Page 1

Burner control units BCU 560, BCU 565

Technical Information · GB

6 Edition 02.16

• For monitoring and controlling modulating or staged burners for multiple

burner applications with a central air supply

• For directly ignited burners of unlimited capacity in intermittent or

continuous operation

• Optionally with valve proving system

• Optionally with menox

thermal NO

• Flexible range of applications due to parameterization possibilities

• PROFINET fieldbus connection using optional bus module

• Assume safety functions pursuant to EN746-2

• EU certified

• Certified for systems up to SIL 3 and PL e

x

®

operating mode to reduce the formation of

Page 2

Contents

Burner control units BCU 560, BCU 565 ............... 1

Contents........................................2

1 Application.....................................5

1.1 Examples of application..........................7

1.1.1 Single-stage-controlled burner........................7

1.1.2 Two-stage-controlled burner ........................ 8

1.1.3 Modulating-controlled burner ........................9

1.1.4 Flame control using the temperature .................10

1.1.5 menox

1.1.6 PROFINET connection using bus module BCM ..........12

1.1.7 ON/OFF rotary impulse control for burners up to 360kW . 13

1.1.8 Modulating burner control . . . . . . . . . . . . . . . . . . . . . . . . . .14

2 Certification ................................... 15

3 Function...................................... 16

3.1 Connection diagram ...........................16

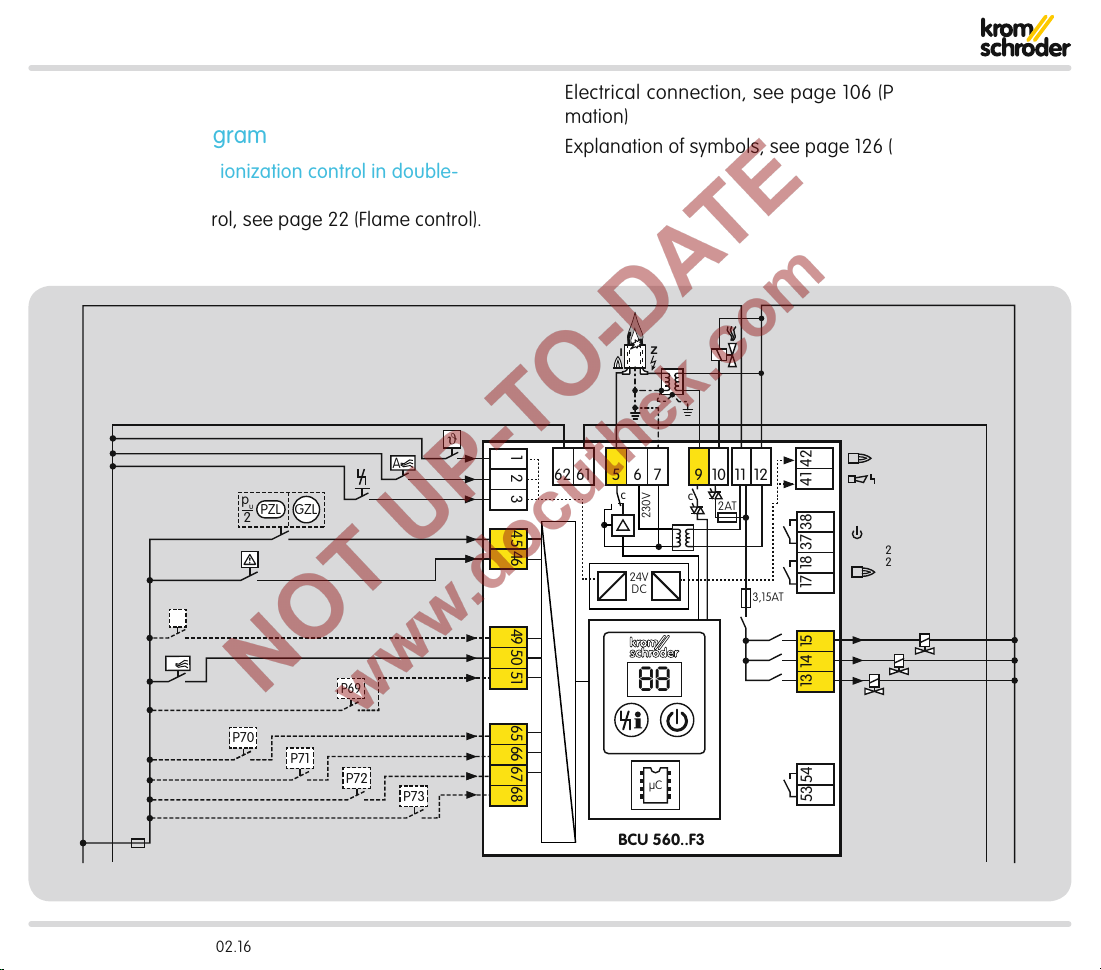

3.1.1 BCU560..F3 with ionization control in double-electrode

operation ............................................16

3.1.2 BCU560..F1......................................17

3.1.3 BCU560..F2 .....................................18

3.1.4 BCU565..F3 with ionization control in double-electrode

operation ............................................19

3.1.5 BCU565..F1..................................... 20

3.1.6 BCU565..F2 .....................................21

3.1.7 Flame control ................................... 22

3.2 BCU 560 program sequence ....................23

3.3 BCU 565 program sequence ....................24

4 Air control ....................................25

4.1 Capacity control ...............................26

4.1.1 BCU..F1/F2 ...................................... 26

4.1.2 BCU..F3 .........................................27

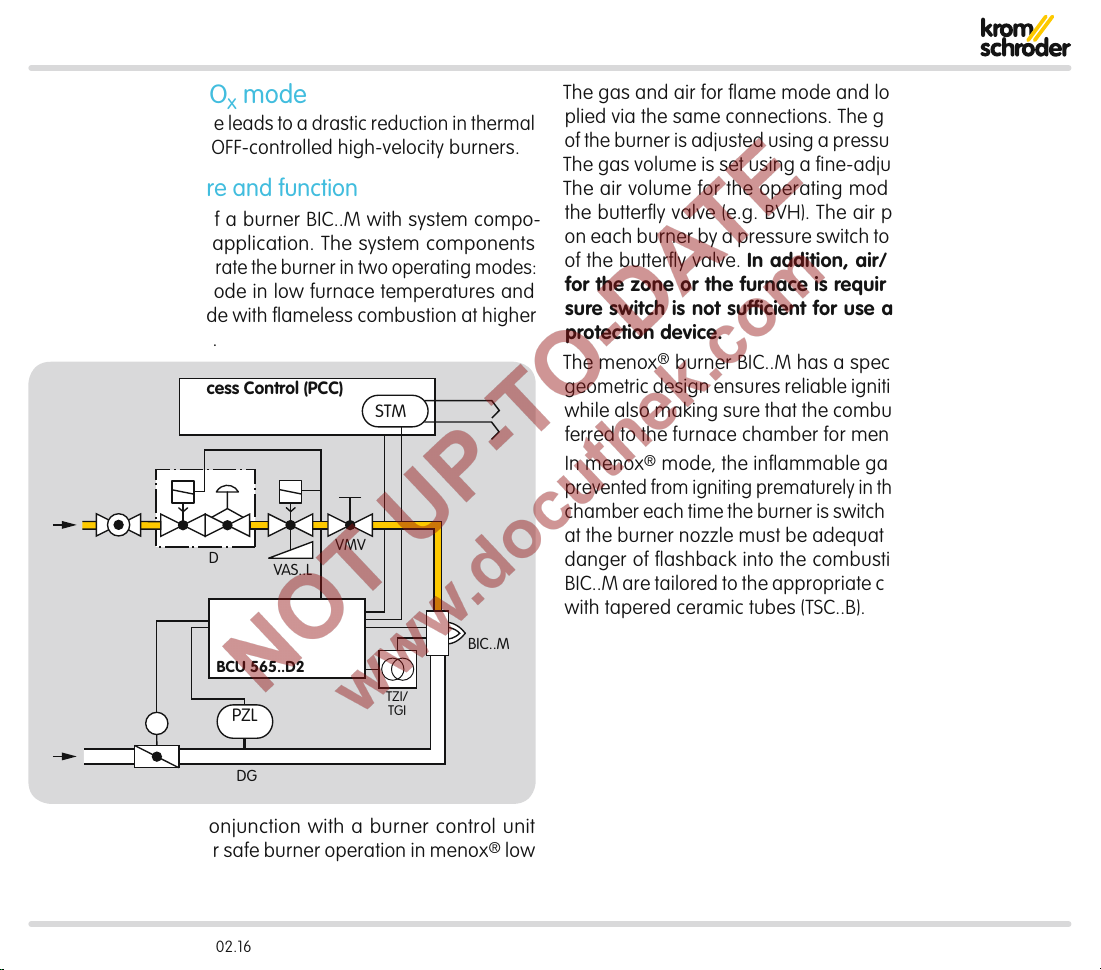

5 menox® low NOx mode .........................28

5.1 System structure and function....................28

5.2 BCU..D2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

6 Valve proving system ........................... 31

®

mode to reduce NOx formation ..............11

6.1 Tightness control ..............................31

6.1.1 Test instant...................................... 32

6.1.2 Program sequence............................... 33

6.1.3 Test period t

6.1.4 Opening time t

6.1.5 Measurement time t

................................... 35

P

................................. 35

L

............................ 35

M

6.2 Proof of closure function........................38

6.2.1 Program sequence............................... 38

7 BCSoft .......................................39

8 Profinet ......................................40

8.1 BCU and bus module BCM......................41

8.2 GSD file for PLC configuration....................42

8.2.1 Modules for cyclic data exchange .................. 43

8.2.2 Indexes for acyclic communication ................. 48

9 Program step/status............................49

10 Fault signalling................................50

11 Parameters...................................53

11.1 Scanning the parameters.......................58

11.2 Flame control ................................58

11.2.1 Burner 1 FS1 flame signal switch-off threshold......... 58

11.2.2 Flame control................................... 59

11.2.3 High temperature operation ...................... 60

11.3 Behaviour during start-up ......................62

11.3.1 Burner 1 start-up attempts......................... 62

11.3.2 Burner application............................... 63

11.3.3 Safety time 1 t

11.3.4 Flame proving period 1 t

SA1 ............................................71

........................71

FS1

11.4 Behaviour during operation.....................72

11.4.1 Restart..........................................72

11.4.2 Minimum operating time t

........................73

B

11.5 Safety limits ..................................74

11.5.1 Low air pressure protection ....................... 74

11.5.2 Air pressure cut-out delay ........................ 74

11.5.3 Safety time during operation .......................75

11.6 Air control ...................................76

BCU 560, BCU 565 · Edition 02.16 2

= To be continued

▼

Page 3

Contents

11.6.1 Pre-purge time tPV ................................76

11.6.2 Air flow monitoring during pre-purge ................76

11.6.3 Pre-ventilation time t

11.6.4 Post-ventilation time t

11.6.5 Capacity control..................................78

11.6.6 Running time selection ........................... 85

11.6.7 Running time ................................... 85

11.6.8 Low fire over-run ................................ 86

11.6.9 Controller enable signal delay time t

11.6.10 Air actuator control ..............................87

11.6.11 Air actuator can be activated externally on start-up ... 89

11.6.12 Air actuator in the event of fault ................... 89

11.6.13 Capacity control (bus) ........................... 90

11.7 menox

11.7.1 menox pre-ventilation time t

11.7.2 Switchover to menox

® ................................................95

VL..................................... 77

NL ................................... 77

.............. 86

RF

.................... 95

VLM

®

operating mode ............. 95

11.8 Valve check..................................96

11.8.1 Valve proving system ............................ 96

11.8.2 Relief valve (VPS) ................................ 96

11.8.3 Measurement time V

11.8.4 Valve opening time t

...........................97

p1

............................97

L1

11.9 Behaviour during start-up ......................98

11.9.1 Minimum pause time tBP ......................... 98

11.10 Manual mode ...............................99

11.10.1 Operating time in Manual mode .................. 99

11.11 Functions of terminals 50, 51, 65, 66, 67 and 68 ..100

11.11.1 Function of terminal 50 ...........................100

11.11.2 Function of terminal 51 ...........................100

11.11.3 Function of terminal 65 ..........................100

11.11.4 Function of terminal 66 ..........................101

11.11.5 Function of terminal 67...........................102

11.11.6 Function of terminal 68 ..........................103

11.12 Password..................................104

11.13 Fieldbus communication .....................104

12 Selection.................................... 105

12.1 Type code ..................................105

13 Project planning information....................106

13.1 Installation..................................106

13.2 Commissioning .............................106

13.3 Electrical connection ......................... 107

13.3.1 OCU ..........................................107

13.3.2 Safety current inputs.............................108

13.3.3 UVD control....................................109

13.4 Actuators .................................. 110

13.4.1 IC20..........................................110

13.5 Parameter chip card ......................... 110

13.6 Overload protection.......................... 110

13.7 Calculating the safety time t

SA.........................111

13.8 Fourth or switchable gas valve on BCU..F3 ........112

14 Accessories ..................................113

14.1 BCSoft ..................................... 113

14.1.1 Opto-adapter PCO 200 ...........................113

14.1.2 Bluetooth adapter PCO 300 .......................113

14.2 OCU ...................................... 113

14.3 Connection plug set.......................... 113

14.4 Stickers for labelling.......................... 114

14.5 “Changed parameters” stickers ................ 114

15 OCU ........................................115

15.1 Application ................................. 115

15.2 Function ....................................116

15.2.1 Manual mode ..................................116

15.3 Electrical connection ..........................117

15.4 Installation ..................................117

15.5 Selection ....................................117

15.6 Technical data for OCU ....................... 118

16 BCM 500 ....................................119

16.1 Application ................................. 119

16.2 Function ................................... 119

16.3 Electrical connection ......................... 119

16.4 Installation ................................. 119

16.5 Selection ...................................120

16.6 Technical data ..............................120

BCU 560, BCU 565 · Edition 02.16 3

Page 4

Contents

17 Technical data ................................121

17.1 Electrical data ............................... 121

17.2 Mechanical data ............................122

17.3 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

17.4 Dimensions.................................122

17.5 Safety-specific characteristic values .............123

17.6 Converting units .............................124

18 Maintenance ................................ 125

19 Legend ..................................... 126

20 Glossary ................................... 127

20.1 Safety time on start-up t

20.2 Ignition time t

............................. 127

Z

20.3 Safety time during operation t

20.4 Safety interlocks ............................ 127

20.5 Safety shut-down ........................... 127

20.6 Safety shut-down with subsequent fault lock-out

(fault lock-out) .................................. 127

20.7 Warning signal .............................128

20.8 Timeout ...................................128

20.9 Lifting .....................................128

20.10 Air valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

20.11 Diagnostic coverage DC .....................128

20.12 Operating mode ...........................128

20.13 Safe failure fraction SFF ......................129

20.14 Probability of dangerous failure PFH

20.15 Mean time to dangerous failure MTTF

Feedback .....................................130

Contact.......................................130

.................... 127

SA1

SB ..................... 127

.........129

D

........129

d

BCU 560, BCU 565 · Edition 02.16 4

Page 5

1 Application

▼

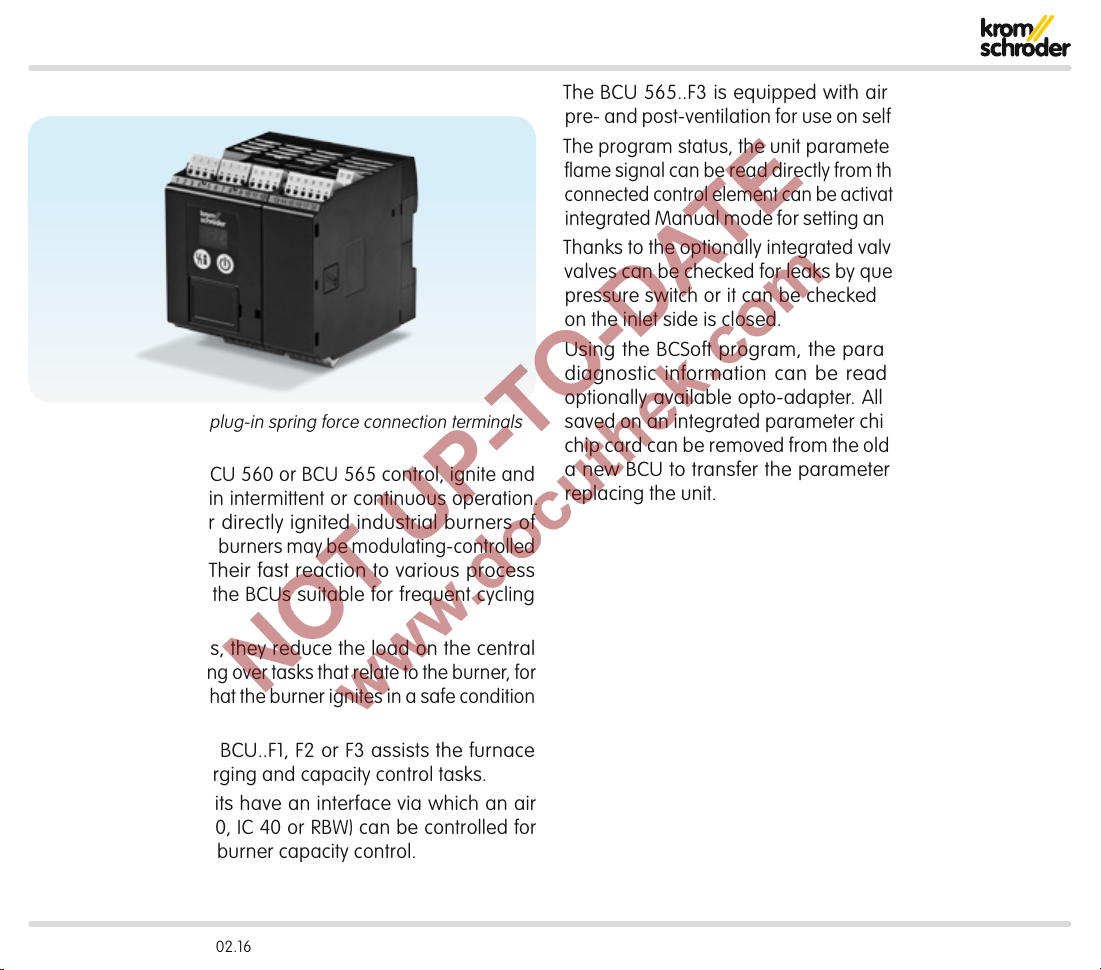

Burner control unit with plug-in spring force connection terminals

Burner control units BCU 560 or BCU 565 control, ignite and

monitor gas burners in intermittent or continuous operation.

They can be used for directly ignited industrial burners of

unlimited capacity. The burners may be modulating-controlled

or stage-controlled. Their fast reaction to various process

requirements makes the BCUs suitable for frequent cycling

operation.

On industrial furnaces, they reduce the load on the central

furnace control by taking over tasks that relate to the burner, for

example they ensure that the burner ignites in a safe condition

when it is restarted.

The air control on the BCU..F1, F2 or F3 assists the furnace

control for cooling, purging and capacity control tasks.

The burner control units have an interface via which an air

valve or actuator (IC20, IC40 or RBW) can be controlled for

staged or modulating burner capacity control.

The BCU 565..F3 is equipped with air flow monitoring and

pre- and post-ventilation for use on self recuperative burners.

The program status, the unit parameters and the level of the

flame signal can be read directly from the unit. The burner or a

connected control element can be activated manually using the

integrated Manual mode for setting and diagnostic purposes.

Thanks to the optionally integrated valve proving system, the

valves can be checked for leaks by querying an external gas

pressure switch or it can be checked whether the gas valve

on the inlet side is closed.

Using the BCSoft program, the parameters, analysis and

diagnostic information can be read from a BCU via the

optionally available opto-adapter. All valid parameters are

saved on an integrated parameter chip card. The parameter

chip card can be removed from the old unit and inserted into

a new BCU to transfer the parameters, for example when

replacing the unit.

BCU 560, BCU 565 · Edition 02.16 5

Page 6

Application

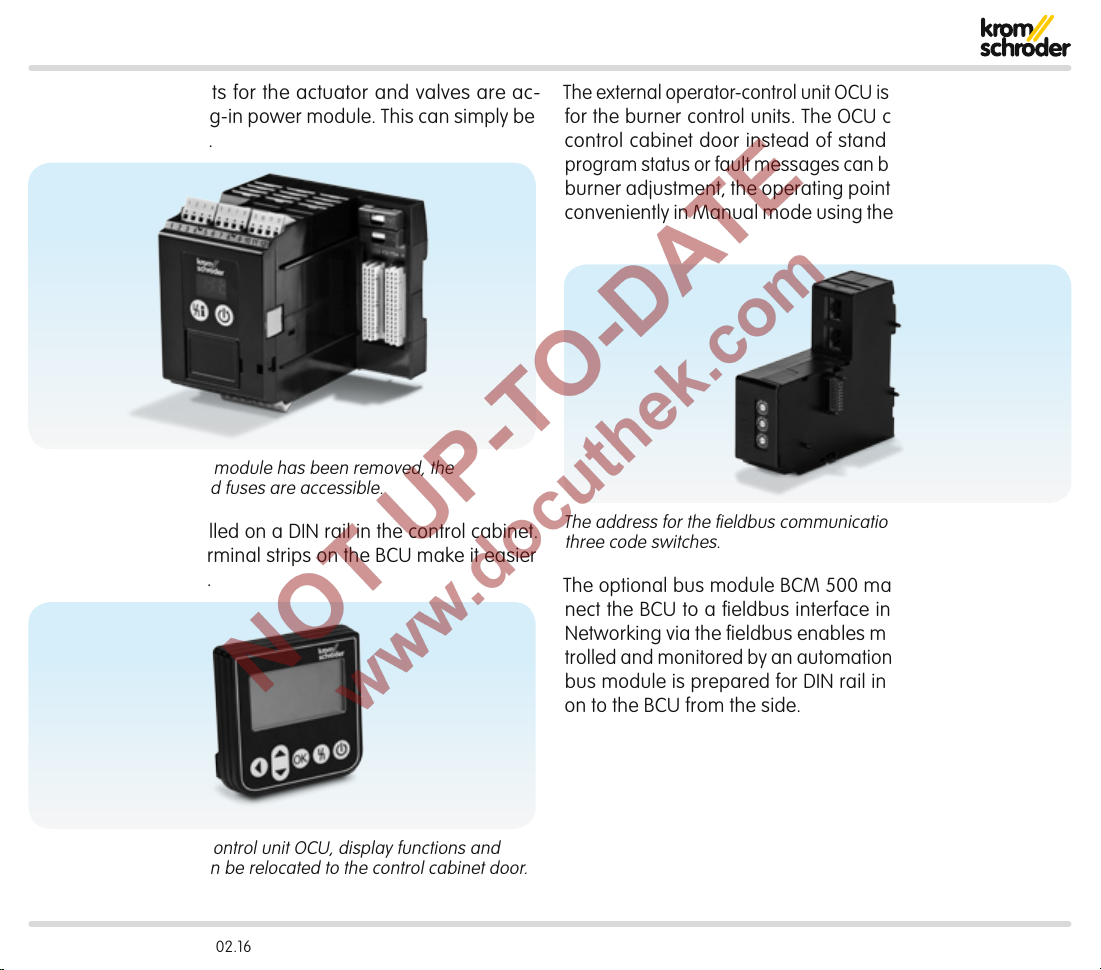

The monitored outputs for the actuator and valves are ac-

commodated in a plug-in power module. This can simply be

replaced if necessary.

Once the plug-in power module has been removed, the

parameter chip card and fuses are accessible.

The BCU can be installed on a DIN rail in the control cabinet.

Plug-in connection terminal strips on the BCU make it easier

to install and remove.

The external operator-control unitOCU is available as an option

for the burner control units. The OCU can be installed in the

control cabinet door instead of standard control units. The

program status or fault messages can be read on the OCU. For

burner adjustment, the operating points can be approached

conveniently in Manual mode using the operator-control unit.

The address for the fieldbus communication is set using

three code switches.

The optional bus module BCM500 makes it possible to con-

nect the BCU to a fieldbus interface in a PROFINET network.

Networking via the fieldbus enables multiple BCUs to be controlled and monitored by an automation system (e.g.PLC). The

bus module is prepared for DIN rail installation. It is pushed

on to the BCU from the side.

Thanks to the operator-control unitOCU, display functions and

operation of the BCU can be relocated to the control cabinet door.

BCU 560, BCU 565 · Edition 02.16 6

Page 7

Application

FCU 500

HT

P

Process control (PCC)

ϑ

A

1 2 3

38371817

BCU 565..F3

46

µC

49

50

47

V1 V2

VG

VG..L

PLC

VMV

ECOMAX

41

42

13

14

9

10

VR..R

TZI/TGI

PDZ

DG

1.1 Examples of application

1.1.1 Single-stage-controlled burner

Control: ON/OFF.

The gas/air mixture is adjusted to the requirements of the

applications using the parameters of pre-ventilation and post-

ventilation. The pressure switch monitors the air flow in the air

supply line or in the flue gas exhaust.

BCU 560, BCU 565 · Edition 02.16 7

Page 8

Application > Examples of application

Process control (PCC)

FCU 500

HT

P

ϑ

38371817

BCU 560..C0F3

46

µC

49

50

10

1 2 3

PLC

A

41

42

13

14

9

7

V1 V2

VAS VAG

VR..L

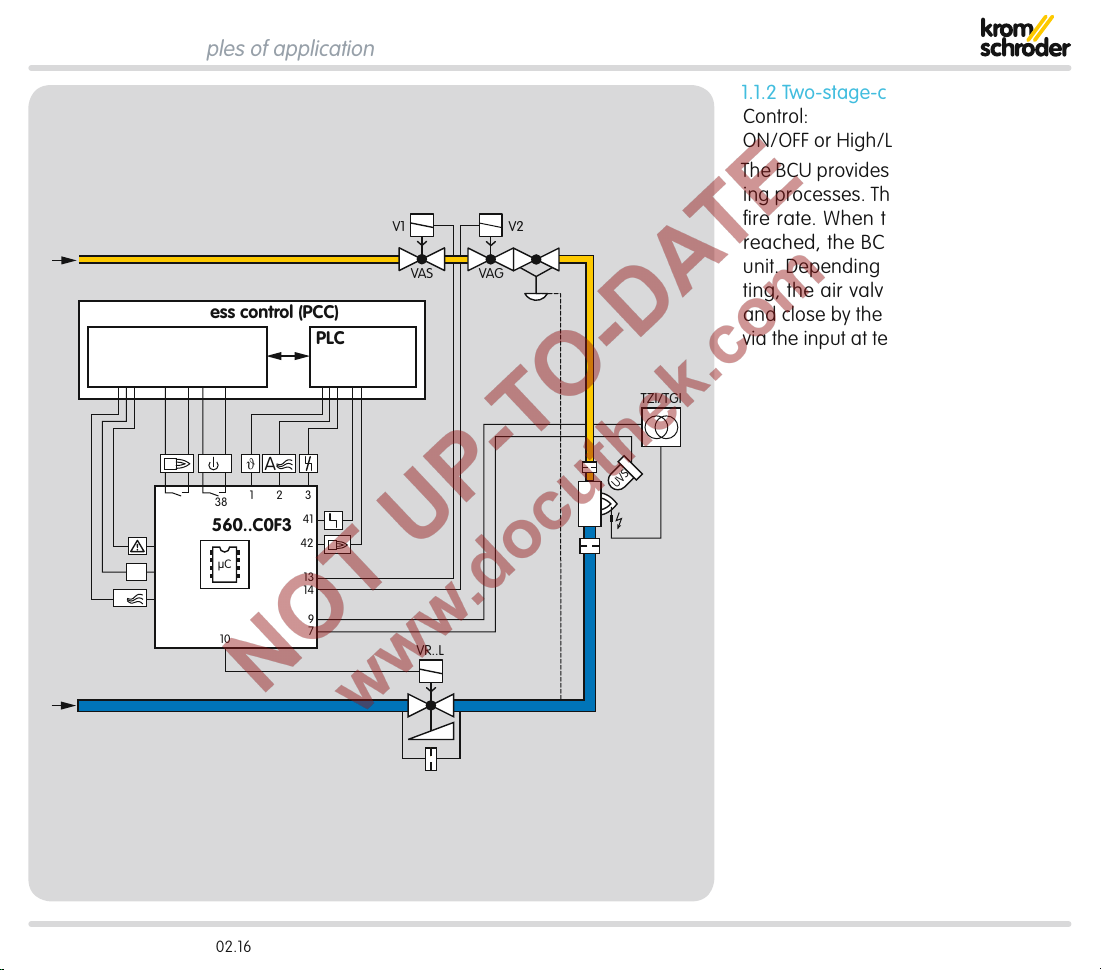

1.1.2 Two-stage-controlled burner

Control:

ON/OFF or High/Low

The BCU provides the cooling and purg-

ing processes. The burner starts at lowfire rate. When the operating state is

reached, the BCU advises the control

unit. Depending on the parameter setting, the air valve is actuated to open

and close by the program or externally

via the input at terminal 2.

TZI/TGI

UVS

BCU 560, BCU 565 · Edition 02.16 8

Page 9

Application > Examples of application

Process control (PCC)

FCU 500

DI

P

ϑ

38371817

BCU 560..C0F1

46

µC

49

50

52 53 54 55 56

1 2 3

PLC

A

41

42

13

14

15

9

7

V1

VAS VAG

VAS 1

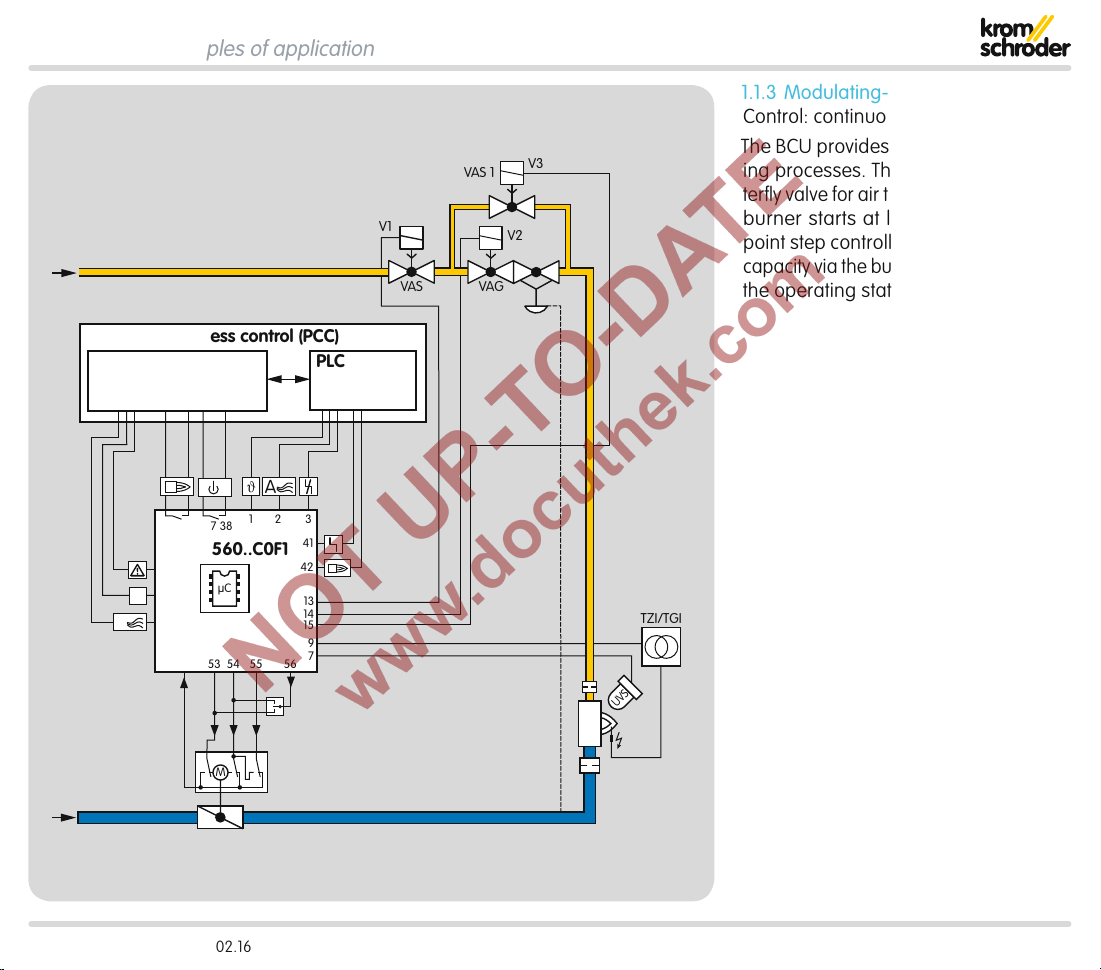

1.1.3 Modulating-controlled burner

Control: continuous

V3

The BCU provides the cooling and purg-

ing processes. The BCU moves the butterfly valve for air to ignition position. The

V2

burner starts at low-fire rate, a threepoint step controller controls the burner

capacity via the butterfly valve for air after

the operating state has been signalled.

TZI/TGI

UVS

M

BCU 560, BCU 565 · Edition 02.16 9

Page 10

Application > Examples of application

FCU 500..H1

M

HT

18

HT

HT

BCU 56x..D

49

5

µC

BCU 56x..D

49

5

µC

5-8

STM

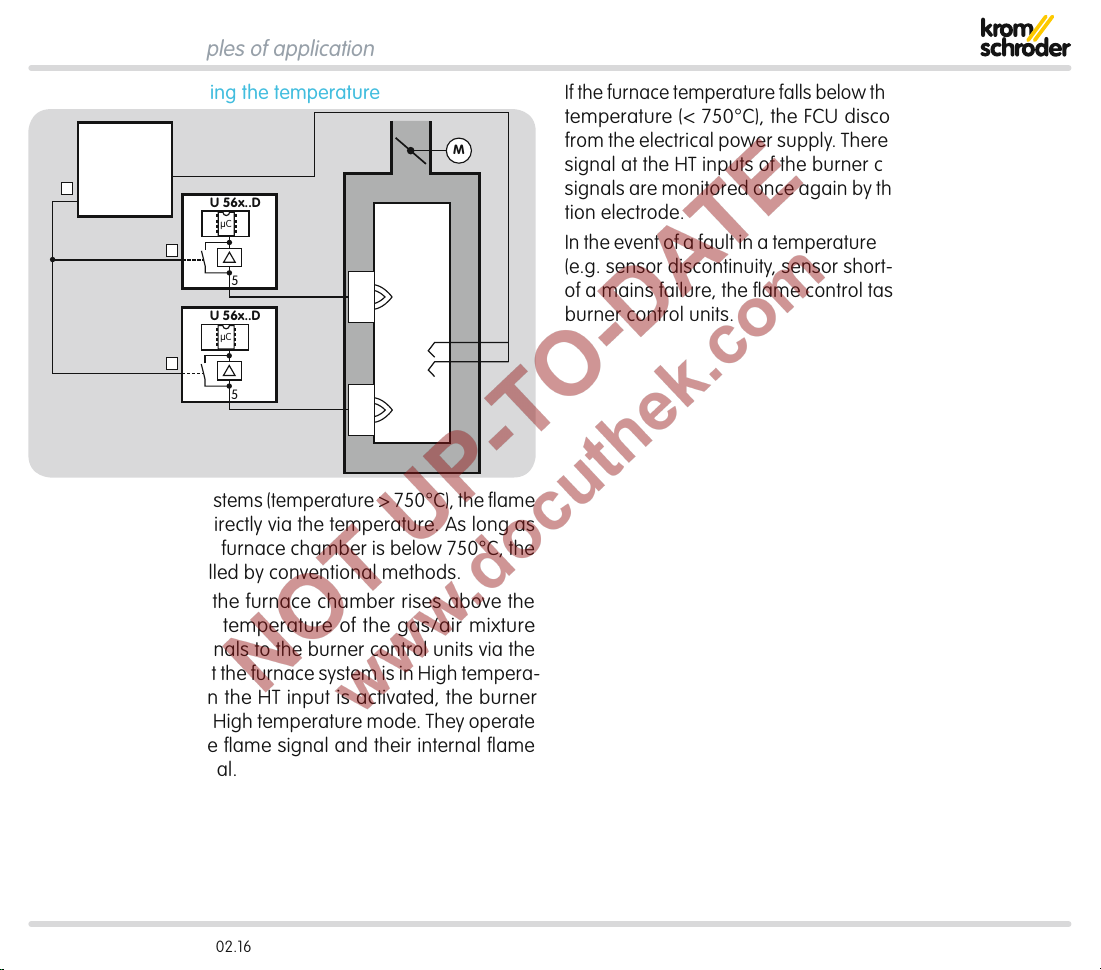

1.1.4 Flame control using the temperature

In high temperature systems (temperature >750°C), the flame

may be controlled indirectly via the temperature. As long as

the temperature in the furnace chamber is below 750°C, the

flame must be controlled by conventional methods.

If the temperature in the furnace chamber rises above the

spontaneous ignition temperature of the gas/air mixture

(>750°C), the FCU signals to the burner control units via the

fail-safe HT output that the furnace system is in High tempera-

ture mode (HT). When the HT input is activated, the burner

control units switch to High temperature mode. They operate

without evaluating the flame signal and their internal flame

control is non-functional.

If the furnace temperature falls below the spontaneous ignition

temperature (<750°C), the FCU disconnects the HToutput

from the electrical power supply. There is no longer an active

signal at the HT inputs of the burner control units. The flame

signals are monitored once again by the UV sensor or ionization electrode.

In the event of a fault in a temperature monitoring component

(e.g. sensor discontinuity, sensor short-circuit) or in the event

of a mains failure, the flame control task is transferred to the

burner control units.

BCU 560, BCU 565 · Edition 02.16 10

Page 11

Application > Examples of application

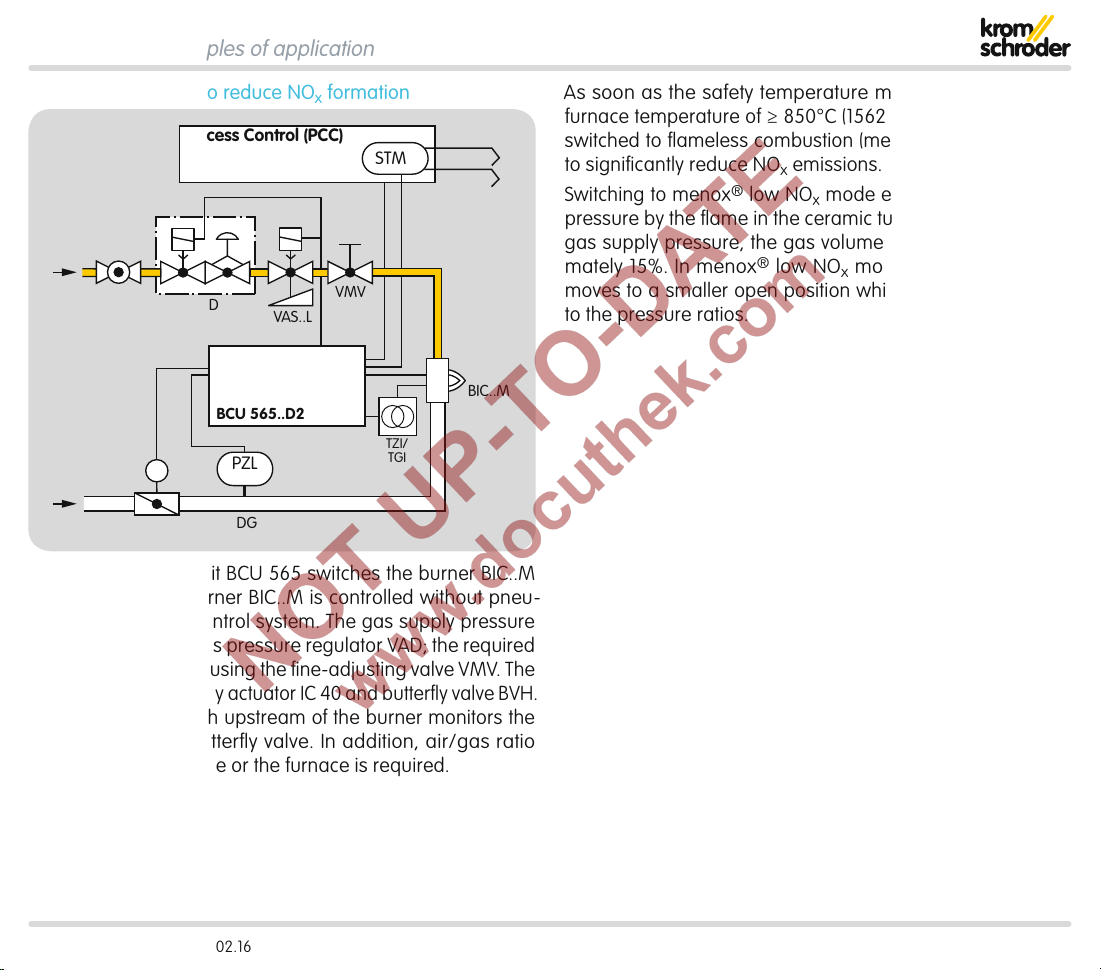

1.1.5 menox® mode to reduce NOx formation

Process Control (PCC)

STM

AKT

M

IC 40 + BVH

VAD

BCU 565..D2

PZL

VAS..L

DG

VMV

TZI/

TGI

BIC..M

The burner control unit BCU 565 switches the burner BIC..M

ON/OFF in cycles. Burner BIC..M is controlled without pneu-

matic air/gas ratio control system. The gas supply pressure

is controlled by the gas pressure regulatorVAD; the required

burner capacity is set using the fine-adjusting valveVMV. The

capacity is controlled by actuator IC40 and butterfly valveBVH.

An air pressure switch upstream of the burner monitors the

functioning of the butterfly valve. In addition, air/gas ratio

monitoring for the zone or the furnace is required.

As soon as the safety temperature monitor STM signals a

furnace temperature of ≥850°C(1562°F), the burner can be

switched to flameless combustion (menox® low NOx mode)

to significantly reduce NOx emissions.

Switching to menox

®

low NOx mode eliminates the counterpressure by the flame in the ceramic tubeTSC. At a constant

gas supply pressure, the gas volume increases by approximately15%. In menox® low NOx mode, the butterfly valve

moves to a smaller open position which has been adapted

to the pressure ratios.

BCU 560, BCU 565 · Edition 02.16 11

Page 12

Application > Examples of application

1

2 3

BCU 56x

BCM

BCU 56x

BCM

BCU 56x

BCM

PROFINET

L1

BUS

FCU

P

HT

PLC

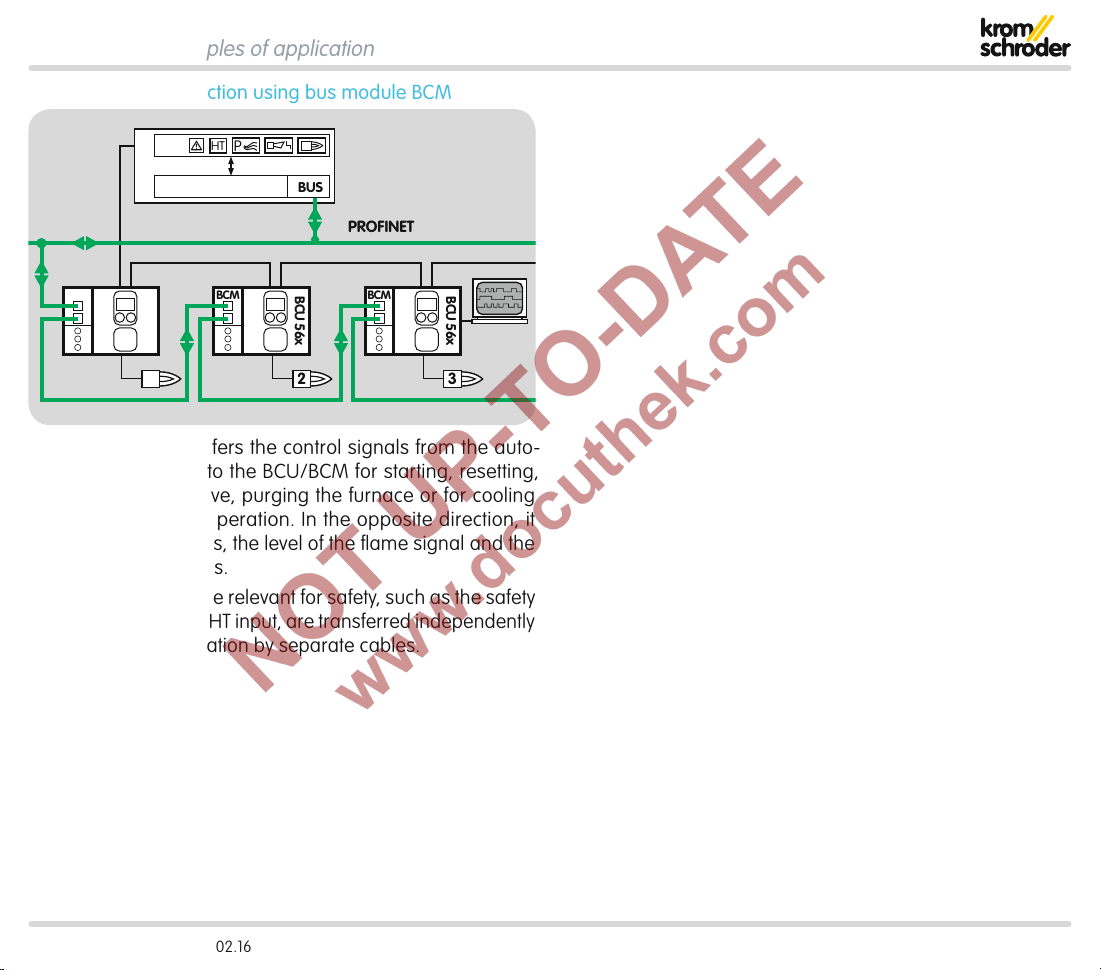

1.1.6 PROFINET connection using bus module BCM

The bus system transfers the control signals from the auto-

mation system (PLC) to the BCU/BCM for starting, resetting,

controlling the air valve, purging the furnace or for cooling

and heating during operation. In the opposite direction, it

sends operating status, the level of the flame signal and the

current program status.

Control signals that are relevant for safety, such as the safety

interlocks, purge and HT input, are transferred independently

of the bus communication by separate cables.

BCU 560, BCU 565 · Edition 02.16 12

Page 13

Application > Examples of application

PZL PZH PZ

45

P

>750°

47 4858

DL

minDLPurge

PZL PDZ

DG DG

VAS

VAS

pu/2

DG DG DG

DG

46

1

ϑ

2

3

min

49 15 131450

DG

max

µC

FCU 500..F0

STM

M

VAS

BCU 560..F3

BCU 560..F3

VCG

VR..L

VCG

VR..L

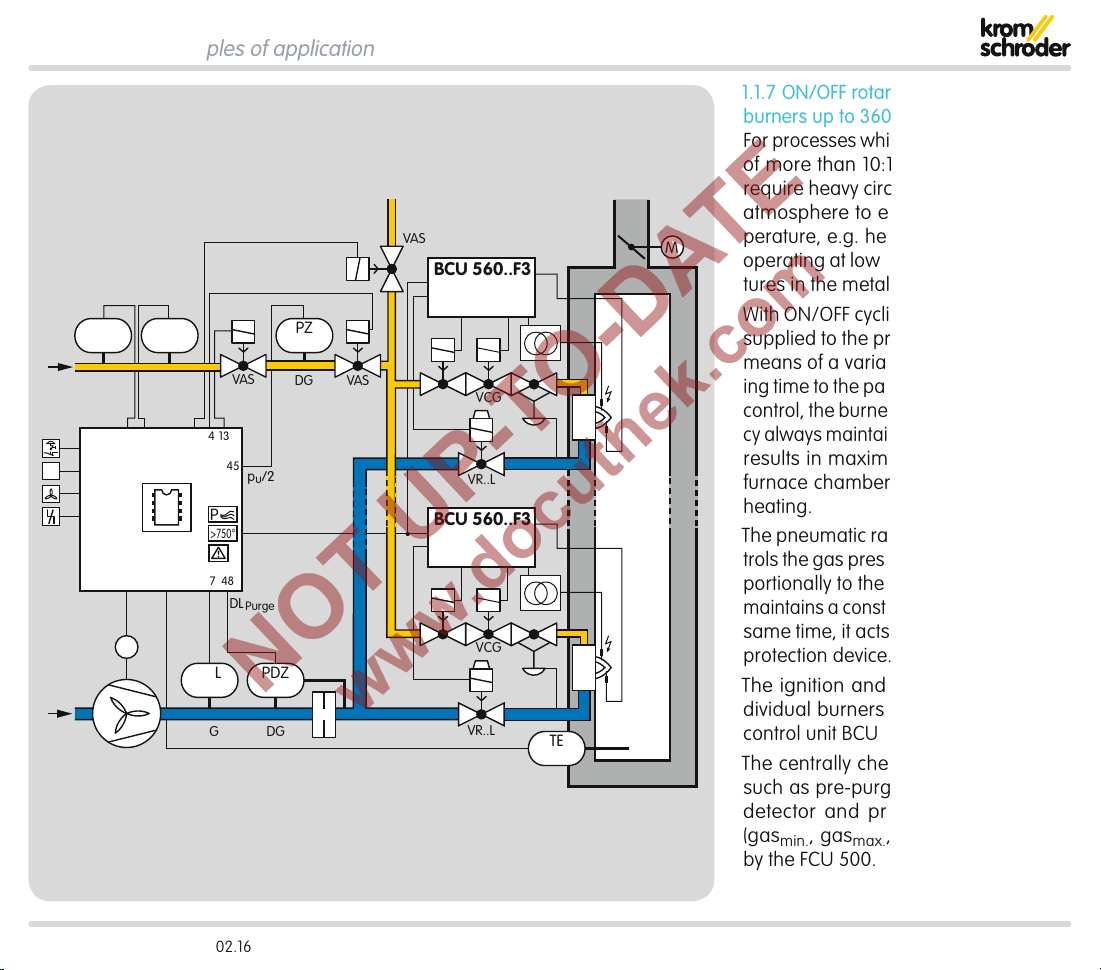

1.1.7 ON/OFF rotary impulse control for

burners up to 360kW

For processes which require a turndown

of more than 10:1 and/or those which

require heavy circulation of the furnace

atmosphere to ensure a uniform tem-

M

perature, e.g. heat treatment furnaces

operating at low and medium temperatures in the metallurgical industry.

With ON/OFF cyclic control, the capacity

supplied to the process is controlled by

means of a variable ratio of the operating time to the pause time. In this type of

control, the burner output pulse frequency always maintains full momentum and

results in maximum convection in the

furnace chamber, even with regulated

heating.

The pneumatic ratio control system con-

trols the gas pressure on the burner proportionally to the air pressure and thus

maintains a constant air/gas ratio. At the

same time, it acts as a low air pressure

protection device.

The ignition and monitoring of the in-

dividual burners is ensured by burner

TE

control unit BCU560.

The centrally checked safety functions

such as pre-purge, tightness test, flow

detector and pressure switch check

(gas

min.

, gas

max.

, air

) are provided

min.

by the FCU500.

BCU 560, BCU 565 · Edition 02.16 13

Page 14

Application > Examples of application

PZL PZH PZ

DG DG DG

min

49 15 131450

DG

max

µC

DG

1

ϑ

2

3

FCU 500..F1

STM

DL

minDLPurge

M

PZL PDZ

VAS

pu/2

45

P

57

16

>750°

TC

0°➔90°

53

90°➔0°

54

55

47 4858

VAS

M

VAS

BCU 560..F0

66

BCU 560..F0

66

VCG

VCG

1.1.8 Modulating burner control

For processes that do not require heavy

circulation in the furnace, e.g. aluminium

smelting furnaces.

This system is suitable for processes in

which infiltrated air may flow into the

M

furnace through switched off burners.

The capacity can be adjusted continu-

ously by activating the control element

(analogue or 3-point step signal). The

pneumatic ratio control system controls

the gas pressure proportionally to the air

pressure and thus maintains a constant

air/gas ratio. At the same time, it acts

as a low air pressure protection device.

One burner control unit per burner is

required for ignition and monitoring.

The centrally checked safety functions

such as pre-purge, setting the valve

to ignition position via a butterfly valve

control system, tightness test, flow detector and pressure switch check (gas

gas

max.

, air

) are provided by the

min.

min.

,

FCU500.

DGDG

TE

BCU 560, BCU 565 · Edition 02.16 14

Page 15

2 Certification

Certified to SIL and PL

For systems up to SIL 3 pursuant to EN 61508 and PL e pursu-

ant to ISO 13849

EU certified pursuant to

– Gas Appliances Directive (2009/142/EC)

Meets the requirements of the

– Low Voltage Directive (2006/95/EC),

– EMC Directive (2004/108/EC).

FM approved

Factory Mutual Research Class: 7400 Process Control Valves.

Designed for applications pursuant to NFPA 85 and NFPA 86.

www.approvalguide.com

Eurasian Customs Union

The products BCU 560 and BCU 565 meet the technical speci-

fications of the Eurasian Customs Union.

BCU 560, BCU 565 · Edition 02.16 15

Page 16

3 Function

3.1 Connection diagram

3.1.1 BCU560..F3 with ionization control in double-

electrode operation

Alternative flame control, see page22 (Flame control).

Electrical connection, see page106 (Project planning information)

Explanation of symbols, see page126 (Legend)

Z

I

HT

P

0,6 × I

ϑ

A

p

u

PZL

GZL

2

P69

P70

P70

P72P71

P72P72

P73

N

1 2 3 4645 65 66 67 6849 50 51

5 6 9 11

61

c

24V

DC

c

230V

2AT

1210762

3,15AT

41 42

17 18 37 38

max. 1 A;

24

V

DC,

250 V AC

V3

88

µC

13 14 15

53 54

V2

V1

BCU 560..F3

0 V+24 V

NL1

BCU 560, BCU 565 · Edition 02.16 16

Page 17

Function > Connection diagram

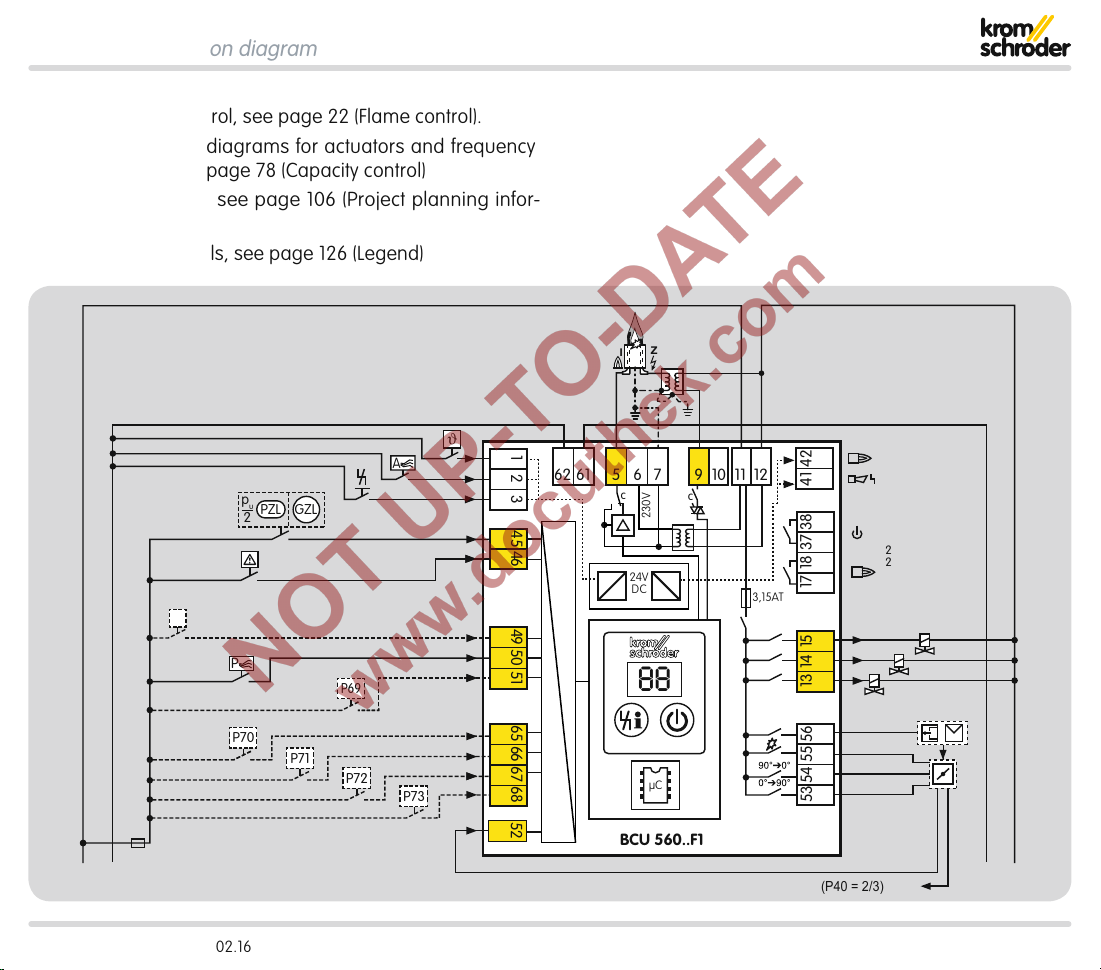

3.1.2 BCU560..F1

Alternative flame control, see page22 (Flame control).

Detailed connection diagrams for actuators and frequency

converters, see from page78 (Capacity control)

Electrical connection, see page106 (Project planning infor-

mation)

Explanation of symbols, see page126 (Legend)

Z

I

ϑ

A

p

u

PZL

GZL

2

HT

P

P69

P70

P70

P72P71

P72P72

P73

1 2 3 4645 65 66 67 6849 50 51

5 6 9 11

61

c

24V

DC

c

230V

1210762

3,15AT

41 42

17 18 37 38

max. 1 A;

24

V

DC,

250 V AC

V3

88

µC

13 14 15

53 54 55 56

V2

V1

mA

52

0,6 × I

N

BCU 560..F1

(P40 = 2/3) => 51

0 V+24 V

NL1

BCU 560, BCU 565 · Edition 02.16 17

Page 18

Function > Connection diagram

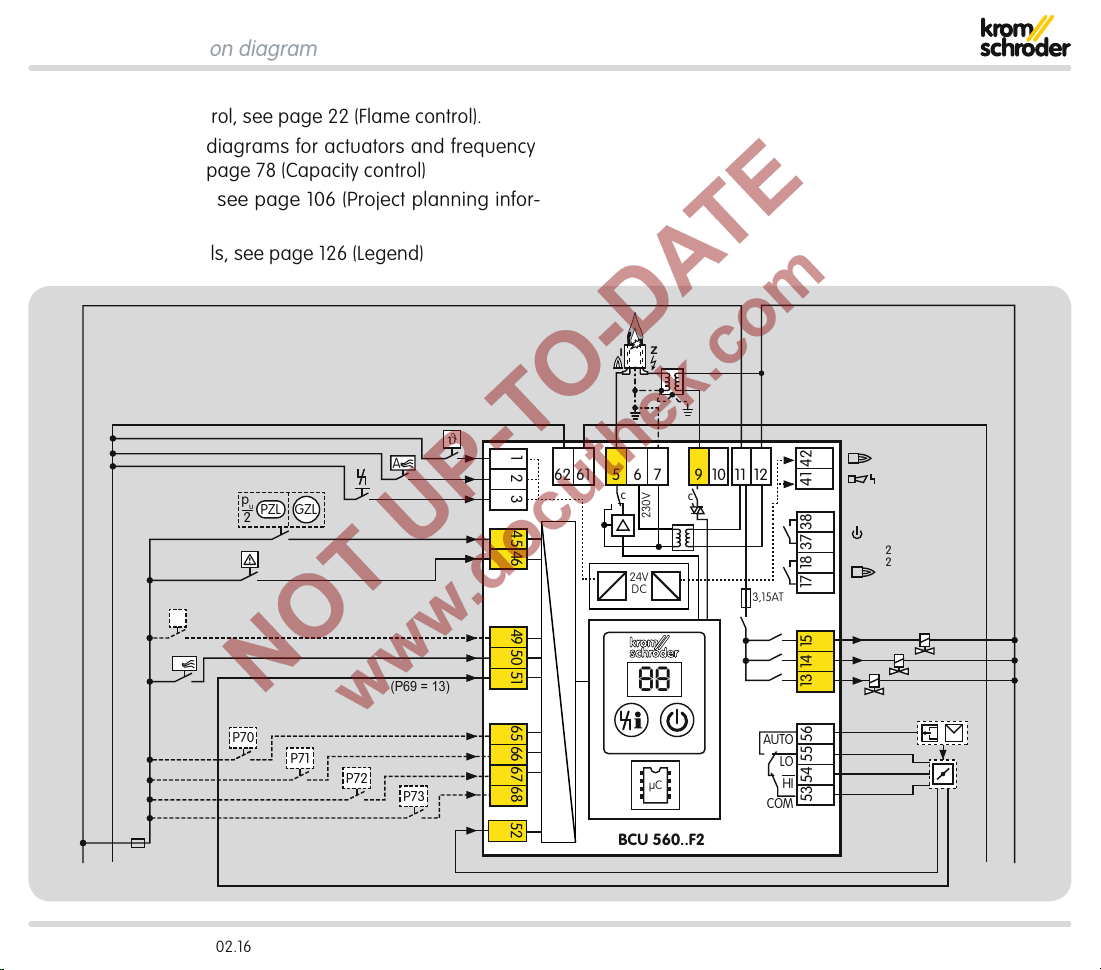

3.1.3 BCU560..F2

Alternative flame control, see page22 (Flame control).

Detailed connection diagrams for actuators and frequency

converters, see from page78 (Capacity control)

Electrical connection, see page106 (Project planning infor-

mation)

Explanation of symbols, see page126 (Legend)

Z

I

HT

P

0,6 × I

ϑ

A

p

u

PZL

GZL

2

(P69 = 13)

P70P70

P72P71

P72P72

P73

N

1 2 3 4645 65 66 67 6849 50 51

52

5 6 9 11

61

c

230V

24V

DC

88

µC

BCU 560..F2

1210762

3,15AT

41 42

17 18 37 38

max. 1 A;

24 V DC,

250 V AC

c

V3

V2

V1

mA

0 V+24 V

NL1

AUTO

LO

COM

13 14 15

HI

53 54 55 56

BCU 560, BCU 565 · Edition 02.16 18

Page 19

Function > Connection diagram

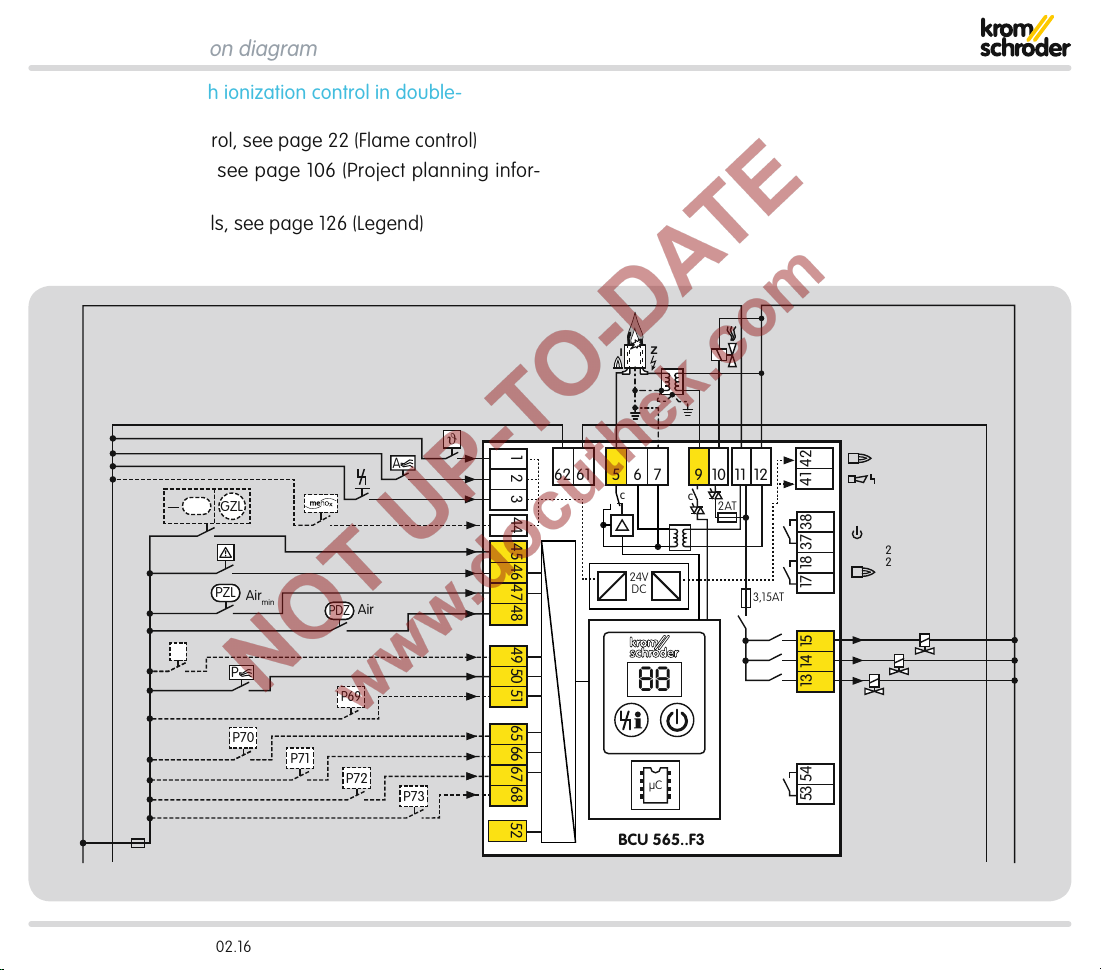

3.1.4 BCU565..F3 with ionization control in double-

electrode operation

Alternative flame control, see page22 (Flame control)

Electrical connection, see page106 (Project planning infor-

mation)

Explanation of symbols, see page126 (Legend)

Z

I

ϑ

A

p

u

PZL

GZL

2

PZL

PZL

Air

min

HT

P

P70P70

P72P71

PDZ

PDZ

Air

P69

P72P72

P73

1 2 3

44

4645 4847 65 66 67 6849 50 51

5 6 9 11

62 61

c

24V

DC

88

7

c

2AT

1210

3,15AT

41 42

17 18 37 38

max. 1 A;

24 V DC,

250 V AC

V3

13 14 15

µC

53 54

V2

V1

52

0.6 × I

N

L1

BCU 565..F3

0 V+24 V

N

BCU 560, BCU 565 · Edition 02.16 19

Page 20

Function > Connection diagram

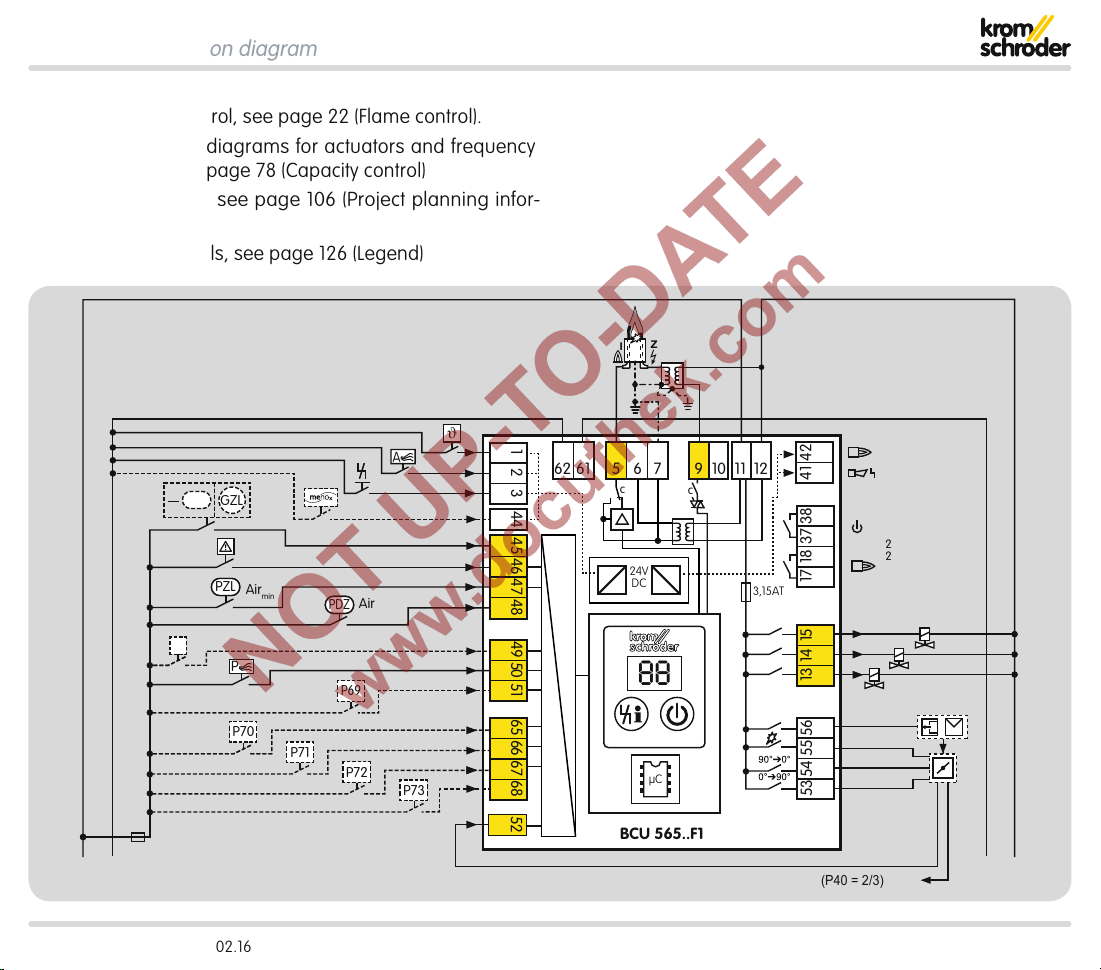

3.1.5 BCU565..F1

Alternative flame control, see page22 (Flame control).

Detailed connection diagrams for actuators and frequency

converters, see from page78 (Capacity control)

Electrical connection, see page106 (Project planning infor-

mation)

Explanation of symbols, see page126 (Legend)

Z

I

ϑ

A

p

u

PZL

GZL

2

PZL

PZL

Air

min

HT

P

P70P70

P72P71

PDZ

PDZ

Air

P69

P72P72

P73

1 2 3 4645 4847 65 66 67 6849 50 51

44

5 6 9 11

62 61

c

24V

DC

88

7

c

1210

3,15AT

41 42

17 18 37 38

max. 1 A;

24 V DC,

250 V AC

V3

13 14 15

µC

53 54 55 56

V2

V1

mA

52

0.6 × I

N

L1

BCU 565..F1

(P40 = 2/3) => 51

0 V+24 V

N

BCU 560, BCU 565 · Edition 02.16 20

Page 21

Function > Connection diagram

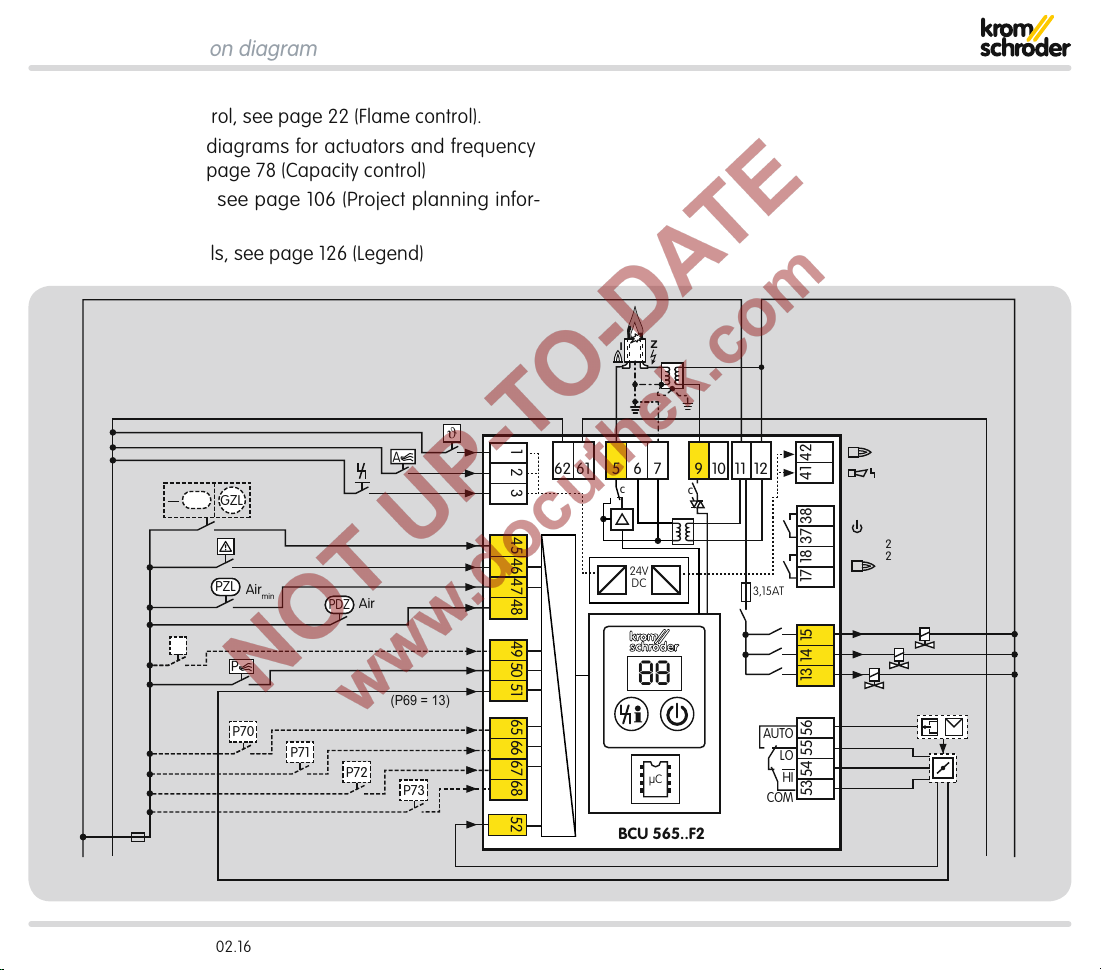

3.1.6 BCU565..F2

Alternative flame control, see page22 (Flame control).

Detailed connection diagrams for actuators and frequency

converters, see from page78 (Capacity control)

Electrical connection, see page106 (Project planning infor-

mation)

Explanation of symbols, see page126 (Legend)

Z

I

ϑ

A

p

u

PZL

GZL

2

PZL

PZL

Air

HT

0.6 × I

min

P

P70P70

P72P71

N

PDZ

PDZ

Air

(P69 = 13)

P72P72

P73

L1

1 2 3 4645 4847 65 66 67 6849 50 51

52

5 6 9 11

62 61

7

c

24V

DC

c

88

µC

BCU 565..F2

1210

3,15AT

AUTO

COM

41 42

max. 1 A;

24 V DC,

250 V AC

17 18 37 38

V3

13 14 15

LO

HI

53 54 55 56

V2

V1

mA

0 V+24 V

N

BCU 560, BCU 565 · Edition 02.16 21

Page 22

Function > Connection diagram

1 2 3 4645 65 66 67 6849 50 51

41 42

5 6 9 11

1210762

61

Z

NL1

1 2 3 4645 65 66 67 6849 50 51

41 42

5 6 9 11

1210762

61

UVS

1

2

3

Z

NL1

1 2 3 4645 65 66 67 6849 50 51

41 42

5 6 9 11

1210762

61

ϑ

0 V

24 V

+–

0–20 mA

UVD1

1

2

4

3

5

6

Z

NL1

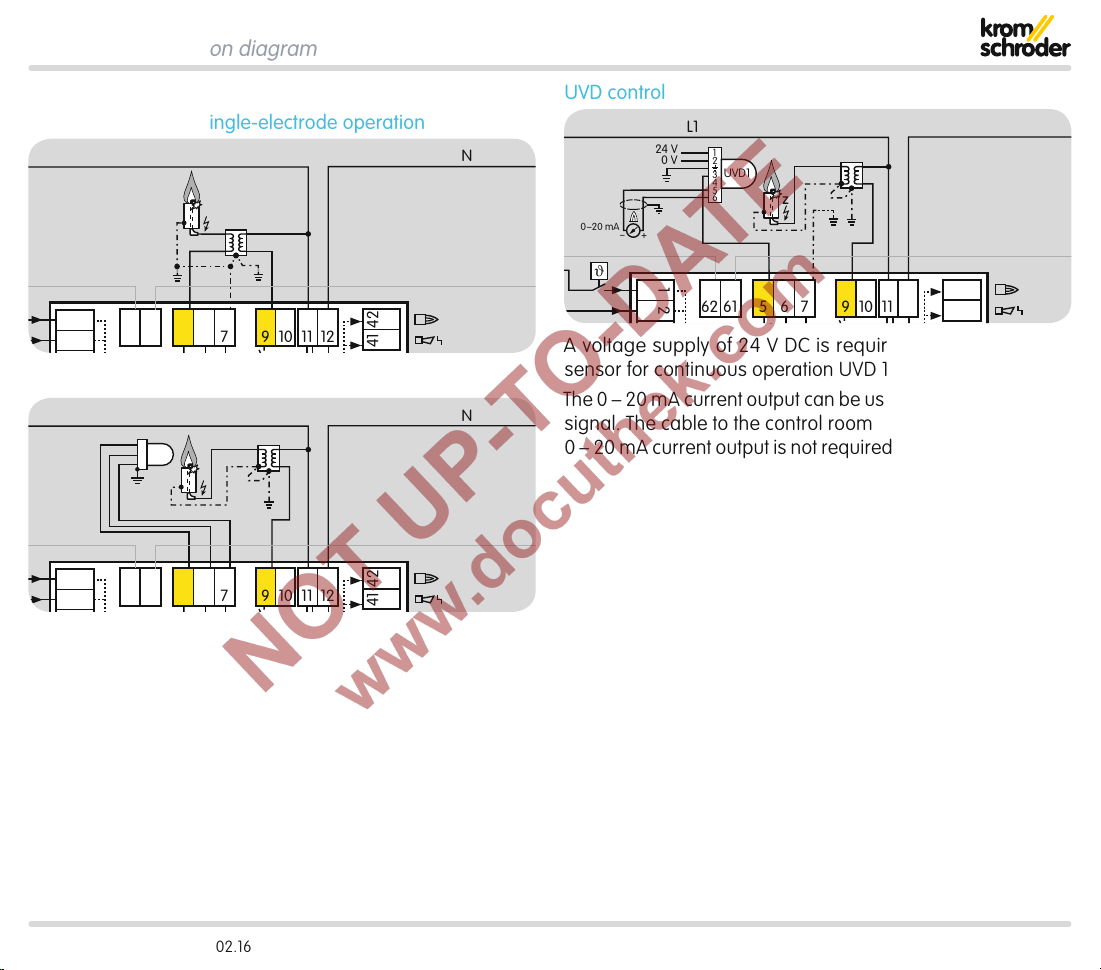

3.1.7 Flame control Ionization control in single-electrode operation

UVS control

UVD control

A voltage supply of 24 VDC is required to operate the UV

sensor for continuous operation UVD1.

The 0 – 20mA current output can be used to display the flame

signal. The cable to the control room must be screened. The

0 – 20mA current output is not required for normal operation.

BCU 560, BCU 565 · Edition 02.16 22

Page 23

Function

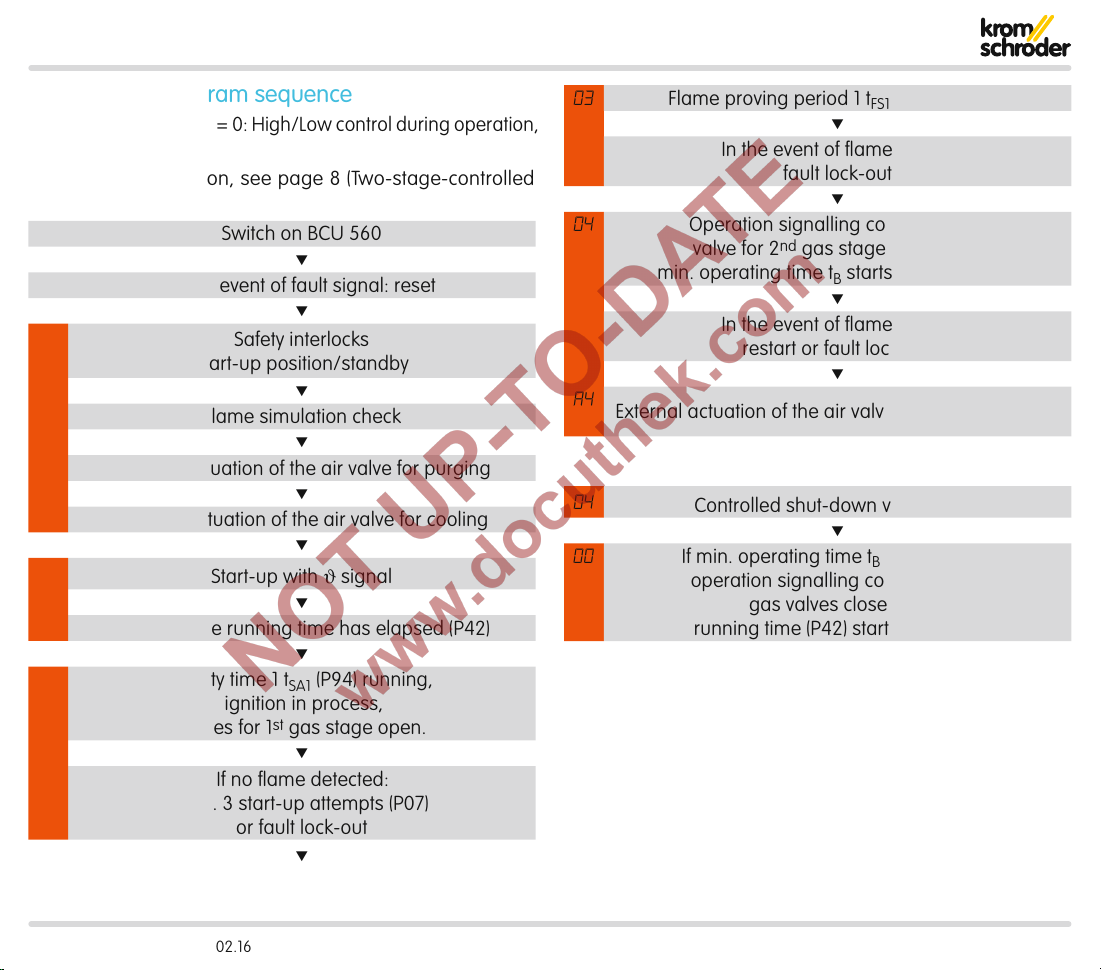

3.2 BCU 560 program sequence

Parameters 48 and 49 = 0: High/Low control during operation,

cooling in standby

Example of application, see page8 (Two-stage-controlled

burner)

Switch on BCU 560

▼

In the event of fault signal: reset

▼

00

P0

A0

H1

02

External actuation of the air valve for purging

External actuation of the air valve for cooling

Wait until the running time has elapsed (P42)

Safety interlocks

Start-up position/standby

▼

Flame simulation check

▼

▼

▼

Start-up with ϑ signal

▼

▼

Safety time 1 t

(P94) running,

SA1

ignition in process,

valves for 1st gas stage open.

▼

If no flame detected:

max. 3 start-up attempts (P07)

or fault lock-out

▼

03

Flame proving period 1 t

FS1

▼

running (P95)

In the event of flame failure:

fault lock-out

▼

04

Operation signalling contact closes,

valve for 2nd gas stage opens and

min. operating time tB starts to elapse (P61)

▼

In the event of flame failure:

restart or fault lock-out

▼

A4

External actuation of the air valve for capacity control

04

00

Controlled shut-down via ϑ signal

▼

If min. operating time tB has elapsed:

operation signalling contact opens,

gas valves close and

running time (P42) starts to elapse

BCU 560, BCU 565 · Edition 02.16 23

Page 24

Function

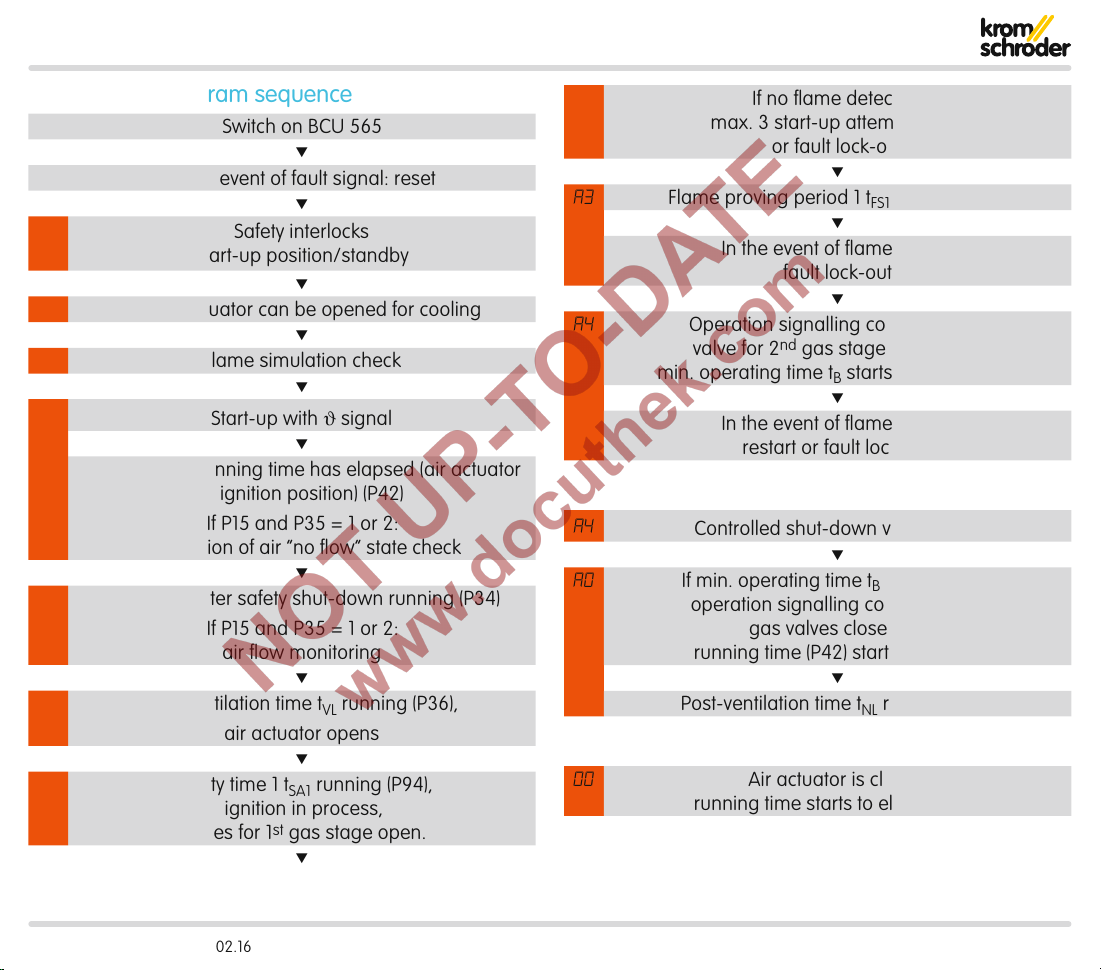

3.3 BCU 565 program sequence

Switch on BCU 565

▼

In the event of fault signal: reset

▼

00

A0

The air actuator can be opened for cooling

00

H1

Wait until the running time has elapsed (air actuator

verification of air “no flow” state check

P1

A1

Pre-purge after safety shut-down running (P34)

Pre-ventilation time tVL running (P36),

A2

Safety interlocks

Start-up position/standby

▼

▼

Flame simulation check

▼

Start-up with ϑ signal

▼

in ignition position) (P42)

If P15 and P35 = 1 or 2:

▼

If P15 and P35 = 1 or 2:

air flow monitoring

▼

air actuator opens

▼

Safety time 1 t

running (P94),

SA1

ignition in process,

valves for 1st gas stage open.

▼

A3

A4

A4

A0

00

If no flame detected:

max. 3 start-up attempts (P07)

or fault lock-out

▼

Flame proving period 1 t

FS1

▼

running (P95)

In the event of flame failure:

fault lock-out

▼

Operation signalling contact closes,

valve for 2nd gas stage opens and

min. operating time tB starts to elapse (P61)

▼

In the event of flame failure:

restart or fault lock-out

Controlled shut-down via ϑ signal

▼

If min. operating time tB has elapsed:

operation signalling contact opens,

gas valves close and

running time (P42) starts to elapse

▼

Post-ventilation time tNL running (P39)

Air actuator is closed,

running time starts to elapse (P42)

BCU 560, BCU 565 · Edition 02.16 24

Page 25

4 Air control

M

PZL PZH PZ

PZL PDZ

TE

M

FCU 500..F0

µC

P

DG DG DG

VAS

VAS

VCG

VCG

VR..L

VR..L

DG DG

DG

minDGmax

49 15 131450

45

47 4858

>750°

pu/2

DL

minDLPurge

BCU 5xx..F3

BCU 5xx..F3

ϑ

1

46

2

3

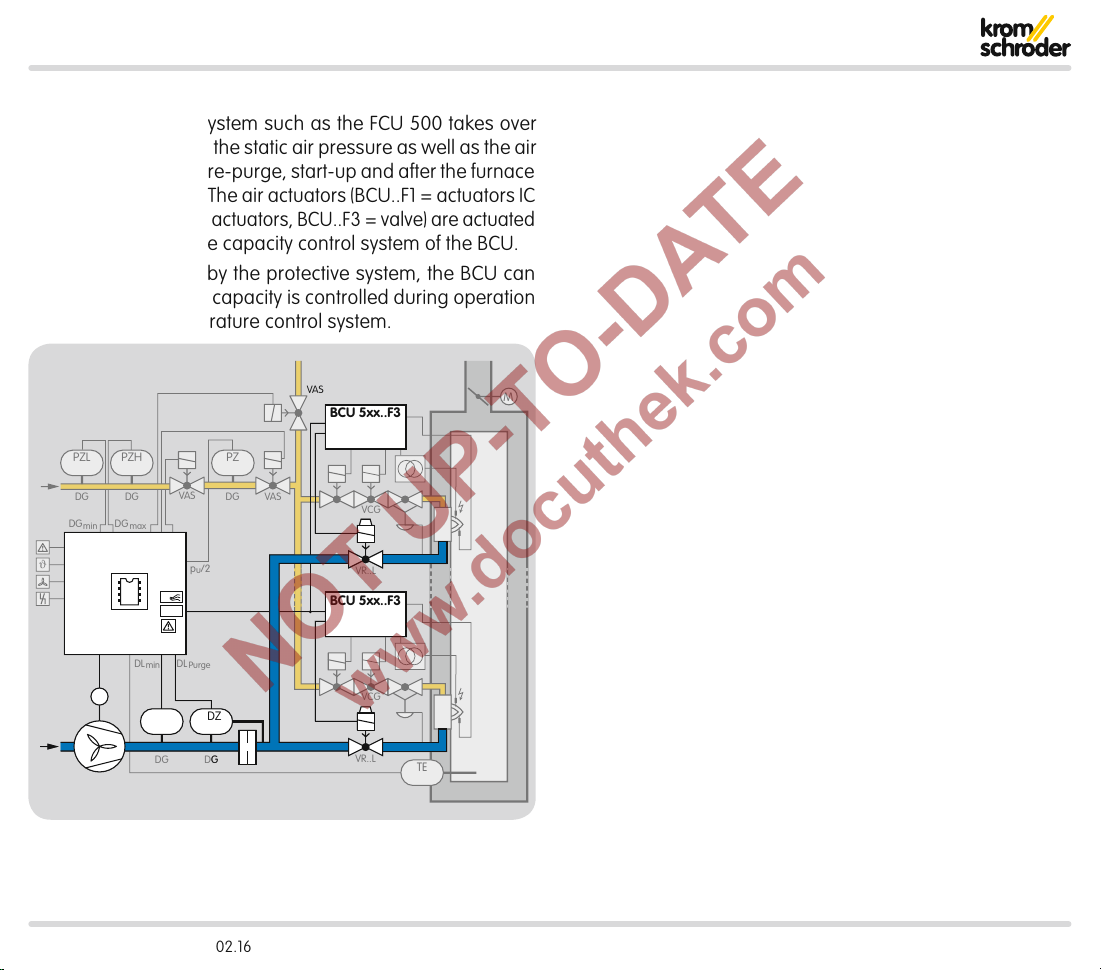

A central protective system such as the FCU500 takes over

air control. It monitors the static air pressure as well as the air

volume required for pre-purge, start-up and after the furnace

has been shut down. The air actuators (BCU..F1 = actuators IC

20/40, BCU..F2 = RBW actuators, BCU..F3 = valve) are actuated

for this purpose by the capacity control system of the BCU.

After being enabled by the protective system, the BCU can

start the burners. The capacity is controlled during operation

by an external temperature control system.

VAS

BCU 5xx..F3

49 15 131450

46

1

2

3

FCU 500

M

µC

P

>750°

DL

minDLPurge

PZL PDZ

DG DG

45

BCU 5xx..F3

BCU 560, BCU 565 · Edition 02.16 25

Page 26

Air control

BCU 560..C0F1

µC

VAS VAG

TZI/TGI

V1

V2

V3

14

15

13

9

7

UVS

38371817

1 2 3

46

49

50

41

42

M

52 53 54 55 56

VAS 1

Process control (PCC)

ϑ

A

P

DI

FCU 500

SPS

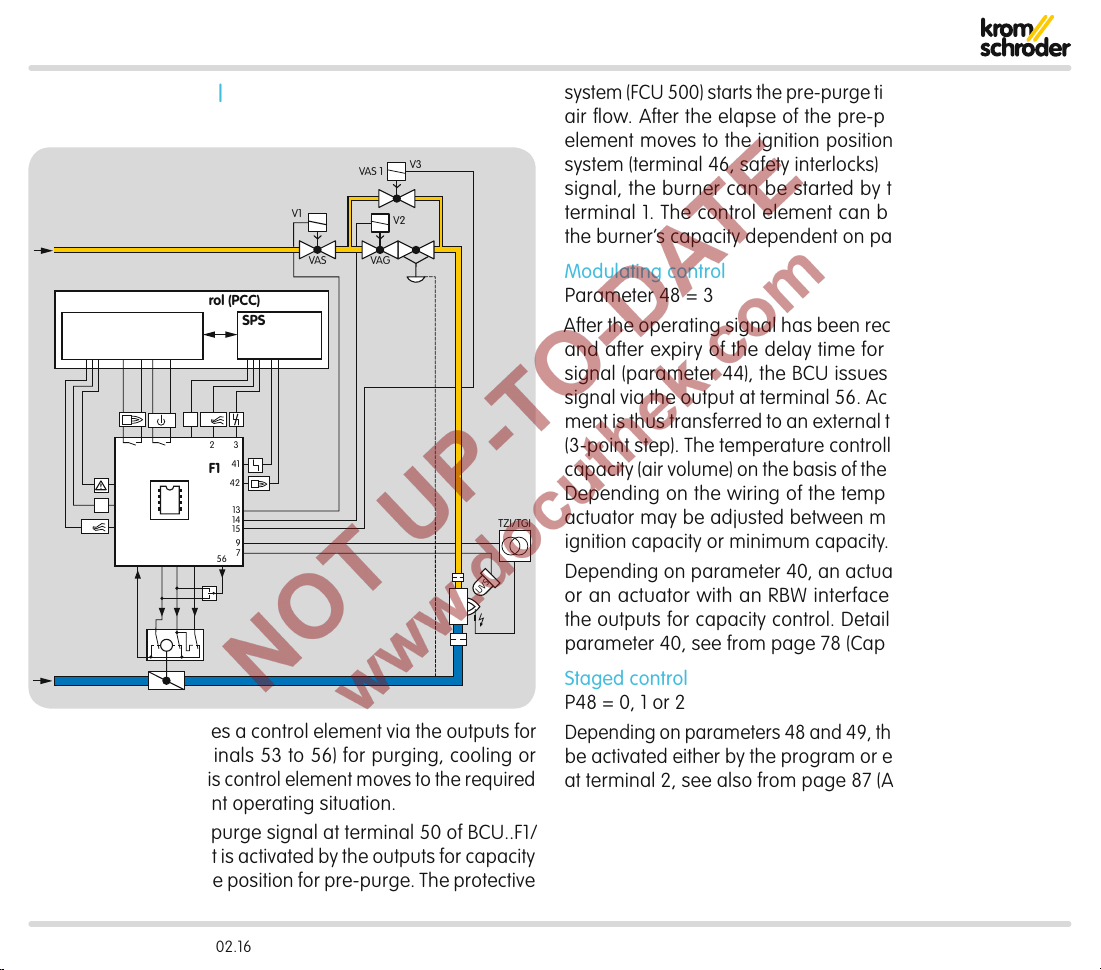

4.1 Capacity control

4.1.1 BCU..F1/F2

system (FCU 500) starts the pre-purge time if there is adequate

air flow. After the elapse of the pre-purge time, the control

element moves to the ignition position. Once the protective

system (terminal 46, safety interlocks) has issued the enable

signal, the burner can be started by the start-up signal at

terminal 1. The control element can be activated to control

the burner’s capacity dependent on parameters 48 and 49.

Modulating control

Parameter 48 = 3

After the operating signal has been received from the burner

and after expiry of the delay time for the controller enable

signal (parameter 44), the BCU issues the controller enable

signal via the output at terminal 56. Access to the control element is thus transferred to an external temperature controller

(3-point step). The temperature controller controls the burner

capacity (air volume) on the basis of the required temperature.

Depending on the wiring of the temperature controller, the

actuator may be adjusted between maximum capacity and

ignition capacity or minimum capacity.

Depending on parameter40, an actuator IC20, IC40, IC50

or an actuator with an RBW interface can be actuated via

the outputs for capacity control. Detailed information about

parameter 40, see from page78 (Capacity control).

The BCU..F1/F2 activates a control element via the outputs for

capacity control (terminals 53 to56) for purging, cooling or

starting the burner. This control element moves to the required

position for the relevant operating situation.

As soon as there is a purge signal at terminal 50 of BCU..F1/

F2, the control element is activated by the outputs for capacity

Staged control

P48 = 0, 1 or 2

Depending on parameters 48 and 49, the control element may

be activated either by the program or externally via the input

at terminal 2, see also from page87 (Air actuator control).

control to approach the position for pre-purge. The protective

BCU 560, BCU 565 · Edition 02.16 26

Page 27

Air control > Capacity control

BCU 560..C0F3

µC

VAS VA G

TZI/TGI

VR..L

V1 V2

14

13

9

7

10

UVS

38371817

1 2 3

FCU 500

Process control (PCC)

46

49

50

P

HT

ϑ

41

42

A

SPS

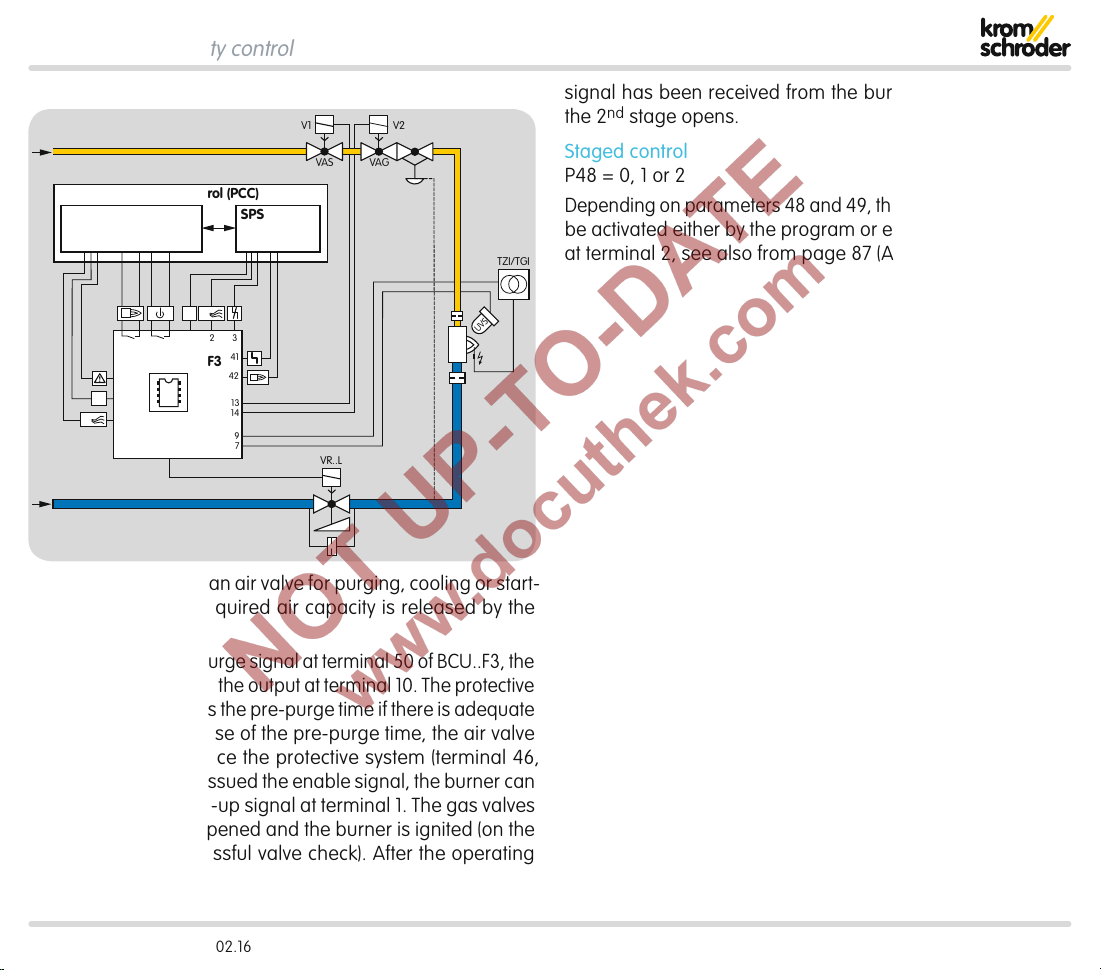

4.1.2 BCU..F3

The BCU..F3 activates an air valve for purging, cooling or start-

ing the burner. The required air capacity is released by the

air valve.

As soon as there is a purge signal at terminal 50 of BCU..F3, the

air valve is activated by the output at terminal 10. The protective

system (FCU 500) starts the pre-purge time if there is adequate

air flow. After the elapse of the pre-purge time, the air valve

closes for ignition. Once the protective system (terminal 46,

safety interlocks) has issued the enable signal, the burner can

be started by the start-up signal at terminal 1. The gas valves

for the 1st stage are opened and the burner is ignited (on the

BCU..C1 after a successful valve check). After the operating

signal has been received from the burner, the gas valve for

the 2ndstage opens.

Staged control

P48 = 0, 1 or 2

Depending on parameters 48 and 49, the control element may

be activated either by the program or externally via the input

at terminal 2, see also from page87 (Air actuator control).

BCU 560, BCU 565 · Edition 02.16 27

Page 28

5 menox® low NOx mode

▼

menox® low NOx mode leads to a drastic reduction in thermal

NOx formation in ON/OFF-controlled high-velocity burners.

5.1 System structure and function

The system consists of a burner BIC..M with system compo-

nents tailored to the application. The system components

make it possible to operate the burner in two operating modes:

conventional flame mode in low furnace temperatures and

menox® low NOx mode with flameless combustion at higher

furnace temperatures.

Process Control (PCC)

STM

AKT

VAD

M

VAS..L

BCU 565..D2

PZL

VMV

TZI/

TGI

BIC..M

The gas and air for flame mode and low NO

mode are sup-

x

plied via the same connections. The gas pressure upstream

of the burner is adjusted using a pressure regulator (e.g. VAD).

The gas volume is set using a fine-adjusting valve (e.g. VMV).

The air volume for the operating modes is set by adjusting

the butterfly valve (e.g. BVH). The air pressure is monitored

on each burner by a pressure switch to check the functioning

of the butterfly valve. In addition, air/gas ratio monitoring

for the zone or the furnace is required since the air pres-

sure switch is not sufficient for use as a low air pressure

protection device.

The menox

®

burner BIC..M has a special mixing unit whose

geometric design ensures reliable ignition and a stable flame

while also making sure that the combustion process is transferred to the furnace chamber for menox® mode.

In menox

®

mode, the inflammable gas/air mixture must be

prevented from igniting prematurely in the ceramic combustion

chamber each time the burner is switched on. The flow velocity

at the burner nozzle must be adequately high to prevent the

danger of flashback into the combustion chamber. Burners

BIC..M are tailored to the appropriate capacity and combined

with tapered ceramic tubes (TSC..B).

IC 40 + BVH

DG

A burner BIC..M in conjunction with a burner control unit

BCU..D2 is required for safe burner operation in menox® low

NOx mode.

BCU 560, BCU 565 · Edition 02.16 28

Page 29

menox® low NOx mode > System structure and function

850 1050 1250120011501100900 1000950

0

100

200

300

400

Furnace temperature [°C]

NO

x

[mg/m

3

, ref. 5% O

2

]

Flame mode

Natural gas, air preheating to 450°C

Flame mode

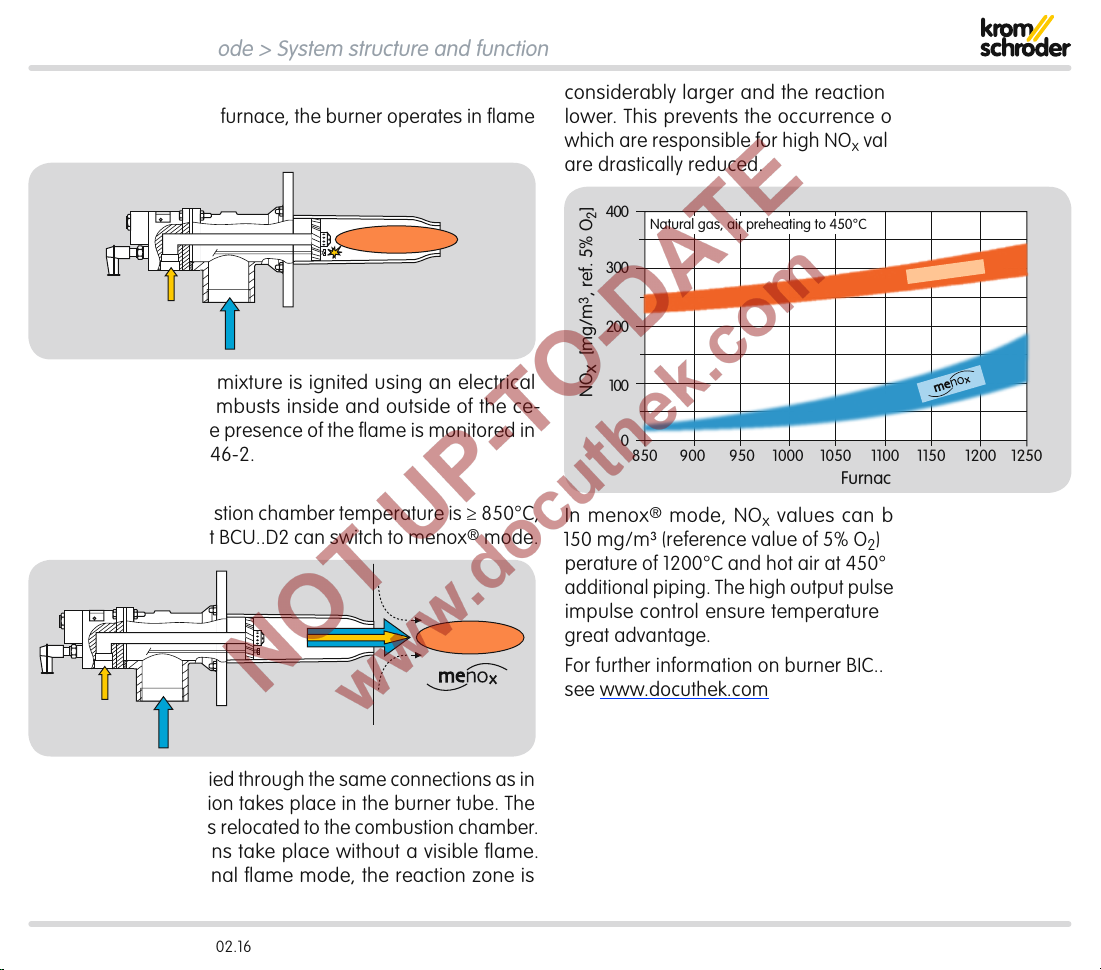

In order to heat up the furnace, the burner operates in flame

mode.

The ignitable gas/air mixture is ignited using an electrical

ignition spark and combusts inside and outside of the ce-

ramic burner tube. The presence of the flame is monitored in

compliance with EN746-2.

®

menox

mode

As soon as the combustion chamber temperature is ≥ 850°C,

the burner control unit BCU..D2 can switch to menox® mode.

considerably larger and the reaction density considerably

lower. This prevents the occurrence of peak temperatures

which are responsible for high NOx values. Emissions of NOx

are drastically reduced.

In menox® mode, NOx values can be reduced to below

150mg/m³ (reference value of 5% O2) even at a furnace tem-

perature of 1200°C and hot air at 450°C– without expensive

additional piping. The high output pulse frequency and rotary

impulse control ensure temperature uniformity which is of

great advantage.

For further information on burner BIC..M,

see www.docuthek.com

Gas and air are supplied through the same connections as in

flame mode. No ignition takes place in the burner tube. The

combustion process is relocated to the combustion chamber.

The oxidation reactions take place without a visible flame.

Compared to traditional flame mode, the reaction zone is

BCU 560, BCU 565 · Edition 02.16 29

Page 30

menox® low NOx mode

38371817

1 2 3

46

50

41

44

42

ϑ

A

P

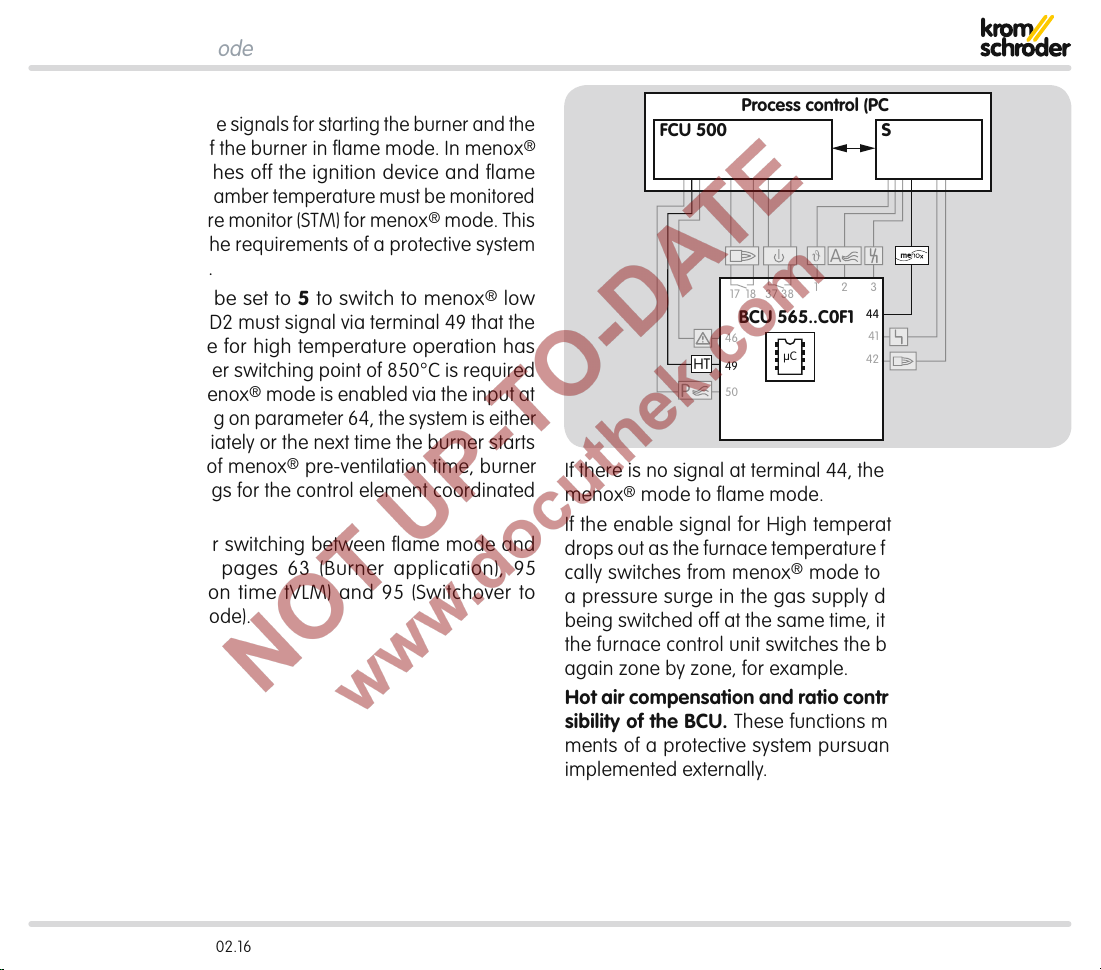

5.2 BCU..D2

The BCU coordinates the signals for starting the burner and the

fail-safe monitoring of the burner in flame mode. In menox®

mode, the BCU switches off the ignition device and flame

control. The furnace chamber temperature must be monitored

by a safety temperature monitor (STM) for menox® mode. This

function must satisfy the requirements of a protective system

pursuant to EN746-2.

Parameter 06 must be set to 5 to switch to menox® low

NOx mode. The BCU..D2 must signal via terminal 49 that the

required temperature for high temperature operation has

been reached. A higher switching point of 850°C is required

for menox® mode. menox® mode is enabled via the input at

terminal 44: depending on parameter 64, the system is either

switched over immediately or the next time the burner starts

with the parameters of menox® pre-ventilation time, burner

application and settings for the control element coordinated

for menox® mode.

Parameter settings for switching between flame mode and

menox® mode, see pages 63 (Burner application), 95

(menox pre-ventilation time tVLM) and 95 (Switchover to

menox® operating mode).

Process control (PCC)

FCU 500

HT

BCU 565..C0F1

µC

49

SPS

44

If there is no signal at terminal 44, the system switches from

menox® mode to flame mode.

If the enable signal for High temperature mode (HT mode)

drops out as the furnace temperature falls, the BCU automatically switches from menox® mode to flame mode. To avoid

a pressure surge in the gas supply due to several burners

being switched off at the same time, it is recommended that

the furnace control unit switches the burners to flame mode

again zone by zone, for example.

Hot air compensation and ratio control are not the responsibility of the BCU. These functions must satisfy the require-

ments of a protective system pursuant to EN 746-2 and be

implemented externally.

BCU 560, BCU 565 · Edition 02.16 30

Page 31

6 Valve proving system

V2

p

u

V

p1

V1

PZ

p

u

2

The BCU500..C1 is fitted with an integrated valve proving

system. This allows either the tightness of the gas solenoid

valves and the pipework between them to be checked (tight-

ness test) or the closed position of a solenoid valve (proof of

closure function) to be checked.

Once the test has been carried out successfully, the burner

enable signal is issued.

For details, see pages31 (Tightness control) and38 (Proof

of closure function)

6.1 Tightness control

The aim of the tightness control is to identify an inadmissible

leak on one of the gas solenoid valves and to prevent burner

start. Gas solenoid valves V1 and V2 are tested as is the pipework between the valves.

European standards EN 746-2 and EN 676 stipulate tightness

controls for capacities over 1200kW (NFPA 86: from 117kW or

400,000 Btu/h).

The tightness control function satisfies the requirements of

EN1643 (Valve proving systems for automatic shut-off valves

for gas burners and gas appliances).

BCU 560, BCU 565 · Edition 02.16 31

Page 32

Valve proving system > Tightness control

PZH

VAS

VAS 1

VAG

TZI/TGI

V1

V2

V3

p

u

/2

14 151345

9

V

p1

6.1.1 Test instant

Depending on the parameter setting, the tightness control

checks the tightness of the pipework and the gas solenoid

valves before each start-up and/or after each shut-down of

the burner, see page96 (Valve proving system).

The gas line is always safeguarded by a gas solenoid valve

during this check.

Before burner start-up

The valve check is started when the start-up signalϑ is present

at terminal1. The BCU checks the tightness of the gas solenoid

valves and the pipework between the valves. The gas line

is always safeguarded by a gas solenoid valve during this

check. The burner is ignited when pre-purge is ended and

the tightness has been checked successfully.

After burner shut-down

After the burner has been shut down, the BCU checks the tightness of the gas solenoid valves and the pipework between

them. Once the test has been carried out successfully, the

next burner start is enabled. The BCU immediately conducts

a tightness test if mains voltage is available or if it is reset

after a fault lock-out.

An additional bypass/relief valve must be installed in gas

sections with an air/gas ratio control. This ensures that the

test volume V

can be vented during the tightness test with

p1

the air/gas ratio control closed.

BCU 560, BCU 565 · Edition 02.16 32

Page 33

Valve proving system > Tightness control

▼

START

V1

tL = P59

V1

tM = P56

p

u

pZ >

2

+

V2

OK

V2

tL = P59

V2

tM = P56

+

Programm A Programm B

pZ >

V1 V2

–

V2

PZ

pu/2

–

p

u

2

p

z

V1

+

V2

tL = P59

V2

tM = P56

p

u

pZ >

2

–

V1

OK

V1

tL = P59

V1

tM = P56

6.1.2 Program sequence

The tightness test starts by checking the external pressure

switch. If pressure pZ> pu/2, programA starts.

If pressure pZ < pu/2, programB starts, see page34 (Pro-

gram B).

Program A

Valve V1 opens for the opening timet

set in parameter59. V1

L

closes again. During the measurement time tM, the tightness

control checks the pressurepZ between the valves.

If pressurepZ is less than half the inlet pressurepu/2, valveV2

is leaking.

If pressure pZ is greater than half the inlet pressurepu/2,

valveV2 is tight. ValveV2 is opened for the set opening timetL.

V2 closes again.

During the measurement time tM, the tightness control checks

the pressurepZ between the valves.

If pressurepZ is greater than half the inlet pressurepu/2,

valveV1 is leaking.

If pressurepZ is less than half the inlet pressurepu/2, valveV1

is tight.

The tightness test can only be performed if pressurepd down-

stream of V2 is around atmospheric pressure and the volume

downstream of V2 is at least 5 × higher than the volume

between the valves.

+

p

u

pZ >

2

–

V1

OK

BCU 560, BCU 565 · Edition 02.16 33

V1

V2

–

p

u

pZ >

2

+

V2

OK

Page 34

Valve proving system > Tightness control > Program sequence

Program B

Valve V2 opens for the set opening timetL. V2 closes again.

During the measurement time tM, the tightness control checks

the pressurepZ between the valves.

If pressurep

If pressure p

the set opening timetL. V1 closes again.

During the measurement time tM, the tightness control checks

the pressurepZ between the valves.

If pressurep

If pressurep

The tightness test can only be performed if pressurepd down-

stream of V2 is around atmospheric pressure and the volume

downstream of V2 is at least 5 × higher than the volume

between the valves.

V1

tL = P59

V1

tM = P56

p

u

pZ >

2

+

V2

OK

START

+

Programm A Programm B

pZ >

V1 V2

PZ

pu/2

–

p

u

2

p

z

–

V2

V1

+

V2

tL = P59

V2

tM = P56

p

u

pZ >

2

–

V1

OK

>pu/2, valveV1 is leaking.

Z

< pu/2, valve V1 is tight. ValveV1 is opened for

Z

<pu/2, valveV2 is leaking.

Z

>pu/2, valveV2 is tight.

Z

V2

tL = P59

V2

tM = P56

+

p

u

pZ >

2

–

V1

OK

BCU 560, BCU 565 · Edition 02.16 34

V1

V2

tL = P59

tM = P56

–

pZ >

V1

V1

p

u

2

+

V2

OK

Page 35

Valve proving system > Tightness control

P

13

1

4

4

5

p

u

/2

PZ

ϑ

1

pu/2

PZ

V

p1

V1 V2

p

u

p

z

p

d

▼

6.1.3 Test period tP

Depending on the burner capacity, the tightness of the gas so-

lenoid valves must be checked in accordance with the relevant

application standard, e.g. EN676, EN746, NFPA85 and NFPA86.

The test period tP is calculated from:

– Opening times t

– Measurement times t

for V1 and V2,

L

for V1 and V2.

M

tP [s] = 2 x tL + 2 x t

M

6.1.4 Opening time tL

Standard EN1643:2000 allows a maximum opening time of

3s for the tightness test if the main gas valves are actuated

directly. If gas can flow into the combustion chamber when a

valve is opened, the gas volume must not exceed 0.083% of

the maximum flow rate.

6.1.5 Measurement time t

M

The sensitivity of the tightness control in the BCU can be ad-

justed for each individual system by adapting the measure-

ment timetM. The longer the measurement timetM, the greater

the sensitivity of the tightness control. The measurement time

is set using parameter 56 to a value between 3 and 3600s,

see page97 (Measurement time Vp1).

The required measurement time tM is calculated from:

Inlet pressure pu [mbar]

Leakage rate QL [l/h]

Test volume Vp1 [l]

Calculation of the test volume, see page36 (Test vol-

ume Vp1)

For one test volume V

between 2gas solenoid valves

p1

Adjustable using parameter56

t

M

[s] =

(

2 x pu x V

Q

p1

L

)

For a large test volume Vp1 with reduced testing time

Adjustable using parameter56

t

M

[s] =

0.9 x pu x V

(

Q

p1

L

)

Conversion into US units, see page124 (Converting units)

Leakage rate

The BCU tightness control makes it possible to check a specific

leakage rate QL. Within the scope of the European Union, the

maximum leakage rate QL is 0.1% of the maximum flow rate

Q

[m3/h].

(N)max.

Leakage rate QL [l/h] =

Q

(N)max.

[m3/h] x 1000 [l/h]

3

1000 x 1 [m

/h]

BCU 560, BCU 565 · Edition 02.16 35

Page 36

Valve proving system > Tightness control > Measurement time tM

▼

Test volume Vp1

Test volume Vp1 is calculated from the valve volume VV, add-

ed to the volume of the pipe VR for each additional metre in

lengthL.

V

L

= VV + L x V

p1

R

Valves Pipework

Type Volume VV [l] DN

VAS 1 0.25 10 0.1

VAS 2 0.82 15 0.2

VAS 3 1.8 20 0.3

VAS 6 1.1 25 0.5

VAS 7 1.4 40 1.3

VAS 8 2.3 50 2

VAS 9 4.3 65 3.3

VG 10 0.01 80 5

VG 15 0.07 100 7.9

VG 20 0.12 125 12.3

VG 25 0.2 150 17.7

VG 40/VK 40 0.7 200 31.4

VG 50/VK 50 1.2 250 49

VG 65/VK 65 2

VG 80/VK 80 4

VK 100 8.3

VK 125 13.6

VK 150 20

VK 200 42

VK 250 66

Volume per metre

V

[l/m]

R

The measurement time required for the test volumeVp1 must

be set on the basis of the calculation using parameter56.

For the calculation, see page37 (Calculation examples).

BCU 560, BCU 565 · Edition 02.16 36

Page 37

Valve proving system > Tightness control > Measurement time tM

µC

131415

V

p1

VAS 665 VAS 665

p

u

= 50 mbar

Q

(N) max.

=

200 m

3

/h

DN65

9,5 m

Calculation examples

2 valves VAS 665,

distance L = 9.5 m,

inlet pressure pu = 50 mbar,

max. flow rate Q

Leakage

rate Q

=

L

Test volume V

= 200 m3/h.

(N)max.

3

200 m

/h x 1000 l/h

1000 x 1 m

= 1.1 l + 9.5 m x 3.3 l/m = 32.45 l

p1

see page36 (Test volume Vp1)

Measurement time for one test volume V

tM [s] =

2 x 50 mbar x 32.45 l

200 l/h

p1

= 16.23 s

Set the next highest value (20s) using parameter56, see

page97 (Measurement time Vp1).

/h

= 200 l/h

3

BCU 560, BCU 565 · Edition 02.16 37

Page 38

Valve proving system

13

14

ϑ

1

V1 V2

45

GZL

6.2 Proof of closure function

The proof of closure function monitors the function of the gas

solenoid valveV1. The proof of closure function can be activated

using parameter51=4, see page96 (Valve proving system).

A limit switch on gas solenoid valveV1 signals the closed

position of the valve to the BCU (terminal 45) for this purpose.

By checking the closed position using the proof of closure

function, the BCU complies with the requirements of NFPA85

(Boiler and Combustion Systems Hazards Code) and NFPA86

(Standard for Ovens and Furnaces).

6.2.1 Program sequence

When the start-up signalϑ is received at terminal1, the BCU

checks that valve V1 is in its closed position using the POC

switch. If a signal is not received at terminal45 from the POC

switch after a timeout time of 10s (valve V1 is closed), the BCU

performs a fault lock-out with fault messagec1.

As soon as the BCU has opened valve V1, it queries the open

position of the valve via the POC switch. If a signal is still re-

ceived at terminal45 from the POC switch after a timeout time

of 10s, the BCU performs a fault lock-out with fault messagec8.

BCU 560, BCU 565 · Edition 02.16 38

Page 39

7 BCSoft

The BCSoft engineering tool provides extended access to the

BCU via the optical interface. BCSoft makes it possible to set

device parameters on Windows-based PCs in order to adjust

the BCU to the specific application. In addition, BCSoft provides

extended access to the individual statistics and protocol func-

tions.

In addition to the engineering tool BCSoft, an opto-adapter or

Bluetooth adapter is required to read the device parameters

in and out, see also page113 (BCSoft).

BCU 560, BCU 565 · Edition 02.16 39

Page 40

8 Profinet

1

2 3

BCU 56x

BCM

BCU 56x

BCM

BCU 56x

BCM

PROFINET

L1

BUS

FCU

P

HT

PLC

Profinet is a manufacturer-independent, open standard for

industrial Ethernet. It covers the requirements for automation

technology (manufacturing automation, process automation,

drive applications with or without functional safety).

Profinet is a bus variant for fieldbus communication, optimized

for speed and low connection costs.

The basic function of Profinet is the exchange of process and

required data between an IO controller (e.g. PLC) and several

distributed IO devices (e.g. BCU/FCU).

The signals from the IO devices are read into the IO controller

cyclically. There, they are processed and are then output to

the IO devices again.

In addition to cyclic data exchange, Profinet also provides

acyclic data exchange for events which are not constantly

repeated such as sending parameter settings and configu-

ration data when the IO devices start up or sending a diag-

nostic message from the IO device to the IO controller during

operation. The data read or written acyclically by read/write

services are specified by an index, see page48 (Indexes

for acyclic communication).

The technical properties of an IO device are described by the

manufacturer in a device master data file (GSD file). The GSD

file contains the device image, the communications properties

and all fault messages from the IO device in text form which

are important for the configuration of the Profinet network

and the data exchange. The configuration is completed using

an engineering tool which is supplied by the manufacturer

of the IO controller. Modules defined in the GSD file may be

selected for configuration to include them in the system, see

also page42 (GSD file for PLC configuration).

BCU 560, BCU 565 · Edition 02.16 40

Page 41

Profinet

BUS

FCU

P

HT

56

BCUBCM

L1,

M

ϑ

PROFINET

53 55 5254

90° ➔ 0

0 ➔ 90°

3PS

Temperature

controller

PLC

8.1 BCU and bus module BCM

The optional bus module BCM 500 is required to integrate the

BCU in the Profinet system.

Control signals (for start, reset and air actuator control), signal

states from the device inputs and outputs and information

about the device status (operating states, flame signal and

current program step), warnings and faults can be transferred

via the bus module between the BCU (IO device) and PLC

(IOcontroller).

Bus module BCM 500 has two RJ45 connection sockets for

connection to the fieldbus on its front. The connection sockets

are combined with an internal 2-port switch. This allows the

BCM500 together with the BCU to be integrated in various

network topologies (star, tree or line topology). Requirements

such as Auto Negotiation and Auto Crossover are satisfied.

Safety-related signals and interlocks (e.g. safety interlock) must

be wired independently of the fieldbus communication direct

to the BCU and the protective system (e.g. FCU).

All network components which connect the automation system

and the field devices must be certified for Profinet use.

For information on planning and the structure of a Profibus

network and the components to be used (e.g. cables, lines and

switches), see Profinet Installation Guide at www.profibus.com.

BCU 560, BCU 565 · Edition 02.16 41

Page 42

Profinet

8.2 GSD file for PLC configuration

Before commissioning, the Profinet system must be configured

for data exchange using an engineering tool.

The device master data file (GSD) is required for the integra-

tion of the BCU in the configuration of the PLC. The GSD file

contains the device image and communications properties of

the BCU. Modules defined in the GSD file may be selected for

configuration to integrate the BCU, see page43 (Modules

for cyclic data exchange).

The GSD file for the bus module can be ordered at

www.docuthek.com. The steps required to integrate the file

are described in the instructions for the engineering tool for

your automation system.

For parameter settings on the BCU and code switch settings

on the BCM, see page104 (Fieldbus communication).

BCU 560, BCU 565 · Edition 02.16 42

Page 43

Profinet > GSD file for PLC configuration

▼

8.2.1 Modules for cyclic data exchange

The modules for cyclic data exchange are defined in the GSD

file for the bus module BCM 500. All modules required for cyclic

data exchange between the controller and the burner control

units BCU 560 and BCU 565 are shown in the following table.

The modules are assigned to the slots.

Module Slot

Input ad-

dress

Output ad-

dress

Inputs/outputs 1 n…n+2 n

Burner 1 flame signal 2 n

Free 3 n

Status signal 4 n

Fault and warning signals 5 n…n+1

Remaining times 6 n…n+1

TC remaining times

1)

7 n…n+1

PLC output information 8 n

BCU input terminal informa-

tion

BCU output terminal informa-

tion

1) Only for BCU..C1. Slot 7 is not transferred with other device ver-

sions.

9 n…n+2

10 n…n+1

BCU 560, BCU 565 · Edition 02.16 43

Page 44

Profinet > GSD file for PLC configuration > Modules for cyclic data exchange

▼

“Inputs/outputs” module – slot 1

The digital input and output signals from the burner control

units BCU 560, BCU 565 and BCU 580 are included in this

module.

Input bytes (device ➔ controller)

The input bytes describe the digital signals which are trans-

ferred from the BCU(IO device) to the digital inputs of the PLC

(IO controller). The digital signals take up 2bytes (16bits).

Bit Byte n Byte n+1 Byte n+2 Format

Burner 1 operat-

0

ing signal

Free

1

BCU system

2

fault

3 Fault lock-out

Safety shut-

4

down

5 Warning

6 ON

Manual

7

mode

1)

Only with three-point step control via bus.

Max. capacity

reached

1)

Min. capacity

reached

1)

menox ON BOOL

Free BOOL

Air ON Free

Pre-purge ON Free

DI ON Free

Ready for op-

eration

Free

Burner 1 flame

signal

Free

Free

Free

BOOL

BOOL

BOOL

BOOL

BOOL

BOOL

Output byte (controller ➔ device)

The output byte describes the digital signals which are output

by the PLC (IO controller) to the BCU (IO device). The digital signals to control the burner control unit BCUoccupy 1byte (8bits).

Parallel to the bus communication, terminals 1 to3, 44 and

50 of the BCU can be wired. This allows the BCU to be controlled using the digital signals of the bus communication or

the inputs at the terminals.

In the event that the bus communication is faulty or interrupted

and during the initialization of the bus communication after

switching on, the digital signals are interpreted as“0”. If the

BCU is controlled using the inputs at the terminals during this

time, the normal program runs even if the bus communication

is faulty or interrupted.

Bit Byte n

0 Reset

1)

1 Burner 1 star

2 External air ON

1)

1)

Format

BOOL

BOOL

BOOL

3 Pre-purge ON BOOL

4 Free BOOL

5 menox ON BOOL

2)

2)

BOOL

BOOL

6 Open control element, three-point step Open

7 Close control element, three-point step Close

1)

Parallel to the bus communication, terminals 1 to 3 can be

wired.

2)

Only with three-point step control via bus.

BCU 560, BCU 565 · Edition 02.16 44

Page 45

Profinet > GSD file for PLC configuration > Modules for cyclic data exchange

▼

“Burner 1 flame signal” module (device ➔ controller) – slot 2

The flame signal is transferred from the BCU to the PLC as an

analogue value using this module. The flame signal occupies

one byte with values from 0 to255 (=flame signal from 0 to

25.5µA).

Bit Byte n Data type Format Value

0

1

2

3

Burner 1 flame signal

4

Byte DEC

0 – 255

(0 – 25.5 μA)

5

6

7

“Status signal” module (device ➔ controller) – slot 4

This module transfers the status signals from the BCU to

thePLC. The status signals occupy one byte (0to255). Every

status signal is allocated a code. The allocation is described

in the code table “BCU56x_GSD_Codetabelle.xlsx”.

Bit Byte n Data type Format Value

0

1

2

3

Status signals Byte DEC

4

5

0 – 255

(see

code table “BCU56x_

GSD_Codetabelle.

xlsx” at

www.docuthek.com)

6

7

“Fault and warning signals” module (device ➔

controller) – slot5

The fault and warning signals are transferred from the BCUto

the PLC using this module. The fault and warning signals occupy one byte each (0to255).

The allocation of the output codes to the fault and warning sig-

nals is described in the code table “BCU56x_GSD_Codetabelle.

xlsx”. The same allocation table applies to the fault signals

and the warning signals.

Bit Byte n Data type Format Value

0

1

2

3

Fault signals Byte DEC

4

5

0 – 255

(see

code table “BCU56x_

GSD_Codetabelle.

xlsx” at

www.docuthek.com)

6

7

Bit Byte n+1 Data type Format Value

0

1

2

3

Warning signals Byte DEC

4

5

0 – 255

(see

code table “BCU56x_

GSD_Codetabelle.

xlsx” at

www.docuthek.com)

6

7

BCU 560, BCU 565 · Edition 02.16 45

Page 46

Profinet > GSD file for PLC configuration > Modules for cyclic data exchange

▼

“Remaining times ” module (device ➔ controller) – slot 6

This module transfers the remaining times of various processes

from the BCU to thePLC. The remaining time occupies 2bytes.

Bit Byte n Byte n+1 Data type Format Value

0

1

2

3

Remaining times Word DEC

4

0 – 6554

(0 – 6554 s)

5

6

7

“Remaining times of the valve proving system” module

(device ➔ controller) – slot 7

Only for BCU..C1.

The module in BCU..C0 contains no information.

This module transfers the remaining time of the valve prov-

ing system from the BCU..C1 to thePLC. The remaining time

occupies 2bytes.

The valve check runs parallel to other time-related processes,

e.g. pre-purge. To display the remaining time of the valve

proving system separately, it is transferred separately.

Bit Byte n Byte n+1 Data type Format Value

0

1

2

Remaining times

3

of the valve prov-

4

ing system

5

Word DEC

0 – 6554

(0 – 6554 s)

6

7

BCU 560, BCU 565 · Edition 02.16 46

Page 47

Profinet > GSD file for PLC configuration > Modules for cyclic data exchange

“PLC output information” module (device ➔ controller) –

slot8

This module transfers information on signals which the PLC

uses to control the BCU back to the PLC. This allows the signal

transfer from the PLC to the BCUto be checked.

Bit Byte n

Format

0 Reset BOOL

1 Burner 1 start BOOL

2 External air ON BOOL

3 Pre-purge ON BOOL

4 Free BOOL

5 menox ON BOOL

1)

1)

BOOL

BOOL

6 Open control element, three-point step Open

7 Close control element, three-point step Close

1)

Only with three-point step control via bus.

“BCU input terminal information” module (device ➔

controller) – slot 9

This module transfers the signal states of the digital inputs on

the BCU(input terminals) to thePLC.

Bit Byte n Byte n+1 Byte n+2 Format

0 Terminal 1 Terminal 48

1 Terminal 2 Terminal 49

2 Terminal 3

3 Free

4 Terminal 44

5 Terminal 45

6 Terminal 46

7 Terminal 47

Terminal 50 Free

Terminal 51 Free

Terminal 52 Free

Terminal 65 Free

Terminal 66 Free

Terminal 67 Free

Terminal 68

Free

BOOL

BOOL

BOOL

BOOL

BOOL

BOOL

BOOL

BOOL

“BCU output terminal information” module (device ➔

controller) – slot 10

This module transfers the signal states of the digital outputs

on the BCU(output terminals) to thePLC.

Bit Byte n Byte n+1 Format

0 Terminal 9

1 Terminal 10

2 Terminal 13 Terminal 53

Terminal 42

Terminal 43

BOOL

BOOL

1)

BOOL

3 Terminal 14 Terminal 54 BOOL

4 Terminal 15

5 Terminal 17/18

6 Terminal 37/38

7 Terminal 41

1)

Only for BCU..F2: terminal53 is used as an input. Bit 6 has no

function.

Terminal 55

Terminal 56

Terminal 57

Free

BOOL

BOOL

BOOL

BOOL

BCU 560, BCU 565 · Edition 02.16 47

Page 48

Profinet > GSD file for PLC configuration

8.2.2 Indexes for acyclic communication

With the help of acyclic communication between the PLC (IO

controller) and BCU/FCU (IO devices), it is possible to read infor-

mation on parameters, statistics and fault history on an event

basis (e.g. using system function block Siemens FSB52RDREC).

The available data records differ in terms of their indexes.

Index Description

1001 Parameters

1002 Device statistics, counter

1003 Device statistics, faults/warnings

1004 Operator statistics, counter

1005 Operator statistics, faults/warnings

1006 Fault history

1007 Power module statistics

The contents and description of the indexes are described

in the code table “GSD Codes BCU56x” (download from

www.docuthek.com).

BCU 560, BCU 565 · Edition 02.16 48

Page 49

9 Program step/status

1)

DISPLAY

00

A0

P0

H0

01

A1

0

A

A

P0

P1

A

H2

02

03

04

09

P9

U I

– –

1)

In Manual mode, two dots blink on the display.

2)

Air actuator (control element/valve) is open.

Program step/status

Start-up position/standby

Cooling

2)

Pre-purge

Delay

Burner pause time t

Pre-ventilation

BP

2)

Fan OFF check

Low air pressure protection check

1

Approaching minimum capacity

Approaching maximum capacity

Pre-purge

Pre-purge

Approaching ignition capacity

Delay

Valve check

Safety time 1

Flame proving period 1 t

Burner 1 operation/controller enable

Over-run up to minimum capacity

Post-purge

Remote control with OCU

Data transfer (programming mode)

Device Off

2)

FS1

2)

2)

BCU 560, BCU 565 · Edition 02.16 49

Page 50

10 Fault signalling

▼

Fault message (blinking)

Burner 1 flame simulation

No flame after safety time 1

Flame failure during flame proving period1 t

Flame failure during burner 1 operation

Too many remote resets

Too many restarts

Controller enable output (terminal 56)

Simultaneous activation (terminals 51 and 52)

Actuator wiring (terminals 52 – 55)

Actuator feedback (terminal 52)

Simultaneous Min./Max. bus command

Non-fail-safe parameters (NFS) inconsistent

Fail-safe parameters (FS) inconsistent

Mains voltage

Faulty parameterization

Air valve control defective

Incompatible bus module

Power module defective

Fuse defective

Inlet valve(s) leaking

FS1

DISPLAY

01

02

03

04

10

11

20

21

22

23

24

30

31

32

33

34

35

36

39

40

Description

Flame simulation/flame signal before ignition