Page 1

<v>T-Typ1</v>

Swadro 807

<v>T-Typ2</v>

Swadro 809

<v>T-Typ3</v>

Swadro 810

<v>T-Typ4</v>

Swadro 907

Rotary Swather

</v>

</v>

</v>

</v>

<v>T-Typ6</v></v>

<v>T-Typ7</v></v>

<v>T-Typ8</v></v>

<v>T-Typ9</v></v>

<v>T-Typ5</v></v>

(

<v>T-abMasch.-Nr.</v>

from serial no.

<v>T-Bestell-Nr.</v>

Order no.

</v>

: 150 000 030 06 en

</v>

: 829 360)

<v>T-Typ10</v></v>

Or i g i n a l o p e r a t i n g i n s t r u c t io n s

<v>B-Titelbild</v> </v>

19.08.2011

Page 2

Table of Contents

Pos:1/BA /Konformitätserklärungen/Schwader/N euab2 010/Swadro807_809_81 0_907@ 75\mod_1309416177020_78.doc @662790

CV0

EC Declaration of Conformity

We Maschinenfabrik Bernard Krone GmbH

Heinrich-Krone-Str. 10, D-48480 Spelle, Germany

hereby declare as manufacturer of the product named below, on our sole responsibility,

that the

Machine: Rotary rake KRONE

Type / types: Swadro 807, Swadro 809, Swadro 810, Swadro 907

to which this declaration refers is in compliance with the relevant provisions of

EC directive 2006/42/EC (machines).

The signing Managing Director is authorised to compile the technical documents.

Spelle, 18.08.2011

Dr.-Ing. Josef Horstmann

(Managing Director, Design and Development)

Year of manufacture: Machine No.:

Pos:2/BA /Vorwort/Sehrgeehrter Kunde@ 0\mod_11956263003 26_78.doc@ 905

Dear customer,

Dear customer,

You have now received the operating instructions for the KRONE

product which you have purchased.

These operating instructions contain important information for the

proper use and safe operation of the machine.

If these operating instructions should become wholly or partially

unusable, you can obtain replacement operating instructions for

your machine by stating the number given overleaf.

Pos:3/BA /-----Seitenumbruch------ @0\mod_1196175311 226_0.doc@ 4165

2

Page 3

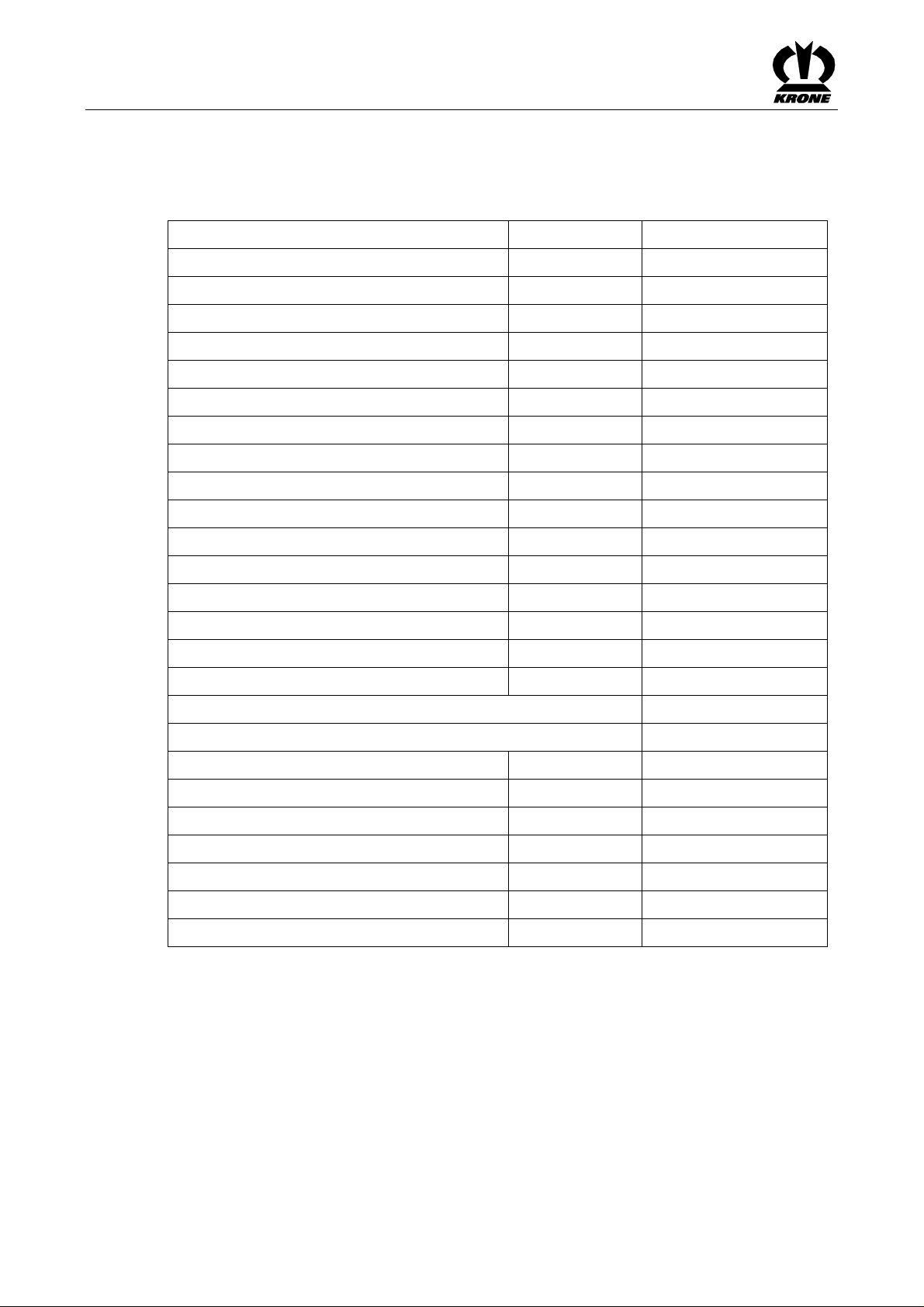

Table of Contents

Pos:4/BA /Inhaltsverzeichnis@ 0\mod_1196861555655 _78.doc@ 15165

1 Table of Contents

1 Table of Contents...................................................................................................................................3

2 Foreword .................................................................................................................................................6

3 Introduction.............................................................................................................................................7

3.1 Purpose of Use.................................................................................................................................. 7

3.2 Validity............................................................................................................................................... 7

3.3 Identification Plate .............................................................................................................................7

3.4 Information Required for Questions and Orders................................................................................ 8

3.5 Intended Use .....................................................................................................................................9

3.6 Technical data ...................................................................................................................................9

4 Safety.....................................................................................................................................................14

4.1 Introduction...................................................................................................................................... 14

4.2 Identification of the hazard warnings............................................................................................... 14

4.2.1 Re-Ordering the Adhesive Safety and Information Labels..........................................................15

4.2.2 Affixing the Adhesive Safety and Information Labels..................................................................15

4.2.3 Contact......................................................................................................................................... 15

4.3 Position of the Adhesive Safety Stickers on the Machine............................................................... 16

4.4 Position of the General Information Labels on the Machine............................................................ 18

4.5 Identifying Symbols in the Operating Instructions ........................................................................... 19

4.6 Identification of the hazard warnings............................................................................................... 19

4.6.1 Personnel Qualification and Training Fehler! Textmarke nicht definiert...................................... 20

4.6.2 Dangers in Case of Non-compliance with the Safety Instructions............................................... 20

4.6.3 Safety-conscious work practices .................................................................................................20

4.7 Safety Instructions and Accident Prevention Regulations............................................................... 21

4.8 Hitched Implements.........................................................................................................................22

4.9 PTO operation .................................................................................................................................23

4.10 Hydraulic system .............................................................................................................................24

4.11 Tyres................................................................................................................................................ 24

4.12 Maintenance ....................................................................................................................................25

4.13 Working in the vicinity of power transmission lines ......................................................................... 26

4.14 Unauthorised Conversion/Modification and Spare Parts Production ..............................................26

4.15 Inadmissible Modes of Operation.................................................................................................... 26

4.16 Safety Instructions on the Machine ................................................................................................. 26

5 Commissioning.....................................................................................................................................27

5.1 First installation................................................................................................................................ 27

5.2 Preparations on tractor....................................................................................................................28

5.2.1 Adjusting the lower suspension arms.......................................................................................... 28

5.3 PTO shaft......................................................................................................................................... 29

5.3.1 Length adjustment .......................................................................................................................29

3

Page 4

Table of Contents

5.4 Height of tractor lower suspension arms.........................................................................................30

6 Start-up..................................................................................................................................................31

6.1 Mounting onto the Tractor................................................................................................................ 31

6.2 Hydraulics........................................................................................................................................ 32

6.2.1 Special Safety Instructions ..........................................................................................................32

6.2.2 Connecting the hydraulic lines..................................................................................................... 33

6.3 Lighting connection.......................................................................................................................... 34

6.4 Connecting the electrical controls.................................................................................................... 35

6.5 Install the PTO shaft........................................................................................................................ 36

7 Driving and Transport..........................................................................................................................37

8 Operation...............................................................................................................................................39

8.1 Overload protection .........................................................................................................................39

8.2 From transport into working position ............................................................................................... 40

8.3 Removing the tine protections from the tine tips ............................................................................. 40

8.4 Lowering the rotor arms into working position.................................................................................40

8.5 Adjusting the Rear Swath Cloth....................................................................................................... 41

8.5.1 Height adjustment of the swath former........................................................................................ 42

8.6 Adjusting the Front Swath Cloth (Swadro 810) ............................................................................... 42

8.7 Adjusting the Rear Swath Cloth (Swadro 907)................................................................................44

8.7.1 Adjusting the swath former lengthwise........................................................................................ 45

8.7.2 Height adjustment of the swath former........................................................................................ 45

8.8 Swivel tine arms to working position................................................................................................ 46

8.8.1 For design with collapsible tine arm ............................................................................................ 47

8.9 Move the hoop guards to the working position................................................................................ 48

8.10 Adjusting the raking height mechanically ........................................................................................ 49

8.10.1 Adjusting the raking height - electrically (optional for Swadro 810, Swadro 907) ................... 50

8.10.2 Function of switches on the control unit (optional for Swadro 810, Swadro 907) ................... 50

8.11 Travelling on an incline.................................................................................................................... 52

8.12 Travelling speed und drive speed.................................................................................................... 52

8.13 Switching from working position to transport position .....................................................................53

8.14 Move the hoop guards to transport position....................................................................................53

8.15 Swivelling tine arms into transport position ..................................................................................... 54

8.15.1 With rigid tine arms design ...................................................................................................... 54

8.15.2 For design with collapsible tine arm ........................................................................................ 55

8.16 Pushing the Swath Cloth into Transport Position............................................................................56

8.17 Pushing the Swath Cloth into Transport Position............................................................................57

8.18 Raising the Rotor Arms to Transport Position.................................................................................58

8.19 Protecting the Tine Tips (Transport Position and Swather Switched Off)....................................... 58

8.20 Switching from One Side Swath to Two Individual Swaths............................................................. 59

8.21 Switching from Two Individual Swaths to One Side Swath (Swadro 810) ...................................... 60

4

Page 5

Table of Contents

8.22 Parking.............................................................................................................................................61

9 Settings .................................................................................................................................................62

9.1 To adjust the rotor running gear...................................................................................................... 62

9.2 Regulating direction of travel...........................................................................................................63

9.3 Adjustable throttles .......................................................................................................................... 64

10 Maintenance..........................................................................................................................................65

10.1 Special Safety Instructions ..............................................................................................................65

10.2 Compensation Spring(s)..................................................................................................................65

10.3 Test run............................................................................................................................................65

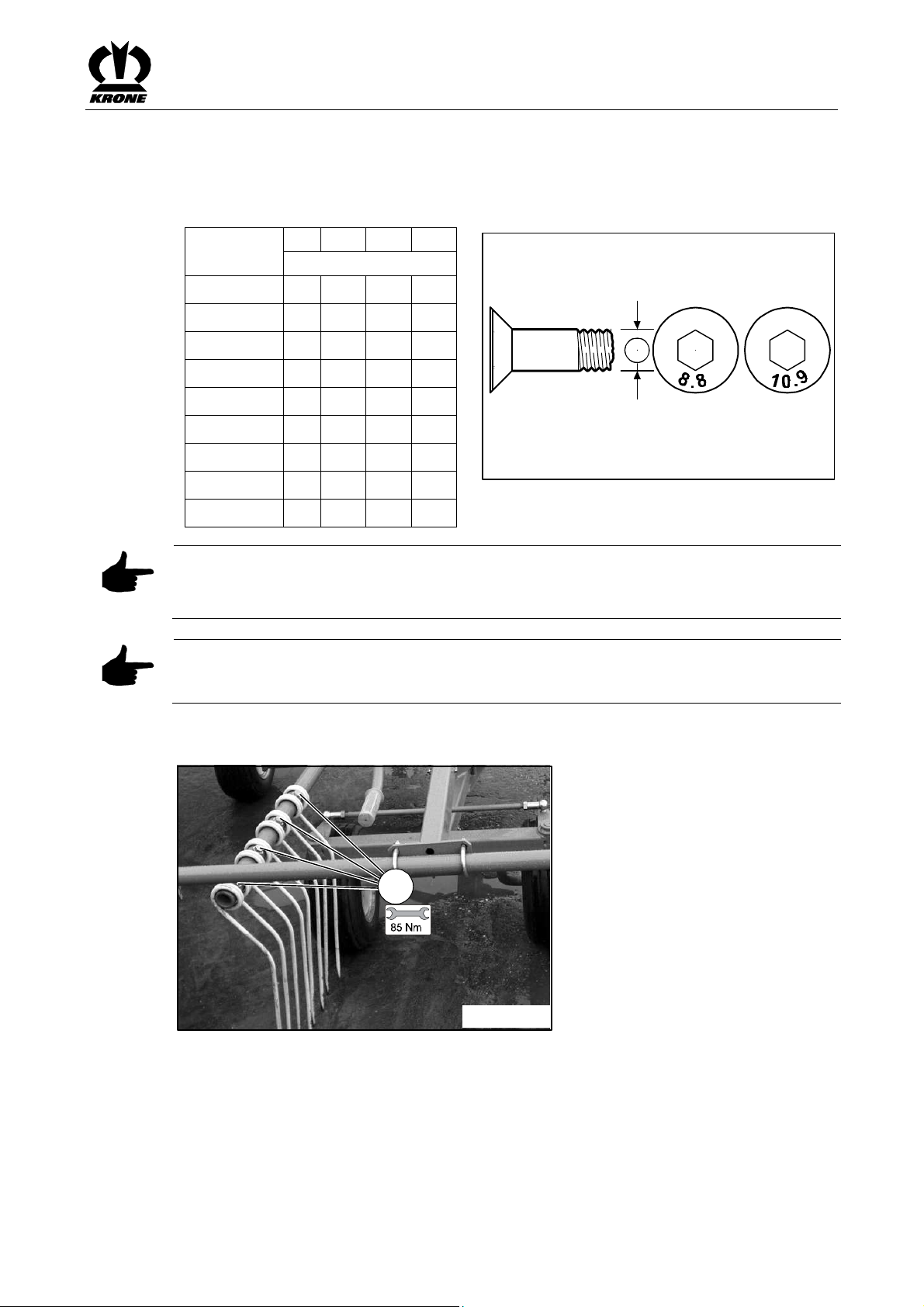

10.4 Tightening Torques..........................................................................................................................66

10.5 Tightening Torques (Countersunk Screws)..................................................................................... 67

10.6 Testing the screws on the tines.......................................................................................................67

10.7 Tyres................................................................................................................................................ 68

10.7.1 Checking and maintaining tyres...............................................................................................68

10.7.2 Torque of wheels on the running gear.....................................................................................69

10.7.3 Tyre air pressure......................................................................................................................69

10.8 Replacing the tine arms(in case of repair).......................................................................................70

10.9 Replacing the tine arms(in case of repair).......................................................................................72

11 Maintenance – lubrication chart .........................................................................................................74

11.1 Special Safety Instructions ..............................................................................................................74

11.2 PTO shaft.........................................................................................................................................75

12 Maintenance – lubrication chart .........................................................................................................76

12.1 Lubrication Chart .............................................................................................................................77

13 Maintenance - hydraulic system.........................................................................................................79

14 Maintenance - Gearbox........................................................................................................................80

14.1 Filling Quantities and Lubrication Designations for Gearboxes....................................................... 80

14.2 Rotor gear / rotor housing................................................................................................................ 80

14.3 Transfer gearbox front and rear....................................................................................................... 81

15 Special equipment................................................................................................................................82

15.1 Tine loss safeguard .........................................................................................................................82

15.2 Chain for height restriction of suspension arms .............................................................................. 83

16 Placing in Storage................................................................................................................................84

16.1 Special Safety Instructions ..............................................................................................................84

16.2 At the End of the Harvest Season................................................................................................... 85

16.3 Before the Start of the New Season................................................................................................86

16.4 Special Safety Instructions ..............................................................................................................86

17 Malfunctions - Causes and Remedies................................................................................................87

17.1 Special Safety Instructions ..............................................................................................................87

18 Appendix ...............................................................................................................................................89

Pos:5/BA /-----Seitenumbruch------ @0\mod_1196175311 226_0.doc@ 4165

5

Page 6

Foreword

Pos:6.1/Ü berschriften/Überschriften 1/U-Z/Vorwort@ 0\mod_1195627720123 _78.doc@9 82

2 Foreword

Pos:6.2/ BA/Vorwort/Schwader/Verehrter KundeSchwad er@1\m od_1202129116819_78.doc @57456

Dear Customer,

By purchasing your rotary rake, you have acquired a quality product from KRONE.

We are grateful for the confidence you have invested in us in buying this machine.

It is important to read the operating instructions very carefully before you start operating the

machine to allow you to use the rotary rake to its full capacity.

The contents of this manual are laid out in such a way that you should be able to perform any

task by following the instructions step by step. It contains extensive notes and information about

maintenance, how to use the machine safely, secure working methods, special precautionary

measures and available accessories. This information and these instructions are essential,

important and useful for the operational safety, reliability and durability of the rotary rake.

Pos:6.3/ BA/Vorwort/Schwader/Weiterer VerlaufSchw ader@1\ mod_1202129119147_78.doc @57476

Note

In the operating instructions which follow, the rotary rake will also be referred to as the

"machine".

Pos:6.4/ BA/Vorwort/BeachtenSie fürMasc hine@ 0\mod_1195626904076_78.doc @944

Please note:

Pos:7/BA /-----Seitenumbruch------ @0\mod_1196175311 226_0.doc@ 4165

The operating instructions are part of your machine.

Only operate this machine after you have been trained to do so and according to these

instructions.

It is essential to observe the safety instructions!

It is also necessary to observe the relevant accident prevention regulations and other generally

recognised regulations concerning safety, occupational health and road traffic.

All information, illustrations and technical data in these operating instructions correspond to the

latest state at the time of publication.

We reserve the right to make design changes at any time and without notification of reasons.

Should you for any reason not be able to use these operating instructions either wholly or

partially, you can receive a replacement set of operating instructions for your machine by

quoting the number supplied overleaf.

We hope that you will be satisfied with your KRONE machine.

Maschinenfabrik Bernard Krone GmbH

Spelle

6

Page 7

Pos:8.1/ BA/Einleitung/Einleitung@ 0\mod_1195562498 677_78.doc@ 416

3 Introduction

These operating instructions contain fundamental instructions. These must be observed in

operation and maintenance. For this reason, these operating instructions must be read by

operating personnel before commissioning and use, and must be available for easy reference.

Follow both the general safety instructions contained in the section on safety and the specific

safety instructions contained in the other sections.

Pos:8.2/Ü berschriften/Überschriften 2/U-Z/Verwendungszweck @1\mod_120 1707246738_78.doc@ 54055

3.1 Purpose of Use

Pos:8.3/ BA/Einleitung/Schwader/Verwendungsz weckSchwader KATI undKAT IIamH eck.@ 1\mod_1202129727897_78.doc @5751 7

The rotary rake is used for swathing of cut crops. It is attached on the rear in the three-point

Pos:8.4/ BA/Einleitung/Gültigkeit/Schwader/S wadro807_809_810_907 @75\ mod_1309416339176_78.doc @662818

3.2 Validity

Pos:8.5/Ü berschriften/Überschriften 2/K-O/Kennzeichnung @0\mod_119556462 2099_78.doc@ 496

3.3 Identification Plate

Pos:8.6/ BA/Einleitung/Kennzeichnung/Schwad er/KennzeichnungSwadr o@ 1\mod_1202130022522_7 8.doc@5 7558

block KAT I and KAT II.

These operating instructions apply to rotary rakes of series:

Swadro 807; Swadro 809, Swadro 810; Swadro 907

Introduction

Pos:8.7/ BA/-----Seitenumbruch------ @0\mod_11961753 11226_0.doc@ 4165

1

SW9070001

Figure 1

The machine data is located on the type plate (1).

7

Page 8

Introduction

Pos:8.8/ BA/Einleitung/Angaben fürAnfrage undBestellungen_Fa hrzeugident-Nr.@ 0\mod_1195565119708_78. doc@5 15

3.4 Information Required for Questions and Orders

Type

Year of manufacture

Vehicle ID number

Note

The entire identification plate represents a legal document and should not be altered or

rendered illegible!

When asking questions concerning the machine or ordering spare parts, be sure to provide type

designation, vehicle ID number and the year of manufacture : To ensure that these data are

always available, we recommend that you enter them in the fields above.

Note

Authentic KRONE spare parts and accessories authorised by the manufacturer help to ensure

safety. The use of spare parts, accessories and other devices which are not manufactured,

tested or approved by KRONE will result in the revoking of the liability for damages resulting

thereof.

Pos:8.9/ BA/-----Seitenumbruch------ @0\mod_11961753 11226_0.doc@ 4165

8

Page 9

Pos:8.10.1 /Überschriften/Überschriften 2/A-E/Bestimmungsgemäßer Gebrauch@ 0\mod_119640154 5090_78.doc@ 7728

3.5 Intended Use

Pos:8.10.2 /BA/Einleitung/Bestimmungsgemäßer Gebrauch/Schwader/B estimmungsgemäßerG ebrauchSchwader @1\mod_1 202215704310_78.doc@ 57818

Pos:8.10.3 /BA/Einleitung/Bestimmungsgemäßer Gebrauch/Nicht bestimmungsg emäss@ 0\mod_1196401324340_78.doc @7690

The rotary rake is built exclusively for conventionaluse in agricultural work (intended use).

Any use of the machine for other purposes is deemed not to be in accordance with intended

use. The manufacturer shall not be liable for any resulting damage; the user alone shall bear

the risk.

Operation in accordance with intended use also includes observing the operating, maintenance

and service instructions specified by the manufacturer.

Unauthorised modifications to the machine may affect the properties of the machine or disrupt

proper operation. For this reason, unauthorised modifications shall exclude any liability of the

Pos:8.11/B A/Einleitung/TechnischeD aten@ 0\mod_1195566374865_78.doc @594

manufacturer for consequential damage.

3.6 Technical data

All information, illustrations and technical data in these operating instructions correspond to the

latest state at the time of publication. We reserve the right to make design changes at any time

and without notification of reasons.

Pos:8.12/B A/-----Seitenumbruch------ @0\mod_1196175 311226_0.doc@ 4165

Introduction

9

Page 10

Introduction

Pos:8.13/B A/Einleitung/TechnischeD aten/Schwader/Straßenfahrt: geschwenkteKr eiselarme4 Meternicht überschreiten@ 76\mod_131001 5862571_78.doc@ 666075

Road travel is only permitted with the swivelled rotary arms in transport position.

The max. height of 4 m must not be exceeded.

Pos:8.14/A bkürzungen/Abkürzu ngensprachneutral/Sch wader/Swadro807 @78\mod_ 1313746086911_0.doc@ 693653

Pos:8.15/B A/Einleitung/TechnischeD aten/Schwader/Swadro 807@ 78\mod_1313740801861_78.doc @69362 5

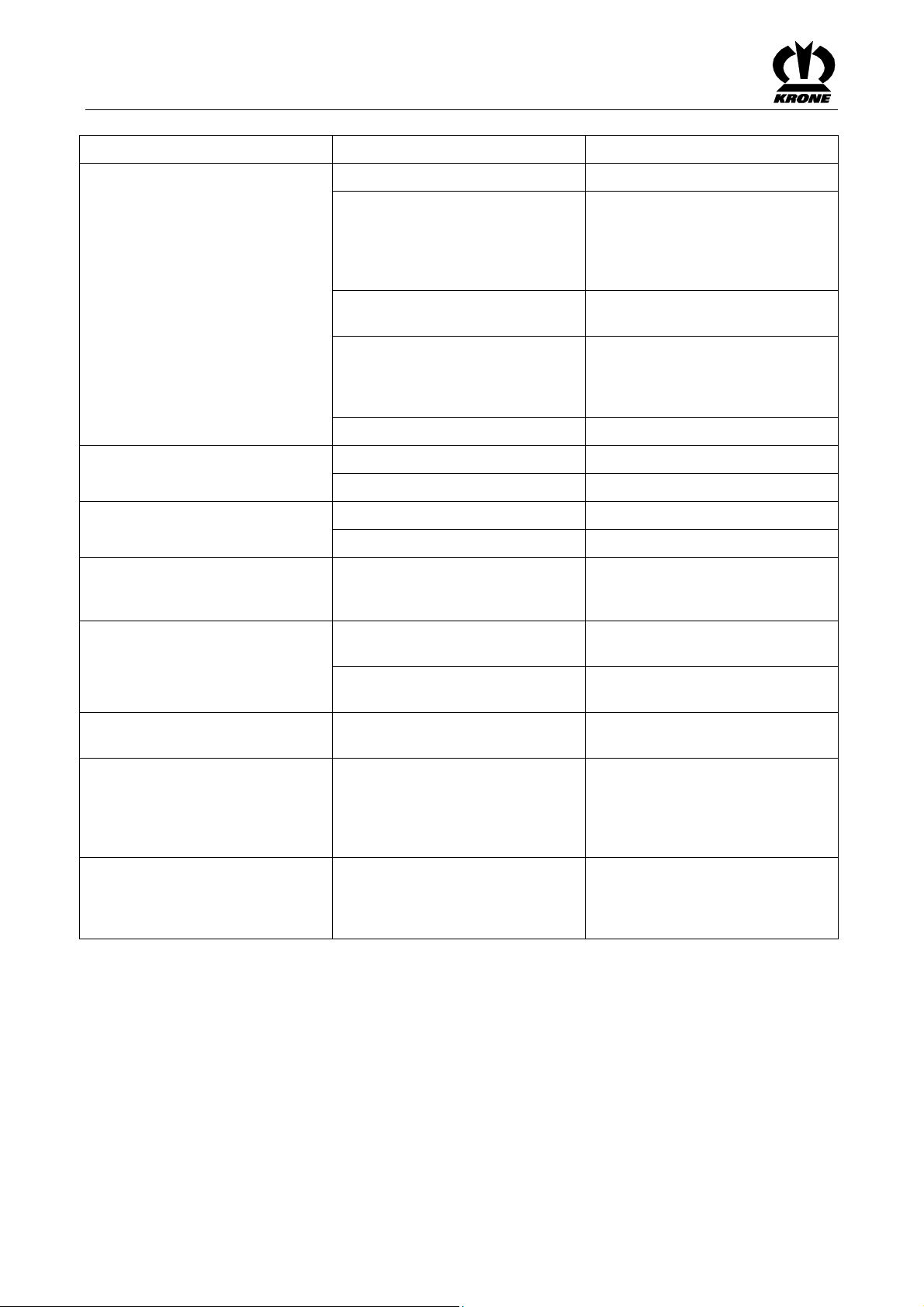

Swadro 807

Type Swadro 807

Understeering coupling Piece standard

Number of rotors Piece 2

Number of arms / rotors Piece 10/13

Number of double tines / arm Piece 4

Working width of side swath approx. mm 6200

Rotor diameter approx. mm 2960

Height with tine arms/transport position approx. mm 3900

Height of tine arms folded in /transport position approx. mm 3500

Height in working position approx. mm 2200

Length approx. mm 7370

Width in transport position approx. mm 2995

1)

2)

Pos:8.16/B A/Einleitung/TechnischeD aten/Schwader/1)A usführung:Zinkenarm starr@ 77\mod_131003857377 1_78.doc@ 666759

Pos:8.17/B A/Einleitung/TechnischeD aten/Schwader/2)A usführung:Zinkenarm klappbar@ 77\mod_131003 8658714_78.doc@ 666786

Pos:8.18/A bkürzungen/Abkürzu ngenBeschreibung/*) EW=Ein fachwirkendesSteuerg erät@7 6\mod_1309963843144_78.doc @666011

Pos:8.19/B A/-----Seitenumbruch------ @0\mod_1196175 311226_0.doc@ 4165

Width in working position approx. mm 6200

Power consumption approx. kW/HP 37/50

PTO speed rpm max. 540

Equivalent continuous sound pressure level less than 70 d B(A)

Side swath acreage approx./h 6

Tyres for rotor running gear 16x6.50-8 4PR

Tyres for main running gear 4PR10.0/75-15.3 8PR

Lighting voltage Volts 12

Max. operating pressure of hydraulic system bar 200

Required hydraulic connections 1x single-action*

Max. permissible transport speed 40 km/h

Dead weight kg 1750

Permissible axle load kg 1000

Permissible supporting load kg 750

1) Design: Tine arm rigid

2) Design: Tine arm folding

*) SA= Single-action control unit

10

Page 11

Pos:8.20/B A/Einleitung/TechnischeD aten/Schwader/Straßenfahrt: geschwenkteKr eiselarme4 Meternicht überschreiten@ 76\mod_131001 5862571_78.doc@ 666075

Road travel is only permitted with the swivelled rotary arms in transport position.

The max. height of 4 m must not be exceeded.

Pos:8.21/A bkürzungen/Abkürzu ngensprachneutral/Sch wader/Swadro809 /Swadro 810@ 78\mod_1313746213644_0. doc@6 93681

Pos:8.22/B A/Einleitung/TechnischeD aten/Schwader/Swadro 809/810@ 75\mod_1309515330532_78.d oc@66 3743

Swadro 809 / Swadro 810

Type Swadro809 Swadro810

Understeering coupling Piece standard

Number of rotors Piece 2

Number of arms / rotors Piece 13 13

Number of double tines / arm Piece 4

Working width of side swath approx. mm 6750 6750

Rotor diameter approx. mm 3300 3300

Height with tine arms/transport position approx. mm 4170 4170

Introduction

two swaths approx. mm - 2 x 3700

Height of tine arms folded in /transport

approx. mm 3720 3720

position

Height in working position approx. mm 2200

Length approx. mm 7770 7770

Width in transport position approx. mm 2995

Width in working position approx. mm 6750 7850

Power consumption approx. kW/HP 37/50

PTO speed rpm max. 540

Equivalent continuous sound pressure level less than 70 d B(A)

Side swath acreage approx./h 6,5 6,5

Acreage of two swaths approx./h - 7,5

Tyres for rotor running gear 16x6.50-8 4PR

Tyres for main running gear 4PR10.0/75-15.3 8PR

Lighting voltage Volts 12

Max. operating pressure of hydraulic

bar 200

system

Required hydraulic connections 1x single-

action*

1x single-

action*

Pos:8.23/A bkürzungen/Abkürzu ngenBeschreibung/*) EW=Ein fachwirkendesSteuerg erät@7 6\mod_1309963843144_78.doc @666011

Pos:8.24/A bkürzungen/Abkürzu ngenBeschreibung/**) DW=D oppelwirkendesSteuerg erät@7 6\mod_1309963889815_78.doc @666039

Pos:8.25/B A/-----Seitenumbruch------ @0\mod_1196175 311226_0.doc@ 4165

1x double-

action**

Max. permissible transport speed 40 km/h

Dead weight kg 1980 1980

Permissible axle load kg 1150 1150

Permissible supporting load kg 830 830

*) SA= Single-action control unit

**) DA= Double-action control unit

11

Page 12

Introduction

Pos:8.26/A bkürzungen/Abkürzu ngensprachneutral/Sch wader/Swadro907 @1\mod_1 202226168013_0.doc@ 58250

Pos:8.27/B A/Einleitung/TechnischeD aten/Schwader/Swadro 907@ 75\mod_1309416757003_78.doc @66284 6

Swadro 907

Road travel is only permitted with the rotor arm swivelled out in transport position. The max.

height of 4 m must not be exceeded.

Type Swadro 907

Understeering coupling Piece standard

Number of rotors Piece 2

Number of arms / rotors Piece 15

Number of double tines / arm Piece 2

Working width of side swath approx. mm 8000

Rotor diameter approx. mm 3800

Height with tine arms/transport position approx. mm 4400

Height of tine arms folded in /transport position approx. mm 3900

Height in working position approx. mm 2200

Length approx. mm 9800

Width in transport position approx. mm 2995

Width in working position approx. mm 8000

Power consumption approx. kW/HP 51/70

PTO speed rpm max. 540

Equivalent continuous sound pressure level less than 70 d B(A)

Side swath acreage approx./h 8-9

Tyres for rotor running gear 16x6.50-8 4PR

Tyres for main running gear 15/55-17 10PR

Lighting voltage Volts 12

Max. operating pressure of hydraulic system bar 200

Required hydraulic connections 1x single-action*

1x double-action**

Max. permissible transport speed 40 km/h

Dead weight kg 2800

Permissible axle load kg 1400

Permissible supporting load kg 1400

*) EW= Single-action control unit

Pos:9/BA /-----Seitenumbruch------ @0\mod_1196175311 226_0.doc@ 4165

12

**) DW= Double-action control unit

Page 13

Pos:10/BA/Di eseSeite istbewusst freigelassen worden.@ 1\mod_1201783680373_78.doc @54443

Pos:11/BA/-- ---Seitenumbruch------ @0\mod_119617531 1226_0.doc@ 4165

Introduction

This page has been left blank deliberately!!

13

Page 14

Safety

Pos:12.1/Üb erschriften/Überschriften 1/P-T/Sicherheit@ 0\mod_11955667486 46_78.doc@ 635

4 Safety

Pos:12.2/B A/Sicherheit/Schwader/Sicherheit Einführung Schwader@ 1\mod_1202219372123_78.doc @58050

4.1 Introduction

The rotary rake is equipped with all safety devices (protective devices). However, it is not

possible to eliminate all potential hazards on this machine as this would impair its full functional

capability. Hazard warnings are attached to the machine in the relevant areas to warn against

any dangers. The safety instructions are provided in the form of so-called warning pictograms.

Pos:12.3/B A/Sicherheit/Beschädigte oderunlesbare Aufkleber@ 0\mod_119556721411 5_78.doc@ 674

Pos:12.4/B A/Sicherheit/Kennzeichnung derGefahrenhi nweise@ 28\mod_1250244370070_78.doc @274714

4.2 Identification of the hazard warnings

Important information on the position of these safety signs and what they mean is given below!

Danger! - Danger zone of the machine

Effect: Danger to life or serious injuries.

• Immediately replace damaged or illegible adhesive labels.

• Following repair work, always attach appropriate adhesive safety stickers to all the

replaced, modified or repaired components.

• Never clean areas carrying an adhesive safety label using a high-pressure cleaner.

• Familiarise yourself with the statement of the warning pictograms. The adjacent text and

the selected location on the machine provide information on the special danger spots on

the machine.

Pos:12.5/B A/-----Seitenumbruch------ @0\mod_1196175 311226_0.doc@ 4165

Danger!

DANGER! - Type and source of the hazard!

Effect: Danger to life or serious injuries.

• Measures for hazard prevention

Warning !

WARNING! - Type and source of the hazard!

Effect: Injuries, serious material damage.

• Measures for hazard prevention

Caution!

CAUTION! - Type and source of the hazard!

Effect: Property damage

• Measures for risk prevention.

14

Page 15

Pos:12.6/B A/Sicherheit/Nachbestellung/ AnbringungAuf kleber@ 0\mod_1195637337107_78.doc @1079

4.2.1 Re-Ordering the Adhesive Safety and Information Labels

Note

Every adhesive safety and information label is assigned an order number and can be ordered

directly from the manufacturer or from an authorized dealer (see Section "Contact").

4.2.2 Affixing the Adhesive Safety and Information Labels

Note - Affixing an adhesive label

Effect: Adhesion of the label

• The surface for affixing the adhesive label must be clean and free of dirt, oil and grease.

Pos:12.7/Üb erschriften/Überschriften 3/A-E/Ansprechpartner @0\mod_119556 9394286_78.doc@ 839

4.2.3 Contact

Pos:12.8/A dressen/AdresseMasc hinenfabrikKRONE Spelle@ 0\mod_1195568531083_ 78.doc@ 734

Maschinenfabrik Bernard Krone GmbH

Heinrich-Krone-Strasse 10

D-48480 Spelle (Germany)

Safety

Pos:12.9/B A/-----Seitenumbruch------ @0\mod_1196175 311226_0.doc@ 4165

Telephone: + 49 (0) 59 77/935-0 (Head Office)

Fax.: + 49 (0) 59 77/935-339 (Head Office)

Fax.: + 49 (0) 59 77/935-239 (Spare parts - domestic)

Fax.: + 49 (0) 59 77/935-359 (Spare parts - export)

Email: info.ldm@krone.de

15

Page 16

Safety

Pos:12.10/Ü berschriften/Überschriften 2/K-O/Lageder Sicherheitsaufkleber ander Maschine@ 0\mod_1195634967326 _78.doc@ 1020

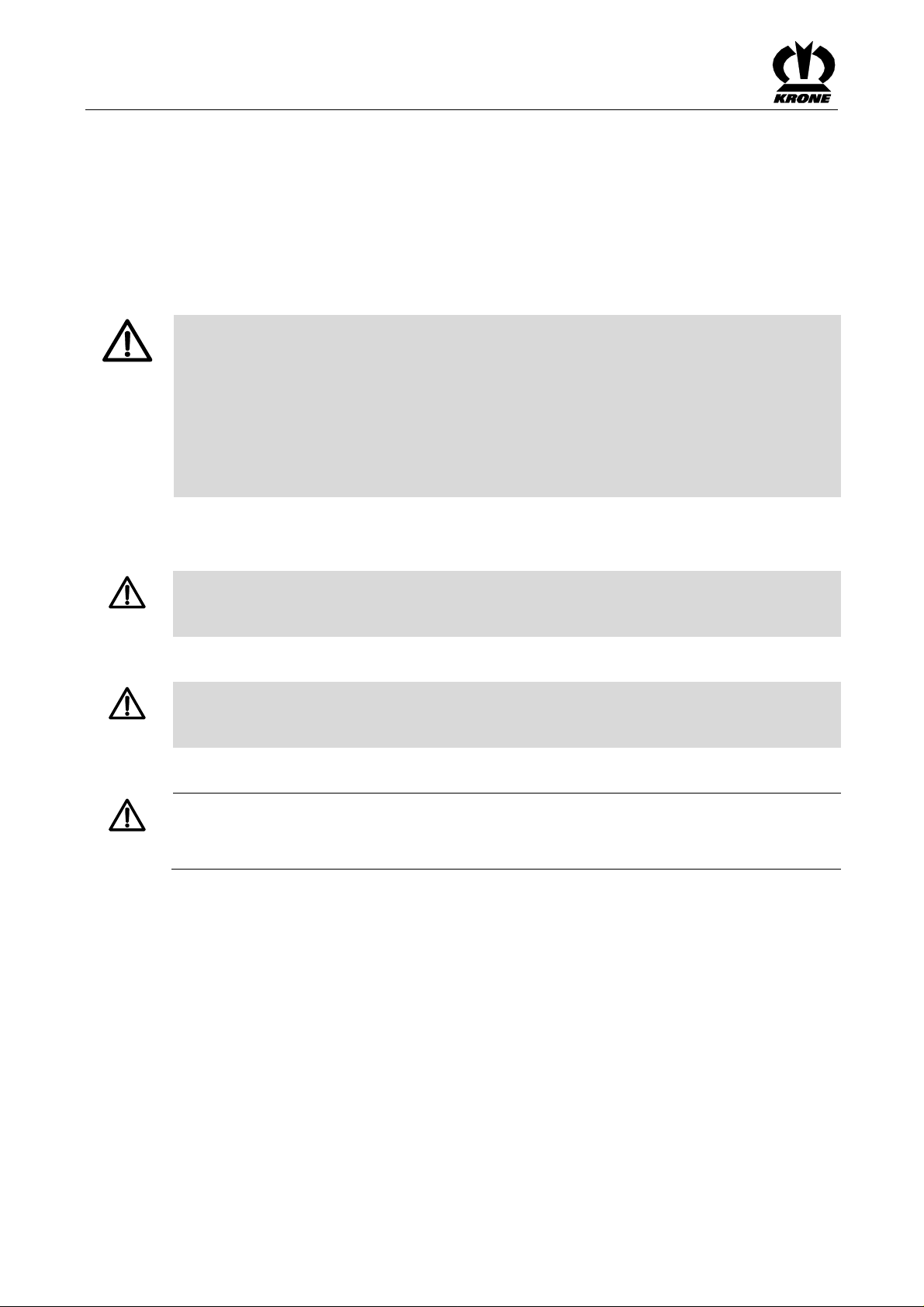

4.3 Position of the Adhesive Safety Stickers on the Machine

Pos:12.11/ BA/Sicherheit/Aufkleber/Schwader/Sich erheitsaufkleberSchw ader807/810/907 @1\mod_1 202220808716_78.doc@ 58071

GL

Fig. 2

6

3

6

2

6

1

7

5

4

6

SW810018

16

Page 17

Safety

1)

Before starting the machine,

read and observe the

operating instructions and

safety instructions.

Order No. 939 471-1 (1x)

3)

Before starting work, move

the hoop guards to the

protective position (fold

down).

Order No. 939 574 0 (2x)

939 574-0

5)

Do not stay in the swivel range of the outrigger

arms. Keep your distance!

2)

The PTO speeds must not exceed 540 rpm! The

operating pressure of the hydraulic system must

not exceed 200 bar!

939100-4

MAX. 540/min

MAX. 200 bar

Order No. 939 100-4 (1x)

4)

Danger in the area where rotors are turning -

Keep your distance!

939 472-2

Order No. 939 472-2 (2x)

6)

Never reach into the area where

there is danger of crushing as

long as parts could be moving.

Order No. 939 414-2 (1x)

7)

Keep the stipulated safe distance from power

transmission lines.

Order No. 942 293-0 (1x)

(Swadro 810, Swadro 809; Swadro 907)

Pos:12.12/ BA/-----Seitenumbruch------ @0\mod_119617 5311226_0.doc@ 4165

Order No. 942 196-1 (4x)

8)

17

Page 18

Safety

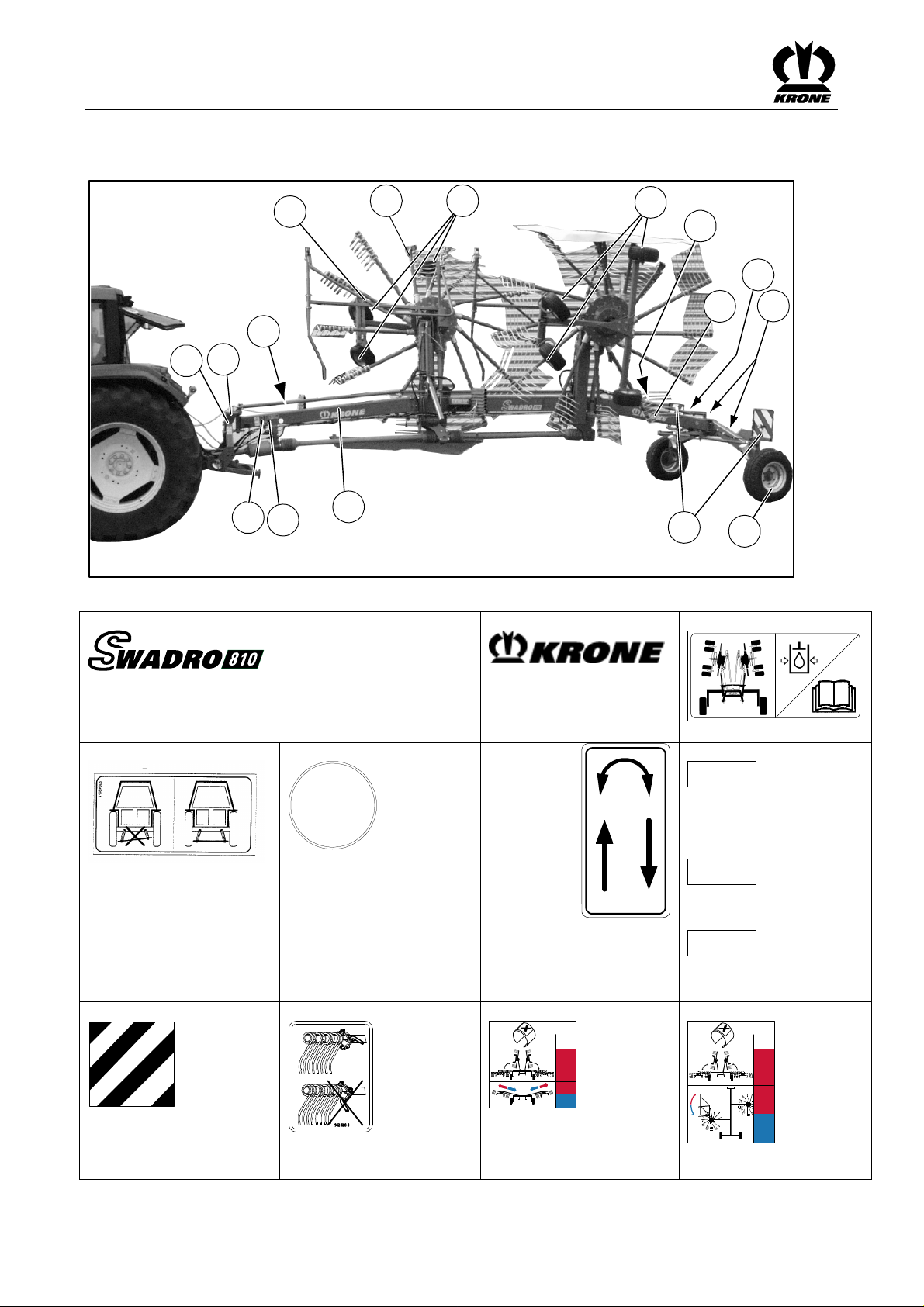

Pos:12.13/Ü berschriften/Überschriften 2/K-O/Lageder allgemeinen Hinweisaufklebera nderMasc hine@ 0\mod_1195635067920_78.doc @1039

4.4 Position of the General Information Labels on the Machine

Pos:12.14/ BA/Sicherheit/Aufkleber/Schwader/Hi nweisaufkleberSchwa der807/809/810/907 @75\mo d_1309756781199_78.doc @663805

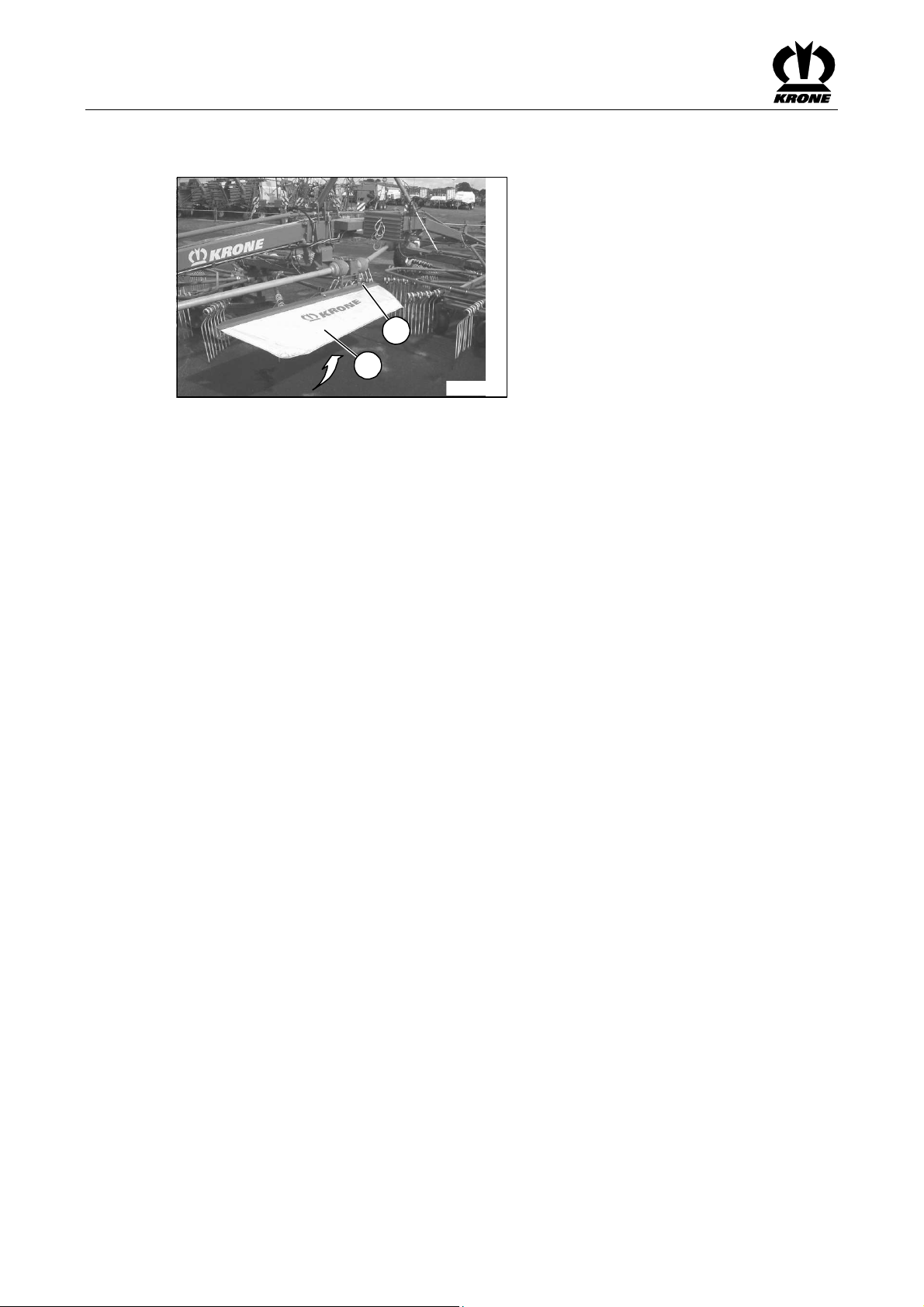

Figure 3

1)

11

10

6

9

7a

7a

2

5

1

2

1

3

4

2

8

2)

7b

SW810019_4

3)

939 486-2

27 000 066 0 (2x) Swadro 807

27 008 496 0 (2x) Swadro 809

942 416 1 (2x) Swadro 810

27 001 557 0 (2x) Swadro 907

4)

939 420 1 (1x)

8)

924 569 0 (4x)

5)

40

939 145-1 (1x) 40 km

9)

942 480 0 (6x)

942 301 0 (2x) 775 mm

942 320 0 (2x) 600 mm

6)

942 339 0

942 339 0 (2x)

Mechanical in the Swadro

design.

10)

27 003 081 0 Swadro 810

270030 810

X

11

2

2

939 468 -2 (1x)

7a)

1,8 bar

939 183 1 1,8 bar

(16x Swadro 907 /

8x Swadro 807/809/810)

7b)

1,0 bar

Swadro 807/809/810

939 183 1 (2x) 1,0 bar

2,0 bar

Swadro 907

939 170-1 (2x) 2,0 bar

10)

X

11

2

2

27 003 080 0

Swadro 907

18

Page 19

11)

Safety

350-450/ min

942119-2

942 119 2 (1x)

Pos:12.15/ BA/Sicherheit/Kennzeichnung vonHinweis eninder Betriebsanleitung Einführungstext @0\ mod_1195637804826_78.doc @1098

4.5 Identifying Symbols in the Operating Instructions

The safety instructions contained in this manual which could result in personal injury if not

Pos:12.16/ BA/Sicherheit/Kennzeichnung derGefahren hinweise@ 28\mod_1250244370070_78.doc @274714

followed are identified by the general danger sign:

4.6 Identification of the hazard warnings

Danger!

DANGER! - Type and source of the hazard!

Effect: Danger to life or serious injuries.

• Measures for hazard prevention

Warning !

WARNING! - Type and source of the hazard!

Effect: Injuries, serious material damage.

• Measures for hazard prevention

Caution!

CAUTION! - Type and source of the hazard!

Pos:12.17/ BA/Sicherheit/Allgemeine Funktionshinweise @0\ mod_1196869714452_78.doc @15185

Pos:12.18/ BA/-----Seitenumbruch------ @0\mod_119617 5311226_0.doc@ 4165

Effect: Property damage

• Measures for risk prevention.

General function instructions are indicated as follows:

Note!

Note - Type and source of the note

Effect: Economic advantage of the machine

• Actions to be taken

Instructions which are attached to the machine need to be followed and kept fully legible.

19

Page 20

Safety

Pos:12.19.1/ BA/Sicherheit/Personalqualifikation und-Schulung @0\mod_119563 9383185_78.doc@ 1136

4.6.1 Personnel Qualification and Training Fehler! Textmarke nicht definiert.

The machine may be used, maintained and repaired only by persons who are familiar with it

and have been instructed about the dangers connected with it. The operator must define areas

of responsibility and monitoring of personnel. Should personnel lack the required knowledge,

they must receive the required training and instruction. The operator must ensure that the

contents of these operating instructions have been fully understood by personnel.

Repair work not described in these operating instructions should only be performed by

Pos:12.19.2/ BA/Sicherheit/Gefahren beiNichtbeachtung derSich erheitshinweise@ 0\mod_1195639434013_7 8.doc@1 155

4.6.2 Dangers in Case of Non-compliance with the Safety Instructions

Pos:12.19.3/ BA/Sicherheit/Sicherheitsbewußtes Arbeiten @0\mod_1195639792 576_78.doc@ 1174

4.6.3 Safety-conscious work practices

authorised service centres.

Failure to follow the safety instructions could result in personal injury and environmental

hazards as well as damage to the machine. If the safety instructions are not respected, this

could result in the forfeiture of any claims for damages.

Failure to follow the safety instructions could result, for example, in the following hazards:

• Endangering of persons due to not protected working areas.

• Breakdown of important machine functions

• Failure of prescribed methods for repair and maintenance

• Endangering of persons due to mechanical and chemical effects

• Damage to the environment due to leaking hydraulic oil

Pos:12.19.4/ BA/-----Seitenumbruch------ @0\mod_11961 75311226_0.doc@ 4165

Always observe the safety instructions set out in these operating instructions, all existing

accident prevention rules and any internal work, operating and safety rules issued by the

operator.

The safety and accident prevention regulations of the responsible professional associations are

binding.

The safety instructions provided by the vehicle manufacturer should also be observed.

Observe the applicable traffic laws when using public roads.

Be prepared for emergencies. Keep the fire extinguisher and first aid box within reach. Keep

emergency numbers for doctors and fire brigade close to the telephone.

20

Page 21

Pos:12.19.5/ BA/Sicherheit/Sicherheits- undUnfallverhüt ungs-VorschriftenSwa dro_Ladewagen_EasyCut @73\mod_130829858 9597_78.doc@ 655493

4.7 Safety Instructions and Accident Prevention Regulations

1 Please follow all generally applicable safety and accident prevention regulations in

addition to the safety instructions contained in these operating instructions!

2 The attached warning and safety signs provide important information for safe operation.

Pay attention to these for your own safety!

3 When using public roads, make sure to observe the applicable traffic regulations!

4 Make sure that you are familiar with all equipment and controls as well as with their

functions before you begin working with the machine. It is too late to learn this when you

are using the machine for work!

5 The user should wear close fitting clothes. Avoid wearing loose or baggy clothing.

6 Keep the machine clean to prevent the danger of fire!

7 Before starting or moving the machine, make certain that nobody is in the vicinity of the

machine! (Watch for children!) Make sure that you have a clear view!

8 Carrying passengers during operation and transport on the working implement is not

permitted.

9 Couple implements correctly! Attach and secure implements to specified devices only!

10 When attaching or detaching implements, place the supporting devices in the correct

positions!

11 Use extreme caution when attaching or detaching implements onto or from the tractor!

12 Always attach ballast weights properly to the fixing points provided!

13 Observe permitted axle loads, gross weight and transport dimensions!

14 Check and attach transport equipment, such as lighting, warning devices and protective

equipment!

15 Actuating mechanisms (cables, chains, linkages etc.) for remote controlled devices must

be positioned in such a way that no movements are unintentionally triggered in any

transport or working positions.

16 Ensure that implements are in the prescribed condition for on-road travel and lock them in

place in accordance with the manufacturer's instructions!

17 Never leave the driver's seat when the vehicle is moving!

18 Always drive at the correct speed for the prevailing driving conditions! Avoid sudden

changes in direction when travelling uphill or downhill or across a gradient!

19 Hitched implements and ballast weights affect the driving, steering and braking response

of the machine. Make sure that you are able to brake and steer the machine as required!

20 Take into account the extension radius and/or inertia of an implement when turning

corners!

21 Start up implements only when all safety devices have been attached and set in the

required position!

22 Keep safety equipment in good condition. Replace missing or damaged parts.

23 Keep clear of the working range of the machine at all times!

24 Do not stand within the turning and swivel range of the implement!

25 Never operate the hydraulic folding frames if anyone is inside the swivel range!

Safety

21

Page 22

Safety

26 Parts operated by external power (e.g. hydraulically) can cause crushing and shearing

injuries!

27 Before leaving the tractor, lower the implement onto the ground, apply the parking brake,

Pos:12.19.6/ BA/Sicherheit/Angehängte Geräte/Geräte angehängt@ 0\mod_1199699679381_78.doc @33245

4.8 Hitched Implements

Pos:12.19.7/ BA/-----Seitenumbruch------ @0\mod_11961 75311226_0.doc@ 4165

switch off the engine and remove the ignition key!

1 Secure implements against rolling.

2 Observe the maximum supported load on the trailer coupling, swing drawbar or hitch!

3 If a drawbar coupling is used, make certain that there is enough play at the coupling

point.

22

Page 23

Pos:12.19.8/ BA/Sicherheit/Zapfwellenbetrieb Traktor@ 0\mod_119969989935 0_78.doc@ 33264

4.9 PTO operation

1 Use only PTO shafts specified by the manufacturer!

2 The guard tube and guard cone of the PTO shaft and the PTO guard must be attached

and in good working condition (on the implement side, too)!

3 Make sure that the required tube covers are in place for PTO shafts in transport and

working position!

4 Before installing or detaching PTO shafts, disengage the PTO, switch off the engine and

remove the ignition key!

5 When using PTO shafts with an overload safety or free-running coupling which are not

shielded by the guard on the tractor, mount the overload safety or free-running coupling

on the implement side!

6 Always make sure that the PTO shaft is properly installed and secured!

7 Attach chains to prevent the PTO shaft guard from rotating with the shaft!

8 Before switching on the PTO, make sure that the selected PTO speed of the tractor

matches the permissible implement speed!

9 Before switching on the PTO shaft make sure that no person is in the danger zone of the

device!

10 Never switch on the PTO if the engine is switched off!

11 No one should be in the vicinity of the rotating PTO or PTO shaft when the PTO is in use.

12 Always switch off the PTO shaft when the angle is too large or the PTO shaft is not

required!

13 Caution! After disengaging the PTO danger due to the flywheel running on! Keep away

from the implement during this time. The machine may be worked on only if it is

completely at standstill and if the flywheel is secured by the parking brake.

14 Cleaning, lubricating or adjusting PTO driven implements or the PTO shaft only with PTO

disengaged, engine switched off and ignition key withdrawn! Secure the fly-wheel with the

parking brake.

15 Place the disconnected PTO shaft onto the support provided!

16 After detaching the PTO shaft, attach the protective cover to the PTO end!

17 If damage occurs, correct this immediately before using the implement!

Pos:12.19.9/ BA/Sicherheit/Zapfwellenbetrieb Zusatz@ 2\mod_1203524761314_ 78.doc@ 66513

Safety

Pos:12.19.10 /BA/-----Seitenumbruch------ @0\mod_1196 175311226_0.doc@ 4165

Note

The instructions of the manufacturer must be observed with regard to the PTO shaft. (separate

operating instructions)

23

Page 24

Safety

Pos:12.19.11 /BA/Sicherheit/Hydraulikanlage @2\mod_1 203503691986_78.doc@ 66225

4.10 Hydraulic system

1 The hydraulic system is pressurised!

2 When connecting hydraulic cylinders and motors, make sure the hydraulic hoses are

connected as specified!

3 When connecting the hydraulic hoses to the tractor hydraulics, make sure that the

hydraulics of both the tractor and the implement have been depressurized!

4 In the case of hydraulic connections between tractor and machine, the coupling sleeves

and plugs should be marked to ensure a proper connection! Bei Vertauschen der

Anschlüsse umgekehrte Funktion (z.B. Heben/Senken) - Unfallgefahr!

5 When searching for leaks, use suitable aids to avoid the risk of injury!

6 Liquids escaping under high pressure (hydraulic oil) can penetrate the skin and cause

serious injury! Seek medical help immediately should injuries occur! Danger of infection!

7 Before working on the hydraulic system, depressurise the system and switch off the

Pos:12.19.12 /Überschriften/Überschriften 2/P-T/Reifen@ 0\mod_119735799566 7_78.doc@ 18075

4.11 Tyres

Pos:12.19.13 /BA/Sicherheit/Reifen @0\mod_119564643 5716_78.doc@ 1346

Pos:12.19.14 /BA/-----Seitenumbruch------ @0\mod_1196 175311226_0.doc@ 4165

engine!

1 When working on the tyres, make sure that the implement is safely lowered and secured

against rolling (wheel chocks).

2 Installing wheels and tyres requires adequate knowledge and suitable tools!

3 Repair work on the tyres and wheels should be done by specially trained personnel using

appropriate installation tools only!

4 Check tyre pressure regularly! Inflate the tyres to the recommended pressures!

5 Check the wheel nuts periodically! Missing wheel nuts can result in a wheel falling off and

the machine tipping over.

24

Page 25

Pos:12.19.15 /BA/Sicherheit/Wartung/Wartung Swadro@ 2\mod_1203504022 126_78.doc@ 66245

4.12 Maintenance

1 Always make certain that the drive and the engine are switched off before doing any

repairs, maintenance or cleaning! - Remove the ignition key!

2 Regularly check that nuts and bolts are properly seated and tighten if necessary!

3 When performing maintenance work with the machine raised, always secure it with

suitable supporting elements!

4 Oils, greases and filters must be disposed of correctly!

5 Always disconnect the power supply before working on the electrical system!

6 If protective devices and guards are subject to wear, check them regularly and replace

them in good time!

7 When performing electrical welding work on the vehicle and mounted devices, turn power

supply off at main battery switch or disconnect generator cable and battery!

8 Replacement parts must at least comply with the technical requirements set by the

Pos:12.19.16 /BA/-----Seitenumbruch------ @0\mod_1196 175311226_0.doc@ 4165

manufacturer of the implements! This is guaranteed by original KRONE spare parts!

Safety

25

Page 26

Safety

Pos:12.19.17 /BA/Sicherheit/Arbeiteni mBereich vonHochspan nungsleitungen@ 11\mod_1223357468516_78 .doc@ 145505

4.13 Working in the vicinity of power transmission lines

1 Always take great care when working under or in the vicinity of power transmission lines.

2 Ensure that when in operation or being transported, the machine cannot exceed a total

height of approx. 4m.

3 If there is any need to travel under overhead lines, the machine operator must request

information on the rated voltage and the minimum height of the overhead lines from the

overhead line operator.

4 Always keep the safety distances according to the table.

Rated voltage

kV

Safe distance from overhead lines

m

To 1 1

Above 1 to 110 2

Above 101 to 220 3

Above 220 to 380 4

Pos:12.19.18 /BA/Sicherheit/Eigenmächtiger Umbauund Ersatzteilherstellung @1\mo d_1201937705539_78.doc @55745

4.14 Unauthorised Conversion/Modification and Spare Parts Production

Conversions or modifications of the machine are permitted only with prior consultation with the

manufacturer. Original spare parts and accessories authorised by the manufacturer help to

Pos:12.19.19 /BA/Sicherheit/Unzulässige Betriebsweisen @11\mod_1223357 699923_78.doc@ 145527

ensure safety. Use of other parts may void liability for resulting damage.

4.15 Inadmissible Modes of Operation

The operating safety of the delivered machine is guaranteed only when it is used as intended in

compliance with the introductory section "Intended use" of the operating instructions. The limit

Pos:12.19.20 /BA/Sicherheit/Sicherheitshinweise ander Maschine@ 1\mod_120193786 1961_78.doc@ 55783

values listed in the data charts should not be exceeded under any circumstances.

4.16 Safety Instructions on the Machine

The safety instructions on the machine warn of residual risks associated with the machine. They

consist of warning pictograms and a work safety symbol. All safety instructions must be

followed. Always keep the safety instructions clean and in clearly legible condition! If any safety

instructions are damaged or missing, request them from your dealer and then put them in the

places provided for them. Where these safety instructions are and what they mean will be

described in the following chapters.

Pos:13/BA/-- ---Seitenumbruch------ @0\mod_119617531 1226_0.doc@ 4165

26

Page 27

Pos:14.1/Üb erschriften/Überschriften 1/A-E/Erstinbetriebnahme @0\mod_11963 14201498_78.doc@ 5855

5 Commissioning

Pos:14.2/B A/Sicherheit/Gefahrenhinweise/Fehlerh afterZusammenbau @1\m od_1202224212591_78.doc@ 58171

Danger! - Incorrect assembly

Effect: Danger to life, serious injuries or serious damage to the machine.

• Only authorised service centres may assemble the machine.

• The machine must be assembled with special care.

• Always heed the applicable accident prevention regulations.

• Use only safe and sufficiently dimensioned lifting equipment and load-securing

equipment.

• The machine may be taken into operation only after all the safety devices have been

installed.

• If unauthorised modifications are made to the machine, the manufacturer is released

from liability for any resulting damage.

Pos:14.3/B A/Sicherheit/Gefahrenhinweise/Einstell arbeitengezogene Maschinen@ 0\mod_1199717 011038_78.doc@ 33980

Danger! - Unexpected movements of the machine

Effect: Danger to life or serious injuries.

• Setting tasks must only be performed when the drive is switched off and the engine is at

a standstill!

• Switching off the engine

• Remove the ignition key.

• Secure the machine against the possibility of rolling back.

Pos:14.4/Üb erschriften/Überschriften 2/A-E/Erstmontage @1\mod_12022262 61982_78.doc@ 58270

5.1 First installation

Pos:14.5/B A/Erstinbetriebnahme/Erstmontage @1\mod _1202224111998_78.doc @58190

Pos:14.6/B A/-----Seitenumbruch------ @0\mod_1196175 311226_0.doc@ 4165

The document "Assembly Instructions" describes how to install the device for the first time.

Commissioning

27

Page 28

Commissioning

Pos:14.7.1 /Überschriften/Überschriften 2/U-Z/Vorbereitungen amTraktor @2\mod_120 2363643678_78.doc@ 58694

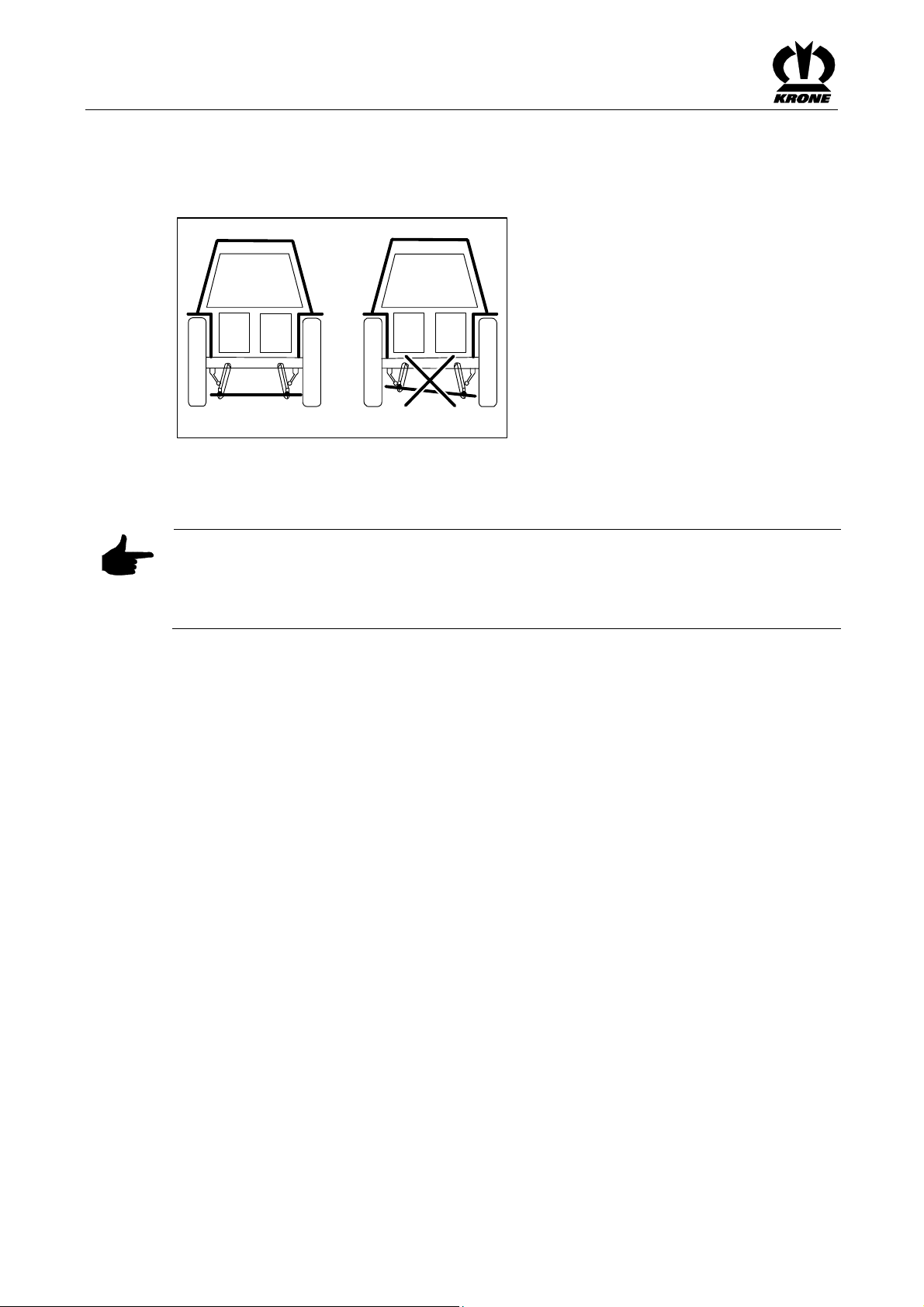

5.2 Preparations on tractor

Pos:14.7.2 /Überschriften/Überschriften 3/U-Z/Unterlenker einstellen@ 6\mod_1214454896135_78.doc @941 86

5.2.1 Adjusting the lower suspension arms

Pos:14.7.3 /BA/Erstinbetriebnahme/Schwader/S wadro807_810_907/Bil d_AushubvorrichtungTr aktor@2 \mod_1202364384960_78.doc @58789

KS-0-030

Pos:14.7.4 /BA/Erstinbetriebnahme/Schwader/S wadro807_810_907/Vor bereitungan Traktor_TextKAT Iund II@ 2\mod_1202363818163_78.d oc@ 58732

Fig. 4

The machine is equipped with Cat. I and II trunnions for three-point hydraulics.

Pos:14.7.5 /BA/Erstinbetriebnahme/Schwader/S wadro807_810_907/Hinw eisUnterlenker @2\mod_1 202364126303_78.doc@ 58751

Note

The tractor lower suspension arms must always be installed so that the lifting points of the

lower suspension arms are all at the same distance from the ground. In order to prevent

swivelling of the machine during transport or operation, the lower suspension arms must be

secured by limiting chains or bars.

Pos:14.8/B A/-----Seitenumbruch------ @0\mod_1196175 311226_0.doc@ 4165

28

Page 29

Pos:14.9.1 /Überschriften/Überschriften 2/F-J/Gelenkwelle @0\mod_11997818 79794_78.doc@ 34542

5.3 PTO shaft

Pos:14.9.2 /Überschriften/Überschriften 3/K-O/Längenanpassung @1\mod_120 1687632810_78.doc@ 53589

5.3.1 Length adjustment

Pos:14.9.3 /BA/Erstinbetriebnahme/Gelenkwelle/Sc hwader/Längenanpassung BildSchwader @2\mod _1202364902991_78.doc@ 58848

3

1

Commissioning

2

SW9070007

Pos:14.9.4 /BA/Erstinbetriebnahme/Gelenkwelle/Sc hwader/Längenanpassung_mit WeitwinkelTe xt_Schwader@ 2\mod_1202365111491_78.doc @5 8868

Fig. 5

The PTO shaft (1) length must be adjusted.

• Disassemble the PTO shaft.

• Install each half (1) and (2) on the tractor and machine side respectively.

(The wide-angle coupling must be installed onto the machine. Observe the marking on

the PTO shaft.)

• Position rotary rake in the shortest PTO shaft position setting. (Completely the three-

• For additional operating instructions refer to the operating instructions of the PTO shaft

Note

Check the swivel range and clearance of the PTO shaft! Damage can be caused if the tractor

or the machine touch the PTO shaft. (e.g. hitching device, hitching frame)

Pos:14.10/ BA/-----Seitenumbruch------ @0\mod_119617 5311226_0.doc@ 4165

point frame inwards.)

manufacturer.

29

Page 30

Commissioning

Pos:14.11/Ü berschriften/Überschriften 2/F-J/Höheder Traktorunterlenker @35\mod_12 57862892625_78.doc@ 332062

5.4 Height of tractor lower suspension arms

Pos:14.12/ BA/Erstinbetriebnahme/Schwader/Sw adro807_810_907/Höh ederTr aktorunterlenker@ 2\mod_1202734685720_ 78.doc@ 60755

SW9070025

Figure 6

Perform basic setting on a level surface.

The tractor lower suspension arms must be set at a height which ensures that the steerable

pinions are at a height of H approx. 63 cm from the ground. Fix the lower suspension arms at

this height (see Chapter on special equipment "Chain for height restriction of lower suspension

Pos:15/BA/-- ---Seitenumbruch------ @0\mod_119617531 1226_0.doc@ 4165

arms").

30

Page 31

Pos:16.1/Üb erschriften/Überschriften 1/F-J/Inbetriebnahme @0\mod_1196327 075811_78.doc@ 6375

6 Start-up

Pos:16.2/B A/Sicherheit/Gefahrenhinweise/Schwa der/An-/Abau derMaschine gezogene Schwader@ 2\mod_1202363265522_78.doc @58675

Danger! - Assembling / dismantling the machine

Effect: Danger to life or serious injuries.

• No persons may remain between the tractor and the machine.

• Nobody should be within the swivel range of the rotary arms or of the working range of

the rotary rake!

• Only perform jobs under or on the machine when it is raised if it is securely supported.

• Setting tasks must only be performed when the drive is switched off and the engine is at

a standstill!

• Switching off the engine

• Remove the ignition key.

• Secure the machine against the possibility of rolling back.

Pos:16.3/Üb erschriften/Überschriften 2/A-E/Anbauan denTrakt or@0\m od_1199717845194_78.doc @34039

6.1 Mounting onto the Tractor

Pos:16.4/B A/Sicherheit/Gefahrenhinweise/Lad ewagen/Stütz-und Anhängelastend esSchleppers nichtbeachtet @0\m od_1199720048038_78.doc @34118

Danger! - Support and hitching loads of tractor not observed!

Effect: Danger to life, injuries or damage to the machine.

• Observe the maximum permissible support and hitching loads for the tractor!

• Hitch and secure the machine to the tractor hitch in accordance with specifications.

Pos:16.5/B A/Inbetriebnahme/Schwader/Hinweis Maschine befindetsich inTransportstellu ng@2 \mod_1202388231928_78.doc @59050

Start-up

Note

The description below assumes that the

swather is in transport position, following final assembly.

Pos:16.6/B A/Inbetriebnahme/Schwader/Anbau anden Traktor/Anbau anden Traktor angehängteSch wader@2\ mod_1202389539585_78.doc @59089

Figure 7:

• Hitch double swather with steerable pinions onto tractor.

• Place the machine onto the parking supports.

Pos:16.7/B A/-----Seitenumbruch------ @0\mod_1196175 311226_0.doc@ 4165

SW9070002

31

Page 32

Start-up

Pos:16.8/Üb erschriften/Überschriften 2/F-J/Hydraulik@ 0\mod_119977603495 0_78.doc@ 34205

6.2 Hydraulics

Pos:16.9/Üb erschriften/Überschriften 3/P-T/SpezielleSic herheitshinweise@ 0\mod_1197301069931_7 8.doc@1 7662

6.2.1 Special Safety Instructions

Pos:16.10/ BA/Sicherheit/Hydraulik/Gefahr Anschlussd erHydraulikleitungen @0\mo d_1199776548685_78.doc @34225

Warning ! - Connection of the hydraulic line

Effect: severe injuries due to penetration of hydraulic oil under the skin.

• When connecting the hydraulic hoses to the hydraulic system of the tractor, the system

must be relieved of the pressure on either side.

• Due to the risk of injury when searching for leaks, always use suitable tools and wear

protective goggles.

• Seek medical help immediately should injuries occur! Danger of infection.

• Depressurise prior to uncoupling the hydraulic hoses and working on the hydraulic

system!

• Check the hydraulic hose lines at regular intervals and replace them if damaged or worn!

The replacement hoses must fulfil the technical requirements set by the equipment

manufacturer.

Pos:16.11/ BA/Sicherheit/Hydraulik/Verschmutzu ngderH ydraulikanlage@ 2\mod_1202393336803_7 8.doc@5 9155

Caution! - Soiling of the hydraulic system

Effect: Damages to the machine

• When connecting the quick couplings, ensure that these are clean and dry.

• Note chafing areas or points of contact.

Pos:16.12/ BA/-----Seitenumbruch------ @0\mod_119617 5311226_0.doc@ 4165

32

Page 33

Pos:16.13/Ü berschriften/Überschriften 3/A-E/Anschlussd erHydraulikleitunge n@0\mo d_1199777037794_78.doc @34244

6.2.2 Connecting the hydraulic lines

Pos:16.14/ BA/Inbetriebnahme/Schwader/Hydr aulikanschluss/Hydraulikanschluss BildSchwadr o807_809_810_907 @75\mo d_1309764074531_78.doc @664029

2

1

Start-up

SW9070003

Pos:16.15/ BA/Inbetriebnahme/Schwader/Hinw eisHydraulikaufkleber beachten@ 9\mod_12199975317 85_78.doc@ 124879

Figure 8

Note

Connect the hydraulic lines correctly

• The hydraulic hoses are identified by coloured hose clips.

• When connecting the hydraulic lines, observe the sticker for the tractor hydraulics (see

Pos:16.16/ BA/Inbetriebnahme/Schwader/Hydr aulikanschluss/Amtraktor benötigteS teuergeräte@ 75\mod_1309762615205_7 8.doc@6 64001

Pos:16.17/ Abkürzungen/Abkürz ungensprachneutral/Sc hwader/Swadro807 /Swadro 809@ 76\mod_1309764684788_ 0.doc@ 664085

Pos:16.18/ BA/Inbetriebnahme/Schwader/Hydr aulikanschluss/Hydraulikanschluss Schwadro80 7_809Text @75\mod_1309762 054242_78.doc@ 663973

The following control units are required on the tractor to operate the machine:

Swadro 807 / Swadro 809

The machine requires a single-action control unit on the tractor.

Connect the hydraulic hose as follows:

to the single-action control unit:

• (2) red= - lift/lower rotor arms

Pos:16.19/ Abkürzungen/Abkürz ungensprachneutral/Sc hwader/Swadro810 @2\mod_ 1202740024298_0.doc@ 60813

Pos:16.20/ BA/Inbetriebnahme/Schwader/Hydr aulikanschluss/Hydraulikanschluss Schwadro81 0Text@ 75\mod_13097616346 63_78.doc@ 663945

Swadro 810

The machine requires a single-action and a double-action control unit on the tractor.

Connect the hydraulic hoses as follows:

to the single-action control unit:

• (1) red= - lift/lower rotor arms

to the double-action control unit:

• (2) red = increase working width setting

• (2) blue= - reduce working width setting

Pos:16.21/ Abkürzungen/Abkürz ungensprachneutral/Sc hwader/Swadro907 @1\mod_ 1202226168013_0.doc@ 58250

Pos:16.22/ BA/Inbetriebnahme/Schwader/Hydr aulikanschluss/Hydraulikanschluss Schwadro90 7Text@ 75\mod_13097609676 69_78.doc@ 663917

Swadro 907

The machine requires a single-action and a double-action control unit on the tractor.

Connect the hydraulic hoses as follows:

to the single-action control unit:

• (1) red= - lift/lower rotor arms

to the double-action control unit:

• (2) red= - adjust swath cloth forwards

• (2) blue= - adjust swath cloth backwards

Pos:16.23/ BA/-----Seitenumbruch------ @0\mod_119617 5311226_0.doc@ 4165

the "Safety" chapter: "Position of the general information labels on the machine").

33

Page 34

Start-up

Pos:16.24/Ü berschriften/Überschriften 2/A-E/AnschlussB eleuchtung@ 33\mod_1254385308979_78. doc@3 19105

6.3 Lighting connection

Pos:16.25/ BA/Inbetriebnahme/Schwader/Ansc hlussBeleuchtung/Ansc hlussBeleuchtung Swadro807 810S wadro907 @2\mod_1202391626 522_78.doc@ 59135

3

Fig. 9

The lighting system is connected via the 7-pin connection cable (1).

To do this:

• Insert the 7-pin connection cable plug (1) into the appropriate socket (2) of the tractor.

• Insert the 7-pin connection cable plug (1) into the appropriate socket (3) of the machine.

Pos:16.26/ BA/Inbetriebnahme/Schwader/Hinw eisSauberkeit derStecker undSteckdose n@2\ mod_1202399563131_78.doc @59273

Pos:16.27/ BA/-----Seitenumbruch------ @0\mod_119617 5311226_0.doc@ 4165

• Position the cable so that it will not come in contact with the wheels.

Note

Before inserting the plugs, make certain the plugs and sockets are clean and dry. Dirt and

moisture may result in short circuits!

2

1

1

SW9070004

34

Page 35

Pos:16.28/Ü berschriften/Überschriften 2/A-E/Anschlußd erelektrischen Bedienung@ 2\mod_1202396974288_ 78.doc@ 59195

6.4 Connecting the electrical controls

Pos:16.29/ BA/Inbetriebnahme/Schwader/Option alfürSw adro810_907 @2\mod_12023 97282038_78.doc@ 59214

Pos:16.30/ BA/Inbetriebnahme/Schwader/Ansc hlusselektrische Bedienung/Anschluss elektrische Bedienung SW807_810_907 @2\mod_1202 396707631_78.doc@ 59175

(Optional for Swadro 810; Swadro 907)

Start-up

Pos:16.31/ BA/Inbetriebnahme/Schwader/Hinw eisSauberkeit derStecker undSteckdose n@2\ mod_1202399563131_78.doc @59273

Pos:16.32/ BA/-----Seitenumbruch------ @0\mod_119617 5311226_0.doc@ 4165

1

2

1

3

SW9070005

Fig. 10

The connection of the electrical controls is made with the power supply plug (1)

Note

If necessary, the continuous power socket and support for the control unit must be previously

installed on the tractor.

To do this:

• Insert the plug for the electrical power supply cable (1) into the appropriate socket (2) of

the tractor.

• Insert the plug for the electrical power supply cable (1) into the appropriate socket (3) of

the machine.

• Position the cable so that it will not come in contact with the wheels.

Note

Before inserting the plugs, make certain the plugs and sockets are clean and dry. Dirt and

moisture may result in short circuits!

35

Page 36

Start-up

Pos:16.33/Ü berschriften/Überschriften 2/F-J/Gelenkwelle montieren@ 2\mod_1202398342788_78.doc @592 53

6.5 Install the PTO shaft

Pos:16.34/ BA/Sicherheit/Gelenkwelle/Sich drehendeGel enkwelle_2@ 0\mod_1199781692950_78.doc @3452 3

Danger! - Rotating PTO shaft

Effect: Danger to life or serious injuries

• Install or detach the PTO shaft only with the engine switched off and the ignition key

removed.

• Secure the tractor against rolling.

• Make sure that the PTO shaft is coupled properly (the lock of the PTO shaft must have

snapped in).

• Make sure that the protective devices are attached properly.

• Never use a PTO shaft, the protective devices of which have not been attached.

• Replace damaged protective devices immediately

• Attach the safety chain of the PTO shaft so that the guard tube does not rotate

simultaneously with the PTO shaft.

Pos:16.35/ BA/Inbetriebnahme/Schwader/Anba uGelenkwelle/Anbau Gelenkwellea ngehängteSchwa derBild@ 2\mod_12023980779 60_78.doc@ 59233

3

Pos:16.36/ BA/Inbetriebnahme/Schwader/Anba uGelenkwelle/Anbau Gelenkwellea ngehängteSchwa derText@ 37\mod_12634637723 93_78.doc@ 339645

Figure 11

• Switch off the engine and remove the ignition key.

• Install the PTO shaft (1) on the machine side (wide angle on machine side).

• Rotate the PTO shaft support (2) upwards.

• Then slide PTO shaft onto the PTO of the tractor. In doing this, ensure that the sliding pin

Pos:16.37/ BA/Inbetriebnahme/Schwader/Maschin eanheben wennBedienseil @2\mod _1202826885966_78.doc@ 61845

• Secure the PTO shaft guard against turning with the retaining chain (3).

Lifting the Machine

• The actuator rope (6) must be routed in such a way that no movements are

• Lift the machine slightly.

• Rotate the parking support (4) back 90°. Lock it in that position with the bracket (5) and

Pos:17/BA/-- ---Seitenumbruch------ @0\mod_119617531 1226_0.doc@ 4165

6

3

2

1

5

4

SW9070008

is securely engaged.

unintentionally triggered in any transport or working positions. The actuator rope must not

come into contact with the tractor tyres.

secure with spring cotter pin.

36

Page 37

Pos:18.1/Üb erschriften/Überschriften 1/F-J/Fahrenund Transport@ 0\mod_119633004 9217_78.doc@ 6553

7 Driving and Transport

Pos:18.2/B A/Sicherheit/Fahrenu ndTransport/Mitfahren Straßenfahrt/Gefahr Straßenfahrt,M itfahrengezogen eSwadros@ 2\mod_12024563155 26_78.doc@ 59426

Danger! - Road travel, carrying passengers, driving conduct

Effect: Danger to life, injuries or damage to the machine.

• The machine must be fully and correctly hitched.

• The side hoop guards of the machine must be attached.

• The collapsible tine arms must be rotated.

• The machine must be in transport position.

• The tine guards must be installed on tines.

• The control unit must be turned off.

• Do not exceed the maximum permissible speed (see type plate).

• Carrying passengers on the machine is not permitted.

• When driving on public roads, the provisions of the Road Traffic Licensing Regulations

must be adhered to (lighting, identification).

• Before starting, ensure that you have perfect visibility on and around the tractor as well

as the machine.

Pos:18.3/B A/Sicherheit/Fahrenu ndTransport/Mitfahren Straßenfahrt/Gefahr Straßenfahrt,M itfahrenSwadro zusatzSW 807/810/907 @2\mod_12029 20546961_78.doc@ 63113

Danger! - Road travel, passengers and handling

Effect: Danger to life, injuries or damage to the machine.

• The width setting of the rotor arms must always be completely retracted (Swadro 810)

• Check to make certain the locks have engaged correctly.

• Before each transport trip, charge the outrigger arm hydraulic cylinders with pressure and

then set the tractor hydraulics to "Neutral" so the outrigger arm transport interlocks are

not under any load.

Driving and Transport

Pos:18.4/B A/-----Seitenumbruch------ @0\mod_1196175 311226_0.doc@ 4165

37

Page 38

Driving and Transport

Pos:18.5/B A/Fahrenund Transport/Schwader/Vorbereitu ngfürd enTransport Swadro807_809_8 10_907@ 76\mod_1309765675876_78.doc @664143

Swadro 907

1

1

2

1

SW9070015

Swadro 807, Swadro 809, Swadro 810

1

1

SW810004_1

Fig. 12

• Switch off the control unit (Swadro 810; Swadro 907 optional)

• Fold over the folding tine arms (right and left side of machine) (see section on Operation

"Swivelling the Tine Arms into Transport Position").

• Fix the rotor in place (see section on Operation "Swivelling the Tine Arms into Transport

Position").

• Move the swath cloth to transport position (see section on Operation "Pushing the Swath

Cloth into Transport Position")

• Fold up the bar. (see section on Operation "Moving the Outer Guards into Transport

Position").

• Lift the rotor until the front and rear locks engage in the retaining bolt (see section on

Operation "Lifting the Rotor Arms to Transport Position").

Pos:19/BA/-- ---Seitenumbruch------ @0\mod_119617531 1226_0.doc@ 4165

38

Note

Make certain the transport locks engage correctly and the actuator rope is not tight.

Swadro 907

The locks (1) on the Swadro 907 have engaged correctly when the white spotlights (2) can be

seen from the tractor with the outrigger arms in vertical position (front rotor and rear rotor).

Swadro 807, Swadro 809, Swadro810

Perform a visual inspection to ensure the locks (1) have engaged correctly.

• Move the hydraulic control unit to neutral position.

• Insert the tine guard onto the tines, which are in transport position below 2 m. (see

section on Operation "Protecting the Tine Tips")

• Check the lighting system.

Page 39

Pos:20.1/Üb erschriften/Überschriften 1/A-E/Bedienung@ 0\mod_119978950540 3_78.doc@ 34825

8 Operation

Pos:20.2/B A/Bedienung/Schwad er/Maschineist fürVorwärtsf ahrtkonzipiert. @66\mod_13021 75087311_78.doc@ 615098

WARNING! – Do not drive in reverse when using the machine for work.

Effect: Damage to the machine.

The machine is designed to travel forwards. Never reverse while the machine is in operation

and in working position. Lift the rotor first.

Pos:20.3.1 /Überschriften/Überschriften 2/U-Z/Überlastsicherung @2\mod_12 02465560433_78.doc@ 59567

8.1 Overload protection

Pos:20.3.2 /BA/Bedienung/Sch wader/Überlastsicherung/Überlastsicheru ngBild Swadro807_809_810_ 907@7 6\mod_1309768647507_78.doc @664230

Operation

Swadro 907

1

SW9070031

Pos:20.3.3 /BA/Bedienung/Sch wader/Überlastsicherung/Überlastsicheru ngTextS W807_810_907_10 00@2\m od_1202465701839_78.doc @59605

Fig. 13

Star ratchet couplings protect the machine against overloading. These star ratchets (1) are

located on the side output shafts of the transfer gearbox behind the rotor arms. They emit a

vibrating sound when the machine is overloaded. They transfer the related torque by pulsations.

In order to avoid premature wear of the overload protection, turn the PTO shaft of immediately

when the star ratchets respond to the overload.

Pos:20.3.4 /BA/Bedienung/Sch wader/Überlastsicherung/Hinweis Überlastsicherung nichtverändern @2\mod_1 202465626026_78.doc@ 59586

Pos:20.4/B A/-----Seitenumbruch------ @0\mod_1196175 311226_0.doc@ 4165

Note

The overload protection must not be changed. The guarantee becomes invalid if an overload

protection is used other the protection provided!

39

Page 40

Operation

Pos:20.5/Üb erschriften/Überschriften 2/U-Z/VonTransport inAr beitsstellung@ 2\mod_1202466185276_78.doc @596 62

8.2 From transport into working position

Pos:20.6/B A/Sicherheit/Gefahrenhinweise/Schwa der/GefahrMaschine absenken@ 5\mod_121369480 5078_78.doc@ 88774

Danger! – Lowering the machine into working position

Danger to life, injuries or damage to the machine.

• Lower the machine only when you are absolutely sure that neither persons, animals nor

objects are in the swivel range of the machine.

• Switch the PTO on only when the machine is in working position, the collapsible tine

arms are swivelled into the working position and the hoop guards are turned downwards.

Pos:20.7/B A/Bedienung/Schwad er/Zinken/Zi nkenarme/Zinkenschutze entfernenSW 807/810/907 @2\mod_1202467 038839_78.doc@ 59738

8.3 Removing the tine protections from the tine tips

1

2

1

Figure 14

• Remove the tine protections (1).