Fiber Moving Equipment

OWNERS MANUAL

MODEL #5200-P

50 YEARS OF QUALITY AND SERVICE

KRENDL MACHINE COMPANY • 1201 SPENCERVILLE AVE

DELPHOS, OHIO 45833 • TELEPHONE 419-692-3060 • FAX 419-695-9301

E - MAIL: krendl@krendlmachine.com • WEB SITE: www.krendlmachine.com

MODEL #5200-P

CONGRATULATIONS ON YOUR PURCHASE OF KRENDL EQUIPMENT

THIS IS YOUR

MODEL #5200-P OWNER'S MANUAL

FOR ASSURED SAFETY AND CONFIDENCE, PLEASE READ THIS

MANUAL CAREFULLY BEFORE INSTALLING AND OPERATING YOUR

MACHINE.

KRENDL E-MAIL ADDRESS IS: krendl@krendlmachine.com

KRENDL WEB SITE IS: www.krendlmachine.com

MODEL #5200-P

T able of Contents

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

UNPACKING & INSPECTING EQUIPMENT . . . . . . . . . . . . 2

GENERAL SAFETY INFORMATION . . . . . . . . . . . . . . . . . 2-5

DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

RETURNED GOODS PROCEDURE . . . . . . . . . . . . . . . . . . 9

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

BASIC COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-13

OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . 14-17

GENERAL MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . 18-21

ELECTRICAL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . 23-24

SPARE PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-31

GLOSSARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. 10

SERVICE RECORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

MODEL #5200-P

INTRODUCTION

Thank you for purchasing a KRENDL FIBER MOVING MACHINE. With over fifty years experience in manufacturing fiber moving equipment, we have designed and built your machine with the

highest quality parts and workmanship to provide years of reliable service.

This manual has been prepared to help you obtain the maximum efficiency and service from your

Krendl equipment. This machine is designed to blow cellulose, fiberglass and rockwool into attics. Our

primary objective is to build equipment which will provide complete satisfaction so that you may

confidently recommend Krendl to others.

We do not manufacture or sell fiber. Our interest lies only in the proper performance of the

equipment we manufacture. The fiber material manufacturer’s instructions prevail when it comes to

applying their product, since they guarantee the final results.

This manual contains important information regarding the safe assembly and operation of your

machine. We urge you to read it carefully and THOROUGHLY before putting your machine to work. If

your questions are not answered in this manual, please contact us. We want you to be able to operate

this equipment safely and confidently.

Upon receipt of this machine, check it carefully for any shipping damage. If there is damage or if

any of the parts are missing, notify the delivery trucking company immediately and file a claim for

damages, saving all packaging materials for inspection. Our warranty covers manufacturer’s defects

only. If Krendl Machine Company delivered or set up your machine and any parts are missing or

damaged, notify the authorized representative before they leave.

Krendl Machine Company Telephone: 419-692-3060

1201 Spencerville Avenue Fax: 419-695-9301

Delphos, Ohio 45833 U.S.A. E-Mail: krendl@krendlmachine.com

Web Site: www.krendlmachine.com

For your protection in the event of theft or loss, please fill in the information requested for your own

records. This information will be needed for in-warranty repairs. You may also want to attach a copy of

your invoice.

Machine Model No. __________________________________________________________________

Machine Serial No. __________________________________________________________________

Engine Manufacturer ________________________________________________________________

Engine Model No. , Serial No. _________________________________________________________

Blower Manufacturer ________________________________________________________________

Blower Model No., Serial No. __________________________________________________________

Blower Clutch Manufacturer __________________________________________________________

Blower Clutch Model No., Serial No. ____________________________________________________

Airlock Clutch Manufacturer ___________________________________________________________

Airlock Clutch Model No., Serial No. _____________________________________________________

Rev. Date: 12/14/10 Page 1

MODEL #5200-P

UNP ACKING AND INSPECTING EQUIPMENT

RECEIVING YOUR MODEL #5200-P KRENDL MACHINE:

Immediately check the condition of your Model #5200-P machine when it is received. It

should be received in the same condition that it was shipped to you. If there are any visible problems with your machine or any other items in the shipment, it is imperative that you place any

claim with the delivery carrier. Please save all packaging materials for inspection. The delivery

carrier should also contact our office before leaving the premises to notify us of a claim. The ownership

to your machine and all other items in the shipment were transferred to your name as soon as the

shipment left our premises, thus it is your responsibility to contact us with any claims. Contact the

truck line to arrange for an independent inspector to come out to inspect the damage and to prepare

the inspection report. It is imperative that this inspection is done prior to unpacking or using any of the

equipment. Please contact us for assistance or with any questions you may have regarding the claim

process.

UNPACKING:

Handle all cartons with care to avoid damage from dropping or bumping. Completely remove

machine from the packaging and from any shipping pallet or skid to which it might be attached. In

addition, completely remove all shipping materials from inside the machine. Check that all parts are

included as stated on the list below .

ACCESSORIES INCLUDED:

• 150’ REMOTE CONTROL CORD

• MULTIMETER

• SPANNER WRENCH FOR BELT TENSIONERS

• #50 CHAIN MASTER LINK

• SECTION OF CHAIN FOR CHANGING SHREDDER DIRECTION

• 5/16 ALLEN WRENCH FOR ADJUSTMENT OF CHAIN IDLERS

• OWNERS MANUAL

GENERAL SAFETY INFORMATION

Important: Read all instructions before operating this equipment. This equipment can be poten-

tially dangerous and must be used in strict accordance with instructions.

Disclaimer Notice: The manufacturer will not be legally responsible for any injury or damage

resulting from the improper use of this equipment or the failure to follow instructions.

Unpacking

Handle cartons with care to avoid damage from dropping or bumping. Completely remove the

machine from the packaging and from any shipping pallet or skid to which it may be attached. In

addition, completely remove all shipping materials from the inside of the machine.

Important: Please recheck inside the hopper for any loose items or damaged equipment.

Injury may occur when equipment is started with foreign material in the hopper .

Rev. Date: 12/14/10 Page 2

MODEL #5200-P

General Safety

1. Read this manual carefully and become familiar with your machine. It is important to know it’s

applications, limitations, and any hazards involved prior to operating the machine.

2. This machine was designed and manufactured for blowing cellulose, fiberglass and

rockwool. Do not attempt to modify the unit or use it for any application it was not designed

for. If you have any questions about your intended use or the machine’s suitability, ask your

dealer/distributor or consult the factory . The manufacturers could not possibly anticipate every

circumstance that might involve a hazard. For that reason, warnings in the manual and

warning tags or decals affixed to the unit, are not all-inclusive. If you intend to handle, operate, or

service the unit by a procedure or a method not specifically recommended by the manufacturer,

first make sure that such a procedure or method will not render this equipment unsafe or pose

a threat to you and others.

3. Do not disable any of the safety features on the equipment. These features are for your

protection and safety .

4. Read and obey all safety and operating instructions in the manual and on the machine.

5. Equipment is to be operated and/or maintenanced by TRAINED & QUALIFIED personnel ONL Y!!

6. BEFORE PERFORMING ANY MAINTENANCE ON THE MACHINE, YOU MUST FIRST:

#1 TURN THE DISCONNECT SWITCH TO THE “OFF” POSITION

#2 DISENGAGE PTO AND TURN THE TRUCK OFF

#3 TURN THE IGNITION TO THE “OFF” POSITION AND REMOVE KEY

7. Do not operate the machine without all guards and safety equipment installed in the proper

location and in working order. Always follow the proper shut down procedures outlined in Item 6

when guards are removed from the machine or when compartment or electrical control doors

need to be opened.

8. If a malfunction occurs while running the machine, turn it off immediately, follow the directions

under item 6 and correct the problem prior to restarting the machine.

9. Keep body and all clothing away from rotating equipment. Rotating shafts can be dangerous.

10. Always wear proper safety equipment when operating the machine. This includes steel toed

shoes, safety glasses and a respirator.

11. Under no circumstances should your hand, a stick or a broom be used to force material down

into the hopper. The machine is a self feeding design and requires no outside assistance.

12. Stand on the floor, not a platform while operating the machine. The operator may lose balance

and fall while loading bags of material.

All Model #5200 Machines are factory equipped with side, front, and main drive belt guards. The top

of the machine is not guarded since it poses no safety threat for normal insulation blowing operations

when mounted as shown in the installation guide. The machine is designed to be mounted in the van

body of the contractor’s truck and the rear of the machine against the wall of the van body.

Always turn the main power switch (located on the electrical box) to off and unplug the remote cord

from the receptacle for any type of machine maintenance or adjustments. An additional safety feature

is the ability to adjust the material slide gate from the outside of the machine. Rotate the adjustment

handle clockwise to open the slide to the desired setting, no entrance into the machine is required.

All safety features are incorporated into the machine to protect everyone from serious

injury. Operate your machine according to the outlined instructions in the manual with all

guards in place and securely latched. Operation with any guards removed can result in injury

to or loss of fingers, hands, arms, toes, feet, legs, hair, and even your eyes.

Rev. Date: 12/14/10 Page 3

MODEL #5200-P

Electrical Safety

• The National Electric Code (NEC) in the United States and many international electrical

codes require frame and external electrically conductive parts of this machine to be properly

connected to an approved earth ground. Local electrical codes may also require proper

grounding of machine. Consult with local electricians for grounding requirements in your area.

• Never handle any kind of electrical cord or device while standing in water, while barefoot or while

hands or feet are wet. Dangerous electrical shock will result.

• Use a ground fault circuit interrupter (GFCI) in any damp or highly conductive area. (metal decking

or steel work)

• Reference NFPA 79, 70E, or OSHA safe work practices when preforming energized work procedures.

Safety/Caution

• Be Safe - Keep away from moving parts.

• Be Safe - Make sure all guards and hopper extensions are in proper place before operating machine.

Guards and safety devices/switches should not be removed, modified or by-passed.

Hands should never pass between rotating parts.

• Be Safe - Make sure remote control hand pendant switch is in off position before connecting the

power supply to the machine.

• Be Safe - Make sure machine is properly grounded. Protect all electrical supply cords from sharp

objects, moisture, and other potentially hazardous materials. Keep power cords in good

repair. Electrical service must be performed by a qualified electrician.

• Be Safe - Disconnect power supply before inspecting or adjusting unit.

• Be Safe - Consult a qualified technician to answer questions before attempting to operate, or injury

may result.

• Be Safe - Emergency Kill Switch - In case of emergencies, always use red stop button located on

the front of Main Control Panel and on the side of the hopper. It will stop all feeding and

agitation.

• Be Safe - Do not remove motors or lift hopper when unit is connected to power supply.

• Be Safe - Do not operate machine alone.

• Be Safe - Do not leave machine unattended and energized.

• Be Safe - Turn machine off and disconnect electricity before clearing and feeding jam or attempting

to remove any object dropped in the hopper.

• Be Safe - Keep hands, loose clothing, jewelry and hair away from agitators, gears, chains and other

moving parts.

• Be Safe - Use proper lifting when moving fibers and loading machine.

• Be Safe - Keep work area clear of debris.

• Be Safe - Wear proper safety equipment, including protective gear, such as respirators, eye and ear

protection.

• Be Safe - Violation of the Owner's Manual or safety precautions may void warranty.

Rev. Date: 12/14/10 Page 4

MODEL #5200-P

Make Sure!

• Hopper is empty of foreign objects before starting.

• Adequate electrical power is supplied or damage to unit will result.

• Machine must be on before adding fiber.

• Blower filter is kept clean and in place when blower is on.

• Machine is turned off immediately if hose is plugged, or blower will overheat.

• Blower must be on, when agitators are running, or machine will bind.

• Agitator motor is not run with hopper empty for more than a few minutes, or damage to seals will result.

• Sprockets, chains, belts and pulleys are correctly aligned and tensioned.

• Pieces of bag are not left in the machine as this can bind and stall your machine.

• This machine should only be used with good quality fibers that are dry, undamaged and that meet a

certain industry specification or quality standards.

IF THERE ARE ANY QUESTIONS WITH YOUR KRENDL MACHINE, DO NOT HESITATE TO

CONTACT US AT: 1-800-459-2069

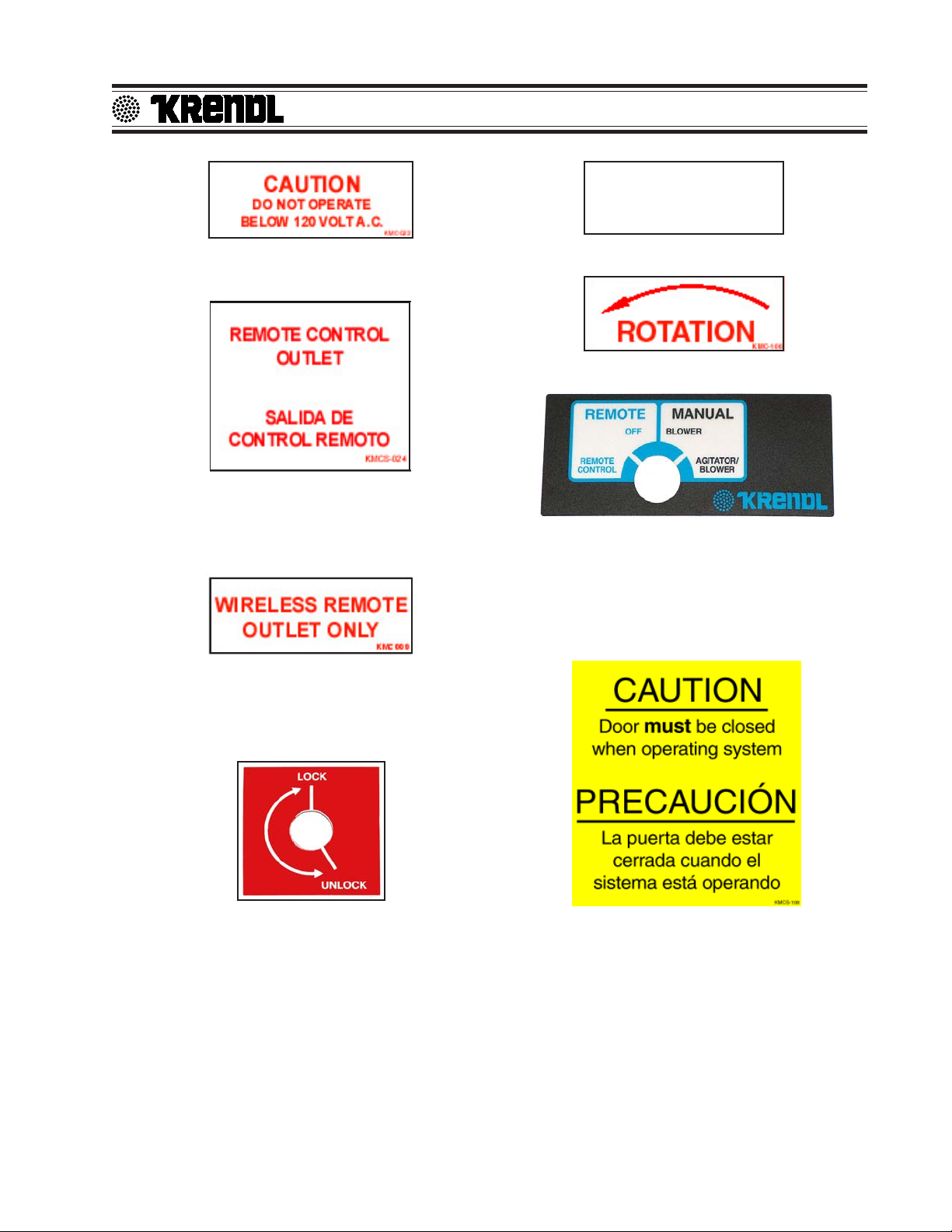

DECALS

General safety information intended to reduce the risk of serious

injury or death

Indicates that the electrical box on the machine is in compliance with UL codes.

Indicates which employee inspected equipment and on what date.

Indicates if blower is off, on, or on with agitator .

Electrical maintenance information and schedule provided here.

Rev. Date: 12/14/10 Page 5

MODEL #5200-P

Keeping the filter clean will result in longer

blower life and better performances.

Manufacturer information is provided here

along with machine model, and serial number.

Emergency stop button for machine.

Rotating parts can be dangerous! You can

snag clothes, skin, hair, hands, etc. This

can cause serious injury or death.

Opens and closes the material feed gate

which in turn controls the production.

Made in the U.S.A.

Read manual before operating machine for assured safety.

T ake caution when handling electrical cords

or electrical shock or death may result.

Machine should be used with these products.

Rev. Date: 12/14/10 Page 6

Identifies position of material feed gate.

MODEL #5200-P

KMC-01234

Operating machine at specified voltage will result

in longer machine life and better performance.

Indicates that this outlet is intended for only the

remote control outlet. Each time machine cycle

starts, an audible alarm warns the operator that

the machine is about to come on.

Indicates that this outlet is intended for only the

wireless remote. Each time machine cycle

starts, an audible alarm warns the operator that

the machine is about to come on.

Part number for identification and tracking.

Rotating parts will be moving in this direction.

Identifies if machine is in remote mode, manual

mode, or off position. In manual mode this switch

operates machine. In remote mode the hand

pendant operates machine. Each time machine

cycle starts, an audible alarm warns the operator that the machine is about to come on.

Indicates if the latches on the access door are

locked or unlocked

Rev. Date: 12/14/10 Page 7

Keeping the door closed will keep bystanders

safe from rotating parts.

MODEL #5200-P

WARRANTY :

Krendl Machine Company (Company) warrants to each original purchaser (Buyer) of its

equipment or accessories that such products will be free of manufacturing defects for a period

of 12 months from the date of shipment to the Buyer.

No warranty is made with respect to:

1. Components or accessories manufactured and warranted by others. Warranties for

purchased component parts as supplied from vendor such as engine, electric motor,

blower, gearbox, transmission, etc., if furnished by the manufacturer of the component,

are on file at the Company’s main office and copies will be furnished at request of Buyer.

Component(s), shipping costs prepaid, shall be sent to Company who in turn shall forward

to vendor for evaluation and warranty determination.

2. Any defect caused by repair, alteration and/or adjustment performed by Buyer or

customer/vendor of Buyer without the express written authorization of the Company.

3. The labor costs of replacing parts by parties other than the Company.

4. Any machine that has not been operated and/or maintained in accordance with normal

industry practice and the written recommendations of the Company. (e.g. machine operated with an improperly sized, worn or damaged hose, improper or inattention to preventative maintenance, etc.)

5. The product has been subjected to misuse, negligence or accident or results of any

application or use of the blowing equipment not in accordance with the Company recommendations.

This limited warranty does not cover the free replacement of component parts that become

inoperative due to wear and usage and need to be replaced on a regular basis, including but

not limited to: airlock seal(s), agitator(s), shredder(s), auger(s), fuse(s), switch(es), clutch(es),

hose(s), shaft seal(s), chain(s), belt(s), sprocket(s), pulley(s), bearing(s), cable(s), battery(ies),

filter(s), fan(s), etc.

The Company’s obligation under this warranty is limited to repairing or replacing (at Company

option) any part that is determined by the Company to be suffering from a manufacturing defect.

The Company (at Company option) will provide any required parts and labor to the Buyer. If the

equipment or parts must be returned to the Company for repair, all transportation costs shall

be the Buyer’s responsibility.

THIS LIMITED WARRANTY IS EXPRESSLY IN LIEU OF ANY OTHER GUARANTEES AND / OR

WARRANTIES, ORAL OR WRITTEN, EXPRESSED OR IMPLIED, INCLUDING WITHOUT LIMITATION, THE IMPLIED WARRANTY OF MERCHANTABILITY. NO WARRANTY, EXPRESS OR

IMPLIED, OTHER THAN THE AFORESAID WARRANTY IS MADE OR AUTHORIZED BY COMPANY. COMPANY SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES TO PROPERTY OR INJURY TO ANY PERSON OR COSTS

ASSOCIATED WITH LOSS OF PRODUCTION RESULTING IN LOSS OF REVENUE, PROFITS

OR LOSS OF EQUIPMENT THROUGH THE USE OF THIS EQUIPMENT.

Note: Special job circumstances incurring costs for specialized repair and next day delivery

of parts will not be reimbursed by the manufacturer unless authorized by factory.

Rev. Date: 12/14/10 Page 8

MODEL #5200-P

RETURNED GOODS PROCEDURE

IF MACHINE WAS NOT PURCHASED DIRECTLY FROM KRENDL MACHINE COMPANY, CONTACT YOUR SUPPLIER / DISTRIBUTOR.

When returning products to Krendl for repair, first obtain a return goods authorization (RGA), at

which time you will be given shipping instructions. The product must be shipped PREPAID:

Krendl Machine Company Telephone: 419-692-3060

1201 Spencerville Ave. Fax: 419-695-9301

Delphos, Ohio 45833 U.S.A. E-mail:krendl@krendlmachine.com

Web Site: www.krendlmachine.com

Once the unit is received, it will be inspected. In-warranty units will be repaired and returned

immediately. An estimate of repair charges will be provided for out-of-warranty units.

SPECIFICATIONS

MODELS: #5200-P

MACHINE: 14” Diameter x 18” Length airlock feeder

electromagnetic clutches on agitator and blower

in line helical gearbox (driving the machine)

HEIGHT: 83.00 inches

LOAD HEIGHT: 59.00 inches

WIDTH (DEPTH): 43.00 inches

LENGTH: 80.00 inches

WEIGHT: 2000 pounds

ELECTRICAL: 12VDC remote control system (6000 watt generator supplying

120VAC to convenience outlets & accessories)

BLOWER VOLUME: 250 CFM

BLOWER PRESSURE: 6.0 PSI maximum

HOSE OUTPUT: 4” diameter

MAXIMUM FEED RATES:

CELLULOSE: 5200 lbs./hr. FIBERGLASS: 2300 lbs./hr.

WARNING:Recommended hose size, type and length must be used to achieve maximum

results. Krendl cannot guarantee performance of the #5200-P machine if hoses are

undersized, worn, damaged, or hoses other than those we recommend are used.

BEFORE YOU RUN THIS MACHINE...PLEASE READ THE REST OF THIS MANUAL!!

Rev. Date: 12/14/10 Page 9

MODEL #5200-P

BASIC COMPONENTS

This is a view of the basic components of your Model #5200-P machine. It shows the location of

each item and gives the function of each. Use this as a guide throughout the manual.

(Illustration 1)

A ) Base Unit - Lower frame unit supporting blower

box, speed reducer, motor, airlock and hopper.

B) Airlock - Traps air and fiber while providing a

metered flow.

C) Shredder System - Increases production and

coverage on all fiber products while reducing

clumps that may exist in various fibers.

D) Slidegate - Meters the amount of fiber dropping

into the airlock by controlling size of airlock

opening.

E) Speed Reducer - Increases output power while

decreasing speed of agitator/airlock drive motor.

F) Agitator - Conditions fiber in the hopper.

G) Hopper - Upper unit of machine holding fiber.

(Illustration 2)

H) Main Control Panel - Connects with main

power, allowing operation of unit at machine or

Remote Cord.

I) Kill Switch - Safety device for immediate stop-

ping of machine.

J) Blower - Provides the air necessary to move

fiber from the airlock.

K) Hydraulic Motor - Provides driving power for

speed reducer, blower, generator, and agitator/

airlock system.

Illustration 1

L) Generator - Provides power to all auxiliary

electrical components.

M) Hopper Extension - Increases overall hopper

capacity.

Rev. Date: 12/14/10 Page 10

Illustration 2

MODEL #5200-P

INSTALLATION

MACHINE DRIVE AND TRUCK SPECIFICATIONS:

Your Model #5200-P Krendl Machine can be mounted in any truck and chassis configuration. We

recommend a minimum chassis rating of 26,000 GVWR. We also recommend a minimum 22 feet van

body . The body should have a full width rear door . The Krendl Model #5200-P Machine can be mounted

anywhere in the truck body . The factory recommended positions are shown in Illustration 3.

TOOLS NEEDED: CUSTOMER SUPPLIED ITEMS:

1/2” Heavy Duty Drill 1/2” Bolts, washers, locknuts for fastening machine

Drill Bits: 9/16” for bolts

Fork Lift (means to lift the machine)

Pry Bars

Basic Wrenches

5” hole saw & 2” hole saw

INSTALLATION INSTRUCTIONS:

1) Place the machine in either of the two locations so that the machine will not be in the way of the

truck’s doors and you are still able to open the hood of the machine.

2) Using illustration 3 as a reference, check under the truck body that the opening will not interfere

with any truck components underneath. If there is any interference with any of the truck parts,

then you will need to adjust the position of the machine to clear the obstruction. The holes for the

blower inlet and machine hold down do not have much room for adjustment. However , the holes

for the hydraulic lines do have room for slight adjustments.

Illustration 3

3) Remove the machine after the holes are located.

Rev. Date: 12/14/10 Page 11

4) Cut the following holes: (Using illustration 4 as reference ONLY)

a. Blower Inlet: 5”

b. Hydraulic Lines: 2”I

MODEL #5200-P

A

B

B

A

Illustration 4

5) Place the machine in the truck lining it up with the holes.

6) Locate and drill 9/16” holes for the four hold down holes located in the bottom of the base flange.

Again, check the underside of the truck body for any obstructions. Use 1/2” bolts and nuts to bolt

the base to the truck floor.

7) Run hydraulic lines to the machine.

8) Attach hydraulic lines to the hydraulic motor. Note: The shaft on the hydraulic motor should be

running counter clockwise. If the motor is running in the wrong direction, disconnect the hydraulic lines and reverse the hook-up.

Hydraulic Lines

Rev. Date: 12/14/10 Page 12

MODEL #5200-P

10) Coming off of the positive terminal on the truck battery, att ach a 15 amp inline circuit breaker.

15 Amp Circuit Breaker

11) Run power from the truck battery to the machines electrical box.

White wire from battery to

block three (3)

Red wire from battery to

power distribution block

12) Attach 4” hose to the filter box inlet so that the hose sticks through the 5” hole cut into the floor of

the truck.

If you need more information, please call your sales agent. Y our Krendl Model #5200-P Machine is

now ready for operation.

Y our Krendl Model #5200-P Machine was checked and thoroughly run before it was shipped but it

is always a good idea to check all belts and chains for proper tension and that all fluid levels are

checked and topped off where required.

Rev. Date: 12/14/10 Page 13

MODEL #5200-P

OPERATING INSTRUCTIONS

Starting Your Krendl Model 5200-P Machine:

1) After installing your Model #5200-P according to the installation instructions, it is now time to start

your machine. Again, check all fluid levels, belt tension, and that all guards are inst alled properly.

2) Attach the blowing hose to the machine and run the hose into the building.

3) Run the remote control cord into the building.

4) Make sure the Control Switch on the remote control cord is in the OFF position. Now, you may plug

in the remote control cord.

5) With truck engine running engage PTO. Make sure PTO is running at proper speed. (With Main

Disconnect ON generator voltmeter should read 120 volts.)

6) Y our machine is now ready for operation.

Note: Agitator motor and blower should only be operated with steady or constant flow of electricity

between 110-120 volts.

Note: When using extension cords, wire gauge size should not be less than input cord on unit and

not exceed 50' in length. (See Voltage Drop Chart Below.)

Ex : A two-wire 20-ampere circuit using 12 AWG with a one-way distance of 25 feet will drop 1.98 volts;

120 volts - 1.98 volts = 118.02 volts as the load voltage.

Rev. Date: 12/14/10 Page 14

MODEL #5200-P

Electrical Operation:

NOTE: PRESS KILL SWITCH TO IMMEDIATELY STOP MACHINE AT ANY TIME!

1. Make sure Kill Switch is out by twisting clockwise/right. (See illustration 5)

2. Turn red Main Disconnect Switch to ON position. (See illustration 5)

3. Set 4-Position Selector Switch to OFF. (See illustration 5)

4. Press green start Button. Machine will not run unless start button is pressed after Kill Switch

is out and red Main Disconnect Switch is on. (See illustration 5)

5. Select operating mode on 4-Position Selector Switch from one of the following options:

Remote: Remote control hand pendant will control machine.

Off: Machine will not run. (overrides remote hand pendant)

Blower: Only the blower will run continuously. (manual control at machine)

Agitator-Feed/Blower: Both the blower and the agitator-feed will run continuously. (manual

control at machine)

Main Control Panel (lid closed)

Illustration 5

Main Control Panel (back)

Illustration 6

Rev. Date: 12/14/10 Page 15

MODEL #5200-P

6. When operating in Remote mode, the 4-Position Selector Switch must be set to Remote

position. (See illustration 5 on page 15.)

7. Remote control hand pendant positions will be selected from the following:

BLOWER-FEED - operates both blower and agitator-feed simultaneously

OFF - (middle position) all functions stop

BLOWER - operates the blower only

8. Use the Auxiliary Outlet on the Main Control Panel for supplying continuous power (while red Main

Disconnect Switch is ON) to accessories.

Stopping Y our Machine:

1) Switch the Remote Switch to “AIR ONLY” and wait until the hose is clear of all material.

2) Turn the Control Switch on the remote control cord to the OFF position.

3) Turn the Main Disconnect Switch to the OFF position.

4) Disengage the PTO.

SAFETY NOTE:

DO NOT FILL THE HOPPER TO CAPACITY AT THE END OF THE DAY. THE MATERIAL

WILL COMPRESS AND CAN CAUSE MACHINE LOCKUP DURING THE NEXT ST ART -UP.

Mechanical Settings:

The controls of your machine contain the blower and slidegate controls to adjust your machine for

each application and type of fiber. (See illustration 7 on page 17.) Blower control (air) and slidegate

(material feed) are adjusted according to:

TYPE OF MATERIAL: Cellulose and fiberglass have different textures and densities that

respond to machine settings.

HOSE: Corrugations or roughness of interior surface, diameter, length and

elevation of hose will also require varying adjustments.

WEATHER CONDITIONS: Temperature and humidity may require day to day adjustment of

machine settings.

Blower Control and Slidegate General Settings:

Blower control can increase or decrease the amount of air in the system, affecting the velocity

(speed) and spread rate (coverage) of fiber. (See illustration 7 on page 17.) The blower control valve

is used for controlling air pressure and amount of air flow.

Opening or closing slidegate (material feed) controls the amount of fiber dropping into the airlock

which changes the production rate (lbs. per hour). (See illustration 7 on page 17.) For calibration

purposes the scale located on the machine indicates how many inches the airlock slidegate is opened.

Rev. Date: 12/14/10 Page 16

MODEL #5200-P

The blower and slidegate controls working together

affect the distance fiber can be blown through a hose without

plugging. These controls also affect the accurate blowing of

fibers for spraying applications.

These settings control the following:

• Density of fiber blown in application.

• Velocity of material impact when spraying.

• Dust on open blow.

• Material spread rate or coverage.

• Production rate (lbs. per hour blown).

General Blower Control and Slidegate Settings for Open Blow:

With the slidegate closed and blower control valve on low (valve open), turn agitator-feed and

blower on. Fill hopper with insulation and adjust blower valve and slidegate. Move controls

proportional to each other. (i.e. If blower valve is half open, slidegate should be half open.) As hose

length is increased, air pressure/volume is increased by closing off the blower valve while closing the

slidegate proportionally. This will increase the distance fiber can be blown through the hose, while

decreasing the blowing production rate (lbs. per hour blown). (See illustration 7)

Illustration 7

Shredder Assembly:

This unit is supplied with a shredder assembly; airlock/agitator speeds are preset at the factory. No

further sprocket setting speeds are needed, as this system will accommodate most fibers and

applications. However, the shredder and agitator direction can be adjusted as described below.

Shredder & Agitator Adjustment:

Illustration 8 Illustration 9

Unidirectional Rotation (See illustration 8) is preferred as an all-around setting for a combination of

materials and applications. This setting provides the greatest coverage and best control for internal

wetting (stabilized) and open blow applications.

Center-Down Rotation (See illustration 9) force feeds the fiber into the airlock at a faster rate. This

direction provides the greatest production for cellulose fibers in an open attic blow application

although coverage may decrease.

Rev. Date: 12/14/10 Page 17

MODEL #5200-P

GENERAL MAINTENANCE

Your Krendl Model #5200-P Machine is designed to be used with minimal maintenance for all its

components. The following is only a guide; experience is the best guide for the right maintenance

schedule for you.

DESCRIPTION

CHECK GUARDS X

CHECK DRIVE ALIGNMENT & TENSION X

VISUALL Y INSPECT COUPLING

ELEMENTS FOR FATIGUE CRACKS X

(OVER 1/2”) (located behind hydraulic motor)

CLEAN BLOWER AIR FIL TER X

CHECK BLOWER OIL LEVEL X

(needs to be changed after first 100 hours of operation and thereafter every 1000 hours)

GREASE BLOWER BEARINGS X

LUBRICA TE DRIVE CHAINS WITH A DRY

LUBRICANT X

GREASE SHREDDER, AIRLOCK,

AGIT A TOR, & JACK SHAFT BEARINGS X

CHANGE BLOWER OIL X

(needs to be changed after first 100 hours of operation and thereafter every 1000 hours)

EACH SHIFT

40

HOURS

200

HOURS

1000

HOURS

NOTE: When further maintenance is needed, please refer back to other manufacturer’s

manuals for additional assistance!

SAFETY NOTE

WHEN MAINTENANCE IS TO BE PERFORMED ON THE MACHINE ALWAYS:

1) STOP THE ENGINE COMPLETEL Y .

2) TURN THE IGNITION TO THE “OFF” POSITION AND REMOVE THE KEY .

Rev. Date: 12/14/10 Page 18

Shredder 4

(2 per side)

MODEL #5200-P

RECOMMENDED LUBRICATION

ALL BEARINGS: GREASE: MOBILITH AW-2 (NLGI grade #2)

DRIVE CHAIN: DRY LUBRICANT (EG: DRY GRAPHITE)

BLOWER: OIL: PNEULUBE (Refer to blower manual)

GREASE: MOBILITH AW-2 (NLGI grade #2)

AIRLOCK REDUCER: OIL: KLUBERSYNTH UH1 6-460

Bearing Grease Zerks

Agitator 6

(3 per side)

Blower 2

Airlock 2

(1 per side)

Jack Shaft 2

PTO Shaft 2

Rev. Date: 12/14/10 Page 19

MODEL #5200-P

Airlock: (Seal Replacement)

The purpose of the airlock seal is to trap air and fiber until it rotates 180O to the 6:00 o'clock position.

At this point, fiber is pushed by air from the blower, out of the chamber. Worn or damaged seals allow

air and fiber to escape back into hopper, thus reducing production and coverage. When it is necessary

to replace seals, follow these directions:

Remove chain and air hoses from both input and output of airlock. Using a 9/16” socket, remove

hold down bolts from airlock. Lower the front of the airlock down by loosening the jamb nuts and

turning the liftbolts counter clockwise. Slide the airlock out of the machine. (See illustration 10) Airlock

rotor plates that are damaged (bent) will need replaced. (Refer to Rotor Plate Replacement below.)

Take out rubber seal by removing seven plate fastening bolts and nuts and top plate. The base plate

will remain attached to airlock shaft. To install a new seal, reverse procedure. Seal should be inserted

tight against the back base plate, pressing the lower tabs of the seal down under the adjacent seal with

a flat blade screwdriver. Make sure all bolt holes are aligned while each side of seal is equally pressed

against the end plates, before tightening bolts. Seal should be bent forwards for counter clockwise

rotation. (See illustration 12)

Airlock

Chain

Lift Bolt &

Jamb Nut

Hold Down Bolts

Illustration 10 Illustration 11

Air Hose & clamps

Base Plate Replacement:

1.Remove damaged baseplate assembly from shaft using

ratchet drive wrench with extension and 9/16" socket.

2.Check seal for wear and damage. (Installing seal and top

plate on the bench is quick and easy). Remove bolts

from plate assembly and replace with new seal. Make

sure seal and top plate are assembled on correct side of

base plate before assembling in airlock. Seal should

press backward towards top plate when

rectly into airlock chamber. (Illustration 12)

3. Install the rotor plate assembly into the airlock. The

airlock runs counter clockwise viewing it from the

sprocket drive shaft. (Illustration 12) Align the base plate

with holes on airlock shaft using a tapered punch. Cau-

tion: Do not mount rotor plate backwards. If installed

Rev. Date: 12/14/10 Page 20

installed cor-

Illustration 12

(Note: Entire rotor plate assembly

may be removed and replaced. This

procedure maybe easier than

replacing just the seals.)

MODEL #5200-P

improperly, damage to seals will result and put undue stress on agitator motor. This causes

overheating and poor production. Seal should be bent backward to allow for a clockwise rotation

of rotor.

5. As rotor plate is installed, press bottom tab of seal under adjacent seal with flat blade screwdriver. (See illustration 12 on page 20)

Chain: (Adjustment) (#50 Nickel Plated)

A smooth operating chain drive should have a slight sag on the idler side of the chain. New chains

should be installed under slight tension as they will elongate a small amount due to seating of pins and

bushings during the first few days of operation. Chain should be kept in good condition by proper

lubrication (use dry film lubricant Dow 321) and occasional cleaning. Soaking chain in container of 10

weight oil will provide for internal lubrication of pins and bushings. However, excess oil must be

drained and wiped away as excessive lubrication will cause fiber accumulation on chain. Worn out

chain should be replaced. When chain is replaced, worn sprockets should also be replaced,

preventing further damage to new chain.

Sprockets:

Check Sprockets For Wear. Misalignment and/or loose sprockets and improper chain tension

causes the premature wear of chain and sprockets. All sprockets, except speed reducer and idler

sprockets, have been secured with a medium grade Loctite (general purpose thread locker), to prevent

gradual movement. The set screws and key are also inserted with a medium grade Loctite. If sprocket

is difficult to remove, it may be heated with a propane torch to loosen.

Caution: Do not overheat sprocket or damage to bearing will result. A pulley or bearing puller

can then be used to remove the sprocket and key. Replace new sprocket on shaft with key and

medium grade Loctite applied to shaft. Align sprocket with corresponding sprocket, using a

straightedge placed along face of teeth and tighten set screws.

Bearings:

Agitator Bearings in hopper are double-sealed, self aligning ball bearings. They have grease fittings

and should be periodically lubricated. At least every 3 months. If bearings produce noise or heat (too-

hot-to-touch), the bearings should be replaced.

Agitator Bearing Replacement:

Spray area with rust penetrant (WD-40). Remove sprocket (See SPROCKET section above).

Remove the four bolts from bearing flange. Loosen set screws on bearing hub at each end of agitator

shaft. Since all set screws are installed with a medium grade Loctite, a propane torch may be used to

assist in removing them. Do not overheat unit, causing shaft to expand. Using a rubber mallet, drive

agitator shaft an inch in one direction, creating a space between hopper and bearing unit. A bearing

puller can then be used to remove the bearing. Eliminate any metal burrs from shaft with file and install

new bearings with felt seals. Use a medium grade Loctite on set screws before securing bearing to

shaft. (Check shaft diameter before ordering bearings)

Rev. Date: 12/14/10 Page 21

ELECTRICAL SYSTEM

MODEL #5200-P

Illustration 13

MODEL #5200-P

12 V.D.C. with 120V Generator

ELECTRICAL DIAGRAM:

Periodically, disconnect machine from power source and check all electrical connections and components for broken or

loose wires, loose screws or fasteners. Machine Vibration can cause fasteners to loosen.

Rev. Date: 12/14/10 Page 22

MODEL #5200-P

TROUBLESHOOTING

W ARRANTY

This unit is backed by a warranty for manufacturer’s defects. If your machine needs service during

the warranty time period, call your supplier immediately . DO NOT attempt to service the machine, as

this voids the warranty!

IMPORT ANT

At any signs of trouble with your machine, stop immediately, disconnect power and call your supplier. Refer to the GENERAL MAINTENANCE section of this manual for further details. Always disconnect the electrical power before making any inspections or repairs.

TROUBLESHOOTING

PROBLEM CORRECTIVE ACTION

1.) PTO will not engage A. See truck manufacturer’s PTO accessory manual.

2.) Engine starts or PTO engages but there A. Check for loose or damaged wires, ground shorts.

are no other machine functions - no which may be caused from machine vibration.

electrical power to the front panel B. Turn of f all power to machine before opening the

panel box.

3.) Engine starts or PTO engages - but the A. Check to see if the blower clutch is operating

blower will not operate B. Check clutch electrical connections.

C. Check belts, adjust or replace as required.

D. Check battery, clutch will not cycle or will slip if

battery is not fully charged.

E. Check that blower can be turned by hand. If not,

blower may be tied up.

F . Weak/Worn clutch- replace or rebuild as required.

4.) Insufficient air - clutch is operating A. Check that the blower control valve isn’t fully open.

Close or adjust the handle control as needed.

Blower Control

Air Filter

Illustration 14

You should be able to get over 4 p.s.i. of air on

gauge. See illustration 14.

B. Check that the blower relief valve is not stuck open.

See illustration 15 on page 24.

C. Check if blower air filter and intake hose is clogged.

See illustration 14.

D. Check airstream and bypass air hose connec-

tions, clamps, etc.

E. Check that the one way air check valve isn’t stuck

closed. See illustration 15 on page 24.

Rev. Date: 12/14/10 Page 23

MODEL #5200-P

F . Check belts, adjust /replace as required and check

for missing keys under drive pulleys.

G. Fiber hose plugged. Make sure the air bypass

valve is completely closed, then switch machine

to blower only to blow out the hose. If problems

still occur, try hitting the hose where it is plugged

to release the material.

Check Valve

Illustration 15

5.) No material flow - clutch is operating A. Check material level in main hopper.

Relief Valve

H. If the airlock seals and/or airlock components are

worn or damaged, replace all the parts as needed.

B. If the material slide gate is closed or adjusted in

too far for material feed rate, open the slidegate.

C. Check the belts coming from the main drive shaft

pulley to the reducer shaft drive pulley and blower

shaft drive pulley. Adjust or replace belts as

required. Check for missing keys under the drive

pulleys.

D. Check chains, adjust or replace as required.

Check for missing keys under drive sprockets.

E. Fiber hose plugged. Make sure the air bypass

valve is completely closed, then switch machine

to blower only to blow out the hose. If problems

still occur, try hitting the hose where it is plugged

to release the material.

SPARE PARTS LIST

The following is a recommended spare parts list. To keep your machine up and running, these are

the parts we suggest you keep on hand for your Model #5200 Krendl Machine.

PAR T DESCRIPTION QUANTITY

NUMBER REQUIRED

250503-8 AGIT A TOR BEARINGS 6

8036-2 SHREDDER BEARINGS 4

8065-2 AIRLOCK BEARINGS 2

1032 JACK SHAFT BEARINGS 2

5200-72 V-BELT PTO SHAFT TO GENERATOR 1

5200-38 V-BELT PTO SHAFT TO JACKSHAFT 1

5200-37 V-BELT JACKSHAFT TO BLOWER 1

5200-9M AIRLOCK SEALS 6

150526 #50 MASTER LINK 4

Rev. Date: 12/14/10 Page 24

PARTS LIST

#5200 Exploded Parts View

MODEL #5200-P

Unidirectional Center - Down

Rev. Date: 12/14/10 Page 25

#5200 Exploded Parts View

MODEL #5200-P

Rev. Date: 12/14/10 Page 26

#5200 Exploded Parts View

MODEL #5200-P

Rev. Date: 12/14/10 Page 27

MODEL #5200-P

#5200 Exploded Parts List

Item#

1

2

2-1

3

4

5

6

7

8

9

10

11

12

13

13

14

15

16

17

18

19

19-1

19-2

19-3

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

39-1

39-2

39-3

40

41

Rev. Date: 12/14/10 Page 28

Part#

5200-1

4000-15

4000-29

5200-47

250503-7

250503-8

5200-42

250504

250505-1

40052

150513

FSB120

561

109806

109809

109801

5200-1 12

2502028

5200-5

5200-6

5200-9-ASSY

5200-7

5200-9M-2PLYF

5200-8

8065-3

8065-2

5200-43

5200-54

339A

RM-OTH095-MI

5200-10

5200-1 1-A

5200-1 1-B

517-7

8036-2

8037

448

5200-3

5200-98

5200-102

5200-87

5200-86

5200-89

5200-99

16-2 SJ

434

5200-1 14

250325

5200-1 11

Description

Base, (Upper&Lower Portion)

Agitator, Hopper , 16 Tine

Agitator, Middle & Shredder, 17 Tine (2)

Guard, Chain

Seal, Felt, 1 1/4”

Bearing, Flange, 4-Bolt, 1 1/4” (6)

Sprocket, #50 40T x 1 1/4”HT (2)

Sprocket, #50 20T x 1 1/4” (3)

Sprocket, #50 25T x 1 1/4” (2)

Nut, 1” x 1” x 1/2” (Plated)

Sprocket #50, Idler, 15HT x 5 (5)

5/8” X 3/4” Shoulder Bolt (5)

1/4” x 1/4” x 1” Key (3)

Chain, #50 x 47 1/4”Long (Center Down)

Chain, #50 x 55” Long (Unidirectional)

Chain, #50 x 38 1/2” Long

Chain, #50 x 80” Long

Chain, #50 x 41” Long

Chamber, Airlock, 5200

Shaft, Airlock, 5200

Seal Assy, 5200, 18” (2 PLY/FAB) (6)

Plate, T op, Airlock (6)

Seal, Airlock (6)

Plate, Bottom, Airlock (6)

Felt Seal, 1 1/2” (2)

Bearing, 4-Bolt, 1 1/2” (2)

Sprocket, #50 20T x 1 1/2”

3/8” Square Stock, 1 1/2” Long

Clamp, Hose, 3” (12)

Hose, Radiator, 3” x 23”

Shredder Box

Shredder Agt., Short (18 Tine)

Shredder Agt., Long (20 Tine)

Seal, Felt Airlock 1” Bore (4)

Bearing, 2-Bolt, 1” (4)

Sprocket, #50, 1 1T x 1” (2)

Key , 3/16” x 3/16” x 7/8”

Mount, Reducer, 5200

Reducer, 5200

Bushing, JA 3/4”

Hub, F/E4 Element (2)

Element, Coupling, E4

Bushing, JA 1”

Clutch, Shaft Mount, 5 Groove

Wire, 16-2 SJ00W, 18” long

Plug, NEMA# L6-15P

Spring, 9/16 x 6 x .072 (2)

Key , 1/4” x 1/4” x 2” Long (5)

Jack Shaft, Reducer

#5200 Exploded Parts List

MODEL #5200-P

Item#

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

77-1

77-2

78

79

80

81

82

83

84

85

86

87

88

89

Part#

1032

5200-51

5200-38

5200-20

2100-8

5200-28

5200-30

5200-72

5200-57-A-R1

5200-56

5200-59

5200-64

8051

81-1063

5200-63

FN014

5200-81

5200-106

RM-OTH103-MI

H440

5200-105

5200-22

5200-97

5200-96

5200-108

5200-25

5200-104

5200-109

150314

5200-31

5200-95

5200-94

5200-1 10

4200-4

250300-1

5200-101

16-2 SJ

1538

5200-37

8306SB-1

5200-76

5200-61

4200-12

RM-OTH095-MI

5200-62

250539

5200-66

5200-65

IWS-32

IWS-25A

Description

Bearing, 1” P .B. (2)

Shim, Bearing (2)

Belt, 3/3VX425

Generator, 6000 watt

Mount, Motor

Pulley, 3GR3V3.65 SH

Bushing, SH 1 1/8”

V-Belt, 3/3VX475

Panel Box Assy

Filter Box

Guage, Pressure, 0-10 PSI

Elbow, 2”, 90 Street

Ball Valve, 2”

Filter, F/250300-2-R1 (Blue)

Cover, Filter

5/16-18 Locknut-Crimped

Adapter, 2” Barb

Muffler Clamp (2)

Pipe, Exhaust Flex (70”)

Hose, 3” Master Flex (44”)

Idler Bracket (2)

T ensioner , H.D., Rotary (2)

Idler, 3GR3V3.35

Idler, 2GR3V3.35

Motor, Hydraulic Pump

Pulley , 8GR3V4.75

Bushing, SK 1 1/2” (2)

Mount, Hydraulic Pump Motor

Bearing, P.B. 1 1/2” (2)

Bushing, SK 1”

Hub, F/E-20 Element (2)

Element, Coupling,E-20

Shaft, Drive, PTO

Blower Mount

Blower, Rotary , 10HP, #4007

Clutch, Shaft Mount, 2 Groove

Wire, 16-2 SJ00W, 13” long

Plug, NEMA# L5-15P

Belt, 2/3VX450

Nipple, 3”x4” (Painted)

Elbow, 3” 90 Black Pipe (Painted)

Pressure Relief T ube

Pressure Reflief Valve

3” Heater Hose, 19” long

Adapter, 2” Long, Male

Check Valve, 3”

Elbow, Pressure Guage

Elbow, Inlet

Male Connector (2)

Water Line, 1/4” x 6’ w/swivel

Rev. Date: 12/14/10 Page 29

#5200 Exploded Parts List

MODEL #5200-P

Item#

89-1

89-2

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

Part#

IWS-H-1/4

IWS-29

5200-45

5200-46

5200-60

FSB078

FN015

5200-58

5200-74

5200-67

5200-69

5200-68

5200-2

109078-1E

102020

109078-1D

109078-1-1

109078-1-2

5200-49

5200-48

5200-50

340

RM-OTH108-MI

5200-12-B

541

FSB080

8065-6

8076

508-1

508-2

543-M-18

4000-47

543-M-75

190

Description

1/4” Hose

Swivel, SAE 37

Slidegate, 5200

Crankrod w/ Handle Bracket

Handle

Pin, Cotter, 1/8” x 1”

N 3/8-16 Lock Nut-Crimped

Support, Crankrod

Cover, Slidegate Cable 18 1/4”

Cable, Slidegate, Indicator, 33”

Mount, Indicator Cable

Cover, Slidegate Indicator

Hopper Extension, 5200

Finger Bracket RH

Latch Finger (2)

Finger Bracket, LH

Clevis Pin (3)

Roll Pin (3)

Guard, Side (Back Side)

Guard, Side (Crankrod Side)

Tube, Output

4” Hose Clamp (4)

4 1/4” Radiator Hose, 5” long

Hood, PTO

Hinge Pin (2)

Roll Pins (2)

Compression Latch (3)

Enclosure

Contact Block

Killswitch

Connector, Conduit, 1/2” S traight

Spacer Block

Conduit, 1/2” Flexible, 5ft long

Link, Chain, 1/2 #50 NP (Not Shown)

Rev. Date: 12/14/10 Page 30

MODEL #5200-P

12 V.D.C Electrical Exploded Parts View

12 V.D.C.

Item # Part # Description

50-1 5200-57-1 Box, Electrical

50-2 1563 Plate, Backing, 9” x 11 1/8”

50-3 1542-A Receptacle, NEMA# L5-15R

50-4 KMC-021 Decal, Blower Motor (not shown)

50-5 1542-B Receptacle, NEMA# L6-15R

50-6 KMC-015 Decal, Agitator (not shown)

50-7 543-M-2 Receptacle, RC Plug #509-1050 (remote)

50-8 KMCS-024 Decal, (SP) Remote Control

50-9 132-B Receptacle, NEMA# 6-15R (2)

50-10 KMCS-131 Decal,(SP) 12 Volt D.C. Outlet

50-11 1531-B Voltmeter, 0-300V

50-12 KMC-022 Decal, Do Not Operate Below 120V

50-13 151080-49 Clamp, f/1 3/8” Din Rail (4)

50-14 ELU07-C Dinrail, 1 3/8”, 8 1/2” Long

50-15 151080-61 Terminal Block, Small (3)

50-16 543-M-33-D* Operator Handle Assembly

50-17 543-M-33-D Switch, Disconnect 40A #XA324BY

50-18 543-M-22 Switch, 4-position Selector

50-19 543-M-15 Contact Block, for Selector Switch(white) #KA-1 (not shown)

50-20 543-M-16 Contact Block for Selector Switch(red) #KA-3 (3) (not shown)

50-21 KMC-068 Decal, (Remote/Manual - 4-Position)

50-22 543-M-59 Switch, Pushbutton ON

50-23 543-M-60 Start Legend Plate

50-24 260302-4 Cover Plate, Weatherproof

50-25 251080-5 GFCI Outlet

50-26 433-E Manual Reset, 15 AMP

50-27 543-M-38 Alarm for Pre-Alarm System, 24V

50-28 508-2 Switch, Kill

50-29 8075-1 Contactor, Kill Switch (not shown)

50-30 KMCS-012 Decal, (SP) Kill Switch (not shown)

50-31 4000-32-3 Socket, (4)

50-32 4000-32-7 Timer, On Delay

50-33 4000-32-8 Clip, Timer Relay

50-34 4000-32-2 Relay, 12VDC Cube (3)

50-35 4000-32-4 Relay Clips (3)

50-36 543-M-18 Connector, Conduit,1/2" Straight (2)

50-37 121 Cord Clamp, 3/4"

50-38 KMCS-132 Decal,(SP) 12 Volt D.C. ON/OFF Outlet

50-39 1534 Terminal Board

Rev. Date: 12/14/10 Page 31

MODEL #5200-P

GLOSSARY

BRIDGING A tendency for fiber to cling in the hopper forming an air pocket above the

airlock. This hinders the normal feeding process of the machine.

CFM (Cubic feet per minute). A measurement of volume or quantity of air

flowing at a certain rate, or air moving capability, of a blower. It is the

volume of air moved per minute. Higher volume provides increased

coverage and velocity of fiber as it leaves the hose.

CHECK V AL VE A valve that allows air to flow in one direction only. When mounted on

the outlet of the blower, it protects the blower from fiber contamination through the air hose when using one blower. When the blower stop s,

the valve closes.

COMMERCIAL The application of fiber with adhesive to a surface which will remain

SPRAY-ON exposed. The application must therefore be impacted in a smooth,

uniform manner.

COVERAGE Refers to the amount of fiber coverage, usually measured in square

feet, according to the R-value desired. This information is given on the

fiber package.

NEW CONSTRUCTION The spray application of fiber with water or adhesive into an exposed

WALL CA VITY SPRA Y wall cavity to later be covered with drywall sheathing, etc.

PSI Pounds of pressure per square inch of force exerted on a surface

by air or liquid. High-pressure blowers push the fiber through the hose.

Higher pressure provides less hose plugging and increased compaction

in side wall.

PRODUCTION RATE Pounds of fiber blown per hour.

RPM (Revolutions per minute). Speed at which the shaft of a rotating device

(i.e. blower fan, agitator) is moving.

R-V ALUE Resistance value. A precise measurement of the insulation’ s resistance

to heat transfer. The higher the resistance value, the slower the heat will

transfer through the insulating material.

RETRO-SIDEWALL This refers to the installation of fiber into an unexposed wall cavity . Fiber

is usually installed through holes drilled into the exterior siding.

SETTLED DENSITY The point at which the fiber will not continue to settle further. Any

insulation blown will have a certain amount of progressive settling that

occurs over a period of time. Following the fiber manufacturer’s

recommendations for bag rate coverage will provide useful information

to accommodate for settling.

SETTLING Compression or compaction of insulation fibers caused by the weight of

the material, vibration of structure, temperature, and humidity cycles.

Rev. Date: 12/14/10 Page 32

MODEL #5200-P

SERVICE RECORD

DATE MAINTENANCE PERFORMED COMPONENTS REQUIRED

Rev. Date: 12/14/10 Page 33

Loading...

Loading...