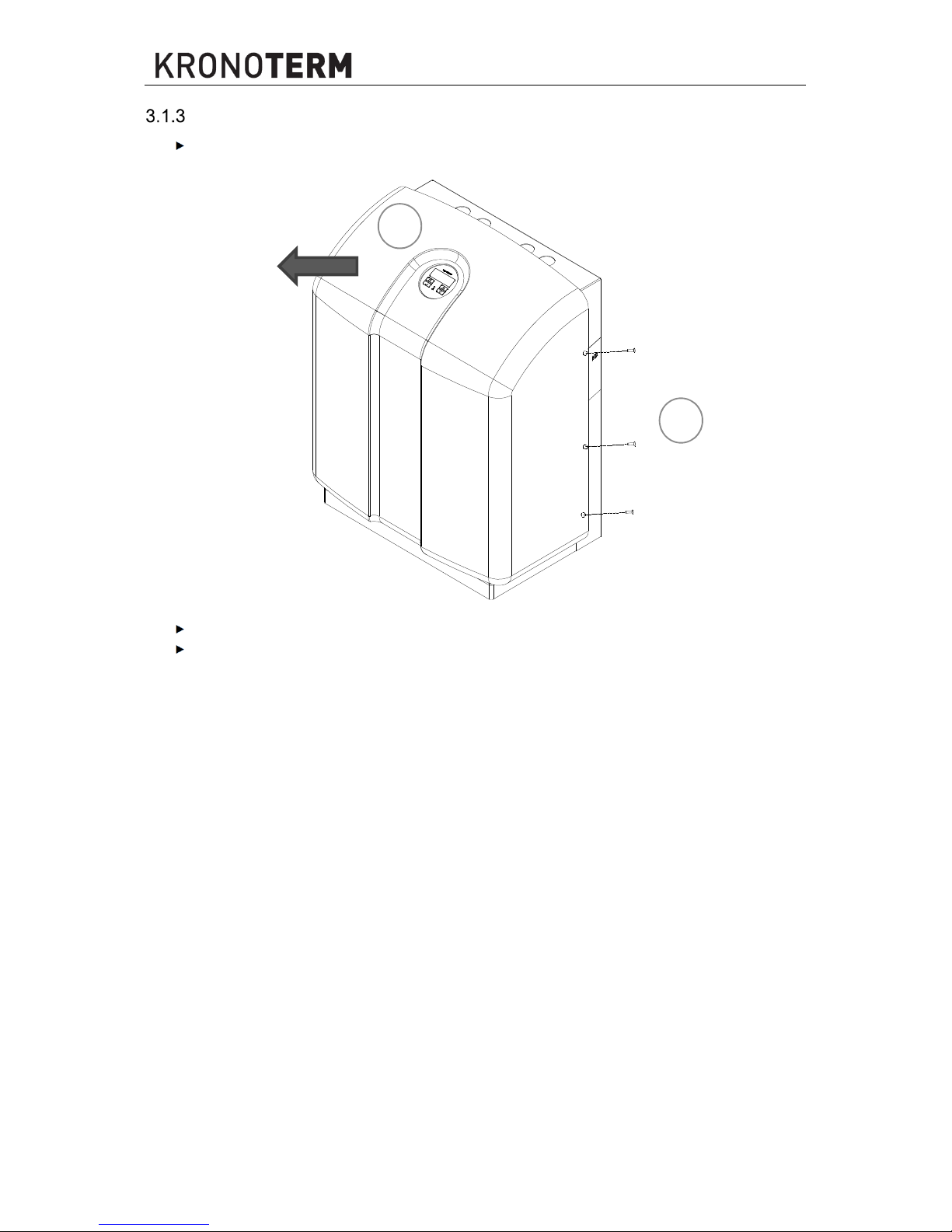

Removal of the lid.

The main switch of the device must be in the “OFF” position.

Unscrew the screws marked with 1 on the left and right side of the device.

Open the upper part of the lid (2) towards you.

1

2

Page 17

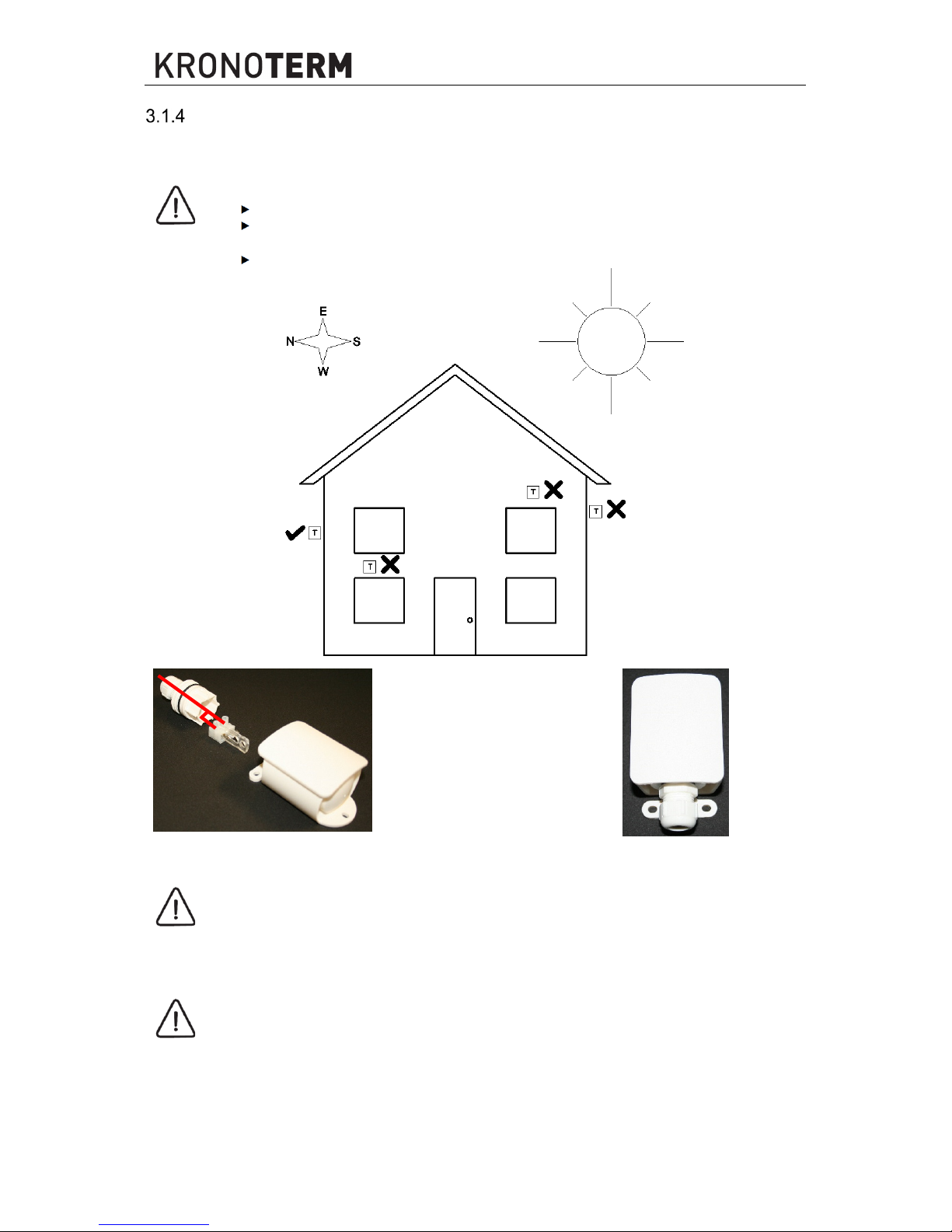

Set up and connection of the external sensor.

For controlling the heating according to the external temperature, it is necessary to install the external

temperature sensor.

CAUTION

The sensor must be set up in a shady spot.

The sensor must not be set up above a window or door. It must be located away

from heat sources.

For measuring external temperature, the sensor type PT 1000 is used.

The direction of connecting

cables.

Temperature sensor for external

temperature.

CAUTION

The external sensor must be connected and watertight to prevent water penetration.

3.2 Heating system of machine installations

WARNING

The dimensioning of circulation pumps, valves, safety elements and pipes has to be

performed by the designing engineer according to the heating/cooling capacity of the device.

Page 18

The scheme of the heating system

Below you can see an example of the basic hydraulic and control scheme of the heating system. For

other circuits see The Catalogue of Hydraulic Circuit Diagram.

MD1

MD2

M

M

M

The elements on the scheme are marked in the following

manner:

Legend of read

ing:

GOC

Mark of the element

MD1:Q3

Mark of the connecting clip on the

input/output module - MD

Mark of the input/output module

Page 19

ELEMENTS

CONNECTING

CLIPS

MARK

CHARACTERISTICS

COMB A…G

Connection to various types of heat pumps

A

The device’s supply pipe for heating

B

The device’s return pipe for heating

OK

Current oil DHW

SP

Backup source

TSV

Warm sanitary water

BO

Boiler for sanitary water

HSV

Cold sanitary water

OCSV

Circulating pump for DHW

GOC

Main circulation pump

PLC

Processing unit

KT-1

Room temperature corrector KT-1 (can be used in all

heating cycles)

KT-2

Room temperature corrector KT-2 (can be used in all

heating cycles)

TS

Connector on PLC

Q1-Q12

Digital outputs of regulation ~ 230 V (input/output module

MD1 and MD2)

A1-A8

Analogue input (input/output module MD1 and MD2)

D1-D9

Digital input (input/output module MD1 and MD2)

HYB

Switch to hybrid operation

KH

Krono-hybrid

MD1

Basic input/output module 1

T1

Thermostat of heating cycle 1

T2

Thermostat of heating cycle 2

OC1

Circulation pump of heating cycle 1

OC2

Circulation pump of heating cycle 2

MV2

Mixing valve of heating cycle 2

OGK-1

Heating cycle 1

OGK-2

Heating cycle 2

MD2

Expansion input/output module 2

T3

Thermostat of heating cycle 3

T4

Thermostat of heating cycle 4

OC3

Circulation pump of heating cycle 3

OC4

Circulation pump of heating cycle 4

MV3

Mixing valve of heating cycle 3

MV4

Mixing valve of heating cycle 4

OGK-3

Heating cycle 3

OGK-4

Heating cycle 4

PST

Pipe safety thermostat

MARK

CHARACTERISTICS

MARK

CHARACTERISTICS

Closing valve

Manometer

Circulation pump

Temperature sensor

Closing valve with exhaust

Thermometer

Drain valve with plug

Consumer of heat / coolness

Cleaning piece

Automatic vent

Expansion tank

3-way switching valve with em drive

Safety valve

3-way mixing valve with em drive

Non-return valve

Supply pipe for heating

Pipe safety thermostat

Return pipe for heating

CAUTION

The supply pipe of each heating cycle must be fitted with an abutment safety thermostat

connected sequentially with the circulation pump to safeguard against the inflow of a

medium of excessive temperature.

Page 20

Preparing the heating hydraulic system - secondary

Prepare the system according to one of the recommended hydraulic schemes (Catalogue of Hydraulic

Wiring Diagrams) which is specified by the manufacturer of the device. This is the only way to ensure

reliable and effective operation of the device. After connecting the device to the heating system, it is

necessary to examine all circulating pumps and electric motor valves if they function correctly.

The device must be connected to the heating system via rubber compensator or flexible pipes. The

latter must not be under tension in final position, this would worsen the devices noise and vibration

protection. In extreme cases this can also lead to damage to the device.

Quality of heating water

Maximal allowed content of individual substances in the heating water and the influence of these on the

heat exchanger are presented in the table below. It is not allowed to use heating water which contains

any substance in concentrations which cause corrosion in the heating system (influence “-”). It is also

not allowed to use heating water which contains two or more substances in concentrations which could

cause corrosion in the heating system (influence “0”).

TYPE OF PRESENT

SUBSTANCE

UNIT CONCENTRATION

INFLUENCE TO THE HEAT

CONDUCTOR

Organic sediment mg / L 0

Ammonia NH3 mg / L

< 2

1 to 20

> 20

+

0

-

Chloride mg / L

< 300

> 300

+

0

Allowed water hardness °dH 5 – 10

Electrical conductivity µS / cm

< 10

10 to 500

> 500

0

+

-

Iron (Fe) removed mg / L

< 0.2

> 0.2

+

0

Free carbonic acid mg / L

< 5

5 to 20

> 20

+

0

-

Manganese (Mn) removed mg / L

< 0.1

> 0.1

+

0

Nitrates (NO3) removed mg / L

< 100

> 100

+

0

pH value mg / L

< 7.5

7.5 to 9

> 9

0

+

0

Oxygen mg / L

< 2

> 2

+

0

Hydrogen sulphide (H2S) mg / L

< 0.05

> 0.05

+

-

HCO3- / SO

4

2

- mg / L

> 1

< 1

+

0

Hydrogen carbonate mg / L

< 70

70 to 300

> 300

0

+

0

Aluminium (Al) removed mg / L

< 0.2

> 0.2

+

0

Sulphates mg / L

< 70

70 to 300

> 300

+

0

-

Sulphite (SO3) mg / L < 1 +

Chlorine (gas) (Cl2) mg / L

< 1

1 to 5

> 5

+

0

-

Table: Influence of various aggressive substances in the heating water on the stability of stainless

copper welded plate transmitters. (+ = no influence, 0 = danger of corrosion, - = corrosion - use not

permitted).

Page 21

CAUTION

The heating system has to be filled with water with the hardness between 5 °dH and 10

°dH. Malfunctions of the device because of water hardness are not covered by the warranty.

CAUTION

The same quality requirements apply for underground water.

The quality of the water used in the heating system is very important. The water from the water supply

is mostly not suitable for use in the heating system. To ensure adequate water hardness you must built

the water softener into the system.

The heating systems must not be filled with dirty or corrosive water. The heating water must be prepared

by adding anti-corrosion and anti-biological agents as well as agents against algae.

CAUTION

The water used for heating DHW via the built-in heat exchanger in the buffer tank for DHW

has to be in accordance with the requirements of standard VDI 2035 and must not contain

microorganisms. The heating system has to be filled with soft water which has been added

anti-corrosion and antibacterial agents for preventing corrosion. Before filling the heating

system has to be cleaned of all impurities.

The heating system has to be thoroughly vented. You must prevent air, including diffusion

air entering the device.

NOTE

To prevent damage to the components of the hydraulic system, we recommend the

additional installation of SpiroVent RV2 air (micro-bubble) venting system.

The presence of micro bubbles in the system eventually forms larger bubbles which in time

can cause corrosion of the system, system component malfunction and operation

disturbance.

In new systems, the impurities are a consequence of welding, soldering, dirty pipes (oil, grease), etc.

In case the impurities start accumulating in the device this can worsen the flow and heat transfer, in

worst cases also freezing of water in the heat exchanger and consequently the destruction of the device.

WARNING

To protect the device from intake and accumulation of dirt in the heat exchanger you must

install the strainer on the return line, before entry into the device.

WARNING

A galvanic disconnection between individual elements of the heating system (i.e. boiler,

container ...) is obligatory.

In the case of using grey steel pipes in the heating system, it is necessary to degrease them (the interior

of the pipe) before connecting them to the heat pump.

Page 22

Charging of the heating system

WARNING

Thorough venting of the system has to be ensured. Otherwise, malfunctions in operation

may occur.

CAUTION

An expansion vessel of suitable dimensions must be fitted to the heating system. The

expansion vessel must be dimensioned in accordance with standard EN 12828.

CAUTION

For normal operation of the expansion vessel, it is necessary to perform proper adjustments

of the tank’s working pressure. The settings have to be checked every 12 months.

The pressure settings of the expansion vessel and filling the hating system

B

C

D

A

H[m]

psv

A - Filling the system.

B - Expansion vessel.

C - Ball valve with exhaust.

D - Air filling valve.

H - Height of the heating system.

psv - Pressure of the safety valve.

CAUT

ION

Consider the maximal operational pressure of the vessel.

NOTE

Unsuitable pre-load of the expansion vessel with the pressure p0 is the reason for incorrect

operation of the heating system.

NOTE

The dimensions of the expansion vessel must be in accordance with standard EN 12828.

Page 23

Setting the pressure for the expansion vessel p0

Before filling the system with water, check and set the pressure p0.The expansion vessel is

factory set to the pressure specified on the standard label. For correct operation of the system,

set the pressure p0 according to the equation below. The filling must not exceed the maximal

operational pressure specified on the serial label of the expansion vessel.

Calculate the p0 pressure value with the help of the equation:

ሾ

MPaሿ=

ுሾ୫

ሿ

ଵ

+ 0,02 ሾMPaሿ,

ቀ

ሾ

barሿ=

ுሾ୫

ሿ

ଵ

+ 0,2 ሾbarሿቁ.

CAUTION

If the calculation shows a pressure lower than 0,1 MPa (1 bar), set the pressure of the

expansion vessel to 0,1 MPa (1 bar).

p0 [MPa (bar)] – pressure in the expansion vessel,

p

0min

[MPa (bar)] – minimal allowed pressure of the heating system,

p

0max

[MPa (bar)] – maximal allowed pressure of the heating system,

H [m] – Height of the heating system.

Set the amount of pressure in the expansion vessel by releasing or supplementing dry nitrogen.

Record the new value of the pressure p0 on the serial label.

Open the ball valveof the expansion vessel carefully, open the vents and close the drain.

Filling the heating system

Use the filling valve to fill the system with water of suitable quality (with anti-corrosion additives,

etc.) to the pressure pF.

ி ሾMPaሿ=

ሾ

MPaሿ+ 0,03 ሾMPaሿ,

ሺ

ி ሾbarሿ=

ሾ

barሿ+ 0,3 ሾbar

ሿ

ሻ

.

pF [MPa (bar)] – filling pressure,

p0 [MPa (bar)] – pressure in the expansion vessel.

Filling the system to the final pressure

The final pressure of the system is determined by heating the system to the maximal heating

temperature (thermal degassing).

Turn off the circulation pumps, open the vents and vent the system.

Fill the system up to the final pressure which is 0,05 MPa (0.5 bar) lower than the venting

pressure of the safety valve.

ሾ

MPaሿ≤

ୱ୴

ሾ

MPaሿ− 0,05 ሾMPaሿ,

ሺ

ሾ

barሿ≤

ୱ୴

ሾ

barሿ− 0,5 ሾbar

ሿ

ሻ

.

pE – the final pressure of the system,

pSV – the pressure of the safety valve.

Page 24

Heat source - primary

WARNING

The primary hydraulic system of the heat source can only be filled with a medium

recommended by the manufacturer.

Surface collector / depth probe

To prepare an efficient antifreeze liquid, water needs to be added at least 30 % of ethylene glycol. Such

a mixture provides protection against freezing up to -15 °C. Prepare the mixture according to the

recommendations in the table below.

NOTE

Before use, mix the mixture in a large container so as to ensure a homogeneous mixture.

Use a minimal concentration of 30 %, up to the temperature of -15 °C.

The entire volume of the pipes and the quantity of the antifreeze agent at each 100 m section at various

pipe diameters.

Pipe according to SIST

EN 12201

(PN 12,5)

in mm

The entire volume of

the pipe

for each 100 m section

of the pipe

in litres.

Quantity of antifreeze agent

for each 100 m section of the pipe

in litres (30 % concentration up to -15 °C).

WATER / antifreeze agent

32 x 3,0 (DN25) 53.1 37.1 / 16.0

40 x 3,7 (DN32) 83.5 58.4 / 25.1

50 x 4,6 (DN40) 130.7 91.4 / 39.3

63 x 5,8 (DN50) 207.5 145.2 / 62.3

75 x 6,9 (DN60) 294.2 205.9 / 88.3

90 x 8,2 (DN80) 425.5 297.8 / 127.7

NOTE

When determining the sufficient amount of the antifreeze mixture it is necessary to consider

the length of the pipe (supply and return) from the ground collector shaft to the utility room.

Filling procedure:

1. Check the main hydraulic system for tightness.

2. Connect the filling pipe to the collector / depth probe.

3. Open the vents (valves) on the device and the primary hydraulic system.

4. Start filling the antifreeze mixture. Make sure the system will be vented during filling.

5. Perform the filling until the vents (valves) lets out water without air mixed in.

6. Close the vents (valves) and fill the system as described in the chapter 3.2.3.

Underground water - primary

In case of using ground water as primary heat source, use the intermediate heat exchanger to protect

the device from the influences of undesirable substances and impurities in the ground water. Fill the

system between the exchanger and the device with an appropriate mixture of water and antifreeze

agent. The mixture should have a freezing point of at least -5 °C.

To fill the system with an intermediate heat exchanger, use the same procedure as when filling the

ground collector or depth probe.

CAUTION

In case that the quality of ground water does not meet the requirements of Chapter 3.2.2,

corrosion may occur over time. In extreme case the failure of the heat exchanger can

occur.

Page 25

3.3 Electrical connection

Connect the internal device to the mains according to the instructions described in this chapter.

CAUTION

Connecting the device to the electrical network has to be performed in accordance with the

standards for connecting devices to the electrical network. The device has to be connected

to the electrical network via the power supply cut-off which is installed into the electrical

installation under the regulations in force. The power supply cut-off has to separate all

contacts under the regulations of the overvoltage category III - minimal spacing between

contacts is 3 mm.

DANGER

The final electrical connection, before commissioning can only be performed by the person

authorised by the manufacturer to ensure the correct and efficient operation of the device.

IT IS STRICTLY PROHIBITED FOR UNAUTHORISED PERSONS TO TAMPER WITH

THE ELECTRICAL CONNECTION OF THE DEVICE.

DANGER

The device must be connected to the mains, which has a built-in RCD

residual-current device,

switch type A.

CAUTION

The device must be connected to the mains with a cable with an appropriate diameter. The

electrician defines the diameter of the cable according to the installation method, distance

of the device from the main electrical cabinet and the power of the device.

CAUTI

ON

The supply and communication cables have to be laid into the device and electrical cabinet

through separate envisioned ducts and overflows which are installed before the cable clamp.

This way we ensure the cable is relieved and the electrical cabinet is protected from water

penetration.

CAUTION

The communication cable must not be laid together with energy cables (in accordance with

good engineering practise and regulations).

Page 26

Description of elements in the electrical cabinet

Remove the lid of the device to access the electrical cabinet. See chapter 3.1.3.

X1 X2

5

N

TE1

TE2

GND

12V

PWM +

Q13

12V

D1 D2 D3 D 4 D5 D6 D7 D8 12V

SK Q10 Q11 Q12

A1

5V 5V

GND

A2

~230V ~230V ~230V

SK Q7 Q8 Q9

~230V ~230V ~230V

SK Q4 Q5 Q6

~230V ~230V ~230V

SK Q1 Q2 Q3

~230V ~230V ~230V

A3

5V 5V

GND

A4 A5

5V 5V

GND

A6 A7

5V 5V

GND

A8

MD1 (MBIO12)

PWM -

OPCIJSKO

3

JMP

11

10

2

9

3

5

6

8

7

4

1

1 Electrical contactor 6 Grounding lath

2 Overvoltage protection relay 7 Grounding connecting clips

3 Transformer 8 Connecting clips of the power line

4 Internal control unit TT3000 9 Input/output module MD1

5 Zero lath 10 Phase control, voltage relay

11 Electrical fuses

Page 27

PLC - process module

P

L

C

1

2

3

4

5

6

7

1 Process module (PLC). 5

WM - connection with the WEB module (factory

made).

2

TE2 - connection with the input/output module

(factory made).

6

RQ2 - connection for resetting the alarm (factory

made).

3

TS - connection of the room corrector KT-1(2)

7

RQ1 - connection of the signal for reporting an

alarm (optional).

4

TEX - MODBUS communication with the control

system of the building (MBS).

Schematic display of the control system - TT3000

ELEMENTS

CONNECTING CLIPS

MARK

CHARACTERISTICS

A Room temperature corrector

B Internal control unit TT3000

3 Basic input/output module MD1

TE1

Not in use

TE2

Communication with PLC

JMP

Set-up of bridges (without

5 Web module

K5

Internet (Ethernet) connection

K7

Communication with PLC

K8

Not in use

KT - 1

Room temperature corrector KT

-

1 (optional)

A +

Communication

B -

GND

Power supply

+12 V

KT - 2

Room temperature corrector KT

-

2 (optional)

A +

Communication

B -

GND

Power supply

+12 V

PLC Process module

WM

Communication with Web module

TEX

MODBUS communication with the control system of the building

(BMS)

TS

Communication with the room corrector

TE2

Communication with the basic V/I module MD1

Page 28

TEX

TE2

WM

TERMOTRONIC

K5

K8 K7

5

TE1

TE2

MD1 (MBIO12)

3

JMP

PLC

B

A+

B-

GND

+12V

KT - 2

KT - 1

A

A+

B-

GND

+12V

A+

B-

GND

+12V

TS

Connection of the internal control unit – TT3000

DANGER

Connecting the device to the power source can only be performed by a qualified installer.

In the scope of the internal control unit, MD1 has to be connected to:

main circulation pump,

temperature sensor for DHW,

power cable,

temperature sensor for external air temperature,

circulation pump for DHW (optional)

circulation pump of heating cycle 1 (optional),

circulation pump of heating cycle 2 (optional),

Page 29

mixing valve (optional),

cooling valve (optional),

additional external source (optional),

internet connection with UTP cable (optional),

temperature sensor of mixing-heating cycle 2 (optional),

remote on/off (optional)

thermostat of heating cycle 1 (optional),

thermostat of heating cycle 2 (optional),

switch for heating/cooling (optional).

Connecting clamps for connecting utility room elements on the pictures are marked with a dark

colour.

X1 X2

5

MD1

5

6

32

1

7

7

1 Constant voltage clamp ~230 V, 50 Hz 5 Connecting inputs of the heating system

2 Neutral lath for connecting neutral wires. 6

TE1

- connection for communication with the

expansion V/I MD2 module

3 Grounding lath for connecting grounding

wires.

7 Connecting outputs of the heating system

Page 30

Electrical connection of the power cable

DANGER

Connecting the device to the power source can only be performed by a qualified installer in

a voltage-free state.

CAUTION

The cable must be routed through the cord anchorage installed before the connecting

terminals in the indoor unit. Make sure the cable connected in the indoor unit is relieved from

strain.

CAUTION

Wrong dimensioning of the power cable or too weak terminal fuses of the device could lead

to an overload of the safety elements on the power grid of the building which could lead to

overheating of the electrical installation. Follow the requirements listed in this manual.

CAUTION

In case of connecting the multi-wire flexible cable to the connecting clamp, it always has to

have a necking die at the end.

1 Necking die 2

Multi-wire flexible cable

3 Massive single-wire cable

To connect to connecting clamps of the device, use cables with necking dies or a massive

single-wire cable.

Connecting clips of the supply cable

Connect the electrical supply (3N ~ 400 V / 50 Hz) to the connecting clips L1, L2, L3, N and

PE ( ). For choosing the appropriate diameters of the cables, see technical data (chapter 6.2).

Connect the connecting clamp 1 with a connecting wire to the connecting clamp on the

circulation pump of the heat source.

Connecting clamp 3, see chapter 3.4.1.

The stationary phase ~ 230 V, 50 Hz is connected to connecting clamp 5.

Connecting clamp PE ( yellow-green

cable),

Connecting clamp N (blue cable),

Connecting clamp L1 (black cable),

Connecting clamp L2 (black cable),

Connecting clamp L3 (black cable),

N L1 L2 L3 4 5 6 71 2 3

~ 230V

Page 31

Connect the ethernet communication UTP cable (connector RJ-45) to the marked input above

the main switch of the device. See picture below.

WEB module ethernet connection.

Main switch of the device

Page 32

Connecting clamps for choosing the type of device safeguard

CAUTION

The device is factory set for safeguarding the water-water type of device. In case of

safeguarding the device type earth-water, it is necessary to move the bridge 2.4 on element

X2. For safeguarding the device type earth-water, change the bridge on element X2 from

connecting clamp 2-4 to clamp 2-3.

Connecting the safeguard bridge on the device type water

-

wat

er (factory set)

► Factory connection on the bridge 2-4.

Connecting the safeguard bridge o the device type earth

-

water (installer)

► For safeguarding the device type

earth-water, change the bridge on

element X2 from connecting clamp 2-4

to clamp 2-3.

Page 33

3.4 Basic input-output module MD1 - WPG

The connecting clamps enable the connection of electrical valves, pumps and other elements of the

heating system to digital outputs Q1 to Q13 which are controlled via analogue inputs A1 to A8

(temperature sensors) and digital inputs D1 to D8.

3

List of inputs and outputs on the internal basic input/output module MD1

Analogue inputs

Digital inputs

Digital outputs

GND – grounding GND – grounding SK – phase (230 V / 50 Hz)

A1 – return temp. sensor D1 – TZ (current protection) Q1 – heat source

A2 – DHW temp. sensor D2 – HP (pressure switch) Q2 – connecting compressor 1

A3 – temp. sensor for outlet water D3 – LP (pressure switch) Q3 – main circulation pump

A4 – temp. sensor for inlet water D4 – flow switch Q4 – circulating pump for DHW

A5 – external temp. sensor D5 – remote on/off Q5 – reserve source

A6 – temp. sensor for supply pipe

for heating

D6 – thermostat of heating cycle 1 Q6 - reversible valve

A7 – temperature sensor of mixingheating cycle 2

D7 – thermostat of heating cycle 2 Q7 – circulation pump of heating cycle

1

A8 – passive cooling temperature

sensor

D8 – external regime switch Q8 – circulation pump of heating cycle

2

Q9 – mixing valve - opening

Q9 – mixing valve - closing

Q11 – cooling valve

SK – joint phase Q12 – additional external source

JMP – bridge layout Q13 – connecting compressor 2

TE1 (connector RJ45) - communication with the expansion V/I MD2 module

TE2 (connector RJ45) - communication with PLC

CAUTION

It is important to correctly connect the inputs and outputs. Incorrect connection can lead to

damage to the device. For the characteristics of inputs and outputs of the basic module MD1

see picture in chapter 3.4.1.

CAUTION

The joint electrical power of the devices which can be directly connected to the regulation

must not exceed 500 W. Otherwise, it is necessary to ensure separate power to the external

devices and to connect control cables to the V/I module.

CAUTION

Circulation pumps with EC drive (energy saving) must not be directly connected to the V/I

module because of capacitive influences. They have to be connected via external power

elements - relays.

Page 34

Connection of the elements to the internal control unit TT3000

To connect the elements of the heating system to the basic V/I module MD1, use a cable with the

diameter of wires 0.75 mm2. Connect the cable according to the wiring diagram specific to the case on

hand to the designated terminal clip. Connecting all possible elements of the heating system can be

seen on the diagram below. The places of connecting the elements to the connecting clamps are

marked with a dark dot. Standard and optimal connections of the utility room elements are given later

in this chapter 3.4.1.

TE1

TE2

GND

12V

PWM +

Q13

12V

D1 D2 D3 D4 D5 D6 D7 D8 12V

SK Q10 Q11 Q12

A1

5V 5V

GND

A2

~230V ~230V ~230V

SK Q7 Q8 Q9

~230V ~230V ~230V

SK Q4 Q5 Q6

~230V ~230V ~230V

SK Q1 Q2 Q3

~230V ~230V ~230V

A3

5V 5V

GND

A4

A5

5V 5V

GND

A6

A7

5V 5V

GND

A8

MD1 (MBIO12)

230V/12V

TR

RQ1

UTP

PWM -

OPCIJSKO

3

JMP

M6M5

M7

DZVOG

M8

M4M3

F1

C10A

RV

C2

C1

KF

N L 1L2 L3

N

1 2 3 4 5 6 7

~ 230V

OCTV

LP1

LP2

K

S2S1 S3 S4 S5 S6 S7 S8

T2

T1

VT

PS

C3

TV

C3

C2

F2

C10A

F3

B10A

F4 F5

R

R1

C1

GS

UTP

CAUTION

The device is factory set for safeguarding the water-water type of device. In case of

safeguarding the device type earth-water, it is necessary to move the bridge 2.4 on element

X2. For safeguarding the device type earth-water, change the bridge on element X2 from

connecting clamp 2-4 to clamp 2-3.

Page 35

ELEMENTS

CONNECTING

CLIPS

MARK

CHARACTERISTICS

X1

Connecting clip

Grounding wire

N

Neutral wire

L1

Connecting phase of the input cable

L2

Connecting phase of the input cable

L3

Connecting phase of the input cable

X2

Connecting clip

1

Connecting the CP of the heat source

2

Joint connecting clip LP switch

3

Connecting clip LP switch earth - water

4

Connecting clip LP switch water - water

5

Connecting clip 230 V

6

Connecting clip thermal fuse

7

Connecting clip thermal fuse

3

MD1

Basic input/output module 1

JMP

Set-up of bridges (without)

C2 Q1

Heat source

C1 Q2

Connecting compressor 1.

M3 Q3

Main circulation pump

PWM

-

Circulation pump speed regulation

PWM +

Circulation pump speed regulation

M4 Q4

Switching valve for sanitary water

RS Q6

Reversible valve

M5 Q7

Circulation pump - heating cycle 1

M6 Q8

Circulation pump - heating cycle 2

M7

Mixing valve

Q9

Opening of mixing valve

Q10

Closing of mixing valve

M8 Q11

Valve for cooling

DZVOG

Q12

Additional external source

S1 A1

Return temperature sensor

S2 A2

Temperature sensor of sanitary water

S3 A3

Outlet water temperature sensor

S4 A4

Inlet water temperature sensor

S5 A5

Temperature sensor for external temperature

S6 A6

Temperature sensor of the supply pipe

S7 A7

Heating cycle 2 temperature sensor

S8

Passive cooling temperature sensor

R D1

Overvoltage protection

VT D2 P

High-pressure switch

LP1 D3

Low-pressure switch 1 in water-water mode

LP2 D3

Low-pressure switch 2 in earth-water mode

PS D4 F

Flow switch

T1 D6 T

Thermostat of heating cycle 1

T2 D7 T

Thermostat of heating cycle 2

TE1

Connection with the expansion module MD2

TE2

Communication with PLC

PLC Process module

WM

Communication with Web module

TEX

MODBUS communication with the control system of the building (BMS)

TS

Communication with the room corrector

TE2

Communication with the basic V/I module MD1

5 Web module

K5

Internet connection

K7

Not in use

K8

Communication with PLC

F1

C10A

Fuse

F2

C10A

Fuse

F3

B10A

Fuse

F4

B10A

Fuse

F5

B10A

Fuse

TR

Transformer 230 V / 12 V

EG

Electrical boiler

RQ1

ALARM voltage-free contact

UTP

UTP cable

GS

Main switch

Page 36

OCTV

Heat source circulation pump

TF T

thermal fuse

C1

Electrical contactor

C2

Electrical contactor

C3

Electrical contactor

KF

Phase control, voltage relay

M 3~

Three-phase motor

K

Compressor

R

Overvoltage protection

N

Neutral lath

Grounding lath

Main circulation pump connection

Basic connection

Connect the main circulation pump to Q3.

Digital output

connection clamp Q3

MD1 (MBIO12)

3

JMP

Page 37

Main circulation pump speed regulation (optional)

The internal basic input/output module MD1 with the appropriate choice of circulation pump type offers

linear speed adjustment of water flow. The circulation pump M3 with built-in control input is connected

to the digital output Q3. Setting the speed is enabled by connecting the PWM pump input and PWM - /

PWM + outputs on the internal basic V/I module MD1.

Digital output

connection

clamp Q3

Connection

clamps output

PWM - and

PWM +.

Connecting heating cycle 2 (direct cycle - optional)

Connect the circulation pump M5 from mixing cycle 1 to connecting clamp of the digital output Q7. The

cycle is controlled via room thermostat signal between GND and D6 (picture below) or room corrector

KT-1(2) signal (chapter 3.5) or via weather curve.

Connecting clamp of

the digital output Q7

(heating cycle).

Voltage-free connection

clamp digital input D6

(thermostat - optional)

Connection of heating cycle 2 (optional)

Direct circuit

MD1 (MBIO12)

3

JMP

MD1 (MBIO12)

3

JMP

Page 38

To connect the direct heating cycle 2, connect the circulation pump M6 to the output Q8. The request

to turn on the direct heating cycle 2 is the room thermostat signal connected between GND and D6

(picture below) or room corrector KT-1(2) signal (chapter 3.5) or weather curve.

Digital output

connection clamp Q8

(heating cycle).

Voltage-free

connection clamp

digital input D7

(thermostat optional).

MD1 (MBIO12)

3

JMP

Page 39

Mixing circuit

To connect the mixing heating cycle 2, connect the circulation pump M6 to the output Q8. And the

mixing valve M7 to Q9 and Q10. To control the temperature, connect the mixing cycle sensor to input

A7. The request to turn on the mixing heating cycle 2 is the room thermostat signal connected between

GND and D6 (picture below) or room corrector KT-1(2) signal (chapter 3.5) or weather curve.

Digital output connection

clamp Q8

(heating cycle).

Connecting clamp of the

digital output Q10 (mixing

cycle).

Connecting clamp of the

digital output Q9 (mixing

cycle).

Connecting clamp of the

analogue input A7 (mixing

heating cycle 2

temperature sensor).

Voltage-free connection

clamp digital input D7

(thermostat - optional).

MD1 (MBIO12)

3

JMP

Page 40

DHW connection (optional)

Connecting the DHW can be performed in two different ways:

1. Along with the main circulation pump M3, connect the digital output Q4 with the separate pump

M4 which ensures the flow for the DHW. The circulation pump M4 is controlled via analogue

input A2 which is connected with the DHW temperature sensor S2 for DHW.

Connecting clip

digital output Q4

(DHW pump).

Connecting clamp

analogue input A2

(DHW temperature

sensor).

2. Along with the main circulation pump M3 which ensures flow also for DHW, connect the digital

output Q4 with the switch valve M4.1. The switch valve M4.1 is controlled via analogue input

A2 which is connected with the DHW temperature sensor S2 for DHW.

Connecting clip digital

output Q4 (switch valve

for DHW).

Connecting clamp

analogue input A2

(DHW temperature

sensor).

MD1 (MBIO12)

3

JMP

JMP

3

MD1 (MBIO12)

Page 41

Connection of the device’s remote on/off (optional)

Device’s remote on/off is performed via the switch between the digital input D5 and GND. Use it if you

are using BMS (building management system), cascade regulation of multiple devices and additional

source in the heating system, and in case of a demand from the electricity distributor for a remote shut

down of the device.

Voltage

-

free connection cla

mp digital input D5

External switch of heating/cooling (optional)

The function of switching between heating/cooling is used when you would like to manually turn on

cooling in winter mode. External operating mode switch is performed between the clamp of the digital

input D8 and GND.

MD1 (MBIO12)

3

JMP

Voltage

-

free connection clamp digital input D8

MD1 (MBIO12)

3

JMP

Page 42

Connecting the cooling valve (optional)

The cooling valve M8 connect to the digital output Q11. You can use it in case of active and/or passive

cooling.

Connecting clamp of

the

digital output Q11 (switch

valve).

Connecting the relay of the additional source DOVOG- gas/oil DHW (optional)

Additional external heat source (DZVOG) is connected to the relay which is connected to the digital

output Q12. DZVOG does not function as reserve source. Use it when you have a larger need for heat

than the device can provide you at a given moment.

Digital output

connection

clamp Q12

JMP

3

MD1 (MBIO12)

JMP

3

MD1 (MBIO12)

Page 43

3.5 Connection of the room temperature corrector KT-1 and KT-2

Spatial corrector KT-1(2) is connected according to the circuit diagram below. Care should be taken to

correctly connect the UTP cable with the connector RJ-45.

KT - 1 KT - 1 KT - 1

KT - 1

KT - 1

KT - 1

RQ1

RQ2

TEX

TE2

TS

WM

1

.

.

.

.

.

.

8

KT - 1

A+B-GND + 12V

1 2 3 4 5 6 7 8

RJ-45

UTP

RJ-45

P

PLC

A+B-GND + 12V

A+B-GND + 12V

A+

B- GND +12V

A+B-GND + 12V

A+B-GND +12V

A+B-GND +12V

S

ELEMENTS

CONNECTING

CLIPS

MARK

CHARACTERISTICS

KT-1(2) Room temperature corrector KT

-

1(2) (optiona

l)

A +

Communication

B -

GND

Power supply

+12 V

PLC Process module

RQ1

ALARM voltage-free contact

RQ2

RESET voltage-free contact

WM

Communication with Web module

TEX

MODBUS communication with the control system of

the building (BMS)

TS

Communication with the room corrector

TE2

Communication with the basic module MD1

UTP

UTP cable

RJ-45

Connector RJ-45

P

Parallel connection

S

Sequential connection

Page 44

4. Commissioning of the device

After professional installation, the authorised contractor for commissioning has to perform the

commissioning of the device.

CAUTION

The commission can only be performed by a person authorised by the manufacturer! If the

commission is performed by an unauthorised person, the warranty is not recognised.

Management of the device must be performed in accordance with current instructions for use.

5. Maintenance

The device must be inspected once a year. The electrical and hardware installation of the device have

to be inspected. In the case of detected irregularities, contact the authorised technician.

CAUTION

The servicing and maintenance of the device can only be performed by a person authorised

by the manufacturer. In case of a malfunction, first contact the installer who installed the

device.

5.1 Cleaning the water filter

NOTE

Cleaning of water filters on the return into the device is advised to be performed at least once

yearly.

CAUTION

A blocked water purifying component and magnetic filter can lead to a malfunction of the

device or incorrect functioning of the device. In case the display displays a warning of flow

malfunction (”Caution, flow!”).

5.2 Monitoring the pressure in the heating system

NOTE

Periodically, once yearly, check the water temperature in the heating system. The pressure

in the system should be between 1.5 and 2 bar.

NOTE

In case the pressure falls (i.e. Leakage of the system) the display displays a warning of flow

malfunction (”Caution, flow!”).

CAUTION

Before the commission it is necessary all the required tasks and inspections from the tasks

for commission.

Page 45

5.3 Cleaning of the heat conductors

Cleaning of the heating system (water side)

Residue of grease and sealants in pipes can pollute the condenser of the device up to a point where

cleaning is necessary. In this case the authorised person should perform the cleaning with a mild

solution (up to 5 %) of phosphorous acid which should be heated to room temperature. The condenser

has to be completely disconnected from the heating system and rinsed with diluted phosphorous acid

in the opposite direction of normal flow.

After cleaning the condenser has to be rinsed thoroughly with an agent neutralising the acid detergent

so as to prevent contamination of the heating system.

CAUTION

Acid detergents should be used carefully, instructions of the manufacturer and

environmental regulations must be followed. The cleaning can only be performed by a

qualified person.

If any doubts about using the detergents arise, consult with the manufacturer of the detergent.

5.4 Operation malfunctions

In case of a malfunction during the operation of the device, the display of the TERMOTRNIC controller

displays the warning “Caution, malfunction”.

Find the malfunction description in the manual. For error correction call the installer who installed the

device.

Page 46

6. Technical data

6.1 Dimensions of the device

Device WPG H WPG HK

Dimensions G [mm] 480 600

Page 47

6.2 Technical data

Device WPG-07-1 HT WPG-10-1 HT WPG-15-1 HT

Version

Heat source primary side1)

Geothermal energy

2)

Heat sink secondary side Water

3)

Controller TERMOTRONIC 3000 WEB

Device placement Internal

Placement of the controller un. Installed in the heat pump

Compressor 1 x scroll

Electric heater 3 x 2 kW

Soft start-up Yes (optional)

Circulation pump, primary /

Circulation pump, secondary /

Capacity

Heating

Heating power / electrical power / COP

11)

W10/W30-35

kW / kW / -

7,4 / 1,4 / 5,48

10,3 / 1,9 / 5,42

15,0 / 2,7 / 5,50

W10/W47-55

kW / kW / 6,6 / 2,0 / 3,30

9,2 / 2,7 / 3,41

13,2 / 3,9 / 3,38

B0/W30-35

4)

kW / kW / -

5,4 / 1,2 / 4,53

7,8 / 1,7 / 4,58

11,4 / 2,5 / 4,60

B0/W47-55

4)

kW / kW / -

4,8 / 1,6 / 3,00

7,1 / 2,4 / 2,95

10,3 / 3,5 / 2,90

Cooling

5)

Cooling power / electrical power / EER

12)

W20/W12-7

kW / kW / -

5,7 / 1,3 / 4,46 8,1 / 1,8 / 4,52 11,8 / 2,6 / 4,61

B20/W12-7

kW / kW / -

5,7 / 1,3 / 4,46 8,1 / 1,8 / 4,52 11,8 / 2,6 / 4,61

Electrical data

Rated voltage 3N~ 400 V; 50 Hz

Max. operational current A 15.4 16.7 19.0

Max. electrical power kW 8.8 9.8 11.1

Z

max

14)

Ω

no limit 0.065

Current of blocked rotor (LRA) A 26 32 64

Fuses

15)

A 3 x 16 3 x 16 3 x 20

Electrical power cable

6), 7)

Internal unit mm

2

5 x 2.5 5 x 2.5 5 x 2.5

Cooling system

WPG H

Refrigerant - type R407C

Refrigerant - quantity kg 1.6 2.1 2.3

Max. operational pressure MPa 2.9

WPG HK

Refrigerant - type R407C

Refrigerant - quantity kg 2.1

2.2 2.5

Max. operational pressure MPa 2.9

Primary side

1)

(heat source)

- water

Min. / Max. pressure in the system MPa 0,05 / 0,3 (0,5 / 3 bar)

Pipe connections G 1” (int. dev.)

G 1” (int. dev.)

G 5/4” (int. dev.)

Recommended dimensions of pipes

leading to the device

8)

DN 25 25 32

Device inlet water temp. 10 °C (i.e. ground water)

- operation as “water

-

water”

Rated flow

m3 / h

1.7 2.3 3.4

Pressure drop at rated flow kPa 14 18 15

Heating

Operating envelope -

min. / max. water temperature

°C 7 / 25

Cooling

Operating envelope min. / max. water temperature

°C 10 / 40

Page 48

Device WPG-07-1 HT WPG-10-1 HT WPG-15-1 HT

Inlet temp. 30% soluti

on of ethylene glycol in the device 0 °C (i.e. ground collector, borehole)

- operation as “earth

-

water”

Rated flow

m3 / h

1.1 1.6 2.2

Pressure drop at rated flow kPa 9 13 9

Heating

Operating envelope -

min. / max. medium temperature

°C -7 / 25

Coolin

g

Operating envelope min. / max. medium temperature

°C 10 / 40

Recommended main circulation

pump

8)

YONOS

Yonos PARA RS

25/7.0

Yonos PARA RS 25/7.5

Yonos PARA RS

25/7.5

Secondary side

1)

(heat sink)

- water

3)

Min. / Max. pressure in the system MPa 0,05 / 0,3 (0,5 / 3 bar)

Pipe connections G 1” (int. dev.) G 1” (int. dev.) G 1” (int. dev.)

Recommended dimensions of pipes

leading to the device

DN 25 25 25

Recommended main circulation

pump

8)

WILO Yonos PARA RS 25/7.0

Yonos PARA RS

25/7.5

Heating

Operating envelope -

min. / max. water temperature

°C 25 / 63

Cooling

Operating envelope -

min. / max. water temperature

°C 75) / 25

Heat pump inlet water temp. 10 °C (i.e. ground water)

- operation as “water

-

water”

Rated flow

m3 / h

1.2 1.7 2.5

Pressure drop at rated flow kPa 12 16 14

Inlet temp. 30% solution of ethylene glycol in the device 0 °C (i.e. ground collector, borehole)

- operation as “earth

-

water”

Rated flow

m3 / h

0.9 1.2 1.8

Pressure drop at rated flow kPa 9 11 10

Dimensions and mass

WPG H

Dimensions (W x H x D)

mm 700 x 1150 x 480

Transport mass kg 108 113 133

Net mass kg 98 103 123

WPG HK

Dimensions (W x H x D)

mm 700 x 1150 x 600

Transport mass kg 110 122 134

Net mass kg 100 112 124

Noise level

9)

Level of sound power dB (A)

53 54 55

The level of sound pressure

at a distance of 1 m

dB (A)

45 46 47

The level of sound pressure

at a distance of 5 m

dB (A)

31 32 33

The level of sound pressure

at a distance of 10 m

dB (A)

25 26 27

Communication

Connection to BMS

MODBUS protocol (UTP cable – connection RJ45) – RS 485

Connection to the internet

10)

UTP 5e cable - connection RJ45 - Ethernet

Miscellaneous

Protection class

Internal unit IP20

Page 49

Device

WPG-18-1 HT WPG-21-1 HT

Version

Heat source primary side

1)

Geothermal energy

2)

Heat sink secondary side Water

3)

Controller TERMOTRONIC 3000 WEB

Device placement Internal

Placement of the controller un. Installed in the heat pump

Compressor 1 x scroll

Electric heater 3 x 2 kW ~ 230V

Soft start-up Yes (optional)

Circulation pump, primary /

Circulation pump, secondary /

Capacity

Heating

Heating power / electrical power / COP

11)

W10/W30-35 kW / kW / - 18,3 / 3,3 / 5,54 21,5 / 3,9 / 5,50

W10/W47-55 kW / kW / 16,3 / 4,7 / 3,46 19,4 / 5,7 / 3,30

B0/W30-35

4)

kW / kW / - 13,9 / 3,1 / 4,55 16,6 / 3,6 / 4,61

B0/W47-55

4)

kW / kW / - 12.7 /4.3 / 2.95 15,2 / 5,1 / 2,98

Cooling

5)

Cooling power / electrical power / EER

12)

W20/W12-7 kW / kW / - 14,4 / 3,1 / 4,56 17.3 /3.7 / 4.65

B20/W12-7 kW / kW / - 14,4 / 3,1 / 4,56 17.3 /3.7 / 4.65

Electrical data

Rated voltage 3N~ 400 V; 50 Hz

Max. operational current A 21 22.5

Max. electrical power kW 12 13.1

Z

max

14)

Ω

0.055

0.083

Current of blocked rotor (LRA)

A 64 74

Fuses

15)

A 3 x 20 3 x 25

Electrical power cable

6)7)

Internal unit mm

2

5 x 2.5 5 x 4

Cooling system

WPG H

Refrigerant - type R407C

Refrigerant - quantity kg 2.4 2.8

Max. operational pressure MPa 2.9

WPG HK

Refrigerant - type R407C

Refrigerant - quantity kg 2.5 3.3

Max. operational pressure MPa 2.9

Primary side

1)

(heat source)

- water

Min. / Max. pressure in the system MPa 0,05 / 0,3 (0,5 / 3 bar)

Pipe connections G 5/4” (int. dev.) G 5/4” (int. dev.)

Recommended dimensions of pipes leading to the

device

8)

DN 32 32

Device inlet water temp. 10 °C (i.e. ground water)

- operation as “water

-

water”

Rated flow m3 / h

4.2 4.9

Pressure drop at rated flow kPa 16 20

Heating

Operating envelope -

°C 7/25

min. / max. water temperature

Cooling

Operating envelope -

°C 10/40

min. / max. water temperature

Inlet temp. 30% solution of ethylene glycol in the device 0 °C (i.e. ground collector, borehole)

- operation as “earth

-

water”

Rated flow m3 / h

2.7 3.3

Pressure drop at rated flow kPa 11 14

Heat

ing

Operating envelope -

°C -7/25

min. / max. medium temperature

Cooling

Operating envelope -

°C 10/40

min. / max. medium temperature

Recommended main circulation pump

8)

WILO Stratos PARA 25/1-8 Stratos PARA 25/1-8

Page 50

Device

WPG-18-1 HT WPG-21-1 HT

Secondary side

1)

(heat sink)

- water

3)

Min. / Max. pressure in the system MPa 0,05 / 0,3 (0,5 / 3 bar)

Pipe connections G 5/4” (int. dev.) G 5/4” (int. dev.)

Recommended dimensions of pipes leading to the

device

DN 32 32

Recommended main circulation pump

8)

WILO Stratos 25/1-8

Heating

Operating envelope -

°C 25 / 63

min. / max. water temperature

Cooling

Operating envelope -

°C 75) / 25

min. / max. water temperature

Device inlet water temp. 10 °C (i.e. ground water)

- operation as “wat

er-water”

Rated flow m3 / h

3 3.5

Pressure drop at rated flow kPa 15 20

Inlet temp. 30% solution of ethylene glycol in the device 0 °C (i.e. ground collector, borehole)

- operation as “earth

-

water”

Rated flow m3 / h

2.2 2.6

Pressure drop at rated flow kPa 16 18

Dimensions and mass

WPG H

Dimensions (W x H x D)

mm 700 x 1150 x 480

Transport mass kg 136 139

Net mass kg 129 132

WPG HK

Dimensions (W x H x D)

mm 700 x 1150 x 600

Transport mass kg 139 146

Net mass kg 132 138

Noise level

9)

Level of sound power dB (A) 55 57

The level of sound pressure

dB (A) 47 49

at a distance of 1 m

The level of sound pressure

dB (A) 33 35

at a distance of 5 m

The level of sound pressure

dB (A) 27 29

at a distance of 10 m

Communication

Connection to BMS

MODBUS protocol (UTP cable – connection RJ45) –

RS 485

Connection to the internet

10)

UTP 5e cable - connection RJ45 - Ethernet

Miscellaneous

Protection class

Internal unit IP20

1)

The marks heat source and heat sink or primary and secondary side of the device by default refer to the heating mode

although cooling mode and heat source and heat sink can switch according to the mode.

2)

Geothermal energy in heat pumps can be used via ground water (the so-called water-water systems) or via ground

collector or borehole (the so-called earth-water system). In case of a water-water system, the installation of an

intermediate heat exchanger is required because ground water can contain substances which could be harmful to the

components of the heat pump. Requirements regarding water quality are stated in the installation manual of the device.

The requirements must be taken into account! In case of an earth-water system, the use of an adequate antifreeze

agent is required.

3)

A water solution with up to 30% propylene glycol or ethylene glycol can also be used as secondary medium; the use of

other substances is prohibited or prior consultation with the manufacturer of the device is necessary. Requirements

regarding water quality are stated in the installation manual of the device. The requirements must be taken into account!

4)

The use of adequate antifreeze liquid is required. The data applies to the use of a 30 % solution of ethylene glycol.

5)

All devices are available also as reversible models which means they can also be used to cool. The factory setting of

the minimal supply pipe for heating lock is set to 12 °C (suitable for example for wall cooling etc.). If there is a need for

a lower outlet water temperature (i.e. Convector heating), the lock for outlet water can be lowered to 7 °C (by an

authorised commission contractor) but only in case the system is set up according to one of the hydraulic piping diagrams

from the current Catalogue of

Hydraulic Piping Diagrams

approved by the manufacturer of the device.

Page 51

6)

With the cable we have taken into account laying B2 from the table A.52.4 – IEC 60364-5-52. The cable in the installation

pipe is fixed to the wall. The dimensions of the electrical cables must always be checked or determined by the designing

engineer of electrical installations.

6*)

7)

The joint maximal load (circulation pumps, electronic valves ...) which can be used or fed by the device must not exceed

500 W. Higher consumers (i.e. pumps) should have their own supply.

8)

Applies to pipe connections of appropriate dimensions and joint distance of up to 20 m. Pipe dimensions and types of

pumps must always be verified or determined by the designing engineer of electrical installations. Circulation pumps

must be dimensioned in such a way so as to ensure rated voltage (see table) through the device.

9)

The sound pressure is mathematically specified in case of a free sound field.

10)

Connection to the internet is not necessary for the operation of the device but it is necessary for remote control through

the Home Cloud service. It is recommended to enable the connection because this enables faster and simpler device

troubleshooting.

11)

COP (Coefficient of Performance) is a card for performance efficiency of the device, the heating number which is a

quantity without unit. Mathematically, COP is the ratio between the energy gained - heat (in cooling it is heat taken away)

and electrical energy needed for the functioning of the device.

12)

EER (Energy Efficiency Ratio) is an abbreviation for the coefficient of the cooling energy efficiency. Mathematically, EER

is the ratio between the effective cooling power and effective electrical power in [kW].

13)

After connecting the device it is necessary to acquire the guarantee or consult the operator of the distribution network

that the impedance of the network is lower than

Z

max

. This way the device will operate within acceptable limits of

disruptions. Otherwise it is necessary to connect the device to the network using a soft start device.

14)

Circuit breaker with “slow” characteristics for devices with very high inrush current.

Page 52

6.3 Operating envelope

Devices can operate inside the operation ranges shown below.

Heating mode

Cooling mode

Applies to reversible models

10

20

30

40

50

60

70

-10 -5 0 5 10 15 20 25 30

Temp. of outlet water [°C]

Temperature of heat source [°C]

0

10

20

30

0 10 20 30 40 50

Outlet water temperature [°C]

Air temperature [°C]

Page 53

6.4 Noise

Noise is any kind of sound which causes a disturbance, interferes with a person’s work and causes

harm to health and well-being. Individuals can have different reactions to the same noise at different

occasions. Perception of sound also depends on the current mood of an individual.

Every device which operates with fluctuation is a source of sound. The spread of sound or noise is also

affected by walls and other obstacles in the in the vicinity of the device. This is why the correct choice

of location of the device is very important.

Sound emissions of the device into the surroundings are described by physical quantities such as sound

power and sound pressure. Both physical quantities are given in the dimensionless unit decibel (dB).

Level of sound power (L)

The power level of sound is the energy of sound which the device emits into the environment per

second. It is a quantity which is used for the basic comparison of various sound sources and for

determining whether the machine or device complies with the regulations and standards for noise

radiation. The power of sound is independent on the environment in which the source is located.

The reference sound power is 10

-12

W.