DM4

DM4 DL

Operating Manual

DM4E

Advanced Test Equipment Rentals

www.atecorp.com 800-404-ATEC (2832)

®

E

s

t

a

b

l

i

s

h

e

d

1

9

8

1

Operating Manual

for

Ultrasonic Thickness Gauge

Models DM4E, DM4 and

DM4 DL with On-board data Logger

Manual Part No. 021-002-073 REV. S

Copyright 2002 Agfa NDT Inc.

THIS PAGE INTENTIONALLY BLANK

Important Notice

Important Notice

The following information must be read

and understood by any user of a

Krautkramer ultrasonic thickness

gauge. Failure to follow these instructions can lead to errors in thickness

measurements or other test results.

Decisions based on erroneous results

can, in turn, lead to property damage,

personal injury or death.

General Warnings

Proper use of ultrasonic test equipment

requires three essential elements:

• Selection of the correct test

equipment.

• Knowledge of the specific “test

application requirements.”

• Training on the part of the

instrument operator.

This operating manual provides instruction in the basic set up and operation of the Krautkramer thickness

gauge.

There are, however, additional factors

which affect the use of ultrasonic test

equipment. Specific information regarding these additional factors is beyond the

scope of this manual. The operator

should refer to textbooks on the subject

of ultrasonic testing for more detailed

information.

Operator Training

Operators must receive adequate

training before using ultrasonic test

equipment. Operators must be trained in

general ultrasonic testing procedures and

in the set up and performance required

by a particular test. Operators must

understand:

• Soundwave propagation theory .

• Effects of the velocity of sound of

the test material.

• Behavior of the sound wave

where two different materials are

in contact.

• Areas covered by the sound

beam.

More specific information about operator training, qualification, certification,

and test specifications is available from

various technical societies, industry

groups, and government agencies.

Testing Limitations

In ultrasonic testing, information is

obtained only from within the limits of the

sound beam. Operators must exercise

great caution in making inferences about

the test material outside the limits of the

sound beam. For example, when testing

large materials it may be impossible or

impractical to inspect the entire test

piece. When a less-than-complete

inspection is to be performed, the

operator must be shown the specific

areas to inspect. Inferences about the

condition of areas not inspected, based

on data from the evaluated areas, should

only be attempted by personnel fully

qualified and trained in applicable

standards of statistical evaluation. In

particular, materials subject to erosion or

corrosion, in which conditions can vary

significantly in any given area, should

only be evaluated by fully trained and

experienced operators.

Sound beams reflect from the first

interior surface encountered. Because

of part geometry and overlapped flaws

or overlapped surfaces, thickness

gauges may measure the distance to an

internal flaw rather than to the back wall

of the material. Operators must take

steps to ensure that the entire thickness

of the test material is being examined.

Ultrasonic Thickness Measurement

Critical Operating Procedures

The following operating procedures must

be observed by all users of

ultrasonic thickness gauges in order to

minimize errors in test results.

1.

Calibration of Sound Velocity

The principle of operation of an ultrasonic thickness gauge is that the instrument measures the time of flight of an

ultrasonic pulse through the test piece

and multiplies this time by the velocity of

sound in the material. Thickness

measuring error is minimized by ensuring

that the sound velocity to which the

instrument is calibrated is the sound

velocity of the material being tested.

Actual sound velocities in materials

often vary significantly from the values

found in published tables. In all cases,

best results are obtained if the instrument is calibrated on a velocity reference block made from the same

material as the test piece; this block

should be flat and smooth and as thick

as the maximum thickness of the test

piece.

Operators should also be aware that the

sound velocity may not be constant in the

material being tested; heat treating, for

example, can cause significant changes

in sound velocity . This must be considered when evaluating the accuracy of the

thickness provided by this instrument.

Instruments should always be calibrated

before testing, and the calibration should

be checked after testing, to minimize

testing errors.

2.

Probe Zero Procedure

The probe zero procedure must be

performed as described in this manual.

The probe zero block should be clean, in

good condition and without noticeable

wear. Failure to properly perform the

probe zero procedure will cause inaccurate thickness readings.

3.

Effects of Temperature on

Calibration

T emperature variations change the

sound velocity of materials and transducer delay lines and, therefore, calibrations. All calibrations should be performed on-site, and with test blocks at

the same temperature as the test piece,

to minimize errors due to temperature

variations.

4.

Transducer Selection

The transducer used in testing must be in

good condition without noticeable wear

of the front surface. Badly worn transducers will have a reduced effective

measuring range. The specified range of

the transducer must include the complete

range of thicknesses to be tested. The

temperature of the material to be tested

must be within the transducer’s temperature range.

5.

Use of Couplants

Operators must be familiar with the use

of ultrasonic couplants. Testing skills

DM4E, DM4, DM4 DL Operating Manual

Page 1

Important Notice

must be developed so that couplant is

used and applied in a consistent

manner to minimize variations in

couplant layer thickness and errors in

test results. Calibration and actual

thickness being measured. This effect,

commonly known as “doubling,” can

occur below the minimum specified

range of the transducer. If the transducer being used is worn, doubling is

possible at a thickness greater than the

minimum of the specified range.

When using a new transducer, any

reading which is less than twice the

minimum specified range of the transducer may be a “doubled” reading, and

the thickness of the material being tested

should be verified by the use of other

methods. If the transducer shows any

sign of wear, doubling may occur at a

thickness greater than twice the minimum of the specified range. This

thickness should be determined by

calibrating the instrument/transducer

combination on reference blocks that

represent the complete range of possible

thicknesses that may be encountered in

testing. This is particularly important

when the test piece is being ultrasonically

measured for the first time or in any case

where the history of thickness of the test

specimen is unknown.

Page 2 DM4E, DM4, DM4 DL Operating Manual

Table of Contents

Important Notice ....................................................... 1

Table of Contents ...................................................... 3

Warranty / Service ..................................................... 4

1. Introduction ........................................................... 5

1.1 How To Use This Manual................................. 5

1.2 DM4E, DM4, DM4DL Features....................... 5

1.3 How Instrument Measures Thickness.............. 5

2. Operation ............................................................... 7

2.1 Battery Installation ........................................... 7

2.2 Display Symbols............................................. 7

2.3 Keyboard Controls........................................... 8

2.4 Getting Started ................................................ 9

2.5 Calibration To A Known Thickness,1-Point...... 9

2.6 Calibration To A Known Thickness,2-Point.... 10

2.7 Calibration To A Known Velocity ....................11

2.8 Normal Measurement - THK Mode .............. 12

2.9 Minimum Capture Measurement ................... 12

2.10 Receiver Gain Control

(DM4, DM4 DL) ............................................. 12

2.11 Using LO/HI Thickness Limits

(DM4, DM4 DL) ............................................. 13

2.12 Differential Measurement

(DM4, DM4 DL) ............................................. 13

2.13 Band Pass Filter Control

(DM4, DM4 DL) ............................................. 14

2.14 Resolution And Units of Measure .................. 14

2.15 Display Backlight........................................... 14

2.16 Disabling/Enabling Functions ........................ 14

2.17 Recording Measurements

(DM4 DL)....................................................... 15

2.18 Dual Multi Measurement Mode

(DM4, DM4 DL) ............................................. 15

2.19 DA3 Operating Mode..................................... 16

3. Data Logger Operation ....................................... 17

3.1 The DM4 DL Data Logger ............................. 17

3.3 Selecting A File ............................................. 17

3.4 Logging Readings Into Memory..................... 18

3.4.1 Recording an OBSTRUCT Value ........ 18

3.5 Selecting Locations ....................................... 18

3.6 Reviewing Stored Thickness Readings ......... 18

3.7 Clearing and Replacing Readings ................. 19

3.8 Clearing Selected Files ................................. 19

3.9 Clearing Entire Memory ................................ 19

3.10 Permanent Storage ....................................... 19

4. Serial I/O Interface .............................................. 20

4.1 The DM4 DL Serial Interface......................... 20

4.2 Setting Baud Rate ......................................... 20

4.3 Report Language Selection ........................... 20

4.4 Printing Data ................................................. 20

4.5 Sending Data To A Personal Computer......... 21

4.6 Importing Data Into A Spreadsheet ............... 22

4.7 Interrupted Transmission Procedure ............. 22

5. Specifications...................................................... 23

5.1 Instrument Specifications .............................. 23

5.2 Probe Specifications ...................................... 24

5.3 Dual Multi “Through Coating”Mode Probe.........

Specifications ................................................ 25

6. Application .......................................................... 26

6.1 General Notes ............................................... 26

6.1.1 Flaws ................................................... 26

6.1.2 Surface Conditions .............................. 26

6.1.3 Curved Surfaces ................................. 26

6.2 Thickness Meas. On Hot Test Pieces............. 26

7. Worldwide Service Centers ................................ 28

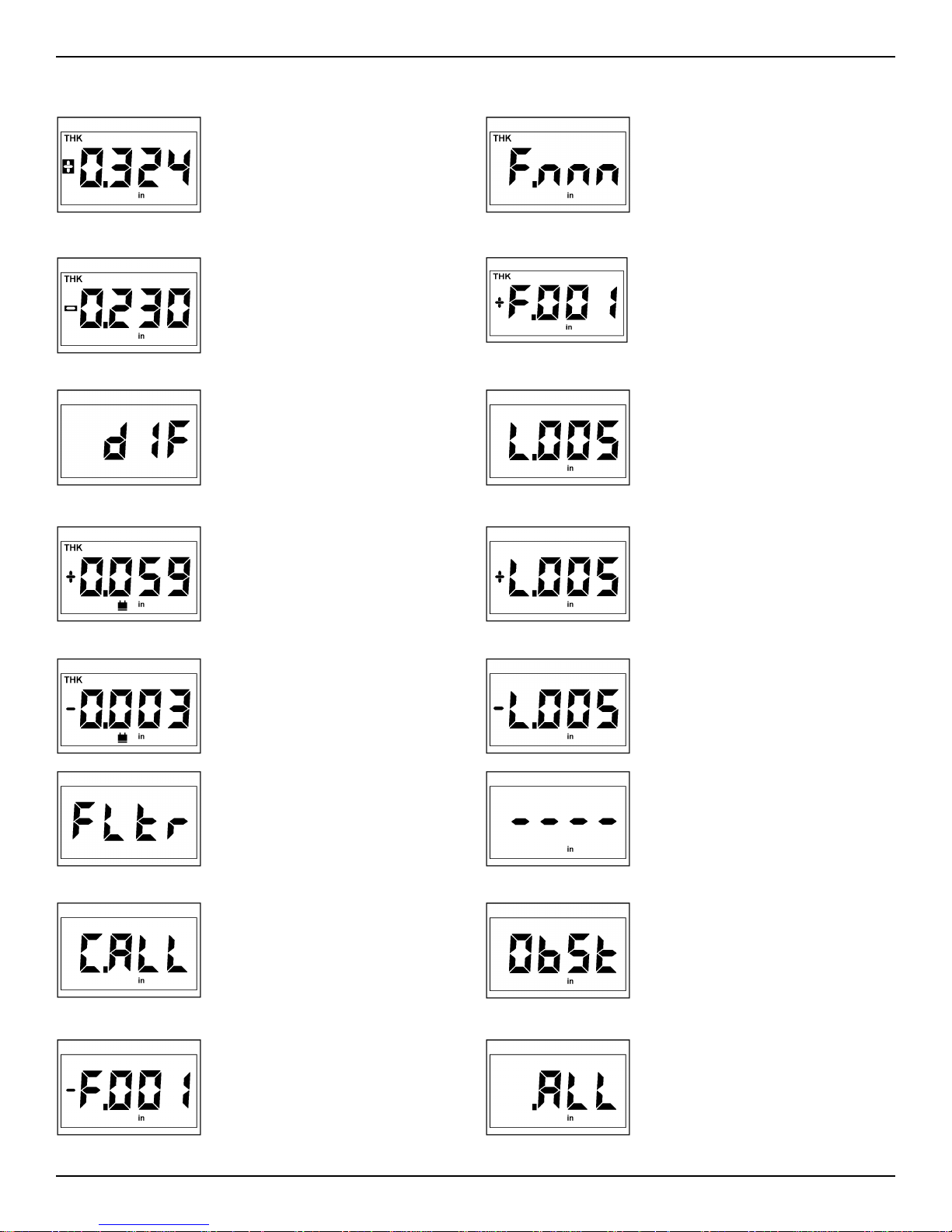

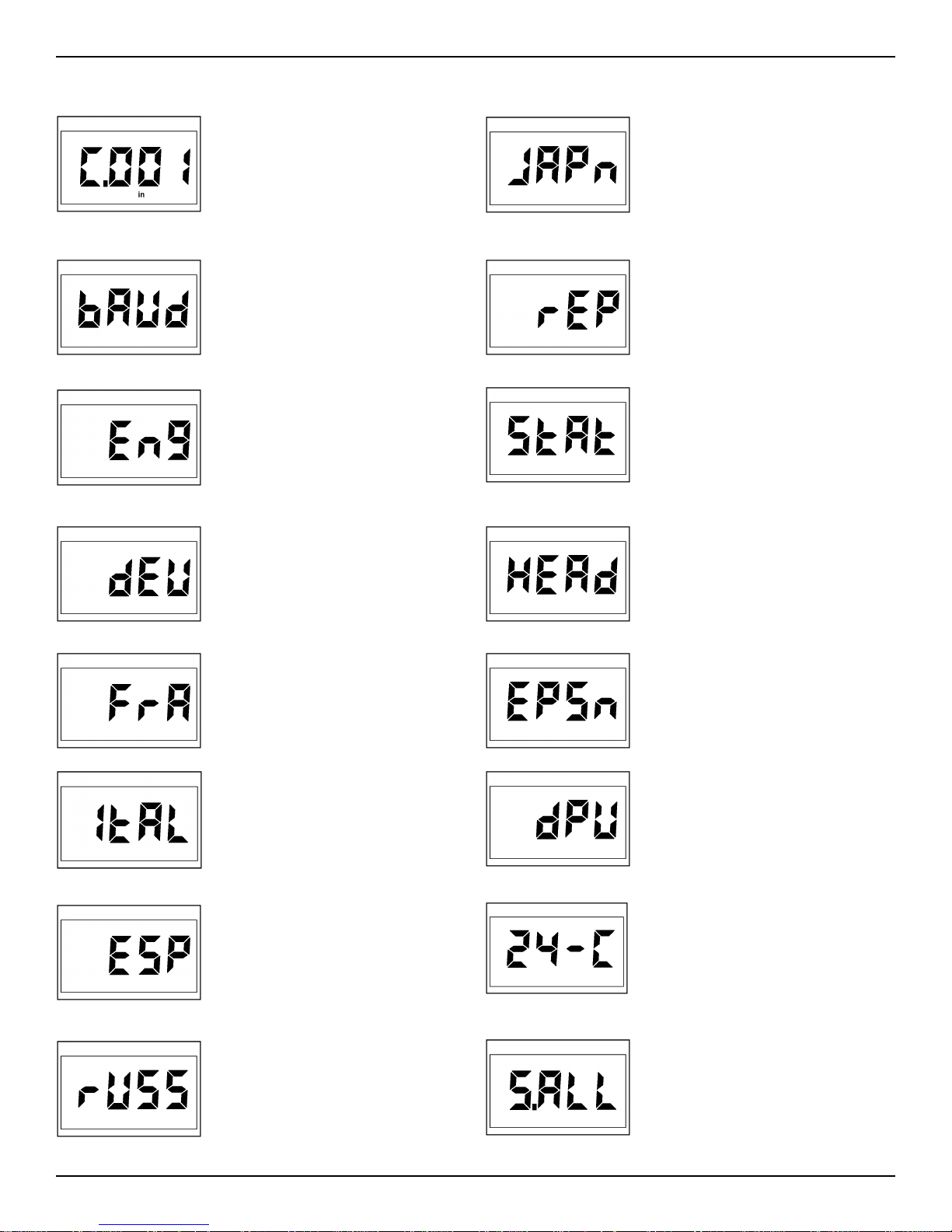

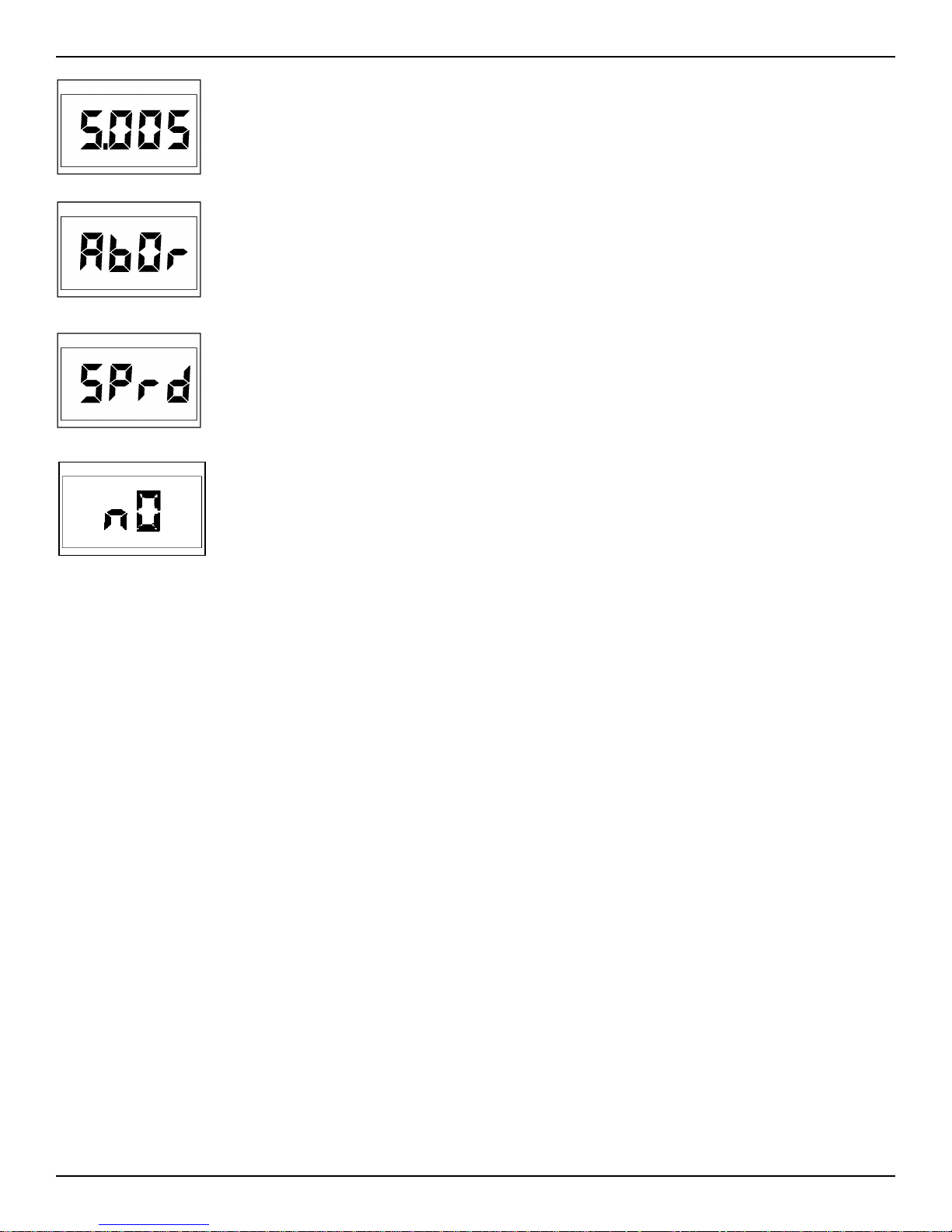

Appendix A: Displays, Quick Reference ............... 29

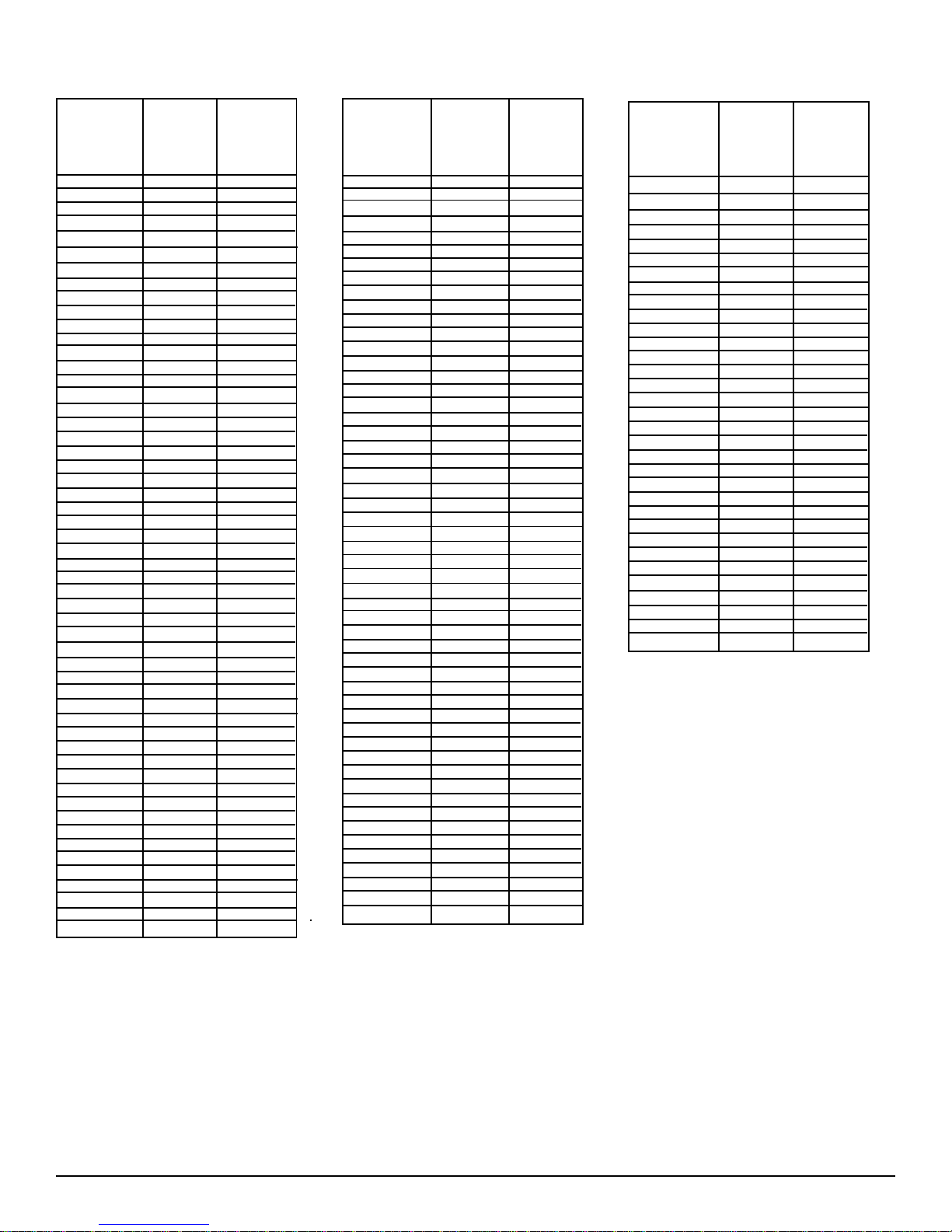

Appendix B: Locations Per File ............................. 33

Appendix C: Operational Software Reset ............. 34

Index ...................................................................... 35

3.2 Setting Number of Files ................................. 17

DM4E, DM4, DM4 DL Operating Manual

Page 3

Warranty/Service

Warranty

When used in accordance with the manufacturer’s written

instructions and under normal operating conditions, the

Krautkramer DM4E, DM4, and DM4 DL test instruments

are conditionally guaranteed to be free from defects in

material and workmanship for a period of two (2) years

from date of shipment.

All repair work will be made FOB Lewistown, Pennsylvania, or at a Factory Trained Service Center as advised

by Agfa NDT Inc., provided the defective unit is returned

properly packed with all transportation charges prepaid.

Any and all equipment replacement will be at the sole

discretion of Agfa NDT Inc.

This warranty shall not apply to equipment subjected to

misuse or abuse, improper installation, alteration, neglect,

or accident. Excluded from this warranty are expendable

items such as transducers, interconnecting cables, and

batteries. Accessory items such as printers, etc. will be

covered under the original manufacturer’s warranty as given

to Agfa NDT Inc.

This warranty is limited to the original purchaser and is not

transferable. No other warranty, expressed or implied, is

Service

Every effort has been made to provide you with a reliable product. However, should service become necessary, Agfa NDT Inc.

has established a number of Factory Trained Service Centers.

For the location of the nearest facility, refer to Chapter 7 or

contact:

Agfa NDT Inc.

Krautkramer Ultrasonic Systems

Manager of Customer Service

50 Industrial Park Road

Lewistown, PA 17044

Page 4

DM4E, DM4, DM4 DL Operating Manual

1. Introduction

1.1 How To Use This Manual

This manual describes the features and operation of the DM4E,

DM4, and DM4 DL (with on-board data logger) Ultrasonic Thickness Gauges.

If you are a first time user of the instrument, review Chapter 1 of

this manual to become acquainted with it’s general capabilities.

Follow the instructions in Chapter 2 to prepare the instrument for

operation and perform thickness measurements.

If you are using a model DM4 DL, Chapter 3 provides detailed information and operating instructions for the on-board data logger.

Chapter 4 describes how to interface model DM4 DL with a variety of external devices, such as a printer or personal computer,

via the serial I/O interface.

Chapter 5 provides important specifications, particularly Section

5.2, which lists compatible probes (transducers) and their capabilities.

All users should read “Important Notice” at the beginning of the

manual and Chapter 6, “Application Notes”, for important

information on operator qualification, test conditions, and procedures that affect measurement results.

1.2 DM4E, DM4, DM4 DL Features

The DM4E, DM4, and DM4 DL Ultrasonic Thickness Gauges are

hand-held, microprocessor controlled instruments designed for

general thickness measurements on a variety of equipment having access to one side only. It is especially applicable to the

measurement of remaining wall thickness on tubes, pipes, pressure vessels, and other parts subject to wall thickness loss due to

corrosion or erosion.

The on board Data Logger of the DM4 DL improves the reliability

of recording thickness

and misrecorded data. A total of 5390 readings can be stored in

up to 999 separate data files. Displayed readings are recorded

by simply pressing the SEND key or an optional remote hand or

foot switch. Measurement, statistical and instrument data can

be transmitted via the Serial I/O port, in 80 column format,

to a serial printer or personal computer for documentation,

storage and analysis.

readings by avoiding the errors of misread

Features of the DM4E, DM4, and DM4 DL:

• Rugged, sealed case and keypad for reliability

• Lightweight, ergonomically designed case

• 200 hours on two AA alkaline batteries

• Five keys (nine keys on DM4 DL) control all functions for simple

operation.

• Automatic probe zero for fast calibration

• Automatically recognizes DIALOG Intelligent Transducers.

• Automatic V-path error correction compensates for non-

linearity of dual element probes.

• Resolution of .001 in, .01 in, .1 mm, or .01 mm

• Large, easily read display with backlight

• Automatic gain adjustment

• Measures a wide range of materials

• Minimum Capture mode captures thinnest reading

Advanced Features of the DM4 and DM4 DL:

• Manual gain adjustment

• Dual Multi “Through Coating (Paint)” Measurement Mode

• Programmable HI/LO thickness limits with LED alarm

• Differential mode displays the difference between measured

thickness and user-set nominal thickness value.

• Band Pass Filter selection to match the frequency of the probe

for best performance.

DM4 DL Data Logging and Communications Features:

• Stores up to 5390 readings.

• Memory can be divided into a maximum of 999 separate data

files of equal length.

• Individual readings or files can be accessed

editing, and clearing data.

• Serial I/O port provides output to a serial printer or IBM compatible personal computer.

• Built-in report format includes instrument, inspector, and probe

IDs, settings,

• DM4 DL Data Transfer Utility Software

IBM compatible PC for viewing, printing transfer to other software.

• UltraMATE

ible software programs.

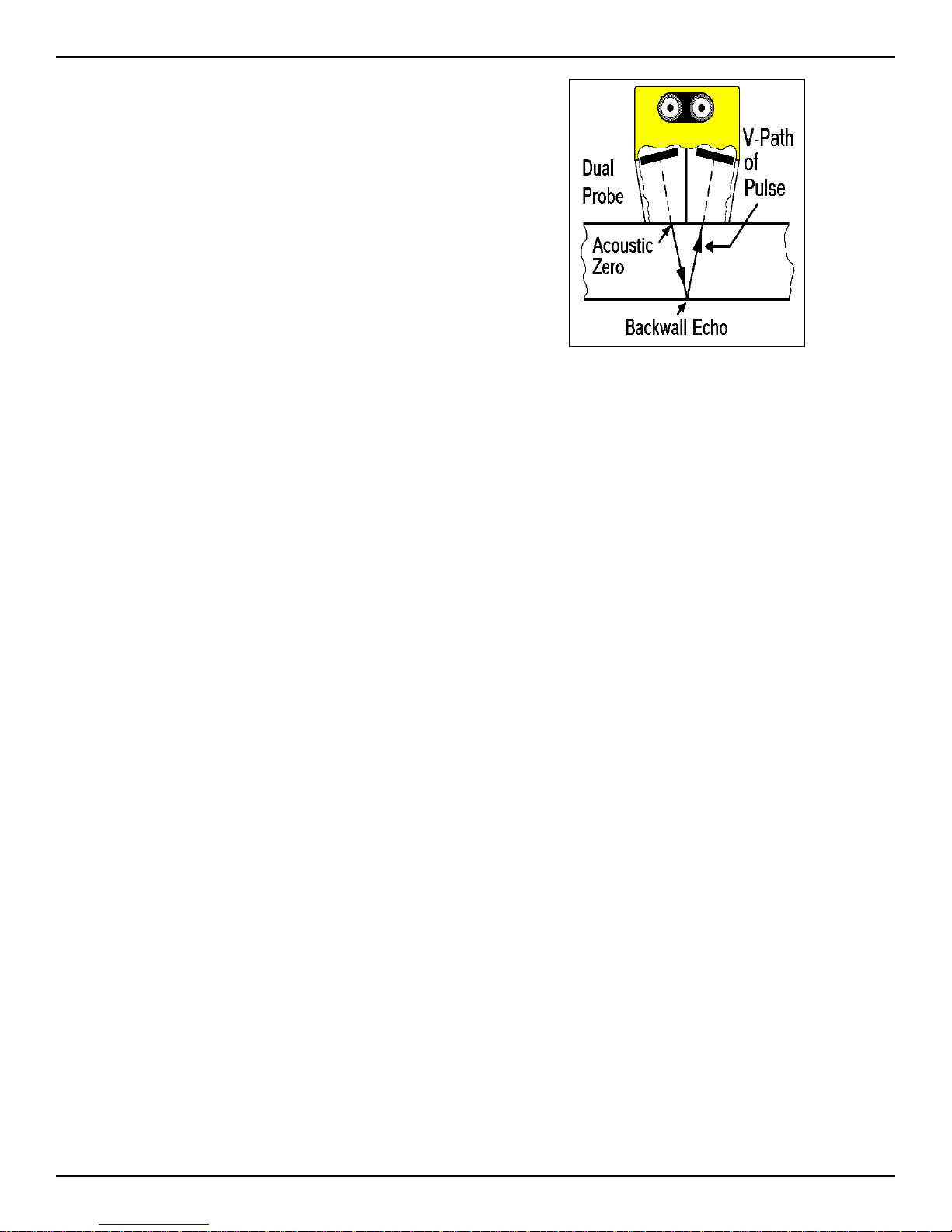

1.3 How DM4E, DM4, DM4 DL Measure Thickness

These instruments operate on the ultrasonic pulse-echo principle,

similar to sonar. A short ultrasonic pulse is transmitted into the

part by a probe (transducer). The pulse travels through the material under test until it encounters an interface, that is a material

with substantially different physical characteristics, such as air or

liquid, at the back surface of the part. At the interface, the pulse

is reflected back to the probe.

statistics, and readings.

®

and UltraPIPE® Windows 95/98/NT compat-

for reviewing,

transfers data to an

DM4E, DM4, DM4 DL Operating Manual

Page 5

1.0 Introduction

The time needed for the pulse to make this round trip is divided

by two and multiplied by the velocity of sound in the material

under test. The result is the thickness of the material.

The figure at right illustrates the pulse-echo principle of ultrasonic

thickness measurement.

Dual Element Thickness Measurement

Page 6

DM4E, DM4, DM4 DL Operating Manual

2. Operation

2.1 Battery Installation

NOTE: When low battery indicator lights (below), replace batteries as soon as possible. Automatic shutoff occurs when batteries are too weak for reliable

operation. Settings are saved and restored when

turned on. When testing in remote locations, always

carry spare batteries.

Low battery indicator:

To install batteries, loosen the two battery cover screws on the

back of the instrument and remove the battery cover.

Insert 2 “AA” alkaline batteries as shown at right. The instrument

is protected against incorrect battery installation. If the batteries

are installed with polarity reversed, no damage will occur, but the

instrument will not operate.

After batteries have been installed, replace the battery cover and

tighten the screws.

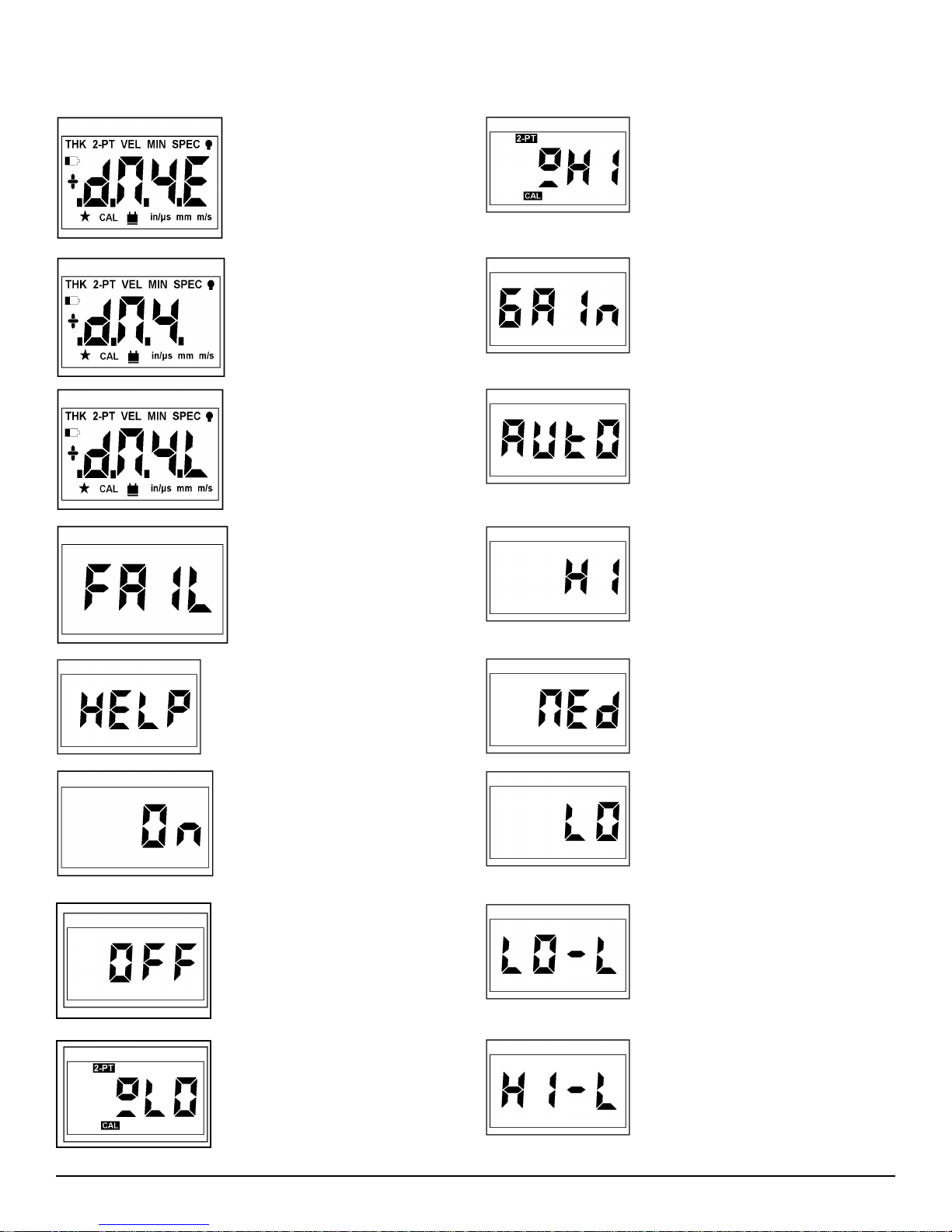

2-PT 2-point calibration mode.

VEL Velocity display and callibration mode.

MIN Minimum capture mode

SPEC Special modes (DM4, DM4 DL) (Sections 2.10

through 2.13 and 2.18)

Display backlight control.

Low barery indicator. Replace batteries when

indicator illuminates as shown.

In dIF mode, reading is greater than nominal.

If HI thickness limit is on, reading exceeds limit.

(DM4, DM4 DL)

In dIF mode, reading is less than nominal. If LO

thickness limit is on, reading violates limit.

(DM4, DM4 DL)

« DIALOGIntelligent Transducer automatically

recognized

2.2 Displays Symbols

CAL Flashes when CAL key is pressed. Scrolling

keys are enabled to adjust displayed value or

control parameter.

Coupling indicator lights when satisfactory

acoustic coupling between the probe and test

piece has been achieved.

in Unit of measure of displayed value is inches

(in/µs in VEL mode).

Mm Unit of measure of displayed value is millimeters

(m/s in VEL mode).

Note:

To charge the unit of measure and display

resolution refer to Section 2.14.

THK Thickness measurement and standard 1-point

calibration mode.

THK Dual Multi “Through Coating (paint)”

SPEC measurement mode.

DM4E, DM4, DM4 DL Operating Manual

Page 7

2.0 Operation

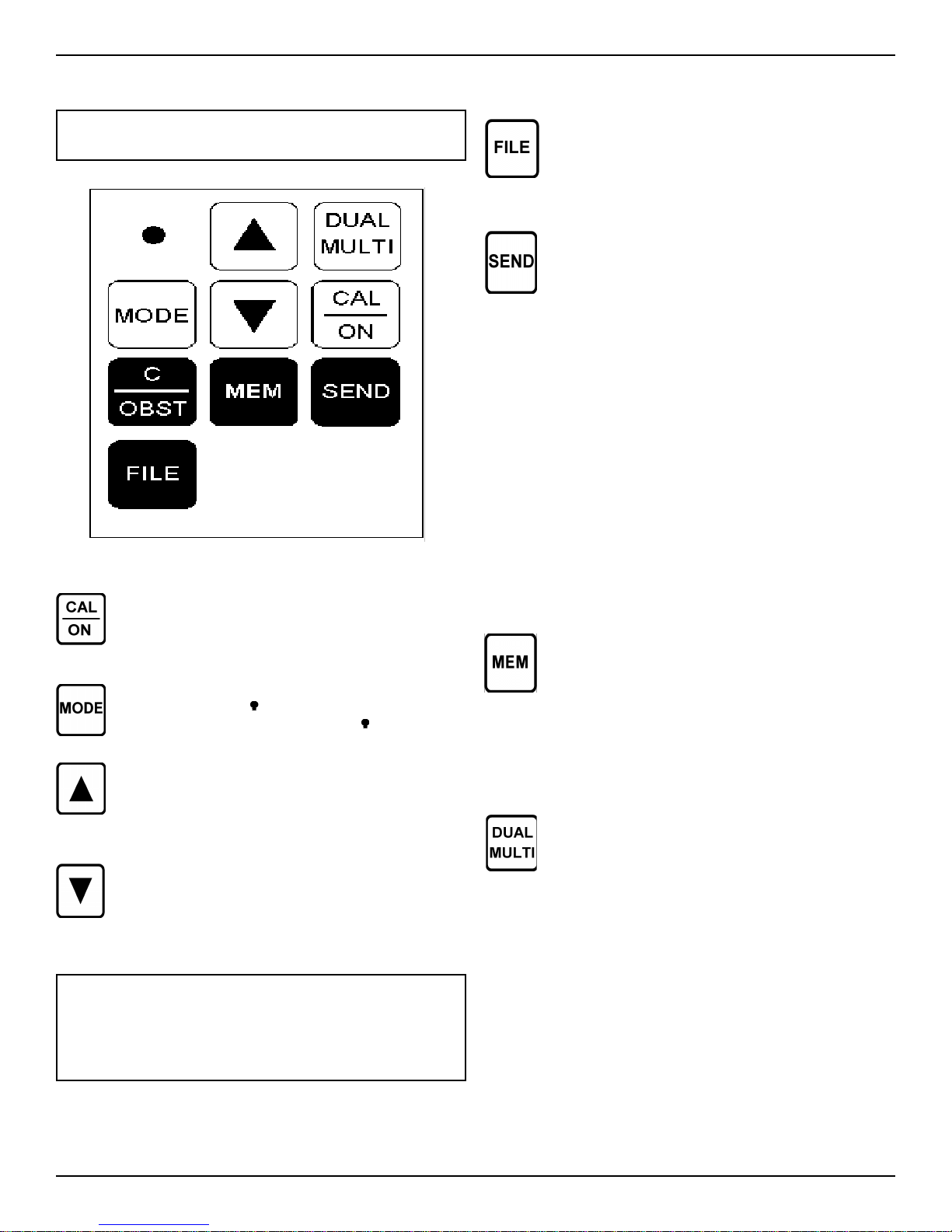

2.3 Keyboard Controls

NOTE: SEND, C/OBST, MEM, and FILE keys

are DM4 DL only.

Instrument Control Keys

Turns on the instrument. When on, activates CAL

(calibration) mode and enables scrolling keys

Selects the operating mode - THK, 2-PT, VEL,

MIN, SPEC, and

modes from left to right, and from

The SCROLLING keys, when enabled by the

CAL key, change the displayed value or instrument control option.

When enabled by the FILE key , they are used to

set the number of Data Logger files and select

files.

. Multiple presses activate

back to THK.

DM4 DL Data Logging and Communication Keys

Activates the scrolling keys to select a file

(File Select) or, if Data Logger memory is

clear, setting the number of files. Setting

number of files can only be performed when

the entire memory is clear.

Transmits data to the on board Data Logger,

or to an external device via the Serial I/O

port. The function of the SEND key is

dependent upon the type of cable connected

to the Serial I/O port:

No connection - SEND is active in all measurement modes. Displayed thickness is sent

to the on board Data Logger, if configured.

DR1 Data Recorder connected - SEND is

active in THK (Thickness), and MIN (Minimum Capture) modes. Displayed thickness

is sent to the DR1.

RS232C peripheral connection (PC/software,

printer, data logger, etc.) - Pressing SEND in

any measurement mode transmits the displayed value. Pressing SEND during the File

Select function transmits the displayed file or

all files. Second push of SEND aborts the transmission.

Provides access to the selected file of the onboard Data Logger for selecting locations and

reviewing stored thickness readings.

Clears the data logger readings, files, or entire

memory. Displays “OBSTRUCT” value, when

probe is uncoupled, to be sent to active data

logger location. Refer to Chapter 3 for detailled

instructions.

Sets the Dual element Multi-echo mode for through

coating measurements. A second press turns off

Dual-Multi mode and returns the instrument to conventional thickness measurement mode.

When enabled by the MEM key , they are used to

select file locations and review readings stored in

memory.

NOTE: The scrolling keys are also used to

change the resolution and unit of measure by

pressing both keys simultaneously in THK

mode (CAL indicator must be off)

Page 8

DM4E, DM4, DM4 DL Operating Manual

2.0 Operation

Model DM4E

2.4 Getting Started

Read “Important Notices” at the beginning of this manual, and

Chapter 6, “Application Notes,” for important information on test

conditions that affect measurement results.

Select a suitable probe (Section 5.2) and connect it to the probe

connector on the top panel. See Section 4.3 to select a report

language other than English.

Press

annunciators are briefly displayed as shown above, followed by

the current software revision number. Then, the operating mode

and settings from the last session are restored. NOTE: If using

a NON-DIALOG KBA560 Family Probe (i.e. KBA560, KBA560WR, KBA560-V) or DA301

Probe, either P560 or P301 may be displayed. If this occurs,

the user must tell the instrument which probe is connected by

toggling with the Up and Down arrow keys to select P560 for a

KBA560 style probe or P301 for the DA301 probe, and press

the CAL/ON key to perform the probe zero procedure and operate the instrument.

Automatic shut-off occurs after 3 minutes of inactivity.

Coupling probe or pressing a key restarts the timing.

To change the unit of measure or select a different display

resolution setting refer to Section 2.14.

to turn on the instrument. The model and display

Model DM4

2.5 Calibration to a Known Thickness, 1-Point

NOTE:

velocity of sound as the material to be measured is required . For best results, the thickness of the calibration

standard should be equal to, or slightly greater than the

thickest part to be measured.

NOTE:

ment or connecting probe to instrument for best Automatic

Probe Zero results.

A calibration standard of the same material and

Wipe face of probe clean before turning on instru-

Model DM4 DL

1-point calibration can only be performed if 2-PT mode is

OFF (Section 2.6).

If necessary , press until THK is displayed.

Press

no action until “PO” disappears indicating Automatic Probe

Zero is complete. With CAL flashing, couple the probe to the

calibration standard. Be sure the coupling indicator (

lights and the reading is stable, as in Figure 2-3. The displayed value may not match the known thickness of the calibration standard at this point. You may keep the probe coupled

or uncouple the probe and wipe the excess couplant from the

probe face.

. All symbols and “PO” are briefly displayed. Take

)

If low light makes the display difficult to read, refer to Section

2.15 for instructions on using the backlight.

Before taking measurements, perform 1-point calibration

(Section 2.5) or 2-point calibration (Section 2.6).

NOTE:

DM4E, DM4 and DM4 DL feature automatic probe

zero for standard probes and automatic probe recognition for

DIALOG Intelligent Transducers.

Figure 2-3

DM4E, DM4, DM4 DL Operating Manual

Use and to adjust the displayed value to match the

thickness of the calibration standard. Scrolling speed accelerates as

the key is held. If a key is released for less than 1 second, scrolling

will resume at the same speed. Figure 2-4 shows how the display

should appear with a 0.200 inch calibration standard.

Press again to end the calibration procedure.

Proceed to Section 2.8 for normal thickness measurement (THK

mode) procedure.

Figure 2-4

Page 9

2.0 Operation

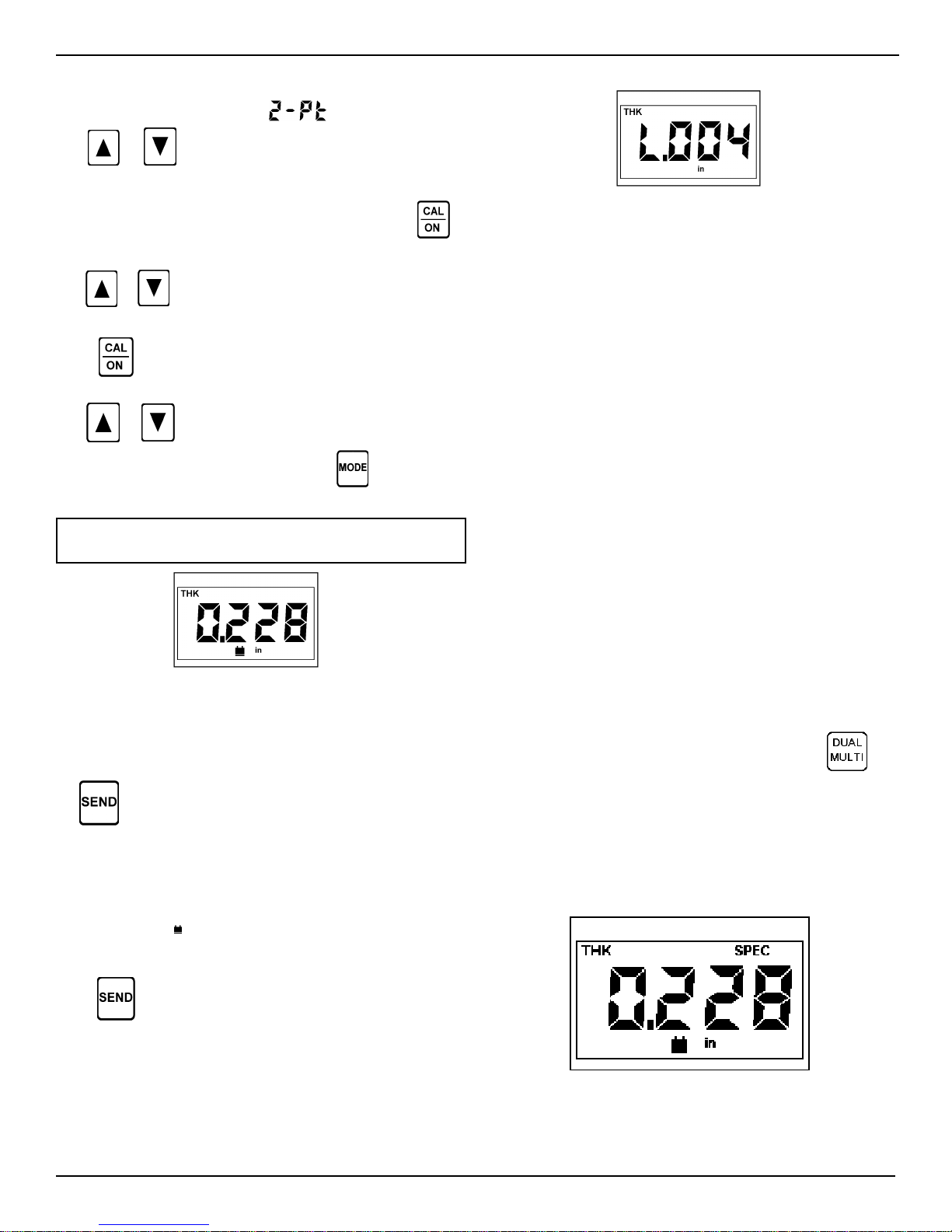

2.6Calibration to a Known Thickness, 2-Point

NOTE:

dard with two thicknesses) of the same material, velocity ,

and curvature as the material under test.

For best results, the thicker standard should be equal to, or

slightly greater than the maximum thickness to be measured.

The thickness of the thin standard should be as close as possible to the lower end of the expected measurement range.

If necessary , press

is displayed.

Press

Requires two calibration standards (or one stan-

until 2-PT (2-point calibration mode)

to display current status, On or Off.

Figure 2-5

Figure 2-7

Press again. The prompt to couple to the “HI” (thick) calibration standard is displayed -

Couple the probe to the thick calibration standard. Again, be

sure the coupling indicator (

Use

thick calibration standard.

Press

remains illuminated (Figure 2-7) to show that the current cali-

bration is 2-point and that automatic probe zero,

and to adjust the displayed value to match the

to exit 2-point calibration mode. The 2-PT indicator

) lights and the reading is stable.

Use or to enable 2-PT (On as in Figure 2-5).

Press

prompt to couple to the “LO” (thin) calibration standard appears,

as shown in Figure 2-6.

again. The 2-PT indicator now flashes and the

Figure 2-6

Couple the probe to the thin calibration standard. Be sure the

coupling indicator (

may keep the probe coupled or uncouple and wipe the excess

couplant from the probe face.

Use and to adjust the displayed value to match the

) lights and the reading is stable. You

Figure 2-8

1-point calibration, and velocity calibration functions are disabled.

The 2-point calibration procedure is complete and the instrument

is ready for thickness measurement (Section 2.8).

To disable 2-PT calibration mode:

T o disable 2-PT calibration, press

to change the status to OFF (Figure 2-8).

The CAL and 2-PT indicators are turned off and the instrument

returns to THK mode.

and use or

thickness of the thin calibration standard.

Page 10

DM4E, DM4, DM4 DL Operating Manual

2.0 Operation

Figure 2-9

2.7 Calibration to a Known Velocity

NOTE:

If you know the velocity of sound of the material to be measured,

the instrument can be calibrated to the known velocity without

the use of a calibration standard. However, the calibration should

always be verified by measuring a known thickness (or calibration standard) of the same material and velocity as the material

to be measured.

T o calibrate to a known velocity , press

The current velocity setting is displayed, as illustrated in

Figure 2-9.

Press

Table 2-1: Typical Sound Velocities in Various Materials (Longitudinal Wave)

2-PT calibration mode must be set to OFF.

until VEL illuminates.

to enable calibration mode.

Material in/µs m/s Material in/µs m/s

Figure 2-10

With the CAL indicator flashing, use and to set the

displayed velocity to that of the material under test.

Figure 2-10 shows how the display would appear for a calibration of .2328 inches per microsecond.

Press

THK mode.

Table 2-1, below, shows typical sound velocities for some common materials. Because processing, exact composition, and temperature affect velocity, the values may not precisely match the

velocity in the material to be measured.

again to exit velocity calibration mode and return to

Aluminum .2500 6300 Nylon .1000 2500

Brass .1700 4300 Phenolic .0560 1400

Cadmium .1100 2800 Platinum .1600 4100

Cast Iron .1800 4600 Plexiglas .1100 2800

Copper .1800 4600 Polyethylene .0700 1800

Epoxy Resin .1100 2800 Polystyrene .0930 2400

Glass (Crown) .2200 5600 Polyurethane .0700 1800

Glass (Window) .2700 6800 Porcelain .2200 5600

Gold .1300 3300 Rubber (Butyl) .0730 1900

Inconel .2200 5600 Rubber (Vulc.) .0900 2300

Lead .0850 2200 Silver .1400 3600

Magnesium .2300 5800 Steel .2300 5800

Manganese .1800 4600 Tin .1300 3300

Molybdenum .2500 6300 Titanium .2400 6100

Monel .2100 5300 Tungsten .2100 5300

Neoprene .0630 1600 Zinc .1600 4100

Nickel .2200 5600 Zircaloy 2 .1900 4700

NOTE: This information is provided for the convenience of the user and Agfa NDT Inc. assumes no responsibility for inaccuracies. Actual velocities depend on exact composition, temperature, and processing of each material.

DM4E, DM4, DM4 DL Operating Manual

DM4E, DM4, DM4 DL Operating Manual

Page 11

2.0 Operation

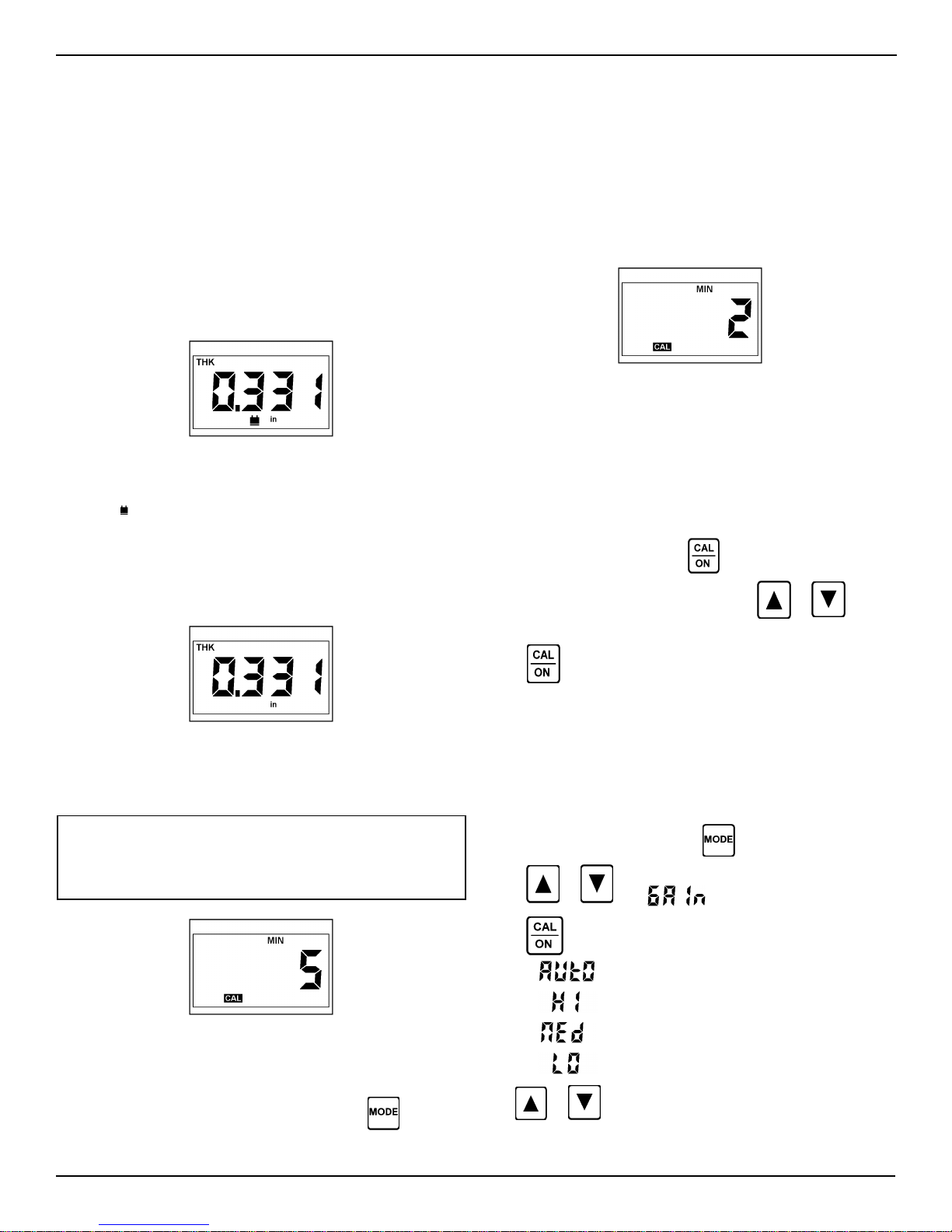

2.8 Normal Thickness Measurement - THK Mode

This procedure applies to parts with ambient surface temperatures. Refer to Section 6.2 for information on taking measurements on hot surfaces.

Be sure that the instrument is on and that the appropriate calibration procedures in Section 2.5, 2.6, or 2.7 have been completed

for the selected probe type and material to be measured.

If using the alarm feature (DM4 and DM4 DL), make sure the

correct LO and HI limits are set and the alarm is on (Sect. 2.11).

Remove any dirt, loose scale, or flaking from the test surface

and spread a thin layer of couplant on it.

Figure 2-11

Place the probe gently but firmly on the surface. The coupling

indicator ( ) must light, as in Figure 2-11. Use firm, steady pressure to obtain a stable reading.

MIN mode is used to capture the thinnest value during a series of

readings or rapid sequence of measurements. The measurement updates at high speed to assure detection of thinnest value

during the cycle.

When the probe is uncoupled, the detected minimum is displayed

and MIN flashes to indicate that the time-out sequence has begun. Recoupling the probe while MIN is flashing allows the capture cycle to continue.

Figure 2-14

To end the capture cycle, uncouple the probe for at least the

number of seconds set in the current time-out setting, that is, until

MIN stops flashing. Coupling the probe begins a new minimum

capture cycle.

Setting MIN Time-Out:

The MIN time-out is adjustable from 1 to 5 seconds. With the

The digital thickness reading can be read from the display while

coupled, or the probe can be uncoupled and the last reading will

be held on the display.

Figure 2-12

If incorrect values occur repeatedly, check probe selection

(Sect. 5.2) or contact your Agfa NDT Inc. representative.

NOTE: If a reading is not possible due to low signal caused

by poor coupling or high material attenuation, or if “doubling”

is detected (see page 3), the coupling indicator will not light

and the display will not update.

instrument in MIN mode, press

out setting in seconds (Figure 2-13). Use

select a new setting (Figure 2-14).

Press again to activate the new time-out setting and

return to MIN mode for minimum capture measurement

2.10 Receiver Gain Control (DM4, DM4 DL)

The DM4 and DM4 DL have four gain setting options, Automatic,

High, Medium, and Low. The default is Automatic, which automatically selects a gain setting based on the velocity value.

T o change the gain setting, press

Press

Press

or until appears in the display .

to display current setting:

Automatic gain

High gain

to display the current time-

or to

until SPEC illuminates.

Figure 2-13

2.9 Minimum Capture Measurement

To enable the minimum capture mode, press

illuminates.

Page 12

until MIN

Use

Medium gain

Low gain

or to select a new setting.

DM4E, DM4, DM4 DL Operating Manual

Press again to exit the gain select function.

When the instrument shuts off, current setting is saved and re-

stored when the instrument is turned on again.

2.0 Operation

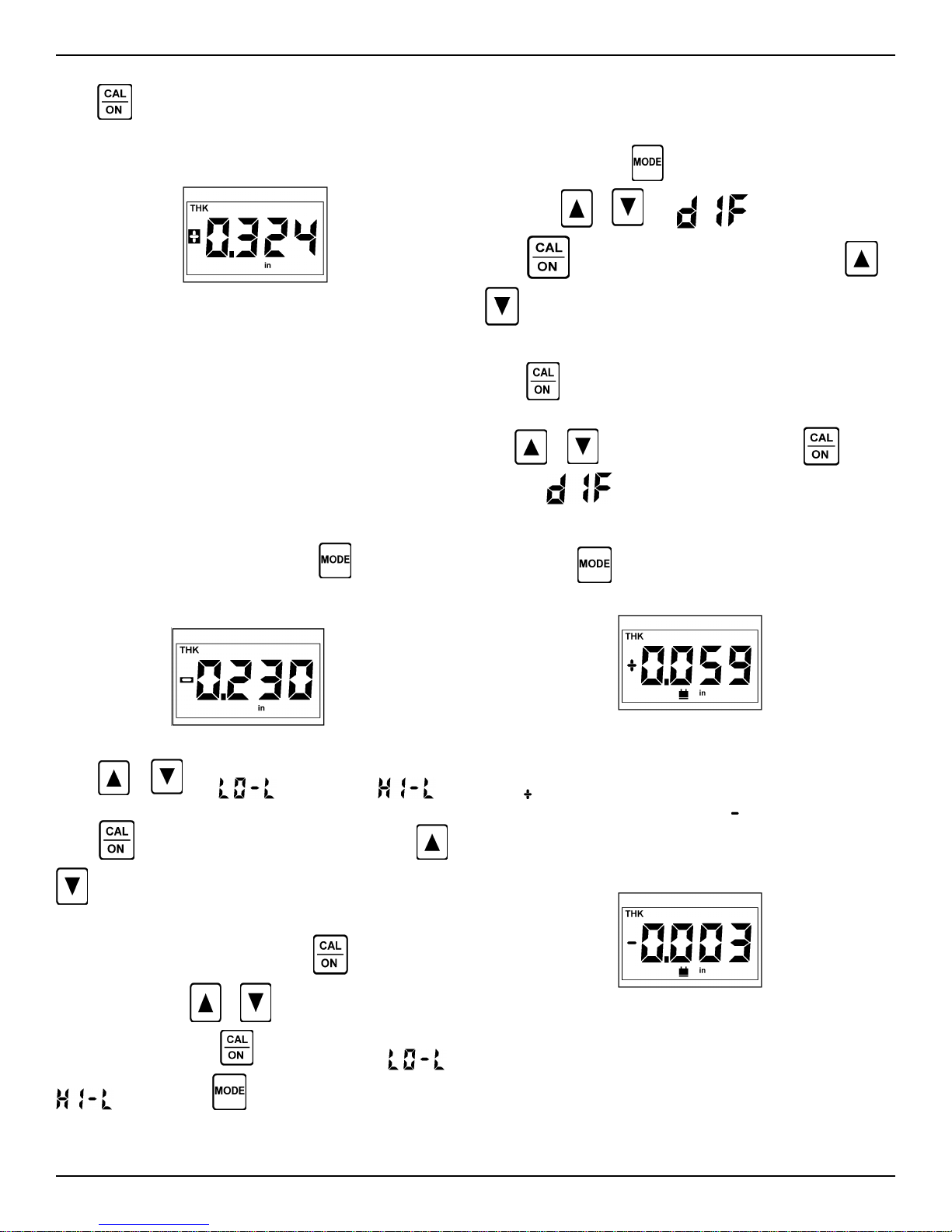

2.12 Differential Measurement (DM4, DM4 DL)

Differential measurement mode displays the difference between

the measured thickness and a nominal value set by the user. To

enter dIF mode, press

until SPEC illuminates.

Figure 2-15

2.11 Using LO / HI Thickness Limits (DM4, DM4 DL)

WARNING: If a file containing normal thickness (THK) data is

currently active, changing the LO or HI limit replaces any settings previously stored in the file.

LO and HI limits identify readings that violate user set lower and

upper limits. When LO and/or HI limits are set, a reading that

violates either causes the red LED (front panel) to light.

A flashing plus sign (Figure 2-15) indicates the reading exceeds

the HI limit. A flashing minus sign (Figure 2-16) indicates a reading that is less than the LO limit.

T o set and enable LO and HI limits press

nates.

until SPEC illumi-

Then press

Press

to turn differential mode On and Off

Setting the Nominal Value:

Press

Use

return to

To perform differential measurement, with dIF mode On, return

to THK mode

Section 2.8.

or until appears in the display .

to display current status, On or Off. Use or

to display the current nominal value setting.

or to set the desired value. Press again to

display.

and follow the measurement procedure in

Figure 2-16

Press or until (lower limit) or (upper limit) appears in the display .

Press

Setting LO and HI Limits:

With the desired alarm mode On, press

rent limit setting. Use

0.5 to 500 mm). Press

to display current status, On or Off. Use or

to turn either alarm mode On or Off.

to display the cur-

or to set the limit (0.020 to 20.00";

again to return to or

display . Press to return to THK mode.

Figure 2-17

Figure 2-17 shows a differential reading that is 0.059 inch greater

than ( ) the user set nominal value. In Figure 2-18 the actual

measurement is 0.003 inch less than ( ) the nominal.

T o disable dif ferential measurement, follow the procedure at the

beginning of this section.

Figure 2-18

DM4E, DM4, DM4 DL Operating Manual

Page 13

2.0 Operation

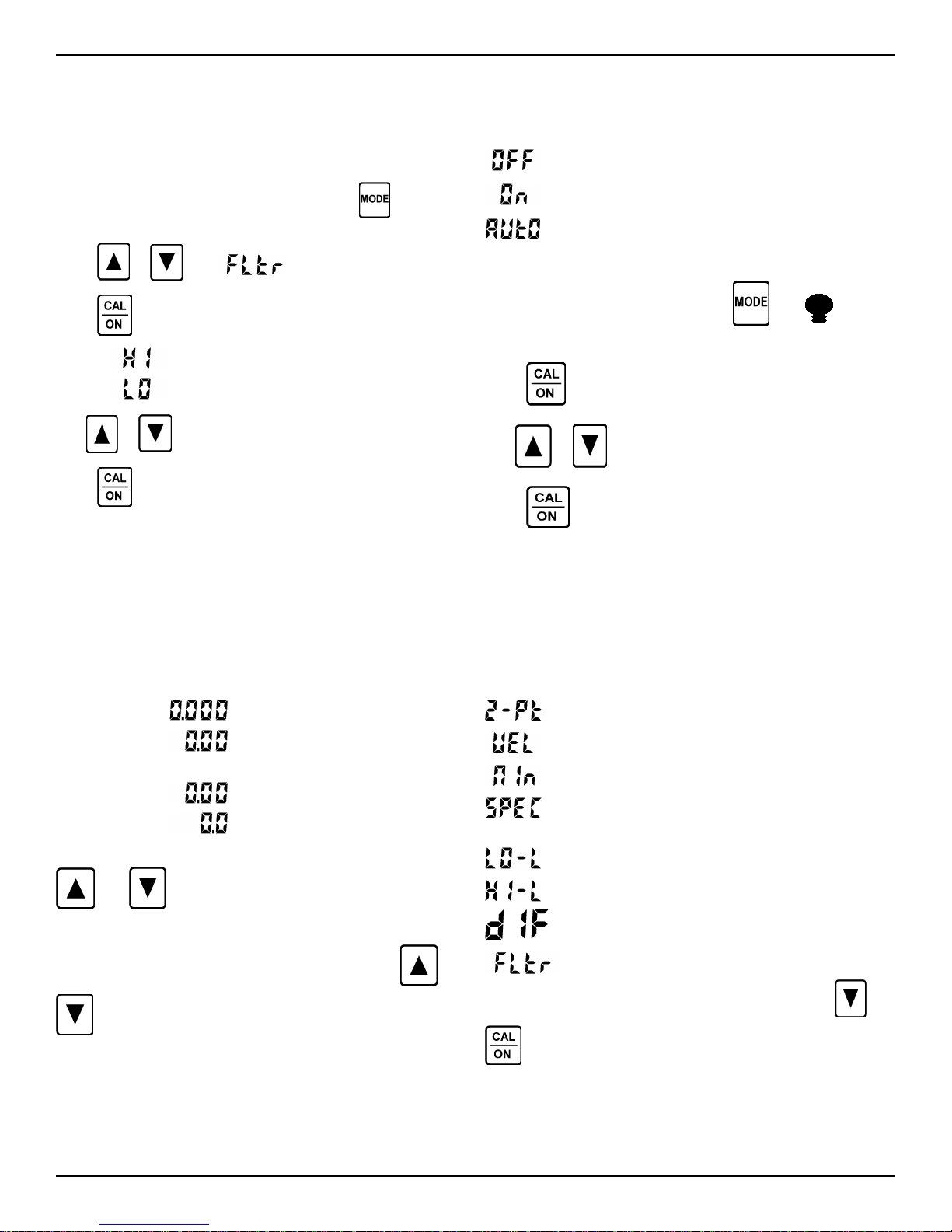

2.13 Band Pass Filter Control (DM4, DM4 DL)

The Band Pass Filter control of the DM4 and DM4 DL sets the

band pass of the instrument receiver for the frequency of the

connected probe. The default setting is HI for probes of 2 MHz

to 10 MHz frequency .

To change the Band Pass Filter setting, press

illuminates.

Press or until appears in the display.

Press

Use

Press

When the instrument shuts off, the current Band Pass Filter setting is saved and restored when the instrument is turned on again.

to display current setting:

High - 2 MHz to 10 MHz

Low - 300 KHz to 2 MHz

or to select the desired setting.

again to exit the gain select function.

until SPEC

2.15 Display Backlight

Three available backlight options are:

Backlight disabled; maximum battery life

Backlight is on continuously; less battery life

Automatic Backlight; backlight activates when probe

is coupled or key is pressed and remains on for 5

seconds

T o change the backlight setting, press until

illuminates.

Press

Use

Press again to exit the backlight function.

When the instrument shuts off, the current backlight setting is

saved and will be restored when the instrument is turned on again

to display the current setting.

or to select a new setting.

2.14 Display Resolution and Unit of Measure

Four display resolution settings are available, two in inch units

and two in metric units, as shown below.

Inch Settings:

(Default)

Metric Settings:

To change display resolution or unit of measure, press both

and at the same time. Keep pressing both keys

until the desired setting is displayed.

In VEL mode, with CAL off, simultaneously pressing

switches between inch and metric units. Velocity will

bedisplayed in the newly selected units.

and

2.16 Disabling/Enabling Functions

Specific instrument functions and modes can be disabled so that

they are not available during normal operation. They can also be

enabled again.

The following functions can be disabled/enabled:

2-point calibration

Velocity mode

Minimum capture mode

Entire SPEC menu (DM4, DM4 DL)

Gain function (DM4, DM4 DL)

Low limit alarm mode (DM4, DM4 DL)

High limit alarm mode (DM4, DM4 DL)

Differential mode (DM4, DM4 DL)

Band Pass Filter Control (DM4, DM4 DL)

To disable or enable one or more of the above, press

simultaneously while the instrument is off and hold both

and

When the instrument shuts off, the resolution setting is saved

and restored when the unit is turned on.

Page 14

keys for 3 seconds..

DM4E, DM4, DM4 DL Operating Manual

After briefly displaying the instrument version and display indicators, the first mode is displayed:

2.0 Operation

Use or to scroll through and select the function or

mode to be disabled or enabled.

When the desired function or mode is displayed, press

display the current setting, On or OFF.

Use

function or mode.

Press

upon will be displayed.

Use

or mode to be disabled or enabled or press

cedure.

or to disable (OFF) or enable (On) the displayed

again. The function or mode that has been acted

or to scroll through and select another function

to end the pro-

to

NOTE: Disabled modes and functions will automatically

be set to their default settings.

Figure 2-20

When a reading is sent to an empty file, the current settings of

the HI/LO limits are saved with the file. Selecting an existing file

automatically activates the limits saved with the file. The settings

may be changed (Section 2.11). However, the previously saved

settings will be replaced in the file by the new ones.

When a differential reading (Section 2.12) is sent to an empty

file, the current setting of the nominal value is saved with the file.

Selecting a file with differential readings automatically activates

differential measurement mode and restores the saved nominal

value. The nominal value saved in a file may not be changed.

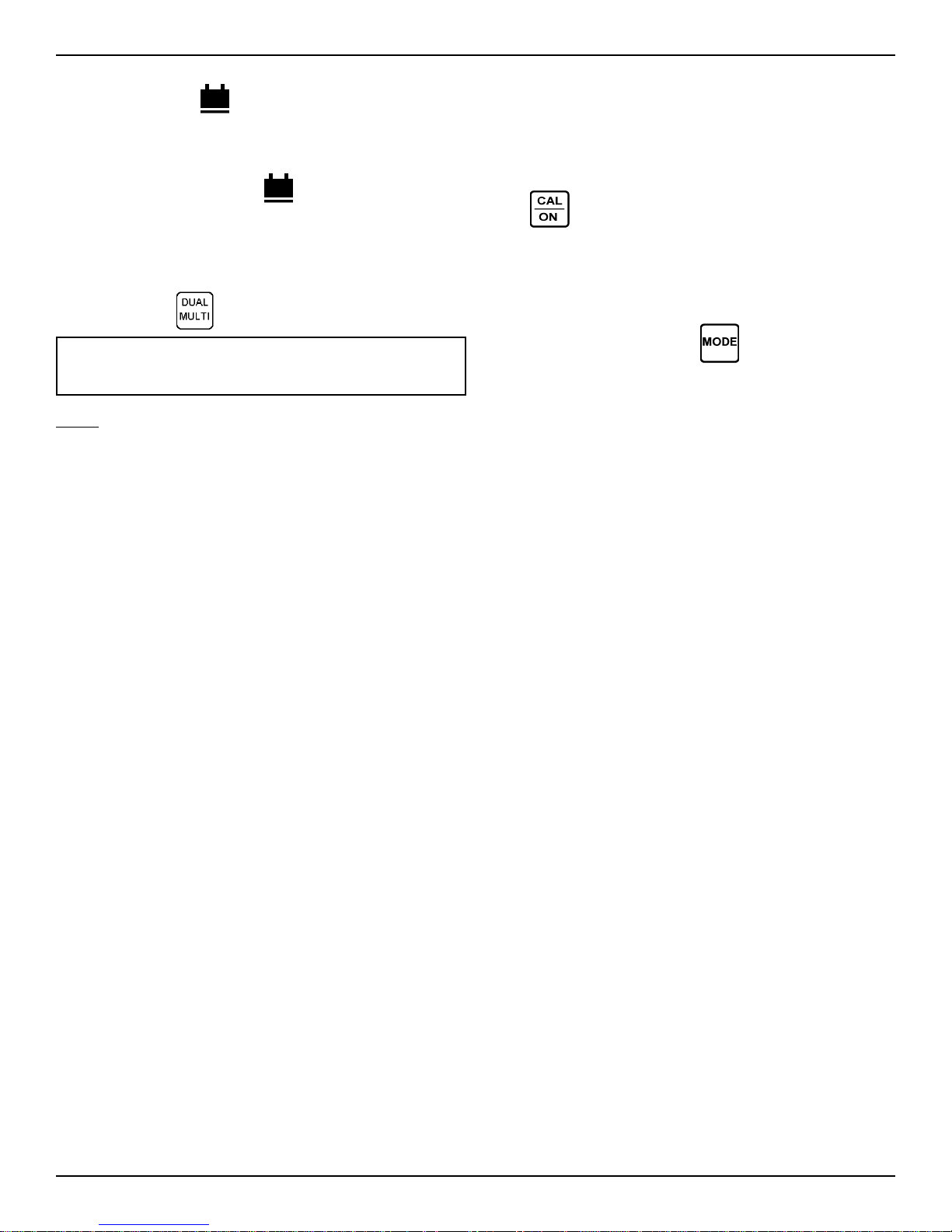

2.18 Dual Multi Measurement Mode (DM4, DM4 DL)

Protective coatings, including paint, contribute significant error to

the thickness measurement of the underlying metal when using

conventional measurement techniques.

The Dual-Multi mode eliminates coating layers from the measurement by measuring between successive backwall reflections

of the metal.

The Dual-Multi mode works with the following standard probes:

Figure 2-19

2.17 Recording Measurements (DM4 DL)

Displayed thickness readings are sent to the on-board Data Logger of the DM4 DL and most external recording devices by press-

ing

vices to the DM4 DL.

To record readings in the on-board Data Logger, follow the in-

structions in Chapter 3 to set up the Data Logger.

To record a reading, first perform the measurement. When the

coupling indicator (

uncouple the probe and wipe the excess couplant from the probe

face.

Press

displayed briefly (Figure 2-20). After a displayed reading has

been sent, the SEND key is disabled until a new reading is taken.

Zero values cannot be recorded.

. See Chapter 4 for details on connecting external de-

) lights (Figure 2-19) and the reading is stable,

. The location where the reading has been stored is

KBA560 Family, DA312, DA301, DA311, DM401

The measurement range for each probe will vary depending upon

the type and thickness of the coating, the thickness of the metal,

and the quality of the bond between the coating and metal.

To activate or deactivate the Dual-Multi mode, press

The THK and SPEC annunciators will illuminate to indicate that

the DUAL MULTI mode is activated. See figure 2-21. NOTE:

The SPEC annunciator will not illuminate unless one of the

above compatible probes is attached. If the DUAL MULTI key

is pressed when a non-compatible probe is connected, “nO”

will briefly be displayed and then the instrument will return to

the standard (THK) thickness mode.

.

DM4E, DM4, DM4 DL Operating Manual

Figure 2-21

Page 15

2.0 Operation

The coupling indicator ( ) will illuminate only when two backwall

echoes are detected.

In the event two backwall reflections are NOT detected:

The coupling indicator (

A row of dashes will be displayed.

The red LED will flash.

If a Dual-Multi measurement is not obtainable, the operator must

return the instrument to the standard thickness measurement

mode by pressing

Note: Complete removal of the coating may not be necessary . First try smoothing the surface and removing any loose

top layers.

and/or remove the coating.

) will not illuminate.

NOTE: If two backwall echoes are attainable on the calibration standard, a 1-Point Calibration can be performed in the

DUAL MULTI Mode. Press the DUAL MULTI key, verify that

both THK and SPEC are illuminated in the display, and refer to

section 2.5 ( 1-PT Calibration) beginning with “Press CAL/ON

KEY.”

The use of a DIALOG Intelligent Probe automatically selects either the standard “AUTO” or “DA3” mode.

T o select the DA3 mode when using non-dialog probes or to override the last selection:

Press

The model and display annunciators are briefly displayed (see

section 2.4 Getting Started), followed by the current software

revision number. Then, the operating mode used from the last

session is displayed. It will flash for approximately 3 seconds.

While the display is flashing, press

mode and DA3 mode.

Press any other key to start instrument operation using the selected mode. If no key is pressed within 3 seconds, the instrument will go into operation with the last selected zero mode.

CAUTION: Only DA Series Probes are to be used in the DA3

Operating Mode.

to turn the instrument on.

to toggle between AUTO

2.19 DA3 Operating Mode

This mode is characterized by the implementation of “on-block

zero”. This means that the acoustic zero point is dynamically

adjusted during the measurement process, compensating for

wear and “growth” during measurements.

This mode may offer advantages for certain applications such as

high temperature measurements.

Page 16

DM4E, DM4, DM4 DL Operating Manual

3. Data Logger Operation

3.1 The DM4 DL Data Logger

The DM4 DL on-board Data Logger provides a simple, reliable

way to record thickness measurements. Readings are stored in

one or more files by pressing the SEND key. A file is a number

of Data Logger memory locations that have been grouped together for storing readings, one reading per location, and reporting measurement data.

File size is determined automatically when the operator sets the

desired number of files, up to a maximum of 999. The DM4 DL

divides the total memory capacity , 5390 readings, by the number

of files specified and creates the maximum number of files, of

equal size, that Data Logger capacity allows.

The first reading is stored in each file starting with location number 1, unless the operator selects a different starting location.

Subsequent readings are stored sequentially until the last location has been filled or another file is selected to receive readings.

Location numbers and stored readings can be viewed and edited in the display . Individual file locations, entire files, or entire

memory can be cleared. Single files, or all files, can be transferred via the Serial I/O port to a printer or IBM compatible PC.

Report format is compatible with most serial printers. A utility

program is available from Agfa NDT Inc. for transferring data to

a PC (Section 4.5). Individual readings and velocity can be

sent to the Krautkramer DR1 Data Recorder. Refer to Chapter

4 for information on connecting external devices.

Stored readings are retained indefinitely in the memory of the

DM4 DL, even when the batteries are removed. However, backup

is recommended whenever possible.

The following Data Logger operations are described in Sections

3.2 through 3.10:

WARNING: Clearing memory permanently erases all readings stored in the DM4 DL Data Logger.

Figure 3-1

While C.ALL (Figure 3-1) is displayed, use or to set

the desired number of files (1 is the minimum): “n.001” = 1 file,

“n.002” = 2 files, etc.

Press

while memory is being configured.

The number of files set determines the size of each file, that is,

the number of available locations. Appendix B provides a table

showing the number of locations per file based on the number of

configured files, 1 through 806.

to terminate the procedure. “ConF” is displayed

NOTE: DIALOG Intelligent Transducer I.D., LO limit, HI

limit, and dIF value are saved with each file.

To log readings a file must be selected (ref. Section 3.3).

Default selection is File 1, Location 1.

Setting Number of Files Section 3.2

Selecting a File Section 3.3

Logging Readings into Memory Section 3.4

Selecting Locations Section 3.5

Reviewing Stored Readings Section 3.6

Clearing and Replacing Readings Section 3.7

Clearing Selected Files Section 3.8

Clearing Entire Memory Section 3.9

Permanent Storage Section 3.10

3.2 Setting Number of Files

Readings can not be stored until the desired number of files has

been set and one file has been selected to receive readings.

Follow the procedure in this section to set the number of files and

the size of each.

Setting number of files can only be done when entire memory is

clear. To check memory status, press

1) indicates memory is clear. If memory is not clear, refer to

Section 3.9 for instructions on clearing memory.

. C.ALL (Figure 3-

Figure 3-2

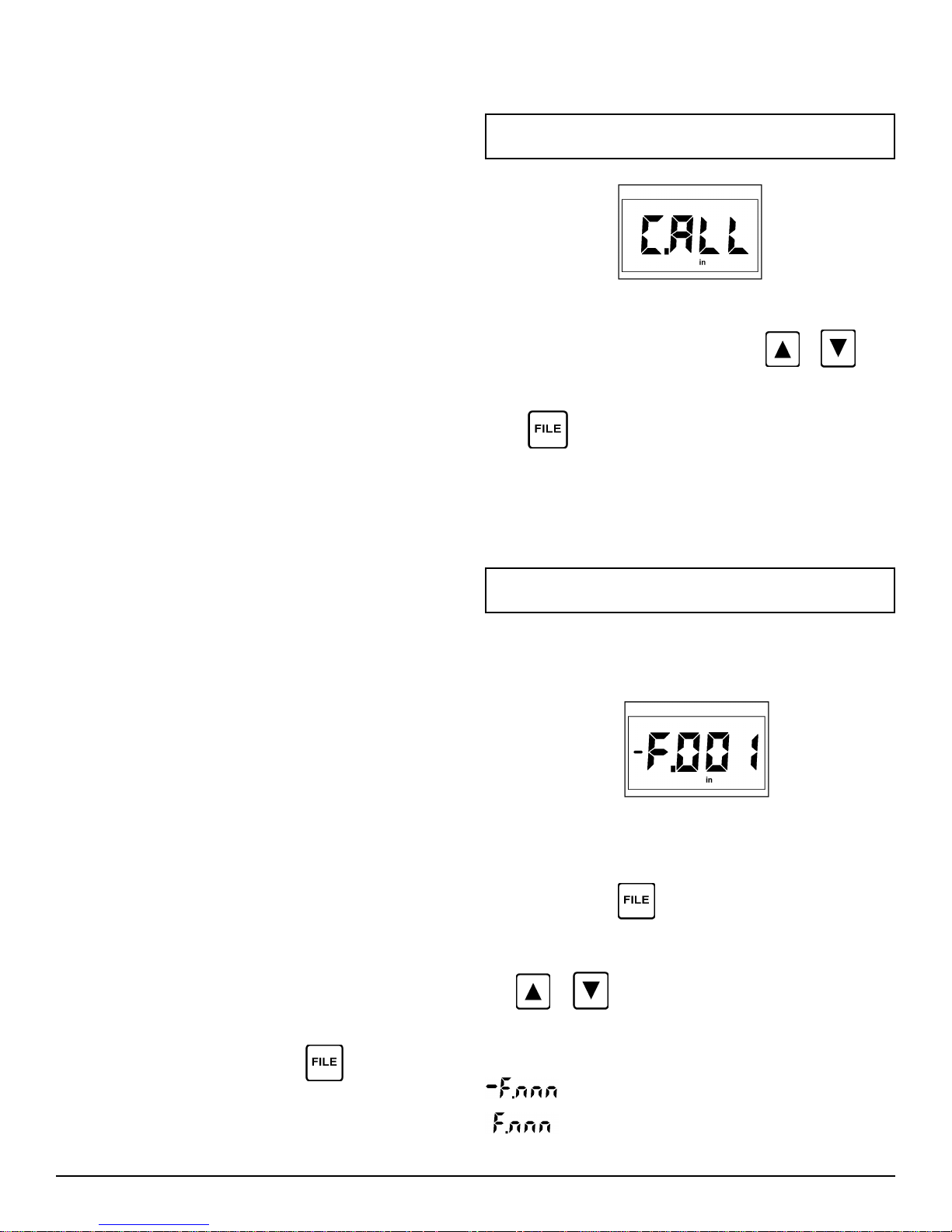

3.3 Selecting a File

Before measurements can be logged, a file must be selected

(Section 3.2). Press

file has been selected, “-F.001” is displayed (Figure 3-2). If “C.ALL”

is displayed, no files exist. Return to Section 3.2.

Use

above the highest number loops to “.ALL” (all files) and back to

File 1. Scrolling below File 1 loops through “.ALL” to the highest

file number.

or to change the active file number. Scrolling

indicates empty file, no readings.

indicates active file with readings but not full.

to display the active file number. If no

DM4E, DM4, DM4 DL Operating Manual Page 17

3.0 Data Logger Operation

indicates a full file, no empty locations.

“nnn” (001 to 999) is the number of the selected file.

When the desired file number is displayed, press

again.

The current active location number of the selected file is

displayed briefly . Then the DM4 DL returns to measurement

mode and is ready to log readings

NOTES: When a file containing differential readings is

selected the DM4 DL switches to dIF mode and uses the

nominal value saved in the file as the current nominal value.

When a file containing HI/LO thickness limits is selected the

DM4 DL switches to THK mode and uses the limits saved in

the as the current limits.

When a file contains data collected using a DIALOG Intelligent Transducer, report sent to a printer or computer automatically include the model and serial numbers of the probe.

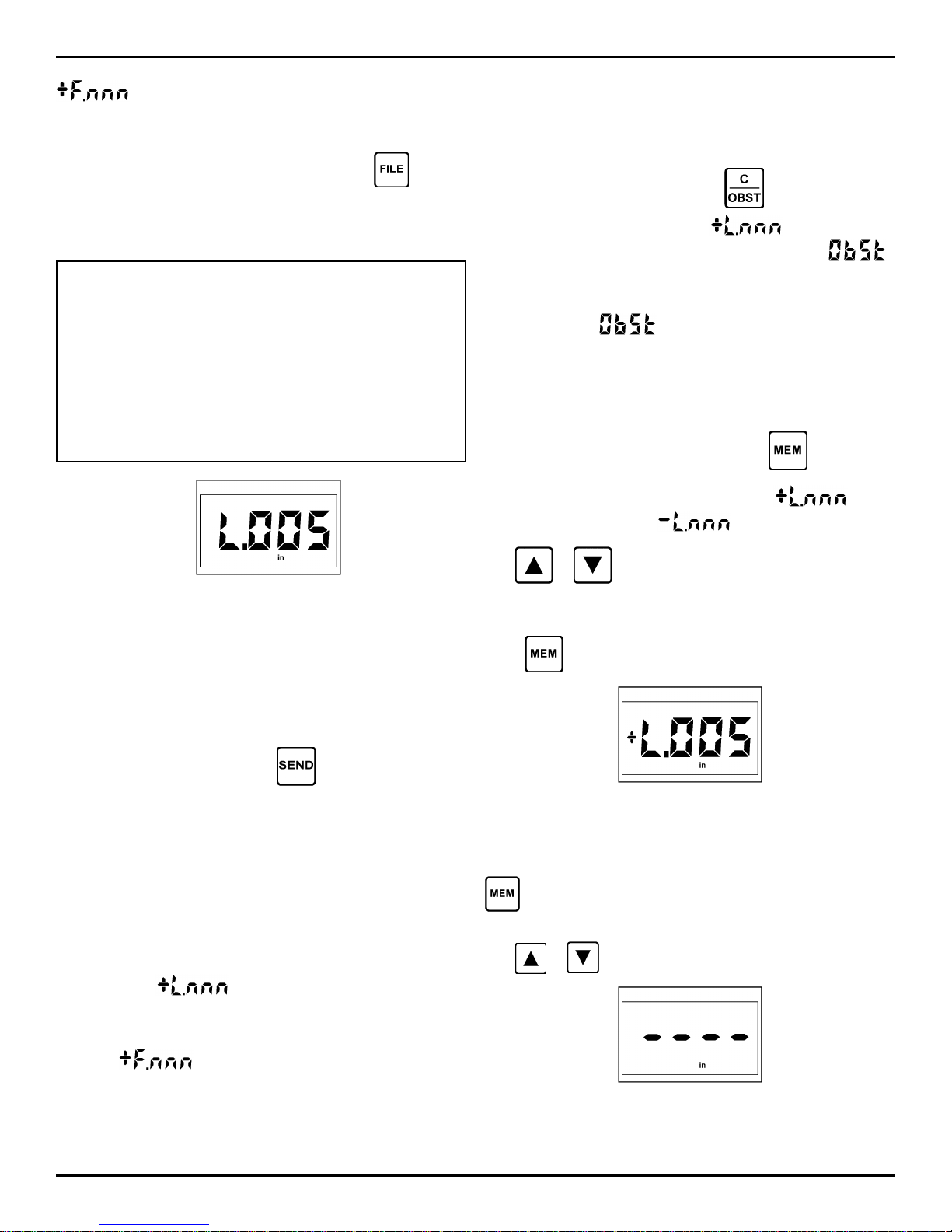

3.4.1 Recording an OBSTRUCT Value

If a measurement cannot be made or a location is inaccessible,

an “OBSTRUCT” value can be logged into the current active location.

While in THK or MIN mode, press

coupled. The location number,

with the probe un-

, where the OB-

STRUCT was stored is briefly displayed, followed by

An “OBSTRUCT” is stored in the current data logger location.

When reviewing stored readings (Section 3.6) obstructed

locations display .

3.5 Selecting Locations

While in THK or MIN mode, the MEM key is used to select file

locations and review stored readings.

To select a location in the current file, press

The current location number is displayed as

cation, as in Figure 3.4) or

(empty location).

.

(full lo-

.

Figure 3-3

3.4 Logging Readings into Memory

Measurements taken in THK (normal), dlF (differential), and MIN

(minimum capture) modes can be stored in the Data Logger if a

file with at least one empty location has been selected (Section

3.3). The Data Logger is disabled when an external recording

device is connected to the Serial I/O port (Chapter 4).

A reading is logged by pressing

(Section 2.17). If the

current file location is empty, the Data Logger stores the reading

and briefly displays the location number, “L.nnn” (Figure 3.3) as

confirmation.

After a displayed reading has been sent, the SEND key is

disabled until a new reading is taken. Unless a valid thickness

reading is in the display , no action occurs when SEND is

pressed. Zero values will not be logged. All readings in a

given file should be stored at the same resolution to assure

accurate statistics.

Location Full:

displays when trying to log to a loca-

tion that contains a reading. No data is recorded. To select an

empty location see Section 3.5.

Use

or to display the desired location.

To review stored readings, proceed to Section 3.6.

T o select the displayed location and return to THK or MIN mode,

press

two times.

Figure 3-4

3.6 Reviewing Stored Thickness Readings

While a location number is displayed, as in Figure 3-4, press

a second time to display the reading. Readings are dis-

played in the current unit of measure.

Use

or to view readings at other locations.

File Full:

displays when SEND is attempted to a file

with no empty locations. No data is recorded. To select another

file, refer to Section 3.3.

Figure 3-5

DM4E, DM4, DM4 DL Operating ManualPage 18

3.0 Data Logger Operation

A row of dashes (Figure 3-5) indicates an empty location.

indicates an obstructed location. A flashing plus sign

indicates the reading exceeds the HI limit stored with the file. A

flashing minus sign indicates a reading that is less than the LO

limit. “Err” (unlikely to occur) indicates that the reading has

been corrupted in memory and must be retaken.

Press

again to return to measurement mode.

Figure 3-6

3.7 Clearing and Replacing Readings

While a stored thickness reading is displayed (Section 3.6), the

C/OBST key (C = Clear) can be used to erase the reading from

that location.

T o clear a stored reading, display the reading to be cleared (Sect.

3.5 and 3.6) and press

cleared, dashes appear (Figure 3.6).

Press

now be logged to the cleared location.

to return to measurement mode. A new reading can

. When the reading has been

NOTE: “ Obstructed” locations do not need to be cleared.

Sending a thickness value automatically overwrites the

stored ObSt.

Press to return to measurement mode, or use or

to select another file.

Figure 3-8

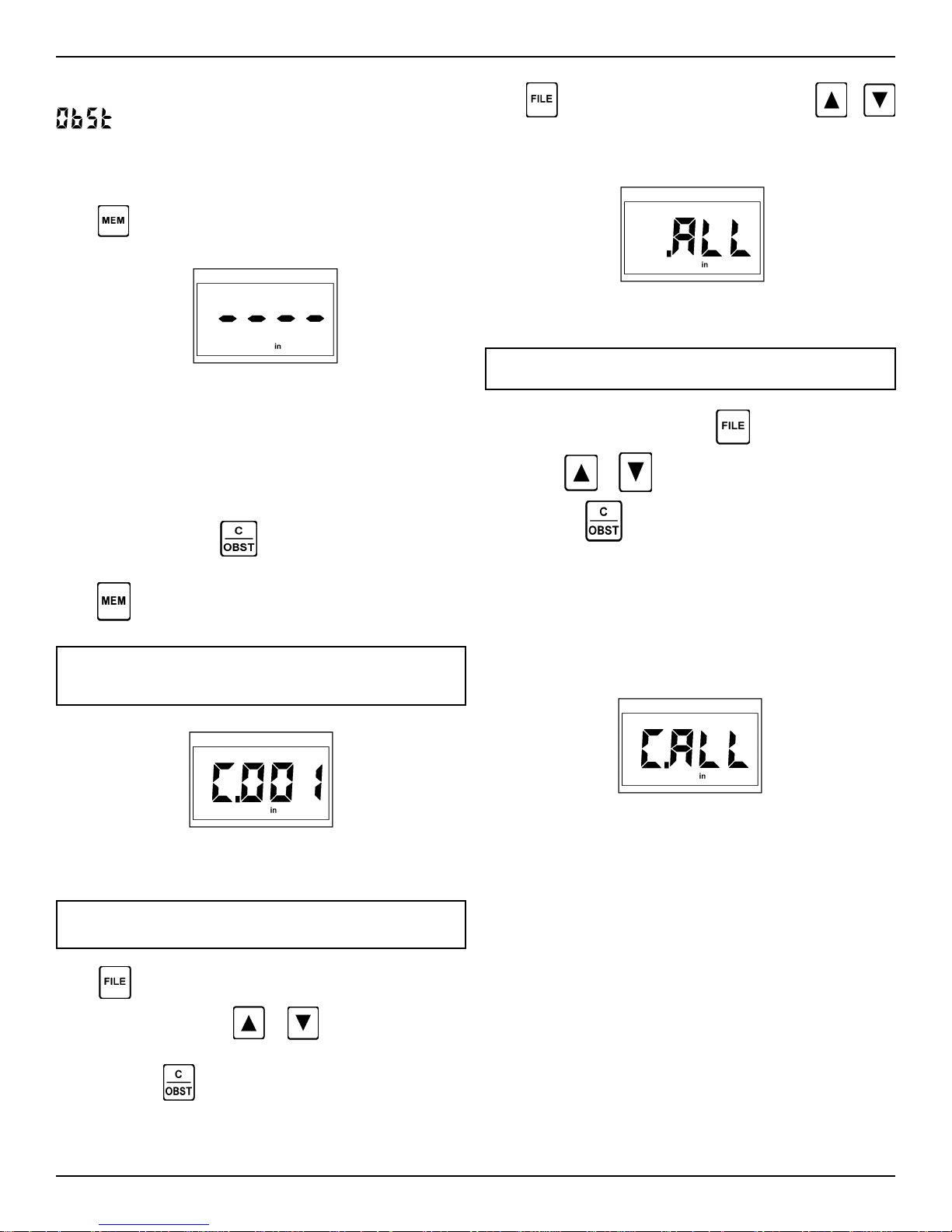

3.9 Clearing Entire Memory

WARNING: This operation permanently erases all read-

ings stored in the Data Logger of the DM4 DL.

To clear and reset memory, press while in THK or MIN

mode. Use or to display “.ALL” (Fig. 3-8).

Press and hold

display changes to “C.ALL” (Figure 3-9).

Data Logger memory is now clear. Readings can not be recorded until new files have been configured.

Follow the procedure in Section 3.2 to create new files and prepare the Data Logger to record readings.

for 3 seconds. When memory is clear, the

Figure 3-7

3.8 Clearing Selected Files

WARNING: This operation will permanently erase all

readings in the cleared file.

Press while in THK or MIN mode. The active file is dis-

played (Section 3.3). Use

cleared.

Press and hold

“C.nnn” (Figure 3-7). “nnn” is the cleared file number. Then “-

F.nnn” is displayed (empty file, Figure 3-2 on page 31).

DM4E, DM4, DM4 DL Operating Manual Page 19

for 3 seconds. DM4 DL briefly displays

or to select the file to be

Figure 3-9

3.10 Permanent Storage

Stored readings are retained in memory indefinitely , even when

the batteries have been removed. However, data could be lost

or corrupted if the DM4 DL were damaged or exposed to extreme environmental conditions.

For extended storage, files should be transferred to a computer

for storage on disk or tape. The DM4 DL Data Transfer Utility

program is available for this purpose. Contact your local Agfa

NDT Inc. representative for information.

Chapter 4 provides information needed to interface the DM4 DL

with an external device, such as a printer or computer, for file

storage.

4. Serial I/O Interface

4.1 The DM4 DL Serial Interface

The 7-pin Lemo #0B connector the top panel of the DM4 DL, is

the Serial I/O port. It is used to transmit readings and statistical

data to an external device, such as a printer or a personal computer.

For simple communication with a PC, an optional DM4 DL Data

Transfer Utility Program is available for use with any IBM PC, XT,

or A T compatible computer with at least 256K of available memory

and DOS version 3.3 or higher. Contact Agfa NDT Inc., or your

local representative for information.

The type of device connected to the Serial I/O port determines

the status of the on board Data Logger and how the DM4 DL

responds when the SEND key is pressed. Special cables, available from Agfa NDT Inc., must be used when connecting external devices to assure proper operation and transfer of data.

T able 4-1 summarizes the Data Logger and SEND operations of

the DM4 DL, based on the device connected.

Table 4-1: Data Logger and SEND Operation,

Based on Device Connected

Connected Data Logger SEND

Device Operation Operation

No Device Enabled Logs displayed thickness

in DM4 DL memory

DR1 Data Disabled Sends displayed thick-

ness or velocity to DR1

Recorder*

RS232C Device* Read Only Sends displayed

(PC, printer, thickness, material

RS232 data velocity, a selected

logger, etc.) file, or all files to periph-

eral device

*Special cable required; available from Agfa NDT Inc.

Press or to select .

Press

Press

Press

Available RS232 baud rate settings are 1200, 2400, 4800, and

9600.

to display the current setting.

or to select the new setting.

again to exit.

Figure 4-1

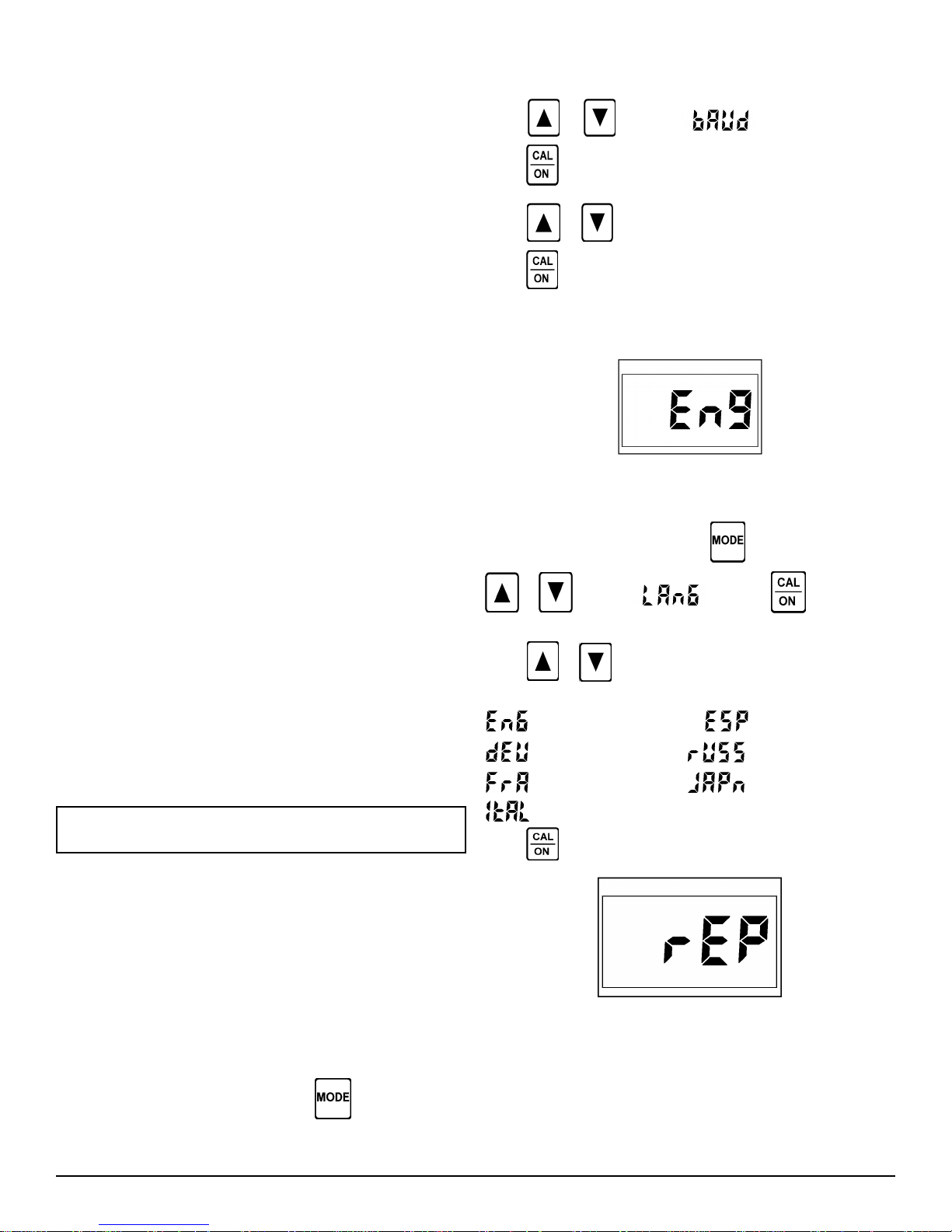

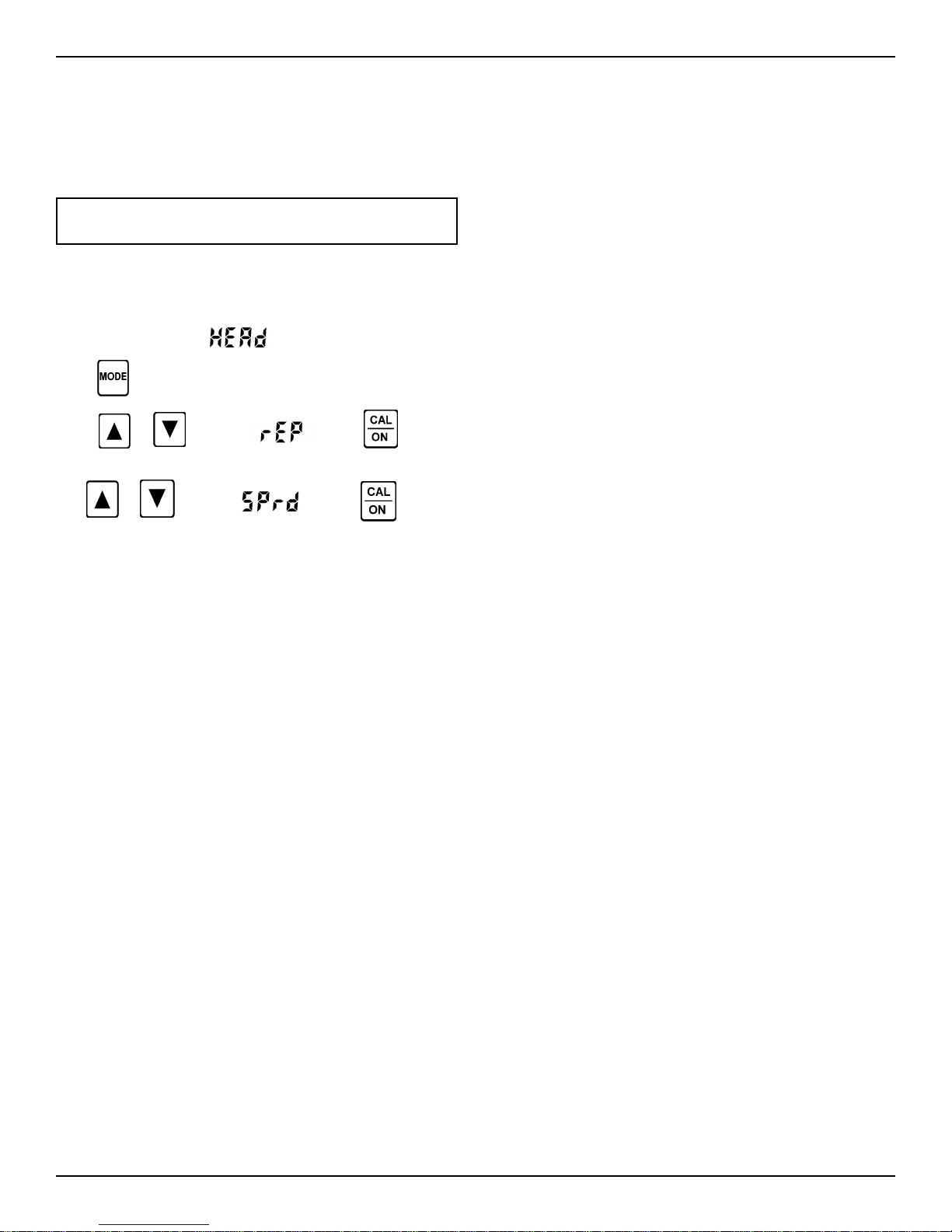

4.3 Report Language Selection

To change report language, press

or to select and then to display the

current setting (Fig. 4-1).

Press

Options are:

or to select the new setting.

- English - Spanish(Español)

- German (Deutsch) - Russian

- French (Francais) - Japanese

to display SPEC. Use

NOTE: DM4 DL should be off when connecting a cable

for an external device to the I/O port.

4.2 Setting Baud Rate

To enable communication between the DM4 DL and a printer,

computer, or other device, the baud rate must be set to match

that of the connected device.

Default RS232 protocol of the DM4 DL is as follows:

Baud Rate: 9600

Data Bits: 8

Stop Bits: 1

Parity: NONE

Baud rate is adjustable. All other parameters are fixed.

To change the baud rate setting, press

nates.

Page 20 DM4E, DM4, DM4 DL Operating Manual

until SPEC illumi-

- Italian (Italiano)

Press

again to exit

Figure 4-2

4.4 Printing Data

Data Logger files can be transferred to a printer. Output is compatible with most 80 and 132 column serial printers. With the

DM4 DL off, connect the printer to the I/O port using the DM4 DL

- Printer cable from Agfa NDT Inc. If necessary, follow the

procedure in Section 4.2 to set baud rate to match that of the

printer.

4.0 Serial I/O Interface

Selecting Printer Driver:

Before printing, the appropriate printer driver must be selected.

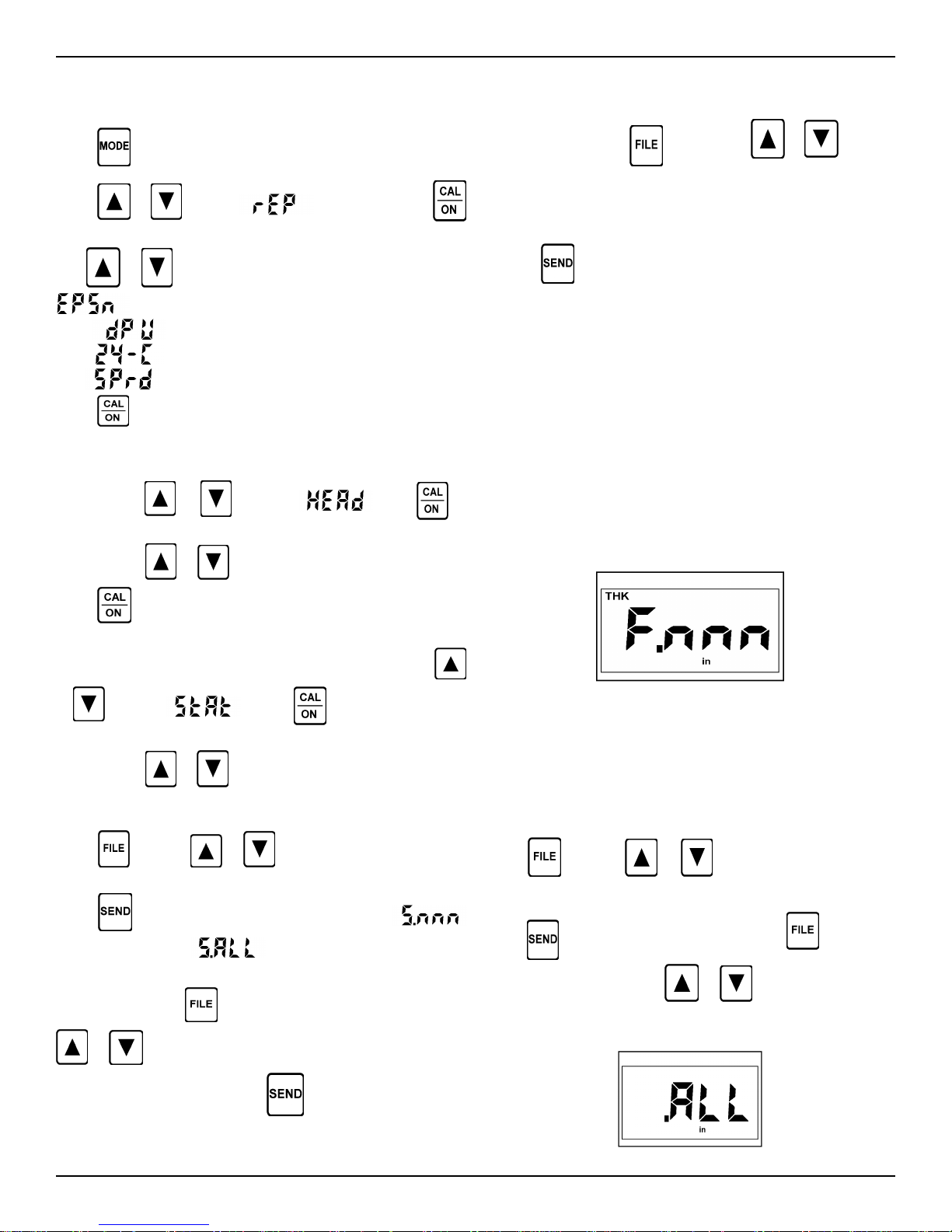

Press

Press

to display the current setting.

Use

- Spreadsheet

Press

until SPEC illuminates.

or to select (Figure 4-2), then

or to select:

- Epson FX 850 with 8148 serial interface

- Seiko DPU 411

- 24 column DATAMATE format

again to exit.

Printing File Header Information:

To print file header information with the file, with SPEC illuminated, press

display the current setting, On or OFF.

If OFF, press

or to select , then to

or to set file header On.

If the printer is accidentally disconnected during transmission,

follow the procedure in Section 4.7 to avoid losing data. When

printing is done, press to exit or use or to select

another file.

Printed files remain in memory after printing has been completed. Individual readings can be sent to a printer simply be

pressing

4.5 Sending Data to a Personal Computer

Stored thickness data can be transmitted to an IBM compatible

computer. Files are transmitted as ASCII text files. Once saved

on disk, data can be viewed on screen, printed, or transferred to

standard word processing, data base, spreadsheet, and applications software. The ASCII format also simplifies the transfer of

data for users who wish to use standard communications software or write their own.

The DM4 DL Data Transfer Utility Program is available to

simplify the transfer of data to the PC. This simple utility can

be used with any IBM PC, XT, or AT compatible computer with

at least 256K of available memory and DOS version 3.3 or

higher. Contact Agfa NDT Inc. or your local representative for

information.

when the desired thickness value is displayed.

Press

again to exit.

Printing Statistics:

T o print statistics with the file, with SPEC illuminated, press

or to select . Press to display the current

setting, On or OFF.

If OFF, press

To print files DM4 DL must be in THK or MIN mode.

Press

Section 3.3, or scroll to .ALL to print all files that contain data.

Press

(sending file nnn) or (sending all files). Empty files

and file locations will not be printed.

After printing, press

or to select another file to report.

or to set file statistics On.

and use or to select the file to report per

to start printing. The DM4 DL displays

to return to measurement mode or use

Figure 4-3

Connect the DM4 DL to PC cable, available from Agfa NDT

Inc., to the I/O port and to the serial port of the PC. If necessary, follow the procedure in Section 4.2 to set baud rate to

that of the serial port.

To include file header and/or statistical information, see Section

4.4 to enable header and statistics.

Press

.ALL (Fig. 4-4) to transmit all non-empty files.

Press

measurement mode or use

to report. Abort and accidental disconnect procedures are

identical to those at the end of Section 4.4.

and use or to select a file (Fig. 4-3) or

to send file(s). When done, press to return to

or to select another file

To abort the transmission, press

printed. The DM4 DL displays Abor.

DM4E, DM4, DM4 DL Operating Manual Page 21

while readings are being

Figure 4-4

4.0 Serial I/O Interface

4.6 Importing Data Into a Spreadsheet

Stored thickness data can be transferred to an IBM compatible

computer and saved on disk in a format that can be imported

into spreadsheet programs, such as LOTUS 1-2-3

Microsoft EXCELTM.

NOTE: Refer to the operating manual of your speadsheet

program for file import instructions.

Follow procedures in Sections 4.5 and 4.2 to connect the DM4

DL to the computer and set baud rate.

To enable statistics see Section 4.4. File header information is

included regardless of

setting.

TM

and

Press

Press

until SPEC illuminates.

or to select , then to display

the current setting.

Use

or to select . Press to exit.

Select the file or .ALL files and transfer them to the PC by following the procedure at the end of Section 4.5.

4.7 Interrupted Transmission Procedure

If a faulty or disconnected cable, or other problem, causes an

interruption while data is being transmitted to an external device,

the DM4 DL will resume transmission if the connection is restored

within 15 seconds. When the interrupted transmission has been

completed, review the transmitted data carefully to be sure that

no data has been lost or corrupted, or repeat the entire transmission as a precaution.

If the connection is not restored within 15 seconds, DM4 DL will

abort the transmission, briefly display Abor, and return to the currently selected file number.

In this case, the entire transmission must be repeated by

following the procedure in Section 4.4, if printing data, or

Section 4.5

Page 22 DM4E, DM4, DM4 DL Operating Manual

5.1 Instrument Specifications

Operating Principle: Ultrasonic, pulse-echo measurement

Probe Zero Adjustment: Automatic or 2-point calibration

Probe Recognition: Automatic for DIALOG Intelligent Transducers

V-Path Correction: Automatic, microprocessor controlled

AUTO Mode Linearity: ±.002 inch (±.05 mm) when calibration point < 1 inch (25 mm); ±.003 inch

DA3 Mode Linearity: ±.004 inch (± .1 mm)

Measuring Range: .020 to 20.00 inch (.5 to 500 mm) depending on probe and material

Dual Multi Measuring Range: .080 to 1.00 inch (2 to 25 mm) depending on probe, coating and material

Displayed Resolution: .001 or .01 up to 9.999 inches, .01 above 9.999 inches;

Measurement Rate: 4 Hz; 25 Hz in Minimum Capture mode

5. Specifications

(±.075 mm) when calibration point > 1 inch (25 mm)

.01 or .1 up to 99.99 mm, .1 above 99.99 mm

Material Velocity Range: .0394 to .3937 in/µs; 1000 to 9999 m/s

Receiver Gain Level: Three options, selectable via the keypad:

Automatic: High gain enabled for material velocities up to 246,000 in/s

(6,248 m/s). Low gain enabled for velocities over 246,000

in/s.

Manual Low: Low gain enabled over the entire velocity range.

Manual High: High gain enabled over the entire velocity range.

Receiver Bandwidth: 300 KHz to 10 MHz

Reading Stability: Nominal measured value ±0.001 inch (±0.025 mm) over the operating

temperature range of the instrument

Data Logger Capacity: 5,390 readings maximum; 999 readings if number of files is set to 1 through

5; readings are stored sequentially

Number of Data Files: 1 - up to 999; see Appendix B for number of readings per file based on

number of configured files.

Serial Protocol: 1200, 2400, 4800, or 9600 baud; 8 data bits; 1 stop bit; no parity

Data Transfer: Via SEND key

Report Languages: English, German, French, Italian, Spanish, Russian, and Japanese

Memory Retention: Typically 10 years

Display Type: Four digit, 0.5 inch (12.7 mm) high, Liquid Crystal Display with

DM4E, DM4, DM4 DL Operating Manual Page 23

electroluminescent backlight

5.0 Specifications

Power Requirements: 2 each 1.5 volt, AA alkaline cells

Battery Life (Operating Time): 200 hours at 25% duty cycle, without backlight, with steel velocity and .001

Automatic Shut-off: 3 minutes after last probe couple or last press of any key

Operating Temperature

Range: +10°F to +120°F (-10°C to +50°C)

Storage Temperature Range: -40°F to +140°F (-40°C to +60°C) without batteries

Dimensions (L x W x D): 5.75 “ (146.0 mm) x 3.00” (76.2 mm) x 1.35" (34.3 mm) at thickest part of

Weight: 9 ounce (255 grams) with batteries

Probe Connector: Dual Lemo #00 located on top panel

RS232 Serial I/O Connector: 7 pin, Lemo #0B located on top panel

inch displayed resolution

-40°F to +125°F (-40°C to +50°C) with alkaline batteries

case

5.2 Probe Specifications

Model Probe Description Frequency Diameter Range (Steel) Range

DIALOG

Intelligent Transducers

FH2E-D High Sensitivity Fingertip 8 MHz .38" .030" to 2.0" <130°F

KBA560-D General Purpose 5 MHz .625" .060" to 8.0" <250°F

DM401/411 G P 5 MHz .700" .060" to 8.0" <300°F

NOTE: DIALOG

NOTE:

Instrument specifications are subject to change without notice.

Nominal Contact Measurement Temp.

9.6 mm .75 to 50 mm <54°C

15.9 mm 1.5 to 200 mm <121°C

17.8 mm 1.5 to 200 mm <148°C

Intelligent Transducers are recognized automatically for optimium performance

STANDARD PROBES:

FH2E High Sensitivity Fingertip 8 MHz .3 8" .030" to 2.0" <130°F

9.6 mm .75 to 50 mm <54°C

KBA560 General Purpose 5 MHz .625" .060" to 8.0" <450°F

HT400 High Temperature 5 MHz .500" .030" to 10.0" <1000°F

NOTE: HT400

HT400 temperature cycling required with surface temperatures above 400°F per Krautkramer

instruction card.

Page 24 DM4E, DM4, DM4 DL Operating Manual

actual measurement range depends upon surface condition and couplant.

15.9 mm 1.5 to 200 mm <230°C

.

12.7mm .75 to 250 mm <538°C

5.0 Specifications

Nominal Contact Measurement Temp.

Model Probe Description Frequency Diameter Range (Steel) Range

DP-104 High Penetration 1 MHz 1.25" .200" min <130°F

31.8 mm 5.0 mm min <54°C

DA301 General Purpose 5 MHz .475" .0 6 0" to 8.0" <130°F

12.1 mm 1.5 to 200 mm <54°C

DA303 High Penetration 2 MHz .635" .200" min <130°F

16.2 mm 5.0 mm min <54°C

DA312 Thin Materials 10 MHz .30" .025" to 1.0" <130°F

7.6mm .6 to 25 mm <54°C

DA312B16 * Small Footprint 10 MHz .120” .025 to .5” <130°F

3 mm .63 to 12.7mm <54°C

KB550BTH * Boiler Tube 5 MHz .375" .060" to 2.0" <130°F

9.5 mm 1.5 to 50 mm <54°C

KB550FH * Fingertip 5 MHz .375" . 06 0" to 2.0" <130°F

9.5 mm 1.5 to 50 mm <54°C

FH2E-WR High Sensitivity Fingertip 8 MHz .550” .0 3 0" to 2.0" <130°F

Wear Resistant 14.0 mm .75 to 50 mm <54°C

KBA560-WR General Purpose 5 MHz .700" .0 60" to 8.0" <450°F

Wear Resistant 17.8 mm 1.5 to 200 mm <230°C

KBA525 Small Footprint 10 MHz .200” .025” to 1.0” <130°F

5 mm .63 to 25.4 mm <54°C

NOTE:

Probe specifications are subject to change without notice.

5.3 Dual Multi “Through Coating” Mode Probe Specifications

Nominal Contact Through Coating Temp.

Model Description Frequency Diameter Measurement Range Range

KBA560-D Dialog-General Purpose 5 MHz .625” .120” to .800” <250°F

KBA560 General Purpose 5 MHz .625” .120” to .800” <450°F

KBA560-WR General Purpose 5 MHz .700” .120” to .800” <450°F

Wear Resistant 17.8mm 3 to 20mm <230°C

DA312 Thin Materials 10 MHz .30 ” .080” to .50” <130°F

DA301/DA311 General Purpose 5 MHz .475” .120” to .800” <130°F

DM401-GP General Purpose 5 MHz .700” .120” to .800” <300°F

15.9mm 3 to 20 mm <121 °C

15.9mm 3 to 20 mm <230°C

7.6mm 2 to 13 mm < 54°C

12.1mm 3 to 20 mm < 54°C

17.8mm 3 to 20 mm <150°C

NOTE: The Auto Mode Linearity for the DA301 probe is ± 0.005 inch (± 0.13 mm)

NOTE:

Actual “Through Coating” measurement will vary depending upon the

type and thickness of the coating, the thickness of the metal and the quality

of the metal and the quality of the bind between the coating and the metal.

Probe specifications are subject to change without notice.

DM4E, DM4, DM4 DL Operating Manual Page 25

6. Application

6.1 General Notes

The DM4 is easy to use and will produce reliable, consistent

measurements when used correctly and with an understanding of factors that may affect measurement reliability. This

section explains some of the more common considerations.

6.1.1 Flaws

If, during testing, the DM4 suddenly reads a value which is

much thinner than the apparent thickness of the part, it may

be reading the distance to a flaw in the test piece, rather than

the distance to the backwall. See Section 1.3, How the DM4

Measures Thickness, for more information. If the cause is

unclear, further examination of the part with an ultrasonic flaw

detection instrument or other suitable NDT method is recommended.

6.1.2 Surface Conditions

A regular pattern on the surface under test, such as machine

grooves, may cause a false thickness reading when using a

dual element probe. Higher frequency

probes, such as the DA312, are especially sensitive to this

condition. The problem can usually be corrected by rotating

the probe so that the crosstalk barrier is at a right angle to the

grooves, or using the Dual Multi measurement mode.

Crosstalk Barrier Orientation

6.2 Thickness Measurement on Hot Test Pieces

The instrument can be used to measure the thickness of

materials with surface temperatures of up to 1,000°F (538°C)

with special, high temperature, dual element probe Model

HT400. A special couplant, Krautkramer ZGM, and duty

cycle are also required for high temperature use. The

following procedure is recommended

It is possible for the surface of a test piece to be too rough to

permit a good reading. Excess couplant could be trapped

between the probe and surface under test, causing a false

reading. A very rough surface may prevent coupling altogether

(no coupling indicator). This problem can be corrected by grinding the surface until it is smooth enough to permit good coupling.

6.1.3 Curved Surfaces

When measuring on curved surfaces, such as tubes or pipes,

be sure to keep the probe centered on the part and as stable

as possible.

As a rule, smaller diameter probes improve coupling and

minimize “rocking” on curved parts. In some cases, special

probes with contoured faces to match surface curvature may

be needed. Practice may be helpful to develop the proper

technique.

When using a flat dual probe, position the crosstalk barrier at

a right angle to the long axis of the part, as shown in the

following figure

Calibrate the DM4 according to the appropriate procedure in

Section 2.5 or 2.6.

Thoroughly clean the surface to be tested, using a wire

Knead the ZGM high temperature couplant in the tube before

using. Then place a drop, about the size of a pea,

contact face of the probe, not on the test piece

Carefully couple the probe to the surface under test. To prevent damage to the probe face, do not twist the probe while it is

in contact with the test surface. On a curved surface with a

dual probe, orient the crosstalk barrier as described in Section

6.1.3. Allow 2 or 3 seconds for the ZGM couplant to melt and

provide good coupling. At temperatures above 1020°F (550°C),

the ZGM couplant may ignite spontaneously. This will not

affect thequality of the coupling.

Do not allow the probe to be coupled for more than 5 seconds.

If a thickness reading does not appear within 5 seconds, remove the probe and cool it in air. On curved surfaces, gently

rocking the probe may help achieve good coupling.

While coupled, readings tend to drift upward as the probe

warms. Using MIN (minimum capture) mode (Section 2.9)

may be helpful in minimizing this problem.

.

on the

Page 26 DM4E, DM4, DM4 DL Operating Manual

6.0 Application Notes

A 100% duty cycle can be employed when taking measurements below 400°F (204°C). No cooling of the probe is required.

If taking thickness readings at temperatures above 400°F, cool

the probe in air as follows:

• 15 seconds for temperatures from 400°F to 550°F

• 30 to 120 seconds for temperatures from 550°F to 1,000°F

Before taking another reading, carefully remove the remaining

couplant and residue from the probe.

Thickness measurements made at high temperatures must be

corrected for the effect of temperature on the material sound

velocity. Velocity in steel changes at an approximate rate of -

0.5% per 100°F (-1.0% per 100°C).

Some applications may exceed the instrument’s capabilities.

If high temperature measurements are unsatisfactory after several attempts using this procedure, better results may be

achieved by using a high temperature probe with an ultrasonic

flaw detection instrument.

DM4E, DM4, DM4 DL Operating Manual Page 27

Agfa NDT GmbH

Robert-Bosch-Strasse 3

D-50354 Huerth (Efferen)

Cologne, Germany

Phone: (49) 2233-6010