GB

F

NL

I

E

05155

D GB F NL I E

TR CZ PL RUS H

DK S N P GR

➔ www.docuthek.com

Operating instructions

Burner control unit BCU56x,580

© 2018 Elster GmbH · Edition 07.18

Cert. version 07.18

Translation from the German

Contents

Contents

Burner control unit BCU56x,580..........1

Contents ..............................1

Safety.................................1

Checking the usage .....................

Installation ............................

Replacing the power module/parameter

chip card ..............................

Cable selection.........................4

Wiring ................................4

Connection diagram ....................5

Flame control ..........................13

Adjustment ...........................14

Commissioning........................14

Manual mode .........................15

Assistance in the event of malfunction ....16

Reading off the flame signal, fault

messages and the parameters...........

Parameters and values...................23

Legend...............................5

Technical data ........................6

Designed lifetime .......................26

Logistics .............................7

Accessories ..........................7

Certification ..........................8

Contact ..............................8

Safety

Safety

Please read and keep in a safe place

Please read through these instructions

carefully before installing or operating. Following the

installation, pass the instructions on to the operator. This unit must be installed and commissioned

in accordance with the regulations and standards

in force. These instructions can also be found at

www.docuthek.com.

Explanation of symbols

• , 1 , , ... = Action

▷ = Instruction

Liability

We will not be held liable for damage resulting from

non-observance of the instructions and non-compliant use.

Safety instructions

Information that is relevant for safety is indicated in

the instructions as follows:

DANGER

Indicates potentially fatal situations.

WARNING

Indicates possible danger to life and limb.

CAUTION

Indicates possible material damage.

All interventions may only be carried out by qualified

gas technicians. Electrical interventions may only be

carried out by qualified electricians.

Conversion, spare parts

All technical changes are prohibited. Only use OEM

spare parts..

Changes to edition 0.18

The following chapters have been changed:

– Wiring

– Technical data

– Certification

GB-1

GB

F

NL

I

E

Checking the usage

Burner control units BCU 560, 565 and580 are

designed to monitor and control gas burners in intermittent or continuous operation.

The outputs for controlling the burners, e.g. for fan,

actuator and valves, are activated via a replaceable

power module. All the parameters required for operation are saved on the integrated parameter chip card.

BCU 560, BCU 565

For directly ignited burners of unlimited capacity.

BCU 580

For pilot and main burners of unlimited capacity. Pilot

and main burners can be monitored independently.

BCU..F1, BCU..F, BCU..F

Burner control units with interfaces for air control

using an air valve or actuators IC20, IC40,RBW.

BCU 565..F1, BCU 565..F, BCU 565..F

With air flow monitoring as well as pre-ventilation

and post-ventilation to control and monitor a selfrecuperative burner.

This function is only guaranteed when used within the

specified limits – see page 26 (Technical data). Any

other use is considered as non-compliant.

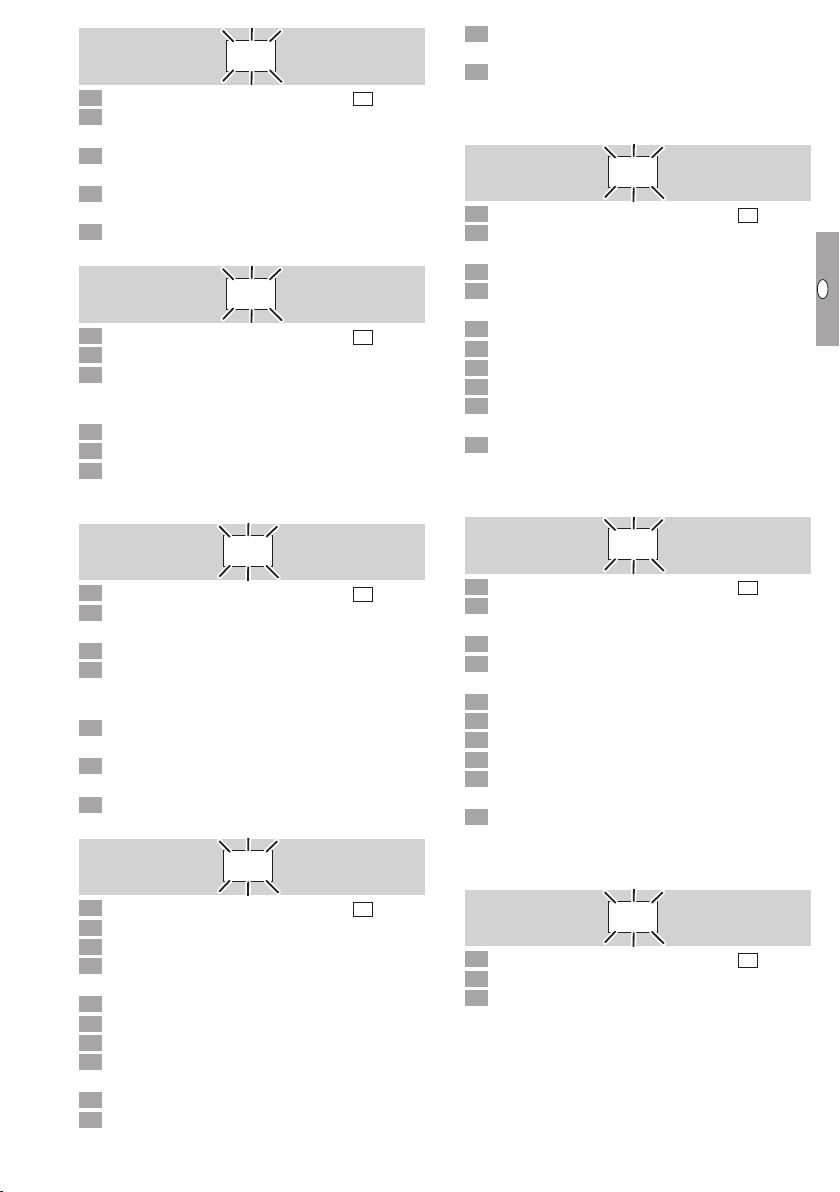

Type code

Code Description

BCU Burner control unit

560

565

580

Q

W

C0

C1

120VAC, 50/60 Hz

230VAC, 50/60 Hz

No valve proving system

With valve proving system

F0

F1

F2

F3

with interface for actuator IC

with interface for RBW actuators

with air valve control

D0

D1

Operation on high temperature equipment

D2

K0

K1

K2

Connection plugs with screw terminals

Connection plugs with spring force terminals

Operation with menox burner

No connection plugs

Series 560

Series 565

Series 580

Mains voltage:

Capacity control:

none

With flame control

Part designations

1

2

3

4

5

6

7

1 LED display for program status and fault

messages

Reset/Information button

On/Off button

4 Type label

5 Connection for opto-adapter

6 Power module, replaceable

7 Power module type label

8 Parameter chip card, replaceable

Input voltage– see type label.

BCU

8

GB-2

GB

F

NL

I

E

Installation

1

4 5

CAUTION

Please observe the following to ensure that the

burner control unit is not damaged:

– Dropping the device can cause permanent dam-

age. In this event, replace the entire device and

associated modules before use.

Installation position: vertically upright, horizontal

▷

or tilted to the left or right.

▷ The BCU mounting is designed for horizontally

aligned 35×7.5mm DINrails.

▷

If the DINrail is aligned vertically, end clamps are

required (e.g. Clipfix35 by Phoenix Contact) to

prevent the BCU from slipping.

Replacing the power module/ parameter chip card

1 Disconnect the unit from the electrical power

supply.

2

Disengage the BCU from the DINrail.

▷

Install in a clean environment (e.g. a control

cabinet) with an enclosure ≥IP54, whereby no

condensation is permitted.

6 Remove the old parameter chip card from the

BCU and insert the new one.

▷ All the parameter settings of the BCU are saved

on the parameter chip card.

7 Slide the power module back on.

8 Reconnect the connection terminals.

9 Mount the BCU on the DINrail again.

GB-3

GB

F

NL

I

E

Cable selection

▷ Signal and control line for screw terminals max.

2.5mm2 (min.AWG24, max.AWG12), for spring

force terminals max. 1.5mm2 (min.AWG24,

max.AWG12).

▷

Do not route BCU cables in the same cable duct

as frequency converter cables or cables emitting

strong fields.

▷

The control lines must be selected in accordance

with local/national regulations.

▷

External electrical interference must be avoided.

Ionization cable, UVcable

▷ Cable lengths of 100m are acceptable if there

is no electromagnetic interference.

▷

The flame signal is adversely affected by EMCin-

fluences.

▷

Lay cables individually (with low capacitance)

and, if possible, not in a metal conduit.

Wiring

▷

Do not reverse phaseL1 and neutral conductorN.

▷

Do not connect different phases of a three-phase

current system to the inputs.

▷ Do not supply voltage to the outputs.

▷ A short-circuit on the outputs causes one of the

replaceable fuses to trip.

▷ Do not set the remote reset so that it operates

(automatically) in cycles.

▷ Wire the safety circuit inputs via contacts (relay

contacts) only.

▷

The limiters in the safety interlock (e.g. safety

temperature limiter, emergency stop) must isolate terminal 46, as well as the optional safetyrelevant inputs at terminals 65 to 68 if these are

parameterized, from the voltage supply. If the

safety interlock is interrupted, the display shows

a blinking

BCU’s control outputs are disconnected from

the electrical power supply.

▷ Connected control elements must be equipped

with protective circuits in accordance with the

manufacturer’s instructions. The protective circuit

prevents high voltage peaks which can cause

malfunctioning of the BCU.

▷

Observe the maximum duty cycle for the ignition

transformer (see manufacturer’s instructions). Adjust the minimum pause timetBP (parameter62)

correspondingly, if required.

▷

Functions of terminals 51, 65, 66, 67 and 68 are

dependent on parameter values:

Terminal Dependent on parameter

See page23 (Parameters and values).

1 Disconnect the system from the electrical power

supply.

Before wiring, ensure that the yellow parameter

chip card has been inserted in the BCU– see

page 3 (Replacing the power module/parameter chip card).

▷

Screw terminals or spring force terminals are

available for the BCU– see page27 (Accessories).

Wire as shown on the connection diagram– see

page5 (Connection diagram) onwards.

▷ Ensure a good PE (ground) wire connection to

the BCU and burners.

▷

To safeguard the safety current inputs (terminals

45 to52 and 65to68), the fuse must be de-

signed so that the sensor with the lowest switching capacity is protected.

as a warning signal and all of the

51

51 69

65 70

66 71

67 72

68 73

GB-4

+24 V

GB

F

NL

I

E

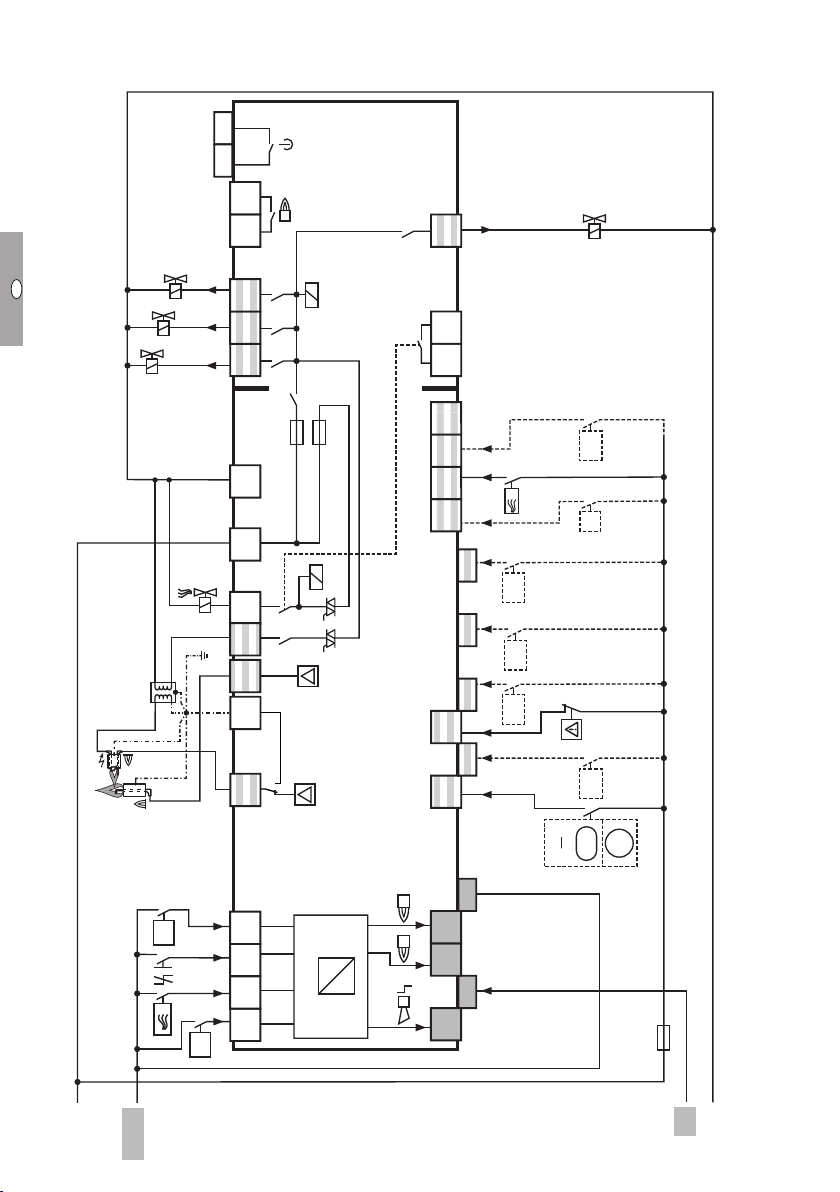

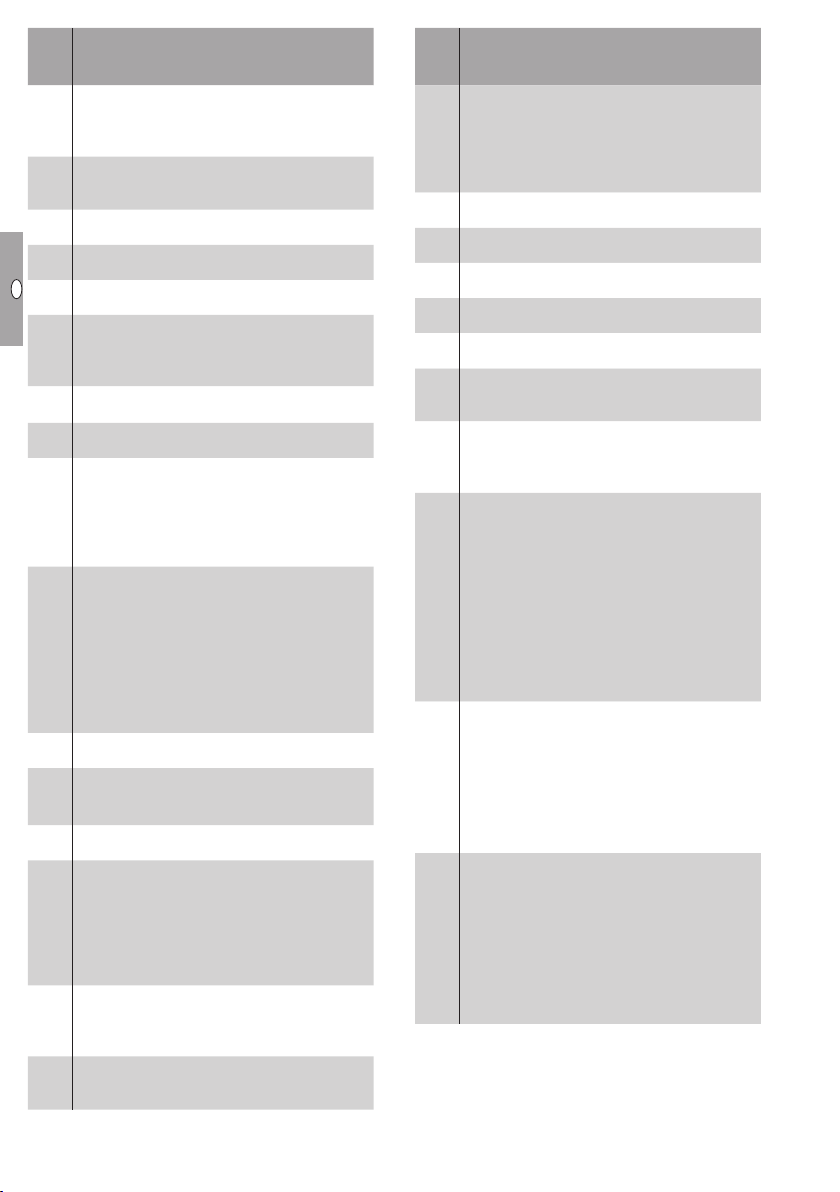

Connection diagram

BCU 560..F0

V2

V1

▷ Legend– see page25 (Legend).

3837

FS

V3

13 14 15 17 1811 1231 2

F1:T3,15AT

P69

49 50 51

HT

68

9

67

P72

66

65

61 62

P71 P73

P70

u

2

p

PZ

GZL

N

0,6 x I

Z

I

c

5 7

A

BCU 560..F0

+24 V DC

45

41 42

ϑ

46

L1

GB-5

0 V

N

+24 V

GB

F

NL

I

E

BCU 560..F

▷ Legend– see page25 (Legend).

V3

V2

V1

3837

FS

13 14 15 17 181110 1231 2

53 5449 50 51 52

F1:T3,15AH

F2:T2AH

P69

P

HT

FS

9

68

67

P72

66

65

61 62

P71 P73

P70

u

2

p

PZ

GZL

N

0,6 x I

Z

I

c

5 7

A

BCU 560..F3

+24 V DC

45

41 42

ϑ

46

L1

GB-6

N

0 V

GB

F

NL

I

E

BCU 565..F

+24 V

▷ Legend– see page25 (Legend).

3837

V3

V2

V1

FS

13 14 15 17 181110 129

53 5449 50 51 52

F1:T3,15AH

F2:T2AH

P69

P

HT

47 48

68

67

P72

Air

min

PZL

FS

9

66

65

61 62

P71 P73

P70

u

2

p

PZ

GZL

N

0,6 x I

Z

I

c

5 7

31 2

A

BCU 565..F3

+24 V DC

45

42

41 44

ϑ

46

L1

GB-7

0 V

N

+24 V

GB

F

NL

I

E

BCU 580..F

▷ Legend– see page25 (Legend).

3837

V3

V2

V1

V4

FS

13 14 15 17 181110 129831 2

53 54 5749 50 51 52

F1:T3,15AH

F2:T2AH

P69

P

HT

FS

c

9

2

68

67

P72

66

65

P71 P73

P70

u

2

p

PZ

GZL

46

I

Z

I

c

5 7

BCU 580..F3

1

45

62

ϑ2

4

43

1 2

42

61

A

+24 V DC

41

ϑ1

N

0,6 x I

L1

GB-8

0 V

N

GB

F

NL

I

E

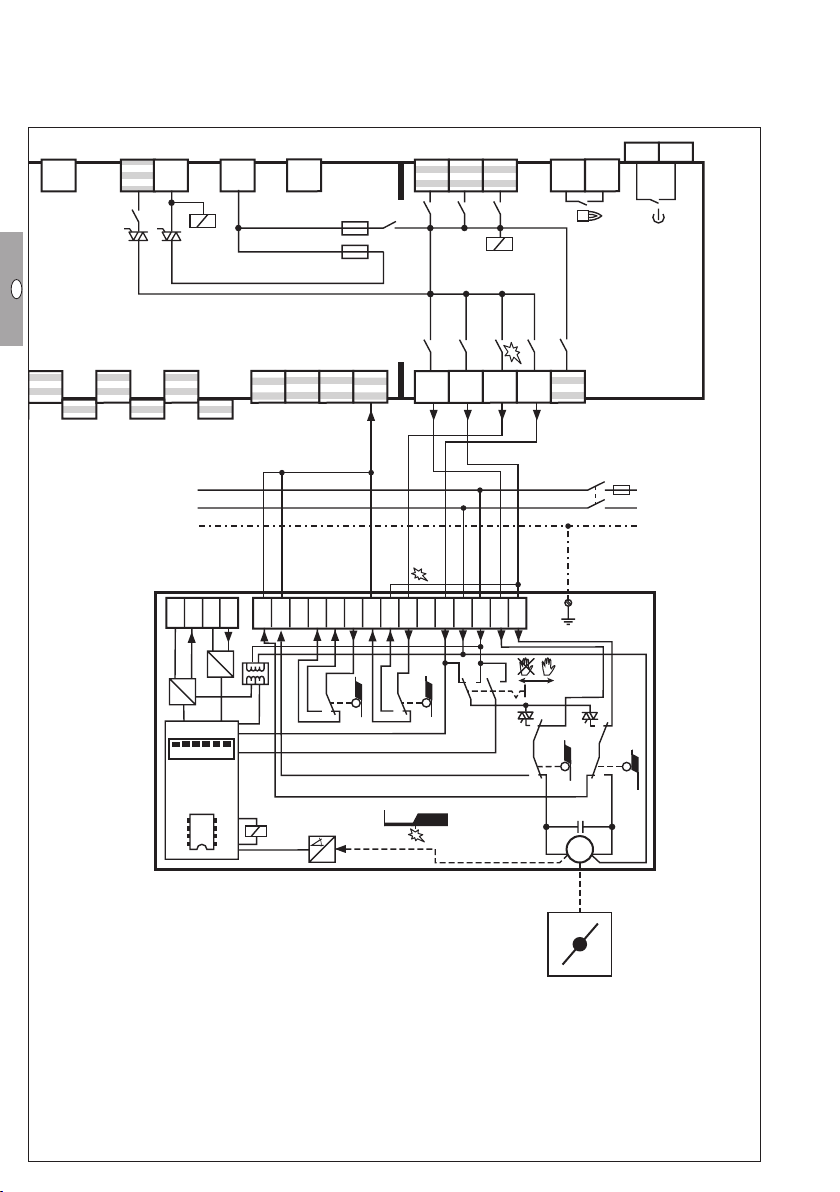

IC 0 connected to BCU..F1

▷ Parameter 40 = 1.

▷

Continuous control via three-point step controller.

7

9

FS

BCU..F1

46

47 48

66

67

68

0°

90°

F1:T3,15AH

F2:T2AH

S11

3837

13 14 15 17 181110 12

FS

90°➔0°

0°➔90°

53 54 55 56 5749 50 51 52

L1

N

PE

90°➔0°

0°➔90°

32116 674812 1115 13

PE

IC 20

S10

S1S2

S3 S4

S1

Min Max

M

GB-9

GB

F

NL

I

E

IC 0..E connected to BCU..F1

▷ Parameter 40 = 1.

▷

Continuous control via an analogue signal (directly connected to the control actuator).

7

9

FS

BCU..F1

46

47 48

66

67

68

OUT

IN

20 19 18 321674812 11

D

A

D

0°

++

A

90°

F1:T3,15AH

F2:T2AH

131516

S2

3837

13 14 15 17 181110 12

FS

90°➔0°

0°➔90°

53 54 55 56 5749 50 51 52

L1

N

0°

90°

➔

➔

OK

0°

90°

517

S1

PE

S10

PE

IC 20..E

ON

123456

µC

R

S1

Min Max

R

R

S3

S4

M

GB-10

GB

F

NL

I

E

IC 40 connected to BCU..F1

▷ Parameter 40 = 2.

▷ Set IC 40 to operating mode27, see operating

instructions Actuators IC 20, IC 40, IC 40S.

7

F1:T3,15AH

FS

BCU..F1

46

66

47 48

67

68

mA

F2:T2AH

3837

13 14 15 17 181110 129

FS

90°➔0°

0°➔90°

53 54 55 56 5749 50 51 52

L

N

22 21 20

19 18 16 15 14 12 11 10 87 54 21

A

D

AC

DC

IC 40

R..

M

GB-11

PE

GB

F

NL

I

E

RBW valve connected to BCU..F

▷ Parameter 40 = 3.

Continuous control via three-point step controller

5 7

F1:T3,15AH

FS

BCU..F2

F2:T2AH

3837

13 14 15 17 181110 129

FS

45

65

46

66

47 48

67

Continuous control via PLC

5 7

BCU..F2

COM

HI

AUTO

LO

53 54 55 56 5749 50 51 52

68

R B W

0°➔90°

RBW

90°➔0°

M

L1

N

3837

13 14 15 17 181110 129

F1:T3,15AH

FS

FS

F2:T2AH

COM

HI

AUTO

LO

45

65

46

47 48

66

53 54 55 56 5749 50 51 52

67

68

OUT

mA

+

A

D

-

PLC

+ F -

0°➔90°

RBW

M

L1

N

GB-12

GB

F

NL

I

E

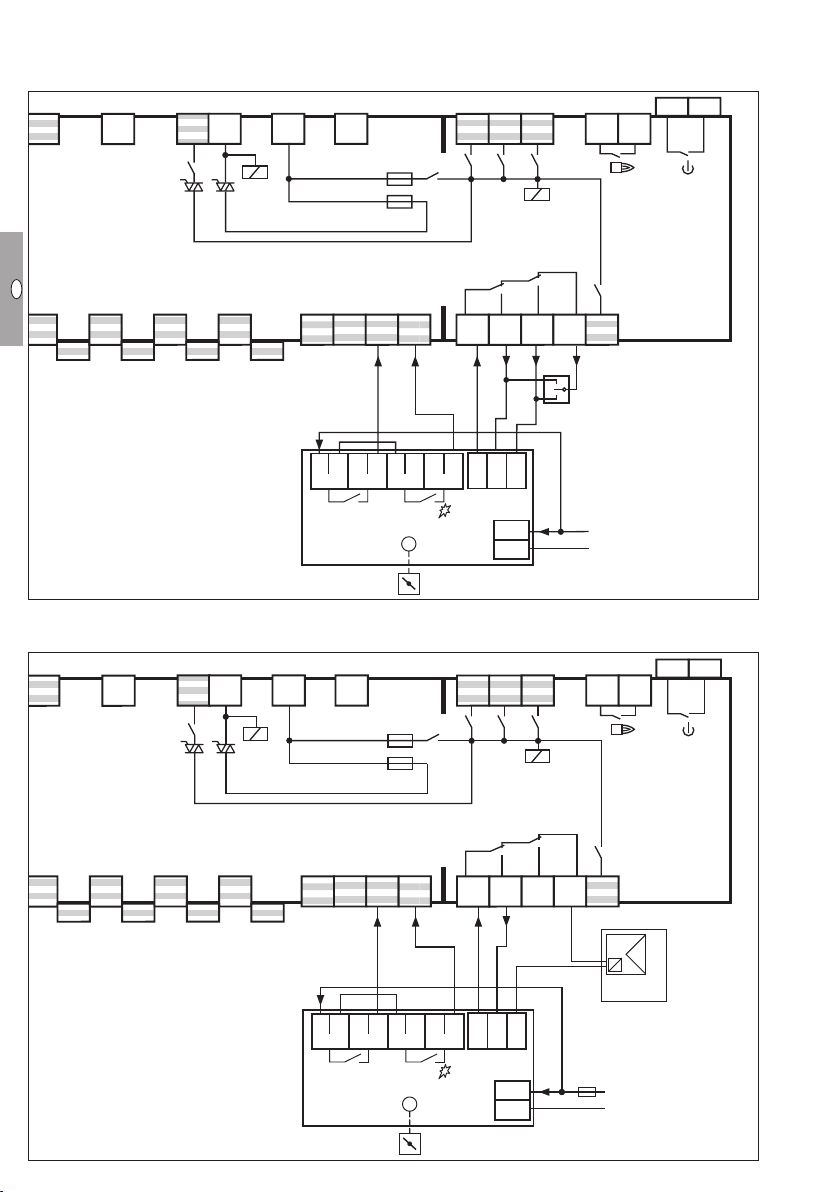

Flame control

V1

V2

V3

13 14 15 17 18

1231 2

3837

V1

V2

V3

13 14 15 17 18

3837

▷ BCU 560, 565 = 1 flame amplifier

▷ BCU 580 = 2 flame amplifiers

▷

In the case of UV control, use Elster UV sensors

for intermittent operation (UVS 1, 5, 6, 10) or

flame detectors for continuous operation (UVC1).

BCU 560, 565

Ionization/single-electrode operation:

▷ Parameter 04 = 0

Z

BCU 580

Pilot burner = single-electrode operation/

main burner = ionization:

▷ Pilot burner in single-electrode operation

▷ Ionization control for main burner

▷ Parameter 04 = 0

I

5 7

UV control:

UVS 1, 5, 6, 10

▷ Parameter 01 ≥ 5 µA

▷ Parameter 04 = 3

1

2

UVS

3

765

UVC 1

▷ Parameter 04 = 2

L

N

PE

765

4

3

2

1

UVC 1

5 7

9

1110 1298

Pilot burner = single-electrode operation/

9

1110

main burner = UVS:

▷ Parameter 01 ≥ 5 µA

▷ Parameter 04 = 3

1

2

UVS

3

Z

9 12

Pilot burner = single-electrode operation/

main burner = UVC 1:

7 865

9 12

▷ Parameter 04 = 4

L

N

PE

4

3

UVC 1

2

1

Z

9

7 865

9

Pilot burner = UVS/main burner = ionization:

▷ Parameter 02 ≥ 5 µA

▷ Parameter 04 = 5

2

3

1

UVS

I

7 865

GB-13

9 12

GB

F

NL

I

E

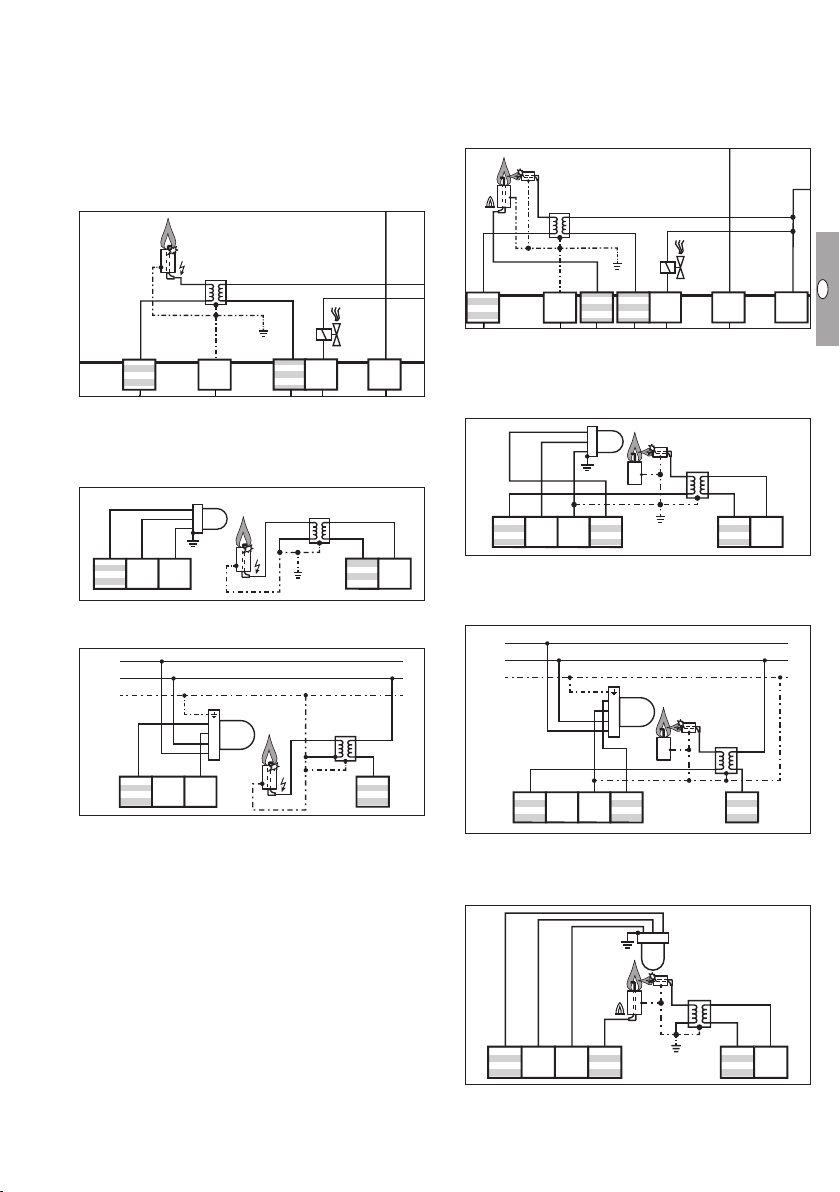

Pilot burner = UVC/main burner = UVC:

▷ Parameter 04 = 6

L

N

PE

2

4

3

1

4

3

2

1

7 865

UVC 1

UVC 1

9

Pilot burner = UVC/main burner = ionization:

▷ Parameter 04 = 7

L

N

PE

2

4

3

1

UVC 1

I

7 865

9

Pilot burner = UVC/main burner = UVS:

▷ Parameter 02 ≥ 5 µA

▷ Parameter 04 = 8

L

N

PE

2

4

3

1

UVC 1

1

2

UVS

3

7 865

9

Adjustment

In certain cases, it may be necessary to change the

parameters set at the factory. Using the separate

software package BCSoft and a PC opto-adapter, it

is possible to modify parameters on the BCU, such

as the pre-purge time or the behaviour in the event

of a flame failure.

▷

The software package and the opto-adapter

are available as accessories– see page27

(Accessories).

▷

Changed parameters are saved on the integrated

parameter chip card.

The factory settings are secured with a program-

▷

mable password.

▷

If the password has been changed, the end customer can look up the changed password in the

plant documentation or ask the system supplier.

Commissioning

▷

During operation, the 7-segment display shows

the program status:

Standby

00

Delay

H0

Approaching minimum capacity

A

Cooling

A0

Fan run-up time

01

Pre-ventilation

A1

Approaching maximum capacity

A

Delay

H1

Pre-purge

P0

Pre-purge

P1

Approaching ignition capacity

A

Valve check

Safety time 1 t

02

Safety time 1 t

A2

Flame proving period 1

03

Flame proving period 1

A3

Burner 1 operation

04

Burner 1 operation

A4

Burner 2 waiting time

05

Delay

A5

Delay time during burner 2 waiting time

H5

Safety time 2 t

06

Safety time 2 t

A6

Flame proving period2t

07

Flame proving period2t

A7

Burner 2 operation

08

Burner 2 operation

A8

Delay

H8

Device Off

––

Remote control (with OCU)

U I

Data transfer (programming mode)

(blinking dots) Manual mode

0.0.

SA1

SA1

SA2

SA2

FS2

FS2

WARNING

Risk of explosion! Check the system for tightness

before commissioning.

Do not start the BCU until the parameter settings

and wiring are correct and the faultless processing

of all input and output signals has been ensured.

1 Switch on the system.

▷ The display indicates

Switch on the BCU by pressing the On/Off but-

ton.

▷ The display indicates

▷

If the display blinks (fault), reset the BCU by

pressing the Reset/Information button.

GB-14

––

00

.

.

GB

F

NL

I

E

BCU 560..F0

Apply the start-up signal to terminal1.

▷ The display indicates

▷ The display indicates

01

.

. The gas valves open

02

and the burner ignites. Safety time1 starts to

elapse.

▷

The display indicates 03 during flame proving

period1.

▷

The display indicates 04. The burner is in op-

eration.

BCU 560..F, BCU 565..F

▷ If the air actuator is activated externally for cool-

ing in the start-up position, the display indicates

.

A0

Apply the start-up signal to terminal1.

▷ The display indicates 01 or A1 if the air actuator

has been activated.

▷ The display indicates 02 or A2 if the air actuator

has been opened. The gas valves open and the

burner ignites. Safety time1 starts to elapse.

▷

The display indicates 03 during flame proving pe-

riod1 or A3 if the air actuator has been opened.

▷ The display indicates 04 or A4 if the air actuator

has been opened. The burner is in operation.

BCU 580..F

▷ If the air actuator is activated externally for cool-

ing in the start-up position, the display indicates

.

A0

Apply the start-up signal to terminal1.

▷ The display indicates 01 or A1 if the air actuator

has been opened.

▷

The display indicates 02 or A2 if the air actua-

tor has been opened. The gas valves open, the

pilot burner (burner1) ignites and safety time1

starts to elapse.

▷

The display indicates 03 during flame proving pe-

riod1 or A3 if the air actuator has been opened.

▷ The display indicates 04 or A4 if the air actuator

has been opened. The pilot burner is in operation.

▷ The display indicates 06 or A6 if the air actuator

has been opened. The main burner (burner2)

ignites and safety time2 starts to elapse.

▷

The display indicates 07 during flame proving pe-

riod2 or A7 if the air actuator has been opened.

▷ The display indicates 08 or A8 if the air actuator

has been opened. The main burner is in operation. The controller enable signal has been issued.

▷ Manual mode is terminated by switching off the

BCU or in the event of a power failure.

▷

Parameter 67 = 0: Manual mode unlimited in

time. The burner control unit may continue to

be operated manually in the event of failure of

the control system or the bus.

▷ Parameter 67 = 1: The BCU will terminate Man-

ual mode 5minutes after the last time the Reset/

Information button is pressed. It switches to the

start-up position/standby (display

).

00

1 Switch on the BCU while holding the Reset/

Information button. Hold the Reset/Information

button until the two dots in the display start to

blink.

If the Reset/Information button is pressed briefly,

▷

the current step in Manual mode is shown.

▷

If the Reset/Information button is pressed for

>1s, the BCU proceeds to the next program

step.

Keep pressing the Reset/Information button (for

>1s at a time) until the BCU has reached the

Burner operation program step (BCU560, 565=

display

/BCU580= display

0.4.

0.8.

).

BCU..F1 with IC 0

▷

Following the burner operating signal (BCU56x=

display

0.4.

, BCU580= display

0.8.

), actuator

IC20 can be opened and closed as required.

Press the Reset/Information button.

▷

If the button continues to be held down, the

actuator opens further until it reaches the position for maximum capacity.

▷ The display indicates

▷

Once the button has been released, the butterfly

with blinking dots.

A.

.

valve stops in the relevant position.

4 Press the Reset/Information button again.

▷

If the button continues to be held down, the

actuator closes further until it reaches the position for minimum capacity.

▷ The display indicates

with blinking dots.

A.

.

▷ A change of direction takes place each time the

button is released and pressed again. When the

butterfly valve has reached its final position, the

dots disappear.

BCU..F1 with IC 40, BCU..F with RBW or

frequency converter

▷ Following controller enable (BCU56x= display

0.4.

, BCU580 = display

0.8.

), it is possible to

move between the positions for maximum and

Manual mode

minimum capacity on a binary basis.

▷ For adjustment of the burner control unit or for

fault-finding.

▷

In Manual mode, the BCU operates independently of the status of the inputs for start-up

signal (terminal1), controlled air flow (terminal2)

and remote reset (terminal3). The function of the

controller enable/emergency stop input (terminal46) is retained.

GB-15

GB

F

NL

I

E

Assistance in the event of malfunction

DANGER

Electric shocks can be fatal! Before working on

possible live components, ensure the unit is disconnected from the power supply.

Fault-clearance must only be undertaken by authorized trained personnel.

▷ Faults may be cleared only using the measures

described below.

▷

If the BCU does not respond even though all

faults have been remedied: remove the unit and

return it to the manufacturer for inspection.

? Faults

! Cause

• Remedy

? The 7-segment display does not light up.

! Mains voltage is not applied.

• Check the wiring, apply mains voltage (see type

label).

! Ignition cable has no contact in the ignition trans-

former.

• Check the connection.

! Ignition cable has short-circuited to ground.

• Check installation, clean the spark electrode.

• If the fault cannot be remedied by doing this,

remove the unit and return it to the manufacturer

for inspection.

? Start-up without flame – no gas supply – the

display blinks and indicates

or

02

.

A 2

! A gas valve does not open.

• Check the gas pressure.

• Check voltage supply to the gas valve.

! There is still air in the pipe, e.g. after installation

work has been carried out or if the system has

not been in operation for a long period.

• “Purge” the pipeline and reset the BCU.

• If the fault cannot be remedied by doing this,

remove the unit and return it to the manufacturer

for inspection.

0 2

0 3

0 6

0 7

0 1

? The display blinks and indicates

!

The BCU has detected an incorrect flame signal

without the burner having been ignited (extraneous signal).

• Direct the UV sensor exactly at the burner to be

monitored.

!

The UV tube in the UV sensor is defective (service

life ended) and issues a continuous flame signal.

• Replace the UV tube, see UV sensor operating

instructions.

! Flame signal through conductive ceramic insula-

tion.

• Increase value of parameter01 in order to adapt

the switch-off threshold of the flame amplifier for

burner1.

0 2

? Start-up – no ignition spark – the display

blinks and indicates

02

A 1

A 2

or

A 2

01

or

.

! The ignition cable is too long.

• Shorten it to 1m (max.5m).

! Gap between spark electrode and burner head

is too great.

• Adjust gap to max. 2mm.

!

Ignition cable has no contact in the terminal boot.

• Screw the cable on firmly.

A 1

A 2

.

? Start-up– flame burning – nevertheless, the

display blinks and indicates

pilot burner/burner (burner1) or

on the main burner (burner).

! Flame failure on start-up.

• Read off the flame signal.

▷

If the flame signal is lower than the switch-off

threshold for the flame signal from burner1 (parameter01) or burner2 (parameter02), this may

be attributable to the following causes:

!

The set value for the cut-off sensitivity is too high.

!

Short-circuit on the flame rod as the result of

soot, dirt or moisture on the insulator.

A 3

A 6

2

! Flame rod not correctly positioned at the flame

edge.

! Terminal boot not properly connected to flame

rod.

! Gas/air ratio incorrect.

!

Flame not contacting burner ground as the result

of excessively high gas or air pressure.

! Burner or BCU not (adequately) grounded.

! Short-circuit or discontinuity on the flame signal

cable.

! Soiled UV sensor.

! UV sensor wiring is defective.

• Remedy fault.

or

A 7

3

6

on the

or

7

GB-16

GB

F

NL

I

E

0 5

A 5

1 0

? The display blinks and indicates

05

or

A 5

! The BCU has detected an incorrect flame sig-

nal without burner2 (main burner) having been

ignited (extraneous signal).

• Direct the UV sensor exactly at the burner to be

monitored.

! The UV tube in the UV sensor is defective (service

life ended) and issues a continuous flame signal.

• Replace the UV tube, see UV sensor operating

instructions.

! Flame signal through conductive ceramic insula-

tion.

• Increase value of parameter02 in order to adapt

the switch-off threshold of the flame amplifier for

burner2.

0 8

?

Operation– flame burning – burner interrupted– the display blinks and indicates

or

.

A8

! Flame failure during operation or during delayed

controller enable.

• Read off the flame signal, see page23 (Read-

ing off the flame signal, fault messages and the

parameters).

▷

If the flame signal is lower than the switch-off

threshold for the flame signal from burner2

(parameter02), this may be attributable to the

following causes:

!

The set value for the cut-off sensitivity is too high.

!

Short-circuit on the flame rod as the result of

soot, dirt or moisture on the insulator.

A 8

08

! Flame rod not correctly positioned at the flame

edge.

! Gas/air ratio incorrect.

!

Flame not contacting burner ground as the result

of excessively high gas or air pressure.

! Burner or BCU not (adequately) grounded.

! Short-circuit or discontinuity on the flame signal

cable.

! Soiled UV sensor.

• Remedy fault.

.

? The display blinks and indicates

! Actuation of the remote reset input is faulty.

! Too many remote resets. More than 5resets

have been conducted within the last 15minutes,

either automatically or manually.

! Consecutive fault caused by a previous fault

whose actual cause has not been remedied.

• Pay attention to previous fault messages.

• Remedy cause.

▷ The cause will not be remedied by performing a

reset every time a fault lock-out occurs.

• Check whether remote reset complies with

standards (EN746 allows resetting only under

supervision) and correct if necessary.

▷ The BCU may only be reset manually under su-

pervision.

• Press the Reset/Information button on theBCU.

? The display blinks and indicates

! Too many restarts for burner1. More than 5re-

starts initiated within the last 15minutes.

• Check burner setting.

• Press the Reset/Information button on theBCU.

1 1

1 2

? The display blinks and indicates

! Too many restarts for burner2. More than 5re-

starts initiated within the last 15minutes.

• Check burner setting.

• Press the Reset/Information button on theBCU.

2 0

? The display blinks and indicates

! Voltage is applied to the output at terminal56.

• Check the wiring and ensure that the voltage

outputs and inputs have the same polarity and

are not reversed.

! The unit has suffered an internal fault in the power

module.

• Replace the power module.

10

11

12

20

.

.

.

.

GB-17

GB

F

NL

I

E

2 1

? The display blinks and indicates

! Inputs 51 and 52 are activated simultaneously.

• Check input 51.

▷

Input 51 may only be activated if the valve is open.

• Check input 52.

▷ Input 52 may only be activated if the valve is in

the position for ignition capacity.

21

.

2 2

? The display blinks and indicates

! Actuator IC 20 has been wired incorrectly.

• Check the wiring. Wire the outputs and inputs

of connection terminals 52–55 as shown in

the connection diagram – see page 9 (IC

20 connected to BCU..F1).

! The unit has suffered an internal fault in the power

module.

• Replace the power module.

.

22

2 3

? The display blinks and indicates

! The butterfly valve position is not constantly sig-

nalled back to theBCU.

• Check the wiring and ensure that the position

for max. capacity/ignition capacity/Closed of

the butterfly valve is constantly signalled back

via terminal52.

23

.

2 4

? The display blinks and indicates

! Faulty activation via the bus. Requirements for

“Open” and “Close” set simultaneously.

• Ensure that “Open” and “Close” are not activated

simultaneously.

24

.

3 0

? The display blinks and indicates

! Abnormal data change in the parameters set for

theBCU.

• Reset the parameters to their original values using

the BCSoft software.

• Establish the cause of the fault to avoid repeat

faults.

• Ensure that the cables have been installed prop-

erly– see page4 (Cable selection).

.

30

• If the measures described above do not help,

remove the unit and return it to the manufacturer

for inspection.

3 1

? The display blinks and indicates

! Abnormal data change in the parameters set for

theBCU.

• Reset the parameters to their original values using

the BCSoft software.

• Establish the cause of the fault to avoid repeat

faults.

• Ensure that the cables have been installed prop-

erly– see page4 (Cable selection).

• If the measures described above do not help,

remove the unit and return it to the manufacturer

for inspection.

31

.

3 2

? The display blinks and indicates

! Supply voltage too low or too high.

• Operate the BCU in the specified mains voltage

range (mains voltage +10/-15%, 50/60Hz).

! The unit has suffered an internal fault.

• Remove the unit and return it to the manufacturer

for inspection.

.

32

3 3

? The display blinks and indicates

! Faulty parameterization.

• Check parameter settings using BCSoft.

! The unit has suffered an internal fault.

• Remove the unit and return it to the manufacturer

for inspection.

33

.

43

? The display blinks and indicates

! Faulty actuation of the air valve.

! The unit has suffered an internal fault.

• Remove the unit and return it to the manufacturer

for inspection.

.

34

GB-18

GB

F

NL

I

E

53

? The display blinks and indicates

! The bus module and control unit are incompat-

ible.

• Check the bus system and PLC for Profibus

compatibility.

! Bus module does not support the selected func-

tion.

• Check the setting of parameter75.

35

.

3 6

? The display blinks and indicates

! Voltage is applied to the device outputs.

• Check the wiring and ensure that the voltage

outputs and inputs have the same polarity and

are not reversed.

! The unit has suffered an internal fault.

• Replace the power module.

• Remove the unit and return it to the manufacturer

for inspection.

36

.

• Change parameter56 (Measurement timeVp1)

using BCSoft.

• If the fault cannot be remedied by doing this,

remove the unit and return it to the manufacturer

for inspection.

4 1

? The display blinks and indicates

! The downstream gas solenoid valve (V2) is leak-

ing.

• Check the downstream solenoid valve.

! The gas pressure switch DGpu/2 for the tightness

test has been set incorrectly.

• Check the inlet pressure.

• Set DGpu/2 to the correct inlet pressure.

• Check the wiring.

! The test period is too long.

• Change parameter56 (Measurement timeVp1)

using BCSoft.

• If the fault cannot be remedied by doing this,

remove the unit and return it to the manufacturer

for inspection.

41

.

3 9

? The display blinks and indicates

! Short-circuit on one of the outputs of the safety

circuit.

• Check the wiring.

• Check fine-wire fuseF1 (3.15A, slow-acting,H).

▷

The fine-wire fuse can be replaced once the

power module has been removed.

• Then check the faultless processing of all input

and output signals.

! The unit has suffered an internal fault in the power

module.

• Replace the power module.

.

39

? The display blinks and indicates

! One of the burner-side gas solenoid valves (V2/

V3) is leaking.

• Check the burner-side solenoid valves.

! The gas pressure switch DGpu/2 for the tightness

test has been set incorrectly.

• Check the inlet pressure.

• Set DGpu/2 to the correct inlet pressure.

• Check the wiring.

! The test period is too long.

• Change parameter56 (Measurement timeVp1)

using BCSoft.

• If the fault cannot be remedied by doing this,

remove the unit and return it to the manufacturer

for inspection.

4 2

.

42

4 0

? The display blinks and indicates

! The gas solenoid valve V1 is leaking.

• Check the gas solenoid valve V1.

! The gas pressure switch DGpu/2 for the tightness

test has been set incorrectly.

• Check the inlet pressure.

• Set DGpu/2 to the correct inlet pressure.

• Check the wiring.

! The test pressure between V1 andV2 has not

decreased.

• Check the installation.

! The test period is too long.

.

40

? The display blinks and indicates

! Faulty pressure switch signal.

• Check the wiring and setting of the pressure

switch.

4 4

.

44

GB-19

GB

F

NL

I

E

4 5

• Check the wiring.

? The display blinks and indicates

! Faulty valve actuation, reversed valve connection.

• Check the wiring of the solenoid valves.

45

.

5 1

? The display blinks and indicates

! Interruption of signal at the “Safety interlock/

Controller enable/Emergency stop” input (terminal46).

• Check voltage supply to terminal46.

51

.

5 2

? The display blinks and indicates

! The BCU is permanently reset by remote reset.

• Check voltage supply to terminal3.

• Apply voltage to terminal3 only for reset, approx.

1second.

.

52

5 3

? The display blinks and indicates

! The time between two starts is less than the

min.time (timingcycle).

• Comply with the min. timing cycletz

tz

[s] = (tVZ + 0.6 × t

min

Example:

Pre-ignition time t

1st safety time on start-up t

tz

= (2 + 0.6 × 3) + 9 = 12.8 s

min

VZ

= 2 s

SA1

SA1

= 3s

53

min

) + 9

.

:

5 7

? The display blinks and indicates

! Faulty actuation of the input at terminal44. The

BCU is prompted to go into menox mode, even

though there is no signal for high temperature

operation (>750°C) at terminal49.

• Check the wiring.

8 9

9 8

? The display blinks and indicates

,

96

! System fault – the BCU has performed a safety

shut-down. The cause may be a unit defect or

abnormal EMC influence.

• Ensure that the ignition cable has been installed

properly– see page4 (Cable selection).

• Ensure that the EMC regulations for the sys-

tem are satisfied– particularly for systems with

frequency converters – see page 4 (Cable

selection).

• Reset the unit.

• Disconnect the burner control unit from the mains

supply and then switch it on again.

• Check mains voltage and frequency.

•

If the measures described above do not help, the unit

has probably suffered a hardware defect– remove the

unit and return it to the manufacturer for inspection.

9 4

9 5 9 6

9 9

or

98

.

99

.

57

,

,

89

94

95

9 4

,

5 4

? The display blinks and indicates

! Faulty feedback signal of the control element

position for ignition capacity.

• Check wiring from central actuator to BCU (ter-

minal66).

• Check whether parameter 71=20 (LDS ignition

position check).

.

54

5 6

? The display blinks and indicates

! Faulty wiring of multi-flame control. A flame signal

and an incorrect flame signal are sent to the BCU

at the same time.

56

.

? The display blinks and indicates

! The inputs are supplied with different phases of

a three-phase current system.

• Check the wiring and ensure that the device and

the inputs are supplied with the same phase.

9 7

? The display blinks and indicates

! No PCC.

• Insert compatible PCC.

! Contact problems on the power module.

• Remedy contact problems.

! Power module is defective.

• Replace power module.

GB-20

94

.

.

97

GB

F

NL

I

E

• If the measures described above do not help, the

unit has probably suffered a hardware defect –

remove the unit and return it to the manufacturer

for inspection.

0

? The display blinks and indicates

! The “no flow” state check of the air pressure

switch has failed.

• Check the function of the air pressure switch.

Before the fan is switched on, there must be no

high signal at the input for air monitoring (terminal47) when air monitoring is activated.

.

0

2 3

6

? The display blinks and indicates

5, 6, 7

! The input signal for the air pressure switch has

dropped out during start-up/operation at program stepX (02to08).

!

Failure of the air supply at program stepX

• Check the air supply.

• Check the air pressure switch setpoint.

or

7

.

8

4

8

2

,

3, 4

5

.

,

1

A

? The display blinks and indicates

! The operating check of the air pressure switch

has failed. The air monitor, depending on the

parameter setting for input 47 or 48 (P15 and

P35), has not switched after fan start-up.

• Check the air monitor wiring.

• Check the air pressure switch setpoint.

• Check the function of the fan.

.

1

? The display blinks and indicates

! No “Minimum capacity reached” signal from

actuator.

• Check the butterfly valve and the function of the

limit switches in the actuator.

• Check the wiring.

• Check the actuator.

• If the fault cannot be remedied by doing this,

remove the unit and return it to the manufacturer

for inspection.

.

A

P

? The display blinks and indicates

! The input signal (terminal48) for the air pressure

switch has dropped out during pre-purge.

• Check the air supply during the purging process.

• Check the electrical wiring of the air pressure

switch.

• Check voltage supply to terminal48.

• Check the air pressure switch setpoint.

8 0

? The display blinks and indicates

! Burner 1 flame amplifier is defective.

• Remove the unit and return it to the manufacturer

for inspection.

8 5

? The display blinks and indicates

! Burner 2 flame amplifier is defective.

• Remove the unit and return it to the manufacturer

for inspection.

P

80

85

.

? The display blinks and indicates

! No “Maximum capacity reached” signal from

actuator.

• Check the butterfly valve and the function of the

limit switches in the actuator.

• Check the wiring.

• Check the actuator.

• If the fault cannot be remedied by doing this,

remove the unit and return it to the manufacturer

for inspection.

.

? The display blinks and indicates

! No “Ignition capacity reached” signal from actua

tor.

• Check the butterfly valve and the function of the

limit switches in the actuator.

.

• Check the wiring.

• Check the actuator.

• If the fault cannot be remedied by doing this,

remove the unit and return it to the manufacturer

for inspection.

A

A

.

A

.

A

-

GB-21

GB

F

NL

I

E

E

? The display blinks and indicates

! Internal communication with bus module has

suffered a fault.

• Connected control elements must be equipped

with protective circuits in accordance with the

manufacturer’s instructions.

▷

This prevents high voltage peaks which can

cause malfunctioning of the BCU.

• Use suppressed terminal boots (1kΩ).

• If the fault cannot be remedied by doing this,

remove the unit and return it to the manufacturer

for inspection.

! The bus module is defective.

• Replace the bus module.

.

E

! One of the external flame detectors detects an

extraneous signal (an incorrect flame signal).

• Eliminate extraneous signal.

! Incorrect voltage supply to terminal67.

• Check voltage supply to terminal67.

! Parameter 45 has been set incorrectly.

• Check whether multi-flame control is required.

If not, set parameter45 to0.

F 2

? The display blinks and indicates

! One of the external flame detectors does not

detect a flame signal during the safety time.

• Check voltage supply to terminal68.

.

F2

F 3

? The display blinks and indicates

! Incorrect or defective parameter chip card (PCC).

• Only the intended parameter chip card is to be

used.

• Replace defective parameter chip card.

.

1

? The display blinks and indicates

! No input signal for the valve proof of closure

switch (POC) during standby.

• Check the wiring.

▷ Mains voltage must be supplied to the BCU (ter-

minal45) if the valve is closed and no voltage is

to be applied if the valve is open.

• Check that the proof of closure switch and valve

function perfectly, replace defective valves.

1

.

8

? The display blinks and indicates

! The BCU is receiving no information as to wheth-

er the POC switch contact is still open.

• Check the wiring.

• During start-up, mains voltage must be supplied

to the BCU (terminal45) if the valve is closed and

no voltage is to be applied if the valve is open.

• Check that the proof of closure switch and valve

function perfectly, replace defective valves.

.

8

F 1

? The display blinks and indicates

F1

.

? The display blinks and indicates

! One of the external flame detectors does not

detect a flame signal during the flame proving

period.

• Check voltage supply to terminal68.

F 4

? The display blinks and indicates

! One of the external flame detectors does not

detect a flame signal during operation.

• Check voltage supply to terminal68.

0

? The display blinks and indicates

! No connection established between BCU

andPLC.

• Check the wiring.

• Check the PLC program to ensure that the net-

work name and IPconfiguration of the BCU are

valid.

• Switch on the PLC.

1

? The display blinks and indicates

▷ Fault occurs on devices with fieldbus communi-

cation with address check (P80=1) only.

! An invalid or incorrect address has been set on

the bus module.

• Assign the correct address (001toFEF) to the

bus module.

GB-22

F3

F4

0

1

.

.

.

.

GB

F

NL

I

E

• Press the Reset/Information button again for

2

? The display blinks and indicates

! The bus module has received an incorrect con-

figuration from thePLC.

• Check whether the correct GSD file was im-

ported.

2

.

2s to go to the next item of information (fault

message, parameter value).

▷

Each time the button is released, the corresponding fault message or parameter value is displayed.

▷ To go to one of the last fault messages or to a

parameter more quickly, hold the Reset/Infor

mation button pressed down for longer (≥2s).

▷ If the button is pressed briefly, the display indi-

-

cates what parameter number is currently being

displayed.

3

? The display blinks and indicates

▷ Fault occurs on devices with fieldbus communi-

cation with address check (P80=1) only.

! The BCU has been assigned an invalid network

name or has not been assigned a network name

in thePLC.

• Assign a network name corresponding to the

default network name (e.g. bcu-560-xxx) or use

the default name as a suffix of an individually

assigned name in the following form: “individualpartofnamebcu-560-xxx”.

▷

“xxx” stands for the address set on the device

(e.g. 4a5).

3

.

4

▷

The normal program status is displayed again

approx. 60seconds after the last time the button is pressed.

▷

If an operator-control unit OCU is connected,

information about the flame signal intensity, fault

messages and parameter values can only be

queried using the OCU, see page 27 (Accessories).

Parameters and values

Pa-

Parameter name

rameter

Parameter value

No.

Burner 1 flame signal switch-off threshold

01

2 – 20 = µA

Burner 2 flame signal switch-off threshold

02

2 – 20 = µA

Flame control

0 = Ionization

? The display blinks and indicates

4

.

! PLC in STOP position.

• Check whether the PLC can be started.

Reading off the flame signal, fault

messages and the parameters

▷

During operation (BCU 56x = display

BCU580= display

0 8

), information about the

flame signal intensity, the last 10fault messages

and the parameter values can be read off by

repeatedly pressing the Reset/Information button.

Display Information

F1

F2

E0

to

E9

01

to

99

* Only on BCU 580

Flame signal intensity:

Burner 1

*

Burner 2*

Last fault message

to

tenth to last fault message

Parameter 01

to

parameter 99

• Press the Reset/Information button for approx.

2s until the display indicates

.

F1

• Release the button. The display indicates the

flame signal intensity inµA.

0 4

,

1 = UVS

2 = UVD

3 = Ionization 1 and UVS 2

04

4 = Ionization 1 and UVD 2

5 = UVS 1 and ionization 2

6 = UVD 1 and UVD 2

7 = UVD 1 and ionization 2

8 = UVD 1 und UVS 2

High temperature operation

0 = Off

2 = Intermittent operation with UVS

06

3 = Continuous operation with ionization/UVD

5 = menox intermittent

Burner 1 start-up attempts

1 = 1 start-up attempt

07

2 = 2 start-up attempts

3 = 3 start-up attempts

Burner 2 start-up attempts

1 = 1 start-up attempt

08

2 = 2 start-up attempts

3 = 3 start-up attempts

Restart

0 = No

1 = Burner 1

2 = Burner 2

09

3 = Burner 1 and burner 2 (pilot and main burners)

4 = Max. 5 times in 15 min. for burner1

5 = Max. 5 times in 15 min. for burner2

6 = Max. 5 times in 15 min. for burners 1 and2

GB-23

GB

F

NL

I

E

Pa-

Parameter name

rameter

Parameter value

No.

Low air pressure protection

0 = Off

15

1 = With safety shut-down

2 = With fault lock-out

Delayed low air pressure protection

0 = Off

16

1 = On

Safety time during operation

19

0; 1; 2 = Time in seconds

menox pre-ventilation time t

28

0 – 250 = Time in seconds

Pre-purge time tPV

34

0 – 6000 = Time in seconds

VLM

Air flow monitoring during pre-purge

0 = Off

35

1 = With safety shut-down

2 = With fault lock-out

Pre-ventilation time t

36

0 – 250 = Time in seconds

Post-ventilation time tNL

39

0 – 3 = Time in seconds

VL

Capacity control

1 = IC 20

2 = IC 40

40

3 = RBW

4 = Frequency converter

5 = Air valve

Running time selection

0 = Off; checking the positions for min./max.

capacity

1 = On; for approaching the positions for min./

max. capacity

41

2 = On; for approaching the position for

maximum capacity

3 = On; for approaching the position for

minimum capacity

Running time

42

0 – 250

= Time in seconds

Low fire over-run

0 = Off

43

1 = Up to minimum capacity

Controller enable signal delay timetRF

44

0 – 250 = Time in seconds

Air actuator control

0

= Opens on external activation

1

= Opens with valve V1 (1st stage)

2

= Opens with valve V2 (2nd stage)

48

3

= Controller enable following operating signal

or in standby

4

= Opens with V4 burner 1

Air actuator can be activated externally on

start-up

49

0 =

Cannot be activated

1 =

Can be activated externally

Air actuator in the event of fault

0 =

50

Cannot be activated

1 =

Can be activated externally

Pa-

Parameter name

rameter

Parameter value

No.

Valve proving system

0 = Off

1 = Tightness test before start-up

51

2 = Tightness test after shut-down

3 =

Tightness test before start-up and after shut-down

4 = Proof of closure function

Measurement time Vp1

56

0 – 3600 = Time in seconds

Valve opening time 1 tL1

59

2 – 25 = Time in seconds

Minimum operating time tB

61

0 – 250

=

Minimum pause time tBP

62

0 – 3600

Switch-on delay time tE

63

0 – 250 = Time in seconds

Time in seconds

=

Time in seconds

Operating time in Manual mode

0 = Unlimited

67

1 = 5 minutes

Function of terminal 50

0 = Off

68

23 = Purge with Low signal

24 = Purge with High signal

Function of terminal 51

0 = Off

8 = AND gating with emergency stop input

(terminal46)

9 = AND gating with air pressure switch input

(terminal47)

69

10 =

AND gating with purge pressure switch input

(terminal48)

11 = AND gating with Gas max input (terminal50)

12 = AND gating with Gas min input (terminal49)

13 = IC40/RBW purge position feedback

Function of terminal 65

0 = Off

8 = AND gating with emergency stop input

(terminal46)

70

9 = AND gating with air pressure switch input

(terminal47)

10 =

AND gating with purge pressure switch input

(terminal 48)

Function of terminal 66

0 = Off

8 = AND gating with emergency stop input

(terminal46)

9 = AND gating with air pressure switch input

71

(terminal47)

10 =

AND gating with purge pressure switch input

(terminal 48)

20 = LDS ignition position check

GB-24

GB

F

NL

I

E

P

PZ

PZH

PZL

PDZ

P

xx

M

Pa-

Parameter name

rameter

Parameter value

No.

Function of terminal 67

0 = Off

8 = AND gating with emergency stop input

(terminal46)

9 = AND gating with air pressure switch input

72

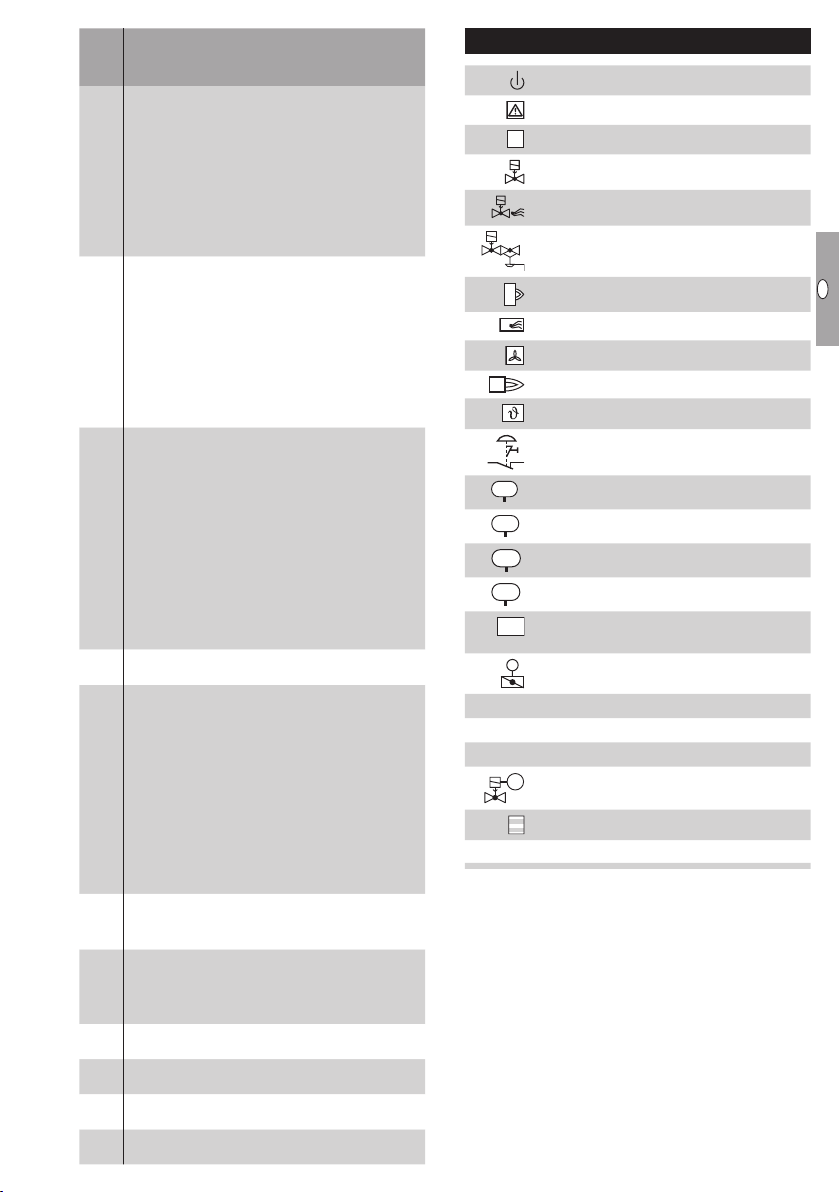

Legend

HT

Ready for operation

Safety interlocks (limits)

High temperature operation

Gas valve

(terminal47)

10 =

AND gating with purge pressure switch input

(terminal 48)

21 = Multi-flame control (MFC) start-up conditions

Function of terminal 68

0 = Off

8 = AND gating with emergency stop input

(terminal46)

9 = AND gating with air pressure switch input

73

(terminal47)

10 =

AND gating with purge pressure switch input

(terminal 48)

22 = Multi-flame control (MFC) operating conditions

Air valve

Air/gas ratio control valve

Burner

Purge

Controlled air flow

Burner operating signal

Start-up signal (BCU)

Capacity control (bus)

0 =

Off

1 =

MIN. to MAX. capacity; standby in position for

MIN. capacity

2 =

MIN. to MAX. capacity; standby in CLOSED

position

75

3 =

IGNITION to MAX. capacity; standby in

CLOSED position

4 =

MIN. to MAX. capacity; standby in position for

MIN. capacity; burner quick start

5 =

IGNITION to MAX. capacity; standby in

CLOSED position; burner quick start

Password

77

0000 – 9999

Burner application

0 = Burner 1

1 = Burner 1 with pilot gas

2 = Burner 1 and burner 2

3 = Burner 1 and burner 2 with pilot gas

4 = Two-stage burner 1

78

Emergency stop

Pressure switch for tightness control (TC)

Pressure switch for maximum pressure

Pressure switch for minimum pressure

Differential pressure switch

Input signal

depending on parameter xx

Control element with butterfly valve

Tightness control

TC

Half of the inlet pressure

pu/2

Outlet pressure

p

d

GZL

Valve with proof of closure switch

5 = Burner 1 and two-stage burner 2

= 1/0 in menox and 1/0 in flame mode

11

12 = 1/0 in menox and L/H/O in flame mode

13 = 1/0 in menox mode with 2 gas paths

Input/Output, safety circuit

I

Current consumption of sensor/contactor

N

14 = L/H/O in menox mode with 2 gas paths

Pilot burner

0 = With shut-down

79

1 = Continuous operation

Fieldbus communication

0 = Off

80

1 = With address check

2 = No address check

Safety time 1 t

94

2, 3, 5, 10 = Time in seconds

Flame proving period 1 t

95

0 – 20 = Time in seconds

Safety time 2 t

96

2, 3, 5, 10 = Time in seconds

Flame proving period 2 t

97

0 – 20 = Time in seconds

SA1

FS1

SA2

FS2

GB-25

GB

F

NL

I

E

Technical data

Electrical data

Mains voltage:

BCU..Q: 120 VAC, -15/+10%, 50/60 Hz, ±5%,

BCU..W: 230 VAC, -15/+10%, 50/60 Hz, ±5%,

for grounded mains.

Flame control:

with UV sensor or ionization sensor.

For intermittent or continuous operation.

Flame signal current:

ionization control: 1 – 25 μA,

UV control: 1 – 35 μA.

Ionization cable, UV cable:

max. 100m (328ft).

Contact rating:

Valve outputs V1, V2, V3 and V4 (terminals 13, 14, 15

and 57):

max. 1 A each, cos φ ≥ 0.6.

Actuator outputs (terminals 53, 54 and 55):

max. 1 A each, cos φ = 1.

Air valve output (terminal 10):

max. 1 A, cos φ = 1.

Ignition transformer (terminal 9):

max. 2 A.

Total current for the simultaneous activation of the

valve outputs (terminals 13, 14, 15, 57), of the

ignition transformer (terminal 9) and of the actuator

(terminals 53, 54, 55):

max. 2.5A.

Signalling contact for operating and fault signals:

max. 1 A (external fuse required).

Number of operating cycles:

The fail-safe outputs (valve outputs V1, V2, V3

andV4) are monitored for correct functioning and

are thus not subject to a max. number of operating

cycles.

Control actuator (terminals 53, 54 and 55):

max. 1,000,000,

signalling contact for operating signals:

max. 1,000,000,

signalling contact for fault signals:

max. 10,000,

On/Off button:

max. 10,000,

Reset/Information button:

max. 10,000.

Input voltage of signal inputs:

Rated value 120 V AC 230 V AC

Signal “1” 80 – 132 V 160 – 253 V

Signal “0” 0 – 20 V 0 – 40 V

Signal input current:

Signal “1” max. 5 mA

Fuses, replaceable, F1: T 3.15A H,

F2: T 2A H, pursuant to IEC 60127-2/5.

Mechanical data

Weight: 0.7 kg.

Dimensions (W × H × D): 102 × 115 × 112 mm.

Connections:

Screw terminals:

nominal cross-section 2.5mm²,

wire cross-section (rigid) min. 0.2mm²,

wire cross-section (rigid) max. 2.5mm²,

wire cross-section AWG min.24,

wire cross-section AWG max.12.

Spring force terminals:

nominal cross-section 2 x 1.5mm²,

wire cross-section min. 0.2mm²,

wire cross-section AWG min.24,

wire cross-section AWG max.16,

wire cross-section max. 1.5mm²,

rated current 10 A (8A UL), to be observed in

case of daisy chain.

Environment

Ambient temperature:

-20 to +60°C (-4 to +140°F),

no condensation permitted.

Storage temperature: -20 to +60°C (-4 to +140°F).

Enclosure: IP 20 pursuant to IEC529.

Installation location: min. IP 54 (for installation in a

control cabinet).

Designed lifetime

This information on the designed lifetime is based on

using the product in accordance with these operating

instructions. Once the designed lifetime has been

reached, safety-relevant products must be replaced.

Designed lifetime (based on date of manufacture)

in accordance with EN230 and EN298 forBCU:

20years.

You can find further explanations in the applicable

rules and regulations and on the afecor website

(www.afecor.org).

This procedure applies to heating systems. For

thermoprocessing equipment, observe local regulations.

GB-26

GB

F

NL

I

E

Logistics

Transport

Protect the unit from external forces (blows, shocks,

vibration). On receipt of the product, check that the

delivery is complete, see page2 (Part designations). Report any transport damage immediately.

Storage

Store the product in a dry and clean place.

Storage temperature: see page26 (Technical data).

Storage time: 6months before using for the first

time. If stored for longer than this, the overall service

life will be reduced by the corresponding amount of

extra storage time.

Packaging

The packaging material is to be disposed of in ac-

cordance with local regulations.

Disposal

Components are to be disposed of separately in

accordance with local regulations.

Accessories

▷ Spare parts, see www.partdetective.de

BCSoft

The current software can be downloaded from our

Internet site at http://www.docuthek.com. To do so,

you need to register in the DOCUTHEK.

Opto-adapter PCO 00

Including BCSoft CD-ROM,

Order No. 74960625.

Bluetooth adapter PCO 00

Including BCSoft CD-ROM,

Order No. 74960617.

Stickers for labelling

Connection plug set

For wiring the BCU.

74923998 74924000

Connection plugs with screw terminals for

FCU500/BCU 56x/580..K1,

Order No. 74923998.

Connection plugs with spring force terminals for

FCU500/BCU 56x/580..K2,

Order No. 74924000.

OCU

Operator-control unit for installation in the control

cabinet door. The program status or fault messages

can be read on the OCU. In Manual mode, the OCU

can be used to proceed through the sequence of

operating steps.

OK

OCU 500-1,

Switchable display: D, GB, F, NL, E, I,

Order No. 84327030,

OCU 500-2,

Switchable display: GB, DK, S, N, TR, P,

Order No. 84327031,

OCU 500-3,

Switchable display: GB, USA, E, P (BR), F,

Order No. 84327032,

OCU 500-4,

Switchable display: GB, RUS, PL, HR, RO, CZ,

Order No. 84327033.

BCU 570

Brenner 1

For printing with laser printers, plotters or engraving

machines, 27 × 18mm or 28 × 17.5mm.

Colour: silver.

GB-27

GB

F

NL

I

E

Certification

Declaration of conformity

We, the manufacturer, hereby declare that the products BCU560, BCU565 and BCU580 comply with

the essential requirements of the following Directives

and Standards.

Directives:

– 2014/30/EU

– 2014/35/EU

Regulation:

– (EU) 2016/426 – GAR

Standards:

– EN 298:2012

– EN 1643:2014

– EN 61508:2010, suitable for SIL3

The relevant product corresponds to the tested type

sample.

The production is subject to the surveillance proce-

dure pursuant to Regulation (EU) 2016/426 AnnexIII

paragraph3.

Elster GmbH

SIL, PL

For systems up to SIL 3 pursuant to EN 61508.

Pursuant to EN ISO 13849-1, Table 4, the BCU can

be used up to PL e.

FM approved

Factory Mutual (FM) Research Class:

7610 “Combustion Safeguards and Flame Sensing

Systems”

Suitable for applications pursuant to NFPA 86.

ANSI/CSA approved

Canadian Standards Association –

ANSI Z21.20 and CSA 22.2

Eurasian Customs Union

Scan of the Declaration of conformity (D,GB)– see

www.docuthek.com

Contact

Contact

If you have any technical questions, please contact

your local branch office/agent. The addresses are

available on the Internet or from ElsterGmbH.

We reserve the right to make technical modifications

in the interests of progress.

The products

BCU560, BCU 565 and BCU580

meet the technical specifications of the Eurasian

Customs Union.

Directive on the restriction of the use of

hazardous substances (RoHS) in China

Scan of the Disclosure Table China RoHS2 – see

certificates at www.docuthek.com

Strotheweg 1, D-49504 Lotte (Büren)

Tel. +49 541 1214-0

Fax +49 541 1214-370

hts.lotte@honeywell.com, www.kromschroeder.com

GB-28

Elster GmbH

Loading...

Loading...