Krom Schroder GIK 40TN02-5, GIK 50TN02-5, GIK 15TN02-5B, GIK 25TN02-5B, GIK 40TN02-5B Technical Information

...Page 1

AIR/GAS RATIO CONTROLS

GIK, GIK..B

Technical Information

T-Product 2004 November

For maintaining constant gas/air ratios

Cross-connected operation with modulating or

high-low control of nozzle mix burners

Zero regulator operation for premix burners

Precise pressure regulation over wide turndown

ranges

Low maintenance

Valve seat design for consistent low fire repeatability

Balanced double diaphragm design allows regula-

tor to operate over a wide range of inlet pressures

while minimally affecting outlet pressure

CE certified models available

Page 2

2

T-Product · GIK, GIK..B · 2004 November

▼ = To be continued

Table of Contents

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . 2

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

Nozzle Mix Burner . . . . . . . . . . . . . . . . . . . . . . . . . .

4

Premix Burners . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

Dimensions and Weights. . . . . . . . . . . . . . . . . . .

6

Sizing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

Bypass Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

How to install the air control line. . . . . . . . . . . . . .

10

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

To adjust the low fire position at GIK. . . . . . . . . . . .

11

To adjust the low fire position at GIK..B (with internal

Bypass) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

Special Features Conversion Kit for zero

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14

Order Information . . . . . . . . . . . . . . . . . . . . . . .

15

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . .

16

Flow at low fire position too high? . . . . . . . . . . . .

16

Air control pressure too high? . . . . . . . . . . . . . . .

16

Gas/Air ratio is not 1:1 at high fire . . . . . . . . . . . . .

17

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . .

18

Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19

Spare parts GIK ½" to 2" . . . . . . . . . . . . . . . . . . .

19

Spare parts GIK 2½" to 4" . . . . . . . . . . . . . . . . . .

20

Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21

Page 3

3

T-Product · GIK, GIK..B · 2004 November

M

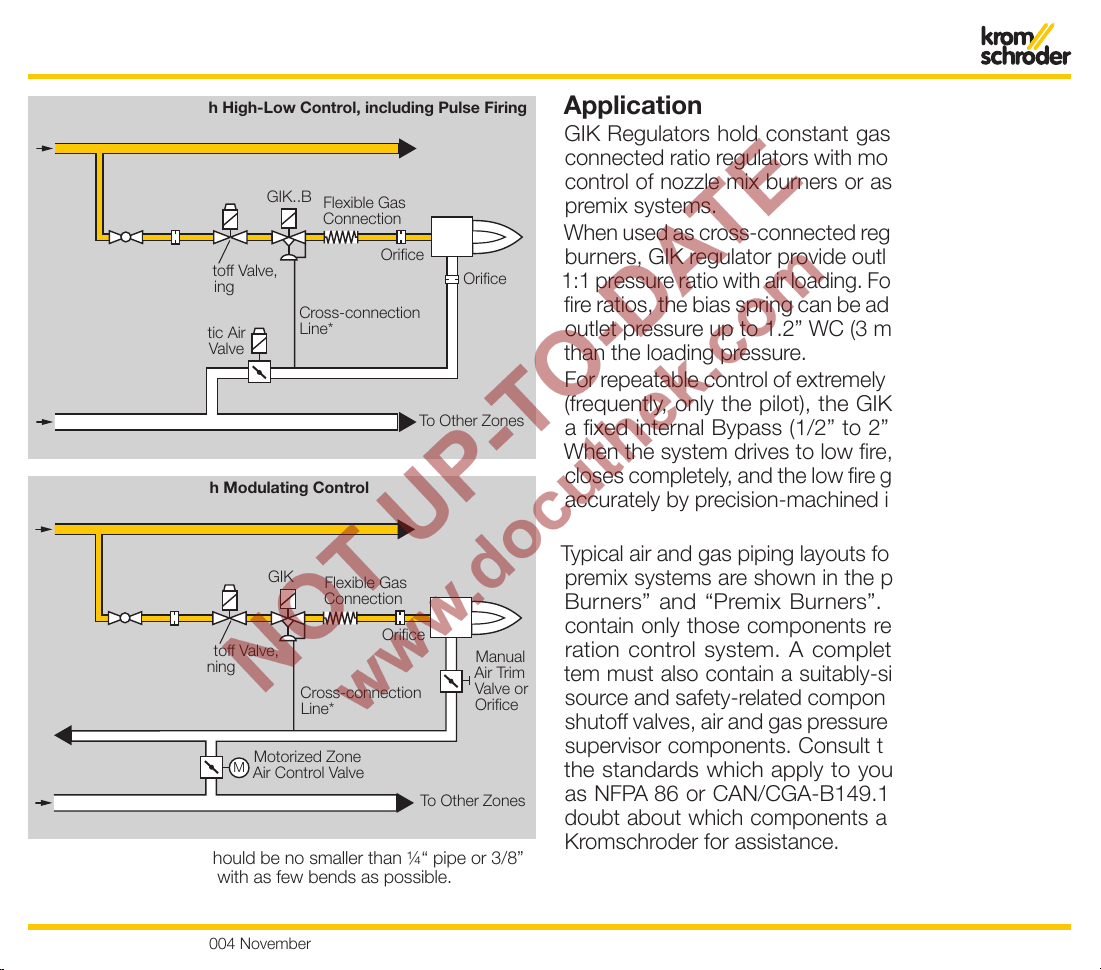

* Cross connection line should be no smaller than ¼“ pipe or 3/8”

OD tubing, as short and with as few bends as possible.

Application

GIK Regulators hold constant gas/air ratios as crossconnected ratio regulators with modulating or high-low

control of nozzle mix burners or as zero governors on

premix systems.

When used as cross-connected regulator for nozzle mix

burners, GIK regulator provide outlet gas pressure at a

1:1 pressure ratio with air loading. For leaner or richer low

fire ratios, the bias spring can be adjusted to provide an

outlet pressure up to 1.2” WC (3 mbar) higher or lower

than the loading pressure.

For repeatable control of extremely small low fire inputs

(frequently, only the pilot), the GIK..B Regulator, with

a fixed internal Bypass (1/2” to 2”), is recommended.

When the system drives to low fire, the regulator valve

closes completely, and the low fire gas flow is controlled

accurately by precision-machined internal orifice.

Typical air and gas piping layouts for nozzle-mixing and

premix systems are shown in the pictures “Nozzle Mix

Burners” and “Premix Burners”. These schematics

contain only those components related to the gas-air

ration control system. A complete combustion system must also contain a suitably-sized combustion air

source and safety-related components, such as safety

shutoff valves, air and gas pressure switches and flame

supervisor components. Consult the latest versions of

the standards which apply to your installation, such

as NFPA 86 or CAN/CGA-B149.1, for guidance. If in

doubt about which components are required, contact

Kromschroder for assistance.

Nozzle Mix Burners with High-Low Control, including Pulse Firing

Manual

Shutoff Valve

Orifice

GIK..B

Flexible Gas

Connection

Orifice

Orifice

Safety Shutoff Valve,

Slow Opening

Automatic Air

Control Valve

Cross-connection

Line*

To Other Zones

GAS

AIR

Nozzle Mix Burners with Modulating Control

Manual

Shutoff Valve

Orifice

GIK

Flexible Gas

Connection

Orifice

Manual

Air Trim

Valve or

Orifice

Safety Shutoff Valve,

Slow Opening

Motorized Zone

Air Control Valve

Cross-connection

Line*

To Other Zones

GAS

AIR

To Other Zones

Page 4

4

T-Product · GIK, GIK..B · 2004 November

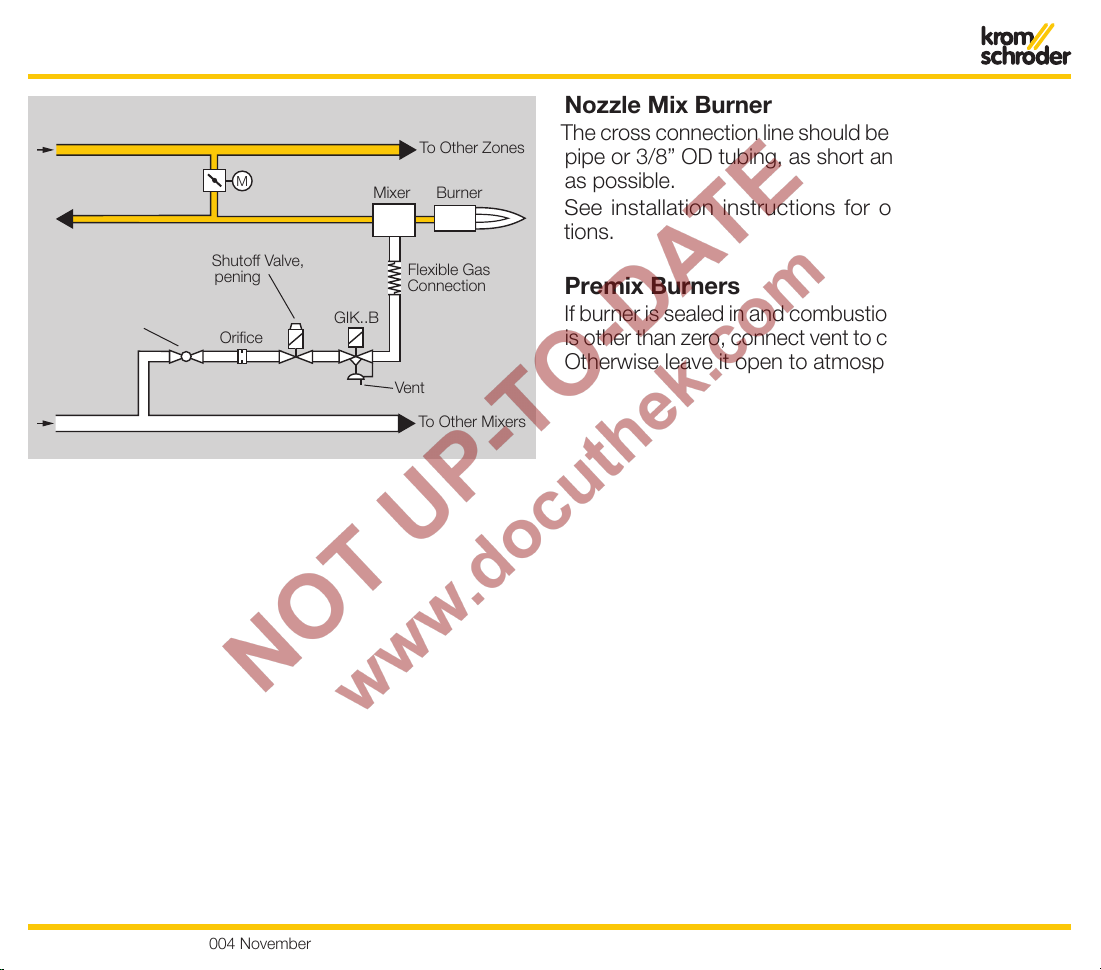

Application

M

Premix Burners

Manual

Shutoff Valve

Mixer

GIK..B

Flexible Gas

Connection

Orifice

Safety Shutoff Valve,

Slow Opening

Motorized Zone

Air Control Valve

Burner

To Other Mixers

GAS

AIR

To Other Zones

Nozzle Mix Burner

The cross connection line should be no smaller than 1/4”

pipe or 3/8” OD tubing, as short and with a few bends

as possible.

See installation instructions for other recommendations.

Premix Burners

If burner is sealed in and combustion chamber pressure

is other than zero, connect vent to combustion chamber.

Otherwise leave it open to atmosphere.

Vent

Page 5

5

T-Product · GIK, GIK..B · 2004 November

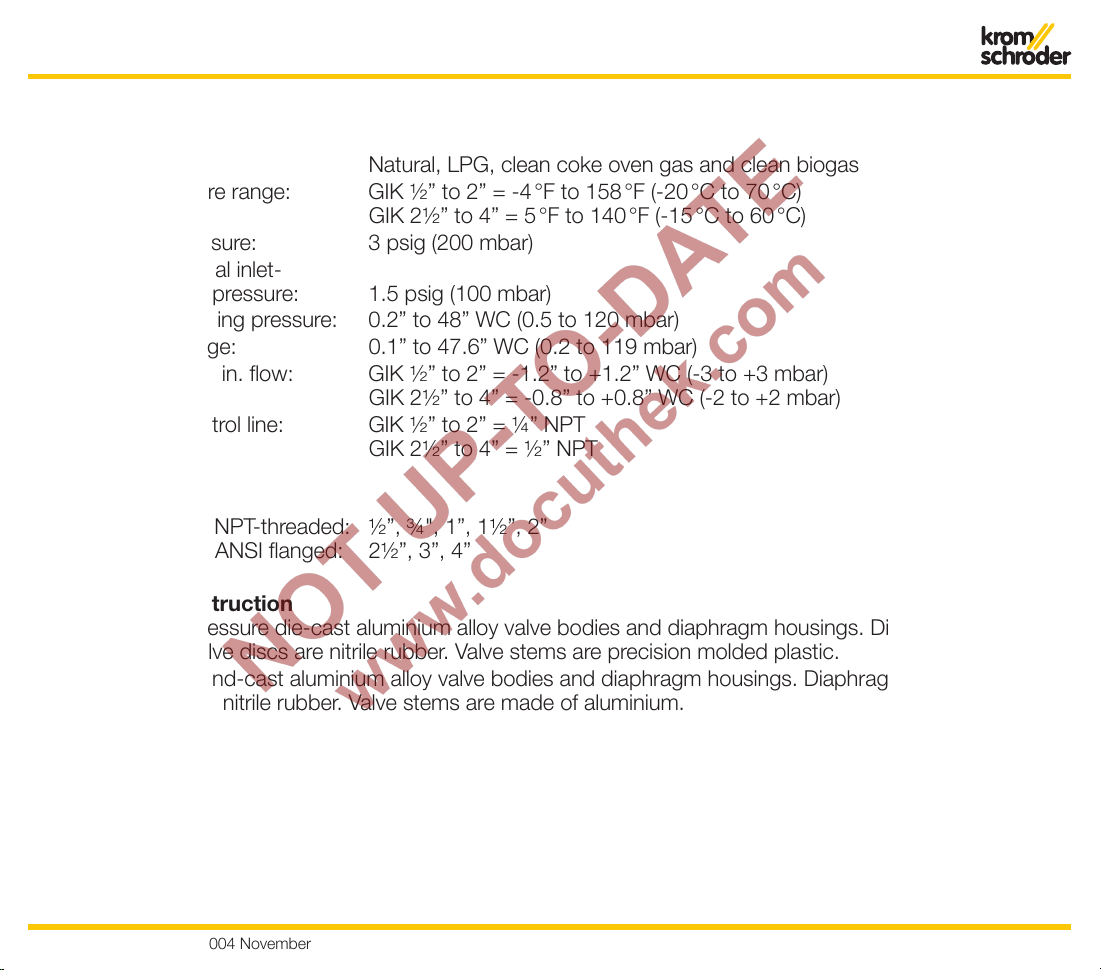

Specifications

Operating Limits

Type of gas: Natural, LPG, clean coke oven gas and clean biogas

Ambient temperature range: GIK ½” to 2” = -4 °F to 158 °F (-20 °C to 70 °C)

GIK 2½” to 4” = 5 °F to 140 °F (-15 °C to 60 °C)

Maximum inlet pressure: 3 psig (200 mbar)

Maximum operational inlet-

to-outlet differential pressure: 1.5 psig (100 mbar)

Combustion air loading pressure: 0.2” to 48” WC (0.5 to 120 mbar)

Outlet pressure range: 0.1” to 47.6” WC (0.2 to 119 mbar)

Adjusting range at min. flow: GIK ½” to 2” = -1.2” to +1.2” WC (-3 to +3 mbar)

GIK 2½” to 4” = -0.8” to +0.8” WC (-2 to +2 mbar)

Connection for Control line: GIK ½” to 2” = ¼” NPT

GIK 2½” to 4” = ½” NPT

Mechanical Data

Available pipe sizes NPT-threaded: ½”, ¾", 1”, 1½”, 2”

ANSI flanged: 2½”, 3”, 4”

Materials of Construction

GIK ½” to 2”: Pressure die-cast aluminium alloy valve bodies and diaphragm housings. Diaphragms and

valve discs are nitrile rubber. Valve stems are precision molded plastic.

GIK 2½” to 4”: Sand-cast aluminium alloy valve bodies and diaphragm housings. Diaphragms and valve discs

are nitrile rubber. Valve stems are made of aluminium.

Page 6

6

T-Product · GIK, GIK..B · 2004 November

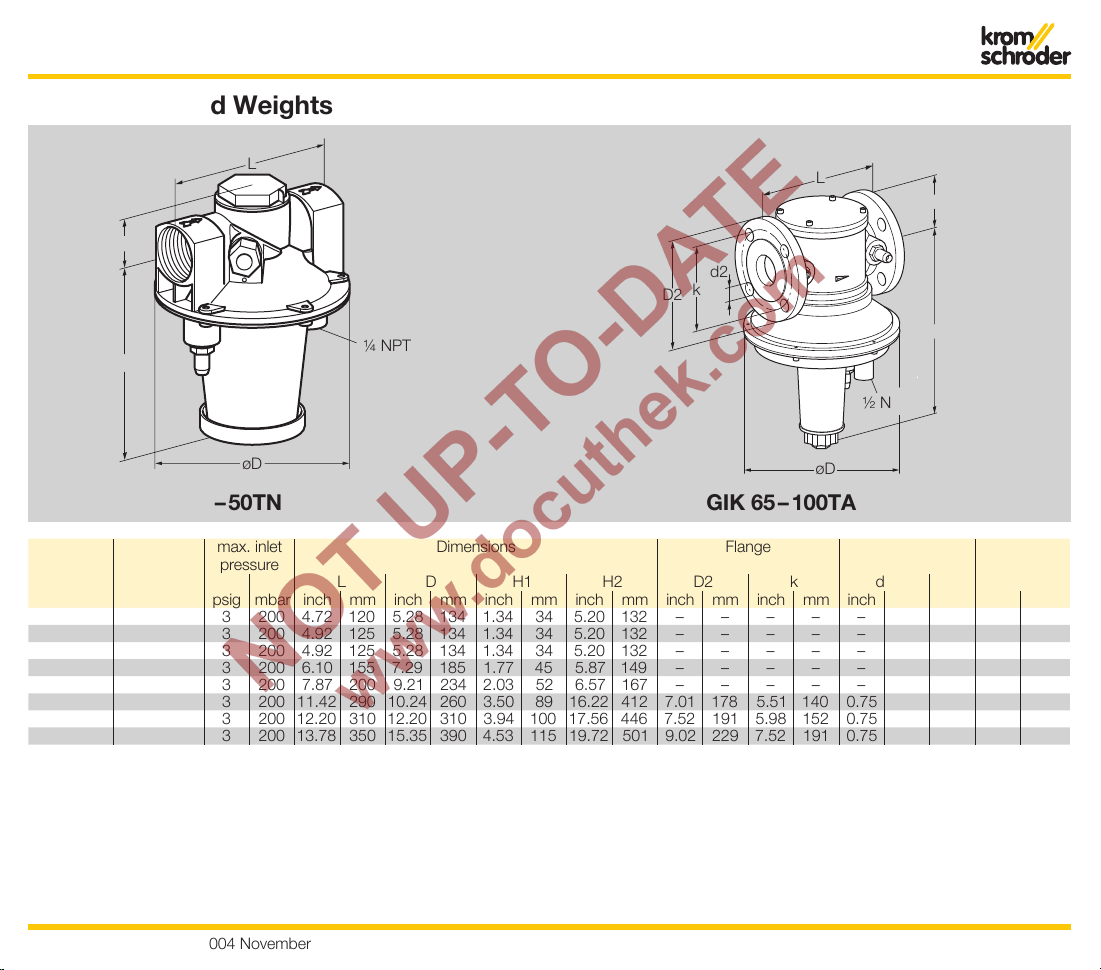

Dimensions and Weights

GIK 15 – 50TN GIK 65 – 100TA

H1

L

H2

øD

Rp

1

/4

¼ NPT

d2

k

D2

H2

øD

H1

L

Rp

1

/2

½ NPT

Type Connection max. inlet

pressure

Dimensions Flange Drilling Weight

L D H1 H2 D2 k d2 No.

psig mbar inch mm inch mm inch mm inch mm inch mm inch mm inch mm lbs kg

GIK 15TN NPT ½"

3 200 4.72 120 5.28 134 1.34 34 5.20 132 – – – – – – – 2.20 1.0

GIK 20TN NPT ¾"

3 200 4.92 125 5.28 134 1.34 34 5.20 132 – – – – – – – 2.20 1.1

GIK 25TN NPT 1"

3 200 4.92 125 5.28 134 1.34 34 5.20 132 – – – – – – – 2.20 1.1

GIK 40TN NPT 1½"

3 200 6.10 155 7.29 185 1.77 45 5.87 149 – – – – – – – 4.19 1.8

GIK 50TN NPT 2"

3 200 7.87 200 9.21 234 2.03 52 6.57 167 – – – – – – – 6.82 2.8

GIK 65TA

ANSI 2½"

3 200 11.42 290 10.24 260 3.50 89 16.22 412 7.01 178 5.51 140 0.75 19 4

26.46

12.0

GIK 80TA ANSI 3"

3 200 12.20 310 12.20 310 3.94 100 17.56 446 7.52 191 5.98 152 0.75 19 4

35.50

16.1

GIK 100TA ANSI 4"

3 200 13.78 350 15.35 390 4.53 115 19.72 501 9.02 229 7.52 191 0.75 19 8

57.33

26.0

Page 7

7

T-Product · GIK, GIK..B · 2004 November

Sizing

Selection

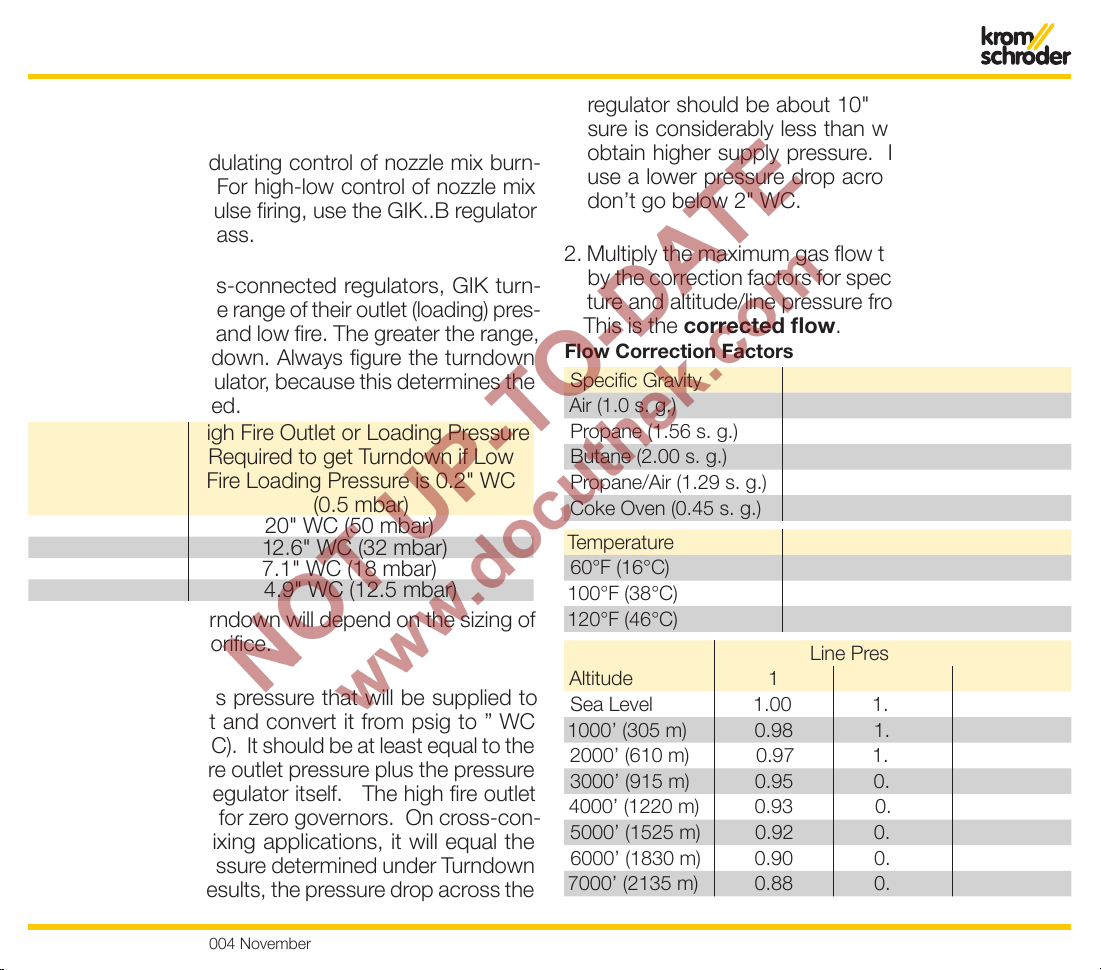

For premix and modulating control of nozzle mix burn-

ers, select the GIK. For high-low control of nozzle mix

burners, including pulse firing, use the GIK..B regulator

with the internal bypass.

When used as cross-connected regulators, GIK turn-

down depends on the range of their outlet (loading) pres-

sures between high and low fire. The greater the range,

the greater the turndown. Always figure the turndown

before sizing the regulator, because this determines the

inlet pressure required.

Flow Turndown

Ratio

High Fire Outlet or Loading Pressure

Required to get Turndown if Low

Fire Loading Pressure is 0.2" WC

(0.5 mbar)

10 to 1 20" WC (50 mbar)

8 to 1 12.6" WC (32 mbar)

6 to 1 7.1" WC (18 mbar)

5 to 1 4.9" WC (12.5 mbar)

GIK..B Regulator turndown will depend on the sizing of

the internal bypass orifice.

1. Determine the gas pressure that will be supplied to

the regulator inlet and convert it from psig to ” WC

(psig x 27.7 = " WC). It should be at least equal to the

regulator’s high fire outlet pressure plus the pressure

drop across the regulator itself. The high fire outlet

pressure will be 0 for zero governors. On cross-con

-

nected nozzle-mixing applications, it will equal the

high fire outlet pressure determined under Turndown

above. For best results, the pressure drop across the

regulator should be about 10" WC. If the inlet pressure is considerably less than what’s needed, try to

obtain higher supply pressure. If this isn’t possible,

use a lower pressure drop across the regulator, but

don’t go below 2" WC.

2. Multiply the maximum gas flow through the regulator

by the correction factors for specific gravity, tempera

-

ture and altitude/line pressure from the tables below.

This is the corrected flow

.

Flow Correction Factors

Specific Gravity Factor

Air (1.0 s. g.) 1.27

Propane (1.56 s. g.) 1.61

Butane (2.00 s. g.) 1.83

Propane/Air (1.29 s. g.) 1.47

Coke Oven (0.45 s. g.) 0.87

Temperature Factor

60°F (16°C) 1.0

100°F (38°C) 0.96

120°F (46°C) 0.95

Line Pressure [psig]

Altitude

1 2 3

Sea Level 1.00 1.03 1.06

1000’ (305 m) 0.98 1.01 1.05

2000’ (610 m) 0.97 1.00 1.03

3000’ (915 m) 0.95 0.98 1.01

4000’ (1220 m) 0.93 0.97 1.00

5000’ (1525 m) 0.92 0.95 0.98

6000’ (1830 m) 0.90 0.94 0.97

7000’ (2135 m) 0.88 0.92 0.95

Page 8

8

T-Product · GIK, GIK..B · 2004 November

3. On the sizing chart, find where the corrected flow intersects the pressure drop from Step 1. Move down

from this point. The first regulator curve you come to

is the size to use.

Bypass Sizing

1. Correct the low fire bypass flow you want with the

same factors used to size the regulator.

2. Find this flow at the bottom of the bypass orifice sizing

chart and read up to the pressure drop that will be

available across the regulator. (At low fire, this nearly

equals the inlet pressure to the regulator, so you can

simply use the inlet pressure.)

3. Move down from this point. The first orifice curve you

come to is the size to use.

Sizing

Flow rates natural gas [m3/h]

mbar

inch WC

Pressure drop ∆p

207 9 30 40 50 60 80 100

8 10

0.2 0.3 0.4 0.6 0.8 1 2

200 700300 400 500

3 4 5 6 8 10 20

SCFH

20

30

40

4

5

6

8

10

10

20

30

40

50

60

80

100

ø

GIK: bypass plug – standard no hole

GIK..B: bypass plug – standard * GIK 15–25..B: 0.06 inch (1,5 mm)

** GIK 40–50..B: 0.197 inch (5 mm)

Bypass screw GIK..B

inch (mm) Ø

0.06 (1.5)*

0.079 (2

)

0.118 (3

)

0.157 (4

)

0.197 (5)*

*

0.236 (6

)

0.267 (7

)

0.315 (8

)

0.354 (9)

GIK 15–25..B

GIK 40–50..B

inch WC

mbar

Pressure drop ∆p

2

3

4

5

6

8

1000 2000 3000 6000 10000 20000

Flow rates natural gas [m3/h]

SCFH

Flow rate

300 500

10 20 30 40 60 80100 200 300 500 1000

10

0.8

1

20

30

40

50

2

3

4

5

6

8

10

20

30

40

50

60

80

100

GIK 15

GIK 20

GIK 25

GIK 40

GIK 50

80000

40000

2000

G

IK

65

G

IK

80

G

IK 10

0

Page 9

9

T-Product · GIK, GIK..B · 2004 November

Installation

WARNING: Improper installation, adjustment, modifi-

cation, operation or maintenance could lead to injury or

damage. All adjustments must be made by a qualified

technician.

Wiring must comply with local codes and National

Electrical Codes. To prevent the posibility of property

damage, turn off electrical power, depressurize installation, vent fluid to safe area before servicing.

• Remove thread protectors

• Observe direction of flow: arrow on housing

• Spring dome must point vertically downwards

• The housing must have clearance of ¾" from any

vertical surface. Allow access to spring adjustment

at top of housing

• Use suitable sealant, apply sparingly, only to outer

threads.

• Check for gas leaks. Apply pressure to regulator (do

not exceed name plate rating) – measured at test

point.

• Soap pipe joints and check for leaks.

Page 10

10

T-Product · GIK, GIK..B · 2004 November

5x

nominal Diameter

Air

5x

nominal Diameter

Installation

How to install the air control line

GIK ½” to 4”

The connection of the air control line must be at a

distance of 5 × nominal Diameter from other air control

elements.

Connection of the air control line

GIK ½” to 2”: NPT ¼”

GIK 2 ½” to 4”: NPT ½”

Page 11

11

T-Product · GIK, GIK..B · 2004 November

0

0

−

0

+

p

a

p

L

0

p

L

3 mm

−

+

p

a

6 mm

pa = pL± 2 mbar

p

a

=

pL± 3 mbar

Operation

To adjust the low fire position

at GIK

• Set the high fire rate using restricting orifices or adjustment

element on the burner

• At low fire position: Control pressure at least 0.2 “WC (0,5 mbar).

• Factory setting without Bypass:

outlet pressure = control line

pressure

Factory setting with Bypass:

outlet pressure = control line

pressure – 0.8“ WC (2 mbar)

➔

to keep the valve closed for constant low fire

• GIK ½" to 2" the outlet pressure

is adjustable between ± 1.2" WC

(3 mbar)

• GIK 2½" to 4" the outlet pressure

is adjustable between ± 0.8" WC

(2 mbar)

Page 12

12

T-Product · GIK, GIK..B · 2004 November

1 2 3

4 5

max. 300 mbar

GIK 15–25..B,

GIKH 25..B

GIK 40–50..B

The bypass screws

and the housing

have had markings

since November

2000. Only marked

screws may be used

with marked

housings.

Flow rates natural gas [m3/h]

mbar

inch WC

Pressure drop ∆p

207 9 30 40 50 60 80 100

8 10

0.2 0.3 0.4 0.6 0.8 1 2

200 700300 400 500

3 4 5 6 8 10 20

SCFH

20

30

40

4

5

6

8

10

10

20

30

40

50

60

80

100

ø

GIK: bypass plug – standard no hole

GIK..B: bypass plug – standard * GIK 15–25..B: 0.06 inch (1,5 mm)

** GIK 40–50..B: 0.197 inch (5 mm)

Bypass screw GIK..B

inch (mm) Ø

0.06 (1.5)*

0.079 (2

)

0.118 (3

)

0.157 (4

)

0.197 (5)*

*

0.236 (6

)

0.267 (7

)

0.315 (8

)

0.354 (9)

GIK 15–25..B

GIK 40–50..B

To adjust the low fire position at GIK..B (with

internal Bypass)

• The air control line (air control pressure) must be

less than 0.8" WC (2 mbar) at low fire position

• The bypass screw and the housings have been

marked since Nov. 2000. Only marked screws may

be used with marked housings

• The bypass orifices determines the low fire rate.

Standard:

GIK 15 to 25 (½” to 1”) = 0.059 “ (1.5 mm)

GIK 40 to 50 (1½” to 2”) = 0.20 “ (5 mm)

GIK 65 to 100 (2½” to 4”) = use external Bypass

• Enlarge the orifice if necessary (max.)

GIK 15 to 25 (½” to 1”) = 0.16 “ (4 mm)

GIK 40 to 50 (1½” to 2”) = 0.35 “ (9 mm)

Operation

Order-No. Bypass Screws

For GIK 15 to 25 (½" to 1")

Bypass screw ∅ 0.059" (1.5 mm)

03089217

Bypass screw without orifice

03089215

Bypass variable 74919806

For GIK 40 to 50 (1½" to 2")

Bypass screw ∅ 0.2" (5 mm)

03089218

Bypass screw without orifice

03089216

Bypass variable

74919821

Page 13

13

T-Product · GIK, GIK..B · 2004 November

GIK..N

GIK..A

1

1

Order No.:

03351039

Order No.:

74910853

Special Features Conversion Kit for zero Pressure

Page 14

14

T-Product · GIK, GIK..B · 2004 November

Function

The GIK has 4 basic elements that allow to operate.

These are:

1 Valve seat

A valve seat or orifice through which the gas supply will

flow. This has a disc or plug that can close against the

seat to limit the flow of gas. By moving the disc, the outlet

flow and pressure can be altered from fully open to fully

closed. The position of the disc will determine the flow

and pressure the outlet of the regulator.

2 Internal or external impulse

Usually a tube located on the regulator outlet senses the

outlet pressure. The diaphragm is linked to the valve stem.

A change in the sensed pressure above the diaphragm

causing the restricting element to alter it’s position.

3 Air control line

The air control pressure acts against the force of the

measuring element. When state of equilibrium is achieved

between the measuring element and the loading element the resulting position of the restricting element

will determine the outlet pressure. The spring is for fine

adjusting at low fire.

4 Compensating diaphragm

A secondary diaphragm is used in compensated regu

lators. This diaphragm has the same area as the valve,

so it compensates the effect of varying inlet pressures

on the valve.

Compensating

Diaphragm

Valve seat

Internal or ex

-

ternal Impuls

Air Control Line

Spring

Working

Diaphragm

Page 15

15

T-Product · GIK, GIK..B · 2004 November

GIK 15 – 50TN

GIK 65– 100TA

Order Information

GIK air/gas ratio regulator

15 – 100 (½" to 4") nominal diameter

T T-product

A ANSI-flanged

N NPT-internal thread

02 max. inlet pressure 3 psig (200 mbar)

-3 screw plug at the inlet and outlet

-5 pressure test point at the outlet

B

with drilled bypass screw

Designation Order no.

For continous control, with NPT internal thread

GIK 15TN02-5 03155176

GIK 20TN02-5 03155128

GIK 25TN02-5 03155140

GIK 40TN02-5 03155152

GIK 50TN02-5 03155164

For High/Low/Off control, with NPT internal thread

GIK 15TN02-5B 03155177

GIK 20TN02-5B 03155129

GIK 25TN02-5B 03155141

GIK 40TN02-5B 03155153

GIK 50TN02-5B 03155165

For continous control, with ANSI flange

GIK 65TA02-3 85092320

GIK 80TA02-3 85093320

GIK 100TA02-3 85094320

Page 16

16

T-Product · GIK, GIK..B · 2004 November

1

2

Trouble Shooting

Trouble Shooting is a term used to indicate a systematic

approach to locate regulator malfunction. As with installation and maintenance, successful regulator troubleshooting depends on careful analysis and planning before

taking action. Regulators are relatively simple devices

with few faults. The most common faults are:

Flow at low fire position too high?

– It sometimes happens that the flow rate at low fire

position is to high. This is due to dirt at the valve

seat or disc. These parts should be cleaned with

suitable solvent.

– Spring adjustment set too high.

Air control pressure too high?

– The maximum possible gas outlet pressure is lower

than the max. air control pressure (air impulse line).

Use a reducing fitting

(Order no. GIK 15 to 50 = 03351040)

(Order no. GIK 65 to 100 = 74910779)

Regulator is not responding?

– The working or compensating diaphragm could

be broken. Should these happen in short intervals

check the diaphragms. Always use special air dia

-

phragms for air media.

Page 17

17

T-Product · GIK, GIK..B · 2004 November

Real characteristic Curve

Ideal characteristic Curve

1:1

Gas outlet

Pressure

Air Control Pressure

Gas/Air ratio is not 1:1 at high fire

– For example:

at low fire the air control pressure is

2" WC (5 mbar),

the gas outlet pressure is also 2" WC (5 mbar)

at high fire the air pressure is 40" WC (100 mbar),

the gas outlet pressure is lower depending on the

flow rate.

– For the gas/air ratio for high fire use gas limiting orifice

valve for fine adjustments

Trouble Shooting

Page 18

18

T-Product · GIK, GIK..B · 2004 November

Maintenance

All regulators which control the systems pressure are

subject to periodic servicing by authorized personnel.

By carrying out a regular maintenance schedule, you can

prevent problems from occuring. The regulator type and

its service conditions will help you determine how often

to conduct inspections. The more severe the working

conditions, the more frequently you should examine the

regulator.

Generally, small, modern regulators can operate for

considerable periods without attention, minimizing the

need for periodic maintenance.

When a regulator is serviced, the following general pro

-

cedure should be followed.

1 Check that a shut off valve is located in the area of

the regulator.

2 Try to ensure that there is a clear working area, and

that you have somewhere to put the regulator com

-

ponents, once removed, so they will not be lost or

damaged.

3 Always use the correct tools, in the proper sizes, to

dismantle the regulator. Rough treatment can dam

-

age an otherwise useable component.

4 If available, follow the maintenance instructions issued

by the manufacturer of the regulator.

5 Make careful note of the position of each component

before removal to aid reassembly.

6 Unless the maintenance instructions say otherwise,

take off the top cover and remove the loading

spring.

7 Dismantle the regulator, removing the diaphragm(s)

and valve.

8 Clean all parts of the body and casings.

9 Check the diaphragms and replace if necessary.

10 Clean the regulator valve. If it has a rubber seat, check

and replace if necessary.

11 Examine the orifice or valve seating. Check for burrs

and replace if damaged or worn. Avoid the use of

abrasives on valve or seats.

12 Reassemble the parts in reverse order.

13 When reassembling a ring of screws or bolts, tighten

gradually and in opposing pairs.

14 Check the regulator for leakage.

15 Reset outlet pressure to the regulator.

16 Update maintenance records for the unit.

Page 19

19

T-Product · GIK, GIK..B · 2004 November

1

1

1

1

1

1

1

Spare parts

Spare parts GIK ½" to 2"

Spare part kit (1) contains the diaphragms and orings.

Type

For Gas For Air

GIK 15

03089204 03089201

GIK 20

03089204 03089201

GIK 25

03089204 03089201

GIK 40

03089205 03089202

GIK 50

03089206 03089203

Page 20

20

T-Product · GIK, GIK..B · 2004 November

1

3

2

4

5

6

7

8

Spare parts GIK 2½" to 4"

Pos. Description GIK 65

(2½")

GIK 80

(3")

GIK 100

(4")

1 O-ring 03109276 03109277 03109277

2 O-ring 03110203 03109170 03109232

3 Valve train 74960325 74960024 74960316

4 Compensating diaphragm 35454179 34328850 35442690

5 Working diaphragm 34328846 34328856 34212875

6 Safety diaphragm 74324141 74324291 74324201

7 O-ring 03109170 03109170 03109170

8 O-ring 03109159 03109159 03109159

Spare parts

Page 21

21

T-Product · GIK, GIK..B · 2004 November

Warning

Situations dangerous to personnel and property can result from the misapplication and incorrect operation of

combustion equipment.

Kromschroder advises compliance with the National Fire Protection Association standards that apply for related

equipment and Insurance Underwriters recommendation, and care of operation.

We reserve the right to make technical changes designed to improve our products without prior notice.

For current product information, visit our website at www.kromschroder.co

m.

Contact

G. Kromschröder AG

Strotheweg 1

D-49504 Lotte (Büren)

Tel.:+49 (0)5 41 / 12 14 - 0

Fax:+49 (0)5 41 / 12 14 - 370

KROMSCHRODER INC.

1595-H Georgetown Rd.

Hudson, OH 44236

Ph. 330-342-0595

Fax 330-342-0596

info@kromschroeder.com info@kromschroder.com

www.kromschroeder.co

m www.kromschroder.com

Loading...

Loading...