Page 1

E8.5064 V1

System Manager

Operating instructions

Please observe the safety instructions and

read through this manual carefully before

commissioning the equipment.

Page 2

Safety information General information

General information

Safety information

Power connection regulations

Please note the connection conditions specified by your

local electrical power supply company and the VDE

regulations.

Your heating control system may only be installed and

serviced by appropriately authorised specialists.

E If the system is not installed properly, persons using it

are at put at risk of fatal or serious injury.

Warranty conditions

If the system is not installed, commissioned, serviced and

repaired properly, it will render the manufacturer's warranty

null and void.

Important text passages

! Important information is highlighted by an

exclamation mark.

E This attention symbol indicates dangerous situations.

Note

! The operating manual describes the maximum

version of the controller, meaning that not all

statements are relevant for your device.

Description

Declaration of conformity

This device corresponds to the requirements

of the relevant guidelines and standards, if the

corresponding regulations and the manufacturer's

instructions are complied with.

Function

The device contains a number of functions and must be

set in accordance with use. The following functions are

mapped in the System Manager:

• Cascade modulating HS

• Cascade modulating HS

• Control of 2 HS or 2-stage HS via relay

• Water heating, 2 mixed heating circuits, as well as 2

extra functions

• Demand-related circulation pump control

• Automatic toggle between summer and winter time

• Activation of a timer is possible

2

Page 3

General information Contents

Contents

General information 2

Safety information 2

Power connection regulations 2

Warranty conditions 2

Important text passages 2

Note 2

Description 2

Declaration of conformity 2

Function 2

Contents 3

Part 2: Overview of display values and settings 14

Installation 13

Hot water 13

Heating circuit I / II 13

Solar/MF 13

General area 14

Date/Time/Holiday 14

Service 16

Code number Entry 16

RELAY TEST 16

SENSOR TEST 17

Part 1: Operation 8

Operation in normal mode 8

Operating elements 8

Ç Operating mode selection 8

Effect of the operating mode 9

Display in normal operation 10

Changing the settings 11

Operating elements 11

Operating level 12

Areas 13

General 13

Display 13

User 13

Time programs 13

Expert 13

Expert FA (only for FA via BUS) 13

Levels 13

SW NO XXX-XX 18

CASC MANUAL (only with code no.) 18

BURNER TIME and BURNER START 18

LIMITER TEST 18

SERVICE 19

RESET … 19

Display Range 20

INSTALLATION 20

T-OUTSIDE 20

EXT SETPOINT 20

T-HEADER DES (Heat requirement) 20

T-HS 1

(and T-HS 2 – 8 where cascades apply) 20

BUFFER-T/M/B 20

MOD DEPTH

(only in the case of HS via BUS connection) 20

Hot water 21

3

Page 4

Contents General information

T-DHW L (storage tank lower temperature) 21

T-ROOM DES A

(current value for set room temperature) 21

T-ROOM (room temperature) 21

Solar/MF 22

Solar integration 22

T-MF(1-4) 22

User Area 23

INSTALLATION 23

GERMAN => Language 23

CONTRAST 23

DISPLAY SEL 23

SELECT PROG 23

Hot water 24

1X DHW (1x Hot water) 24

T-DHW 1-3 DES

(Hot water temperature setting) 24

BOB-VALUE (Operation Without Burner) 24

CIRCL-P-DHW (Circulation with hot water) 24

ANTILEGION

(Hot water short time heating function) 24

Heating circuit I / II 25

MODE 25

T-ROOM DES 1-3 25

T-REDUCED 25

T-ABSENCE 25

T-LIMIT DAY/T-LIMIT N (Day/Night) 26

HEATSLOPE 26

ADAPTION (Heat slope adaptation) 27

ROOM INFL (Room sensor influence) 27

T-ROOM ADJ (room sensor adaptation) 27

OPT HEAT UP (Heating optimisation) 28

MAX OPT-TIME (Maximum bring-forward) 28

OPT REDUCED (Reduction optimisation) 28

PC-ENABLE 28

RETURN 28

Timer Program Area 29

List of available time programs 29

Selecting a timer program 29

Timer/heating program adjustment 30

Expert area 33

INSTALLATION 33

CODE-NO 33

BUS-ID HS (- - - -) 33

BUS ID 1 / 2 (Heat circuit number) 33

AF SUPPLY (Outdoor sensor power supply) 33

BUS TERMIN (Bus terminating resistor) 33

EBUS SUPPLY (supply for eBUS) 34

TIME MASTER 34

MAX T-HS1/2 (Max. temperature HS) 34

MIN T-HS1/2 (min temperature HS) 34

MAX/MIN T-HEADER (only for cascades) 34

0-10 V Function 35

V-CURVE (only for 0-10V input/output) 35

CURVE 11-xx 35

T-WARM UP (Warm-up relief) 36

MIN DELIMI (minimum delimiter HS) 36

4

Page 5

General information Contents

HYSTERESIS

(Dyn. switching hysteresis stage 1) 36

with HYST TIME (Hysteresis time) 36

DETECTED HSS (number of heat generators) 37

CAP/STAGE (boiler output for each stage) 37

NEW CONFIG (new BUS configuration) 38

MIN MOD CASC (min. modulation cascade) 38

HW-BOILER

(number of stages for HW operation) 38

CONTROL DEV (header control variance) 38

DES OUTPUT (required system output [in %]) 38

SWITCH VALUE (-99 – +99) 38

BLOCK TIME (currently remaining value) 38

RESET TIME (resetting time for I-Controller) 39

MODULAT MAX 39

MODULAT MIN 39

MIN MOD HS 39

MODULAT DHW (only for HW-boiler) 40

SEQUENCE 1 (boiler sequence 1) 40

SEQUENCE 2 (boiler sequence 2) 40

SEQU CHANGE (sequence change mode) 40

SEQ SW TIME(time to sequence change) 41

BLOCK-TIME (delay time for next stage) 41

HYST BURNER2 (for solid fuel / 2. burner) 41

HS COOL-FCT (cooling function for boiler) 41

with T-HS COOL

(starting temperature for cooling) 41

Switching pattern for 2-stage burners 42

HS 1 TYPE (primary heat generator type) 43

HS1 BUS (connection for HS) 43

HS 2 TYPE

(secondary heat generator type HS => A7) 43

STORAGE HS2 (heat accumulator for HS2) 43

BUFFER (heater buffer storage type) 44

Screed program 45

SCREED (activation of screed drying process) 45

Hot water 46

DHW RELIEF (Charge pump blocking) 46

PARALLEL DHW (Pump parallel running) 46

T-HS DHW (increase during HW operation) 47

HYST DHW (hot water hysteresis) 47

DHW FOLLOWUP (pump run-down time) 47

THERM INPUT (storage tank with thermostat) 47

WALL HUNG (for modulating HS) 47

LOAD THROUGH (only with F12 = T-DHWLOWER) 47

Heating circuit I / II 48

HC FUNCTION

(heating circuit function selection) 48

PUMP MODE (pump operating mode) 49

MIXER OPEN (open mixer dynamic) 49

MIXER CLOSE (close mixer dynamic) 50

MAX T-FLOW (max. flow temperature) 50

MIN T-FLOW (min. flow temperature) 50

T-FROST PROT (frost protection temperature) 50

T-OUT DELAY (outside temperature delay) 50

SLOPE OFFSET (heating slope distance) 51

B-HEAT SINK (circuit enable) 51

5

Page 6

Contents General information

Auxiliary relay functions 52

FUNC RELAY 1 (function selection relay MF1) 52

T-MF1 SETP

(switching temperature relay MF1) 52

MF 1 HYST (hysteresis relay MF1) 52

F15 FUNCTION (sensor function F15) 55

Part 3: General function description 56

Heat circuit control 56

Weather-dependent control 56

Room sensor influence 56

Hot water generation 56

OwB => operation without burner 56

Frost protection function 56

eBUS burner controls 57

EEPROM check 57

Circulation pump control 58

Switched according to heating requirement 58

Switched according to heating limits 58

Delayed pump switch-off 58

Pump blocking protection 58

Mixer motor blocking protection 58

Part 4:Appendix 59

Remote controls 59

Operation-control module Merlin BM, BM 8,

Lago FB 59

Remote control FBR2 59

DCF receiver 60

PC 60

Telephone switch 60

System bus 61

The heating system 61

Error messages 62

Troubleshooting 63

Technical data 64

6

Page 7

General information Contents

7

Page 8

Operation in normal mode Part 1: Operation

Part 1: Operation

Part 1: Operation

For initial start-up or the "level Installation"

please read the installation manual.

Operation in normal mode

Operation in normal mode

Ç Operating mode selection

Turn the knob to select the operating mode required. The

operating mode selected is indicated by a symbol at the

bottom of the display. It takes effect when the setting is not

changed for 5 s.

The following operating modes are available for selection:

(operating flap closed)

Operating elements

Ç Change the set operating mode

8

i Standby / OFF

(Heating OFF and hot water preparation OFF,

only frost protection mode)

F1 Automatic mode 1

(Heating according to timer program 1; HW according to

HW program)

F2 Automatic mode 2

(Heating according to timer program 2; HW according to

HW program)

h Day mode

(24 h heating with comfort temperature 1; HW according to

HW program)

C Night mode

(24 h heating with reduced temperature; HW according to

program)

F Summer mode

(Heating OFF, HW according to HW program)

Page 9

Part 1: Operation Operation in normal mode

W Service (automatic reset after 15 min)

Boiler regulated at Boiler temperature = max. boiler

temperature= see page 34 ; when the boiler temperature

has reached 65°C, the consumers are regulated to their

flow temperature to dissipate heat (cooling function).

! The cooling function must be explicitly enabled in

the consumer circuits by means of a set value.

Effect of the operating mode

The operating mode set here affects the boiler regulation

and the integrated heating circuits of the controller.

Each heating circuit can be assigned a separate operating

mode from the one set by means of the "operating mode"

parameter in the user level of the corresponding heating

circuit.

When the "i = Standby/OFF", and "F = Summer mode"

operating modes are set, they have a reducing effect on

system controllers with respect to all heating circuits and

consumer circuits in the entire system.

! For mixer controllers the reduction of operating

mode is only effective for internal heating circuits.

9

Page 10

Operation in normal mode Part 1: Operation

A

Display in normal operation

B

I

C

24

18

12

D

D

6

F

2

F

E

G

H

! Due to the tolerances of sensors, deviations of

+/- 2K (2°C) are normal between various

temperature displays. Temperatures which change

rapidly can have higher deviations for short periods

due to the different time-related behaviour of various

sensors.

! The display of the current heating program applies

to the device's first heating circuit.

In case of having two heating circuits the display can

be set to the 2nd circuit

Explanations

A Current time

B Freely selectable display

(refer to "DISPLAY SEL" parameter)

C DCF reception OK

(only if receiver is connected via eBUS)

D Bus icon (if this icon does not appear, check data

line to connected CAN controllers

=> check eBUS via DISPLAY level)

E Display of the active heating program for the first

heating circuit

(here: 6:00 to 08:00 hrs and 16:00 to 22:00 hrs)

F Status display: H internal burner 1 relay ON;

D heating mode; F hot water preparation

G Mode selector switch, the display applies to all

internal heating circuits for which a separate

operating mode has been selected via the "MODE"

set value (here: F

=> Heating according to timer

2

program 2).

H Display of current temperature of HS 1 or header

temperature in the case cascades

I Display of numbers of active heat generators

(only applies to cascades)

! With HS1 BUS = 5 is indicated firmly here 0

10

Page 11

Part 1: Operation Changing the settings

Changing the settings

The operating flap must be opened first in order to change

Operating elements

or request set values.

=> Controller switches to Operation mode

Ç A => Shaft encoder

Search for value/level or adjust value

Ä B => Programming key

• Select a value level

• Select a value level to change

• Save a new value

C => Change display

LED ON => The value in the display can be changed by

actuating the shaft encoder (A).

F

a Display indicating the current level

b Holes to unlock the controller fixation.

Insert a thin screwdriver deep into the holes and

then lift up the controller.

x

In Manual mode, all the pumps and first burner stage are

switched on. The mixers are not changed / accessed

(“DISPLAY EMERGENCY OPERATION”).

Limitation (switch-of with 5K hysteresis):

• Burner => MAX T-MODULE (expert)

• Heating circuit pumps => MAX T-FLOW (expert)

• Cylinder charging pump => T-DHW I (user)

E Caution, overheating, e.g. with floor or wall heating! =>

E => PC connection via optical adapter

D => Manual-Automatic switch.

Set mixer by hand!

11

Page 12

Changing the settings Part 1: Operation

Operating level

SERVICE

Open

operating

flap

INSTALLATION

HOT WATER

HEAT CIRCUIT I

HEAT CIRCUIT II

INSTALLATION

HOT WATER

HEAT CIRCUIT I

HEAT CIRCUIT II

CIRCL TIME

HOTW-PROG

INSTALLATION

HOT WATER

HEAT CIRCUIT I

HEAT CIRCUIT II

Expert FA INSTALLATION

General

DATE/TIME/HOLIDAY

Ç Turn anticlockwise

Ç Turn clockwise

Display

SOLAR/MF

User

SOLAR/MF

Time programs

HTG-PROG ID 1

etc...

Expert

SOLAR/MF

Ê

Ì

Operation is divided into different areas:

General - Display - User - Time programs – Expert Expert FA.

Opening the hinged control panel cover automatically

takes you to the display and indicator area.

• The current area "DISPLAY" appears in the display for

a short time (1 clock circuit).

• After the clock circuit the display switches to the

current operating level "INSTALLATION".

• This is displayed for a short time (1 clock circuit) when

you switch to a new area.

Ç Select the level in which the value to be adjusted or

displayed can be found using the rotary knob.

Ä Press Prog button! =>

Open / select level

Ç Search for value using rotary knob

Ä Press Prog button! => Select value

LED lights up => adjustment can now be made

Ç Modify value using rotary knob

Ä Press Prog button! => Store value - LED goes off

When the operating flap is first opened after voltage is

applied, the level SETUP is displayed once only

the values grouped here have been set the controller

is operable.

. Once

12

Page 13

Part 1: Operation Changing the settings

Areas

General

Value selection summary

Service => for service engineers

Date/Time/Holiday => for users

Display

System value display (e.g. sensor values and setpoints).

No adjustments can be made. Operating errors are

therefore excluded in this area.

User

Summary of settings that can be made by the operator.

Levels

The settings in the different areas are sorted into operating

levels

• INSTALLATION

• HOT WATER

• HEATING CIRCUIT I

• HEATING CIRCUIT II

• SOLAR/MF

Installation

All display values and settings that relate to the heat

generator or the entire system and cannot be assigned to

a consumer circuit.

Hot water

Time programs

Summary of time programs for heating circuits, the hot

water circuit and extra functions where applicable

Expert

Summary of values for which expert knowledge is required

to make settings (installation technician).

E Values in the expert level are protected by a code no.

(damage/malfunction possible).

Expert FA (only for FA via BUS)

Summary of values transmitted by the automatic firing

device.

All display values and settings that affect central hot water

preparation and circulation.

Heating circuit I / II

All indicator and set values that relate to the corresponding

consumer circuit (also, for example, as decentral hot-water

circuit).

Solar/MF

All indicator and set values that relate to solar energy

recovery and settings for the multifunction relay.

! An overview of all settings can be found on the

following pages.

13

Page 14

General area Part 2: Overview of display values and settings

Part 2: Overview of display values and settings

Part 2: Overview of display values and settings

General area

(Select main level using Ç and open with Ä)

Date/Time/Holiday

This area contains a series of different values in order to

provide rapid access.

(Select values/value group using Ç and open with

Ä)

Date/time => Value group

(General -> Date/Time/Holiday level)

All the values in this group are set in sequence =>

adjust using Ç => continue with Ä

TIME

(Minutes)

TIME

(Hours)

Current minutes blink and can be

adjusted

Current hours blink and can be

adjusted (seconds are set to "00"

when stored)

YEAR Adjust current year

MONTH Adjust current month

DAY Adjust current day (date)

~ Hinged cover OPEN Î search for level to the left with Ç,

open with

Ä

! If a heating system controller has been set to be the

TIME MASTER (time setting for all controllers, see

EXPERT/INSTALLATION) or a DCF (Radio time

receiver) has been installed in the system, the time

is blanked out on all the other controllers in the

system.

! There may be a time difference of up to 2 minutes

per month (correct time if necessary). If a DCF

receiver is connected the correct time is always

displayed.

The current weekday is calculated automatically. Checking

can take place using the selectable additional display in

the standard display => set to "Day"

It is possible to change from summer to winter time by

entering the date.

14

Page 15

Part 2: Overview of display values and settings General area

Holiday => Value group

(General -> Date/Time/Holiday level)

All the values in this level are set in sequence => adjust

using Ç => continue with Ä

YEAR START Set current holiday start year

MONTH START Set current holiday start month

DAY START Set current holiday start day

YEAR STOP Set current holiday end year

MONTH STOP Set current holiday end month

DAY STOP Set current holiday end day

Summer time => Value group

(General -> Date/Time/Holiday level)

All the values in this level are set in sequence => adjust

using Ç => continue with Ä

MONTH START Set month for start of summer time

DAY START Set earliest day for start of summer

time

MONTH STOP Set month for start of winter time

DAY STOP Set earliest day for start of winter time

! Please do not enter the day of travel as the start

date, but the first day of the holiday (no more

heating from this day).

! Please do not enter the day of travel as the end

date, but the last day on which there is to be no

heating. When you arrive home the house should be

warm and there should be hot water.

! Stop holiday function => e.g. for early return by

pressing the program switch.

! Not with Time Master or DCF

! The default setting is valid for Central European time

zones. A modification is only required if the date for

the time change is changed by political decree.

! The earliest date on which the change will occur

must be set. The controller performs the time

change on the Sunday following this date at 2.00 am

or 3.00 am.

! If no time change is required, please set

MONTH STOP to the same value as MONTH

START and DAY STOP to the same value as

DAY START.

15

Page 16

General area Part 2: Overview of display values and settings

Service

This area contains values for the customer service

engineers in order to provide rapid access.

(Select operating level using Ç and open with Ä)

Relay test => Value group (code no. required)

(General -> Service level)

Select relay using Ç => relay switches

00 No relay

01 A1: Pump, heating circuit 1

02 A2: Pump, heating circuit 2

03 A3: Hot water charging pump

04 A4: Mixer OPEN, heating circuit 2

05 A5: Mixer CLOSED, heating circuit 2

06 A6: HS 1 ON

07 A7: HS2 ON [2-stage:HS 1+2 (after 10s) ON]

08 A8: Mixer OPEN heating circuit 1 / Multifunction 1

09 A9: Mixer CLOSED heating circuit 1 / Multifunction 2

10 A10: Multifunction 3

11 A11: Collector pump / Multifunction 4

~ Hinged cover OPEN Î search for level to the left with Ç,

open with

Ä

A code number must be entered for this function.

Ä Select Relay Test => "Code number" level

Code number Entry

Ä Start code number entry => [LED]

Ç Select 1st digit

Ä Confirm entry

Ç Select 2nd digit

Ä Confirm entry

Ç Select 3rd digit

Ä Confirm entry

Ç Select 4th digit

Ä Confirm entry

=> "Relay Test"

RELAY TEST

Ä Start relay test

Ç Select relay => Relay switches

Ç Select next relay or use

Ä to stop relay test

16

Page 17

Part 2: Overview of display values and settings General area

SENSOR TEST

Start sensor test with Ä, use Ç to select sensor =>

temperature is displayed; Use Ä to stop sensor test

Sensor test => Value group

(General -> Service level)

Select sensor using Ç => value is displayed

F1 Buffer storage temperature Lower

F2 Buffer storage temperature middle or

room temperature heating circuit 1

F3 Upper buffer storage temperature

F5 Flow temperature, heating circuit 2

F6 Upper hot water temperature

F8 Heat generator /header temperature

F9 Outside temperature

F11 Flow temperature heating circuit 1

or temperature multifunction 1

F12 Hot water temperature lower or temperature

multifunction 2

F13 Solid fuel boiler temperature or collector 2

or temperature multifunction 3

F14 Collector 1 temperature or

temperature 4

F15;

Light;

0-10V I

Room temperature heating circuit 2 or

measured value of the light sensor or

voltage value 0-10V input

17

Page 18

General area Part 2: Overview of display values and settings

Other entries

(General -> Service level)

Select value using Ç => value is displayed

SW NO XXX-XX Software number with index

CASC MANUAL

(1-8; only with code

no.)

BURNER TIME (1-8)

BURNER START (1-8)

LIMITER TEST (1-8) Safety temperature limiter test

SERVICE

(only with code no.)

RESET USER 00 Load user parameter factory

RESET EXPERT 00

(only with code no.)

RESET T-PRG 00 Load time program factory

RETURN

Starting different burner stages of

the cascade

Ä Burner time for all stages

Ä Burner start for all stages

with heat generator temperature

display

Start with Ä (hold down)!

Input of date or operating hours

for service messages

settings (except language)

Load expert parameter factory

settings (except sensors)

settings

Exit level using Ä

SW NO XXX-XX

Display software number with index (please specify if you

experience problems / have questions about the controller)

CASC MANUAL (only with code no.)

(only for cascades and only in that operating mode

“Service“ => see operating mode selection)

With Ä open level and select burner stage using Ç.

After the heat generator Ä has been selected the output

for this heat generator can be set.

With respect to multi-stage heat generators, the second

stage can be activated by means of presetting an output

value > 50%.

After closing the service functions the entries are reset

automatically .

BURNER TIME and BURNER START

Ä => Display of current value ÄReturn

Hold down Ä until indicator "RESET" goes out => Reset

display

LIMITER TEST

Use Ä to open level and select heat generator with Ç.

=> Display heat generator temperature.

Ä Hold down prog. button until LIMITER activates

Burner I ON

all pumps OFF

all mixers CLOSE

The temperature can be observed in the display.

18

Page 19

Part 2: Overview of display values and settings General area

SERVICE

Input of values for the yearly service message or operating

hours.

Delete active maintenance display

:

Open control panel cover, press prog. button ÄÄ, set

repeat value to "00" using Ç and confirm with Ä.

Delete programmed annual message:

In the General/Service level, set value for

SERVICE=>DAY or

SERVICE => OPERATNG HOURS to hyphens.

RESET …

The three value groups can be reset to the factory setting

using the Reset function.

Select function using Ä, set to "01" using Ç and confirm

with Ä.

19

Page 20

Display Range Part 2: Overview of display values and settings

Display Range

! Display only - no adjustment possible. Display only

appears if the sensor is connected and the value is

present in the system, otherwise "----" or no display.

INSTALLATION

(HS => heat generator) use Ç to select parameters

T-OUTSIDE Outside temperature

EXT SETPOINT External set value specification (0-

10V)

T-HEADER DES HS / Header set value (cascade)

T-HEADER HS / Header temperature (cascade)

T-HS

T-SOLID FUEL For HS2 = Solid fuel boiler (A7)

T-RETURN 1 Return flow temperature of HS 1

T-RETURN 2 Return flow temperature of HS 2

T-BUFFER T Buffer storage tank temperature

T-BUFFER M Buffer storage tank temperature

T-BUFFER B Buffer storage tank solar zone

T-STORAGE 3 Temperature of storage tank 3 (e.g.

MOD DEPTH 1-8 Modulation degree of HS (BUS)

RETURN

Level Ä => Temperature and Status

of the HS (HS 1 – HS 8)

removal

charging zone HS

solar pool-heating)

Exit level using Ä

T-OUTSIDE

The measured outside temperature is smoothed for control

purposes. The smoothed value is displayed here.

EXT SETPOINT

The 0-10V input can be used to preset an accumulative set

value for the control system (see V-CURVE p. 35).

T-HEADER DES (Heat requirement)

Corresponds to the maximum required temperature of the

consumer circuits from the heating system (incl. hot water

preparation). The mixer circuits request the temperature +

heating curve distance (expert value)

T-HS 1 (and T-HS 2 – 8 where cascades apply)

Measured current temperature of the corresponding heat

generator. Additionally it is indicated whether the heat

generator is switched on ( H ), in the case of two-stage

heat generators the status of the second stage is also

displayed ( II H ).

BUFFER-T/M/B

(only if buffer storage is installed)

Buffer storage tank temperatures in the discharge area,

the charging area and the infeed of alternative energy.

MOD DEPTH (only in the case of HS via BUS

connection)

Only if a modulating heat generator is connected via BUS

and transmits this value.

20

Page 21

Part 2: Overview of display values and settings Display Range

Hot water

T-DHW DES Current hot water set temperature

according to heating program and

operating mode

T-DHW Current hot water temperature

T-DHW L Temperature of HW tank in the lower

section (infeed)

T-CIRCL Return flow temperature of the circulation

RETURN

Exit level using Ä

Heating circuit I / II

T-ROOM DES A Current room set temperature

according to heating program and

operating mode

T-ROOM Current room temperature

HUMIDITY ***)

T-POOL DES *)

T-POOL *) Current swimming pool temperature

T-DHW DES **)

T-DHW **)

T-FLOW DES Current flow temperature setting

T-FLOW Current flow temperature

N-OPTI-TIME Previous time required to heat up

RETURN

Display of room humidity (if value is

available)

Swimming pool temperature setting

Hot water temperature setting

Current hot water temperature

with heat-up optimisation activated

Exit level using Ä

! Display only appears if the sensor is connected and

the value is present in the system.

If the set value is not present it is masked out, or

hyphens appear in the display (- - - -).

T-DHW L (storage tank lower temperature)

For example for solar infeed or for active charge-through

function (CHARGE-THROUGH = 01). Display hot-water

tank temperature in infeed area.

T-ROOM DES A (current value for set room

temperature)

If a control unit is connected there will be no display

"- - - -" => display on control unit

T-ROOM (room temperature)

Only if a sensor or a FBR is connected.

*) These values only appear if the heating circuit is

programmed as a controller for the pool.

**)These values only appear if the heating circuit is

programmed as a hot water circuit.

***) These values only appear if an operating device is

connected and parameters have been set for the

corresponding heating circuit.

“- - - -„ => no humidity sensor available in control device

21

Page 22

Display Range Part 2: Overview of display values and settings

! This page only displays those parameters where the

corresponding functions have been implemented

and activated.

Solar/MF

T-MF1 Temperature MF sensor 1 (=F11)

T-MF2 Temperature MF sensor 2 (=F12)

T-MF3 Temperature MF sensor 3 (=F13)

T-MF4 Temperature MF sensor 4 (=F14)

T-SOL PANEL 1 Temperature collector 1

T-DHW Upper hot water temperature

T-DHW L Hot water temperature infeed

RETURN

Exit level using Ä

Solar integration

See the description for multifunction 1-4 under Expert.

T-MF(1-4)

A sensor is assigned to the four available multifunction

relays respectively. If the sensor is not used by another

standard function, a function that requires the sensor may

be selected for the relay. In this case the measured value

is displayed here.

In some special cases, e.g. when selecting the functions

"return flow temperature increase“ or "collector pump“ the

measured value is additionally displayed as T-RETURN

under installation or as T-SOL PANEL under Solar/MF

22

Page 23

Part 2: Overview of display values and settings User Area

User Area

All the settings that can be made by the operator of the

system.

INSTALLATION

All settings that cannot

be assigned to a consumer circuit

(consumer circuits: heating circuits and HW).

Ä Select value, Ç adjust and Ä save

Designation Value range Default IV*)

GERMAN Acc. to version GERMAN

CONTRAST (-20) – (20) 00

DISPLAY SEL Sensor, weekday, ... - - - -

SELECT

PROG

RETURN

Heating circuit 01,

Heating circuit 02

Exit level using Ä

01

*) IV = Internal Values:

Space for entering the parameters stored in the system!

*) only with remote control connected

**) only if corresponding configuration applies

~ Hinged cover OPEN Î search for level to the right with Ç,

open with

Ä

GERMAN => Language

Select controller language

CONTRAST

Adjust intensity of display

DISPLAY SEL

Select additional display in standard operation

- - - - => no additional display

WEEKDAY => Day of week (Mo, Tu, We, ....)

T-OUTSIDE => Outside temperature

T-FLOW D 1 => Flow temperature,

heating circuit 1

T-FLOW D 2 => Flow temperature,

heating circuit 2

T-DHW => Hot water temperature (upper)

T-HS => Heat generator temp

T-ROOM D 1 => Room temperature,

heating circuit 1=> *)

T-ROOM D 2 => Room temperature 2=> *)

T-SOL PANEL 1 => Collector 1 temperature => **)

SELECT PROG

Select heating circuit whose heating program is shown in

the standard display.

23

Page 24

User Area Part 2: Overview of display values and settings

Hot water

Designation Value range Default IV

1X DHW 00, 01 (OFF/ON) 00 = OFF

T-DHW 1 DES 10°C - 70°C 60°C

T-DHW 2 DES 10°C - 70°C 60°C

T-DHW 3 DES 10°C - 70°C 60°C

BOB-VALUE 0K – 70K 0 K

CIRCL-P-DHW 00, 01 (OFF/ON) 00 = OFF

ANTILEGION 00, 01 (OFF/ON) 00 = OFF

RETURN

Exit level using Ä

Hot water short time heating function

T-DHW 1-3 DES (Hot water temperature setting)

Required hot water temperature setting

T-DHW 1 DES => used in first enable time,

T-DHW 2 DES => used in second enable time ,

T-DHW 3 DES => used in third enable time of hot water

program.

Special application – flow heater

Without storage tank sensor connection, this function is

available for external boilers with bus connection.

T-DHW 1 => in operation 24 hours

BOB-VALUE (Operation Without Burner)

Energy saving function for solar or solid fuel integration

For settings > "0" the burner is not activated for hot water

preparation until the hot water temperature has dropped

ANTILEGION = 01 => Every 20th time that heating takes

place or once per week on Saturday at 01:00 hrs the

below the temperature setting by the set value + the

switching hysteresis.

storage tank is heated up to 65°C.

! Alternative external energy sources with a bus

It is possible to set up your own hot water short time

heating function using the third hot water enable facility.

1X DHW (1x Hot water)

01 => The storage tank is enabled for charging

(e.g. for showering outside hot water times).

Charging starts when the temperature falls below

"temperature setting 1" by the switching hysteresis. After

charging, the value is automatically set to "00“ .

connection may affect this function (e.g. SD3-Can).

CIRCL-P-DHW (Circulation with hot water)

01 => The circulation pump runs when the hot water is

enabled, but the circulation program is disabled.

ANTILEGION (Hot water short time heating function)

01 => Activation of hot water short time heating function

24

Page 25

Part 2: Overview of display values and settings User Area

Heating circuit I / II

Designation Value range Default IV

MODE

T-ROOM DES 1*)

T-ROOM DES 2*)

T-ROOM DES 3*)

T-REDUCED*)

T-ABSENCE 5°C - 40°C 15°C

T-LIMIT DAY ----, (-5)°C–40°C 19°C

T-LIMIT N ----, (-5)°C–40°C 10°C

HEATSLOPE 0.00 – 3.00 1,20

ADAPTION 00, 01 (OFF/ON) 00 = OFF

ROOM INFL 00 – 20 10

T-ROOM ADJ (-5.0)K – (5.0)K 0,0 K

OPT HEAT UP 00, 01, 02 00

MAX OPT-TIME 0:00 – 3:00 [h] 2:00 [h]

OPT REDUCED 0:00 – 2:00 [h] 0:00 [h]

PC-ENABLE 0000 - 9999 0000

RETURN

----,i,F1,F2,B,B

- - - -

5°C - 40°C 20°C

5°C - 40°C 20°C

5°C - 40°C 20°C

5°C - 40°C 10°C

Exit level using Ä

MODE

- - - - => The controller programming switch applies in this

case.

When setting an alternative operating mode this only

applies to the assigned heating circuit.

When the "i = Standby/OFF", and "F = Summer mode"

controller programming switch

operating modes are set,

this has a reducing effect on all heating circuits and

consumer circuits in the entire system.

T-ROOM DES 1-3

Required room temperature setting

T-ROOM DES 1 => used in first enable time,

T-ROOM DES 2 => used in second enable time,

T-ROOM DES 3 => used in third enable time of active

heating program for this heating circuit.

T-REDUCED

Required room temperature setting during night reduction

T-ABSENCE

Required room temperature setting during holidays

*) depending on function selector Heating circuit T-POOL,

T-DHW, T-FLOW-DAY or T-FLOW REDUC (see page 48)

25

Page 26

User Area Part 2: Overview of display values and settings

T-LIMIT DAY/T-LIMIT N (Day/Night)

Only valid if the function is activated => Set value

"Expert/Heating circuit/PUMP MODE= 01=> Pump

switching according to heating limit"

If the outside temperature that is measured and calculated

by the controller exceeds the heating limit specified here,

heating is disabled, the pumps switch off and the mixers

are closed. The heating is enabled again when the outside

temperature drops below the set heating limit by 1K

(= 1°C).

T-LIMIT DAY => applies during heating times

T-LIMIT N => applies during reduction times

"----" => The heating limit is deactivated. The circulation

pump is switched in accordance with the standard function

(see chapter entitled "Circulation pump control")

HEATSLOPE

The gradient of the heat slope indicates by how many

degrees the flow temperature changes if the outside

temperature rises or drops by 1 K.

Setting tip:

At cold outside temperatures, room temperature too low =>

Increase heat slope (and vice-versa)

At high outside temperature (e.g.16°C) room temperature

too low => correction via set room temperature

Flow temperature [°C]

10 0

80

60

40

Outside temperature [°C]

20

20 16 12 8 4 0 -4 -8 -12 -16

3

2,5

2

1, 5

1, 2

1

0,8

0,6

0,4

0,2

Heat slope diagram (setting aid)

Setting 0 => Room control only

! The heat slope can best be set at outside

temperatures below 5°C. The change in heat slope

setting must be made in small steps and at long

intervals (min. 5 to 6 hours) because the system

must first adjust to the new values each time the

heat slope is changed.

Guideline values

• Underfloor heating S = 0.4 to 0.6

• Radiator heating S = 1.0 to 1.5

26

Page 27

Part 2: Overview of display values and settings User Area

ADAPTION (Heat slope adaptation)

Only active if an FBR analogue room device is connected

(room sensor + operating mode selection) and an outdoor

sensor.

Function for automatic heal slope setting

Starting Conditions:

• External temperature < 8°C

• Operating mode is automatic (I or II)

• Duration of lowering phase at least 6 hours

At the beginning of the lowering period, the current room

temperature is measured. During the next four hours, this

temperature is used as the set point for the room regulator.

The heating curve is calculated from the values

determined during this time by the regulator for the flow

pipe nominal temperature and the external temperature.

! If the adaptation is interrupted, e.g. by a start-up

discharge or the hot water demand from an external

heating circuit, then the warning triangle will appear

in the display until the function is carried out

successfully the next day or is ended, e.g. by

adjusting the operating mode switch.

ROOM INFL (Room sensor influence)

Only active if an FBR analogue room device is connected

(room sensor + operating mode selection).

The boiler temperature is increased by the set value when

the temperature drops below the required room

temperature by 1K.

=> High values lead to fast control and large boiler

temperature fluctuations.

- - - - => pure weather-dependent control

0 => pure weather-dependent control *)

20 => pure room temperature control

*) Special function with ROOM INFL = 0

For one-off heating requirements during the night reduction

the heating pump continues to run until the next heating

period is reached (see chapter entitled "Circulation pump

control").

T-ROOM ADJ (room sensor adaptation)

In the case of room control (e.g. with FBR) the

measurement can be corrected using this setting if the

room sensor is not measuring correctly.

! During the adaptation, the water heating and the

heating optimisation of the regulator are blocked.

27

Page 28

User Area Part 2: Overview of display values and settings

OPT HEAT UP (Heating optimisation)

Activation of function for automatically bringing forward the

start of heating.

Example: Heating program 6.00 hrs – 22.30 hrs

OFF: Building starts to be heated at 6.00 hrs.

ON: Depending on weather and room temperature,

heating starts soon enough so that building just reaches

the set room temperature at 6.00 hrs.

00 => start of heating not brought forward

01 => brought forward depending on weather

02 => brought forward depending on room temperature *)

*) Only active if an FBR analogue room device is

connected (room sensor + operating mode selection).

The burner is not restarted before the end of the heating

period during the set time period (last heating time only) if

it not already in operation.

This function prevents short-term heating of the heat

generator to the end of the heating period.

PC-ENABLE

Code number for enabling access to heating circuit data

from a PC

"0000" => access is blocked.

RETURN

Exit heating circuit level => Return to "User" area.

! Warm-up optimisation occurs only if the reduced

time of the heating circuit is at least 6 hours.

MAX OPT-TIME (Maximum bring-forward)

Only active with "OPT HEAT UP = 01 or 02"

The start of heating is brought forward by no more than

this time.

OPT REDUCED (Reduction optimisation)

Automatic reduction of burner disabling to end of set

heating time.

28

Page 29

Part 2: Overview of display values and settings Timer Program Area

Timer Program Ar ea

All the time programs can be set in this area.

List of available time programs

With maximum controller configuration

Select timer program using Ç Ä select timer program for

display or adjustment

CIRCL TIME Prg for circulation pump

HOTW-PROG Prg for hot water charging pump

HTG-PROG 1 D 1

1st heating program for first

~ Hinged cover OPEN Î search for level to the right with Ç,

open with

Ä

Selecting a timer program

Open hinged cover => "Display => System",

Ç to the right until clock

=> "USER => INSTALLATION",

controller heating circuit

HTG-PROG 2 D 1

HTG-PROG 1 D 2

HTG-PROG 2 D 2

RETURN

2nd heating program for first

controller heating circuit

1st heating program for second

controller heating circuit

2nd heating program for second

controller heating circuit

Exit level using Ä

Ç to the right until clock => "TIME PROGRAM

=> CIRCL TIME"

Ç Select timer program

=> e.g. "HTG-PROG 2 D 1"

= Heating program 2 for controller heating circuit 1

Ä

Confirm/open timer program

=> "MONDAY"

When connecting a digital room controller with heating

program input, the corresponding heating program in this

controller is automatically superceeded.

29

Page 30

Timer Program Area Part 2: Overview of display values and settings

I

D

Timer/heating program adjustment

Ç Select weekday (Mo-Su) or block

(MO-FR => Monday-Friday, SA-SU => Saturday-Sunday,

MO-SU => Monday-Sunday)

F

2

D

I

D

F

2

B

Symbols:

I ON = First switch-on time (I OFF = first switch-off time)

20 °C = Set room temperature for displayed heating time

Clock = Approximate program display [full hours]

D 1 = Program for heating circuit 1

= Heating program 2, F1 = Heating program 1

F

2

DI = Start time 1, IB = Stop time 1, DII = Start time 2,

IIB = Stop time 2, DIII = Start time 3, IIIB = Stop time 3

Ä Open weekday/block (see left)

=> "I ON 20°C" First switch-on time – set value I = 20°C

Ç Set first switch-on time => for example 6:00 hrs

Ä Confirm first switch-on time

=> „I OFF 20°C" First switch-off time – set value I = 20°C

Ç Set first switch-off time => for example 8:00 hrs

Ä Confirm first switch-off time

=> „II ON 20°C" Second switch-on time – set value II

= 20°C

Ç Ä Switch-on and switch-off times 2 and 3 are entered

in the same way - please enter all values!

Ç Select another weekday/block for entry or exit heating

program 2 with "RETURN" and set another program.

! The heating times are not saved until all the times

for a weekday/block have been entered.

"- - - -" for a switch-on/switch-off time => The relevant

heating timer is deactivated.

30

Page 31

Part 2: Overview of display values and settings Timer Program Area

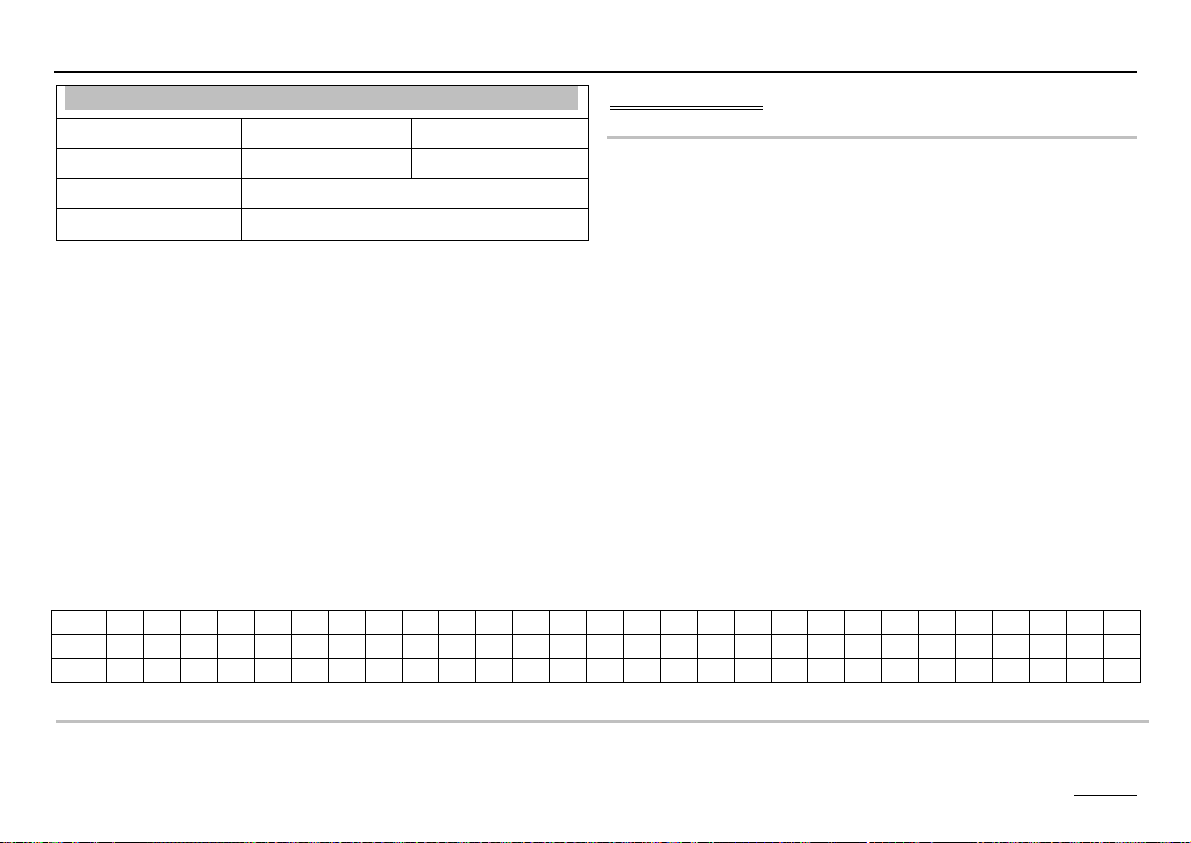

Heat circuit 1

Heating program 1 => factory setting:

Mo. to Fr.: 06:00 to 22.00

Sa. and Su.: 07:00 to 23:00

Heating time 1 Heating time 2 Heating time 3

Mo.

Tu.

We.

Th.

Fr.

Sa.

Su.

Heating program 2 => factory setting:

Mo. to Fr.: 06:00 to 08.00, 16:00 to 22:00

Sa. and So.: 07:00 to 23:00

Heating time 1 Heating time 2 Heating time 3

Mo.

Tu.

We.

Th.

Fr.

Sa.

Su.

Heat circuit 2

Heating program 1 => factory setting:

Mo. to Fr.: 06:00 to 22.00

Sa. and Su.: 07:00 to 23:00

Heating time 1 Heating time 2 Heating time 3

Mo.

Tu.

We.

Th.

Fr.

Sa.

Su.

Heating program 2 => factory setting:

Mo. to Fr.: 06:00 to 08.00, 16:00 to 22:00

Sa. and So.: 07:00 to 23:00

Heating time 1 Heating time 2 Heating time 3

Mo.

Tu.

We.

Th.

Fr.

Sa.

Su.

31

Page 32

Timer Program Area Part 2: Overview of display values and settings

Hot water

Factory setting:

Mo. to Fr.: 05:00 to 21.00

Sa. and So.: 06:00 to 22:00

Heating time 1 Heating time 2 Heating time 3

Mo.

Tu.

We.

Th.

Fr.

Sa.

Su.

Circulation

Factory setting:

Mo. to Fr.: 05:00 to 21.00

Sa. and So.: 06:00 to 22:00

Heating time 1 Heating time 2 Heating time 3

Mo.

Tu.

We.

Th.

Fr.

Sa.

Su.

32

Page 33

Part 2: Overview of display values and settings Expert area

Expert area

These settings can only be changed if the code no. is

entered (see page 16).

CODE-NO

Entering the code number (see page 16) allows all of the

expert settings to be modified => including the code

E If these values are set incorrectly, they may cause

malfunctions or damage to the system.

INSTALLATION

Designation Value range Default IV

CODE-NO 0000 - 9999 Entry

->CODE-NO Adjustment 0000

BUS-ID HS ----, 01 - 08 ----

BUS ID 1 (00), 01-15 01

BUS ID 2 (00), 01-15 02

AF SUPPLY 00.01 (Off/On) 01 = ON

BUS TERMIN 00, 01 01

EBUS SUPPLY 00.01 (Off/On) 01 = ON

TIME MASTER 00, 01 (OFF/ON) 00 = OFF

MAX T-HS1 or

30°C - 110°C 85°C

MAX T-HEADER

MIN T-HS1 or

10°C - 80°C 40°C

MIN T-HEADER

MAX T-HS2 30°C - 110°C 85°C

MIN T-HS2 10°C - 80°C 40°C

See following pages for continuation

number itself (first parameter)

(Ç on right => CODE-NO 0000 Ä

2nd digit Ä

=> Ç 3rd digit Ä=> Ç 4th digit Ä=>Ç)

=>Ç 1st digit Ä=>Ç

BUS-ID HS (- - - -)

(not an option in all models)

The controller will be used as cascade with setting "01-08".

The heating circuits are then not available anymore.

BUS ID 1 / 2 (Heat circuit number)

The heating circuits are sequentially numbered starting

with "01". heating circuit numbers must not be assigned

twice. For replacement controllers however, please enter

exactly the same heating circuit numbers as the replaced

controller.

AF SUPPLY (Outdoor sensor power supply)

Switching off the power supply to the outdoor sensor.

Switching off allows up to 5 controllers to be operated with

a single outdoor sensor. The power supply must only be

switched on if there is one controller per sensor = "01".

BUS TERMIN (Bus terminating resistor)

The bus terminating resistor must be available once in the

bus system (HS controller or cascade controller).

When installing with a CoCo, set 1 to „00“.

33

Page 34

Expert area Part 2: Overview of display values and settings

00 = OFF => The resistor is not set

01 = ON => The resistor is set

EBUS SUPPLY (supply for eBUS)

Switching the eBUS supply on / off in relation to connected

devices (power supply balance) => see part 3:

Description of functions – eBUS burner controls.

TIME MASTER

(Only without or TIME MASTER in system)

00 no time master => each heating circuit has its own time

01 controller is time master => all controllers and remote

controls take over the time settings of this controller.

MIN T-HS1/2 (min temperature HS)

Decreased condensation build-up in HS with low heat

requirements. Switching the HS off is always done earlier

when achieving the HS minimum temperature MIN T-HS +

HYSTERESIS (Standard 5K)

(see MIN DELIMI as well).

MAX/MIN T-HEADER (only for cascades)

See MAX/MIN T HS1/2.

! No more than 1 TIME MASTER is permitted in the

system!

MAX T-HS1/2 (Max. temperature HS)

Protects the HS from overheating / prevents triggering the

LIMITER.

! Caution: Also works with hot water preparation.

34

Page 35

Part 2: Overview of display values and settings Expert area

Installation

0-10 V Function

If the controller assigns the HS with the set temperature

Designation Value range Default IV

V-CURVE 00 - 11 00

CURVE 11-U1 0,00V – 10,00V 4,00V

CURVE 11-U2 0,00V – 10,00V 0,10V

CURVE 11-T1 00°C - 120°C 20°C

CURVE 11-T2 00°C - 120°C 90°C

CURVE 11-UO 0,00V – 10,00V 5,00V

See following pages for continuation

Table of voltage curves that can be chosen

through a voltage input, the 0-10V output on the controller

can be adjusted using the following parameters on the

voltage input of the HS.

If the 0-10V input of the controller is used for a temperature

requirement, the evaluation of the current signal is defined

using the same parameters.

V-CURVE (only for 0-10V input/output)

One of the defined voltage curves or free-definition curve

11 can be selected here for configuring the voltage input

and the voltage output.

CURVE 11-xx

No. U1 U2 T1 T2 UA

0 2,0 10,0 0 90 2,0

Using parameters U1, U2, T1, T2 and UO, a special

voltage curve can be defined.

1 2.5 0.3 38 80 5,0

2 2.5 0.3 38 75 5,0

3 2.5 0.3 38 45 5,0

4 4.0 0.1 20 85 5,0

5 4.0 0.1 20 75 5,0

6 4.0 0.1 20 55 5,0

7 4.0 0.1 30 87 5,0

8 4.0 0.1 38 87 5,0

U = Voltage, T = Temperature, UO = HS OFF

U1, T1 => Point 1 on the voltage curve

U2, T2 => Point 2 on the voltage curve

The line between these limit points defines the voltage

curve.

UO => Starting with this voltage, HS = OFF

(Must lie outside of the valid voltage values)

9 4.0 0.1 38 73 5,0

10 4.0 0.1 38 53 5,0

11 4.0 0.1 20 90 5,0

35

Page 36

Expert area Part 2: Overview of display values and settings

Installation

Designation Value range Default IV

T-WARM UP 10°C - 85°C 35°C

MIN-DELIMI 00, 01, 02 00

HYSTERESIS 2K – 20K 5 K

HYST TIME 00 min – 30

00 min

min

See following pages for continuation

T-WARM UP (Warm-up relief)

(Not in cascade operation)

Reduces operation in condensation zone. The circulation

pumps are switched off and the mixers are shut until the

boiler has reached the start-up temperature.

MIN DELIMI (minimum delimiter HS)

(Not in cascade operation)

Decreased condensation build-up in HS with low heat

requirements. Switching the HS off is always done earlier

when achieving the HS minimum temperature MIN T-HS +

HYSTERESIS (Standard 5K)

00 = Minimum delimiter for heat CURVE

The HS switches on if the requested temperature

has been exceeded by the using components.

01 = Minimum delimiter with heat requirement

The HS holds at least the set minimum temperature

MIN T-HS. at heating requirements

(Pump release).

02 = Permanent minimum delimiter (24) The HS holds 24h

at least the set minimum temperature MIN T-HS. at

heating requirements (Pump release).

HYSTERESIS (Dyn. switching hysteresis stage 1)

with HYST TIME (Hysteresis time)

Function for optimising boiler operation with differing boiler

loads.

The effective

switching hysteresis is reduced linearly after

the burner is switched on from the set HYSTERESIS to the

minimum hysteresis (=5K) during the hysteresis time

"HYST TIME".

Low heat consumption

In this case the higher HYSTERESIS setting takes effect.

Short run-times and frequent burner operation are

prevented.

High heat consumption

During longer periods of burner operation (high heating

load) the hysteresis is automatically reduced to 5K. This

prevents the boiler from heating to unnecessary high

temperatures.

36

Page 37

Part 2: Overview of display values and settings Expert area

Installation (only for cascades via BUS)

Designation Value range Default IV

DETECTED HSS Display only

CAP/STAGE 00 – 9950 kW 00 kW

NEW CONFIG 00.01 (Off/On)

MIN MOD CASC 00 - 100 00

HW-BOILER 00 - 08 00

CONTROL DEV [K] Display

DES OUTPUT 0-100 [%] Display

SWITCH VALUE (-99) - 0 – (99) Display

BLOCK TIME Remaining

Display

[min]

MAX T-HS 50°C – 110°C 90°C

DYN UPWARD 20 - 500 K 100 K

DYN DOWNWARD 20 - 500 K 100 K

RESET TIME 5 - 500 50

MODULAT MAX 0% - 100% 80 %

MODULAT MIN 0% - 100% 30 %

MIN MOD HS 0% - 100% 0 %

MODULAT DHW 40% - 100% 80 %

SEQUENCE 1 SEQUENCE 2 -

1 2 3 4 5 6 7 8

8 7 6 5 4 3 2 1

SEQU CHANGE 01 - 06 01

See following pages for continuation

DETECTED HSS (number of heat generators)

Display of heat generators automatically reported via BUS

with bus id (boiler no.)

CAP/STAGE (boiler output for each stage)

Display of the HS number and the stage => Selection with

Prog button => Input/Adjustment of HS output

- - - - = Stage/ Boiler not available

0 = Stage/ Boiler not active

In the case of boilers of the same power, a boiler release is

sufficient; e.g.:

HS 1 01 => 01

HS 1 02 => 01

HS 2 01 => 01 etc.

(depending on the number of boilers)

Automatic assignment:

After restarting or after a new configuration, the controller

searches the bus systems for a heat generator. Within this

time period (approx. 2 min) no manual output entries are

allowed [Display „SCAN“]. In the case that a heat

generator answers with output information, this output is

automatically entered into the list. In the case that a heat

generator answers without output information, 15kW is

entered into the list. This value can then be adjusted

manually.

37

Page 38

Expert area Part 2: Overview of display values and settings

If a boiler, which had been configured previously, is no

longer found after a restart, or after updating the parameter

CONFIG NEW, an error message is put out. Pressing

CONFIG OK after entering the performance data, the

boiler is deleted from the configuration and the error

message is deleted.

NEW CONFIG (new BUS configuration)

If the BUS configuration was modified (e.g. additional heat

generators connected), the automatic search for heat

generators on the BUS may be activated here.

MIN MOD CASC (min. modulation cascade)

Every time the cascade controller calculates a total degree

of modulation greater than null and less than MIN MOD

CASC, the total degree of modulation is set to the value

MIN MOD CASC. Simultaneously, the clock inhibition is set

to 10 seconds.

HW-BOILER (number of stages for HW operation)

00 = HW preparation via header

01 - 08 = Number of heat generators in the cascade which

are coupled out of the cascade hydraulically for hot water

preparation.

CONTROL DEV (header control variance)

Display of the header control variance

(set temperature – actual temperature).

DES OUTPUT (required system output [in %])

Display of currently required total output % (0-100)

=> Calculated set value from control system = System load

in per cent. The value is calculated, floating, and does not

take any skips caused by the switching operation into

account.

SWITCH VALUE (-99 – +99)

Internal control value => only for switching cascade!

If this value reaches "0", the next heat generator is also

connected (only after the delay time has elapsed). If the

switching value reaches "-0", the last heat generator is

switched off.

If the desired temperature is exceeded by 1K the boiler is

also switched off.

BLOCK TIME (currently remaining value)

Display of current delay time. Only if "delay = 0“ is it

possible to operate the next heat generator.

! It is essential that the HW-BOILER are at the

beginning of the BUS ID sequence => 01 - xx.

38

Page 39

Part 2: Overview of display values and settings Expert area

MAX HS-T (maximum temperature of the heat

generator)

Protects individual heat generators in the cascade from

overheating /

prevents triggering LIMITER (limiter value).

This parameter is used to set a temperature at which the

different boilers switch themselves off, or - in the case of

modulating heat generators - modulate themselves down.

The boilers are switched on again if they drop below this

temperature by 5K

! The temperature selected for MAX T-HS must be

higher than the maximum header temperature.

DYN UPWARD (dyn. heat generator connection [K])

Small value = fast connection

Large value = slow connection

E Values set too low can lead to overheating or short-

term connection of a heat generator.

Calculation: If the cumulative system deviation in Kelvin

reaches the set value A, this results in connection of all

heat generator stages.

DYN DOWNWARD (dynamic heat generator

deactivation [K])

Small value = fast deactivation

Large value = slow deactivation

E Values set to high can lead to overheating and

triggering the STB

Calculation: If the cumulative system deviation in Kelvin

reaches the set value A, this results in deactivation of all

heat generators.

RESET TIME (resetting time for I-Controller)

E Control value: Changing this value can cause the

control system to overshoot. The recommended default

settings should be retained.

! Small values cause the mixer motor to adjust quickly

and can lead to oscillation.

MODULAT MAX

If this modulation degree is exceeded the next heat

generator in sequence is connected after the delay time

elapses.

MODULAT MIN

If values drop below this modulation degree the last heat

generator of the current sequence is switched off.

MIN MOD HS

Connection of the next heat generator will only occur, if the

resulting modulation degree for the different heat

generators then exceeds the value set here.

=> For optimum operation with maximum number of

burners: MODULAT MAX = 0 and MIN MIN MOD HS set to

minimum modulation degree for heat exchanger stages.

39

Page 40

Expert area Part 2: Overview of display values and settings

MODULAT DHW (only for HW-boiler)

Entry of the set modulation degree for the heat generators

in hot water operation (see HW-boiler).

SEQUENCE 1 (boiler sequence 1)

Entry of the sequence in which the boilers are set into

operation in sequence 1. => Selection of start no. => Prog.

button => Entry of the boiler number

SEQUENCE 2 (boiler sequence 2)

Entry of the sequence in which the boilers are set into

operation in sequence 2. => Selection of start no. => Prog.

button => Entry of the boiler number

! With respect to two-stage heat generators, the

second stage is always switched after the first stage.

SEQU CHANGE (sequence change mode)

01 = Only boiler sequence 1

02 = Only boiler sequence 2

03 = Change between sequence 1 and 2 according to

operating hours of the first heat generator of the active

sequence

04 = 1/3 <-> 2/3 Switching for boilers with a different

nominal power: When the second boiler is activated, the

first is put out of operation until activated again.

05 = Rotating boiler sequence; the first boiler of the

sequence is placed in last position of the current sequence

after the sequence switching time has elapsed.

06 = New boiler sequence by means of automatic sorting

according to operating hours in the event of sequence

change (sequence change according to operating hours of

the first heat generator of the active sequence).

40

Page 41

Part 2: Overview of display values and settings Expert area

Installation (only for cascades or two-stage

operation)

Designation Value range Default IV

SEQ SW TIME 10 - 800 hours 200 hours

BLOCK-TIME 00 min – 30 min 00 min

HYST BURNER2 2K – 20K 2 K

Cooling function

HS COOL-FCT 00-01 00

T-HS COOL 30°C - 120°C 95°C

See following pages for continuation

SEQ SW TIME(time to sequence change)

For operation with at least 2 heat generators there is the

option to swap the boiler sequence after the operating

hours specified here of the first heat generator of the active

sequence.

BLOCK-TIME (delay time for next stage)

Min. delay time after switching on or with switching HS,

also when switching a layer off until switching the next

layer on.

HYST BURNER2 (for solid fuel / 2. burner)

(only for 2-stage burners or solid fuel integration)

Solid fuel integration: Hysteresis for the charging pump

2nd Burner 2 and burner stage 2: see next page =>

Switching pattern for 2-stage burners

HS COOL-FCT (cooling function for boiler)

with T-HS COOL (starting temperature for cooling)

! Applies to all boilers connected to the controller!

If the cooling function for the boiler is activated (HSCOOLFCT = 01), then the heating circuits commence

operation with T-FLOW MAX as soon as the set starting

temperature T-HS COOL is exceeded by one of the

boilers. the cooling function terminates when the

temperature drops below the starting temperature T-HS

COOL by 5K.

! 00 = 10 sec.; Please consider the internal block-

times of the connected burner controllers to make

the correct settings.

41

Page 42

Expert area Part 2: Overview of display values and settings

Switching pattern for 2-stage burners

! This switching patterns is also effective for operating

two switching heat generators via the burner relays

A6 and A7.

Switch on the 1st Burner stage when temperature drops

below set temperature of the heat generator.

Switch off the 1st burner stage

setting is exceeded by the HYSTERESIS.

Switch on the 2nd burner stage

- after start of 1st Burner stage and

- undercutting the set temperature by 5K

(= Start the BLOCK-TIME)

- and progress of the BLOCK-TIME

(= Release 2nd burner stage)

Switch off 2nd burner stage

is exceeded by the HYSTERESIS.

Switch 2nd Burner stage

set temperature of the heat generator.

Switch off the 1st burner stage

after set temperatures are exceeded by [HYSTERESIS +

HYST BURNER2]

when the temperature

when the temperature setting

when temperature drops below

when 2nd stage enabled

A

57°C

55°C

50°C

C

45°C

e

E

a

b

d

d

c

c

D

A Boiler temperature

B Time

C Boiler temperature setting

D BLOCK-TIME (blocking time 2. burner stage)

E HYSTERESIS (dynamic switching hysteresis)

F HYST BURNER2 (Hysteresis for shut-off)

a Stage 1 on

b Start of blocking time 2. Burner stage

c Stage 2 on (stage 2 enable)

d Stage 2 off

e Stage 1 off (cancel stage 2 enable)

e

5K

B

F

42

Page 43

Part 2: Overview of display values and settings Expert area

Installation (configuring the installation)

Designation Value range Default IV

HS 1 TYPE 00 – 06 03

HS1 BUS 00 – 05 00

HS 2 TYPE 00 – 05 00

STORAGE HS2 00 - 03 00

BUFFER 00, 01, 02 00

See following pages for continuation

HS 1 TYPE (primary heat generator type)

00 = No primary heat generator

01 = Single stage HS switching

02 = Single stage modulating

03 = 2-stage HS switching (second stage via A7)

04 = Two individual HS switching (second HS via A7)

05 = Multi-stage switching (cascade via BUS)

06 = Multi-stage modulating (cascade via BUS)

HS1 BUS (connection for HS)

00 = Relay => Standard (switching HS)

01 = CAN-BUS => Standard (cascade switching)

02 = eBUS => HS without temperature controller

=> Preset modulation depth

=> Standard (cascade modulating)

03 = eBUS => HS with temperature controller

=> Preset desired temperature

[ not suitable for cascade ]

04 = 0-10V Preset Boiler set temperature

only for HS 1 TYPE = 01, 02 or 03

Burner relays are controlled in parallel

Cooler KF [F8] must be connected

05 = 0-10V Preset Modulation degree

only for HS 1 TYPE = 02

HS 2 TYPE (secondary heat generator type

HS => A7)

(For HS1 with 2-stage burner – not active)

00 = No secondary heat generator

01 = Solid fuel boiler => function see “STORAGE HS2”

02 = (no function in V1)

03 = (no function in V1)

04 = Collector pump

05 = Pump for HS1 (e.g. additional HS for cascades)

STORAGE HS2 (heat accumulator for HS2)

(Only where HS 2 TYPE = Solid fuel)

Warm-up relief applies superordinated:

ON: T-HS2 > MIN T-HS2

OFF: T-HS2 < [MIN T-HS2 – 5K]

T-HS2 = Solid fuel burner temperature

00 = Heating vis-à-vis collector (no storage tank) => F8

ON: T-HS2 > [F8 + HYST BURNER2 + 5K]

OFF: T-HS2 < [F8 + HYST BURNER2]

43

Page 44

Expert area Part 2: Overview of display values and settings

01 = Heating vis-à-vis buffer storage tank => F1, F3

ON: HS2-T > [F3 + HYST BURNER2 + 5K]

OFF: HS2-T < [F1 + HYST BURNER2]

02 = Heating vis-à-vis HW tank => F6

ON: HS2-T > [F6 + HYST BURNER2 + 5K]

OFF: HS2-T < [F6 + HYST BURNER2]

03 = Heating vis-à-vis STORAGE III (pool) => F15

ON: HS2-T > [F15 + HYST BURNER2 + 5K]

OFF: HS2-T < [F15 + HYST BURNER2]

Switching pattern

Switching the pump on is done if the temperature of the

solid fuel boiler exceeds the temperature of the Reference

sensor by the hysteresis (HYST BURNER2 + 5K).

Switching off occurs when the temperature drops 5K below

the switch-on temperature.

Start-up relief

Switching off occurs when the temperature of the solid fuel

boiler drops below the set limit temperature

(MIN T-HS2) by 5K. The pump is enabled again when the

temperature of the solid fuel boiler exceeds the set limit

temperature (MIN T-HS2).

Blocking HS1

ON: T-HS2 > HS set temperature + 5K and

pump HS2 = ON

OFF: T-HS2 <= HS set temperature or

pump WE2 = OFF

No HS1 blocking for

HS1 type = "Multi-stage switching“

HS1 type = "Multi-stage modulating“

STORAGE HS2 = "Heating against HW storage ( F6 )“

STORAGE HS2 = "Heating against STORAGE III ( F15 )“

! If activated, the cooling function will also affect the

solid-fuel boiler function.

BUFFER (heater buffer storage type)

! After activation (>0) it is not possible to connect a

FBR for heating circuit 1.

00 = no buffer storage for heating operation

01 = Buffer storage for heating operation (F1-F3)

(Sensor switching- in V1 no other function)

02 = Combination storage tank for heating and HW

operation

44

(Sensor switching- in V1 no other function)

Page 45

Part 2: Overview of display values and settings Expert area

Installation

Designation Value range Default

SCREED 00, 01 (OFF/ON) 00 = OFF

SCREED PROGR See explanation!

RETURN

Exit level using Ä

! Start day is not included:

The screed program starts with the "Day 1"

temperature setting and switches to "Day 1" at

00.00 hrs and then to the next day at 00.00 hrs and

so on. The current day is marked with an "x" in the

"SCREED PROGR" program.

! After the function has been cancelled/terminated the

controller continues heating using the set operating

mode. If no heating is required, set the operating

mode to i = Standby / OFF.

Screed program

SCREED (activation of screed drying process)

The screed program can be used for function heating in

accordance and for heating freshly laid screed ready for

flooring.

! Screed drying can only be carried out for mixer

circuits.

After starting, the program runs through the set flow

temperatures. The integrated mixer circuits control to the

set flow temperature. The boiler provides this temperature

irrespective of the operating mode that has been selected.

This is marked in the standard display by the entry

"SCREED" and a display of the current flow temperature.

The freely adjustable program runs for a maximum of

28 days. The flow temperatures can be set to a value of

between 10°C and 60°C for each day. The entry "----"

stops the program (also during operation for the following

day).

DAY 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28

VT 25 25 25 55 55 55 55 25 40 55 55 55 55 55 55 55 55 55 55 40 25 --- --- --- --- --- --- --=>

SCREED PROGR (Program setting)

Ä => Screed program; Ç Select day; Ä => Activate adjustment date; Ç Set flow temperature;

Ä => Save setting; Ç Select next day or exit screed program using "RETURN" + Ä.

45

Page 46

Expert area Part 2: Overview of display values and settings

Hot water

Designation Value range Default IV

DHW RELIEF 00, 01

(OFF/ON)

PARALLEL DHW 00, 01, 02, 03 01

T-HS DHW 00K – 50K 20K

HYST DHW 5K – 30K 5 K

DHW FOLLOWUP 00 min – 30

min

THERM INPUT 00, 01

(OFF/ON)

WALL HUNG 00, 01

(OFF/ON)

LOAD THROUGH 00, 01

(OFF/ON)

RETURN

Exit level using Ä

DHW RELIEF (Charge pump blocking)

The charging pump is not switched until the boiler

temperature exceeds the storage tank temperature by 5K.

It is switched off when the boiler temperature drops below

the storage tank temperature. This prevents the storage

tank from being cooled by the boiler when hot water

preparation starts.

01 = ON

00 min

00 = OFF

00 = OFF

00 = OFF

PARALLEL DHW (Pump parallel running)

00 => Hot water priority operation: The heating circuits are

blocked during hot water preparation. The mixers close

and the heating circuit pumps switch off.

01 => HW partial priority

: The heating circuits are blocked

during hot water preparation. The mixers close and the

heating circuit pumps switch off. The mixer

circuits are

enabled again when the boiler has reached the

temperature of hot water temperature setting + boiler

superheating

[T-DHW + T-HS DHW]. If the boiler temperature drops

below the enable temperature by the switching hysteresis

[HYST DHW] again, the mixer circuits are blocked again.

02 => Pump parallel running

: Only the direct heating

circuits are blocked during hot water preparation. The

mixer circuits continue to be heated. The hot water

preparation is extended by this function.

03 => Pump parallel running also for the direct heating

circuit: During hot water preparation all heater circuits

continue to be heated. The hot water preparation is

extended by this function. When the boiler temperature

exceeds the maximum flow temperature of the direct

heating circuit by 8K, the heating circuit pump for this

circuit is switched off (overheating protection). The heating

circuit pump is switched on again when the boiler

temperature drops below the temperature [maximum flow

temperature + 5K].

46

Page 47

Part 2: Overview of display values and settings Expert area

T-HS DHW (increase during HW operation)

Boiler temperature setting with hot water preparation =

hot water temperature setting + T-HS DHW

! The boiler must be run at a higher temperature

during hot water preparation so that the hot water

temperature in the storage tank can be reached via

the heat exchanger.

HYST DHW (hot water hysteresis)

Hot water preparation is started when the temperature of

the hot water storage tank drops below the temperature

setting by the hysteresis [HYST DHW]. The hot water

preparation stops when the storage tank reaches the

temperature setting (the temperature setting is set to 65°C

during hot water short time heating operation).

DHW FOLLOWUP (pump run-down time)

00 min => Standard function: The charging pump

continues to run for 5 minutes after the burner has

switched off.

If heat is requested by a heating circuit the run-down is

cancelled.

The charge pump blocking kicks in and can also cause the

run-down function to be cancelled.

greater than 00 min

set time when storage tank charging is complete. The

after-run can only be cancelled by the activated charge

pump blocking.

=> The charge pump runs down by the

THERM INPUT (storage tank with thermostat)

00 => Hot water preparation via storage tank sensor

01

=> Hot water preparation via thermostat:

The hot water preparation is started by a short circuit at the

storage tank sensor connecting terminals. It stops when

the short circuit is removed.