Operating instructions

150 000 054 00 EN

Maize header

EASYCOLLECT 6000

EASYCOLLECT 7500

EASYCOLLECT 9000

(Machine No. 535 500 or higher)

Dear Customer:

These are the operating instructions for the KRONE product that

you have purchased.

These operating instructions contain important information for

the correct use and safe operation of the machine.

Should these operating instructions have become unusable

completely or partially for any reason, you can obtain

replacement operating instructions for your machine by stating

the number quoted on the reverse.

EC Declaration of Conformity

corresponding to the EC Directive 98/37/EC

We Maschinenfabrik Bernard Krone GmbH

Heinrich-Krone-Str. 10, D-48480 Spelle, Germany

declare in our sole responsibility that the product

Krone Maize Header

Types: EasyCollect 6000; EasyCollect 7500; EasyCollect 9000

tto which this declaration refers corresponds to the relevant basic safety and health requirements of the

EC Directive 98/37/EC.

Spelle, 13.05.04

(Dr.-Ing. Josef Horstmann, Managing Director)

(Wolfgang Ungruh, Head of Quality Assurance)

Contents

Contents

1 General aspects ................................................................................ I -1

1.1 Intended use............................................................................................................. I -1

1.2 Technical data .......................................................................................................... I -1

1.2.1 General aspects ...................................................................................................... I -1

1.2.2 Address of the manufacturer.................................................................................... I -1

1.2.3 Declaration .............................................................................................................. I -1

1.2.4 Designation ............................................................................................................. I -1

1.2.5 Information for enquiries and orders ........................................................................ I -1

1.2.6 Intended use............................................................................................................ I -2

1.2.7 Technical data .............. ...................... ..................................................................... I -2

2 Safety................................................................................................ IV -1

2.1 Identifying important information in the operating instructions .................................. IV -1

2.2 Safety instructions and accident prevention regulations .......................................... IV -1

2.2.1 Personnel qualification and training ...................................................................... IV -1

2.2.2 Dangers in failure to comply with the safety instructions ....................................... IV -1

2.2.3 Safety-conscious work practices ........................................................................... IV -1

2.2.4 Safety and accident prevention regulations........................................................... IV -2

2.2.5 Attached devices ................................................................................................... IV -3

2.2.6 PTO operation ....................................................................................................... IV -3

2.2.7 Hydraulic system ................................................................................................... IV -3

2.2.8 Maintenance.......................................................................................................... IV -4

2.2.9 Unauthorised conversion/modification and Manufacture of spare parts ................ IV -4

2.2.10 Impermissible modes of operation......................................................................... IV -4

2.3 Safety instructions on the machine.......................................................................... IV -5

2.3.1 Location of the warning pictograms on the machine.............................................. IV -6

2.3.2 Location of the general warning signs on the machine.......................................... IV -8

3 Start-up ............................................................................................. III -1

3.1 S pecial safety instructions ....................................................................................... III -1

3.2 S top points.............................................................................................................. II I -1

3.3 Storage ................................................................................................................... III -1

3.4 Attaching................................................................................................................. III -2

3.4.1 Adjusting the adapter frame................................................................................... III -2

3.4.2 Pendulum frame .................................................................................................... III -3

3.4.3 Coupling................................................................................................................ III -3

3.5 T ransport position.................................................................................................... III -5

3.5.1 Folding in the tubular bar on the right/left .............................................................. III -5

3.5.2 Swinging the maize header up.............................................................................. III -5

3.5.3 Parking supports in transport position on the right/left ........................................... III -6

3.5.4 Installing guard on the right/left.............................................................................. III -6

3.5.5 Connecting indicators and position lights on the right/left...................................... III -6

3.5.6 Installing the front guard ........................................................................................ III -7

3.5.7 Road travel ............................................................................................................ III -7

3.6 Working position..................................................................................................... III -7

3.6.1 Removing the protective cover .............................................................................. III -7

3.6.2 Adjusting skids ...................................................................................................... III -7

3.6.3 Folding up the tubular bar on the right/left ............................................................. III -8

3.6.4 Adjusting the plant dividers ................................................................................... III -8

Contents

3.7 Using the machine for work ..................................................................................... III -9

3.7.1 Special safety instructions..................................................................................... III -9

3.7.2 Using the maize header ........................................................................................ III -9

3.7.3 Lifting gear spacing control (optional).................................................................... III -9

3.7.4 Autopilot (optional) .............................................................................................. III -10

3.8 Detaching ............................................................................................................. III -10

4 Maintenance.................................................................................... IV -1

4.1 S pecial safety instructions ...................................................................................... IV -1

4.2 General aspects..................................................................................................... IV -1

4.2.1 Tightening torques on the aluminium gears .......................................................... IV -2

4.3 Gearboxes............................................................................................................. IV -3

4.3.1 Lubricant quantities and designations for gearboxes ............................................ IV -3

4.3.2 Checking the oil level and changing the oil in the main angular gearbox.............. IV -3

4.3.3 Checking the oil level and changing the oil in the transfer gearbox (right/left)....... IV -4

4.3.4 Checking the oil level and changing the oil in the collector gearbox (right/left) ..... IV -4

4.3.5 Checking the oil level and changing the oil in the angular gearbox (right/left)....... IV -5

4.3.6 Checking the oil level and changing the oil in the dresser gearbox (right/left)....... IV -6

4.4 Laid maize worm drive belt (right / left).................................................................... IV -7

4.4.1 Checking the drive belt tension ............................................................................. IV -7

4.4.2 Correcting the drive belt tension............................................................................ IV -7

4.5 Collector pre-tension (right / left)............................................................................. IV -8

4.5.1 Checking the collector pre-tension ........................................................................ IV -8

4.5.2 Correcting the collector pre-tension....................................................................... IV -8

4.6 Scraper (right / left)................................................................................................. IV -9

4.6.1 Adjusting the scraper............................................................................................. IV -9

4.7 Tips...................................................................................................................... IV -10

4.7.1 Adjusting the side tips (right / left)........................................................................ IV -10

4.7.2 Adjusting the central tip ....................................................................................... IV -10

4.7.3 Replacing tips ..................................................................................................... IV -10

4.8 Removing the upper insert finger ...........................................................................IV -11

4.9 Installing PTO shafts ..............................................................................................IV -1 1

4.10 Hydraulic hose lines ..............................................................................................IV -1 1

4.11 Changing blades.................................................................................................. IV -12

4.11.1 Changing bow and step blades........................................................................... IV -12

4.11.2 Changing cutting blades ...................................................................................... IV -13

4.11.3 Changing dresser segments (right / left) .............................................................. IV -13

4.11.4 Changing scraper blades (right / left)................................................................... IV -14

4.12 Lubrication ........................................................................................................... IV -15

4.12.1 PTO shafts........................................................................................................... IV -15

4.12.2 Lubrication chart.................................................................................................. IV -16

4.13 Storing when not in use......................................................................................... IV -17

A1 Commissioning.................................................................................A -1

A1.1 Fitting the additional weights ................................................................................... A -1

A1.2 Fitting the discharge extension (only for EasyCollect 7500; EasyCollect 9000) ........ A -2

I - 1

General aspects

1 General aspects

These operating instructions contain basic information

that has to be observed in mounting, operation and

maintenance. For this reason these operating

instructions must be read by the staff prior to operation

and must be accessible to the staff at all time.

Not only must the general safety instructions listed

under this main item of safety be complied with, but

also the special safety instructions inserted under the

other main items.

1.1 Intended use

The Krone EASYCOLLECT 6000, EASYCOLLECT

7500 and EASYCOLLECT 9000 maize header is a

harvesting attachment with adapter frame for

attachment to forage harvesters and is used for

harvesting maize and other forage crop with stalks

independently of the rows.

1.2 Technical data

1.2.1 General aspects

These operating instructions apply to the

EASYCOLLECT 6000; EASYCOLLECT 7500 and

EASYCOLLECT 9000 maize header.

1.2.2 Address of the manufacturer

Maschinenfabrik Bernard Krone GmbH

Heinrich-Krone-Str. 10

D-48480 Spelle (Germany)

Telephone: 0 59 77/935-0

Fax: 0 59 77/935-339

Email: info.ldm@krone.de

1.2.3 Declaration

EC Declaration of Conformity

corresponding to the EC Directive

See the inside of the title page.

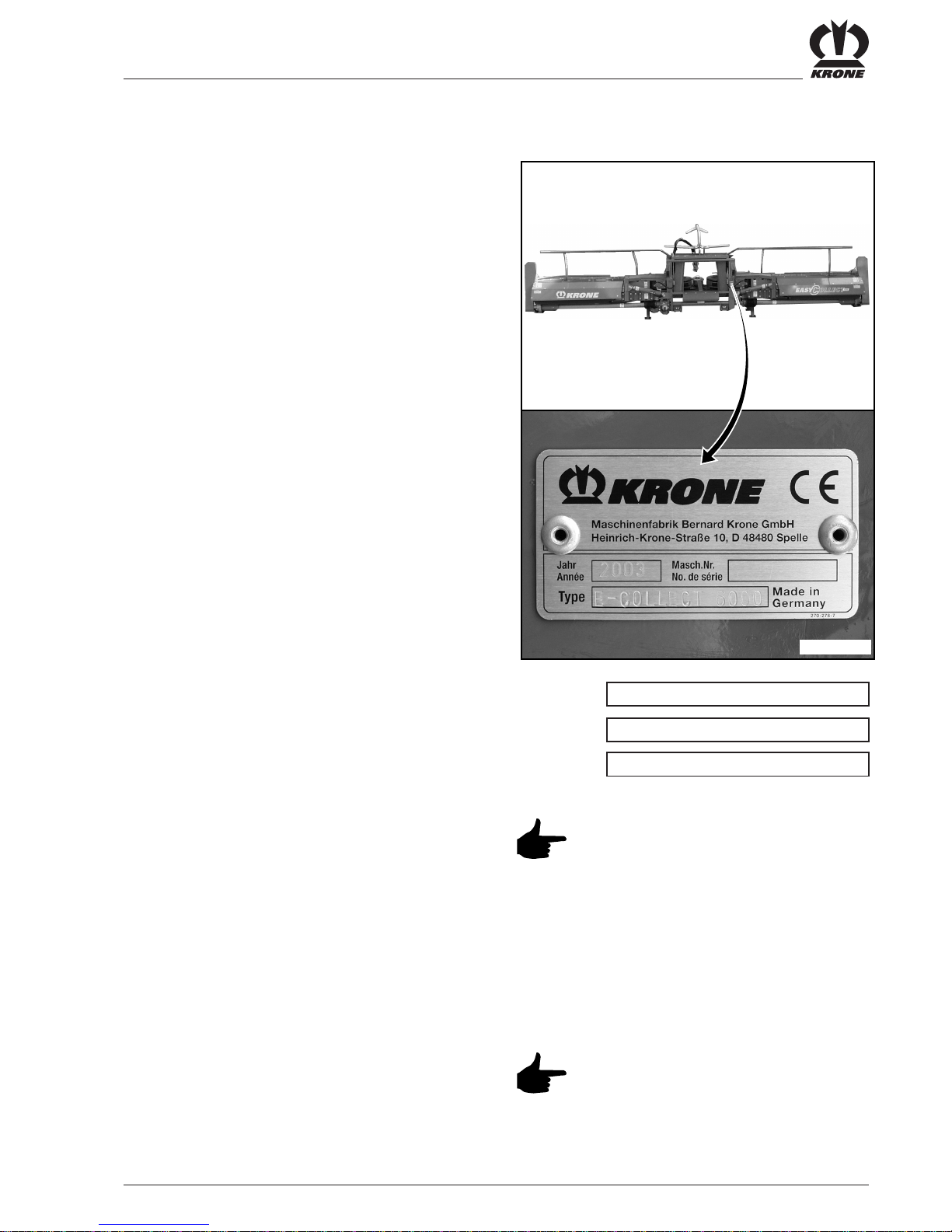

1.2.4 Designation

The rating plate is located on the adapter frame on the right.

Year

Mach. No.

Type

The entire designation has

documentary value and may not be

modified or made indecipherable!

1.2.5 Information for enquiries and orders

When enquiring about the machine and ordering spare

parts, state the type designation, the Machine ID No.

and the year of manufacture of the machine.

Authentic spare parts and accessories

authorised by the manufacturer

increase safety. The use of other parts

may void the liability for any

consequences.

EC200020

I - 2

General aspects

1.2.6 Intended use

The Krone EASYCOLLECT 6000, EASYCOLLECT

7500 and EASYCOLLECT 9000 may be attached only

to carrier vehicles for which the relevant adapter frame

is released (observe operating permission of the carrier

vehicle).

It is built exclusively for customary use in agricultural

work (use as intended), see also Section 1.1 Intended

use.

Any use extending beyond this is considered as not as

intended. The manufacturer is not liable for damage

resulting from this, the user alone bears the risk for

this.

The intended use shall also include the adherence to

the operating, maintenance and repair conditions set by

the manufacturer.

1.2.7 Technical data

All information, illustrations and technical data in

this operating manual are in keeping with the

latest state of technology at the point of

publication. Design modifications at any time

without statement of reason shall be reserved.

Type EASYCOLLECT 6000 EASYCOLLECT 7500 EASYCOLLECT 9000

Length (mm) 2190 2190 2190

Height in working position (mm) 1500 1500 1500

Total width in working position (mm) 6150 7650 9150

Working width (mm) 6000 7500 9000

Height, folded in (mm) 3000 3750 4500

Width, folded in (mm) 2900 2900 2900

Weight (kg) 2800 3200 3600

Power requirement (kW) 40 50 6 0

Drive speed (min-1) 300 - 700 300 - 700 300 - 700

Max. permissible operating pressure (bar) 200 20 0 20 0

Hydraulic connections 2x DW 2x DW 2x DW

Electr. connection (lighting) 7-pole 7-pole 7-pole

I - 3

General aspects

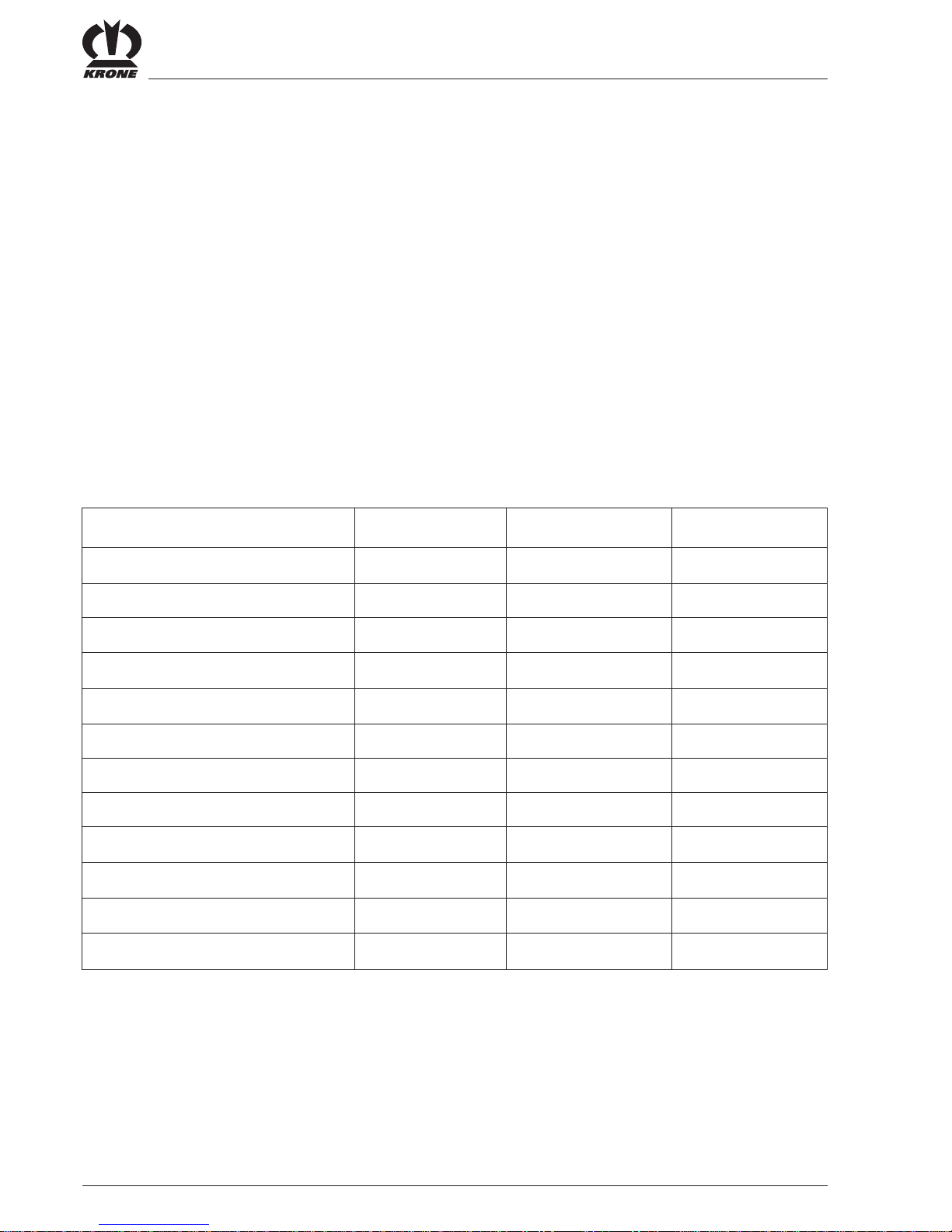

1.2.8 Additional weights on the BigX

To ensure safe and reliable operation of the selfpropelled forage harvester with the maize header

attached, especially in road traffic, additional weights

(Z) must be connected to the rear frame.

Item Designation of Number of weights Number of weights

weights for Big X V8 for BigX V12

EasyCollect 6000 EasyCollect 7500 EasyCollect 6000 EasyCollect 7500

1 Cover plate 3 3 3 3

2 Base plate 1 1 1 1

3 Intermediate plate 4 6 3 5

4 Floor plate 1 1 1 1

Steel design

Item Designation of Number of weights Number of weights

weights for Big X V8 for BigX V12

EasyCollect 6000 EasyCollect 7500 EasyCollect 6000 EasyCollect 7500

1 Main weight 1 1 1 1

2 Floor plate 2 4 1 3

Cast design

1

1

1

2

3

4

EC100665

Z

1

2

EC100666

Z

I - 4

General aspects

II - 1

Safety

2 Safety

2.1 Identifying important

information in the operating

instructions

Important safety instructions in the present operating

instructions are identified with the general hazard

symbol. Non-observance of these safety instructions

may result in personal injury.

Safety symbol according to DIN 4844 - W9

General notes on functions are identified as follows:

Instructions affixed directly to the machine must be

complied with and kept in a completely legible

condition by all means. If illegible, they must be

replaced.

2.2 Safety instructions and

accident prevention

regulations

2.2.1 Personnel qualification and training

The maize header may be used, maintained and

repaired only by persons who are familiar with it and

have been instructed about the dangers connected with

it. The area of responsibility, the competence and the

supervision of the personnel must be precisely defined

and regulated by the operator. If operating staff

members do not have the necessary knowledge, they

must be trained and instructed appropriately. The

operator must also ensure that the personnel

understands the full scope of the information and

instructions contained in the operating instructions.

Repair work not described in these operating

instructions may be performed by authorised specialist

workshops only.

2.2.2 Dangers in failure to comply with the

safety instructions

Failure to comply with the safety instructions may put

people, the environment and the machine at risk.

Failure to comply with the safety instructions can lead

to the forfeiture of any claims for damages.

Specifically, non-compliance can for example result in

the following hazards:

– Danger of persons due to not protected working

areas

– Failure of important functions of the machine

– Failure of specified methods for maintenance and

repair

– Danger of persons due to mechanical and chemical

effects

– Danger of the environment due to leakage of

hydraulic oil

2.2.3 Safety-conscious work practices

The safety instructions laid down in these operating

instructions, the existing accident prevention

regulations as well as any internal work, operating and

safety instructions of the operator must be complied

with.

The labour protection and accident protection

regulations of the responsible employers’ liability

insurance associations are binding.

The safety instructions of the vehicle manufacturer

must be complied with.

II - 2

Safety

Compliance with the relevant legal regulations is

mandatory in traffic on public roads (in the Federal

Republic of Germany, for example, the StVZO (Road

Traffic Type Approval Law and the StVO (Road Traffic

Law)).

2.2.4 Safety and accident prevention

regulations

1. In addition to the instructions in these operating

instructions, you must comply with the generally

applicable safety and accident prevention

regulations!

2. The affixed warning and safety signs provide

important information for safe operation. Heed them

for your own safety!

3. When using public roads, observe the relevant

regulations!

4. Before starting work make yourself familiar with all

devices and operating elements as well as with

their functions. It is too late once you have started

operating the machine!

5. The user should wear tightly fitting clothes. Avoid

loosely fitting clothing.

6. To avoid the danger of fire, keep the machine clean!

7. Before starting and before placing the machine in

operation, check the immediate surroundings!

(Children!) Ensure good visibility conditions!

8. Riding on the machine during working and transport

is not permitted.

9. Couple implements according to regulations and

attach and secure them only to the specified

devices.

10. When attaching and removing implements, position

the supports as required!

11. Special care is required when coupling and

uncoupling the maize header onto or from the

forage harvester!

12. Always attach ballast weights according to

regulations and to the mounting points provided!

13. Observe the permissible axle loads, the permissible

maximum weight and the transport dimensions!

14. Check and attach transport equipment, such as

lighting, warning signs and necessary protective

devices

15. Operating devices (ropes, chains, rods, etc.) of

remotely operated devices must be run so that they

do not trigger unintended movements in all

transport and working positions.

16. Ensure that the maize header is in the prescribed

condition for road travel and lock it according to the

instructions of the manufacturer!

17. Never leave the driver’s cab while the machine is

moving!

18. The speed must always be adapted to the

prevailing conditions! Avoid sudden changes of

direction when travelling uphill, downhill or when

crossing a slope!

19. Attached or suspended implements and ballast

weights affect the driving, steering and braking

response of the machine. For this reason, make

sure that you are able to steer the machine and

brake as required!

20. When cornering, take into account the large

overhang and/or flywheel mass of the device!

21. Take the maize header into operation only after all

protective devices have been attached and are in

their proper positions!

22. It is strictly forbidden to stay in the operating range

of the machine!

23. Do not stay in the turning and swivelling area of the

implement!

24. Hydraulic hinged frames may be operated only if no

persons are in the swivel area!

25. Parts operated by external power (e.g.

hydraulically) constitute crush and shear hazards!

26. Before leaving the forage harvester turn off the

engine and withdraw the ignition key!

27. Nobody may stay between the forage harvester and

the maize header without the vehicle being secured

against rolling off through the holding brake and/or

wheel chocks.

28. Observe all additional information related to safety

in the operating instructions for the forage

harvester.

II - 3

Safety

2.2.5 Attached devices

1. Special care is required when coupling and

uncoupling the maize header onto or from the

forage harvester!

2. The maize header must only be attached to the

forage harvester for which it is intended.

3. Work on the maize header must only be performed

when the engine is stopped and turned off and the

ignition key has been removed. All operating levers

must be in the neutral setting and no hydraulic

lines may be under pressure.

4. Only perform jobs under the maize header when it

is raised if it is securely supported.

5. The maize header must be brought basically into

the transport position on public roads and paths.

Attach protective cloths and front guard to the

maize header and connect the lighting.

2.2.6 PTO operation

1. Only PTO shafts specified by the manufacturer

may be used!

2. The protective tube and protective funnel of the PTO

shaft as well as the PTO shield - also on the implement end - must be attached and in proper condition!

3. Make sure that the required tube covers for PTO

shafts are in place in transport and working position!

4. Before installing or removing PTO shafts, switch off

the PTO shaft, turn the engine off and remove the

ignition key!

5. When using PTO shafts with an overload or free-wheel

couplings that are not covered by the protective equipment on the tractor, the ov erload or free-wheel couplings must be attached to the device!

6. Always make sure that the PTO shafts are mounted

correctly and secured properly!

7. Secure the PTO shaft guard against turning by hooking in the chains!

8. Before switching on the PTO shaft, make sure that

the selected PTO shaft speed of the tractor agrees

with the permissible speed of the device!

9. Before switching on the PTO shaft make sure that

no person is in the hazard area of the device!

10. Never switch on the PTO with the engine turned off!

11. While working with the PTO, nobody is permitted to

stay in the range of the turning PTO or PTO shaft.

12. Always switch off the PTO in the case of excessive

bending and if the PTO is not required!

13. Caution! After switching off the PTO, there is

danger due to the inertia of the flywheel mass! Do

not come near the implement during this time. Start

working on the machine only when it has come to a

complete halt.

14. Cleaning, lubricating or adjusting PTO driven

implements or the PTO shaftonly with PTO

disengaged, engine turned off and ignition key

withdrawn!

15. Place the uncoupled PTO shaft on the holder

provided!

16. After removal of the PTO shaft, fit the protective

sleeve on the PTO stump!

17. Immediately repair any damage before working with

the device.

2.2.7 Hydraulic system

1. The hydraulic system is under pressure!

2. When connecting hydraulic cylinders and motors

pay attention to the specified connection of the

hydraulic hoses!

3. When connecting the hydraulic hoses to the forage

harvester hydraulics, take care that the hydraulic

system is depressurised both on the tractor side

and on the device side!

4. When functions are connected hydraulically between

the forage harvester and the machine, coupling

sleeves and plugs should be identified so that faulty

operation is excluded! On changeover of the

connections reversed function (e.g. raising/lowering)

- Danger of accident!

5. Check hydraulic hose lines periodically and replace

them if they are damaged or worn through age! The

replacement hose lines must meet the technical

requirements of the device manufacturer!

II - 4

Safety

6. Use suitable tools when looking for leaks. Risk of

injury!

7. Fluids (hydraulic oil) exiting under high pressure

can penetrate the skin and cause severe injuries! In

the case of injuries, seek medical assistance

immediately. Danger of infection!

8. Before working on the hydraulic system,

depressurise the system and turn off the engine!

2.2.8 Maintenance

1. Always perform repair, maintenance and cleaning

work as well as troubleshooting only with the drive

switched off and the engine stopped!

- Remove the ignition key!

2. Periodically check nuts and bolts for firm seating

and tighten them if required!

3. When performing maintenance work with the

implement raised, always secure it with suitable

supporting elements!

4. When replacing work tools with cutting edges, use

suitable tools and protective gloves!

5. Dispose of oils, greases and filters according to

the regulations!

6. Before working on the electrical system, always

disconnect the power supply!

7. If protective equipment is subject to wear, check it

periodically and replace it in due time!

8. When performing electric welding work on the forage

harvester and mounted implements, disconnect

cables at the generator and battery!

9. Spare parts must at least correspond to the

technical requirements defined by the device

manufacturer!

This is guaranteed by original KRONE spare

parts!

2.2.9 Unauthorised conversion/

modification and Manufacture of

spare parts

Conversions or modifications of the machine are

permitted only with prior consultation with the

manufacturer. Authentic spare parts and accessories

authorised by the manufacturer increase safety. The

use of other parts may void the liability for any

consequences.

2.2.10 Impermissible modes of

operation

The operating safety of the delivered machine is

guaranteed only when it is used as intended in

compliance with the General chapter of the operating

instructions. The limit values stated in the data sheets

must not be exceeded under any circumstances.

II - 5

Safety

2.3 Safety instructions on the

machine

The KRONE maize header is equipped with all

necessary safety devices (protective devices). Not all

dangerous places on this machine can be completely

secured in reference to maintaining the functionality of

the machine.

Corresponding hazard information referring to residual

dangers is located on the machine.

We have implemented the hazard warnings in the form

of warning pictograms.

In the following, you will find important information on

the locations of these warning pictogram and an

associated description/supplementation!

Familiarise yourself with the

statement of the warning pictograms.

The adjacent text and the selected

location on the machine provide

information on the special danger

spots on the machine.

II - 6

Safety

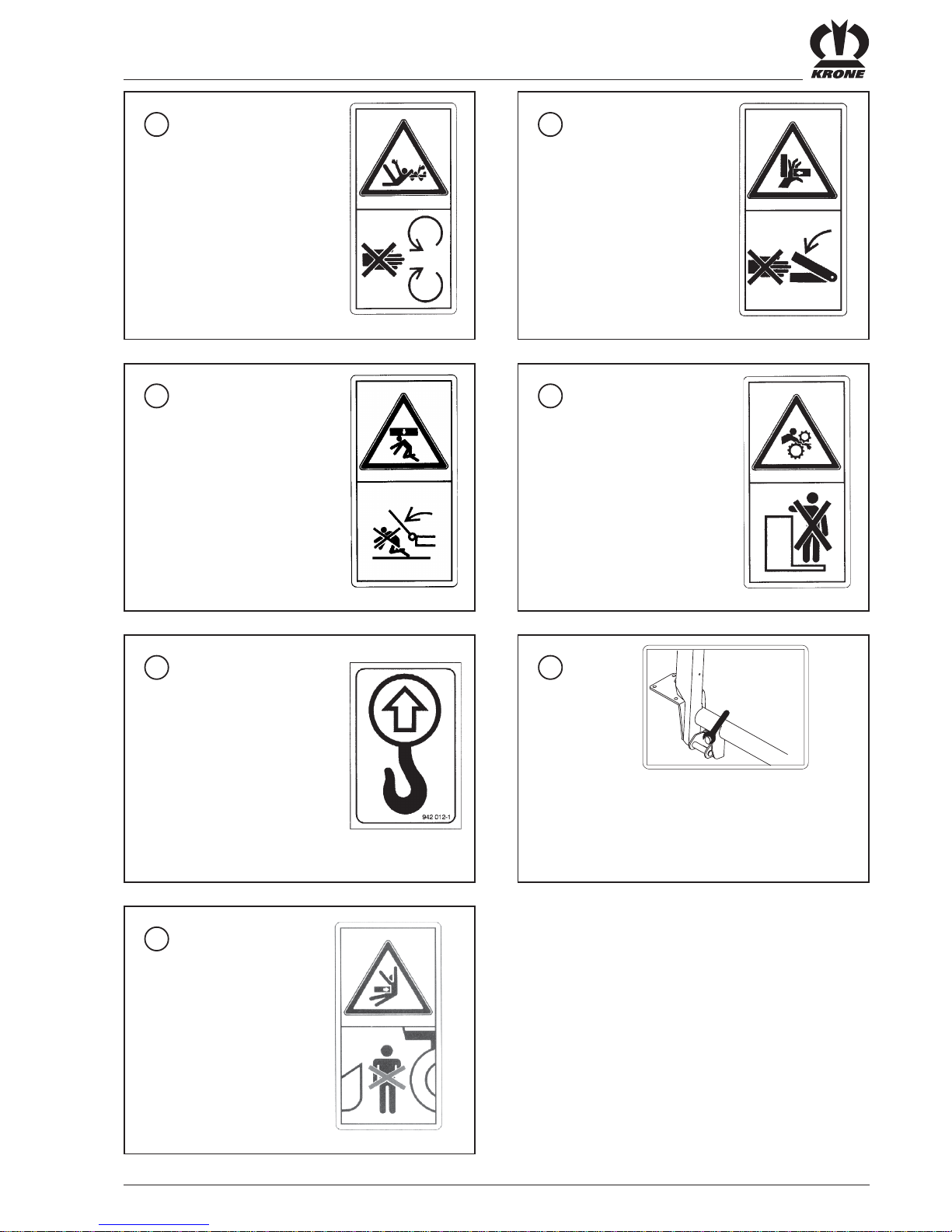

2.3.1 Location of the warning pictograms on the machine.

1

Before commissioning the

machine, read the

operating instructions and

safety instructions and

heed them.

Order no. 939 471-1 (1x)

2

Do not touch any moving

parts of the machine.

Wait until they have come

to a complete stop.

Order No. 939 410-2 (2x)

Spænd fastgørelsesskruerne

EC200021

2

4

4

6

6

6

5

8

5

3

2

3

1

9

9

7

7

II - 7

Safety

3

Danger due to revolving

worm auger.

Order No. 939 520-1 (2x)

4

Never reach into the area

where there is danger of

crushing as long as parts

may be in motion there.

Order No. 942 196-1 (2x)

6

Do not climb onto the

machine if the PTO shaft is

connected and the engine

runs.

Order No. 939 408-2 (3x)

5

Do not stay in the swivel

area of the outrigger arms!

Keep your distance!

Order No. 939 469-1 (2x)

7

Stop points

Order No. 942 012-1 (2x)

8

Tighten the fastening bolts

Order No. 27 000 182 0 (1x)

210 Nm

27 000 182 0

9

Do not enter the

hazardous area between

the front attachment

unit and the machine.

Order No. 942 312-0 (2x)

II - 8

Safety

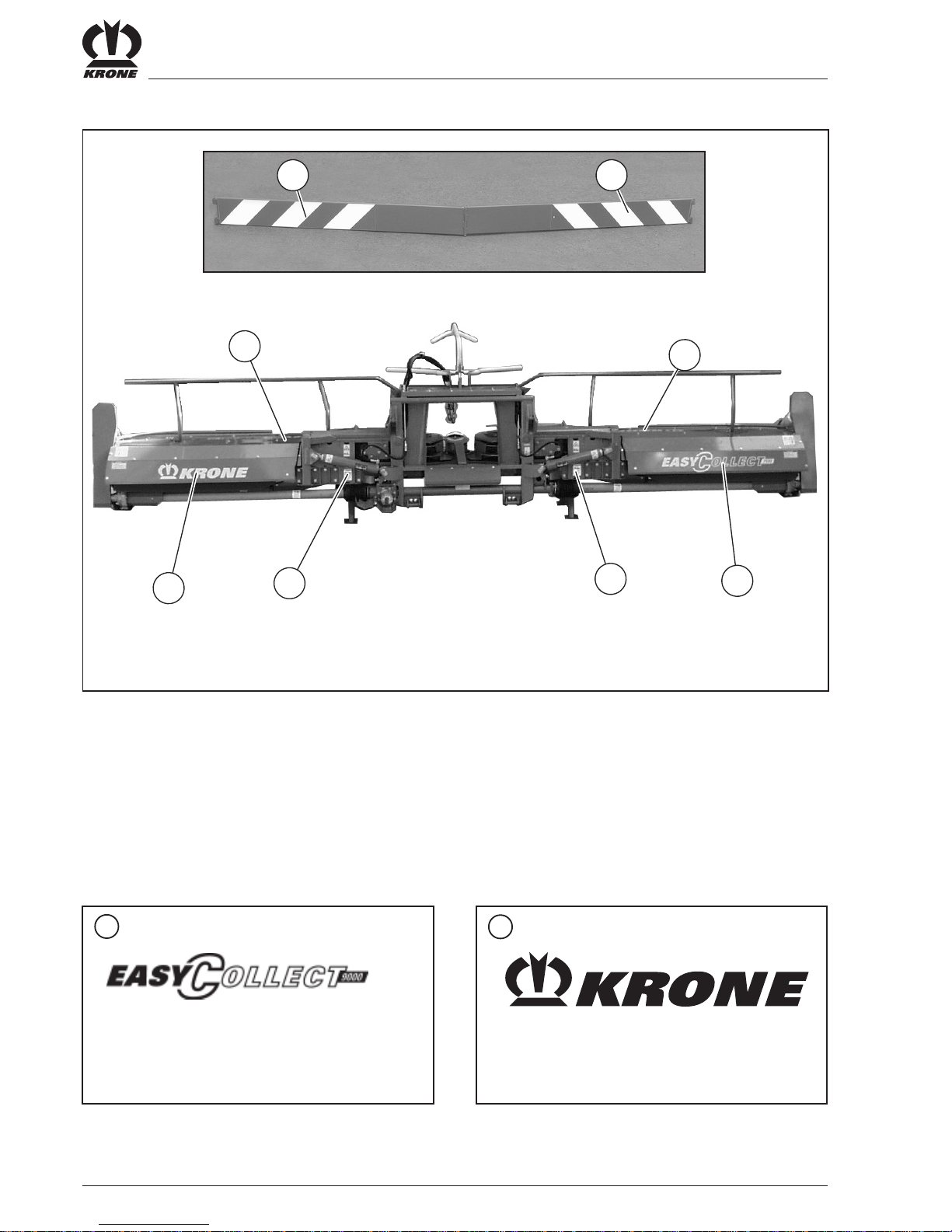

EC200022

1

2

4

5

5

3

6 6

2.3.2 Location of the general warning signs on the machine

1

EASYCOLLECT 6000 Order No. 942 437-0

EASYCOLLECT 7500 Order No. 942 414-0

EASYCOLLECT 9000 Order No. 942 415-0

2

EASYCOLLECT 6000 Order No. 942 301-0

EASYCOLLECT 7500/9000 Order No. 942 341-1

II - 9

Safety

3

Order No. 942 301-0 (7500/6000)

Order No. 942 320-0 (9000) (2x)

5

Order No. 942 440-0 (2x)

4

EASYCOLLECT 6000 Order No. 942 437-0

EASYCOLLECT 7500 Order No. 942 438-0

EASYCOLLECT 9000 Order No. 942 439-0 (2x)

6

Fully reflecting adhesive

strips Order No. 924 625-0

Order No. 924 626-0

II - 10

Safety

III - 1

Start-up

3 Start-up

3.1 Special safety instructions

The maize header must only be

attached to the forage harvester for

which it is intended.

No one is permitted in the hazardous

area of the machine during

operation.

The protective equipment on the

maize header protects against access

to hazardous areas. Because of this,

you must always move them to their

protective position before starting

week.

Do not open or remove the protective

equipment when the engine is

running

No one is permitted in the rotation

area when the maize header is

swinging away from the transport into

the working position or vice versa.

Special caution is required when

mounting and detaching the maize

header on and from the forage

harvester. The accident prevention

regulations must be complied with

absolutely.

On public roads and paths, the

EASYCOLLECT 6000 and

EASYCOLLECT 7500 maize header

must always be in the transport

position.

In this case the transport height must

be set so that the max. permissible

height of 4 m is not exceeded.

The EASYCOLLECT 9000 maize

header must be placed on a special

transport carriage for road transport.

3.2 Stop points

Use only transportation equipment of

suitable dimensions (crane, ropes)!

• For transporting from one place to another onsite,

(moving) brace the lifting tool against the points

illustrated here.

3.3 Storage

• Set the maize header (1) down with the parking

supports (2) extended on a solid and level surface

and park it in a dry and clean place.

Danger of accident and damage!

Place hydraulic hoses and electrical

connection cable (3) on the maize

header (1).

EC200011

1

3

2

EC200070

III - 2

Start-up

3.4 Attaching

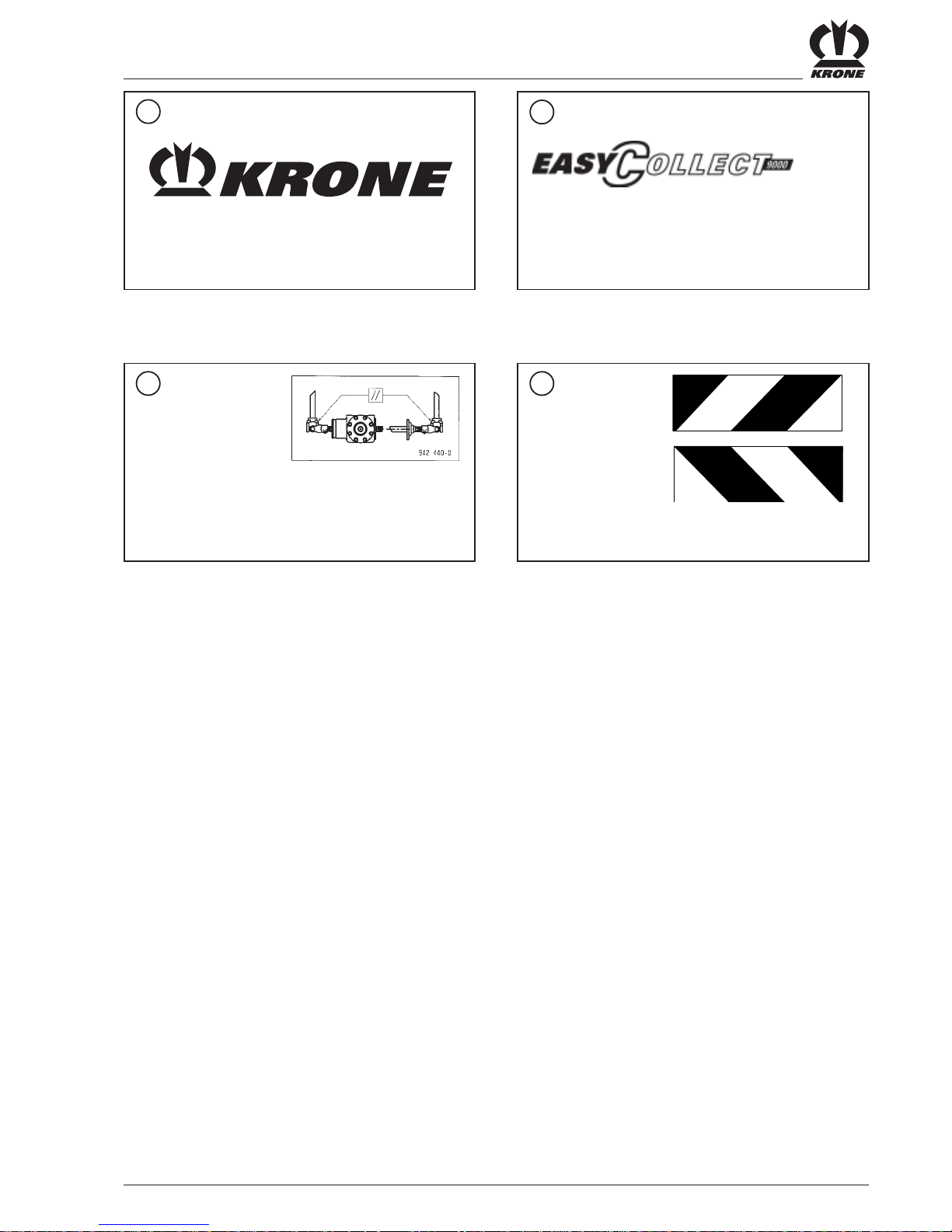

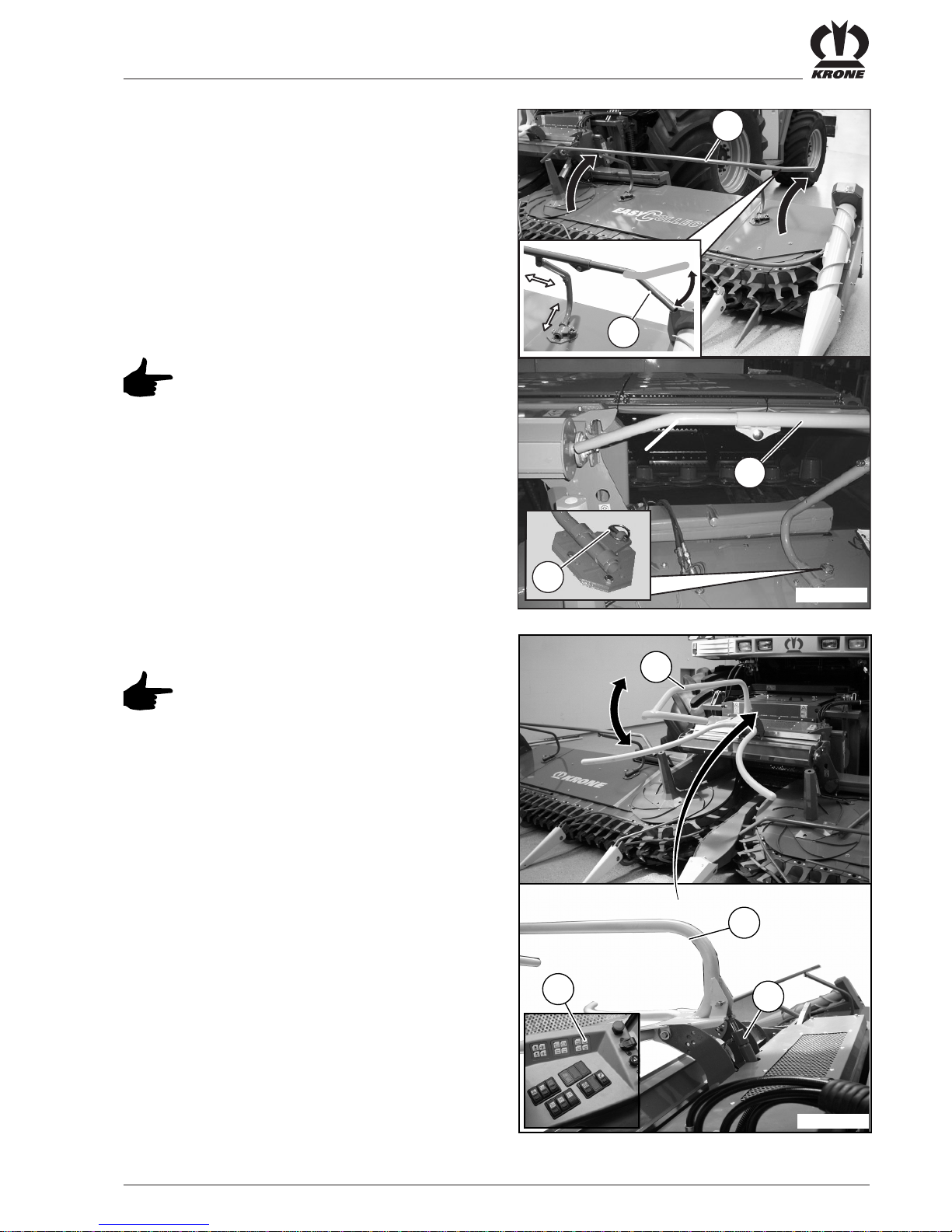

3.4.1 Adjusting the adapter frame

Only when the forage harvester is

initially attached or replaced.

• Measure the axle base „a“ between holding claw (1)

and locking hook (2) on the pendulum frame of the

forage harvester.

1

2

3

a

EC200090

4

1

2

EC200080

a

• Check the axle base „a“ between the holding bolt

(1, 3) of the adapter frame on the maize header and

if necessary adapt it to the size of the pendulum

frame.

Make the adjustment equally on the

right and left of the adapter frame.

• Loosen the screw connections (2) and shift the

pendulum frame holders (3) to the correct distance.

• Tighten the screw connections (2).

• Before driving the forage harvester into position,

fold down the protective cover (4).

III - 3

Start-up

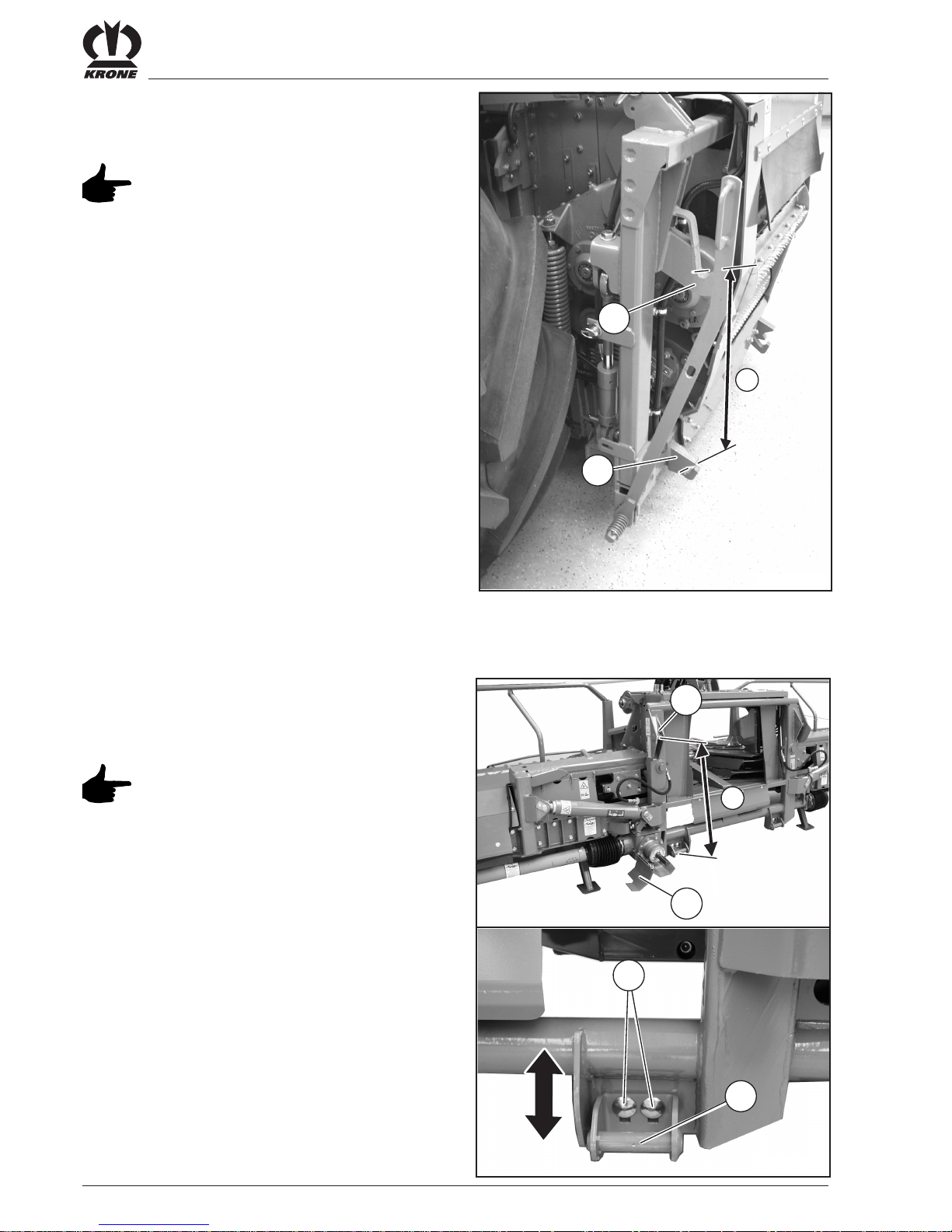

3.4.2 Pendulum frame

• Lower the pendulum frame (1) of the forage harvester

all the way.

• Align the pendulum frame (1) of the forage harvester

horizontally.

• Locking hooks (2) must be opened. If necessary,

open them with the locking lever (3).

• Disconnect the spring-loaded plug (5), pull the

locking lever (3) from the locking pin (4) and swing it

forward.

• The pendulum frame (1) must be unlocked and the

locking pin (6) must be in position II (unlocked).

3.4.3 Coupling

• Drive the forage harvester up to the maize header so

that the pendulum frame (1) stands just in front of

the adapter frame (2) and the holding bolts (4) are

located against the stop surfaces of the holding

claws (3).

• Raise the pendulum frame (1) with lifting hydraulics

until the locking hooks (5) lie in the pendulum frame

holder (6) on the adapter frame.

• Stop the machine.

1

2

3

I

EC200081

6

II

4

5

6

2

1

4

5

6

3

EC100120

III - 4

Start-up

The system should be without

pressure on both sides when

connecting the hydraulic hoses.

Make sure the plugs and couplings

are clean; clean them if necessary.

• Connect the hydraulic hoses (1) to the plug-in

connections provided for this purpose on the forage

harvester.

• Connect the lighting cable (2) to the socket.

• Connect the connection cable (3) of the sensors.

• Swing the locking lever (2) to the rear and engage it

on the locking pin (3) with spring plug (4).

Check that the pendulum frame hooks

correctly into the holding bolts (1) and

the locking hooks on both sides.

• Push the joint fork (1) onto the drive journal (2) of the

main angular gear until the closure engages.

For additional settings to operate the

maize header, see the operating

instruction „Self-propelled forage

harvester BiG X“.

• Close the cover guard (3).

3

2

EC200170

1

1

2

EC200160

3

2

3

4

EC200150

1

III - 5

Start-up

3.5 Transport position

Before folding the maize header into

its transporting position, turn off the

drive.

The maize header may be folded in

only with complete standstill of the

drive.

3.5.1 Folding in the tubular bar on the

right/left

Transport must only be performed

with the right/left tubular bars folded

inward.

• Pull off the linch pins (2) on both holders and fold

the tubular arm (1) over to the inside.

1

EC200180

1

2

2

• Push the middle tubular bar (3) before folding the

side parts in until it no longer protrudes beyond the

central part (4).

EC200570

4

3

III - 6

Start-up

3.5.2 Swinging the maize header up

• Swing the maize header (1) up completely with the

forage harvester hydraulics until the latch (2) snaps

into place.

• Check that the outriggers are locked on both sides

in the latches (2).

1

2

EC200200

III - 7

Start-up

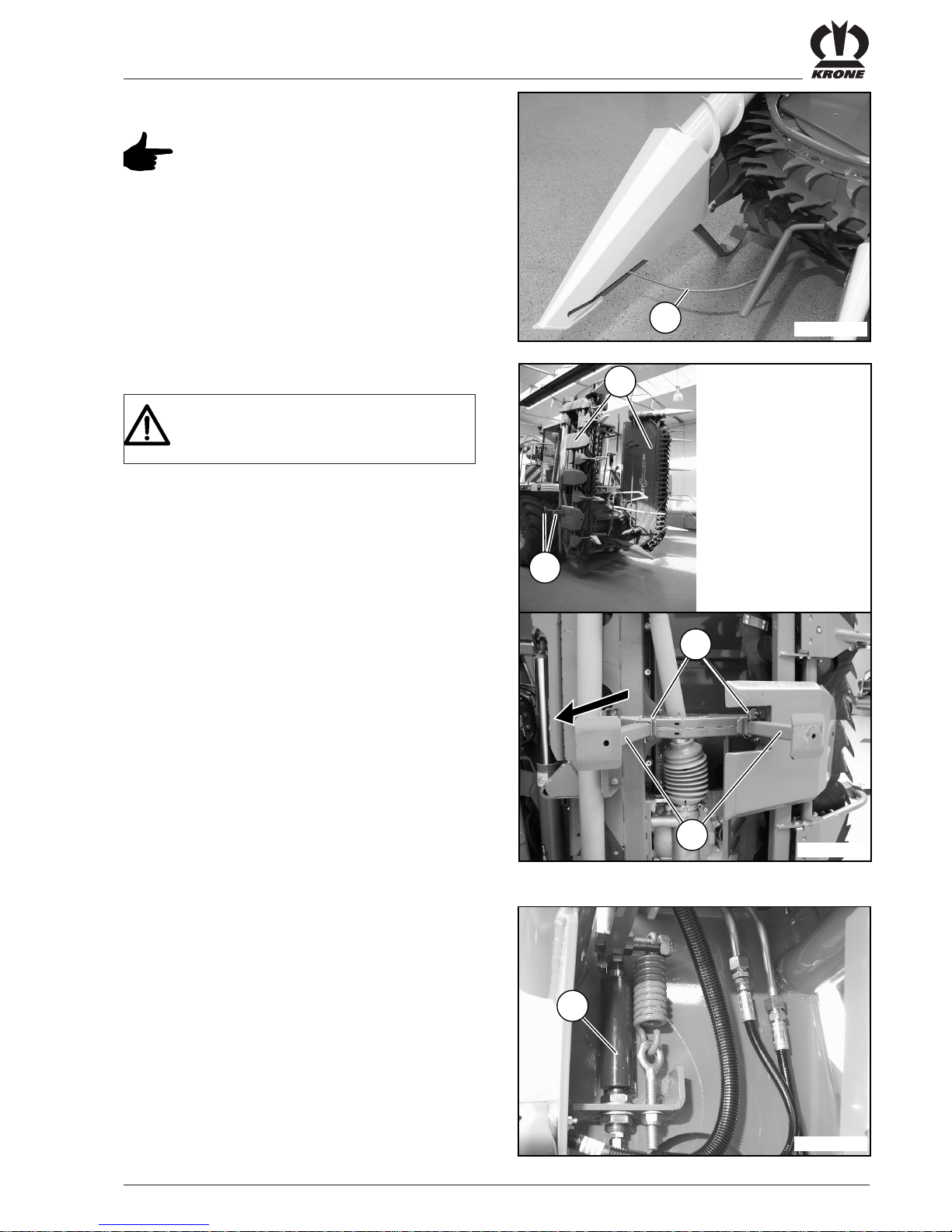

3.5.4 Installing guard on the right/left

• Push the guard (1) on the right and left onto the tips.

• Fasten protective cloths (1) with tension springs (2)

to the frame.

3.5.5 Connecting indicators and position

lights on the right/left

• Connect connection cables (2) of the indicators and

position lights (1) in the relevant socket (3) on both

sides of the maize header.

• Check the lighting for function.

3.5.3 Parking supports in transport

position on the right/left

• Stop the machine.

• Remove the spring cotter pins (2) and push in

parking supports (1) .

• Secure position with spring cotter pin (2).

1

1

1

2

EC200230

1

2

3

EC200250

1

2

EC200220

III - 8

Start-up

3.5.6 Installing the front guard

• Fit the front guard (1) on the right and left onto the

holder on the support and centrally on the central

tip, pay attention to the prescribed position of the

warning stripes (2) (the hatching must point

downwards and outwards).

• Secure front guard (1) on the right and lift with spring

cotter pins (3) and hook tension springs (4) on the

central tip.

3.5.7 Road travel

When driving on roads, the general

requirements or special conditions of

the Road Traffic Type Approval Law

(StVZO) and the Road Traffic Law

(StVO) must be observed.

In the case of self-propelled working

machines the harvesting attachments

must be included in the operating

permission of the working machine (if

necessary extend the operating

permission). The conditions of the

operating permission must be

complied with.

The driving speed of the forage

harvester has to be adapted to the

local conditions.

3.6 Working position

3.6.1 Removing the protective cover

• Stop the machine.

• Remove the front guard (1).

• Pull off the lighting cables and remove the guards (2)

on the right and left.

3.6.2 Adjusting skids

The position of the skids (1)

determines the min. stubble length.

• Loosed the screw connections (2) and fasten the

skid (1) on the wanted position on the bearing plate

(3).

Adjust all skids equally.

1

2

3

3

4

EC200260

1

2

2

EC200270

1

2

3

EC200280

III - 9

Start-up

3.6.3 Folding up the tubular bar on the

right/left

• Swing the maize header into the working position

with the forage harvester hydraulics.

• Stop the machine.

• Pull off the linch pins (2) on both holders and fold

the tubular arm (1) up to the outside.

• Secure the working position of the tubular bar (1)

with linch pins (2).

3.6.4 Adjusting the plant dividers

Adjust the plant divider (1) to the

height of the crop in question so that

the plants are guided by the tubular

bars in the upper plant area when

being drawn into the cutting unit.

• The height of the plant divider (1) can be adjusted

with hydraulic cylinders (2) by pressing the

activation keys (3).

1

2

1

EC200290

3

The length of the tubular bar (3)

must be adjusted to match the crop

to be harvested

1

2

1

EC200181

3

III - 10

Start-up

Work on the maize header must only

be performed when the engine is

stopped and turned off and the

ignition key has been removed. All

operating levers must be in the

neutral setting and no hydraulic lines

may be under pressure.

Check the maize header each time

before it is used and after it has been

driven to make certain there are no

impediments.

Worn, used or deformed blades must

be replaced immediately.

The same applies for all fastening

parts.

Do not turn on the drive until the

maize header is in the working

position.

3.7 Using the machine for work

3.7.1 Special safety instructions

Keep persons out of the hazardous

area. If persons do approach the

hazardous area, please turn off the

machine immediately.

Never allow the machine to run

unsupervised.

Check the safety devices each time

before the machine is used. Replace

damaged safety devices immediately.

3.7.2 Using the maize header

• Move the maize header to the working position and

lower it down to the ground or to the wanted cutting

height..

• Turn on the maize header drive and adjust it to

working speed.

• Drive into the crop material with the forage harvester.

• The driving and collector speed should be based on

the conditions of usage at hand (ground conditions,

the height and nature of the crop, etc.).

The collector speed must not be

higher than the speed of drawing the

crop into the cutting unit.

It must be set so high that a clean cut

of the crop is guaranteed.

The travelling speed is based

primarily on the throughput of the

forage harvester.

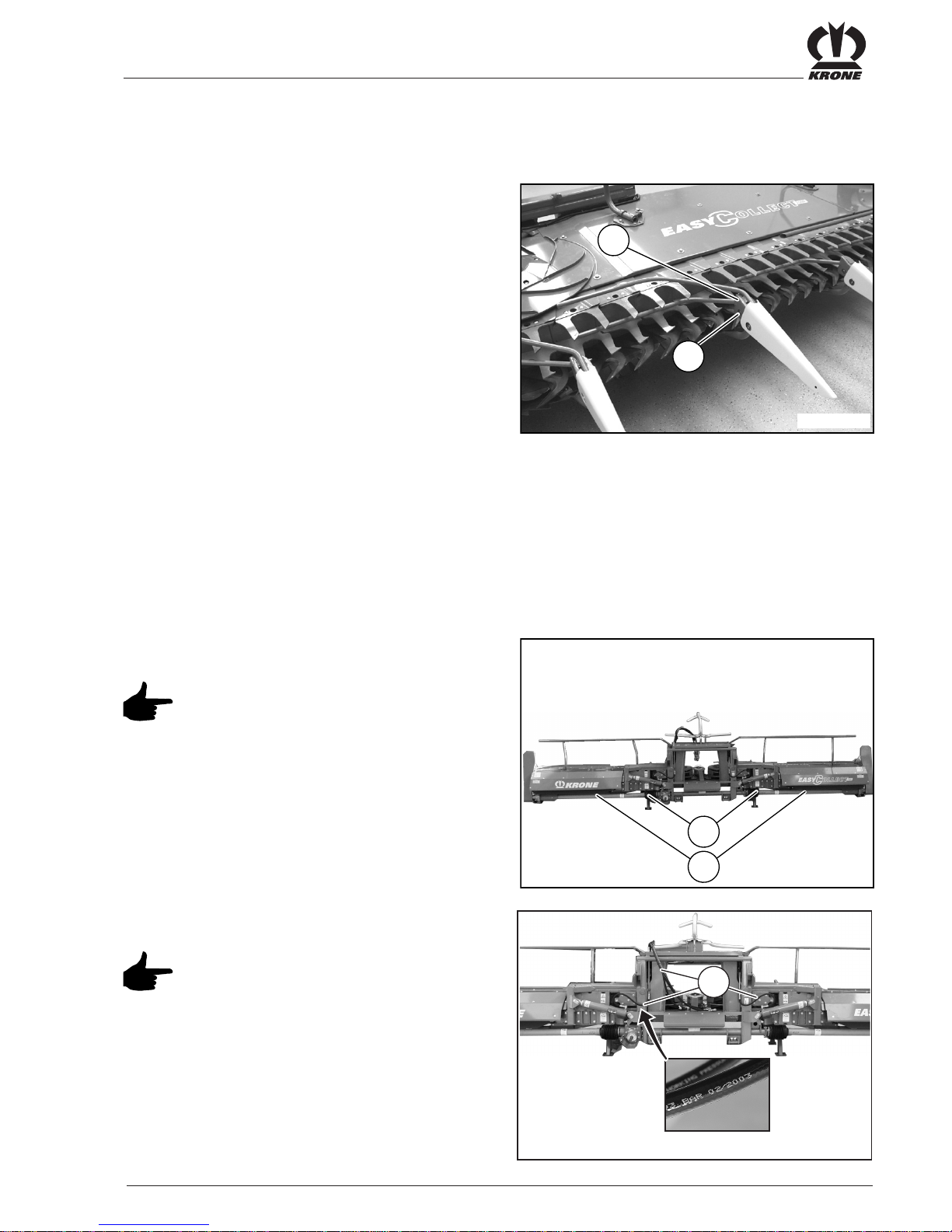

3.7.3 Lifting gear spacing control

(optional)

The lifting gear spacing control is

available only if spacing sensors (1)

have been fitted.

When the lifting gear spacing control

is active, the control of the forage

harvester sets the height constant

relative to the ground (ground

copying).

1

EC100620

III - 11

Start-up

3.8 Detaching

Set the maize header down only on

solid and level ground and only with

the parking supports extended.

• Remove the spring cotter pins (3) and extend the

parking supports (2) .

• Secure position with spring cotter pins (3).

• Swing the maize header (1) with the forage harvester

hydraulics into the working position and let it down

on the ground.

• Move in the locking cylinder (1) with the forage

harvester hydraulics (Activation keys for folding in

the maize header).

• Stop the machine.

3.7.4 Autopilot (optional)

The autopilot function is available

only if sensors (1) and autopilot

equipment have been fitted.

The automatic pilot guides the forage

harvester along the maize row with

the sensors on the maize header.

1

EC100630

2

3

1

EC200201

2

1

EC100310

III - 12

Start-up

The system should be without

pressure on both sides when

disconnecting the hydraulic hoses (1).

• Disconnect the hydraulic lines (1) at the hydraulic

couplings and close off with dust caps.

• Pull off the lighting cable (2).

• Loosen the connection cable (3) of the sensors.

Danger of accident and damage!

Place hydraulic hoses and electrical

connection cable on the maize header.

• Open the protective cover (3).

.

• Pull the joint fork (1) off of the drive journal (2) of the

main angular gear.

• Open the locking hook (1):

Remove the spring cotter pin (3), pull the locking

lever (2) from the locking pin (4) and swing it

forward.

• Lower the pendulum frame of the forage harvester

until the receiving claws are below the holding bolts.

• Move the forage harvester back.

3

2

EC200170

1

1

2

EC200160

3

2

3

4

EC200151

1

IV - 1

Maintenance

4 Maintenance

4.1 Special safety instructions

Repair , maintenance and cleaning

tasks must only be performed while the

engine is stopped!

Remove the ignition key and secure the

forage harvester from being placed in

operation or rolling away

unintentionally.

For repair , maintenance and cleaning

jobs on a raised maize header always

secure it with suitable supporting

pieces and close the shut-off valve!

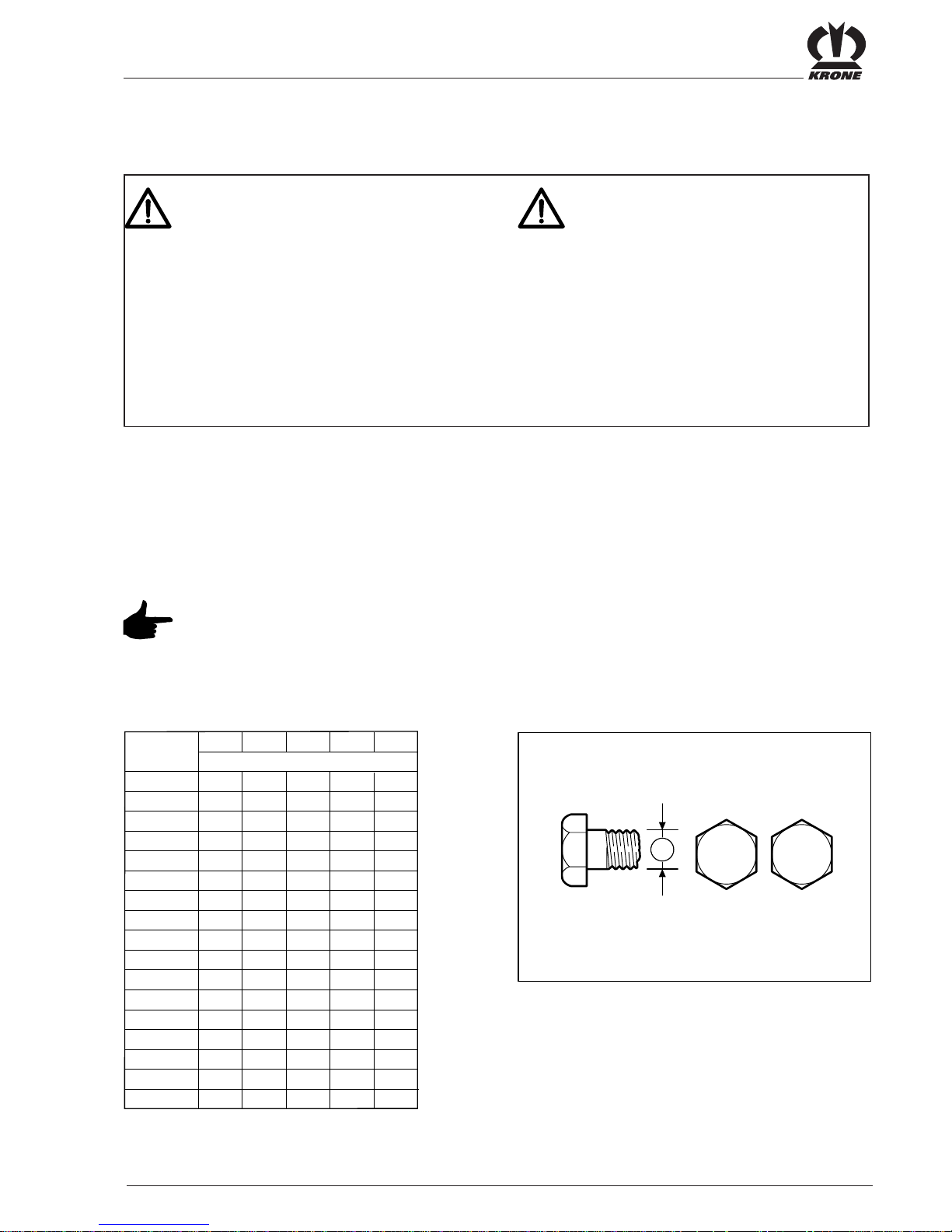

4.2 General aspects

• Test nuts and screws regularly (about every 50

hours) for firm seat and tighten according to the

tightening torque tables if necessary! Deviating

tightening torques are indicated separately in the

text.

Self-locking nuts must always be

replaced.

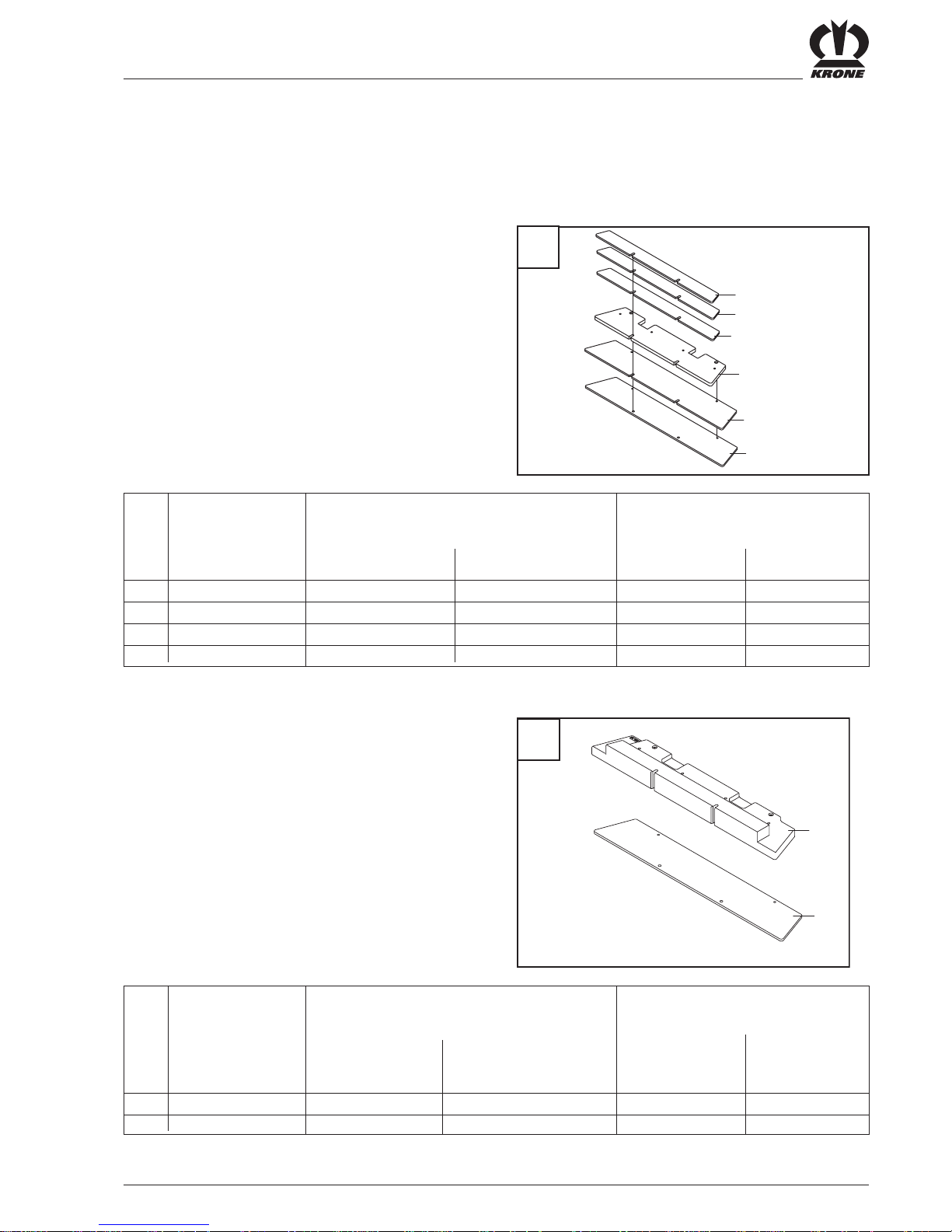

Tightening torque M

A

Only perform tasks on the hydraulic

system when all excess pressure has

been released.

Liquid escaping under high pressure

can penetrate through the skin and

cause severe injuries. In the event of

injuries, find a physician immediately .

There is danger of infection.

After all rep air, maintenance and

cleaning tasks are complete, all

protective coverings and safety mechanisms must be put in place again.

A = thread size

(stability class can be seen on the head of the screw).

A

5.6

29

42

2,2

4,5

7,6

18

37

64

100

160

4,4

8,7

15

36

72

125

200

215

310

1050

330

350

M 4

M 5

M 6

M 8

M 10

M 12

M 14

M 14x1,5

M 16

M 16x1,5

M 20

M 24

6.8

M (Nm)

8.8 10.9

A

O

/

12.9

M 24x1,5

M 24x2

M 27

M 27x2

M 30

5,1

10

18

43

84

145

235

255

365

2450

390

3,0

5,9

10

25

49

85

135

145

210

225

730

710

1220

1350

1800

1950

2100

1150

1550

1650

1450

800

1100

1150

610

425

8

.

8

1

0

.

9

A

BP380-7-073

IV - 2

Maintenance

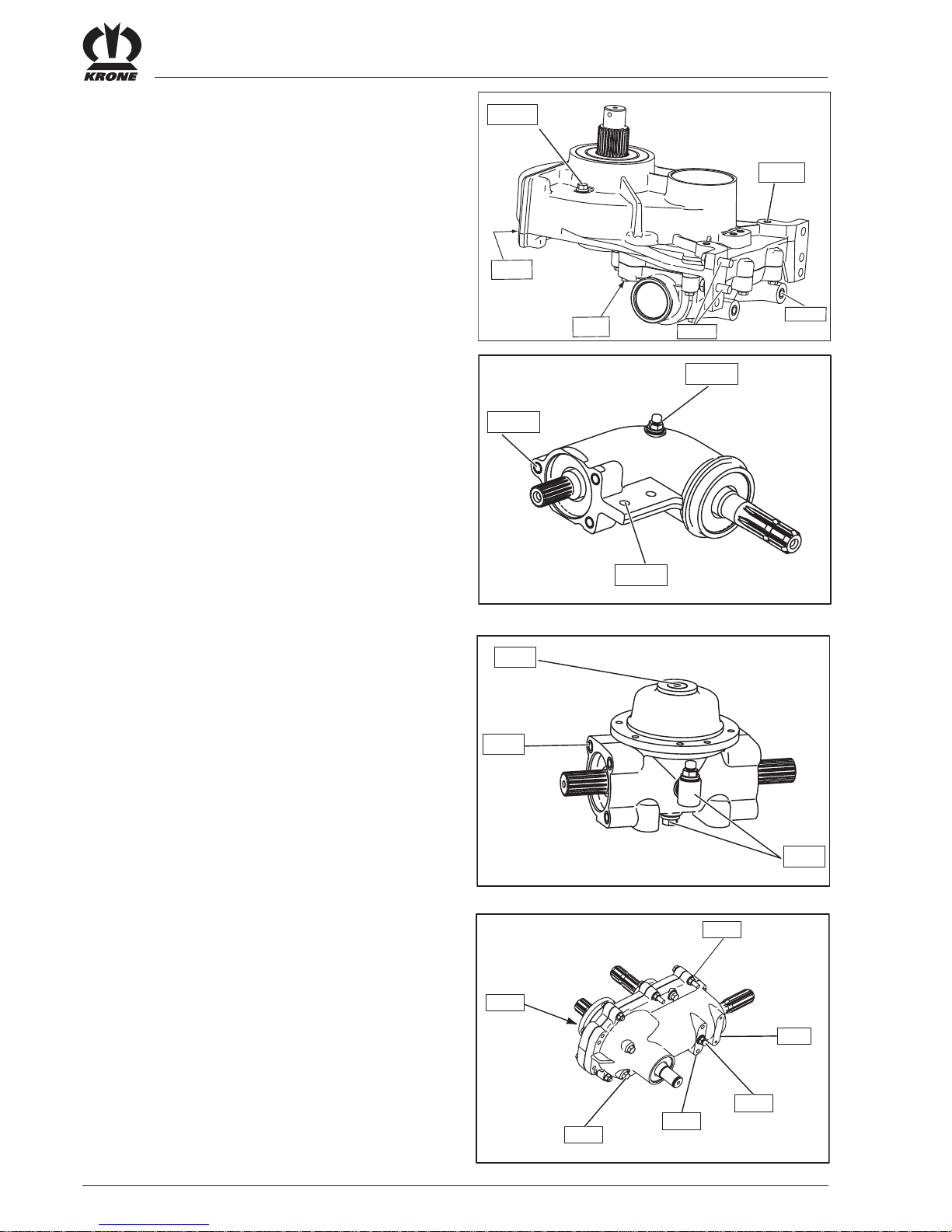

4.2.1 Tightening torques on the

aluminium gears

EC100660

72 Nm

9 Nm

17 Nm

210 Nm

210 Nm

49 Nm

EC100662

49 Nm

85 Nm

72 Nm

72 Nm

72 Nm

80 Nm

EC100661

17 Nm

72 Nm

30 Nm

72 Nm

9 Nm

49 Nm

EC100663

IV - 3

Maintenance

4.3 Gearboxes

• If no other instructions are given, change the oil

once a year on all gears.

• Check the oil level before the beginning of the season.

• Check all gears daily for any leaks and check the

oil level if necessary.

4.3.1 Lubricant quantities and

designations for gearboxes

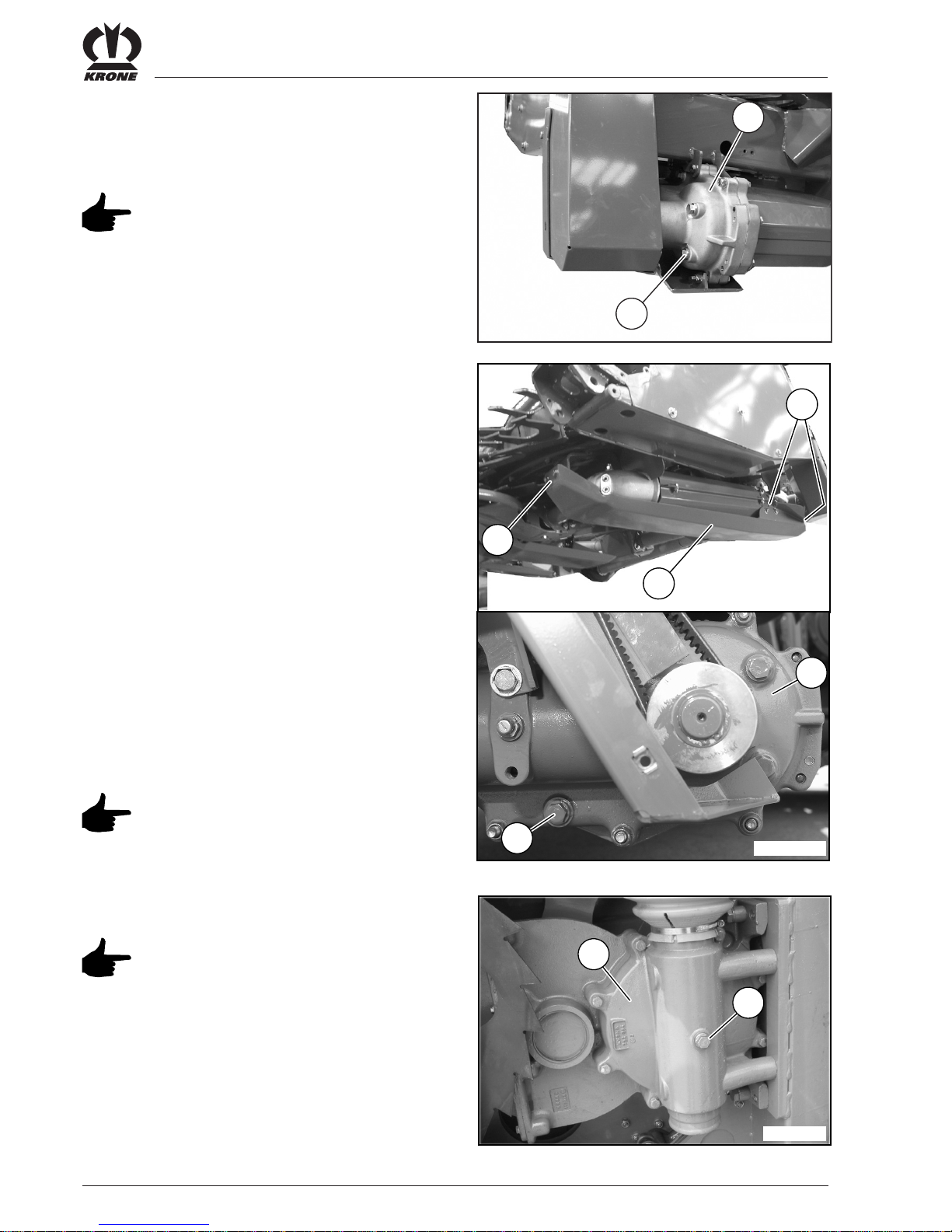

4.3.2 Checking the oil level and changing

the oil in the main angular gearbox

Check the oil level and change the oil

while the maize header is in a

horizontal position!

Checking the oil level

• Unscrew the oil level monitoring screw (2) on the

main angular gearbox (1).

• The oil level must reach up to the monitoring drill

hole. If necessary, add more oil through the

monitoring drill hole.

• Screw in the oil level monitoring screw (2) again.

Changing the oil

• Unscrew the oil drain screw (3) on the main angular

gearbox (1). Capture the oil in a suitable container.

• Screw on the oil drain screw (3) again.

• Unscrew the oil level monitoring screw (2) on the

main angular gearbox (1).

• Add oil (for filling quantity and type of oil, see

Chapter 4.3.1)

• Screw in the oil level monitoring screw (2) again.

Dispose of old oil properly.

1

2

1

3

EC200320

Filling quantities (litres) Type of oil Bio-degradable lubricants

Main angular gearbox 1,9

Transfer gearbox 0,35

Collector gearbox 4,2

Angular gearbox 0,2 on request

Dresser gearbox 0,14

SAE 90 GL 4 or

Esso-Spartan EP 150

Shell Omala Oil 150

Fuchs - EP 85 W90

Castrol EPX 90

IV - 4

Maintenance

4.3.3 Checking the oil level and changing

the oil in the transfer gearbox (right/

left)

Perform oil level checks and oil change

while the maize header is in its working

position!

Checking the oil level

• Unscrew the oil level control screw (2) on the

transfer gearbox (1).

• The oil level must reach up to the control hole. If

necessary, add more oil through the control hole .

• Screw in the oil level control screw (2) again.

Changing the oil

• Remove the gear skid (4) by loosening the screws

(5).

• Unscrew the oil drain screw (3) on the transfer

gearbox (1). Collect the oil in a suitable container .

• Screw on the oil drain screw (3) again.

• Unscrew the oil level control scre w (2) on the

transfer gearbo x (1).

• Add oil (for filling quantity and type of oil, see

Chapter 4.3.1)

• Screw in the oil level control screw (2) again.

• Mount the gear skid (4).

Dispose of old oil properly.

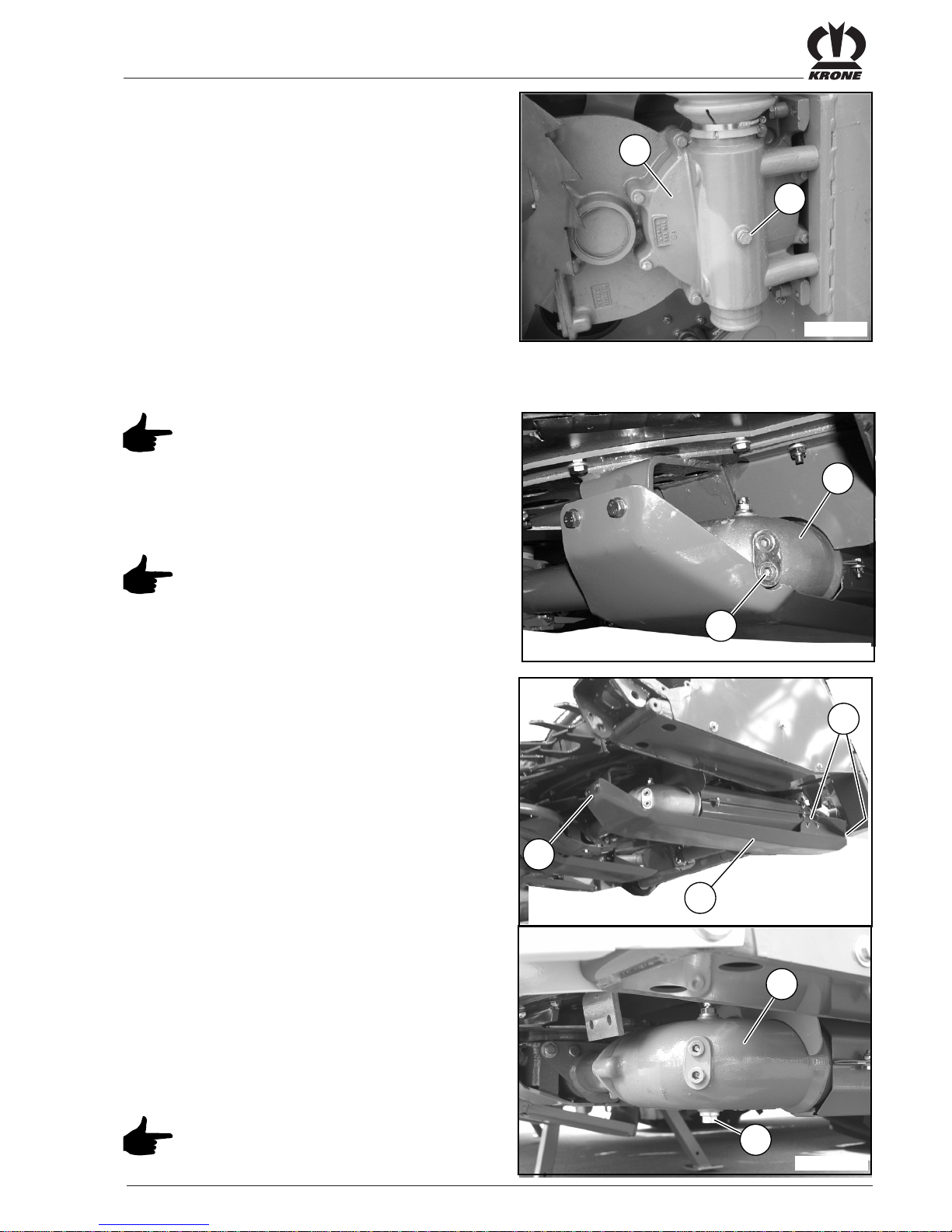

4.3.4 Checking the oil level and changing

the oil in the collector gearbox

(right/left)

Check the oil level in the horizontal

position of the maize header in

transport position!

Checking the oil level

• Unscrew the oil level control scre w (2) on the collector gearbox (1).

• The oil level must reach up to the control hole. If

necessary, add more oil through the control hole .

• Screw in the oil level control scre w (2) again.

1

2

EC07600

5

5

3

EC200340

4

1

2

1

EC200345

IV - 5

Maintenance

Changing the oil

• Swing the maize header into its working position.

• Unscrew the oil level control screw (2) on the

collector gearbox (1) . Collect the oil in a suitable

container.

• Screw in the oil level control screw (2) again.

• Swing the maize header into its transport position.

• Unscrew the oil level control screw (2) on the

collector gearbox (1).

• Add oil (for filling quantity and type of oil, see

Chapter 4.3.1)

• Screw in the oil level control screw (2) again.

Dispose of old oil properly .

4.3.5 Checking the oil level and changing

the oil in the angular gearbox (right/

left)

Perform oil level checks and oil

changes while the maize header is

horizontal in it s working position!

Checking the oil level

• Unscrew the oil level control screw (2) on the

angular gearbox (1).

• The oil level must reach up to the control hole. If

necessary, add more oil through the control hole .

• Screw in the oil level control screw (2) again.

Changing the oil

• Getriebekufe (4) durch Lösen der Schraubverbindungen (5) demontieren.

• Unscrew the oil drain screw (3) on the angular

gearbox (1). Collect the oil in a suitable container .

• Screw on the oil drain screw (3) again.

• Unscrew the oil level control screw (2) on the

angular gearbox (1)

• Add oil (for filling quantity and type of oil, see

Chapter 4.3.1)

• Screw in the oil level control screw (2) again.

• Mount the gear skid (4).

Dispose of old oil properly.

1

2

EC07600

1

3

5

5

EC200360

4

1

2

EC200365

IV - 6

Maintenance

4.3.6 Checking the oil level and changing

the oil in the dresser gearbox (right/

left)

Check the oil level in the horizontal

position of the maize header in

transport position!

Checking the oil level

• Unscrew the oil level control scre w (2) on the

dresser gearbox (1).

• The oil level must reach up to the control hole. If

necessary, add more oil through the control hole .

• Screw in the oil level control scre w (2) again.

Changing the oil

• Swing the maize header into its working position.

• Unscrew the oil level control scre w (2) on the

dresser gearbox (1). Collect the oil in a suitable

container.

• Screw in the oil level control screw (2) again.

• Swing the maize header into its transport position.

• Unscrew the oil level control scre w (2) on the

dresser gearbox (1).

• Add oil (for filling quantity and type of oil, see

Chapter 4.3.1)

• Screw in the oil level control scre w (2) again.

Dispose of old oil properly .

1

2

EC100370

IV - 7

Maintenance

4. 4 Laid maize worm drive belt

(right / left)

4.4.1 Checking the drive belt tension

Check the drive belt tension after the

first 10 operating hours, then every 60

operating hours.

• Unscrew the hexagon head screws (2) and remove

the protective plate (1).

• Check the drive belt (1) for cracks or other damage,

if necessary renew the drive belt.

Always change the drive belts in p airs.

• Check the drive belt (3) tension in the middle by

pressing in (pressing force about 50 N). If the depth

of pressing in is a = approx 20 mm, the tension of

the drive belt is correct, if necessary correct it.

4.4.2 Correcting the drive belt tension

• Loosen the mounting screws (1) a little.

• Loosen the counter nut (2) and correct the

pretension by turning the nut (3).

• Check the tension of the drive belt, if necessary

repeat the process.

• Tighten the counter nut (2) and mounting screws

(1).

• Fit the guard.

3

EC100390

a

1

1

3

2

EC100400

1

2

2

EC200380

IV - 8

Maintenance

4. 5 Collector pre-tension (right /

left)

4.5.1 Checking the collector pre-tension

Check the collector pre-tension after

the first 10 operating hours, then every

60 operating hours.

• The compression spring (1) is correctly pre-

tensioned if the dimension is “a = 325 - 330” mm. If

necessary correct the collector pre-tension.

4.5.2 Correcting the collector pre-tension

• Loosen the counter nut (2) and correct the

pretension of the compression spring (1) by turning

the hexagonal nut (3).

• Check the dimension “a” again, if necessary repeat

the process.

• Tighten the counter nut (2).

a

3

EC100410

1

2

3

EC100411

IV - 9

Maintenance

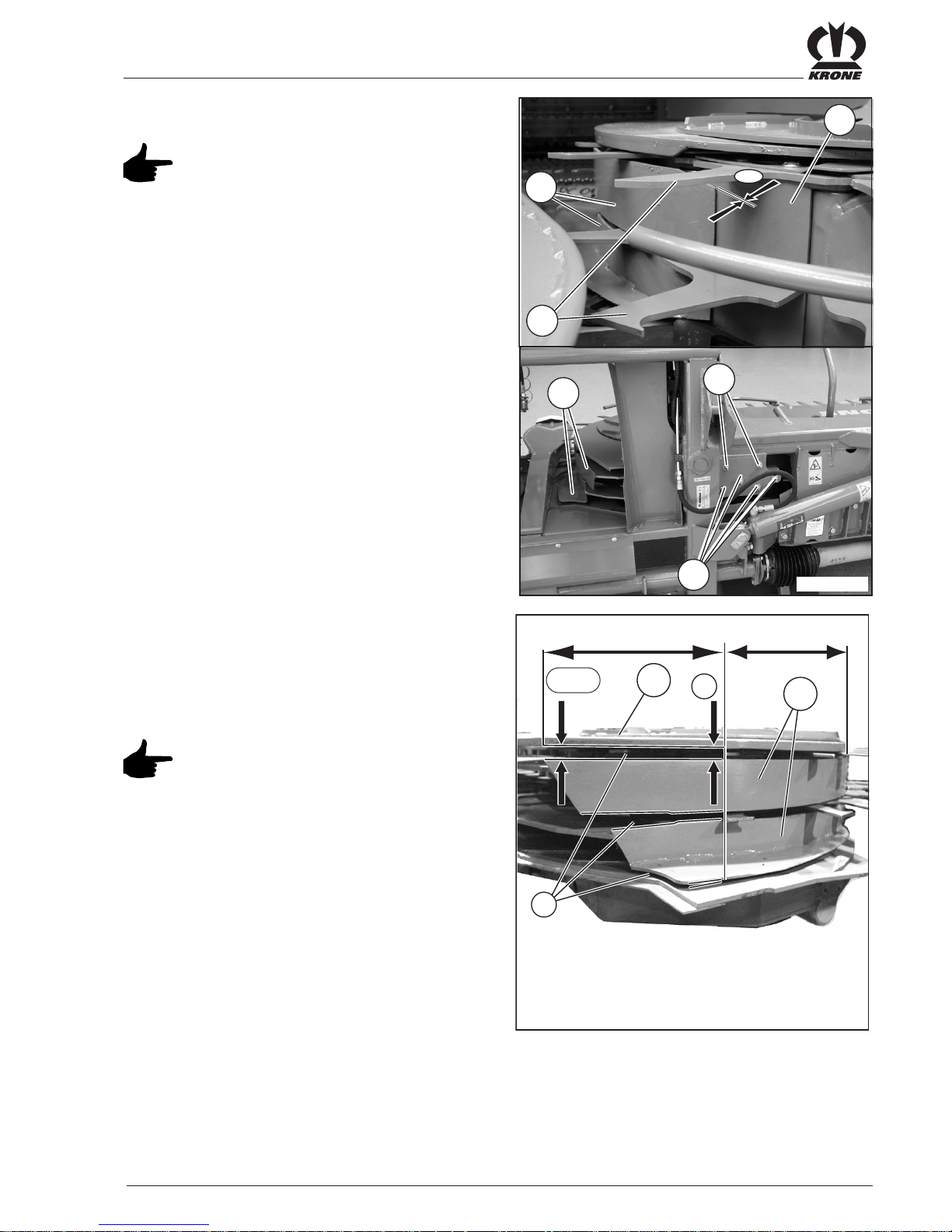

4. 6 Scraper (right / left)

The distance between the back of the

collector (2) and the scraper (1) must

not exceed the dimension «a = 3 mm».

4.6.1 Adjusting the scraper

• Loosen the screws (3) a little and press the scraper

(1) against the back of the collector (2). Distance

“a = 1 - 3 mm”.

EC100664

X

y

a+4

a

b

1

5

Setting of the gaps (b):

• The scrapers (1) must be aligned parallel to the

collector fingers (4) in the area marked «X». The

scrapers (1) must be extended back conically in the

area marked «Y» (a+4)

If necessary, align the cover (5) as well

by loosening the screws (6).

2

3

EC200420

a

1

1

4

6

• Tighten the screw connections (3).

IV - 10

Maintenance

4.7 Tips

The lower edges of the side tips (1

right/ 1 left) should be at the same

height as the lower edges of the tips

(2). The lower edges of the central

tip (3) should be about x = 30-50

mm lower than the lower edges of

the other tips (a = freely selectable

distance to the ground).

If necessary correct the height

adjustment of the side or central

tips.

4.7.1 Adjusting the side tips (right / left)

• Loosen the screws (2) a little.

• Shift the adjusting plate (3) until the bottom edge of

the side tip (1) is at the height of the bottom edges

of the tips.

• Tighten the screw connections (2).

4.7.2 Adjusting the central tip

• Loosen the screws (2) a little.

• Adjust the central tip (1) so that the bottom edge is

approx. x = 30-50 mm below the bottom edges of

the tips.

• Tighten the screw connections (2).

4.7.3 Replacing tips

• Unscrew the cheese head screws (2) on both sides

of the tip (1) and remove the tip (1).

• Remove the bearing rings (3) from the tip (1) and

insert them in the new tip.

• Fit the new tip (1) with the cheese head screws (2).

1

2

3

EC200430

a

a-x

a

2

EC200440

1

1

2

3

EC200450

1

EC200460

2

3

IV - 11

Maintenance

4.9 Installing PTO shafts

T ake care in the installation of the PTO

shafts (1) that the cross joints (2) are

fitted parallel to one another.

4.10Hydraulic hose lines

Hydraulic hose lines may be used for 6

years at the most after manufacture.

The date of manufacture (month/year)

is stated on the hydraulic hose line.

• Check all hydraulic hose lines regularly and replace

them if they are damaged or show signs of ageing.

Replacement hose lines must meet the technical

requirements of the device manufacturer!

!

EC200490

1

EC200465

2

1

2

EC200025

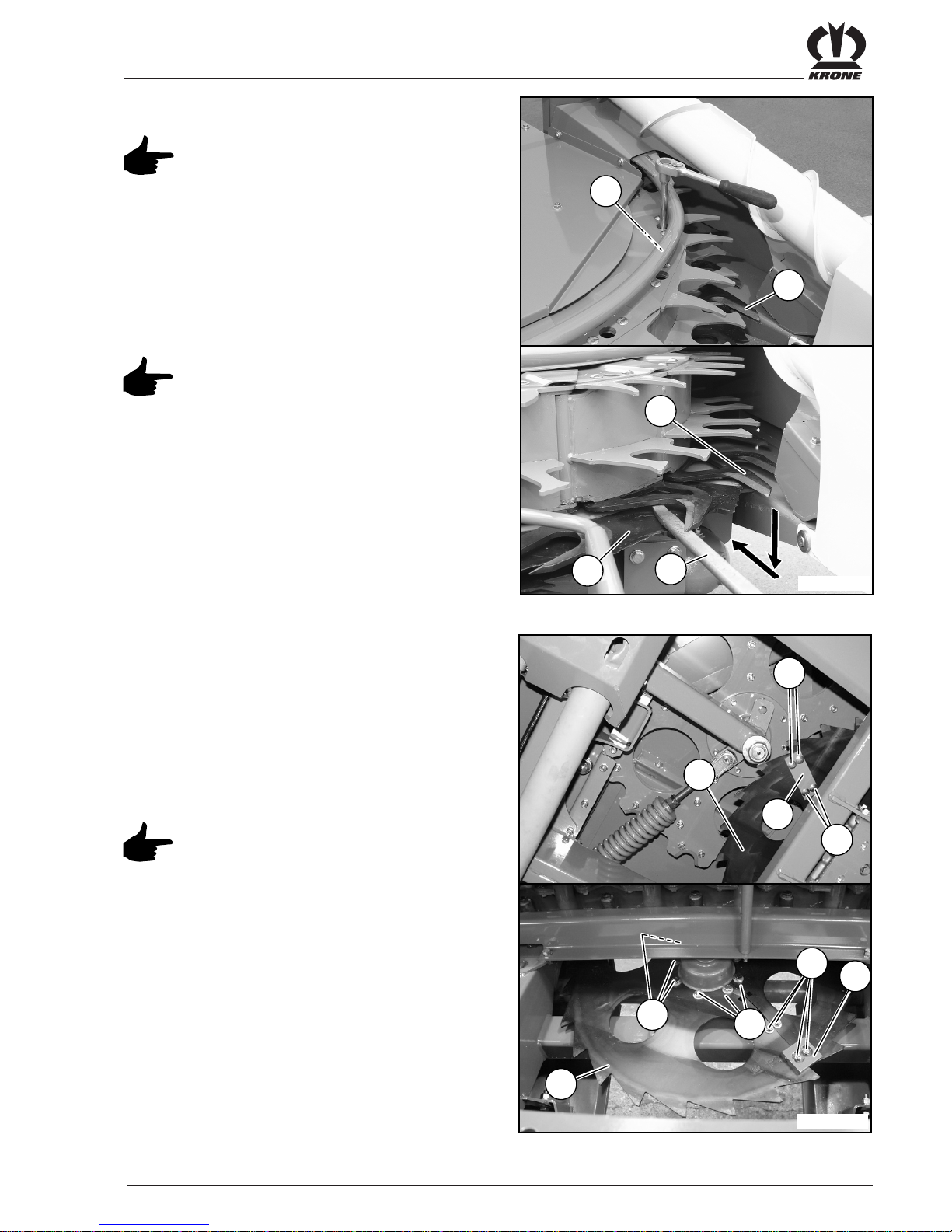

4.8 Removing the upper insert

finger

• Removing the upper insert finger

IV - 12

Maintenance

4.11Changing blades

Wear protective gloves when working

on the blades!

Check the blades each time before

using them and each time after driving

for obstacles.

Worn, damaged or deformed blades

must be replaced immediately .

4.11.1 Changing bow and step blades

When replacing observe the left/right

cutting direction!

• Unscrew the hexagon head screws (2) and pull off

the bow blade, inside (1) to the front.

• Insert a new bow blade (1) and fasten it with the

hexagon head screws (2).

• Unscrew the hexagon head screws (2) and pull off

the bow blade, outside (1) to the front.

• Insert a new bow blade (1) and fasten it with the

hexagon head screws (2).

• Unscrew the 2 hexagon head screws (4) and pull off

the step blade, inside (3) to the front.

• Insert a new step blade (3) and fasten it with the 2

hexagon head screws (4).

After replacement of the blades make

sure that no abutting edges arise.

If necessary use shims or grind off

projecting edges.

1

2

2

EC200520

1

2

EC200530

3

4

EC100510

IV - 13

Maintenance

4.11.2 Changing cutting blades

When replacing observe the cutting

direction right/left and the number of

blades 1 or 2!

• To remove the cutting blades (1) (only possible

outside in the area of the bow) unscrew the internal

hexagon head screw (2).

• Push up the collector on the step blade (4) with tyre

lever (3) and first pull the cutting blade down (1) off

the cam and then remove it to the rear.

• Tightening torque of the hexagonal

screw (2) = 85 Nm (8.8)

• Tightening torque of the hexagonal

screw (2) = 110 Nm (10.9)

• Use a high-strength screw locking

agent (for example Loctite).

• Installation of the new cutting blade (1) in the

reverse order of remov al.

4.11.3 Changing dresser segments (right /

left)

• Release the tension on the connectors (3, 4) on

both sides of the dresser segment (1) by loosening

the screws (2).

• Unscrew the hexagon head screws with the locking

washers (5) and remove the dresser segments (1).

On assembly observe the tooth

direction of the dresser segments!

Renew the self-locking nuts of the

screw connections (2)!

Absolutely comply with the position of

the carriage bolts (2) and connectors

(3, 4)!

• Installation of the new dresser segments (1) in the

reverse order of remov al.

1

2

2

3

4

5

5

2

1

EC200560

1

1

3

4

EC200540

2

IV - 14

Maintenance

4.11.4 Changing scraper blades (right /

left)

• Unscrew the 2 hexagon head screws (2) and

remove the scraper blade (1).

• Installation of the new scraper blade (1) in the

reverse order of remov al, take care that the cutting

edge lies against the collector .

1

2

EC100580

IV - 15

Maintenance

4.12Lubrication

4.12.1 PTO shafts

• All PTO shafts have to be lubricated after 250

operating hours in keeping with the data in the

operating instructions of the manufacturer of the

PTO shaft.

EC200024

100 h

250 h

25 h

IV - 16

Maintenance

4.12.2 Lubrication chart

• The lubricating points mentioned below must be

lubricated after the operating hours indicated.

EC200023

250

h

250

h

25

h

25

h

250

h

250

h

25

h

25

h

optional

IV - 17

Maintenance

4.13Storing when not in use

• Clean the machine thoroughly inside and out. Dirt

attracts moisture, which leads to the formation of

rust. When cleaning with high-pressure washing

devices, do not point the stream of water at the

bearing.

• Check movable parts (joints, etc.) to make certain

they move easily. If necessary, dismount them,

clean them and check them for wear. If necessary,

replace with new parts!

• Oil all joint points!

• Lubricate the machine thoroughly.

• Grease the protective tubes of the PTO shafts to

prevent freezing up .

• Repair places with worn paint and preserve all bear

metal places thoroughly with rust protection agent.

• Park the machine in a dry place. Do not store it in

the vicinity of artificial fertilisers.

• List all required spare parts and order them in good

time. It is easier for your KRONE dealer to provide

and install the required parts outside the season.

Then the machine will be completely ready for use

the coming season.

EC200026

IV - 18

Maintenance

I - 1

Anhang

A1 Commissioning

• Repair, maintenance and cleaning tasks must only be performed while the engine is stopped!

Remove the ignition key and secure the forage harvester from being placed in operation or

rolling away unintentionally.

• After completing maintenance work reattach all protective devices properly. Avoid skin contact

with oil and grease. Contact a doctor immediately if injuries are caused by escap-ing oil.

• Use only suitable and approved tools to assemble and disassemble the parts.

A1.1Fitting the additional weights

1

2

3

4 5

EC100667

a

b

EC100668

a

1

EC100669

3

a

EC100670

b

2

EC100671

b

4

EC100672

I - 2

Anhang

b

5

EC100673

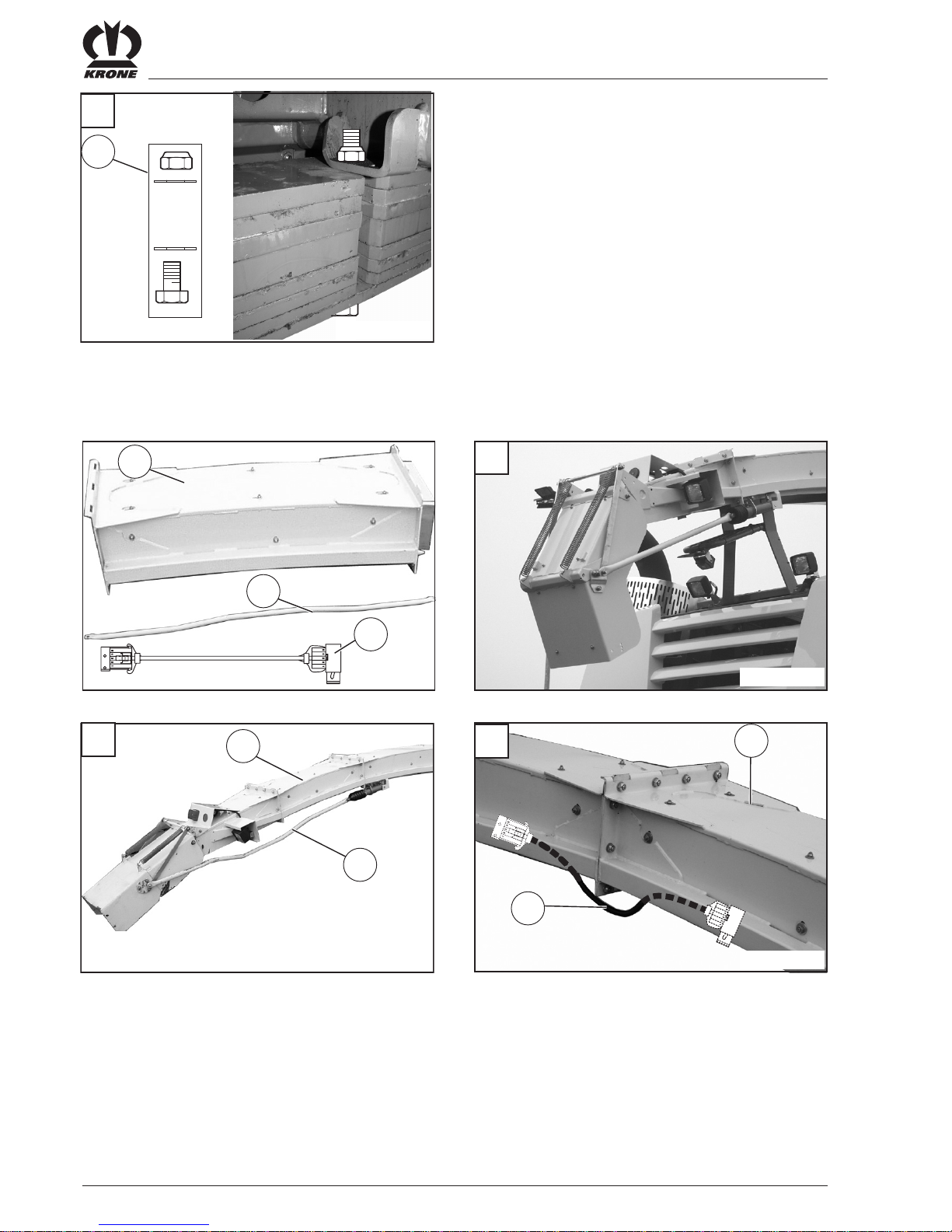

A1.2Fitting the discharge extension (only for EasyCollect 7500;

EasyCollect 9000)

1

2

3

EC100674

a

EC100675

b

EC100676

1

2

c

3

EC100677

1

I - 3

Anhang

Maschinenfabrik

Bernard Krone GmbH

Heinrich-Krone-Straße 10, D-48480 Spelle

Postfach 11 63, D-48478 Spelle

Phone +049 (0) 59 77/935-0

Fax +049 (0) 59 77/935-339

Internet: http://www.krone.de

eMail: info.ldm@krone.de

. . . konsequent, kompetent

12-Jan-2006

Loading...

Loading...