Kronoterm HM-130 S1, HM-140 S1, HM-180 S1 Instructions For Installation, Use And Maintenance Manual

Page 1

Instructions for installation, use

and maintenance

Hydro module

HM-130 S1

HM-140 S1

HM-180 S1

The manual has to be handed over to the end user after installation.

Id.: 17-17-46-4358-01 | 09.2017

Page 2

2

Content

1 Important information 4

1.1 Symbols 5

1.2 Definitions 5

1.3 General warnings 5

1.4 Safety warnings and instructions 6

1.5 Obligations of the end user 7

1.6 Obligations of the installer 8

1.7 Obligations of the authorised contractor for commissions 8

1.8 Package and worn-out device management 8

1.9 Delivery package 9

2 INSTRUCTIONS FOR THE END USER 10

2.1 Controlling the device and heating system 11

2.2 Maintaining the device and heating system 11

2.2.1 Operation malfunctions 11

3 Instructions for the installer 14

3.1 Transport and storage 15

3.2 Installation space 15

3.3 Wall mounting 16

3.4 Connection with the outdoor unit 17

3.4.1 Cooling connection with the outdoor unit - HM-140 S1 and HM-130 S1. 20

3.4.2 Cooling connection with the outdoor unit - HM-180 S1 22

3.4.3 Make a leak test, drain and fill the cooling connection. 23

3.5 Hydraulic connection 24

3.5.1 General 24

3.5.2 Buffer tank for DHW connection 25

3.5.3 Connecting the heating system 27

3.5.4 Filling the heating system 35

3.6 Electrical connection 36

3.6.1 Description of elements in the electrical cabinet 37

3.6.2 Electrical connection with the outdoor unit 38

3.6.3 Cable installation 39

Page 3

3

3.6.4 Power connection 39

3.6.5 Connecting the communication with the external device 41

3.6.6 Connecting the external temperature sensor 42

3.6.7 Connection KT-1 and/or KT-2 42

3.6.8 Connecting the heating for DHW 43

3.6.9 Heating cycle connection 43

3.6.10 External additional source connection 46

3.6.11 Connecting the valve for switching between cooling / heating 47

3.6.12 Connecting the signal for PV signal 48

3.6.13 Connecting the signal for remote off 48

3.7 Commissioning of the device 48

4 Technical characteristics 49

4.1 Dimensions and characteristics 50

4.1.1 HM-130-S1 and HM-140-S1 50

4.1.2 HM-180-S1 51

4.1.3 Features 52

4.1.4 Machine scheme 52

4.1.5 Electrical scheme 53

4.2 Technical data 54

4.3 Legend of serial labels 56

4.4 Accessories 57

4.4.1 Installation of the Expansion vessel 57

Page 4

4

1 IMPORTANT INFORMATION

The manual describes the process of installation, maintenance and safe use. The

installation and maintenance can only be performed by qualified personnel. Read this

manual carefully before installation, maintenance or use.

The manual has to be handed over to the end user after installation.

In case the product shall be given to a third person for use, the manual has to be

handed over to them as well.

Page 5

5

1.1 Symbols

Incorrect installation, maintenance or use can cause a malfunction of the device, damage

the user o property. For limiting risks, the important information in this manual is highlighted

with symbols.

These symbols mark various risks for the user or the device.

DANGER: Risk of situations which can lead to serious physical injuries.

WARNING: Risk of situations which can lead to minor physical injuries.

CAUTION: Risk of situations which can lead to damage or malfunction

of the device.

This symbol marks information for the user.

NOTE: A notice which holds important information regarding

requirements of the manufacturer and the device.

1.2 Definitions

An informed person is a person who reads this manual.

A qualified person is a professionally qualified person.

An authorised commission contractor is trained by the manufacturer and

authorised to perform commission.

An authorised technician is trained and authorised by the manufacturer to

perform maintenance and servicing of the device.

The user uses the device according to its use.

The installer is a person professionally trained for performing hardware and/or

electro-installation work and mounting of the device.

1.3 General warnings

NOTE

Read the instructions for use and installation before installation.

NOTE

Any remaking or replacement of original components of the device eliminates the

manufacturer’s guarantee for safe and functional operation. In the case of

undesignated and incorrect use of the device, the manufacturer is not responsible for

the consequences and will not acknowledge claims for damages in these cases. The

user is solely responsible for injuries and damages on the device itself or on other

objects resulting from undesignated and incorrect use of the device.

NOTE

The installation of the device has to be performed in accordance with the manual;

otherwise the manufacturer does not acknowledge the warranty.

Page 6

6

NOTE

High pressure in the heating system can cause water dripping from the safety valve.

Make sure the drainage pipe on the side of atmospheric pressure is open.

CAUTION

A yearly inspection of the safety valve is necessary to ensure its proper operation;

when performing it, remove lime scale and make sure the safety valve is not blocked.

CAUTION

The drainage hole of the safety valve must be directed downwards. Make sure it does

not freeze.

DANGER

Failure to comply with the manual and good practise while connecting the device to

the power supply can lead to serious injury or death.

WARNING

Connecting the device to the power source can only be performed by a qualified

installer.

1.4 Safety warnings and instructions

DANGER

It is prohibited to move, shift, clean or service the device while in operation.

WARNING

It is prohibited to play with the device. Children are not allowed to clean the device

without supervision.

WARNING

The device can be operated independently only by informed persons who are familiar

with the safe operation of the device and understand possible hazards of its operation.

Children older than 8 and people with reduced physical and mental capacities and

with lack of experience and knowledge can only operate the device under the

supervision of an informed person.

WARNING

Before installation and any further adjustments to the device, it is necessary to

consider the instructions for safe use and maintenance.

WARNING

Installation has to be performed in accordance with national regulations on electrical

installations and with the instructions of the manufacturer. It has to be performed by a

professionally trained person.

WARNING

It has to be made sure that the device does not endanger anybody. Access to the

device has to be denied to children and persons who are not informed about the

operation of the device.

WARNING

The device must never be cleaned with cleaning agents containing sand, soda, acid

or chlorides because these might damage the surface of the device.

WARNING

The device contains the refrigerant HFC which is classified as a greenhouse gas

according to the Kyoto protocol. This is why tampering with the cooling cycle is only

allowed to persons authorised for working with the coolant as defined by the national

Page 7

7

legislation in force. While performing works on the device, it is necessary to prevent

the coolant to leak into the atmosphere.

WARNING

It is necessary to consider all technical data and instructions in this manual as well as

all warnings and notes during planning, design, installation and use of the device.

WARNING

Electrical installations have to be inspected in accordance with regulations on the

requirements for low voltage electrical installations in buildings by the installer of

electrical installations.

DANGER

Connecting the devices power cable must be performed by a qualified electrician.

During the procedure, the device must not be live.

WARNING

In case the power cable of the device is damaged it has to be immediately replaced.

The replacement can only be performed by the installer or authorised maintenance

worker.

WARNING

Before opening the device, disconnect all electrical circuits and make sure the device

is not live.

CAUTION

Putting any kinds of items on or next to the device is prohibited.

CAUTION

The device must not be placed in a room where it cannot be removed. Later walling or

setting up of other obstacles next to the device is forbidden.

CAUTION

For the correct operation of the device, the electrical distributor has to provide

electricity of adequate quality (SIST EN 50160). In normal conditions, this is within ±

10 % of the rated voltage. The data about the state of the electrical grid have to be

acquired from the electrical distributor.

CAUTION

Connecting the device to the electrical network has to be performed in accordance

with the standards for connecting devices to the electrical network. Connect the

device to the electrical network via the power supply cut-off which is installed into the

electrical installation under the regulations in force.

1.5 Obligations of the end user

The user must ensure uninterrupted and efficient operation of the device by considering the

following instructions:

To thoroughly study the instructions for use and installation accompanying the

device before use.

To have a qualified and authorised installer perform the installation of the device.

To have a contractor for commissions perform the commission.

Allow the authorised contractor for commissioning or ask him or require him to

thoroughly explain the functioning and how to operate the device.

Ensure regular yearly inspections and maintenance of the device by the authorised

maintenance worker.

Page 8

8

Store this manual in an appropriate dry place close to the device.

1.6 Obligations of the installer

The installer is responsible for installing the device in accordance with the following

requirements:

To thoroughly study the instructions for use and installation accompanying the

device before installation.

To install the device in accordance with the instructions and national legislation,

policies and standards in force.

1.7 Obligations of the authorised contractor for

commissions

CAUTION

The first commission can only be performed by the contractor of commissions

appointed by the manufacturer in accordance with the instructions for commission.

The contractor for commissions is responsible for commissioning the device in accordance

with the following requirements:

The contractor performs the first commission and eliminates all eventual

irregularities found during commission.

Trains the user for operating the device and settings.

Alerts the user to regularly maintain the device for keeping the device functioning

properly throughout its entire lifespan.

To give the user all the documentation accompanying the device.

1.8 Package and worn-out device management

Sort the package according to cardboard, wood and foil and dispose of it in

appropriate containers.

After the lifespan of the device ends it has to be disposed of in accordance with the

legislation in force on waste electrical and electronic devices and devices with F-

gasses.

Refrigerant

The device has to be connected to the outdoor unit which holds the HFC coolant which is a

fluorinated greenhouse gas covered in the Paris protocol. You have to prevent leakage of

the gas into the atmosphere. During a maintenance procedure or removal of the device it

has to be made sure that the gas is removed in accordance with the current regulations on

the use of fluorinated greenhouse gasses.

Page 9

9

1.9 Delivery package

The package includes:

1. Hydro module.

2. Instructions for management and instructions for installation, use and maintenance.

3. Wall bracket for the device,

4. Accessories:

o Outdoor air temperature sensor (only HM-140 S1),

o DHW buffer tank temperature sensor,

o Second mixing cycle temperature sensor,

o Equalisation screw -2x

Picture 1: Delivery package

Page 10

10

2 INSTRUCTIONS FOR THE END USER

Page 11

11

2.1 Controlling the device and heating system

Use the device and heating system in accordance with this manual and instructions for use

of the heat pump which explains the use off the device and heating system.

2.2 Maintaining the device and heating system

The device must be visually inspected once a year. The electrical and hardware installation

of the device have to be inspected. In the case of detected irregularities, contact the

authorised technician.

CAUTION

The servicing and maintenance of the device can only be performed by a person

authorised by the manufacturer. In case of a malfunction, first contact the installer

who installed the device.

NOTE

Cleaning of water filters on the return into the device is advised to be performed at

least once yearly.

CAUTION

A blocked water purifying component and magnetic filter can lead to a malfunction

of the device or incorrect functioning of the device. In case the display displays a

warning of flow malfunction (”Caution, flow!”).

NOTE

Periodically, once yearly, check the water temperature in the heating system.

NOTE

In case the pressure falls (i.e. Leakage of the system) the display displays a

warning of flow malfunction (”Caution, flow!”).

2.2.1 OPERATION MALFUNCTIONS

In case of a malfunction during the operation of the device, the display of the

TERMOTRONIC controller displays the warning “Caution, malfunction”.

Find the malfunction description in the “Owner’s manual”. For error correction call the

installer who installed the device.

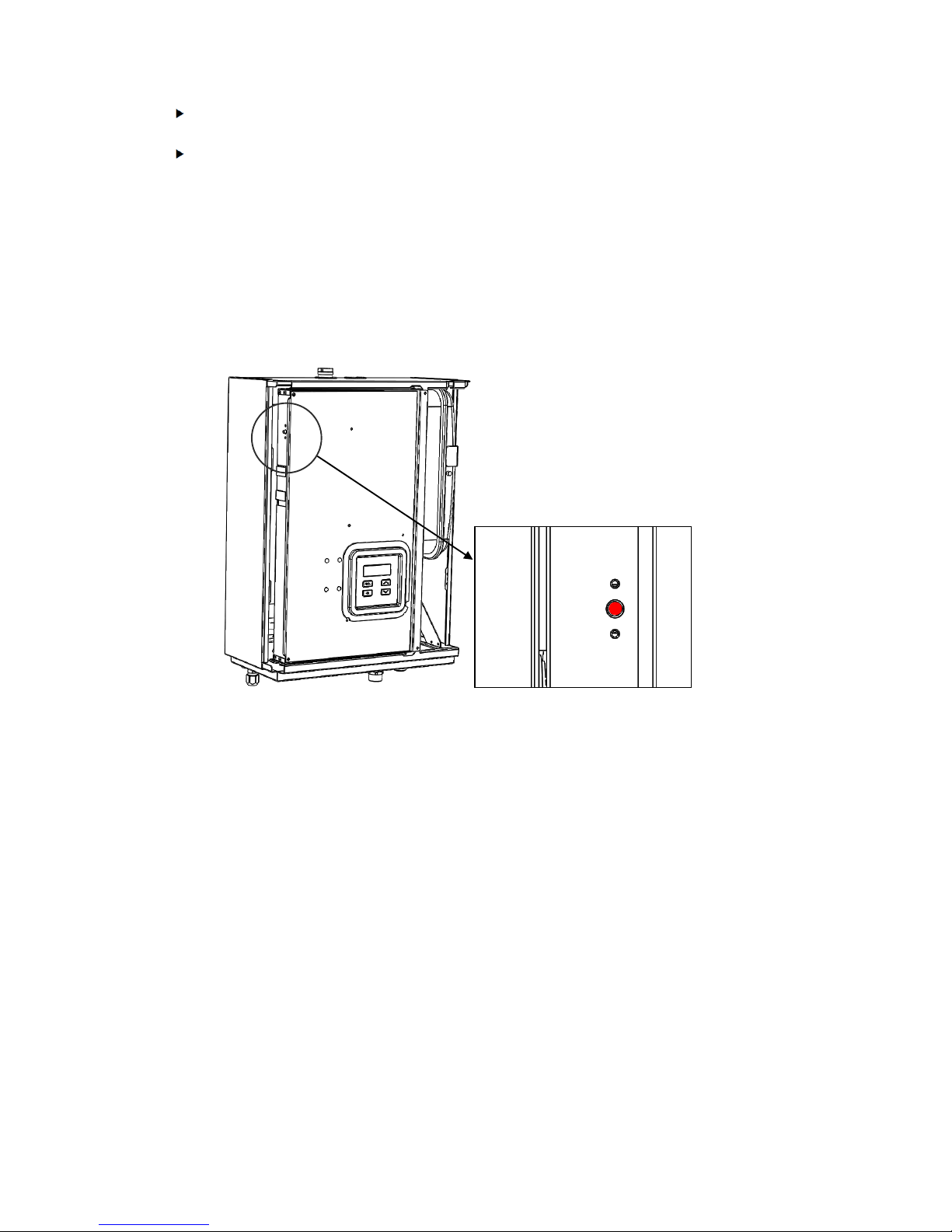

2.2.1.1 Resetting the thermal protection of the built-in electrical

heater

The thermal protection of the electrical heater is an additional safeguard protecting the

device in the following cases:

Page 12

12

The electrical contactor which turns on the electrical flow heater can be

permanently short-circuited.

At commission, air is in the system, which causes heating without heat extraction.

The easiest way to determine whether the thermal protection of the electrical heater is

turned off is to turn on the operation of the auxiliary source on the TERMOTRONIC control

unit. If the electric heater is operational, the water temperature in the heating system will

start to rise.

In case the electrical heater does not work because of one of the before mentioned

reasons, the safety thermostat has to be reset after the problem is resolved. It is reset by

pushing the red button. If the reset is successful, you will hear a “CLICK”.

Picture 2: Resetting the safety thermostat of the built-in electrical heater

Page 13

13

Page 14

14

3 INSTRUCTIONS FOR THE INSTALLER

Page 15

15

3.1 Transport and storage

WARNING

Valves, safety elements and pipes must be checked, calculated and

determined by the system or hardware installations contractor.

WARNING

Before connecting the device, it is necessary to rinse the pipe system

thoroughly and remove impurities (solid particles, oils, greases ...).

Use suitable detergents if necessary.

NOTE

The device must be connected via closing valves.

CAUTION

The device must be transported with transport devices.

Secure the device during transport to prevent damage.

The device must not be stacked and other objects must not be placed on it.

CAUTION

Appropriate transport equipment must be used for installing the device. Safety

regulations and good practise have to be used.

CAUTION

The device has to be stored in a dry and clean place. The allowed storing

temperature is between 10 °C and 45 °C, for a short period (up to 24h) also up to

50 °C.

3.2 Installation space

The device must be installed in a space which meets the following requirements:

NOTE

The installation space must be accessible by manual transport devices for the

purposes of installation, maintenance and servicing.

Costs connected with hiring special equipment for installing the device,

servicing and maintenance are charged to the operator separately and are

not subject of the warranty.

NOTE

The location of the internal unit must be dry and in the temperature range between

+10 °C and 40 °C.

WARNING

The space has to be fitted with a drain.

CAUTION

It is forbidden to install the device under water pipes; in case of leakage water

could enter the device and cause a malfunction.

NOTE

It is obligatory to consider the minimal clearance from obstacles for ensuring

unobstructed access for maintenance and service of the device.

Page 16

16

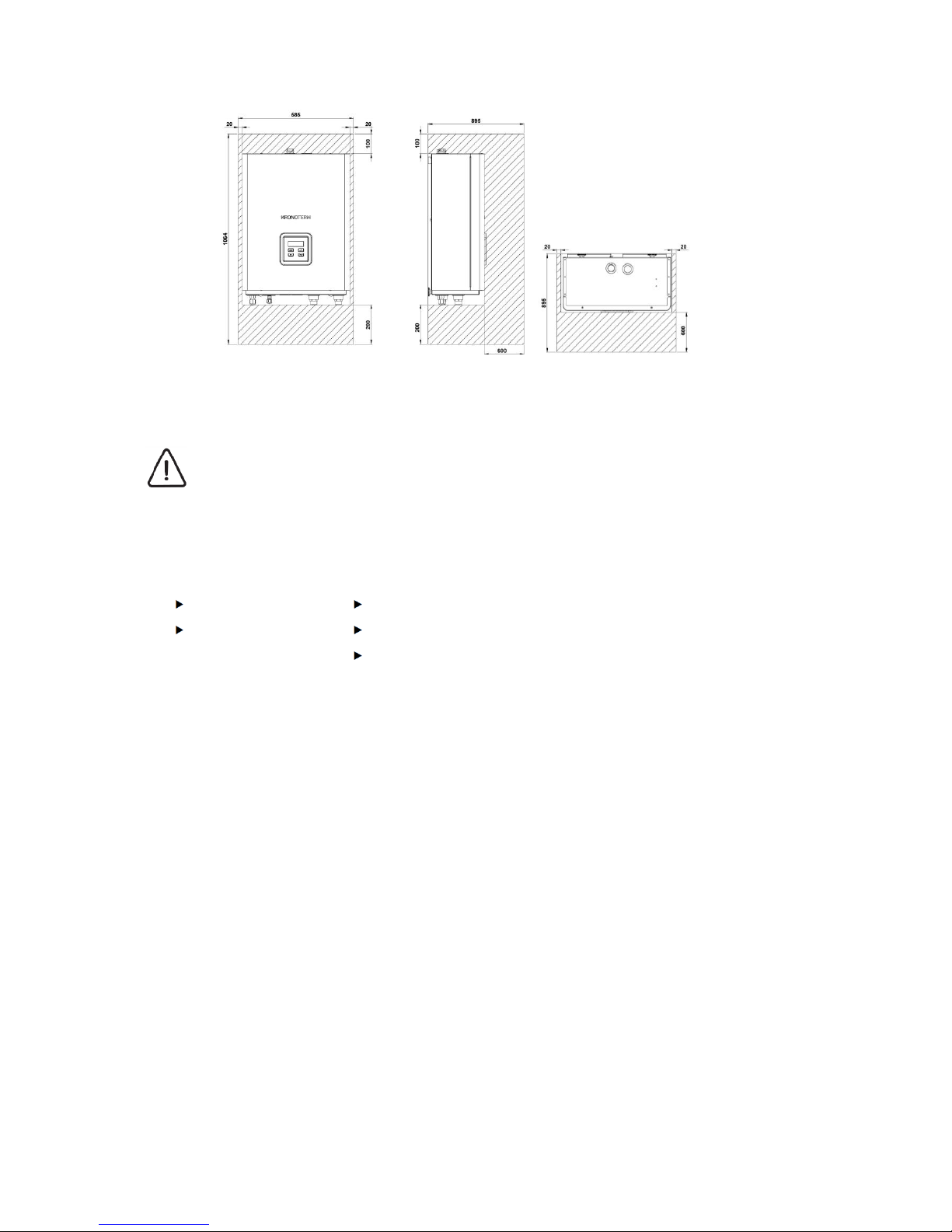

Picture 3: Minimal clearance between the device and obstacles

3.3 Wall mounting

CAUTION

For wall mounting, you need to use wall plugs and screws suitable for the wall.

Take into account the mass of the device. For technical information, see section

on technical information.

For wall mounting, you will need:

Spirit level,

Drilling machine,

Plugs and screws suitable for the wall,

Pencil or pen for marking the places for holes and screws,

Device wall mount (part of the delivery package).

1. Attach the wall mount:

a. Mark the position of holes for

attaching the wall mount - use the wall

mount of the device and the spirit

level.

b. Drill holes suitable for selected

mounts and screws.

c. Insert the plugs, fasten the wall mount

and level it.

2. Tighten the equalisation screws in the

device - 2x.

Page 17

17

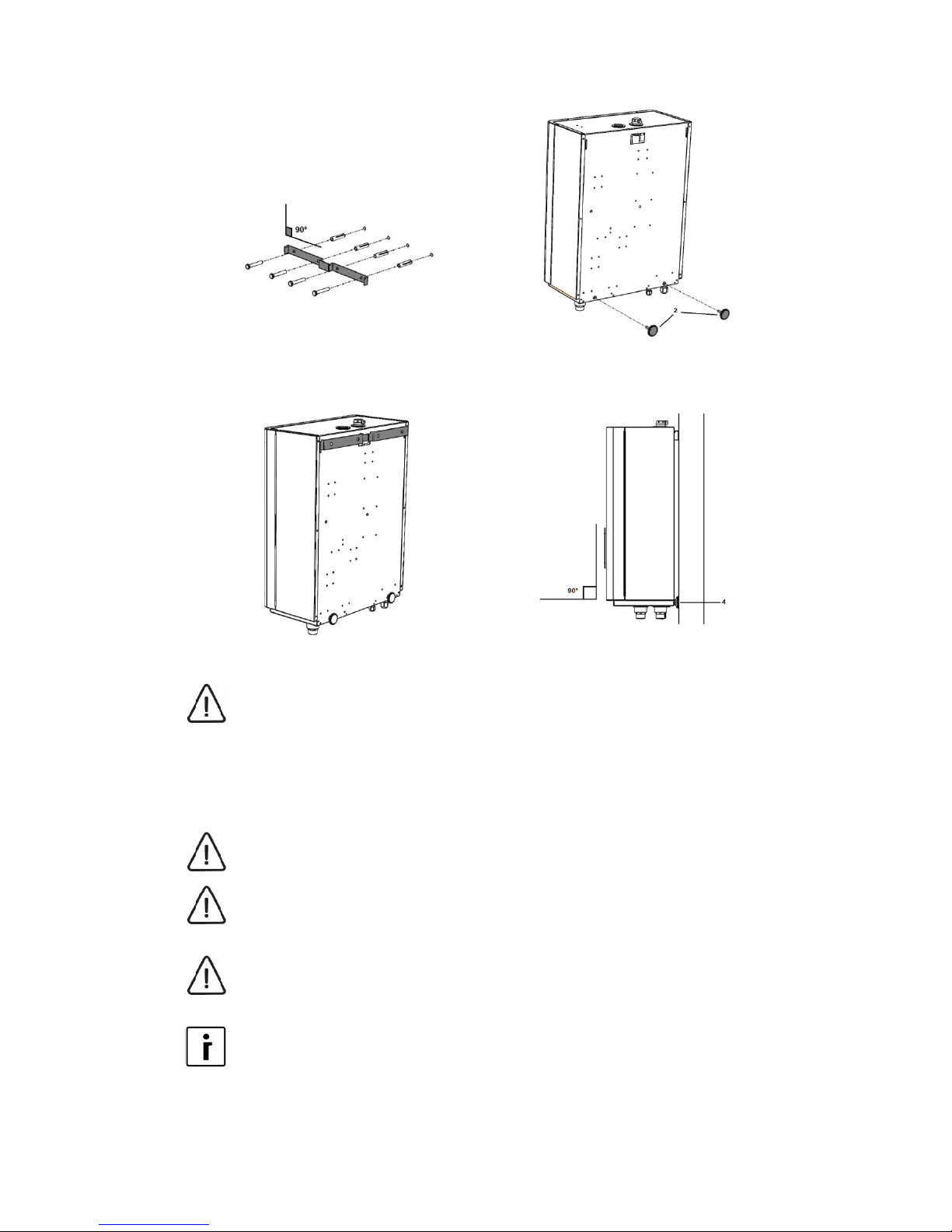

Picture 4: Fastening the device’ s wall mount

to the wall

Picture 5: Installation of equalisation screws.

3. Hang the device on the wall mount.

4. Level the device using the spirit level

and equalisation screws.

Picture 6: Hang the device on the wall mount.

Picture 7: Level the device using the

equalisation screws.

CAUTION

The mass of the device, safety regulations and good practise have to be followed

when lifting the device. For technical information, see section 4.2.

3.4 Connection with the outdoor unit

CAUTION

Connection with the outdoor unit must be performed by a refrigeration expert.

CAUTION

The pipeline and electrical cables have to be protected with heat and waterproof

insulation in a protective pipe.

CAUTION

The device is filled with pressurised N2. Before attaching the pipe, it must be

released from the device.

NOTE

For making the connection with the external device, see Instructions for

Installation of the external device.

Page 18

18

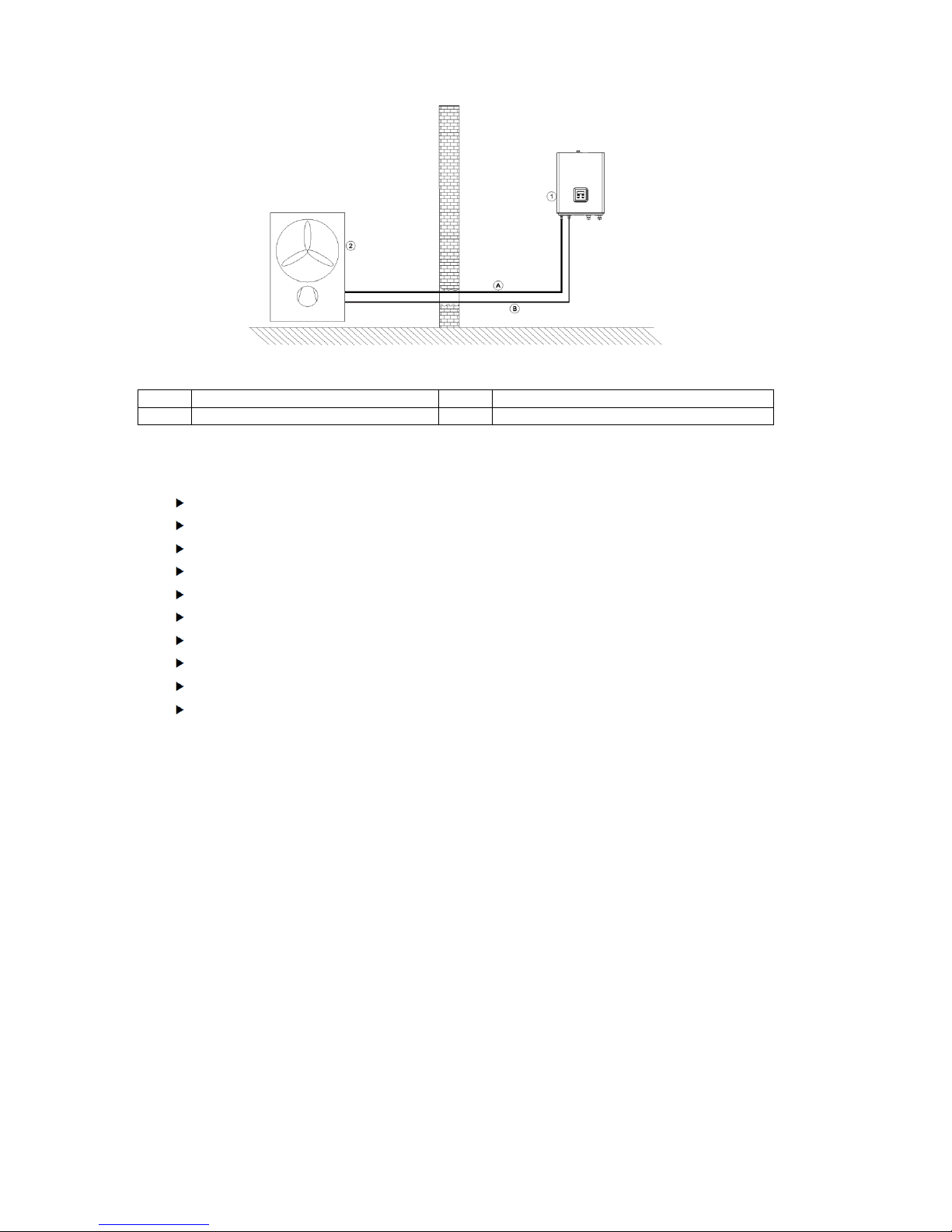

Picture 8: Coolant connection between the exterior and interior device.

1

Hydro module

A

Gas pipe

2

Outdoor unit

B

Liquid pipe

You will need the following tools:

Screwdriver.

Coolant service manometer.

Tool for cutting pipes.

Tool for deburring pipes.

Fork wrench and fork torque wrench - for HM-140 S1 and HM-130 S1.

Tool for pipe edging - for HM-140 S1 and HM-130 S1.

POE oil is suitable for cooling systems - for HM-140 S1 and HM-130 S1.

Pipe expander - for HM-180 S1.

Acetylene burner, oxygen - for HM-180 S1.

Wet towel.

Page 19

19

For making a cooling connection with the external device, follow these steps:

1. Remove the front cover of the device.

Picture 9: Removal of the device cover.

2. Unscrew the screws of the electrical cabinet and open it to ensure access to the

cooling pipes. Unscrew the lid of the service valve.

Picture 10: Opening the electrical cabinet.

Page 20

20

3. If you are installing HM-140 S1 or HM-130 S1, continue on chapter 3.4.1. If you

are installing HM-180 S1, continue on chapter 3.4.2.

3.4.1 COOLING CONNECTION WITH THE OUTDOOR UNIT - HM140 S1 AND HM-130 S1.

4. Connect the manometer and drain the N2 from the device.

5. Unscrew the bolts on the end of the pipe and save them. You will use them to

mount the pipes.

6. Cut the connecting pipes to the required length. When cutting, consider the

following:

Use a pipe cutter which does not leave chips to cut the pipe.

The cut must be perpendicular to the pipe’s axis and straight.

1

Copper pipe

3

Uneven

2

Inclined

4

Rough

7. Deburr the end of the pipe:

Remove all chips from the part where the pipe was cut.

Hold the pipe downwards during deburring so that the chips do not fall into

the pipe.

1

Copper pipe

3

Deburring tool.

Page 21

21

2

Copper pipe held downwards

8. Attach the bolt you have previously removed from the device onto the pipe as seen

below.

1

Copper pipe

2

Screw nut

9. Edge the end of the pipe with the edging tool.

1

Holder

4

Cone

2

Copper pipe

5

Bracket

3

Fitting

6

Handle

7

Holder

Mount the copper pipe firmly into the tool for edging. Consider the dimensions listed

in the table below.

External diameter

‘'A''

[mm]

[inch]

[mm]

9.52

3/8

1.5 ~ 1.7

15.88

5/8

1.6 ~ 1.8

10. Check the end of the pipe:

Compare the edging of the pipe with the picture below.

In the case of damaged edging cut the part off and repeat the edging procedure.

Page 22

22

1

Circular edging of the pipe of the same length.

4

Inclined edge

2

Circularly smooth edge

5

Uneven surface

3

Interior edge and surface without scratches

6

Cracked / rough

7

Unequal thickness

11. Align the edged cooling pipe with the connection of the same dimension on the

internal unit.

12. Apply a drop of oil on the bolt thread (POE oil, suitable for cooling systems) to

grease the thread.

13. Tighten the bolt manually.

14. Set the torque wrench to the suitable setting.

External diameter of the pipe

Torque

[mm]

[inch]

[Nm]

9.52

3/8

34 – 42

15.88

5/8

65 – 81

15. Use the fork wrench and fork torque wrench to tighten the bolt until it clicks.

16. Repeat the process for both pipes.

3.4.2 COOLING CONNECTION WITH THE OUTDOOR UNIT - HM180 S1

The pipe connection for HM-180 S1 is performed with soldering the connecting pipes to the

connections on the device. Follow the steps below.

1. Use the pipe cutter to cut the pipes approximately 3 cm from the end of the pipe.

2. Clean the pipes with an abrasive cloth to remove impurities. When cleaning, be

careful not to let the impurities enter the pipe.

3. Expand the pipe with the tool for expanding pipes.

Page 23

23

Inside diameter – Φ22,2 - ±0,2

4. Align the expanded connecting pipes with the connections. Wrap a wet towel

around the connections on the internal unit for cooling. Solder the pipes with

soldering which contains at least 5% Ag.

5. Check the quality of the joints.

3.4.3 MAKE A LEAK TEST, DRAIN AND FILL THE COOLING

CONNECTION.

NOTE

To perform the leak test, drain the system and fill the system, see Instructions for

Installation, Use and Maintenance of the outdoor unit.

Page 24

24

3.5 Hydraulic connection

3.5.1 GENERAL

WARNING

Circulation pumps, valves, safety elements and pipes must be checked,

calculated and determined by the system or hardware installations contractor.

WARNING

Before connecting the device, rinse the whole heating system and remove

impurities. Remove all detergent residue. Flushing the system must be performed

with new and existing heating systems.

3.5.1.1 Legend of symbols of the hydraulic piping diagrams

Symbol

Description

Symbol

Description

Circulation pump

Drinking water filter

Ball valve

Manometer

Ball valve with exhaust

Thermometer

Three-way switch valve

Pressure regulator

Three-way mixing valve

Consumer of heat / coolness

Expansion vessel

KT-1, KT-2

Safety valve

Thermostat

Hydraulic divider

Pipe safety thermostat

Non-return valve

Electrical cabinet for powering the

devices of the heating system

Cyclone magnetic separator

of impurities

Temperature sensor

Automatic vent

Automatic by-pass control valve

1

Hydro module

17

Buffer tank

2

Air-water Heat Pump

18

Circuit circulation pump

3

Buffer tank for DHW

19

Pipe safety thermostat

4

Three-way switch valve

20

Three-way mixing valve

5

Heat consumer

21

Gas furnace

6

Overflow valve

22

Hydraulic divider

7

Cyclone magnetic separator of impurities

23

Oil or pellet furnace

8

Heating system Expansion vessel

24

Drain

9

Heating system safety valve

25

Expansion regulation TT 3003 - MD2

10

Circulation pump

26

Submersible electric heater

Page 25

25

11

Irreversible flaps

27.1

Combined buffer tank with submersed buffer

tank for DHW

12

Safety valve of the DHW system

27.2

Buffer tank for DHW submersed in the buffer

tank

13

Expansion vessel of the DHW system

28

Biomass furnace

14

Irreversible flaps

29

Biomass furnace circulation pump

15

DHW system pressure regulator

30

Solar collectors circulation pump

16

DHW water filter at the inlet of the building

31

Three-way cooling switch valve

A

Cooling connection - gas pipe

C3

Modbus cable for communication between

internal and outdoor unit

B

Cooling connection - liquid pipe

C4

Expansion regulation TT 3003 - MD2 electrical

supply cable

C1

Internal unit electrical supply cable

C5

Cable for communication between internal unit

and expansion regulation TT 3003 - MD2.

C2

Outdoor unit electrical supply cable

Certain elements are additionally marked with the designation of the electrical connection.

MD1

:

A2 Designation of the connecting clamp.

MD1 - electrical connection of the element to the device’s connecting terminal

.

MD2 - electrical connection of the element on the connecting terminal of the

expansion regulation TT3003 - MD2.

3.5.2 BUFFER TANK FOR DHW CONNECTION

CAUTION

Connect the buffer tank for DHW in accordance with the national and local regulations

in force. The space where the device, DHW buffer tank, etc. are installed, must have a

floor drain to allow water to drain in case of a spill.

CAUTION

Connect the DHW buffer tank so as to prevent galvanic cells and corrosion to form

because of the use of different materials. We recommend connections made of red

brass at least twice the length of the rated diameter of the connection.

CAUTION

The DHW buffer tank is intended for storing drinking water. The drinking water must be

in accordance with the national regulations on drinking water in force.

CAUTION

For normal operation of the Expansion vessel, it is necessary to perform proper

adjustments of the tank’s working pressure. The settings have to be checked every 12

months.

3.5.2.1 Choosing the buffer tank for DHW

For reliable DHW heating, you need a DHW buffer tank which has a heat exchanger with

the appropriate surface. Consider the recommendations below.

Hydro module

Min. surface of the DHW buffer tank heat exchanger

HM-140-S1

1,8 m2

HM-130-S1

3.0 m2

HM-180-S1

4.5 m2

Choose the DHW buffer tank volume to meet the needs for comfort.

Page 26

26

3.5.2.2 Connecting the buffer tank for DHW

Connect the buffer tank for DHW as shown on the scheme below.

NOTE

For circulation regulation (10), you must install the expansion regulation TT3003 (25).

Picture 11: Connecting the buffer tank for DHW

3.5.2.3 Choosing and setting the expansion vessel of the DHW

system

NOTE

The cold DHW connection must be fitted with an expansion vessel suitable for

drinking water. The selection and installation must be in accordance with the

standard DIN 4807 T5.

CAUTION

Consider the maximal operational pressure of the vessel.

The size and type of the expansion vessel must be determined by the installer / contractor

according to the size of the system. The table below lists some recommendations.

Adjusting the safety valve [MPa (bar)]

0.6 (6.0)

System pressure [MPa (bar)]

0.3 (3.0)

0.35 (3.5)

0.4 (4.0)

Volume of the DHW [l]

Expansion vessel [l]*

200

5 8 12

300

15

19

26

Expansion vessel for DHW is factory filled to a precharge pressure p0 with dry nitrogen.

The pressure must be set depending on the settings of the pressure reducing valve on the

DHW supply to the building.

The pressure in the expansion vessel must be set according to the following formula:

,

Page 27

27

p0 – precharge in the Expansion vessel

prv – setting pressure regulator

Example:

The Expansion vessel is filled with nitrogen to a pressure of p0 = 2,0 bar (0,2 MPa).

The pressure regulator for drinking water at the inlet of the building is set to prv = 4.0 bar

(0,4 MPa).

Consequently, the Expansion vessel must have the following pressure:

The expansion vessel must be supplemented with dry nitrogen to 3.8 bar.

3.5.3 CONNECTING THE HEATING SYSTEM

WARNING

Thorough venting of the system has to be ensured. Otherwise, malfunctions in

operation may occur.

CAUTION

The device can be integrated with an expansion vessel with the volume of 12l. This is

sufficient for heating systems up to the joint volume of 300 l and maximal operating

pressure of 0.3 MPa (3bar). In case of a heating system of a larger volume, it is

necessary to install an external expansion vessel. The dimensions of the Expansion

vessel must be in accordance with standard EN 12828.

For installing the expansion vessel, see chapter 4.4.1

CAUTION

For normal operation of the Expansion vessel, it is necessary to perform proper

adjustments of the tank’s working pressure. The settings have to be checked every 12

months.

CAUTION

The heating system must be fitted with a safety valve set to 0.3 MPa (3 bar).

3.5.3.1 Mono-energy system

A mono-energy system is a heating system which supplies all the heat from the heat pump

and integrated electric heater.

3.5.3.2 System with one heating cycle and DHW buffer tank

The scheme below shows a heating system with one cycle and a DHW buffer tank.

CAUTION

This model is suitable only for systems with floor, wall or ceiling heating.

Page 28

28

CAUTION

Ensure the minimal volume of the heating system as stated in the table below. If

needed, install an additional buffer tank on the return pipe.

Max. Thermal power (kW)

System min. volume (L)

8

150

11

200

16

300

19

350

22

400

CAUTION

To ensure sufficient flow, make sure that at least 30% of the branches of the heating

system do not have electrical or thermostat closing valves.

CAUTION

Set the overflow valve (6) not to let water through in normal operation. Consider

manufacturer’s instructions.

NOTE

For circulation regulation (10), you must install the expansion regulation TT3003

(25).

Picture 12: One cycle heating system with cooling switch and DHW buffer tank

3.5.3.2.1 System with several heating cycles, buffer tank and DHW buffer

tank

NOTE

An expansion regulation TT 3003 - MD2 must be installed for regulation of the third

cycle (5.3), fourth cycle (5.4) and circulation (10).

CAUTION

A buffer tank with the volume of at least 15 l / kW of heating power has to be

installed.

Example:

The highest heating power of the device Q

hmax

= 11 kW.

Page 29

29

The minimal volume of the buffer tank V

min

= 11 kW x 15 L/kW = 165 L

Picture 13: Scheme of a system with several heating cycles, buffer tank and DHW buffer tank

3.5.3.3 Bivalent system

A bivalent system uses an additional heat generator in addition to the heat pump to heat

the building.

Set up the bivalent system in accordance with the schemes below.

Page 30

30

3.5.3.3.1 Bivalent system with oil or pellet furnace

NOTE

An expansion regulation TT 3003 - MD2 must be installed for regulation of the third

cycle (5.3), fourth cycle (5.4) and circulation (10).

Picture 14: Scheme of a bivalent system with oil or pellet furnace.

3.5.3.3.2 Bivalent system with gas furnace

NOTE

An expansion regulation TT 3003 - MD2 must be installed for regulation of the third

cycle (5.3), fourth cycle (5.4) and circulation (10).

Picture 15: Scheme of a bivalent system with gas furnace.

Page 31

31

3.5.3.3.3 Bivalent system with biomass furnace

NOTE

An expansion regulation TT 3003 - MD2 must be installed for regulation of the third

cycle (5.3), fourth cycle (5.4), circulation (10) and biomass furnace (28).

Picture 16: Scheme of a bivalent system with biomass furnace

3.5.3.3.4 Bivalent system with solar collectors

Install a system with solar collectors according to the scheme below.

NOTE

An expansion regulation TT 3003 - MD2 must be installed for regulation of the third

cycle (5.3), fourth cycle (5.4), circulation (10) and solar collectors (28).

Picture 17: Scheme of a heating system with solar collectors

Page 32

32

3.5.3.4 Cascade piping of devices

The scheme below shows parallel or cascade piping of devices.

NOTE

Contact our clerk for regulation of parallel operation of multiple devices.

Picture 18: Cascade piping of devices

Page 33

33

3.5.3.5 Quality of heating water

WARNING

The table below lists maximal allowed content of substances in heating water. If the

influence of a substance on the device is marked as »-« or »0«, the water must not be

used.

TYPE OF PRESENT

SUBSTANCE

UNIT

CONCENTRATION

INFLUENCE TO THE

HEAT CONDUCTOR

Organic sediment

mg / L

0

Ammonia NH

3

mg / L

< 2

1 to 20

> 20

+

0

-

Chloride

mg / L

< 300

> 300 + 0

Allowed water hardness

°dH

5 – 10

Electrical conductivity

µS / cm

< 10

10 to 500

> 500

0

+

-

Iron (Fe) removed

mg / L

< 0.2

> 0.2 + 0

Free carbonic acid

mg / L

< 5

5 to 20

> 20

+

0

-

Manganese (Mn) removed

mg / L

< 0.1

> 0.1 + 0

Nitrates (NO3)

removed

mg / L

< 100

> 100 + 0

pH value

mg / L

< 7.5

7.5 to 9

> 9

0

+

0

Oxygen

mg / L

< 2

> 2 + 0

Hydrogen sulphide

(H2S)

mg / L

< 0.05

> 0.05 + -

HCO3- / SO

4

2

-

mg / L

> 1

< 1 + 0

Hydrogen carbonate

(HCO3-)

mg / L

< 70

70 to 300

> 300

0

+

0

Aluminium (Al) removed

mg / L

< 0.2

> 0.2 + 0

Sulphates

mg / L

< 70

70 to 300

> 300

+

0

-

Sulphite (SO3)

mg / L

< 1

+

Chlorine (gas) (Cl2)

mg / L

< 1

1 to 5

> 5

+

0

-

Table: Influence of various aggressive substances in heating water on the device. (+ = no

influence, 0 = danger of corrosion, - = corrosion - use not permitted).

CAUTION

The heating system has to be filled with water with the hardness between 5 °dH and

10 °dH. Malfunctions of the device because of water hardness are not covered by the

Page 34

34

warranty.

The heating systems must not be filled with dirty or corrosive water. Add corrosion

inhibitors and anti-microbial agents to water.

CAUTION

The water in the heating system must be in accordance with the regulations of

standard VDI 2035 and must not contain micro-organisms. Fill the heating system

with soft water with added additives for ensuring the required quality.

NOTE

To prevent malfunctions of the hydraulic components of the system, we

recommend installing a SpiroVent RV2 air bleeder (micro-bubbles). The presence

of micro bubbles in the system eventually forms larger bubbles which in time can

cause corrosion of the system, system component malfunction and operation

disturbance.

In new systems, impurities are the result of residue from welding, soldering, dirty pipes (oil,

grease), etc. In case the impurities start accumulating in the device, this can worsen the

flow and heat transfer, in worst cases also freezing of water in the heat exchanger and

consequently the destruction of the device.

WARNING

To protect the device from intake and accumulation of dirt in the heat exchanger

you must install the strainer and magnetic separator on the return pipe for heating,

before entry into the device.

WARNING

A galvanic disconnection between individual elements of the heating system (i.e.

boiler, buffer tank...) is obligatory.

In the case of using steel pipes in the heating system, it is necessary to degrease them

(the interior of the pipe) before connecting them to the heat pump.

Page 35

35

3.5.4 FILLING THE HEATING SYSTEM

Picture 19: Static height of the heating system

7

Expansion vessel

8

Safety valve

H

Static height (the height difference between the expansion vessel and the highest

point of the heating system).

CAUTION

Consider the maximal operational pressure of the vessel.

NOTE

Inappropriate filling of the expansion vessel with precharge p0 and filling the

heating system, the function of the expansion vessel and operation of the heating

system is not guaranteed.

NOTE

The dimensions of the Expansion vessel must be in accordance with standard

EN 12828.

Setting the pressure for the Expansion vessel

Before filling the system with water, check and set the pressure of the expansion

vessel p0. The surcharge and maximal pressure of the expansion vessel are

specified on the standard label.

Calculate the value of the lowest needed surcharge p0 setting:

Page 36

36

CAUTION

If the calculation shows a pressure lower than 0.1 MPa (1 bar), set the pressure of

the expansion vessel to 0.1 MPa (1 bar).

p0 [MPa (bar)] – surpressure in the Expansion vessel,

p

0min

[MPa (bar)] – minimal needed pressure of the heating system,

p

0max

[MPa (bar)] – maximal allowed pressure of the heating system,

H [m] – static height.

Set the surcharge in the expansion vessel by releasing or supplementing dry

nitrogen.

Record the new value of the surcharge p0 on the serial label.

Open the closing valve of the Expansion vessel carefully, open the vents and close

the drain.

Filling the heating system

Use the filling valve to fill the system with water of suitable quality to the pressure

pF.

,

Filling the system to the final pressure

The final pressure of the system is determined by heating the system to the

maximal heating temperature (thermal degassing).

Turn off the circulation pumps, open the vents and vent the system.

At maximal operating temperature, fill the system to the end pressure which is 0.05

MPa (0.5 bar) lower than the releasing pressure of the safety valve.

],

( )

pE – the end pressure of the system,

pSV – the pressure of the safety valve.

3.6 Electrical connection

Connect the internal unit to the mains according to the instructions described in this

chapter.

CAUTION

Connecting the device to the electrical network has to be performed in accordance

with the standards for connecting devices to the electrical network. The device has

to be connected to the electrical network via the power supply cut-off which is

Page 37

37

installed into the electrical installation under the regulations in force. The power

supply cut-off has to separate all contacts under the regulations of the overvoltage

category III - minimal spacing between contacts is 3 mm.

DANGER

Checking the electrical connection before commissioning can only be performed

by the person authorised by the manufacturer to ensure the correct and efficient

operation of the device.

IT IS STRICTLY PROHIBITED FOR UNAUTHORISED PERSONS TO TAMPER

WITH THE ELECTRICAL CONNECTION OF THE DEVICE.

DANGER

The device can only be connected to the electrical supply with built in RCD

residual-current device, switch type A.

CAUTION

The device must be connected to the mains with a cable with an appropriate

diameter. The diameter of the cable is determined by the installer according to

method of laying the cable, distance of the device from the electrical cabinet

and power of the device.

It is necessary to use a harmonised cable H05VV-F.

CAUTION

The wires must be routed through the overflows installed before the connecting

terminal in the device. Make sure the cable connected in the device is relieved.

CAUTION

The joint electrical power of the devices directly connected to the regulation must

not exceed 500 W. Otherwise, it is necessary to ensure separate power to the

external devices and to connect control elements to the regulation.

WARNING

Pay attention to the characteristics of the inputs and outputs. Incorrect connection

can lead to damage to the device.

CAUTION

The communication cable must not be laid together with energy cables (in

accordance with good engineering practise and regulations).

3.6.1 DESCRIPTION OF ELEMENTS IN THE ELECTRICAL

CABINET

1

Safety thermostat.

6

Terminal for connecting odbus

communication and sensors of the

heating system.

2

Electrical contactor

7

DC charger.

3

Connecting the actuators of the

heating system.

8

Input output module.

4

Cable glands for cable elements of the

heating system.

9

PLC

5

WEB module.

10

Element for galvanic separation of

communication signals.

Page 38

38

Picture 20: Electrical cabinet

Picture 21: The lid of the electrical cabinet

3.6.2 ELECTRICAL CONNECTION WITH THE OUTDOOR UNIT

NOTE

For characteristics of power cables, see technical data (chapter 4.2).

Picture 22: Electrical connection with the outdoor unit

Page 39

39

1

Hydro module

C1

Hydro module electrical supply cable.

2

Outdoor unit air - water

C2

External unit air - water (electrical supply cable).

A

Cooling connection - gas

pipe

C3

Modbus cable for communication between internal and

outdoor unit

B

Cooling connection - liquid

pipe

3.6.3 CABLE INSTALLATION

CAUTION

Lay the cables of the heating system elements as shown on the picture below. The

cables must be of sufficient length to allow the electrical cabinet to be opened

during service.

Picture 23: Laying the cables in the electrical cabinet.

3.6.4 POWER CONNECTION

DANGER

Connecting the device to the power source can only be performed by a qualified

installer in a voltage-free state.

CAUTION

The supply and communication cables have to be laid into the device and electrical

cabinet through separate cable glands and cord anchorage, which are installed

before the cable terminals. This way we ensure the cable is relieved from strain and

the electrical cabinet is protected from water penetration.

CAUTION

Wrong dimensioning of the power cable or too weak terminal fuses of the device

could lead to an overload of the safety elements on the power grid of the

building which could lead to overheating of the electrical installation. Follow the

requirements listed in this manual.

Page 40

40

CAUTION

In case of connecting the multi-wire flexible cable to the connecting terminal, it always

has to have an end sleeve end sleeve at the end.

1

End sleeve

2

Multi-wire flexible conductor

3

Massive single-wire cable

To connect to connecting terminal of the device, use cables with necking dies or

massive single-wire cables.

The dimensions of the power cables are listed in the chapter under technical

information 4.2.

3.6.4.1 One-phase connection ~230 V / 50 Hz – 16 A

NOTE

In one-phase connection ~230 V / 50 Hz – 16 A the power of the electric heater is

2 kW.

Connect the cable of an appropriate cross-section

to the terminal , N and L1.

3.6.4.2 One-phase connection ~230 V / 50 Hz – 20 A

NOTE

In one-phase connection ~230 V / 50 Hz – 16 A the power of the electric heater is

4 kW.

Connect the cable of an appropriate cross-section

to the terminal , N and L1. Make a bridge

between terminal L1 and L2.

Page 41

41

3.6.4.3 Three-phase connection 3N ~ 400 V / 50 Hz – 16 A

NOTE

In three-phase connection 3N ~ 400 V / 50 Hz – 16 A the power of the electric

heater is 6 kW.

Connect the cable of an appropriate crosssection to the terminal , N, L1, L2 and L3.

3.6.5 CONNECTING THE COMMUNICATION WITH THE

EXTERNAL DEVICE

NOTE

For characteristics of power cables, see technical data (chapter 4.2).

3.6.5.1 Connection with the outdoor unit WPLV-09(14)-S1 NT

Connect the communication cable to

terminal X5 as shown on the picture

below.

Ground the cable shield!

3.6.5.2 Connection with the outdoor unit WPL-08(18)-S2 HT

Connect the communication cable

to terminal X7 as shown on the

picture below.

Ground the cable shield!

Page 42

42

3.6.6 CONNECTING THE EXTERNAL TEMPERATURE SENSOR

NOTE

The external temperature sensor must be installed only in HM-140 S1 devices.

CAUTION

Install the external temperature sensor on the shaded part of the building.

The sensor must not be installed above a window or door. The distance to

windows or doors must be at least 1 m.

Install the sensor on an insulated wall to prevent wrong temperature

measurements.

Picture 24: Installing external temperature sensor

3.6.6.1 Connecting external temperature sensor

Connect the external temperature sensor to

serial clamp X4, connect it to A5 and GND.

3.6.7 CONNECTION KT-1 AND/OR KT-2

Connect the temperature corrector KT-1 or

KT-2 to serial clamp X6. The connection on

KT-1(2) and on the serial clamp must be in

the same colour order.

Up to 4 KT-1(2) can be connected to the

same clamp.

Page 43

43

3.6.8 CONNECTING THE HEATING FOR DHW

Connect the three-way switch valve to serial

clamp X2, connect it to terminal , N, Q4

and L1230 V.

See three-way switch valve manufacturer

instructions for correct sequence of the

permanent and control phase.

Connect the DHW temperature sensor to

serial clamp X4, connect it to A2 and GND.

3.6.9 HEATING CYCLE CONNECTION

3.6.9.1 Connection of the first cycle

NOTE

The first cycle can only be direct. You have to connect the circulation pump; the

thermostat is optional.

3.6.9.1.1 Circulation pump connection

Connect the circulation pump of the first cycle

to serial clamp X2, connect it to Q7, and

GND.

Page 44

44

Connect the phase (Q7) of the circulation

pump sequentially with the pipe safety

thermostat (15).

3.6.9.1.2 Thermostat connection

NOTE

Connecting the thermostat is not obligatory. Perform the connection in case KT1(2) is not connected and you want to control the room temperature with a

thermostat.

Connect the thermostat of the first cycle to

serial clamp X4, connect it to D6 and GND.

3.6.9.2 Mixing cycle connection

The second cycle can be a direct or a mixing cycle. In any case, connecting the

temperature sensor of the riser pipe is necessary for safeguarding.

Page 45

45

3.6.9.2.1 Circulation pump connection

Connect the circulation pump of the first cycle

to serial clamp X2, connect it to Q8, and

GND.

Connect the phase (Q7) of the circulation

pump sequentially with the pipe safety

thermostat (15).

3.6.9.2.2 Mixing valve connection

NOTE

Perform the connection of the mixing valve in case you have a mixing cycle.

Connect the mixing valve to serial clamp X3,

connect it to terminal Q9, , N and Q10.

3.6.9.2.3 Thermostat connection

NOTE

Connecting the thermostat is not obligatory. Perform the connection in case KT1(2) is not connected and you want to control the room temperature with a

thermostat.

Page 46

46

Connect the thermostat of the first cycle to

serial clamp X4, connect it to D7 and GND.

3.6.9.2.4 Temperature sensor of the second cycle connection

NOTE

The temperature sensor for the riser pipe is used as a safeguard of the cycle

and for controlling the mixing valve.

Connect the riser pipe temperature sensor of

the second cycle to serial clamp X4, connect

it to A7 and GND.

3.6.10 EXTERNAL ADDITIONAL SOURCE CONNECTION

CAUTION

The device can only be connected with the control signal for the external

additional source. Perform the connection of the external additional source

separately.

Connect the signal for controlling the external

additional source (electric heater, oil, pellet

or gas furnace) to serial clamp X3, connect it

to terminal Q12, N and .

Consider manufacturer’s instructions for

the external additional source when

connecting the control signal!

Page 47

47

3.6.11 CONNECTING THE VALVE FOR SWITCHING

BETWEEN COOLING / HEATING

NOTE

Connect the valve for switching between cooling / heating in case you do not

use the same heating / cooling bodies for cooling.

Example:

Floor heating is used for room heating. Only convectors are used for cooling.

NOTE

Connect the signal for remote switch for heating / cooling only in case the

heating system is controlled by an external controller.

NOTE

The PV signal and remote switch between heating / cooling cannot be

connected at the same time.

Connect the valve for switching between

cooling / heating to serial clamp X3, connect

it to Q11, N and .

Connect the signal for remote switching

between heating /cooling to serial clamp X4,

connect it to D8 and GND.

The signal must be short-circuited and

potential-free.

Page 48

48

3.6.12 CONNECTING THE SIGNAL FOR PV SIGNAL

NOTE

Connect the PV signal in case you have a combination of PV collectors and a

heat pump. Set the controller for the desired function when the signal is present.

NOTE

The PV signal and remote switch between heating / cooling cannot be

connected at the same time.

Connect the PV signal to serial clamp X4,

connect it to D8 and GND.

The signal must be short-circuited and

potential-free.

3.6.13 CONNECTING THE SIGNAL FOR REMOTE OFF

NOTE

Connect the signal for remote off in case the heating system is controlled by an

external controller.

Connect the signal for remote switch to serial

clamp X4, connect it to D5 and GND.

The signal must be short-circuited and

potential-free.

3.7 Commissioning of the device

After professional installation, the authorised contractor for commissioning has to perform

the commissioning of the device.

CAUTION

The commission can only be performed by a person authorised by the

manufacturer! If the commission is performed by an unauthorised person, the

warranty is not recognised.

CAUTION

Before commissioning, it is necessary to perform all the required tasks and

inspections from the tasks for commission.

Page 49

49

4 TECHNICAL CHARACTERISTICS

Page 50

50

4.1 Dimensions and characteristics

4.1.1 HM-130-S1 AND HM-140-S1

1

Refrigerant (freon) line - gas pipe

4

Return line system

2

Refrigerant (freon) line - liquid pipe

5

Electrical connection

3

Supply pipe system

Page 51

51

4.1.2 HM-180-S1

1

Refrigerant (freon) line - gas pipe

4

Return line system

2

Refrigerant (freon) line - liquid pipe

5

Electrical connection

3

Supply pipe system

Page 52

52

4.1.3 FEATURES

Picture 25: Features of the device

1

Heat exchanger

4

Vent

2

Circulation pump

5

Electrical cabinet

3

Electrical heater

6

Integrated expansion vessel

4.1.4 MACHINE SCHEME

Picture 26: Machine scheme of the device

1

Heat exchanger - condenser

4

Electric heater

2

Vent

5

Circulation pump

3

Expansion vessel - only HM-130(140)S1

Page 53

53

4.1.5 ELECTRICAL SCHEME

Picture 27: Electrical scheme of the device

Page 54

54

4.2 Technical data

Internal unit (HM)

HM-140 S1

HM-130 S1

HM-180 S1

External device

WPLV–

09 S1

NT

WPLV–

14 S1 NT

WPL-11-

S1 NT

WPL-13-

S1 HT

WPL-16-S2 NT

WPL-18-S2 HT

Version

Controller

TT3000 (MD1)

Device placement

Interior, wall

Electrical data

Internal unit5) 1f connection

Electric heater 1 x 2 kW ~ 230 V

2 x 2 kW ~ 230 V

Frequency

Hz

50

Rated voltage

V

~ 230

Max. operational

current

A

11.8

20.6

Max. electrical

power

kW

2.6

4.6

Z

max

14)

Ω

/

/

Fuses

12)

A

1 x C16

1 x C25

Electrical power

cable4)

mm2

3 x 2.5

3 x 4

Internal unit5) 3f connection

Frequency

Hz

50

Rated voltage

V

3N ~ 400

Max. operational

current

A

11.8

Max. electrical

power

kW

6.6

Fuses

12)

A

3 x C16

Electrical power

cable4)

mm2

5 x 2.5

Electric heater

3 x 2 kW ~ 230 V

Cooling system

Max. operational

pressure

MPa

5.0

2.9

Cooling (freon) line pipe connections

Pipe connection of

the liquid pipe

3/8''

Φ12

Pipe connection of

the gas pipe

5/8''

Φ22

Primary side (heat source) - air

Heating and cooling

Operating range -

min. / max. air

temperature

°C

Depending on the external air - water unit

Secondary side (heat sink) - water

Min. / Max.

pressure in the

system

MPa

0,1 / 0,3 (1,0 / 3.0 bar)

Recommended

dimensions of pipes

of the device7)

DN

25

32

Heating

Rated flow6)

m3 /

h

1.0

1.4

1.8

2.1

2.7

3.0

Pressure drop at

rated flow

kPa 9 12

14

16

18

20

Range of operation

-

min. / max. water

temperature

°C

25 / 58

25 / 63

25 / 57

25 / 63

Cooling

Operating range min. / max. water

temperature

°C

7 / 25

Pipe connections for the water connection

Return line system

G1’’ (ext. u.)

G5/4''

Supply pipe system

G1’’ (ext. u.)

Page 55

55

Dimensions and mass - transport

Dimensions (W x H

x D)

mm

610X900X425

Mass

kg

63

71

Dimensions and mass - net

Dimensions (W x H

x D)

mm

545x787x287

Mass

kg

50

58

Noise

Level of sound

power

dB

35

Level of sound

pressure at a

distance of 1 m

dB

(A)

27

Communication

Connection

between ext. and

inter. unit

Cable H05VV-F 4 x

0,75 mm2

(IEC 60227-53) or

similar

Plated cable 4x0.75 mm2 /

2x2x0,6 mm2 (LiYCY)

Connection to the

internet8)

UTP 5e cable - connection RJ45 - Ethernet

Miscellaneous

Protection class

Internal unit

IPX1

1)

/

2)

/

3)

/

4)

With the cable, we have taken into account laying B2 from the table A.52.4 – IEC 60364-5-52. The cable in

the installation pipe is fixed to the wall. The dimensions of the electrical cables must always be checked or

determined by the designing engineer of electrical installations.

5)

Joint maximal load (circulation pumps, electronic valves ...) which can be connected to or powered by the

internal unit, must not exceed 500 W. Higher consumers (i.e. pumps) should have their own supply.

6)

The circulation pump must be dimensioned in such a way that it ensures rated voltage through the device.

7)

This is true for pipe connections of suitable dimensions and joint distance of up to 20m. Pipe dimensions and

types of pumps must always be verified or determined by the designing engineer of electrical installations.

Circulation pumps must be dimensioned in such a way so as to ensure rated voltage (see table) through the

device.

8)

Connection to the internet is not necessary for the operation of the device but it is necessary for remote

control through the Home Cloud service. It is also advisable for faster troubleshooting of the device’s

operation.

9)

/

10)

/

11)

/

12)

The size of the fuse depends on the choice of the connection power of the electrical heater.

Page 56

56

4.3 Legend of serial labels

Symbol

Description

Maximal compressor electrical power

Maximal electric heater power

Maximal additional load electrical power (circulation pump, etc.)

+ +

Maximal electrical power of the device (compressor + electric heater +

additional load)

Cooling circuit

Buffer tank for DHW

Heat exchanger in the buffer tank for DHW

Heating system

Internal unit (hydraulic module or Termotronic)

Outdoor unit (WPL or WPLV)

Device mass

Note about handling waste electronic equipment

CE sign for the compliance of the device with CE directives

Page 57

57

4.4 Accessories

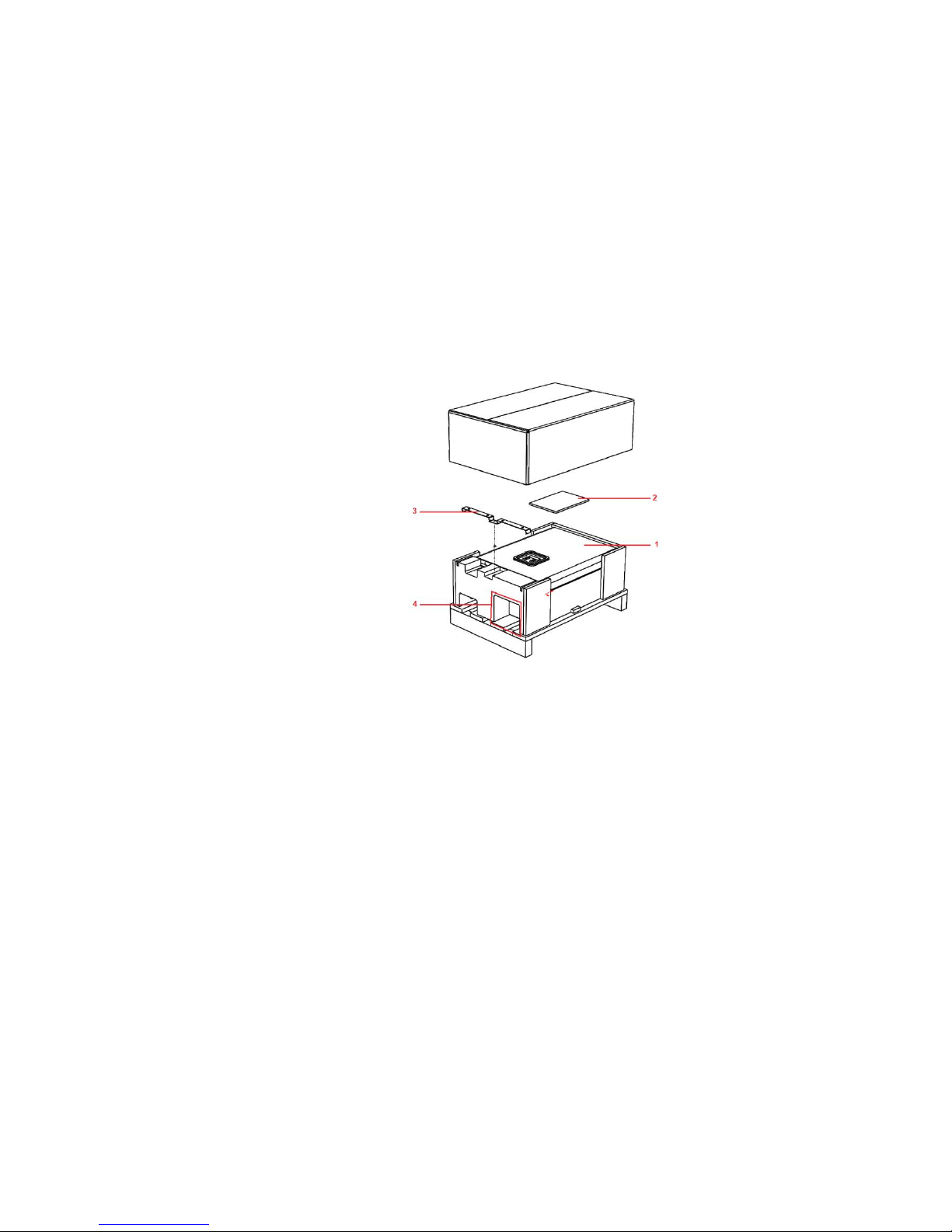

4.4.1 INSTALLATION OF THE EXPANSION VESSEL

Install the expansion vessel as shown on the picture below

Picture 28: Installation of the Expansion vessel

The set with the expansion vessel can be ordered with our supplier.

No. of order

2222000092917

Expansion vessel set

Content of the expansion vessel set

No. of order

Expansion vessel set

2222000092917

1

Expansion vessel

2

Mount of the Expansion vessel

3

Screws for mounting

4

Flexible hose 3/8'’

Page 58

58

Page 59

59

Page 60

Headquarters and manufacturing

Kronoterm d.o.o.

Trnava 5e

3303 Gomilsko

Tel.: (00386) 3 703 16 20 | Fax: (00386) 3 703 16 33 | Web page: www.kronoterm.com |

E-mail: info@kronoterm.com | Customer support and service.: (00386) 3 703 16 26 |

E-mail: servis@kronoterm.com

Loading...

Loading...