Page 1

03250523

F

NL

I

E

D GB F NL I E

TR CZ PL RUS H

DK S N P GR

➔ www.docuthek.com

Operating instructions

Burners for gas ZIC

© 2014 Elster GmbH · Edition 05.14

Contents

Translation from the German

Burners for gas ZIC . . . . . . . . . . . . . . . . . . . . .

Contents ..............................

Safety.................................

Checking the usage .....................

Installation ............................

Installing the ceramic tube . . . . . . . . . . . . . . . . . 3

Installation on the furnace .................4

Air connection, gas connection .............4

Installing the burner insert .................5

Wiring ................................5

Preparing commissioning ................6

Determining the flow rates . . . . . . . . . . . . . . . . . 6

Notes on the flow rate curve ............... 7

Restrictors .............................7

Hot-air compensation .................... 7

Commissioning.........................8

Igniting and adjusting the burner ............8

Tightness test...........................9

Cooling air .............................9

Blocking and recording the settings .........10

Maintenance ..........................0

Assistance in the event of malfunction ....

Accessories ..........................

Technical data ........................

Logistics .............................

Declaration of Incorporation.............4

Certification ..........................4

Contact ..............................4

Safety

Please read and keep in a safe place

Please read through these instructions

carefully before installing or operating. Following the

installation, pass the instructions on to the operator. This unit must be installed and commissioned

in accordance with the regulations and standards

in force. These instructions can also be found at

www.docuthek.com.

Explanation of symbols

• , , , ... = Action

▷ = Instruction

Liability

We will not be held liable for damage resulting from

non-observance of the instructions and non-compliant use.

Safety instructions

Information that is relevant for safety is indicated in

the instructions as follows:

DANGER

Indicates potentially fatal situations.

WARNING

Indicates possible danger to life and limb.

CAUTION

Indicates possible material damage.

All interventions may only be carried out by qualified

gas technicians. Electrical interventions may only be

carried out by qualified electricians.

Conversion, spare parts

All technical changes are prohibited. Only use OEM

spare parts.

Changes to edition .

The following chapters have been changed:

– Checking the usage

– Installation

– Preparing commissioning

– Commissioning

– Technical data

– Logistics

– Declaration of Incorporation

GB

GB-1

Page 2

F

NL

I

E

Checking the usage

Burner for heating industrial thermoprocessing equipment. The burner ZIC can be used in conjunction

with the ceramic tube set TSC in industrial furnaces

or firing systems with brick lining or ceramic fibre

lining. No burner quarl is necessary. For natural gas,

town gas and LPG. Other types of gas on request.

This function is only guaranteed when used within the

specified limits – see also page13 (Technical data). Any

other use is considered as non-compliant.

Burner

Construction stage, rated capacity Q

see type label.

GB

D-49018 Osnabrück Germany

ZIC 165HB-0/35-(18)D

BR 84246518

Qmax

BE 74970471 BK 18

Gas N SN

630 kW

Type code

Code Description

ZIC

Burner for gas with cast steel

ZICW

Burner for gas with cast steel

housing and internal insulation

65 – 00 Burner size

R

H

B

G

M

L

D

Butane, propane, propane/butane

Butane, propane, propane/butane

Low calorific value gas

Coke oven gas, town gas

L

R

Reduced max. connection rating

Length of burner extension [mm]:

-0

-00

-00…

/5/5-

Position of burner head [mm]

/5-…

-() to

Burner head identifier

-(99)

-(E) to

High temperature version

-(99E)

A – F Construction stage

, gas type–

max

D

17.11.

housing

Normal flame

Long, soft flame

Natural gas

Ignition lance

none

100

200

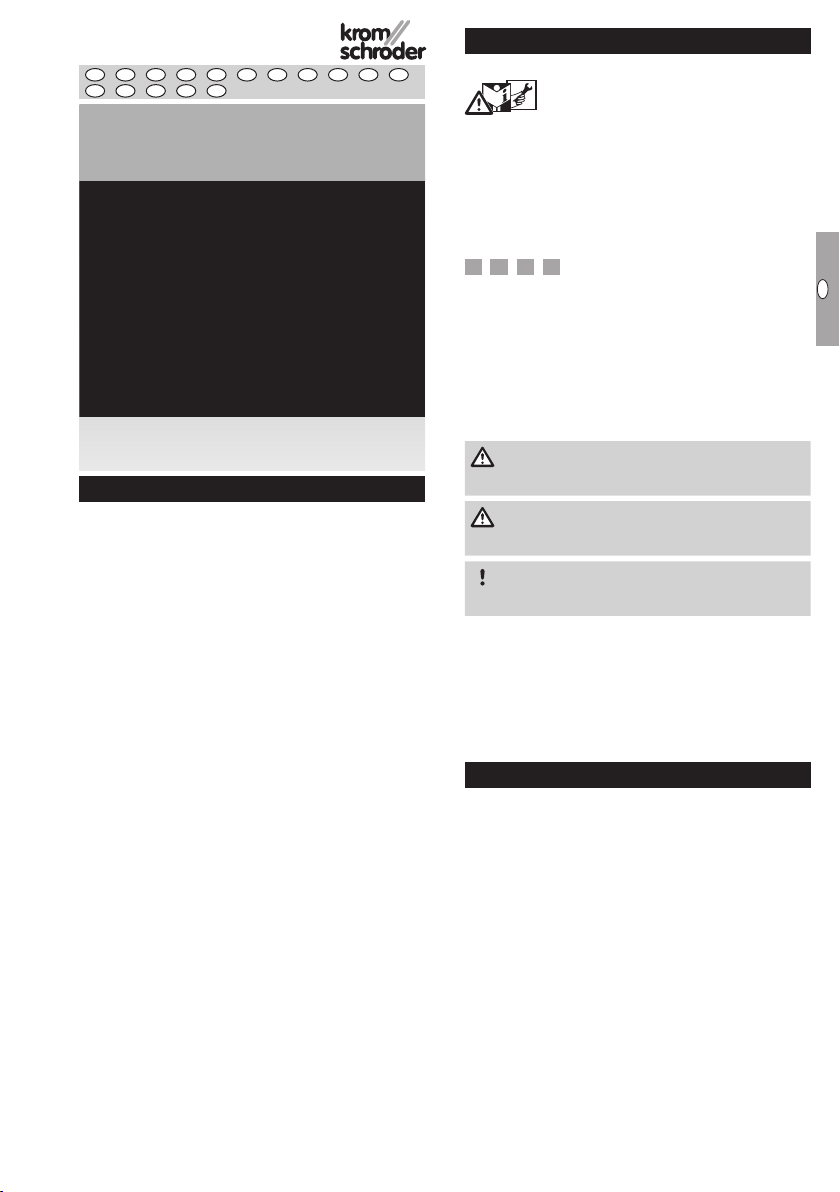

Part designations

4

2

3

5

1

9

6

7

8

Burner insert

Gas housing gasket

Air housing

4 Mounting flange

5 Mounting gasket

6 Type label

7 Burner extension (for ZIC..-100, ZIC..-200)

8 Clamping ring

9 Enclosed documentation (flow rate curves,

operating characteristic diagrams, dimension

sheet, spare parts list, spare parts drawing

and Declaration of Incorporation)

• Check letter marking and identification marks on

the burner head using the information provided

on the type label.

Ceramic tube

Length and diameter – see type label.

D-49018 Osnabrück Germany

TSC 165A154-300/35-Si-1500

RS MA Si-1500 SN

Type code

Code

TSC

65 – 00

A

54, 80

-00

/5Si-500

Position of burner head L9 [mm]

Tube length L8 [mm]

Ceramic tube material

Description

Ceramic tube set

Burner size

Cylindrical

Outlet dia. D4 [mm]

GB-2

Page 3

F

NL

I

E

L9

76

L8

5 Place the burner insert in such a way that the

insulators are protected against damage.

No burner extension

D4

Part designations

2

1

3

Burner tube gasket

Ceramic tube

Type label

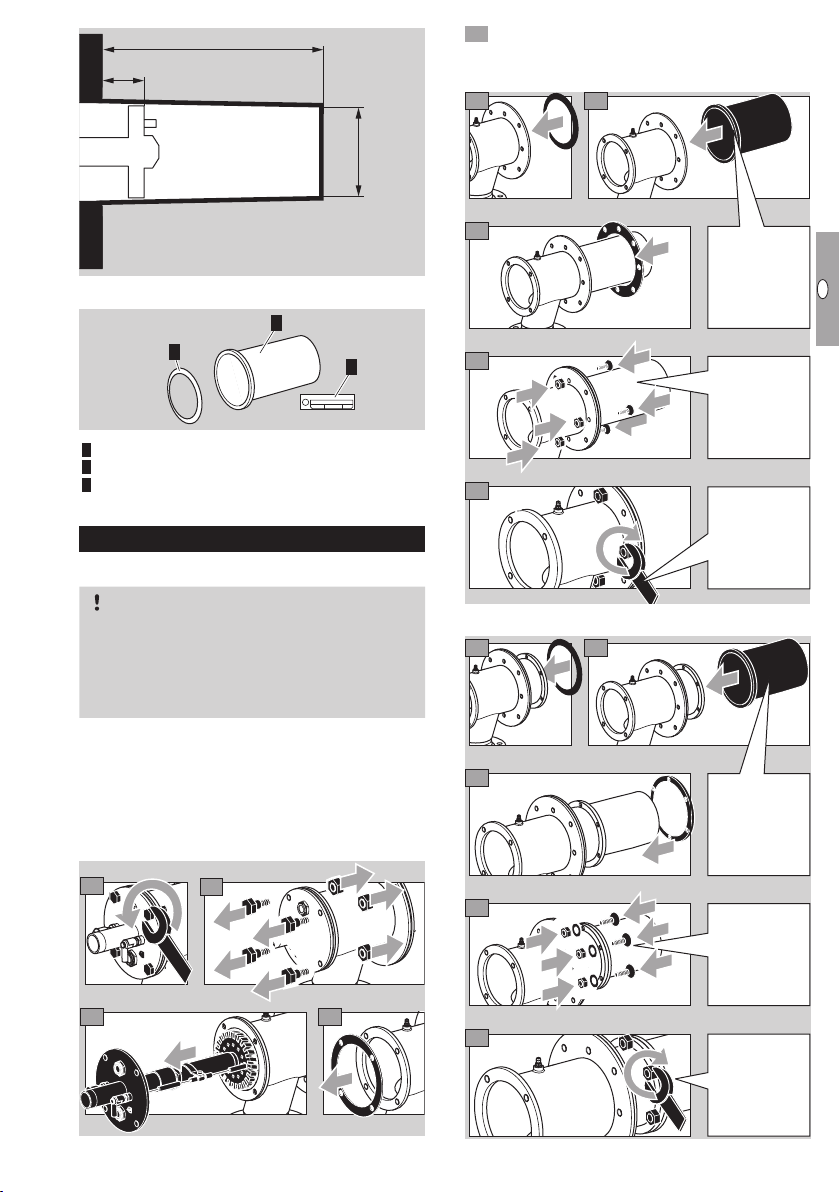

Installation

Installing the ceramic tube

CAUTION

Install the ceramic tube centrally and free of mechanical stress to avoid damage.

Remove and dispose of the transport safety device; to do this, remove the mounting flange or

clamping ring.

▷ Remove the burner insert in order to install the

ceramic tube. For this purpose, the air housing

can be placed in a vertical position on a smooth

working surface.

▷ On ZICW, avoid the formation of dust when dis-

mantling the burner insert and do not damage

the surface of the internal insulation.

1

2

8

9

10

With burner extension

76

8

9

Install the ceramic tube

centrally and

free of mecha nical stress.

Centre the

ceramic tube.

Tighten in

crosswise

fashion.

Install the ce ramic tube

cen trally and

free of mechanical stress.

Insert lock

washer pairs.

GB

3

4

10

Tighten in

crosswise

fashion.

GB-3

Page 4

F

NL

I

E

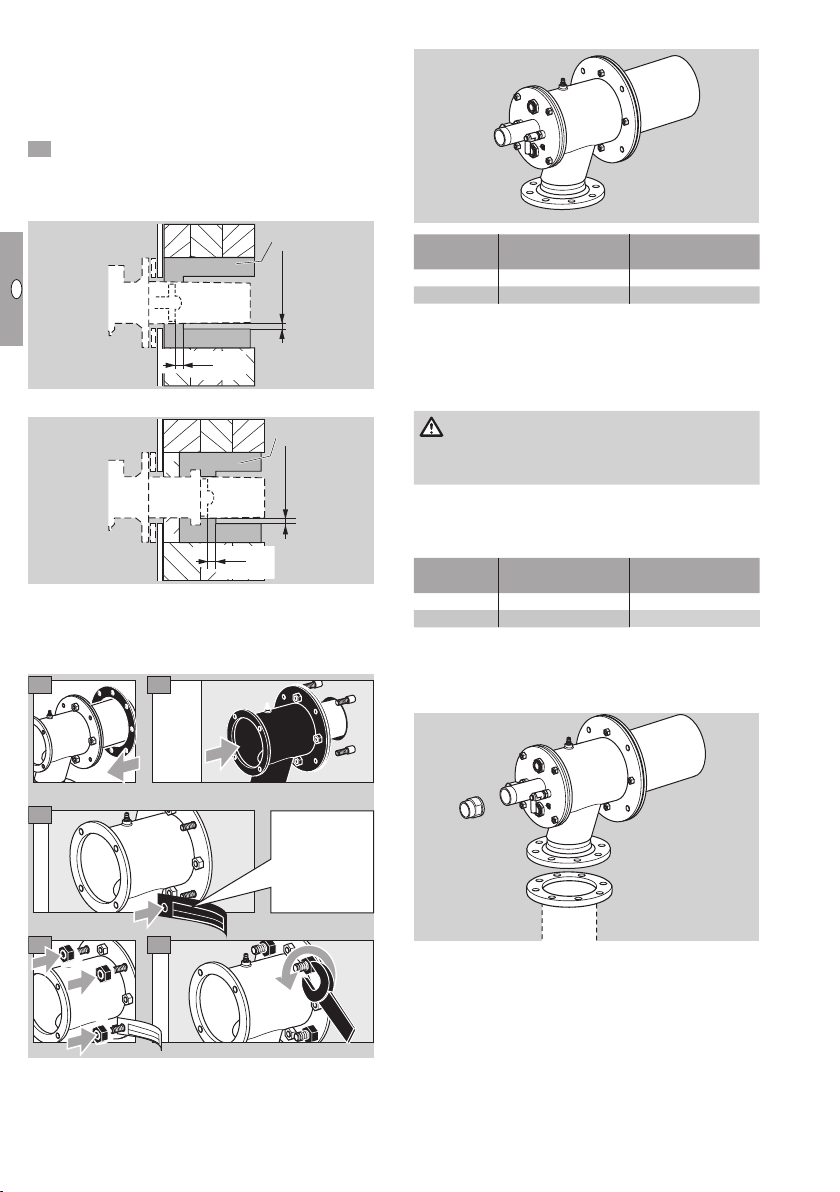

Insulating the ceramic tube

A/B

≥ 10 mm

≥ 0.4 in

20 mm

0.8 in

▷

Protect the burner extension from thermal stress.

▷

We recommend solid shaped parts A or high

temperature resistant ceramic fibrous material

B for insulation.

▷

Observe an annular gap of at least 10mm (0.4").

Insulate the ceramic tube at least as far as the

burner head, to a maximum of 20mm (0.8")

behind the burner head.

▷ Burner without extension:

A/B

GB

20 mm

0.8 in

≥ 10 mm

≥ 0.4 in

▷ Burner with extension:

A/B

≥ 10 mm

≥ 0.4 in

20 mm

0.8 in

Installation on the furnace

▷

When installing, always ensure that when the

burner is mounted, it is sealed tightly on the

furnace wall.

1

2

Air connection, gas connection

GA

LA

Type

ZIC 165 Rp 1½ DN 100

ZIC 200 Rp 2 DN 150

▷

Threaded connection to DIN 2999, flange dimen-

sions to DIN 2633, PN 16.

▷ Install flexible tubes or bellows units to prevent

mechanical stress or transmission of vibration.

▷ Ensure that the seals are undamaged.

DANGER

Risk of explosion! Ensure the connection is gastight.

Connection to ANSI/NPT

An adapter set is required for connection to ANSI/

▷

NPT, see page12 (Adapter set).

Type

ZIC 165 1½ – 11.5 NPT

ZIC 200 1½ – 11.5 NPT

* Flange hole diameter.

▷

Weld flange J to air pipe P for air connection

LA and use NPT thread adapter H for gas con-

nection GA.

Gas connection GAAir connection

LA

Gas connection GAAir connection

LA*

4.57"

6.72"

3

D

-

4

9

0

1

8

O

s

n

a

b

r

ü

c

k

G

e

r

m

a

n

y

T

S

C

6

5

A

O

4

8

-

3

0

0

/

3

5

-

S

S

i

1

i

-

1

5

5

0

0

4

5

0

0

Attach the

ceramic tube

type label.

▷ The nozzle set with NPT coupling is required for

GA

H

LA

J

P

integrated ignition lances, see page12 (Nozzle set).

GB-4

Page 5

F

NL

I

E

Ignition lance connections on the ZIO..L:

▷ Air connection la.

▷ Gas connection ga.

▷ Ignition lance capacity: 1.5kW.

la

ga

Type

gas connection

ga

ZIC..L Rp ¼ Rp ½

Ignition lance

ZIC..L with

adapter set

¼" NPT ½" NPT

Installing the burner insert

▷ The burner insert can be rotated to the required

position in increments of 90°.

▷

Insert the gas housing gasket between the

burner insert and the air housing.

On ZICW, avoid the formation of dust and do

▷

not damage the surface of the internal insulation.

1 2

▷ Tighten the burner insert in a crosswise fashion

with max. 37Nm (27.3lbfft).

Ignition lance

air connection

la

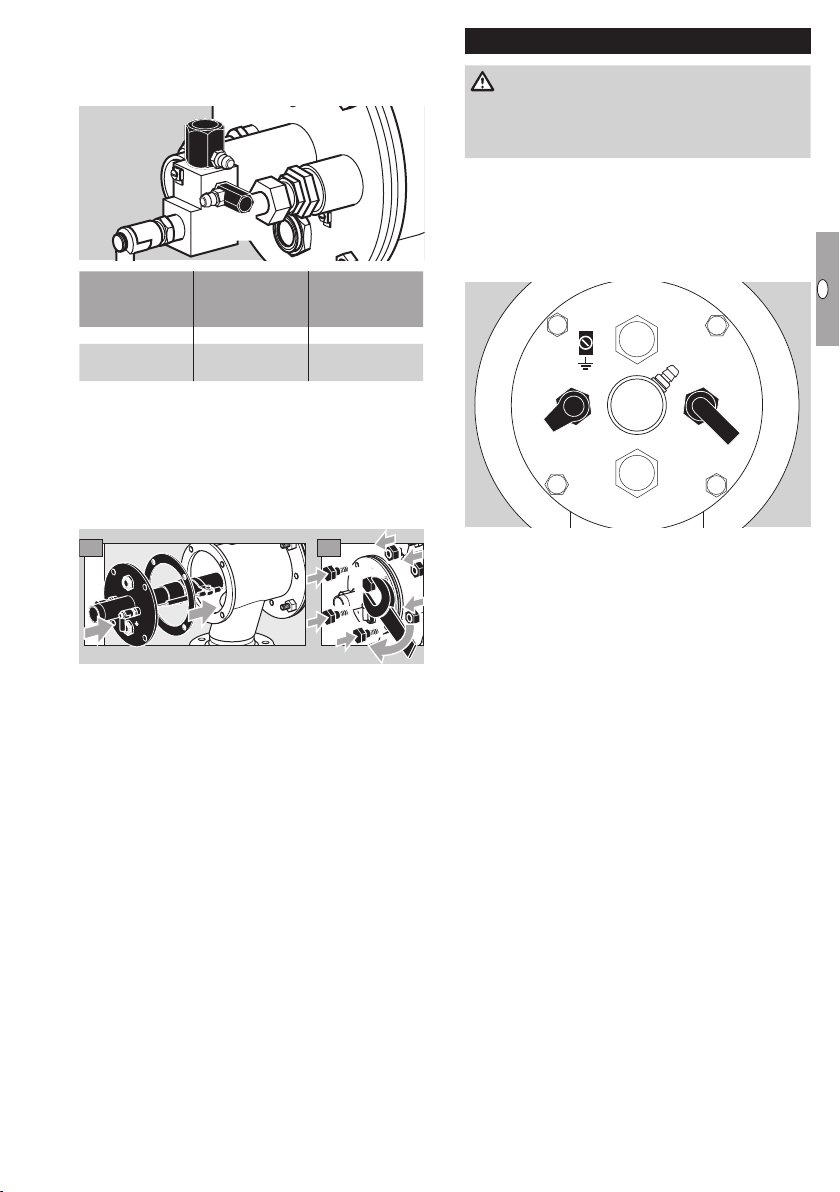

Wiring

DANGER

Electric shocks can be fatal! Before working on

possible live components, ensure the unit is disconnected from the power supply.

▷

For the ignition and ionization cables, use (un-

screened) high-voltage cable:

FZLSi 1/6 up to 180°C (356°F),

Order No. 04250410, or

FZLK 1/7 up to 80°C (176°F),

Order No. 04250409.

I

Ionization electrode I

▷

Install the ionization cable well away from mains

cables and interference from electro-magnetic

sources and avoid external electrical interference.

Max. length of ionization cable – see automatic

burner control unit operating instructions.

▷

Connect the ionization electrode to the automatic

burner control unit via the ionization cable.

Ignition electrode Z

▷

Length of ignition cable: max. 5 m (15 ft), recom-

mended < 1 m (40").

▷

For permanent ignition, max. ignition cable length

1 m (40").

Lay the ignition cable individually and not in a

▷

metal conduit.

▷

Install the ignition cable separately from ionization

and UV cables.

▷ A ≥ 7.5kV, ≥ 12mA ignition transformer is rec-

ommended; 5kV for ignition lance.

Z

GB

GB-5

Page 6

F

NL

I

E

Ionization and ignition electrodes

1

3

GB

6 Connect the PE wire for burner ground to the

4

2

5

burner insert. In the case of single-electrode operation, route the PE wire from the burner insert

directly to the terminal on the automatic burner

control unit.

WARNING

High-voltage risk! It is essential that a high-voltage

warning label is attached to the ignition cable.

7 For more detailed information on how to wire

the ionization and ignition cables, refer to the

operating instructions and connection diagrams

of the automatic burner control unit and ignition

transformer.

Preparing commissioning

Safety instructions

▷ Arrange the adjustment and commissioning of

the burner with the system operator or manufacturer.

▷

Check the entire system, upstream devices and

electrical connections.

▷

Note the operating instructions for individual

controls.

DANGER

The burner must only be commissioned by author-

ized trained personnel.

Risk of explosion! Please observe the appropriate

precautions when igniting the burner.

Risk of poisoning! Open the gas and air supply

so that the burner is always operated with excess

air – otherwise CO will form in the furnace chamber.

CO is odourless and poisonous! Conduct a flue

gas analysis.

▷

Pre-purge the furnace chamber with air (5 x

furnace chamber volume) before every ignition

attempt.

▷ If the burner does not ignite although the auto-

matic burner control unit has been switched on

and off several times: check the entire system.

▷

After ignition, monitor the flame and the gas and

air pressure measured on the burner. Measure

the ionization current. Switch-off threshold – see

automatic burner control unit operating instructions.

Z

+ µA –

I

▷

The burner must only be ignited at low fire

(between 10 and 30% of the rated capacity

Q

) – see type label).

max

DANGER

Risk of explosion! Fill the gas line to the burner

carefully and correctly with gas and vent it safely

into the open air – do not discharge the test volume

into the furnace chamber.

Determining the flow rates

Q

= PB/H

Gas

Q

Luft

▷ Q

: Gas flow rate in m3/h (ft3/h)

Gas

▷ PB: Burner capacity in kW (BTU/h)

▷ Hu: Gas calorific value in kWh/m3 (BTU/ft3)

▷ Q

: Air flow rate in m

Luft

▷ λ: Lambda, air index

▷

L

: Minimum air requirement in m

min

(SCF/SCF)

• Use the lower calorific value Hu.

▷ Information on the gas quality supplied can be

obtained from the competent gas supply company.

Common gas qualities

Gas type

Natural gas H

Natural gas L

Propane

Town gas

Butane

* Data in kWh/m

and data in BTU/SCF refer to the upper calorific

3

(n)

value Ho.

For safety reasons, a minimum air excess of 5%

▷

(lambda = 1.05) should be ensured.

u

= Q

. λ . L

Gas

min

3

/h (SCFH)

(n)

3

/m

(n)

H

u

3

kWh/m

(BTU/SCF)

11

(n)

L

min

3

3

m

/m

(n)

(SCF/SCF)

10.6

(n)

(1114)

8.9

8.6

(901)

25.9

24.4

(2568)

4.09

3.67

(425)

34.4

32.3

(3406)

refer to the lower calorific valueHu

3

(n)

GB-6

Page 7

F

NL

I

E

Notes on the flow rate curve

▷

If the gas density in the operating state differs

from that reflected in the flow rate curve, convert

the pressures according to the local operating

state.

pB = p

▷ δ

: Gas density reflected in the flow rate curve

M

[kg/m3 (lb/ft3)]

▷

δ

: Gas density in operating state [kg/m3 (lb/ft3)]

B

▷

pM: Gas pressure reflected in the flow rate curve

M

δ

M

δ

B

.

▷ pB: Gas pressure in operating state

• Read off the gas pressure p

p

from the enclosed flow rate curve for cold

air

air on the basis of the calculated flow rates.

[mbar ("WC)]

p

air

p

gas

and air pressure

gas

Hot-air compensation

▷

The combustion air pressure p

creased in hot-air operating mode (lambda =

must be in-

Air

constant).

250

[%]

200

Air

p

150

100

0 100 200 300 400

T

[°C]

Air

▷ The gas pressure is increased by 5–10mbar.

▷

The total burner capacity PB rises as the air tem-

perature T

[%]

B

120

P

increases.

Air

110

GB

p

gas

p

air

Q

gas

[m

Q

3

/h (ft3/h)]

air

▷ Note possible capacity changes due to positive

or negative pressures in the furnace/combustion

chamber. Add positive pressures or subtract

negative pressures.

▷ As not all the effects caused by the equipment

are known, setting the burner using the pressure

values is only approximate. It is possible to set

the burner precisely by measuring the flow rates

or flue gas.

Restrictors

▷ The air volume required for the low-fire rate at a

given air pressure is determined by the ignition

position of a butterfly valve, a bypass hole in the

air valve or an external bypass with restrictor.

100

0 100 200 300 400

T

[°C]

Air

Setting the air pressure for low fire and high

fire

Shut off the gas and air supply.

▷

Air measuring nipple L, external dia. = 9 mm (0.35").

2

Loosen

the screw

L

3

2turns.

4

Fully open

the air supply.

5

p

atm.

p

0

air

=

p

atm

atmospheric

pressure.

GB-7

Page 8

F

NL

I

E

Low fire:

▷ The burner must only be ignited at low fire (be-

tween 10 and 30% of the rated capacity Q

see type label).

max

• Reduce the air supply on the air control valve

and set the desired low-fire rate, e.g. using a

limit switch or mechanical stop.

On air control valves with bypass, the bypass

▷

orifice should be determined on the basis of the

required flow rate and the existing supply pressure if required.

High fire:

• Set the required air pressure p

tor upstream of the burner.

GB

on the air restric-

air

• When using air restricting orifices: check the air

pressure p

.

air

Preparing the gas pressure measurement for

low fire and high fire

• Connect all measuring devices for subsequent

fine adjustment of the burner.

▷ Leave the gas supply closed.

▷ Gas measuring nipple G, external dia. = 9 mm

(0.35").

• Read off the gas pressure p

flow rate from the enclosed flow rate curve for

for the required

gas

cold air.

[mbar ("WC)]

p

air

p

gas

1

Loosen the

p

gas

2

p

air

Q

gas

[m

Q

3

/h (ft3/h)]

air

G

screw 2 turns.

G

Integrated ignition lance on the ZIC..L:

▷ Air pressure test nipple l, external dia. = 9mm

–

(0.35").

▷

Gas pressure test nipple g, external dia. = 9mm

(0.35").

1

l

g

▷ Ignition lance:

p

= 30 – 50 mbar,

gas

p

= 30 – 50 mbar.

air

▷ Check flame stability and ionization current.

▷

The gas and air pressure of the ignition lance

must be higher than the gas and air pressure of

the main burner.

Commissioning

Igniting and adjusting the burner

WARNING

Ensure adequate ventilation of the furnace chamber

before each burner start!

▷ The burner housing will become hot during op-

eration with preheated combustion air. Provide

protection against accidental contact as required.

• All valves of the installation must be checked for

tightness before ignition.

Setting the low-fire rate:

• Set the valves to ignition position.

• Limit the maximum gas volume.

▷ Should an adjustable gas restrictor be installed

upstream of the burner, open the restrictor by

approx. a quarter.

• Open the gas supply.

• Ignite the burner.

▷ The safety time of the automatic burner control

unit starts to elapse.

• If no flame forms, check and adjust the gas and

air pressures of the start gas adjustment.

• In the case of operation with bypass (e.g. when

using an air/gas ratio control): check the bypass

nozzle and adjust if required.

• In the case of operation without bypass (e.g.

when using an air/gas ratio control without bypass):increase the low-fire rate setting.

• Check the basic setting or bypass of the air control valve.

GB-8

Loosen the

screws

2 turns.

2

l

g

Page 9

F

NL

I

E

• Check the position of the restrictor in the air line.

p

0

p

2

p

1

• Check the fan.

• Reset the automatic burner control unit and re-

ignite the burner.

▷ The burner ignites and proceeds to normal op-

eration.

• Check flame stability and ionization current at

low fire. Switch-off threshold – see automatic

burner control unit operating instructions.

Z

Tightness test

DANGER

To ensure that there is no danger resulting from a

leak, check the gas connections on the burner for

leaks immediately after the burner has been put

into operation.

1

+ μA –

I

• Monitor flame formation.

• Adjust the low-fire rate settings if required.

• If no flame forms – see page12 (Assistance in the

event of malfunction).

Setting the high-fire rate:

• Set the air and gas circuit of the burner to high

fire while continuously monitoring the flame.

▷

Avoid CO formation – always operate the burner

with excess air when starting up!

▷ When the desired maximum valve positions are

reached, set the gas pressure p

restrictor upstream of the burner.

p

atm.

p

gas

0

using the

gas

Re-adjusting the air flow rate:

• Check the air pressure p

adjust using the air restrictor if required.

on the burner and

air

• When using air restricting orifices: check the air

pressure p

and rework the orifice if required.

air

DANGER

Risk of explosion and poisoning during burner

adjustment with an air deficiency! Adjust the

gas and air supply so that the burner is always operated with excess air – otherwise CO will form in the

furnace chamber. CO is odourless and poisonous!

Conduct a flue gas analysis.

• Measure the gas and air flow rates if possible.

Determine the lambda value and re-adjust the

settings if required.

▷

Avoid condensation due to the furnace atmosphere entering the burner housing. While the

burner is switched off, at furnace temperatures

above 500°C (932°F), it must be cooled with a

low air volume – see page 9 (Cooling air).

Cooling air

▷ While the burner is switched off and depending

on the furnace temperature, there must be a certain air flow for cooling the burner components

6

5

4

Cooling air at 20°C

3

2

Air volume at rated capacity [%]

1

0

700 800 900 1000 1100 1200 1300 1400 1500

▷

Diagram: the relative air volume in percentage

Furnace temperature °C

ZIC

ZIC..KB..E

12

10

8

6

4

2

0

values, based on the air volume for the rated capacity of the relevant size, is given in the diagram.

For hot air (450°C), the values on the right-hand

axis are based on the standard air volume for

the relevant rated capacity.

▷ Leave the air fan switched on until the furnace

has cooled down completely.

GB

]

Cooling air at 450°C

Air volume at rated capacity [%

GB-9

Page 10

F

NL

I

E

Blocking and recording the settings

6 5

11 12

Produce a measurement report.

Set the burner to low fire and check the settings.

Set the burner to low and high fire several times

while monitoring the pressure settings, flue gas

values and flame patterns.

4 Remove the measuring devices and close off

the test nipples – tighten the grub screws.

5 Block and seal the adjusting elements.

6 Induce a flame failure, e.g. by pulling the plug off

the ionization electrode. The flame detector must

close the gas safety valve and signal a fault.

7 Switch the system on and off several times while

monitoring the automatic burner control unit.

GB

8 Produce an acceptance report.

DANGER

An incorrect change of the burner settings may

change the gas/air ratio and lead to unsafe operating conditions. Risk of explosion in case of CO

being formed in the furnace chamber! CO is odourless and poisonous!

Maintenance

We recommend that a function check is carried out

every six months.

WARNING

Risk of burning! Outflowing flue gases and burner

components are hot.

Check the ionization and ignition cables.

Measure the ionization current.

▷ The ionization current must be at least 5µA and

must not vary.

3

4

2

1

L

8 If the star 4 or insulator is damaged, replace

the electrode.

Before changing the electrode, measure the

▷

total length L.

9 Connect the new electrode with the spark plug

using the dowel pin .

0 Adjust spark plug and electrode to the measured

total length L.

▷

Turning the spark plug makes it easier to feed

the electrode into the burner insert.

Checking the burner

13

14

15

Z

+ μA –

I

Disconnect the system from the electrical power

supply.

4 Shut off the gas and air supply – do not change

the restrictor settings.

Checking the ignition and ionization

electrodes

▷

Ensure that the electrode length does not change.

7 Remove dirt from electrodes or insulators.

16

▷

If the burner insert is dismantled, the gas housing

gasket will have to be renewed.

7 Place the burner insert in a safe place.

Depending on the amount of dirt or wear: replace

▷

the ignition/ionization electrode rod and dowel

pin during servicing – see page10 (Checking the

ignition and ionization electrodes).

8 Check burner head for dirt and thermal cracks.

WARNING

Risk of injury! Burner heads have sharp edges.

GB-10

Page 11

F

NL

I

E

▷ When replacing any burner components: apply

21

ceramic paste to the screw connections in order

to avoid cold-setting – see page12 (Ceramic

paste).

9 Check the electrode positions.

▷ The insulator must be flush with the front edge

of the burner air disc.

▷

Distance of ignition electrode from ground pin or

gas nozzle: 2 ± 0.5 mm (0.08 ± 0.02").

)

mm

0.02"

0,5

2 ±

(0.08 ±

0 When the furnace chamber has cooled down,

check the ceramic tube through the furnace

flange.

New gas

housing

gasket.

27

8 Set the burner to low fire and compare the pres-

sure settings to those stated in the acceptance

report.

9 Set the burner to low and high fire several times

while monitoring the pressure settings, flue gas

values and flame patterns.

DANGER

Risk of explosion and poisoning during burner

adjustment with an air deficiency! Adjust the

gas and air supply so that the burner is always operated with excess air – otherwise CO will form in the

furnace chamber. CO is odourless and poisonous!

Conduct a flue gas analysis.

0 Produce a maintenance report.

GB

22

23

▷

Tighten the burner insert with max. 37 Nm

24

(27.3lbft).

5 Connect the system to the electrical power sup-

ply.

6 Open the gas and air supply.

GB-11

Page 12

F

NL

I

E

Assistance in the event of malfunction

DANGER

Electric shocks can be fatal! Before working on

possible live components, ensure the unit is disconnected from the power supply.

Risk of injury! Burner heads have sharp edges.

Fault-clearance must only be undertaken by authorized trained personnel.

▷ If no fault is detected when checking the burner,

proceed to the automatic burner control unit and

GB

check for faults in accordance with the relevant

operating instructions.

? Faults

! Cause

• Remedy

! Automatic burner control unit signals a fault.

• Check the ionization cable.

• Measure the ionization current by connecting a

micro-ammeter into the ionization cable: min.

5µA ionization current– stable signal.

Z

+ μA –

I

! Burner head dirty.

• Clean gas and air bore holes and air slots.

• Remove deposits on the burner head.

WARNING

Risk of injury! Burner heads have sharp edges.

? Burner does not function?

! Valves do not open.

• Check the voltage supply and wiring.

! Tightness control signals a fault.

• Check the valves for tightness.

• Note the tightness control operating instructions.

! Control valves do not move to low-fire position.

• Check the impulse lines.

! Gas inlet pressure is too low.

• Check the filter for dirt.

! Gas and air pressures on the burner are too low.

• Check the restrictors.

! Automatic burner control unit signals a fault.

• Check the ionization cables and ionization current.

• Check whether the burner is adequately

grounded.

• Note the automatic burner control unit operating

instructions.

? Burner performs a fault lock-out after burn-

ing faultlessly in normal operation?

! Incorrect gas and air flow rate settings.

• Check the gas and air pressures.

! No ignition spark is created.

• Check the ignition cable.

• Check the voltage supply and wiring.

• Check whether the burner is adequately

grounded.

• Check the electrodes – see page10 (Checking

the ignition and ionization electrodes).

! Excessive pressure fluctuations in the furnace

chamber.

• Ask Elster Kromschröder for control concepts.

Accessories

Ceramic paste

Apply ceramic paste to the relevant screw connections after replacing any burner components in order

to avoid cold-setting.

Order number: 05012009.

Adapter set

8×

For connecting ZIC to NPT/ANSI connections.

Burner Adapter set Order No.

ZIC 165

ZIC 200

Nozzle set

Available on request for connecting integrated

▷

ignition lances to NPT threads.

BR 165 NPT

BR 200 NPT

8×

74922636

74922637

GB-12

Page 13

F

NL

I

E

Technical data

Gas supply pressure: approx. 20 to 50 mbar,

air supply pressure: approx. 25 to 40 mbar,

each depending on flame shape, gas type and air

temperature (gas and air pressures – see operating

characteristic diagrams at www.docuthek.com).

Burner length increments: 100mm.

Gas types: natural gas, LPG (gaseous) and coke

oven gas; other gases on request.

Control type:

staged: On/Off, High/Low/Off,

continuous: constant λ value.

Most of the burner components are made of corrosion-resistant stainless steel.

Housing:

ZIC: St.

Flame control: with ionization electrode (UV sensor

as an option).

Ignition: direct spark ignition; ignition lance as an

option.

Maximum furnace temperature:

up to 1450°C (higher temperatures on request).

Maximum air temperature:

ZIC: 450°C,

ZICW: 500°C.

Storage temperature: -20°C to +40°C.

Burner Weight* [kg]

ZIC 165 23

ZIC 200 34.6

* Shortest overall length.

WARNING

applies to ZICW only

Information pursuant to REACH Regulation No.

1907/2006, Article 33. Insulation contains refrac-

tory ceramic fibres (RCF)/aluminium silicate wool

(ASW). RCF/ASW are listed in the Candidate List of

the European REACH Regulation No. 1907/2006.

Logistics

Transport

Protect the unit from external forces (blows, shocks,

vibration). On receipt of the product, check that the

delivery is complete, see page2 (Part designations). Report any transport damage immediately.

Storage

Store the product in a dry and clean place.

Storage temperature: see page13 (Technical data).

Storage time: 2 years before using for the first time.

If stored for longer than this, the overall service life

will be reduced accordingly (by the corresponding

amount of extra storage time).

Packaging

The packaging material is to be disposed of in ac-

cordance with local regulations.

Disposal

Components are to be disposed of separately in

accordance with local regulations.

GB

GB-13

Page 14

F

NL

I

E

Declaration of Incorporation

Sandra Runde

Die speziellen technischen Unterlagen gemäß Anhang VII B wurden erstellt und werden der zuständigen nationalen Behörde auf

according to 2006/42/EC, Annex II, No. 1B

The product ZIC is a partly completed machine pur-

suant to Article 2g and is designed exclusively for

installation in or assembly with another machine or

other equipment.

The following essential health and safety requirements

in accordance with Annex I of this Directive are applicable and have been fulfilled:

Annex I, Articles 1.1.3, 1.1.5, 1.3.2, 1.3.4, 1.5.2, 1.7.4

The relevant technical documentation has been com-

piled in accordance with part B of Annex VII and will

be sent to the relevant national authorities on request

GB

as a digital file.

The following (harmonized) standards have been

applied:

– EN 746-2 (2010) – Industrial thermoprocessing

equipment; Safety requirements for combustion

and fuel handling systems

– EN ISO 12100 (2010) – Safety of machinery –

General principles for design – Risk assessment

and risk reduction (ISO 12100:2010)

The partly completed machine may only be commis-

sioned once it has been established that the machine

into which the product mentioned above is to be

incorporated complies with the provisions of the

Machinery Directive 2006/42/EC.

Elster GmbH

Einbauerklärung / Declaration of Incorporation

nach 2006/42/EG, Anhang II, Nr. 1B / according to 2006/42/EC, Annex II No. 1B

Folgendes Produkt / The following product:

Bezeichnung: Brenner für Gas

Description Burner for gas

Typenbezeichnung / Type: BIO, BIOA, ZIO, BIC, BICA, ZIC

ist eine unvollständige Maschine nach Artikel 2g und ausschließlich zum Einbau in oder zum Zusammenbau mit einer anderen

Maschine oder Ausrüstung vorgesehen.

is a partly completed machine pursuant to Article 2g and is designed exclusively for installation in or assembly with another

machine or other equipment.

Folgende grundlegende Sicherheits- und Gesundheitsschutzanforderungen gemäß Anhang I dieser Richtlinie kommen zur

Anwendung und wurden eingehalten:

The following essential health and safety requirements in accordance with Annex I of this Directive are applicable and have

been fulfilled:

Anhang I, Artikel / Annex I, Article

1.1.3, 1.1.5, 1.3.2, 1.3.4, 1.5.2, 1.7.4

Verlangen in elektronischer Form übermittelt.

The relevant technical documentation has been compiled in accordance with part B of Annex VII and will be sent to the relevant

national authorities on request as a digital file.

Folgende (harmonisierte) Normen wurden angewandt: / The following (harmonized) standards have been applied:

EN 746-2:2010 – Industrielle Thermoprozessanlagen; Sicherheitsanforderungen an Feuerungen und Brennstoffführungssysteme

– Industrial thermoprocessing equipment; Safety requirements for combustion and fuel handling systems

EN ISO 12100:2010 – Sicherheit von Maschinen – Allgemeine Gestaltungsleitsätze – Risikobeurteilung

und Risikominderung (ISO 12100:2010)

– Safety of machinery – General principles for design – Risk assessment

and risk reduction (ISO 12100:2010)

Die unvollständige Maschine darf erst dann in Betrieb genommen werden, wenn festgestellt wurde, dass die Maschine,

in der das oben bezeichnete Produkt eingebaut werden soll, den Bestimmungen der Richtlinie für Maschinen

(2006/42/EG) entspricht.

The partly completed machine may only be commissioned once it has been established that the machine into which

the product mentioned above should be incorporated complies with the provisions of the Machinery Directive

2006/42/EC.

Lotte (Büren)

24.03.2014

Datum / Date

Sandra Runde ist bevollmächtigt, die speziellen technischen Unterlagen gemäß Anhang VII B zusammenzustellen.

Sandra Runde is authorized to compile the relevant technical documentation according to Annex VII B.

BIOW, ZIOW, BICW, ZICW

Konstrukteurin / Designer

Certification

Approval for Russia

Elster GmbH

Postfach 28 09

D-49018 Osnabrück

Strotheweg 1

D-49504 Lotte (Büren)

Tel. +49 (0)541 12 14-0

Fax +49 (0)541 12 14-3 70

info@kromschroeder.com

www.kromschroeder.com

Certified by Gosstandart under Technical Regulations.

Approved by Rostekhnadzor (RTN).

Contact

If you have any technical questions, please contact

your local branch office/agent. The addresses are

available on the Internet or from ElsterGmbH.

We reserve the right to make technical modifications

in the interests of progress. info@kromschroeder.com, www.kromschroeder.com

Elster GmbH

Postfach 28 09, D-49018 Osnabrück

Strotheweg 1, D-49504 Lotte (Büren)

T +49 541 1214-0

F +49 541 1214-370

GB-14

Loading...

Loading...