4-

®

Kreg Jig

INSTRUCTIONAL MANUAL

MANUAL DE INSTRUCCIONES

GUIDE D’UTILISATION

Model R3

Modelo R3

Modèle R3

Item# R3

Artículo N.° R3

ART. N° R3

Covered by the following US patent

#5,676,500. Other patents pending.

Cubierto por la patente de los EE. UU. N.° 5 676 500.

Otras patentes en trámite.

Couvert par le brevet américain

5 676 500. Autres brevets en instance.

www.kregtool.com

4-

Version 20061001

NK7539

xxxxx

1

Thank You!

Thank You for your purchase! Kreg Tool Company is proud to

manufacture top-quality tools and accessories that are surpassed

only by our commitment to customer service. If, after reviewing this

manual you still have a question or concern, please contact us.

You can visit us online for additional resources such as accessories,

project plans, product manuals, and more tips and techniques for

getting the most out of your Kreg Jig

®

.

See The Quick Start Guide On Page 3.

4-

English

4-

Online: www.kregtool.com

Phone: 800.447.8638

Email: customerservice@kregtool.com

For Your Safety

The drill bit is very sharp! Please handle with care.

Always clamp the pocket hole jig and workpiece

securely before drilling Pocket Holes. Never hold the jig

byhand when drilling.

Always allow the drill bit to reach full speed before

plunging into the workpiece.

www.kregtool.com

4-

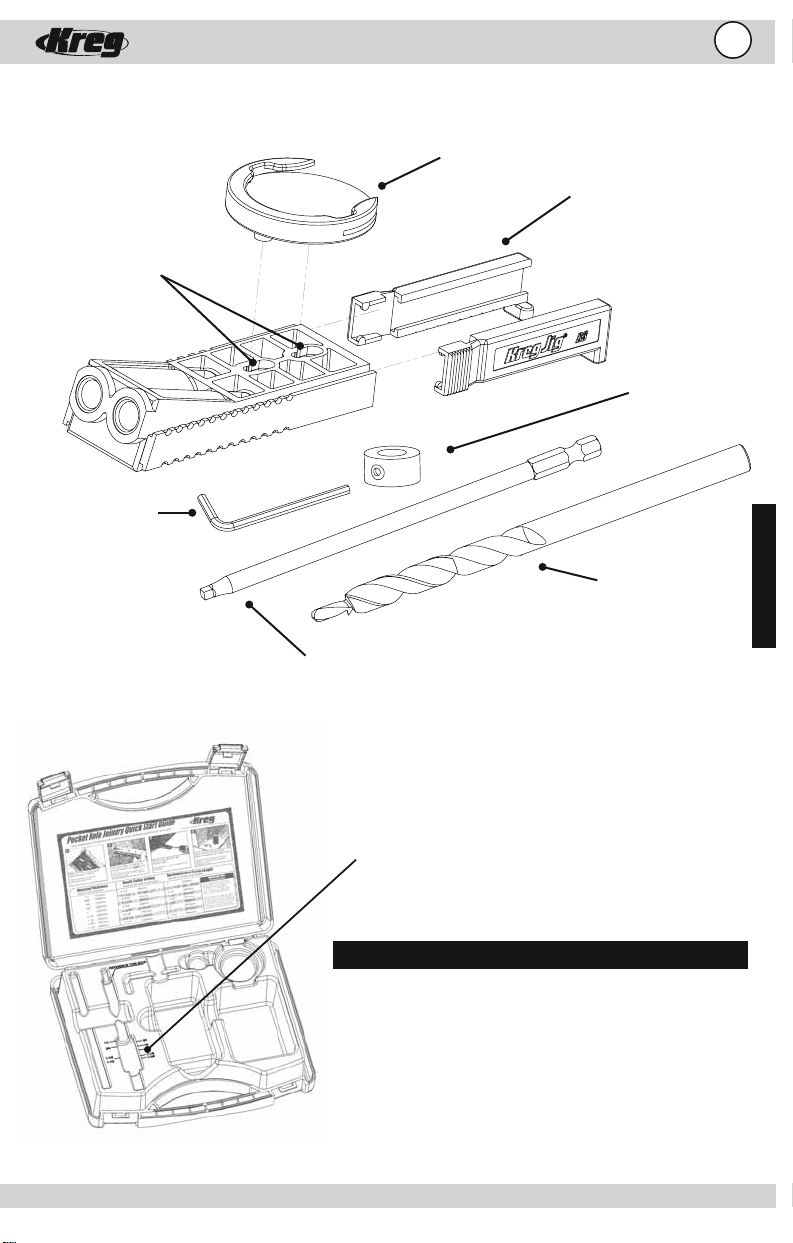

Parts Identifi cation

2

Mounting holes

allow you to

screw the jig to

the workpiece

for drilling. The

clamp adapter

snaps into these

holes for use

with the

optional face

clamp.

Allen wrench

secures the

depth collar on

the drill bit.

Clamp adapter can be used with the

optional face clamp (not included) for

clamping the jig in place while drilling.

The square driver bit

drives our speciallydesigned Pocket Hole

screws without slipping.

Set the sliders for the

thickness of the

workpiece you’ll be

drilling as indicated on

the jig body.

Depth collar fi ts

the drill bit to control

the depth of the

Pocket Hole.

English

The step drill bit

makes quick work out

of drilling the guide

hole for the screw and

the Pocket Hole in

one quick operation.

Use the handy scale molded into the case

to set the depth collar on the drill bit to the

correct position. The numbers indicate the

thickness of the material you’ll be drilling.

Part Number Description

KJD ............................................

D6 ...............................................

AW18 ..........................................

KJSC ..........................................

Sliders .......................................

Clamp Adapter ..........................

Jig Body with Drill Guides .......

www.kregtool.com

Step Drill Bit

6”- #2 Square Driver Bit

Allen Wrench

Depth Collar

Sliders

Clamp Adapter

Jig Body with Drill Guides

3

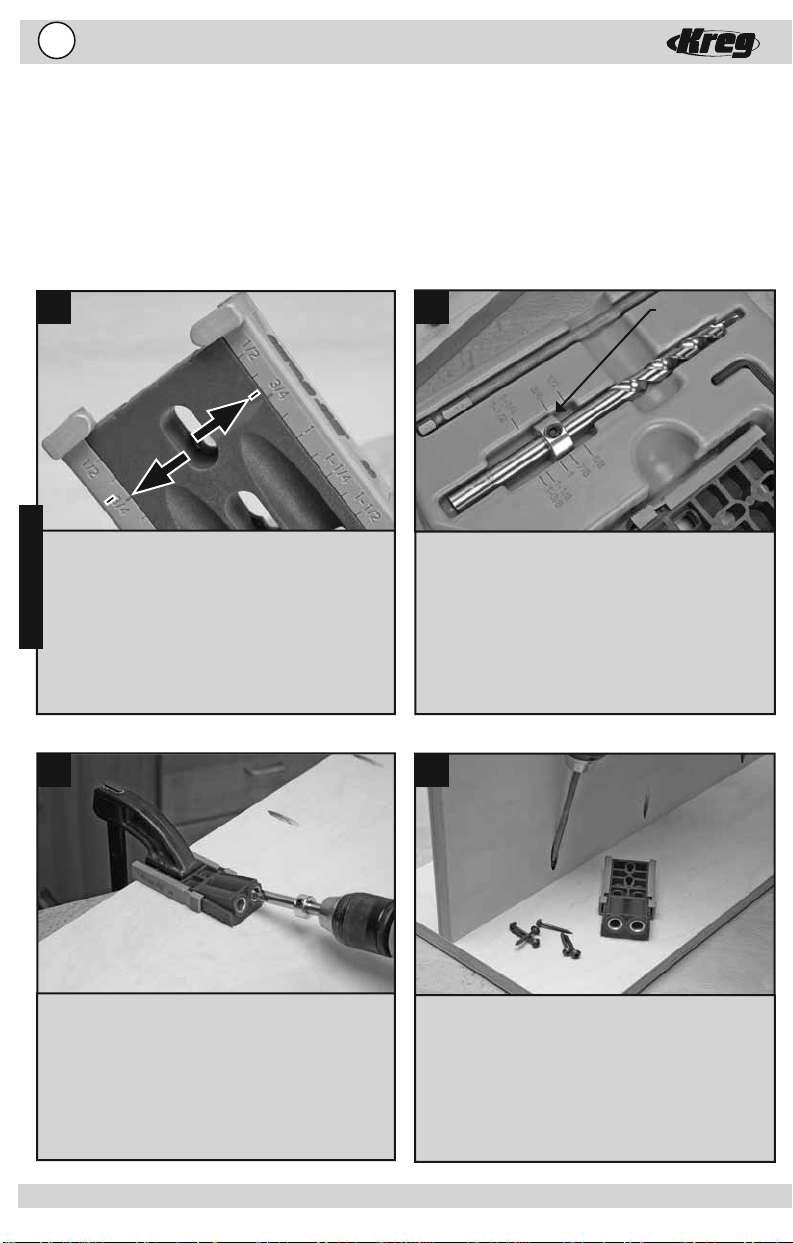

Quick Start Guide

4-

Quick Start Guide

Using Pocket Screw Joinery at Home.

Pocket Screw Joinery is useful for all sorts of applications in your home. All you need

is a saw, a portable drill and the Kreg Jig®. It’s easy to get started. Just follow the

simple steps below to get professional results and strong joints in no time at all.

1. 2.

English

Measure the thickness of the material

that you’ll be drilling Pocket Holes into.

Move each slider on your Kreg Jig

the number on the slider lines up with the

arrows on the Kreg Jig

should correspond to your material

thickness and locates the Pocket Hole in

the proper position on your workpiece.

®

body . This number

®

so

Set to 3/4”

Next, it is important to set the depth collar

on the drill bit properly . This will make your

Pocket Holes the correct depth for a strong

joint and proper screw penetration. Use the

built-in scale in the Kreg Jig

the depth collar to the thickness of the

material you’re drilling into. Tighten it with

the allen wrench provided.

®

tool case to set

4.3.

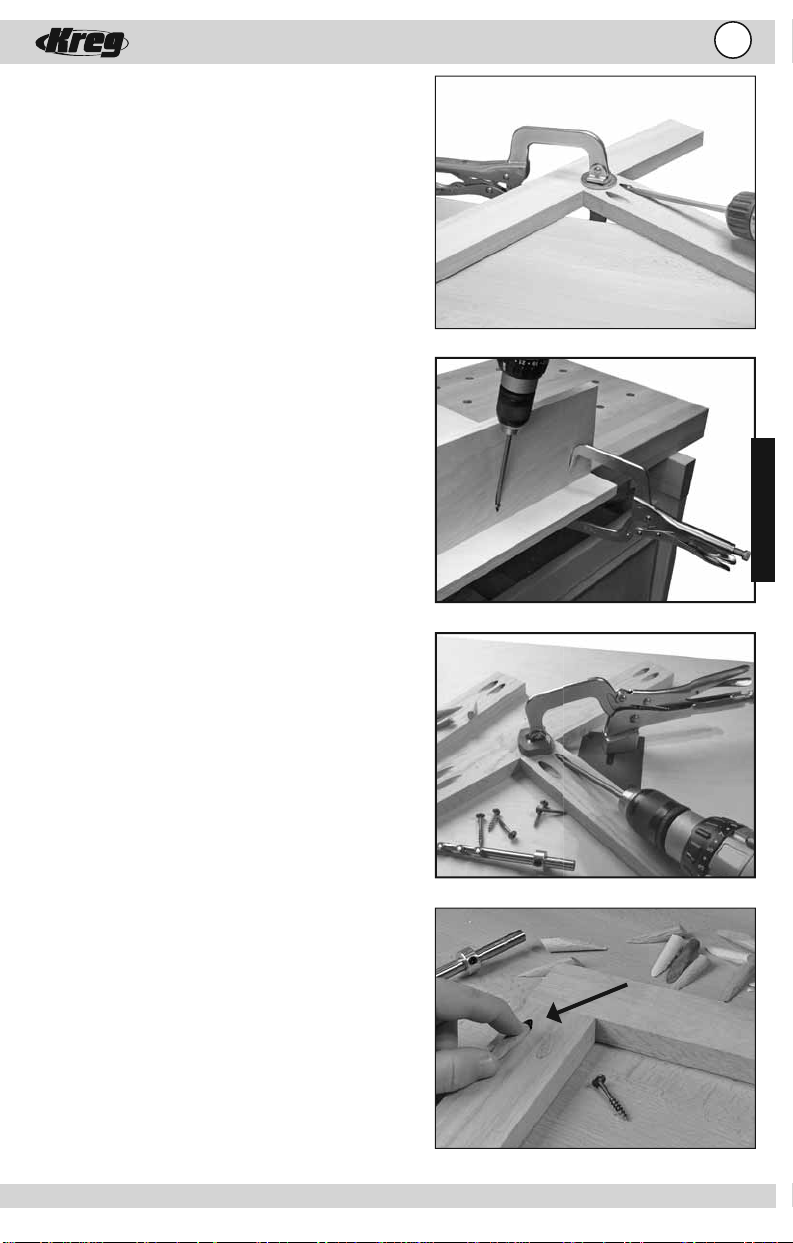

Next, securely clamp the Kreg Jig® to your

workpiece. Use the vertical lines on the jig

body to help you align it to drill a Pocket

Hole. The next step is to drill the hole.

You’ll want to drill until the depth collar on

the bit contacts the jig body.

www.kregtool.com

Finally, align the two workpieces and

fasten them with Pocket Screws.

Clamp the pieces together while driving

the screws to eliminate shifting. Use the

square driver bit in your drill and drive

the screws until they seat in the bottom of

the Pocket Holes.

4-

Setting the thickness guide-

The gray sliders on the sides of your Kreg Jig® control the

location for the Pocket Hole in relation to the edge of the

material. If your wood measures 3/4” thick, simply depress the

button and move the sliders so that the arrows align with the

3/4 mark. This setting will cause the screw to exit directly on the

center of your 3/4” thick material.

Find the numbers on the gray sliders that represent the

thickness of the workpiece you’ll be drilling. Align each slider

with the arrow and you’re set to go. Securely fasten the jig to

your workpiece, making sure the tabs at the end of the sliders

butt up against the edge of your workpiece as shown at right.

Setting the drill depth-

Now that you’ve got your Kreg Jig® securely fastened to your

workpiece, you need to control the depth of the Pocket Hole you

will drill. This is accomplished by positioning the depth collar

on the drill bit according to the thickness of your material to be

joined. The quickest way to position the depth collar along the

length of the drill bit is to use the scale molded into your

Kreg Jig

jig body, these numbers correspond to the thickness of the

material you’ll be drilling. Just make sure the “step” on the drill

bit is tight against the step in the case, then move the collar to

the appropriate location aligned with the scale and lock it into

place with the allen wrench.

®

case. Like the numbers on the depth sliders on the

Details

4

English

Another way you can set the position of the depth collar is to use

a ruler or tape measure. The chart on the inside of your case lid

shows you the correct tape measure settings. Again, measure

from the step of the bit to the edge of the depth collar as shown.

Clamping-

For safety, it’s important to make sure your Kreg Jig® is securely

clamped or fastened to your workpiece before drilling. You can

accomplish this by using a C-clamp or bar clamp that can be

found at most homecenters or hardware stores. It is often helpful to clamp your jig directly to the workbench with the bar clamp

while drilling the Pocket Holes as shown in the image at right.

You can also use our dual purpose Face Clamp to clamp the jig

in position (Item# PFC). Our Face Clamp is designed to be used

with the gray clamp adapter that came with this jig. The pad of

this clamp snaps into directly into the clamp adapter and locks

your Kreg Jig

clamp can be used for assembly of the joint to keep everything

fl ush while you drive the screws.

®

securely in place while drilling. In addition, the

www.kregtool.com

5

Details Continued

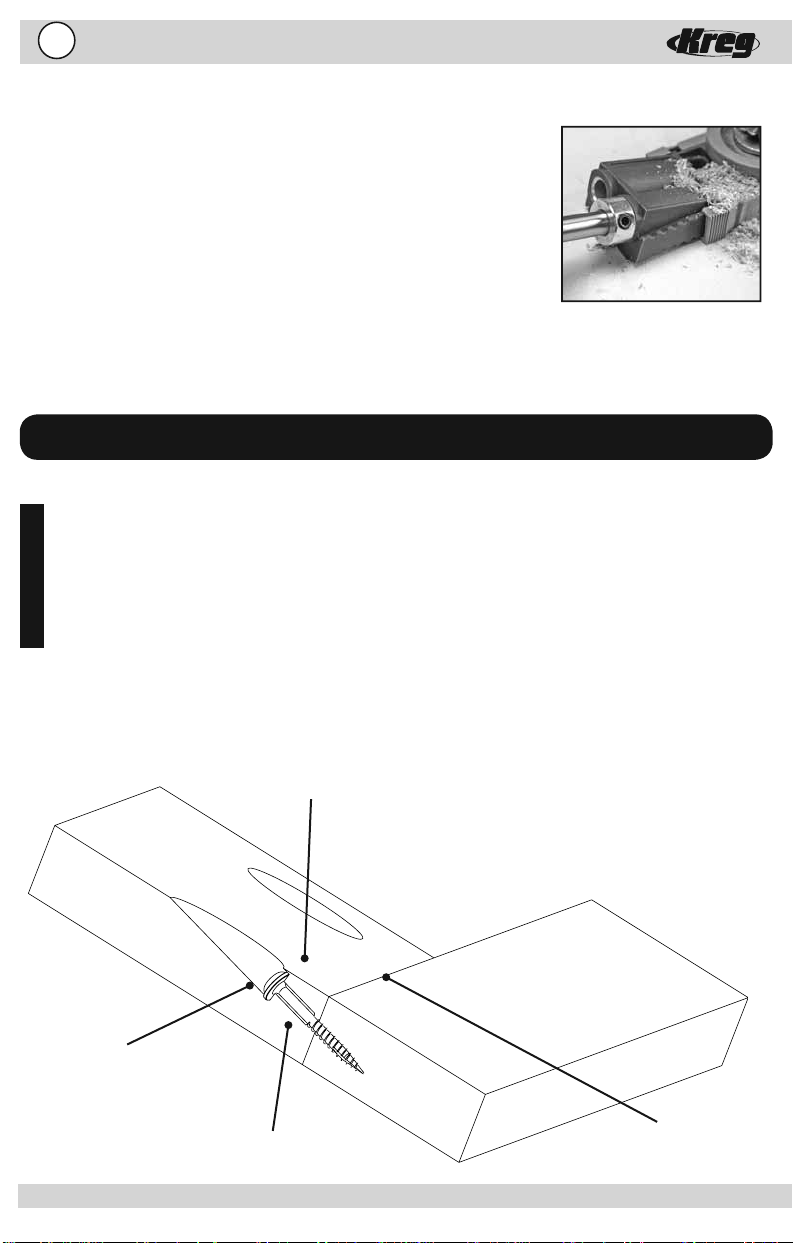

Drilling-

The drill bit included in this kit is specially-designed for drilling

Pocket Holes. The narrow tip drills the guide hole for the

Pocket Screw. The larger diameter drills the actual “pocket” to

house the screw and create a fl at bottom to allow the screw

to seat securely. The key to drilling clean Pocket Holes it to

use a smooth, continuous motion. Bring your portable drill

up to its highest speed and smoothly plunge the bit into the

steel drill guide. The wood chips and sawdust will automatically be ejected for a nice, clean Pocket Hole. When you use

your Kreg Jig

plastic chips while drilling. But don’t worry—this is perfectly

normal and won’t affect the life of the Kreg Jig

of your Pocket Holes.

®

for the fi rst few times, you may see some blue

®

or the quality

Basics of a Pocket Screw Joint

4-

Strong

Pocket Screw joinery is among the strongest of joints in woodworking. When the

English

workpieces are cut accurately , the large

head of the screw creates a lot of clamping

force in the bottom of the Pocket, drawing the pieces together for an extremely

tight joint. Of course, it’s important to use

the right screw and one that’s the proper

length. You can read more about our

Pocket Screws on page 7.

Pocket Screws are designed

to exert a lot of clamping pressure,

creating a stong, tight joint line

Large pocket hole

diameter provides

clearance for screw head

Guide hole for screw shank

Fast and Easy

What can be easier about joining two pieces

of wood? Unlike biscuits or dowels, with

Pocket Screw joinery , you’re drilling holes

into only one workpiece and driving a screw.

Once you’re set up, it only takes a few

seconds to drill the Pocket Hole and drive

the screw home. No other woodworking joint

takes so little time to produce, yet provides

such a strong joint.

Glue is Optional

We’re often asked, “Should I use glue

for my Pocket Screw joints?” It certainly

doesn’t hurt, but it’s not mandatory. Of

course, whether or not you use glue will

depend on the type of project you’re

building and the stresses it will see

over its lifetime.

Joint line

www.kregtool.com

4-

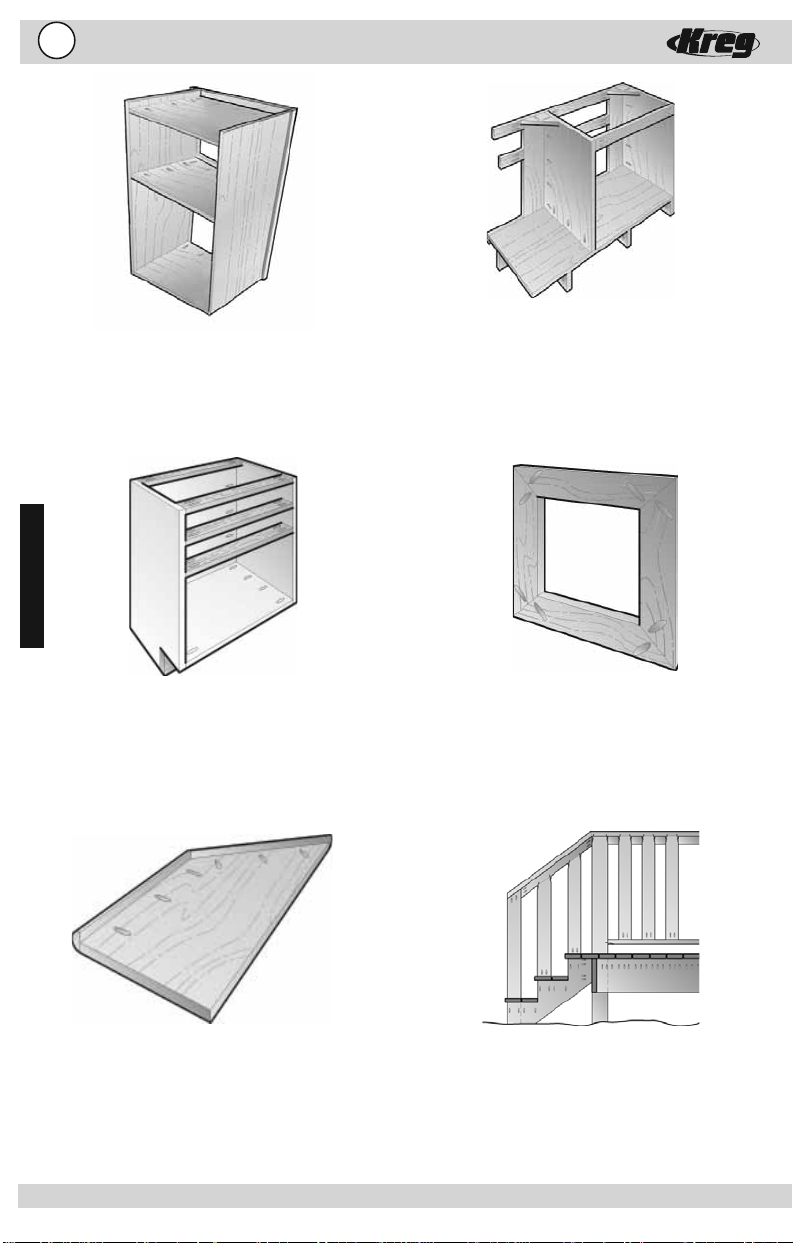

Pocket Screw Uses Around Your Home

6

• Make Fine Furniture

The nice thing about Pocket Hole joinery

is that it’s quick and strong. And you don’t

need to be an experienced craftsman to

build heirloom-quality furniture you can

be proud of. See our web site for lots of

furniture plans.

• Build Your Own Cabinets

Buying custom-made cabinets can be

expensive. And stock cabinets don’t always

fi t where you need them. Build your own

custom cabinets with Pocket Hole joinery.

It’s easier than you think. Check our web

site for a preview of our cabinetmaking

booklet.

• Outdoor Projects

With our weather-resistant Pocket screws,

you can build those outdoor projects.

Garden benches, planters, decks, and other

projects go together quickly with Pocket

Screw joinery.

• Furniture Repair

Wobbly table legs or loose table tops are

an easy fi x with Pocket Screw joinery. Your

Kreg Jig

spots to add extra strength with a Pocket

Screw.

®

is small enough to fi t into tight

• Eliminate Floor and Stair Squeaks

If you’ve got access to your squeaky fl oor or

stairs from underneath, a Pocket Screw is a

quick, permanent fi x. It’ll draw loose boards

tight, eliminating those annoying squeaks.

English

www.kregtool.com

7

Pocket Screw Selection

4-

Pocket Screw Joinery is not really new technology . It was actually invented by the Egyptians. They

clamped two workpieces together and then bored a hole at an angle from one workpiece into the

second workpiece—just like a Pocket Hole. They then inserted a dowel with some glue and cut

it off fl ush with the surface. The modern Pocket Screw joint grew in popularity with the creation of

the self-tapping screw in the 1980’s. Our self-tapping screws eliminate the need to pre-drill the mating workpiece. And the self-tapping screw also serves as an “internal” clamp, which eliminates the

need to clamp the joint. And that makes a joint that is as strong or stronger than joints made with

biscuits, dowels, or mortise and tenons.

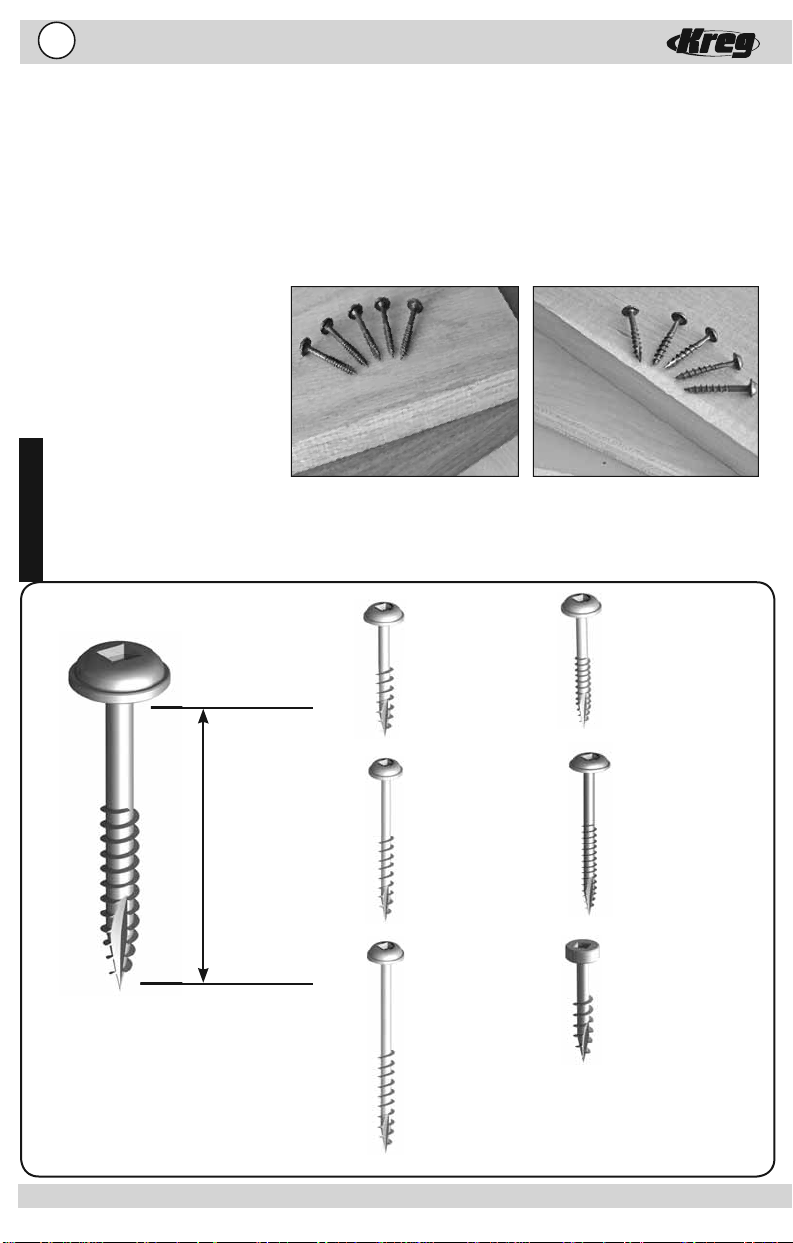

Our Pocket Screws are

engineered for strength.

But it’s important to use

the right screw. That’s

why we make our screws

to work with a variety of

materials. We offer them

in the lengths you need for

almost all of your projects.

English

Fine thread screws are the

preferred choice in harder

woods such as Ash, Oak,

Maple, Birch, Walnut, Hickory,

Cherry, and Mahogany.

Coarse thread screws are

the preferred choice in softer

woods such as Pine, Cedar,

Fir, Spruce, Basswood,

Plywood, Melamine and MDF.

Our Most Popular Screws

SCREW

LENGTH

Measure

from bottom

of head to

point of

screw.

* Weather Resistant Screws

Some of our Pocket Screws are

available in a weather-resistant coating.

This coating offers protection from the

elements which means you can use them

for outdoor applications. See our web site

for details.

*See our website for a complete screw selection guide.

SML-C125

Washer-Head;

#8 Coarse-Thread,

1-1/4” Length. Our

most popular screw,

perfect for joining ¾”

to ¾” softwoods.

SML-C150

Washer-Head;

#8 Coarse-Thread,

1-1/2” Length.

Coarse thread, longer

length for joining 7/8”

to 1-1/8” thick softwoods.

SML-C250

Washer-Head;

#8 Coarse-Thread,

2-1/2” Length.

The ideal screw for

joining 2 x 4’s.

www.kregtool.com

SML-F125

Washer-Head;

#7 Fine-Thread,

1-1/4” Length.

Our second most

popular screw, perfect

for joining ¾” to ¾”

hardwoods.

SML-F150

Washer-Head;

#7 Fine-Thread,

1-1/2” Length.

Fine thread, longer

length for joining

7/8” to 1-1/8” thick

hardwoods.

SPS-C1

Pan-Head;

#8 Coarse-Thread,

1” Length.

This is the screw

to join ½” to ½”

softwoods as the

head easily seats

below fl ush.

4-

Premium Face Clamp Item# PFC

The Premium Face Clamp is a handy addition

to your Kreg Jig

clamp adapter. You can also use it without the

Kreg Jig

driving the Pocket Screws. This clamp makes the

process of drilling many Pocket Holes go a lot

faster. You’ll appreciate it’s quick-release

mechanism and adjustable locking handle.

®

®

. It’s designed to snap into the

to hold your workpieces fl ush when

Right Angle Clamp Item# RAC

When you’re fastening two pieces at right

angles, clamping them while driving the Pocket

Screws can be tricky . That’s why we’ve designed

this Right Angle Clamp. It’s got a

specially-designed tip that fi ts snugly into

a drilled Pocket Hole. Its long reach and

fast-acting clamping mechanism makes this

a must-have accessory.

Accessories

8

English

Bench Clamp Item# KBK

Once you realize all the applications for Pocket

Screw Joinery around your home, you’ll

appreciate the usefulness of our Bench Clamp.

A special aluminum plate routed into your

workbench makes an ideal clamping station for

drilling Pocket Holes and fastening workpieces.

The bench clamp features a special “foot” that

locks into the mounting plate. And the clamp

has the same quick-acting, adjustable clamping

mechanism as our other clamps.

Pocket Hole Plugs

Pocket Screw joints are usually hidden, but from

time to time they appear in a visible location and

you need to conceal them. That’s why we’ve

developed a variety of solid wood Pocket Hole

plugs and plastic caps for laminated surfaces

such as melamine to hide the holes. You can also

make your Pocket Screw joints a design feature

by using a contrasting-colored plug or cap.

www.kregtool.com

9

Pocket Hole Ideas

4-

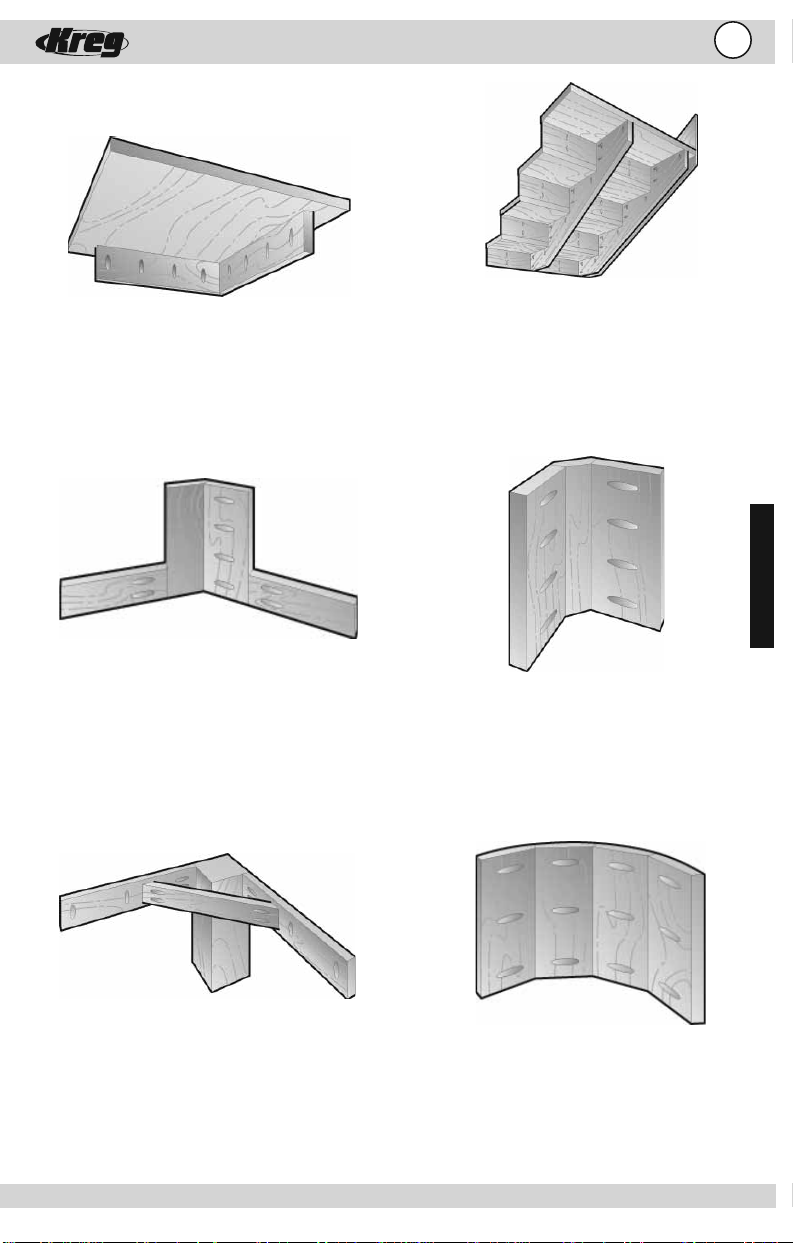

Get professional results and strong

joints using Pocket Screw oinery for

cabinets and bookcases.

(shown upside down)

English

Build your own modern,

European-style cabinets

quickly and easily.

Make strong, traditional

face-frame cabinets and built-in storage.

Mitered joints on picture frames go

together fast with Pocket Screw Joinery.

Add decorative edging to shelves

and countertops for a custom look.

(shown upside down)

Build strong decks with invisible

fasteners using Pocket Screw Joinery.

www.kregtool.com

4-

Pocket Hole Ideas

10

Add table aprons or cabinet toe-kicks

just like a professional.

Get tight joints at any angle for custom

cabinets, shelving, or bookcases.

Quiet old, squeaky stairs or

build strong new ones with

Pocket Screw Joinery.

English

Be creative with strong

joinery options.

Traditional table construction is easy and

strong with Pocket Screw Joinery.

www.kregtool.com

Gentle curves are no problem with

Pocket Screw Joinery.

11

Contact Information

Give us your feedback!

Feel free to contact us with any questions, comments, concerns, or product

suggestions. Send via email to customerservice@kregtool.com or mail to...

Kreg Tool Company

201 Campus Drive

Huxley, IA 50124

Toll Free: 800-447-8638

Local: 515-597-2234

(fax) 515-597-2354

website: www.kregtool.com

email: customerservice@kregtool.com

English

4-

www.kregtool.com

News and Reviews

Testimonials

Pocket Hole Tools

Pocket Hole Machines

Precision Measuring Systems

Kreg Accessories

Visit

Today!

Pocket Hole Applications

FAQ’s

Product Manuals

Local Dealer Locator

Tradeshow Calendar

Request a Catalog

www.kregtool.com

4-

Notes

12

English

www.kregtool.com

13

¡Gracias!

¡Gracias por su compra! En Kreg Tool Company, estamos orgullosos

de fabricar herramientas y accesorios de la más alta calidad,

superados solamente por nuestro compromiso de atención al cliente.

Si tiene dudas o consultas después de leer el manual, contáctenos.

Puede visitarnos en línea para obtener recursos, como accesorios,

planos de proyectos, manuales de productos y más consejos

y técnicas para sacar el mayor provecho de su juego Kreg Jig

®

.

Vea la Guía rápida de la página 15.

4-

Espanol

~

4-

En línea: www.kregtool.com

Teléfono: 800-447-8638

Dirección de correo electrónico:

customerservice@kregtool.com

Para su seguridad

¡La broca es muy fi losa! Manipúlela con cuidado.

Antes de realizar los agujeros de ocultación, sujete fi rmemente

con una prensa la plantilla para agujeros de ocultación.

Nunca sostenga la plantilla con la mano cuando taladre.

Permita siempre que la broca alcance la velocidad máxima

antes de insertarla en la pieza de trabajo.

www.kregtool.com

4-

Identifi cación de las piezas

14

Los agujeros

de montaje le

permiten atornillar

la plantilla a la

pieza de trabajo

para taladrar.

El adaptador para

la prensa se calza

en estos agujeros

y se utiliza con

la prensa para

marcos opcional.

La llave Allen

asegura el collar

de profundidad

en la broca.

Puede utilizar el adaptador para la prensa con

la prensa para marcos opcional (no incluida)

a fi n de sujetar la plantilla en su lugar con la

La broca para atornillar

de punta cuadrada

coloca nuestros tornillos

especialmente diseñados

para agujeros de ocultación

sin que se suelten.

prensa mientras taladra.

Coloque los deslizadores

para el espesor de la pieza

de trabajo que perforará

como se indica en el cuerpo

de la plantilla.

El collar de

profundidad se

ajusta a la broca

para controlar la

profundidad del

agujero de ocultación.

Espanol

~

La broca escalonada

realiza rápidamente el

agujero guía para el

tornillo y el agujero de

ocultación en una sola

operación rápida.

Utilice la práctica escala grabada en la caja para

colocar el collar de profundidad en la broca en la

posición correcta. Los números indican el espesor

del material que perforará.

Número de pieza Descripción

KJD ..........................................

D6 .............................................

AW18 ........................................

KJSC ........................................

Deslizadores

Adaptador para la prensa

Cuerpo de la plantilla con

guías de perforación

www.kregtool.com

.................................

................

........................

Broca escalonada

Broca para atornillar de punta

cuadrada N.° 2, de 6”

Llave Allen

Collar de profundidad

Deslizadores

Adaptador para la prensa

Cuerpo de la plantilla con

guías de perforación

15

Guía rápida

4-

Guía rápida

Utilización del sistema de unión con tornillos de ocultación en el hogar.

El sistema de unión con tornillos de ocultación es útil para varios tipos de aplicaciones en su hogar.

Todo lo que usted necesitará será una sierra, un taladro portátil y el juego Kreg Jig

®

. Comenzar

es muy sencillo. Sólo siga los pasos sencillos de abajo para obtener resultados profesionales

y uniones resistentes en muy poco tiempo.

1. 2.

Mida el espesor del material en el que realizará

Espanol

agujeros de ocultación. Mueva cada deslizador

de su juego Kreg Jig

~

del deslizador quede alineado con las fl echas del

cuerpo de la plantilla Kreg Jig

corresponderse con el espesor del material que

usted va a perforar y ubica el agujero de ocultación

en la posición adecuada, en la pieza de trabajo.

®

de modo que el número

®

. Este número debe

Luego es importante fi jar correctamente la profundidad

del collar en la broca. Esto hará que los agujeros de

ocultación tengan la profundidad adecuada para que la

unión sea resistente y los tornillos penetren correctamente.

Utilice la escala incorporada en la caja de herramientas

®

Kreg Jig

para fi jar el collar de profundidad según el

espesor del material que vaya a perforar. Ajústelo con

la llave Allen que se proporciona.

Set to 3/4”

4.3.

Luego es importante fi jar correctamente la profundidad

del collar en la broca. Esto hará que los agujeros de

ocultación tengan la profundidad adecuada para que la

unión sea resistente y los tornillos penetren correctamente.

Utilice la escala incorporada en la caja de herramientas

®

Kreg Jig

para fi jar el collar de profundidad según el

espesor del material que vaya a perforar. Ajústelo con

la llave Allen que se proporciona.

www.kregtool.com

Luego es importante fi jar correctamente la profundidad

del collar en la broca. Esto hará que los agujeros de

ocultación tengan la profundidad adecuada para que la

unión sea resistente y los tornillos penetren correctamente.

Utilice la escala incorporada en la caja de herramientas

®

Kreg Jig

para fi jar el collar de profundidad según el

espesor del material que vaya a perforar. Ajústelo con

la llave Allen que se proporciona.

4-

Fijación de la guía de profundidad

Los deslizadores grises ubicados a los costados de su plantilla Kreg Jig®

controlan la ubicación del agujero de ocultación en relación con el borde

del material. Si la madera mide 3/4 de pulgada de espesor, simplemente

presione el botón y mueva los deslizadores hasta que las fl echas queden

alineadas con la marca de 3/4. Esta confi guración hará que el tornillo

quede justo en el centro del material de 3/4 de pulgada.

Encuentre los números en los deslizadores grises que representan el

espesor de la pieza de trabajo que perforará. Alinee cada deslizador

con la fl echa y estará listo para empezar. Ajuste bien la plantilla en la

pieza de trabajo, asegurándose de que las pestañas del extremo de los

deslizadores queden a tope con el borde de la pieza de trabajo como

se muestra a la derecha.

Fijación de la profundidad de perforación

Una vez que haya ajustado en forma segura la plantilla Kreg Jig® a la

pieza de trabajo será necesario controlar la profundidad del agujero de

ocultación que realizará. Esto se logra ubicando el collar de profundidad

en la broca según el espesor del material que se va a unir. La forma

más rápida de ubicar el collar de profundidad a lo largo de la broca es

utilizar la escala grabada en la caja de herramientas Kreg Jig®. Al igual

que los números de los deslizadores de profundidad del cuerpo de la

plantilla, estos números se corresponden con el espesor del material

que perforará. Sólo asegúrese de que el “escalón” de la broca esté bien

ajustado al escalón de la caja, luego mueva el collar hacia la posición

adecuada que esté alineada con la escala y fíjelo en su lugar con la

llave Allen.

Detalles

16

Espanol

~

También puede determinar la posición del collar de profundidad utilizando

una regla o una cinta métrica. El cuadro del interior de la tapa de la caja

le muestra la forma correcta de medición con la cinta. Nuevamente, mida

desde el escalón de la broca hasta el borde del collar de profundidad

como se muestra.

Sujeción

Por razones de seguridad, es importante verifi car que la plantilla Kreg Jig®

esté bien sujetada o ajustada antes de comenzar a perforar. Esto puede

lograrse utilizando una prensa C o una prensa de barra, que pueden

adquirirse en la mayoría de los centros para el hogar o de las ferreterías.

A menudo, es aconsejable fi jar la plantilla directamente en el banco

de trabajo con la prensa de barra mientras se realizan los agujeros

de ocultación como se muestra en la imagen de la derecha.

También puede utilizar nuestra prensa para marcos para sujetar la

plantilla en su posición (artículo N.o PFC). Nuestra prensa para marcos

está diseñada para ser utilizada con el adaptador para prensa gris que

viene incluido en este juego. La superfi cie de apoyo de esta prensa se

ajusta directamente al adaptador para prensa y se traba en la plantilla

Kreg Jig® en forma segura durante la perforación. Además, la prensa

puede utilizarse para el ensamblaje de las juntas para mantener todo

a ras mientras se colocan los tornillos.

www.kregtool.com

17

Detalles (continuación)

Perforación

La broca incluida en este juego está diseñada especialmente para

realizar agujeros de ocultación. La punta angosta realiza el agujero

guía para el tornillo de ocultación. La parte de la broca de mayor

diámetro realiza el “bolsillo” para ocultar el tornillo y crea un fondo

plano para que el tornillo se asiente fi rmemente. La clave para

realizar agujeros de ocultación parejos es utilizar un movimiento

suave y continuo. Deje que el taladro alcance la velocidad máxima

e introduzca suavemente la broca en la guía de perforación

de acero. Las astillas de madera y el aserrín serán expulsados

automáticamente, lo que dará como resultado un agujero de

ocultación prolijo y liso. Cuando utilice su plantilla Kreg Jig

primeras veces, es probable que vea algunos trozos pequeños

de plástico durante la perforación. No se preocupe, esto es

completamente normal y no afectará la duración de la plantilla

Kreg Jig® ni la calidad de sus agujeros de ocultación.

®

las

Características básicas de las juntas con tornillos de ocultación

4-

Resistencia

El sistema de unión con tornillos de ocultación es

una de las uniones más resistentes en carpintería.

Espanol

Cuando las piezas de trabajo están bien cortadas,

la cabeza grande del tornillo produce una gran

~

fuerza de sujeción en la parte inferior del agujero

de ocultación y junta las piezas en una unión muy

resistente. Desde luego, es importante utilizar los

tornillos adecuados y con el largo correcto. Puede

leer más acerca de nuestros tornillos de ocultación

en la página 7.

Los tornillos de ocultación están

diseñados para aplicar mucha

presión de sujeción, lo que crea

una línea de unión ajustada

y resistente

El diámetro grande del

agujero de ocultación

brinda espacio para

la cabeza del tornillo

Agujero guía para el vástago

del tornillo

www.kregtool.com

Rapidez y facilidad

¿Qué método para unir dos pedazos de madera

puede ser más fácil? A diferencia de los óvalos

o las espigas para uniones, el sistema de

unión con tornillos de ocultación sólo requiere

realizar perforaciones en una sola pieza de

trabajo y colocar tornillos. Una vez realizada la

preparación, sólo lleva algunos segundos realizar

el agujero de ocultación y colocar el tornillo.

Ningún otro sistema de unión de carpintería lleva

tan poco tiempo y brinda una unión tan resistente.

El pegamento es opcional

A menudo, nos preguntan: “¿Debo utilizar

pegamento para las juntas con tornillos de

ocultación?” Es cierto que no será perjudicial,

pero tampoco es necesario. Por supuesto,

utilizar pegamento o no dependerá del tipo

de proyecto que se esté realizando y de

los esfuerzos a los que ese proyecto será

sometido durante su duración.

Línea de unión

4-

Aplicaciones de agujeros de ocultación en su hogar

18

• Fabrique muebles fi nos

Lo bueno de la unión con agujeros de ocultación

es que es rápida y resistente. Y no es necesario

que usted sea un artesano experimentado para

que pueda fabricar muebles de calidad que

durarán toda la vida y de los cuales estará

orgulloso. En nuestro sitio web encontrará

muchos proyectos de muebles.

• Construya sus propios gabinetes

Comprar gabinetes hechos a medida puede ser

caro. Y los gabinetes en existencia no siempre

caben donde usted los necesita. Construya sus

propios gabinetes hechos a medida con el sistema

de unión con agujeros de ocultación. Es más

fácil de lo que piensa. Vea nuestro sitio web

para obtener una vista previa de nuestro folleto

de fabricación de gabinetes.

• Proyectos para exteriores

Con nuestros tornillos resistentes a la intemperie,

usted podrá realizar proyectos en exteriores.

Bancos para jardín, jardineras, terrazas y otros

proyectos se ensamblan rápidamente con el

sistema de unión con tornillos de ocultación.

• Reparación de muebles

Las patas o las cubiertas fl ojas de las mesas son

fáciles de reparar con el sistema de unión con

tornillos de ocultación. La plantilla Kreg Jig® es

sufi cientemente pequeña para caber en lugares

reducidos, a fi n de agregar una resistencia extra

con tornillos de ocultación.

• Elimine los chirridos en pisos y en escaleras

Si tiene acceso desde abajo a su piso o escalera

chirriante, un tornillo de ocultación es un arreglo

rápido y permanente. Hará que las tablas se

ajusten y eliminará los chirridos molestos.

Espanol

~

www.kregtool.com

19

Selección de los tornillos de ocultación

4-

El sistema de unión con tornillos de ocultación. De hecho, fue inventado por los egipcios. Ellos sujetaban

dos piezas de trabajo y luego realizaban un agujero en ángulo desde una pieza de trabajo hasta la segunda

(al igual que un agujero de ocultación). Luego, insertaban una espiga con pegamento y la cortaban a ras de la

superfi cie. El sistema moderno de juntas con tornillos de ocultación tuvo gran popularidad con la creación del

tornillo autorroscante en 1980. Nuestros tornillos autorroscantes eliminan la necesidad de perforar previamente

la segunda pieza de trabajo. Y el tornillo autorroscante también sirve como una prensa “interior” que elimina

la necesidad de sujetar la unión. Y esto produce una unión que es tan fuerte como las uniones hechas con

óvalos, espigas o con mortajas y espigas, o más fuerte aún.

Nuestros tornillos de ocultación

están diseñados para ser

resistentes. Pero es importante

utilizar el tornillo adecuado.

Por eso, fabricamos nuestros

tornillos para que puedan

utilizarse con una variedad de

materiales. Tenemos tornillos

disponibles en todos los largos

que usted necesita para casi

cualquiera de sus proyectos.

Espanol

~

Nuestros tornillos más populares

Los tornillos con rosca fi na son la

elección preferida para las maderas

más duras, como fresno, roble, arce,

abedul, nogal, nogal americano,

cerezo y caoba.

SML-C125

Cabeza de arandela:

Rosca gruesa N.° 8,

de 1-1/4 de pulgada

de largo. Nuestro tornillo

más popular, ideal para

unir maderas blandas de

3⁄4 con maderas blandas

de 3⁄4 de pulgada.

Las roscas gruesas son la elección

preferida para las maderas más

blandas, como pino, cedro, abeto,

abeto del norte, tilo americano,

madera contrachapada, melamina

y MDF (fi bra de mediana intensidad).

SML-F125

Cabeza de arandela:

Rosca fi na N.° 7, de

1-1/4 de pulgada de

largo. Nuestro tornillo

más popular, ideal para

unir maderas duras de

3⁄4 con maderas duras

de 3⁄4 de pulgada.

LARGO DEL

TORNILLO

Mida desde la

parte inferior

hasta la punta

del tornillo.

* Tornillos resistentes

a la intemperie

Algunos de nuestros tornillos de ocultación están

disponibles con un revestimiento impermeable.

Este revestimiento les brinda protección de los

elementos, lo que signifi ca que los puede utilizar

para aplicaciones en exteriores. Vea nuestro sitio

web para conocer los detalles.

* Vea nuestro sitio web para obtener una guía completa de selección de tornillos.

SML-C150

Cabeza de arandela:

Cabeza de arandela.

Rosca gruesa N.° 8,

de 1-1/2 de pulgada

de largo. Rosca gruesa,

mayor longitud para unir

maderas blandas de 7/8

a 1-1/8 de pulgadas de

espesor.

SML-C250

Cabeza de arandela:

Rosca gruesa N.° 8,

de 2-1/2 de pulgada

de largo. El tornillo

ideal para unir

maderas de

2 x 4 pulgadas.

www.kregtool.com

SML-F150

Cabeza de arandela:

Rosca fi na N.° 7, de

1-1/2 de pulgada de

largo. Rosca fi na,

mayor longitud para

unir maderas duras

de 7/8 a 1-1/8 de

pulgadas de espesor.

hardwoods.

SPS-C1

Cabeza ovalada:

Rosca gruesa N.° 8,

de 1 pulgada de largo.

Este es el tornillo para

unir maderas blandas

de 1⁄2 pulgada, ya que

la cabeza se asienta

fácilmente debajo del

nivel de la superfi cie.

4-

Accesorios

20

o

RAC

o

PFC

Prensa superior para marcos. Artículo N.

La prensa superior para marcos es un agregado

práctico al juego Kreg Jig®. Está diseñada para

calzarse en el adaptador para prensa. También

puede utilizarla sin el juego Kreg Jig® para mantener

sus piezas de trabajo a ras cuando coloque los tornillos

de ocultación. Esta prensa acelera considerablemente

el proceso de perforación de agujeros de ocultación

múltiples. Usted estará muy satisfecho con el

mecanismo de liberación rápida y con el mango

de sujeción ajustable.

Prensa en ángulo recto. Artículo N.

Cuando sujete dos piezas en ángulo recto, sujetarlas

durante la colocación de los tornillos de ocultación

puede ser difícil. Por eso, hemos diseñado esta prensa

en ángulo recto. Tiene una punta especialmente

diseñada que cabe cómodamente en un agujero

de ocultación. Su mecanismo de largo alcance

y acción rápida hace de esta prensa un accesorio

imprescindible.

Prensa de banco. Artículo N.

Cuando descubra todas las aplicaciones para

las uniones con tornillo de ocultación en su hogar,

estará muy satisfecho con la utilidad de nuestra

prensa de banco. Una placa especial de aluminio

atornillada a su banco para trabajo representa un

punto de sujeción ideal para realizar agujeros de

ocultación y sujetar piezas de trabajo. La prensa

de banco tiene una “pata” especial que se traba

en la placa de montaje. Y la prensa tiene el mismo

mecanismo de sujeción, ajustable y de acción

rápida, que el resto de nuestras prensas.

o

KBK

Espanol

~

Tapones para agujeros de ocultación

Normalmente, las juntas con tornillos de ocultación

no quedan a la vista, pero, a veces, aparecen en una

ubicación visible y usted necesita ocultarlos. Por eso,

hemos desarrollado una variedad de tapones de madera

sólida para agujeros de ocultación y tapas plásticas

para superfi cies laminadas, como melamina, para

ocultar los agujeros. También puede agregarle detalles

de diseño a sus juntas con tornillos de ocultación

utilizando tapones o tapas con colores contrastantes.

www.kregtool.com

Ideas para utilizar agujeros de ocultación

21

4-

Obtenga resultados profesionales y juntas

resistentes utilizando el sistema de unión

con tornillos de ocultación en gabinetes

y libreros (se muestra al revés).

Espanol

~

Construya sus propios gabinetes

modernos, de estilo europeo,

en forma rápida y sencilla.

Realice gabinetes resistentes

y tradicionales con marco frontal,

y empotrados, para almacenaje.

Las juntas a inglete de los marcos para

pinturas se fi jan rápidamente con el sistema

de unión con tornillos de ocultación.

Agregue bordes decorativos a las

estanterías y a las cubiertas prefabricadas

para lograr una apariencia personalizada.

(se muestra al revés)

www.kregtool.com

Construya terrazas resistentes con

sujetadores invisibles utilizando el sistema

de unión con tornillos de ocultación.

4-

Ideas para utilizar agujeros de ocultación

22

Agregue frentes para mesas o placas

de protección como un profesional.

Obtenga uniones resistentes a cualquier

ángulo para realizar gabinetes,

estanterías o libreros.

Repare escaleras viejas y chirriantes,

o fabrique unas nuevas y resistentes

utilizando el sistema de unión con

tornillos de ocultación.

Espanol

~

Sea creativo con opciones

de uniones resistentes.

La construcción tradicional de mesas

es sencilla y resistente con el sistema

de unión con tornillos de ocultación.

www.kregtool.com

Las curvas suaves no son problema

con el sistema de unión con tornillos

de ocultación.

23

¡Sus comentarios nos interesan!

Contáctenos si tiene preguntas, comentarios, dudas o sugerencias acerca

de los productos. Escríbanos a customerservice@kregtool.com o a

Kreg Tool Company

201 Campus Drive

Huxley, IA 50124

Número gratuito: 800-447-8638

Local: 515-597-2234

(fax) 515-597-2354

sitio web: www.kregtool.com

dirección de correo electrónico: customerservice@kregtool.com

Espanol

~

Información de contacto

4-

www.kregtool.com

Novedades y reseñas

Testimonios

Herramientas para realizar agujeros

de ocultación

Máquinas para realizar agujeros

de ocultación

Sistemas de precisión para realizar

mediciones

¡VISITE

HOY!

Accesorios Kreg

Aplicaciones con agujeros de ocultación

PREGUNTAS FRECUENTES

Manuales de productos

Localizador de distribuidores locales

Calendario de ferias

Ordenar un catálogo

www.kregtool.com

4-

Notes

24

Espanol

~

www.kregtool.com

25

Merci !

Nous vous remercions de votre achat ! Kreg Tool Company est fi ère

de fabriquer des outils et des accessoires de la meilleure qualité

surpassés uniquement par l’engagement de notre service à la clientèle.

Si, après avoir consulté ce manuel, vous avez encore des questions,

veuillez nous contacter.

Vous pouvez nous rendre visite en ligne pour obtenir des ressources

additionnelles telles que des accessoires, des plans, des guides

d’utilisation et d’autres conseils et techniques pour tirer le maximum

de votre guide Kreg Jig

®

.

Voir le Guide de démarrage rapide à la page 27.

4-

Francais

4-

Web : www.kregtool.com

Tél. : 800.447.8638

Courriel : customerservice@kregtool.com

Pour votre sécurité

La mèche est très acérée ! Veuillez la manipuler avec soin.

Tenez toujours le guide de trou de vis caché et la pièce

avec une pince solide avant de percer les trous. Ne tenez

jamais le guide avec la main lorsque vous percez.

Laissez toujours la mèche atteindre sa vitesse maximale

avant de la plonger dans la pièce.

www.kregtool.com

4-

Identifi cation des pièces

26

Trous de montage

vous permettant

de visser le guide

sur la pièce

pour le perçage.

L’adaptateur

de serre-joint

s’enclenche dans

ces trous pour

l’utilisation avec

la pince serre-joint

en option.

La clé Allen sert

à fi xer la bague

de profondeur

sur la mèche.

L’adaptateur de pince peut être utilisé avec

la pince serre-joint en option (non comprise)

pour tenir le guide en place lors du perçage.

Le tournevis à prise carrée

visse sans glisser nos vis

à trou caché spécialement

conçues.

Réglez les coulisses pour

l’épaisseur de la pièce

que vous percez selon les

indications sur le corps

du guide.

La bague de

profondeur s’installe

sur la mèche pour

contrôler la profondeur

du trou de vis caché.

Francais

La mèche à épaule ment

découpe facilement

le trou-guide pour la vis

et le trou caché en une

opération rapide

Servez-vous de la commode échelle moulée

dans le boîtier pour régler la bague de profondeur

à la bonne position sur la mèche. Les nombres

représentent l’épaisseur du matériau que vous

allez percer.

N° de pièce Désignation

KJD ................................

D6 ...................................

AW18 .............................

KJSC .............................

Coulisses

Adaptateur de pince

Corps du guide avec

guides de perçage

www.kregtool.com

..........................

............

..............

Mèche à épaulement

Embout tournevis carré

n° 2 – 15 cm (6 po)

Clé Allen

Bague de profondeur

Coulisses

Adaptateur de pince

Corps du guide avec guides de perçage

27

Guide de démarrage rapide

Guide de démarrage rapide

La menuiserie à vis cachées à la maison

La menuiserie à vis cachées est utile pour une foule d’applications à la maison. Tout ce qu’il vous

faut est une perceuse portative et le guide Kreg Jig

simples ci-dessous pour obtenir des résultats professionnels et des joints solides en un rien de temps.

®

. Rien de plus simple. Il suffi t de suivre les étapes

4-

1. 2.

Francais

Mesurez l’épaisseur du matériau dans lequel vous

allez percer les trous cachés. Déplacez chaque

coulisse sur votre guide Kreg Jig® de manière

à ce que la coulisse s’aligne sur les fl èches

du corps du guide Kreg Jig®. Ce nombre

correspond à l’épaisseur du matériau et place

le guide à la bonne position sur votre pièce.

Régler à 3/4 po

Ensuite, il est important de correctement régler

la bague de profondeur sur la mèche. Cela

produit des trous cachés de la bonne profondeur

et un joint solide avec une pénétration adéquate

de la vis. Utilisez l’échelle moulée dans le coffret

du guide Kreg Jig

de la bague de profondeur pour le matériau

que vous percez. Fixez la bague avec la clé

Allen fournie.

®

pour régler la position

4.3.

Ensuite, fi xez solidement le guide Kreg Jig® sur

la pièce. Servez-vous des lignes verticales sur

le corps du guide pour vous aider à l’aligner

pour percer un trou caché. L’étape suivante

est le perçage du trou. Il faut percer jusqu’à

ce que la bague de profondeur atteigne

le corps du guide.

www.kregtool.com

Enfi n, alignez les deux pièces et joignez-les

avec les vis à trou caché. Tenez les pièces

avec un serre-joint lorsque vous vissez pour

prévenir le mouvement. Utilisez l’embout à prise

carrée dans votre perceuse pour visser les vis

jusqu’à ce qu’elles s’assoient dans le fond des

trous cachés.

4-

Réglage du guide d’épaisseur –

Les coulisses grises sur les côtés du guide Kreg Jig® contrôlent

la position du trou caché relativement au rebord de la pièce.

Si la pièce est de 3/4 po (19 mm), appuyez sur le bouton

et déplacez les coulisses jusqu’à ce que les fl èches s’alignent

avec la marque 3/4. Ce réglage permettra à la vis de sortir

exactement au centre de la pièce de 3/4 po (19 mm).

Trouvez les nombres sur les coulisses grises qui représentent

l’épaisseur de la pièce que vous voulez percer. Alignez chaque

coulisse avec la fl èche et vous êtes prêt. Fixez solidement le guide

sur votre pièce en vous assurant que les languettes à l’extrémité

des coulisses reposent contre le rebord de la pièce, tel que montré

à droite.

Réglage de la profondeur de perçage –

Maintenant que votre guide Kreg Jig® est solidement attaché

à la pièce, vous devez régler la profondeur du trou caché que

vous allez percer. Cette tâche est accomplie en plaçant la bague

de profondeur sur la mèche en fonction de l’épaisseur des

matériaux qui seront joints. La manière la plus rapide de positionner la bague sur la mèche est d’utiliser l’échelle moulée dans

le coffret de votre guide Kreg Jig

nombres sur les coulisses du corps du guide, ces nombres correspondent à l’épaisseur du matériau que vous percez. Il suffi t

de veiller à ce que l’épaulement de la mèche repose bien contre

l’épaulement dans le coffret, puis de glisser la bague jusqu’à

l’emplacement indiqué sur l’échelle et de la serrer en place

à l’aide de la clé Allen.

®

. Comme dans le cas des

Détails

28

Francais

Une autre manière de régler la position de la bague de profondeur

est d’utiliser une règle ou un galon à mesurer. Le tableau dans

le couvercle du coffret montre la bonne mesure avec un galon

à mesurer. Encore une fois, mesurez de l’épaulement de la mèche

à la bague de profondeur, tel qu’illustré.

Serrage –

Pour des questions de sécurité, il est important de vous assurer que

votre guide Kreg Jig

de percer. Vous pouvez le faire avec un serre-joint en C ou à barre

que vous trouverez dans la plupart des quincailleries. Il est souvent

utile de serrer le guide directement sur l’établi avec un serre-joint

à barre pour le perçage, tel qu’illustré à droite.

Vous pouvez également utiliser notre pince serre-joint à deux

usages pour serrer le guide en place (article n° PFC). Notre

pince serre-joint est conçue pour servir avec l’adaptateur

de serre-joint gris fourni avec le guide. Le coussinet de la pince

s’enclenche directement dans l’adaptateur et fi xe le guide Kreg

®

solidement en place pour le perçage. De plus, la pince peut

Jig

servir à l’assemblage du joint pour garder les pièces de niveau

lorsque vous posez les vis.

®

est solidement serré ou fi xé à la pièce avant

www.kregtool.com

29

Détails (suite)

Perçage –

La mèche incluse dans cette trousse est conçue spécialement

pour percer des trous de vis cachées. La pointe étroite perce

le trou-guide pour la vis cachée. La partie plus large perce

la partie du trou caché où loge la tête de la vis et crée un fond

plat pour qu’elle soit bien assise. La clé pour percer des trous

cachés nets est de suivre un mouvement continu et uniforme.

Faites tourner votre perceuse portative à sa vitesse maximale

et plongez la mèche dans le guide de mèche en acier. Les

copeaux et le bran de scie seront automatiquement éjectés

et vous aurez un trou caché propre. Lorsque vous utilisez

votre guide Kreg Jig

pourriez voir des copeaux bleus lors du perçage. Ne vous

inquiétez pas – c’est parfaitement normal et n’affectera pas

la durée de vie du guide Kreg Jig

®

pour les quelques premières fois, vous

®

ou la qualité des trous.

Caractéristiques d’un joint à vis cachées

4-

Résistant

La menuiserie à vis cachées produit des

joints parmi les plus résistants pour joindre

Francais

des pièces de bois. Lorsque les pièces sont

coupées avec précision, la tête large de

la vis crée une grande force de serrage,

tirant les pièces ensemble en un joint

extrêmement serré. Évidemment, il faut

utiliser des vis du bon type et de la bonne

longueur. Vous pouvez en apprendre

davantage sur nos vis à la page 7.

Les vis à trous cachés sont conçues

pour exercer une grande force de serrage et créer un joint serré et résistant.

Les trous cachés

de grand diamètre

offrent un dégagement

pour les têtes de vis.

Trou-guide pour la tige

de la vis.

Simple et rapide

Quoi de plus simple pour joindre deux

morceaux de bois ? Contrairement aux

lamelles ou aux goujons, avec les vis à trous

cachés, vous percez des trous dans une

seule pièce et vous vissez une vis. Une

fois réglé, le système n’exige que quelques

secondes pour percer les trous et poser les

vis. Aucun autre joint pour le bois ne prend

si peu de temps à produire et fournit un joint

aussi résistant.

La colle est facultative

On nous demande souvent : « Est-ce que

je devrais utiliser de la colle dans mes joints

à vis cachées ? » Cela ne nuira certainement

pas, mais ce n’est pas obligatoire. Évidemment, que vous utilisiez de la colle ou non

dépend du projet que vous construisez

et des tensions auxquelles il sera sujet

avec le temps.

Ligne du joint

www.kregtool.com

4-

Usage des vis cachées dans la maison

30

• Fabriquer des meubles de qualité

L’avantage des trous de vis cachées est

qu’ils sont rapides à faire et résistants.

Vous n’avez pas besoin d’être un artisan

chevronné pour fabriquer des meubles

de grande qualité dont vous pourrez être

fi er. Vous trouverez de nombreux plans

de meubles sur notre site Web.

• Construisez vos propres armoires

L’achat d’armoires sur mesure est dispendieux.

Les armoires standard ne conviennent pas

toujours à vos besoins. Vous pouvez construire

vos propres armoires avec la menuiserie

à vis cachées. C’est plus simple que vous

ne le croyez. Rendez-vous à notre site

Web pour un aperçu de notre livret sur

la construction d’armoires.

• Projets pour le jardin

Avec nos vis résistantes aux intempéries,

vous pouvez construire ces projets dont

vous rêvez. Des bancs de jardin, des

jardinières, des terrasses et d’autres

projets sont rapidement construits à l’aide

de la menuiserie à vis cachées.

• Réparation de meubles

Des pattes de table chancelantes ou des

dessus de table lâches sont faciles à réparer

avec des vis cachées. Le guide Kreg Jig

assez petit pour se rendre dans des endroits

restreints pour ajouter de la résistance avec

une vis à trou caché.

®

est

• Éliminez les grincements du plancher

et des marches d’escalier.

Si vous avez accès au plancher ou aux

marches d’escalier par en-dessous, une

vis cachée est une manière rapide et permanente

de corriger le problème. Elle tire les planches

ensemble et élimine les grincements.

Francais

www.kregtool.com

31

Sélection des vis

4-

La menuiserie à vis cachées n’a rien de nouveau. En effet, elle a été inventée par les Égyptiens.

Ils serraient deux pièces ensemble, puis perçaient un trou incliné d’une pièce à l’autre, comme une

vis à trou caché. Ils inséraient alors un goujon encollé et le coupaient de niveau avec la surface.

Le joint à vis cachée moderne est devenu plus populaire avec la création des vis autotaraudeuses

dans les années 1980. Nos vis autotaraudeuses éliminent la nécessité de faire un avant-trou dans

la pièce correspondante. La vis autotaraudeuse sert également de serre-joint « interne » ce qui

élimine la nécessité d’employer des serre-joints. De plus, cela crée un joint qui est aussi solide,

sinon plus, que des joints faits avec des lamelles, des goujons ou des mortaises.

Nos vis sont conçues

pour la résistance. Il est

cependant important

d’utiliser la bonne vis.

C’est pourquoi nous avons

des vis qui fonctionnent

avec une variété de

matériaux. Nous les

offrons également dans

des longueurs pour

répondre à la plupart de

vos besoins.

Francais

Les vis à pas fi n sont préférables

pour les bois durs tels que le frêne,

le chêne, l’érable, le bouleau,

le noyer, l’hickory, le cerisier

et l’acajou.

Les vis à pas grossier sont

préférables pour les bois mous tels

que le pin, le cèdre, le sapin, l’épinette,

le tilleul d’Amérique, le contre-plaqué,

la mélamine et les panneaux de fi bres

à densité moyenne.

Nos vis les plus populaires

LONGUEUR

DE LA VIS

Mesurez du

dessous de la

tête à la pointe

de la vis.

* Vis résistantes aux intempéries

Certaines de nos vis cachées sont offertes

avec un revêtement résistant aux intempéries. Ce revêtement procure une protection

contre les éléments ce qui signifi e que vous

pouvez les utiliser à l’extérieur. V ous trouverez les détails sur notre site Web.

*Consultez notre site Web pour voir le guide complet de sélection des vis.

SML-C125

Tête à embase;

N° 8, pas grossier,

longueur de 1 1/4 po.

Notre vis la plus

popu laire, pour les

joints de bois mous

de 3/4 po à 3/4 po

(19 mm à 19 mm).

SML-C150

Tête à embase;

N° 8, pas grossier,

longueur de 1 1/2 po.

Pas grossier, plus longue

pour joindre les bois

mous de 7/8 po à 1 1/8 po

(22 mm à 28 mm)

d’épaisseur.

SML-C250

Tête à embase;

N° 8, pas grossier,

longueur de 2 1/2 po.

La vis parfaite pour

joindre des 2 x 4.

www.kregtool.com

SML-F125

Tête à embase;

N° 7, pas fi n, longueur

de 1 1/4 po.

Notre seconde vis

en popularité, parfaite

pour les joints de bois

durs de 3/4 po à 3/4 po

(19 mm à 19 mm).

SML-F150

Tête à embase;

N° 7, pas fi n, longueur

de 1 1/2 po.

Pas fi n, plus longue pour

joindre les bois durs

de 7/8 po à 1 1/8 po

(22 mm à 28 mm)

d’épaisseur.

SPS-C1

Tête ronde;

N° 8, pas grossier,

longueur de 1 po.

C’est la vis servant

à joindre des pièces

de bois mou de 1⁄2 po

à 1⁄2 po (13 mm

à 13 mm) car la tête

s’assoie un peu sous

le niveau.

4-

Pince serre-joint Premium, art. n° PFC

La pince serre-joint Premium est un accessoire

utile pour votre guide Kreg Jig

pour s’enclencher dans l’adaptateur de serre-joint.

Vous pouvez également l’utiliser sans le guide

Kreg Jig

vous posez les vis cachées. Cette pince permet

d’accélérer grandement le processus de percer

plusieurs trous cachés. Vous apprécierez son

mécanisme à dégagement rapide et sa poignée

verrouillable réglable.

®

pour tenir les pièces de niveau lorsque

®

. Elle est conçue

Pince à angle droit, art. n° RAC

Lorsque vous joignez deux pièces à angle droit,

le serrage pendant que vous posez les vis peut

être diffi cile. C’est pourquoi nous avons conçu

cette pince à angle droit. Elle est munie d’une

pointe qui s’insère parfaitement dans le trou

caché que vous avez percé. Sa longue portée

et son mécanisme à action rapide en font

un accessoire indispensable.

Accessoires

32

Francais

Pince d’établi, art. n° KBK

Lorsque vous découvrirez tous les usages

que vous pouvez faire de la menuiserie à vis

cachées à la maison, vous apprécierez l’utilité

de notre pince d’établi. Une plaque d’aluminium

spécialement sertie dans votre établi en fera

une station de serrage parfaite pour percer des

trous cachés et joindre les pièces. La pince

possède un pied spécial qui se verrouille dans

la plaque de montage. La pince est dotée

du même mécanisme à action rapide réglable

que nos autres pinces.

Bouchons de trous cachés

Les joints à vis cachées sont généralement

dissimulés, mais parfois ils peuvent se trouver

dans un endroit visible et vous aimeriez les

dissimuler également. C’est pourquoi nous avons

conçu divers bouchons de trous de vis en bois

massif et des bouchons de plastique pour les

surfaces laminées telles que la mélamine pour

dissimuler les trous. Vous pouvez également

intégrer vos trous de vis cachées à l’apparence

générale de votre création en utilisant des

bouchons contrastants.

www.kregtool.com

33

Idées de menuiserie à vis cachées

4-

Obtenez des résultats professionnels

et des joints résistants en utilisant des

vis cachées pour construire des armoires

et des bibliothèques. (Montré à l’envers)

Francais

Construisez rapidement et facilement

vos propres armoires de cuisine

de style européen.

Construisez de robustes armoires

et rangements traditionnels à façade.

Construisez des cadres à onglets simples

et rapide avec des vis cachées.

Ajoutez une bordure décorative à des

tablettes ou des comptoirs pour une

apparence personnalisée.

(Montré à l’envers)

www.kregtool.com

Construisez des terrasses plus robustes

avec des vis invisibles.

4-

Idées de menuiserie à vis cachées

34

Ajoutez une jupe à une table ou un coup

de pied à une armoire comme

un professionnel.

Obtenez des joints serrés à n’importe quel

angle pour des armoires, des tablettes

ou des bibliothèques.

Éliminez les grincements des vieux

escaliers ou construisez en de nouveaux

qui seront solides grâces aux vis cachées.

Francais

Découvrez des possibilités créatives grâce

à l’utilisation des joints à vis cachées.

La construction traditionnelle de table

est simplifi ée grâce à la menuiserie à vis

à trous cachés.

www.kregtool.com

Les assemblages courbés sont possibles

et sans problèmes avec des vis cachées.

35

Information de contact

Faites-nous part de vos commentaires !

N’hésitez pas à communiquer avec nous si vous avez des questions, des

commentaires ou des suggestions de produits. Faites-nous parvenir un courriel

au customerservice@kregtool.com ou écrivez-nous à :

Kreg Tool Company

201 Campus Drive

Huxley, IA 50124

Sans frais : 800-447-8638

Local : 515-597-2234

(Télécopie) 515-597-2354

Site Web : www.kregtool.com

courriel : customerservice@kregtool.com

Francais

4-

www.kregtool.com

Nouvelles et essais

Témoignages

Outils de menuiserie à vis cachées

Machines à vis cachées

Systèmes de mesure de précision

Accessoires Kreg

RENDEZ-NOUS

VISITE DÈS

AUJOURD’HUI

Applications de la menuiserie à vis cachées

FAQ

Guides d’utilisation

Localisateur de dépositaires

Calendrier des expositions

Demande de catalogue

www.kregtool.com

Loading...

Loading...