Page 1

F

NL

I

E

057 · Edition 08.

D GB F NL I E

TR CZ PL RUS H

DK S N P GR

➔ www.docuthek.com

Operating instructions

Pressure switches for gas DG..H, DG..N Pressure switch for gas DG..I

Translation from the German

© 2012 Elster GmbH

Contents

Contents

Pressure switches for gas DG..H, DG..N

Pressure switch for gas DG..I .............

Contents ..............................

Safety.................................

Checking the usage .....................

Type code .............................2

Part designations ........................2

Type label.............................. 2

Installation ............................

Connection facilities ......................3

Installing DG..H, DG..N ...................3

Installing DG..I ..........................4

Wiring ................................4

Adjustment ............................5

Tightness test ..........................5

Maintenance ...........................5

Accessories ...........................5

Technical data .........................7

Designed lifetime ........................8

Declaration of conformity ................8

Contact ...............................8

Safety

Safety

Please read and keep in a safe place

Please read through these instructions

carefully before installing or operating. Following the

installation, pass the instructions on to the operator. This unit must be installed and commissioned

in accordance with the regulations and standards

in force. These instructions can also be found at

www.docuthek.com.

Explanation of symbols

• , , , ... = Action

▷ = Instruction

Liability

We will not be held liable for damages resulting

from non-observance of the instructions and noncompliant use.

Safety instructions

Information that is relevant for safety is indicated in

the instructions as follows:

DANGER

Indicates potentially fatal situations.

WARNING

Indicates possible danger to life and limb.

CAUTION

Indicates possible material damage.

All interventions may only be carried out by qualified

gas technicians. Electrical interventions may only be

carried out by qualified electricians.

Conversion, spare parts

All technical changes are prohibited. Only use OEM

spare parts.

Transport

On receipt of the product, check that the delivery is

complete (see Part designations). Report any transport damage immediately.

Storage

Store the product in a dry place. Ambient temperature: see Technical data.

GB

GB-1

Page 2

F

NL

I

E

Checking the usage

-6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6

Increasing

DG..H, DG..N, DG..I

For monitoring increasing and decreasing gas or

air pressure.

negative pressure

Decreasing

negative pressure

Increasing pressure

Decreasing pressure

Type label

D-49018 Osnabrück, Germany

DG

CE – 0085AP0467

2

1

3

Positive

pressure

DG..H,

DG..N

GB

DG..I Air, flue gas

Gas, air, flue

gas

Negative

pressure

Differential

pressure

Air, flue gas Air, flue gas

Gas, air, flue

gas

Air, flue gas

DG..H switches and locks off with rising pressure,

DG..N switches and locks off with falling pressure.

They can be unlocked using the manual reset.

This function is only guaranteed when used within

the specified limits– see page 7 (Technical data).

Any other use is considered as non-compliant.

Type code

Code Description

DG Pressure switch for gas

,5 – 500 Max. setting in mbar

H

N

I

Locks off with rising pressure

Locks off with falling pressure

Negative pressure for gas

G With gold-plated contacts

-

-4

-5

-6

-9

K

T

T

N

4-pin plug, with socket, IP 65

Red/green pilot LED for 24 V DC/AC

Red/green pilot LED for 230 V AC

Electrical connection

via screw terminals

via screw terminals, IP 65

4-pin plug, without socket

4-pin plug, with socket

Blue pilot lamp for 230 V AC

Blue pilot lamp for 120 V AC

A External adjustment

Part designations

2

1

5

3

4

Upper housing section with cover

Lower housing section

Hand wheel

4 M16 cable gland

5 DG..H, DG..N with manual reset

Max. inlet pressure, mains voltage, ambient tem-

perature, enclosure: see type label.

Installation

CAUTION

Please observe the following to ensure that the DG

is not damaged during installation and operation:

– Continuous operation at high temperatures accel-

erates the ageing of elastomer materials. In places

where a high thermal capacity is required, thermal

equipment trips must be installed upstream of

theDG.

– Use approved sealing material only.

– Check max. ambient temperature – see

page7 (Technical data).

– When using silicone tubes, only use silicone tubes

which have been sufficiently cured.

– Vapours containing silicone must not be allowed

to get into the housing.

– Condensation must not be allowed to get into the

housing. At subzero temperatures malfunctions/

failures due to icing can occur.

– The service life will be shorter if subject to ozone

concentrations exceeding 200μg/m3. When in-

stalling outdoors, place the DG in a roofed area

and protect from direct sunlight (even IP65 ver-

sion). To avoid condensation, a cover with pres-

sure equalization element (see page6 (Pres-

sure equalization element)) can be used.

– Avoid subjecting the DG to strong or violent vibra-

tions.

– In case of highly fluctuating pressures, install a

restrictor orifice (see page6 (Restrictor orifice)).

▷

The DG must not be in contact with masonry.

Minimum clearance 20mm.

▷ Ensure that there is sufficient installation space.

▷ Ensure unobstructed view of the hand wheel.

▷ Installation position as required, preferably with

vertical diaphragm. Then the switching pointpS

corresponds to the scale valueSK set on the

hand wheel. In other installation positions, the

switching pointpS will change and no longer

correspond to the scale valueSK set on the

hand wheel. Check the switching point.

GB-2

Page 3

F

NL

I

E

Positive pressure measurement at port

2

p

max

=

600 mbar

Rp 1/4

1

3

Rp 1/8

4

p

max

=

-600 mbar

5 Seal port.

p

= SK pS = SK + 0.18 mbar pS = SK - 0.18 mbar

S

= SK pS = SK - 0.5 mbar

p

S

= SK pS = SK - 0.2 mbar

p

S

= SK

p

S

= SK

p

S

DG..H, DG..N

DG 18I

DG 120I, DG 450I

DG 1,5I

Negative pressure:

p

= SK - 0.4 mbar

S

Positive pressure:

p

= SK + 0.4 mbar

S

DG 12I

Negative pressure:

p

= SK - 0.5 mbar

S

Positive pressure:

p

= SK + 0.5 mbar

S

Connection facilities

2

1

3

▷

Ports and 4 are suitable for air and flue gas only.

▷

If the electrical contacts in the DG could be soiled

1 and 2

Gas, air, flue gas

3 and 4

4

Air, flue gas

by dirt particles in the surrounding air or in the

medium, use a filter pad (see page5 (Filter

pad set)) at port/4. On IP65 units, the filter pad

is fitted as standard, see type label.

Disconnect the system from the electrical power

supply.

Shut off the gas supply.

Ensure that the pipeline is clean.

4 Purge the pipe.

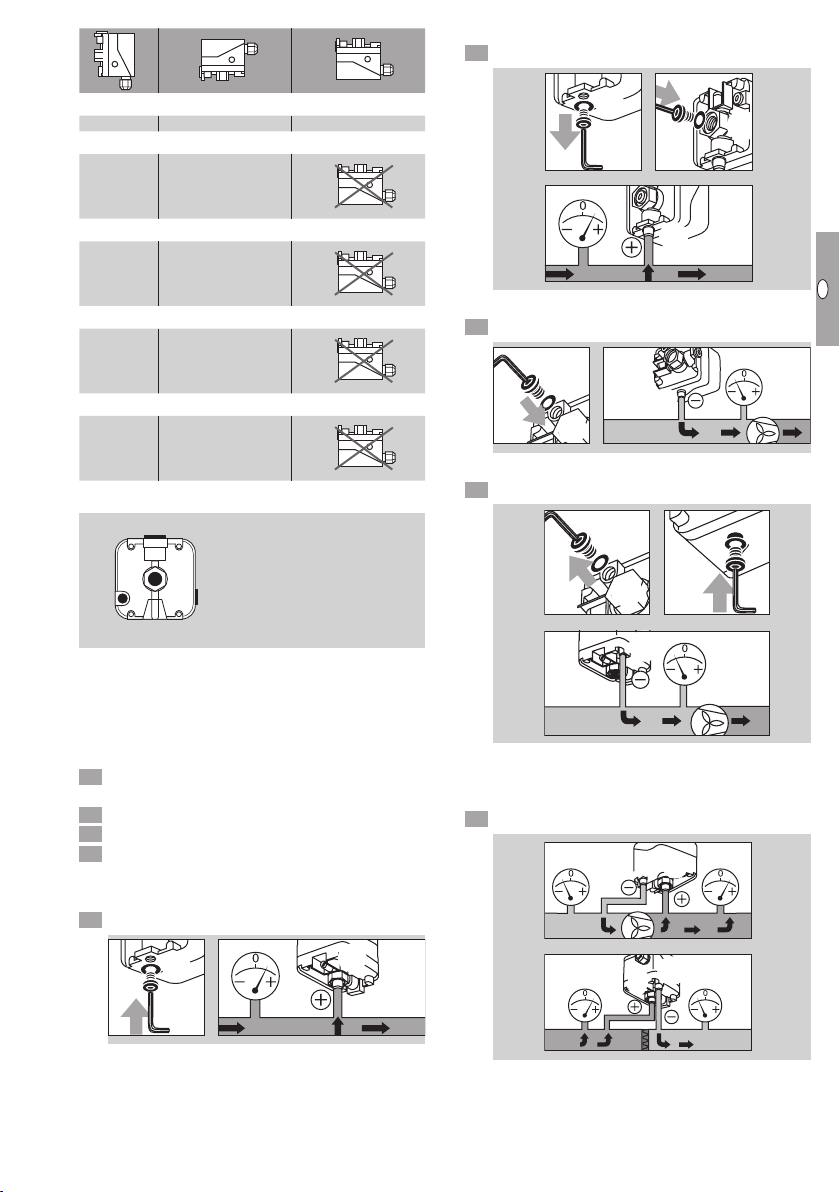

Installing DG..H, DG..N

Positive pressure measurement at port

5 Seal port.

2

1

Rp 1/4

p

=

max

600 mbar

0

2

1

Rp 1/4

2

p

=

max

600 mbar

Rp 1/4

p

=

max

Negative pressure measurement at port4

5 Seal port.

Rp 1/8

p

=

max

4

-600 mbar

3

Negative pressure measurement at port

5 Seal port4.

0

4

3

3

p

=

max

-600 mbar

Differential pressure measurement

▷ Use port or for the higher absolute pressure

and port or 4 for the lower absolute pressure.

5 Seal the remaining ports.

600 mbar

∆p

max

600 mbar

∆p

=

max

=

Rp 1/8

3

1

1

3

GB

GB-3

Page 4

F

NL

I

E

Installing DG..I

2

p

max

=

-600 mbar

Rp 1/4

1

–

3 42

COM

3

▷

It is recommended that the port which is best

protected from dirt and water be left open.

Negative pressure measurement at port

5 Seal port.

Disconnect the system from the electrical power

supply.

3 42

2

1

Rp 1/4

p

max

–

-600 mbar

Negative pressure measurement at port

5 Seal port.

GB

0

2

1

Rp 1/4

2

p

=

–

Wiring

▷ If the DG..G has switched a voltage >24V and

a current >0.1A once, the gold plating on the

contacts will have been burnt through. It can

then only be operated at this power rating or

higher power rating.

▷

Pressure switch DG can be used in Zone1 and2

hazardous areas if an isolating amplifier is installed

upstream in the safe area as “Ex-i” equipment

pursuant to EN60079-11 (VDE0170-7):2007.

▷

DG as “simple electrical equipment” pursuant to

EN60079-11:2007 corresponds to the Temperature classT6, GroupII. The internal inductance/

capacitance is Lo= 0.2μH/Co= 8pF.

CAUTION

To ensure that the DG is not damaged during opera-

tion, note the switching capacity, see page7

(Technical data).

▷ In the case of low switching capacities, such as

24V, 8mA, for example, we recommend using

an RCmodule (22 Ω, 1μF) in air containing

silicone or oil.

C = 1 µF R = 22 Ω

NO

2

NC

1

max

-600 mbar

Rp 1/4

p

max

COM

3

=

=

5 6 7

M16 x 1,5:

ø 4,5–10 mm

▷

Contacts and close when subject to increasing pressure. Contacts and close when subject to falling pressure.

NO

L1

3

COM

2

NC

1

NO

1

2

NC

3

COM

DG ,5I and DG I

▷ The connection of DG 1,5l and DG 12l depends

on the positive or negative adjusting range.

7

-

6

1

2

-

1

1

-

1

r

0

a

b

m

-

9

7

–

1

-

;

8

1

-

-

7

-

6

5

1

0

0

P

4

a

=

1

3

m

b

a

2

r

1

1

–

2

1

-

-

5

-

s

p

=

2

-

3

-

-

4

1

,

5

.

.

.

.

;

-

5

1

,

0

.

-

–

.

5

.

,

1

.

-

-

0

=

,

s

5

.

p

.

.

.

.

.

.

-

,

0

.

.

.

3

.

.

m

b

a

3

–

5

0

,

.

.

.

r

5

,

.

2

.

.

.

1

0

2

.

0

P

.

a

.

=

.

1

5

m

,

b

a

1

r

.

.

.

.

1

5

.

.

.

.

DG 12I DG 1,5I

▷

In the negative adjusting range, the template

which can be found in the unit displays the connection diagram.

1

2

NC

NO

NC

NO

1

3

2

N

COM

µ

▷ In the positive adjusting range, remove the tem-

plate and wire the unit as shown in the engraved

connection diagram.

NO

NC

2

1

COM

3

GB-4

Page 5

F

NL

I

E

Adjustment

NO

2

NC

1

COM

3

COM

3

NC

1

NO

2

▷

The switching point is adjustable via hand wheel.

Disconnect the system from the electrical power

supply.

Detach the housing cover, see page7 (Tech-

nical data).

Connect an ohmmeter.

NO

1

2

NC

3

COM

NO

NC

COM

2

3

1

Tightness test

Shut off the downstream gas pipeline close to

the valve.

Open the valve and the gas supply.

▷ Check all used ports for tightness.

3 4

N2

900 mbar

max. 2 bar

< 15 min

4 Set the switching point using the hand wheel.

5 Connect a pressure gauge.

Maintenance

In order to ensure smooth operation: check the tight-

GB

ness and function of the DG every year, or every

0

six months if operated with biologically produced

methane.

1 cm = 1 mbar

6 Apply pressure. In doing so, monitor the switch-

ing point on the ohmmeter and the pressure

▷ A function check can be carried out in case of

decreasing pressure control e.g. with the PIA.

▷ After carrying out the maintenance work, check

for tightness, see page5 (Tightness test).

gauge.

Accessories

Connecting set

For monitoring a minimum and maximum inlet pressure pu with two pressure switches attached to one

another.

Type

Adjusting

range*

[mbar]

Reset pressure**

[mbar]

DG 10H, ..N 1 – 10 0.4 – 1

DG 50H, ..N 2.5 – 50 1 – 2

DG 150H, ..N 30 – 150 2 – 5

DG 500H, ..N 100 – 500 4 – 17

Type

DG 1,5I

DG 12I

Adjusting range*

[mbar]

-1.5 to -0.5 and

+0.5 to +3

-12 to -1 and

+1 to +7

DG 18I -2 to -18 0.5 – 1.5

DG 120I -10 to -120 4 – 11

Switching

differential***

[mbar]

0.2 – 0.5

0.5 – 1

Order No.: 74912250

1

2

2

1

Remove from

2

both pressure

switches.

DG 450I -80 to -450 10 – 30

* Adjusting tolerance = ± 15% of the scale value.

** Difference between switching pressure and pos-

sible reset.

*** Mean switching differential at min. and max. setting.

▷

Deviation from the switching point during testing

3

1

Install on one

pressure

switch.

4

pursuant to EN1854:

Gas pressure switches: ± 15%.

Air pressure switches:

DG..H, ..N, ..I

DG 1,5I

DG 12I

DG 18I

▷

If the DG does not trip at the desired switch-

Deviation

± 15%

± 15% or ± 0.4 mbar

± 15% or ± 0.5 mbar

± 15% or ± 0.5 mbar

Filter pad set

To protect the electrical contacts in the DG from dirt

particles in the surrounding air or in the medium, use

a filter pad at the 1/8" negative pressure port. As

standard on IP 65 units.

5-piece filter pad set, Order No.: 74916199

ing point, correct the adjusting range using the

hand wheel. Relieve the pressure and repeat

the process.

GB-5

Page 6

F

NL

I

E

External adjustment

In order to set the switching pressure from the outside,

the cover for external adjustment (6mm Allen key)

for DG..I can be retrofitted.

Fastening set with screws, U-shape bracket

47,5 (1.87")

75 (2.95")

Order No.: 74916155

2 31

GB

4

Pressure equalization element

To avoid the formation of condensation, the cover

with pressure equalization element can be used. The

diaphragm in the screw connector is designed to

ventilate the cover, without allowing water to enter.

Order No.: 74923391

Restrictor orifice

In the case of high pressure fluctuations, we recommend using a restrictor orifice (contains non-ferrous

metals).

Rp

¼

20

(0.79")

M4 x 12

50 (1.97")

30 (1.18")

20

(0.79")

45 (1.77")

25 (0.98")

6 (0.24")

16

24 (0.94")

43

-0,3

64 (2.52")

Order No.: 74915387

Tube set

To be used with air only.

(0.63")

(1.69")

40 (1.57")

M4 x 10

5,2

(0.2")

+0,1

(0.17")

4,20

10

(0.4")

39 (1.53")

¼

R

Hole diameter 0.2 mm, Order No.: 75456321,

hole diameter 0.3 mm, Order No.: 75441317.

Test key PIA

To test the min. pressure switch, the DG can be

vented in its switched state using the PIA test key

(contains non-ferrous metals).

R

¼

Rp

¼

Order No.: 74329466

Click

TEST

Order No.: 74912952

Standard socket set

Order No.: 74915388

GB-6

COM

12

N

L1

NO

L1

NO

3333333

3

3

2

N

1

Page 7

F

NL

I

E

Standard coupler plug

2 31

Order No.: 74920412

Pilot lamp set, red or blue

Pilot lamp, red:

110/120 V AC, I = 1.2 mA, Order No.: 74920430;

220/250 V AC, I = 0.6 mA, Order No.: 74920429.

Pilot lamp, blue:

110/120 V AC, I = 1.2 mA, Order No.: 74916121;

220/250 V AC, I = 0.6 mA, Order No.: 74916122.

2 31

4

N

COM

NO

2

NO

L1

3

2

1

NC

L1

3

COM

1

NC

N

NO

NC

NO

NO

1

2

NC

1

2

NC

3

COM

3

COM

LED set, red/green

4

Technical data

Gas type: natural gas, town gas, LPG (gaseous),

flue gas, biologically produced methane (max.

0.1%-by-vol. H2S) and air.

Max. test pressure for testing the entire system:

temporarily <15minutes 2mbar.

Switching capacity:

DG:

U = 24 – 250 VAC,

I = 0.05 – 5 A at cos ϕ = 1,

I = 0.05 – 1 A at cos ϕ = 0.6.

DG..G:

U = 5 – 250 V AC,

I = 0.01 – 5 A at cos ϕ = 1,

I = 0.01 – 1 A at cos ϕ = 0.6.

U = 5 – 48 VDC,

I = 0.01 – 1 A.

Maximum medium temperature:

N

N

DG..H, DG..N: -15 to +60°C,

DG..I: -15 to +80°C.

Storage and transport temperature:

-40 to +80°C.

RoHS compliant pursuant to 2002/95/EC.

Diaphragm pressure switch, silicone-free.

Diaphragm: NBR.

Housing: glass fibre reinforced PBT plastic with

low gas release.

Lower housing section: AlSi 12.

Enclosure: IP54 or IP65.

Safety class: 1.

Line entrance: M16 x 1.5, clamping range: diameters of 4 to 10mm.

Type of connection: screw terminals.

Weight: 270 to 320g depending on equipment.

NO

2

+

3 COM

1 NC

1

2

NC

NO

–

3

COM

N

GB

24 V DC, I = 16 mA; 24 V AC, I = 8 mA,

Order No.: 74921089;

230 V AC, I = 0.6 mA, Order No.: 74923275.

GB-7

Page 8

F

NL

I

E

Designed lifetime

The Pressure Equipment Directive (PED) and the

Energy Performance of Buildings Directive (EPBD)

demand regular checks on and maintenance of heating systems in order to ensure a high level of use

in the long term, a clean method of operation and

safe function.

The service life on which the construction is based,

hereinafter referred to simply as the “designed

lifetime”, is compiled from the relevant standards.

You can find further explanations in the applicable

rules and regulations and on the afecor website

(www.afecor.org).

This information on the designed lifetime is based on

GB

using the product in accordance with these operating instructions.

The product must be serviced at regular intervals.

Once the specified designed lifetime has been

reached, the safety-related functions must be

checked in accordance with the section entitled

“Maintenance”.

If the product passes the aforementioned function

tests, you can continue to use it until the next scheduled maintenance operation. At this point, these tests

must be repeated.

If the product fails one of the aforementioned tests,

it must be replaced immediately.

This procedure applies to heating systems. For

thermoprocessing equipment, observe national

regulations.

Designed lifetime (based on date of manufacture) in

accordance with EN13611, EN1854 for pressure

switches:

Medium

Switching cycles Time [years]

Designed lifetime

Gas 50,000 10

Air 250,000 10

Long-term use in the upper ambient temperature

range accelerates the ageing of the elastomer materials and reduces the service life (please contact

manufacturer).

Declaration of conformity

We, the manufacturer, hereby declare that the product

DG, marked with product ID No. CE-0085AP0467,

complies with the requirements of the listed Directives and Standards.

Directives:

– 2009/142/EC

– 2006/95/EC

Standards:

– EN 13611

– EN 1854

The relevant product corresponds to the type tested

by the notified body 0085.

The production is subject to the surveillance proce-

dure pursuant to annex II, paragraph 3 of Directive

2009/142/EC and to the Quality System pursuant to

DIN EN ISO 9001:2008.

Elster GmbH

Scan of the Declaration of conformity (D, GB) – see

www.docuthek.com

SIL, PL

Suitable for Safety Integrity Level SIL1 and2, in the

case of 2DG also for SIL3, and Performance Level

PLa, b, c, d,e, depending on the demand ratenop

(mean number of annual operations).

B

value (mean number of cycles until 10% of the

10d

components fail dangerously)= operating cycles.

U I B

24 V DC 10 mA

230 V AC 4 mA

24 V DC 70 mA

230 V AC 20 mA

230 V AC 2 A 974,800

RoHS compliant

RoHS

2002/95/EC

value

10d

6,689,477

3,887,652

Contact

Contact

If you have any technical questions, please contact

your local branch office/agent. The addresses are

available on the Internet or from ElsterGmbH.

We reserve the right to make technical modifications

Elster GmbH

Postfach 28 09, D-49018 Osnabrück

Strotheweg 1, D-49504 Lotte (Büren)

T +49 541 1214-0

F +49 541 1214-370

in the interests of progress. info@kromschroeder.com, www.kromschroeder.com

GB-8

Loading...

Loading...