Krone AM 203 CV, AM 243 CV, AM 283 CV + B, AM 243 CV + B, AM 283 CV Operating Instructions Manual

No. 227-4 GB

Operating Instructions

Disc Mower

AM 203 CV

AM 243 CV / + B

AM 283 CV / + B

(from machine no. 403 700)

We

declare under our sole responsibility, that the product

to which this declaration relates corresponds to the relevant basic safety and health

requirements of the Directive 89/392 (EEC) and to the requirements of the other rlevant

Directives:

Heinrich-Krone-Str. 10, D-48480 Spelle

Maschinenfabriken Bernard Krone GmbH

Spelle, 10.05.95

(Heinz Krone, Board of Directors)

(Dr. Josef Horstmann, Designing office sub-manager)

(Josef Jungehüser, Quality assessment manager)

EC Declaration of Conformity

according to Directive 89/392/EEC

Dear customer,

Here are the operating instructions for the KRONE product you

purchased.

These operating instructions contain important information for the

proper use and safe operation of the machine.

If these operating instructions have for any reason become

completely or partially redundant, you can obtain replacement

operating instructions for your machine with the specification

numbers listed overleaf.

Krone-Disc Mower

Models: AM 203 CV; AM 243 CV; AM 243 CV + B;

AM 283 CV; AM 283 CV + B

1

This symbol is designed to draw attention

to the safety instructions contained in the

operating instructions. These instructions

must be observed to prevent accidents.

I. Foreword

Dear customer,

We thank you for the trust you have placed in us by

purchasing this machine.

When you received this machine, the dealer should

have given you instructions for the operation,

maintenance and adjustment of the machine.

However, this brief introduction to the machine can

not replace a detailed acquaintance with the different

tasks and functions of the machine and the proper way

of treating it.

These operating instructions are designed so that you

are extensively informed of the activities required in

each area, from commissioning and operation to the

maintenance and care of the machine. The structure of

the individual chapters in the text and illustrations

corresponds to the sequence of work procedures when

you use the machine.

Read these operating instructions carefully before you

use the machine, and pay special attention to the

safety instructions.

Important: To avoid accidents and to ensure

maximum results, no alterations may

be made to the machine without the

manufacturer´s permission. Similarly,

the machine must only be used under

the conditions prescribed by Krone.

All information, illustrations and technical information in

the operating instructions represent the latest status at

the date of publication. The company reserves the right

to make constructional alterations at any time and

without prior notice or obligation.

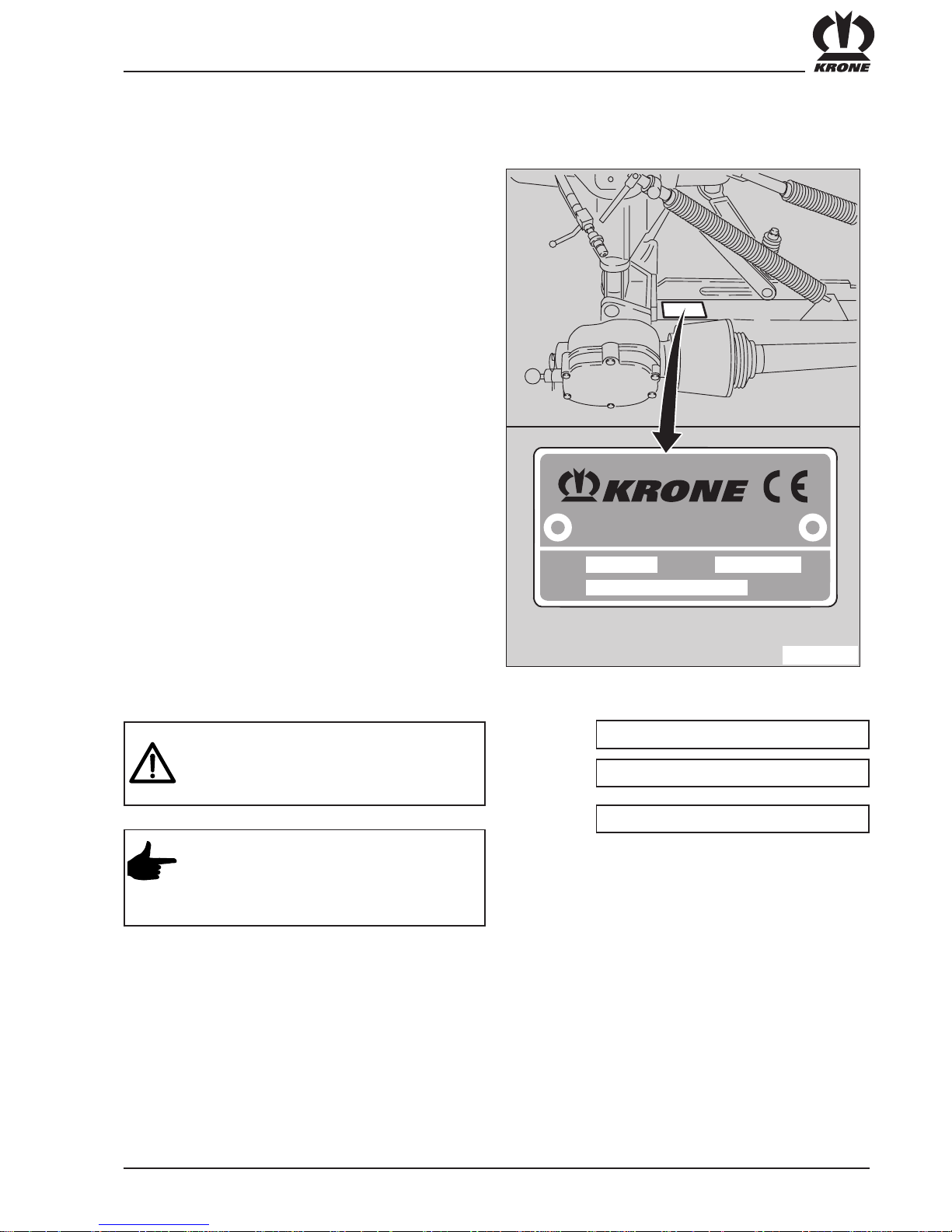

Mach. No.

Type

Year

When ordering replacement parts, the machine type,

machine number and year of manufacture must be

given. These details can be found on the identification

label on the machine.

We recommend that these details be entered in the

above boxes so that they are readily available.

And please remember that imitations and copies of

parts, especially wearing parts, do not keep what they

appear to promise. Material quality is difficult to test

visually, therefore special care is required when

purchasing cheap offers and imitation parts!

The simplest remedy:

Purchase only original KRONE parts!

Ordering Replacement Parts

You will find this symbol at various point in

the operating instructions. It gives special

handling instructions which should be

particularly observed in the use of the

machine

AM-1-006

Maschinenfabrik Bernard Krone GmbH

Heinrich-Krone-Straße 10, D 48480 Spelle

Jahr

Année

Masch. Nr

No. de série

Type

Made in

W.-Germany

2

List of Contents

I. Foreword ..............................................................................................................................1

II. List of Contents .....................................................................................................................2

III. General..................................................................................................................................3

1. Introduction

1.1 Position of Information Labels with safety-relevant contents on the Machine.......................6

1.2 Position of General Information Labels on the Machine .......................................................8

1.3 Technical Data for Disc Mower .............................................................................................9

2. Preparing for Operation

2.1 Attaching the Disc Mower to the Tractor.............................................................................10

2.2 P.T.O. Shaft.........................................................................................................................12

2.3 Jack Stand...........................................................................................................................13

2.4 Conditioner Drive (lever change gearbox) ..........................................................................13

2.5 The angle of the mower to the tractor .................................................................................14

2.6 Preparing to turn .................................................................................................................14

2.7 Transport Position ...............................................................................................................15

2.8 Detaching the Disc Mower to the Tractor............................................................................16

3. Adjusting the Disc Mower

3.1 Adjusting the Top Link Arm Coupling Point ........................................................................18

3.2 Adjusting the Safety Breakaway unit ..................................................................................18

3.3 Adjusting the Compensating Spring for the Cutter Beam ...................................................19

3.4 Adjusting piece for lifting cylinder and flotation spring ........................................................19

3.5 Basic Setting for the Tractor Lower Link Arm .....................................................................19

3.6 Adjusting the Swath Width ..................................................................................................20

3.7 Adjusting the cutting height .................................................................................................20

3.8 Changing Blades on the Cutting Discs with Blade Screw Connectors ...............................21

3.9 Adjusting the Conditioner Speed ........................................................................................22

3.10 Adjusting the Conditioner Cover Plate ................................................................................22

3.11 Adjusting the Position of the Condtioner rotor to the Cutterbar .......................................... 23

4. Maintenance

4.1 General................................................................................................................................25

4.2 Oil Level Check and Oil Change for Cutterbar....................................................................26

4.3 Oil Level Check and Oil Change for Main Gearbox ............................................................26

4.4 Oil Level Check and Oil Change for Gearbox, Mower Drive/Conditioner Drive .................27

4.5 Oil Level Check and Oil Change for the 1000 rpm power take off......................................27

4.6 Unlocking the Overload Coupling on the Drive Shaft to the Cutterbar

and on the Conditioner Drive (Walterscheid) ......................................................................28

4.7 Preparing the overload clutch for use (ByPy) .....................................................................28

4.8 Bleeding the overload clutch of the universal joint drive shaft

and of the double joint.........................................................................................................28

4.9 Lubrication...........................................................................................................................29

5. Conditioner and Protective Cloth Covers.......................................................................31

6. Wide swath hood...............................................................................................................32

7. Winter Storage ...................................................................................................................34

8. Start-up after Winter Storage ...........................................................................................34

Supplement to Operating Instructions

1. Assembly Instructions (initial installation) ........................................................................39

2. Mounting the Gearbox for a 1000 rpm Power Take-Off Shaft .........................................50

3

5. The operator´s clothing should be tight fitting. Avoid

wearing loose fitting clothes.

6. Keep the machine clean to prevent the danger of fire!

7. Before starting the machine and moving off, check the

danger area around the tractor (children!). Good visibility

is absolutely essential!

8. Carrying passengers on the implement during work or

transport is not permitted.

9. Make sure that the implement is correctly coupled, and

that it is only fixed and secured with the prescribed

fittings!

10.Make sure that the supporting devices, jacks etc. are

in the correct position during assembly and removal!

11.Special care is required when equipment is being

coupled to the tractor or detached from the tractor!

12.Ballast weights must always be attached in the

prescribed way at the designed attachment points!

13.Adhere to the permitted axle loads, total weights and

transport dimensions!

14.Check and fit transport equipment – e.g. lighting,

warning signs and, if required, protective equipment!

15.Operating equipment for remote controls (ropes, chains,

rods etc.) must be laid out in such a way that, whatever

the working or transport position, it can not inadvertently

cause any movements.

16.Prepare equipment for road transport as prescribed by

the manufacturer, and lock the equipment in accordance

with the manufacturer's regulations!

17.Never leave the driver´s position when the tractor is in

motion!

18.The speed of travel must always be suited to the

environmental conditions! Avoid any sudden turns

when travelling uphill, downhill or across a slope!

19.The handling, steering and braking of the tractor is

affected by integrated or attached equipment and

ballast weights. Make sure that you allow for more

flexibility in steering and braking!

20.When turning, remember to take account of the wide

load and/or the greater weight of the equipment!

21.Only switch on equipment when all protective

devices are fitted and in protection position!

2. Safety and Accident Prevention

Regulations

1. Take note of both the regulations in these operating

instructions and also the general safety and accident

prevention regulations!

2. The attached warning and information signs give

important advice for safe operation. Observing them

will enhance your safety!

3. When you use public roads, make sure you observe

the relevant traffic regulations!

4. Make sure you know all equipment and controls before

you begin working with the machine. When you are

operating the machine, it´s too late!

Basic rule:

Before any public roads are used and

before the machine is started, check the

disc mower and the tractor for roadworthiness and operational safety.

1. Operation in Accordance with

Specifications

The disc mower is designed solely for normal agricultural

use (operation in accordance with specifications).

Any use of the machine for other purposes is deemed to

be not in accordance with specifications. The manufacturer

bears no responsibility for any resulting damage; such use

is entirely at the operator´s risk.

Use in accordance with specifications also includes

adherence to the operating, maintenance and service

instructions prescribed by the manufacturer.

The disc mower must only be used, maintained and

repaired by personnel who are acquainted with the machine

and have been informed of the danger involved.

The applicable accident prevention regulations and all

other generally recognized safety, health and road traffic

regulations must be adhered to.

Any unauthorized alterations to the machine render any

liability for damage undertaken by the manufacturer null

and void.

III. General

4

,

22.Persons are not allowed to enter the working area!

23.Keep clear of the area of rotation and swing of the

equipment!

24.Hydraulic controls must only be operated if no persons

are in the swing area!

25.Power operated parts (e.g. by hydraulics) contain

danger points which can cause injury by bruising and

grazing!

26.Before leaving the tractor, rest the mower on the

ground, switch off the engine and remove the ignition

key!

27.Make sure that no personnel go between the tractor

and the implement unless the tractor is protected from

rolling by the parking brake and/or wheel blocks!

3. Attached Equipment

1. Special care is required when the implements is

being connected to the tractor or disconnected from

it!

2. The implement must only be coupled to the

appropriate fittings (e.g. the 3-point connection), and

they must be so secured (transport, operation) that

unintentional lifting or lowering of the implement is

not possible.

3. In three-point connection, it is absolutely essential

that the hitching categories of the tractor and

attachment (e.g. power take-off shaft speed,

hydraulics) are matched!

4. When operating the external controls for three-point

connection, make sure that nobody goes between

the tractor and the implement (danger of injury)!

4. Power Take-Off shaft Operation

1. Only the P.T.O. shafts prescribed by the manufacturer

may be used!

2. Both male and female guard tubes and cones of all

P.T.O. shafts must be fitted and in good condition!

3. Observe the tube overlap prescribed for P.T.O. shafts

in transport and operating position!

4. Before installing or removing the P.T.O. shafts, make

sure to turn off the power take-off shaft and the engine,

and remove the ignition key!

5.When using P.T.O. shafts with overload or free wheel

clutches that are not covered by the guards on the

tractor, the overload or free wheel clutches must be

fixed on the implement side!

6. Always ensure correct assembly and guarding of the

P.T.O. shaft!

7. Protect the P.T.O. shaft guard from rotating with the

shaft by fitting the chains!

8. Before switching on the power take-off shaft, make

sure that the p.t.o. speed of the tractor matches the

permitted speed of the implement!

9. Before switching on the power take-off shaft, make

sure that nobody is in the danger area of the implement!

10.Never switch on the power take off shaft when the

tractor engine is turned off!

11.Any work on the power take-off shaft may only be

carried out when nobody is in the area of the rotating

power take-off shaft or P.T.O. shaft.

12.The power take-off shaft should always be turned off

when the angle is too great or the p.t.o. shaft is not

required!

13.Danger! Working elements continue to rotate after the

power take-off shaft is turned off! Do not approach the

machine during this time! Work may only be carried out

on the machine when the machine is fully stationary

and the rotating parts have been secured by the

parking brake.

14.Cleaning, lubrication or adjustment of the P.T.O. shaft

or any equipment driven by the power take-off shaft

may only be carried out when the p.t.o. shaft and the

engine are turned off and the ignition key has been

removed! Rotating parts must be secured with the

parking brake.

15.Place the detached P.T.O. shaft on the support bracket

provided!

16.After removing the P.T.O. shaft, place the protective

cover on the stub of the power take-off shaft!

17.Any damage must be repaired immediately before any

work is carried out with the attachment!

5

4. When there are functional hydraulic connections

between the machine and the implement, all

coupling sleeves and plugs must be marked to

prevent operating errors. If the connections are

switched, the functions are reversed (e.g. lifting

and lowering) – this can cause accidents!

5. Hydraulic hoses must be checked regularly, and

they must be replaced if they are damaged or

worn. Replacement hoses must conform to the

technical requirements of the implement

manufacturer!

6. When tracing leaks, suitable aids should be used

to prevent injury!

7. Fluid leaking under high pressure (hydraulic oil)

can penetrate the skin and cause serious injury!

When injury occurs, consult a doctor immediately!

Danger of infection!

8. Before carrying out any work on the hydraulic

systems, lower the machine to the ground,

depressurize the system and turn off the engine!

5. Hydraulic System

1. The hydraulic system is pressurized!

2. When connecting hydraulic cylinders and motors,

make sure that the hydraulic hoses are correctly

coupled!

3. When connecting hydraulic hoses to the tractor´s

hydraulic system, make sure that all pressure has

been released from the hydraulics of both the

tractor and the implement!

6. Maintenance

1. Repair, maintenance and cleaning work and the

correction of malfunctions must always be carried out

only when the drive is turned off and the engine is at

a standstill! Remove the ignition key! Apply the parking

brake.

2. Nuts and bolts must be checked regularly for tightness,

and tightened if necessary!

3. When carrying out maintenance work on the machine

in a lifted position, it must always be supported on

suitable jacks.

4. When replacing fittings that contain cutting blades,

always use suitable tools and gloves!

5. Oil, grease and filters must be correctly disposed

of!

6. The power supply must always be disconnected

before any work is carried out on the electrical system!

7. If protective devices are subject to wear, they must be

checked regularly and replaced in good time!

8. When electric welding is carried out on the tractor and

any fitted attachments, the cables must be disconnected from the generator and battery!

9. Replacement parts must conform at least to the

technical requirements defined by the manufacturer!

The best guarantee is to use only original KRONE

parts!

10.Where gases are stored, only refill with nitrogen.

Danger of explosion!

6

1. Introduction

1.1 Position of the warning signs, with safety-technical information, on the machine

The KRONE Disc mower is equipped with all necessary safety features (protective equipment). Not all danger

points on this machine can be completely safeguarded with regard to the function of the machine. On the machine

you will find appropriate warnings that point out this residual danger.

We have designed these danger notices in the form of so-called warnings symbols. For the position of these

warning notices and their meaning/explanation, please refer to the following information.

Make sure that you are fully conversant with the meaning of the warning symbols. The text

next to the symbols and the position on the machine where the notices are displayed provide

information about the specific danger points on the machine.

4

2

6

5

6

3

2

1

7

939 572-0

Order No. 939 572-0 (1x)

Move guards into

position.

4

5

6

Do not touch any moving

parts of the machine.

Wait until they are

completely stationary.

Order No. 939 410-2 (1x)

Keep at a safe

distance when the

engine is running.

Order No. 942 197-1 (2x)

3

2

Never put your hand into

the danger area as long as

parts may be moving.

Order No. 942 196-1 (3x)

Read and take note of

the operating

instructions.

Order No. 939 471-1 (1x)

1

The PTO shaft speed must not exceed 540 rpm!

The operating pressure in the hydraulics system

must not exceed 200 bar.

Order No. 939 100-4 (1x)

8

1.2 Positions of the general information labels on the machine

939 428-1 (1x)

3

939 180-2 (1x)

2

939 567-1 (1x)

1

939 515-1 (1x) AM 203 CV

939 518-2 (1x) AM 243 CV

939 519-2 (1x) AM 283 CV

4

942 132-0 (1x)

6

939 511-1 (1x) AM 203 CV

939 512-2 (1x) AM 243 CV

939 513-2 (1x) AM 283 CV

5

8

8

61 274 5

939 531-1 (1x)

7

180

939 531-1

8

139 888-0

139 889-0

112

939 567-1

139-888

139-889

QS

Kontrolle frei

Datum

Unterschrift:

939 428-2

939 548-0 (1x)

with screw

connection blades

942 009-2 (1x)

with quickrelease blades

9

Type

Cutting width [mm] 2000 2400 2800

Transport width Tractor width Tractor width Tractor width

Number of mowing discs 3 4 5

Number of mowing cylinders 2 2 2

Conditioning system V-shaped flail. V-shaped flail. V-shaped flail.

Speed of conditioner rotor [rpm] 600 & 900 600 & 900 600 & 900

Width of conditioning system [mm] 1600 2000 2400

Swath width [m] 0.8 - 1.6 0.9 - 2.0 1.2 - 2.4

(0,9 - 2,3) (1.2 - 2.7)

Area covered [hectares/hour] 2.5 3 3.5

Power consumption [kW/PS] 33/45 37/50 44/60

Power take-off shaft speed [rpm] 540 540 540

Weight of machine [kg] 760 810 860

Required hydraulic connections 1 x Single acting 1 x Single acting 1 xSingle acting

Required Quantities and Lubricant Designations for Gearboxes

SAE 90

For biological lubricants, the oil change intervals must be strictly adhered to due to ageing of

the oils.

AM 203 CV

AM 243 CV

(AM 243 + B)

1.3 Technical Data for Disc Mower AM 203 CV / AM 243 CV / AM 283 CV

Biological lubricants

Required quantity [litres] Oil type Brand name

Main gearbox 0,3 SAE 90

Gearbox of

conditioner drive

Auxiliary gearbox

for 1000 rpm pto

on request

Mowing beam

AM 203 CV 4

AM 243 CV (+B) 5

AM 283 CV (+B) 6

1,5

SAE 90

0,2

SAE 90

AM 283 CV

(AM 283 CV + B)

10

2. Preparing for Operation

2.1 Attaching the Disc Mower to the Tractor

5. The protective cloth covers must be regularly

checked. Covers that are worn or damaged must

be replaced.

6. The protective features on the mower, e.g. cloth

covers and guard plates, are designed as

protection from stones etc. that are thrown out,

and also to prevent access to dangerous parts of

the machine. Therefore it is essential that they

are placed in position before work commences.

7. When the mower is being lowered from transport

position to working position or back to

transport position, nobody must be allowed to

go between the tractor and the mower.

8. Special care is required when fitting implements

to the tractor or removing them. It is essential

that the accident prevention regulations are

observed.

1. The mower is designed solely for nor

mal agricultural use. (Operation in

accordance with specifications)

2. While working with the mower, all

personnel must keep a sufficient

safety distance from the cutting

elements.

3. The support skids must be on the

ground before the machine is

switched on and during operation.

4. Even when the mower is used in

accordance with specifications,

stones etc. may be thrown out.

Therefore, nobody must be allowed to

enter the danger area. Special care

must be taken when working near

roads and buildings.

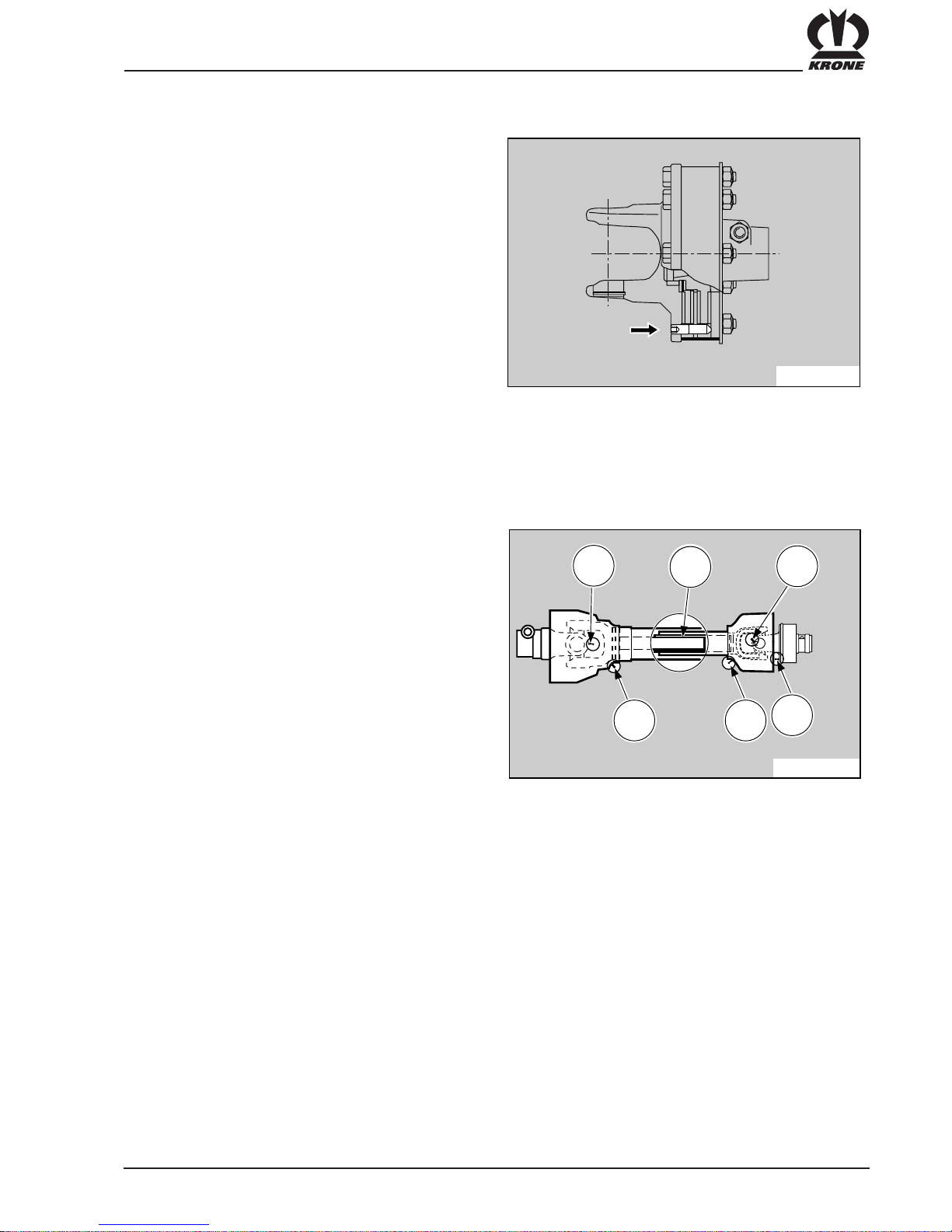

Adapting the hitch points

The hitch points are adjusted as standard for cat. II.

If the mower is to be moved to the side in the case of

cat. II, hitch point (1) must be moved to the outside.

Tighten the bolts (2) firmly after modification.

AM-1-001

Kat. II

AM-1-001

Kat. II

3

2

1

2

11

The lower link arms (3) are connected to the coupling

points provided, and the top link arm (2) is connected to

the newly designed top link arm coupling point (1).

Use hydraulic control device with

floating position!

A single control valve is required on the tractor to

operate the disc mower. The hydraulic hose with the

shut-off tap (3) is coupled into the coupling sleeve (1) of

the control valve. The control cord (2) to activate the

“transport position” locking feature is fixed at a

convenient point on the tractor.

- When the hydraulic hoses are

connected to the tractor, the hydraulic

system on both sides must be free from

pressure!

- When looking for leakages, use

suitable aids and protective goggles to

prevent injuries.

- Liquid escaping under high pressure

(hydraulic oil) can penetrate the skin

and cause serious injury! In case of

injury, consult a doctor immediately!

Danger of infection!

- Release the pressure before disconnecting hoses

and before any work is carried out on the

hydraulic system!

- Check hydraulic hoses regularly, and replace any

damaged or worn hoses. Replacement hoses

must conform to the mower manufacturer's

technical specifications.

When the hydraulic hose is connected,

the hydraulic control device must be in

floating position or in the “Lower”

position.

3

AM-0-010

2

1

3

AM-0-011

1

2

12

This mower is driven with a maximum

power take-off shaft speed of 540 rpm.

Under no circumstances may it be

operated with a higher power take-off

shaft speed.

The PTO shaft must only be fitted

or removed when the power take-off

shaft and the engine are turned off and

the ignition key has been removed!

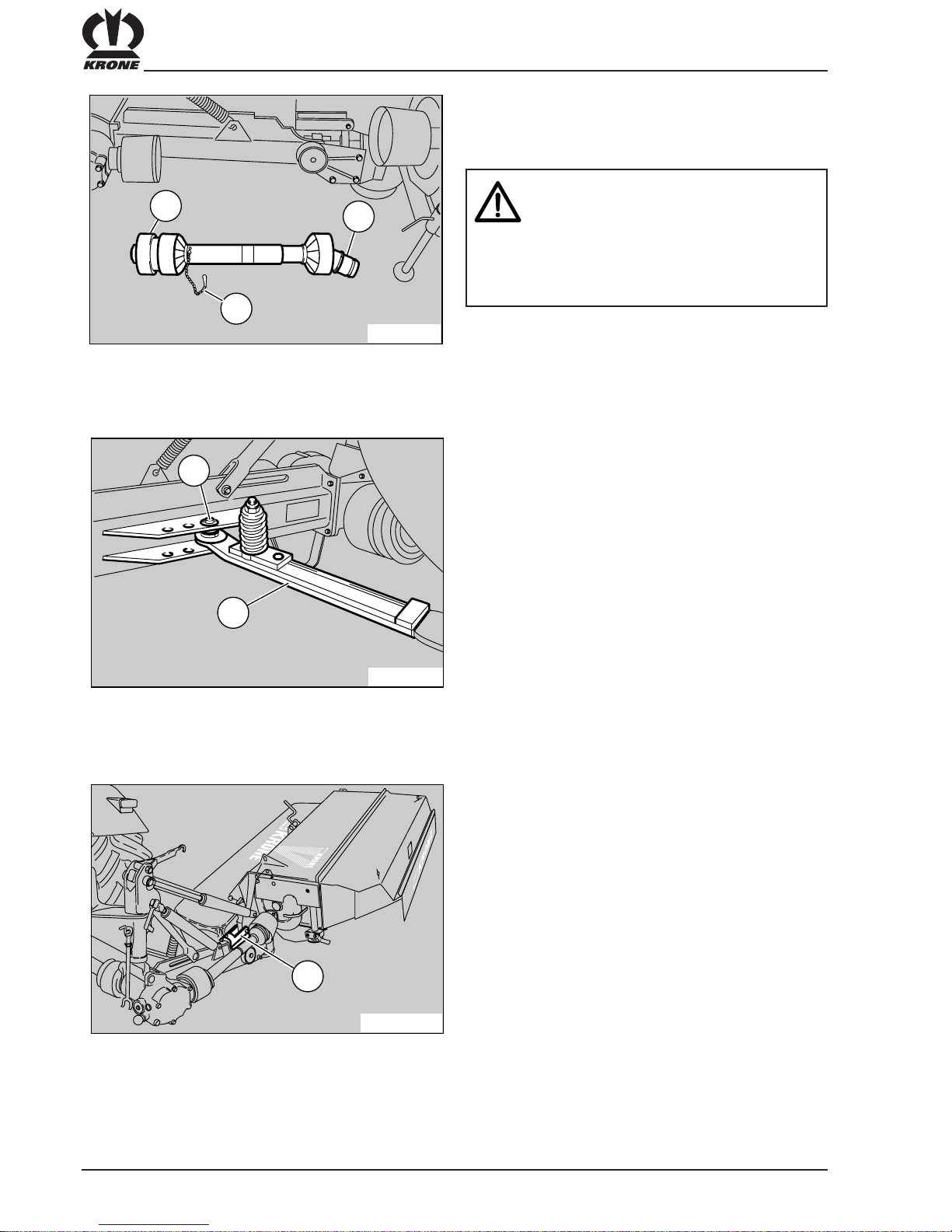

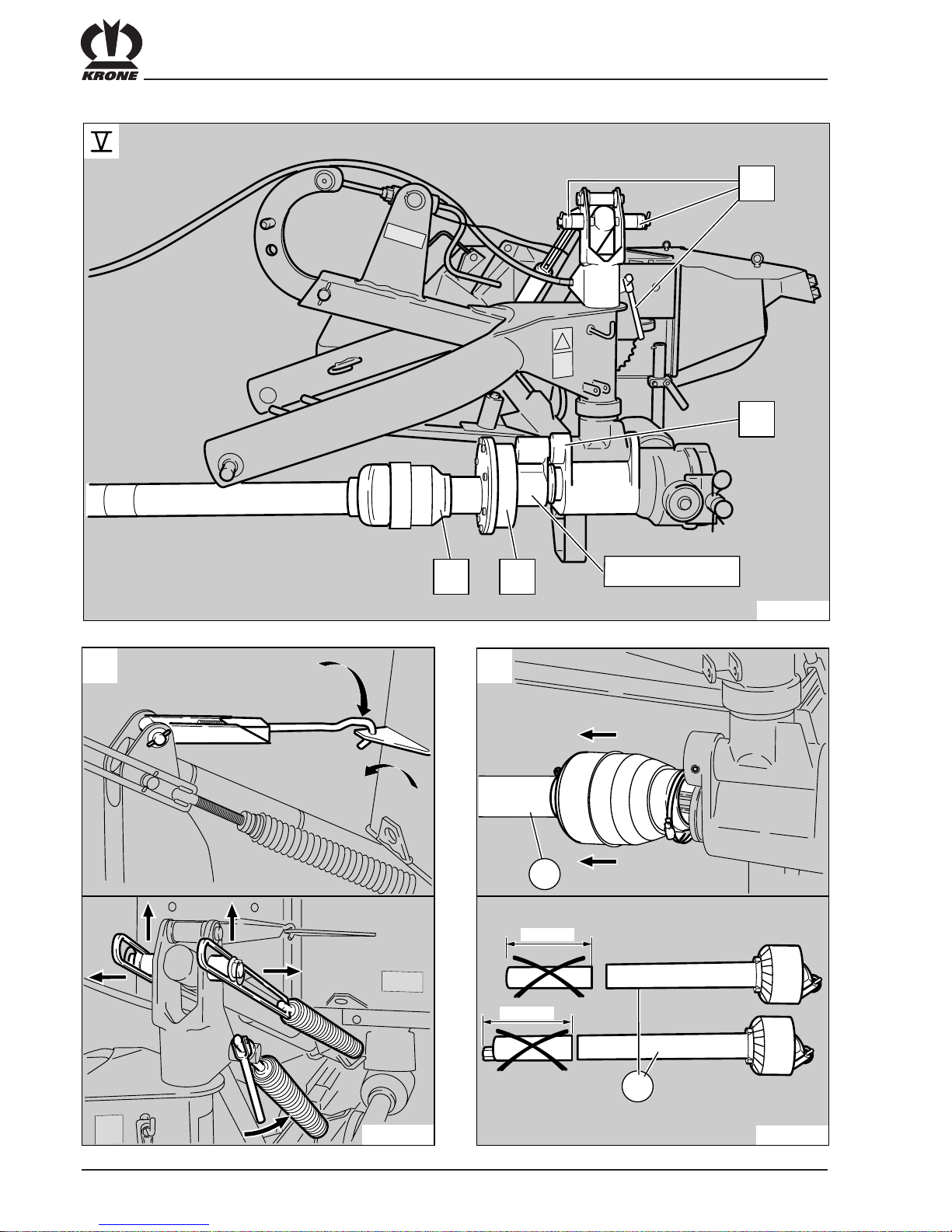

2.2 P.T.O. Shaft

The PTO shaft is slid onto the gearbox input shaft with

the friction clutch towards the disc mower, and it is

rested on the support bracket (1). The safety chains

must never be used to hold the PTO shaft. Make sure

that the locking device of the PTO shaft has snapped

into position.

Adapting the PTO Shaft

In order to adapt the PTO shaft, the two halves of the

shaft (1) and (2) should be held next to each other in

the shortest operating position to check the overlap of

the section tubes. If the overlap is too great, the section

tubes and protecting tubes must be shortened so that

they can move freely in any operating position and do

not knock each other. The exact procedure for

shortening the PTO shaft can be found in the operating

instructions from the PTO shaft manufacturer, which

are supplied with the PTO shaft.

Check the swivel space and the free

movement space of the PTO shaft. If the

PTO shaft touches the tractor or the

attachment, this can cause damage.

Special equipment

Auxiliary gearbox for 1000 rpm power take-off shaft

Operation with a power take-off shaft speed of

1000 rpm at the tractor requires the fitting of an

auxiliary gearbox (1) on the mower unit.

- The retaining chain should be inserted

to prevent the PTO shaft guard from

rotating with the shaft.

- The chain should be inserted in such a

way that the PTO shaft has sufficient

freedom of movement in all operating

positions.

AM-0-002

1

AM-002/4

1

AM-4-054

1

2

13

Make sure that the jack stand is retracted before switching on the mower.

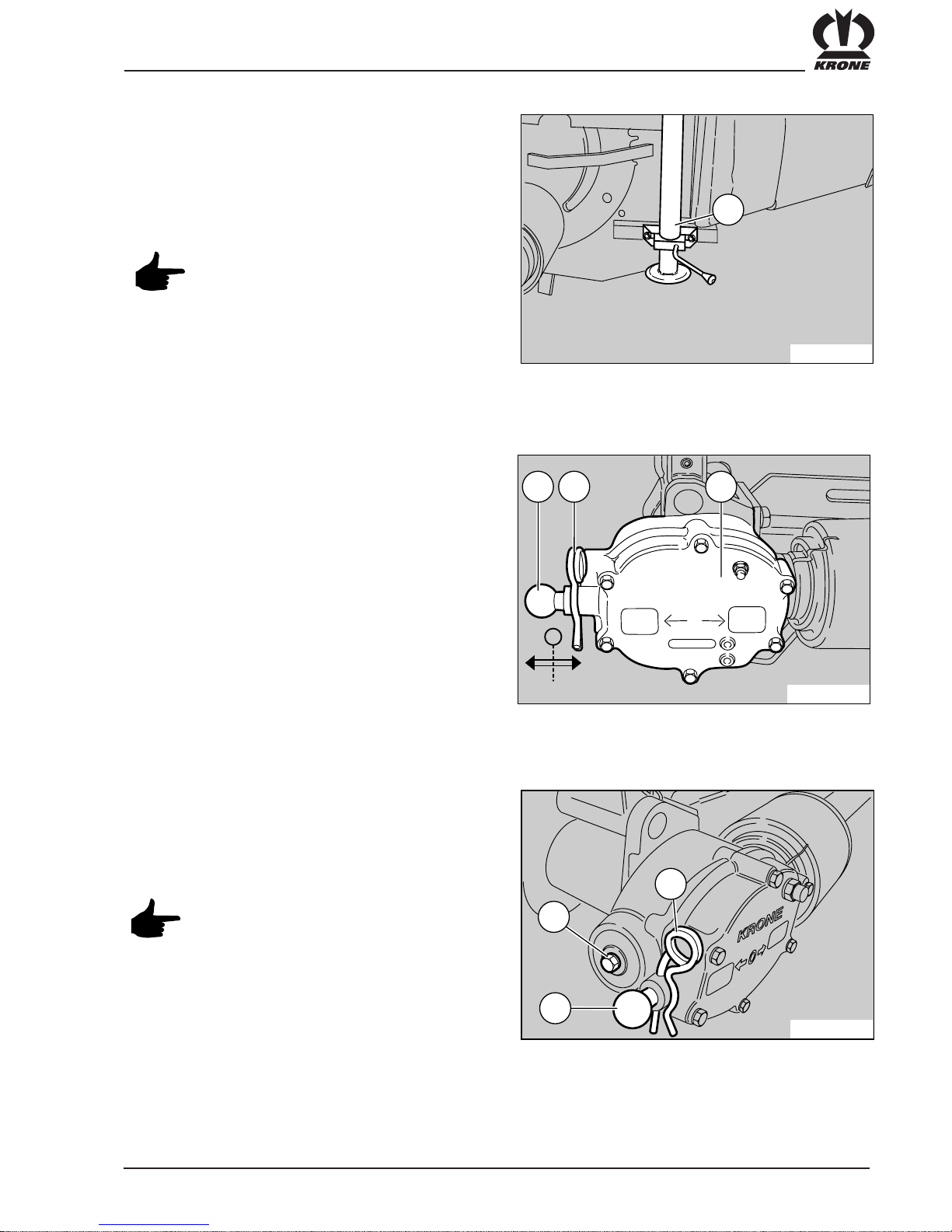

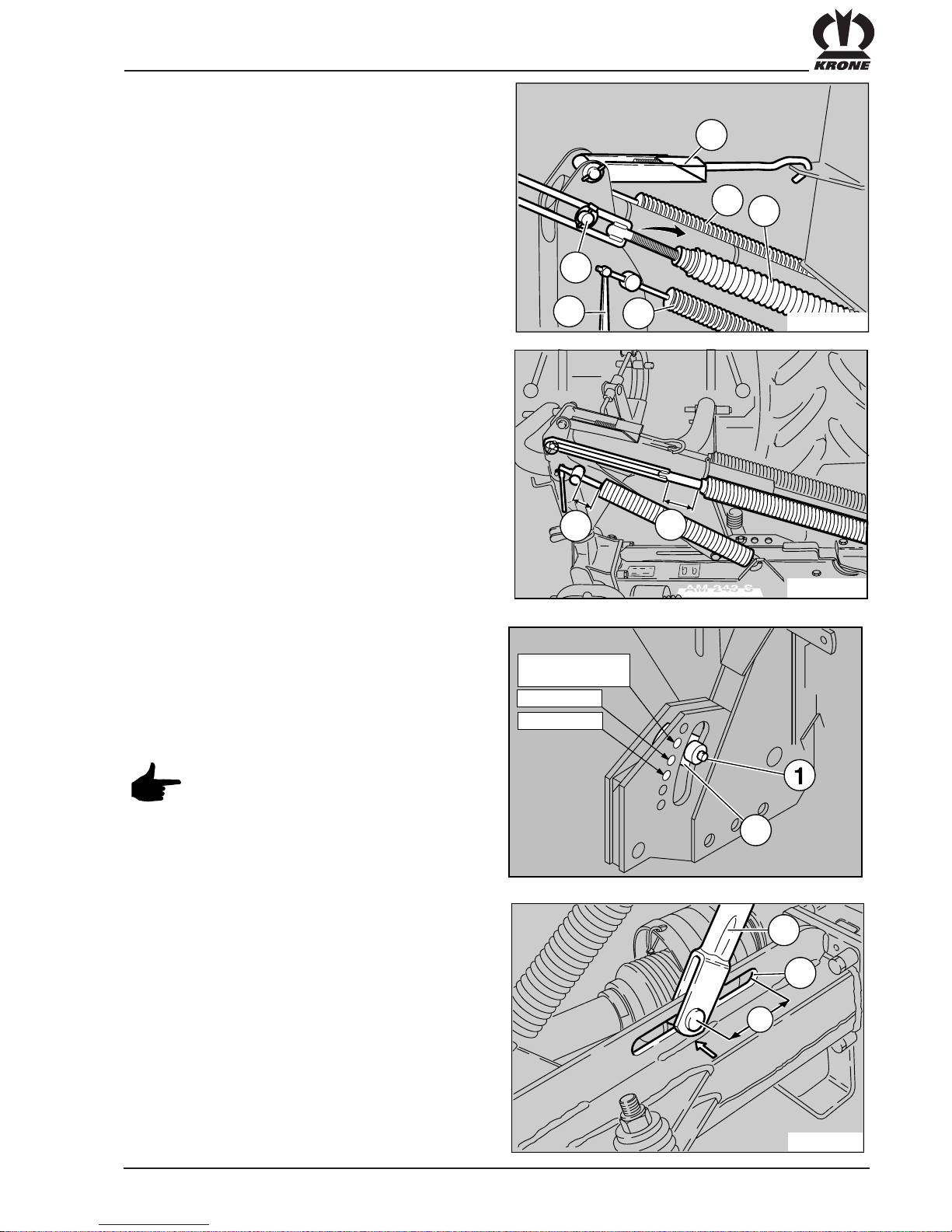

2.4 Conditioner Drive (lever change

gearbox)

The rotation speed of the tine rotor can be adjusted by

means of the change lever (1) after the retaining pin (2)

on the conditioner gearbox (3) has been removed.

The jack stand (1) must be retracted when the disc

mower is in operating position.

By turning the screw (1) with the spanner supplied, the

gear shift process with the gear change lever (3) is

made easier.

After changing the speed, make sure that

the retaining pin (2) is inserted again.

2.3 Jack Stand

KRONE

600

900

0

AM-0-007

0139-441

1 2 3

A

B

AM-0-008

1

2

3

AM-1-078

1

14

The PTO shaft for the conditioner drive is mounted with

the friction clutch (1) towards the gearbox and the freerunning end (2) towards the conditioner. Attach the

retaining chain (3) to the mower.

2.5 The angle of the mower to the tractor

The adjustment of the angle of the mower to the tractor

can be made with the breakaway safety unit (1). Basic

setting is position (2).

The retaining chain should be inserted to

prevent the PTO shaft guard from

rotating with the shaft.

The PTO shaft must only be fitted or

removed when the power take-off shaft

and the engine are turned off and the

ignition key has been removed!

2.6 Preparing to turn

When preparing to turn the tractor, simply lift the disc

mower by means of the hydraulic cylinder on the

machine until the locking mechanism (1) rests against

the catch.

AM-1-083

1

AM-1-08

2

1

2

AM-4-00

9

2

3

1

15

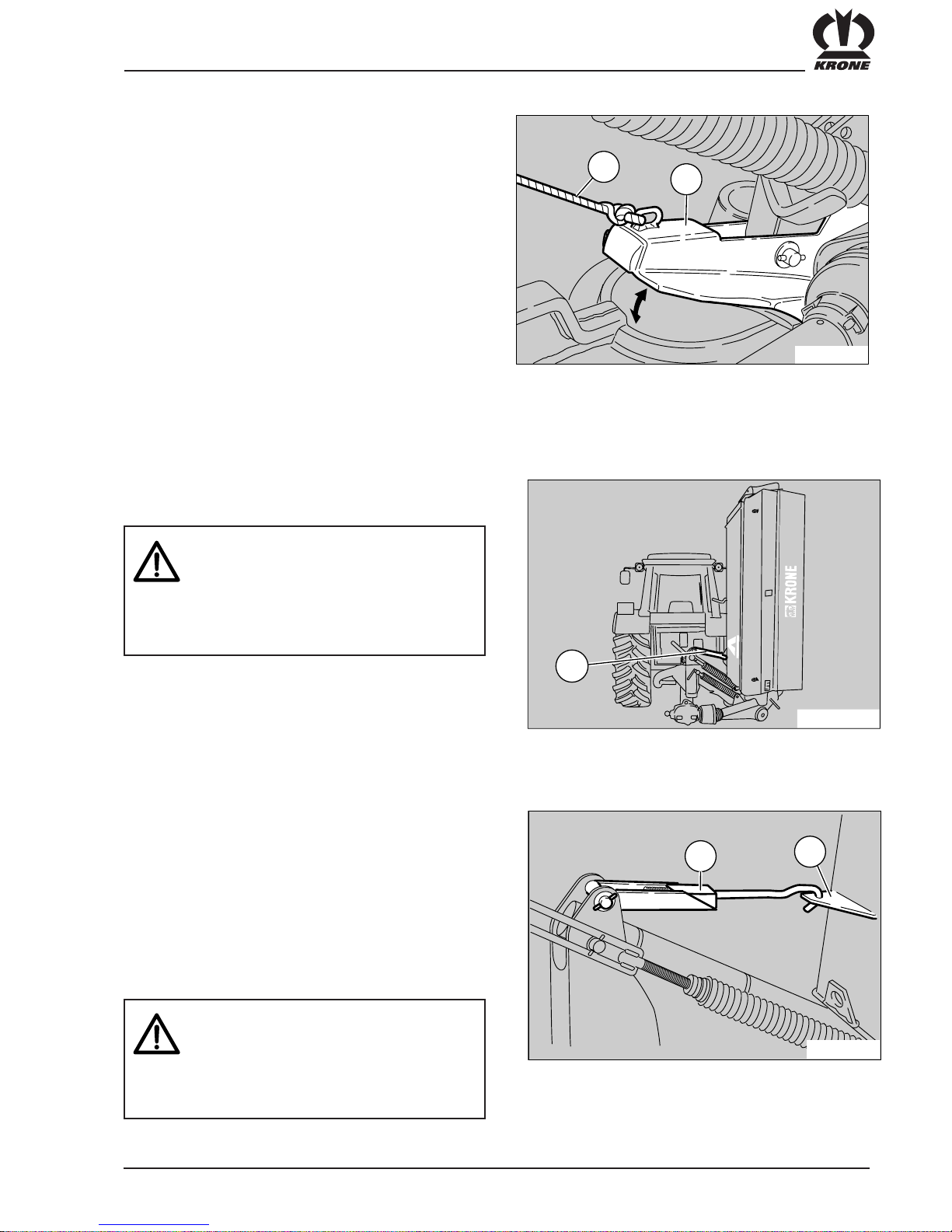

The mower unit must be secured in the transport

position. This is realised via the transport lock (1), which

has to be hooked onto the conditioner housing (2) when

the mower unit is moved to transport position. When

lifting the mower unit to transport position, hold the

synthetic cord taut until the mower unit has reached

transport position. Then release the cord so that the

hook can engage in the lug in the housing. In addition

to this, close the shut-off tap on the tractor-side of

the hydraulic hose pipe.

2.7 Transport Position

- After the drive is turned off, the

mowing discs may continue to rotate.

- It is essential to wait until the machine

is at a complete standstill before the

mower is folded up or any personnel

approach the machine!

To do this, the locking mechanism (2) is pulled from

the tractor with the synthetic cord (1) and the mower

brought to the transport position by activating the lifting

cylinder.

Adjust the transport locking device to

the ideal length.

Ensure that the transport lock is

engaged at all times.

The shut-off tap on the hydraulic hose

must be closed.

The disc mower is folded upwards for transport.

AM-1-059

1

AM-1-060

1

2

AM-1-05

8

2

1

16

The ground underneath must be level

and should be solid.

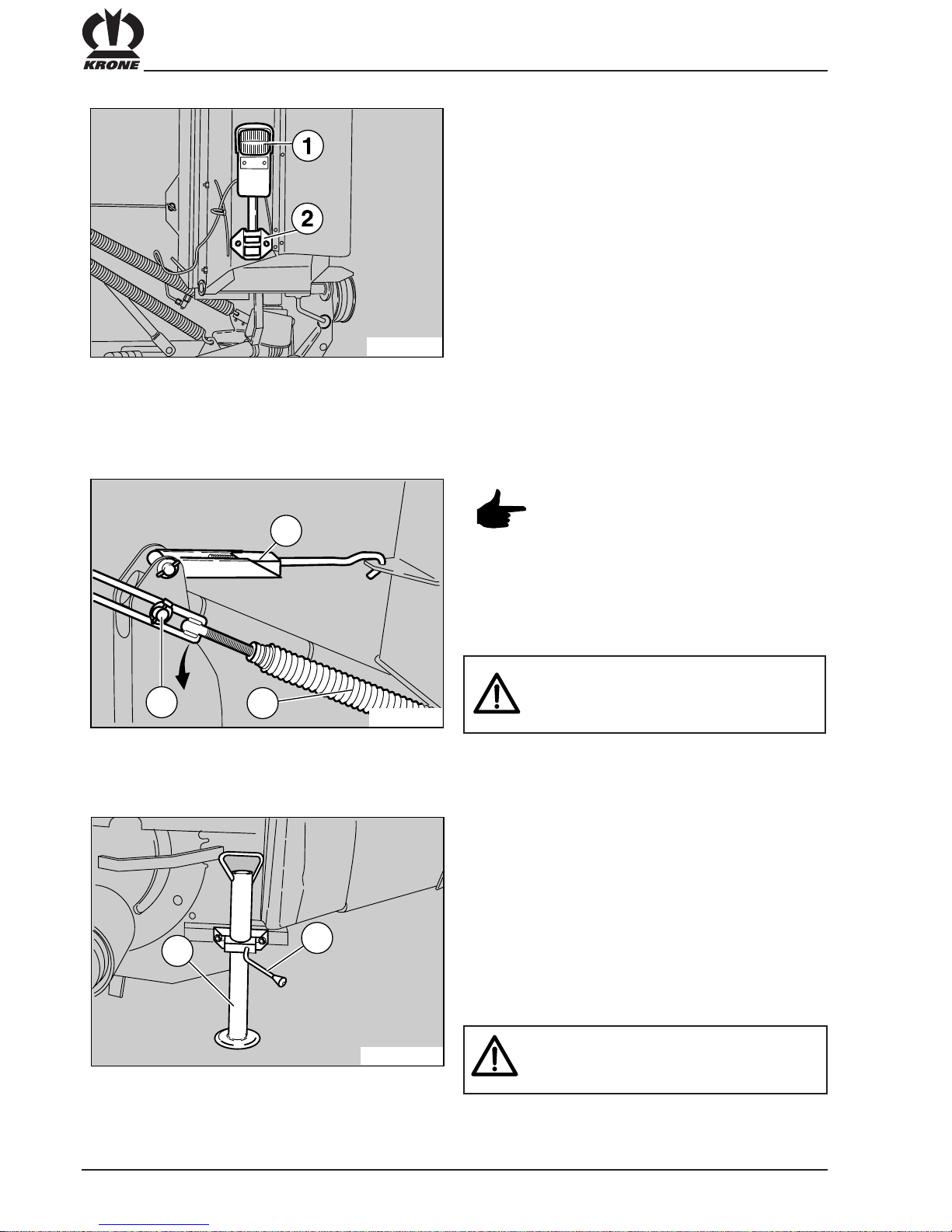

2.8 Detaching the Disc Mower from the

tractor

Always remember to attach the lights (1) to the lights

bracket (2) on the disc mower when driving on public

highways. Use standard attachable lights.

First remove the rear compensation spring (2) from the

upper bearing bolts (1) while mower unit is in transport

position, and set down on the mount.

(This makes mounting the mower unit easier!)

The compensation spring should be

detached from the bolt (1) only when in

transport position. Otherwise there is a

high risk of injury!

Do not pass between tractor and

machine while disassembling the

mower unit!

Set mower unit to transport position and lower to

ground.

Set down support leg (2) and retighten clamping

bracket (1). Detach propeller shaft from tractor and set

down on the support.

Unload the hydraulic system and uncouple hydraulic

hose from tractor - attach dust cap. Detach synthetic

cord from tractor. Unload top link arm and remove bolt

on unit side or unhook top link arm.

Detach lower link arm or disengage tail hook.

AM-1-075

AM-1-08

4

2

1

3

AM-1-061

2

1

17

When coupling the disc mower to the tractor,

it is essential that the compensation spring

(2) be pushed back onto the retaining bolt

(1) and secured with a hinge clip (3) and

washer.

Mounting the compensating spring is

only possible in transport position.

AM-0-013

3

1 2

• Only carry out work on the mower unit once the PTO shaft has been switched off, the

engine switched off and the ignition key removed. Secure the tractor against

unintentional operation and rolling away.

• Always check protective devices for damage before operation. Replace damaged

protective devices immediately. Risk of injury!

• Prop up the cutterbar when raised. Never stand under a suspended load!

• Safe operation is only guaranteed if the cutter blades are fitted according to the

instructions.

• Always check the mower unit for damaged, missing or worn cutter blades before

operation. If necessary, replace cutter blades. The same applies for retaining

components.

• To prevent unbalanced rotation, only replace missing or damaged cutter blades as

complete sets.

• Never fit cutter blades with different levels of wear to one drum/disc.

• Whenever you change cutter blades also check retaining components and replace

them if necessary.

• Move guards into position.

2.9 Safety measures before mower operation

Heavily damaged linings (see illustration)

must be replaced immediately to prevent

any risk of damage to the cutterbar.

MH-0-001

18

3. Adjusting the Disc Mower and Blades

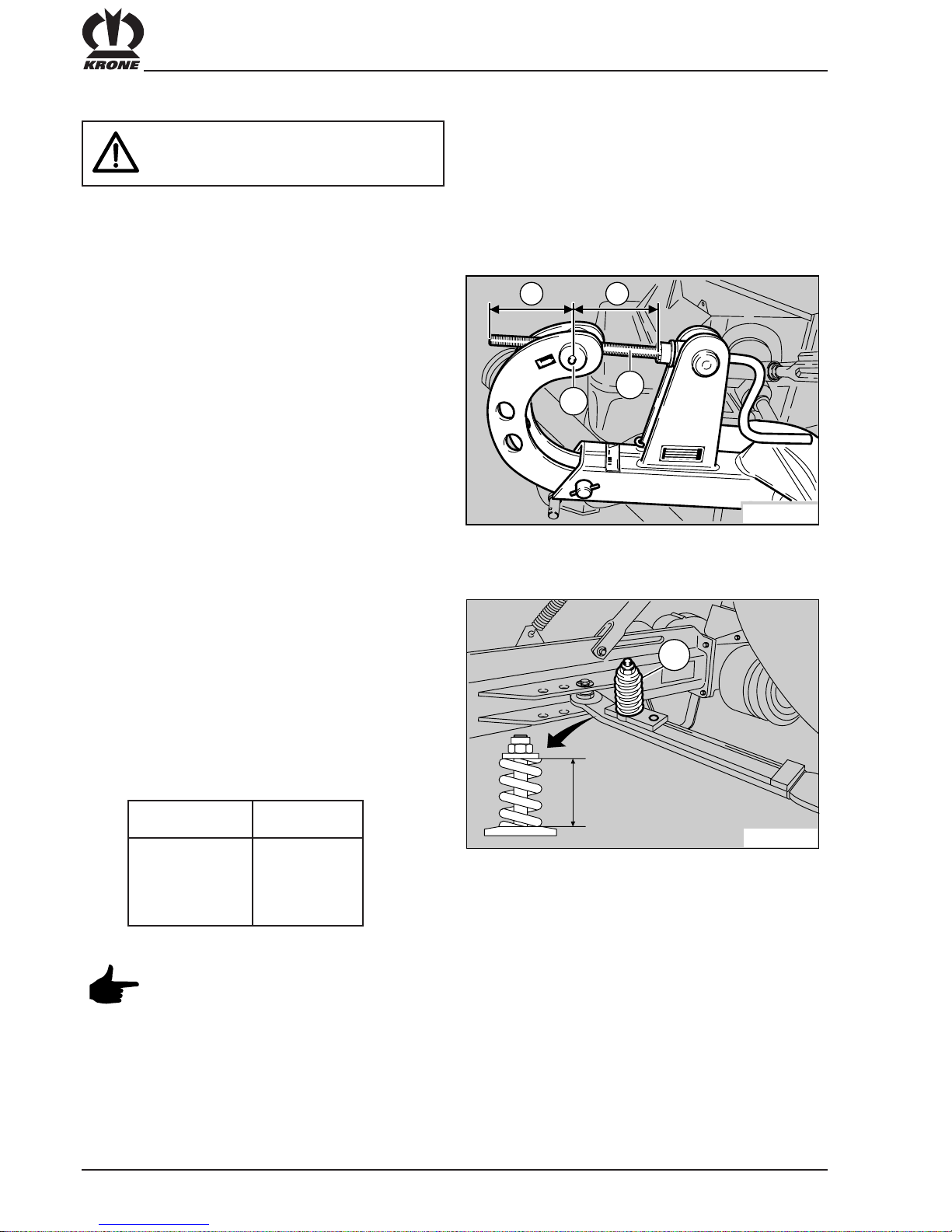

3.1 Adjusting the Top Link Arm

Coupling Point

When the threaded spindle (2) on the top link arm

coupling point is in the basic position, the bolt (1) is

in the centre of the threaded spindle. The distances

marked “a” are equal.

The mower is designed and suited

to cutting grass crops that grow on

the ground.

3.2 Adjusting the Safety Breakaway Unit

To protect the disc mower from damage caused by

driving over any obstacles, the machine is equipped

with a spring loaded breakaway unit.

The most advantageous setting for the moment of

actuation is set in the factory. Should other settings

be required, adjust the length of the spring (1) as

necessary. Greater spring tension increases

the actuation moment.

Type Dimension x

AM 203 CV 81mm

AM 243 CV 80 mm

AM 283 CV 79 mm

AM 283 CV + B 79 mm

Do not set the tension in the spring

on the safety breakaway unit too high.

Risk of damage to the disc mower if the

tension is too high.

1

AM-1-063

X

1

AM- 1-06

2

2

aa

19

3.3 Adjusting the Compensating Spring

for the cutterbar

The three compensation springs adapt the pressure

exerted by the cutter beam on the ground below to local

conditions. In the interests of the turf, the cutter beam

should be provided with enough load compensation to

prevent jumping and subsequently leaving marks in the

ground. To make the appropriate adjustment, set the

disc mower to transport position, ensuring that the

transport lock (6) is engaged.

In this position, the compensation springs (2+3) of the

cutter beam can be taken off the pin (1), making it

possible to change their length. Shortening the length

means that the load compensation of the cutter beam is

greater.

The compensation springs (4) can be adjusted at the

spindle (5). Springs 2 and 3 provide load compensation

for the cutter beam, particularly on the outside. Spring 4

provides more load compensation on the inside.

After the compensation springs have been mounted,

resecure them on the pin with the hinge clip and washer

to prevent them slipping off.

3.5 Basic setting of the tractor lower

link arm

The best working height of the lower link arms is

achieved when the bracket (1) is fitted in the slot (2)

with a distance of a = 90 mm. This guarantees that the

mower unit will be able to adapt to uneven ground.

When preparing for turning, the cutterbar is simply lifted

by means of the hydraulic cylinder fitted to the disc

mower.

3.4 Adjusting piece for lifting cylinder

and flotation spring

The lower bearing bolt for the lifting cylinder and the

flotation spring must be locked in the correct position on

the different mower types. This adjustment is performed

at the factory and must not be changed.

Bolt (1) must be installed through lever (2).

Basic setting: distance "a" = 80 mm

distance "b" = 60 mm

AM-1-064

1

2

a

AM-1-084/

1

1

2

5

4

3

6

AM-1-084/2

a

b

AM 283 CV

AM 243 CV

AM 203 CV

AM 283 CV + B

2

20

3.6 Adjusting the Swath Width

The swath width is adjusted by means of swath

deflector plates (1) located under the swath hood

on the mower. These can be adjusted by loosening

the ring nuts (2) in the slot area. Fasten the ring nuts

securely again after making the adjustment.

1

2

AM-1-065

1

AM-1-05

3

32

AM-4-100

-3

0

+3

+6

-6

-9

+9

5

4

The weight of the disc mower would normally make it

very difficult to adjust the cutting height from the upper

link arm.The cutting height is adjusted using a crank (3).

The inclination of the disc mower and therefore also the

cutting height are adjusted at the top link arm coupling

point (1) using a threaded spindle (2).

The lower link arm must be fixed to the

tractor with chains or bars so that the

mower does not swing out during

transport or mowing!

3.7 Adjusting the cutting height

The adjustment can be checked using the inclinometer

(4) (air level) located on the conditioner housing. For

this move the mower to working position on a level area

and preset the desired cutting height on the

inclinometer.

Adjust the mower tilt by turning crank (3) until the air

level (5) of the inclinometer is in the centre between

both marks.

Indication theoretical Working

z. B. cutting height conditions

+ 6° ca. 11 cm Hight Cut

+ 3° ca. 8 cm Arable forage crop,

moist and soft ground

0° ca. 6 cm Arable forage crop

dry conditions

– 3° ca. 4 cm Normal conditions

– 6° ca. 2 cm Setting the mower to low

risk of sward damage

21

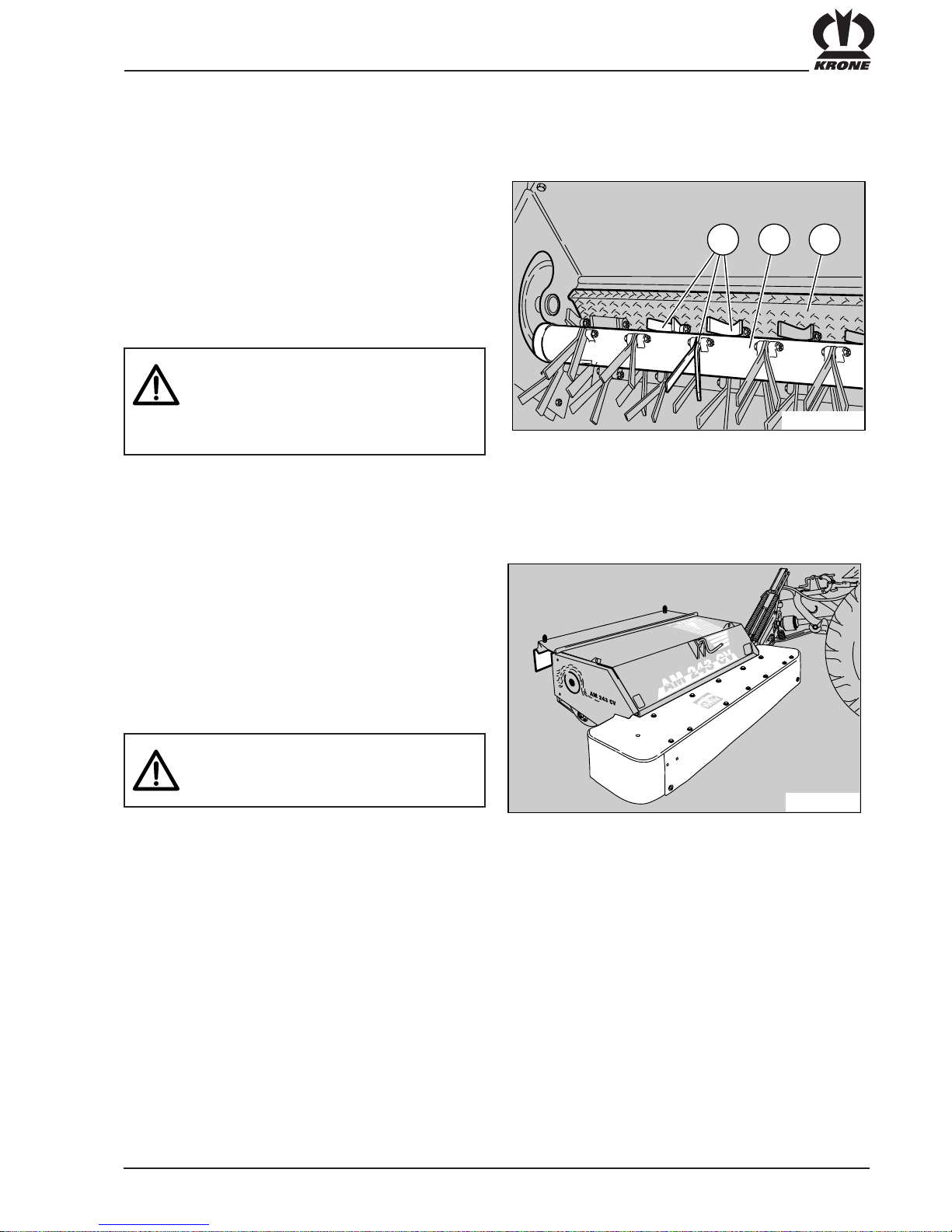

Use only original blades with the

order no. specified next to them.

Employment of wrong or unsuitable

blades may lead to accidents!

3.8 Changing Blades on the Cutting Discs

with Blade Screw Connectors

Safe and reliable operation of the mower is only

guaranteed with correctly fitted cutter blades.

Missing and damaged cutting blades cause dangerous

irregularities in the rotation. Cutting blades and fixing

bolts must therefore be checked daily.

Always inspect the mower before starting work to check

for damaged, missing or worn cutter blades. Replace

blades if necessary.

The upper section of the adjacent diagram shows

individual parts required to mount the blades and the

positions of the blades on one disc. The procedure for

mounting on the mower drums is identical. Screws (3)

and nut and washer assembly (4) are required to mount

the blades (5). Insert the screws from below through the

wear plate (2). The blades are fitted between the wear

plate and the blade disc (1). Tighten the screws from

above with nut and washer assemblies (4).

After mounting, the blades on the screws must be able

to move freely.

A number of different types of blade can be mounted on

this mower unit. The universal blade has a crossed

(twisted) shape. The blades are classed as:

Blades for

Cw rotating disc Order-No. 139-889

Ccw rotating disc Order-No. 139-888

All blades have a corresponding

designation. The arrow on the blade

should be pointing in the direction of

operation!

It is also possible to mount so-called roof shaped

blades. These can be employed identically with discs

which rotate to the left or right.

Roof shaped knife Order-No. 139-800

AM-4-032

2

3

4

1

4

1

2

5

5

22

3.9 Adjusting the Conditioner Speed

The drive speed of the conditioner rotor can be adjusted

on the conditioner gearbox (3). This enables the speed

and effect of the conditioner to be adapted to the

material concerned.

– stem crop = high conditioner speed

– leaf crop = low conditioner speed

First, the retaining pin (2) is removed. Then, the shift

lever (1) is moved out or in to select the tine rotor

speed. When the lever is pulled out (position “A”), the

conditioner speed is 600 rpm. When it is pushed in

(position “B”), the speed is 900 rpm. In the central

position of the lever, (position “0”), no torque is

transmitted.

3.10 Adjusting the Conditioner

Cover Plate

The swath cover plate is adjusted by means of a crank

handle (1) on the front of the disc mower. The setting

depends on the required degree of conditioning of the

crop.

- conditioner cover plate closer to the conditioner

rotor means stronger conditioning

- conditioner cover plate further from the

conditioner rotor means less conditioning.

The material strength of the blade screws used in the

area of the blade receptacle of may not be below

12 mm .

Missing or damaged fixing bolts / cutter

blaes must be replaced immediately!

AM-1-081

18mm

12mm

KRONE

600

900

0

AM-0-007

0139-441

1 2 3

A

B

AM-1-073

1

KRONE

A

M

2

4

3

C

V

23

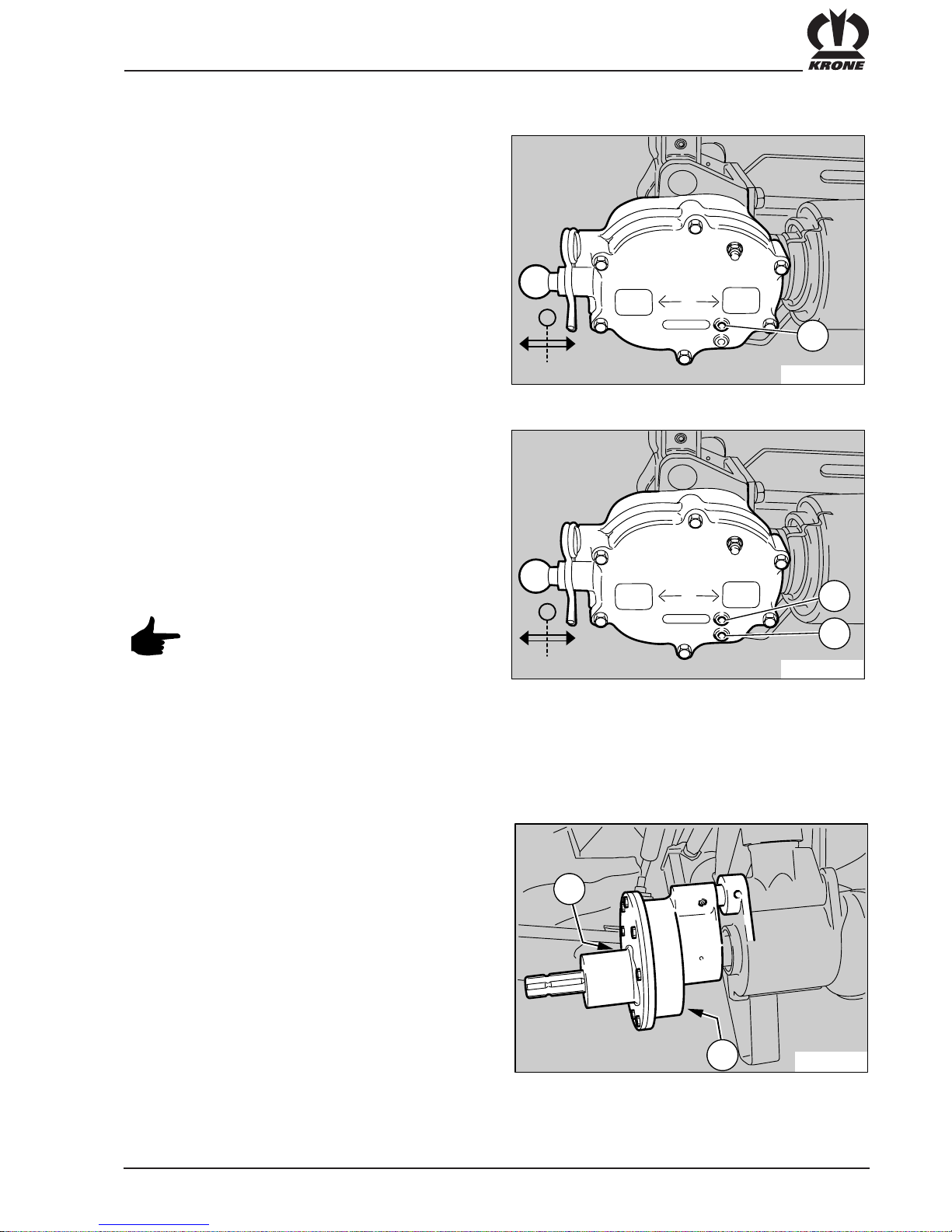

3.11 Adjusting the Position of the

Conditioner Rotor to the Cutterbar

The conditioner rotor (1) of the rotor with the V-shaped

tines (2) can be adjusted to four different positions. This

is done by adjusting the distance of the conditioner from

the cutterbar.

Broken or bent tines cause irregular

rotation. Replace them immediately

when you notice them.

The locking screw (1) on the left and right sides of the

machine must be removed to make the adjustment.

The adjustment to the toothed disc (3) is made by

rotating the right hand ratchet (2). Turn the ratchet until

the desired setting is reached.

AM-1-089

2

1

2

1

AM-1-068

21

24

Fit and remove of the PTO shaft only

when the drive and the

engine is turned off and the ignition

key removed.

Before the conditioner rotor can be brought to standstill

position (position IV, pos.1), the drive PTO shaft (4)

must be completely removed, even from the conditioner

drive gearbox. Put the gearbox in the “0” position. The

PTO shaft guard can only be moved past the spacer

element (3) when the PTO shaft is detached.

Position of conditioner roller on cutter beam

I: basic position

II: position for longer crops

III: position for very long crops

IV: conditioner out of service

The conditioner may not be operated in

position IV. Detach the propeller shaft

completely from the machine. Switch

gearbox to “0” position.

AM-1-069

1

2

I

II

III

IV

3

1

AM-4-072

2

34

25

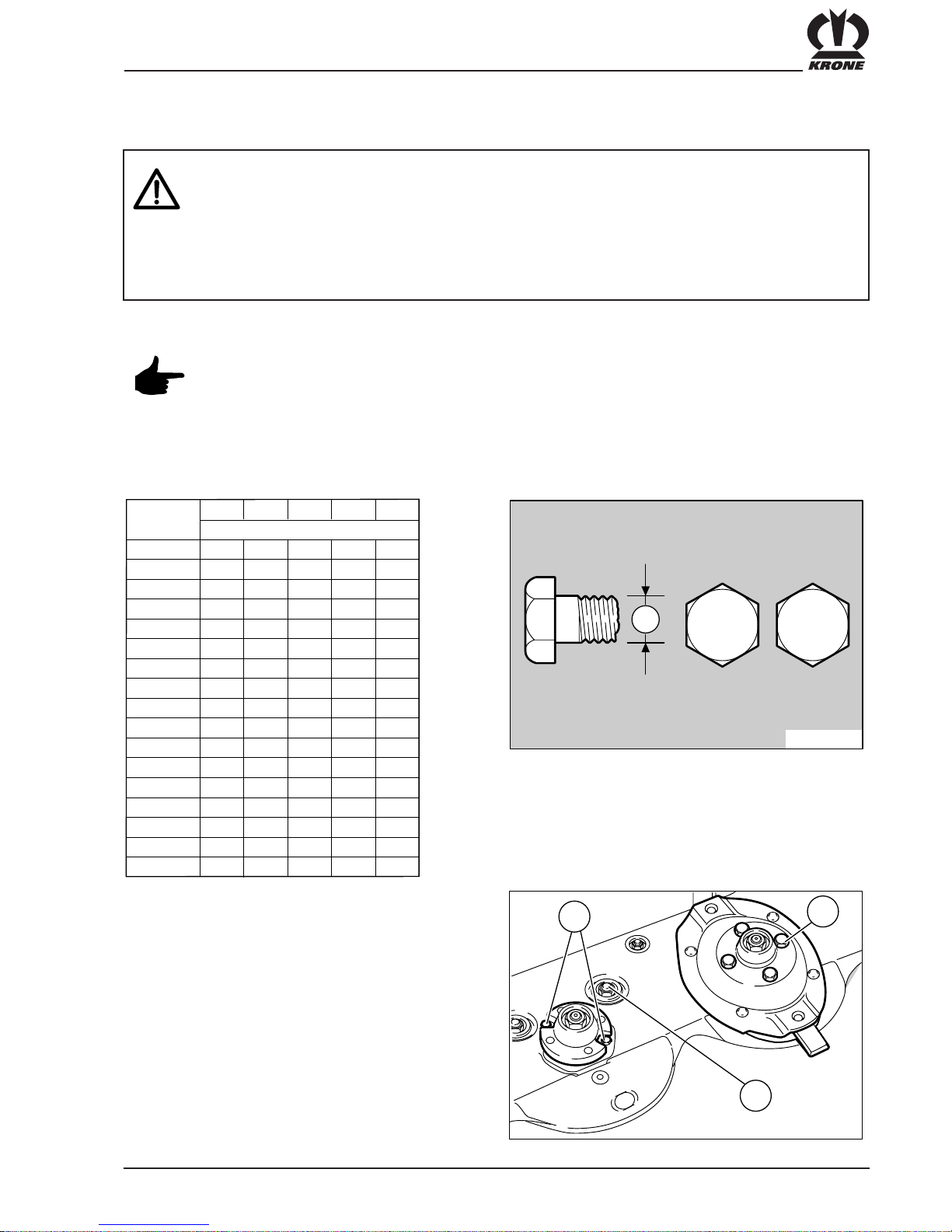

4. Maintenance

4.1 General

A = Thread size

(The bolt grade is visible on the bolt head.)

Torque moment MA in Nm (if not given differently).

Repair, maintenance and cleaning work must be carried out only when the drive and the

engine are turned off!

Danger, cutting discs continue to rotate!

Remove ignition key. Take measures to ensure that the tractor can not be inadvertently started

or roll away.

The transport lock must be engaged when working on the disc mower in transport position.

The shut-off tap on the hydraulic hose must be closed.

Check nuts and bolts regularly (approx. every 50 hrs.) for tightness, and tighten

if necessary!

8

.

8

1

0

.

9

A

AM-0-034

A

5.6

29

42

2,2

4,5

7,6

18

37

64

100

160

4,4

8,7

15

36

72

125

200

215

310

1050

330

350

M 4

M 5

M 6

M 8

M 10

M 12

M 14

M 14x1,5

M 16

M 16x1,5

M 20

M 24

6.8

M (Nm)

8.8 10.9

A

O

/

12.9

M 24x1,5

M 24x2

M 27

M 27x2

M 30

5,1

10

18

43

84

145

235

255

365

2450

390

3,0

5,9

10

25

49

85

135

145

210

225

730

710

122

0

135

0

180

0

195

0

2100

1150

1550

1650

1450

800

1100

1150

610

425

Tightening torque M

A

Screw cutting disc (1) MA = 49 Nm

Screw clamping disc (2) MA = 215 Nm

Hex. nut bearing housing (3) MA = 42 Nm

AM-5-066

1

2

3

26

4.3 Oil Level Check and Oil Change for

Main Gearbox

Oil Change

An oil change should be carried out after approx.

350 hectares of operation. Bring the disc mower to the

transport position and secure with the transport safety

device. Unscrew the oil drain screw (2) and the oil

check screw (1) on the cutterbar. Collect the used oil

(approx. 4–6 litres) in a suitable container. When the oil

has drained, insert the oil drain screw again. Fill up to

the oil control holes (1) with new oil. Insert the oil check

screw with a ring seal. Close the oil check hole with the

screw. For oil quantities and oil types, please refer to

the chapter “Technical Data”.

Bring the disc mower into the working position before

checking the oil. Underneath the breather connection

(1) you can see the oil check hole (2) and the drain

screw (3) in the adjacent diagram. To check the oil, take

the screw out of the oil check hole. The oil in the main

gearbox must come up to the check hole. Top up with

oil if necessary.

NOTE: Change oil in the main gearbox after the first

use and then every 350 hectares.

When changing oil, take out the drain screw and the

check screw. Drain the oil (approx. 0.4 litres) into a

suitable container. Replace the drain screw and fill up to

the check hole with oil. For information on quantities and

types of oil, please refer to the chapter “Technical Data”.

Dispose of used oil in the correct way

after every oil change!

After an oil change, the used oil must be

disposed of in the correct way!

4.2 Oil Level Check and Oil Change for

Cutterbar

When checking the oil in the cutterbar,

always ensure that the cutterbar is

secured by the transport safety device.

High risk of injury!

Oil Level Check

To check the oil level in the cutterbar, first move it to

transport position and secure with the transport safety

device. Unscrew the oil level check screw (1)

on the side of the cutterbar. The oil level in the cutterbar

must reach up to the oil check hole.

Refill if necessary.

Check the oil level regularly every 100 operating hours!

AM-1-09

2

3

2

1

27

4.4 Oil Level Check and Oil Change for

the mower and conditioner drive

Oil Level Check

The gearboxes for the mower and conditioner drive

units have a common oil supply.

To check the oil level for the gearbox, twist out the

screw (1). The oil must come up to the oil check hole.

Top up with oil if necessary.

Oil Change

The oil should be changed after about 350 hectares of

operation. Unscrew the oil drain screw (2) and the oil

check screw (1) on the main gearbox. Collect the

drained oil (approx. 1 litre) in a suitable container. After

the oil has drained, insert the oil drain screw. Fill with

new oil up to the oil check hole. Close the oil check hole

with the screw. For oil quantities and oil types, please

refer to the chapter “Technical Data”.

After an oil change, the used oil must be

disposed of in the correct way!

KRONE

600

900

0

AM-0-032

0139-441

A

B

1

KRONE

600

900

0

AM-0-033

0139-441

A

B

1

2

4.5 Oil level check and oil change in the

gearbox for the 1000 rpm power take-off

Oil level check

To check the oil level, move the disc mower to working

position. Unscrew oil level check plug (1). The oil must

reach the hole of the check plug. Fill in fresh oil if

necessary.

Oil change

To change the oil, unscrew oil drain plug (2) and oil

level check plug (1). Collect the oil (approx. 0,2 litres )

in an appropriate container. Drive home the oil drain

plug again and fill fresh oil up to the hole of the oil level

check plug. For the oil quantity and quality see the

chapter "Technical Data".

NOTE: Change the oil after the first cut, then

every 350 hectares.

AM-3-095

2

1

28

4.6 Unlocking the Overload Coupling on

the Drive Shaft to the Cutterbar and on

the Conditioner Drive (Walterscheid)

The overload coupling on the cutterbar

drive can only be unlocked with the

disc mower in the transport position.

The cutterbar must be secured with the

transport bracket.

The overload coupling must be unlocked after not

being used for long periods (e.g. before the start of

harvesting). To do this tighten the nuts (1) on the

overload coupling (2) on the cutterbar drive. Fix

the PTO shaft into place. Turn the blade drum manually

in either direction. When turned, the discs in the

overload coupling separate from each other. Loosen

the nuts again after doing this until there is a clearance

between the nut and the housing of at least 3 mm.

Follow the same procedure for the overload coupling

on the conditioner drive PTO shaft.

AM-1-080

1

2

AMS-1-04

5

1

AMS-1-04

6

2

Totally release the four hex. socket head cap screws

(2) using the special key (1) supplied. the thread does

not extend over the full length of the screws, so they

cannot be turned out of the clutch.

The clutch is now ready for use.

4.7 Preparing the overload clutch for use

Firmly tighten the hexagon socket head cap screws (2)

of the overload clutch at the start of the idle period.

This will release the clutch linings from the pressure of

the cup springs and minimise the risk of sticking. The

disc clutch is bled. At the start of the next operation

hitch the mower to the tractor and switch on the pto:

the mowing discs must not rotate. If the discs should

rotate, the clutch is stuck or rusted and must first be

disassembled (remove linings from the plates and if

necessary smooth the friction surfaces using emery

paper). Then reinstall the universal drive shaft and

proceed as described above.

4.8 Bleeding the overload clutch of the

universal joint drive shaft and of the

double joint

29

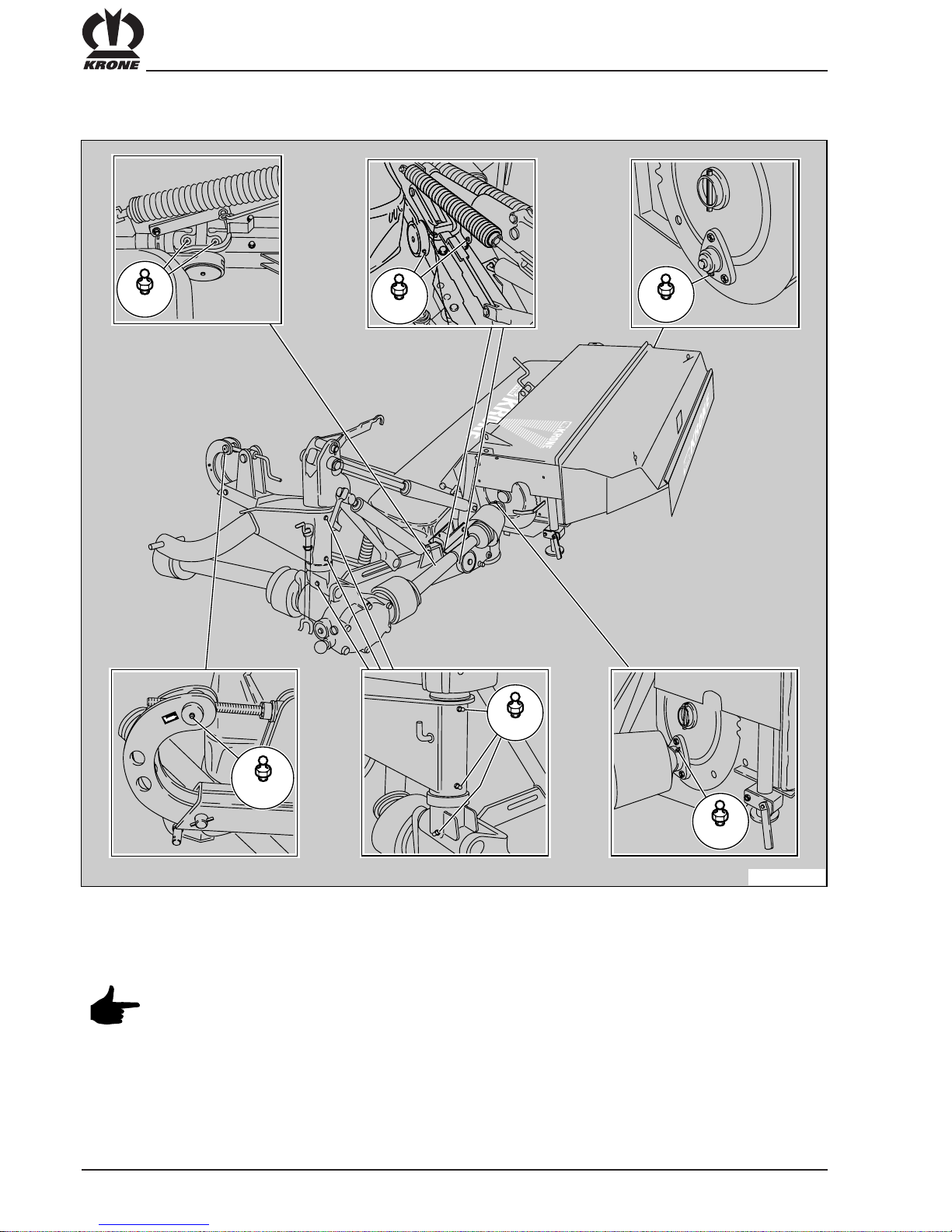

4.9 Lubrication

PTO Shafts

Lubricate the PTO shafts for the main drive and the

conditioner drive at the points indicated and the time

intervals indicated.

* Apply grease to the protective tube from time to time.

AM-4-098

40h

40h

8h

20h

8h

8h

AMS-1-04

7

Storage

Before the next idle period (after the campaign or before

a prolonged period of disuse) the hex. socket head cap

screws have to be tightened firmly again.

30

Lubrication Plan for Disc Mowers

Refer to the section entitled “Technical Data” for the recommended types of oil and lubricant

Lubricate at the lubrication points listed below after the specified number of operating hours.

AM-1-077

10 h

10 h 10 h

50 h

10 h

50 h

31

1 32

AM-0-044

AM-1-076

K

R

O

N

E

Protective Cloth Covers

The protective cloth covers (1) must be checked

regularly. Worn or damaged coth covers must be

replaced.

Protective features on the cutter bar, e.g. coth covers

and cover plates, protect from thrown up stones etc.

and from access to the dangerous part of the machine.

They must therefore be put in protective position before

work commences.

Safety first! Take no risks. Do not

experiment with imitation parts. Use only

original KRONE parts!

Conditioner

The conditioner processes the cut crop so that it can

dry faster. To ensure the best possible effectiveness, the conditioner shaft (2) must be inspected for

damaged tines before each use. Bent tines must be

straightened. Broken tines must be replaced. The

degree of processing of the crop is adjusted by means

of the distance setting of the cover plate (3) of the

conditioner (see chapter “Adjustments”).

The conditioner shaft rotates at speeds

of up to approx. 1000 rpm. Broken tines

cause dangerous irregularities in the

rotation. Therefore, broken tines must be

replaced immediately.

5. Conditioner and Protective Cloth Covers

32

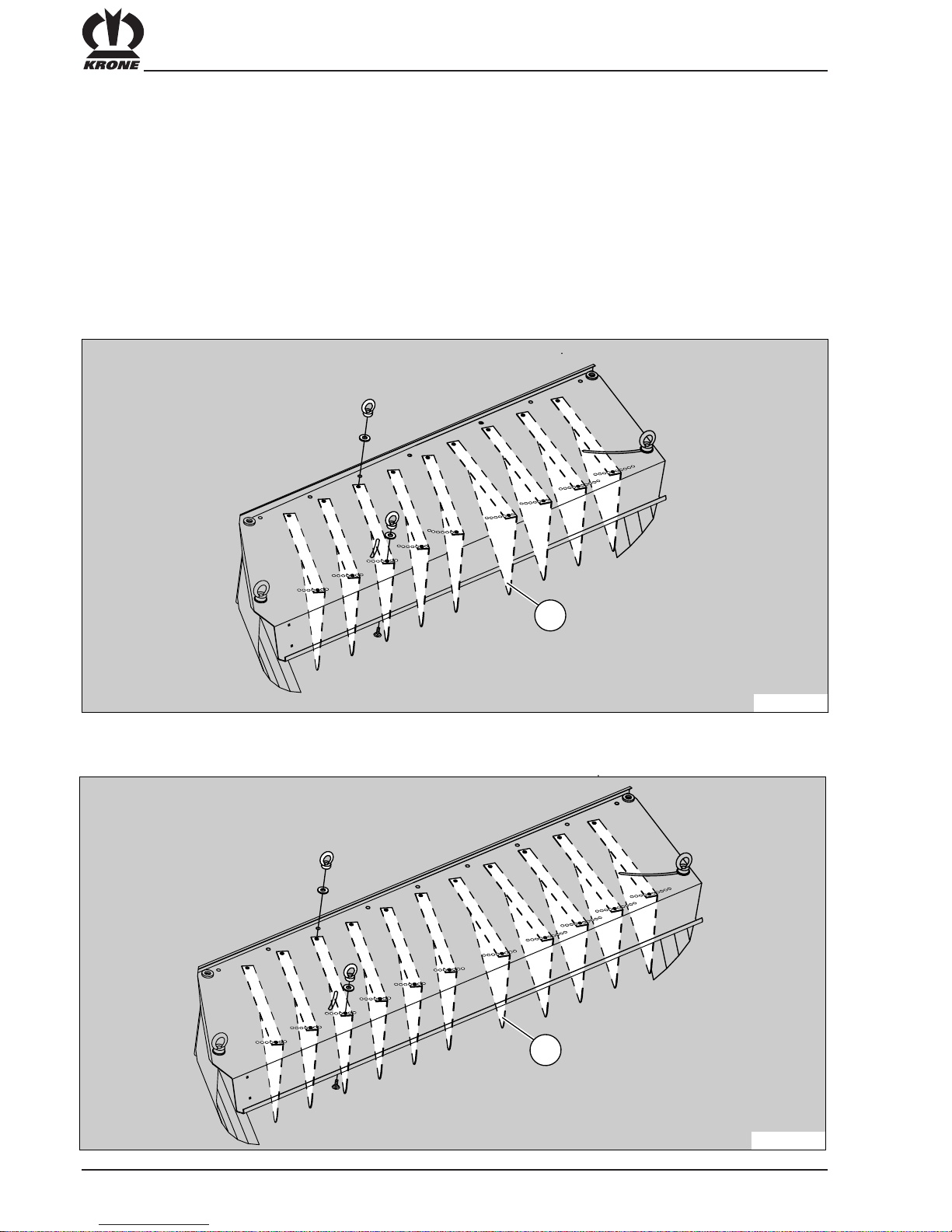

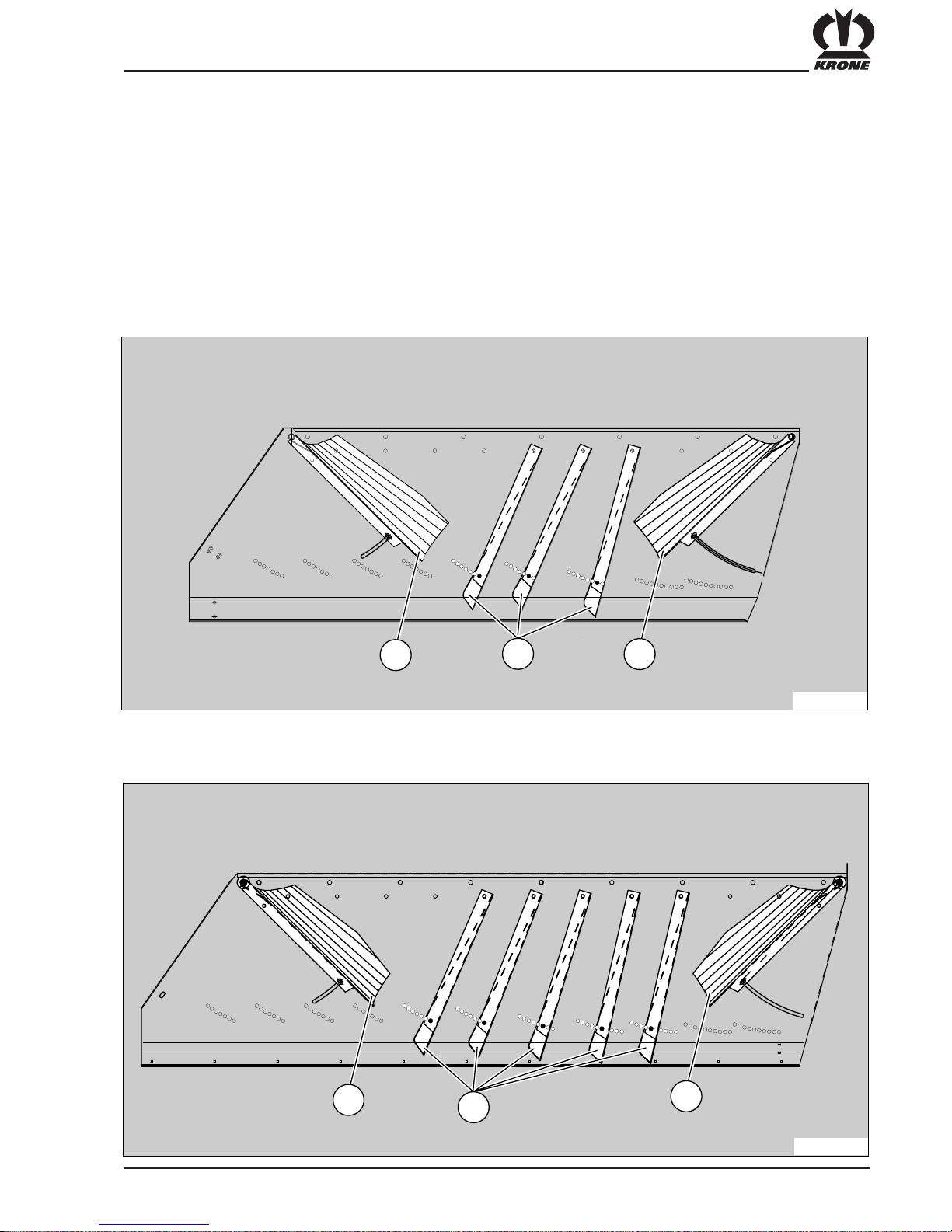

6. Wide swath hood

The disc mower AM 243 CV + B an AM 283 CV + B are fitted with a wide swath hood.

Once conditioned by the V-shaped steel tines of the conditioner rotor, the cut forage crop is evenly spread over the

entire surface which considerably speeds up the drying process.

The deflector plates (1) are secured in the marked holes when in the basic setting.

Basic setting

AM-97-0

1

1

AM 243 CV + B

AM 283 CV + B

AM-4-01

2

1

33

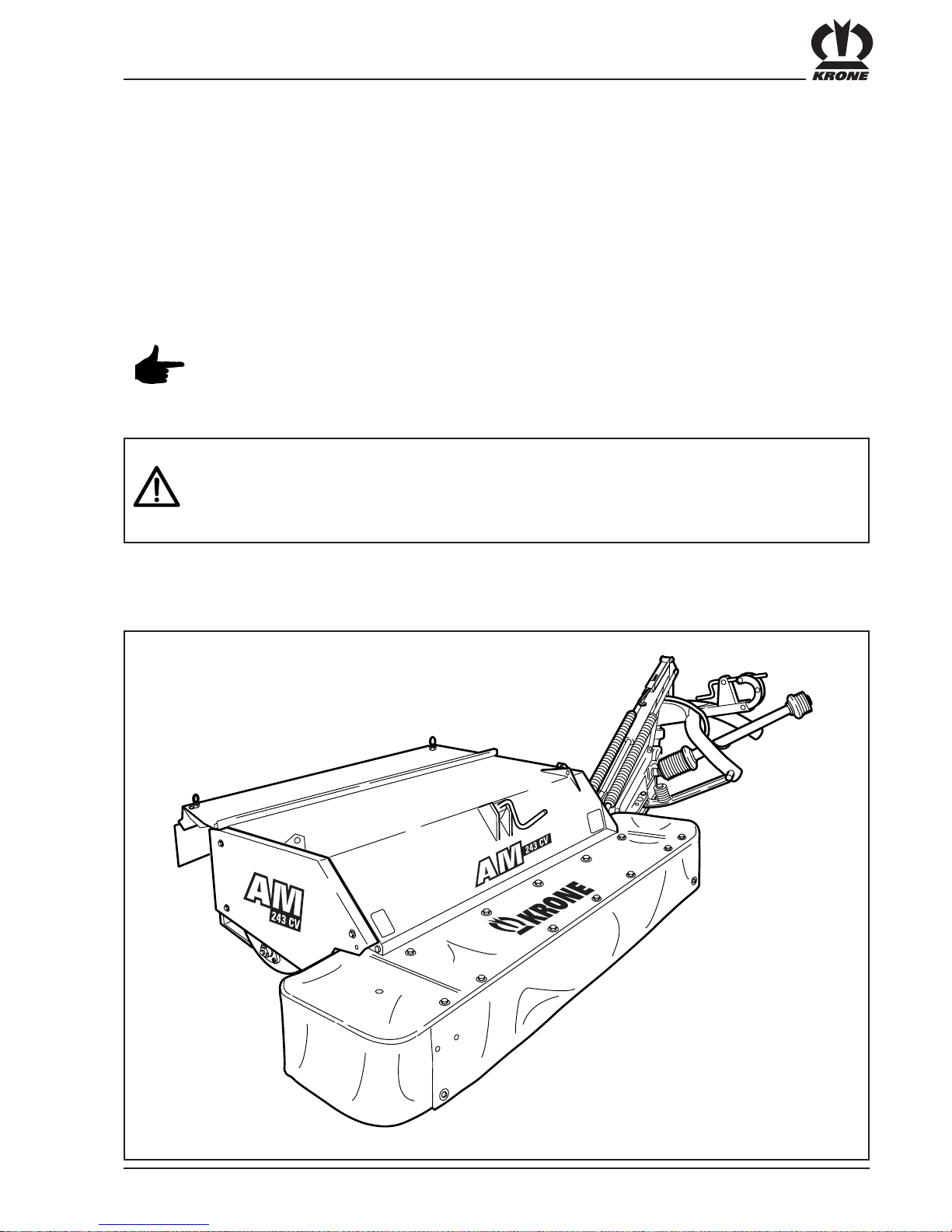

If required the grass can also be laid in a swath.

For this secure the deflector plates (1) in the marked holes and fold in the swath deflectors (2).

Change-over to swathlaying mode

AM-97-02

2

1

2

AM 243 CV + B

AM 283 CV + B

AM-4-01

3

1

2

2

34

7. Winter storage

• Store the machine in a dry place that is not near

artificial fertilizers.

• Clean the machine thoroughly from the inside and the

outside. Dirt attracts moisture and causes corrosion.

When cleaning the machine with high pressure water

jet cleaners, do not aim the water jet at the bearings.

• Check moving parts (joints etc.) for freedom of

movement, and if necessary remove them, clean

them and check for wear. If necessary, replace them

with new parts.

• Lubricate all moving parts.

• Thoroughly grease the machine.

• Grease the protective tubes of the PTO shaft to

prevent it from freezing.

• Touch up the paint work. Thoroughly treat any bare

metal with rust protection.

• Make a list of all replacement parts required, and

order them in good time. It is easier for your KRONE

dealer to obtain and fit the required parts out of the

main season. This ensures that your machine is fully

operational for the coming season.

8. Start-up after winter storage

• Wipe off the grease and oil used for machine

conservation.

• Carry out in full the steps described in the chapter on

maintenance.

• Spin the friction clutch to release sticking friction

surfaces.

• Once bled the overload clutch has to be released by

switching on the pto with the mower attached to the

tractor: the universal drive shaft must rotate freely up

to the clutch hub, whilst the mowing discs must not

rotate (also see section 4.8)

• Carefully read through the operating instructions

again.

35

Appendix

Push the special tool (1) {blade key} between the

cutter disc (4) and leaf spring (3) and press down

with one hand. Guide blade (2) onto retaining bolt

and allow the blade key to return upwards.

Disc mower AM . . . S operating manual

Appendix for

• The blades may continue to rotate after the drive has been switched off. Only

approach the mower once the working parts have come to a complete standstill.

• Only carry out work on the mower unit once the PTO shaft has been switched off,

the engine switched off and the ignition key removed. Secure the tractor against

rolling away.

• Safe operation is only guaranteed if the cutter blades are fitted according to the

instructions.

• Always check the mower unit for damaged, missing or worn cutter blades before

operation. If necessary, replace cutter blades. The same applies for retaining

components.

• To prevent unbalanced rotation, only replace missing or damaged cutter blades as

complete sets.

• Never fit cutter blades with different levels of wear to one drum/disc.

• Whenever you change cutter blades also check retaining components and replace

them if necessary.

TAKE NO RISKS!

Use only original KRONE parts!

1. Changing blades on cutter discs

with quick-release blades

1 2 3

4

AMS-1-031

36

Appendix

Check the retaining bolt according to the

instructions each time you change the

cutter blades. In case of damage or wear

replace all sets of complete blade

holders per cutting disc.

The cutter blades can be turned around

and used on both sides. When cutter

blades are missing or damaged, they

must be replaced as a complete set. This

prevents dangerous unbalanced rotation.

If the thickness of the material between the hole and the

end of the cutter blade has reduced to less than a = 7

mm, you must replace the cutter blade.

∅ 15 mm

min. 9 mm

✓

AMS-0-03

3

min. 3 mm

KRONE

139-889

KRONE

139-888

KRONE KRONE

a

AMS-1-03

2

Clockwise blade Order no.: 139 889

Anticlockwise blade Order no.: 139 888

alternativ

roof shaped knife Order no.: 139-800

(for cw and ccw rotation)

The blade key (1) is part of the shipping package. After

installation it is attached to a mount (2) at the rear hinge

pipe of the three-point frame. The open mount at the

front is secured by means of a linch pin.

AM-1-036

1

2

3

4

5

6

37

Appendix

38

39

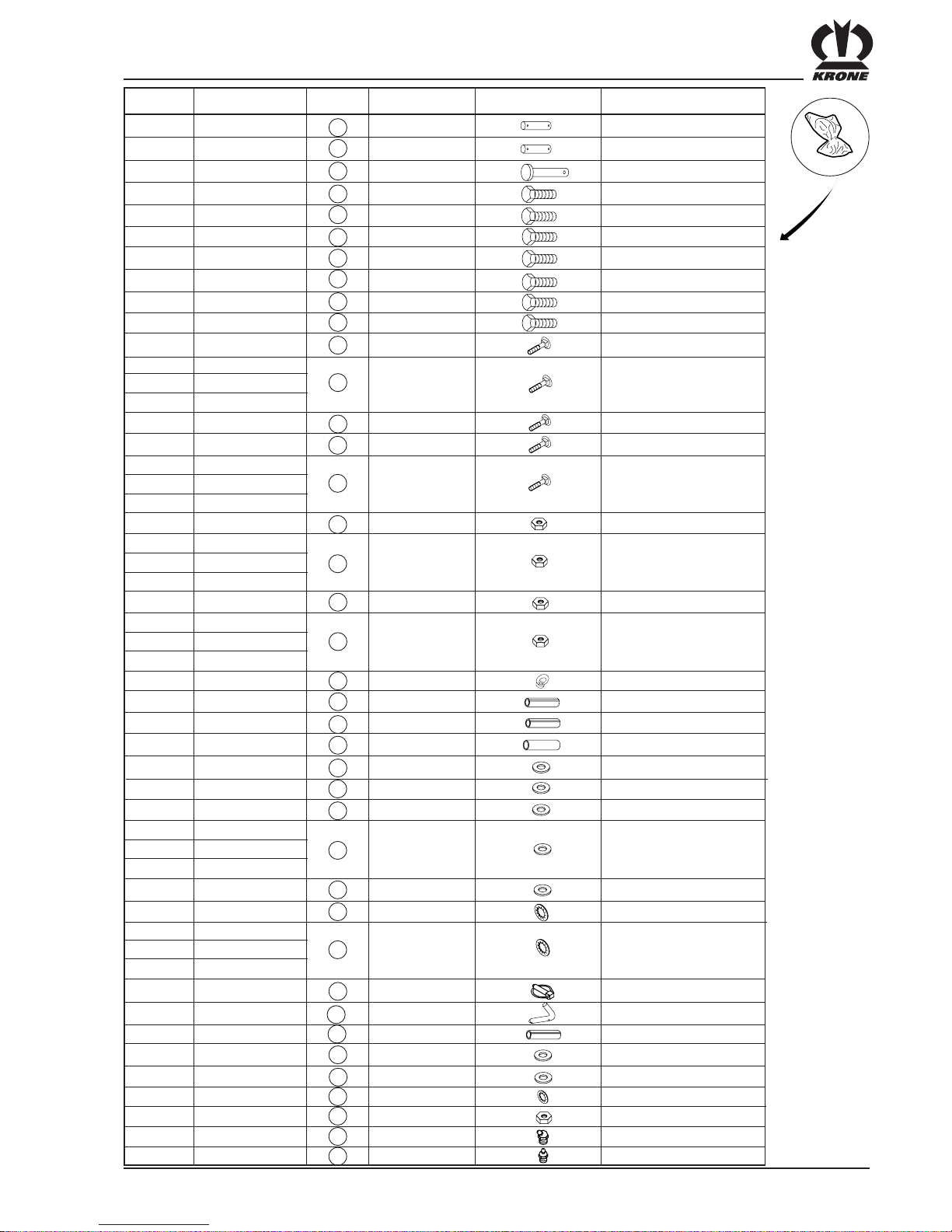

Supplement to

Operating Instructions

AM 203 CV / AM 243 CV / AM 243 CV + B / AM 283 CV / AM 283 CV + B

The following instructions give a detailed description of the assembly procedure for the above mentioned

KRONE disc mowers.

The mowers must only be assembled by an approved specialist workshop.

All steps described in the following instructins must be carried out in the described sequence.

The assembly of the mower must be performed with the greatest possible care. All

relevant accident prevention regulations must be complied with. Use only lifting gears

and tools of adequate dimensions. The mower must only be set into operation if all

guards and protective devices are installed. Never carry out changes yourself.

Otherwise no warranty will be assumed for resulting damage.

The operation of the mowers is described in the respective Operator's Manual.

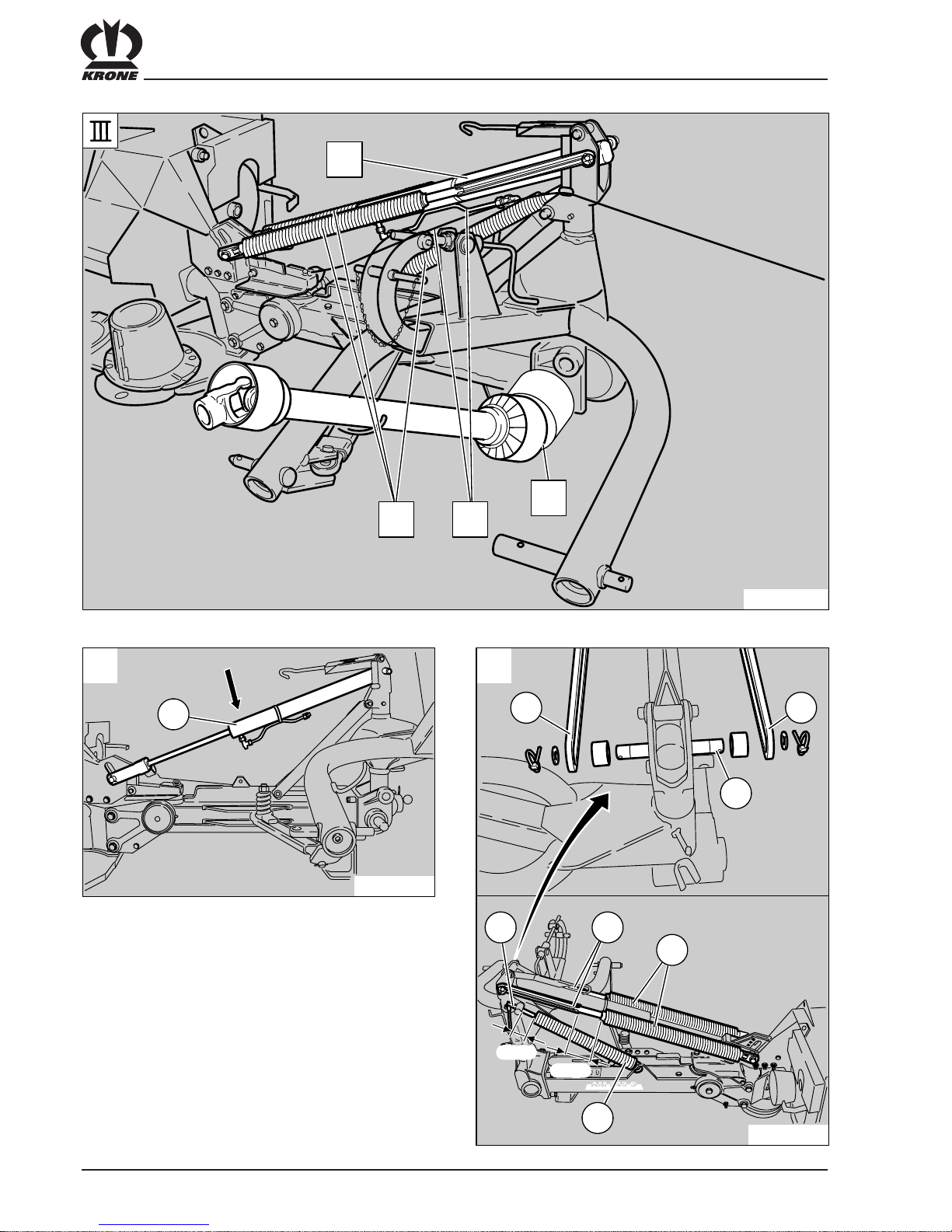

1. Assembly Instructions

40

4

27

8

7

13

2/3

30

6

1

26

5

25

28

34

24

11

32

33

10

9

20

19

18

39

AM-4-00

0

16 15

14

23

31

22

36

21

38

37

12

29

35

17

1

+ 9

+ 6

+ 3

0

– 3

– 6

– 9

40

41

Anzahl Typ Pos. Teile-Nr. Maße

1 50 916 096 Ø 20 x 110

– 51 Ø 20 x 95

– 52 916 082 Ø 20 x 45

– 53 901 155 M 16 x 240

2 54 900 674 M 16 x 35

– 55 901 162 M 14 x 70

– 56 901 122 M 12 x 70

– 57 900 632 M 10 x 16

– 58 M 8 x 110

3 59 901 425 M 8 x 60

2 60 904 882 M 12 x 25

6 AM 203 CV

7 AM 243 CV 61 904 751 M 10 x 20

9 AM 283 CV

2 62 904 732 M 8 x 25

2 63 904 730 M 8 x 16

6 AM 203 CV

7 AM 243 CV 64 904 710 M 6 x 16

9 AM 283 CV

2 65 908 716 M 16

6 AM 203 CV

7 AM 243 CV 66 908 758 M 10

9 AM 283 CV

7 67 908 706 NM 8

8 AM 203 CV

9 AM 243 CV 68 908 704 M 6

11 AM 283 CV

2 69 909 503 M 12

– 70 ø 13 x 85

– 71 ø 5 x 40

– 72 139 567 Ro. 26,9/2,65 x 191

2 73 910 512 21 x 37 x 3

2 74 910 303 17 x 30 x3

2 75 910 347 17 x 37 x 3 Kunststoff

6 AM 203 CV

7 AM 243 CV 76 910 609 13 x 37 x 3

9 AM 283 CV

2 77 910 353 11 x 34 x 3

5 78 909 908 SKM 8

6 AM 203 CV

7 AM 243 CV 79 909 906 SKM 6

9 AM 283 CV

1 80 917 007 7,5 x 42

1 81 150 032 20 x 185

1 82 912 670 8 x 40

1 83 910 414 10,5 x 21 x 2

8 84 910 363 15 x 36 x 6

2 85 909 909 10 x 22 x 1,6

4 86 908 714 M 14

1 87 919 106 M 8 x 1

2 88 919 105 M 8 x 1

42

AM-2-004

a

9

8

AM-4-005

g

d

h

b

a

c

e

i

ia

f

da

AM-3-008

d

87

AM-3-006

b

27

28

55

84

84

86

AM-3-007

c

56

88

43

AM-4-101

-3

0

+3

+6

-6

-9

+9

40

66

83

ia

AM-2-011

g

52

10

71

73

AM-2-013

13

i

AM-2-012

h

32

71

71

51

82

81

80

AM-4-010

f

58

70

10

67

AM-4-009

e

11

AM-4-102

da

44

AM-4-015

II

p

j

r

k

q

m

n

l

l

o

AM-2-01

8

KRONE

6

7

I

KRONE

5

AM-2-01

9

76

66

61

m

AM-3-016

j

36

53

72

65

85

AM-3-017

k

31

57

77

77

57

45

o

AM-2-021

29

78

63

67

78

67

AM-2-022

3

64

79

68

p

26

AM-2-020

n

69

75

60

7

q

AM-2-023

37

25

AM-4-024

r

33

37

46

AM-2-027

s

14

AM-2-028

60 mm

80 mm

15

1618

17

16 16

35

t

AM-4-026

t

u

v

s

47

AM-2-029

20

u

19

AM-4-030

v

37

24

25

48

2

AM-2-03

3

x

AM-2-03

4

1

1

1

2

1

67

62

77

y

AM-2-035

z

AM-2-031

KRONE

KRONE

K

R

O

NE

B

K

w

x

z

z

yy

ab

KRONE

4

AM-2-03

2

w

65

54

74

49

ab

67

67

30

59

AM-2-036

50

ac

AM-2-03

8

2. Montage Getriebe für 1000er Zapfwelle

AM-4-03

7

ad

af

ae

ac

1000

1

/min

AM-4-03

9

250mm

250mm

ad

24

24

51

AM-2-041

af

AM-2-04

0

ae

52

53

KRONE: EIN STARKES PROGRAMM!

KRONE: EIN STARKES PROGRAMM!

THE BEST PROGRAMME!

LE PROGRAMME FORT!

THE BEST PROGRAMME!

LE PROGRAMME FORT!

Maschinenfabrik Bernard Krone GmbH, Heinrich-Krone-Straße 10,

D-48480 Spelle (Germany), Tel.: 05977/935-0, Fax: 05977/935-339

Internet: http://www.krone.de; e-mail: bkrone-ldm@t-online.de

SCHEIBENMÄHWERKE

DISC MOWERS /

CONDITIONER

FAUCHEUSES À DISQUES /

FAUCHEUSES À DISQUES

CONDITIONNEUSES

KREISELSCHWADER

ROTAR Y WINDROWERS

ANDAINEURS ROTA TIFS

RUNDBALLENPRESSEN

ROUND BALERS

PRESSES À BALLES RONDES

GROßPACKENPRESSEN

BIG BALERS

PRESSES À GRANDES

BALLES CUBIQUES

DREISEITEN-KIPPER

THREE-WA Y TIPPING

TRAILER

REMORQUES BASCULANTES

TRIBENNES

SELBSTFAHRENDER HOCH-

LEISTUNGS-MÄH-AUFBEREITER

SELF-PROPELLED

MOWER CONDITIONER

FAUCHEUSE AUT OMOTRICE

LADE- UND DOSIERWAGEN

SELF-LOADING AND FEEDER WAGON

ENSILEUSES-AUTOCHARGEUSES

ET ENSILEUSES AUTOCHARGEUSES-

DISTRIBUTRICES

KREISELZETTWENDER

ROTAR Y TEDDERS

FANEUSES ROT A TIVES

Loading...

Loading...