Page 1

GB

F

NL

I

E

03250197

D GB F NL I E

TR CZ PL RUS H

DK S N P GR

➔ www.docuthek.com

Operating instructions

Fieldbus interface PFA Module subrack BGT

© 2017 Elster GmbH · Edition 08.17

Safety

Please read and keep in a safe place

Please read through these instructions carefully

before installing or operating. Following the installation,

pass the instructions on to the operator. This unit must

be installed and commissioned in accordance with the

regulations and standards in force. These instructions can

also be found at www.docuthek.com.

Explanation of symbols

• , , , ... = Action

▷ = Instruction

Liability

We will not be held liable for damage resulting from nonobservance of the instructions and non-compliant use.

Safety instructions

Information that is relevant for safety is indicated in the

instructions as follows:

DANGER

Indicates potentially fatal situations.

Translation from the German

Contents

Fieldbus interface PFA

Module subrack BGT .........................

Contents ...................................

Safety......................................

Checking the usage .........................

Installing the BGT...........................

Wiring the BGT .............................

Setting the PFA.............................

Installing the PFA ........................... 4

Replacing the PFA . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Labelling the PFA ........................... 5

Commissioning............................. 5

Manual operation ........................... 5

Faults..................................... 6

Technical data ..............................7

Logistics ...................................7

BGT SA-9U/DP connection diagram .......... 8

BGT SA-8U/DP connection diagram ......... 0

Accessories ..............................

Certification ..............................

Contact ..................................

WARNING

Indicates possible danger to life and limb.

CAUTION

Indicates possible material damage.

All interventions may only be carried out by qualified gas

technicians. Electrical interventions may only be carried

out by qualified electricians.

Conversion, spare parts

All technical changes are prohibited. Only use OEM spare

parts.

Changes to edition 06.

The following chapters have been changed:

– BGT SA-9U/1DP connection diagram

– Certification

GB-1

Page 2

GB

F

NL

I

E

Checking the usage

PFA 700

Fieldbus interface for interworking of up to nine automatic

burner control units PFU 760 or PFU 780 to industrial communication networks using PROFIBUS DP. The PFA700

can be plugged into the pre-wired module subrack BGT

SA-9U/1DP, together with the automatic burner control

units.

PFA 70

Fieldbus interface for interworking of up to eight automatic

burner control units PFU 780 to industrial communication networks using PROFIBUS DP. The PFA710 can

be plugged into the pre-wired module subrack BGT SA8U/1DP, together with the automatic burner control units.

PFA 700, PFA 70

This function is only guaranteed when used within the

specified limits – see page 7 (Technical data). Any

other use is considered as non-compliant.

Type code

Code Description

PFA Fieldbus interface

700

0

7

T

Mains voltage: 220/240 V AC

N

Z Special version

Part designations

For connecting:

PFU 760

PFU 780

110/120 V AC

BGT SA-9U/DP

Pre-wired module subrack for a fieldbus interface PFA700

with nine further slots for automatic burner control units

PFU 760 or PFU 780.

BGT SA-8U/DP

Pre-wired module subrack for a fieldbus interface PFA710

with eight further slots for automatic burner control units

PFU 780.

BGT SA-9U/DP, BGT SA-8U/DP

This function is only guaranteed when used within the

specified limits – see page 7 (Technical data). Any

other use is considered as non-compliant.

Type code

Code Description

BGT 19" module subrack

SA For PFA and PFU

-9U

-8U

Slots: 9 × for PFU

8 × for PFU

/DP 1 PFA with PROFIBUS DP

Part designations

3

1

2

1

6

1

3

2

4

6

5

7

8

LED display for program status and error messages

Reset/Information button

On/Off button

4 Type label

5 Connection for opto-adapter

6 Screws for attachment to the subrack

7 Code switches for address setting

8 CD with device master data (GSD file)

Input voltage and ambient temperature – see type label.

PFA 700

Perforated plate

Fieldbus interface PFA 700/PFA 710

Type label

Input and output voltage, enclosure and ambient temperature – see type label.

BGT SA

GB-2

Page 3

GB

F

NL

I

E

Installing the BGT

483 mm

1, 2

A

P

DI

on

on

on

1, 2

A

P

DI

on

on

on

1, 2

1, 2

A

P

DI

on

on

on

1, 2

A

P

DI

on

on

on

1, 2

1, 2

A

P

DI

on

on

on

1, 2

1, 2

1, 2

A

P

DI

on

on

on

1, 2

1, 2

A

P

DI

on

on

on

1, 2

1, 2

A

P

DI

on

on

on

1, 2

1, 2

A

P

DI

on

on

on

1, 2

1, 2

A

P

DI

on

on

on

1, 2

1, 2

A

P

on

on

CAUTION

Please observe the following to ensure that the PFA and

the automatic burner control units PFU are not damaged

during operation:

– It must be ensured that the module subrack is well

ventilated in order to avoid overheating.

– In the case of several module subracks mounted on

top of one another, we recommend removing the perforated plates A from between the module subracks,

and inserting a rack-mounted fan B underneath the

module subracks.

88 88 88 88 88 88 88 88 8888

88 88 88 88 88 88 88 88 8888

A

Wiring the BGT

Disconnect the system from the electrical power sup-

ply.

▷

Use a resistor with low impedance at high frequencies

for grounding the BGT.

▷

Ensure an equipotential bond between the various

slaves.

▷ Switch on the terminal resistor on the first (PLC) and

last (BGT/PFA) station on the Profibus plug– see page

12 (Profibus plug for PFA).

▷ There are four digital inputs (X10.1 to X10.4) and four

digital outputs (X10.6 to X10.9) available.

▷ Load per input: 24 V DC, ± 10%, <10mA.

▷ Load per output: relay contact, max. 1 A, 24 V (not

fused internally).

BGT SA-9U/DP

Wire as shown on the circuit diagram, see page 8

(BGT SA-9U/1DP connection diagram).

BGT SA-8U/DP

Wire as shown on the circuit diagram, see page 10

(BGT SA-8U/1DP connection diagram).

88 88 88 88 88 88 88 88 8888

Setting the PFA

▷

All the unit-specific parameters for the PFA are saved

in a device master data file (GSD file, see www.

docutheck.com).

Copy device master data for the PFA into the program-

B

mable logic controller (PLC).

▷

The steps required to copy the file are described in

the instructions for the PLC.

A

Configure the PROFIBUS DP using the appropriate

tools for the PLC you are using.

▷

The PFA will automatically identify the baud rate (max.

1.5 Mbit/s).

132

mm

200 mm

58

mm

465 mm

▷ The max. range depends on the baud rate:

Baud rate Range

[kBit/s] [m] [yd]

93.75 1200 1300

187.5 1000 1090

500 400 545

1500 200 220

▷ The ranges may be increased by using repeaters. Do

not connect more than three repeaters in series.

DANGER

Electric shocks can be fatal! Module subracks must be

integrated in the equipotential bonding system.

▷ Installation position: any.

Distance between PFU and burner: max. 100m

▷

(328 ft).

PFA 700

▷ Input/output bytes: inputs 5 bytes, outputs 3bytes.

Input bytes (PFA ▶ master)

Bit Byte 0 Byte 1 Byte 2 Byte 3 Byte 4

PFU 1

0

1

PFU 2

2

PFU 3

3

PFU 4

4

PFU 5

5

PFU 6

6

PFU 7

7

PFU 8

PFU 9

PFU 1

PFU 2

PFU 3

PFU 4

PFU 5

PFU 6

PFU 7

PFU 8

PFU 9

PFU 1

PFU 2

PFU 3

PFU 4

PFU 5

PFU 6

PFU 7

PFU 8

PFU 9

1

2

3

4

PFA

GB-3

PFA

Page 4

GB

F

NL

I

E

Output bytes (master ▶ PFA)

1, 2

ϑ

A

P

DI

on

on

on

1, 2

ϑ

A

P

DI

on

on

on

1, 2

ϑ

A

A

P

DI

on

on

on

1, 2

ϑ

A

P

DI

on

on

on

1, 2

ϑ

A

A

P

DI

on

on

on

1, 2

ϑ

A

A

P

DI

on

on

on

1, 2

ϑ

A

P

DI

on

on

on

1, 2

ϑ

A

A

P

DI

on

on

on

1, 2

A

P

DI

on

on

on

1, 2

ϑ

A

P

DI

on

on

on

1, 2

ϑ

A

A

P

DI

on

on

on

1, 2

A

P

on

on

1, 2

ϑ

A

P

DI

on

on

on

1, 2

ϑ

A

A

P

DI

on

on

on

1, 2

ϑ

A

P

DI

on

on

on

1, 2

ϑ

A

A

P

DI

on

on

on

1, 2

ϑ

A

P

DI

on

on

on

1, 2

ϑ

A

A

P

DI

on

on

on

1, 2

ϑ

A

P

DI

on

on

on

1, 2

ϑ

A

A

P

DI

on

on

on

1, 2

A

P

DI

on

on

on

1, 2

A

P

DI

on

on

on

1, 2

A

P

DI

on

on

on

1, 2

A

P

DI

on

on

on

1, 2

A

P

DI

on

on

on

1

1

2

1

2

1

2

1

2

1, 2

A

P

DI

on

on

on

1, 2

A

P

DI

on

on

on

1, 2

A

P

DI

on

on

on

1, 2

A

P

DI

on

on

on

1

1, 2

A

P

on

on

1

2

1

2

1

2

1

2

1

1, 2

A

P

DI

on

on

on

1

2

1

2

1

2

1

2

1, 2

ϑ

A

A

P

DI

on

on

on

1, 2

ϑ

A

A

P

DI

on

on

on

1, 2

ϑ

A

A

P

DI

on

on

on

1, 2

ϑ

A

A

P

DI

on

on

on

1

1

2

1

2

1

2

1

2

1, 2

A

P

on

on

1, 2

ϑ

A

A

P

DI

on

on

on

1, 2

ϑ

A

A

P

DI

on

on

on

1, 2

ϑ

A

A

P

DI

on

on

on

1, 2

ϑ

A

A

P

DI

on

on

on

1, 2

A

P

DI

on

on

on

1, 2

ϑ

A

P

DI

on

on

on

1

1

2

1, 2

A

P

on

on

1, 2

ϑ

A

A

P

DI

on

on

on

1

1

2

1, 2

1, 2

A

P

DI

on

on

on

2

1

Bit Byte 0 Byte 1 Byte 2

0

1

2

3

4

5

6

7

PFU 1

PFU 2

PFU 3

PFU 4

PFU 5

PFU 6

PFU 7

PFU 8

PFU 9

PFU 1

PFU 2

PFU 3

PFU 4

PFU 5

PFU 6

PFU 7

PFA 70

▷ Input/output bytes: inputs 5 bytes, outputs 5bytes.

Input bytes (PFA ▶ master)

Bit Byte 0 Byte 1 Byte 2 Byte 3 Byte 4

PFU 1

0

1

PFU 11PFU 31PFU 51PFU 7

2

PFU 1

3

PFU 1 PFU 3 PFU 5 PFU 7

4

PFU 2

5

PFU 21PFU 41PFU 61PFU 8

6

PFU 2

7

PFU 2 PFU 4 PFU 6 PFU 8

PFU 3

PFU 3

PFU 4

PFU 4

PFU 5

PFU 5

PFU 6

PFU 6

PFU 7

PFU 7

PFU 8

PFU 8

Output bytes (master ▶ PFA)

Bit Byte 0 Byte 1 Byte 2 Byte 3 Byte 4

PFU 11PFU 31PFU 51PFU 7

0

PFU 1

1

2

PFU 1

PFU 3

PFU 3

PFU 5

PFU 5

PFU 7

PFU 7

3

4

PFU 21PFU 41PFU 61PFU 8

5

PFU 2

6

PFU 2

PFU 4

PFU 4

PFU 6

PFU 6

PFU 8

PFU 8

7

Legend

Ready for operation

Burner start-up signal

Start-up signal, pilot burner

Start-up signal, main burner

Purge

External air valve control

Burner operating signal

Operating signal, pilot burner

Operating signal, main burner

Fault signal

Reset

Input signal

Output signal

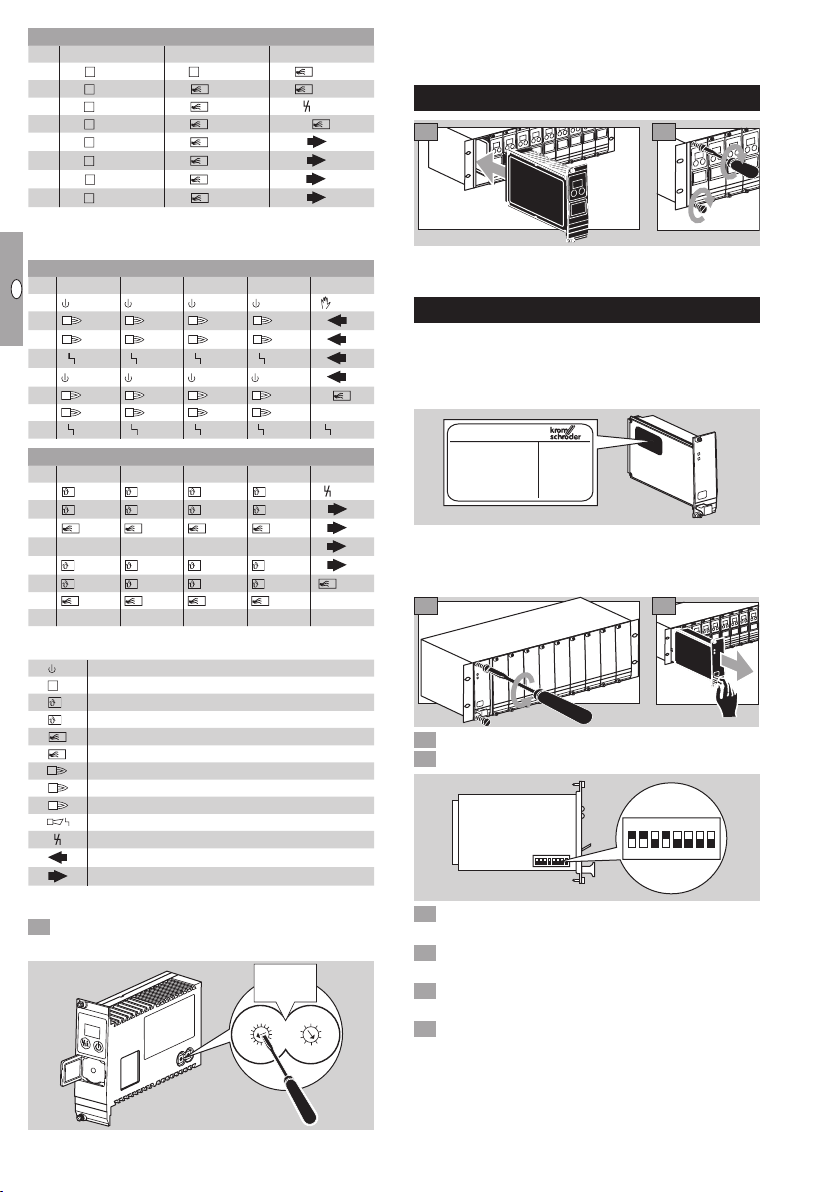

Address setting

Set the Profibus address on the PFA using the code

switches.

114 dec

1

0

0

F

2

9

3

E

4

D

8

5

C

7

6

B

7

A

6

8

9

PFU 8

PFU 9

PFA

1

2

3

4

PFA

PFA

PFA

PFA

1

2

3

4

5

▷

At the factory, the Profibus address on the PFA is

set to 04.

Installing the PFA

1

▷ Ensure that the PFA is correctly inserted.

1

2

3

4

Replacing the PFA

▷

The old PFA 700 (Order No. 84395100 – see type

label) can be replaced with the new PFA 700 (Order

No. 84395101 or 84395102) in the module subrack

BGT SA-9U/1DP (Order No. 84402283).

84395100

1

2

3

4

▷ To increase the EMC interference immunity, the new

Profibus plug supplied must be used for the new PFAs

(Order No. 84395101 or 84395102).

Check the voltage.

4 Read off the Profibus address on the old PFA.

5 Accept and set the Profibus address on the new PFA

– see page 4 (Address setting).

6 Install the new PFA – see page 4 (Installing the

PFA).

7 Check the operating parameters for manual mode on

the new PFA and adjust where applicable.

8 Replace the Profibus plug on the BGT with the Profi-

bus plug with shielding capacitor – see page 12

(Profibus plug for PFA).

GB-4

2

ON

12345678

Page 5

GB

F

NL

I

E

Labelling the PFA

▷ Each PFA can be labelled individually.

Attach label or sticker to the space provided on the

handle of the fieldbus interface.

When using operating mode parameters set at the

factory

PFA 700, PFA 70

Parameter 43 = 1

4 Press the Reset/Information button for 1 s.

▷ The display indicates step

▷

The PFUs start the burners and open the air valve

04

.

via the external control system (programming of the

operating mode at the factory).

PFA

Zone 3

▷

The size of this space is 28 × 18 mm

(1.10×0.71").

Commissioning

▷ During operation, the 7-segment display shows the

program status:

Unit Off

––

Programming mode

(blinking dots) Manual mode

0.0.

Normal operation

OP

Profibus fault

P

WARNING

Check the system for tightness before commissioning.

Do not start the PFA until the downstream automatic

burner control units have been properly commissioned.

Switch on the system.

▷ The display indicates

––

.

Switch on the PFA by pressing the On/Off button.

▷

As soon as the flashing display P goes out and

the display indicates

, the data traffic is operating.

OP

Manual operation

The PFA can be started in manual mode for burner adjust-

ment or for fault-finding:

Using the opto-adapter and the BCSoft software, the

▷

operating mode parameters for manual mode can

be changed.

CAUTION

If parameters are changed, stick the supplied adhesive

When using adjusted operating mode parameters

ON/OFF operating mode

PFA 700 in conjunction with PFU 760

Parameter 43 = 2

4 Press the Reset/Information button for 1 s.

▷ The display indicates step

03

.

▷ The PFUs start the burners.

5 Press the Reset/Information button for 1 s.

▷ The display indicates step

.

00

▷ The PFUs switch off all the burners.

▷ By pressing the Reset/Information button repeatedly,

the PFUs are activated to switch between burner start

(the display indicates step

indicates step

00

03

) or burner off (the display

).

PFA 700 in conjunction with PFU 760..L

Parameter 43 = 3

4 Press the Reset/Information button for 1 s.

▷ The display indicates step

01

.

▷ The PFUs start the burner pre-purge procedure.

WARNING

The pre-purge duration is not included in the program.

Pre-purge until the combustion chamber has been adequately ventilated.

5 Press the Reset/Information button for 1 s.

▷ The display indicates step

▷ The PFUs start the burners.

6 Press the Reset/Information button for 1 s.

▷ The display indicates step

▷ The PFUs switch off all the burners.

▷ By pressing the Reset/Information button repeatedly,

the PFUs are activated to switch between pre-purge

(the display indicates step

indicates step

step

00

03

) or burner off (the display indicates

).

.

03

.

00

burner start (the display

01

),

label “Changed parameters” on the PFA– see page12

(Accessories).

Switch on the system.

Apply voltage to terminals 19 and 20 on the terminal

strip X10.

Switch on the PFA by pressing the On/Off button while

holding down the Reset/Information button. Hold the

button until both dots in the display start to blink.

▷ The display indicates

▷

Deactivate manual mode by pressing the On/Off

0.0.

.

button.

▷

back to normal operation automatically.

After 5 minutes in manual mode, the PFA switches

GB-5

Page 6

GB

F

NL

I

E

PFA 70 in conjunction with PFU 780..L

Parameter 43 = 3

4 Press the Reset/Information button for 1 s.

▷ The display indicates step

01

.

▷ The PFUs start the burner pre-purge procedure.

WARNING

The pre-purge duration is not included in the program.

Pre-purge until the combustion chamber has been adequately ventilated.

5 Press the Reset/Information button for 1 s.

▷ The display indicates step

.

02

▷ The PFUs start the pilot burners.

6 Press the Reset/Information button for 1 s.

▷ The display indicates step

▷

The PFUs start the main burners, the pilot burners

03

.

remain switched on.

7 Press the Reset/Information button for 1 s.

▷ The display indicates step

.

00

▷ The PFUs switch off all the burners.

▷ By pressing the Reset/Information button repeatedly,

the PFUs are activated to switch between pre-purge

(the display indicates step

display indicates step

display indicates step

indicates step

00

).

pilot burner start (the

01

),

main burner start (the

02

),

03

) or burner off (the display

High/Low operating mode

PFA 700 in conjunction with PFU 760..L

Parameter 43 = 4

4 Press the Reset/Information button for 1 s.

▷ The display indicates step

01

.

▷ The PFUs start the burner pre-purge procedure.

WARNING

The pre-purge duration is not included in the program.

Pre-purge until the combustion chamber has been adequately ventilated.

5 Press the Reset/Information button for 1 s.

▷ The display indicates step

▷ The PFUs start the burners.

6 Press the Reset/Information button for 1 s.

▷ The display indicates step

▷ The PFUs 760..L activate the external air valves, the

burners switch to high-fire rate.

7 Press the Reset/Information button for 1 s.

▷ The display indicates step

▷

The PFUs 760..L deactivate the external air valves,

the burners switch to low-fire rate.

▷

Each time the Reset/Information button is pressed, the

air valves are opened (the burners switch to high-fire

rate, the display indicates

ers switch to low-fire rate, the display indicates

.

03

.

04

.

03

) or closed (the burn-

04

03

PFA 70 in conjunction with PFU 780..L

Parameter 43 = 4

4 Press the Reset/Information button for 1 s.

▷ The display indicates step

01

.

▷ The PFUs start the burner pre-purge procedure.

WARNING

The pre-purge duration is not included in the program.

Pre-purge until the combustion chamber has been adequately ventilated.

5 Press the Reset/Information button for 1 s.

▷ The display indicates step

.

02

▷ The PFUs start the pilot burners.

6 Press the Reset/Information button for 1 s.

▷ The display indicates step

▷

The PFUs start the main burners, the pilot burners

03

.

remain switched on.

7 Press the Reset/Information button for 1 s.

▷ The display indicates step

.

04

▷ The PFUs 780..L activate the external air valves, the

main burners switch to high-fire rate.

8 Press the Reset/Information button for 1 s.

▷ The display indicates step

▷

The PFUs 780..L deactivate the external air valves,

03

.

the main burners switch to low-fire rate.

▷

Each time the Reset/Information button is pressed, the

air valves are opened (the burners switch to high-fire

rate, the display indicates

) or closed (the burn-

04

ers switch to low-fire rate, the display indicates

Faults

DANGER

Electric shocks can be fatal! Before working on possible

live components, ensure the unit is disconnected from

the power supply.

Fault-clearance must only be undertaken by authorized,

trained personnel.

▷

Faults may be cleared only using the measures described below.

▷

If the PFA does not respond even though all faults

have been remedied: remove the unit and return it to

the manufacturer for inspection.

? Faults

! Cause

• Remedy

? The 7-segment display does not light up.

! Mains voltage is not applied.

• Check the wiring, apply mains voltage (see type label).

.

)

03

.

)

GB-6

Page 7

GB

F

NL

I

E

? The display blinks and indicates

P

or

? A bus fault is indicated on the automation sys-

tem.

! The PROFIBUS DP data traffic has suffered a fault.

! Bus cable interrupted.

• Check bus cable.

! Bus cable connections confused in the plug.

• Check the wiring.

! A and B cables confused.

• Check cables.

! Terminal resistors connected incorrectly.

• Switch on the terminal resistors on the first and last

station in the segment and switch them off for all other

stations.

! Incorrect PROFIBUS address set.

• Correct the address setting – switch the unit off and

then on again to save the address.

! Bus cables too long.

• Reduce cable length or baud rate – see page 5

(Commissioning).

▷

If the transfer rate is reduced, remember that this

will increase the signal running times to and from the

individual units.

! Poor shielding.

• The shield must be connected to the shield clips in

the PROFIBUS DP plugs in full and over a wide area.

! Poor equipotential bond.

• The PROFIBUS DP shield should be connected at all

points to the same ground potential by grounding the

BGT. If necessary an equipotential bond cable must

be laid.

! If faults only occur sporadically in the PROFIBUS DP

system, and are mostly only indicated briefly in the

bus master, the terminal resistors, shielding, cable

lengths/routes, equipotential bond and the use of

interference-suppressed ignition electrode plugs (1kΩ)

in particular should be checked.

▷

Further notes on building PROFIBUS DP networks

are set out in the instructions for the automation

system or, for example, in the “Installation Guideline

for PROFIBUS DP/FMS”, available from the PUO

(PROFIBUS User Organization).

? All the burners are constantly in operation, re-

gardless of data traffic.

! The PFA is set to manual mode.

• Switch the PFA to “normal operation”.

? The display indicates

.

! Profibus module fault.

• Remove the unit and return it to the manufacturer.

? The display indicates

95, 96, 97, 98

30, 31, 34, 80, 89, 94

.

99

or

! Internal faults.

• Remove the unit and return it to the manufacturer.

Technical data

BGT

Weight: 2.3 kg.

PFA

Front width 8 depth units = 40.6 mm.

Overall height 3 height units = 128.4 mm.

Ambient temperature: -20°C to +60°C.

4 digital inputs: 24 V DC, ± 10%, < 10 mA.

4 digital outputs for contr

olling small relays 24 V, max.

250 mW (10 mA).

Mains voltage:

220/240 V AC, -15/+10%, 50/60 Hz,

110/120 V AC, -15/+10%, 50/60 Hz,

for grounded and ungr

ounded mains.

Weight: approx. 0.75 kg.

Designed lifetime

This information on the designed lifetime is based on using

the product in accordance with these operating instructions. Once the designed lifetime has been reached, safetyrelevant products must be replaced.

Designed lifetime (based on date of manufacture) in accordance with EN 230 and EN 298 for PFA/BGT: 10 years.

You can find further explanations in the applicable rules and

regulations and on the afecor website (www.afecor.org).

This procedure applies to heating systems. For thermopro-

cessing equipment, observe local regulations.

Logistics

Transport

Protect the unit from external forces (blows, shocks, vibration). On receipt of the product, check that the delivery is

complete, see page 2 (Part designations). Report any

transport damage immediately.

Storage

Store the product in a dry and clean place.

Storage temperature: see page 7 (Technical data).

Storage time: 6 months in the original packaging before

using for the first time. If stored for longer than this, the

overall service life will be reduced by the corresponding

amount of extra storage time.

Packaging

The packaging material is to be disposed of in accordance

with local regulations.

Disposal

Components are to be disposed of separately in accordance with local regulations.

,

GB-7

Page 8

sk1

PFU 7xx

GB

F

NL

I

E

BGT SA-9U/DP connection diagram

BGT SA-9U/1DP700 (8 440 229 1)

30e

26e

22a

30a

20c

230 V

28c

26a

18a

10e

12e

14a

14e

10a

12a

10c

12c

32c

24c

c2

c1

F1

1

2

PFU 7xx

l

22e

sk1

v1

16c

v2

18e

2a

4a

2e

4e

2c

1

4c

6a

6e

2

..8, ..7,

..6, ..5,

..4, ..3,

9

..2

30e

26e

22a

30a

20c

230 V

28c

26a

18a

10e

12e

14a

14e

10a

12a

10c

12c

32c

24c

c2

c1

F1

1

2

X9

1

2

3

4

5

6

7

8

X9.5

1

2

X9.3

UVS

3

X10.21

1

X9.6

N

ZI

V1

V2

1

2

1

DI

GB-8

UVS

1

2

3

X1.5

X1.3

X10.21

X1.6

N

1

ZI

V1

V2

Page 9

sk1

GB

F

NL

I

E

v1

v2

7xx

l

22e

16c

18e

2a

4a

2e

4e

2c

1

4c

6a

6e

2

1

+24 V

1. PFU

9. PFU

1. PFU

9. PFU

1. PFU

9. PFU

1. PFU

9. PFU

1. PFU

5. PFU

6. PFU

9. PFU

PFU

…

…

…

…

…

…

24 V

0 V

15b

16b

1c

9c

10c

18c

1a

9a

10a

18a

19a

23a

20c

23c

19c

17b

30c

A

P

PFA 700

C

I/O

32b

30a

PROFIBUS DP

8b

11b

12b

14b

18b

1

19b

2

20b

3

21b

4

22b

23b

1

24b

2

25b

3

26b

4

L1

N

VP

RxD/TxD-P

RxD/TxD-N

DGND

+24 V

+24 V

+24 V

+24 V

0 V

K2

K4

PROFIBUS DP

ex

ex

ex

ex

ex

K1

K3

k5

X1

2

30e

X10

11

12

13

K5

14

1

2

3

4

5

6

7

8

15

16

17

18

19

20

21

22

PFU 7xx

1…9

X10

1

2

3

4

5

6

7

8

9

max. 1 A, 24 V

E1 E2 E3 E4

COM

10

k1

k2

k3

k4

+24 V

0 V

ex

ex

DI

PE

GB-9

N

L1

Page 10

sk1

PFU 780

GB

F

NL

I

E

BGT SA-8U/DP connection diagram

BGT SA-8U/1DP710 (84402292)

30e

26e

22a

30a

20c

230 V

28c

26a

18a

10e

12e

14a

14e

10a

12a

10c

12c

32c

24c

c2

c1

F1

sk1

1

2

PFU 780

l

22e

v1

16c

v2

18e

2a

4a

2e

4e

2c

1

4c

6a

6e

2

..7, ..6,

..5, ..4,

..3, ..2,

8

30e

26e

22a

30a

20c

230 V

28c

26a

18a

10e

12e

14a

14e

10a

12a

10c

12c

32c

24c

c2

c1

F1

1

2

X8

1

2

3

4

5

6

7

8

X8.5

1

2

X8.3

UVS

3

X10.21

1

X8.6

N

ZI

V1

V2

1

2

1

DI

GB-10

UVS

1

2

3

X1.5

X1.3

X10.21

X1.6

N

1

ZI

V1

V2

Page 11

sk1

l

GB

F

NL

I

E

22e

v1

16c

v2

18e

2a

4a

2e

4e

2c

1

4c

6a

6e

2

1

+24 V

1. PFU

8. PFU

1. PFU

7. PFU

8. PFU

1. PFU

8. PFU

1. PFU

8. PFU

1. PFU

8. PFU

1. PFU

2. PFU

3. PFU

5. PFU

6. PFU

8. PFU

1. PFU

5. PFU

6. PFU

8. PFU

PFU

...

...

...

...

...

...

...

...

...

24 V

0 V

15b

16b

1c

8c

27a

10c

17c

1a

8a

10a

17a

27c

27b

24a

26a

24c

26c

19a

23a

20c

22c

19c

17b

30c

32b

L1

30a

N

1

1b

7b

2

A

1

2

P

C

PROFIBUS DP

8b

11b

12b

14b

18b

1

19b

2

20b

3

21b

4

22b

I/O

23b

1

24b

2

25b

3

26b

4

PFA 710

VP

RxD/TxD-P

RxD/TxD-N

DGND

+24 V

+24 V

+24 V

+24 V

0 V

K2

K4

PROFIBUS DP

ex

ex

ex

ex

ex

K1

K3

k5

X1

2

30e

X10

11

12

13

K5

14

1

2

3

4

5

6

7

8

15

16

17

18

19

20

21

22

PFU 7xx

1…8

X10

1

2

3

4

5

6

7

8

9

max. 1 A, 24 V

E1 E2 E3 E4

COM

10

k1

k2

k3

k4

+24 V

0 V

ex

ex

DI

PE

GB-11

N

L1

Page 12

GB

F

NL

I

E

Accessories

“Changed parameters” stickers

D-49018 Osnabrück, Germany

Achtung, geänderte Parameter!

Die Angaben auf dem Typenschild

gelten nicht mehr in vollem Umfang.

Aktuelle Parameter direkt auslesen.

Important, changed parameters!

The details on the type label are no

longer completely accurate. Read the

current parameters direct from the

unit.

Attention, paramètres modifiés !

Les informations figurant sur la plaque

signalétique ne sont plus valables

dans leur intégralité. Veuillez vous

référer directement aux paramètres

actualisés.

Affix on the PFA if parameters set at the factory have been

changed.

100 pcs, Order No.: 74921492.

Opto-adapter PCO 00 including BCSoft CD-ROM

Order No.: 74960625.

Bluetooth adapter PCO 00 including BCSoft

CD-ROM

Order No.: 74960617.

▷

Downloading the BCSoft software, see

www.docuthek.com

Profibus plug for PFA

For connecting Profibus stations to the Profibus bus cable. To replace existing PROFIBUS plug connectors if a

new PFA700 is operated in an old module subrack with

the OrderNo.84402283 in order to improve EMC– see

page4 (Replacing the PFA).

A B A’ B’

▷ Data cablesA and B must not be reversed (A’ is

connected toA, B’ is connected toB).

▷

The power supply for the bus terminator is provided by

the PFA. The bus terminator can be connected in the

PROFIBUS plug. If the switch is set toON, outputsA’

andB’ are switched off.

▷ To ensure optimum cable clamping, insert one of the

fillers supplied into the housing depending on the

thickness of the cables.

Scope of delivery: Profibus plug with shielding capacitor,

fillers for cable clamping,

Order No.: 74960621.

Certification

Declaration of conformity

We, the manufacturer, hereby declare that the products

BGT and PFA comply with the essential requirements of

the following Directives and Standards.

Directives:

– 2006/95/EC,

– 2004/108/EC,

– designed for applications pursuant to

Directive 98/37/EC.

Standards:

– EN 50170-2,

– EN 60730.

The production is subject to a Quality Management System

pursuant to DIN EN ISO 9001.

Elster GmbH

ON OFF

5

5

15

Data cable:

fold back the

woven shield.

A and B =

incoming

cables, A’ and

B’ = outgoing

1stand last

stations = ON,

other stations

= OFF

cables

Contact

Contact

If you have any technical questions, please contact your

local branch office/agent. The addresses are available on

the Internet or from ElsterGmbH.

We reserve the right to make technical modifications in

the interests of progress.

Scan of the Declaration of conformity (D, GB) – see

www.docuthek.com

Eurasian Customs Union

The product BGT meets the technical specifications of the

Eurasian Customs Union.

Elster GmbH

Strotheweg 1, D-49504 Lotte (Büren)

Tel. +49 541 1214-0

Fax +49 541 1214-370

hts.lotte@honeywell.com, www.kromschroeder.com

GB-12

Loading...

Loading...