Krick 20360, Policeboat WSP 47 Building Instructions

Stand Juli 2014 Seite 1 © Krick Modelltechnik Knittlingen

Building Instructions Policeboat WSP 47

Order-No. 20360

Congratulations for buying this model kit of the

police boat WSP 47. This model is mainly designed for the beginner, but is also a very interesting kit for more experienced modellers as

a basis for own ideas.

For building this model you should have following glues, fillers and paints:

- Superglue Krick ruck-zuck 20g thin (80491)

- Superglue Krick ruck-zuck 20g medium

(80495)

- 5min-Epoxy glue 100g (80479)

- wood glue UHU Holz waterresistant 75g

(48515)

- 2-component glue UHU-Plus acrylit 30g

(48315)

- Filler Micro-Fill white 295 ml (80480)

- Primer (Lord Nelson 80110)

- Clear Varnish for stairs, doors, (80112)

- paint spray blue (320053), light grey (Primer

and for deck), and white (320010)

- lacquer red, grey, silver and black for fittings

Following tools are recommended for building

WSP 47

- modelling knife (416002)

- hand drill (473841)

- sandpaper files (491016)

- sanding block (490080)

- sand paper of grane 180, 320, 400 and 600

(Set 490190)

- round file ca. Ø 6 mm

- drills Ø 1 mm, 1,5 mm, 2 mm, 3 mm, 4 mm,

6,5 mm

- wet sand paper 400 und 600 for filler, primer

and paints

- side cutter (455550)

When painting use masking tape to cove r the

areas not to be painted. Use a 3 mm wide

tape should be used for the water line.

For running and radio control you should have

following parts:

- 2 channel radio control including one Servo

- electronic speed control 20 A, forward/back

including BEC

- battery pack 7,2V NiCd, NiMH or lead battery

6V/1,1 Ah

- charger 220V AC or 12V DC

Stand Juli 2014 Seite 2 © Krick Modelltechnik Knittlingen

If you like to install the special features such as

- rotating radar

- Lighting

- And working fire monitor,

You will also need following items:

- Pump ( 65150)

- Mini lights

- Geared motor 1:300 (42203)

If you wish to install these items you will also

need a 4/6 radio control

Pictures in the following instruction should

help to make the building of the model as easy

as possible.

For identifying the laser cut parts in the

wooden sheets, there is a drawing at the end

of this instruction book. Before you start building you should identify all wooden parts and

mark the part nos. on the part with a soft pencil. During the building process you should

carefully cut out the required parts only. Cut at

the tabs with a sharp knife.

Starting this hobby is much easier, if you have

an experienced modeller to call on. Often the

best way is to join a local model boat club.

We wish you good fun and success with building this nice model.

I. BOAT STAND and HULL

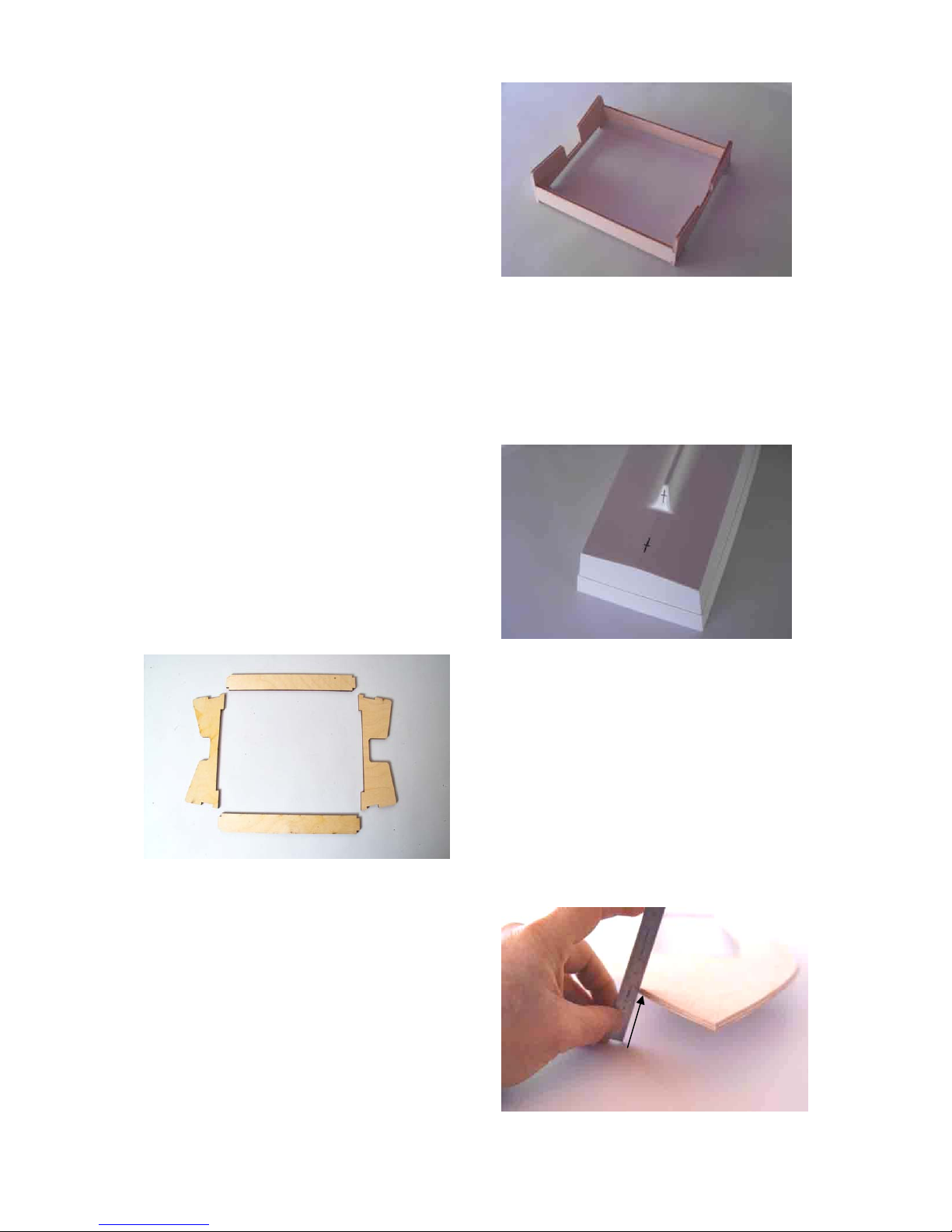

1. Boat stand

First build the boat stand with parts 2, 3 and 4.

After the glue is dry carefully sand and varnish

the stand several times. As you will later place

your wet model on the stand, it is important to

have this water resistant. To protect the model

you can use some pieces of foam tape on the

stand parts which will come in contact with the

hull.

2. Hull

Mark the positions of the rudder tube and of

the prop shaft on the hull (1). First measure the

centre line of the hull and mark. Then mark the

rudder tube position 35 mm from the stern of

the hull. Mark the position of the prop shaft 15

mm down from keel end.

Now drill the holes for prop shaft and rudder

tube.

First use a small drill of about 2 – 3 mm and

then enlarge to the correct size – rudder tube 4

mm and prop shaft tube 6 mm. You can do this

best with a round file to stop the hull from splitting.

3. Deck

Now fit the deck to the inside of the hull (5). At

the area of the bow it is necessary to chamfer

the deck so it is a snug fit and sits in the hull

without any pressure being applied.

2

3

4

4

1

5

chamfer in the front

area

Stand Juli 2014 Seite 3 © Krick Modelltechnik Knittlingen

Now place the deck into the hull and mark a

line on the sides 2 to 3 mm over deck level.

Cut the hull down only until to this line with a

sharp knife or strong scissors.

Now place strips (6 to 9) on the underside of

the deck around the inner cut out. Place a

weight on the deck until the glue is dry so the

deck cannot twist.

Now the coaming strips (10 to 13) have to be

glued vertical to the strips so that they are flush

on the underside and protruding on the upper

side. The superstructure will sit over this so

that no water can ingress the hull.

4. Rudder Tube

Glue the rudder tube (14 ) to the 2 supports

(15). Use medium or thick super glue or UHU

plus acrylit glue for this. Place the parts onto a

flat surface. Once dry place the assembly into

the hull along with the third support. Glue this

support to the rudder tube, but do not yet glue

into the hull.

5. Rudder

Make the rudder from parts 160 – 163. First

glue parts 162 and 161 to each other.

5

1

5

6

5

5

10 to 13

15

14

162 161

163

160

Stand Juli 2014 Seite 4 © Krick Modelltechnik Knittlingen

Then glue these inner parts onto one outer

side (160) that a gap remains for the rudder

shaft.

Roughen well the rudder shaft on the area,

which will be glued into the rudder.

Now glue in the rudder shaft with Uhu Acrylit

and the second outer plate (160) on top.

Now make a profile on the rudder, sharp at the

end and round at the front.

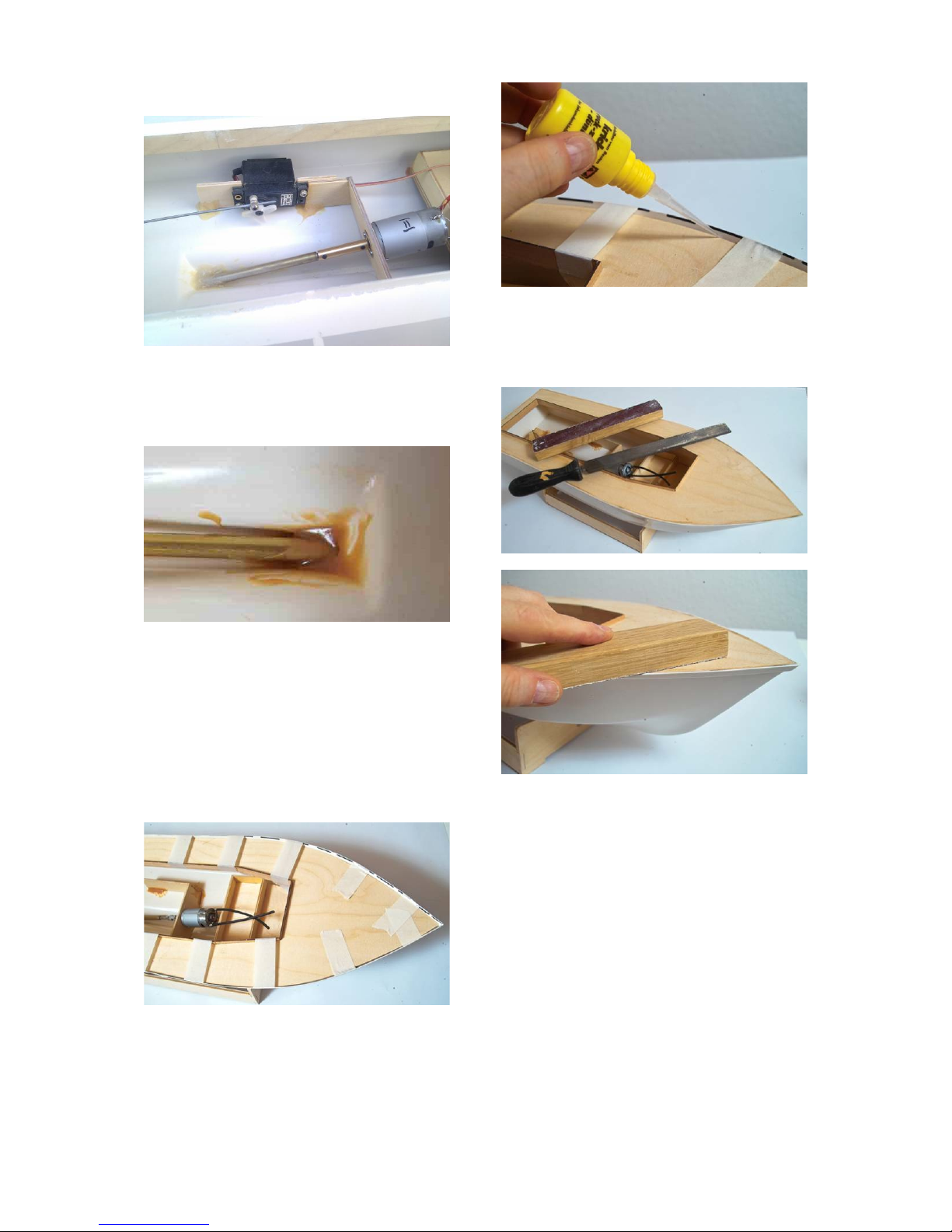

6. Motor Mount

Make the motor mount / Servo tray assembly

from parts 16-17 and 18 and glue. You will find

on the laser sheets two different motor mounts.

First compare with the motor, which motor

mount is the correct one for your motor.

For 400 motors there are parts on sheet 2.For

500/600 motors on sheet 3.

Now make the battery and receiver tray with

parts 19, 20 and 21.

16

17

18

19

20 20

21

21

Stand Juli 2014 Seite 5 © Krick Modelltechnik Knittlingen

All parts for the inside of the hull should be

ready now. Please varnish them 2 to 3 times

and sand between each application so that

they are water proofed. Also the deck should

be varnished on the underside.

Place the Servo temporarily into the tray and

drill the holes with 1.5 mm drill for the Servo

screws.

7. Preparation of the Motor

Solder on the motor the suppression capacitors 103 (10nf) to the connections and to the

motor housing as shown. Sand before soldering, to ensure a good connection for the solder.

Then solder the third capacitor 473 (47 nf)

between the two motor connections. Place

insulation tube on the ends before soldering.

Now solder motor wires to the connections.

After that you can assemble the motor to the

motor frame.

8. Fitting out the Hull

Push the prop shaft through the hole in the hull

and fit the motor on the motor mount. Now

attach the brass coupling between Motor and

prop shaft with grub screws M3. Please check

that there is a gap of about 1 mm between

motor housing and coupling.

Now align the motor together with motor

mount, prop shaft and tube inside the hull. The

whole setup should be placed in the centred of

the hull so that the tube of the prop shaft is

protruding 25 mm out of the hull.

Before proceeding double check that the assembly is placed in the centre of the hull.

Servo

Drill

Stand Juli 2014 Seite 6 © Krick Modelltechnik Knittlingen

Now fix the tube and the motor mount with

UHU Plus Acrylit inside the hull and fill the end

of the hull around the shaft with glue so that it

is water tight.

After the glue is set, you can also fix the rudder

shaft and the battery platform in the same way.

9. Gluing the Deck

Now all interior is placed correctly inside the

hull. So it is time to fix the deck permanently on

the hull. Fix the deck with adhesive tape to the

hull in a way, that the side walls of the hull are

pressed equally to the deck without getting

waves.

Fix the deck at several points with thin superglue. After that you can fix the deck complete

with medium superglue You can use an activator spray to shorten the drying process.

After the glue is dry you should sand the overlying border of the hull down to deck level. If

gaps appear, you can fill them with a wood

filler.

Stand Juli 2014 Seite 7 © Krick Modelltechnik Knittlingen

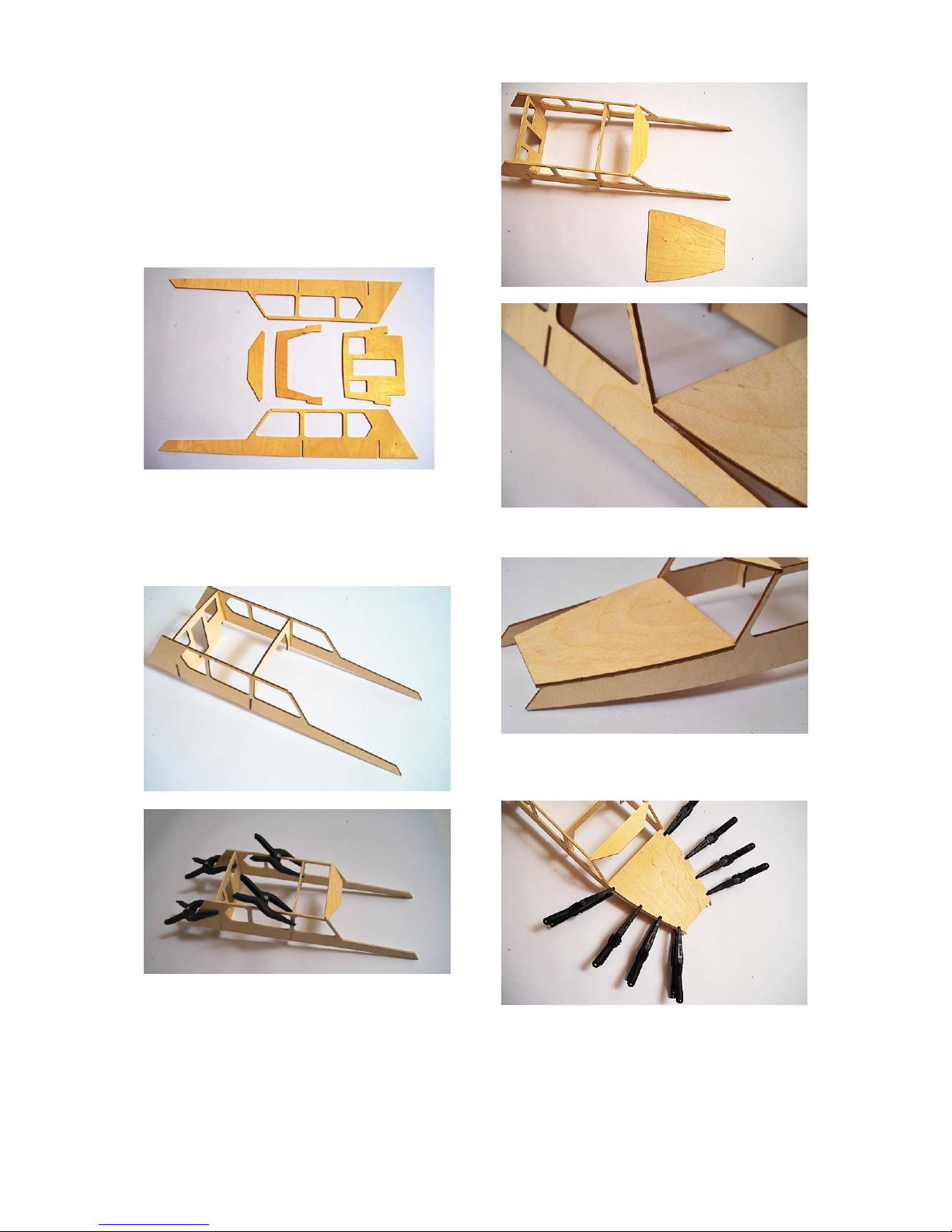

II SUPERSTRUCTURE

1. Cabin

For the first step of building the superstructure

you will need parts 32, 33, 34 und 40.

Now draw the outline of the windows to the

glazing material of PVC (100). Make them

slightly oversize to allow for gluing to the

frames.

Dry fit the parts first. If necessary sand the

slots or tenons for a perfect fit. Now first glue

the side walls to the frame and back wall.

When the gluing points are dry you can glue

the bar (40) in place.

2. Cabin Roof Front

Now place the front roof (35) with its cut out

corners between the two side walls and glue

only at the cut outs.

Fix the roof at its cut outs with superglue.

When the glue is dry, bend the side to the

curve of the roof and fix with superglue.

When the glue is dry, do the same on the other

side. After this apply glue from inside, and then

fix with clamps.

Now fit the front part (37) to the superstructure.

The upper edge needs to be sanded at an

angle to fit correctly.

32

34

33

32

40

35

Stand Juli 2014 Seite 8 © Krick Modelltechnik Knittlingen

Now sand the flush the overlaying ends.

3. Front Windows

In the next step the front windows 38 and 39

will be fitted..

First bevel the lower edge of the centre part

about 45 degrees.

The front windows at the side have to be bevelled at the lower edge and at the edge to the

centre window.

In the next step you have to sand the contour

of the main roof on top of the front windows in

the same way as the contours of the frame and

back wall. Then sand the side edges flush with

the side walls.

4. Cockpit

At this stage you will make the cockpit. For this

you will need parts 49, 50 and 51.

37

sand

to the required angle.

38 39 39

sand to the

required angle

angular

sand to the

required

angle

49

50

51

50

Loading...

Loading...