Page 1

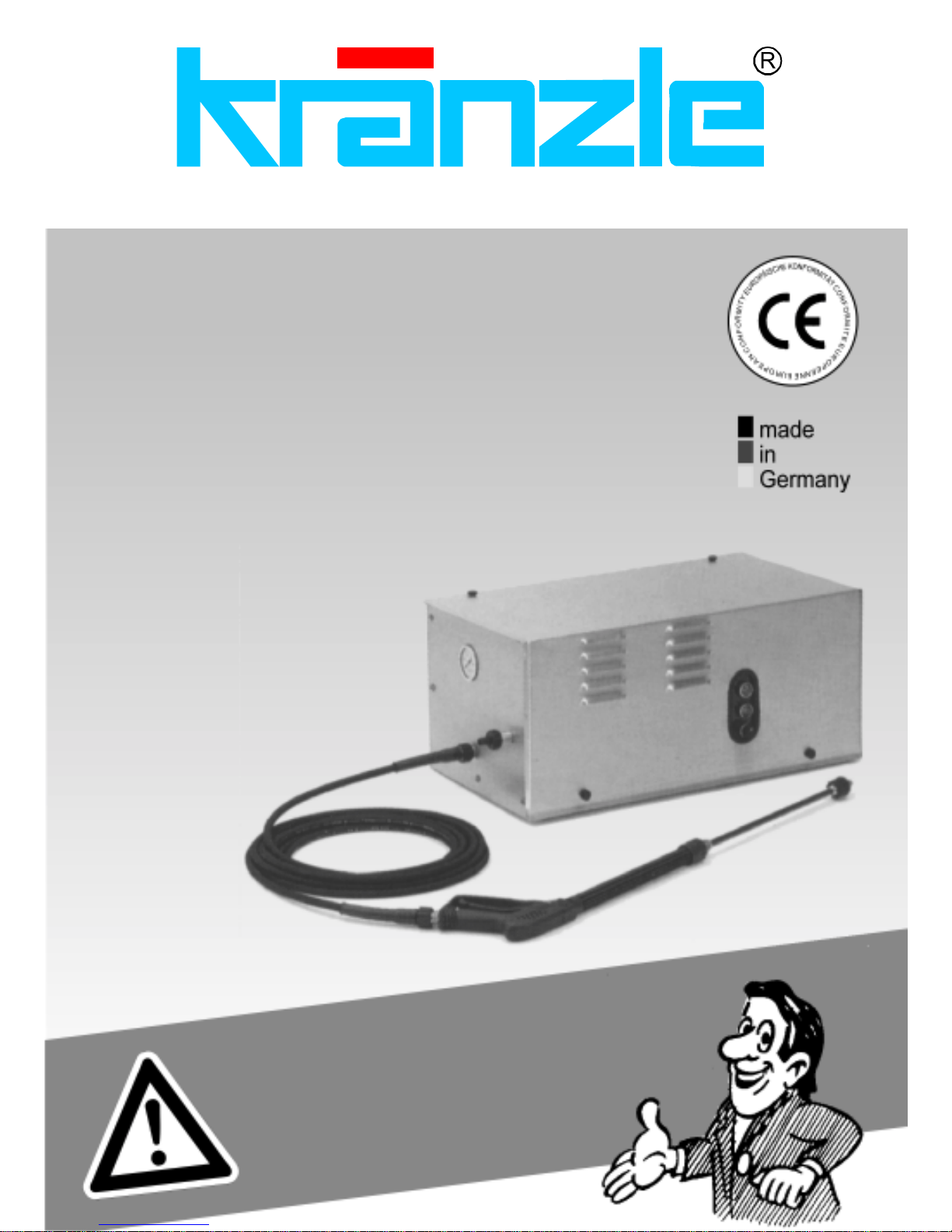

W 11/135

W 13/230

W 15/200

W 19/160

R

High PrHigh Pr

High PrHigh Pr

High Pr

essuressur

essuressur

essur

e Cleanerse Cleaners

e Cleanerse Cleaners

e Cleaners

Operating manualOperating manual

Operating manualOperating manual

Operating manual

Read and conforRead and confor

Read and conforRead and confor

Read and confor

m safetym safety

m safetym safety

m safety

instructions befor instructions befor

instructions befor instructions befor

instructions befor

e usee use

e usee use

e use

GB

Page 2

Dear Customer

We would like to congratulate you on your new high pressure cleaner and to

thank you for the purchase.

To ease your introduction to the use of the cleaner, we have provided the following pages of explanations, tips and hints, which we ask you to read before using

for the first time.

The equipment will assist you professionally in all cleaning tasks, e.g.:

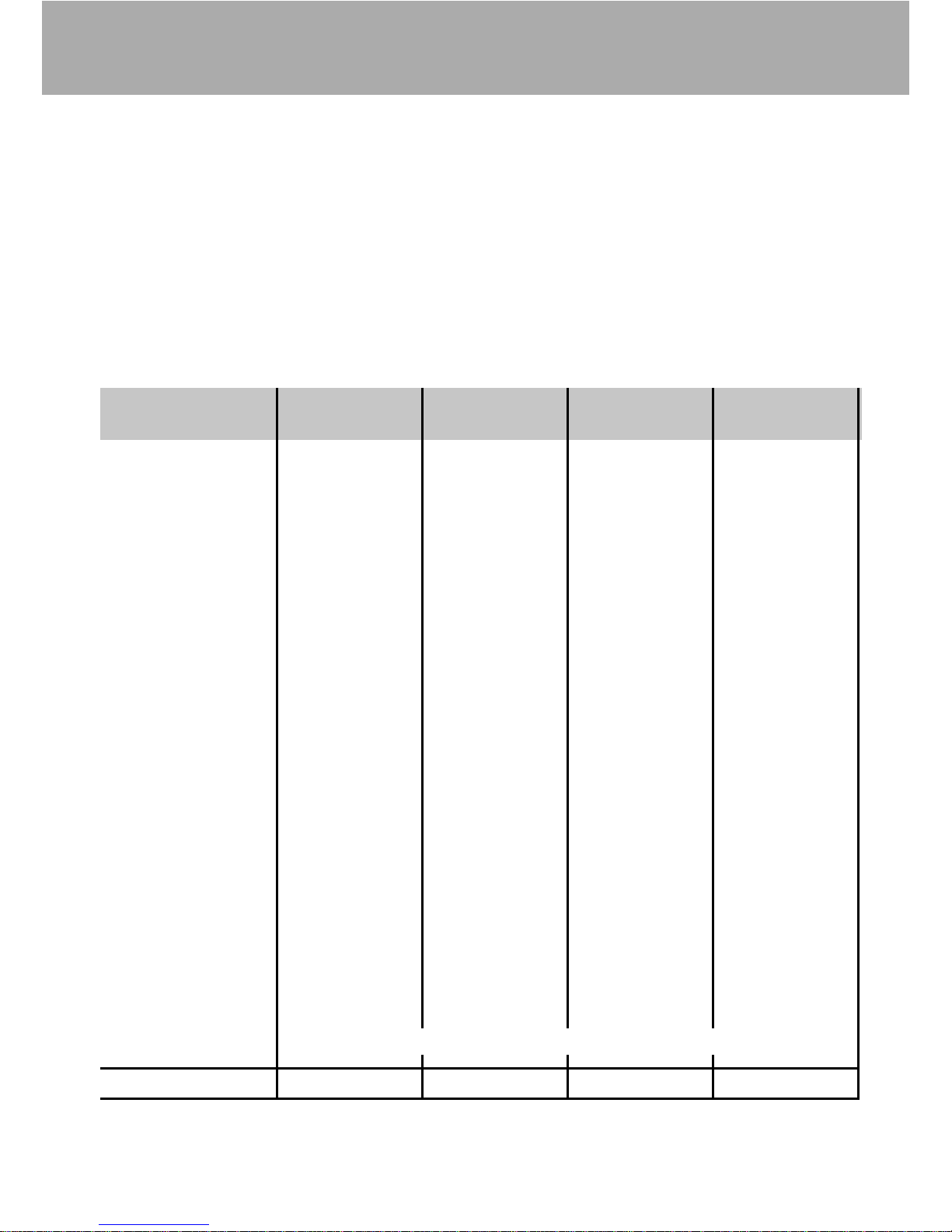

Description

- vehicles of all types

- barrels and containers

- machines etc. - Removing old

paint

Operating pressure

steplessly adjustable

Permis. overpressure

Water output

Hot water input

High pressure hose

Electrical ratings

Connect. Watt. Input

Output

Weight

Dimensions

Sound lever accord.

to DIN 45 635 (rel. to

working place)

with dirtkiller

Recoil at lance

Torque

Oder No.

10 - 135 bar

150 bar

11l/min.

at 1400 rpm

max. 70 °C

10 m

230 V ; 50 Hz ;

13,5 A

P1: 3,3 kW

P2: 2,4 kW

76 kg

730 x 410 x 350

89 dB

84 dB

approx. 25 Nm

26 Nm

41 312

Kränzle

W 11 / 135

Technical

specifications

Kränzle

W 19 / 160

Kränzle

W 15 / 200

Kränzle

W 13 / 230

10 - 180 bar

200 bar

19l/min.

at 1400 rpm

max. 70 °C

10 m

400 V ; 50 Hz ;

12 A

P1: 7,5 kW

P2: 5,5 kW

90 kg

730 x 410 x 350

89 dB

93 dB

approx. 22 Nm

24,3 Nm

41 310

10 - 220 bar

250 bar

15l/min.

at 1400 rpm

max. 70 °C

10 m

400 V ; 50 Hz ;

12 A

P1: 7,5 kW

P2: 5,5 kW

90 kg

730 x 410 x 350

89 dB

93 dB

approx. 25 Nm

28,8 Nm

41 309

10 - 250 bar

270 bar

13l/min.

at 1400 rpm

max. 70 °C

10 m

400 V ; 50 Hz ;

12 A

P1: 7,5 kW

P2: 5,5 kW

90 kg

730 x 410 x 350

89 dB

93 dB

approx. 27 Nm

28,8 Nm

41 308

(Assumed length of lance: 0,9 m)

Permissible tolerance for figures ±5% in accordance with VDMA, uniform sheet 24411

2

Page 3

3

Preparation for use

Stationary cold water high pressure cleaner:

The stationary wall-mounted systems are supplied with a stainless steel housing.

Equipped with an AQ pump, 10m steel fabric heavy duty hose, pressure fully adjustable, automatic total-stop feature and adjustable after-running. 1-5 bar ad-

vance pressure required (not self-intake).

The control is switched via a flow detector and controlled via a time relay. After

the gun is closed, the device continues to run for a time and then cuts out. It restarts when the gun is opened. Incorrect operation by unauthorised persons is

therefore not possible. Time setting of 1 to 180 seconds is possible. The factory

setting is 30 seconds. The device is connected to a water supply with advance

pressure. Temperatures of up to 70 °C are possible.

Features

Stainless steel housing,

10 m heavy duty hose with gun

Lance 800 mm

Control nozzle and HD nozzle.

Start-up

Open the water tap.

Set the black turn-knob to 1, and the device is in WAIT mode.

The high pressure pump starts if you then press the gun.

After closing the gun, it continues to run for approx. 30 seconds, and then

switches back to WAIT mode.

The device continues to run if the gun is pressed during the 30 seconds.

Green lamp: device in operation

Red lamp : malfunction

Page 4

4

Description

Water and Cleaning System

The water is fed to the high pressure pump under pressure.The water is then

forced under pressure by the high pressure pump to the lance. The high pressure

jet is formed by the nozzle at the end of the lance.

The machine can only be operated when the safety trigger is squeezed.

The machine can only be operated when the safety trigger is squeezed. When the

leve r is squeezed, the spray gun opens. The liquid is then pumped to the nozzle.

The spray pressure increases and quickly reaches the selected operating

pressure.(Not with W 11/135).

When the trigger is released, the trigger gun closes and any further spraying of

liquid from the lance is stopped and the manometer must show 0 bar.

The increase in pressure when the trigger gun is closed causes the unloader

valve-safety valve to open. The pump remains switched on and continues to

pump liquid through the pump at reduced pressure. When the trigger gun is

opened, the unloader valve - safety valve closes and the pump ressumes pressure spraying from the lance.

The trigger gun is a safety device. Repairs should only be

performed by qualified persons. Should replacement parts be

required, use only components authorized by the manufacturer.

Lance with trigger gun

The unloader valve - safety valve protects the machine from a build p of excess

pressure, and is designed not to permit an excess pressure to be selected for

operation. The limit nut on the handle is sealed with a spray coating.

The operating pressure and spray rate can be steplessly adjusted by turning the

handle.

Replacements, repairs, new adjustments and sealing should only

be performed by qualified persons.

Unloader valve - safety valve

Environmental, refuse disposal and water protection

regulations must be observed !

Page 5

5

Description

With delayed motor cut-out

Frequent, work-necessitated switching on and off of motors on

machines of this size puts a heavy load on the power network

and causes increased wear on internal electrical parts. That’s why the motor on

the new KRÄNZLE switches itself off 30 seconds after the trigger is released, and

switches itself back on again when the trigger is pressed.

When running your high pressure cleaner with hot water of 80° C

raised temperatures occur. Do not touch the machine without

safety gloves!

CAUTION !

CAUTION !

Never use liquid containing solvents such as paint thinners, petrol, oil

or similar liquid matter. Pay attention to the instructions of the

manufacturers of the cleaning agents. The seals in the machine are

not resistant to solvents. The spray of solvents is inflammable, explosive and poisonous.

Setting up

Location

Neither set up and operate the machine in rooms where there is a risk

of fire or explosion nor put it into puddles. Do not use the machine

under water.

Replacements and inspection work should only be performed by

qualified persons when the machine is disconnected from the

power supply, i.e. pull out the plug from the electrical socket.

Page 6

6

Description

Electrical connection

The machine is supplied with an electrical power cord with plug.

The mains plug must be fitted to a standard grounded socket with a

30mA residual current operated device.

The socket must be protected with a 16A delay action fuse on the

mains side.

When using an extension cable, this must have an earthed lead which

is properly connected to the socket. The conductors in the extension

cable must have a minimum cross section of 1.5 mm². Plug connections must be of a spray-proof design, and may not be located on a

wet floor.

(with extension cables of more than 10 m - 2.5 mm2 )

CAUTION !

The use of extension cables which are too long may lead to malfunctions and

start up difficulty.

Page 7

7

Description

Brief operating instructions:

1. Connect the high pressure hose with spray gun and machine.

2. Connect to suitable water supply.

3. Flush the air from the pump (open and close the spray gun several

times).

4. Make the electrical connection - (400 Volt three-phase current).

5. Switch on the machine and commence cleaning.

6. After having completed the work switch off the tap and completely empty the

pump.

(Switch on the motor for approx. 20 sec. without the water hose and gun).

Afterwards you can roll up the high pressure hose.

- Only use clean water ! - Protect from frost !

CAUTION !

Please pay attention to the regulations of your waterworks company.

In accordance with DIN 1988, the machine may not be directly connected to the

public drinking water supply lines.

A brief connection however is permissible according to DVGW (German Associa-

tion for Gas and Water Affairs) if a tube ventilator with check valve (Kränzle Order-No. 410 164) is built into the water supply.

Also indirect connection to the public drinking water supply lines is permissible by

way of free emission in accordance with DIN 1988, part 4; e.g. by using a reservoir with a float valve.

Direct connection to a non-drinking water supply line is permissible.

High pressure hose and spray device

The high pressure hose and spraying device supplied with the machine are made

of high grade material, they are also optimized for the machine and marked as

required by the appropriate regulations.

If replacement parts are required, only such parts that are authorized

by the manufacturer and which bear the markings required by the appropriate regulations may be used. The high pressure hose and spray

device must be connected in a pressure-tight manner.

The high pressure hose may not be driven over, pulled excessively, or

twisted. The hose may under no circumstances be pulled over sharp

edges, since otherwise the guarantee is automatically void.

High pressure hose lines and spraying equipment must not be repaired, but

replaced by a new hose or spraying equipment.

Page 8

8

Safety notes

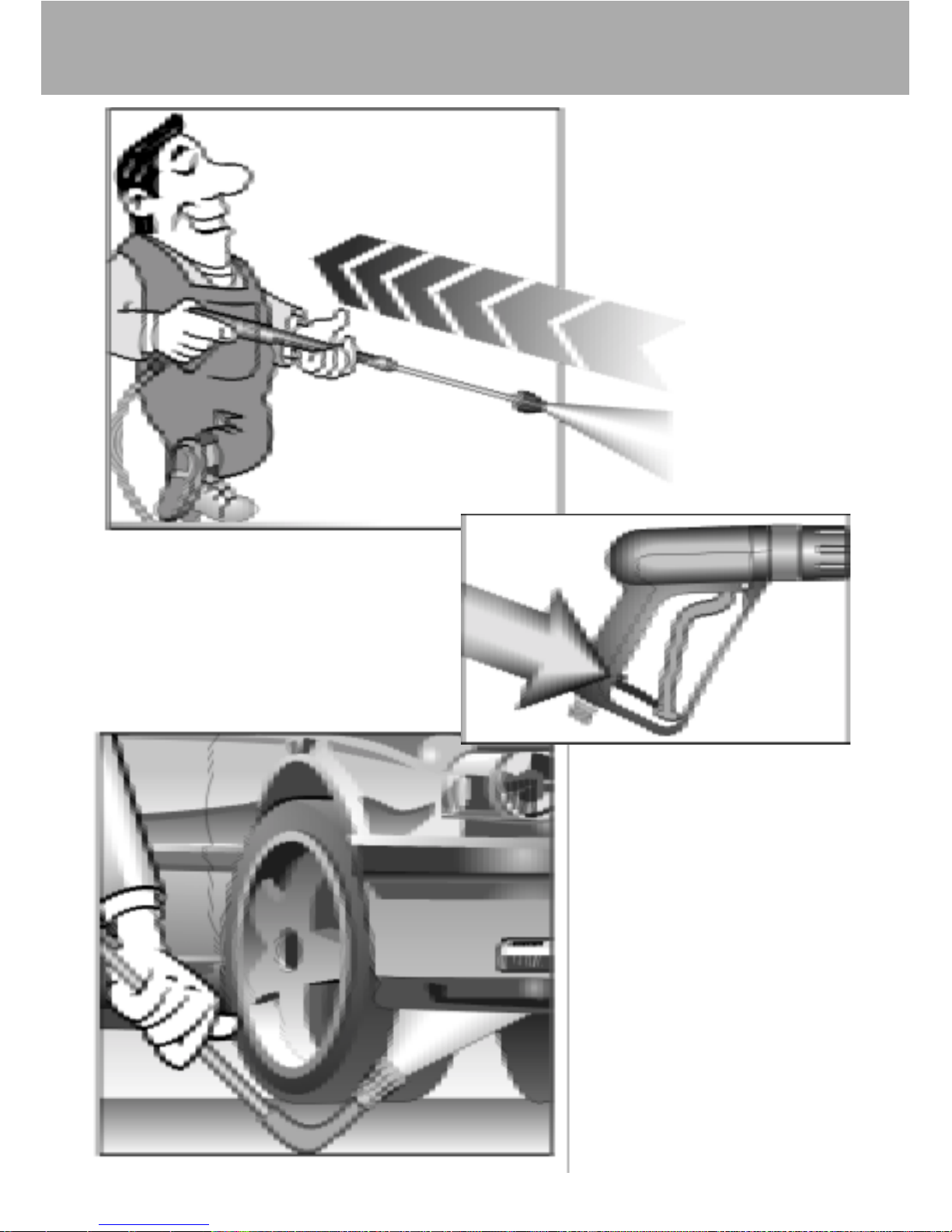

As to the recoil - see notice on page 2!

Apply the safety catch on the

spray gun after each use, in order

to prevent unintentional spraying!

Always aim the underbody

lance. Note when using an

angled underbody lance,

like for example lance No.

41.075, that there is a certain amount of torque in

the recoil.

(See also notice on page 2)

Page 9

9

Operation

Adjusting the pressure at the gun

Simply turn the adjustment ring.

(not with W 11/135).

The machine is set to operate at maximum pressure.

Page 10

10

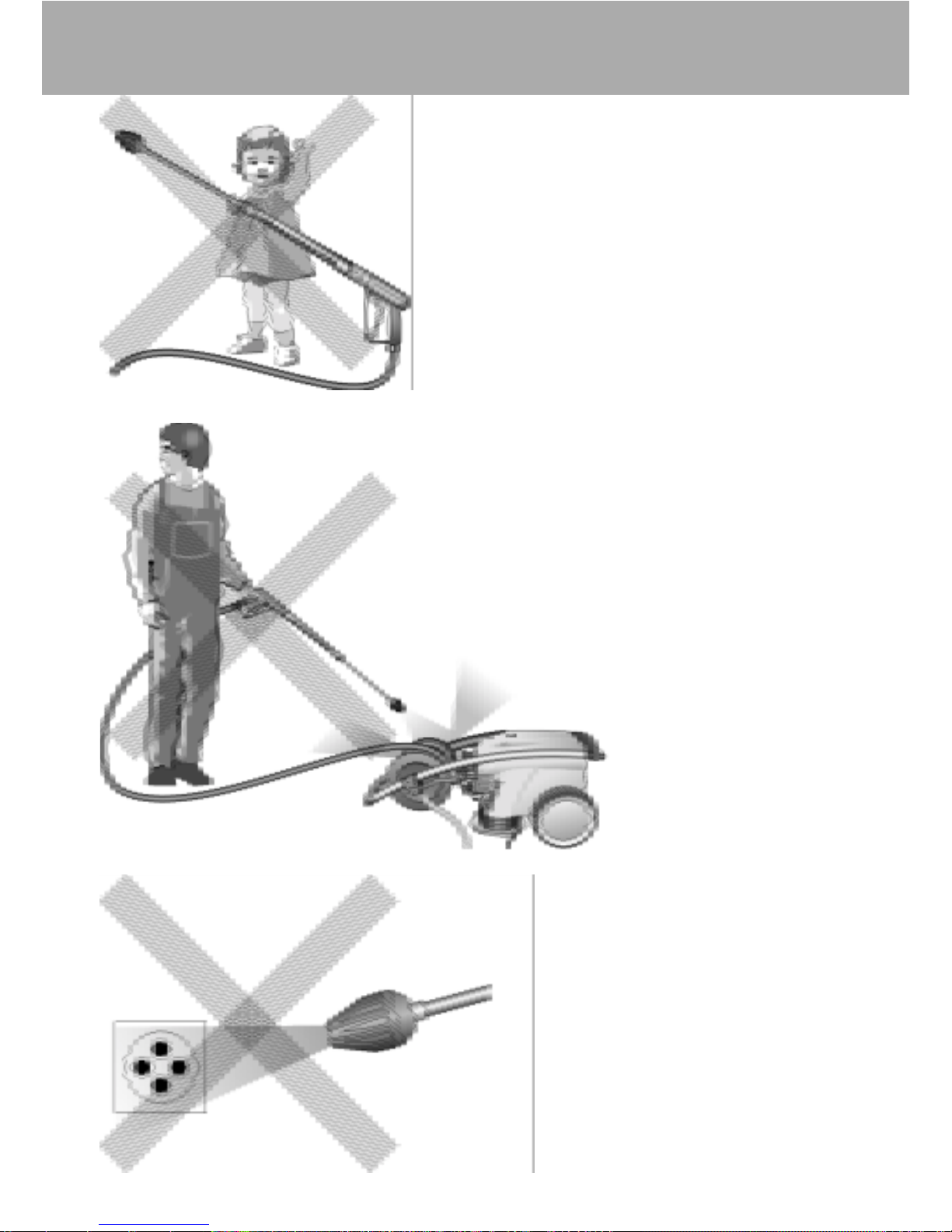

This is prohibited !

Never allow children

to use the high

pressure cleaner !

Never direct the

water jet at the

machine itself !

Never direct the

water jet at a power

socket !

Page 11

11

This is prohibited !

Do not damage the

power cord or repair

it incorrectly !

Never direct the

water jet at people or

animals !

Never pull the high

pressure hose if it has

formed kinks or

“nooses”!

Never pull the hose

over sharp edges !

Page 12

12

Valve housing

Page 13

13

Spare parts list

Spare parts list

Valve housing for AQ-pump

No Description Qty. Ord.-No

1 Ventilgehäuse 1 40.502

2 O-Ring 18 x 2 6 40.016

3 Einlaß- / Auslaß- Ventil 6 42.024

4 O-Ring 21 x 2 6 42.025

5 Ventilstopfen 6 42.026

6 Sicherungsring 4 40.032

7 Innensechskantschraube M 12 x 45 4 40.504

13 Gewebemanschette 3 40.023

14 Backring 20 mm 6 40.025

15 O-Ring 31,42 x 2,62 3 40.508

16 Leckagering 20 x 36 x 13,3 3 40.509

17 Cu-Dichtring 21 x 28 x 1,5 1 42.039

18 Gummimanschette 3 40.512

19 Verschlußschraube R 1/2" 1 42.032

20 Distanzring mit Abstützung 3 40.507

21 Cu-Dichtring 17 x 22 x 1,5 1 40.019

22 Verschlußschraube R 3/8" 1 40.018

23 Druckring 3 40.021

24 Zwischenring 3 40.516

Repair kit for sleeves and brass parts 40.065 1

consisting of: 3x Pos. 13; 6x Pos. 14; 3x Pos. 15;

3x Pos. 16; 3x Pos. 18; 3x Pos. 20; 3x Pos. 23

Repair kit for sleeves 40.517

consisting of: 3x Pos. 13; 6x Pos. 14; 3x Pos. 15;

3x Pos. 18; 3x Pos. 23

Repair kit valves 40.062 1

consisting of: 6x Pos. 2; 6x Pos. 3; 6x Pos. 4

Valve housing compl. 40.515

Page 14

14

Motor

Page 15

15

Spare parts list

Spare parts list

Motor BG 112

No Description Qty. Ord.-No

1 Stator 112 5,5 kW 400V / 50Hz 1 40.540

2 A-Lager Flansch 1 40.530

3 Rotor 112 400V / 50Hz 1 40.531

4 Lüfterrad BG112 1 40.532

5 Lüfterhaube BG 112 1 40.533

6 Klemmkasten 1 40.534

7 Flachdichtung 1 43.030

8 Lüsterklemme 2,5 mm² 4-polig 1 43.031 1

9 PG-Verschraubung PG 13,5 1 40.539

10 Kegelrollenlager 31306 1 40.103

11 Öldichtung 35 x 47 x 7 1 40.080

12 Paßfeder 8 x 7 x 32 1 40.104

13 Kugellager 6206 - 2Z 1 40.538

14 Innensechskantschraube M 6 x 30 4 43.037

16 Blechschraube 2,9 x 16 1 43.036

17 Vierkantmutter M 5 2 41.416

18 Schraube M 5 x 14 2 40.536

19 Schraube M 4 x 12 4 41.489

20 Schelle für Lüfterrad BG112 2 40.535

21 Schraube M 4 x 12 4 41.489

22 Erdungsschraube kpl. 1 43.038

Motor with terminal box 400 V / 50 Hz 24.060

Motor with terminal box 3x 220 V / 50 Hz 24.060 2

Page 16

16

Drive unit AQ

Page 17

17

Spare parts list

Spare parts list

Drive unit AQ

No Description Qty. Ord.-No

1 Ölgehäuse 1 40.501

2 CU_Dichtung 1 40.052

3 Ölablaßschraube 1 40.051

4 Innensechskantschraube M 8 x 25 6 40.053

5 Sicherungsscheibe 6 40.054

6 Flachdichtung 1 40.511

7 Öldichtung 20 x 30 x 7 3 40.044 1

8 Wellenscheibe 1 40.043

9 Axial-Rollenkäfig 1 40.040

10 AS-Scheibe 1 40.041

11.1 Taumelscheibe AQ 12,0° bei 19 l/min 1 40.042 1-12,0

11.2 Taumelscheibe AQ 10,4° bei 15 l/min 1 40.042 1-10,4

11.3 Taumelscheibe AQ 8,5° bei 13 l/min 1 40.042 1-8,5

11.4 Taumelscheibe AQ 7,0° bei 11 l/min 1 40.042 1-7,0

please specify the degree of the swash plate

12 Plungerfeder 3 40.506

13 Federdruckscheibe 3 40.510

14 Plunger 20 mm (lang) 3 40.505

15 Sprengring 3 40.048

16 O-Ring 14 x 2 2 43.445

17 Ölschauglas M 18 x 1,5 1 42.018 1

18 Flachdichtung 1 41.019 3

19 Deckel 1 41.023 1

20 Innensechskantschraube M 5 x 12 4 41.019 4

21 Ölschraube M 18 x 1,5 1 41.022 1

22 Stützscheibe für Plungerfeder 3 40.513

Drive unit complete with plunger without swash plate 40.514

Page 18

18

Power-Colt

Page 19

19

Spare parts list

Spare parts list Power Colt

W 13 / 230; W 15 / 200; W 19 / 160

No Description Qty. Ord.-No

1 Ventilkörper kunststoffumspritzt 1 12.375 1

2 Griffhülle 1 12.376

3 Regulierring 1 12.377 1

5 Lanze 1 12.379

6 Überwurfmutter ST 30 M 22 x 1,5 IG 1 13.276 1

7 Abzug-Hebel 1 12.380

8 Sicherungshebel 1 12.381

9 Regulierkolben 1 12.386

10 Außen-Sechskant-Nippel R1/4" IG 1 13.277 1

11 Parbaks 7 mm 2 15.013

12 Abschlußschraube 1 12.247

13 Stopfen 1 12.287

14 Gewindeführungshülse 1 12.250

15 Aufsteuerbolzen 1 12.284

16 Stift 1 12.148

17 Stift 1 12.253

18 Edelstahlfeder 1 12.246

19 Edelstahlkugel 8,5 mm 1 12.245

20 Edelstahlsitz 7 mm 1 13.146

20.1 Sicherungsring 1 12.258

No Description Qty. Ord.-No

21 Sprengring 1,3 x 18 1 12.384

22 O-Ring 9,3 x 2,4 1 13.273

23 O-Ring 11 x 1,44 1 12.256

24 O-Ring 3,3 x 2,4 1 12.136

26 Druckstück 1 12.252

27 Blechschraube 3,9 x 8 2 12.297

29 Aluminium-Dichtring 4 13.275

30 O-Ring 15 x 1,5 1 12.129 1

Power-colt with pressure regulation 12.390

for W 13 / 230; W 15 / 200; W 19 / 160

Power-colt without pressure regulation 12.391

for W 11/135

Repair kit

Power-colt with pressure regulation 12.299 4

consisting of 2x Pos.11; Pos. 15; Pos. 19;

Pos. 20; Pos. 20.1; Pos. 22; Pos. 23; Pos. 24;

Pos. 29; Pos. 30

Power-colt without pressure regulation 12.299

consisting of Pos. 15; Pos. 19;

Pos. 20; Pos. 20.1; Pos. 22; Pos. 23; Pos. 24;

Pos. 29; Pos. 30

Page 20

20

ULH 250

Page 21

21

Spare parts list

Spare parts list

Combi-valve ULH 250

No Description Qty. Ord.-No

1 Ventilkörper 1 14.145

2 Kolbenführung (ULH) 1 14.130

3 Steuerkolben (ULH) M 8 x 1 1 14.133

4 Eingangsstück R 3/8" IG 1 13.136

5 Ausgangsstück R 1/4" IG 1 14.136

5.1 Ausgangsstück R 3/8" IG 1 14.115

5.2 Ausgangsstück R 3/8" AG 1 14.137

5.3 Ausgangsstück ST30 M 22 x 1,5 1 14.117

6 O-Ring 11 x 1,44 1 12.256

7 Edelstahlsitz 1 14.118

8 Sprengring 1 13.147

9 Edelstahlkugel 8,5 mm 1 13.148

10 Edelstahlfeder 1 14.119

11 O-Ring 15 x 2 1 13.150

12 Rückschlagfeder 1 14.120

13 O-Ring 6 x 3 1 14.121

15 Rückschlagkörper 1 14.122

16 Parbaks 16 mm 1 13.159

17 O-Ring 15 x 2 1 13.150

19 Stopfen M 10 x 1 1 13.158

20 Parbaks 8 mm 1 14.123

21 Stopfen R3/8" 1 14.139

22 Ventilfeder bis 210 bar 1 14.125

23 Federdruckscheibe 1 14.126

24 Elastic-Stop-Mutter M 8 x 1 1 14.152

25 Sechskantmutter M 8 x 1 2 14.144

26 Nadellager 1 14.146

27 Handrad 1 14.147

28 Spanstift 1 14.148

29 Kupferdichtring 1 14.149

49 Stopfen R1/4" 1 13.387

50 Alu-Dichtring 3 13.275

Control piston, complete 14.132 2

Repair kit ULH 250 14.129

Page 22

22

Control unit

1

2

1211

3

4

5

6

7

10

9

8

Page 23

23

Spare parts list

Spare parts list

Control unit

No Description Qty. Ord.-No

1 Kabelverschraubung PG 9 1 41.430

2 Kabelverschraubung PG 16 1 41.431

3 Schütz 400 V 1 41.432

3.1 Schütz 230 V 1 41.432 1

4 Motorschütz 10-16 A 400 V 1 13.433

4.1 Motorschütz 16-24 A 230 V 1 41.433 1

5 Lampe rot kpl. 1 41.434

6 Lampe grün kpl. 1 41.435

7 Ein- /Aus-Schalter kpl. 1 41.436

8 Schütz 400 V 1 41.437

8.1 Schütz 230 V 1 41.437 1

9 Zeitrelais 1 41.438

10 Gehäuse 1 41.439

11 Widerstand 10 kΩ 1 41.440

12 Feinsicherung 2 Ampère 1 41.441

Control unit complete for 400 V / 50 Hz 40.309 4

Page 24

24

Hose screw connection

1

2

3

3

4

5

6

7

8

8

8

8

9

10

10

10

11

23

22

21

20

19

18

12

13

14

15

16

17

Page 25

25

Spare parts list

Spare parts list

Hose screw connection

No Description Qty. Ord.-No

1 Abstandsrohr 1/4" AG x 1/4" AG 1 41.039

2 Winkel 1/4" IG x 1/4" IG 1 41.445

3 Doppelnippel 1/4" AG x M 18 x 1,5 AG 1 41.446

4 By-Pass-Schlauch 1 41.447

5 Doppelnippel 3/8" AG x M 18 x 1,5 AG 1 13.288

6 Verschraubung 3/8" AG x M 18 x 1,5 IG 1 41.448

7 ULH 250 1 14.141

8 Dichtring 1 12.129

9 Durchflußwächter 1 12.634

10 Doppelnippel 3/8" AG x 3/8" AG 1 41.449

11 ST30 Nippel 3/8" IG x M 22 x 1,5 AG 1 13.369

12 Winkel 1/4" AG x 1/4" AG 1 41.450

13 Manometerschlauch 1 41.451

14 Nippel 1/4" IG x 1/4" AG 1 41.452

15 Alu-Dichtring 3 13.275

16 Klemmring 1 15.039 9

17 Manometer 1 15.039

18 Winkel 1/2" x M 18 x 1,5 1 41.453

19 Wassereingangsschlauch 1 41.454

20 Doppelnippel 1/2" AG x M 18 x 1,5 AG 1 41.455

21 Schmutzfänger 1/2" IG x 1/2" IG 1 13.299

22 Reduzierring 1/2" AG x 3/8" IG 1 12.019

23 Sauganschluß 3/8" IG x 3/4" AG 1 41.708

Page 26

26

Standard Vario-Jet Nozzle

No Description Qty. Ord.-No

30 Nippel ST30 M22x1,5 AG / M 12 x 1 1 13.363

31 Rohr 400 mm, bds. M 12 x 1 1 15.002

32 Regeldüse mit Regulierring 1 13.201 2

33 Flachstrahldüse 1

Please specify nozzle size:

D25045 with W 11 / 135

D25045 with W 13 / 230

D2505 with W 15 / 200

D2507 with W 19 / 160

Spare parts list Lance with

Standard vario-jet nozzle

Page 27

27

Wiring diagram

Inlet line

Motor

S1 Contact element

F1 Motor protection relais

Through-flow

detector

Malfunction

Operation

blue

brown

brown

brown

Page 28

28

Wall mounting

35 mm

4

2

0

m

m

340 mm

35 mm

10 mm O

730 mm

330 mm 330 mm

( für 8 mm Schrauben )

(For 8 mm screws)

Page 29

29

General rules

Inspections

The guarantee period is 12 months according to VDMA.

The guarantee is void if changes are made to the safety devices or if the machine

is used at excess temperatures or speeds. The guarantee is also void if the

machine is used with a voltage below the required rating, with less than the

required amount of water, with dirty water and external damage to the pressure

gauge, nozzle, high pressure hose and spray device.

This guarantee is not applicable for spare parts.

Our operating instructions must be complied with.

Accident prevention

The machine must be inspected according to the “Guidelines for Liquid Spray

Devices” at least once every 12 months by a qualified person, to ensure that

continued safe operation is guarateed.

The results of the inspection are to be recorded in writing.

This may be done in any form.

The machine is designed for accidents to be impossible if used correctly.

The operator is to be notified of the risk of injury from hot machine parts and the

high pressure water jet. The “Guidelines for Liquid Spray Devices” must be

complied with.

Check the oil level at the oil dip stick prior to each use.

(Ensure horizontal position!)

Oil change:

The oil in your high pressure pump should be changed after approx. 40 hours of

operation, or if it takes on a grey or whitish colour. (Formation of condensate)

The oil must be collected in a container and disposed of in accordance with local

rules or legislation.

New oil: 1,0 l - Motor oil: W10-60 SAE Semi-synthetic oil

Ord.-Nr.: 40.059 1

Guarantee

Page 30

30

for KRÄNZLE - High Pressure Cleaners

Regular inspection every 12 months if used professionally!

Appliance No: Type:

The following must be checked:

1. Safety features

a) Manometer

b) Safety valve (pressure control)

c) Operating pressure

d) Cut out pressure (max. 10% above

operating pressure)

e) Low pressure with trigger released

2. General condition

a) High pressure hose

b) Cable, plug, switch (VDE)

c) Spray gun

d) Motor

e) Oil level

Result of inspection: Date of inspection:

Faults rectified,

Stamp and signature

Excerpt from the Guidelines for Liquid Spray Equipment (ZH 1/46) by the Central Office of the Professional

Trade Association.

Inspection:

Liquid spray equipment should be inspected for safe operation by a qualified person whenever necessary,

but no less than every 12 months. The maker’s or supplier’s instructions must be followed. The inspection

intervals may be extended if the equipment is not in active use.

In Germany, inspections compliant with the (German) Emission Controls Act may be required for oil and

gas-fired equipment, and the owner must arrange for these to be carried out independently of the main

inspection.

The results of inspections must be recorded in writing and presented to the respective authorities on

demand. There is no set form for these records.

The information in the operating instructions are a part of the inspection

Inspection report

Page 31

(Managing Director)

Herewith we W 11 / 135, W 19 / 160,

declare that W 15 / 200, W 13 / 230

complies with the following 91/368 EEC Ann. I N° 1

provisions applying to it 73/23 EEC

79/113 EEC 81/1051 EWG

Applied EN 292 T 1 and T 2

harmonized standards EN 60 204 T 1

in particular EN 50 082-2

EN 61 000 3-2 3-3 4-12

EN 55 014

EN 55 104

Applied national technical DIN VDE 0700 Part 265/79 3.95

standards and specifications DIN IEC 61 S (Co) 17

in particular DIN IEC 801 2-6 601 1-2

DIN IEC 1000 4 2-11

Notified body

1)

within the TÜV Hanover

meaning of Annex VII

engaged for

2)

- safe keeping of the file as defined by Annex VI

- verification of correct application of harmonized standards and certification

of adequacy of the file as defined by Annex VI

- EC type-examination (EC type-examination certificate No. ...)

Bielefeld, 10/10/97

I. Kränzle GmbH

Elpke 97 . 33605 Bielefeld

EC declaration of conformity as

defined by machinery directive 89/392/EEC Annex II A and

the EC low-voltage directive 73/23 EEC and the

EC-EWV directive 89/336 EEC

Hochdruckreiniger

High-pressure-cleaners

Nettoyeurs à Haute Pression

Page 32

Reprint only allowed with the authorization of

As of date of 13. 09. 1999

Ord.-No: 30 242 1

Loading...

Loading...