GB

F

NL

I

E

554

0

D GB F NL I E

TR CZ PL RUS H

DK S N P GR

➔ www.docuthek.com

Operating instructions

Gas pilots ZMI, ZMIC

© 2018 Elster GmbH · Edition 07.18

Translation from the German

Contents

Contents

Gas pilots ZMI, ZMIC ....................

Contents ..............................

Safety.................................

Checking the usage .....................

Checking the gas type...................

Installation ............................

ZMIC .................................4

ZMIC..K

...............................4

Wiring ................................4

Leak test ..............................4

Commissioning.........................5

ZMI...................................5

ZMIC .................................5

Maintenance

Replacing the electrode

ZMIC..K: replacing the bellows unit ..........6

ZMIC: replacing the ceramic tube............6

Accessories ...........................7

Technical data

Logistics

Declaration of Incorporation..............8

Certification

Contact ..............................0

...........................5

...................5

.........................7

..............................8

...........................9

Safety

Safety

Please read and keep in a safe place

Please read through these instructions

carefully before installing or operating. Following the

installation, pass the instructions on to the operator. This unit must be installed and commissioned

in accordance with the regulations and standards

in force. These instructions can also be found at

www.docuthek.com.

Explanation of symbols

• , , , ... = Action

▷ = Instruction

Liability

We will not be held liable for damage resulting from

non-observance of the instructions and non-compliant use.

Safety instructions

Information that is relevant for safety is indicated in

the instructions as follows:

DANGER

Indicates potentially fatal situations.

WARNING

Indicates possible danger to life and limb.

CAUTION

Indicates possible material damage.

All interventions may only be carried out by qualified

gas technicians. Electrical interventions may only be

carried out by qualified electricians.

Conversion, spare parts

All technical changes are prohibited. Only use OEM

spare parts.

Changes to edition 07.7

The following chapters have been changed:

– Checking the usage

– Wiring

– Maintenance

GB-1

GB

F

NL

I

E

Checking the usage

Intended use

Ionization-controlled gas pilot for safely igniting gas

burners. The capacity of the gas pilot should be 2

to 5% of that of the main burner.

Can also be used as independently operated burner.

For natural gas, coke oven gas, town gas and LPG.

Other types of gas on request.

This function is only guaranteed when used within

the specified limits – see also page7 (Technical

data). Any other use is considered as non-compliant.

ZMI

Type code

Code Description

ZMI Ionization pilot with forced air supply

6 – 5 Burner size

T T-product

B

G

D

For coke oven gas, town gas

50 – 000 Flame tube length

R Rp internal thread

N NPT internal thread

Part designations

and one electrode

For natural gas

For LPG

ZMIC

Type code

Code Description

ZMIC Ionization pilot with forced air supply,

one electrode and a ceramic flame

tube tip

8 Burner size

B

G

D

For coke oven gas, town gas

For natural gas

For LPG

00 – 000 Flame tube length

R Rp internal thread

K Bellows unit

Part designations

8

7

3

5

1

4

2

6

3

1

8

7

9

ZMIC

9

ZMIC..K

3

1

2

4

7

5

Burner housing

Interference-suppressed terminal boot with

protective cap

Air nozzle

4 Gas nozzle

5 Burner bracket

6 Flame tube

7 Enclosed documentation: operating

instructions and flow rate curves

Burner size, gas type, rated capacity P

tube length, connection– see type label.

D-49018 Osnabrück Germany

ZMI

Gas

Pmax.

max.

6

, flame

4

2

10

12

11

Burner housing

Interference-suppressed terminal boot with

protective cap

Air nozzle

4 Gas nozzle

5 Burner bracket with reducing nipple

6 Bellows unit with nut

7 Ceramic tube retaining piece

8 Ceramic tube clamping ring

9 Ceramic tube

0 Transport safety device (plastic tube and

O-ring)

Insulation strip

Enclosed documentation: operating instruc-

tions and flow rate curves

Burner size, gas type, rated capacity P

tube length, connection– see type label.

D-49018 Osnabrück Germany

ZMIC

Gas

Pmax.

max.

, flame

GB-2

GB

F

NL

I

E

Checking the gas type

2

1

2

1

Check if the gas nozzle diameter is suitable for

the required gas type.

Gas

type

ZMI 16 ZMI 25 ZMIC 28

B 0.94 (0.037) 1.40 (0.055) 1.40 (0.055)

G 0.76 (0.029) 1.05 (0.041) 1.05 (0.041)

D 1.30 (0.051) 1.78 (0.070) 1.78 (0.070)

▷ When changing the nozzle, remove the residue

of sealant from the burner housing.

▷ Suitable nozzles– see page7 (Accessories).

Nozzle

dia. [mm (inch)]

3

4

Position the

burner before

tightening the

cap screw.

5

Installation

DANGER

Risk of explosion! Ensure the connection is air-

tight.

CAUTION

Burner fault! If used as gas pilot, the gas and

air pressures must be higher than the connection

pressures of the main burner.

▷ Install the gas pilot so that reliable ignition of the

main burner is guaranteed.

▷ Attach the gas pilot securely.

▷

We recommend that a filter be installed in the

gas and air supply line respectively.

6 For air-tight installation, hand-tighten the union

nut then tighten it with a further turn (olive fitting

is secured).

7 Connect the pilot gas supply line with Rp¼ and

the air line with Rp½.

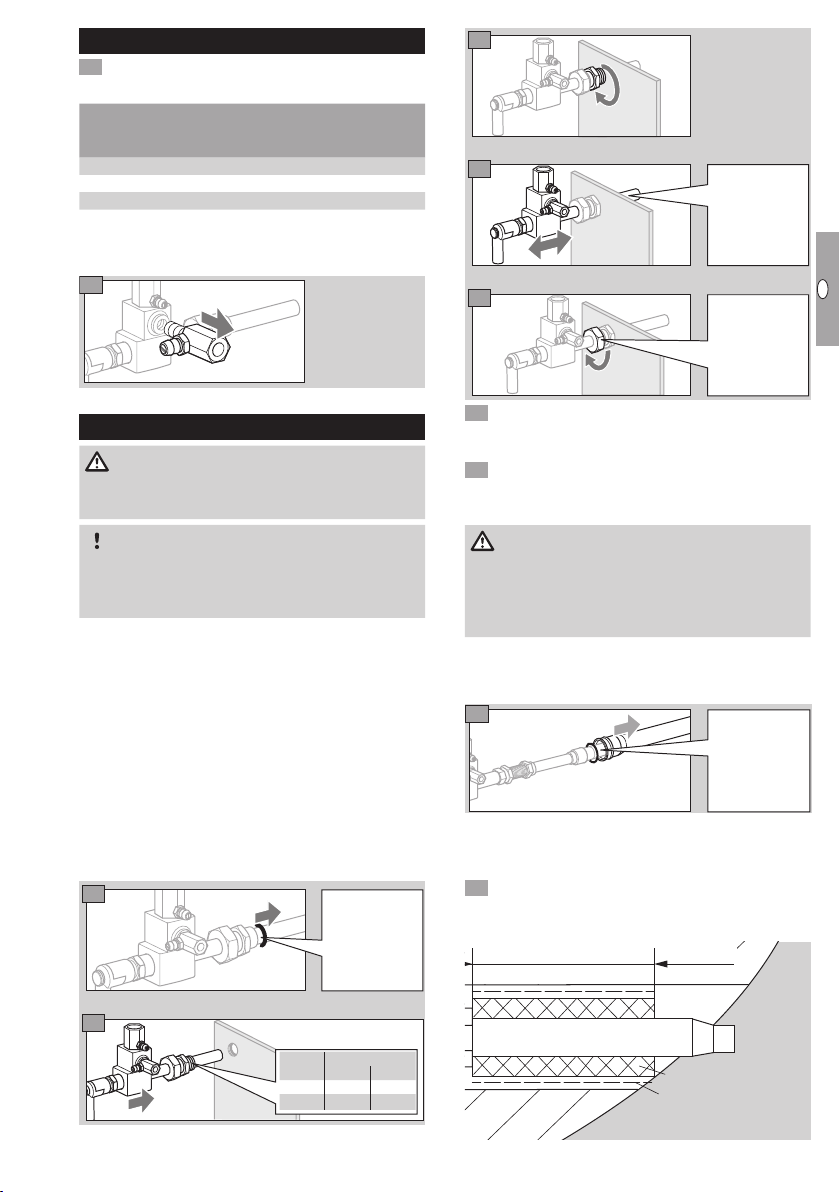

ZMIC

IMPORTANT

Only install the ZMIC when the burner block is cold.

When installing in a hot burner block, the fibre insulation can be damaged in such a way that the

burner can be thermally destroyed.

▷ Recommended inlet pressures:

gas: up to 100mbar (up to 40"WC),

air: up to 120mbar (up to 47"WC).

▷ Install pressure regulators and adjusting cocks

in the air and gas supply lines upstream of the

burner so that the air and gas pressures can

be adjusted.

To tighten the

union nut, use

a lubricant.

Remove

transport safety

device, masking tape and

O-ring.

ZMI

▷ Recommended inlet pressures:

gas: up to 80mbar (up to 32"WC),

air: up to 120mbar (up to 47"WC).

1

Remove the

transport

safety device.

Insulating the ceramic tube

▷ Protect the ceramic tube from thermal stress.

▷ Insulation with enclosed insulation strips.

Compress insulation strips by wrapping adhesive

foil around them tightly until they press tightly

against the ceramic tube.

5,5"

2

Burner

ZMI G½"

ZMI..T

Size

16

25

G1"

½" NPT 1" NPT

Insulation strip

Adhesive foil

GB-3

GB

F

NL

I

E

Check that the burner block hole is not blocked,

5

1 2 3

1

e.g. using a wooden stick.

ZMIC

4

6

Position the

burner before

tightening the

burner bracket.

7

8 Follow the reverse procedure when dismantling.

ZMIC..K

4

5

Wiring

DANGER

Electric shocks can be fatal! Before working on

possible live components, ensure the unit is disconnected from the power supply.

▷

For the ionization and ignition cables, use un-

screened high-voltage cable:

FZLSi 1/7 -50 to +180°C (-58 to +356°F),

Order No. 04250410,

or

FZLK 1/7 -5 to +80°C (23 to 176°F),

Order No. 04250409.

▷

Wire the burner as shown in the connection

diagrams of the automatic burner control unit/

ignition transformer.

▷ Flame control and ignition by a single electrode

(single-electrode operation).

4 Route the PE wire directly to the automatic burner

control unit.

Leak test

6

7

Position the

burner before

tightening the

bellows unit nut.

Secure the bel-

lows unit here

while tightening

the bellows unit

nut.

DANGER

Risk of explosion and poisoning! To ensure that

there is no danger resulting from a leak, check the

gas connections on the burner for leaks immediately

after the burner has been put into operation.

2

GB-4

GB

F

NL

I

E

Commissioning

76

7

DANGER

Risk of explosion! Please observe the appropriate

precautions when igniting the burners.

Risk of poisoning! Open the gas and air supply

so that the burner is always operated with excess

air– otherwise CO will form in the furnace chamber.

CO is odourless and poisonous! Conduct a flue

gas analysis.

▷ Arrange the adjustment and commissioning of

the burner with the system operator or manufacturer.

▷

Check the entire system, upstream devices and

electrical connections.

▷ Pre-purge the furnace chamber with air before

every ignition attempt.

DANGER

Risk of explosion! Fill the gas line to the burner

carefully and correctly with gas and vent it safely

into the open air – do not discharge the test volume

into the furnace chamber.

▷ If the burner does not ignite although the auto-

matic burner control unit has been switched on

and off several times: check the entire system.

▷ After ignition, monitor the gas and air pressures

measured on the burner and the flame. Measure

the ionization current. Switch-off threshold– see

automatic burner control unit operating instructions.

Switch on the system.

Open the manual valve.

Ignite the burner via the automatic burner control

unit.

4 Adjust the burner.

▷

Set the ionization current by adjusting the air

volume.

▷ The ionization current must be at least 5µA and

must not vary.

DANGER

Risk of explosion in case of CO being formed

in the furnace chamber! An incorrect change of

the burner settings may change the gas/air ratio

and lead to unsafe operating conditions. CO is

odourless and poisonous!

5 Set the pressure regulators for the gas and air

supply pressures to the maximum admissible

values, whereby the gas and air supply pressures

should be identical.

6

p

Gas

0

▷

Gas and air pressures: flow rate curves – see

p

Air

Adjust the burner

pressures for gas

and air on the

0

adjusting cocks

upstream of the

ZMI or ZMIC.

www.docuthek.com.

ZMI

▷ Inlet pressure:

gas: up to 80mbar (up to 32"WC),

air: up to 120mbar (up to 47"WC).

ZMIC

▷ Inlet pressure:

gas: up to 80mbar (up to 32"WC),

air: up to 120mbar (up to 47"WC).

Maintenance

▷ We recommend an annual function check.

DANGER

Electric shocks can be fatal! Before working

on possible live components, ensure the unit is

disconnected from the power supply.

Risk of burning! Dismantled burner components

can be hot due to outflowing flue gases.

Risk of explosion and poisoning in case of

burner adjustment with an air deficiency! Ad-

just the gas and air supply so that the burner is

always operated with excess air – otherwise CO

will form in the furnace chamber. CO is odourless

and poisonous! Conduct a flue gas analysis.

Check the ionization and ignition cables.

Measure the ionization current.

▷ The ionization current must be at least 5µA and

must not vary.

Disconnect the system from the electrical power

supply.

4 Shut off the gas and air supply– do not change

the restrictor settings.

5 Check the nozzles for dirt.

Replacing the electrode

ZMI 16

ZMIC 28

ZMI 25

GB-5

GB

F

NL

I

E

▷

1

2

1

Ensure that the electrode length does not change.

3

2

1

L

3

4

5

4

Spark plug

Dowel pin

Insulators

4 Burner head

5 Electrode tip

8 Remove dirt from electrode and insulators.

9 If the electrode tip or insulators are damaged,

replace the electrode.

▷

Before changing the electrode, measure the

total length L.

0 Connect the new electrode with the spark plug

using the dowel pin.

Adjust spark plug and electrode to the measured

total length L.

Screw the electrode into the burner housing.

Check distance L:

ZMI

L2

Burner L2

ZMI 16B 25 mm

ZMI 16D 21 mm

ZMI 16G 25 mm

ZMIC

Burner L2

ZMI 25B 35 mm

ZMI 25D 20 mm

ZMI 25G 35 mm

Burner L2

L2

ZMIC 28B

ZMIC 28G

• Reconnect the terminal boot.

• Produce a maintenance report.

ZMIC..K: replacing the bellows unit

Make a mark

to show the

length for reinstalling.

2

Secure the bel-

lows unit here

while unscrewing the bellows

unit nut.

50 mm

50 mm

5

6

7

Lubricate

thread with

ceramic

paste before

assembly.

8

Thread (R1)

must be facing

in the direction

of the furnace.

The bellows

unit gasket

cord must not

be twisted

when installing.

9

0 Insulate the ceramic tube and reinstall the burner,

see page3 (Installation).

ZMIC: replacing the ceramic tube

Remove the ZMIC – see page 6 (ZMIC..K:

replacing the bellows unit).

2

Spray screw

connection with

penetrating oil

and unscrew

clamping ring.

GB-6

GB

F

NL

I

E

3

2

Replace

ceramic tube

and copper

ring.

Ceramic paste

Apply ceramic paste to the screw connections after

4

50 mm

replacing any burner components in order to avoid

cold-setting.

Order number: 05012009.

Technical data

5

▷

Tighten the clamping ring with a torque of 30 Nm.

Lubricate retaining piece with

ceramic paste

before fitting

the clamping

ring.

6 Insulate the ceramic tube.

7 Reinstall the burner, see page3 (Installation).

Accessories

Gas nozzle

Burner Gas

type*

ZMI 6

ZMI 5

ZMIC 8

*

B = Natural gas

G = LPG

D = Coke oven gas, town gas

mm

(inch)

0.94

B

(0.037)

0.76

G

(0.029)

1.30

D

(0.051)

1.40

B

(0.055)

1.05

G

(0.041)

1.78

D

(0.070)

1.40

B

(0.055)

1.05

G

(0.041)

1.78

D

(0.070)

Order No.

ZMI/ZMIC ZMI..T

75455010 75442157

75455147 75448032

75455146 –

75455012 75443157

75455149 75448031

75455148 –

75455012 –

75455149 –

75455148 –

ZMI

Capacity:

ZMI 16: 1 to 2 kW (3.8 to 7.6 103 BTU/h),

ZMI 25: 2.5 to 4 kW (9.5 to 15.1 103 BTU/h)

(1.5 to 3.3kW in conjunction with coke oven gas,

town gas).

Capacities in kW refer to the lower calorific

valueHu and capacities in BTU/h refer to the upper

calorific valueHo.

Gas inlet pressure: 15 to 70 mbar (6 to 27"WC),

air inlet pressure: 15 to 90 mbar (6 to 35"WC),

each depending on the gas type

(burner pressures– seewww.docuthek.com,

Type of document: Flow rate curve).

Burner length increments: 100 mm (4").

Gas types: natural gas, LPG (gaseous) and coke

oven gas; other types of gas on request.

For cold air only.

Flame control: with flame rod.

Ignition: direct spark ignition (5kV ignition transformer).

Right-angle terminal boot: interference-suppressed.

Housing: aluminium.

Flame tube: heat-resistant steel.

Max. temperature at the tip of the flame tube:

<1000°C (< 1832°F),

< 900°C (< 1652°F) for lambda <1.

Storage temperature: -20°C to +40°C.

ZMIC

Capacity:

2.5 to 4.2 kW (9.5 to 15.9 10

3

BTU/h).

Capacities in kW refer to the lower calorific

valueHu and capacities in BTU/h refer to the upper

calorific valueHo.

Gas inlet pressure: up to 100mbar (up to 40"WC),

air inlet pressure: up to 120mbar (up to 47"WC),

each depending on the gas type

(burner pressures– see www.docuthek.com,

Type of document: Flow rate curve).

Burner length increments: 100 mm (4"),

"

length increments of the ZMIC28..K: 50 mm (2

).

Gas types: natural gas, LPG (gaseous) and coke

oven gas; other types of gas on request.

GB-7

GB

F

NL

I

E

For cold air only.

Matthias Rieken, Sebastian Escher

Konstrukteur / Designer

ist eine unvollständige Maschine nach Artikel 2g und ausschließlich zum Einbau in oder zum Zusammenbau mit einer anderen

is a partly completed machine pursuant to Article 2g and is designed exclusively for installation in or assembly with another

Folgende grundlegende Sicherheits- und Gesundheitsschutzanforderungen gemäß Anhang I dieser Richtlinie kommen zur

The following essential health and safety requirements in accordance with Annex I of this Directive are applicable and have

EN 746-2:2010 – Industrielle Thermoprozessanlagen; Sicherheitsanforderungen an Feuerungen und Brennstoffführungssysteme

06.07.2018

Die speziellen technischen Unterlagen gemäß Anhang VII B wurden erstellt und werden der zuständigen nationalen Behörde

The relevant technical documentation has been compiled in accordance with part B of Annex VII and will be sent to the

Die unvollständige Maschine darf erst dann in Betrieb genommen werden, wenn festgestellt wurde, dass die

The partly completed machine may only be commissioned once it has been established that the machine into which

– Industrial thermoprocessing equipment; Safety requirements for combustion and fuel handling systems

EN ISO 12100:2010 – Sicherheit von Maschinen – Allgemeine Gestaltungsleitsätze – Risikobeurteilung

und Risikominderung (ISO 12100:2010)

– Safety of machinery – General principles for design – Risk assessment

and risk reduction (ISO 12100:2010)

Diese Produkte entsprechen den Stoffbeschränkungen, die in RoHS II gelistet sind, fallen aber nicht in den

Anwendungsbereich der RoHS II (2011/65/EU).

These products comply with the substance restrictions of RoHS II, but they are not within the scope

of the Directive RoHS II (2011/65/EU).

Elster GmbH

Flame control: with flame rod.

Ignition: direct spark ignition (5kV ignition transformer).

Terminal boot: interference-suppressed.

Housing: aluminium.

Flame tube: ceramic flame tube.

Max. temperature at the tip of the flame tube:

1450°C (2642°F).

Storage temperature: -20°C to +40°C.

Logistics

Transport

Protect the unit from external forces (blows, shocks,

vibration). On receipt of the product, check that the

delivery is complete, see page2 (Part designations). Report any transport damage immediately.

Storage

Store the product in a dry and clean place.

Storage temperature: see page7 (Technical data).

Storage time: 2 years before using for the first time.

If stored for longer than this, the overall service life

will be reduced accordingly (by the corresponding

amount of extra storage time).

Packaging

The packaging material is to be disposed of in ac-

cordance with local regulations.

Disposal

Components are to be disposed of separately in

accordance with local regulations.

Declaration of Incorporation

pursuant to 2006/42/EC, Annex II, No. 1B

The products “Burners for gas ZMI and ZMIC” are

partly completed machines pursuant to Article2g and

are designed exclusively for installation in or assembly

with another machine or other equipment.

The following essential health and safety requirements

in accordance with Annex I of this Directive are ap-

plicable and have been fulfilled:

Annex I, Articles 1.1.3, 1.1.5, 1.3.2, 1.3.4, 1.5.2,

1.7.4, 1.5.10

The relevant technical documentation pursuant to

AnnexVIIB has been produced and will be transmitted to the competent national authorities in electronic

form on request.

The following (harmonized) standards have been

applied:

– EN 746-2:2010 – Industrial thermoprocessing

equipment – Safety requirements for combustion

and fuel handling systems

– EN ISO 12100:2010 – Safety of machinery– Gen-

eral principles for design – Risk assessment and

risk reduction (ISO 12100:2010)

These products comply with the substance restric-

tions of RoHS II, but they are not within the scope

of Directive RoHS II (2011/65/EU).

The partly completed machine may only be com-

missioned once it has been established that the

machine where the product mentioned above is to

be incorporated complies with the provisions of the

Machinery Directive 2006/42/EC.

Elster GmbH

Einbauerklärung / Declaration of Incorporation

nach 2006/42/EG, Anhang II, Nr. 1B / according to 2006/42/EC, Annex II No. 1B

Folgendes Produkt / The following product:

Bezeichnung: Zündbrenner für Gas

Description Pilot burner for gas

Typenbezeichnung / Type: ZAI, ZMI, ZMIC, ZKIH

Markenname / Branding:

Maschine oder Ausrüstung vorgesehen.

machine or other equipment.

Anwendung und wurden eingehalten:

been fulfilled:

Anhang I, Artikel / Annex I, Article

1.1.3, 1.1.5, 1.3.2, 1.3.4, 1.5.2, 1.7.4, 1.5.10

auf Verlangen in elektronischer Form übermittelt.

relevant national authorities on request as a digital file.

Folgende (harmonisierte) Normen wurden angewandt:

Maschine, in der das oben bezeichnete Produkt eingebaut werden soll, den Bestimmungen der Richtlinie für

Maschinen (2006/42/EG) entspricht.

the product mentioned above is to be incorporated complies with the provisions of the Machinery Directive

2006/42/EC.

Lotte (Büren)

Datum / Da te

Matthias Rieken, Sebastian Escher sind bevollmächtigt, die speziellen technischen Unterlagen gemäß Anhang VII B zusammenzustellen.

Matthias Rieken, Sebastian Escher are authorized to compile the relevant technical documentation according to Annex VII B.

/ The following (harmonized) standards have been applied:

GB-8

Postfach 28 09

D-49018 Osnabrück

Strotheweg 1

D-49504 Lotte (Büren)

Tel. +49 (0)541 12 14-0

Fax +49 (0)541 12 14-3 70

hts.lotte@honeywell.com

www.kromschroeder.com

GB

F

NL

I

E

Certification

Eurasian Customs Union

The product ZMI, ZMIC meets the technical specifi-

cations of the Eurasian Customs Union.

GB-9

Loading...

Loading...