Operating instructions

Pressure container, 50 litre capacity,

for operating pressures of 2.5 and 6 bar

Doc-315 Rev. 0

Dokumentation

CONTENTS

1

USE FOR INTENDED PURPOSE ......2

2 GENERAL SAFETY NOTES...............2

3 INSPECTION BY QUALIFIED

EXPERTS IN ACCORDANCE WITH THE

“AD” INFO SHEETS ...................................3

4 BASIC DESIGN...................................4

5 INSTALLATION, MOUNTING OF THE

CONTAINER ..............................................5

5.1 Connections...........................................5

5.2 Filling....................................................5

6 REGULAR CHECKS, MAINTENANCE

6

7 CLEANING, DISPOSAL......................6

8 WEARING PARTS, SPARE PARTS...7

9 TROUBLESHOOTING ........................7

10 TECHNICAL DATA..........................7

DOK-315-GB.doc

Designation MDH

Type 50l

Order-No. 200-0157

only be used following consultation with

Krautzberger.

Krautzberger pressure containers are

equipped as standard with a material outlet

with shutoff device, compressed air connection fitting with overpressure valve, and a

pressure gauge for pressure indication.

Pressure containers may be fitted with stirrers, level gauges, filling devices and other

accessories.

Krautzberger 50-litre and 100-litre pressure

containers are designed for 10,000 stress

reversals (1 stress reversal (or load cycle)

is equivalent to a pressure fluctuation range

> 3bar).

When using hazardous substances:

When using hazardous substances,

note that the substance is released into

the atmosphere if the safety valve is activated.

1 Use for intended pur-

pose

Krautzberger material pressure containers

are containers with detachable covers in

which compressed air can be used to pressurise liquid and low-viscosity materials.

The pressurised material can then be

routed via suitable hoses and pipes to extraction points (e.g. spray guns or similar).

Pressure containers are primarily used in

the painting and coating sector.

The temperature of the coating medium

may not be below -10°C or above +50°C.

Corrosive or highly abrasive materials may

2 General safety notes

Material pressure containers may

not be transported in pressurised

state!

The construction of pressure containers may not be altered!

It is illegal to release certain hazardous

substances directly into the atmosphere, and some substances may not

be present at the workplace in inadmissibly high concentrations. This means

that the safety valve must be of a design that permits connection to a pipeline, via which the hazardous substances can be routed to a treatment

system if necessary. Krautzberger

pressure containers can therefore be

equipped with a safety valve with connection option.

Pressure containers may only be

operated within the operating parameters (pressure, temperature

etc.) specified on the rating plate!

The housing of the pressure containers is made of stainless steel

and may have galvanised or

enameled surfaces. The operator

must check the compatibility of

the materials with the coating

substances used. Please also refer to the instructions of the

manufacturer of the coating substance.

2

Dokumentation

Before opening a pressure container, the compressed air feed

must always be shut off and the

container rendered pressureless

via the venting valve!

Stirring mechanisms must be

switched off and secured against

accidental switch-on!

Please always read and observe

the safety and treatment instructions of the material manufacturer –

in particular instructions relating

to:

the wearing of protective

equipment during the use

of hazardous substances

the avoidance of harmful or

explosive environments

Electrostatic charges during operation of the pressure container can

lead to electric shocks and spark

formation.

The pressure container must therefore be earthed!

Air lines, material pipes and containers, equipment and electrically

conductive surfaces in the working

zones must also be earthed.

Components connected by the operator (hoses and pipes, fittings,

extraction devices etc.) must be reliably able to withstand the loads to

be expected during operation of the

pressure container (pressure, temperature, chemical and mechanical

influences).

Before each operating step, check

hoses and pipes for possible damage and ensure that they are firmly

connected. Loose, pressurised

hoses may cause accidents due to

whiplash-like movement and the

uncontrolled discharge of fluids.

DOK-315-GB.doc

Rooms in which hazardous substances

are stored or processed must have

adequate ventilation. It may be necessary to install a ventilation system.

If the ventilation system fails, work

must be stopped immediately and the

stirrer switched off.

Always comply with the relevant national and regional regulations.

Do not store any flammable substances, empty coating substance containers or other materials that have

been in contact with the coating substance (paper, cloths etc.) in the container or in the working zone.

Do not use halogenated detergents.

Chemical reactions may cause explosive and caustic compounds!

In the working zone, avoid open flames

and red-hot components as well as

equipment, tools and parts that can

create ignitable sparks.

Hang up “No Smoking” signs in a 5metre radius of the container. Make fire

extinguishers available if these are not

already in place!

Comply with all national and regional

water protection regulations!

Comply with all national and regional

waste disposal regulations!

Designation MDH

Type 50l

Order-No. 200-0157

3

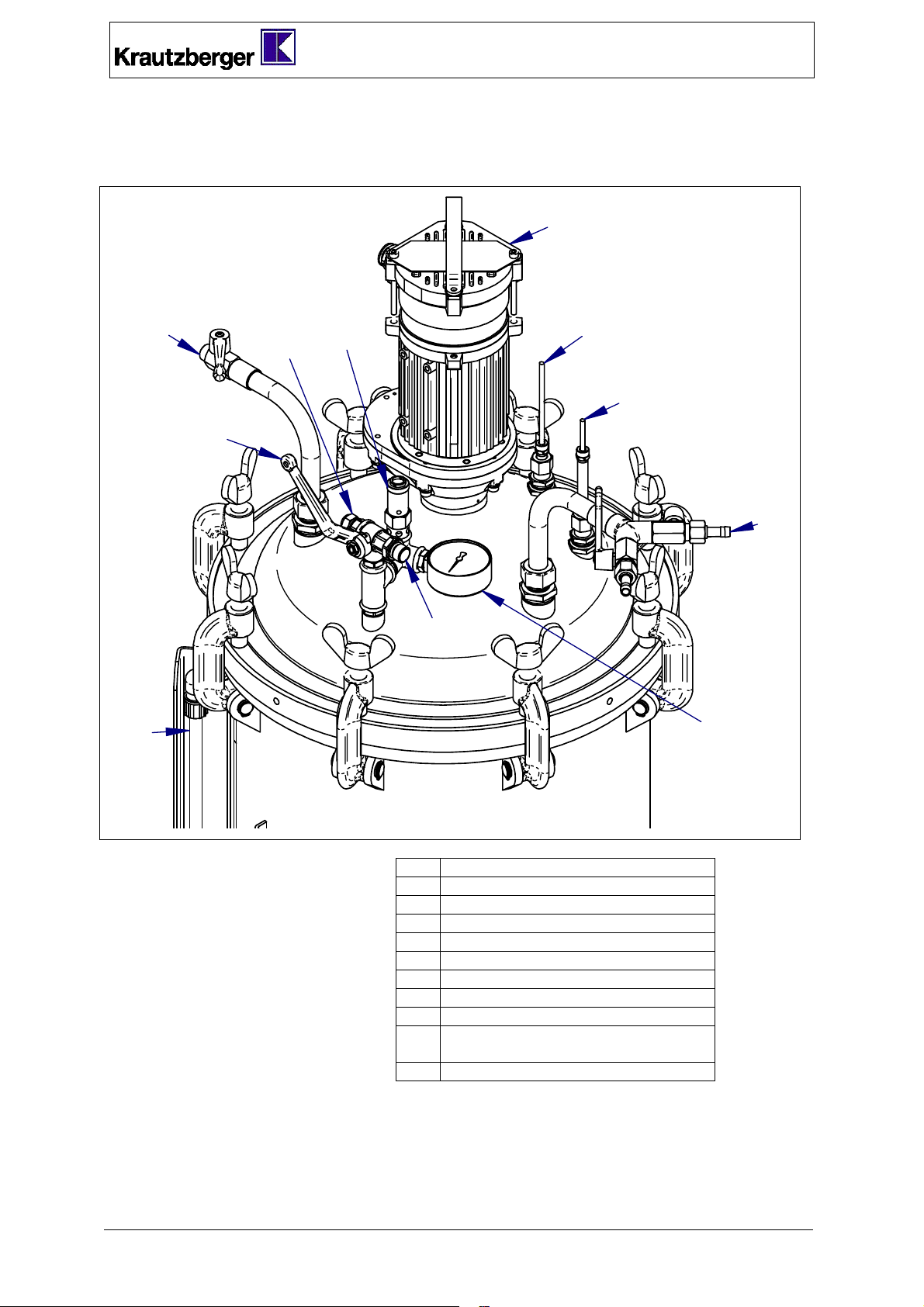

3 Basic design

Dokumentation

DOK-315-GB.doc

Designation MDH

Type 50l

Order-No. 200-0157

1

7

9

8

10

11

2

3

4

6

5

1 Stirrer (optional)

2 “Maximum” level gauge (optional)

3 “Minimum” level gauge (optional)

4 Material extraction point

5 Pressure gauge

6 Compressed air connection

7 Level indicator (optional)

8 Ball cock for venting

9 Material return (optional)

10 Sound dampener or connection option

for waste air line

11 Safety valve

The material extraction point (4) can be located the bottom or routed through the container

cover via a riser pipe. The material extraction point may have more than one port for the connection of more than one consumer. The air fitting can be equipped with connection options for

additional compressed air consumers – such as stirrers, handheld spray guns etc.

4

Dokumentation

DOK-315-GB.doc

Designation MDH

Type 50l

Order-No. 200-0157

4 Installation, mounting of the container

Pressure containers must be installed in such a way that:

neither employees nor third parties are at risk

they are accessible for regular inspection

the rating plate is easily visible

the pressure container can be operated from a safe and stable position

they are protected against external mechanical influences

they are protected against unauthorised access

4.1 Connections

Connect the material pressure hose leading to your extraction point to the material out-

let (4)

The material outlet can be located the bottom or routed through the container cover via a

riser pipe. The material outlet may have more than one port for the connection of more

than one consumer.

Connect the compressed air feed to the air connection (6)

The compressed air supply must be dry and oil-free. Make the necessary provision for a

suitable shutoff device (ball cock).

The compressed air fitting can be equipped with more than one (if necessary adjustable)

outlet for the connection of additional consumers (spray gun, stirrer etc.).

Connect the waste air line to the safety valve

Connect the earthing device and earth all conductive components in the working zone

Check firmness of all connections!

4.2 Filling

Each time before you fill the container:

Shut off the compressed air feed

Vent the container via the ball cock (8) until the container is pressureless

Switch off stirrer – if present

Do not open the container cover until the container has been fully vented!

There is increased risk of fire when you open the cover! In the working zone, avoid open

flames and red-hot components as well as equipment, tools and parts that can create ignitable sparks!

When removing the cover, make sure that the stirrer blades do not knock against the container wall, thus creating ignitable sparks.

Loosen star-grip screws/clamp fasteners

Remove cover

5

Dokumentation

Clean pressure container using a suitable detergent when necessary

Fill pressure container. Do not exceed the maximum filling level (see Technical data)!

Close cover, tighten star-grip screws/clamp fasteners

Open compressed air feed

DOK-315-GB.doc

Designation MDH

Type 50l

Order-No. 200-0157

5 Regular checks, maintenance

Check the proper functioning of the safety

valve every time before you begin operating the system! To test the valve function,

turn the knurled screw of the safety valve

to the left. If the valve does not blow off,

the pressure container must not be operated until a new safety component has

been fitted!

Check the air and material lines and their

connections for seal-tightness and firm

seat every time before you begin operating

the system.

Before opening the pressure container,

check the cover gasket for soiling, wear

and damage.

Before opening a pressure container for all maintenance., servicing and cleaning

work on the open container, the air feed must always be shut off and the container

rendered pressureless!

Stirring mechanisms must be switched off and secured against accidental switchon!

6 Cleaning, disposal

Clean the pressure container after use thoroughly using a suitable detergent. Ensure that the

sealing surfaces between container and container cover are clean.

Dispose of materials accumulating during cleaning (cloths etc.) through the appropriate channels. Comply with the regulations of the local waste disposal authorities.

Comply with the safety instructions of the detergent manufacturer. Detergents may

be harmful to your health and be easily flammable!

Ensure that the detergent is compatible with the container materials!

6

Dokumentation

DOK-315-GB.doc

Designation MDH

Type 50l

Order-No. 200-0157

7 Wearing parts, spare parts

Gaskets are subject to material fatigue and natural wear. Defective gaskets are noticeable from

the leakage of air or coating substance on fittings or connections. Gaskets may be made of

NBR, PE, EPDM or Viton.

When changing gaskets, check compatibility with the coating substance used.

Cover gasket for 50-litre and 100-litre container

Material Article number

NBR 5840-010-0220

PE 5840-010-0221

EPDM 5840-010-0222

Viton 5840-010-0223

8 Troubleshooting

Problem Cause Remedy

Leakage between container

flange and cover

Leakage at compressed air fitting

Leakage at stirrer mounting Gasket defective Replace gaskets

Leakage at material outlet Gasket defective Replace gaskets

Material pressure cannot be adjusted

Container flange, cover gasket soiled or porous

Gaskets defective Replace gaskets

Material pressure regulator

defective

Clean or replace

Replace

9 Technical data

50-litre type 100-litre type

Compressed air feed dry, oil-free, filtered

2.5-6bar

Max. filling volume 58 litres 126 litres

Ambient temperature -10 to +50°C -10 to +50°C

Temperature – coating material -10 to +50°C -10 to +50°C

Test pressure/Date 3.6bar/8.6bar 3.6bar/8.6bar

Setting pressure of over-

pressure valve

Weight (empty) 63-72kg 88-97kg

Dimensions max. 1025x495mm max. 1300x625mm

Mains voltage – electric stirrer 230V/50Hz 230V/50Hz

customer-specific customer-specific

dry, oil-free, filtered

2.5-6bar

7

10 Dimensions

Dokumentation

DOK-315-GB.doc

Je nach Rührwerk

Designation MDH

Type 50l

Order-No. 200-0157

310~

765~

650~

760~Ø

470~

550~

390~Ø

8

Dokumentation

DOK-315-GB.doc

Designation MDH

Type 50l

Order-No. 200-0157

EG-Konformitätserklärung

EC-Declaration of conformity

gemäß Anhang VII der EG – Druckgeräterichtlinie 97/23/EG

as defined by Pressure Equipment Directive 97/23/EC Annex VII

Krautzberger GmbH

Stockbornstraße 13

65343 Eltville am Rhein

HIERMIT ERKLÄREN WIR, DASS FOLGENDES PRODUKT

HEREWITH WE DECLARE, THAT THE PRESSURE EQUIPMENT

Bezeichnung

Type

Artikel-Nummer

Serial-no.

Funktion

Function

Materialdruckbehälter MDH mit 50l Inhalt;

2,5 - 6bar Betriebsdruck

200-0157

Druckluft betriebener Materialdruckbehälter zur Druckbeaufschlagung

von flüssigen und niederviskosen Medien

IN DER GELIEFERTEN AUSFÜHRUNG FOLGENDEN BESTIMMUNGEN ENTSPRICHT:

CORRESPONDS TO FOLLOWING PERTINENT REGULATIONS IN THE DELIVERED IMPLEMENTATION

EG–Druckgeräterichtlinie 97/23/EWG, EG-Niederspannungs-Richtlinie 73/23/EWG (nur bei elektrischen Anbauteilen), EG-EMV-Richtlinie 93/68/EWG (nur bei elektrischen Anbauteilen), EGMaschinenrichtlinie 98/37 EG (bei Elektro- und Druckluftrührwerken)

Folgende harmonisierte EU-Normen wurden angewendet:

APPLIED HARMONIZED STANDARDS, IN PARTICULAR:

DIN EN 1050 (bei Rührwerken)

DIN EN 292-1/2 (bei Rührwerken)

DIN prEN 12757-1 (bei Rührwerken)

DIN EN 60204-1 (bei Elektrorührwerken)

Fluide Gruppe 1

Folgende nationale Normen wurden angewendet:

APPLIED STANDARDS AND TECHNICAL SPECIFICATIONS, IN PARTICULAR

AD 2000 Merkblätter

ANGEWANDTES KONFORMITÄTSBEWERTUNGSVERFAHREN:

Benannte Stelle gem. Artikel 12 DruckgeräteRichtlinie:

ENGAGED NOTIFIED BODIES:

EG-BAUMUSTERPRÜFBESCHEINIGUNG NR.:

EC-TYPE EXAMINATION CERTIFICATE NO.

Datum:

Angaben zum Unterzeichner: M. Stoffels,

9

Modul B+C1

TÜV Technische Überwachung Hessen

GmbH

Rüdesheimer Strasse 119

64285 Darmstadt

482 / 02

i.A.

Leiter Konstruktion

Dokumentation

DOK-315-GB.doc

11 Inspection by qualified experts

Pressure containers must be checked on a regular basis by qualified experts. The inspection intervals depend on operational experience, the substances used, and the

outcome of previous inspections.

However, the following periods may not be exceeded:

Internal inspection: every 5 years

Pressure testing: every 10 years

External inspection: every 2 years

Internal and external inspection must be performed after 5,000 stress reversals. Record each startup and rundown of the container with a pressure fluctuation range >

3bar (equivalent to one stress reversal).

Designation MDH

Type 50l

Order-No. 200-0157

Acceptance test

:

.....................................

inspector

at:

.....................................

date

sign:

..................................................................

10

Installation test

Dokumentation

DOK-315-GB.doc

Designation MDH

Type 50l

Order-No. 200-0157

first periodic inspection

next periodic inspection

11

Dokumentation

DOK-315-GB.doc

Designation MDH

Type 50l

Order-No. 200-0157

next periodic inspection

next periodic inspection

12

Dokumentation

DOK-315-GB.doc

Designation MDH

Type 50l

Order-No. 200-0157

next periodic inspection

next periodic inspection

13

Dokumentation

DOK-315-GB.doc

Designation MDH

Type 50l

Order-No. 200-0157

next periodic inspection

next periodic inspection

14

Dokumentation

DOK-315-GB.doc

Designation MDH

Type 50l

Order-No. 200-0157

next periodic inspection

next periodic inspection

15

Loading...

Loading...