Krautzberger DA3 Operating Instructions Manual

GB

Operating instructions

Steam spray gun DA3

T-Dok-553-GB-Rev.4

Article no. ■200-0348

Translation of the original operating instructions

Thank you for selecting a Krautzberger product.

This product has been manufactured following state-of-the-art manufacturing procedures and

extensive quality assurance measures. We promise you a product of the highest quality.

If you have questions, requests or suggestions, please contact us. We are always glad to assist

you.

Information about the operating manual

This manual provides important information on how to work with the device safely and efficiently.

The manual is part of the device and must always be kept in the immediate proximity of the device

so that it is accessible to the personnel at all times.

The personnel must have read and understood this manual before starting any work. Compliance

with all specified safety information and instructions is a basic requirement for safe working conditions.

In addition, the local occupational safety regulations and general safety rules apply for the area of

application of the device.

Due to optional finishing variants, it is possible that the figures shown in this operating manual

deviate from your device.

Information about explosion protection

Many of our competitors have been marking their products with the Ex symbol as a matter of principle for some time now.

At Krautzberger we do not do that.

We engineer and manufacture our products in line with currently applicable directives.

If the labelling on the product is required, it is affixed to the product as the result of the necessary

analysis of ignition sources. If no labelling is affixed, the analysis of ignition sources and previous

experience with the assessment of the suitability of products for use in a potentially explosive area

have shown that the product described in this operating manual does not represent a potential

source of ignition, with the exception of an electrostatic charge.

Taking into account the potential equalisation (provided by proper earth connection), the use in an

area at risk for explosions is permitted in accordance with the currently valid directives.

GB–2

mail@krautzberger.com, www.krautzberger.com

Steam spray gun DA3

ENGLISH

Table of contents

1 Function and identification................................................................................................ 5

1.1 Function....................................................................................................................... 5

1.2 Identification................................................................................................................. 5

2 Using this operating manual............................................................................................. 6

2.1 Symbols in this manual................................................................................................ 6

2.2 Personnel requirements............................................................................................... 7

2.3 Personal protective equipment.................................................................................... 8

3 Safety and responsibility................................................................................................. 11

3.1 General safety instructions........................................................................................ 11

3.2 Intended use.............................................................................................................. 12

3.3 Specification for the operation of a complete machine.............................................. 12

3.4 Predictable misuse.................................................................................................... 12

3.5 Responsibility of the owner........................................................................................ 13

3.6 Residual risks............................................................................................................ 13

3.7 Course of action in an emergency............................................................................. 13

4 Transport, storage, and packaging................................................................................. 14

4.1 Transport................................................................................................................... 14

4.2 Storage...................................................................................................................... 14

4.3 Packaging.................................................................................................................. 14

5 Menu.................................................................................................................................. 15

6 Installation and disassembly........................................................................................... 16

6.1 Safety......................................................................................................................... 16

6.2 General installation information................................................................................. 16

6.3 Installing the steam spray gun................................................................................... 17

6.4 Connecting connections of the steam spray gun....................................................... 18

6.5 Unfastening connections of the steam spray gun...................................................... 19

6.6 Dismantling the steam spray gun.............................................................................. 20

7 Operation........................................................................................................................... 21

7.1 Safety......................................................................................................................... 21

7.2 General information about commissioning and start-up............................................ 23

7.3 Functional check........................................................................................................ 23

7.4 Adjusting the spray pattern........................................................................................ 25

7.5 Adjusting the needle stroke (optional)....................................................................... 28

7.6 Shutting down............................................................................................................ 28

8 Maintenance...................................................................................................................... 29

8.1 Safety......................................................................................................................... 29

8.2 Maintenance schedule............................................................................................... 30

Article no. ■200-0348

GB–3

Operating instructions

T-Dok-553-GB-Rev.4

8.3 Cleaning the steam spray gun................................................................................... 30

8.4 Changing fluid and steam nozzle............................................................................... 32

8.5 Changing the fluid needle.......................................................................................... 33

8.6 Changing seals and needle pack............................................................................... 36

8.7 Changing connections............................................................................................... 37

9 Troubleshooting............................................................................................................... 38

9.1 Troubleshooting table................................................................................................ 38

9.2 Customer Care.......................................................................................................... 40

10 Spare parts........................................................................................................................ 41

11 Accessories...................................................................................................................... 42

12 Disassembly and disposal............................................................................................... 43

12.1 Safety....................................................................................................................... 43

12.2 Disassembly............................................................................................................ 43

12.3 Disposal................................................................................................................... 43

13 Technical data................................................................................................................... 44

13.1 Dimensions and weight............................................................................................ 44

13.2 General specifications............................................................................................. 44

13.3 Dimensions.............................................................................................................. 44

14 Declaration of incorporation........................................................................................... 45

15 Notes.................................................................................................................................. 46

16 Index.................................................................................................................................. 47

mail@krautzberger.com, www.krautzberger.com GB–4

Steam spray gun DA3

ENGLISH

1 Function and identification

1.1 Function

For steam spray guns, the compressed air that is ordinarily required for the atomisation process at

the nozzle is replaced by steam. This process uses a steam generator to generate pressure. The

control of the steam spray gun is still carried out via compressed air, which is generated by compressors.

Steam spray guns are used for the following applications:

n Automatic coating of surfaces

Especially spray fluids such as lacquers, paints, adhesives, glazing, enamel, debonding agents

and other processing aids are used with this technique.

The geometry of the spray jet and the quantity of the spray fluid to be applied can be changed by

adjusting the following factors:

n Selection of the air and fluid nozzle

n Changing the atomising steam pressure

n Changing the spray fluid pressure

n Adjustment of the needle stroke at the control of the steam spray gun (option)

n Changing the round and flat jet

The steam spray gun can be operated both as an independent device as well as in a larger system

(as a component of a fully-automatic coating system as well as a spray robot).

1.2 Identification

Scope of delivery Model Product number

DA3 steam spray gun 200-0348

Operating manual T-Dok-553

Serial number

The serial number of the steam spray gun is located on the underside. It serves as a unique identifier.

Article no. ■200-0348

GB–5

Operating instructions

T-Dok-553-GB-Rev.4

2 Using this operating manual

2.1 Symbols in this manual

Safety instructions

This manual uses symbols to identify safety instructions. The safety instructions are preceded by

signal words that indicate the severity of the hazard.

DANGER!

This combination of symbol and signal word indicates an immediate dangerous situation,

which will cause death or severe injuries if it is not averted.

WARNING!

This combination of symbol and signal word indicates a possibly dangerous situation which

can cause death or severe injuries if it is not averted.

CAUTION!

This combination of symbol and signal word indicates a possibly dangerous situation which

can cause slight injuries if it is not averted.

NOTICE!

This combination of symbol and signal word indicates a possibly dangerous situation which

can cause property and environmental damage if it is not averted.

ENVIRONMENT!

This combination of symbol and signal word indicates potential dangers to the environment.

Tips and recommendations

This symbol highlights useful tips and recommendations as well as information for efficient

and trouble-free operation.

mail@krautzberger.com, www.krautzberger.com GB–6

Steam spray gun DA3

ENGLISH

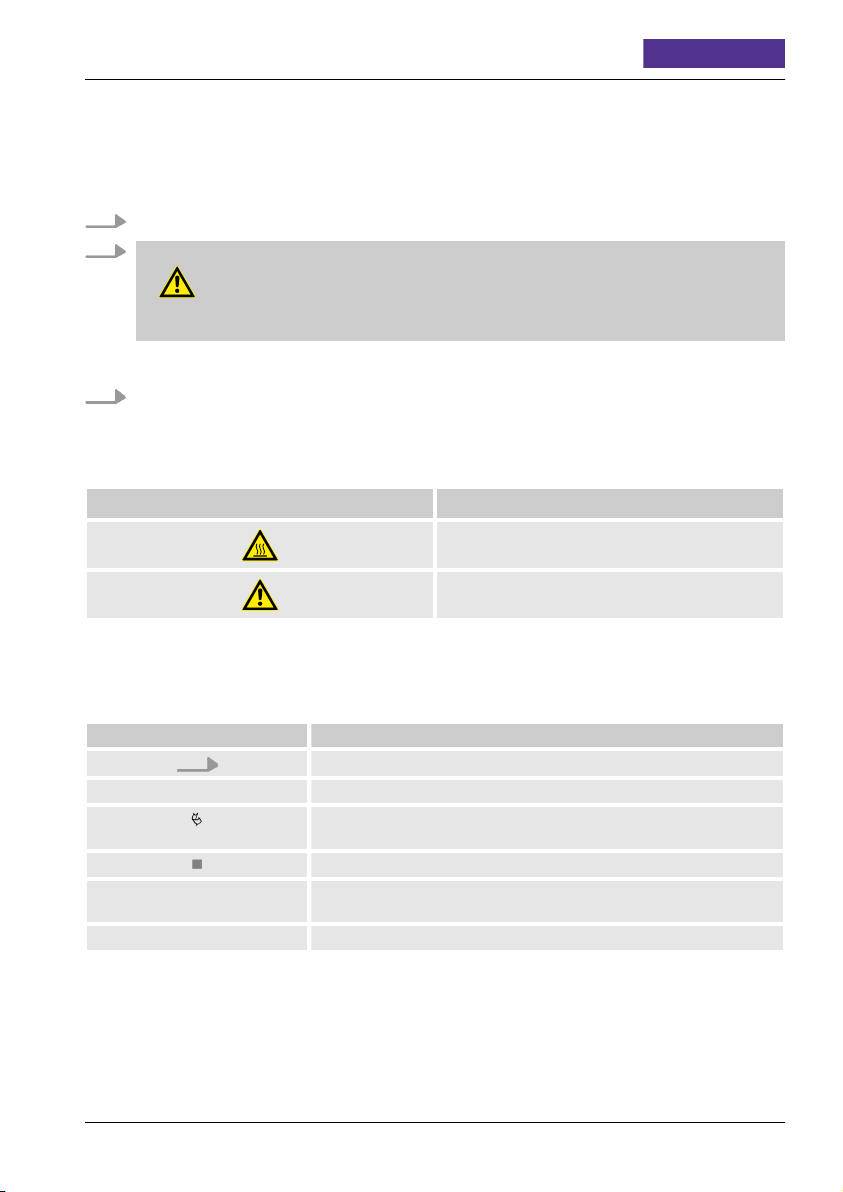

Example for safety instructions in operating instructions

Safety instructions can refer to specific, individual operating instructions. Such safety instructions

are embedded in the operating instructions so that they do not disrupt the reading flow during the

execution of the action. The signal words described above are used.

1. Unfasten screw.

2.

CAUTION!

Pinching hazard at the cover!

Carefully close cover.

3. Tighten screw.

Special safety instructions

The following symbols are used in safety instructions to draw the attention to specific hazards:

Warning signs Type of danger

Warning – hot surface.

Warning – danger zone.

Additional identifications

The following symbols are used in this manual to highlight operating instructions, results, lists, references, and other elements:

Identification Explanation

Step-by-step instructions

ð

Results of procedural steps

References to sections in this manual and other applicable documents

Lists without specified order

[Pushbuttons] Operating elements (e.g. pushbuttons, switches), display ele-

ments (e.g. signal lights)

‘Display’ Screen elements (e.g. pushbuttons, assignment of function keys)

2.2 Personnel requirements

Article no. ■200-0348

GB–7

Operating instructions

T-Dok-553-GB-Rev.4

This manual identifies the qualifications of the personnel for the different scopes of work as listed

below:

Qualified personnel

Due to their specialised professional training, knowledge, and experience as well as knowledge of

the industry-specific standards and regulations, qualified personnel are in a position to perform

assigned tasks and to identify and avert potential risks on their own.

Specialised personnel

Due to their specialised professional training, knowledge, and experience as well as knowledge of

the industry-specific standards and regulations, qualified personnel are in a position to perform

assigned tasks and to identify and avert potential hazards on their own.

User

The user is familiar with the basic regulations on occupational safety and accident prevention.

2.3 Personal protective equipment

Personal protective equipment is used to protect persons against adverse impacts on their occupational health and safety.

The personnel must wear personal protective equipment while carrying out the different tasks and

while working with the device.

The selection of the protective equipment depends on the environmental conditions at the site

of the system owner and the utilised coating material. To ensure the proper selection of personal protective equipment, the information provided by the spray material manufacturer indicated on the safety data sheet must be adhered to.

Description of the personal protective equipment recommended by Krautzberger

The personal protective equipment is described below:

Protective work clothing

Protective work clothing are tight fitting work clothes with low tear resistance, with tight sleeves,

and without any protruding parts.

mail@krautzberger.com, www.krautzberger.com GB–8

Steam spray gun DA3

Ear protection

Ear protection provides protection against hearing damage.

Light respiratory protection

The light respiratory protection is used as a protection against hazardous dusts.

Safety goggles

ENGLISH

Safety goggles are used to protect the eyes from flying parts and splashes of liquid.

Protective gloves

Protective gloves protect hands from friction, abrasion, puncture wounds, or deeper injuries, as

well as from contact with hot surfaces.

Safety shoes

Article no. ■200-0348

GB–9

Operating instructions

T-Dok-553-GB-Rev.4

Safety shoes protect the feet against crushing, falling parts or slipping on slippery ground.

Safety helmet

The helmet protects the head against injuries from falling parts and oscillating loads as well as in

tight spaces.

mail@krautzberger.com, www.krautzberger.com GB–10

Steam spray gun DA3

ENGLISH

3 Safety and responsibility

3.1 General safety instructions

WARNING!

Risk of death, risk of injury or property damage due to hazardous media!

Potential consequences: The application of hazardous media can lead to death, severe injuries or property damage.

When handling hazardous substances, ensure that the current safety data sheets of the hazardous substance manufacturer are available. The necessary measures can be derived from

the content of the safety data sheet. Since the hazardous potential of a material may be reassessed at any time due to new lessons learned, the safety data sheet must be checked regularly and replaced if necessary.

The system owner is responsible for the presence and the up-to-date status of the safety data

sheet and the associated generation of the risk assessment of the effected workstations.

CAUTION!

Risk of injury due to the discharge of hot steam!

Exiting steam can reach high temperatures. Direct contact with expelled hot media can cause

scalding of the skin.

Note:

– Switch off steam generator and wait until the system has cooled down prior to working on

the steam spray gun.

– The steam pressure line of the steam spray gun can be under pressure and must be

closed if necessary.

– Do not direct the steam jet at people.

CAUTION!

Risk of injury from compressed air!

During the work on the steam spray gun, compressed air may exit and thereby cause injuries.

– Switch off compressor prior to any work on the steam spray gun.

– The pressure line of the steam spray gun can be under pressure and must be vented if

necessary.

Article no. ■200-0348

GB–11

Operating instructions

T-Dok-553-GB-Rev.4

3.2 Intended use

The steam spray gun is used for the automatic coating of surfaces. Typical coating materials are

lacquers, paints, adhesives, glazes, enamels, debonding agents, etc.

The steam spray gun can be operated both as an independent device as well as in a larger

system (as a component of a fully-automatic coating system as well as a spray robot).

The intended use also includes the compliance with all the information in this operating manual.

3.3 Specification for the operation of a complete machine

n The operation without CE-marking is prohibited.

n Prior to its use, the steam spray gun must be assembled to form a complete machine.

n Only operate the steam spray gun after properly fastening it on a suitable support structure.

3.4 Predictable misuse

Any use beyond the intended use or any other use constitutes misuse.

n Only carry out the installation and start-up in accordance with the steps described in this oper-

ating manual.

n Always observe the applicable country-specific safety, accident prevention, occupational

safety, and environmental protection regulations etc. for the area of use for the steam spray

gun.

n The chemical resistance of the materials which we use cannot always be assessed with

authority due to the large number of fluids, concentrations, temperatures and impurities used.

For this reason, please test the suitability because we cannot extend any respective guarantees.

n Adhere to the safety data sheets of the spray fluid manufacturer.

n Ensure that the utilised hose lines fulfil the requirements with respect to temperature, pres-

sure, chemical, and mechanical loads.

n Only use the manufacturer's OEM parts.

n The conformity of the product is voided in case of structural modifications.

n Only operate the steam spray gun in compliance with the values specified in the (

13 ‘Technical data’ on page 44).

n Only operate the steam spray gun after properly fastening it on a suitable support structure.

n Do not hold the steam spray gun in your hand during operation.

n Operate the steam spray gun with processed, dried compressed air (air quality pursuant to

DIN ISO 8573-1: quality class 4).

n Never point the compressed air and the steam jet towards living beings.

n Do not operate the steam spray gun in areas that are at risk for explosions.

Ä

Chapter

WARNING!

Misuse of the steam spray gun can cause hazardous situations.

No claims of any kind can be asserted due to damage resulting from misuse!

mail@krautzberger.com, www.krautzberger.com GB–12

Steam spray gun DA3

ENGLISH

3.5 Responsibility of the owner

Owner

The owner is the person, who directly operates the machine for commercial or economical purposes or who allows a third-party to use/apply it and who is responsible for the legal product stewardship for the protection of the user, the personnel or third parties.

Owner responsibilities

The machine is used in an industrial environment. The owner of the machine is therefore subject to

the obligations as stipulated by the Occupational Health and Safety Act.

In addition to the safety information in this manual, the country-specific safety, accident prevention

guidelines and environmental protection regulations, applicable at the site of implementation of the

machine must be adhered to.

Furthermore, the owner is responsible for making sure that the machine is always in perfect technical condition. Therefore, the following applies:

n The owner must ensure that the maintenance intervals described in this operating manual are

adhered to.

n The owner must have all safety equipment checked regularly for functionality and complete-

ness.

3.6 Residual risks

Devices, machines or systems made by Krautzberger GmbH have been manufactured based on

state-of-the-art technology and in compliance with technical safety regulations.

Nonetheless, their use may pose a threat to the life or health of users or third parties, or harm the

device, the machine, the system or other material assets.

n Mechanical hazards (crushing, shearing, cutting, jamming, burning, etc.) are possible at any

time during the installation, during operation as well as during maintenance work and servicing.

3.7 Course of action in an emergency

In principle, the applicable national, regional and internal company regulations concerning the

course of action in case of an emergency must be adhered to and if necessary respective

safety measures must be taken on the system owner's side.

Article no. ■200-0348

GB–13

Operating instructions

T-Dok-553-GB-Rev.4

4 Transport, storage, and packaging

4.1 Transport

n The steam spray gun is protected by cardboard packaging.

n The cardboard packaging can be reused for storage.

4.2 Storage

Store the steam spray gun under the following conditions:

n Store the steam spray gun in the original packaging.

n Do not store outside.

n Store in a dry and dust-free environment.

n Keep away from any aggressive media.

n Protect from UV radiation.

n Avoid mechanical shocks.

n Storage temperature: 15 to 40 °C.

n Relative atmospheric humidity: max. 60%.

4.3 Packaging

The steam spray gun is packaged in accordance with the anticipated transport conditions and the

packaging needs to protect it against transport damage, corrosion, and other damage.

n Remove packaging material.

n Remove potentially present transport safety restraints.

mail@krautzberger.com, www.krautzberger.com GB–14

Steam spray gun DA3

5 Menu

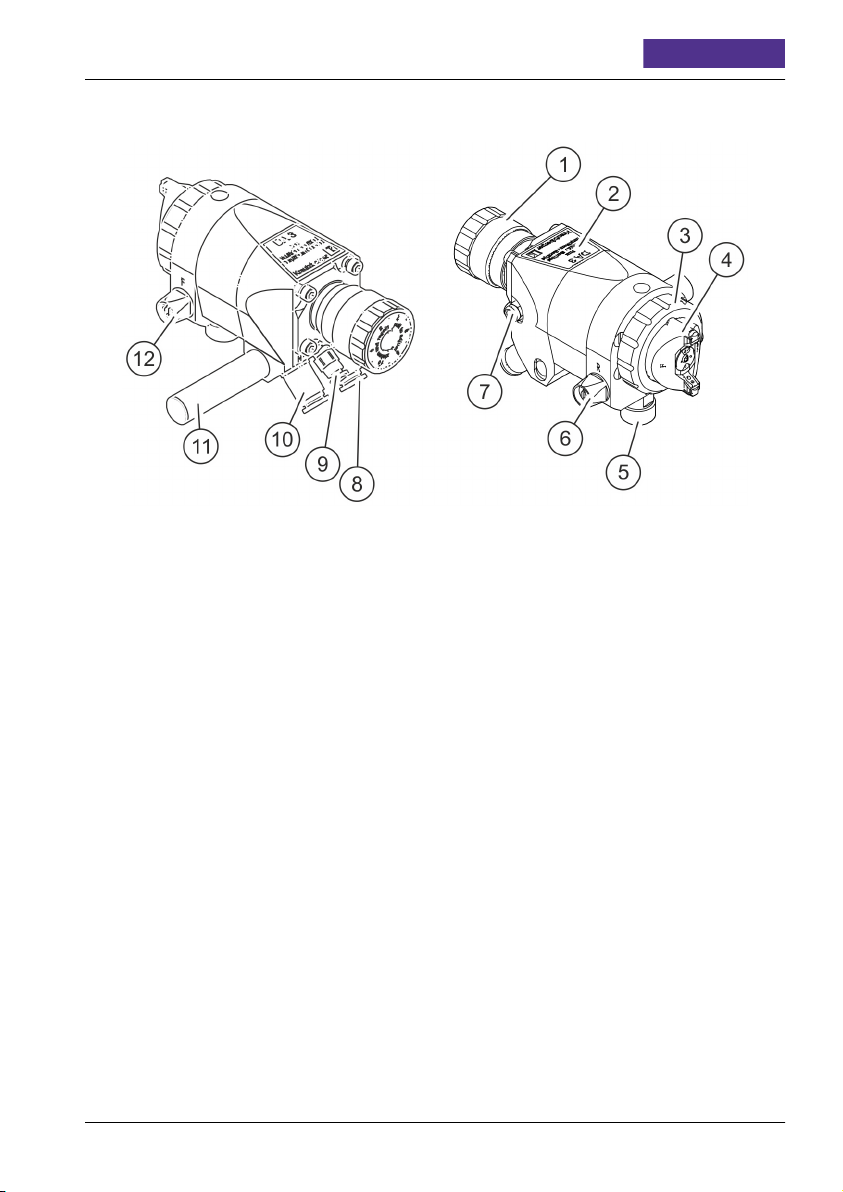

Fig. 1: Menu

1 Needle stroke setting *

2 Type plate

3 Cap nut

4 Steam nozzle

5 Steam connection

6 Round jet control "R"

7 Sound absorber

8 Fluid connection outlet "M" (fluid circulation*)

9 Control air connection "ST"

9 Fluid connection input "M"

10 Retaining bolt *

12 Flat jet control "F"

* Optional

ENGLISH

Article no. ■200-0348

GB–15

Loading...

Loading...