Page 1

F

NL

I

E

0251456

D GB F NL I E

TR CZ PL RUS H

DK S N P GR

➔ www.docuthek.com

Operating instructions

UV sensor UVS 5

© 2016 Elster GmbH · Edition 02.16

Cert. version 02.16

Translation from the German

Contents

Contents

UV sensor UVS 5 .......................1

Contents ..............................1

Safety.................................1

Checking the usage .....................2

Installation ............................2

Replacement...........................

Wiring ................................

Maintenance ...........................4

Replacing the UV tube .................... 4

Assistance in the event of malfunction .....4

Technical data .........................5

Logistics ..............................5

Certification ...........................6

Eurasian Customs Union ..................6

Contact ...............................6

Safety

Safety

Please read and keep in a safe place

Please read through these instructions

carefully before installing or operating. Following the

installation, pass the instructions on to the opera-

tor. This unit must be installed and commissioned

in accordance with the regulations and standards

in force. These instructions can also be found at

www.docuthek.com.

Explanation of symbols

• , 1 , 2 , ... = Action

▷ = Instruction

Liability

We will not be held liable for damage resulting from

non-observance of the instructions and non-com-

pliant use.

Safety instructions

Information that is relevant for safety is indicated in

the instructions as follows:

DANGER

Indicates potentially fatal situations.

WARNING

Indicates possible danger to life and limb.

CAUTION

Indicates possible material damage.

All interventions may only be carried out by qualified

gas technicians. Electrical interventions may only be

carried out by qualified electricians.

Conversion, spare parts

All technical changes are prohibited. Only use OEM

spare parts.

GB

GB-1

Page 2

F

NL

I

E

Checking the usage

UV sensor for intermittent operation for flame

control on gas burners in conjunction with Elster

Kromschröder automatic burner control units (IFS,

IFD, PFS, PFD), flame detectors (IFW, PFF) or burner

control units (BCU,PFU).

This function is only guaranteed when used within the

specified limits– see page5 (Technical data). Any

other use is considered as non-compliant.

Type code

Code Description

UVS UV sensor

GB

5 Series 5

G1

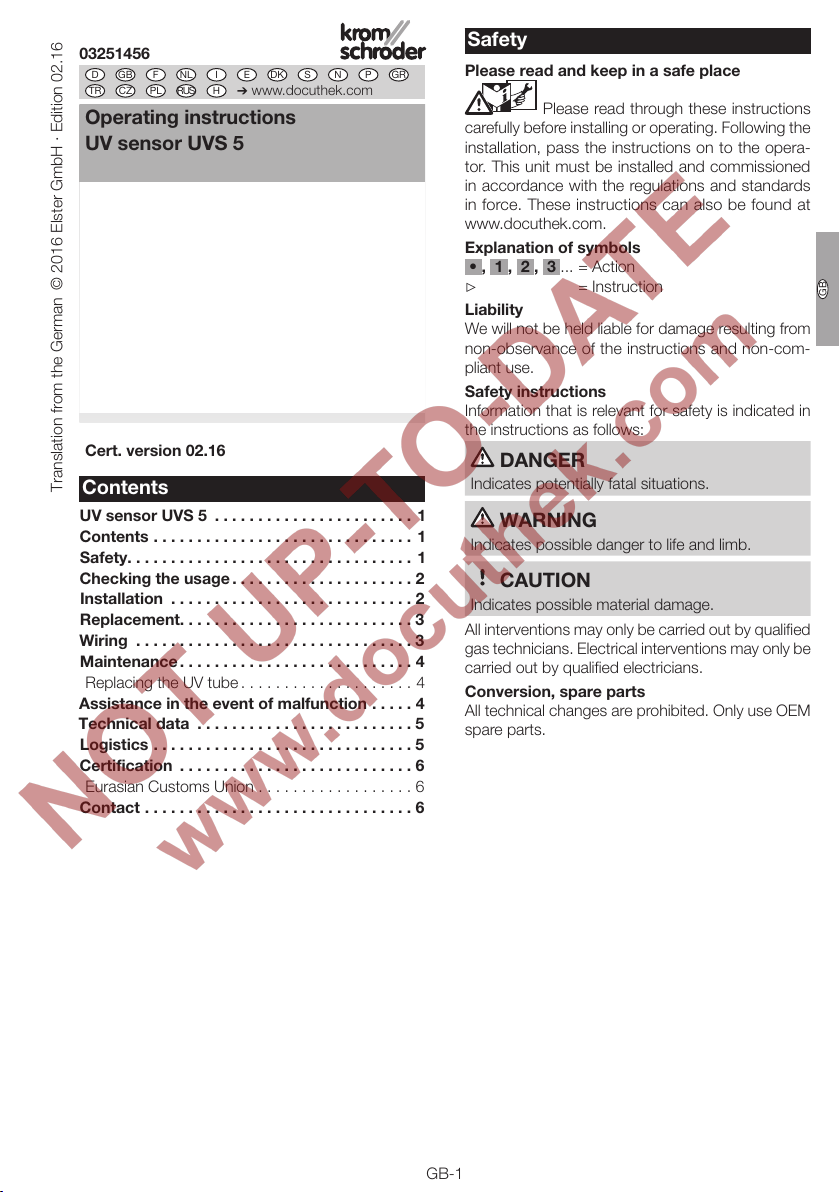

Part designations

4

1

2

3

2

3

Electrical connection:

M20 cable gland

5

6

4

7

8

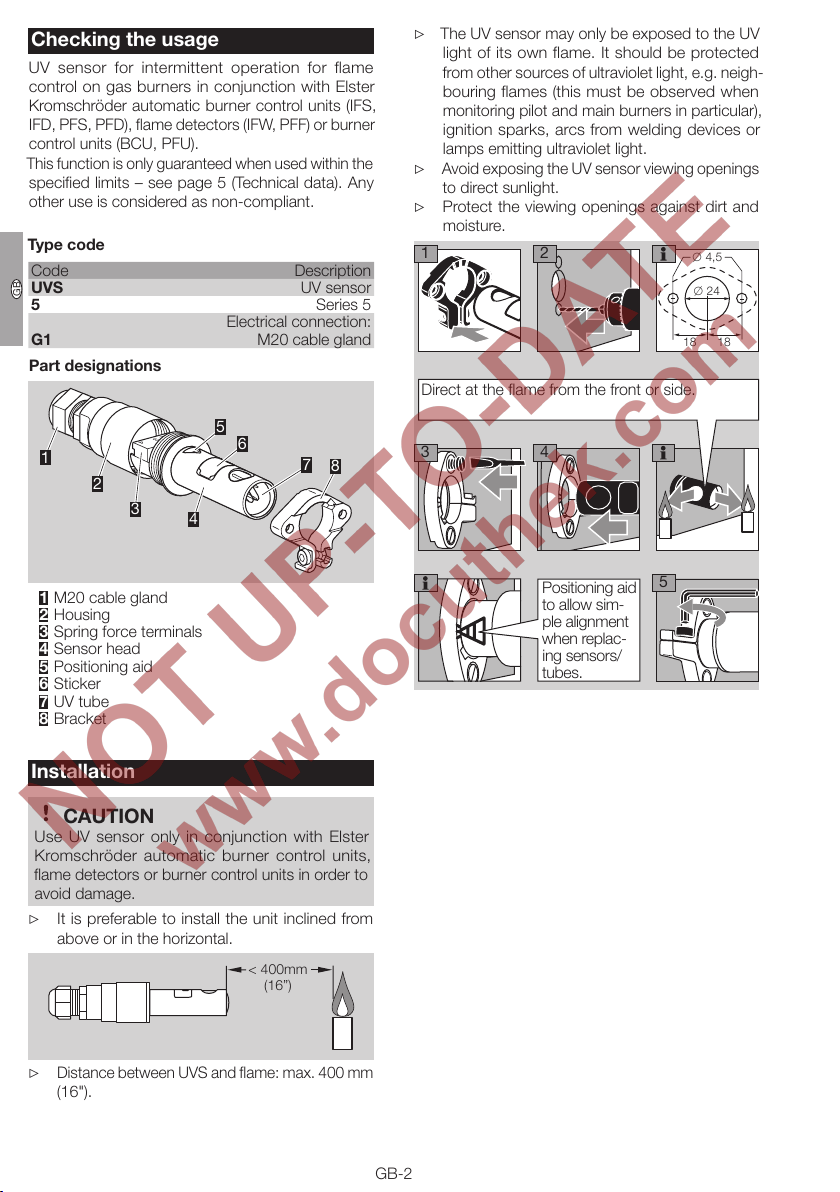

▷ The UV sensor may only be exposed to the UV

light of its own flame. It should be protected

from other sources of ultraviolet light, e.g. neigh-

bouring flames (this must be observed when

monitoring pilot and main burners in particular),

ignition sparks, arcs from welding devices or

lamps emitting ultraviolet light.

Avoid exposing the UV sensor viewing openings

▷

to direct sunlight.

▷

Protect the viewing openings against dirt and

moisture.

21

4,5

N 24

1818

Direct at the flame from the front or side.

3

4

1 M20 cable gland

2 Housing

Spring force terminals

4 Sensor head

5 Positioning aid

6 Sticker

7 UV tube

8 Bracket

Installation

CAUTION

Use UV sensor only in conjunction with Elster

Kromschröder automatic burner control units,

flame detectors or burner control units in order to

avoid damage.

▷

It is preferable to install the unit inclined from

above or in the horizontal.

< 400mm

(16”)

▷

Distance between UVS and flame: max.400mm

(16").

Positioning aid

to allow sim-

ple alignment

when replac-

ing sensors/

tubes.

5

GB-2

Page 3

F

NL

I

E

Replacement

Wiring

WARNING

Electric shocks can be fatal! Before working on

possible live components, ensure the unit is discon-

nected from the power supply.

Replacing the old UVS5 with the new

UVS5G1

The old UVS5 (with non-detachable PVC cable)

▷

can be replaced with the new UVS5G1 (with

cable gland and spring force terminals).

A

B

UVS 5 UVS 5G1

▷

Bracket A and clamping collar B from the old

UVS5 can be used to secure the new UVS5G1.

1 Disconnect the system from the electrical power

supply.

2 Shut off the gas supply.

Old UVS 5

4 5

6 Attach the clamping collar from the old UVS5

to the new UVS5G1.

7 Fit the new UVS5G1 with the clamping collar in

the bracket of the old UVS5.

8 Direct UVS5G1 at the flame from the front or

side.

9 Tighten the bolt of the clamping collar to secure

the UV sensor in the required position.

▷ Electrical connection of the new UVS5G1, see

page 3 (Wiring).

1 3

Clamping

collar

WARNING

Electric shocks can be fatal! Before working on

possible live components, ensure the unit is discon-

nected from the power supply.

▷ Connection cable:

– Use in accordance with local regulations.

– Lay individually and, if possible, not in a metal

conduit.

– Do not lay together with ignition cable but lay

them as far apart as possible.

– M20 cable gland is designed for cable diameters

of 7 to 13mm.

– Spring force terminals for wire cross-sections

>0.2mm² to ≤1.5mm² (AWG24 to AWG16).

– Max. cable length in accordance with the speci-

fications for automatic burner control units IFS,

IFD, PFS, PFD, flame detectors IFW, PFF or

burner control units BCU,PFU.

▷

External electrical interference must be avoided.

1 Disconnect the system from the electrical power

supply.

2 Shut off the gas supply.

4

3

4

4

3

2

1

▷ Flexible wires without wire end ferrules can also

be connected to the spring force terminals. To

insert a flexible wire, the terminal must be opened

using the push-button.

2 31

4

3

2

1

Wiring, see IFS,

UVS

IFD, PFS, PFD,

4321

–

µA

+

IFW, PFF, BCU or

PFU connection

diagram.

PE

GB

GB-3

Page 4

F

NL

I

E

Maintenance

Replacing the UV tube

Assistance in the event of malfunction

WARNING

Electric shocks can be fatal! Before working on

possible live components, ensure the unit is discon-

nected from the power supply.

CAUTION

Do not touch the replacement UV tube with bare

fingers.

▷ The sensor tube must be replaced after approx.

GB

10,000 operating hours (approx. 1year).

▷ Spare parts (tube, sticker, seal), see www.part-

detective.de

1 Disconnect the system from the electrical power

supply.

2 Shut off the gas supply.

2 53

4

6

Use new

sticker.

Insert tube

with seal.

WARNING

– Electric shocks can be fatal! Before working

on possible live components, ensure the unit

is disconnected from the power supply.

– Fault-clearance must only be undertaken by

authorized trained personnel!

– Do not carry out repairs on the UV sensor on

your own as this will cancel our guarantee. Un-

authorized repairs or incorrect electrical con-

nections can cause the UV sensor to become

defective. In this case, fail-safe operation can

no longer be guaranteed.

– (Remote) resets may only be conducted by

authorized trained personnel with continuous

monitoring of the burner to be repaired.

– Safe operation only in conjunction with Elster

Kromschröder automatic burner control units,

flame detectors or burner control units.

• Measure the current in the flame signal cable

(connect the positive pole of the measuring in-

strument to the cable from the automatic burner

control unit and the negative pole to the cable

from the UV sensor).

4

PE

3

UVS

2

1

+

–

µA

▷

The measured direct current must be greater

than 1µA (typically 20µA).

? Fault

! Cause

• Remedy

? A direct current is flowing, but no flame

present.

! The UV sensor is influenced by the flames of

other burners, e.g. by reflection on the furnace

walls.

• Position the sensor so that it can only “view” its

own dedicated flame (e.g. use viewing tube).

! Humidity inside the sensor.

• Vent sensor.

! The service life of the UV tube has expired.

• Replace UV tube in the UV sensor, see page4

(Maintenance).

! The sensitivity of the flame amplifier in the auto-

matic burner control unit is too high.

• Adjust the switch-off threshold on the automatic

burner control unit.

GB-4

Page 5

F

NL

I

E

? No direct current although the flame is burn-

ing.

! The UV sensor is dirty, e.g. sooted.

• Clean sensor.

! Humidity inside the UV sensor.

• Vent sensor.

! The distance between the UV sensor and the

flame is too great.

• Reduce the distance.

? The automatic burner control unit ignites in

pulses.

! The sensor “sees” the ignition spark.

• Reposition the UV sensor so that it cannot “see”

the ignition spark.

• Use an automatic burner control unit that is able

to distinguish between an ignition spark and a

flame signal.

? The intensity of the flame signal decreases

after a longer period of operation.

! UV tube fault due to incorrect UV sensor con-

nections.

• Connect the UV sensor in accordance with the

wiring instructions.

• Remove the UV sensor and return for repair.

? The automatic burner control unit performs

a fault lock-out during start-up or operation.

! The highly fluctuating flame signal temporarily

exceeds the switch-off threshold.

• Reduce the distance between UV sensor and

flame.

• Position the UV sensor so that it can “view” the

flame without hindrance (e.g. smoke curtain).

! The switch-off threshold in the automatic burner

control unit is set too high.

• Adjust switch-off threshold.

Technical data

Plastic housing with connection terminals.

Wire cross-section for connection terminals:

≤1.5mm

2

(≤AWG16).

Cable gland for cable diameters of 7 to 13mm.

Distance between UV sensor and flame:

max.400mm (max.16").

UV tube: P578,

spectral range: 190–270nm,

max. sensitivity: 210 nm ± 10 nm.

Service life of the UV tube:

approx. 10,000 operating hours.

Min. DC signal: 1 μA.

Enclosure:

IP40

IP54

IP54 (Nema 3) in wiring chamber, IP40 around the

viewing openings with fitted tube.

Ambient temperature/storage temperature:

-40 to +80°C (-40 to +176°F).

Weight: 280 g (0.6 lbs).

Max. length of cable UV sensor – automatic burner

control unit: see operating instructions for auto-

matic burner control unit.

Logistics

Transport

Protect the unit from external forces (blows, shocks,

vibration). On receipt of the product, check that the

delivery is complete, see page2 (Part designa-

tions). Report any transport damage immediately.

Storage

Store the product in a dry and clean place.

Storage temperature: see page5 (Technical data).

Storage time: 6months before using for the first time.

Packaging

The packaging material is to be disposed of in ac-

cordance with local regulations.

Disposal

Components are to be disposed of separately in

accordance with local regulations.

GB

GB-5

Page 6

F

NL

I

E

Certification

Eurasian Customs Union

The product UVS5 meets the technical specifications

of the Eurasian Customs Union.

GB

Contact

Contact

If you have any technical questions, please contact

your local branch office/agent. The addresses are

available on the Internet or from ElsterGmbH.

We reserve the right to make technical modifications

Elster GmbH

Postfach 28 09, D-49018 Osnabrück

Strotheweg 1, D-49504 Lotte (Büren)

T +49 541 1214-0

F +49 541 1214-370

in the interests of progress. info@kromschroeder.com, www.kromschroeder.com

GB-6

Loading...

Loading...