Page 1

Instructions For Use And Installation

Heat Pumps for Sanitary Water Heating

This manual is to be handed over to the end user after installation!

WP4 LF-502

ID.: 17-16-20-2979-10 / 3.2018

EN

Page 2

ID.: 17-16-20-2979-10

2

3.2018

Instructions for use and installation - Version 10 / Released on 3.2018

Printed in Slovenia, Copyright by Kronoterm d.o.o.

This document is copyrighted. Any use outside the provisions of the copyright law without the

permission of Kronoterm d.o.o. is illegal and punishable by law. All previous versions of this

document are void. We reserve the right to make changes. We reserve the right to change

this document and for printing errors.

Page 3

ID.: 17-16-20-2979-10

3

3.2018

1. Index

1. Index....................................................................................................................... 3

2. Important Information ........................................................................................... 5

2.1 Symbols .................................................................................................................. 5

2.2 General Warnings and Instructions ......................................................................... 5

2.3 Safety Warnings and Instructions ............................................................................ 6

2.4 Obligations of the Manufacturer............................................................................... 9

2.5 Obligations of the Installer ....................................................................................... 9

2.6 Customer Support - Service .................................................................................... 9

2.7 Obligations of the User ............................................................................................ 9

2.8 Factory Testing ......................................................................................................10

2.9 Storage ..................................................................................................................10

2.10 Transportation ........................................................................................................10

2.11 Delivery Content .....................................................................................................10

3. Technical Description ..........................................................................................11

3.1 General ..................................................................................................................11

3.2 Components ...........................................................................................................11

3.3 Operation Principle .................................................................................................13

4. Position of Connections and Dimensions ..........................................................14

5. Installation ............................................................................................................15

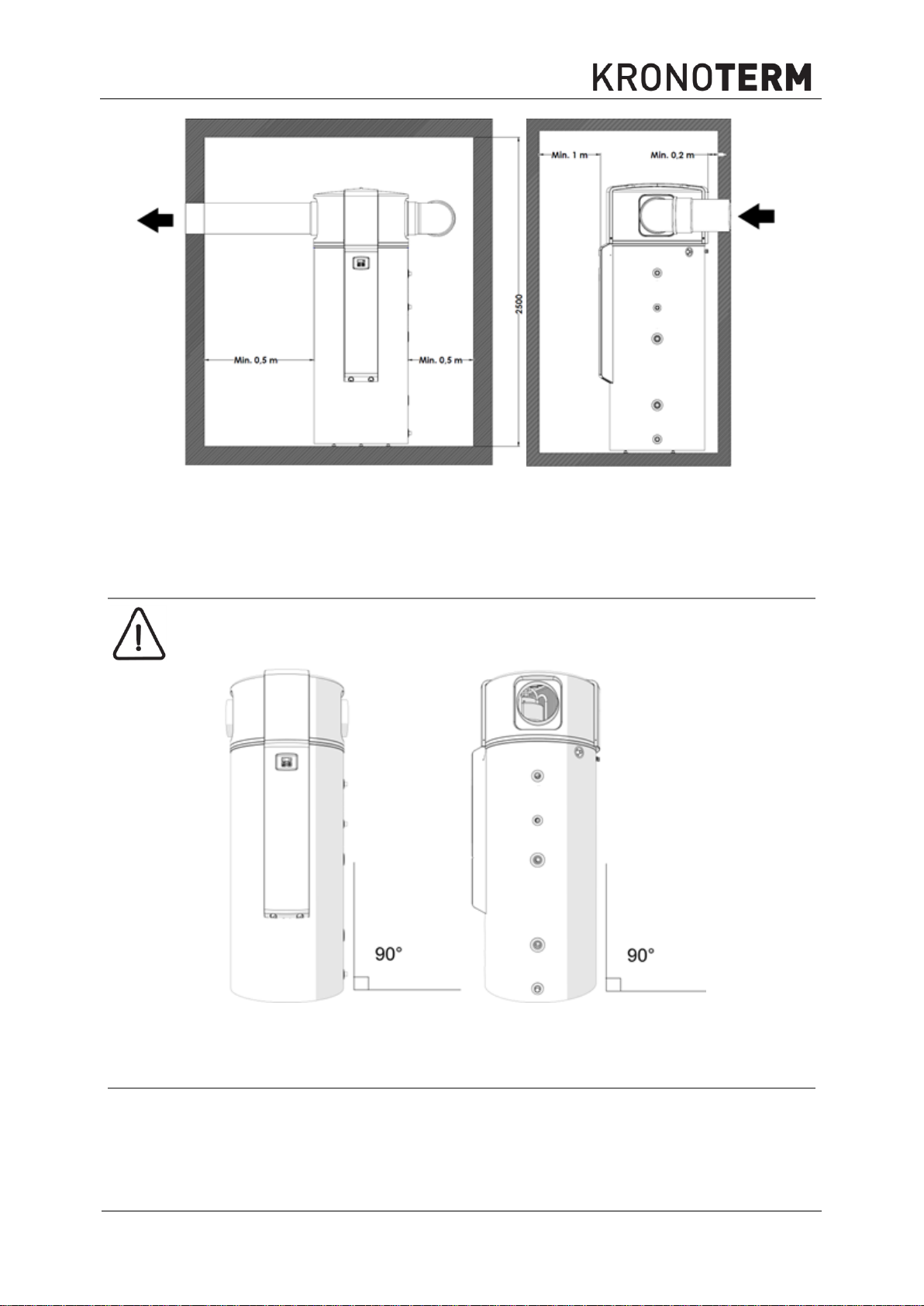

5.1 Minimal spacing of the device: ...............................................................................16

5.2 Device Levelling .....................................................................................................17

5.3 Hydraulic Connection .............................................................................................17

5.4 Air Canal Installation ..............................................................................................19

5.5 Connection of Condensation Outlet ........................................................................20

5.6 Connection of External Heating Source (alternative / additional source) .................21

5.7 Placement of External Controller Temperature Probe ............................................25

5.8 Parallel Connection of Several Devices ..................................................................26

5.8.1 Connection of Cold - Hot Water and Circulation .....................................................26

5.8.2 Connection to Boiler ...............................................................................................27

5.8.3 Air Canal Connection .............................................................................................27

5.9 Electric Connection ................................................................................................28

5.9.1 Power Supply: ........................................................................................................29

5.9.2 Additional Heat Source Connection ................................ ........................................30

6. Device Startup ................................................................ ......................................31

6.1 Filling Device with Water ........................................................................................31

6.2 Controls Before Startup ..........................................................................................31

6.3 Device Startup ........................................................................................................31

7. Controller ..............................................................................................................32

7.1 Basic Window .........................................................................................................32

7.1.1 Sanitary Water Temperature ..................................................................................32

7.1.2 System statuses .....................................................................................................32

7.1.3 Setting of Desired Temperature of Sanitary Water .................................................33

7.2 Screensavers .........................................................................................................33

7.2.1 All screensavers .....................................................................................................33

7.3 Menu ......................................................................................................................34

7.3.1 Error Acknowledgement .........................................................................................35

7.3.2 Quick Water Heating ..............................................................................................35

7.3.3 Basic Operation Programme ..................................................................................35

7.3.4 Temperature Deviation ECO ..................................................................................35

7.3.5 Temperature Deviation COMFORT ........................................................................35

7.3.6 Daily Schedule .......................................................................................................35

7.3.7 Ventilation Schedule ...............................................................................................36

7.3.8 Vacation ................................ ................................................................ .................37

Page 4

ID.: 17-16-20-2979-10

4

3.2018

7.3.9 Time .......................................................................................................................37

7.3.10 Backup Source .......................................................................................................37

7.3.11 Overheating Programme - Anti-legionella ...............................................................38

7.3.12 Automatic Quick Water Heating..............................................................................38

7.3.13 Screen Brightness ..................................................................................................38

7.3.14 System Information ................................................................................................38

7.3.15 Advanced Installation Settings ...............................................................................39

8. Device Operation Setting ................................................................ .....................41

8.1 Basic Operation ......................................................................................................41

8.1.1 Basic Operation Programmes ................................................................................41

8.2 Additional Source ...................................................................................................42

8.2.1 Correct choice of the additional source ...................................................................42

8.2.2 Choosing the correct operation mode of the external source ..................................42

8.3 Additional Operation Programmes ..........................................................................43

8.3.1 Backup Source .......................................................................................................43

8.3.2 Quick Water Heating ..............................................................................................43

8.3.3 Anti-freeze Programme ..........................................................................................44

8.3.4 PHOTOVOLTAICS .................................................................................................44

8.3.5 "Bivalent mode" Programme ..................................................................................44

8.3.6 "Defrost" Programme .............................................................................................44

9. Errors and Warnings ............................................................................................45

9.1 Warnings ................................................................................................................45

9.2 Errors .....................................................................................................................46

9.3 Errors of the OPTITRONIC 2 - WEB module (option): ............................................48

10. Removal and Disposal .........................................................................................49

11. Maintenance and Care .........................................................................................49

12. Errors in Operation ..............................................................................................49

13. Electrical Connection Scheme ............................................................................50

14. Technical data ......................................................................................................51

15. Legend of data label .............................................................................................52

Page 5

ID.: 17-16-20-2979-10

5

3.2018

These symbols mark various risks for the user or the device.

DANGER: Risk of situations which can lead to serious physical injuries.

WARNING: Risk of situations which can lead to minor physical injuries.

CAUTION: Risk of situations which can lead to damage or malfunction of

the device.

This symbol marks information for the user.

NOTE: A notice holding important information regarding requirements of the

manufacturer and the device.

NOTE

Before beginning the installation read the installation and operation manual.

NOTE

Any modification or replacement of original components of the device makes

the guarantee of the manufacturer for safe and functional operation null and

void. In any case of improper use of the devise or uses it was not intended

for, the manufacturer is not liable for consequences and will reject any

claims. Injuries and damage to the device or other property due to improper

2. Important Information

The manuals describe the process of installation and maintenance of the device. The

installation and maintenance can only be performed by qualified personnel. Read the manual

carefully before the installation, this way you will be informed about the intended use,

functionality and process of handling the device.

The manual has to be handed over to the end user after installation.

In case the product is given for use to a third person, the manual has to be handed

over to them as well.

Explanation of Terms

An informed person is a person who reads this manual.

A trained person has a certificate of professional training.

An authorised service technician has been trained and authorised to service and

perform maintenance on the device by the manufacturer.

The user is the one using the device for its intended purpose.

The installation technician is a professional, trained to carry out machine or electrical

installation work and the installation of the device.

Inappropriate handling of the device can cause a defect of the device, injuries to the user or

property damage. To limit risks, the manual uses symbols to emphasize important

information.

2.1 Symbols

When installing, performing maintenance or using, various levels of danger may occur. In

certain parts of these instructions, you will find warnings, with which we wish to ensure the

safety of the user, remove the potential dangers and ensure the proper operation of the

device.

2.2 General Warnings and Instructions

Page 6

ID.: 17-16-20-2979-10

6

3.2018

use are the explicit responsibility of the user alone.

NOTE

Device installation must be carried out in compliance with instructions or the

warranty is null and void.

NOTE

When designing, projecting, installing and using the device, it is obligatory to

take all technical data, warnings and notes from this manual into

consideration.

DANGER

Failure to follow instructions and good practices when performing the

electrical connection of the device may cause severe injuries and death.

WARNING

This device is intended for use in houses. Use of the device in hotels, stores,

farms, light industry and other public buildings is permitted to experts or

properly trained personnel.

WARNING

Electrical connection of the device may only be carried out by a trained

installation technician for electric installations.

WARNING

The device must not be placed where there are harmful substances, which

could damage it, in the air (barns, dangerous substance storage, open air,

etc.).

WARNING

The inflow pipe must obligatorily be equipped with a safety valve with

nominal pressure of 0.6 MPa (6 bar), which prevents pressure increase in

the water heater above the nominal pressure.

WARNING

Transportation of the device is only permitted in upright position.

WARNING

The water heater is intended for potable water storage, so it must obligatorily

comply with valid national regulations on potable water, or the device could

get damaged and the validity of warranty nullified.

WARNING

The device must never operate without water in the hot water tank.

WARNING

The electrical connection of the power supply cable must be carried out by a

qualified electrician.

2.3 Safety Warnings and Instructions

Page 7

ID.: 17-16-20-2979-10

7

3.2018

WARNING

Connection of the device to the power grid must take place in accordance with

standards for connection to electrical grids. The device must be connected to the

electrical grid via a shutdown element, built into the electrical installation according

to valid regulations. The shutdown element must separate all contacts under the

conditions of overload category III.

WARNING

Water from the device is drained through the inflow pipe of the water heater.

For this purpose, it is recommended to add a special link or release valve

between the safety valve and the inflow pipe.

WARNING

To ensure proper operation of the safety valve, carry out regular annual

controls of valve operation. If required, clean limescale and make sure that

the safety valve is not blocked.

WARNING

Water may drip from the release pipe of the overflow. The pipe must be

exposed to outside air. Should you add a valve to the pipe, it has to be

turned downwards, so that the water in it cannot freeze.

WARNING

It is forbidden to play with the device. Children are strictly forbidden from

cleaning the device without supervision.

WARNING

The device may be independently used only by person, familiar with the safe

operation and understanding possible dangers of the device. Children above

8 years of age and persons with reduced physical and mental abilities, or

with the lack of experience and knowledge, may only used the device under

supervision of an instructed person.

WARNING

During operation, it is forbidden to move, shift, clean or repair the device.

WARNING

Cleaning and maintenance of the device is forbidden to unsupervised

children.

WARNING

Before installation and any later intervention in the device, always comply

with instructions for safe use and maintenance.

WARNING

Installation must be carried out in compliance with the valid regulations and

according to the instructions of the manufacturer, by a professionally trained

person.

Page 8

ID.: 17-16-20-2979-10

8

3.2018

WARNING

The device must not be stacked or have items lean against it. If, while the device is

operational, the water temperature exceeds 80 °C, contact service.

WARNING

Ensure, that the device does not represent a danger to anyone. Access to

device must be prevented to children and uninstructed persons.

WARNING

Do not place the device into a room where it could not be removed from.

Later building around it or placement of other obstructions by the device is

forbidden.

WARNING

Service and maintenance of the device may only be carried out by a service

technician, authorised by the manufacturer. In case of a defect, first contact

the installation technician that installed the device.

WARNING

Never clean the device with cleaning agents which contain sand, soda, acid

or chlorides, as they can damage the surface of the device.

WARNING

The device contains the coolant R134a, which, compliant with the Kyoto

Protocol, is listed among greenhouse gasses. Thus work on the device is

only permitted to authorised persons for handling of coolant as defined by

the law in force. During interventions into the device, escape of coolant into

the atmosphere must be prevented.

WARNING

In avoidance of dangers, a damaged power cable may only be replaced by

the manufacturer or an authorised installation technician..

Page 9

ID.: 17-16-20-2979-10

9

3.2018

NOTE

In any case of a change or replacement of original components, forced or improper

use of the device, the warranty becomes null and void. Possible expenses

stemming from a service intervention are charged to the user in their entirety.

During warranty period, only the manufacturer or a service, authorised by the

manufacturer, may carry out service and maintenance procedures. If that is not the

case, the warranty becomes null and void.

2.4 Obligations of the Manufacturer

The manufacturer guarantees that the device is compliant with valid European directives and

standards. The device is marked with the CE mark and has all required documentation.

We reserve the right to change instructions without previous notifications.

The manufacturer accepts no liability in the case of:

Failure to follow device installation instructions.

Failure to follow device use instructions.

Wrong or inadequate device maintenance.

2.5 Obligations of the Installer

The installer is responsible for the installation and start-up of the device in accordance with

the following:

Read instructions for installation and use which come with the device thoroughly

before installation.

The device must be installed in compliance with the valid national legislation,

directives and standards.

First start-up must be carried out and potential initially present defects removed upon

detection.

The user must be trained to use the device and the settings.

The user must be warned to regularly perform maintenance on the device to ensure

proper operation during the entire operational life of the device.

Operation of the entire system must be explained to the user.

The user must be given all documentation that came with the device.

2.6 Customer Support - Service

Customer support and service while warranty lasts are provided by device manufacturer.

When submitting a service claim, we ask you to provide the following information:

Exact name of the product.

Serial number.

Year of manufacture.

All required data is listed on the label on the device.

2.7 Obligations of the User

To ensure uninhibited and efficient operation of the device, the user must take into

consideration the following instructions:

Read instructions for installation and use which come with the device thoroughly.

Installation and start-up of the device must be carried out by a trained and authorised

professional.

Allow the authorised installer or ask them to thoroughly explain the functioning and

means of operation of your device.

You must ensure regular check ups and maintenance of the device by an authorised

service technician.

Keep instructions for installation and use in a suitably dry place, close to the device.

Page 10

ID.: 17-16-20-2979-10

10

3.2018

WARNING

When moving the device, it is obligatory to unplug it from the power grid.

WARNING

The device has impact sensitive parts so it is important to avoid any impacts

during transportation or any instance of the pump falling.

WARNING

The mass of the device exceeds the permitted lifting mass for one person. All

liability for possible personal injury, property or device damage is borne by the

client.

WARNING

It is forbidden to place the device in a horizontal position.

2.8 Factory Testing

To ensure a high quality standard, all heat pumps are tested before leaving the factory in the

following aspects:

Sealing tightness of the cooling circuit.

Watertightness.

Airtightness.

Electric safety.

Functionality.

2.9 Storage

The device must be stored in a dry and clean area. Allowed storage temperature is between

10 and 45 °C, short term (up to 24 hours) also up to 55 °C.

2.10 Transportation

Before transportation, the device has to be protected with a protective foil or cardboard

packaging, in order to prevent mechanical damage.

2.11 Delivery Content

Delivery Content:

1. Heat pump

2. Water condensation removal pipe

3. Instructions for use and installation

Page 11

ID.: 17-16-20-2979-10

11

3.2018

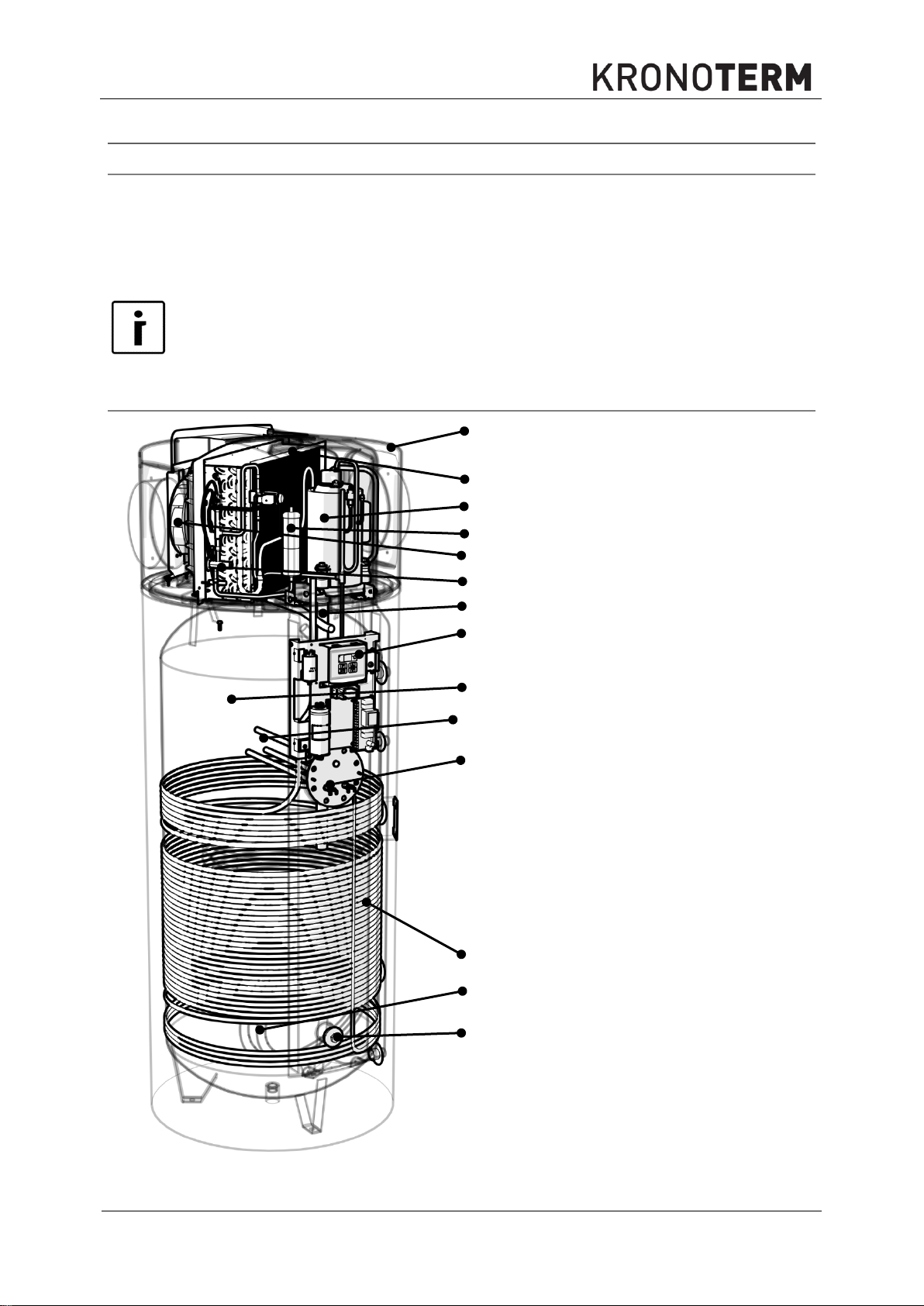

NOTE

For the highest efficiency and savings, we recommend that you use air from areas

with waste heat (boiler room, laundry room, kitchen, cellar, pantry) as a heat

source and that the air temperature is as high as possible.

A

A

Device generator casing

B

Fan

C

Evaporator

D

Compressor

E

Dehydrator

F

Thermoekspansion valve

G

Controller

H

Hot sanitary water tank

(boiler)

I

Heat exchanger (heating

water)

J

Anti-corrosion anode

K

Condenser

L

Electric heater

M

Connection for additional

electric heater

C D E B F J

G

H

J

L

K I

M

3. Technical Description

3.1 General

This device is a heat pump for the heating of sanitary water in residential areas and small

business premises. When heating sanitary water, the heat pump also cools the area, from

which air is captured and / or returned to. The heat pump can thus along with heating of

sanitary water, be used for cooling of indoor areas, whereby it has to be emphasized, that

the heat pump will only cool the area, if there is a need to heat the sanitary water.

3.2 Components

Page 12

ID.: 17-16-20-2979-10

12

3.2018

WARNING

When heating with boiler or solar collectors, you may heat the water in the hot

water tank to a temperature above 80 °C whereby the safety thermostat switches

off. In such a case the thermostat has to be manually reset. To restart the

thermostat, an authorised installation technician must be called.

The device consists from the device generator (compressor, evaporator, fan, ...) and the hot

water tank. The housing of the generator is made of durable plastic and is heat and sound

isolated. The device has two attachments for air channels which enable a remote air intake

and exhaust from neighbouring rooms or the environment. The hot sanitary water tank is

equipped with a piped heat exchanger, which can be connected to an external fossil fuel,

biomass or solar energy collector powered boiler.

Hot Sanitary Water Tank

Sanitary water heater is enamelled with patented technology, heat isolated with polyurethane

and mechanically protected with sheet metal. The tank is serially equipped with a water heat

exchanger that can be connected with a boiler when choosing an additional heat source. An

Mg anode is also placed into the tank, preventing corrosion of the heater upon potential

mechanical damage to the enamel.

Electric Heater

The device is serially equipped with two electric heaters with a power of 2 x 2 kW, which

serves as an additional or backup heating source.

Along with both already installed heaters, it is possible to install an additional heater into the

hot sanitary water tank with a 6/4" attachment with separate power supply.

Anti-freeze probe

Regulator of heat pump senses the temperature of the vaporizer. In the case, that the

temperature of the vaporizer is below -7 °C, it will perform a safety shutdown of the device for

at least 30 minutes. In such a case, the heat pumps with an electric heater automatically

switch to electric heating and the heat pumps with an attached boiler switch to boiler heating

(circulation pump switch on).

Safety thermostat

The electric heater contains a safety thermostat with a limit at 85 °C. This means that, in the

case that the temperature in hot water tank is exceeded, the power supply will be switched

off and the device will stop operating. To restart the device, call authorised installation

technician who must verify and remove the reason of the safety shutdown of the device.

Boiler water temperature control

Monitoring and heating of water to desired temperature is ensured by the advanced

OPTITRONIC 2 touchscreen regulator.

In regards to the set up desired water heating temperature, the controller, as required,

switches the compressor and fan on or off, and, under certain conditions, also switches the

electric heater or circulation pump of the boiler on or off. The maximal temperature of water

heating that can be set up is 65 °C. Should the temperature in hot water tank increase over

75 °C, the controller switches off all sources of heat for safety reasons.

Minimal temperature of water in hot water tank is 7 °C.

High pressure cooling system protection

To prevent pressure in the cooling system to get too high and potential damage, related to it,

a high pressure safety switch is installed, which stops the operation of the heat pump in the

case of pressure rising beyond a preset point.

Conditions of operation

Environment temperature must be between -7 °C and +35 °C. The air must be clean with

relative humidity not exceeding 50% at +35 °C. At lower air temperatures, the relative air

Page 13

ID.: 17-16-20-2979-10

13

3.2018

5

6

4

7

8

3

10

1

2

9

1. Compressor

6. Fan

2. Condenser

7. Magnetic valve

3. Dehydrator

8. Temperature bulb of the expansion valve

4. Thermoexpansion valve

9. Electric heater

5. Evaporator

10. Hot sanitary water tank (boiler)

The cooling system of the heat pump is a closed circuit system, within which the coolant R134a

circles as a heat exchanger. At lower pressure and lower temperature (e.g. 10°C), the coolant is

vaporised in the heat pump vaporizer, thereby drawing heat from the air. Then, the coolant is

compressed to a higher pressure in the compressor, which makes its temperature rise to the

temperature, higher than that of the water in the boiler. The coolant then gives away the heat to

the water in the condenser, whereby it liquefies. The expansion of the coolant, which makes the

coolant pressure and temperature lower to the primary value, the circular process is concluded.

This process is repeated throughout the heat pump operation time.

humidity may be higher. Devices, placed at higher altitudes above sea level may function

less efficiently due to lower air pressure.

3.3 Operation Principle

Page 14

ID.: 17-16-20-2979-10

14

3.2018

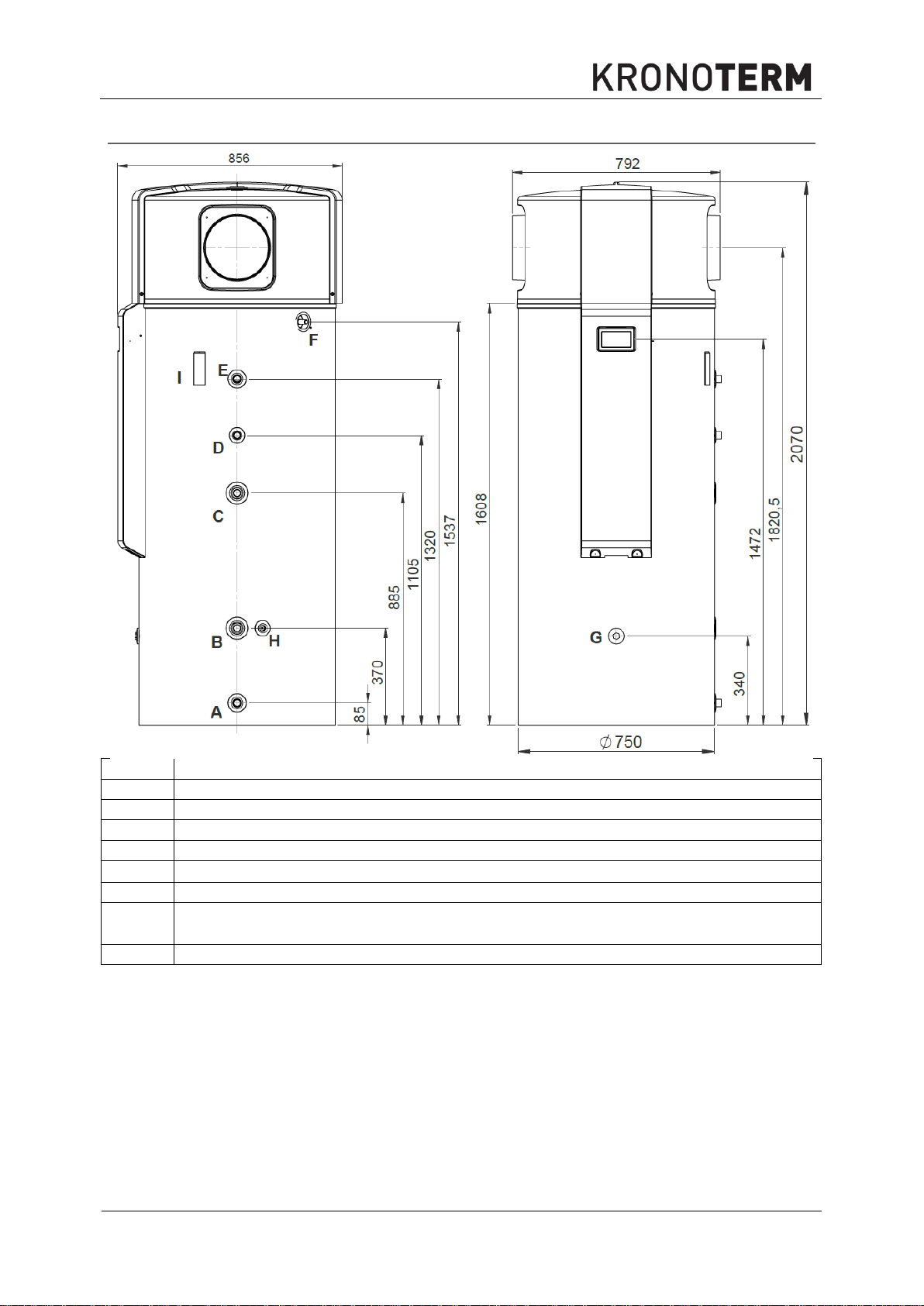

A

Connection cold water G1''

B

Connection heat exchanger – return pipe G1''

C

Connection heat exchanger – supply pipe G1''

D

Circulation connection G3/4''

E

Hot water connection G1''

F

Connection for removal of water condensation 16

G

Connection for additional electric heater 6/4''

H

Connection for the installation of a watertight tube with a threaded plug G1/2’’ for

the measurement of cold water temperature.

I

Channel for the temperature sensor of the heat exchanger

4. Position of Connections and Dimensions

Page 15

ID.: 17-16-20-2979-10

15

3.2018

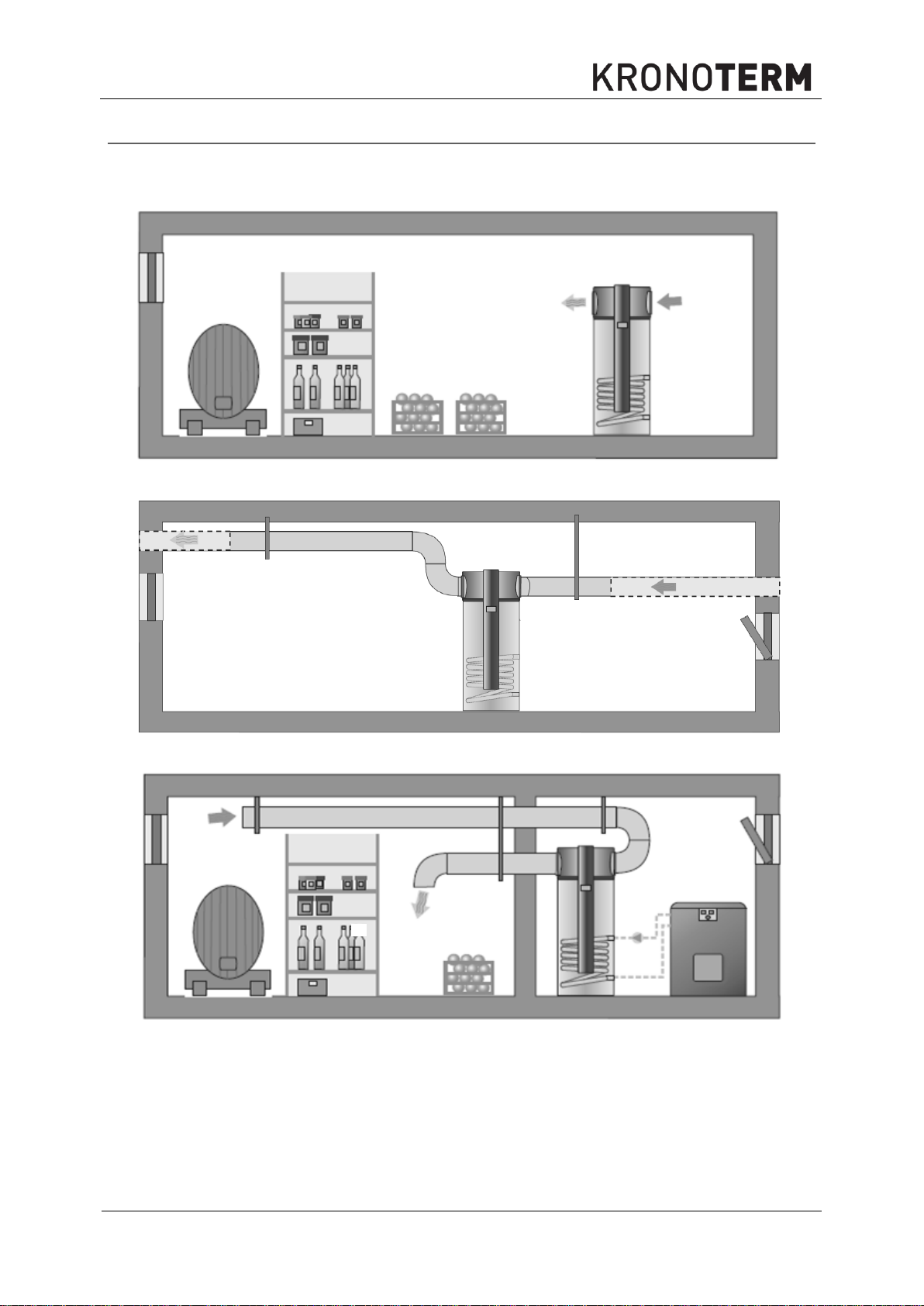

Figure 1: Suction and exhaust in the same room (e.g. pantry cooling).

Figure 2: Suction of the outside air, exhaust into the surroundings

.

Figure 3: Suction and exhaust into neighbouring room (e.g. pantry cooling).

5. Installation

The lowest height of ceiling in the room must be 2500. The device is made so that it takes

heat from surrounding air or sucks it through air channels and blows it into neighbouring

rooms or the environment. The device may be installed in the following ways.

The most common placement of the heat pump is such, that the air is sucked from areas,

where there is a lot of waste heat. This air has a part of its heat removed, then released into

the surrounding. Air in kitchens, laundry rooms, sanitary facilities often contains unpleasant

odours, so it is blown into the environment. Thereby we must be careful that the air flows and

pressures in spaces are evened out, which must be ensured by the projecting engineer for

the ventilation.

Page 16

ID.: 17-16-20-2979-10

16

3.2018

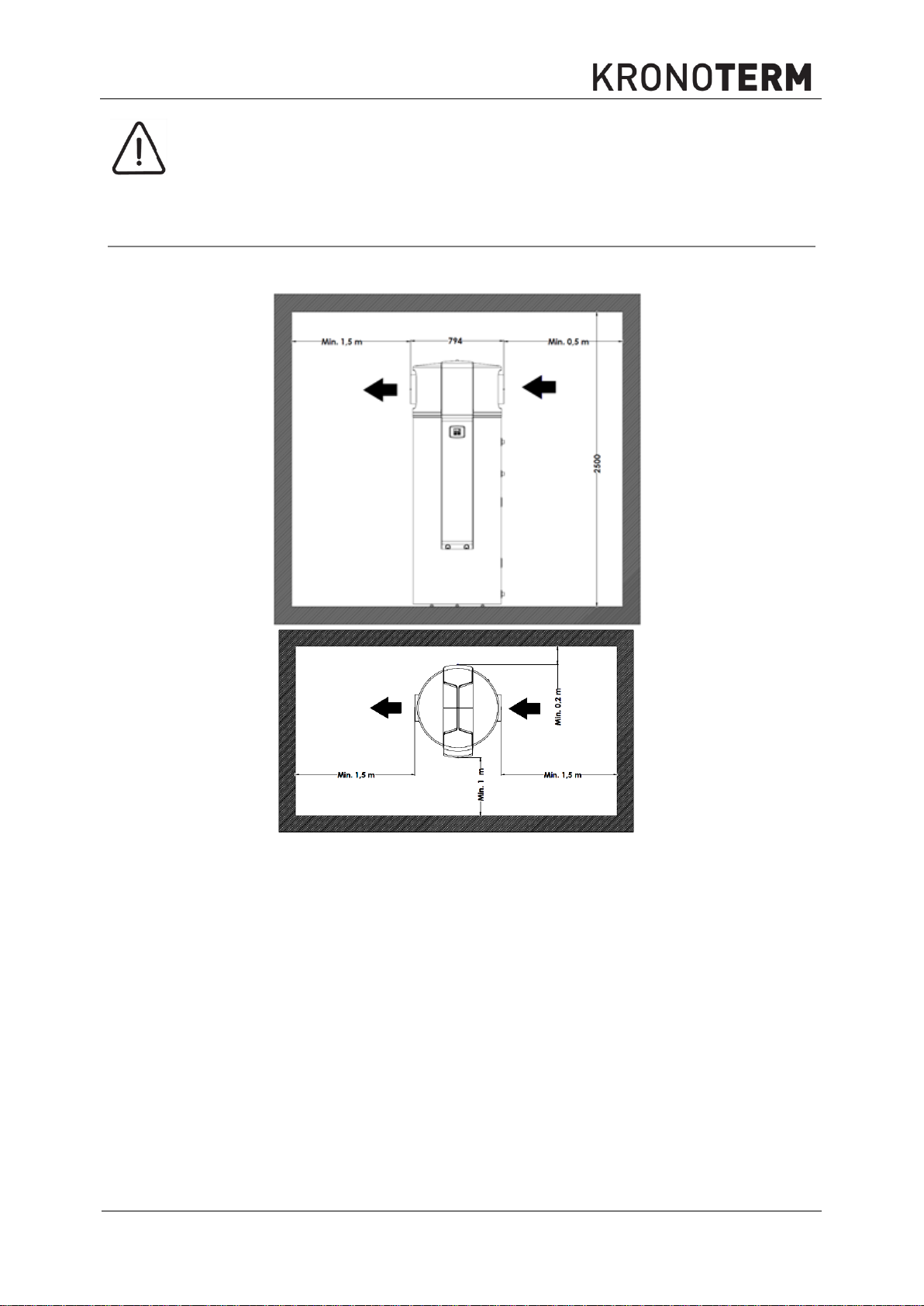

WARNING

The device must not be placed where there are harmful substances, which

could damage it, in the air (barns, dangerous substance storage, open air,

etc.).

Figure 4: Minimal spacing between walls / ceiling in the case of air intake from the same room

5.1 Minimal spacing of the device:

The device may be placed into a room with or without installing air channels. This influences

minimal spacing from the walls, which depend on the direction of entry and exit of air.

Page 17

ID.: 17-16-20-2979-10

17

3.2018

Figure 5: Minimal spacing between walls / ceiling in the case of air intake from other rooms or the

environment

WARNING

The device must be in a vertical position during operation to prevent potential

leaking of water condensation.

In the case of using air heat from the same room where the device is installed, the room

must be at least 50 m3.

5.2 Device Levelling

Figure 6: Device levelling

The device has to be levelled as shown on the image above.

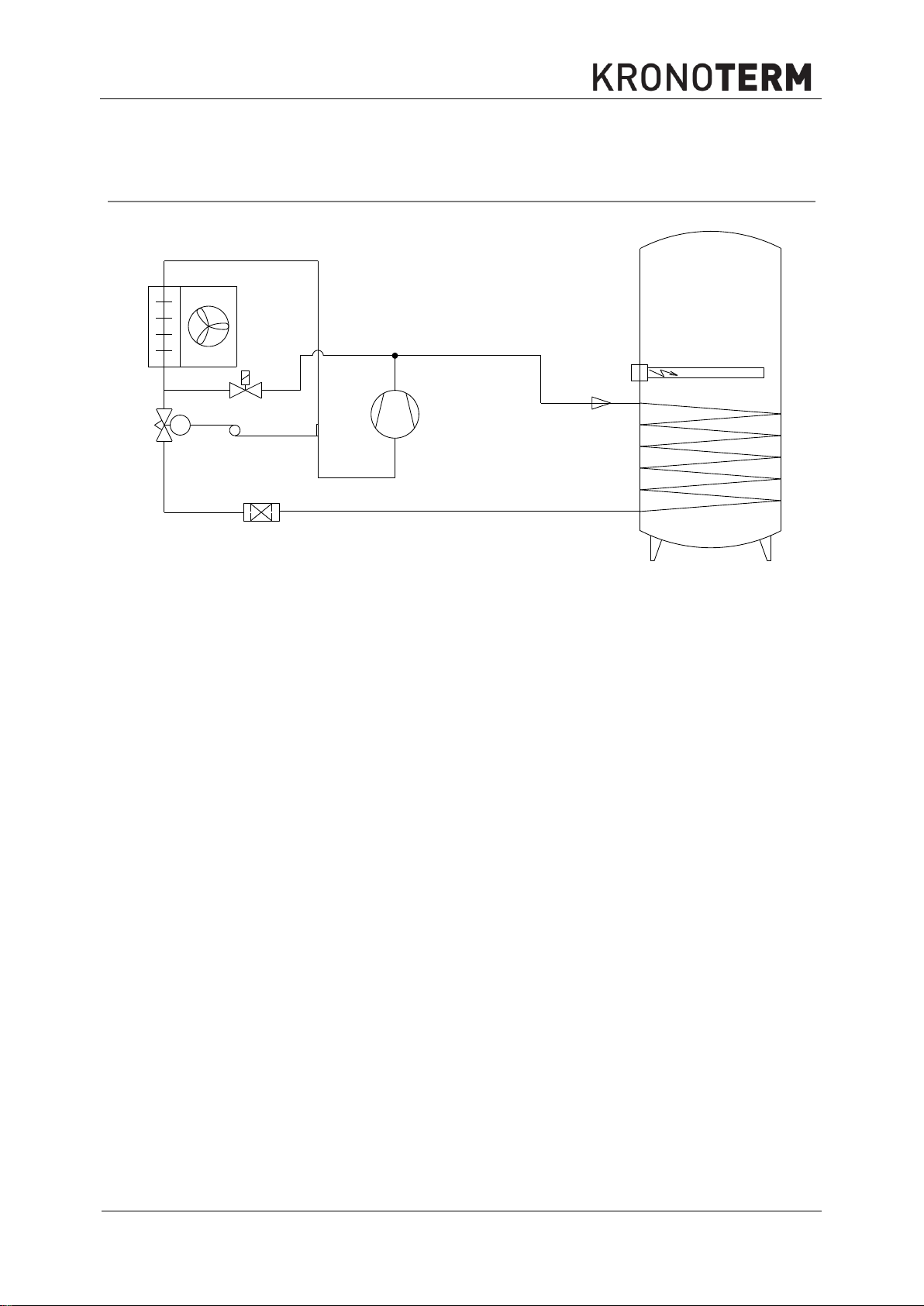

5.3 Hydraulic Connection

Hydraulic connection must be carried out in accordance with the valid national and local

regulations, which are in force for the connection of sanitary water tanks. The room with the

device must have a drain below the level of the device for the drainage in the case of a water

spill. The image below shows the proper hydraulic connection of the device.

Page 18

ID.: 17-16-20-2979-10

18

3.2018

WARNING

Due to use of different materials on the pipe installation, all connections (cold

water, hot water, circulation, heat exchanger) on the device must obligatorily be

galvanically isolated, or the corrosion of connections within the heat storage may

occur. We recommend galvanic separators from red alloy for each attachment, at

least 2x pipe diameter in length.

WARNING

The water tank is intended for potable water so it must obligatorily comply with the

valid national regulations on potable water, or device damage may occur and the

warranty is nullified.

1

Ball valve

5

Expansion vessel

2

Pressure reducing valve

6

Drain tap

3

Check valve

7

Circulation pump

4

Safety valve

8

Device generator

3

1

1

5

6

1

1

1

2

3

4

7

8

Safety valve setting [bar]

6

System pressure [bar]

3,0

3,5

4,0

Volume of sanitary water tank [L]

Expansion vessel [L]*

450

35

50

50

Should the heat exhanger (heating water) in the water tank not be used for water heating, it

must be filled with an anti-freeze liquid, to prevent corrosion in the exchanger. Only close a

full exchanger at the bottom (equalisation of pressure due to temperature changes).

Figure 7: Connection of device to plumbing network

Dimensions of expansion vessel:

* The actual size of the expansion vessel must be set by the installation technician / planner in regards to the size

of the system, in which the device will be installed.

Page 19

ID.: 17-16-20-2979-10

19

3.2018

WARNING

When installing the device obligatorily place expansion vessel into the system.

WARNING

Obligatorily install safety valve onto the inflow pipe, which has a nominal

pressure of 0,6 MPa (6 bar), and prevents the increase of pressure in the hot

water storage for over 0,1 MPa (1 bar) above nominal.

WARNING

For proper operation of expansion vessel, a suitable setting of the operational

pressure of the tank must be made. The pressure is set in regards to the

pressure in the plumbing. The setting needs to be checked every 6 months..

Air canal diameter

Maximal air canal length

Diameter 200 mm

10 m

Diameter 250 mm

15 m

5.4 Air Canal Installation

The device has attachments on left and right for the attachment of air canals, which enables:

the placement of the device into any room which is spacious enough

ventilation of desired room

exhaust of waste air or intake of fresh air from the environment

In the case of air canal use, keep in mind that air pipes and every additional knee represent

additional air resistance and lesser capacity of the device. Table 1 shows maximal permitted

canal lengths. Air canals must be isolated to prevent water condensation on the pipe

surfaces.

Figure 8 shows the device with air canal connections. The connections are 45 mm in length

and an outside diameter of Φ250. Access to inner parts is protected with mesh.

Figure 8: Air canal connection

Table 1: Maximal permitted air canal length.

The final length of air canals needs to take into consideration also the equivalent length of

accessories such as knees, reduction pieces, etc.

Page 20

ID.: 17-16-20-2979-10

20

3.2018

Accessories

Equivalent length in m

Knee 90° (Φ 200 mm)

3

Knee 90° (Φ 250 mm)

2

Reduction piece Φ250 x Φ200

1

Wall blind

2

Attachment of pipe for

condensation outlet to the device.

Siphon for prevention of

unpleasant odour seeping from

the drain.

NOTE

When installing a condensation outlet, pay CAUTION that the pipe is always at a

downwards incline with a siphon and water pillar of at least 5 cm at the outflow.

This prevents the suction of unpleasant odours from outlets.

Table 2: Accessories

5.5 Connection of Condensation Outlet

By removing heat from air, condensation of air moisture also occurs in the heat pump.

Depending on air temperature and relative air humidity, the production of moisture from air

varies. In some cases, no moisture will be removed from air and in others, up to 10 litres of

condensed water may be produced.

The water condensation outlet pipe must be laid in a way, where the water may always freely

flow out. Connect outlet pipe with drain. Should this not be possible, ensure a collection

canister, which must be regularly emptied.

Page 21

ID.: 17-16-20-2979-10

21

3.2018

WARNING

Due to use of different materials on the pipe installation, all connections (cold water,

hot water, circulation, heat exchanger) on the device must obligatorily be

galvanically isolated, or the corrosion of connections within the heat storage may

occur. We recommend galvanic separators from red alloy for each attachment, at

least 2x pipe diameter in length.

WARNING

Water used for sanitary water heating through the installed heat exchanger in the

hot sanitary water tank must comply with requirements of standard VDI 2035. The

heating system must be filled with soft water, which contains anti-corrosive and

anti-bacterial substances for prevention of corrosion. Before filling, the heating

system must be cleaned of all impurities.

The heating system must be thoroughly drained of all air. Prevent the intrusion of

air into the system, including diffusion air.

5.6 Connection of External Heating Source (alternative / additional source)

Sanitary water in the water storage tank may be heated with the device generator - heat

pump (primary source) and / or additional heat sources (serially equipped electric heater or

various external sources).

The external source is that which produces heat separately from the device and is

connected to the device through a pipe heat exchanger inside the DHW tank. External heat

sources are considered those which are available at all times (additional external electric

heater, fuel oil/gas/pellet/biomass boiler) or those which are at disposal only occasionally

(solar panels, wood-fired furnace, fireplace, etc.).

If a temperature sensor is installed into the external source the regulation checks the

temperature of the external source and adjusts the activation of the external source

circulation pump according to the need for domestic hot water and according to the

temperature of the external source. For proper functioning you must connect the circulation

pump and the temperature sensor correctly and set the parameters in the device controller.

For a proper electrical connection of the attachments follow the instructions in the chapter

about the electrical connection, and for the setting of the controller, the chapter on operation.

Page 22

ID.: 17-16-20-2979-10

22

3.2018

TYPE OF SUBSTANCE

UNIT

CONCENTRATION

INFLUENCE ON HEAT EXCHANGER

Organic sediments

mg/L

0

Ammonia NH3

mg/L

< 2

1 do 20

> 20

+

0

-

Chloride

mg/L

< 300

> 300 + 0

Allowed water hardness

°dH

5–10

Electrical conductivity

µS/cm

< 10

10–500

> 500

0

+

-

Iron (Fe) separate

mg/L

< 0,2

> 0,2

+

0

Free carbonic acid

mg/L

< 5

5–20

> 20

+

0

-

Manganese (Mn) separate

mg/L

< 0,1

> 0,1

+

0

Nitrates (NO3) separate

mg/L

< 100

> 100 + 0

pH value

mg/L

< 7,5

7,5–9

> 9

0

+

0

Oxygen

mg/L

< 2

> 2

+

0

Hydrogen sulphide (H2S)

mg/L

< 0,05

> 0,05 + -

HCO3- / SO

4

2

-

mg/L

> 1

< 1

+

0

Hydrogencarbonate (HCO3-)

mg/L

< 70

70–300

> 300

0

+

0

Aluminium (Al) separate

mg/L

< 0,2

> 0,2

+

0

Sulphates

mg/L

< 70

70–300

> 300

+

0

-

Sulphite(SO3)

mg/L

< 1

+

Chlorine (gas) (Cl2)

mg/L

< 1

1–5

> 5

+

0

-

WARNING

The heating system must be filled with water of a hardness between 5 °dH and

10 °dH . Device defects due to unsuitable heating water hardness are not

covered by warranty.

WARNING

Quality of potable water must comply with Potable Water Regulation (Official

Gazette of the Republic of Slovenia, no. 19/04, 35/04, 26/06, 92/06, 25/09).

This regulation complies with the European Council Directive 98/83/EC.

WARNING

For proper operation of active anti-corrosion protection, the hot sanitary water

tank (boiler) must be filled with water, the conductivity of which is at least

200 µS.

Maximal allowed content of individual substances in heated water and their influence on the

heat exchanger are shown in the table below. The heated water which includes any

substance in a concentration which causes corrosion (influence "-") in the heating system is

forbidden. The heating water which contains two or more substances in a concentration,

which may cause corrosion (influence "0") in the heating system is also forbidden.

Table: Influence of various aggressive substances in heating water onto the durability of hot

sanitary water tank (+ = no influence, 0 = danger of corrosion, - = corrosion – use forbidden).

Page 23

ID.: 17-16-20-2979-10

23

3.2018

1

Ball valve

7.1

Circulation pump (SET SOLAR)

2

Pressure reduction valve

8

Device generator

3

Check valve

9

Furnace

4

Safety valve

10

Heating water hopper

5

Expansion vessel

11

Solar energy collectors

6

Drain tap

dT

Differential thermostat

7

Circulation pump

dT1

External differential thermostat

3

1

1

5

6

1

1

1

1

2

3

4

1

7

1

1

7

1

9

8

3

1

1

5

6

1

1

1

2

3

7

1

1

1

3

7

1

4

5

4

11

8

Below, there are several possible connection schemes for external sanitary water heating

sources.

Figure 9: Heat pump combined with furnace.

Figure 10: Heat pump combined with solar collectors.

Page 24

ID.: 17-16-20-2979-10

24

3.2018

1 2 3 1

1

3

1

7

4 5

6

1

11

3

1

1

7.1

3 1

4

5

9

12.3

1

12.2

4

5

7

1

12.1

8

1

1

1

12

dT

12.4

A

B

C

D

Figure 10: Heat pump combined with solar collectors and furnace (SET SOLAR)

Page 25

ID.: 17-16-20-2979-10

25

3.2018

NOTE

To ensure a safe and efficient operation of the additional heat source for the

preparation of sanitary water (boiler, solar collectors), the controller of the external

source needs to be set to a limit of water heating of max 75 °C. It is recommended

to set the temperature at 65 °C or less.

The highest permitted water temperature in the heat exchanger is 110 °C.

A

B

5.7 Placement of External Controller Temperature Probe

In the case of use an external controller of additional source, attach temperature probe of the

external controller into the appropriate canal on the right side of the device, under the black

plastic cap (A), as marked on the image.

Figure 9: Temperature probe canal on the right side of the device

B connection ½'' is intended for installation of the watertight tube of an additional sensor for

the measurement of cold water temperature in the device. The connection is used in

applications where the temperature of the entire water heater volume must be checked with

an external controller.

Page 26

ID.: 17-16-20-2979-10

26

3.2018

1

Ball valve

7

Circulation pump

2

Reduction valve

8

Reduction valve

3

Check valve

9

Device

4

Safety valve

A

Cold water

5

Expansion vessel

B

Hot water

6

Release valve

C

Circulation

3

1

1

5

1

1

2

3

4

7

10

6

3

1 1 1

1

1

3 3 3

10

6

10

6

10

6

DN 25 DN 25 DN 25 DN 25

DN 25DN 25DN 25DN 25

DN 25 DN 25 DN 25 DN 25

9 9 9 9

C

B

A

5.8 Parallel Connection of Several Devices

In case of a need for large quantities of hot water, you can install several devices in a parallel

fashion. For appropriate operation, the installation must comply with the instructions below.

5.8.1 Connection of Cold - Hot Water and Circulation

Page 27

ID.: 17-16-20-2979-10

27

3.2018

1

Ball valve

6

Release valve

2

Reduction valve

7

Circulation pump

3

Check valve

8

Reduction valve

4

Safety valve

9

Device

5

Expansion vessel

10

Boiler

9

Device

A

Intake canal

B

Exhaust canal

Number of devices

Length of

canals

1 2 3 4 5 6 7 8 9

10

10 m

20 m

30 m

10

B

A

5.8.2 Connection to Boiler

5.8.3 Air Canal Connection

Table: Internal diameter of pipes depending on length of canals and number of devices.

Largest allowed pressure drop on an individual device is 55 Pa.

Page 28

ID.: 17-16-20-2979-10

28

3.2018

WARNING

Connection of the device to the power grid must take place in accordance with

standards for connection to electrical grids. The device must be connected to the

electrical grid via a shutdown element, built into the electrical installation according

to valid regulations. The shutdown element must separate all contacts under the

conditions of overload category III.

DANGER

The device must be connected to the electricity supply where the RCD (FID) switch

of type A is installed.

5.9 Electric Connection

Electric connection of the supply cable, external signal, additional temperature probe, and

additional heater is done under the cover on the front of the device. To access electrical

connections the front cover must be removed as shown below:

Figure 10: Front cover removal

All electrical connections are carried out on the bottom holder, where electrical pins with

cable release pins are prepared.

Page 29

ID.: 17-16-20-2979-10

29

3.2018

1

A

1

2

1 2 3 4

a

b

c

Figure 11: Connection pin holder

5.9.1 Power Supply:

Power supply is carried out via pins marked with 1. Three connections of power supply

are possible:

a) Single-phase connection with maximal current load of 16 A is done on pins in the

area a, using pins N and L.

b) Single-phase connection with maximal current load of 25 A is done on pins in the

area b, using pins N and L.

c) Three-phase connection with maximal current load of 2x16 A is done on pins in the

area c, using pins N, L1, L2 and L3.

With all three connection types, the pin is used for earthing, and the pin N for a neutral

lead. 1f detailed connection is described below in points a and b while the 3f connection is

described in point c.

a. Single-phase connection with maximal current load of 16 A

This connection is used when single-phase power supply with 16 A fuses is available. In this

connection type connect power supply phase to pin 3. This is connected to pin 4 with a

bridge (factory connection).

This connection enables the operation of device generator and the first installed electric

heater (2 kW). The second heater is not active in such a case.

Supply cable needs to have a circumsection of 3 x 2,5 mm2.

Maximal total electrical power for this connection is 3,5 kW.

Page 30

ID.: 17-16-20-2979-10

30

3.2018

ATTENTION:

In three-phase connection, it is obligatory to remove the bridge which is factory

placed and connecting pins 3 and 4.

WARNING

Connection pins of the temperature probe for the external heat source are under 5

V tension.

2

B1 B2 C1 C2 D1 D2 D3 A1 A2

b. Single-phase connection with maximal current load of 25 A

This connection is used when single-phase power supply with 25 A fuses is available. In this

connection type, connect power supply phase to pin 3. This is connected to pin 4 with a

bridge (factory connection).

To connect the second electric heater (2 kW) it is necessary to additionally connect the

bridge between connection pins 4 and 5.

This enables the operation of the device generator and both installed electric heaters (2 x 2

kW).

Supply cable needs to have a circumsection 3 x 4 mm2.

Maximal total electrical power for this connection is 5,5 kW.

c. Three-phase connection with maximal current load of 3 x 16 A

This connection is used when three-phase power supply with 3x16 A fuses is available. In

this type of connection, every phase is connected to an individual pin (1, 2, 3, 4 and 5).

This enables the operation of the device generator and both installed electric heaters (2 x 2

kW).

Supply cable needs to have a circumsection 5 x 1,5 mm2.

Maximal total electrical power for this connection is 5,5 kW.

5.9.2 Additional Heat Source Connection

Left connection pin is intended for the connection of the circulation pump, external

switch and temperature probe of the external source.

Temperature probe of the external heat source must be connected to pins with markings

B1 and B2. To measure external heat source temperature (differential thermostat) use

temperature probe of the NTC type (10K 1% BETA 3435 1%). Temperature probe power

supply is 5 V.

Page 31

ID.: 17-16-20-2979-10

31

3.2018

WARNING

The appliance must never function without water in the hot water tank.

WARNING

Bring the tension of ~ 230 V on the pins of the external signal and circulation pump.

A

External signal switch is used to switch on various device functions. Connect external

switch on positions C1 and C2.

Circulation pump must be connected to the pins under the markings D1, D2 and D3.

Connect the steady voltage of ~230 V to D1 and D2 and the neutral lead, and use D3 for the

earthing lead. Maximal load of the circulation pump is 300 W.

Connection of Additional Electric Heater Activation (option)

The holder (figure 11) allows you to use location a to install an additional connector

for the activation and supply of an additional electric heater, installed on the G

connection (figure in chapter 5) at the bottom of the hot sanitary water tank. The

electric heater is available from the manufacturer as an accessory.

Control pins of the contactor (A1, A2) should be connected to the pins under the mark

add. (figure 13) on the pin holder. Then connect the electric heater to the connector,

which you must ensure an external power supply for.

6. Device Startup

6.1 Filling Device with Water

After a professional attachment of the heat pump onto the plumbing, the system needs to be

filled with water and air thoroughly removed from it. This is done by opening all faucets in the

apartment. When water flows without interruptions from all faucets, there is no more air in the

system.

6.2 Controls Before Startup

Before device start-up, the following controls have to be carried out:

Hot water tank must be filled with water and air thoroughly removed from it.

All hydraulic connections must be tightly sealed.

Suitable expansion vessel and appropriate safety valve must be built in.

All safety elements must be operational.

6.3 Device Startup

After the device is connected to the electricity supply, the device starts to heat the water

in the NORMAL program (chapter 7.3.3). The controller display shows clock setting (chapter

7.3.9). Should the clock be factory set, the display shows the basic temperature of sanitary

water after activation (chapter 7.1.1).

Page 32

ID.: 17-16-20-2979-10

32

3.2018

The interface of device controller OPTITRONIC 2 consists of a colour LCD display and four

function keys for operation.

back / screensaver

increase value

forward / confirm / menu

decrease value

system statuses

LCD screen displays currently

measured sanitary water

temperature

sanitary water

temperature

Operation of compressor and backup source

Alternative / additional source state

Device generator heating sanitary water

Internal electric heater active

Backup source programme active

External source active

Device on standby

Internal heater and external source active

Device in startup mode

Active programme

Warningsa nd defects

Anti-freeze programme active

External input influencing operation

Defrosting programme active

Warning

Quick water heating programme active

Error

Overheating - anti-legionella programme active

Operation mode

Holiday programme active

COMFORT PLUS programme active

NORMAL programme active

ADDITIONAL SOURCE programme active

ECO programme active

OFF programme active

COMFORT programme active

PHOTOVOLTAICS (PV) programme

active

1

2

3 4 5

7. Controller

7.1 Basic Window

7.1.1 Sanitary Water Temperature

7.1.2 System statuses

Display current device operation. The statuses show the active operation programme, functioning of

individual system components and potential errors and warnings.

Legend of system statuses:

Page 33

ID.: 17-16-20-2979-10

33

3.2018

Enter into screensaver window with .

When we aren't using the controller, the

screen displays screensavers. Those are

meant for quick display of important heating

system information. Presence of individual

screensavers depends on the activities and

individual functions, type of heat pump and

presence of module Optitronic WEB Module.

Move between windows with the key .

Exit from screensaver view with the key .

Display of device

time

Display of external

source temperature

Display of incoming

air temperature

Display of system

warnings

See chapter 9.1.

Display of system

errors

See chapter 9.2

7.1.3 Setting of Desired Temperature of Sanitary Water

In the basic window, by pressing or we begin setting the desired temperature of

sanitary water.

Currently set desired temperature is displayed. By pressing the key or the value is

increased or decreased. To confirm change of desired sanitary water temperature, press .

7.2 Screensavers

7.2.1 All screensavers

Page 34

ID.: 17-16-20-2979-10

34

3.2018

Display of time and date. Time and

date are automatically

synchronised with local time via the

Water Cloud server.

Display of connection status

with the cloud (server Water

Cloud).

Display of connection status for

local network connection.

Enter menu with key.

Move between menus with keys or .

Use key to enter desired submenu.

Use keys or to select desired setting in

submenu.

Use key to confirm new setting. If you

wish to cancel the change, use key to

return to menu.

Orange indicators indicate current selection on

the controller.

Additional screensavers for built in Optitronic WEB module (option):

7.3 Menu

In the basic window, by pressing , we enter into the menu. The menu contains settings

and programmes of device operation.

Page 35

ID.: 17-16-20-2979-10

35

3.2018

In the case of one or several errors on the device, the menu displays a new

setting "Error Acknowledgement". After acknowledging an error the device

will restart and check if the cause of error has been removed. If the error has

been removed, the setting "Error Acknowledgement" is not visible in the

menu any more.

Enter "Error

Acknowledgement"

setting with the key

.

Use key to acknowledge errors.

The menu shows up again.

The programme for quick heating is intended for one time quick water heating

with the device and chosen additional heat source at the same time (chapter

8.3.2). After achieving a temperature, the quick heating programme switches

off and changes to previous operation mode. The programme is started by

selecting the setting »START«.

Using direction keys and select between basic device operation

programmes. Confirm selection with the key .

NOTE

Additional operation programmes such as "Quick water heating"

(chapter 7.3.2), "Daily schedule" (chapter 7.3.6), "Vacation"

(chapter 7.3.8), etc. have priority over basic operation programmes.

Operation programme NORMAL

Operation programme COMFORT PLUS

Operation programme ECO

Operation programme OFF

Operation programme COMFORT

Operation programme ADDITIOLAN SOURCE

In the ECO operation programme, the device heats water to desired

temperature while considering a negative deviation. The desired deviation is

chosen with keys and . Setting is confirmed with the key .

Setting range: 0 °C – 15 °C.

Setting step: 0,5 °C.

In the COMFORT operation programme, the device heats water to desired

temperature while considering a positive deviation. The desired deviation is

chosen with keys and . Setting is confirmed with the key .

Setting range: 0 °C – 15 °C.

Setting step: 0,5 °C.

7.3.1 Error Acknowledgement

7.3.2 Quick Water Heating

7.3.3 Basic Operation Programme

7.3.4 Temperature Deviation ECO

7.3.5 Temperature Deviation COMFORT

7.3.6 Daily Schedule

Page 36

ID.: 17-16-20-2979-10

36

3.2018

A change of operation programme can be automatic by setting up a daily

schedule. Every daily schedule may have two time intervals. Every interval

has a set starting time, ending time, and programme of operation. In the time

outside the set intervals of the schedule, the device operates according to

basic programme.

Move between schedule setup windows with the key .

Enter schedule

setting with the

key .

Turn schedule

»ON« or »OFF«.

Set starting time of

schedule interval.

Set ending time of

schedule interval.

Set operation

programme in the

time of interval.

The schedule may be set for every day in the week separately. Every daily

schedule can have up to three time intervals. Every interval has a set starting

time, ending time, and programme of operation. In the time outside the set

intervals of the schedule, the device operates according to the basic

programme.

NOTE

To set and operate weekly schedules, the device needs to be

equipped with the Opritronic WEB module (option).

Move between schedule setup windows with the key .

Enter schedule

setting with the

key .

Pick the day of

the week

(1-Monday

7-Sunday).

Turn schedule

»ON« or

»OFF«.

Set starting time

of schedule

interval.

Set ending time

of schedule

interval.

Set operation

programme in

the time of

interval.

The devices with guided air, along with sanitary water heating, also enable

cooling and ventilation of rooms. Ventilation functions according to set

intervals of a ventilation schedule with set start and end times.

NOTE

To set and operate weekly ventilation schedules, the device

needs to be equipped with the Optitronic WEB module (option).

7.3.6.1 Weekly Schedule (option)

7.3.7 Ventilation Schedule

Page 37

ID.: 17-16-20-2979-10

37

3.2018

Move between schedule setup windows with the key .

Enter schedule setting

with the key .

Turn schedule »ON« or

»OFF«.

Set starting time of

schedule interval.

Set ending time of schedule

interval.

NOTE

Ventilation according to timetable is blocked when the defrosting function is in progress.

(chapter 8.3.6).

The vacation programme allows us to shut down the device for a specific

number of days when we know we will not require hot water. In this

period, no programme is active, even if it's set on a schedule. When the

set time interval passes, the device automatically switches back to basic

operation programme.

NOTE

In the case that the vacation programme was activated and in

operation at least for 1 day, the overheating programme will

activate after the ended vacation programme (chapter 7.3.11)

Move between schedule setup windows with the key .

Enter vacation setting

with the key .

Turn vacation

programme »ON« or

»OFF«..

Set number of days

(duration) of vacation

programme.

Manual setting of time on the device.

NOTE

In case that your device has the Optitronic WEB module (option) installed

and is connected to the server Water Cloud, the time and date of the

device are automatically synchronised with the server Water Cloud.

Manual activation and deactivation of the programme Backup Source

(chapter 8.3.1)

7.3.8 Vacation

7.3.9 Time

7.3.10 Backup Source

Page 38

ID.: 17-16-20-2979-10

38

3.2018

Programme heats water to 65 °C, to remove potential legionella bacteria.

Activation can be automatic or manual.

NOTE

The device overheats water and destroys the Legionella bacteria in

the water tank. For complete disinfection a hot water flow through

all pipes of the water installation must be ensured.

NOTE

Factory preset overheating is automatic every 14 days. We advise

against overheating too often, as energy consumption during

overheating is 1/3 higher than during normal operation.

Programme "Quick water heating" (chapter 8.3.2) can be triggered automatically

when water temperature falls below the set value.

Move between setup windows with the key .

Enter setting with the

key .

Turn programme »ON«

or »OFF«...

Set temperature at which

the "Quick Water

Heating" programme

activates.

Screen brightness settings.

Parameters from lowest to full brightness:

In the System information menu data on software and hardware of the

controller, display and Optitronic Web module (optionally) are given.

7.3.11 Overheating Programme - Anti-legionella

7.3.12 Automatic Quick Water Heating

7.3.13 Screen Brightness

7.3.14 System Information

Page 39

ID.: 17-16-20-2979-10

39

3.2018

Move between setup windows with the key .

Enter setting with the key

.

Data about graphic panel

OPTITRONIC 2.

Data about main

controller

OPTITRONIC 2.

Data about module

Optitronic WEB module

(option).

Menu allows access to advanced

controller settings by entering a 4digit security PIN code.

PIN koda: 1234

Use keys and to

select number and the key

to move to the next field.

Overheating programme (chapter 7.3.11) can be set to work on schedule.

Factory setting is a repetition of the programme every 14 days. (Settings allow

for periods of 1 - 99 days).

If we do not wish to use automatic overheating, the period is set to OFF.

WARNING

The overheating period must obligatorily be set in regards to the

national regulation requirement for safe preparation of hot sanitary

water.

Additional source function (chapter 8.2) allows the activation of one or a

combination of heat sources. (Selection depends on heat pump type and

presence of other heat sources in the heating system):

Internal electric heater.

Internal electric heater and external

source.

External source.

Deactivation of additional source

function.

The device may be set to change operation programme upon detecting

an external input signal.

The external input signal may be triggered by a switch (key) or external

device signal (furnace, solar photovoltaic panels, electric counter, etc.).

Several operation programmes are possible:

NORMAL: Switch to programme

NORMAL

OFF: Remote switch to programme OFF during

longer absence from home (device is not in use

for a prolonged time).

ECO: Switch to programme ECO when

power tariff is higher to reduce heating

costs.

Quick water heating:

Remote programme activation.

COMFORT: Switch to programme

COMFORT when power tariff is lower to

increase efficiency of operation.

PHOTOVOLTAICS: Solar photovoltaic system.

7.3.15 Advanced Installation Settings

7.3.15.1 Automatic Overheating Programme - Anti-legionella

7.3.15.2 Additional Source Selection

7.3.15.3 External Input

Page 40

ID.: 17-16-20-2979-10

40

3.2018

COMFORT Plus: Switch to programme

COMFORT Plus, when power from

solar panels is available.

Backup source: Activation of backup source

programme.

Function input 1

Function input 2

Function input 3

When water reaches desired temperature, the heating switches off and

enters standby mode until water temperature doesn't drop for the standby

level difference.

Factory setting for standby difference 7 °C.

Setting area: AUTO or 2 °C – 10 °C.

Setting step: 0,1 °C..

Example: Water heating will deactivate after reaching the desired

temperature 55 °C. Heating will reactivate once temperature drops for the

standby difference 7 °C, thus to 48 °C.

Device in the programme PHOTOVOLTAICS - PV (solar photovoltaic

system) (chapter 8.3.4) heats sanitary water to PV temperature setting.

The factory setting is 70 °C.

Setting range: 55 °C – 75 °C.

Setting step: 0,5 °C..

When the temperature of sanitary water in the programme PV (chapter 8.3.4)

drops under the set desired temperature for the programme PV for the

temperature deviation value (»Standby in PHOTOVOLTAICS Programme«),

the device resumes heating the sanitary water.

Factory temperature deviation setting is 3 °C

Setting range: 1 °C – 20 °C.

Setting step: 0,1 °C

7.3.15.4 Standby Setup

Dynamic standby:

In case of setting the standby temperature to AUTO, the standby temperature changes in

regards to the set desired water temperature. If the temperature set is 40 °C, standby

temperature difference is 5 °C, while in the case of water temperature 55 °C and more,

standby equals 10°C. Between temperatures 40 °C and 55 °C the standby temperature

difference is calculated in a linear way between 5 and 10 °C.

Static standby:

Other standby settings are static and are the same for all water temperatures. The minimal

temperature difference is thus 2 °C, and the maximal 10 °C. Factory standby difference is set

to 7 °C.

7.3.15.5 Temperature Settings for PHOTOVOLTAICS Programme

7.3.15.6 Standby in PHOTOVOLTAICS Programme

Page 41

ID.: 17-16-20-2979-10

41

3.2018

In the case of external source use, maximal temperature is set, up to which

the external source may heat water. The standby temperature in this mode is

set to a fixed value of 10 °C.

Factory temperature setting is 60°C.

Setting range: 20 °C – 75 °C.

Setting step: 0,5 °C

The setting defines the operation of device generator and external

source regime (chapter 8.2.2)

Priority external source

Priority device generator

NORMAL: For heating water to desired temperature (chapter 7.1.3), the device uses

the primary heat source (compressor) whenever it is possible. When the primary

heat source, due to conditions (e.g. entering air temperature) can not provide

enough power, the device adds the additional power source (e.g. electric heater) to

aid in water heating.

ECO: Water is heated to desired temperature (chapter 7.1.3), with a considered

negative deviation ECO. The final water temperature is lower than in the NORMAL

mode. ECO deviation setting can be found in the user menu (chapter 7.3.4).

COMFORT: Water is heated to desired temperature (chapter 7.1.3) with a

considered positive deviation COMFORT. The final water temperature is higher than

in the NORMAL mode. COMFORT deviation setting can be found in the user menu

(chapter 7.3.5)

COMFORT PLUS: Water is heated to desired temperature (chapter 7.1.3) with a

considered positive deviation COMFORT. Water is heated by generator of the

device and internal electric heater at the same time. »COMFORT PLUS programme

may be stated manually (chapter 7.3.2), automatically (chapter 7.3.12) or via

external input (chapter 7.3.15.3).

OFF: The device is off.

ADDITIONAL SOURCE: The water is heated to the set temperature of the

additional source (Chapter 7.3.15.7) with a chosen additional source. The type of

the additional source is important and thereby the setting of the mode of operation of

the additional source and a possible connection of the temperature sensor of the

external source.

7.3.15.7 Setting of Temperature of External Source Programme

7.3.15.8 Setting of External Source Use Priority

8. Device Operation Setting

8.1 Basic Operation

Compressor is used for primary water heating. The compressor operates in a limited

temperature area of entering air (from -7 °C to 35 °C). Outside this area, the controller shuts

down compressor operation for safety reasons. The compressor may heat water to a maximal

temperature of 65 °C.

8.1.1 Basic Operation Programmes

Page 42

ID.: 17-16-20-2979-10

42

3.2018

8.2 Additional Source

For the functioning of the backup source, the following must be done correctly:

Choosing the type of backup source,

Choosing the operation mode of the external source,

Making an electrical connection between the external source and

If needed, connecting the temperature probe of the external source.

The backup source can be triggered automatically by the air temperature outside the

operating range of the device’s generator or possible malfunction of the device’s generator or

by choosing the differential operation of the backup source or the backup source can be

triggered manually by choosing the operation among the basic operation programmes or the

schedule or by the external signal. Heating with the additional source can also be triggered

when the combined programmes “Quick water heating”, “Comfort plus” and “Automatic quick

water heating” are activated.

8.2.1 Correct choice of the additional source

For correct operation of the additional source it is necessary to choose a backup source to

heat the water (chapter 7.3.15.2). The factory choice is an electric heater built into the

device.

In case of using the external heating source, it is necessary to choose the fire icon or the

fire with heater icon ( or ).

8.2.2 Choosing the correct operation mode of the external source

In case of choosing an external heating source as additional source, it is necessary to

determine how the external source will operate (chapter 7.3.15.8).

8.2.2.1 The device's generator priority (additional external electric heater, furnace

oil/gas/pellet/wood biomass ...)

The operation mode of the external source with the device's generator priority is

used in cases when the external source is always available. These methods of

heating are the additional external electric heater, furnace oil/gas/pellet/wood

biomass ... This kind of operation mode means the controller in its basic mode will

always use the primary source (the device's generator) for heating DHW. The external

heating source will be used only when the air temperature is outside the operating range or if

the device's generator is out of order.

Heating only with the external source can be chosen manually with the basic programme

"Additional source « with a set schedule or a set external signal. It can also be used

together with the combined programmes "Quick Water Heating «, »Automatic quick water

heating« and »Comfort plus (only electric heater) «.

Installing an additional temperature sensor for the external source is not obligatory, but it is

preferred. Not using the sensor can result in the external source not being warm enough and

the cooling of the heat pump boiler.

To turn on the external source temperature verification, your authorized installer must

activate the parameter in the service menu.

Operation of the external source temperature verification with the device's generator

as priority:

When the need for the external source arises, the device turns it on via the electric signal

(turning on the external source's circulation pump at the same time). Checking the operation

of the external source is performed by comparing the temperature of the external source with

the temperature of the heat pump boiler. When the temperature of the external source is at

Page 43

ID.: 17-16-20-2979-10

43

3.2018

least 5 °C higher than the temperature of the buffer tank for DHW, the external source is

available and is used for heating water. When n-minutes elapse after turning on the external

source and its temperature is not higher than 5 °C, the electrical signal for turning on the

external source turns off for 3 x n-minutes; then the start-up process is repeated. If after three

successive trials the start-up of the external source is unsuccessful, the device displays error

E07, which has to be confirmed manually 7.3.1).

8.2.2.2 External source priority (solar collectors, wood furnace, fireplace ...)

The operation of the external source with external source priority is used in cases

when the external source is available only occasionally. These kinds of heating

methods are solar collectors, wood furnaces, fireplaces ... This operation mode's

regulation for heating DHW will use the device's generator in its basic operation