Kraus Optima Owner's Manual

OptimaTM Dispenser

Owner’s Manual

Winnipeg, Manitoba, Canada

Kraus Global, Ltd.

25 Paquin Rd.

R2J 3V9

Ph. 204-663-3601

©2014 Kraus Global Ltd.

Retail CNG Dispenser Manual i

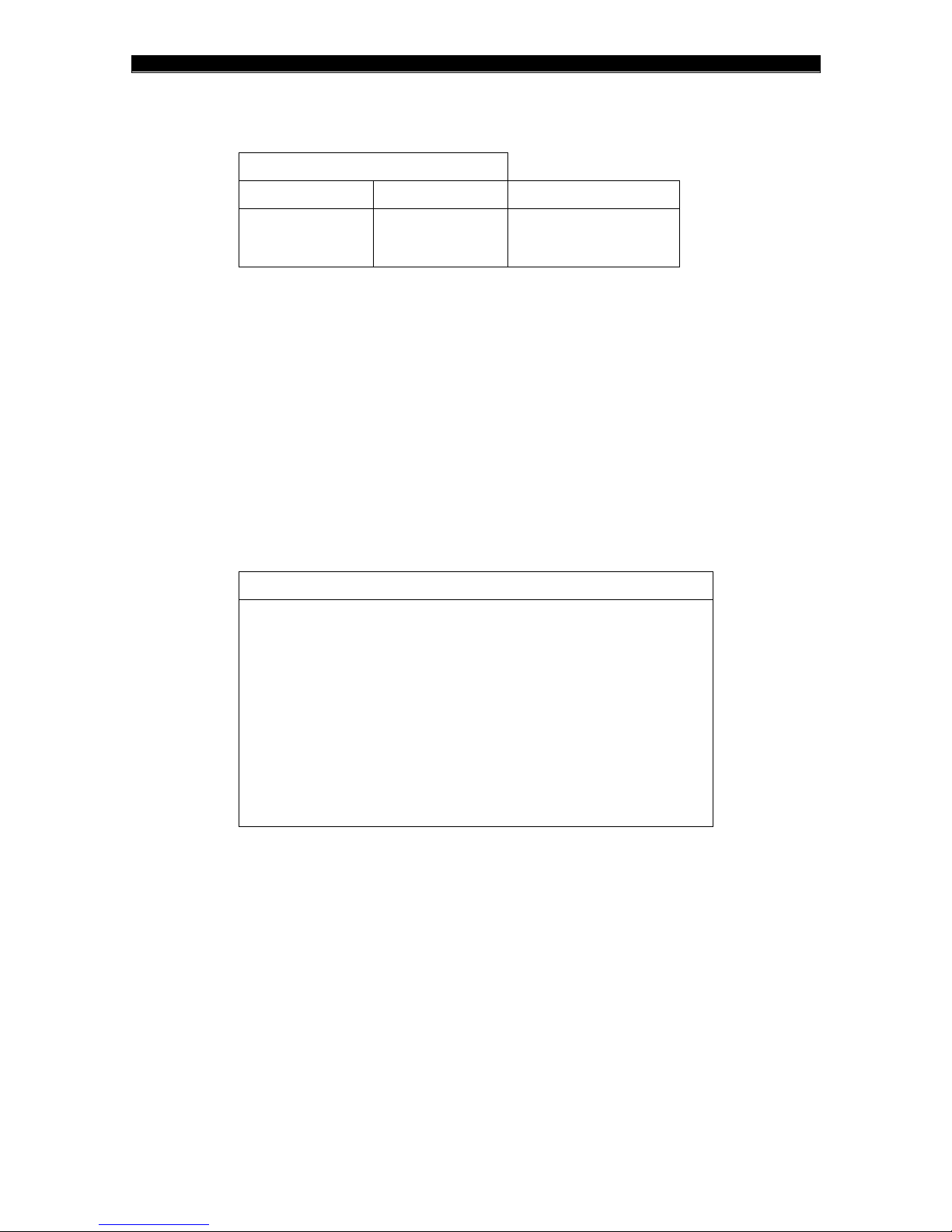

REVISION HISTORY

Document No. RFD.020.MNL.00

Revision #

Date

Description

02

June 2017

Editorial updates and

corrections, Production

release.

North America

American Society of Mechanical Engineers (ASME) Boiler and

Pressure Code

American Society of Mechanical Engineers (ASME) B31.3 – Process

Piping

Canadian Gas Association (CGA) B108 NGV Refueling Stations

Installation Code

Canadian Standards Association (CSA) C22.1 Canadian Electrical

Code (CEC) Part I

National Fire Protection Association (NFPA) 52 Standard for

Compressed Natural Gas (CNG) Vehicular Fuel Systems

National Fire Protection Association (NFPA) 70 National Electrical

Code

Document revision history

Code compliance

Kraus CNG dispensers are manufactured to comply with the following codes and standards:

CONTENTS

CONTENTS

1. INTRODUCTION 1

1.1 About this manual 1

1.2 Additional references 2

1.3 Contact information 2

1.4 Warnings and notifications 3

1.5 Warranty information 3

1.6 The Retail CNG Optima™ dispenser 4

1.7 Dispenser theory of operation 4

1.7.1 MICON NEXTGEN 1.0® 4

1.7.2 Buffer storage systems 5

1.7.3 Cascade storage systems 5

1.7.4 The Retail unit layout 6

2. SAFETY 7

2.1 General safety 7

2.2 Filling safety 8

2.3 Dispenser hose safety 9

2.4 Maintenance safety 10

2.5 Leak test safety 11

3. INSTALLATION AND SETUP 12

3.1 Installation guidelines 12

3.2 Pre-installation 14

3.2.1 Site preparation 14

3.2.2 Uncrating the dispenser 15

3.2.3 Lifting and anchoring the dispenser 16

3.3 Installation 17

3.3.1 Electrical and communication connections 17

3.3.2 Pressure line connection 17

3.3.3 Filters 18

3.3.4 Attaching the hose 21

3.4 Startup procedures 23

3.4.1 Powering the dispenser 23

3.4.2 Pressurizing the dispenser 24

3.4.3 Connecting the Manager-keypad 25

3.4.4 Enabling 2-wire mode and setting pump/hose IDs 27

3.4.5 Configuring the POS System 28

3.4.6 Commissioning 29

4. OPERATION AND MAINTENANCE 30

©2014 Kraus Global Ltd.

Retail CNG Dispenser Manual iii

CONTENTS

4.1 Filling procedure 30

4.2 Programming the MICON® 31

4.2.1 Manager Menu/Programming mode 31

4.2.2 Disabling Programming mode 33

4.3 Dispenser maintenance 35

4.3.1 General dispenser maintenance guidelines 35

4.3.2 Dispenser venting procedure 36

4.3.3 Leak monitoring 37

4.4 Component maintenance 38

4.4.1 MICON® mainboard 38

4.4.2 KAF 402™ solenoid inlet valve 39

4.4.3 Inline filters 39

4.4.4 Air purge system 40

5. TROUBLESHOOTING 41

5.1 MICON® fault codes 41

5.2 System fault codes 45

5.3 Dispenser issues 45

5.3.1 Voltage statuses 49

APPENDIX 1

A.1 Component descriptions and specifications 1

Air purge system components 1

Power supply 5

Air purge system/authorization relay 5

Micro Motion® CNG050 flow meter 6

KAF 402™ solenoid inlet valve 8

Fueling nozzles 9

A.2 Maintenance task list 10

GLOSSARY 1

INDEX 1

©2014 Kraus Global Ltd.

iv Retail CNG Dispenser Manual

CONTENTS

This page intentionally left blank

©2014 Kraus Global Ltd.

Retail CNG Dispenser Manual v

CONTENTS

This page intentionally left blank

©2014 Kraus Global Ltd.

vi Retail CNG Dispenser Manual

CONTENTS

DISCLAIMER

This manual and the information contained herein are not intended to provide

you with any advice on product design, filling station specifications, installation of

equipment, or similar matters and should not be relied upon for such purposes.

Neither Kraus Global Ltd. nor any of its employees or agents are your

professional advisers. You should assess whether you require such advisers and

additional information and, where appropriate, seek independent professional

advice. Kraus, its subsidiaries and affiliates, are not responsible in any manner

for direct, indirect, special or consequential damages however caused arising

from your use of this manual and the information contained herein.

©2014 Kraus Global Ltd.

Retail CNG Dispenser Manual vii

1. INTRODUCTION

1. INTRODUCTION

1.1 About this manual

Purpose

This manual is designed to provide installation, operation, and

maintenance guidelines and procedures for Kraus’ Retail

compressed natural gas (CNG) Optima™ dispensers.

Intended users

This manual is designed to be clear, comprehensive, and available to

anyone installing, maintaining, or overseeing the operation of Kraus’

Retail CNG Optima™ dispensers.

Scope

This manual is divided into five chapters:

1. INTRODUCTION

This chapter provides general information about this manual and

the Retail CNG Optima™ dispenser.

2. SAFETY

This chapter provides general installation, operation, and

maintenance safety guidelines.

3. INSTALLATION AND SETUP

This chapter provides installation and configuration guidelines

and procedures for the Retail CNG Optima™ dispenser.

4. OPERATION AND MAINTENANCE

This chapter provides operation and maintenance guidelines and

procedures for the Retail CNG Optima™ dispenser.

5. TROUBLESHOOTING

This chapter provides general troubleshooting guidelines for

possible installation, operation, and maintenance issues.

©2014 Kraus Global Ltd.

Retail CNG Dispenser Manual 1

1. INTRODUCTION

Kraus Global Ltd.

25 Paquin Road

Winnipeg, Manitoba

Canada, R2J 3V9

www.krausglobal.com

Phone: 204-663-3601

Fax: 204-663-7112

Extensions:

Engineering

203 / 276

Logistics

215

Technical Support

212

Sales

235

1.2 Additional references

In addition to this manual, the following document is also provided

with each dispenser package:

Quick-Start Guide—Optima™ CNG Dispenser (RFD.010)

The following documents are available on request:

MICON NEXTGEN 1.0

Hazardous Locations Control Drawing (MNG0002.MNL)

Engineering package

o Flow schematic

o Electrical schematic

o Construction drawings

Final inspection checklist

Quality control notices

Quality control information packages

®

Owner’s Manual (MNG0001.MNL)

If you are missing any of the documents listed above or require

additional assistance at any time, please contact Technical Support.

1.3 Contact information

©2014 Kraus Global Ltd.

2 Retail CNG Dispenser Manual

1. INTRODUCTION

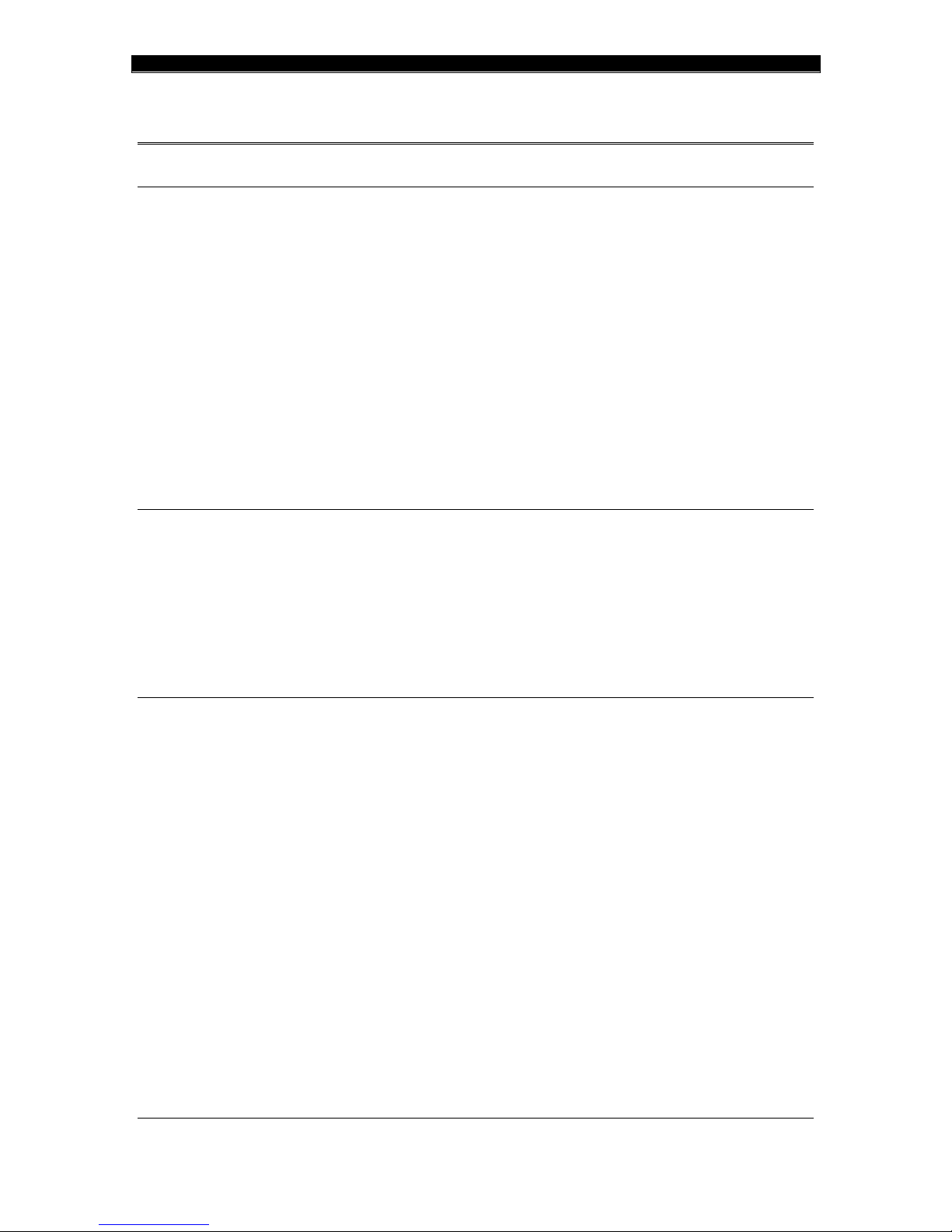

ADVICE

This indicator provides helpful tips and other advice on proper equipment

installation, usage, and maintenance.

ATTENTION

This indicator provides important notifications about the dispenser and its

components.

CAUTION

This indicator provides critical warnings that may help prevent human

injury and equipment damage.

1.4 Warnings and notifications

The following indicators provide various warnings and notifications

throughout this manual:

1.5 Warranty information

For questions or concerns regarding dispenser-warranty policies,

please contact Sales.

©2014 Kraus Global Ltd.

Retail CNG Dispenser Manual 3

1. INTRODUCTION

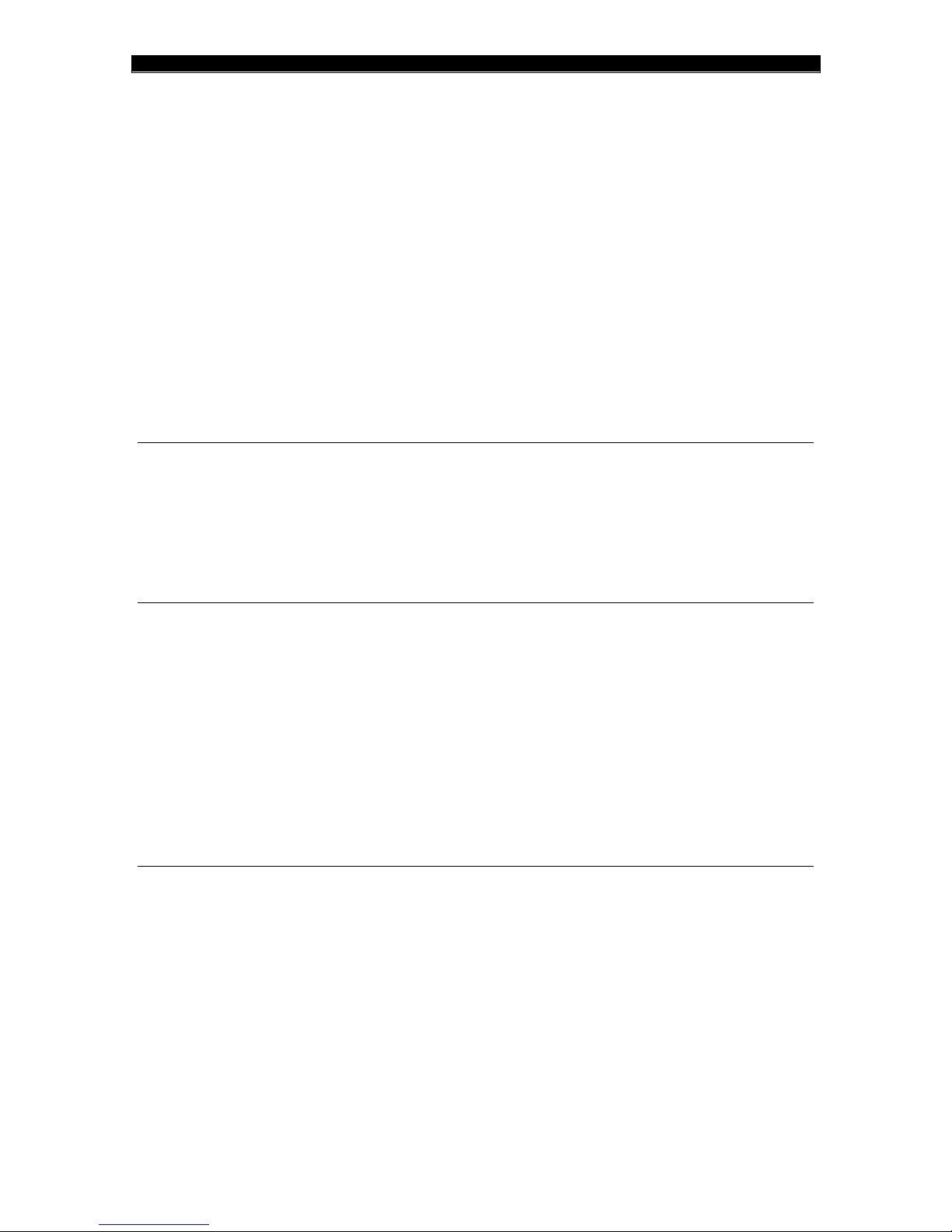

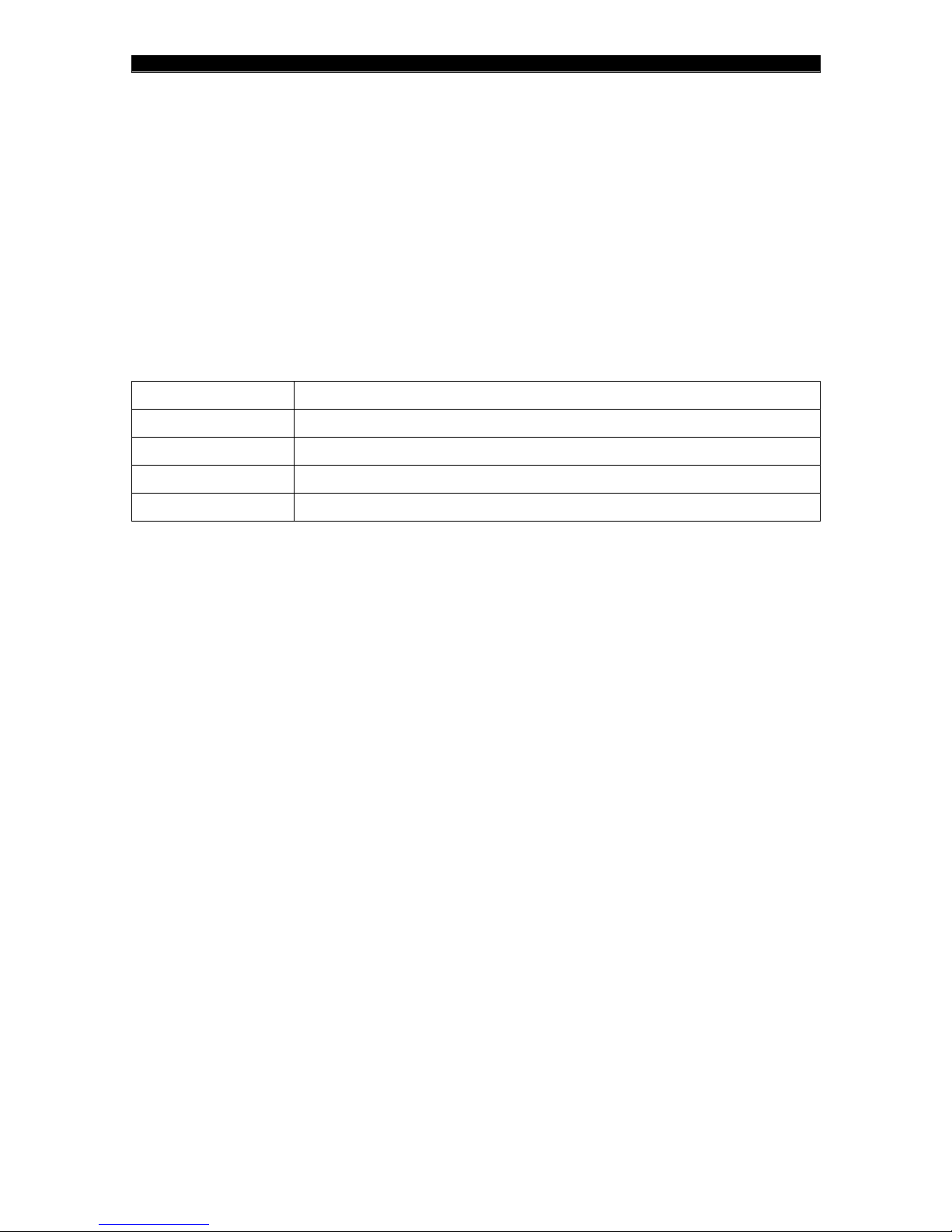

Dispenser model

Retail CNG Optima™ Dispenser

Storage system

Buffer (1 large bank) or Cascade (up to 3 banks)

Filling system

High-flow or Standard-flow or Split-flow

Filling pressure

P30 or P36 or Split-pressure

Hose configuration

Single or Dual

1.6 The Retail CNG Optima™ dispenser

The Retail CNG Optima™ dispenser is available in a single or

multiple-line configuration. Each configuration is available in

standard, high or split-flow systems; P30, P36, or split-pressure;

single or dual hose setup; and buffer or cascade sequencing.

Additionally, the Retail CNG dispenser incorporates an industryleading retail design that includes an embedded card reader, keypad,

receipt printer, full-color display and secondary display. Table 1.1

below describes these customizable features.

Table 1.1: Retail dispenser configurations

1.7 Dispenser theory of operation

This section explains how Kraus’ MICON NEXTGEN 1.0® pump-

controller and KAF 402™ solenoid valves operate to control gas flow

within CNG dispensers.

1.7.1 MICON NEXTGEN 1.0®

Kraus’ MICON NEXTGEN 1.0® pump-controller is an inexpensive

alternative to using PLC units for operating fuel dispensers. For CNG

dispensers, the MICON® takes readings from the mass flow meter,

pressure transducer, and temperature probe to determine a final fill

pressure that is based on a series of algorithms in accordance with

the Ideal Gas Law, “PV = nRT”. The result is a controlled fill of a

vehicle’s CNG tank to a safe maximum limit.

After the fueling nozzle is attached and a fill is authorized, the

MICON® opens all KAF 402™ solenoid valve(s) and dispenses CNG

into the vehicle’s receptacle for four seconds. After the four seconds,

the MICON® closes the valve(s) and performs a reading of the vehicle

tank pressure and ambient temperature. Based on a combination of

the initial reading and Ideal Gas Law calculations, the MICON®

determines a target-fill-pressure.

©2014 Kraus Global Ltd.

4 Retail CNG Dispenser Manual

1. INTRODUCTION

1.7.2 Buffer storage systems

A buffer storage system comprises a large storage bank with a single

supply line to the dispenser, which is controlled by one KAF 402™

solenoid valve to start and stop gas flow.

After the target-fill-pressure is calculated, the solenoid valve remains

open for fuel delivery until the target-fill-pressure or minimum flow

setting is reached.

1.7.3 Cascade storage systems

Cascade storage systems typically consist of three separate storage

banks—a low, mid, and high bank. The low bank holds

approximately 70% of the total volume of storage, while the mid and

high banks hold 20% and 10% respectively.

Upon authorization, the MICON® will open all three banks for 4

seconds to ensure there is sufficient gas flow to continue with the fill.

The banks will then close for another 4 seconds for the target-fill

calculation. Once the target-fill-pressure is calculated, the low-bank

will reopen and deliver fuel until the flow rate drops to a

predetermined level—set in the MICON®. When this level is reached,

the mid-bank solenoid valve will reopen to deliver the fuel. If more

pressure is needed, the same sequence will occur to access the highbank until the target-fill-pressure or minimum flow setting is

reached.

©2014 Kraus Global Ltd.

Retail CNG Dispenser Manual 5

1. INTRODUCTION

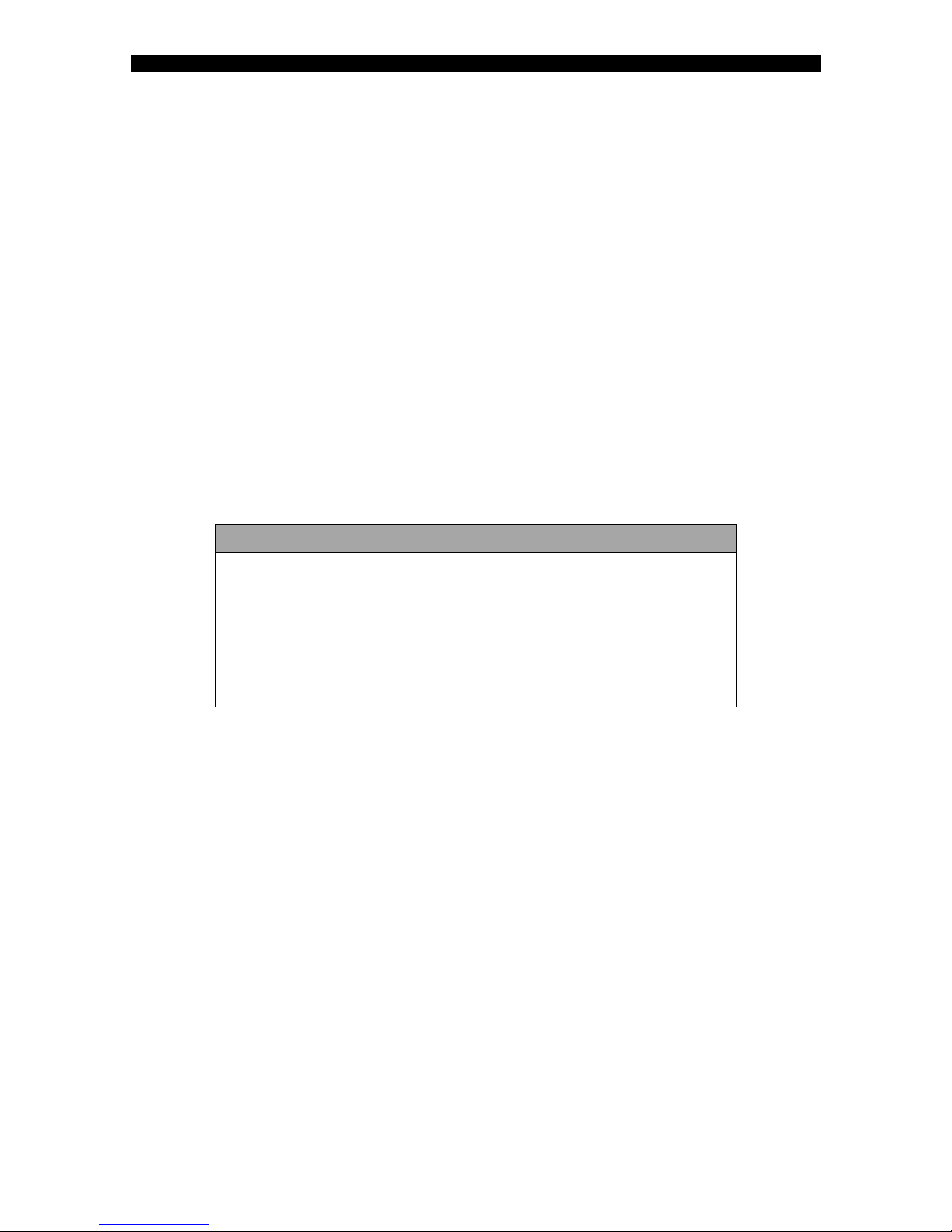

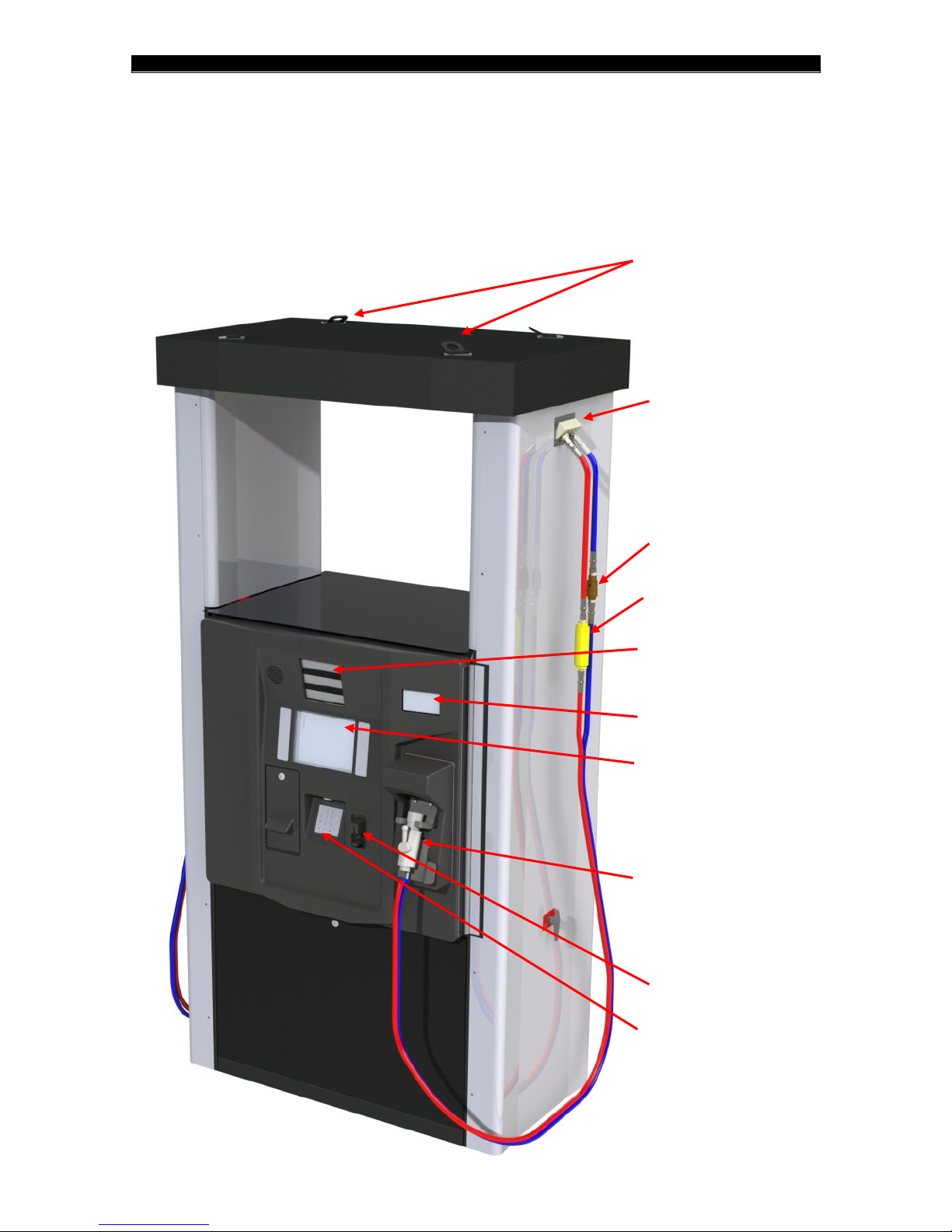

LIFTING

LUGS

HOSE

MANIFOLD

VENT LINE BREAKAWAY

MAIN LINE BREAKAWAY

PRICE, VOLUME, PRICE

PER UNIT DISPLAY

PRESSURE

POS DISPLAY

HOSE NOZZLE

CARD READER

ENCRYPTED KEYPAD

1.7.4 The Retail unit layout

A single-hose Retail CNG Optima™ dispenser—Please refer to the Engineering package for a view of internal components

©2014 Kraus Global Ltd.

6 Retail CNG Dispenser Manual

2. SAFETY

CAUTION

Compressed Natural Gas (CNG) can pose great danger if mishandled.

Please be sure to read and understand this section before installing,

operating, or maintaining CNG dispensers.

ADVICE

It is necessary to comply with all safety precautions and other instructions

described throughout this manual to properly install, operate, and maintain

Kraus-manufactured CNG dispensers.

2. SAFETY

2.1 General safety

Where it is applicable, local regulations take precedence over the

guidelines listed in this section. Please ensure that all personnel are

familiar with all applicable regulations and observe the following

guidelines when working with fuel dispensers:

Do not smoke or allow open flames and

naked lights within 15 feet or 5 meters of

any gas installation.

Do not adjust, remove, or bypass any

protective devices.

Electrical equipment and its protection

must comply with the regulations

applicable to the hazard of the location.

Transportation, installation,

commissioning, operation, maintenance,

and repairs should only be carried out by

qualified personnel in accordance with

the regulations for operation and safety.

Electrical connections must comply with

applicable local regulations.

Piping and other components, which are

not supplied by Kraus Global Ltd., must be

suitable for the respective working

pressure. If necessary, they must be

tested and protected by pressureunloading devices.

Systems must be entirely vented before

any maintenance or repair procedures

are carried out.

Do not store flammable materials, such as

oily rags, in or around the dispensing unit.

©2014 Kraus Global Ltd.

Retail CNG Dispenser Manual 7

2. SAFETY

2.2 Filling safety

Please observe the following guidelines when overseeing the use of

all Kraus-CNG dispensers:

Be aware of emergency procedures and

emergency telephone numbers.

Be aware of the locations of fire

extinguishers and the “Emergency Shut

Down” (ESD) buttons.

Ensure all operators and users are

properly trained before any fueling

transactions.

Do not allow any vehicles to be

unattended while fueling.

Ensure that all automatic transmission

vehicles are placed in “park” or the

emergency brake is applied for all manual

transmission vehicles before allowing any

fueling transactions.

Ensure that all vehicle ignitions, electrical

systems, and radios—including shortwave communication equipment—are

shut-off before allowing any fueling

transactions.

Ensure the fuel receptacle is inspected

and matches the dispenser filling nozzle

before attempting any fueling

transactions.

Ensure all users adhere to the operating

procedures described in Section 4.1 when

fueling.

Ensure all users are aware that pressure

from the nozzle must be vented before

disengaging it from the vehicle.

Ensure that all users replace the

dispenser nozzle firmly onto the holder

immediately after refueling.

©2014 Kraus Global Ltd.

8 Retail CNG Dispenser Manual

2. SAFETY

ATTENTION

The hose assembly for Retail CNG dispensers are designed to convey

static electricity. It is imperative that the hose assembly be properly

grounded to the CNG unit it is attached to.

ATTENTION

For additional information about dispenser hoses, please refer to the

specification tag provided by the manufacturer or contact Technical

Support at 204-663-3601, ext.212.

2.3 Dispenser hose safety

Please observe the following guidelines prior to installing or

maintaining CNG dispenser-hoses and related components:

Replace the hose if any of the following conditions are observed:

o The jacket of the hose appears abnormal

o A gas leak or any reason to believe there is a gas leak

o The couplings are damaged

o The hose is damaged in any way, including cuts, cracks,

bulges, blisters, or abrasions

o The reinforcement is exposed through the jacket

o Spring guards are missing or detached from couplings

o Couplings and spring guards show evidence of slippage or

looseness

Inspect the hose assembly before each

use.

Do not exceed the maximum

recommended working pressure of the

hose: 5,000 psi/345 bar.

Do not twist, kink, or torque the hose

assembly.

Never attempt to repair or re-couple a

damaged hose.

Do not use a strength member for pulling

or lifting equipment.

©2014 Kraus Global Ltd.

Retail CNG Dispenser Manual 9

2. SAFETY

2.4 Maintenance safety

Please observe the following guidelines prior to maintaining any

Kraus CNG dispenser:

Only properly trained or qualified

personnel should be permitted to

maintain and repair CNG equipment.

When in doubt, please refer to the

equipment supplier or service agent.

Always adhere to the manufacturer

guidelines for proper installation and

maintenance of all dispensers and

dispenser-components.

All maintenance and repair work of

pressure vessels and other safety

equipment must be conducted under the

appropriate codes, then tested and

accepted by the inspection authority.

The dispenser must be powered-off and

completely vented, unless otherwise

specified.

Never perform welding processes near

gas systems.

Always cover disassembled parts and

openings with a clean rag, paper, or

adhesive to keep them clean and avoid

contamination.

Do not clean any parts with flammable

solvent. Clean and rinse all parts carefully

with compressed air.

Be sure to wear necessary safety

equipment during maintenance and

repair. Eye protection is absolutely

necessary when cleaning with

compressed air.

Wear hearing, hand, and eye protection

when bleeding filters and lines. Be sure to

keep body parts away from the discharge

orifice.

Do not touch bare wires and live current-

carrying parts while the electrical system

is energized.

Never tighten or loosen any fitting when

it is under pressure.

©2014 Kraus Global Ltd.

10 Retail CNG Dispenser Manual

2. SAFETY

ADVICE

Never allow problems to go unreported. Both your company and supplier

will benefit from the full disclosure of all dispenser issues.

2.5 Leak test safety

Always use proper thread lubricants and

sealant on tapered pipe threads.

Never turn a fitting body. Instead, hold

fitting body and turn the nut.

After completing any work on process gas

piping systems and its components,

always purge the system thoroughly with

a non-corrosive inert gas, such as

nitrogen, before introducing natural gas.

Ensure that you have not left any tools,

cleaning equipment, or any loose parts

inside the dispenser.

Please observe the following guidelines before performing leak tests

on Kraus-manufactured CNG dispensers:

Ensure the area surrounding the

dispenser being serviced is closed off to

all customers and unauthorized

personnel. Use any appropriate barricade

and signage to ensure safety.

It is recommended that protective shields

be placed around potentially harmful

areas of the dispenser being serviced.

Service personnel must wear all

appropriate safety gear, such as helmets

with eye and/or facial protection and

body shields.

©2014 Kraus Global Ltd.

Retail CNG Dispenser Manual 11

3. INSTALLATION AND SETUP

3. INSTALLATION AND SETUP

3.1 Installation guidelines

Please observe the following guidelines prior to installing any Krausmanufactured CNG dispenser:

All electrical and mechanical installations

All electrical installations must only be

All high-pressure gas connections should

Safety valve discharge gases must be

Be sure to allow room inside the

Where soil displacement is apparent, gas

The dispenser frame enclosure must be

A pressure relief device may be installed

o The pressure relief device must communicate directly with

the pressure-containing component it is designed to

protect—valves between the protected component and the

inlet to the pressure relief device are not permitted.

must comply with the provisions of the

local authority having jurisdiction.

carried out by a licensed electrical

journeyman.

only be carried out by qualified and

experienced personnel.

funneled safely away from the working

area using tubing or piping with

comparable pressure ratings to the tubing

or piping used within the dispenser.

dispenser pit to properly tie-in the gas

lines to the inline filters and manual

isolation valves.

connections upstream of the dispenser

must be made with flexible hoses.

securely bolted to a concrete foundation

or to a structural steel base. Adequate

support must be provided for each unit of

the dispensing system, independent of

piping, tubing, or conduit that may be

connected to the dispenser.

directly upstream of the dispenser—in

compliance with the ASME Boiler and

Pressure Vessel Code—to limit the

pressure at the inlet of the dispenser to a

value no greater than the maximum

working pressure of the dispenser.

©2014 Kraus Global Ltd.

12 Retail CNG Dispenser Manual

3. INSTALLATION AND SETUP

All dispensers must be equipped with an

emergency shut-off device that will

terminate the gas supply to the dispenser

in the event that the dispenser is upset or

sheared from its foundation for any

reason.

All dispensers must only be used for gas

compositions specified within SAE J1616:

Recommended Practice for Compressed

Natural Gas Vehicle.

©2014 Kraus Global Ltd.

Retail CNG Dispenser Manual 13

3. INSTALLATION AND SETUP

CAUTION

Kraus CNG dispensers must be situated in such a way that there are no

obstructions, such as a wall or gate, that may entangle the dispenser

hose. This is to ensure proper functioning of the hose assembly’s

breakaway coupling.

ATTENTION

Please refer to your Construction drawings for dispenser dimensions.

3.2 Pre-installation

3.2.1 Site preparation

Please observe the following guidelines prior to constructing

dispenser pits:

Be sure to allow room inside the

dispenser pit to properly tie-in the gas

lines to the inline filters and manual

isolation valves.

Make provisions for tubing and electrical

conduits prior to pouring the concrete

pad.

Filters must be installed upstream of the

dispenser.

Due to potential weld slag, filings, rust,

dirt, and water, dispensing lines should be

purged to the atmosphere at the

dispenser. This can be done by blowing

nitrogen through the lines.

All dispensing lines must be purged,

pressurized, and leak tested. Afterwards,

manual isolating valves in the dispenser

pit must also be leak tested. The

dispenser must only be connected to the

lines after these have been accomplished.

©2014 Kraus Global Ltd.

14 Retail CNG Dispenser Manual

3. INSTALLATION AND SETUP

CAUTION

Ensure that the dispenser crate is placed on a smooth and level surface

before removing any crate panels.

ATTENTION

All dispenser packages contain additional parts, accessories, and

documents that are vital to the installation, operation, and maintenance of

the dispenser. Be sure to set these items aside in a safe and easily

accessible area.

Dispenser keys may be found on one of the authorization handles.

3.2.2 Uncrating the dispenser

1. Inspect the crate for any damages that may have occurred during

shipping. If any damages are found:

o Take pictures of the damages

o Note the damages

o Contact Kraus

2. Starting with the top panel, remove all screws and/or nails and

detach the top panel. Repeat this process to remove all side

panels.

3. Remove all protective wrapping by hand; knives and other sharp

objects may damage the dispenser.

4. Inspect the dispenser for any damages. If any damages are found,

repeat the procedure indicated in step 1.

5. Remove lag bolts from base rails to free the dispenser from the

bottom pallet.

6. Locate and review the crating check list to ensure that all items

are accounted for. If you are missing any items, please contact

Technical Support at 204-663-3601, ext.212.

©2014 Kraus Global Ltd.

Retail CNG Dispenser Manual 15

Loading...

Loading...