Page 1

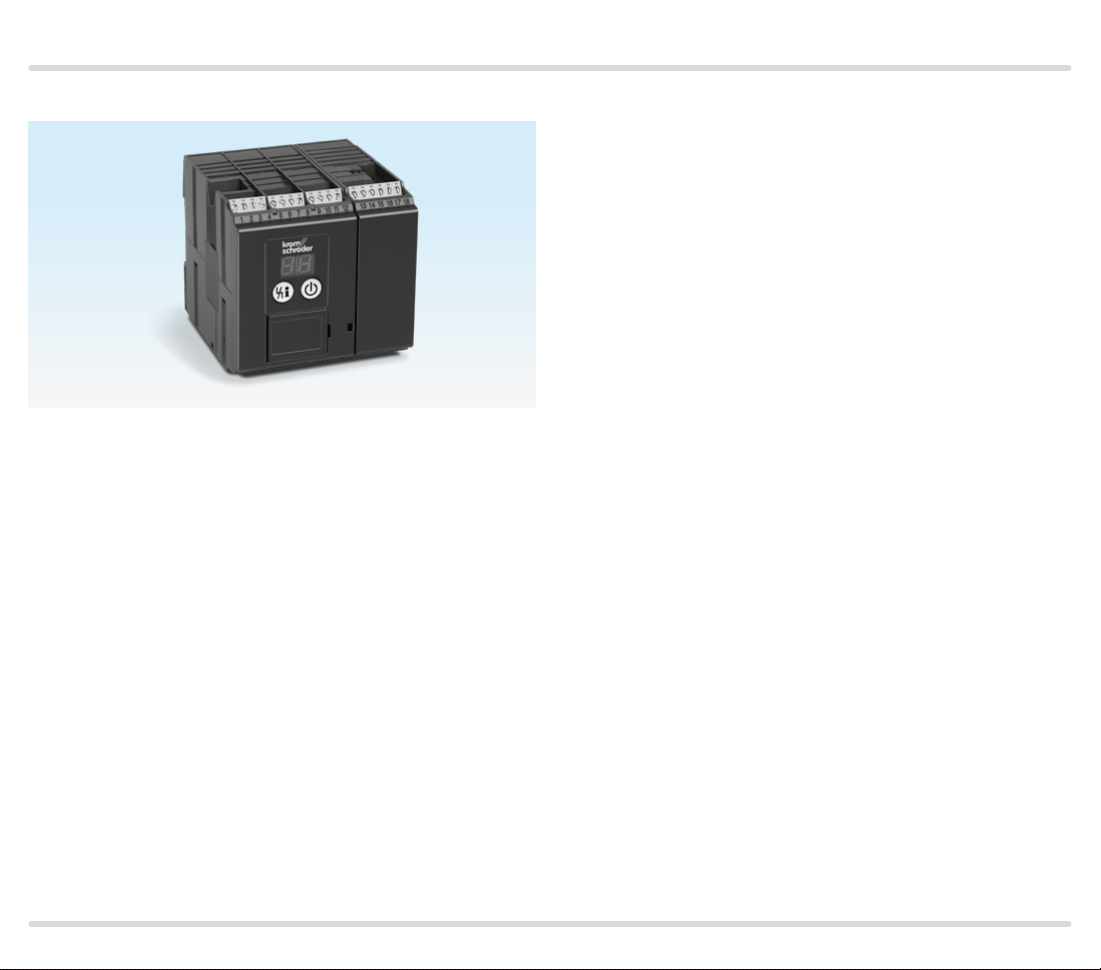

Protective system controls FCU 500, FCU 505

Technical Information · GB

6 Edition 02. 17

• For monitoring and controlling central safety functions in multiple

burner systems on industrial furnaces

• Valve proving system for a valve system leak tightness check

(optional)

• Safety temperature monitor (STM) or safety temperature limiter

(STL) (optional)

• Long service life due to replaceable power module for fail-safe

outputs

• Visualization and adaptation to the specific application via the PC

programming and diagnostic software BCSoft to simplify logistics

management

Page 2

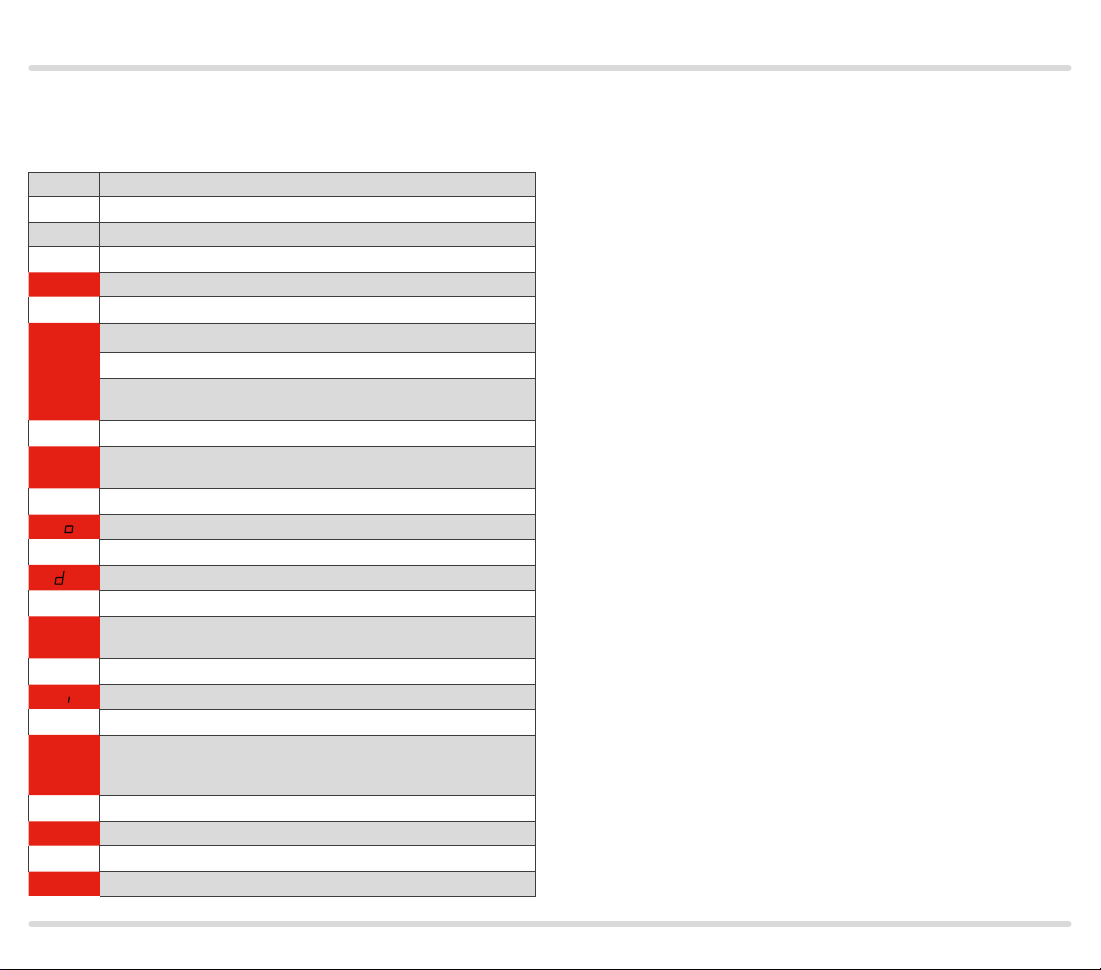

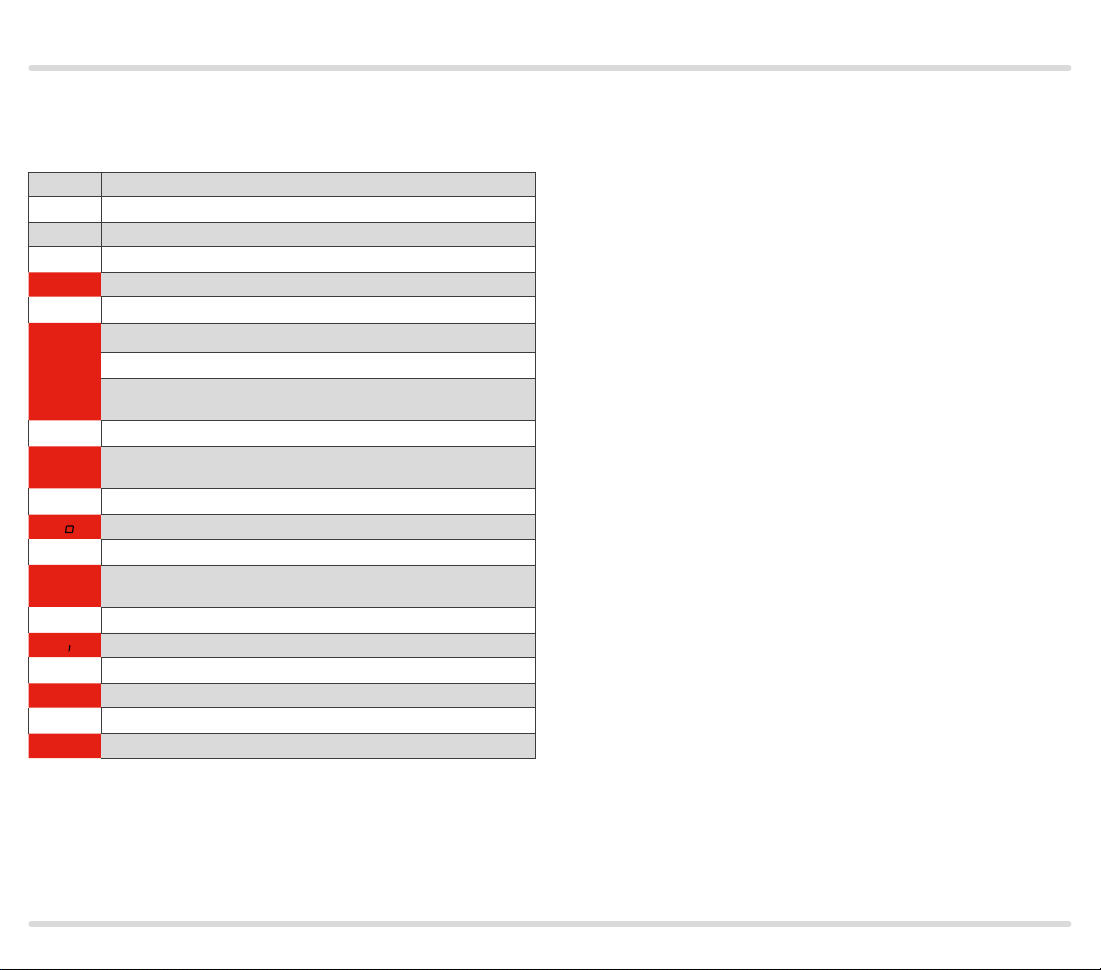

Contents

Protective system controls FCU 500, FCU 505 ......1

Contents ............................................2

1 Application ........................................5

1.1 Application examples ..............................8

1.1.1 ON/OFF rotary impulse control .......................8

1.1.2 Modulating burner control ..........................10

1.1.3 Safety limits (LDS) for modulating burner control ...11

1.1.4 Flame control using the temperature ...............12

1.1.5 Furnace and zone control ...........................13

2 Certification ......................................14

3 Function ..........................................15

3.1 Connection diagram ..............................15

3.1.1 FCU 500 .............................................15

3.1.2 FCU 505 .............................................16

3.1.3 Assignment of connection terminals ................17

3.2 Program sequence................................19

3.2.1 FCU 50 0..F0.........................................19

3.2.2 FCU 500..F1, FCU 50 0..F2..........................20

3.2.3 FCU 505..F1, FCU 505..F2 ...........................21

3.3 Animation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4 Temperature monitoring......................... 23

4.1 High temperature operation with safety

temperature monitor function (STM function) .......24

4.1.1 With integrated STM ................................ 24

4.1.2 With external STM ...................................25

4.1.3 With integrated and external STM .................. 25

4.2 Maximum temperature monitoring with

(flue gas) safety temperature limiter (STL /FSTL

function) ..............................................26

4.2.1 With integrated STL/FSTL ..........................26

4.2.2 With external STL/FSTL ............................26

5 Air control ........................................27

5.1 Controlled air flow ................................28

5.2 Capacity control ..................................29

6 Furnace zone control .............................31

7 Valve proving system ............................ 33

7.1 Tightness control..................................34

7.1.1 Test instant...........................................35

7.1.2 One test volume bet ween 2 gas solenoid valves ....36

7.1.3 One test volume for system tightness...............39

7.1.4 Two test volumes for system tightness .............. 42

7.1.5 Large test volumes with reduced testing time ......46

7.2 Test period tP ..................................... 48

7.2.1 For one test volume Vp1 between 2 gas solenoid

valves ......................................................48

7.2.2 For one test volume V

7.2.3 For two test volumes for system tightness (V

V

) ........................................................49

p2

7.2.4 Extended valve opening time 1 t

7.2.5 Measurement time t

for system tightness .......48

p1

..................50

...............................53

M

L1

p1

+

7.3 Proof of closure function ..........................57

8 BCSoft........................................... 58

9 Fieldbus communication via Ethernet . . . . . . . . . . . 59

9.1 FCU and bus module BCM ...................... 60

9.2 Configuration, planning ..........................61

9.2.1 Profinet/Device master data file (GSD)..............61

9.2.2 Modbus TCP..........................................61

9.2.3 Modules/Registers for process data................62

9.2.4 Device parameters and statistics . . . . . . . . . . . . . . . . . . . 68

10 Program step/status ........................... 69

11 Fault signalling ................................. 70

12 Parameters ......................................74

12.1 Scanning the parameters........................79

12.2 Safety limits .....................................79

12.2.1 Emergency stop....................................79

12.2.2 High gas pressure protection ......................80

12.2.3 Low gas pressure protection.......................80

12.2.4 Low air pressure protection.........................81

FCU 500, FCU 505 · Edition 02.17 2

= To be continued

▼

Page 3

12.2.5 Safet y time during operation tSB ...................81

12.3 High temperature operation.....................82

12.3.1 Temperature monitoring mode ....................82

12.3.2 Thermocouple......................................83

12.3.3 Temperature difference limit value ................83

12.3.4 STM limit value (high temperature operation).....84

12.3.5 STL /FSTL limit value (system protection).........84

12.3.6 Temperature hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

12.3.7 Pre-purge during high temperature operation ....86

12.4 Air control........................................87

12.4.1 Fan in the event of fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

12.4.2 Fan run-up time t

12.4.3 Fan ready for operation .............................87

12.4.4 Air monitoring during controlled air flow...........88

12.4.5 Pre-purge time t

12.4.6 Air flow monitoring during pre-purge ..............89

12.4.7 Post-purge time t

12.4.8 Air flow monitoring during post-purge.............90

12.4.9 Capacit y control.....................................91

12.4.10 Running time selection ..........................10 0

12.4.11 Running time ....................................100

12.4.12 Controller enable signal delay time t

12.4.13 Minimum enable time ...........................101

12.4.14 Burner operating signal..........................101

12.4.15 Controller enable time limit......................102

12.4.16 Capacity control (bus) ...........................103

................................87

GV

.................................88

PV

...............................89

PN

.........101

RF

12.5 Valve check ....................................108

12.5.1 Valve proving system..............................108

12.5.2 Relief valve (VPS) .................................108

12.5.3 Tightness control test volume ....................109

12.5.4 Pressure reduction V

12.5.5 Opening time relief valve V3 ......................110

12.5.6 Measurement time V

12.5.7 Measurement time V

12.5.8 Valve opening time 1 t

12.5.9 Valve opening time 2 t

...........................110

p2

...........................110

p1

and Vp2 ..................110

p1

..........................112

L1

..........................112

L2

12.6 Behaviour during start-up .....................113

12.6.1 Minimum pause time tMP .........................113

12.6.2 Switch-on delay time t

12.6.3 Filling time before start-up .......................113

..........................113

E

12.7 Manual mode .................................. 114

12.7.1 Operating time in Manual mode ..................114

12.8 Functions of terminals 51, 65, 66, 67 and 68 . 115

12.8.1 Function of terminal 51 ...........................115

12.8.2 Function of terminal 65 ...........................116

12.8.3 Function of terminal 66 ...........................116

12.8.4 Function of terminal 67 ...........................117

12.8.5 Function of terminal 68 ...........................117

12.9 Password ......................................118

12.10 Fieldbus communication ....................118

13 Selection ......................................119

13.1 Type code ......................................119

14 Project planning information ..................120

14.1 Installation.....................................120

14.2 Commissioning ................................120

14.3 Electrical connection .......................... 121

14.3.1 OCU ...............................................121

14.3.2 Safety current inputs..............................122

14.4 High temperature operation...................123

14.4.1 Safety temperature monitor (STM) ...............123

14.4.2 Safety temperature limiter (STL)..................124

14.4.3 Temperature sensors (double thermocouples) . . .124

14.4.4 Thermocouples....................................124

14.4.5 PFH

and thermocouple........................................126

value for STM/STL temperature module

D

14.5 Safety interlock output ........................ 127

14.5.1 Safety interlock output in the case of higher

power requirement .......................................127

14.5.2 BCU with power supply for valves and ignition

transformer via safety interlocks.........................128

14.6 Actuators ......................................129

14.6.1 IC 20...............................................129

14.7 Air control ......................................129

14.8 Parameter chip card ...........................130

14.9 System leak tightness check ..................130

15 Accessories.................................... 131

FCU 500, FCU 505 · Edition 02.17 3

= To be continued

▼

Page 4

15.1 BCSoft ..........................................131

15.1.1 Opto-adapter PCO 200 ...........................131

15.1.2 Bluetooth adapter PCO 300 ......................131

15.2 OCU.............................................131

15.3 Connection plug set ...........................132

15.4 Stickers for labelling ...........................132

15.5 “Changed parameters” stickers................132

16 OCU ...........................................133

16.1 Application.....................................133

16. 2 Function .......................................134

16.2.1 Manual mode......................................135

16.3 Electrical connection ..........................135

16.4 Installation.....................................136

16.5 Selection.......................................136

16.6 Technical data for OCU . . . . . . . . . . . . . . . . . . . . . . . . 136

17 BCM 500 ...................................... 137

17.1 Application ......................................137

17. 2 F unction ........................................137

17.3 Electrical connection ...........................137

17.4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

17. 5 S e l e c t ion .......................................138

17.6 Technical data..................................138

18 Technical data .................................139

18.1 Electrical data .................................139

18.2 Mechanical data...............................140

18.3 Environment ...................................140

18.4 FCU..H1........................................140

18.5 Dimensions ....................................140

18.6 Safety-specific characteristic values...........141

18.7 Converting units ...............................142

19 Maintenance ..................................143

20 Legend ........................................144

21 Glossary.......................................145

21.1 Safety shut-down.............................. 145

21.2 Fault lock-out..................................145

21.3 Warning signal.................................145

21.4 Timeout ........................................146

21.5 Lifting .........................................146

21.6 Diagnostic coverage DC.......................146

21.7 Operating mode ...............................146

21.8 Safe failure fraction SFF........................147

21.9 Probability of dangerous failure PFH

21.10 Mean time to dangerous failure MTTF

........147

D

.....147

d

Feedback .........................................148

Contact...........................................148

FCU 500, FCU 505 · Edition 02.17 4

= To be continued

▼

Page 5

Application

▼

1 Application

FCU with plug-in connection terminals

Protective system control FCU 500 is designed to mon-

itor and control central safety functions, e.g. gas

gas

max.

, air

, pre-purge, tightness test, high tempera-

min.

ture operation or start enable for burner control units, in

multiple burner systems on industrial furnaces. In a furnace and zone control system, the FCU 500 assumes

central functions. The FCU 505 is used to monitor local

safety functions and to control the zone capacity. If the

centrally checked safety requirements, e.g. pre-purge,

flow detector and pressure switch check, have been

met, the FCUs issue the start enable signal to the burner control units.

The FCU is optionally available with integrated safety

temperature monitor or safety temperature limiter,

integrated tightness control and with an interface for

min.

,

controlling the capacity of actuators or a frequency

converter interface.

The program status and device parameters can be read

directly from the unit. The FCU can be activated manually using the integrated Manual mode for setting and

diagnostic purposes.

Thanks to the optionally integrated valve proving sys-

tem, the valves can be checked for leaks by querying

an external gas pressure switch or it can be checked

whether the gas valve on the inlet side is closed.

Using the BCSoft program, the parameters, analysis

and diagnostic information can be read from the FCU

via the optionally available opto-adapter. All valid parameters are saved on an integrated parameter chip

card. The parameter chip card can be removed from the

old unit and inserted into a new FCU to transfer the parameters, for example when replacing the unit.

FCU 500, FCU 505 · Edition 02.17 5

Page 6

Application

The monitored outputs for the actuator and valves are

accommodated in a plug-in power module. This can

simply be replaced if necessary.

Once the plug-in power module has been removed, the param-

eter chip card and fuses are accessible.

The FCU can be installed on a DIN rail in the control

cabinet. Plug-in connection terminal strips on the FCU

make it easier to install and remove.

The external operator-control unit OCU is available as

an option for the protective system controls. The OCU

can be installed in the control cabinet door instead of

standard control units. The program status, statistics,

parameter values or fault messages can be read on

the OCU. For burner adjustment, the operating points

can be approached conveniently in Manual mode using

the operator-control unit.

Thanks to the operator-control unit OCU, display functions and

operation of the FCU can be relocated to the control cabinet

door.

The optional bus module BCM 500 makes it possible

to connect the FCU to a fieldbus interface in a Profinet

or Modbus TCP network. Networking via the fieldbus

enables multiple FCUs to be controlled and monitored

by an automation system (e.g. PLC). The bus module is

prepared for DIN rail installation. It is pushed on to the

FCU from the side.

The address for the fieldbus communication is set using three

code switches.

FCU 500, FCU 505 · Edition 02.17 6

Page 7

Application

Roller hearth kiln in the ceramics

industry

Shaft melting furnace Smelting and holding furnace

FCU 500, FCU 505 · Edition 02.17 7

Page 8

Application

PZL PZH PZ

DG DG DG

DG

min

49 15 131450

46

1

ϑ

2

3

FCU 500..F0

M

DG

max

µC

STM

DL

VAS

45

pu/2

P

>750°

47 4858

minDLPurge

PZL PDZ

DG DG

VAS

VAS

BCU 460..L

BCU 460..L

VCG

VR..L

VCG

VR..L

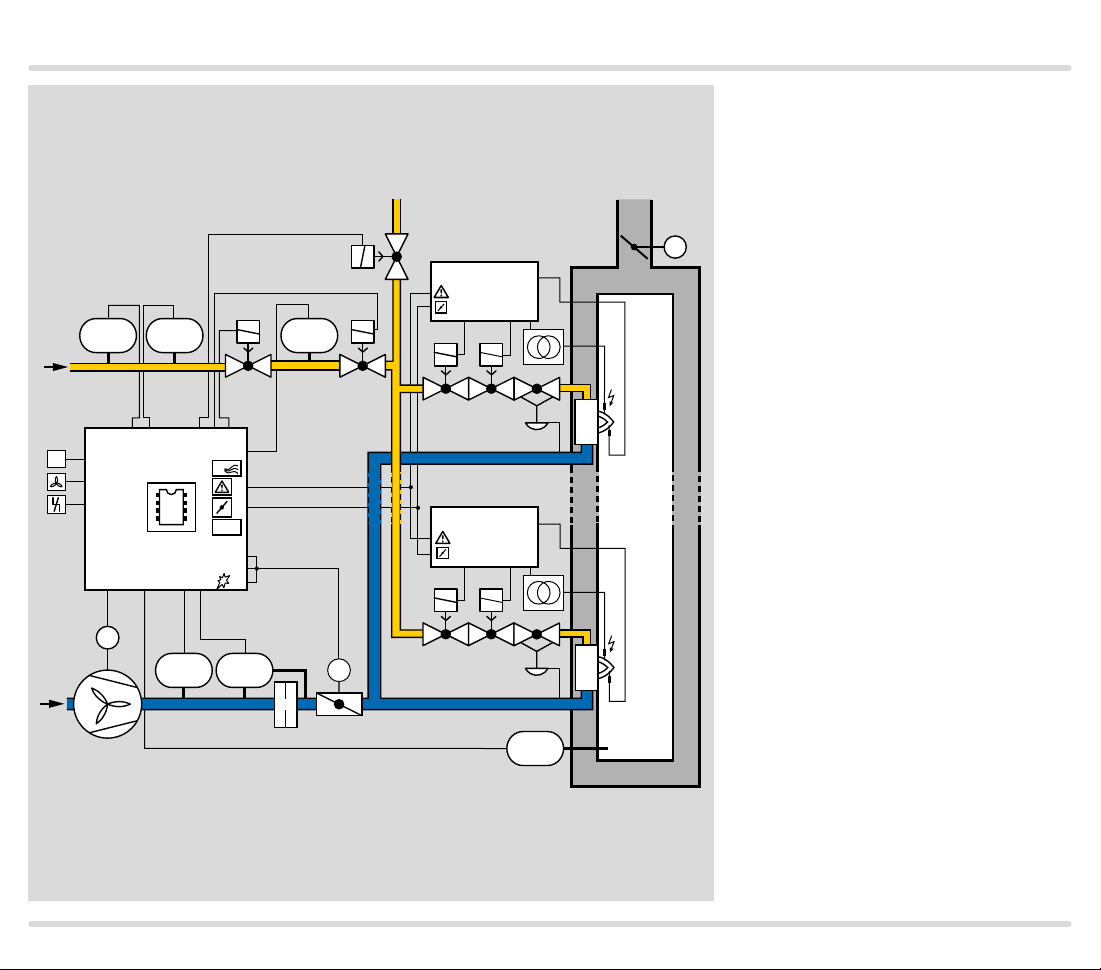

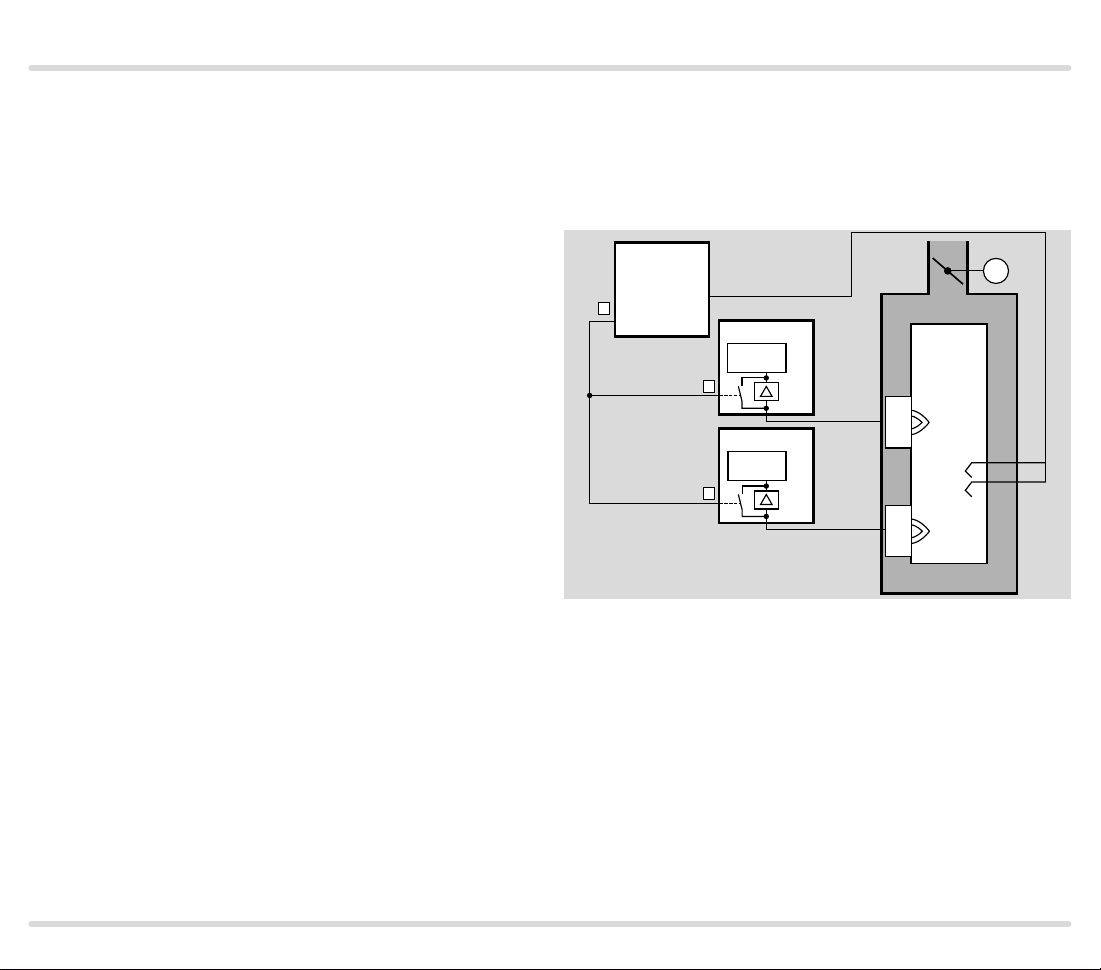

1.1 Application examples

1.1.1

ON/OFF ro tar y impul se contr ol

For processes which require a turndown of more than 10:1 and/or

those which require heavy circula-

M

TE

tion of the furnace atmosphere to

ensure a uniform temperature, e.g.

heat treatment furnaces operating

at low and medium temperatures in

the metallurgical industry.

With ON/OFF cyclic control, the

capacity supplied to the process is

controlled by means of a variable

ratio of the operating time to the

pause time. In this type of control,

the burner output pulse frequency

always maintains full momentum

and results in maximum convection

in the furnace chamber, even with

regulated heating.

The pneumatic ratio control sys-

tem controls the gas pressure on

the burner proportionally to the air

pressure and thus maintains a constant air/gas ratio. At the same time,

it acts as a low air pressure protection device.

▼

FCU 500, FCU 505 · Edition 02.17 8

Page 9

Application

PZL PZH PZ

VAS

BCU 460..L

The ignition and monitoring of the

individual burners is ensured by

burner control unit BCU 460..L.

The centrally checked safety func-

tions such as pre-purge, tightness

M

test, flow detector and pressure

switch check (gas

air

) are provided by the FCU 500.

min.

min.

, gas

max.

,

45

P

>750°

VAS

pu/2

VAS

VCG

VR..L

BCU 460..L

DG DG DG

DG

46

1

ϑ

2

3

min

49 15 131450

DG

max

µC

FCU 500..F0

47 4858

STM

DL

minDLPurge

M

PZL PDZ

DG DG

FCU 500, FCU 505 · Edition 02.17 9

VCG

VR..L

TE

Page 10

Application

PZL PZH PZ

DG DG DG

DG

min

49 15 131450

46

1

ϑ

2

3

FCU 500..F1

M

DG

µC

STM

DL

minDLPurge

VAS

max

45

P

>750°

TC

0°➔90°

53

90°➔0°

54

55

47 4858

PZL PDZ

DGDG

pu/2

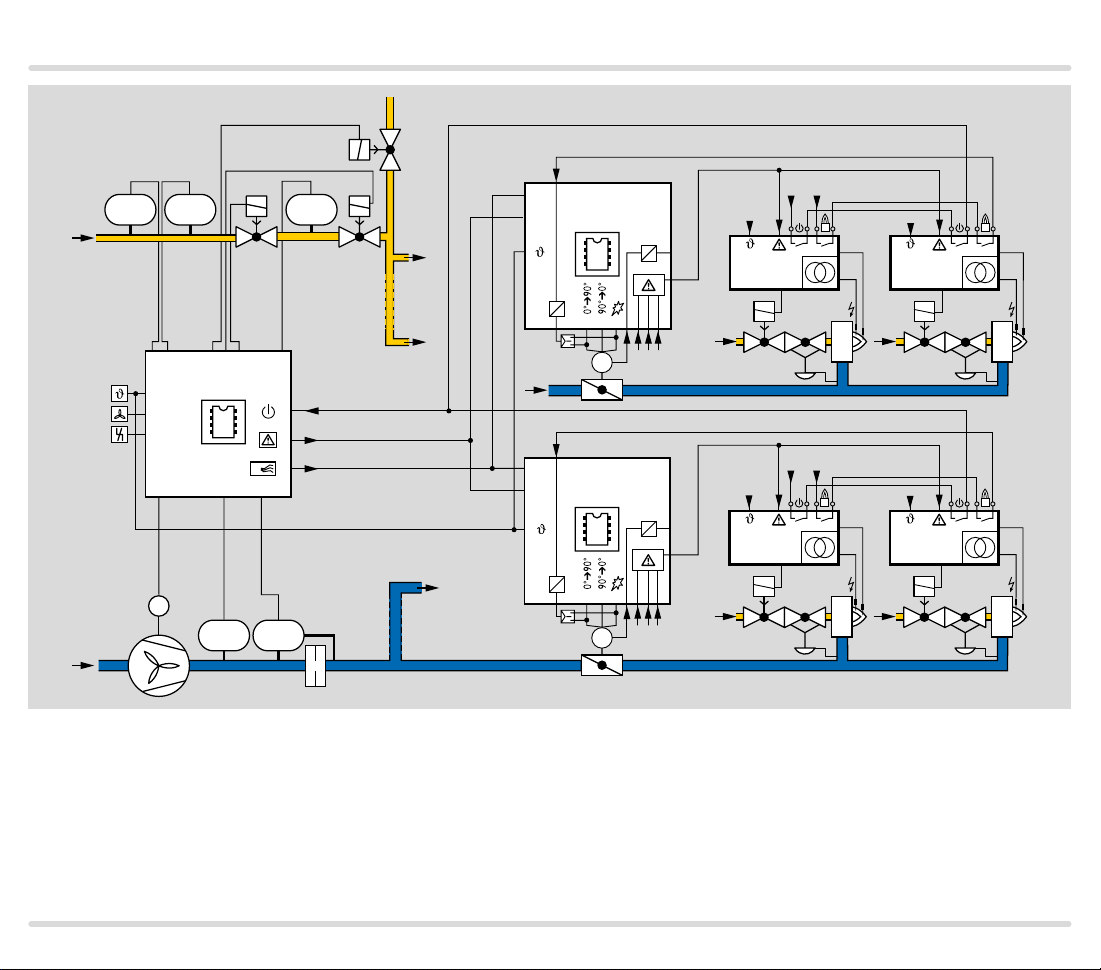

1.1.2 Modulating burner control

For processes that do not require

heavy circulation in the furnace, e.g.

aluminium smelting furnaces.

This system is suitable for process-

VAS

BCU 460..L

M

es in which infiltrated air may flow

into the furnace through switched

off burners. The capacity can be

adjusted continuously by activating

the air control valve (analogue or

VAS

VCG

3-point step signal). The pneumatic

ratio control system controls the

gas pressure proportionally to the

air pressure and thus maintains a

constant air/gas ratio. At the same

BCU 460..L

time, it acts as a low air pressure

protection device.

One burner control unit per burner

is required for ignition and monitor-

VCG

M

ing.

The centrally checked safety func-

tions such as pre-purge, setting the

TE

valve to ignition position via a butterfly valve control system, tightness test, flow detector and pressure switch check (gas

air

) are provided by the FCU 500.

min.

min.

, gas

max.

,

FCU 500, FCU 505 · Edition 02.17 10

Page 11

Application

PZL PZH PZ

DG DG DG

DG

min

49 15 131450

1

ϑ

2

3

FCU 500..F1

M

DG

µC

STM

DL

minDLPurge

VAS

max

45

P

57

16

>750°

TC

0°➔90°

53

90°➔0°

54

55

47 4858

PZL PDZ

DGDG

pu/2

1.1.3 Safety limits (LDS) for modulating burner control

The centrally checked safety func-

tions such as pre-purge, setting the

valve to ignition position via a but-

VAS

BCU 560..F0

66

M

terfly valve control system, tightness test, flow detector and pressure switch check (gas

air

) are provided by the FCU 500.

min.

min.

, gas

max.

,

The capacity can be adjusted con-

VAS

VCG

tinuously by activating the control

element (analogue or 3-point step

signal).

To ensure that the correct air vol-

ume is available for ignition (start

BCU 560..F0

66

fuel flow rate) when starting the

burners, the FCU sends the burner

start enable signal to the BCUs via

the “LDS (limits during start-up)”

output.

VCG

M

The circuit design of the safety

interlock and LDS outputs on the

FCU and the corresponding in-

TE

puts on the BCUs ensures that the

burners can only start if the safety

interlocks and the LDS output have

enabled burner start-up.

FCU 500, FCU 505 · Edition 02.17 11

Page 12

Application

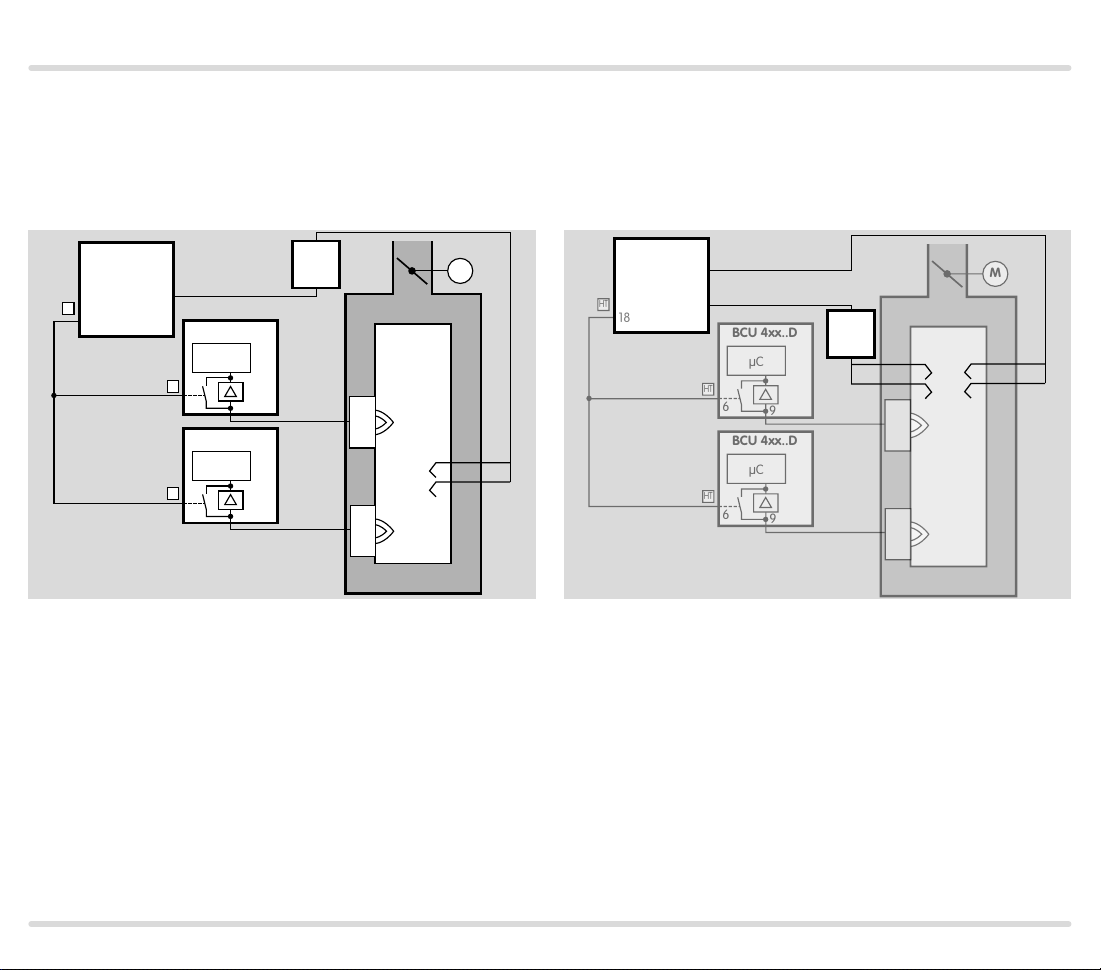

1.1.4 Flame control using the temperature

FCU 500..H1

HT

18

5-8

STM

HT

49

HT

49

BCU 56x..D

µC

5

BCU 56x..D

µC

5

M

In high temperature systems (temperature > 750°C),

the flame may be controlled indirectly via the temperature. As long as the temperature in the furnace chamber

is below 750°C, the flame must be controlled by conventional methods.

If the temperature in the furnace chamber rises above

the spontaneous ignition temperature of the gas/air

mixture (> 750°C), the FCU signals to the burner control

units via the fail-safe HT output that the furnace system is in High temperature mode (HT). When the HT input is activated, the burner control units switch to High

temperature mode. They operate without evaluation of

the flame signal and their internal flame control system

is non-functional.

If the furnace temperature falls below the spontaneous

ignition temperature (< 750°C), the FCU disconnects

the HT output from the electrical power supply. There

is no active signal at the HT inputs of the burner control

units. The flame signals are monitored once again by

the UV sensor or flame rod.

In the event of a fault in a temperature monitoring component (e.g. sensor discontinuity, sensor short-circuit)

or in the event of a mains failure, the flame control task

is transferred to the burner control units.

FCU 500, FCU 505 · Edition 02.17 12

Page 13

Application

PZL PZH PZ

66

46

4

FCU 505..F1

+24V

L1

49 15 131450

1

2

3

FCU 500..F0

µC

4758 48

45

67

57

17

P

M

PZL PDZ

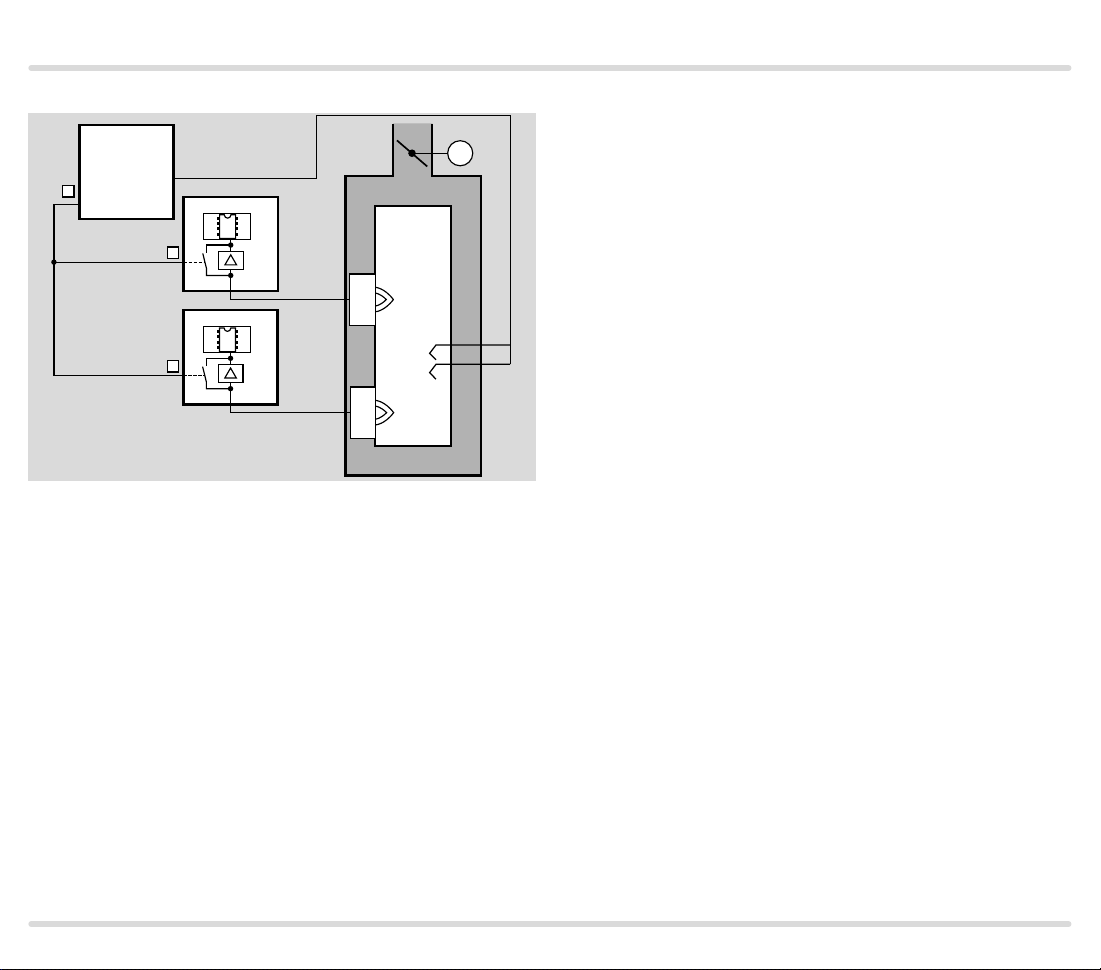

1.1.5 Furnace and zone control

The FCU 500 (furnace FCU) performs central tasks

such as checking the safety interlocks, fan control, system leak tightness check and pre-purge.

It signals to the FCU 505 in the zones that the butterfly

valves can be moved to the purge position. Signals are

1

µC

54 55

53

BCU

V1

V1

BCU

M

L1

BCU

+24V

BCU

V1

V1

66

46

1

4

FCU 505..F1

µC

54 55

53

M

sent to the butterfly valves by the FCU 505. The butterfly valves move into position. A signal is sent to the

FCU 505 via their safety interlock input that the central

FCU 500 has issued the enable signal for the burners.

FCU 500, FCU 505 · Edition 02.17 13

Page 14

Certification

2 Certification

Certificates – see Docuthek.

Certified pursuant to SIL

For systems up to SIL 3 pursuant to EN 61508.

Pursuant to EN ISO 138491:2006, Table 4, the FCU

can be used up to PL e.

EU certified pursuant to

– Gas Appliances Directive (2009/142/EC) in conjunc-

tion with EN 298, EN 1643

Meets the requirements of the

– Low Voltage Directive (2006/95/EC),

– EMC Directive (2004/108/EC).

FM approved

ANSI/CSA approved

American National Standards Institute/Canadian

Standards Association –ANSI Z21.20/CSA C22.2,

No. 199

www.csagroup.org –Class number: 333501 (natural

gas, propane), 333581 (natural gas, LPG).

Eurasian Customs Union

The product FCU 500 meets the technical specifica-

tions of the Eurasian Customs Union.

Factory Mutual Research Class: 7610 “Combustion Safe-

guards and Flame Sensing Systems”. Suitable for applications pursuant to NFPA 86. www.approvalguide.com

FCU 500, FCU 505 · Edition 02.17 14

Page 15

Function

3 Function

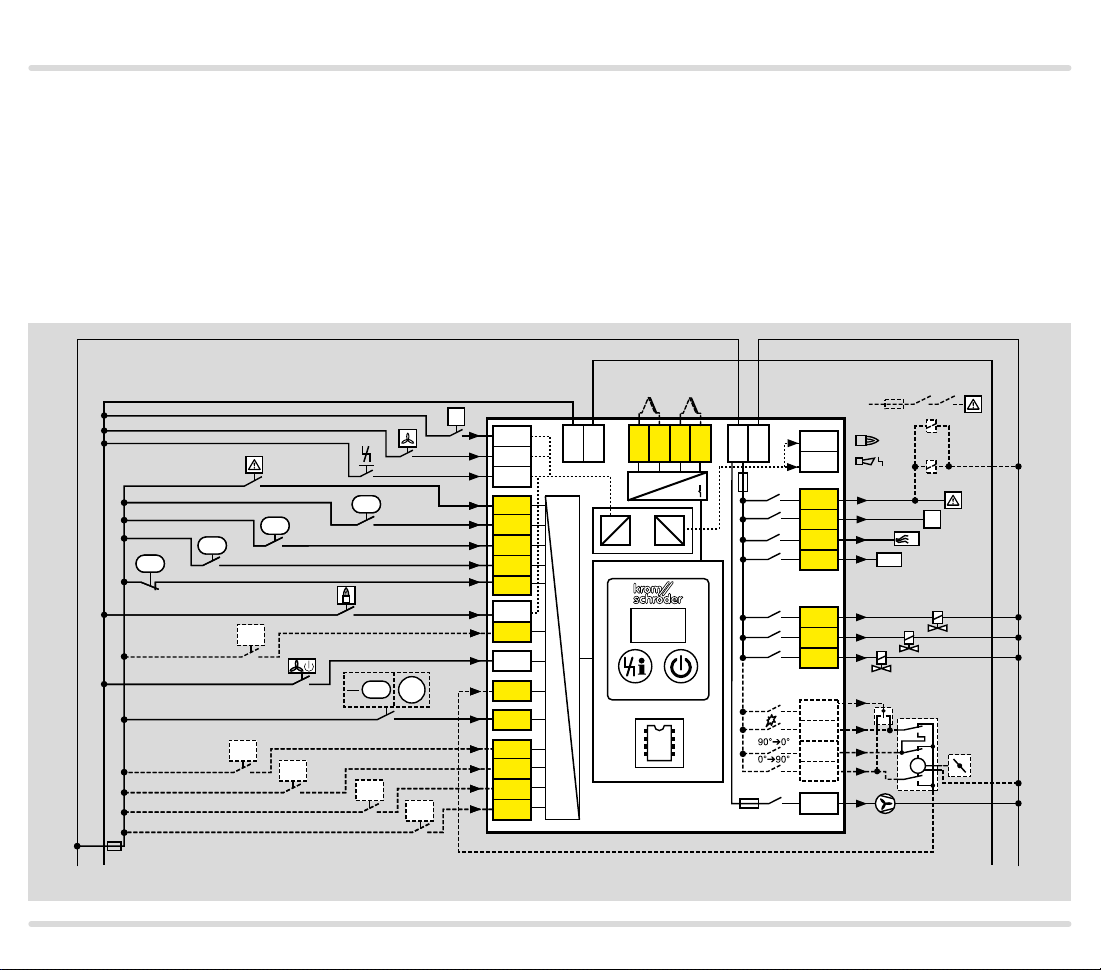

3.1 Connection diagram

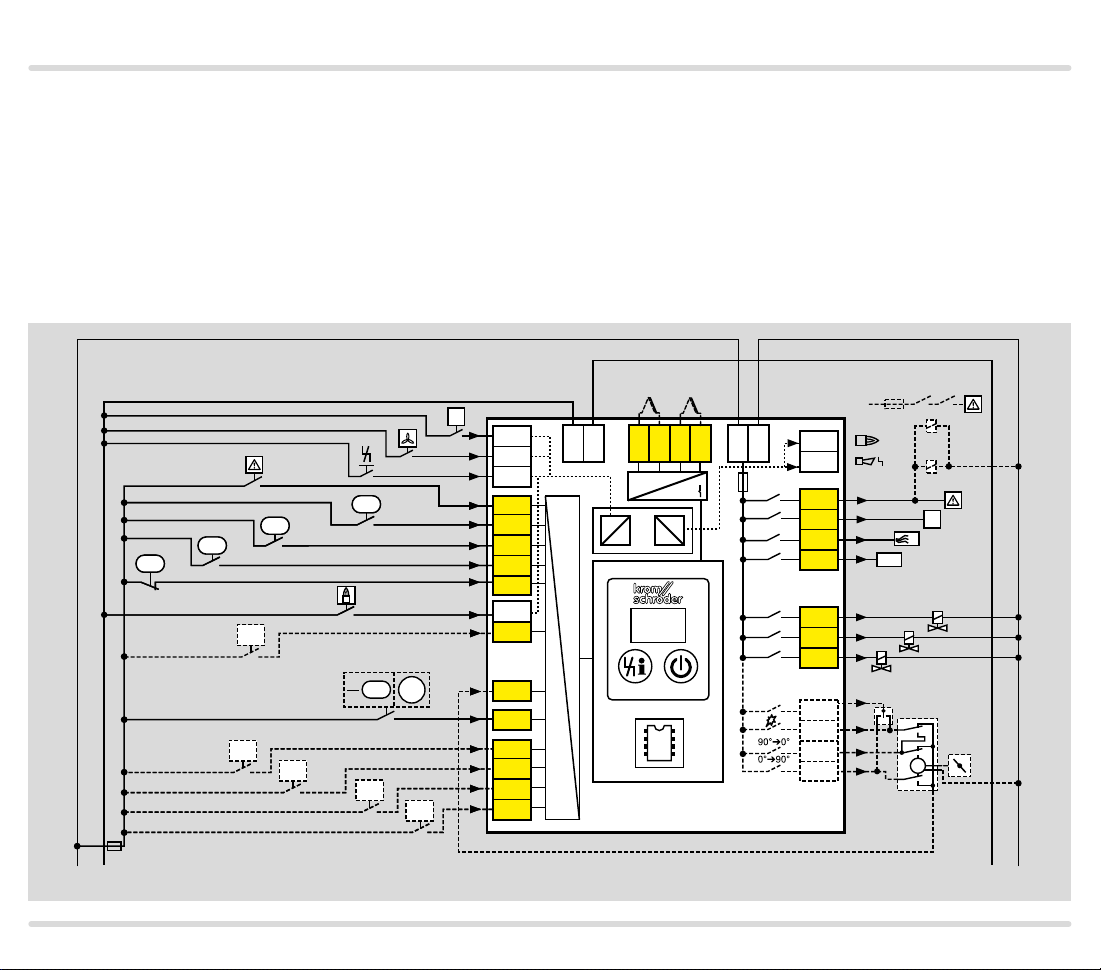

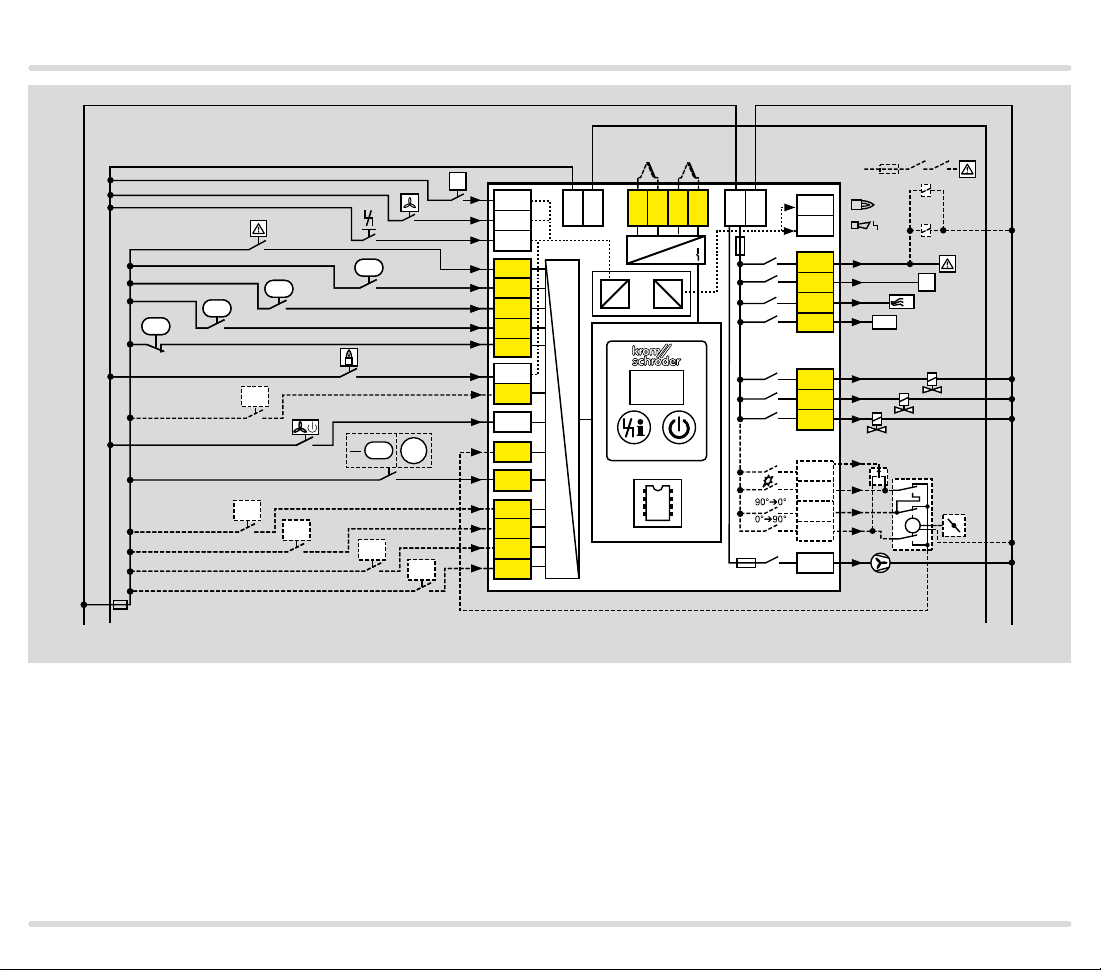

3.1.1 FCU 500

Detailed connection diagrams for actuators and fre-

quency converters, see from page 91 (Capacity control)

ϑ

PZL

PZL

Air

min

p

u

PZL

GZL

2

PZH

PZH

Gas

Air

PDZ

Gas

P72

P72

PDZ

min

PZL

PZL

max

Electrical connection, see page 120 (Project planning

information)

Explanation of symbols, see page 144 (Legend)

1 2 3 46 47 48 49 50 4 67 52 45 51 65 66 68

62 61 5 6 7 8 11

44

STM/

STL

+ - + -

24V

DC

88

12

3,15AT

41 4216

17 18 57

13 14 1553

I

N

× 0.6

LDS

k11 k21

K2

K1

HT

P

V2

V1

V3

µC

FCU 505

FCU 500

5AT

54 55 56

58

M

0 V

N

L1

+24 V

0.6 × I

P69

P70

P70

P71

P71

P73

P73

N

FCU 500, FCU 505 · Edition 02.17 15

Page 16

Function

3.1.2 FCU 505

Detailed connection diagrams for actuators and fre-

quency converters, see from page 91 (Capacity control)

Electrical connection, see page 120 (Project planning

information)

Explanation of symbols, see page 144 (Legend)

L1

+24 V

PZH

PZH

0.6 × I

Gas

N

STM/

STL

ϑ

1 2 3 46 47 48 49 50 4 67 52 45 51 65 66 68

62 61 5 6 7 8 11

PZL

PZL

Air

Air

PDZ

Gas

P72

P72

PDZ

min

PZL

PZL

max

min

+ - + -

24V

DC

88

12

3,15AT

41 4216

17 18 57

13 14 1553

p

u

PZL

GZL

2

P69

P70

P70

P71

P71

P73

P73

µC

FCU 505

54 55 56

I

N

× 0.6

LDS

V1

k11 k21

K2

K1

HT

P

V2

M

V3

0 V

N

FCU 500, FCU 505 · Edition 02.17 16

Page 17

Function

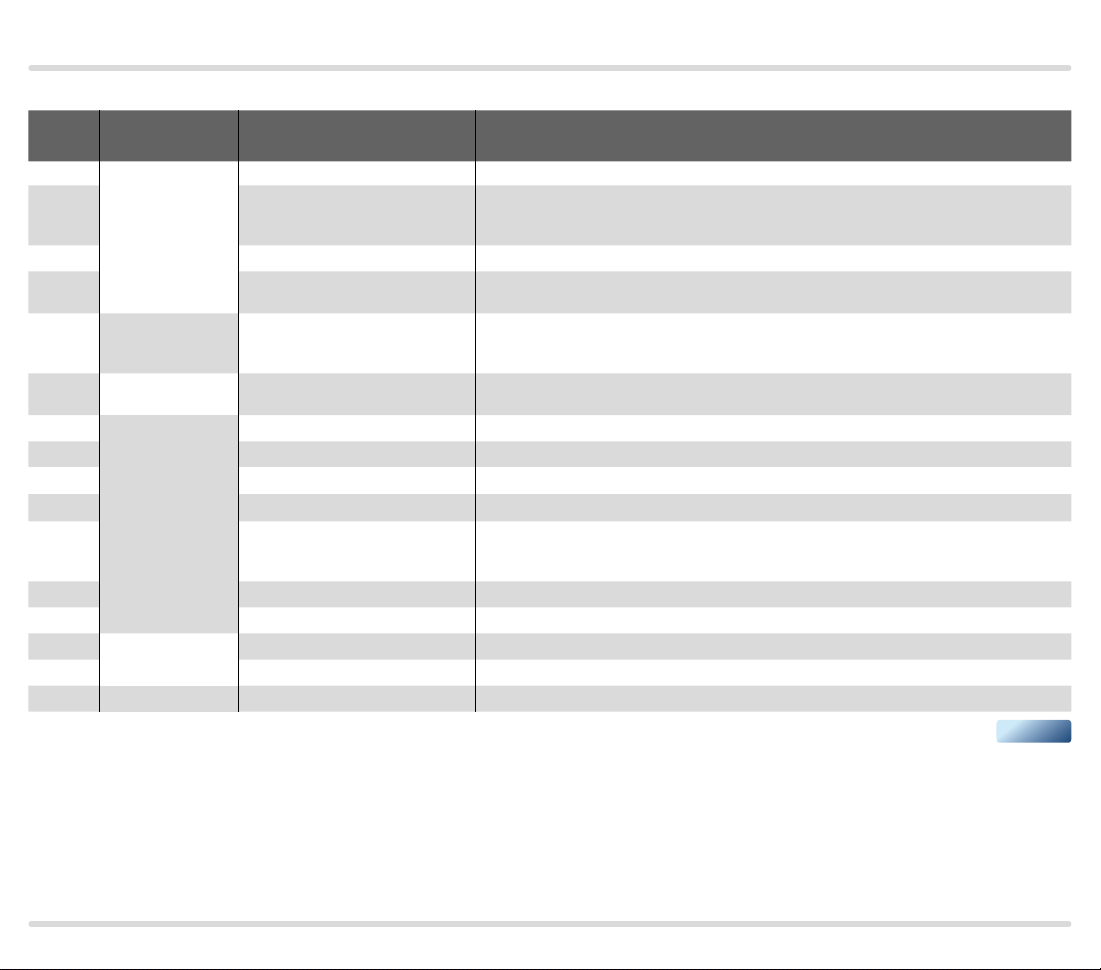

3.1.3 Assignment of connection terminals

Terminal Type Designation Function

1

2 Controlled air flow

24 V DC input

3 Remote reset Input for ex ternal signal (button) to reset the unit after a fault lock-out

4 Operating signal

5, 6

and

7, 8

11, 12 V AC input Supply voltage

13

14 Gas valve V2 Connection of phase for gas valve V2

15 Gas valve V3 Connection of phase for gas valve V3

57 Safety interlocks (limits) Safety enable signal to the burner control units

16 Safety limits (limits during start-up)

17 Purge Signal to FCU 505 or burner control units to inform them that purge is in process

18 High temperature operation Enable signal from the FCU indicating that the furnace system is in High temperature mode

41

42 Operating signal Operation signalling output, 24 V DC, max. 0.1 A

44 24 V DC input Fan ready for operation Feedback signal from fan indicating readiness for operation, see Parameter 31

Double

thermocouple

Safety circuit output

24 V DC output

Start-up signal Signal applied: FCU start; no signal: FCU stop

Signal applied: fan is started to supply air to the combustion chamber for cooling, for

example. Only functional in standby. The function is deactivated as soon as a signal is

received at terminal 1 (FCU start).

Signal from the burner control units to inform the FCU that a sufficient number of burners is

available for temperature control

Safety temperature monitor and/or

safety temperature limiter

Gas valve V1 Connection of phase for gas valve V1

Fault Fault signalling output, 24 V DC, max. 0.1 A

Monitor the spontaneous ignition temperature of the gas/air mixture in High temperature

mode and/or the maximum furnace or flue gas temperature using the integrated

temperature module of the FCU..H1

Voltage to operate the FCU,

11 = phase (L1), 12 = neutral conductor (N)

To ensure that the correct air volume is available for ignition (start fuel flow rate) when

starting the burners, the FCU sends the burner start enable signal to the burner control

units via this output.

▼

FCU 500, FCU 505 · Edition 02.17 17

Page 18

Function

Terminal Type Designation Function

45

46 Controller enable/emergency stop

47 Minimum air pressure

48 Minimum air flow

49 Minimum gas pressure Connection for pressure switch to monitor the minimum gas pres sure, see Parameter 13

50 Maximum gas pressure Connection for pressure switch to monitor the maximum gas pressure, see Parameter 12

51, 65,

66, 67,

68

52

53, 54,

55, 56

58 Fan

Safety circuit input

V AC output

Valve proving system

Programmable inputs

Feedback from actuator/frequency

converter

Capacity control

Connection for the sensor of the valve proving system (tightness control pressure switch or

POC switch for checking the closed position).

Connection for higher-level safety devices and interlocks (e.g. emergency stop, safety

temperature monitor), see Parameter 10

Connection for pressure switch to monitor the minimum air pressure, see

Parameter 15

Connection for a sensor to monitor the minimum air flow during pre-purge or post-purge,

see Parameters 35, 38

The terminals can be assigned a function using parameters. To do so, logical AND gatings

with terminals 46, 47, 48, 49 or 50 are possible.

Connection for the position feedback signal from the actuator/frequency converter

Connection for capacity control using an actuator or frequency converter,

see Parameter 40 to 47

Connection for fan control. Alternatively, this output can be used to activate a valve to check

the function of the air pres sure switch.

FCU 500, FCU 505 · Edition 02.17 18

Page 19

Function

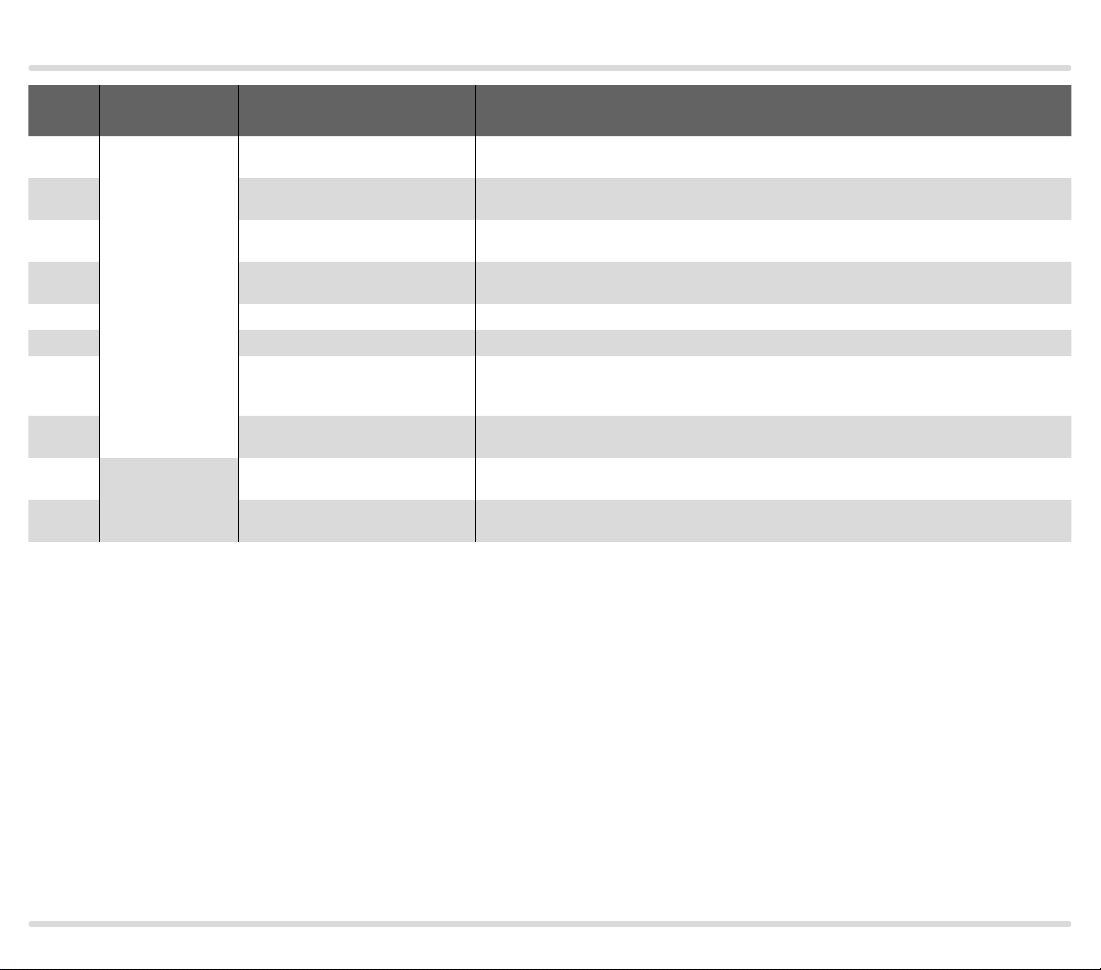

3.2 Program sequence

3.2.1 FCU 500..F0

Example of application, see page 8 (ON/OFF rotary

impulse control)

Switch on the FCU

▼

In the event of fault signal: reset

▼

00

H0

Switch-on delay time t

01

1

P1

08

Enable signal to burner control units for the burner start via the “safety

Start-up position/standby

▼

Start-up with ϑ signal

▼

running (parameter 63)

Safety interlocks check

Fan run-up time tGV running (parameter 30)

Pre-purge time tPV running (parameter 34)

Tightne ss test (if equipped with TC)

Gas enable via valves V1 and V2

E

▼

Pre-purge starts

▼

Air flow monitoring

▼

▼

interlock” output

▼

Operation

FCU 500, FCU 505 · Edition 02.17 19

Page 20

Function

3.2.2 FCU 500..F1, FCU 500..F2

Example of application, see page 10 (Modulating

burner control)

Switch on the FCU

▼

In the event of fault signal: reset

▼

00

H0

01

A

P1

A

H7

H8

08

Switch-on delay time t

Actuator moves to the position for maximum capacity

1

Actuator moves to the position for ignition capacity

Enable signal to burner control units for the burner start via the

Controller enabler signal delay time t

Start-up position/standby

▼

Start-up with ϑ signal

▼

running (parameter 63)

Safety interlocks check

E

▼

Fan run-up time t

running (parameter 30)

GV

Pre-purge starts

▼

▼

Air flow monitoring

▼

Pre-purge time t

Tightne ss test (if equipped with TC)

running (parameter 34)

PV

▼

▼

Gas enable via valves V1 and V2

“safety interlock” output

▼

▼

Operation/controller enable

running

RF

FCU 500, FCU 505 · Edition 02.17 20

Page 21

Function

3.2.3 FCU 505..F1, FCU 505..F2

Example of application, see page 13 (Furnace and

zone control)

Switch on the FCU

▼

In the event of fault signal: reset

▼

00

H0

01

A

P1

H8

08

Switch-on delay time t

Actuator moves to the position for maximum capacity

A

Actuator moves to the position for ignition capacity

Controller enabler signal delay time t

Start-up position/standby

▼

Start-up with ϑ signal

▼

running (parameter 63)

Safety interlocks check

E

▼

Fan run-up time t

running (parameter 30)

GV

Pre-purge starts

▼

▼

FCU 500 pre-purge time t

Tightne ss test (if equipped with TC)

▼

▼

▼

Operation/controller enable

running

PV

running

RF

FCU 500, FCU 505 · Edition 02.17 21

Page 22

Function

3.3 Animation

The interactive animation shows the function of the

protective system control FCU 500.

Click on the picture. The animation can be controlled

using the control bar at the bottom of the window (as

on a DVD player).

To play the animation, you will need Adobe Reader 9 or a

FCU 500, FCU 505 · Edition 02.17 22

newer version. If you do not have Adobe Reader on your

system, you can download it from the Internet. Go to

ww w.adobe.com, click on “Adobe Reader” at the bottom

of the page and follow the instructions.

If the animation does not start to play, you can download it from the document library (www.docuthek.com)

as an independent application.

Page 23

Temperature monitoring

4 Temperature monitoring

The FCU..H1 is fitted with an integrated temperature

module.

This module can be used as a safety temperature moni-

tor (STM) to monitor the spontaneous ignition temperature of the gas/air mixture or as a safety temperature

limiter (STL) to monitor the maximum furnace/flue gas

temperature. Double thermocouples are connected to

the temperature module to measure the temperature.

The functions STM and STL can also be combined. In

this case, the connected double thermocouple must reliably detect whether the spontaneous ignition temperature (> 750°C) has been exceeded and also whether

the maximum permitted furnace temperature has been

exceeded.

The safety temperature monitor and safety temperature

limiter functions can be adjusted to the requirements of

the system using parameters 20, 22, 23, 24 and 25, see

page 82 (High temperature operation).

FCU 500, FCU 505 · Edition 02.17 23

Page 24

Temperature monitoring

4.1 High temperature operation with safety

temperature monitor function (STM function)

As soon as the temperature in the furnace chamber

is above the spontaneous ignition temperature of the

gas/air mixture (> 750°C), the FCU signals to the downstream burner control units via the fail-safe HT output

that the furnace system is in High temperature mode

(HT). When the HT input is activated, the burner control

units switch to High temperature mode. They operate

without evaluating the flame signal and their internal

flame control is non-functional.

If the furnace temperature falls below the spontaneous

ignition temperature (< 750°C), the FCU disconnects

the HT output from the electrical power supply. As soon

as the signal to the HT inputs of the burner control

units is no longer present, the flame signals are once

again monitored by a UV sensor or flame rod.

In the event of a fault in a temperature monitoring component (e.g. sensor discontinuity, sensor short-circuit)

or in the event of a mains failure, the flame control task

is transferred to the burner control units.

Either the temperature module integrated in the FCU..

H1 or an external safety temperature monitor (STM)

can be used for High temperature mode. Pre-purge

can be disabled for both versions in High temperature

mode, see page 86 (Pre-purge during high temperature operation).

4.1.1 With integrated STM

The integrated temperature module (STM) can be used

for high temperature operation. Pre-purge can be disabled in High temperature mode, see page 86 (Prepurge during high temperature operation).

FCU 50x..H1

HT

18

5-8

STM

HT

6

HT

6

BCU 4xx..D

µC

9

BCU 4xx..D

µC

9

M

FCU 500, FCU 505 · Edition 02.17 24

Page 25

Temperature monitoring

M

BCU 4xx..D

µC

9

BCU 4xx..D

µC

9

HT

18

6

6

HT

HT

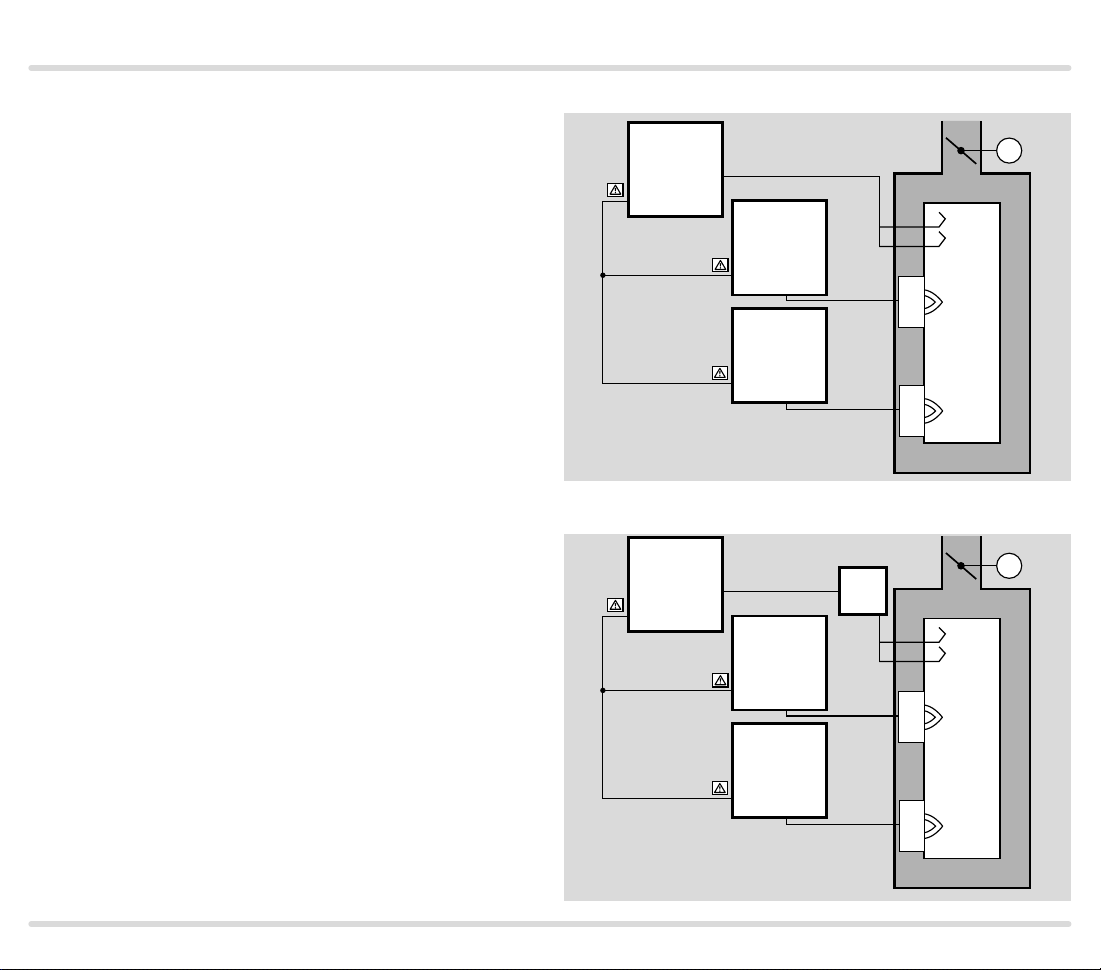

4.1.2 With external STM

An external safety temperature monitor (STM) can be

used for high temperature operation. Pre-purge can

be disabled in High temperature mode, see page 86

(Pre-purge during high temperature operation).

FCU 50x..H0

FCU 50x..H1

HT

18

66

BCU 4xx..D

µC

HT

6

9

BCU 4xx..D

µC

HT

6

9

STM

M

4.1.3 With integrated and external STM

The integrated temperature module can also be used in

conjunction with an external safety temperature monitor (STM). The spontaneous ignition temperature can

then be monitored at two different points in the furnace.

FCU 50x..H1

5-8

STM

66

STM

FCU 500, FCU 505 · Edition 02.17 25

Page 26

Temperature monitoring

4.2 Maximum temperature monitoring with

(flue gas) safety temperature limiter (STL/FSTL

function)

As soon as the maximum permitted temperature limit

is reached in the furnace or in the flue gas or an error

occurs on the monitoring equipment within the permitted temperature range (e.g. sensor discontinuity, sensor

short-circuit), the FCU will perform a fault lock-out. The

safety interlock output will no longer be set.

The temperature module integrated in the FCU..H1 or

an external safety temperature limiter (STL) can be

used for this function.

4.2.1 With integrated STL/FSTL

FCU 50x..H1

5-8

57

STL

BCU 4xx..D

5

BCU 4xx..D

BCU 4xx..D

5

9

9

9

4.2.2 With external STL/FSTL

FCU 50x..H0

FCU 50x..H1

57

46

BCU 4xx..D

STL

M

M

5

9

BCU 4xx..D

BCU 4xx..D

5

9

9

FCU 500, FCU 505 · Edition 02.17 26

Page 27

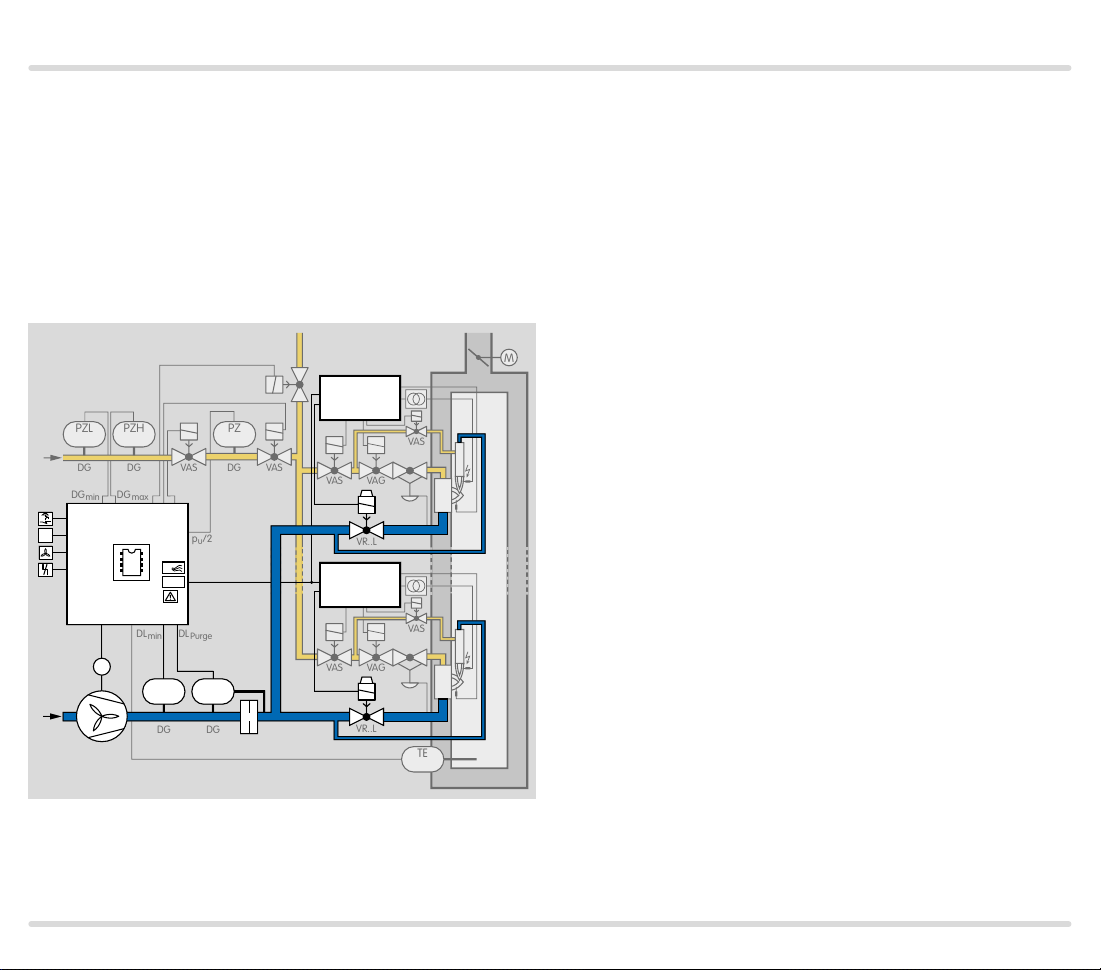

Air control

M

PZL PZH PZ

PZL PDZ

TE

BCU 580..F3

FCU 500..F0

µC

P

DG DG DG

VAS

VAS

VAGVAS

VAS

VR..L

VR..L

DG DG

DG

minDGmax

49 15 131450

45

47 4858

>750°

pu/2

ϑ

1

46

2

3

DL

minDLPurge

BCU 580..F3

VAGVAS

VAS

M

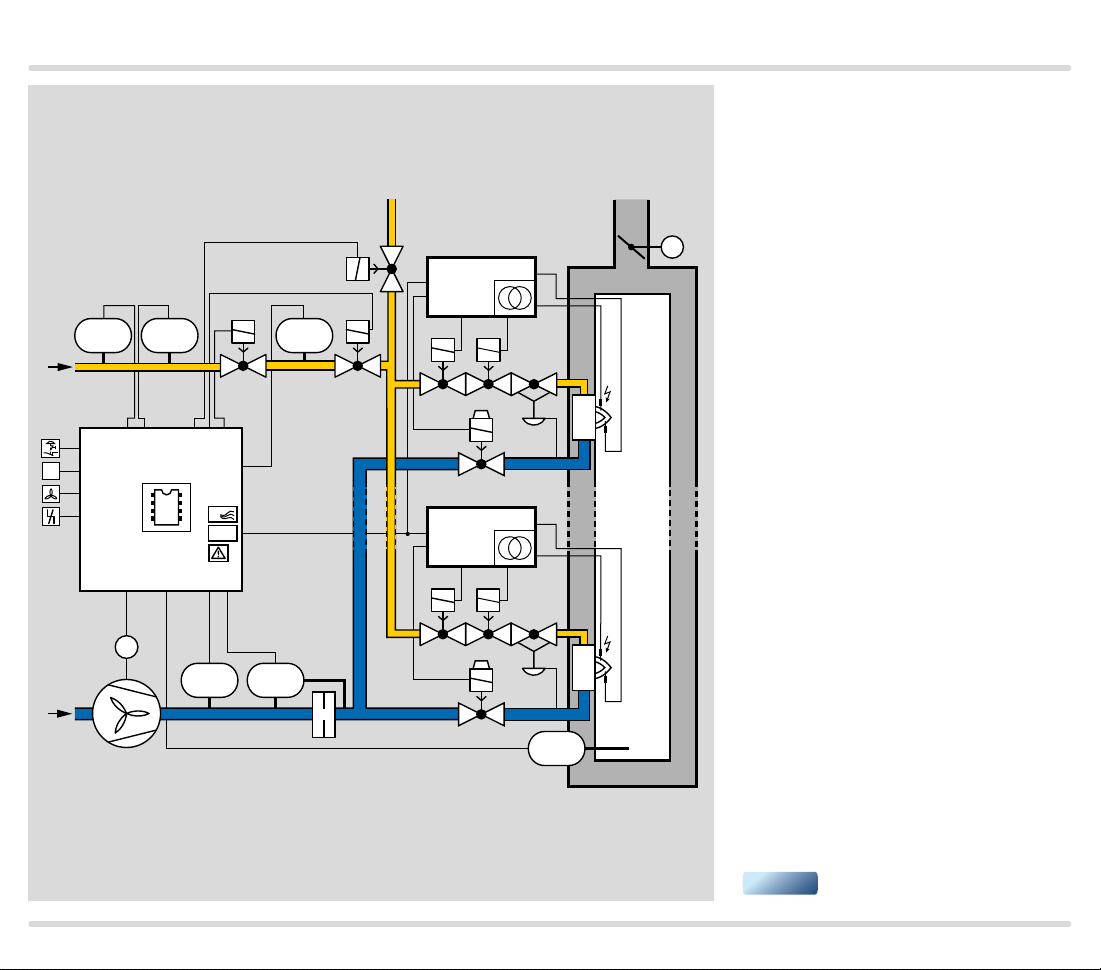

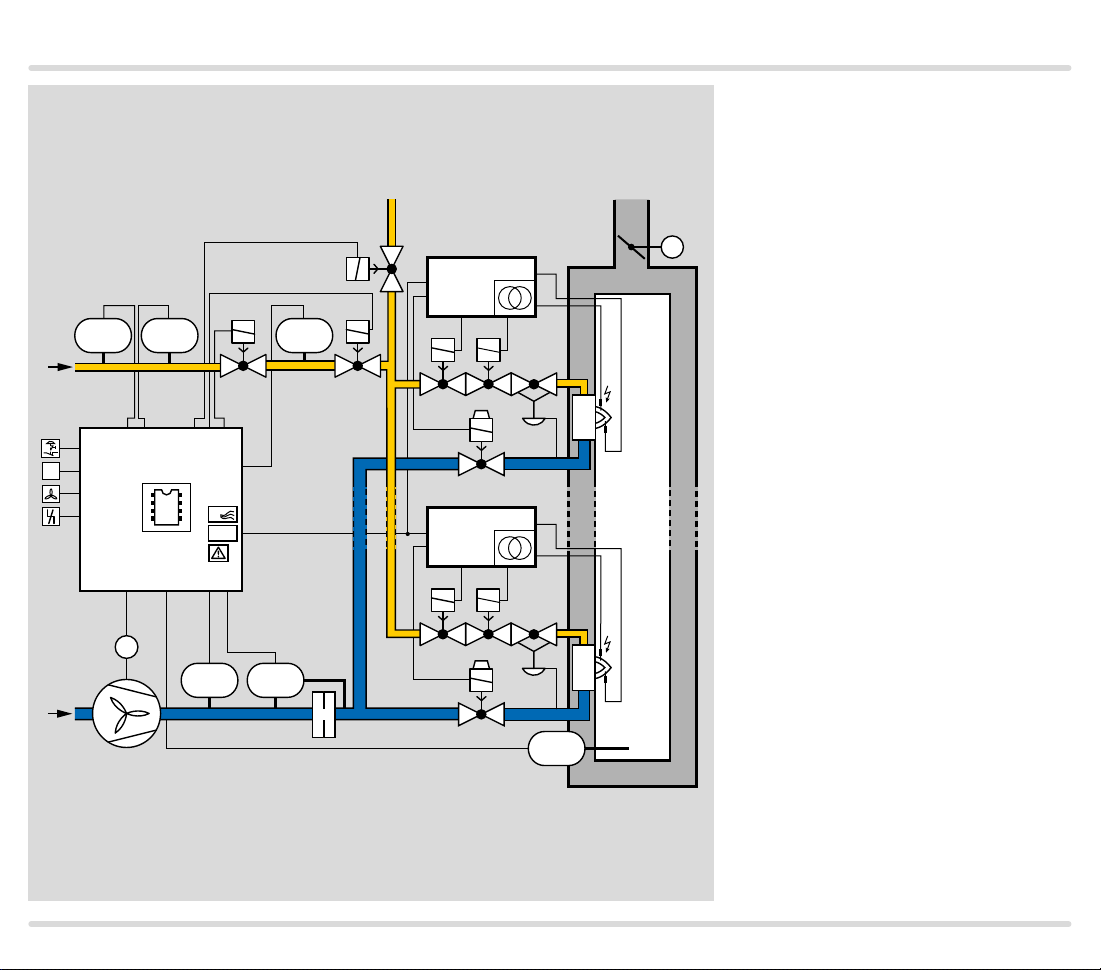

5 Air control

Acting as the furnace protective system, the FCU 500

assumes the task of central air control on a furnace. It

controls and monitors the required air volume for startup, during operation and after the furnace has been

shut down. The fan is activated by the FCU for this purpose. The static air pressure and the air volume for prepurge can be monitored by pressure switches.

VAS

BCU 580..F3

49 15 131450

46

1

ϑ

2

3

FCU 500..F0

M

µC

P

>750°

47 4858

STM

DL

minDLPurge

PZL PDZ

DG DG

45

VR..L

BCU 580..F3

VR..L

The capacity control function provided by the FCU 500..

F1/F2 and FCU 505..F1/F2 allows an additional central actuator or a frequency-controlled fan to be controlled and monitored. While the furnace is starting up,

the capacity control system controls and monitors the

required air volumes for purging and for starting the

burners. During operation, the FCU enables the external temperature control system for capacity control.

FCU 500, FCU 505 · Edition 02.17 27

Page 28

Air control

ϑ

PZL

PZL

Air

min

p

u

PZL

GZL

2

P71

P71

P73

P73

L1

+24 V

PZH

PZH

0.6 × I

Gas

N

Air

PDZ

Gas

P69

P72

P72

PDZ

min

P70

P70

PZL

PZL

max

5.1 Controlled air flow

On FCU 500, actuation of the input at terminal 2 acti-

vates the controlled air flow function. The fan (terminal 58) is started in standby (with no start-up signal).

Air is fed to the combustion chamber, e.g. for cooling.

1 2 3 46 47 48 49 50 4 67 52 45 51 65 66 68

62 61 5 6 7 8 11

44

STM/

STL

+ - + -

24V

DC

88

µC

FCU 505

FCU 500

5AT

12

3,15AT

41 4216

17 18 57

13 14 1553

54 55 56

58

I

N

× 0.6

LDS

k11 k21

K2

K1

HT

P

V3

V2

V1

M

The FCU starts the fan depending on the functions

defined using parameters, see also page 81 (Low air

pressure protection), page 88 (Air monitoring during

controlled air flow) and page 89 (Air flow monitoring

during pre-purge).

The controlled air flow function is no longer performed

once the start-up signal has been received at terminal 1.

0 V

N

FCU 500, FCU 505 · Edition 02.17 28

Page 29

Air control

CU

V1

CU

V1

µC

5455

53

1

6

(

)

V

M

1

7

▼

5.2 Capacity control

As soon as a start-up signal has been received by the

FCU..F1/F2 (terminal 1), the fan of an FCU 500..F1/F2

is started via terminal 58 after the switch-on delay time

has elapsed. The air volume for pre-purge is requested

via the outputs for central capacity control (terminals

53 to 56). Air flow monitoring (terminal 48) starts. The

pre-purge time starts if there is adequate air flow.

After the elapse of the pre-purge time, the air volume

for ignition is requested. After the program has ended

(limits during start-up, pre-purge and also tightness

test for FCU..C1), the gas enable signal is issued via the

valve outputs V1 (terminal 13) and V2 (terminal 14) and

the burner start enable signal is issued to the burner

control units via the “safety interlock” output (terminal 57).

The correct air volume for ignition (start fuel flow rate)

must be available for each burner start, restart or startup attempt. To this end, the FCU sends the burner start

enable signal to the BCUs via the “LDS (limits during

start-up)” output.

A corresponding circuit design between the FCU and

the BCUs ensures that the burners can only start if the

safety interlocks and the LDS output are active.

7

BCU..F0

+24

4

FCU 500..F1

M

6

16

57

5

1

B

B

FCU 500, FCU 505 · Edition 02.17 29

Page 30

Air control

CU

V

CU

V

µC

5455

53

1

6

(

)

V

M

After the burner operating signal from the burner con-

trol units has been received, the FCU enables the control system for operation. For pertinent parameter settings, see page 101 (Burner operating signal).

7

BCU..F0

+24

+24V

4

4

FCU 500..F1

1

B

1

54 55

53

B

1

M

Depending on parameter 40, actuators IC 20 and IC 40,

an actuator with an RBW interface or a fan controlled

by a frequency converter can be actuated via the outputs for central capacity control, see page 91 (Capacity control).

FCU 500, FCU 505 · Edition 02.17 30

Page 31

Furnace zone control

▼

PZL PZH PZ

66

46

4

FCU 505..F1

+24V

L1

49 15 131450

1

2

3

FCU 500..F0

µC

4758 48

45

67

57

17

P

M

PZL PDZ

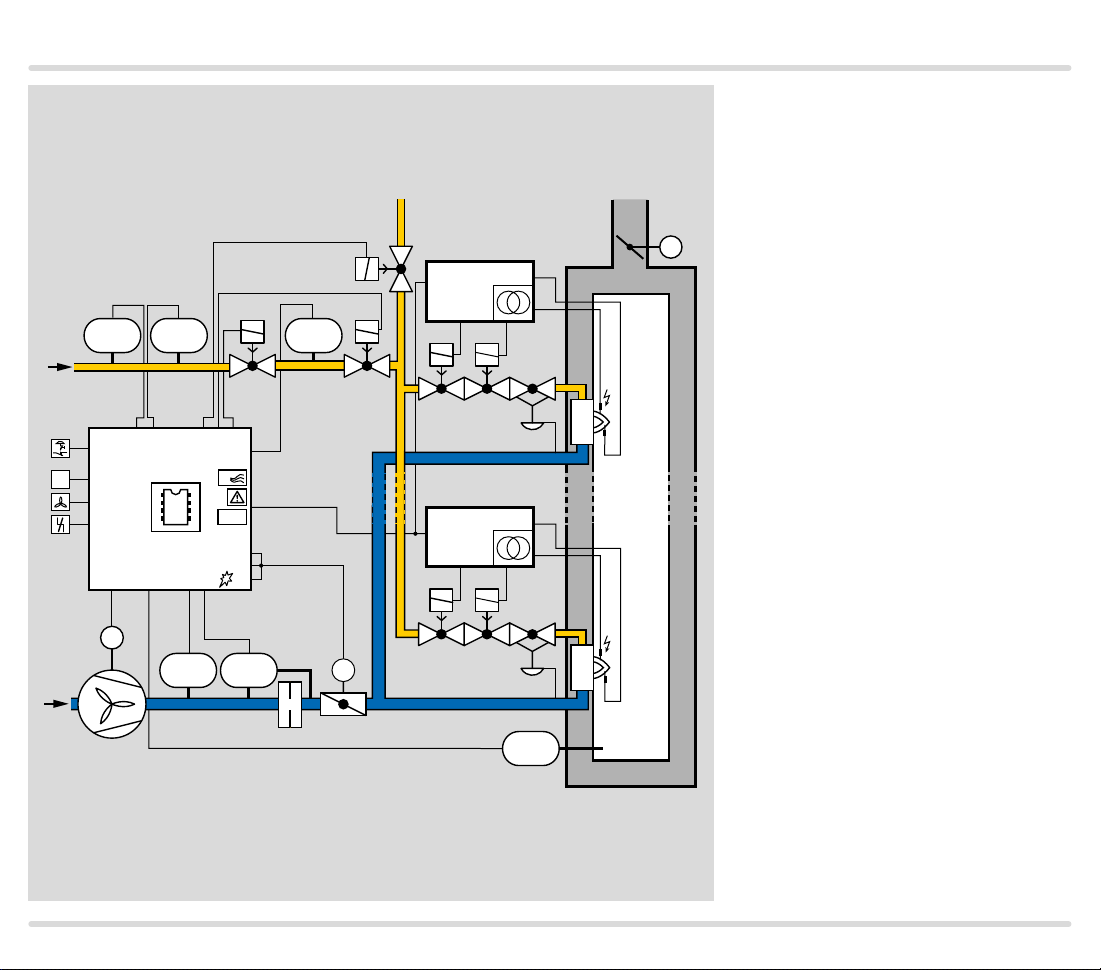

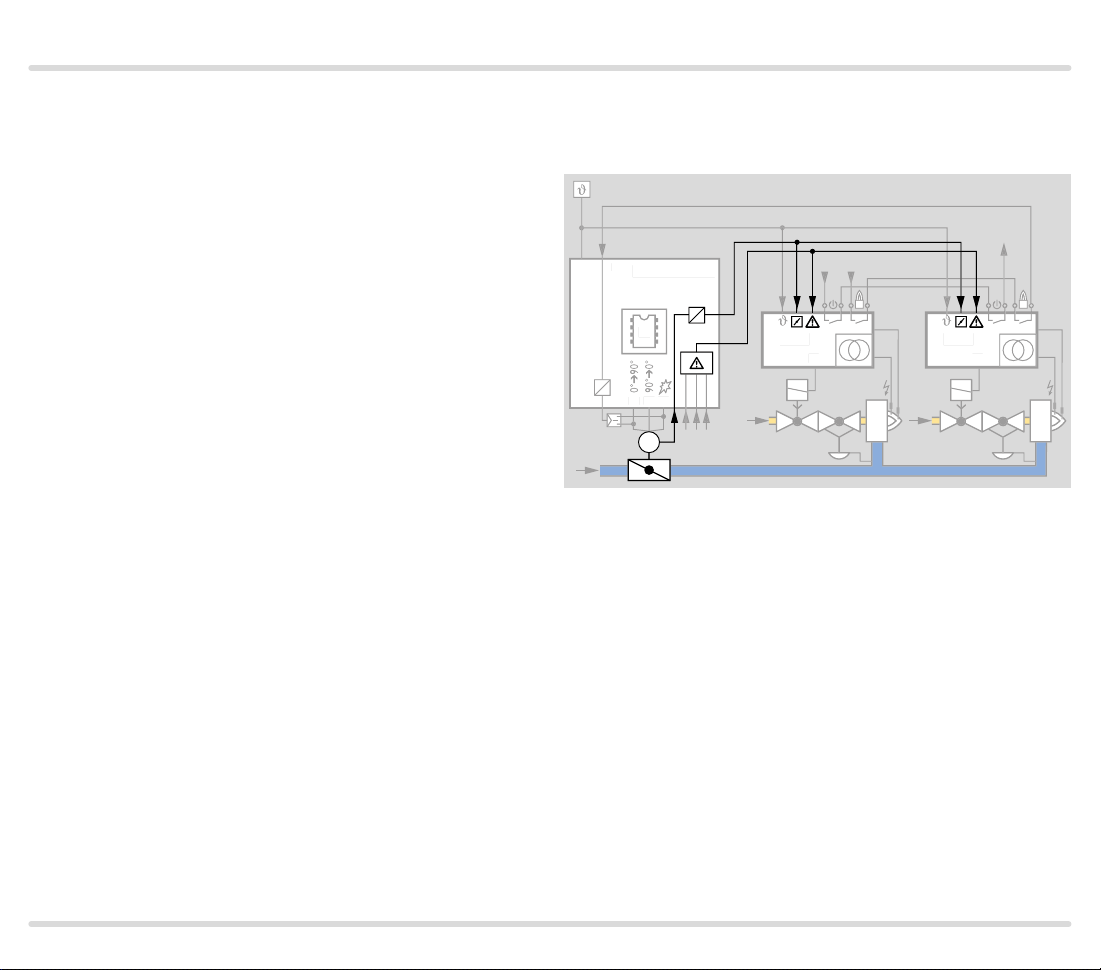

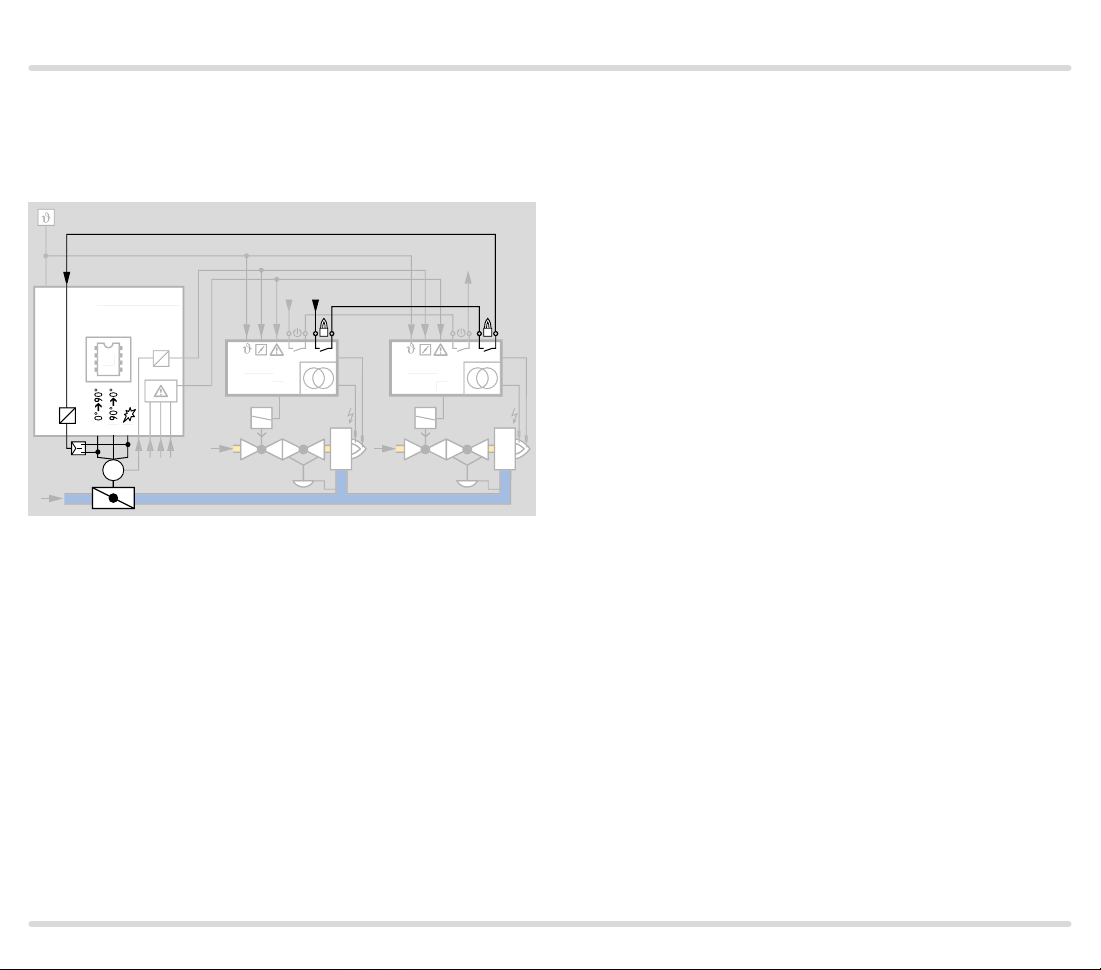

6 Furnace zone control

For furnace zone control, one FCU 500 is used to

control the furnace and several FCU 505 are used to

control the individual modulating zones (FCU 505..F1

or FCU 505..F2). When connecting several FCUs in a

circuit, a hierarchical operating structure is applied.

1

µC

54 55

53

BCU

V1

V1

BCU

M

L1

66

46

1

4

FCU 505..F1

µC

54 55

53

BCU

+24V

BCU

V1

V1

M

The furnace FCU (FCU 500) performs central tasks

such as checking the central safety functions, fan control, system leak tightness check and pre-purge.

FCU 500, FCU 505 · Edition 02.17 31

Page 32

Furnace zone control

The zone FCUs (FCU 505) control the zone capacity.

After checking the safety interlocks (after expiry of the

switch-on delay time) and when the fan run-up time

is started, the furnace FCU signals to the zone FCUs

via the input at terminal 66 that they should move

the actuators to purge position. After the purge (and

the tightness test if applicable) has been ended, the

furnace FCU signals to the zone FCUs via the input at

terminal 46 that burner start is enabled. When they

receive this signal, the zone FCUs move the valves to

ignition position for starting the burners and then issue

the enable signal to the burner control units to start the

burners.

FCU 500, FCU 505 · Edition 02.17 32

Page 33

Valve proving system

7 Valve proving system

The FCU..C1 is fitted with an integrated valve proving

system. This allows the tightness of two or more gas

solenoid valves and the pipework to be checked, see

page 34 (Tightness control). Alternatively, the closed

position of a gas solenoid valve can be checked using a

POC switch, see page 57 (Proof of closure function).

Once the test has been carried out successfully, the

furnace is enabled for start-up.

The tightness control function satisfies the require-

ments of EN 1643 (Valve proving systems for automatic shut-off valves for gas burners and gas appliances).

By checking the closed position using the proof of clo-

sure function, the FCU complies with the requirements

of NFPA 85 (Boiler and Combustion Systems Hazards

Code) and NFPA 86 (Standard for Ovens and Furnaces).

FCU 500, FCU 505 · Edition 02.17 33

Page 34

Valve proving system

7.1 Tightness control

The aim of the tightness control is to identify an in-

admissible leak on one of the gas solenoid valves

and to prevent burner start. European standards

EN 7462 and EN 676 stipulate tightness controls for

capacities over 1200 kW (NFPA 86: from 117 kW or

400,000 Btu/h).

The FCU offers several ways of testing tightness:

1. Between 2 gas solenoid valves with one test volume

(parameter 53 = 1):

p

u

V1

p

u

2. The system tightness of a complete gas inlet section

with one test volume and pressure reduction using a

relief valve (parameter 53 = 2):

V2

2

PZ

V

p1

3. The system tightness of a complete gas inlet section

with two test volumes and pressure reduction using a

relief valve (parameter 53 = 3):

DG

V3

p

u

V

p1

V1

V2

PZ

p

u

2

V

V3

PZ

p2

The valves and the pipework between the valves are

tested.

V3

V1

V

p1

p

u

FCU 500, FCU 505 · Edition 02.17 34

PZ

p

u

2

Page 35

Valve proving system

7.1.1 Test instant

Depending on the parameter setting, the tightness

control checks the tightness of the pipework and the

gas solenoid valves before each start-up and/or after

each shut-down of a furnace system, see page 108

(Valve proving system).

The gas line is always safeguarded by a gas solenoid

valve during this check.

Before furnace start-up

P1HO00 H7 H8

ϑ

1

TC Test

13

1

14

2

57

42

t

PVtRF

The FCU starts testing the tightness of the gas solenoid

valves and pipework between the valves parallel to the

pre-purge time. The gas line is always safeguarded by a

gas solenoid valve during this check. When pre-purge

is finished and the tightness has been checked successfully, the safety valves for operating the system are

opened after the safety interlocks have been enabled.

t

After furnace shut-down

08 00

ϑ

1

TC Test

13

1

14

2

57

42

t

PN

After the furnace has been shut down, the FCU starts

testing the tightness of the gas solenoid valves and

pipework between the valves. After the tightness has

been checked successfully, the next furnace start is

enabled as regards the tightness criteria.

Each time the FCU is reset or connected to mains voltage, a tightness test is performed immediately. The

testing time can be reduced for large volumes, see

page 111 (Large test volumes).

t

FCU 500, FCU 505 · Edition 02.17 35

Page 36

Valve proving system

PZL

PZH

P

4913

1

45

▼

7.1.2 One test volume between 2 gas solenoid valves

V1 V2

PZ

p

u

450

pu/2

p

V

z

p1

p

d

The tightness control checks the tightness of the test

volume Vp1 between gas solenoid valves V1 and V2.

FCU 500, FCU 505 · Edition 02.17 36

Page 37

Valve proving system

▼

+

Program A Program B

V1

tL = P59

V1

tM = P56

p

u

pZ >

2

+

V2

OK

V2

tL = P59

V2

tM = P56

p

u

pZ >

2

–

V1

OK

–

+

V1 V2

V2

V1

START

pZ >

PZ

pu/2

Program sequence

The tightness test starts by checking the external pres-

sure switch. If pressure pZ > pu/2, program A starts.

–

p

u

2

V2

tL = P59

V2

p

z

tM = P56

If pressure p

(Program B).

Program A

Valve V1 opens for the opening time t

eter 59. V1 closes again. During the measurement

time tM, the tightness control checks the pressure pZ

between the valves.

If pressure p

< pu/2, program B starts, see page 38

Z

set in param-

L

is less than half the inlet pressure pu/2,

Z

valve V2 is leaking.

+

V1

pZ >

V1

V1

tL = P59

p

u

2

–

OK

If pressure p

is greater than half the inlet

Z

pressure pu/2, valve V2 is tight. Valve V2 is opened for

the set opening time tL. V2 closes again.

During the measurement time t

, the tightness control

M

checks the pressure pZ between the valves.

If pressure p

is greater than half the inlet

Z

pressure pu/2, valve V1 is leaking.

V2

tM = P56

–

pZ >

V1

p

u

2

+

V2

OK

If pressure p

is less than half the inlet pressure pu/2,

Z

valve V1 is tight.

The tightness test can only be performed if pressure p

downstream of V2 is around atmospheric pressure.

d

FCU 500, FCU 505 · Edition 02.17 37

Page 38

Valve proving system

+

Program A Program B

V1

tL = P59

V1

tM = P56

p

u

pZ >

2

+

V2

OK

–

V1 V2

V2

START

pZ >

PZ

pu/2

Program B

Valve V2 opens for the set opening time tL. V2 closes

again. During the measurement time tM, the tightness

control checks the pressure pZ between the valves.

–

p

u

2

V2

If pressure p

If pressure p

> pu/2, valve V1 is leaking.

Z

< pu/2, valve V1 is tight. Valve V1 is

Z

opened for the set opening time tL. V1 closes again.

tL = P59

V2

p

z

tM = P56

+

pZ >

p

u

2

–

V1

V1

OK

During the measurement time t

, the tightness control

M

checks the pressure pZ between the valves.

If pressure p

If pressure p

< pu/2, valve V2 is leaking.

Z

> pu/2, valve V2 is tight.

Z

The tightness test can only be performed if pressure p

downstream of V2 is around atmospheric pressure.

d

V2

tL = P59

V2

tM = P56

+

p

u

pZ >

2

–

V1

OK

FCU 500, FCU 505 · Edition 02.17 38

V1

V2

tL = P59

tM = P56

–

pZ >

V1

V1

p

u

2

+

V2

OK

Page 39

Valve proving system

LZH

▼

7.1.3 One test volume for system tightness

Z

p

9

V1

u

5

450

P

V3

PZ

p

V

z

p1

22pu/2

The tightness control checks the system tightness

of the test volume Vp1 between the central shut-off

valve V1, relief valve V3 and the burner valves. The

opening times of the relief valve V3 and the shut-off

valve V1 are identical.

FCU 500, FCU 505 · Edition 02.17 39

Page 40

Valve proving system

▼

+

Program A Program B

V1

tL = P59

V1

tM = P56

p

p

>

Z

2

+

V

p1

V3

tL = P59

V3

tM = P56

p

p

>

Z

2

–

V1

u

OK

u

OK

V1

p

Z

–

V

p1

+

V1

V3

pu/2

PZ

START

p

Z

V

p1

Program sequence

The tightness test starts by checking the external pres-

sure switch. If pressure pZ > pu/2, program A starts. If

pressure pZ < pu/2, program B starts, see page 41

–

p

u

>

2

p

d

V3

tL = P59

V3

tM = P56

(Program B).

Program A

Valve V1 opens for the opening time t

set in param-

L

eter 59. V1 closes again. During the measurement

time tM, the tightness control checks the pressure pZ

between the valves.

If pressure p

is less than half the inlet pressure pu/2,

Z

test volume Vp1 is leaking.

+

V1

p

>

Z

V1

V1

tL = P59

p

u

2

–

OK

If pressure p

is greater than half the inlet

Z

pressure pu/2, test volume Vp1 is tight. Valve V3 is

opened for the set opening time tL. V3 closes again.

During the measurement time t

, the tightness control

M

checks the pressure pZ between the valves.

If pressure p

is greater than half the inlet

Z

pressure pu/2, valve V1 is leaking.

V1

If pressure p

is less than half the inlet pressure pu/2,

Z

valve V1 is tight.

tM = P56

–

p

u

p

>

Z

2

+

V

p1

V

OK

p1

The tightness test can only be performed if pressure p

downstream of V3 is around atmospheric pressure.

d

FCU 500, FCU 505 · Edition 02.17 40

Page 41

Valve proving system

+

Program A Program B

V1

tL = P59

V1

tM = P56

p

p

>

Z

2

+

V

p1

u

OK

V1

p

Z

–

V

p1

V3

pu/2

PZ

START

p

Z

V

p1

Program B

Valve V3 opens for the set opening time tL. V3 closes

again. During the measurement time tM, the tightness

control checks the pressure pZ between the valves.

>

2

p

d

V3

If pressure p

If pressure p

> pu/2, valve V1 is leaking.

Z

< pu/2, valve V1 is tight. Valve V1 is

Z

–

p

u

opened for the set opening time tL. V1 closes again.

tL = P59

V3

tM = P56

+

p

u

p

>

Z

2

–

V1

V1

OK

During the measurement time t

, the tightness control

M

checks the pressure pZ between the valves.

If pressure p

If pressure p

> pu/2, test volume Vp1 is tight.

Z

< pu/2, test volume Vp1 is leaking.

Z

The tightness test can only be performed if pressure p

downstream of V3 is around atmospheric pressure.

d

V3

tL = P59

V3

tM = P56

+

p

u

p

>

Z

2

–

V1

OK

FCU 500, FCU 505 · Edition 02.17 41

V1

V

p1

tL = P59

tM = P56

–

p

V1

V1

p

u

>

Z

2

+

V

OK

p1

Page 42

Valve proving system

H

>750°

▼

7.1.4 Two test volumes for system tightness

V3

START

Vent V

Program A Program B

p2

+

V3

tL3 = P55

p

u

pZ >

2

–

Z

p

9

V1 V2

u

5

450

45

pu/2

V

p

p1

Z

PZ

V

p2

The test volumes Vp1 and Vp2 (gas solenoid valves V1

and V2, relief valve V3, the burner valves and the pipework) are checked to test the system tightness of the

entire gas inlet section.

Program sequence

At the start of the tightness test, the relief valve V3 is

opened to reduce the pressure of the test volume V

p2

to around atmospheric pressure. The opening time for

V3 can be defined using parameter 55, see page 110

(Opening time relief valve V3). The tightness control queries the pressure pZ using the external pressure switch to check the first test volume. If pressure

pZ > pu/2, program A starts, see page 43 (Program A).

If pressure pZ < pu/2, program B starts, see page 44

(Program B).

FCU 500, FCU 505 · Edition 02.17 42

Page 43

Valve proving system

tL3 = P55

V3

Vent V

p2

START

▼

Program A Program B

V1

tL = P59

V1

+

pZ >

–

p

u

2

V2

tL = P59

V2

Test of valve 1

V

tM = P56

p

u

pZ >

2

–

p1

+

tM = P56

p

pZ >

+

V2

V2

tL = P59

V2

tM = P56

OK

V2

Program A Program B

Test of valve 2

V

V1

p1

V1

V1

tL = P59

V1

tM = P56

Program A

Valve V1 opens for the opening time tL set in param-

eter 59. Valve V1 closes again. During the measurement time tM set in parameter 56, the tightness control

checks the pressure pZ between the valves V1 and V2.

If pressure p

If pressure p

Valve V2 opens for the opening time t

< pu/2, valve V2 is leaking.

Z

> pu/2, valve V2 is tight.

Z

set in param-

L

eter 59. V2 closes again. During the measurement

time tM, the tightness control checks the pressure pZ

u

2

–

OK

between the valves.

If pressure p

If pressure p

The test volume V

> pu/2, valve V1 is leaking.

Z

< pu/2, valve V1 is tight.

Z

p1

has been successfully checked for

tightness.

For checking the second test volume, see page 45

(Checking the first and second test volumes (V

+ Vp2)).

p1

+

p

u

pZ >

2

–

V1

OK

FCU 500, FCU 505 · Edition 02.17 43

V1

V

p1

V2

OK

–

p

u

pZ >

2

+

OK

V2

Page 44

Valve proving system

tL3 = P55

V3

Vent V

p2

START

▼

Program A Program B

V1

tL = P59

V1

+

pZ >

–

p

u

2

V2

tL = P59

V2

Test of valve 1

V

tM = P56

p

u

pZ >

2

–

p1

+

tM = P56

p

pZ >

+

V2

V2

tL = P59

V2

tM = P56

OK

V2

Program A Program B

Test of valve 2

V

V1

p1

V1

V1

tL = P59

V1

tM = P56

Program B

Valve V2 opens for the opening time tL set in param-

eter 59. Valve V2 closes again. During the measurement time tM set in parameter 56, the tightness control

checks the pressure pZ between the valves V1 and V2.

If the pressure p

If the pressure p

Valve V1 opens for the opening time t

< pu/2, valve V1 is leaking.

Z

> pu/2, valve V1 is tight.

Z

set in param-

L

eter 59. V1 closes again. During the measurement

time tM, the tightness control checks the pressure pZ

u

2

–

OK

between the valves.

If pressure p

If pressure p

The test volume V

> pu/2, valve V2 is tight.

Z

< pu/2, valve V2 is leaking.

Z

p1

has been successfully checked for

tightness.

For checking the second test volume, see page 45

(Checking the first and second test volumes (V

+ Vp2)).

p1

+

p

u

pZ >

2

–

V1

OK

FCU 500, FCU 505 · Edition 02.17 44

V1

V

p1

V2

OK

–

pZ >

V2

p

u

2

+

OK

Page 45

tL = P59

tM = P56

+

–

tL = P59

tM = P56

pZ >

p

u

2

+

–

V2

OK

pZ >

p

u

2

V1

OK

V1

V2

OK

V1

V1

V1

OK

V2

V2

V2

V1

V2

pZ >

p

u

2

+

–

pZ >

p

u

2

+

–

tM = P56

tM = P56

Program A Program B

V

p1

Test of valve 2

V

p1

Valve proving system

Test of valve V3

and

burner-side

valves

V

+ V

p1

p2

V

p1

Wait for 1 s

V1

tL = P59

V1

tM = P57

pZ >

V

p2

END

OK

V2V3

Checking the first and second test volumes

(Vp1 + Vp2)

To check the test volume Vp2, relief valve V3 is closed

and valve V2 is opened. The two test volumes Vp1 and

Vp2 are connected to each other. After a waiting time

of 1 s, valve V1 opens for the opening time tL set in

parameter 59. Valve V1 then closes and the measurement time set in parameter 57 starts to elapse, see

page 110 (Measurement time Vp1 and Vp2). After the

measurement time has elapsed, the tightness control

–

p

u

2

+

OK

V

p2

checks pressure pZ. If pZ < pu/2, the test volume Vp2 is

leaking (relief valve V3, the burner valves or the pipework are leaking). If pZ > pu/2, test volume Vp2 has been

successfully checked for tightness.

Valves V1, V2 and V3, the burner valves and the pipe-

work are tight.

FCU 500, FCU 505 · Edition 02.17 45

Page 46

Valve proving system

LZH

▼

7.1.5 Large test volumes with reduced testing time

The testing time for the tightness test can be reduced

for a large test volume. Two pressure switches are re-

quired for this, see page 111 (Large test volumes).

The first pressure switch is set to ¼ of the inlet pres-

sure pu, the second one to ¾ of the inlet pressure.

Parameter 70 must be set to 1 for this purpose, see

page 116 (Function of terminal 65).

Program sequence

The tightness control queries the pressure pZ using

the first pressure switch (pu/4). If pressure pZ > pu/4,

program A starts, see page 47 (Program A (reduced

testing time)). If pressure pZ < pu/4, program B starts,

see page 47 (Program B (reduced testing time)).

Z

p

9

V1 V2

u

450

45

65

p

PZ PZ

1

pu/4

z

3pu/4

V

p1

2

p

d

FCU 500, FCU 505 · Edition 02.17 46

Page 47

Valve proving system

+

Program A Program B

V1

tL = P59

V1

tM = P56

3p

pZ >

4

+

V2

V2

tL = P59

V2

tM = P56

p

pZ >

4

–

V1

OK

u

OK

–

u

+

V1 V2

p

u

V2

V1

START

p

u

pZ >

4

p

V

z

p1

PZ PZ

3pu/4pu/4

Program A (reduced testing time)

Valve V1 opens for the opening time tL set in param-

eter 59. V1 closes again. During the measurement

time tM, the tightness control checks the pressure pZ

–

V2

tL = P59

p

d

V2

between the valves.

If pressure p

If pressure p

< 3pu/4, valve V2 is leaking.

Z

> 3pu/4, valve V2 is tight. Valve V2 is

Z

opened for the set opening time tL. V2 closes again.

During the measurement time t

, the tightness control

M

checks the pressure pZ between the valves.

tM = P56

+

pZ >

p

u

4

–

V1

V1

OK

V1

If pressure p

If pressure p

< pu/4, valve V1 is tight.

Z

> pu/4, valve V1 is leaking.

Z

Program B (reduced testing time)

Valve V2 opens for the opening time t

set in param-

L

eter 59. V2 closes again. During the measurement

time tM, the tightness control checks the pressure pZ

between the valves.

tL = P59

V1

tM = P56

If pressure p

If pressure p

> pu/4, valve V1 is leaking.

Z

< pu/4, valve V1 is tight. Valve V1 is

Z

opened for the set opening time tL. V1 closes again.

During the measurement time t

, the tightness control

M

checks the pressure pZ between the valves.

–

3p

V2

pZ >

V2

u

4

+

OK

If pressure p

If pressure p

< 3pu/4, valve V2 is leaking.

Z

> 3pu/4, valve V2 is tight.

Z

FCU 500, FCU 505 · Edition 02.17 47

Page 48

Valve proving system

LZH

LZH

7. 2 Test period tP

The test period for the tightness test varies depending

on the selected function (parameter 53).

7.2.1 For one test volume V

valves

Z

p

u

9

The test period tP is calculated from:

– Opening times t

– Measurement times t

for V1 and V2,

L

M

tP [s] = 2x tL + 2x t

between 2 gas solenoid

p1

V1 V2

450

pu/2

PZ

p

V

z

p1

for V1 and V2.

M

p

d

7.2.2 For one test volume Vp1 for system tightness

Z

p

9

V1

u

5

450

P

V3

PZ

p

V

z

p1

22pu/2

The test period tP is calculated from:

– Opening times t

– Measurement times t

for V1 and V3,

L

for V1 and V3.

M

tP [s] = 2x tL + 2x t

M

FCU 500, FCU 505 · Edition 02.17 48

Page 49

Valve proving system

H

7.2.3

For two te st volumes for sy stem tightness ( Vp1 + Vp2)

V3

– Measurement time t

to check the test volumes

M

Vp1 + Vp2 (parameter 57), see page 110 (Measurement time Vp1 and Vp2).

Z

p

9

V1 V2

u

5

450

45

pu/2

V

p

p1

Z

PZ

V

p2

The test period tP is calculated from:

– Opening time of relief valve V3 to reduce the pressure

of V

, see page 42 (Two test volumes for system

p2

tightness) and page 110 (Opening time relief valve

V3),

– Opening times t

for V1 and V2 to check the test vol-

L

ume Vp1 and test volumes Vp1 + Vp2, see page 42

(Two test volumes for system tightness),

– Measurement times t

for V1 and V2 to check the

M

test volume Vp1 (parameter 56), see page 110

(Measurement time Vp1),

– Waiting time 1 s,

tP [s] = tL3 + 3x t

L (P59)

+ 2x t

M(P56)

+ t

M(P57)

+ 1

FCU 500, FCU 505 · Edition 02.17 49

Page 50

Valve proving system

VK VK

▼

7.2.4 Extended valve opening time 1 tL1

Standard EN 1643:2000 allows a maximum opening

time of 3 s for the tightness test if the main gas valves

are actuated directly. If the gas can flow into the combustion chamber when a valve is opened, the gas volume must not exceed 0.05% of the maximum flow rate.

If the pre-set opening time t

= 3 s is inadequate (e.g. if

L

slow opening motorized valves VK are used) to build up

or reduce the test volume pressure, bypass valves with

an extended opening time may be used (e.g. VAS 1 or

bypass valves with an additional orifice).

1. Tightness test between 2 gas solenoid valves with

one test volume (parameter 53 = 1):

141357

VAS 1VAS 1

V1

VK VK

V2

2. System leak tightness check with one test volume

and pressure reduction using relief valve (parameter

53 = 2):

15

13

57

V1

VAS 1

VK

V3

3. System leak tightness check with two test volumes

and pressure reduction using relief valve (parameter

53 = 3):

14 1513

57

V1 V2

VAS 1

VAS 1

V3

Current rating of safety interlock output (terminal 57):

max. 0.5 A, see also page 127 (Safety interlock output

in the case of higher power requirement)

FCU 500, FCU 505 · Edition 02.17 50

Page 51

Valve proving system

▼

Calculation example

Nominal flow rate Q

(N)

:

P (kW): capacity = 1000 kW

H

(kWh/m3):

u

lower calorific value of gas type = 10 kW/m

P (kW)

(kWh/m3)

H

u

3

Q

(N)

Q

(m3/h) =

(N)

(m3/h) =

1000 kW

10 kWh/m

3

= 100 m3/h

Max. gas volume in combustion chamber VO:

VO (l/h) = Q

(m3/h): nominal flow rate = 100 m3/h

Q

(N)

× 0.05%

(N)

(100,000 l/h)

VO (l/h) = 100,000 l/h × 0.05% = 50 l/h

2

× 0.7

:

L

O

×

√

ρ

2 × p

u

Required opening time t

400 × V

tL (s) =

π × d

VO (l/h):

max. gas volume in combustion chamber = 50 l/h,

d (mm): orifice diameter of bypass valve = 9.45 mm,

flow factor = 0.7,

pu (mbar): inlet pressure = 20 mbar,

ρ (kg/m3): density of gas = 0.8 kg/m

400 × 50 l /h

tL (s) =

3.14 × 9.452 × 0.7

×

√

3

0.8 kg/m

3

2 × 20 mbar

= 14.26 s

Enter the next lowest value for parameter 59 (P59 = 14)

to set the opening time, see page 112 (Valve opening

time 1 t

Calculation module for calculating the opening time t

L1

).

L

see page 52 (Calculating the extended valve opening time)

,

FCU 500, FCU 505 · Edition 02.17 51

Page 52

Valve proving system

Erdgas H

914

BTU/scf

0,049

lb/ft3

3782000

BTU/h

40,0

"WC

3531

SCFH

13,2

Gallon

VAS 6 bis 9

0,70

inch2s

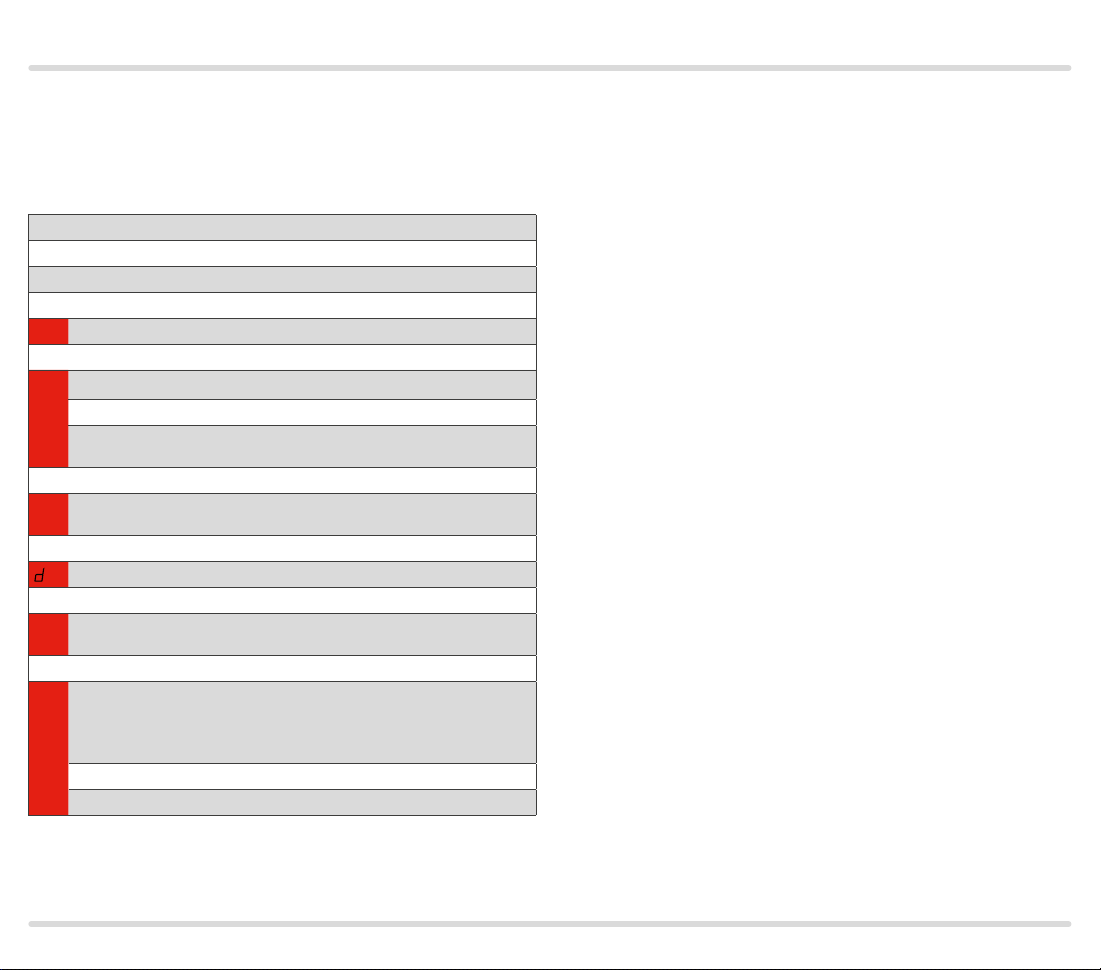

Calculating the extended valve opening time

Metric Imperial

Gas type

Lower calorific value

Density ρ

Capacity P

Inlet pressure p

Nominal flow rate Q

u

(N)

Max. gas volume

in combustion chamber VO

VAS 1 on main valve

or orifice diameter d

Opening time t

L

The calculation module can be used to calculate the

opening time tL for the bypass valves (e.g. VAS 1 or bypass valves with additional orifice) by entering the gas

type, calorific value, density, capacity, inlet pressure

and orifice diameter.

Set the next lowest value for parameter 59 to set the

opening time, see page 112 (Valve opening time 1

t

).

L1

FCU 500, FCU 505 · Edition 02.17 52

Page 53

Valve proving system

▼

7.2.5 Measurement time tM

The sensitivity of the tightness control in the FCU can

be adjusted for each individual system by adapting the

measurement time tM. The longer the measurement

time tM, the greater the sensitivity of the tightness

control. The measurement time is set using parameters 56 and 57 to a value between 3 and 3600 s – see

page 110 (Measurement time Vp1) and page 110

(Measurement time Vp1 and Vp2).

The required measurement time tM is calculated from:

Inlet pressure pu [mbar]

Leakage rate QL [l /h]

Test volume Vp1 + Vp2 [l]

Calculation of the test volume – see page 54 (Test

volume Vp)

For one test volume V

valves or for system tightness)

Adjustable using parameter 56

[s] =

t

M

(between 2 gas solenoid

p1