Krone Big Pack 890, Big Pack 1290, Big Pack 1270, Big Pack 1290 HDP, Big Pack 1290XC Operating Instructions Manual

...

Operating Instructions

150 000 050 01 EN

Big Pack Baler

Big Pack 890/XC

Big Pack 1270/XC/MultiBale

Big Pack 1290/XC

Big Pack 1290 HDP / XC (Machine No. 721 564 or higher)

Dear Customer:

These are the operating instructions for the KRONE product that you

have purchased.

These operating instructions contain important information for the

correct use and safe operation of the machine.

Should these operating instructions have become unusable completely

or partially for any reason, you can obtain replacement operating

instructions for your machine by stating the number quoted on the

reverse.

We

declare in our sole responsibility that the product

to which this declaration refers corresponds to the relevant basic safety and health requirements of the

EC Directive 98/37/EC.

EC Declaration of Conformity

corresponding to the EC Directive 98/37/EC

Maschinenfabrik Bernard Krone GmbH

Heinrich-Krone-Str. 10, D-48480 Spelle, Germany

Krone Big Pack Baler

Types: Big Pack 890; Big Pack 1270; Big Pack 1290

Big Pack 890 XC; Big Pack 1270XC; Big Pack 1290XC

Big Pack 1290 HDP; Big Pack 1290 HDP XC

Spelle, 10.042007

(Dr.-Ing. Josef Horstmann, Managing Director)

(ppa. Dr.-Ing. Klaus Martensen, Director of Design and Development)

1

Contents

Contents

1 General Information ........................................................................... I -1

1.1 Purpose .................................................................................................................. I -1

1.2 Intended Use .......................................................................................................... I -1

1.3 Information Required in Case of Questions and Orders ........................................ I -1

1.4 Technical Data........................................................................................................ I -2

1.4.1 Big Pack 890/XC .................................................................................................... I -2

1.4.2 Big Pack 1270/XC/MultiBale ................................................................................... I -3

1.4.3 Big Pack 1290/XC .................................................................................................. I -4

1.4.4 Big Pack 1290 HDP / XC ........................................................................................ I -5

1.4.5 Lubricants ............................................................................................................... I -6

1.5 Connection Requirements, Tractor ........................................................................ I -7

1.6 General Technical Description................................................................................ I -8

1.7 Overviews ............................................................................................................... I -9

1.7.1 Left Side of the Big Pack Baler with Tandem Axle ................................................. I -9

1.7.2 Right Side of the Big Pack Baler with Tandem Axle ............................................. I -10

1.7.3 How the VFS Conveyor System Works ................................................................ I -11

1.7.4 Functional Description of the Big Pack Baler ........................................................ I -12

2 Safety .................................................................................................. II -1

2.1 Identifying Symbols in the Operating Instructions .................................................. II -1

2.2 Safety Instructions and Accident Prevention Regulations ...................................... II -1

2.2.1 Personnel Qualification and Training ...................................................................... II -1

2.2.2 Dangers in case of Non-Compliance with the Safety Instructions .......................... II -1

2.2.3 Safety-Conscious Working ..................................................................................... II -1

2.2.4 Safety Instructions and Accident Prevention Regulations ...................................... II -2

2.2.5 Hitched Implements................................................................................................ II -3

2.2.6 PTO Operation ....................................................................................................... II -3

2.2.7 Hydraulic System.................................................................................................... II -3

2.2.8 Tyres ...................................................................................................................... II -4

2.2.9 Maintenance ........................................................................................................... II -4

2.2.10 Unauthorised Modifications and Spare Parts Production ....................................... II -4

2.2.11 Non-Permissible Modes of Operation..................................................................... II -4

2.3 Introduction ............................................................................................................ II -5

2.3.1 Location of Safety Stickers on the Machine ........................................................... II -5

2.4 Special Safety Instructions ..................................................................................... II -7

2.4.1 Ladder .................................................................................................................... II -7

2.4.2 Fire Extinguisher..................................................................................................... II -7

3. Start-up and Transport ..................................................................... III -1

3.1 Safety Instructions................................................................................................. III -1

3.2 General Operation ................................................................................................. III -1

3.2.1 Parking Support ..................................................................................................... III -1

3.2.2 Hydraulic Support Base (Optional) ........................................................................ III -2

3.2.3 Parking Brake ........................................................................................................ III -2

3.2.4 Holding Brake for Flywheel .................................................................................... III -3

3.2.5 Adjusting the Drawbar Height ................................................................................ III -3

3.3 Connecting to the Tractor...................................................................................... III -4

2

Contents

3.4 Main PTO Shaft..................................................................................................... III -4

3.4.1 Adapting the Main PTO Shaft................................................................................ III -4

3.4.2 Mounting on the tractor side ................................................................................. III -5

3.5 Hydraulic, Compressed Air and Electrical Connections......................................... III -6

3.5.1 Hydraulic Brake (country-specific) ......................................................................... III -6

3.5.2 Hydraulic Connection for Locking the Coaster Axle (Optional).............................. III -6

3.5.3 Load-Sensing Connection (optional) ..................................................................... III -7

3.5.4 Compressed Air Brake .......................................................................................... III -8

3.5.5 Holders for the Compressed Air Hoses ................................................................. III -8

3.5.6 Electrical Connection Cables ................................................................................. III -9

3.6 Placing in Operation again after an Extended Standstill Time............................. III -10

3.6.1 Safety Instructions............................................................................................... III -10

3.6.2 General Information ............................................................................................ III -10

3.6.3 Overload Coupling on the Flywheel ..................................................................... III -10

3.6.4 Storage for Winter ............................................................................................... III -11

3.7 Transport ............................................................................................................. III -12

3.7.1 Preparations for Road Travel .............................................................................. III -12

3.7.2 Moving ................................................................................................................. III -13

3.7.3 Coaster/Steering Axle (Optional) ......................................................................... III -14

3.7.3.1 Moving the machine without hydraulic connection .............................................. III -14

3.8 Parking the Big Pack Baler .................................................................................. III -15

4 Comfort Control Unit ........................................................................ IV -1

4.1 General Description ............................................................................................... IV -1

4.2 Mounting................................................................................................................ IV -2

4.3 Control Unit ........................................................................................................... IV -4

4.4 Operational Readiness .......................................................................................... IV -5

4.5 Manual Mode......................................................................................................... IV -6

4.5.1 Basic Screen for Manual Mode 1/2 .......................................................................IV -6

4.5.2 Basic Screen for Manual Mode 2/2 .......................................................................IV -8

4.6 Automatic Mode .................................................................................................. IV -13

4.7 Buttons on the Machine ...................................................................................... IV -14

4.8 Description of the Baling Process........................................................................ IV -15

4.8.1 Bale Channel is Empty ........................................................................................ IV -15

4.8.2 Bale Channel is Full ............................................................................................. IV -15

4.9 Menu Level .......................................................................................................... IV -16

4.9.1 Bringing up a Menu Level .................................................................................... IV -16

4.9.2 Main Menu 1 “Settings” ....................................................................................... IV -17

4.9.3 Menu 1-1 “Correction value for bale length” ........................................................ IV -18

4.9.4 Menu 1-2 “Knotter signal”.................................................................................... IV -19

4.9.5 Menu 1-3 “Sensitivity of direction display” ........................................................... IV -20

4.9.6 Menu 1-4 "Contrast" ............................................................................................ IV -21

4.9.7 Menu 1-5 “Central lubrication” ............................................................................. IV -22

4.9.8 Menu 1-6 "Knotter blowing" ................................................................................. IV -23

4.9.8.1 Menu 1-6-1 "Strokes / blow" ................................................................................ IV -24

4.9.8.2 Menu 1-6-2 "Bales / blow" ................................................................................... IV -25

4.9.8.3 Menu 1-6-3 "Blow time" ....................................................................................... IV -26

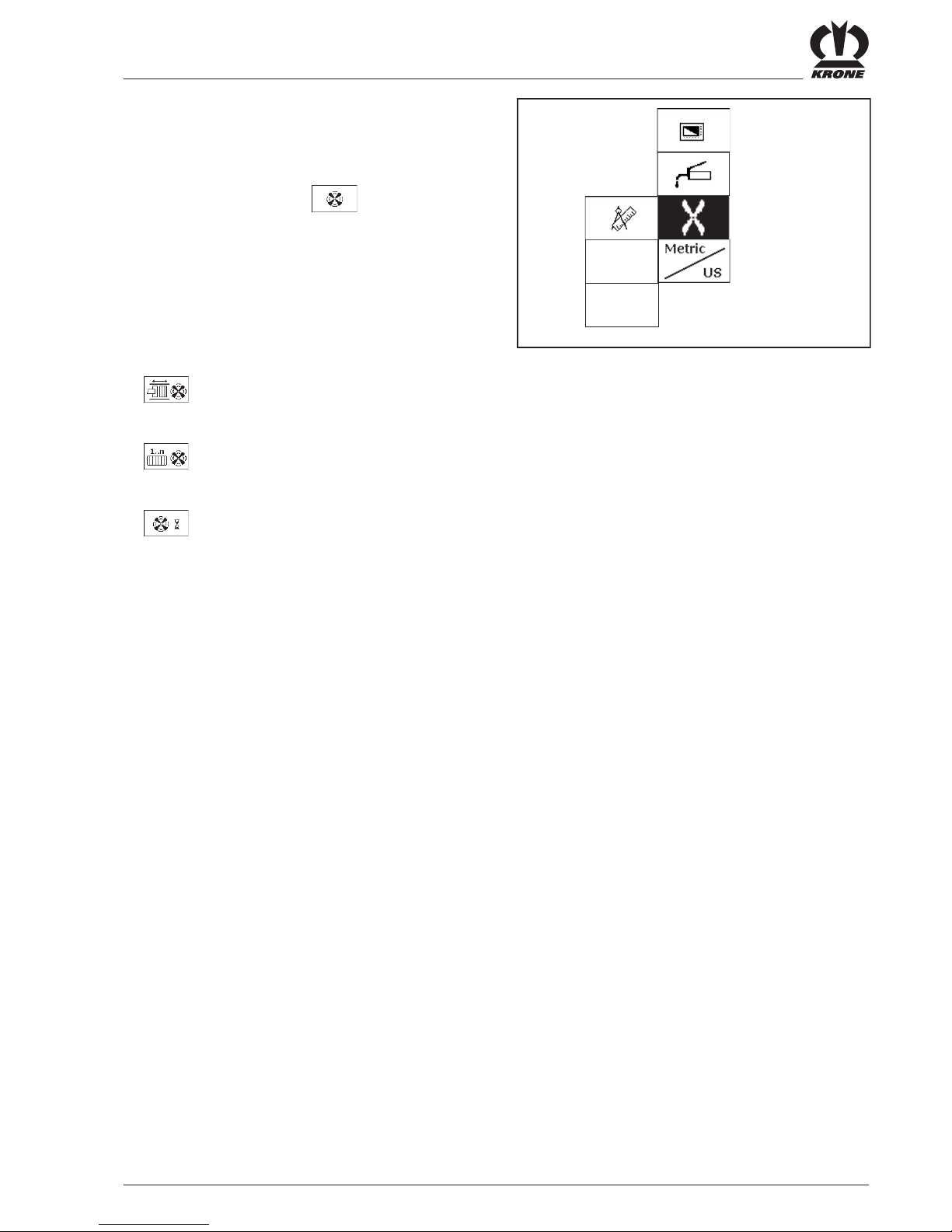

4.9.9 Menu 1-7 "Unit of measure" ................................................................................ IV -27

4.9.10 Main Menu 2 “Counters” ..................................................................................... IV -28

4.9.11 Menu 2-1 “Customer counters” ........................................................................... IV -28

4.9.12 Menu 2-2 “Total counters” ................................................................................... IV -30

3

Contents

4.9.13 Main Menu 4 “Service” ........................................................................................ IV -31

4.9.14 Menu 4-2 “Sensor test, manual” ......................................................................... IV -31

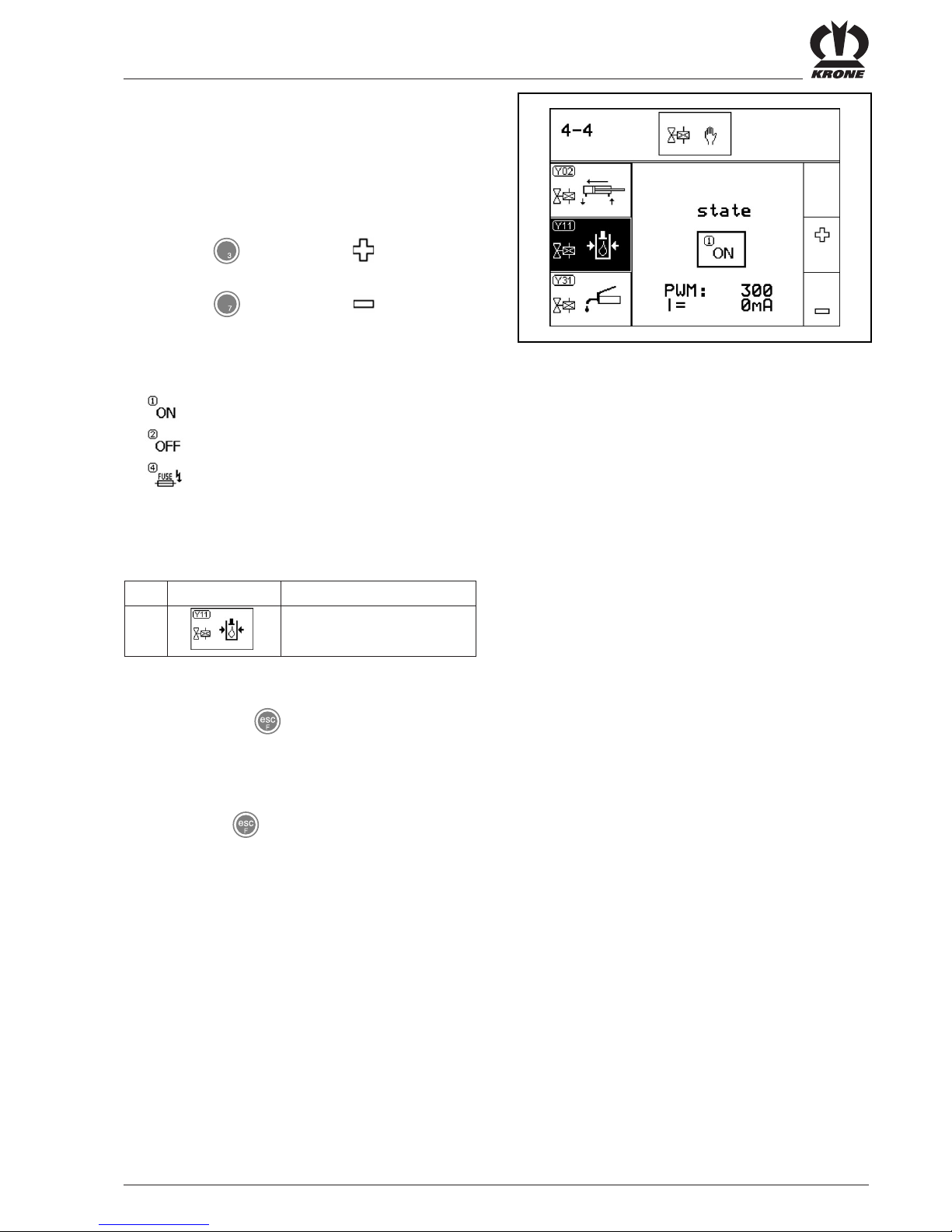

4.9.15 Menu 4-4 “Actuator test, manual” ....................................................................... IV -35

4.9.16 Menu 4-5 “Current alarms” .................................................................................. IV -38

4.9.17 Main Menu 5 “Info” .............................................................................................. IV -39

4.9.18 Info window ......................................................................................................... IV -39

4.9.19 Main Menu 6 “Technician” ...................................................................................IV -40

4.10 Alarm Message ................................................................................................... IV -41

4.11 Alarm messages.................................................................................................. IV -42

4.12 ISO Control ......................................................................................................... IV -49

4.12.1 Working Principle ................................................................................................. IV -49

4.12.2 Mounting.............................................................................................................. IV -49

4.12.3 Functions that Differ from the KRONE In-cab Comfort Kit .................................. IV -50

5 Medium Control Unit ..........................................................................V -1

5.1 General Description ................................................................................................ V -1

5.2 Mounting................................................................................................................. V -2

5.3 Control Unit ............................................................................................................ V -4

5.4 Operational Readiness ........................................................................................... V -5

5.5 Manual Mode .......................................................................................................... V -6

5.5.1 Basic Screen for Manual Mode .............................................................................. V -6

5.6 Automatic Mode ..................................................................................................... V -8

5.7 Description of the Baling Process........................................................................... V -9

5.7.1 Bale Channel is Empty ........................................................................................... V -9

5.7.2 Bale Channel is Full ................................................................................................ V -9

5.8 Menu Level ........................................................................................................... V -10

5.8.1 Bringing up a Menu Level ..................................................................................... V -10

5.8.2 Main Menu 1 “Settings” ........................................................................................ V -11

5.8.3 Menu 1-1 “Bale length setting, To trigger the knotter, Bale length correction value” V 12

5.8.4 Menu 1-2 “Knotter signal” ..................................................................................... V -14

5.8.5 Menu 1-3 “Sensitivity of direction display” ............................................................ V -15

5.8.6 Menu 1-4 “Contrast” ............................................................................................. V -16

5.8.7 Menu 1-5 “Central lubrication” .............................................................................. V -17

5.8.8 Menu 1-6 "Knotter blowing" .................................................................................. V -18

5.8.8.1 Menu 1-6-1 "Strokes / blow" ................................................................................. V -19

5.8.8.2 Menu 1-6-2 "Bales / blow" .................................................................................... V -20

5.8.8.3 Menu 1-6-3 "Blow time" ........................................................................................ V -21

5.8.9 Menu 1-7 "Unit of measure" ................................................................................. V -22

5.8.10 Main Menu 2 “Counters” ...................................................................................... V -23

5.8.11 Menu 2-1 “Customer counters” ............................................................................ V -23

5.8.12 Menu 2-2 “Total counters” .................................................................................... V -25

5.8.13 Main Menu 4 “Service” ......................................................................................... V -26

5.8.14 Menu 4-2 “Sensor test, manual” .......................................................................... V -26

5.8.15 Menu 4-4 “Actuator test, manual” ........................................................................ V -30

5.8.16 Menu 4-5 "Current alarms" ................................................................................... V -33

5.8.17 Main Menu 5 “Info” ............................................................................................... V -34

5.8.18 Info window .......................................................................................................... V -35

5.8.19 Main Menu 6 “Technician” .................................................................................... V -35

5.9 Alarm Message .................................................................................................... V -36

5.10 Alarm messages................................................................................................... V -37

4

Contents

7 Working with the Big Pack Baler..................................................... VII -1

7.1 Safety Instructions................................................................................................VII -1

7.2 Pick-up .................................................................................................................VII -1

7.3 Cutting system XC................................................................................................VII -3

7.4 Baling Force Regulation ....................................................................................... VII -6

7.5 Emptying the Baling Channel ............................................................................... VII -7

7.6 Hydraulically folding roller chute (optional) ........................................................... VII -7

7.7 Length Adjustment of Big Bales ........................................................................... VII -8

7.7.1 Manual Length Adjustment................................................................................... VII -8

7.7.2 Electrical Length Adjustment (Optional) ............................................................... VII -8

7.8 Twine .................................................................................................................... VII -9

7.8.1 Electrical Twine Empty Display ............................................................................. VII -9

7.8.2 Twine Motion Display, Upper Thread (Double Knotter) ........................................VII -9

7.8.3 Initiate the Tying Process Manually .................................................................... VII -10

7.9 Gears ................................................................................................................. VII -11

7.10 Multi-Bale Device(optional) ................................................................................. VII -14

8. Settings ............................................................................................ VIII -1

8.1 Safety Instructions...............................................................................................VIII -1

8.2 Tying Unit ............................................................................................................ VIII -1

8.2.1 Twine ...................................................................................................................VIII -1

8.2.2 Needle Adjustment .............................................................................................. VIII -6

8.2.3 Twine Bar .......................................................................................................... VIII -11

8.2.3.1 Setting of the Twine Bar (Single Knotter) .......................................................... VIII -11

8.2.3.2 Setting of the Twine Bar (Double Knotter)......................................................... VIII -12

8.2.4 Twine Brake.......................................................................................................VIII -14

8.3 Knotter............................................................................................................... VIII -16

8.3.1 Single Knotter ....................................................................................................VIII -16

8.3.2 Double knotter ................................................................................................... VIII -19

8.3.2.1 The knotter hook ............................................................................................... VIII -19

8.3.2.2 Twine retainer .................................................................................................... VIII -19

8.4 Baling Ram Setting ............................................................................................ VIII -21

8.5 Adjusting the Packer Relative to the Baling Ram ..............................................VIII -22

8.5.1 Checking the engaging of the packer coupling .................................................. VIII -22

8.6 Variable filling system VFS ................................................................................VIII -25

8.6.1 Installing the Feeler Rocker ............................................................................... VIII -25

8.6.2 Adjusting the Clutch........................................................................................... VIII -25

8.6.2.1 Setting the zero position .................................................................................... VIII -25

8.6.3 Adjusting the Triggering Sensitivity .................................................................... VIII -26

8.6.4 Absorbing Mechanism ....................................................................................... VIII -27

8.6.5 Setting of the Spring of the Zeroizing Device ....................................................VIII -27

8.7 Adjusting the Flywheel Cleaning (Only for Big Pack 890)..................................VIII -28

8.8 Basic Setting of the Flywheel Belt Brake ........................................................... VIII -28

8.9 Adjusting the Baling Chute ................................................................................VIII -29

8.10 Multi-Bale Setting .............................................................................................. VIII -30

8.10.1 Setting the position of the second needle yoke ................................................ VIII -30

8.10.2 Setting the obstruction ...................................................................................... VIII -30

5

Contents

8.10.3 Adjusting the height of the needle yoke brake .................................................. VIII -30

8.10.4 Setting the lock (frame) .....................................................................................VIII -31

8.10.5 Setting the locks of the needle yoke ................................................................. VIII -31

8.10.6 Setting the rubber buffer between the needle yokes......................................... VIII -31

8.10.7 Possible setting errors and how to eliminate them ............................................ VIII -32

9 Care, Maintenance and Lubrication .................................................IX -1

9.1 Safety Instructions................................................................................................. IX -1

9.2 General Information .............................................................................................. IX -1

9.2.1 Tightening Torques ................................................................................................ IX -1

9.2.2 Cleaning ................................................................................................................ IX -2

9.2.3 Tyres ..................................................................................................................... IX -2

9.3 Hydraulics .............................................................................................................. IX -3

9.3.1 Special Safety Instructions .................................................................................... IX -3

9.3.2 On-board Hydraulic System .................................................................................. IX -3

9.3.3 Work Hydraulics (Comfort) .................................................................................... IX -4

9.3.4 Emergency Manual Activation ...............................................................................IX -5

9.4 Checking and Changing the Oil on the Gearboxes ............................................... IX -6

9.4.1 General Information .............................................................................................. IX -6

9.4.2 Main Gearbox ........................................................................................................ IX -6

9.4.3 Packer Gearbox .................................................................................................... IX -6

9.4.4 Distributor Gearbox ............................................................................................... IX -7

9.4.5 Upper and Lower Pick-up Gearbox ....................................................................... IX -7

9.4.6 Cutting System Drive Gearbox for the Big Pack XC, Upper and Lower ................ IX -8

9.5 Brake System ........................................................................................................ IX -9

9.5.1 Special Safety Instructions .................................................................................... IX -9

9.5.2 Compressed Air Storage Tank .............................................................................. IX -9

9.5.3 Adjusting the Transfer Mechanism ...................................................................... IX -10

9.5.4 Brake Cylinders ................................................................................................... IX -10

9.6 Compressor ......................................................................................................... IX -11

9.7 Replacing Rollers/Cam Follower Rollers .............................................................. IX -11

9.8 Lubrication ...........................................................................................................IX -12

9.8.1 Special Safety Instructions ..................................................................................IX -12

9.8.2 General Information ............................................................................................ IX -12

9.8.3 Lubrication ...........................................................................................................IX -12

9.8.3.1 Main PTO shaft ................................................................................................... IX -12

9.8.3.2 Rollers and Cam Follower Rollers on the Packer Strips ...................................... IX -13

9.8.4 Lubricating Points ................................................................................................ IX -14

9.8.5 Automatic Central Lubrication (Optional)............................................................. IX -20

9.9 Position of the Sensors ....................................................................................... IX -21

9.10 Adjusting the Sensors.......................................................................................... IX -23

9.11 Air Filter for Pneumatic Cylinders ........................................................................ IX -23

10 Malfunctions, Causes and Remedies ............................................... X -1

10.1 Safety Instructions.................................................................................................. X -1

10.2 General Malfunctions ............................................................................................. X -2

10.3 Malfunctions on the Knotter ................................................................................... X -3

10.3.1 Single Knotter ......................................................................................................... X -3

10.3.2 Double Knotter ....................................................................................................... X -6

10.4 Troubleshooting in the Central Lubrication System .............................................. X -16

A1 Circuit Diagrams of the Hydraulic System ...................................... A -1

6

Contents

A1.1 Work Hydraulics Part I for Medium and Comfort Version Electronics .................... A -1

A1.2 Work Hydraulics Part II for Comfort Version Electronics........................................ A -2

A1.3 Work Hydraulics Part II for Medium Version Electronics ........................................ A -3

A1.4 On-board Hydraulics for Medium Version Electronics ............................................ A -4

A1.5 On-board Hydraulics for Comfort Version Electronics ............................................ A -4

A2 Electrical Circuit Diagrams ............................................................... A -5

A2.1 Medium Control Unit ............................................................................................... A -5

A2.2 Comfort Control Unit ............................................................................................ A -11

I - 1

General Information

The intended use shall also include the adherence to

the operating, maintenance and repair conditions set by

the manufacturer.

Permissible crops: Agricultural crops such as hay,

straw and grass silage.

Collecting and baling materials that

are not cited here is permitted only in

agreement with the manufacturer.

A basic prerequisite is in any event

forming windrows of the baled

product and independently collecting

with the pick-up when driving over.

The EC Declaration of Conformity corresponding to

the EC Directive is located on the inside of title page.

1 General Information

These operating instructions contain basic information

that must be observed in mounting, operation and

maintenance. Therefore these operating instructions

must be read without fail by the personnel before use

and start-up. They must also be accessible to the

personnel.

Not only must the general safety instructions mentioned

in Chapter 2 on safety be observed, but also the special

safety instructions added to the other chapters.

Manufacturer:

Maschinenfabrik Bernard Krone GmbH

Heinrich-Krone-Str. 10

D-48480 Spelle (Germany)

Telephone: 0 59 77/935-0

Fax: 0 59 77/935-339

E-mail: info.ldm@krone.de

1.3 Information Required in Case

of Questions and Orders

Original spare parts and accessories

authorised by the manufacturer help to

ensure safety. Use of other parts may

void the liability for any resulting damage.

The machine data are rendered on the type plate (1),

The type plate is on the right side of the machine. When

enquiring about the machine and ordering spare parts,

state the type designation, the vehicle ID No. and the

year of construction of the machine (see below).

Type

Year of

construction

Vehicle

ID No.

The entire identification has the value

of a certificate and may not be

changed or made illegible!

1.2 Intended Use

The Big Pack 890/XC; Big Pack 1270/XC/MultiBale;

Big Pack 1290/XC and BigPack 1290 HDP / XC

Balers are built exclusively for customary use in

agricultural work (use as intended).

Any use extending beyond this is considered as not as

intended. The manufacturer is not liable for damage

resulting from this, the user alone bears the risk for

this.

Maschinenfabrik Bernard Krone GmbH

Heinrich-Krone-Str. 10 D-48480 Spelle

Made in

Germany

BPXC0100

All information, illustrations and

technical data in these operating

instructions correspond to the latest

state at the time of publication. Design

modifications at any time without

statement of reason shall be reserved.

1.1 Purpose

The Big Pack 890/XC; Big Pack 1270/XC/MultiBale;

Big Pack 1290/XC and BigPack 1290 HDP / XC Balers

work with the “Variable Feeding System”. They produce

highly compacted and dimensionally stable big bales

with a length of 1.0 to 2.7 m under all conditions.

These operating instructions apply to Big Pack Balers:

Big Pack 890/XC,

Big Pack 1270/XC/MultiBale,

Big Pack 1290/XC and

BigPack 1290 HDP / XC

I - 2

General Information

1.4.1 Big Pack 890/XC

The technical data specified in the table refer to the basic version of the machine in each case.

Deviations (e.g. due to additional attachments, etc.) are not included in this table.

1.4 Technical Data

*350 km/h with tandem axle braked

40 km/h with tandem axle unbraked

Big Pack 890 Big Pack 890 XC

Single-axle Tandem Single-axle Tandem

Permissible maximum speed 40 km/h 50km/h*

3

40 km/h 50km/h*

3

Length of working position (mm) 9180

Length of transport position (mm) 7930

Height [mm] 3075

Weight [kg]) 6580 6950 7480 7850

500/50-17 500/50-17

Tyres 500/55-20 500/55-20

700/45-22.5 560/45 R22.5 700/45-22.5 560/45 R22.5

620/40 R22,5 620/40 R22,5

Width [mm] 2600 2550/2560/2605/2670 2600 2550/2560/2605/2670

Tyre pressure [bar 1,5 2,4 bei 17" 1,5 2,4 bei 17"

1,8 ( 20" / 22,5") 1,8 ( 20" / 22,5")

Track width [mm] 1820 2040 1820 2040

Baling channe Height (mm) 900

Width (mm) 800

Baling length [mm] from 1000 to 2700 (continuously adjustable)

Scattering width [mm] 1950

Number of knotter devices 4

Power requirement 75 KW (102 PS) 90 KW (122 PS)

Cutting system

(number of blades) -16

Friction clutch drive 1800 Nm

Flywheel overload coupling Wedge switch 4500 Nm

Pick-up overload coupling Star ratchet 800 Nm Star ratchet 1000 Nm

Cam-type cut-out clutch for cutting

system - 7000 Nm

Packer overload coupling Cam-type cut-out clutch 14500 Nm

Needle connecting rod Shear screw M 10 x 55 DIN 931-10.9

I - 3

General Information

1.4.2 Big Pack 1270/XC/MultiBale

The technical data specified in the

table refer to the basic version of the

machine in each case. Deviations (e.g.

due to additional attachments, etc.) are

not included in this table.

*

1

Rigid

*2Guided coast-down

*350 km/h with tandem axle braked

40 km/h with tandem axle unbraked

Big Pack 1270 Big Pack 1270 XC

Single-axle Tandem Single-axle Tandem

Permissible maximum speed 40 km/h 50km/h*

3

40 km/h 50km/h*

3

Length of working position (mm) 9180

Length of transport position (mm) 7930

Height (mm) 2875

Weight (kg) 7240 7610 8430 8800

500/50-17 500/50-17

Tyres 700/45-22.5 500/55-20 700/45-22.5 500/55-20

560/45 R22.5 560/45 R22.5

620/40 R22,5 620/40 R22,5

Width (mm) 2995

Tyre pressure (bar) 1,5 2,4 bei 17" 1,5 2,4 bei 17"

1,8 bei 20" / 22,5" 1,8 bei 20" / 22,5"

Track width (mm) 2200 2250*

1

2350*

2

2200 2250*

1

2350*

2

Baling channel Height (mm) 700

Width (mm) 1200

Baling length (mm) from 1000 to2700 (continuously adjustable)

Scattering width (mm) 2380

Number of knotter devices 6

Power requirement 80 KW (109 PS) 95 KW (129 PS)

Cutting system

(number of blades) -26

Friction clutch drive 1800 Nm

Flywheel overload coupling Wedge switch 4500 Nm

Pick-up overload coupling Star ratchet 800 Nm Star ratchet 1000 Nm

Cam-type cut-out clutch for cutting

system 7000 Nm

Packer overload coupling Cam-type cut-out clutch 14500 Nm

Needle connecting rod Shear screw M 10 x 55 DIN 931-10.9

I - 4

General Information

1.4.3 Big Pack 1290/XC

The technical data specified in the table

refer to the basic version of the machine

in each case. Deviations (e.g. due to

additional attachments, etc.) are not

included in this table.

*

1

Rigid

*2Guided coast-down

*350 km/h with tandem axle braked

40 km/h with tandem axle unbraked

Big Pack 1290 Big Pack 1290 XC

Single-axle Tandem Single-axle Tandem

Permissible maximum speed 40 km/h 50km/h*

3

40 km/h 50km/h*

3

Length of working position (mm) 9180

Length of transport position (mm) 7930

Height (mm) 3075

Weight (kg) 7860 8230 9050 9420

500/50-17 500/50-17

Tyres 700/45-22.5 500/55-20 700/45-22.5 500/55-20

560/45R22.5 560/45R22.5

620/40 R22,5 620/40 R22,5

Width (mm) * 2995

Tyre pressure (bar) 1,5 2,4 bei 17" 1,5 2,4 bei 17"

1,8 bei 20"/22,5" 1,8 bei 20"/22,5"

Track width (mm) 2200 2250*

1

2350*

2

2200 2250*

1

2350*

2

Baling channel Height (mm) 900

Width (mm) 1200

Baling length (mm) from 1000 to 2700 (continuously adjustable)

Scattering width (mm) 2380

Number of knotter devices 6

Power requirement 90 KW (122 PS) 105 KW (143 PS)

Cutting system

(number of blades) -26

Friction clutch drive 1800 Nm

Flywheel overload coupling Wedge switch 4500 Nm

Pick-up overload coupling Star ratchet 800 Nm Star ratchet1000 Nm

Cam-type cut-out clutch for cutting

system - 7000 Nm

Packer overload coupling Cam-type cut-out clutch 14500 Nm

Needle connecting rod Shear screw M 10 x 55 DIN 931-10.9

I - 5

General Information

1.4.4 Big Pack 1290 HDP / XC

Big Pack 1290 HDP Big Pack 1290 HDP XC

Tandem Tandem

Permissible maximum speed 50 km/h

Length of working position (mm) 9940

Length of transport position (mm) 8850

Height (mm) 3075

Weigh (kg) 10200 11500

Tyres 500/55-20 / 560/45 R22,5 / 620/40 R22,5

Width (mm) 2995

Tyre pressure (bar) 2,4

Track width (mm) 2250*

1

2350*

2

2250*

1

2350*

2

Baling channel Height (mm) 900

Width(mm) 1200

Lenght (mm) 3500

Baling length (mm) from 1000 to 3200 (continuously adjustable)

Scattering width (mm) 2380

Number of knotter devices 6

Power requirement 130 KW (177 PS) 145 KW (197 PS)

Cutting system

(number of blades) -26

Friction clutch drive 3000 Nm

Flywheel overload coupling Wedge switch 8000 Nm

Pick-up overload coupling Star ratchet 800 Nm Star ratchet 1000 Nm

Cam-type cut-out clutch for cutting

system - 7000 Nm

Packer overload coupling Cam-type cut-out clutch 14500 Nm

Needle connecting rod Shear screw M 10 x 55 DIN 931-10.9

*

1

Rigid

*2Guided coast-down

I - 6

General Information

Quantity ltr. Designation/brand Bio-degradable lubricants

Main gearbox 890 15,5

Main gearbox 1270 / 1290 16,7

Main gearbox 1290 HDP 35

Packer gearbox 4

Knotter/packer transfer gearbox 1

Pick-up gearbox, upper 0.5

Pick-up gearbox, lower 0.5

Cutting system gearbox

for XC, upper 2.8

Cutting system gearbox

for XC, lower 2.7

Oil quantities and designations for the on-board hydraulic system

Quantity ltr. Designation/brand Bio-degradable lubricants

Oil tank on baler 15 Fuchs Renolin MR 46 MC

BP Energol SHF 46

Shell Tellus 46

Esso Univis N 46

Aral Vitan VS 46

Oil quantities and designations for the compressor

Quantity ltr. Designation/brand Bio-degradable lubricants

up to the top Standard engine oil

dipstick SAE 20

marking or 20 W 40

0.2

SAE 90 GL 4 or

Esso-Spartan EP 150

Shell Omala Oil 150

Fuchs - EP 85 W90

Castrol EPX 90

With bio-degradable oils the changing intervals must be complied with without fail

because of ageing of the oils.

On request

1.4.5Lubricants

On request

Lubricant quantities and designations for the gearboxes

On request

I - 7

General Information

1.5 Connection Requirements, Tractor

Brake connections:

For Big Pack Baler with:

brake activated by compressed air Dual-line brake system required

hydraulically activated brake (6) Connection for hydraulic brake system required

(max. operating pressure 120 bar)

Electrical connections:

Lighting for the Big Pack Baler 7-pin socket DIN ISO 1124

Power supply for the electronic 2-pin socket

control system (direct battery connection required for continuous power)

Baler with 65 km/h approval ABS socket

Hydraulic connections:

Depending of the design of your Big Pack Baler, the following connections are possible:

Depending on version:

Raising the pick-up (1) Single-action control valve (yellow protective cap)

Locking the steering axle (7) Single-action control valve (green protective cap)

Support base (hydraulic) Double-action control valve (green protective cap)

Basic electronics/medium electronics:

Hinging blade bar (2) Double-action control valve (red protective cap)

(2A retract blade bar), (2B extend blade bar)

Residual bale ejector/roller chute (8) Double-action control valve (blue protective cap)

(8A forward motion) , (8B reverse motion)

Comfort version electronics:

Supply control block (4) Single-action control valve (NW 15) (red protective cap)

Return control block (5) Return tank (NW 18) (blue protective cap)

Load sensing line *(3) LS connection (NW 12) (blue protective cap)

* Only for tractors with load-sensing hydraulics

5

4

1

2A

3

2B

BPXC0232

8B

8A

6

7

I - 8

General Information

PTO speed 1000 rpm

PTO shaft Tractor side: Wide-angle

Machine side: Free-wheeling clutch

Hitch Hitch coupling; swinging drawbar

(perm. supporting load 1,300 kg; XC = 1,900 kg)

(drawbar adjustable in height)

Caution! When an adjustment is made, the hexagon

head screws must be tightened to the torque show in the

“Tightening torques” table in Chapter 8.2.

Support Support base, retractable - manually adjustable in height.

Optional: Hydraulic support base

Uncontrolled pick-up (EasyFlow) drum Hydraulic lift

Height adjustment by perforated bar on the supporting

wheel.

Tine mounting: 5

Number of tines: 16 (20) double tines/tine mounting

Lateral feed Right and left worm conveyor

Variable crop feed (VFS) Forced intake by feed packer drum

Feed packer drum with: 5 feed packers and

1 switching feeder packer

With the XC design, there is also a cutting system up front.

Baling ram Length of stroke 750 mm

-50 strokes per minute (Big Pack 890)

- 38.5 strokes per minute (Big Pack 1270 and 1290)

The baling ram moves on 4 rollers

5/7 blades on the baling ram

Setting the baling density Electronic/hydraulic force control (both

adjustable from the tractor)

Twine box on both sides, for a total of 32 balls of twine

Twine Synthetic twine (110-130 m/kg)

For twine roll end and torn twine Electrical twine control with acoustic and optical signal.

Bale ejector/bale unloading One-part bale chute (must be folded up

in transport).

Operation according to Medium - Comfort version

at the machine or from the tractor

Holding brake Operation by hand crank at the rear left of the baler

1.6 General Technical Description

I - 9

General Information

1.7 Overviews

9. Drawbar with adjustable height

10. Wide-angle PTO shaft with overload protection

and free-wheeling

11. Twine box

12. Manual release of knotter and knotter shaft lock

13. Fire extinguisher

14. Wheel chocks

15. Electronic control valve

1. Flywheel parking brake

2. On-board computer

3. Bale length adjustment

4. Crank for parking brake

5. Twine control and tensioning device

6. Pick-up with feeler wheel

7. Roller-type crop guard

8. Tool tray

1.7.1 Left Side of the Big Pack Baler with Tandem Axle

BPXC0101

15

11

8

I - 10

General Information

1. Knotting area

2. Hydraulic oil storage tank

3. Jack

4. Holder for fast-action couplings and plugs

5. XC cutting system drive

6. Pick-up hydraulics shut-off valve

7. Twine brake in the twine box

8. Bale chute

1.7.2 Right Side of the Big Pack Baler with Tandem Axle

BPXC0102

8

3

2

5

4

6

7

1

9

9. Variable filling system VFS

I - 11

General Information

1.7.3 How the VFS Conveyor System Works

1211

16

9876

BPXC0200

1514

32

1

4 5 10

14

13

10987654

3

2

1

1211

13

16

16

16

15

I - 12

General Information

The feed packers (4) fill the conveyor channel. The crop

is collected in the conveyor channel by the work of the

feed packers. The filling level in the conveyor channel is

sensed by the sensing rake (16). When a certain filling

level is reached, the sensing rake is swung back and the

feeder packer takes over the further transport of the crop

into the baling channel.

The baling ram force is controlled electronically by

hydraulic cylinders (9) on the baling channel flaps. Once

the set pack length is reached, the knotter mechanism is

released by the star wheel projecting into the baling

channel. The Big Pack 890 is equipped with 4, the

Big Pack 1270 and 1290 with 6 knotters (7). The big

bales are unloaded through a bale chute (10).

With the optional Multi Bale (Big Pack 1270) design, the

bale can be separated into as many as six smaller

bales.

The crop is pressed by the baling ram (6) in the baling

channel to form a highly compacted big bale. The length

and naturally also the density of the big bales can be

adjusted continuously.

Thus big bales can be generated according to widely

differing requirements.

As a drive, the BIG PACK Baler requires a tractor with a

power of 65 kW or higher.

The BIG PACK Baler is hooked into the hitch coupling or

the swinging drawbar. The drawbar is provided with

height adjustment so that the Big Pack Baler can work

horizontally.

The drive of the BIG PACK is through a PTO shaft,

which transmits the torque coming from the tractor

through a flywheel (11) to a bevel spur gearbox (12). The

maximum input speed of 1000 rpm must not be

exceeded, because this could cause the machine to be

damaged.

The PTO shaft is equipped at the tractor end with a

wide-angle joint. The operating instructions intended for

the PTO shaft are located on the PTO shaft.

Before the Big Pack Baler is started up, the operating

instructions of the PTO shaft should also be read.

Shortening the PTO shaft and any repair and

maintenance work are discussed here.

The pick-up (2), which is 2 m (2.4 m) wide, picks up the

crop cleanly. A height-adjustable roller-type crop guard

(1) ensures trouble-free pick-up and helps to avoid

clogging. The crop is conveyed by 2 worm conveyors

(3), located on the left and right side of the pick-up, to

the feed packer drum (13) or to the cutter rotor (14) and

blades (15).

The pick-up can be raised and lowered by the tractor

hydraulics. The feeler wheels of the pick-up are

adjustable in height so that an optimum pick-up height

can be achieved for the pick-up.

1.7.4 Functional Description of the Big Pack Baler

II - 1

Safety

2 Safety

2.1 Identifying Symbols in the

Operating Instructions

The safety instructions in these operating instructions

that in the case of non-compliance can give rise to

danger for persons are identified with the general

danger symbol:

Safety symbol as per DIN 4844 - W9

General functional instructions are indicated as follows:

2.2 Safety Instructions and Accident

Prevention Regulations

2.2.1 Personnel Qualification and Training

The Big Pack Baler may only be used, maintained and

repaired by persons who are familiar with it and have

been instructed about the dangers connected with it.

The operator must define areas of responsibility and

arrange the monitoring of the personnel. Should

personnel lack the required knowledge, they must

receive the required training and instruction. It must

furthermore be assured by the operator that the

contents of the operating instructions are fully

understood by the personnel.

Repair work not described in these operating

instructions must only be carried out by authorised

service centres.

2.2.2Dangers in case of Non-Compliance

with the Safety Instructions

Non-compliance with the safety instructions can result

in both danger for persons and for the environment and

the machine. If the safety instructions are not

respected, this could result in the forfeiture of any

claims for damages.

If the safety instructions are not respected, this may

result, for example, in the following hazards:

– Danger to persons caused by unguarded working

areas.

– Breakdown of important machine functions.

– Failure to implement the prescribed methods for

repair and maintenance.

– Risk to persons due to mechanical and chemical

effects.

– Danger to the environment due to leaking hydraulic

oil.

2.2.3 Safety-Conscious Working

The safety instructions quoted in these operating

instructions, the existing regulations for accident

prevention as well as possible internal working,

operating and safety instructions of the operator must

be complied with.

The safety and accident prevention regulations issued

by the responsible professional associations are

binding.

The safety instructions of the vehicle manufacturer

must be complied with.

Instructions which are affixed directly to the machine

must be followed and be fully legible at all times.

II - 2

Safety

Always observe the applicable traffic laws when using

public roads (for example, in Germany, the Road

Traffic Type Approval Law and Road Traffic Law).

2.2.4 Safety Instructions and Accident

Prevention Regulations

1. In addition to the instructions in these operating

instructions, you must comply with the generally

applicable safety and accident prevention

regulations!

2. The warning and safety signs affixed to the

vehicle provide important information for safe

operation. For your own safety always pay

attention to these!

3. When using public roads, make sure that you

observe the applicable traffic regulations!

4. Make sure that you are familiar with all equipment

and controls as well as their functions before you

begin working with the machine. It is too late to

learn this when you are operating the machine!

5. Users must wear close-fitting clothes. Avoid

wearing loose or baggy clothing.

6. Keep the machine clean to prevent the danger of

fire!

7. Before starting or moving the machine, make

certain that nobody is in the vicinity of the

machine! (Watch out for children!) Pay attention to

adequate vision!

8. Riding on the machine during working and

transport is not permitted.

9. Attach implements correctly! Only attach and

secure implements to the prescribed devices!

10. When attaching or removing implements, place the

supporting devices in the correct positions!

11. Special care is required when coupling and

uncoupling implements to/from the tractor!

12. Always attach ballast weights properly to the fixing

points provided!

13. Observe permitted axle loads, gross weight and

transport dimensions!

14. Check and attach transport equipment, such as

lighting, warning devices and protective

equipment!

15. Operating devices (ropes, chains, rods, etc.) of

remotely operated devices must be run so that

they do not trigger unintended movements in all

transport and working positions.

16. Ensure that implements are in the prescribed

condition for road travel and lock them according

to the instructions of the manufacturer!

17. Never leave the driver’s seat when the vehicle is

moving!

18. The driven speed must always be adapted to the

ambient conditions! Avoid sudden changes in

direction when travelling uphill or downhill or

across a gradient!

19. The handling, steering and braking ability are

influence by the attached or suspended

implements and ballast weights. For this reason,

make sure that you are able to steer the machine

and brake as required!

20. Take into account the extension radius and/or

inertia of an implement when turning corners!

21. Start up implements only when all protective

devices have been attached and set in the

required position!

22. Keep out of the working range of the machine at

all times!

23. Do not stand within the turning and slewing range

of the implement!

24. Never operate the hydraulic folding frames if

anyone is inside the slewing range!

25. Parts operated by external power (e.g. hydraulics)

can cause crushing and shearing injuries!

26. Before leaving the tractor turn off the engine and

withdraw the ignition key!

27. No one may stay between the tractor and

implement without the vehicle being secured

against rolling away by the holding brake

and/or by wheel chocks.

II - 3

Safety

2.2.5 Hitched Implements

1. Secure implements against rolling away.

2. Observe the max. permissible supporting load of

the hitch coupling, swinging drawbar or hitch!

3. In the case of drawbar coupling pay attention to

sufficient mobility at the coupling point!

2.2.6 PTO Operation

1. Only PTO shafts specified by the manufacturer

may be used!

2. The protective tube and protective funnel of the

PTO shaft as well as the PTO shield - also on the

implement end - must be attached and in proper

condition!

3. Make sure that the required tube covers for PTO

shafts are in place in transport and working

position!

4. Before installing or removing PTO shafts, switch

off the PTO shaft, turn the engine off and remove

the ignition key!

5. When using PTO shafts with an overload or freewheel coupling that is not covered by the

protective equipment on the tractor, the overload

or free-wheel couplings must be attached to the

implement!

6. Always make sure that the PTO shafts are

mounted correctly and secured properly!

7. Secure the PTO shaft guard against turning by

hooking in the chains!

8. Before engaging the PTO make sure that the

selected PTO speed of the tractor agrees with the

permissible speed of the implement!

9. Before engaging the PTO make sure that no one

is in the hazardous area of the implement!

10. Never switch on the PTO with the engine turned

off!

11. While working with the PTO, nobody is permitted

to stay in the range of the turning PTO or PTO

shaft.

12. Always switch off the PTO in the case of

excessive bending and if the PTO is not required!

13. Caution! After switching off the PTO, there is

danger due to the inertia of the flywheel mass!

Keep away from the implement during this time.

The machine may be worked on only if it is

completely at standstill and if the flywheel is

secured by the holding brake.

14. Cleaning, lubricating or adjusting PTO driven

implements or the PTO shaft only with PTO

disengaged, engine turned off and ignition key

withdrawn! Apply the holding brake on the

flywheel.

15. Place the uncoupled PTO shaft on the holder

provided!

16. After removal of the PTO shaft, fit the protective

sleeve on the PTO stump!

17. Immediately repair any damage before working

with the implement.

18. Release the flywheel brake before the PTO is

turned on.

2.2.7 Hydraulic System

1. The hydraulic system is pressurised!

2. When connecting hydraulic cylinders and motors

pay attention to the specified connection of the

hydraulic hoses!

3. When connecting the hydraulic hoses to the

tractor hydraulics take care that the hydraulics are

pressureless both on the tractor side and on the

implement side!

4. In case of hydraulic function connections between

tractor and machine coupling sleeves and plugs

should be marked so that faulty operation is

excluded! On changeover of the connections

reversed function (e.g. raising/lowering) - Danger

of accident!

5. Check the hydraulic hose lines at regular intervals

and replace them if damaged or worn! The new

hoses must comply with the technical

requirements set by the manufacturer of the

implement!

6. When searching for leaks, use suitable aids to

avoid the risk of injuries!

II - 4

Safety

7. Liquids escaping under high pressure (hydraulic

oil) can penetrate the skin and cause serious

injury! In the case of injuries, seek medical

assistance immediately. Risk of infection!

8. Before working on the hydraulic system,

depressurise the system and turn off the engine!

2.2.8 Tyres

1. When working on the tyres make sure that the

implement is safely shut down and has been

secured against rolling away (wheel chocks).

2. You must have adequate knowledge and the

proper tools to undertake the work of fitting wheels

and tyres.

3. Repair work on the tyres and wheels should only

be carried out by specially trained personnel and

only tools appropriate to the job should be used!

4. Check tyre pressure regularly! Inflate the tyres to

the recommended pressures!

2.2.9 Maintenance

1. Always perform repair, maintenance and cleaning

work as well as troubleshooting only when the

drive is switched off and the engine stopped!

- Remove the ignition key! Apply the holding brake

of the flywheel.

2. Regularly check that nuts and bolts are properly

seated and tighten if necessary!

3. When performing maintenance work with the

implement raised, always secure it with suitable

supporting elements!

4. When replacing working tools with cutting edges,

use suitable tools and gloves!

5. Dispose of oils, greases and filters according

to the regulations!

6. Always disconnect the power supply before

working on the electrical system!

7. If protective devices and guards are subject to

wear, check them regularly and replace them in

good time!

8. When performing electric welding work on the

tractor and mounted implements, disconnect

cables at the generator and battery!

9. Replacement parts must, as a minimum, comply

with the technical requirements set by the

manufacturer of the implements!

This is guaranteed by original KRONE spare

parts!

10. Only use nitrogen to fill gas reservoirs -

Risk of explosion!

2.2.10 Unauthorised Modifications and

Spare Parts Production

Modifications to the machine are permitted only with

the prior approval of the manufacturer. Original spare

parts and accessories authorised by the manufacturer

ensure safe use. Use of other parts may void the

liability for any resulting damage.

2.2.11 Non-Permissible Modes of Operation

The operational safety of the machine is only

guaranteed if it is used for its intended purpose in

accordance with the Chapter “General Information“ of

these operating instructions. The limit values stated in

the data sheets must not be exceeded under any

circumstances.

II - 5

Safety

2.3.1 Location of Safety Stickers on the Machine

The KRONE Big Pack Baler is equipped with all safety devices (protective devices). However, it is not possible to

eliminate all potential hazards on this machine since to do so would impair its full functional capability. You will find

corresponding danger warnings on the machine that indicate the remaining residual risks.

The safety instructions are provided in the form of what are known as ‘warning pictograms’. Below you will find

important information on the position of these signs and their meaning!

Familiarise yourself with the meaning of the adjacent warning symbols. The adjacent text and the

selected application site on the machine provide information about the special dangerous spots

on the machine.

2.3 Introduction

6

8

RE/LI

RE/LI

3

RE/LI

4

RE/LI RE/LI

7

5

BPXC0105

6

6

6

1

2

RE/LI

77

II - 6

Safety

Do not climb onto the machine

if the PTO is connected and the

engine is running.

There is one label each on

the left and right side

ladder to the working platform.

Order No. 939 408-2 (1x)

Never reach into the working

area of the pick-up while the

machine is running.

There is one label each on

the left and right side of the

machine.

Order No. 939 407-1 (2x)

3

Danger due to

rotating worm.

Order No. 939 520-1 (2x)

4

5 6

Before start-up,

close the protective

equipment!

Order No. 942 002-4 (6x)

1

The speed of the PTO must not exceed 1000 rpm!

The operating pressure of the hydraulic

system must not exceed 200 bar!

Order No. 939 101-4 (1x)

Before placing the machine

in operation, read the operating

instructions and the safety

instructions and observe them.

Order No. 939 471-1 (1x)

939 101-4

MAX.

1000/

min

MAX.

200

bar

2

Never reach into the area

where there is danger of

crushing as long as parts

could be moving.

(only for roller chute and

XC cutting system)

Order No. 942 196-1 (4x)

7 8

Maintain a safe

distance from hot

surfaces.

(optional)

Order No. 942 210-0 (1x)

II - 7

Safety

2.4 Special Safety Instructions

2.4.1 Ladder

• Climb on the ladder only with PTO shaft switched off, engine turned off and ignition key

withdrawn!

• Riding on the Big Pack Baler or on the ladder is not permitted.

There is a ladder (1) on the left side of the machine at

the rear next to the baling channel that can be used,

among other things, for maintenance work on the

knotting mechanism.

2.4.2 Fire Extinguisher

The fire extinguisher (1) is at the front of the drawbar on

the left when facing in the direction of travel.

Please have the fire extinguisher

registered. This is the only way to

ensure that all the required

inspections will be performed.

BPXC0107

1

BPXC0108

1

II - 8

Safety

III - 1

Start-up and Transport

3. Start-up and Transport

3.1 Safety Instructions

• Special caution is required when mounting and detaching the Big Pack Baler on and from the

tractor. No one may stay between the tractor and Big Pack Baler. After successful coupling

turn off the engine and pull out the ignition key. Apply the flywheel brake.

• In service, maintenance, adjustment and repair work on the Big Pack baler always switch the

PTO shaft off, turn off the engine and pull out the ignition key.

• Put the Big Pack Baler into operation only if all protective devices are attached and in

protective position!

• The Big Pack Baler may be operated with a maximum PTO shaft speed of 1000 rpm.

• Only the PTO shaft specified by the manufacturer with corresponding overload coupling and

free motion may be used.

• Mounting and detaching the PTO shaft only with the PTO disengaged, the engine turned off

and the ignition key withdrawn!

• Run hoses and connection cables so that they are not subject to tension when cornering or

come into contact with the tractor wheels.

• Check hydraulic hose lines regularly and replace them in the case of damage or ageing!

• When connecting and removing the hydraulic hoses to and from the tractor hydraulics take

care that the hydraulics are pressureless both on the tractor side and the machine side!

3.2 General Operation

3.2.1 Parking Support

As long as the Big Pack Baler is not connected to the

tractor, the drawbar is supported on the parking support.

To raise the parking support:

• As soon as the Big Pack Baler is connected to the

tractor, turn the crank (1) several revolutions

clockwise until there is no more weight on the

support base (3).

• Withdraw the locking bolt (5) on the lower part of the

parking support (2), push in the parking support and

secure it in position (4) with the bolt.

• Then crank the parking support up all the way.

To lower the parking support (to support the drawbar):

• To disconnect the Big Pack Baler from the tractor,

first lower the raised parking support (2) a few

revolutions with the crank (1).

• Pull out the bolt (5) and extend the lower part of the

parking support. Secure with the bolt (5).

1

2

3

5

4

BPXC0109

If the ground is soft, enlarge the footprint

of the support base (3) by placing a

wooden plank underneath.

III - 2

Start-up and Transport

3.2.3Parking Brake

The parking brake is used to secure the Big Pack Baler

from rolling away accidentally, especially when the Big

Pack Baler is disconnected from the tractor.

The crank (1) of the parking brake is located at the left

side of the Big Pack Baler under the baling channel.

Set the parking brake:

• Turn the crank anticlockwise until the resistance

grows noticeably greater.

Release the parking brake:

• Turn the crank anticlockwise until the brake cable is

slightly slack.

Crank gear on the parking support:

The crank (2) can be attached to the head of the parking

support in both positions, (a) and (b).

Position a) Direct transmission ratio 1:1 for quickly

cranking the parking support up and down.

Position b) Gear reduction for cranking the Big Pack

Baler up and down if the Big Pack Baler is

resting on the support base.

BP380-7-016

b

2

a

1

BPXC0180

1

3.2.2Hydraulic Support Base (Optional)

It is also possible to park the Big Pack Baler with a

hydraulic support base.

The hydraulic support base can be extended and

retracted with the corresponding valve on the tractor.

To extend the support base:

• From the driver’s cab on the tractor, extend the

support base until it is resting firmly on the ground.

• It is absolutely essential then to close the ball valve

(1) on the head of the support base.

If the ground is soft, enlarge the footprint

of the support base (3) by placing a

wooden plank underneath.

Retracting the support base:

• First, open the ball valve (1) on the head of the

support base.

• Then retract the support base from the driver’s cab

on the tractor.

BPXC0233

1

III - 3

Start-up and Transport

• Secure the Big Pack Baler against rolling away with wheel chocks and by applying the

parking brake.

• Use suitable supporting blocks for supporting the Big Pack Baler.

• There is a risk of crushing one’s feet when cranking down the parking support.

Before starting the adjustment set the Big Pack Baler on the parking support and uncouple the tractor.

The drawbar can be adjusted optionally for top or bottom

attachment.

Both in the “top attachment” position and in the “bottom

attachment” position the Big Pack Baler can still be

adapted in height to the hitching height of the tractor

(hitch or swinging drawbar).

To guarantee optimum working, the Big Pack Baler must

be hitched horizontally. The top edge of the twine box

serves as reference edge in this case.

Setting the hitching height:

• For the adjustment of the drawbar height the hitch (2)

can be adjusted in height by loosening the screws

(1).

• If this is not sufficient the side parts (4) can be

adjusted in height by additionally loosening the

screws (3).

• For adjusting to bottom attachment the two side

parts (4) are turned round.

For the tightening torques, see Chapter 9.2.1.

3.2.5Adjusting the Drawbar Height

The flywheel holding brake (belt brake) is located on the

left side on the machine on the drawbar.

• To brake the flywheel move the brake lever (1) on the

flywheel from position (a) into position (b). The

flywheel is now braked.

When the electronics are turned on, the Big Pack Baler

emits a horn signal.

Caution! Before engaging the PTO always

release the holding brake first.

3.2.4Holding Brake for Flywheel

1

4

BPXC0111

2

3

BPXC0110

1

4

2

3

BPXC0201

a

b

1

III - 4

Start-up and Transport

3.4 Main PTO Shaft

3.4.1Adapting the Main PTO Shaft

• Before pushing the PTO shaft onto the PTO of the tractor, disengage the PTO, turn off the

engine and pull out the ignition key. Apply the flywheel brake.

• Secure the tractor and Big Pack Baler against unintentionally rolling away.

• In the cornering movements required for adapting the length of the PTO shaft no one may

stand between the baler and the tractor.

To adapt the length of the PTO shaft hitch the Big Pack

Baler onto the tractor. The shortest position of the PTO

shaft is reached in close cornering.

• For measuring pull the PTO shaft apart and push one

half each (1) and (2) onto the baler and the tractor.

Please refer to the operating instructions of the PTO

shaft manufacturer for the exact procedure for adapting

the length.

BP800002

1

2

3.3 Connecting to the Tractor

• The Big Pack Baler must only be connected to tractors that are equipped with a matching hitch.

• When the tractor is put back in front of the Big Pack Baler, there must be no one between the

tractor and the baler.

• Observe the maximum supporting and tensile load of the hitch on the tractor.

• Hitch and secure the Big Pack Baler according to the

regulations on the hitch of the tractor.

The Big Pack Baler comes standard equipped with a

ready-to-use hitch hole of Ø 40 mm (DIN 11 026).

Depending on the specific requirement, the following

hitches are also available:

- Ball-head hitch (K 80)

- Rotating hitch hole

- Hitch connection (export only).

BPXC0112

III - 5

Start-up and Transport

Tractor side

• Take the PTO shaft out from the retaining chain (1).

• With the engine turned off and the ignition key

withdrawn, push the PTO shaft onto the tractor PTO

and secure it.

• Secure the PTO shaft guard against turning by

hooking in the locking chain (2).

• Make certain that the PTO shaft is

properly secured after installation and

locked into place.

• Use only the PTO shaft included with

delivery from the factory.

• Before engaging the PTO always

release the flywheel holding brake first.

Before pushing the PTO shaft onto the

tractor PTO, do not fail to set the

flywheel with its holding brake.

3.4.2Mounting on the tractor side

Make certain the chain connection is

ideal:

• The chain guide should be as close

as possible to perpendicular to the

PTO shaft. (see view (a)

• The chain guide should never be

diagonally connected via the guard

cone. (see view (b)

Make certain there is sufficient free

room in the swivel range of the PTO

shaft in all operating states. Contact

with parts of the tractors or device

may result in destruction.

a) b)

BPXC0114

1

2

III - 6

Start-up and Transport

Depending on the version, a different number of hydraulic

control valves is required on the tractor for the Big Pack

Baler. The protective caps of the hydraulic hoses (1)

placed in the stowage (2) are colour-coded. This ensures

problem-free identification of the necessary control valves

(see also Chapter 1 “Connection Requirements, Tractor”).

3.5.1 Hydraulic Brake (country-specific)

A hydraulic brake is provided for certain Big Pack Baler

(export machines). In this version a hydraulic brake

valve on the tractor is required.

The corresponding hydraulic hose is connected with the

control valve on the tractor side. Activating the control

valve causes the brake to be activated.

3.5 Hydraulic, Compressed Air and Electrical Connections

3.5.2Hydraulic Connection for Locking

the Coaster Axle (Optional)

Connect the separate hydraulic hose from the locking

cylinder of the steering axle (green protective cap) onto

the single-action connection of the tractor hydraulics.

Observe the user instructions of the

tractor manufacturer on parallel operation

of the tractor control devices!

Connecting the locking cylinder of the

steering axle must take place before or at

the same time as the other hydraulic