Operating instructions

and spare parts list

- keep for future use -

Airless Spray Gun

Typ: KS-1 Art. no.: 071. -00001

KS-1D Art. no.: 20.. -00001

KS-1L Art. no.: 071. -00001

KS-1M Art. no.: 079. -000

KS-2 Art. no.: 07.. -000

2

Contents

Hazard and warning notes Page 3

1. Use for intended purpose 6

2. Basic design, functional principle 7

3. Startup 8

3.1 Preparations

3.2 Function test and startup

4. Operational interruptions, work breaks 9

5. Finishing work 10

6. Operating faults, spray profile errors 10

7. Replacing parts 11

8. Cleaning, maintenance 12

9. Disposal 13

10. Technical data 13

Declaration of Conformity 13

Spare parts for KS-1/KS-1L/KS-2 17/18

Spare parts for KS-1M 19/20

Spare parts for KS-1D 21/22

Accessories 24

3

Hazard and warning notes!

Only start up the spray gun type: KS after carefully reading the operating instructions

in full!

Prevent unauthorised persons, in particular children and youths, from gaining access

to the hazard zone!

Always store the spray gun well out of the reach of children! In particular during work

breaks and when processing hazardous substances, take measures to prevent

misuse by children and youths as well as other unauthorised persons! Clean

thoroughly before storing and/or transporting!

Take measures to prevent accidental pulling or activation of the trigger (22 or 25 e.g. on the edge of a bench or similar)! During work breaks and after finishing work,

immediately fold the safety latch (29) forward (lock) and make sure that the trigger is

blocked and that no material can escape by pulling the trigger (22 or 25). During

work breaks, hang the spray gun on the bracket (B) out of the reach of children!

Above 4 MPa (40 bar), there is a noticeably greater kickback with increasing material

pressure!

Connection of the material feed may only be performed by suitably qualified

personnel! Only use tubes and tube connections which can withhold the pressures

and any other occurring loads!

Prior to each repeat startup (e.g. after work breaks), monitor the spray gun for seal

tightness (no uncontrolled material, no porous or old hoses!). Check connections,

pressure hoses and wearing parts and replace if necessary! Check for material

fatigue at regular intervals! Ensure that hose lines cannot fly around if they are

accidentally disconnected. Route hose lines in such a way that they cannot become

stuck or driven over.

Always wear the protective equipment (e.g. protective clothing, goggles, breathing

protection, gloves etc.) recommended by the supplier of the coating substance

during maintenance, cleaning or repair work and when changing materials! Wear ear

mufflers if necessary, in particular during continuous operation, when using large

nozzles, and when working at high material pressures!

Ensure that no parts of the body (in particular fingers) can come between the trigger

(22 or 25) and handle of the main element (12)! Risk of crushing.

Comply with the explosion protection regulations when using potentially flammable

and explosive coating substances! Keep away from sources of ignition and open

flames!

Comply with the warning and hazard instructions of the supplier of the coating

material and the detergent with regard to emission, fire or explosion hazard or other

hazards (where applicable)! In case of doubt, consult the supplier(s) of the

components in question!

When mixing different components and/or when using solvents or thinning agents to

make coating materials, take steps to ensure that no substances with increased

hazard potential are created (e.g. flammability, explosion hazard, increased

explosive tendency through spraying in air, toxicity, increased toxicity due to

chemical reaction with air etc.)! Avoid increased hazard potential caused by

undesired chemical reactions! In case of doubt, consult the supplier(s) of the

4

components in question! Where necessary, take protective measures and effect

special notification of the particular hazard(s)!

When using substances such as solvents which can generate an increased

explosion potential due to atomisation or spraying in air, take protective measures

and effect special notification of the particular hazard! In case of doubt, consult the

supplier of the components!

The compatibility of the parts of the spray gun which come into contact with the

material cannot be guaranteed with all potential coating substances (see chart "Parts

in contact with the material" in Section 10, Technical Data). In case of doubt, consult

Krautzberger GmbH!

(!)

Under no circumstances should the spray jet be directed at people or animals!

The jet can penetrate the skin, enter the body and force air into the organism. Risk of

fatal embolism!

The material jet is particularly dangerous if no airless nozzle is mounted and

the jet is discharged directly from the valve seat screw!

There is also the risk of poisoning when using poisonous coating substances or

detergents!

Preventive measures: set up an emergency first aid unit in the plant (e.g. first aid

training of suitable employees).

What do to in the case of an accident:

Immediate measures: correct treatment of wounds.

Further measures: immediate treatment by an emergency service doctor who has

been informed of the substance used.

Do not stand in the area of the material jet!

Never direct the spray jet at electrical systems or equipment!

Do not spray workpieces or surfaces which are insufficiently stable! The high-

powered spray jet is powerful enough to cause parts of the workpiece or surface to

fly around in the working zone.

During spraying and due to rebound off the workpiece, coating material is discharged

into the surrounding atmosphere. Depending on the coating material used, this can

result in environmental hazards, fire and explosion risk, and health hazards. For this

reason, only use spraying equipment in specially designated areas!

Only work in adequately ventilated areas! If necessary, use suitable extraction

systems!

Ensure adequate earthing (e.g. connection to building earth)!

Radiators or water pipes do not provide sufficient earth contact!

During lengthy breaks in operation or when shutting down the equipment as well as

prior to dismantling or the start of repair and maintenance work, close the shutoff

valve at the material source and press the trigger (22 or 25) until the material

pressure has fully dissipated!

5

During every - even a very brief - break in operation, push the safety lever (29)

forward and check to make sure that the trigger is blocked.

Adhere to the pressures and temperatures listed under "Technical Data"!

If high temperatures are exceeded for a certain period (e.g. > 8 hours at > 43°C, > 10

mins. at > 48°C, or > 1 min. at > 51°C, attach suit able protective devices and post

notification concerning the risk of combustion due to coating substance, and draw

particular attention to risks resulting from leakage or bursting of the spray gun and

the hoses and/or hose connections! If necessary, wear suitable protective clothing

(e.g. goggles, gloves etc.).

In the event of unforeseen occurrences, release the trigger (22 or 25) to interrupt the

material flow! Then immediately push the safety catch (29) to block the trigger. Close

the shutoff valve on the pump.

In the event of unforeseen material discharge (e.g. due to loosening of a material

hose connection or bursting of the material hose), close the shutoff valve at the

material source as quickly as possible! It is advisable to mount the shutoff valve

within reach of the operator of the spray gun to ensure that the unforeseen discharge

of material can be stopped quickly - particularly when using hazardous substances.

Ensure that neither spraying nor material discharge can be activated accidentally or

by defects in the unit as long as one or more persons are in the hazard zone. Take

steps to ensure that no alterations can occur or be made to the material pressure

during setting and maintenance work without the knowledge or consent of the setup

technician!

Ensure adequate illumination of the operating zone!

When using flammable and/or potentially explosive materials, ensure that a fire can

be rapidly extinguished!

Only use spare parts and accessories from Krautzberger GmbH! Krautzberger

GmbH assumes no liability for damage if any external parts are used.

The instructions and notes of EN 1953 "Spraying Equipment for Coating Substances;

Safety Requirements" are to be adhered to, in particular the warning, hazard and

safety notes pertaining to risks and safety requirements and/or measures.

Hazards which exceed those normally expected with the use of spraying equipment

have not come to our attention in the handling of the spray gun type KS or versions

KS-1, KS-1D, KS-1L, KS-1M or KS-2. If, however, accidents or hazardous situations

occur during practical applications, please notify us accordingly.

6

1. Use for intended purpose

The airless spray gun type KS is designed to allow coating of metal, plastic,

ceramics, wood and similar materials as well as other suitable surfaces. Typical

coating substances are, for example, lacquers, paints, water-soluble lacquer

systems, adhesives, oil, release agents etc. It is also suitable for the application of

abrasive materials at operating pressures below 5 MPa (50 bar).

The coating substance to be used is applied to the surface by moving the spray gun

by hand over the surface to be coated and pressing the trigger at the desired point.

The coating substance is fed to the spray gun in liquid form under high material

pressure.

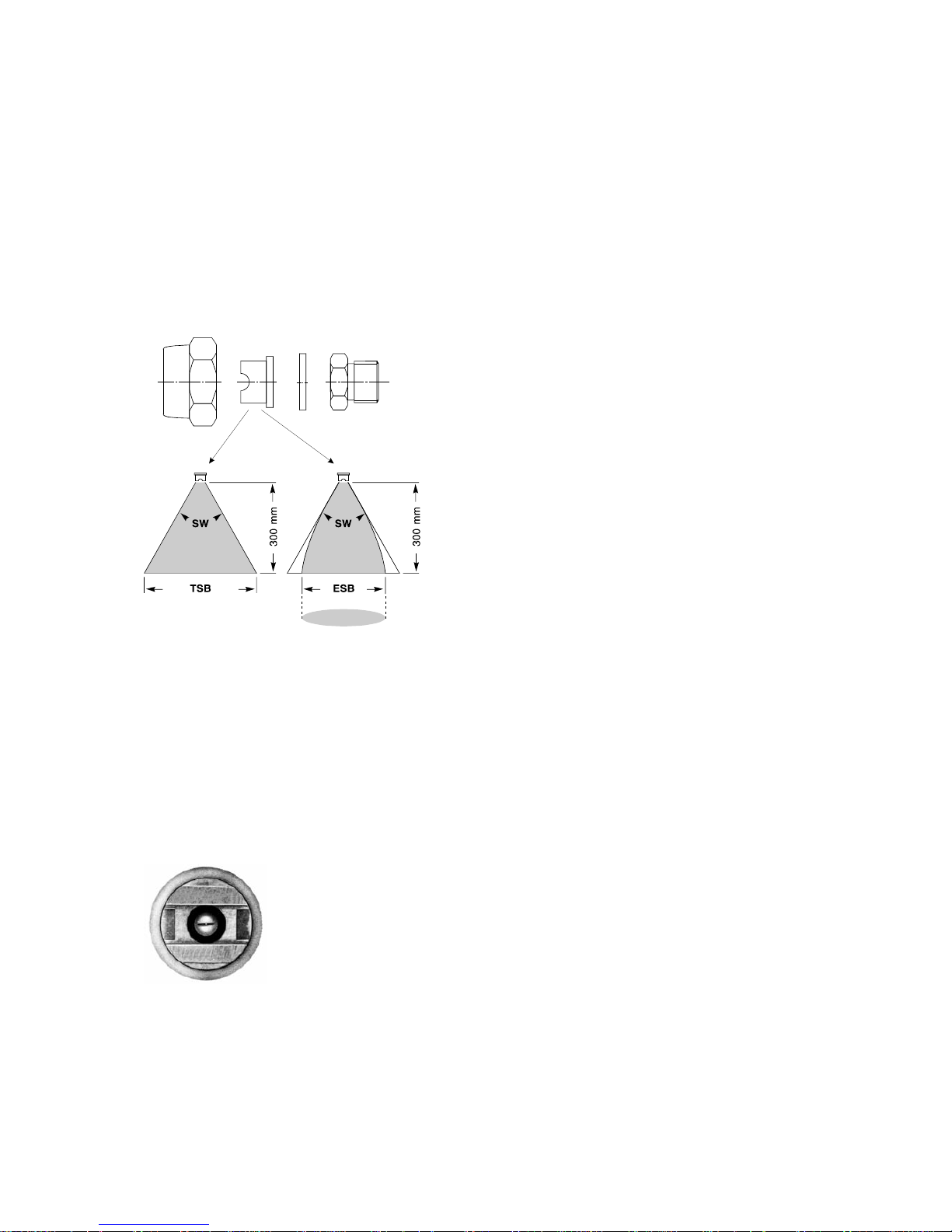

SW = spray angle

TSB = theoretical spraying width

ESB = actual spraying width

The spray gun works on the airless

principle - in other words, the spray jet is

generated exclusively by the material

pressure pressing the material through a

nozzle. After being discharged from the

nozzle, the spray jet takes on the shape

dictated by the nozzle. It is then directed

at the workpiece. The effective spray jet is

not quite as wide as theoretically possible.

The particles of the spray jet reach far

higher speeds than with pneumatically

operated spray guns. The material

throughput is correspondingly higher and

the jet more concentrated (in other words,

the "swirling zone" is smaller). The size

and shape of the jet can only be changed

by changing the nozzle. The diameter of

the nozzle borehole determines the

material flow volume. The size and

geometry of the constantly elliptically

shaped nozzle opening determine the

height and width of the jet (shape of an

elliptical cone).

A wide range of airless nozzles are available and can be obtained from Krautzberger

GmbH.

The nozzle can be rotated steplessly by

360° in the axis of the spray jet and

secured in any position. This allows

optimum adjustment of the angle at which

the jet hits the workpiece to the respective

condition.

The spray gun is particularly suitable for use when relatively large material volumes per

time unit are to be processed. A further advantage compared to pneumatically operated

spray guns is that less spraying mist is created and a far higher percentage of the

material therefore reaches the workpiece. Circulation connection is also possible.

7

(i) Note

The coating substances approved by the manufacturer of the coating substance for

spraying may be used; however, Krautzberger GmbH offers special designs for

o substances dissolved in CFC-containing solvents

o abrasive or

o corrosive materials.

2. Basic design, mode of operation

The design of the airless spray gun type KS as well as typical equipment features and

accessories are shown is the diagrams 140-0059, 140-0060, 140-0128 and 140-0064. A

pump supplies the material at a pressure of max. 35 MPa (350 bar) for the versions KS1, KS-1L, KS-1M and KS-2 or max. 25 MPa (250 bar) for the version KS-1D and KS-2D

(400bar for the KS-1D with stainless-steel head section) through a sufficiently pressureresistant hose to the material connection (27). Pulling the trigger (22 or 25) towards the

handle of the main element (12) pushes the valve needle (16) or the needle

reinforcement backwards against the pull-back pressure of the valve spring (19). The

sealing ball of the valve needle or needle reinforcement lifts from the valve seat of the

valve seat screw (4), thus releasing the material flow to the material nozzle (102), from

which the material is sprayed in the form of an elliptical cone jet. The volume of material

discharged depends solely on the nozzle size and the material pressure.

(!) Warning note!

In the risk or the event of an accident, the spray jet can be shut down quickly by

releasing the trigger (22 or 25).

The airless spray gun type KS is supplied in aluminium as standard; the parts coming

into contact with the material are available in stainless steel on request.

Order/Article nos. for the airless spray gun type KS

Material connection

Version

rigid swivel rigid swivel

(without material nozzle)

short trigger (22) long trigger (25)

Article no.

KS-1 (standard version) 0710-090-0522 0712-090-1128

KS-1D (processing of thick substances) 2007-090-2671 2013-090-1036

KS-1L (long trigger) 0711-090-0526 0713-090-0874

KS-

1M

(material pipe to handle) 0798-090-0531

0799-090-0535

KS-2 (circulation connection) 0718-090-.... 0720-090-.... 0719-090-.... 0721-090-....

(i) Notes

The version KS-1D is equipped with material ducts with enlarged cross-section. Highly

viscous materials can be processed using appropriate material nozzles. During lengthy

use, fatigue is alleviated by the favourable power transmission (version KS-1L) or the

shift in the centre of gravity towards the handle ((i.e. towards the back) in the version KS1M).

8

In the version KS-2, the coating substance can be circulated through the head section.

Circulation connection is recommended, for example, when using coating substances

which have a tendency to settle or materials whose temperature has to be kept constant.

A swivel-type material connection facilitates handling of the spray gun, as the

hose/hoses do not have to be turned when the user turns the gun.

3. Startup

3.1 Preparations

> Push the safety catch (29) forward and make sure that the trigger (22 or 25) can

no longer be activated.

> If necessary, install a suitable spring (19) for 25MPa

> Install the material nozzle (102)

> Earth the spray gun

> Connect the pressure hose to the material connection (27) - or, in the case of

circulation connection, connect both pressure hoses to the material connections (27)

> Prepare the coating substance and the accessories for material feed

> Switch on the material pump

> Set the material pressure on the regulator or on the material pump or in the return

section of the circulation line

> Open the shutoff valve at the material source

No material should be discharged at any point.

(!) Caution!

The material feed should only be connected up by suitably trained personnel! Ensure

that the pressures and temperatures listed under "Technical Data" are not exceeded!

Installation or replacement of the nozzles, springs etc. must be performed by suitably

trained personnel!

3.2 Function test and startup

> Push the safety catch (29) upwards (unlock)

> Point the nozzle of the spray gun at a test surface

> Start the spraying process by pressing the trigger (22 or 25)

> Assess spray profile and, if necessary,

> after securing the gun using the safety catch (push forwards),

> change the nozzle (see Krautzberger GmbH order catalogue for available airless

nozzles)

> If necessary, loosen the nozzle nut (1) again

> Turn the material nozzle (102) in the desired direction (it can be rotated by 360°)

> Tighten the nozzle nut (1)

> Push the safety catch (29) upwards (unlock)

> Guide the spray jet across the workpiece using even movements

> Terminate spraying by releasing the trigger (22 or 25)

(i) Notes

Only use accessories from Krautzberger GmbH!

Only use sufficiently sturdy hoses! Check (and, if necessary, replace) older hoses before

starting up the spray gun.

9

Only use hoses which fit in the hose connections; ensure correct fit and seal-tightness!

It is advisable to rinse the spray gun through using a suitable detergent prior to first

startup (effect spraying using detergent until it is discharged clear).

To ensure that particles do not block the nozzle, it is advisable to clean the coating

substance through a material filter in front of the material connection (27). High-pressure

material filters are available from Krautzberger GmbH.

In order to achieve uniform layer thickness and spray profile when using high-grade

coatings, it is advisable to apply the substance in cross-wise fashion; in other words, first

coat the surface in horizontal lines and then in vertical lines (or vice-versa).

Material feed is effected via a pump. A circulation connection is recommended, for

example, when using settling coating substances or for materials whose temperature has

to kept constant.

In airless units (unlike pneumatic spray guns), it is generally not possible to change the

spray profile by adjusting the nozzle. If a different spray profile is desired, you must

change the airless nozzle. The spray angle can be altered by using adjustable material

nozzles.

The spray profile depends on, among other factors, the viscosity of the coating

substance and can be altered via the material pressure. If changing the material

pressure does not create an optimum spray profile, it is advisable to repeat the trial using

a different material nozzle.

(!) Danger

When changing the airless nozzles, it is essential that you not only push the safety

catch (29) forwards and check that the lever is blocked on the trigger (22 or 25) but

also that you close the material feed!

Although no material can escape from the valve seat screw (4) when the trigger (22 or

25) is blocked by the safety catch (29), accidental (or other) pressing of the trigger during

nozzle changing can result in danger to life and limb of all persons in the area of the

spray jet. In such an event, the material jet is discharged from the front opening of the

valve seat screw (4) at high speed. The jet can penetrate the skin, enter the body and

force air into the organism. Risk of fatal embolism! There is also the risk of poisoning

when using poisonous coating substances or detergents!

4. Interruptions to operation, work breaks

During operational downtimes - e.g. work breaks:

> Close the shutoff valve at the material source

> Switch off the pump (where applicable)

> Push the safety catch (29) forwards (lock)

10

> Pull the trigger (22 or 25) to check that the safety catch (29) blocks the trigger and

no material can be discharged

> Hang the spray gun on a hook (using the bracket (B)) or some other suitably

robust fastening device

In all cases, close off the material feed, and ensure that unauthorised persons - in

particular children and youths - cannot gain access to the spray gun.

5. Finishing work

Releasing the trigger (22 or 25) ends the spraying process. If work is not to be continued,

proceed as follows:

> Close the shutoff valve at the material source

> If necessary, switch off the pump

> Clean the spray gun by filling a suitable detergent (e.g. one recommended or

prescribed by the supplier of the coating substance) into the/a material container

and opening the shutoff valve to convey it through the pump, the material

hose/hoses and the spray gun until it is discharged clear.

> Push the safety catch (29) forwards (lock)

> Close the shutoff valve on the pump

> Switch off the material pump

> Use suitable means to clean parts on which material is still present

> Store the spray gun in a place inaccessible to unauthorised persons (in particular

children and youths). If necessary, unscrew the material hose/hoses, clean any

parts which have not been cleaned, disconnect the earth, and lock the spray gun

away.

(i) Notes

Ensure that no residues of toxic, flammable or explosive material or detergent remain in

the spray gun (avoidance of hazard during storage or transport).

Dispose of any surplus coating substance (e.g. residual amounts) which is not to be

poured back into the storage container in line with the instructions of the producer of the

coating substance. If necessary, effect disposal in a special waste site.

For cleaning of the spray gun and all accessories such as hoses, filters etc. which come

into contact with the material:

o use the detergent recommended or prescribed by the producer of the coating

substance and

o then dispose of the detergent in line with the instructions of the producer of the

coating substance or those of the supplier of the detergent. If necessary, effect

disposal in a special waste site.

6. Operating malfunctions, spray profile defects

If the spray profile is unsatisfactory, check whether the material nozzle is contaminated.

If necessary, insert, clean or replace the material filter.

11

7. Changing parts

Valve needle (KS-1, KS-1L, KS-1M and KS-2)

> Unscrew the valve sealing screw (20)

> Remove the spring (19)

> Unscrew the nozzle nut (1)

> Unscrew the valve seat screw (4)

> Push the valve needle, cmpl. (15) out towards the back using a suitably shaped

(but not sharp-edged) object made (for example) of wood or plastic.

The back end of the valve needle, cmpl. (15) is pushed from the back section of

the main element (12).

> Completely pull out the valve needle, cmpl. (15)

> Unscrew the valve needle (16) from the needle bolt (18)

> Screw the needle pusher (17) onto the new valve needle (16)

> Exactly set the length (70 mm +0.2)

> Screw the needle bolt (18) onto the valve needle (16) and

> counter against the needle pusher (17)

Needle reinforcement (KS-1D)

> Unscrew the nozzle nut (1)

> Unscrew the valve seat screw (4)

> Loosen and unscrew the needle reinforcement (50) from the lock nut (51)

If only the needle reinforcement (50) is to be replaced:

> Screw on the new needle reinforcement (50)

> Set a dimension of 24.5 mm using a calliper gauge and

> counter using the lock nut (51)

If parts (17, 18, 19 and 52) are also to be replaced:

> Remove the needle reinforcement (50) and lock nut (51), then

> unscrew the sealing screw (20)

> Remove the spring (19)

> Push parts (17, 18 and 52) out towards the back using a suitably shaped (but not

sharp-edged) object made (for example) of wood or plastic

The back end of the needle bolt (18) is pushed from the back section of the main

element (12).

> Completely pull out parts (17, 18 and 52). These parts are generally not

dismantled any further

Needle packing (KS-1, KS-1D, KS-1L and KS-2)

After removing the valve needle, cmpl. (15) - or, in the case of KS-1D - the parts (17 to

19 and 50 to 52):

> Loosen the hex nut (14) and remove,

> together with the insulation washer (13)

> Pull the head section (6) towards the front and out of the main element (12)

> Pull the insulating sleeve (11) and the insulating washer (9) off the seal screw (10)

> Unscrew the seal screw (10) from the head section (6)

> Remove the packing parts, each consisting of two gaskets (7) and two cup collars

(8). (Use a wire hook to pull out the packing parts. Take care not to damage any

threads!)

Then thoroughly clean all reusable parts.

Assembly:

> Install new packing parts, each consisting of two gaskets (7) and two cup collars

(8), in the described sequence and direction; do not damage the sealing lips! Do

not use pointed or sharp-edged objects during installation!

> Loosely screw the seal screw (10) into the head section (6)

> Push the insulating sleeve (11) and the insulating washer (9) over the seal screw

(10)

12

> Push the head section (6) with seal screw (10), insulating sleeve (11) and

insulating washer (9) into the borehole of the main element (12)

> Push the insulating washer (13) over the seal screw (10)

> Screw the head section (6) to the seal screw (10) using the hex nut (14), but do

not tighten!

> Insert the valve needle, cmpl. (15) into the main element from the back and push

forwards up to the stop (for KS-1D, see replacement of needle reinforcement)

> Push the spring (19) over the needle bolt (18) into the main element (12)

> Tighten the valve sealing screw (20)

> Only then should you tighten the seal screw (10) until there is noticeable

resistance and

> counter by tightening the hex nut (14)

Procedure for replacing the needle packing of the spray gun type KS-1M:

> First loosen the two union nuts (41)

> Then pull the material pipe (42) from the connecting nipples (after bending it

slightly)

Then proceed as for needle packing replacement in the other KS types.

Valve seat screw and material nozzle

> Unscrew the nozzle nut (1)

> Remove the material nozzle (102) and the gasket (3)

> Unscrew the valve seat screw, cmpl. (4) together with gasket (5)

> Pull the gasket (5) from the valve seat screw, cmpl. (4)

Assembly, unless already described otherwise, is performed in the reverse order. Lightly

lubricate the moving parts using a suitable grease, e.g. article no. 7026-500 from

Krautzberger GmbH (supplied in 250 g cans). Clean soiled parts, and replace parts

which no longer function properly. Ensure correct seat of gaskets!

(i) Notes

Always change the valve needle (16) (or in the KS-1D the needle reinforcement (50))

and the valve seat screw (4) together!

Following assembly of the parts (16) to (18), the valve needle (16) should project exactly

70 mm (or as close as possible) from the needle pusher (17). An overlength of up to 0.2

mm is admissible; short lengths result in inadequate valve seat.

Occasionally check the moving parts for free range of motion and lubricate with grease if

necessary!

8. Cleaning, maintenance, material change

Wearing parts such as material nozzle (102), valve seat screw (4) and valve needle (16)

or needle reinforcement (50), gaskets (3, 5, 7 and 26) and cup collars (8) as well as

springs (19) should be checked at appropriate intervals and replaced if necessary (e.g. if

the valve needle or needle reinforcement does not close sufficiently or if there is

uncontrolled discharge of coating substance).

(!) Danger

During maintenance and repair work and when changing the nozzle, first close the

shutoff valve at the material source and then press the trigger (22 or 25) until the spray

gun is without pressure. Always wait until the pressure has dissipated!. Then push

the safety catch (29) forwards (lock) and check that the safety catch (29) blocks the

13

trigger and that no more material can be discharged by pressing the trigger (22 or 25).

See hazard and warning notes!

(i) Notes

The spray gun is never to be dismantled into its individual parts except when this is

necessary for repair or maintenance purposes. When cleaning and during material

change, the gun should be rinsed through thoroughly using a detergent recommended or

prescribed by the supplier of the coating substance until it is discharged clear.

The spray gun should never be completely immersed in detergent! This could destroy the

gaskets and rinse out the lubricant.

During lengthy breaks in operation, the spray gun should be rinsed through with

detergent, left to dry, and stored in a suitable place until it is to be used again.

Do not clean material nozzles and valve seat screw using hard, sharp-edged objects!

(For cleaning of the nozzles, we recommend the flat brush, article no. 7025-015, or

nozzle cleaning needles (see list of accessories, no. 140-0064) from Krautzberger

GmbH.)

A cloth soaked in detergent is recommended for external cleaning.

9. Disposal

Following dismantling of the spray gun type KS, the metal parts can be sorted and

forwarded to a recycling process; the non-metal parts should be disposed of as special

waste.

10. Technical data

Operating pressures / Operating temperature

Max. material pressure

(KS-1, KS-1L, KS-1M and KS-2): 35 MPa (350 bar)

Max. material pressure (KS-1D, KS-2D): 25 MPa (250 bar)

Max. material pressure (KS-1D st.st. head section): 40 MPa (400 bar)

Max. material temperature: 50°C

Connections

Material connection: G1/4 IG

Weight (without add-on parts)

KS-1, KS-1L, KS-1D and KS-2: approx. 470 g

KS-1M: approx. 580 g

Material spray zone

Angle of material jet in front of nozzle: up to approx. 110° depending on nozzle

Length of material jet in front of nozzle: up to 5 metres depending on nozzle and

material pressure

Length of material jet with removed

nozzle: up to 20 metres

Noise emission

Continuous sound pressure level: nozzle-dependent, 60 to 90 dB(A)

Load due to vibrations

14

Acceleration: < 2.5 metres/sec.2

Available airless nozzles:

A wide range of airless nozzles are available from Krautzberger GmbH, and we will be

happy to send you more detailed information on request. The order catalogue contains

an overview of the available nozzles. The nozzles differ in their equivalent diameter and

spraying angle.

Graduations of equivalent diameters [mm]: 0.13, 0.18, 0.23, 0.28, 0.33, 0.38, 0.41, 0.46,

0.51, 0.53, 0.61, 0.66, 0.74, 0.79, 0.91, 1.04, 1.10, 1.22, 1.32, 1.57, 1.83 and 2.16

Possible graduations of spraying angle [°]: 5, 10, 15, 25, 35, 40, 50, 60, 65, 73, 80, 95

and 110

The description "equivalent diameters" comprises dimensions for circular boreholes

which correspond to the elliptical openings of the nozzles with regard to throughput

volume. Throughput volumes in output tables expressed in l/min. at 7 MPa (70 bar) refer

to water. These figures vary with materials of different density and/or viscosity. The

effective spraying width (which depends on the spraying angle) is measured using water

at a pressure of 10 MPa (100 bar) at a distance of 30 cm from the workpiece.

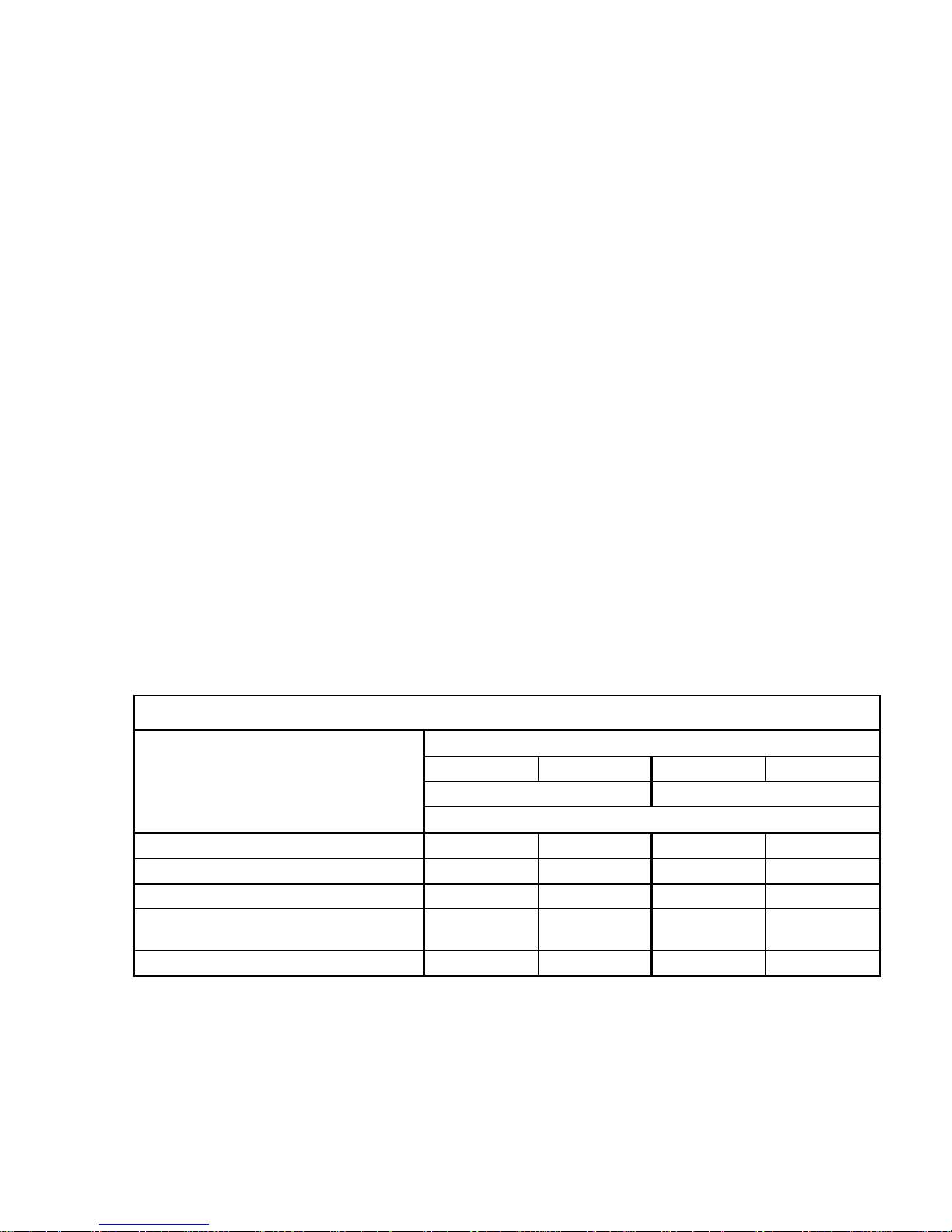

Parts in contact with the material

Part

Standard version Version on request

designation

Material Art. no Material Art. no.

Nozzle nut stainless steel 0700-040-1844

Material nozzle

tungsten carbide

(TC)

0700-050-....

Gasket

polyoxymethylene

(POM)

0700-010-0048

Valve seat screw

stainless steel + TC

0706-080-0015 stainless steel 0707-080-0016

Valve needle stainless steel + TC 0706-070-0777 stainless steel 0707-070-2300

Needle reinforcem. stainless steel + TC 2007-080-0031

Gasket Viton 0700-010-0049

Head section aluminium 0706-080-0514 stainless steel 0765-080-0515

Head section for

circulation

aluminium 0714-080-0687 stainless steel 0773-080-....

Gasket NBR 0700-010-0056

Material connection,

rigid

stainless steel 0700-040-1653

Material connection,

swivel

stainless steel 0700-090-0555

Special equipment

o Nozzle nut, long

The long nozzle nut (101) protects the material nozzle against damage.

o Fine-spray nozzle

The fine-spray nozzle (103) generates a particularly fine spray jet.

15

o Pre-atomiser nozzle

The pre-atomiser nozzle (104) accelerates the material flow and helps to improve the

spray profile. This means that the operator can work using (in some cases) considerably

reduced material pressure and/or larger material nozzle. A large material nozzle - and an

accordingly slower material flow speed - reduces the risk of blockage. The pre-atomiser

nozzle should be chosen to suit the size of material nozzle (see table of airless nozzles in

the Krautzberger GmbH order catalogue). The pre-atomiser nozzle (104) is mounted

directly behind the material nozzle (102) instead of the gasket (3).

o Adjustable material nozzle

The adjustable material nozzle (105) allows adjustment of the spray angle.

o Nozzle reversal switch

The nozzle reversal switch (107) can be used to rapidly remove a nozzle blockage. The

nozzle is turned in the retainer by 180° and the ma terial feed briefly opened until the

blockage has been flushed away.

o Material filter

A material filter can be installed in front of the material connection (27) to prevent

blockage. This is particularly advisable when using small airless nozzles. The filter

screen size should be chosen to suit the nozzle size (see table of airless nozzles in the

Krautzberger GmbH order catalogue).

o Nozzle extensions

Nozzle extensions are particularly suitable for the coating of cavities such as pipes,

canisters, cans or other containers. In many cases it is possible to adapt the length and

shape of the nozzle extension to the special requirements on the customer's premises.

Ready-made nozzle extensions are also available (see Krautzberger GmbH order

catalogue).

(!) Caution

When working with a nozzle extension, note that explosive mixtures can be created

extremely easily due to the interaction of flammable materials and air in cavities! Ensure

adequate ventilation!

16

Declaration of conformity

under the terms of the EC Directive 89/392 EEC and the amendment directives

91/368/EEC and 93/44/EEC

Krautzberger GmbH, Stockbornstrasse 13, D-65343 Eltville

Design of unit: Airless spray gun

Type designation: KS

Versions: KS-1, KS-1D, KS-1L, KS-1M and KS-2

Make: Krautzberger GmbH

Serial nos.: 0700-000 and 2000-000

The spray gun type KS and the versions KS-1, KS-1D, KS-1L, KS-1M and KS-2 were

developed, designed and produced in compliance with the EC Directive 89/392/EEC.

The following harmonised standards were applied:

o EN 292, Safety of Machines, Plant and Equipment

o EN 1953, Spraying Equipment for Coating Substances, Safety Requirements

(German version prEN 1953: 1995)

The following documents are fully available:

o Overall diagram of the spray gun type KS and the versions KS-1, KS-1D, KS-1L,

KS-1M and KS-2

o Detailed and complete diagrams for the checking of compliance of the spray gun

type KS and the versions KS-1, KS-1D, KS-1L, KS-1M and KS-2 with the basic safety

and health safety requirements

o A list of the basic requirements from EC Directives, standards and specifications

applied during the development, design and production of the spray gun type KS and the

versions KS-1, KS-1D, KS-1L, KS-1M and KS-2

o A description of the solutions to prevent hazards arising from use of the spray gun

type KS and the versions KS-1, KS-1D, KS-1L, KS-1M and KS-2

o A copy of the operating instructions

Head of design at Krautzberger GmbH

17

Spare parts list for the airless spray gun, type KS-1/KS-1L/KS-2

Item Article no. Designation

1 0700-040-1844 Nozzle nut

* 3 0700-010-0048 Gasket

4 0706-080-0015 Valve seat screw, cmpl., tungsten carbide (standard)

4 0707-080-0016 Valve seat screw, cmpl., stainless steel

* 5 0700-010-0049 Gasket

6 0706-080-0514 Head section, cmpl., aluminium

6 0765-080-0515 Head section, cmpl., stainless steel

6 0714-080-0687 Head section, cmpl., aluminium, for circulation

6 0773-080-... Head section, cmpl., stainless steel, for circulation

* 7 0700-010-0043 Gasket (2 pcs)

* 8 0700-010-0044 Cup collar (2 pcs)

9 0700-010-0052 Insulating washer

10 0700-040-1648 Seal screw

11 0700-010-0050 Insulating sleeve

12 0710-080-0591 Main element with handle piece

12 0711-080-0592 Main element without handle piece

13 0700-010-0051 Insulating washer

14 0700-040-0808 Hex nut

15 0706-070-0852 Valve needle, cmpl., tungsten carbide (standard)

15 0706-070-2301 Valve needle, cmpl., stainless steel

16 0706-070-0777 Valve needle, tungsten carbide (standard)

16 0707-070-2300 Valve needle, stainless steel

17 0700-070-0727 Needle pusher

18 0700-040-0089 Needle bolt

19 0700-020-0004 Valve spring, for operation up to approx. 250 bar

19 0700-020-0005 Valve spring, for operation up to 350 bar

20 0700-040-1650 Valve sealing screw

21 0706-040-1644 Trigger shaft

22 0706-040-1862 Trigger, short

23 0700-030-1373 Screw

24 0707-040-1676 Trigger shaft

25 0707-040-1662 Trigger, long

*26 0700-010-0056 Gasket (for circ. 2 pcs)

27 0700-090-0555 Material connection, swivel-type, stainless steel

(for circ. 2 pcs)

27 0700-040-1653 Material connection, rigid, brass (for circ. 2 pcs)

27 0706-040-1669 Material connection, rigid, stainless steel (for circ. 2 pcs)

28 0700-040-1645 Washer

29 0700-040-1643 Safety catch

30 0700-040-1646 Spring washer

31 0700-040-1647 Screw

*32 0700-010-0042 Packing, cmpl. (item 7, 8)

0700-010-0632 Gasket set

* Contained in the gasket set.

Please always state article no. and designation when ordering!

18

KS-1/KS-1L/KS-2

19

Spare parts list for the airless spray gun, type KS-1M

Item Article no. Designation

1 0700-040-1844 Nozzle nut

* 3 0700-010-0048 Gasket

4 0706-080-0015 Valve seat screw, cmpl., tungsten carbide (standard)

4 0707-080-0016 Valve seat screw, cmpl., stainless steel

* 5 0700-010-0049 Gasket

6 0706-080-0514 Head section, cmpl., aluminium

6 0765-080-0515 Head section, cmpl., stainless steel

* 7 0700-010-0043 Gasket (2 pcs)

* 8 0700-010-0044 Cup collar (2 pcs)

9 0700-010-0052 Insulating washer

10 0700-040-1648 Seal screw

11 0700-010-0050 Insulating sleeve

12 0798-080-0621 Main element with handle piece

12 0799-080-0608 Main element without handle piece

13 0700-010-0051 Insulating washer

14 0700-040-0808 Hex nut

15 0706-070-0852 Valve needle, cmpl., tungsten carbide (standard)

15 0706-070-2301 Valve needle, cmpl., stainless steel

16 0706-070-0777 Valve needle, tungsten carbide (standard)

16 0707-070-2300 Valve needle, stainless steel

17 0700-070-0727 Needle pusher

18 0700-040-0089 Needle bolt

19 0700-020-0004 Valve spring, for operation up to approx. 250 bar

19 0700-020-0005 Valve spring, for operation up to

350 bar

20 0700-040-1650 Valve sealing screw

21 0706-040-1644 Trigger shaft

22 0706-040-1862 Trigger, short

23 0700-030-1373 Screw

24 0707-040-1676 Trigger shaft

25 0707-040-1662 Trigger, long

* 26 0700-010-0056 Gasket (2 pcs)

27 0700-090-0555 Material connection, swivel-type

28 0700-040-1645 Washer

29 0700-040-1643 Safety catch

30 0700-040-1646 Spring washer

31 0700-040-1647 Screw

* 32 0700-010-0042 Packing, cmpl. (item 7, 8)

40 0796-030-0850 Cutting ring (2 pcs)

41 0796-030-0851 Union nut (2 pcs)

42 0796-040-0254 Material pipe

43 0796-040-0130 Double nipple

0796-010-0632 Gasket set

* Contained in the gasket set.

Please always state article no. and designation when ordering!

20

KS-1M

21

Spare parts list for the airless spray gun, type KS-1D

Item Article no. Designation

1 0700-040-1844 Nozzle nut

* 3 2000-010-0533 Gasket

4 2007-080-0495 Valve seat screw, cmpl., tungsten carbide

* 5 2000-010-0533 Gasket

6 2007-040-9165 Head section aluminium (250bar)

6 2000-080-3126 Head section stainless steel (400bar)

* 7 0700-010-0043 Gasket (2 pcs)

* 8 0700-010-0044 Cup collar (2 pcs)

9 0700-010-0052 Insulating washer

10 0700-040-1648 Seal screw

11 0700-010-0050 Insulating sleeve

12 2007-080-0592 Main element, "Krautzberger"

12 2007-080-0649 Main element, "neutral"

13 0700-010-0051 Insulating washer

14 0700-040-0808 Hex nut

17 0700-070-0727 Needle pusher

18 0700-040-0089 Needle bolt

19 0700-020-0005 Valve spring

20 0700-040-1650 Valve sealing screw

23 0700-030-1373 Screw

24 0707-040-1676 Trigger shaft

25 0707-040-1662 Trigger

* 26 0700-010-0056 Gasket (for circ. 2 pcs)

27 0700-090-0555 Material connection, swivel-type (for circ. 2 pcs)

27 2007-040-1669 Material connection, rigid (for circ. 2 pcs)

28 0700-040-1645 Washer

29 0700-040-1643 Safety catch

30 0700-040-1646 Spring washer

31 0700-040-1647 Screw

* 32 0700-010-0042 Packing, cmpl. (item 7, 8)

50 2007-080-0031 Needle reinforcement, cmpl., tungsten carbide

51 2007-030-2913 Nut

52 2007-070-0640 Threaded needle

2000-010-0661 Gasket set

* Contained in the gasket set.

Please always state article no. and designation when ordering!

22

KS-1D

23

List of accessories for airless spray gun, type KS

Item Article no. Designation

101 0700-040-1846 Nozzle nut, long

*102 0700-050-... Material nozzle

*103 0700-050-... Fine-spray nozzle

*104 0700-050-... Pre-atomiser

*105 8222-050-... Material nozzle, adjustable

*106 8222-050-... Nozzle core for nozzle reversal switch

107 8222-030-2041 Nozzle reversal switch (without nozzle core)

0700-030-2038 Set of nozzle cleaning needles, size 0, for nozzles up to 0.23

mm dia.

0700-030-2039 Set of nozzle cleaning needles, size 1, for nozzles up to 0.33

mm dia.

0700-030-2040 Set of nozzle cleaning needles, size 4, for nozzles from 0.38

mm dia.

Always state article no. and designation when ordering!

* Please additionally specify desired type and size of these articles when ordering!

24

Loading...

Loading...