Page 1

www.kraenzle.com

GB

Original-Operating manual

High-pressure cleaners

W 11/135

W 13/230

W 15/200

W 19/160

Read and conform safety instructions before use!

Keep instructions in a safe place for later use and

pass them on to any future user.

Page 2

2

Dear Customer

We would like to congratulate you on your new high pressure cleaner and to thank

you for the purchase.

To ease your introduction to the use of the cleaner, we have provided the following

pages of explanations, tips and hints.

The equipment will assist you professionally in all cleaning tasks, e.g.:

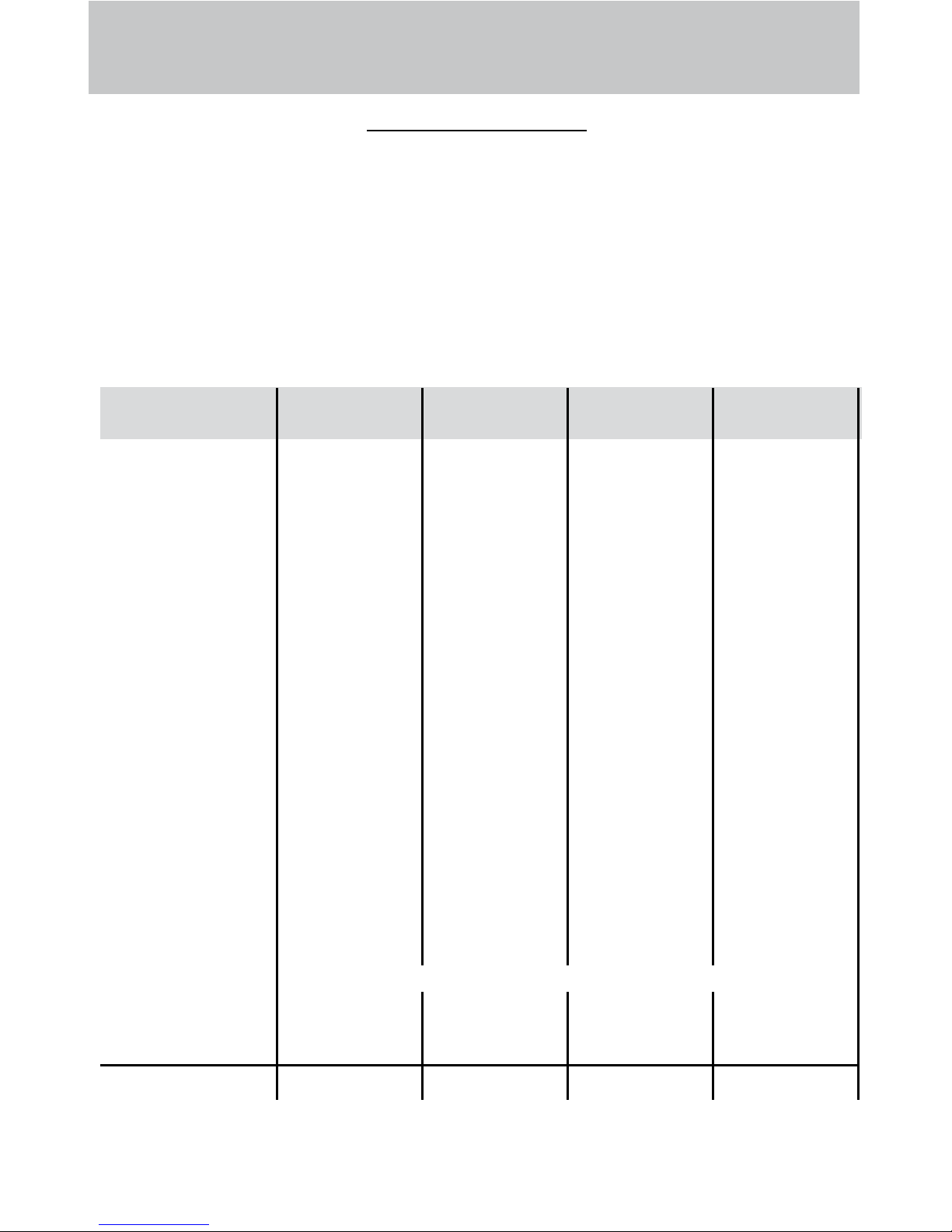

Description

Operating pressure steplessly adjustable

Permiss. overpressure

Water output *

Hot water input

High pressure hose

Electrical ratings

Connected load Input

Output

Weight

Dimensions

Sound lever accord.

to DIN 45 635 (rel. to working place)

with dirtkiller

Recoil at lance

Torque

Vibrations at lance

Order n°:

10 - 135 bar

150 bar

at 1400 rpm

11 l/min

max. 60 °C

10 m

230 V ; 50 Hz ;

14,0 A

P1: 3,3 kW

P2: 2,4 kW

76 kg

710 x 740 x 370

89 dB

84 dB

approx. 25 Nm

26 Nm

2,4 m/s²

41 312

Kränzle

W 11 / 135

Technical

specications

Kränzle

W 19 / 160

Kränzle

W 15 / 200

Kränzle

W 13 / 230

10 - 160 bar

180 bar

at 1400 rpm

19 l/min

max. 60 °C

10 m

400 V ; 50 Hz ;

12 ,5A

P1: 7,5 kW

P2: 5,5 kW

90 kg

710 x 740 x 370

89 dB

93 dB

approx. 22 Nm

24,3 Nm

3,2 m/s²

41 310

10 - 200 bar

220 bar

at 1400 rpm

15 l/min

max. 60 °C

10 m

400 V ; 50 Hz ;

12,5 A

P1: 7,5 kW

P2: 5,5 kW

90 kg

710 x 740 x 370

89 dB

93 dB

approx. 25 Nm

28,8 Nm

3,2 m/s²

41 309

10 - 230 bar

250 bar

at 1400 rpm

13 l/min

max. 60 °C

10 m

400 V ; 50 Hz ;

12,5 A

P1: 7,5 kW

P2: 5,5 kW

90 kg

710 x 740 x 370

89 dB

93 dB

approx. 27 Nm

28,8 Nm

3,2 m/s²

41 308

(Assumed length of lance: 0.9 m)

Permissible tolerance for gures ±5% in accordance with VDMA, uniform sheet 24411

* Min. water quantity to be supplied to the high pressure cleaner!

- Vehicles of all types

- Barrels and containers

- Machines etc.

- Removing old

paint

Page 3

3

Preparation for use

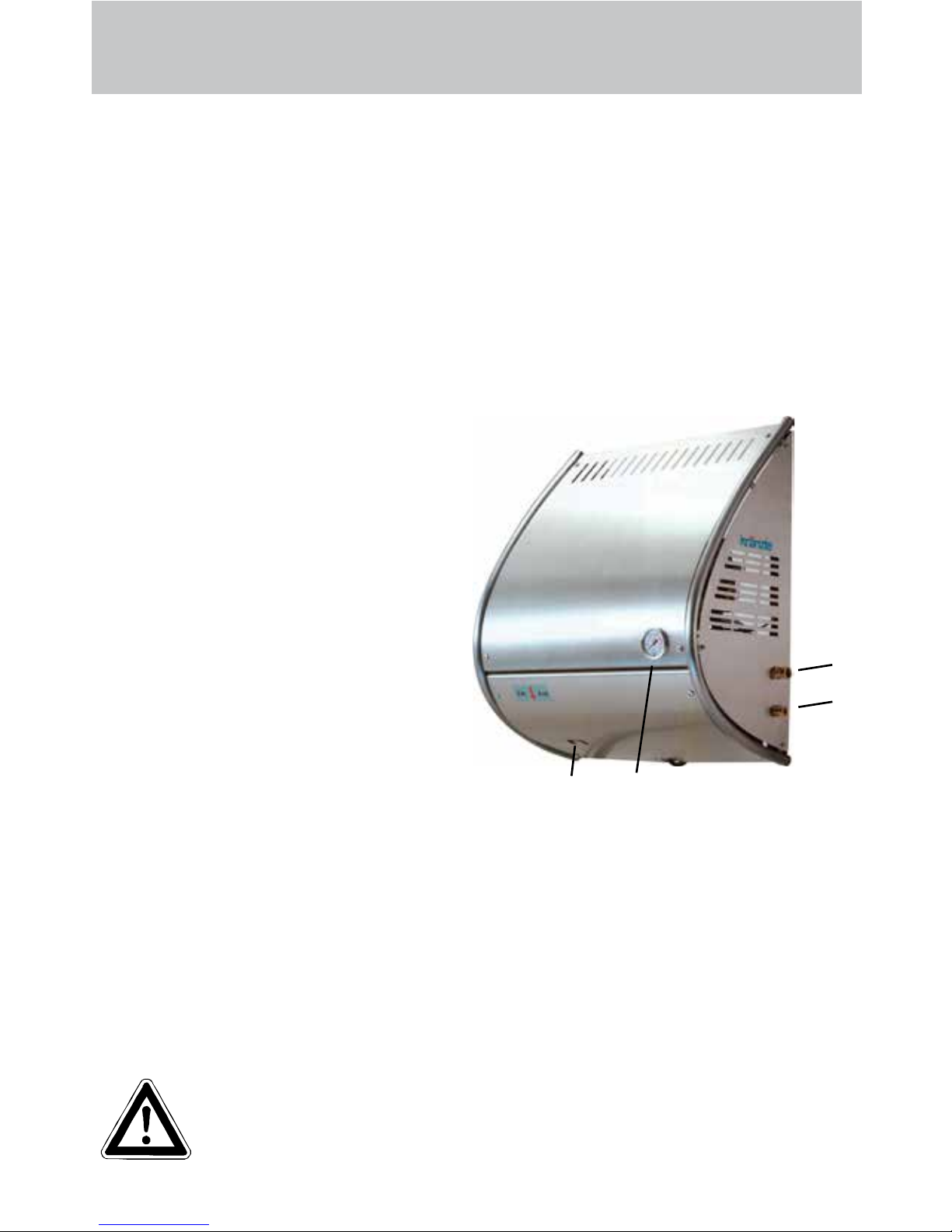

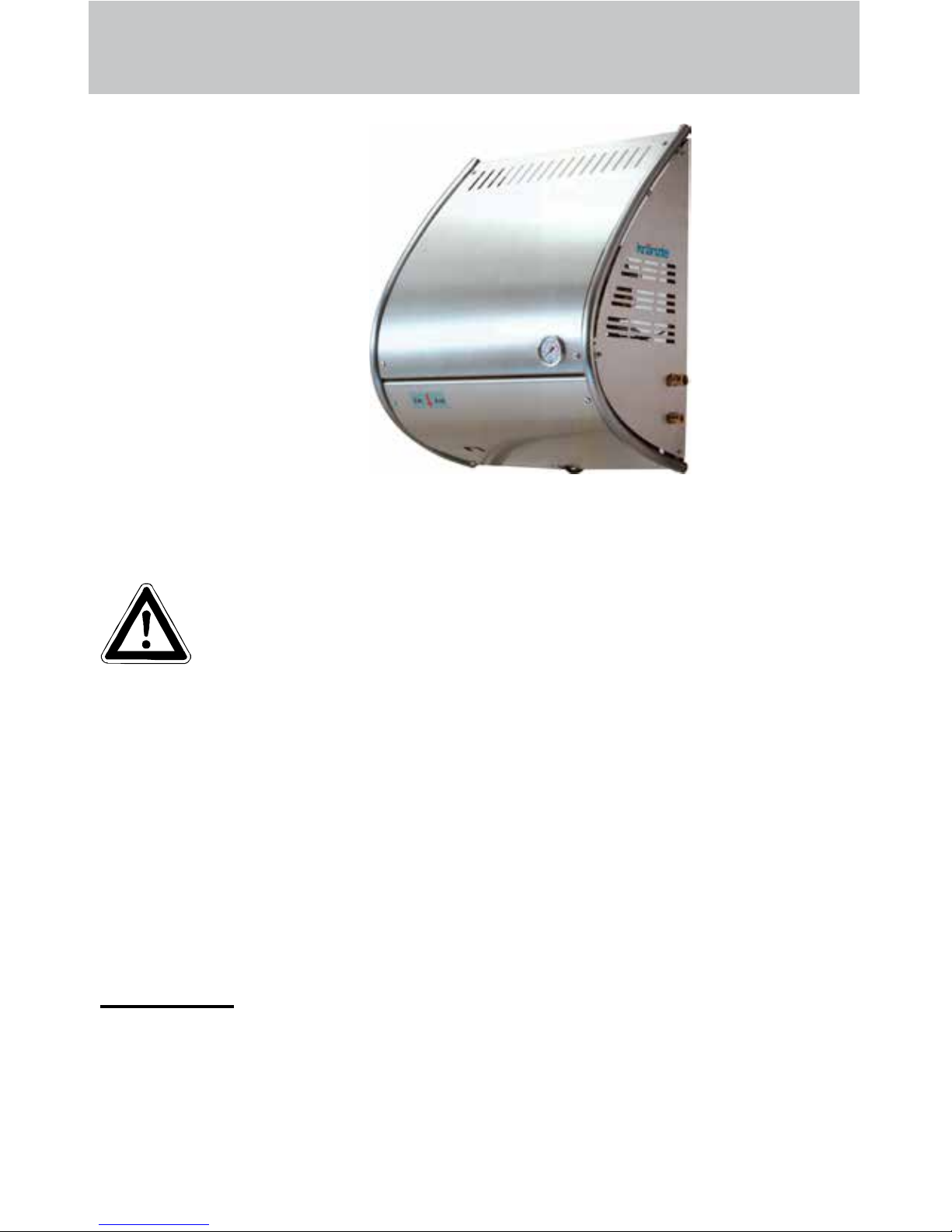

Stationary cold water high pressure cleaner

The stationary wall-mounted systems are supplied with a stainless steel housing

and equipped with an AQ pump (W11/135 with APG pump) and 10m steel fabric

heavy duty hose.

Pressure fully adjustable, automatic total-stop feature.

After the gun is closed, the device continues to run for a time and then cuts out. It

restarts when the gun is opened. Incorrect operation by unauthorised persons is

therefore not possible. The factory setting is 30 seconds. The device is connected

to a water supply with advance pressure. Temperatures of up to 60 °C are possible.

Features

Stainless steel housing,

10 m heavy duty hose with gun,

lance 800 mm

control nozzle and HP nozzle.

Preparation for use

Connect to suitable water supply, open the water tap.

Switch on high-pressure cleaner. The pump is running and the pressure is built

up. If the gun remains closed, the cleaner continues to run for another 30 seconds

and then switches automatically into standby.

As soon as you presser the trigger of the gun the high-pressure pump starts.

After closing the gun, it continues to run for approx. 30 seconds, and then

switches back to standby mode.

The device continues to run once the trigger is pressed during the 30 seconds.

1 Water inlet connection

2 High-pressure outlet

3 Press.gaugewithglycerinlling

4 On-/ Off switch

Function

2

1

34

If you use the HP cleaner for the rst time or if you have not worked

with your cleaner for a longer period of time, the machine has to be

deaerated by opening and closing the gun various times.

Page 4

4

Description

Water supply system

The water is fed under pressure (2 - 8 bar) to the HP pump. Then the water is fed

under pressure from the HP pump to the safety spray lance. The high pressure jet

is formed by the nozzle at the end of the lance.

The machine can only be operated when the safety trigger is squeezed.

When the lever is squeezed, the spray gun opens. The liquid is then pumped to

the nozzle.

When the trigger is released, the spray gun closes and any further spraying of

liquid from the lance is stopped and the manometer must show 0 bar.

The increase in pressure when the spray gun is closed causes the unloader

valve-safety valve to open. The pump remains switched on and continues to pump

liquid through the pump at reduced pressure. When the spray gun is opened, the

unloader valve - safety valve closes and the pump ressumes pressure spraying

from the lance.

The spray gun is a safety device. Repairs should only be performed by qualied persons. Should replacement parts be required, use only components authorized by the manufacturer.

Lance with spray gun

The unloader valve - safety valve protects the machine from a build up of excess

pressure, and is designed not to permit an excess pressure to be selected for

operation. The limit nut on the handle is sealed with a spray coating.

The operating pressure and spray rate can be steplessly adjusted by turning the

handle.

Replacements, repairs, new adjustments and sealing should only

be performed by qualied persons.

Unloader valve - safety valve

Environmental, refuse disposal and water protection

regulations must be observed !

Page 5

Description

5

High pressure hose and spraying device

The high pressure hose and spraying device supplied with the machine are made

of high grade material. They are also optimized for the machine and marked as

required by the appropriate regulations.

If replacement parts are required, only such parts that are authorized

by the manufacturer and which bear the markings required by the appropriate regulations may be used. The high pressure hose and spraying device must be connected in a pressure-tight manner.

The high pressure hose may not be driven over, pulled excessively

or twisted. Make sure that the hose is not damaged on sharp edges.

Hose lines are wear parts. Guarantee is accepted only for manufacturing errors, not for external damages.

High pressure hose lines and spraying equipment must not be

repaired, but replaced by a new hose or spraying equipment.

Unloader valve - safety valve

The unloader valve - safety valve protects the machine from a build up of excess

pressure, and is designed not to permit an excess pressure to be selected for

operation. The limit nut on the handle is sealed with a spray coating.

The operating pressure and spray rate can be steplessly adjusted by turning the

handle.

Replacements, repairs, new adjustments and sealing should only

be performed by qualied persons.

Take care that all screw connections are pressure-tight. A leakage

of gun, high-pressure hose or hose drum has to be repaired at once.

Leakages lead to an increased wear and to a possible malfunction

of the delayed motor cut-out.

Operator’s task:

Prior to each usage of this liquid spraying device, the operator is obliged to

check if all safety relevant parts are in perfect working condition.

(e.g. safty valves, high-pressure hose, cables and connections,

spraying devices, etc. )

Page 6

6

Description

With delayed motor cut-out

Frequent, work-necessitated switching on and off of motors on

machines of this size puts a heavy load on the power network and

causes increased wear on internal electrical parts. That’s why the

motor on the new KRÄNZLE appliances switches itself off 30 seconds after the

trigger is released, and switches itself back on again when the trigger is pressed.

When running your high pressure cleaner with hot water of 60° C

raised temperatures occur. Do not touch the machine without safety

gloves!

CAUTION !

CAUTION !

Never use liquid containing solvents such as paint thinners, petrol, oil

or similar liquid matter. Pay attention to the instructions of the man-

ufacturers of the cleaning agents. The seals in the machine are not

resistant to solvents. The spray of solvents is inammable, explosive

and poisonous.

Setting up

Location

Neither set up and operate the machine in rooms where there is a risk

of re or explosion nor put it into puddles. Do not use the machine

under water.

Replacements and inspection work should only be performed by quali-

ed persons when the machine is disconnected from the power

supply, i.e. the plug is pulled out from the electrical socket.

Page 7

Description

Electrical connection

The machine is supplied with an electrical power cord with plug.

The mains plug must be tted to a standard grounded socket with a

30mA residual current operated device. The socket must be protected with a 16A delay action fuse on the mains side.

KRÄNZLE W 11-135 = 230 Volt / 50 Hz

KRÄNZLE W 13-230 = 400 Volt / 50 Hz (phase-sequence not signicant)

KRÄNZLE W 15-200 = 400 Volt / 50 Hz (phase-sequence not signicant)

KRÄNZLE W 19-160 = 400 Volt / 50 Hz (phase-sequence not signicant)

When using an extension cable, this must have an earthed lead which is properly connected to the socket. The conductors in the extension cable must have a

minimum cross section of 1.5 mm². Plug connections must be of a spray-proof

design, and may not be located on a wet oor.

(with extension cables of more than 10 m - 2.5 mm2 )

CAUTION !

The use of extension cables which are too long may lead to malfunctions and start

up difculty.

W 13-230;

W 15-200;

W 19-160

400V/50Hz

W 11-135

230V/50Hz

7

Page 8

8

Description

Brief operating instructions:

1. Connect the high pressure hose with spray gun and machine.

2. Connect to suitable water supply.

3. Flush the air from the pump (open and close the spray gun several times).

4. Make the electrical connection - (400 Volt three-phase current).

5. Switch on the machine and commence cleaning.

6. After having completed the work switch off the tap and completely empty

the pump.

(Switch on the motor for approx. 20 sec. without the water hose and gun).

Afterwards you can roll up the high pressure hose.

- Only use clean water ! - Protect from frost !

CAUTION !

Please pay attention to the regulations of your waterworks company.

In accordance with EN 61 770, the machine may not be directly connected to the

public drinking water supply lines.

A brief connection however is permissible according to DVGW (German Associa-

tion for Gas and Water Affairs) if a tube ventilator with check valve (Kränzle OrderNo. 41.016 4) is built into the water supply.

Also indirect connection to the public drinking water supply lines is permissible by

way of free emission in accordance with EN 61 770; e.g. by using a reservoir with

a oat valve.

Direct connection to a non-drinking water supply line is permissible.

Page 9

9

Preparation for use

1. Check oil level.

There are two

possibilities for checking the oil level of the pump:

a) Oil must be visible in the viewing window

b) The oil level must be between the two

markings on the oil dipstick.

To check the oil level, loosen the oil cover screw and take out the oil dip stick. The

oil level must be between the two markings.

2. Connect the high pressure lance

or dirtkiller to the spray gun.

4. The machine must be connected to the water line with cold water or up to

60° C warm water (see page 2).

The hose cross section must be at least 3/4“ = 16 mm (free passage).

Itisrecommendedtoinstallawaterlterpriortothecleaner.

(Kränzle order no.: 13.300 3)

3. Unroll hose without kinks and connect with

handgun and pump. Max. extension 20m-HP

hose or 2 x 10m with hose connections.

Page 10

To shut down the pump:

10

1. Switch off the machine. Switch to „0“ position.

2. Cut off the water supply.

3.Openthespraygunbrieyuntilthepressureisreleased.

4. Apply the safety catch on the spray gun.

5. Remove the water hose and spray gun.

6. Pull the plug from the socket.

7. Winter: store the pump in rooms above 0°C.

8.Cleanthewaterlter.

To shut down the pump:

Frost protection

Normally after operation, there is still some water in the device. Thus, you must take

special measures to protect the device from frost.

- Completely drain the device

For this purpose, separate the device from the water supply. Then, turn on the

main switch and open the gun. Now, the pump presses the remaining water out of

the water tank and the pump. However, do not allow the device to operate without

water for longer than one minute.

- Fill the device with antifreeze agent

If the device is not operated for longer periods, especially over the winter, you

should pump an antifreeze agent through the device. For this purpose, ll the anti-

freeze agent into the water box and turn on the device. Wait with opened gun,

until the agent spurts out of the nozzle.

However, the best way to protect the device from frost is

to store it at a frost-free location.

Page 11

Care and Maintenance

Care and Maintenance

Care and maintenance is required to keep the machine in good working order, and

to allow you to enjoy the machine for as long as possible.

IMPORTANT!!!

Always remove the plug before working on the machine!

Only use original Kränzle spare parts

What to do!

- Weekly, or after approx. 40 hours of operation

Check the oil level of the high pressure pump.

Loosen the red oil stopper on the high pressure pump and pull out the oil

dipstick.

If the oil level is too low, add oil until the oil level is between the two markings

on the oil dipstick.

Change the oil if it has a grey or whitish appearance. The oil should be disposed of responsibly.

11

Changing the oil

To do this, take the oil drainage hose (1) connected to the oil drain screw, from the

inside of the machine and open the red oil ller cap on the top side of the black oil

reservoir. Open the cap at the end of the hose. Drain off the oil into an oil pan and

dispose of it responsibly. Close the end of the hose.

Rell with oil, es described above.

Oil leakage

If oil leaks out, contact the nearest customer service (dealer) immediately. (Environmental damages, transmission damages, loss of guarantee.)

Type of oil:

W19/160 Formula RS of Castrol - Quantity: 1.0 l

W15/200

W13/230

W11/135 Motor oil: 15/W40 - Quantity: 0.3 l

Page 12

12

Care and Maintenance

Rules, directives, inspections

Inspections performed by Kränzle

- measurement of earth line resistance

- measurement of voltage and current

- inspection of tension consistency with +/- 1530 V

- visual and functional check as per the inspection sheet provided

Guidelines for liquid sprayers

The machine conforms with the „Guidelines for liquid sprayers“. These

guidelines are issued by the organisation of trade associations and may be

obtained from Carl Heymann-Verlag KG, Luxemburger Str. 49, 50939 Köln.

These guidelines specify that this machine is to be inspected by qualied

personnel whenever necessary, but no less than once every 12 months.

These inspections must be recorded in the inspection log at the end of this

manual.

Duties of owner

The owner is to ensure that all safety-relevant components are in a serviceable

condition before the sprayer is used. (e.g., safety valves*, hoses and electric

cables, spray equipment etc).

* The pressure gauge must show 0 bar once the gun is closed.

Page 13

Safety Information

13

Safety Information

Important !!!

The machine must be disconnected from the power supply when ser-

vicing work is being carried out. The master switch should be in position

„0“ and the plug out of the socket.

Do not use the cleaner if electrical connections or other safety-relevant

parts (e.g. overpressure valve, high pressure hose, spraying equipment

etc.) are damaged.

The machine may only be used by persons who have received the necessary training.

Never operate the machine without supervision.

The water spray can be dangerous. It should never be directed at people, animals,

electrical apparatus or the machine itself.

Never direct the spray at power sockets.

Parts of the machine interior and parts of the gun and lance become hot when hot water

is used. Leave the cover of the machine closed when using the machine and do not

touch the metallic parts of the gun and lance.

Children must not use high pressure cleaning equipment.

Do not damage the cable or repair it incorrectly.

Do not pull the high pressure hose if there are kinks or loops in it. Make sure that the hose

is not damaged on sharp edges.

Persons operating the machine should wear the necessary protective clothing, i.e., wa-

terproof clothing, rubber boots, safety goggles, headwear etc. It is prohibited to use the

machine in close vicinity to people lacking suitable protective clothing.

The high pressure spray can generate a high level of noise. If noise exceeds the maximum

allowed levels, users and others in the vicinity must wear suitable ear protection.

The high pressure spray causes recoil and additional twisting movement if the gun is angled.

The gun must therefore be held rmly with both hands. (see page 2)

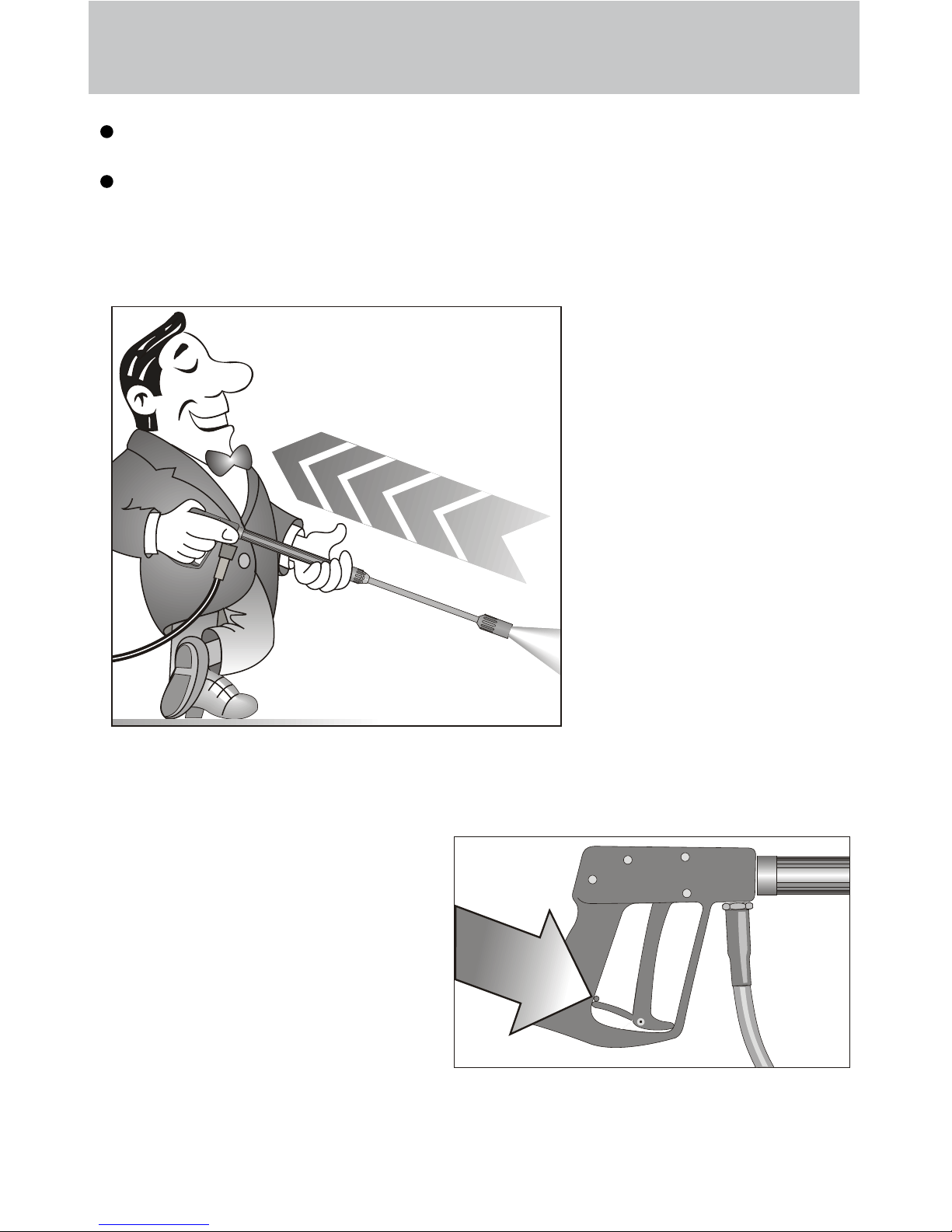

Do not clamp down the trigger of the gun. Apply the safety catch after use, in order to

prevent accidental spraying.

Do not spray against matter containing asbestos or other hazardous substances.

Never spray liquids containing solvents, such as paint thinner, petrol, oil, or anything simi-

lar. Notethespecicationsoftheadditivemakers! The seals in the machine are not

resistant to solvents. The spray vapour of solvents is highly inammable, explosive and

poisonous.

Page 14

14

Safety Information

As to the recoil see notice on page 2!

Apply the safety catch on the

spray gun after each use, in

order to prevent unintentional

spraying!

The machine may not be set up and used in rooms where there is a danger of re or ex-

plosion. The machine may not be used under water.

Never direct the high-pressure jet at yourself or other persons just to clean clothing or

shoes.

Page 15

15

This is prohibited!

Never direct the water jet at the machine

itself!

Never allow children

to use the high pressure cleaner!

Never direct the water

jet at a power socket!

Page 16

16

This is prohibited!

Never direct the water

jet at people or animals!

Do not damage the

power cable or repair

it incorrectly!

Never pull the high

pressure hose if it has

formed kinks or “nooses”!

Never pull the hose

over sharp edges!

Page 17

17

Small repairs - Do it yourself!

Stopping leaks from hose or gun

After closing the gun the manometer shows full pressure!

The pressure regulator switches on and off contunuously!

If the

manometer

shows full

pressure,

Press the

trigger to

release the

pressure!!!

First dis-

connect the

hose!

Then unscrew

the pump outlet

with an open-jaw

wrench.

Clean the return

element or replace

the O-Ring !

The pressure

regulator

switches on

and off due

to pressure

loss!

Water can emerge at

these 3 points.

Check the seals and

replace the O-rings if necessary

or have the gun checked by the dealer.

Replace the O-Ring

at the lance or at the

HP hose respectively!

Reconnect

the hose, gun

and lance!

Problem

solved already!

Pull out the

power plug!

Page 18

Small repairs -

The nozzle is blocked!

No water but the gauge shows full pressure !

18

Rinse the hose through

rst.

You should now have

a powerful stream of

water,

but if you

only get a few

drops from

the lance

remove the lance and clean

the nozzle.

Using the at spray lance

you only have to clean

the front nozzle.

Straighten a paper

clip and clean the

nozzle.

Insert pointed object

into the hole and pull

the cap back!

Check visually whether the

nozzle is clean.

Now it works as well

as before.

Page 19

do it yourself!

Nozzle dirty or sticky!

Pressure gauge does not show full pressure.

Water comes out in spurts.

If you do not use the high-pressure cleaner for some time the valves can stick.

The high-pressure

hose vibrates.

19

Straighten a

paper clip...

When a valve is blokked,

the gauge

shows little

pressure or

no pressure

at all,

or the high

pressure

hose

vibrates!

Open the valve

with a socket

wrench...

and remove the

valve screw, the

valve and the

o-ring.

Replace the rubber o-ring.and remove the

dirt from the valve

- the valve inside

must be closed.

Retighten the

valve screw

...and repeat

on all 6

valves.

Now it works

as well as

before!

Page 20

20

Complete Assembly

Page 21

21

Spare parts list

Spare parts list KRÄNZLE W 11-135; W 13-230; W 15-200; W 19-160

Complete Assembly

No Description Qty. Ord.-No No Description Qty. Ord.-No

1 Tragrahmen Wandaggregat 1 42.750

2 Seitenbügel rechts 1 42.751

3 Seitenbügel links 1 42.752

4 Seitenblech rechts 1 42.753

5 Seitenblech links 1 42.754

6 Motorträger 1 42.755

7 Halteblech Schaltkasten 1 42.756

8 Verbindungsblech Schaltkasten 1 42.757

9 Wasserkasten 1 42.758

10 Abdeckung 170 x 100 1 42.759

11 Verschraubung R3/8“ AG X M22x1,5 1 13.371

12 Winkel 2x R3/8“ IG 2 44.138

13 Kupferdichtring 1 40.019

14 Ermetonippel R3/8“ x 12 2 44.139

15 HD-Schlauch 1 44.093

16 Winkel R3/8“AG x R3/8“IG 1 44.127

17 Durchusswächter 1 12.634

18 Usit-Ring 2 12.129

20 Ausgangsteil R3/8“ x M22x1,5 1 13.365 2

21 Sauganschluss R3/4“ x R1/2“ 1 41.016 1

22 Winkel 2x R1/2“ IG 1 42.764

24 Wassereingangsschlauch R3/4“ 1 42.760

25 Nippel R 1/2“ x 15L 1 42.763

26 Wassereingangsschlauch 15L 1 42.760 1

27 Kabeldurchführung 1 42.513

28 Kunststoffschraube 5,0 x 25 2 41.414

29 Frontblech unten 1 42.761

30 Frontblech oben 1 42.762

31 Manometer 0 – 400 bar 1 15.039 4

32 Klemmbügel für Manometer 1 44.049

33 Anschlussmuffe Manometer 1 44.136

34 Druckmessleitung 1 44.102 1

39 Lanze mit HD-Düse 1 12.392 5-HD25045

40 Starlett -Pistole mit Verlängerung 1 12.320 2

41 Blechmutter 17 42.506

42 Schraube 17 41.414 1

43 Schraube 2 40.290

44 Schraube M4 x 30 4 40.436

45 Zugentlastung 1 43.431

47 Schraube M4 x 20 1 40.313

48 Schwimmerventil 1 46.250

49 Überwurfmutter 1 46.258

50 Unterlegscheibe 4,3 8 44.059

Page 22

22

Valve housing

2

3

4

5

1

7

6

5.1

4

3

13

14

15

16

17

19

2

17

31

23

18

24

14

20

37

38

19.1

21

22

28

29

30

27

35

34

40

41

19

39

9

26

17.1

19.1

Reparatur-Satz Manschetten ohne 40.517

Messingteile bestehend aus:

3x Pos. 13; 6x Pos. 14; 3x Pos. 15;

3x Pos. 18; 3x Pos. 23

Reparatur-Satz Ventile 40.062 1

bestehend aus:

6x Pos. 2; 6x Pos. 3; 6x Pos. 4

Page 23

23

Spare parts list

Spare parts list W13/230; W15/200; W19/160

Valve housing AQ-pump

No Description Qty. Ord.-No

1 Ventilgehäuse AQ mit integr. UL 1 40.521

ohne integr. Druckschalter

2 O-Ring 18 x 2 6 40.016

3 Einlass- / Auslass- Ventil 6 42.024

4 O-Ring 21 x 2 6 42.025

5 Ventilstopfen 5 42.026

5.1 Ventilstopfen mit R 1/4“ IG 1 42.026 2

6 Sicherungsring 4 40.032

7 Innensechskantschraube M 12 x 45 4 40.504

9 Dichtstopfen M8 x 1 2 13.158

13 Gewebemanschette 3 40.023

14 Backring 20 mm 6 40.025

15 O-Ring 31,42 x 2,62 3 40.50

16 Leckagering 20 x 36 x 13,3 3 40.509

17 Kupfer-Dichtring 21 x 28 x 1,5 2 42.039

18 Gummimanschette 3 40.512

19 Verschlussschraube R 1/2“ 2 42.032

19.1 Sauganschluss R1/2“ 1 41.016 1

20 Distanzring mit Abstützung 3 40.507

21 Aluminium-Dichtring 2 13.275

22 Verschlussstopfen 1 13.181

23 Druckring 20 mm 3 40.021

24 Zwischenring 20 mm 3 40.516

26 Anschlussschlauch 1 44.096 6

27 Winkel Einschraub-Verschraubung 1/4“ 1 44.062

28 O-Ring 13 x 2,6 1 13.272

29 Kupfer-Dichtring 17 x 22 x 1,5 1 40.019

30 Verschlussschraube 3/8“ AG 1 40.018

31 Dichtstopfen M 10 x 1 1 43.043

34 Edelstahlkugel Ø10 1 12.122

35 Rückschlagfeder „K“ 1 14.120 1

37 O-Ring 18 x 2 1 43.446

38 Ausgangsstück Injektor ST30 M22x1,5 1 43.447

39 O-Ring 11 x 1,5 1 12.256

40 Edelstahlsitz Ø 7 1 14.118

41 Sprengring 1 13.147

Reparatur-Satz Manschetten 40.065 1

bestehend aus: 3x Pos. 13; 6x Pos. 14;

3x Pos. 15; 3x Pos. 16; 3x Pos. 18;

3x Pos. 20; 3x Pos. 23

Page 24

24

Unloader valve

17

14

25

22 21 20

19

18

5

15

16

23

5

13

12

11

10

9

8

58

54

53

57

70

Page 25

25

Spare parts list

Spare parts list W13/230; W15/200; W19/160

Unloader valve AQ-pump

5 O-Ring 16 x 2 2 13.150

8 O-Ring 11 x 1,44 1 12.256

9 Edelstahlsitz 1 14.118

10 Sicherungsring 1 13.147

11 Edelstahlkugel 1 13.148

12 Edelstahlfeder 1 14.119

13 Verschlußschraube 1 14.113

14 Steuerkolben 1 14.134

15 Parbaks 16 mm 1 13.159

16 Parbaks 8 mm 1 14.123

17 Spanstift 1 14.148

18 Kolbenführung spezial 1 42.105

19 Kontermutter M 8 x 1 2 14.144

20 Ventilfeder schwarz 1 14.125

21 Federdruckscheibe 1 14.126

22 Nadellager 1 14.146

23 Handrad 1 14.147 2

25 Elastic-Stop-Mutter M 8 x 1 1 14.152

53 O-Ring 14 x 2 1 43.445

54 Parbaks 4 mm 1 12.136 2

57 Blindverschluss mit Dichtungen 1 44.551

58 Parbaks 7 mm 1 15.013

70 Steuerkolben kpl. mit Handrad 43.444

No Description Qty. Ord.-No

Page 26

26

Motor

Page 27

27

Spare parts list

Spare parts list

Motor W 13/230; W 15/200; W 19/160

Motor mit Klemmkasten 400 V / 50 Hz 24.060

Motor mit Klemmkasten 3x 220 V / 50 Hz 24.060 2

1 Stator 112 5,5 kW 400V / 50Hz 1 40.540

2 A-Lager Flansch 1 40.530

3 Rotor 112 400V / 50Hz 1 40.531

4 Lüfterrad BG112 1 40.532

5 Lüfterhaube BG 112 1 40.533

6 Klemmkasten 1 40.534

7 Flachdichtung 1 43.030

8 Lüsterklemme 2,5 mm² 4-polig 1 43.031 1

9 PG-Verschraubung PG 13,5 1 40.539

10 Kegelrollenlager 31306 1 40.103

11 Öldichtung 35 x 47 x 7 1 40.080

12 Passfeder 8 x 7 x 32 1 40.104

13 Kugellager 6206 - 2Z 1 40.538

14 Innensechskantschraube M 6 x 30 4 43.037

16 Blechschraube 2,9 x 16 1 43.036

17 Schnorrsicherung S6 4 40.549

19 Schraube M 4 x 12 4 41.489

20 Schelle für Lüfterrad BG112 2 40.535

21 Schraube M 4 x 12 4 41.489

22 Erdungsschraube kpl. 1 43.038

26 Gummidämpfer 4 40.220

27 Unterlegscheibe 8,4 DIN 125 4 41.515

28 Elastic-Stop-Mutter M 8 4 41.410

No Description Qty. Ord.-No

Page 28

28

Drive unit AQ

21

12 13 14 15

16

20

19

18

17

16

7

1

4

5

6

8

9

10

11

22

2

3

Page 29

29

Spare parts list

Spare parts list

Drive unit AQ

1 Ölgehäuse 1 40.501

2 O-Ring 13,94 x 2,62 1 42.167

3 Ölablassstopfen R 3/8“ 1 42.019

4 Innensechskantschraube M 8 x 25 6 40.053

5 Sicherungsscheibe 6 40.054

6 Flachdichtung 1 40.511

7 Öldichtung 20 x 30 x 7 3 40.044 1

8 Wellenscheibe 1 40.043

9 Axial-Rollenkäg 1 40.040

10 AS-Scheibe 1 40.041

11.1 Taumelscheibe AQ 12,75° bei 19 l/min 1 40.042 1-12,75

11.2 Taumelscheibe AQ 10,8° bei 15 l/min 1 40.042 1-10,8

11.3 Taumelscheibe AQ 9,5° bei 13 l/min 1 40.042 1-9,5

bitte Taumelwinkel mit angeben

12 Plungerfeder 3 40.506

13 Federdruckscheibe 3 40.510

14 Plunger 20 mm (lang) 3 40.505

15 Sprengring 3 40.048

16 O-Ring 14 x 2 2 43.445

17 Ölschauglas M 18 x 1,5 1 42.018 1

18 Flachdichtung 1 41.019 3

19 Deckel 1 41.023 1

20 Innensechskantschraube M 5 x 12 4 41.019 4

21 Ölschraube M 18 x 1,5 1 41.022 1

22 Stützscheibe für Plungerfeder 3 40.513

Antrieb kpl. mit Plunger ohne Taumelscheibe 40.514

No Description Qty. Ord.-No

Page 30

30

Valve housing

1

2

2

4

4

5

6

5

12

44

42

7

6

28.1

29

30

31

27

28

29

32

43

11

9

37

13

15

36

14

35

33

34

38

19

19

8

10

26

Page 31

31

Spare parts list

Spare parts list Kränzle W 11 / 135

Valve housing APG for plunger diameter 18 mm

1 Ventilgehäuse 1 43.435

2 Ventilstopfen 6 41.714

4 Ventile (grün) für APG-Pumpe 6 41.715 1

5 O-Ring 16 x 2 7 13.150

6 O-Ring 15 x 2 6 41.716

7 Dichtstopfen R1/4“ mit Bund 1 42.103

8 Winkel 3/8“IG x 3/8“ AG 1 44.127

9 Dichtstopfen M 8 x 1 2 13.158

10 O-Ring 13 x 2,6 1 13.272

11 Aluminiumdichtring 1 13.275

12 Stopfen ¼“ AG mit ISK 1 13.387

13 O-Ring 1 12.256

14 Edelstahlsitz Ø 7 1 14.118

15 Sprengring 1 12.258

17 Kupfer-Dichtring 10 x 15 x 1,5 1 14.149

19 Sauganschluss 1 41.016

26 Anschlussschlauch 1 44.096 5

27 Druckring 3 41.018

28 Manschette 3 41.013

28.1 Gewebemanschette 18 x 26 x 4/2 3 41.013 1

29 Backring 18 x 26 3 41.014

30 O-Ring 28,3 x 1,78 3 40.026

31 Leckagering 18 mm 3 41.066

32 Zwischenring 18 mm 3 41.015 2

33 Verschlussstopfen R3/8“ 1 14.113

34 Kupferring 17 x 22 x 1,5 1 40.019

35 Edelstahlkugel Ø 10 1 12.122

36 Rückschlagfeder „K“ 1 14.120 1

37 O-Ring 18 x 2 1 43.446

38 Ausgangsstück M22x1,5 AG 1 43.447 1

42 Usit-Ring 1 42.104

43 Innenseckskantschraube M 8 x 30 2 41.036 1

44 Innenseckskantschraube M 8 x 55 2 41.017 1

No Description Qty. Ord.-No

Page 32

Unloader

27

37

40

38

28

26

41

17

14

25 22 21 20

19

18

5

15

16

23

58

54

53

57

Page 33

Spare parts list

Spare parts list Kränzle W 11 / 135

Valve housing APG for plunger diameter 18 mm

5 O-Ring 16 x 2 1 13.150

14 Steuerkolben 1 13.134

15 Parpaks 16 mm 1 13.159

16 Parpaks 8 mm 1 14.123

17 Spannstift 1 14.148

18 Kolbenführung spezial 1 42.105

19 Mutter M8 x 1 2 14.144

20 Ventilfeder schwarz 1 14.125

21 Federdruckscheibe 1 14.126

22 Nadellager 1 14.146

23 Handrad 1 14.147 2

25 Mutter M 8 x 1 selbstsichernd 1 14.152

26 Edelstahlsitz 1 14.118

27 Sprengring 1,3 x 15,5 1 13.147

28 O-Ring 11 x 1,44 1 12.256

37 Edelstahlkugel 8,5 mm 1 13.148

38 Edelstahlfeder 1 14.119

40 O-Ring 13,94 x 2,62 1 42.167

41 Druckschalter Blindstopfen 1 44.551

53 O-Ring 14 x 2 1 43.445

54 Parbaks 4 mm 1 12.136 2

57 Blindverschluss mit Dichtungen 1 44.551

58 Parbaks 7 mm 1 15.013

No Description Qty. Ord.-No

Page 34

32

Motor

125

4 6 7

3 5

2

2310

12

212218

16

13

11

24

14

9

26

27

28

Page 35

33

Spare parts list

Spare parts list

Motor W 11/135

1 Ölgehäuse 1 41.417

2 Stator BG90 230V / 50Hz 1 23.003

3 Rotor für 2,2 kW - Motor 1 43.316

4 Paßfeder 6 x 6 x 20 1 41.483 1

5 Rillenkugellager 6205 - 2Z 1 43.317

6 Motor-Lager Schulterlager 7304 1 41.027

7 Öldichtung 25 x 35 x 7 1 41.024

9 Lüfterrad BG 90 1 43.319

10 Lüfterhaube BG 90 1 41.120 1

11 Flachdichtung 1 41.086

12 Lüsterklemme 2,5 mm² 2-polig 1 43.031

13 Klemmkasten 1 41.090 2

14 Klemmschelle für Lüfterrad 1 43.454

16 PG-Einschub mit 1 PG-Verschraubung 1 41.090 4

18 Kondensator 55 µF 1 41.114 8

21 Blechschraube 2,9 x 16 1 43.036

22 Blechschraube 5 x 12 4 41.089

23 Blechschraube 4 x 9 4 41.079

24 Erdungsklemme kpl. 1 43.038

25 Innensechskantschraube M 6 x 30 4 43.037

26 Gummidämpfer 4 40.220

27 Unterlegscheibe 8,4 DIN 125 4 41.515

28 Elastic-Stop-Mutter M 8 4 41.410

No Description Qty. Ord.-No

Page 36

34

Transmission unit 18 mm

23

17

1

4

6

8

9

10

161514

21 20

20

19

13

20

Page 37

35

Spare parts list

No Description Qty. Ord.-No

1 Motor 2,2 kW 230 V 1 24.012

4 Taumelscheibe 12,5° 1 41.028-12,5

6 Axial-Rillenkugellager 3-teilig 1 43.486

8 O-Ring 88 x 2 1 41.021 1

9 Gehäuseplatte 18 mm 1 41.020 2

10 Öldichtung 18 x 28 x 7 3 41.031

13 Öleinfüllstutzen 1 43.438

14 Plungerfeder 3 41.033

15 Federdruckscheibe 3 41.034

16 Plunger 18 mm 3 41.032 1

17 Sprengring 3 41.035

19 Ölverschlussschraube rot 1 43.437

20 O-Ring 14 x 2 3 15.005 1

21 Ölschauglas 1 42.018 1

23 Ölablassstopfen M18x1,5 mit Magnet 1 48.020

Spare parts list

Drive W 11/135

Page 38

36

Control unit 230 V

No Description Qty. Ord.-No

23 Schalter 14,5 A Amazonas 1 41.111 6

24 Kunststoffschraube 4,0 x 16 4 43.417

26 Kunststoffschraube 5,0 x 25 6 41.414

28 Kunststoffschraube 3,5 x 20 2 43.415

29 Lüsterklemme 5-pol. 1 43.326 1

30 Schütz 230V 50/60 Hz 1 46.005

31 Schaltkasten Unterteil 1 46.012

32 Schaltkasten Deckel 1 46.013

33 Steuerplatine Abschaltverz. 1 42.564

34 Klemmrahmen mit Schalterabdichtung 1 43.453

36 Blechschraube 3,5 x 16 2 44.161

37 PG 16-Verschraubung 1 41.419 1

38 Dichtung für Schaltkastendeckel 1 42.525

39 Gegenmutter für PG9-Verschraubung 1 41.087 1

40 Gegenmutter für PG16-Verschraubung 3 44.119

41 PG 9 - Verschraubung 1 43.034

50 Schraube M 4 x 30 4 40.236

51 Unterlegscheibe 4,3 8 44.059

52 Mutter M4 4 12.138

Page 39

37

Control unit 400 V

No Description Qty. Ord.-No

23 Schalter 14,5 A Amazonas 1 41.111 6

24 Kunststoffschraube 4,0 x 16 4 43.417

26 Kunststoffschraube 5,0 x 25 6 41.414

28 Kunststoffschraube 3,5 x 20 2 43.415

29 Lüsterklemme 5-pol. 1 43.326 1

30 Schütz 100-C12KN10 3x400V 50/60 Hz 1 46.005 1

31 Schaltkasten Unterteil 1 46.012

32 Schaltkasten Deckel 1 46.013

33 Steuerplatine Abschaltverz. 400V 50/60Hz 1 42.563

34 Klemmrahmen mit Schalterabdichtung 1 43.453

36 Blechschraube 3,5 x 16 2 44.161

37 PG 16-Verschraubung 1 41.419 1

38 Dichtung für Schaltkastendeckel 1 42.525

39 Gegenmutter für PG9-Verschraubung 1 41.087 1

40 Gegenmutter für PG16-Verschraubung 3 44.119

41 PG 9 - Verschraubung 1 43.034

42 Überstromauslöser 3-polig 12 A 1 46.040 1

50 Schraube M 4 x 30 4 40.236

51 Unterlegscheibe 4,3 8 44.059

52 Mutter M4 4 12.138

Page 40

38

Gun and HP lance

Page 41

39

Spare parts list

Spare parts list Gun and HP lance

W 13 / 230; W 15 / 200; W 19 / 160

No Description Qty. Ord.-No

1 Ventilkörper mit Handgriff 1 12.294

2 Schutzhülse 1 12.295

3 Abdeckschutz 1 12.296

4 Betätigungshebel 1 12.298

5 Sicherungshebel 1 12.149

6 Abschlußschraube M 16 x1 1 12.247

7 Stopfen 1 12.287

8 Gewindeführungshülse R 1/4“ AG 1 12.250

9 Aufsteuerbolzen 1 12.284

10 Stift 1 12.148

11 Lagernadel 1 12.253

12 Edelstahlfeder 1 12.246

13 Edelstahlkugel 1 12.245

14 Edelstahlsitz 1 13.146

15 O-Ring 11 x 1,44 1 12.256

16 O-Ring 3,3 x 2,4 1 12.136

17 Blechschraube 3,9 x 8 4 12.297

18 Druckstück 1 12.252

19 Rohr kunststoffumspritzt bds. R 1/4“ AG 1 15.004 5

20 Überwurfmutter ST 30 M22 x 1,5 IG 1 13.276 1

21 Außen-Sechskant-Nippel R 1/4“ IG 1 13.277 1

22 O-Ring 9,3 x 2,4 1 13.273

23 Aluminium-Dichtring 4 13.275

24 O-Ring 15 x 1,5 1 12.129 1

25 Sicherungsring 1 12.258

No Description Qty. Ord.-No

51 Düsenschutz 1 26.002

52 Rohr 500 mm; bds. R1/4“ 1 12.385 1

53 ST 30 Nippel M 22 x 1,5 / R1/4“ m. ISK 1 13.370

54 Flat jet nozzle 25045 (for therm 890) 1 D25045

54.1 Flat jet nozzle 2507 (for therm 1160) 1 D2507

Starlet-Gun compl. with prolongation 12.320 2

Pos. 1-24

Rep.-kit „Starlet II“ 12.299

consisting of 1x Position: 13, 9, 10, 15, 14

Page 42

40

Wiring diagram 230V 50Hz

Wiring diagram for KRÄNZLE W11-135

230 Volt / 50 Hz

On-Off switch

with 14,5 Ampere

overload protection

Inlet line via

3x 1,5mm²

230 V / 50 Hz

Pumpenmotor

230 V / 50 Hz

Control board with

Trafo 230 V / 50 Hz

Contactor

Pressure switch

Page 43

41

Wiring diagram 400V 50Hz

Wiring diagram for KRÄNZLE W13-230 - W 19-160

400 Volt / 50 Hz

On-Off switch

with 8,5 Ampere

overload protection

Inlet line via

CEE 4x1.5mm²

400 V / 50 Hz

Pump motor

3x 400 V / 50 Hz Pressure switch

Control board with

transformer 400 V / 50 Hz

Contactor

Page 44

42

Warranty

Guarantee

The guarantee is only valid for material and manufacturing errors.

Wearing does not fall within this gurantee.

The instructions in our operating manual must be complied with. The operating

instructions form part of the guarantee. The Guarantee is void if other parts are

used than genuine Kränzle accessory parts or genuine Kränzle spare parts.

For high-pressure cleaners sold to the user the guarantee period is 24 month.

For high-pressure cleaners sold for industrial use the guarantee period is 12

month. In the case of a guarantee please contact your dealer or authorized

seller delivering accessories and your purchase receipt. You can nd them in the

internet under www.kraenzle.com.

The guarantee is also void if the machine is used with exceeding the temperature

and speed limits, a voltage below the required rating, with less than the required

amount of water or with dirty water. Pressure gauge, nozzle, valves, sleeves, high

pressure hose and spray equipment are wear parts and are not covered by the

warranty.

Page 45

I. Kränzle GmbH

Elpke 97 . 33605 Bielefeld

High-pressure-cleaners

Hochdruckreiniger

Nettoyeurs à Haute Pression

EC declaration of conformity

(Managing Director)

We hereby declare,

that the high-pressure models:

techn. documentation available from:

comply with the following guidelines and

specications and their amendments for

high-pressure cleaners:

Applied specications and

standards:

Bielefeld, 24.01.12

W 11/135; W 13/230

W 15/200; W 19/160

Manfred Bauer, Fa. Josef Kränzle

Rudolf-Diesel-Str. 20, 89257 Illertissen

Machine guideline 2006/42/EEC

Specicationforelectromagnetic

compatibility 2004/108/EEC

Outdoor noise directive 2005/88/EC,

Art. 13, High-pressure water jet machines

Appendix 3, part B, chapter 27

EN 60 335-2-79 :2009

EN 55 014-1 :2006

EN 55 014-2 / A2:2008

EN 61 000-3-2 : 2006

EN 61 000-3-3 : 2008

Page 46

44

Inspection report for HP cleaners

Type plate (on hand)

Operating manual (on hand)

Protective covering, -device

Pressure line (tightness)

Pressure gauge (function)

Float valve (tightness)

Spraying device (marking)

HP-hose / connector (damage, marking)

Safety valve opens at 10 % / 20 % exceeding of operating pr.

Power cable (damage)

Protective conductor (connected)

On / Off switch

Used chemicals

Allowed chemicals

High-prsure nozzle

Operating pressure..................bar

Switch off pressure................bar

Conductor reist. not exceeded / value

Insulation

Leakage current

Gun locked

The appliance was checked by an expert according to the Guidelines for Liquid

Spray Equipment, the defects found have been rectied so that the Labour Safety can be

conrmed.

The appliance was checked by an expert according to the Guidelines for Liquid

Spray Equipment. The Labour Safety cannot be conrmed unless the defects found are

rectied by repair or replacement of the faulty parts

The next retest according to the Guidelines for Liquid Spray Equipment has to be carried

out by: Month Year

Place, date Signature

HP cleaners for industrial use have to be checked by an expert every 12 months!

Inspection report on annually carried out Labour Safety Inspection (UVV) according

to the Guidelines for Liquid Spray Equipment. (This inspection sheet serves as proof

for the completion of the retest and must be kept carefully!)

Kränzle test seals: Order no. UVV200106

Scope of inspection o.k. yes no repaired

Inspection data determined value set value

Inspection result (tick)

Owner:

Address:

Type:

Serial no.:

Rep. order

Page 47

45

Inspection report for HP cleaners

The appliance was checked by an expert according to the Guidelines for Liquid

Spray Equipment, the defects found have been rectied so that the Labour Safety can be

conrmed.

The appliance was checked by an expert according to the Guidelines for Liquid

Spray Equipment. The Labour Safety cannot be conrmed unless the defects found are

rectied by repair or replacement of the faulty parts

The next retest according to the Guidelines for Liquid Spray Equipment has to be carried

out by: Month Year

Place, date Signature

HP cleaners for industrial use have to be checked by an expert every 12 months!

Inspection report on annually carried out Labour Safety Inspection (UVV) according

to the Guidelines for Liquid Spray Equipment. (This inspection sheet serves as proof

for the completion of the retest and must be kept carefully!)

Kränzle test seals: Order no. UVV200106

Inspection result (tick)

Type plate (on hand)

Operating manual (on hand)

Protective covering, -device

Pressure line (tightness)

Pressure gauge (function)

Float valve (tightness)

Spraying device (marking)

HP-hose / connector (damage, marking)

Safety valve opens at 10 % / 20 % exceeding of operating pr.

Power cable (damage)

Protective conductor (connected)

On / Off switch

Used chemicals

Allowed chemicals

High-prsure nozzle

Operating pressure..................bar

Switch off pressure................bar

Conductor reist. not exceeded / value

Insulation

Leakage current

Gun locked

Scope of inspection o.k. yes no repaired

Inspection data determined value set value

Owner:

Address:

Type:

Serial no.:

Rep. order

Page 48

Made

in

Germany

www.kraenzle.com

Order No.: 30.246 1

I. Kränzle GmbH

Elpke 97

D - 33605 Bielefeld

Reprint only allowed with the authorisation of Kränzle.

As date of 12/08/2014

Loading...

Loading...