Page 1

High Pressure Cleaners

GB

Operating manual

Read and conform

safety instructions

before use

Page 2

Technical data

Dear Customer

We would like to congratulate you on your new hot water high pressure cleaner, and

to thank you for buying it!

The following pages contain information about the machine in order to familiarise

you with it and facilitate its use.

The machine is a professional cleaning aid in all cleaning tasks, eg:

- facades

- flagstones

- terraces

Technical data

Operating pressure

Permissible overpressure

Water output

Hot water output

Steam phase

High pressure hose

with hose drum

Max. heating output

Heating oil consumption

Exhaust gas mass flow

Electrical rating:

Input

Output

Weight

Dimensions in mm without reel

Sound level acc. to DIN 45 635

Guaranteed sound level L

Vibrations at lance

Recoil at lance

Torque

- vehicles of all types

- containers

- machines

*1

WA

- containers

therm 890

max. 190 bar

205 bar

max. 890 l/h-14.8 l/min

max. 80 °C

max. 150 °C

10 m

20 m

70 kW

5,9 kg/h - heating oil EL

(DIN 51 603)

0,037 kg/s

3x 230V / 50Hz / 21A

3x 400V / 50Hz / 11A

P1: 5.5 kW

P2: 5.0 kW

220 kg

800 x 1200 x 1050

89 dB (A)

91 dB (A)

2,2 m/s²

approx. 20 N

approx. 22 Nm

(Assumed length of lance: 0.9 m)

e.g: food processing

industry

therm 1160

max. 160 bar

175 bar

max. 1160 l/h- 19l/min

max. 80 °C

max. 150 °C

10 m

20 m

80 kW

6,8 kg/h - heating oil EL

(DIN 51 603)

0,043 kg/s

3x 230V / 50HZ / 21A

3x 400V / 50Hz / 11A

P1: 5.5 kW

P2: 5.0 kW

220 kg

800 x 1200 x 1050

89 dB (A)

91 dB (A)

2,2 m/s²

approx. 22 N

approx. 24 Nm

Permissible tolerance for figures ± 5 % in acc. with VDMA uniform sheet 24411

*1

2

Min. water quantity to be supplied to the high pressure cleaner!

Page 3

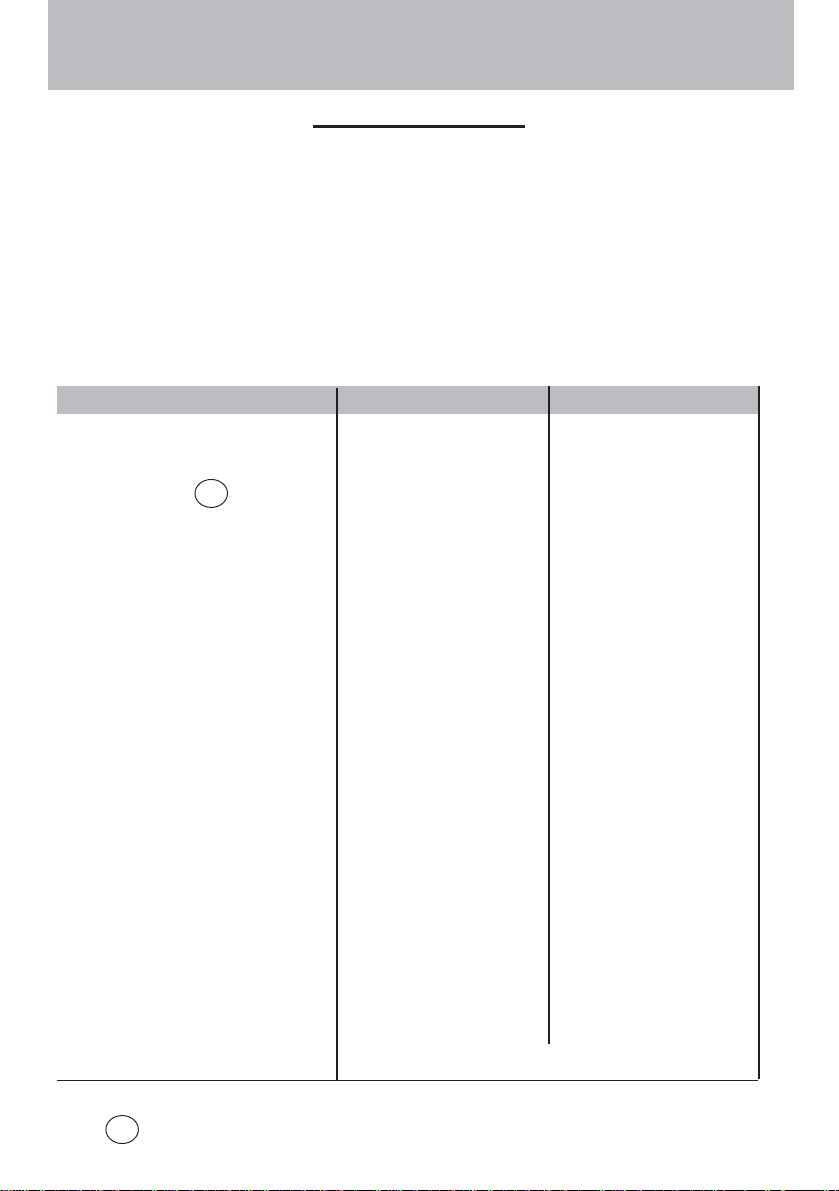

Description

Construction and Function

12

3

4

8

2

10

5

1 Water inlet connection with filter

2 Power cable

3 Winder for cable

4 Suction hose for detergent

5 High pressure hose

6 Spray gun

7 Spray pipe attachment

,,,

15 16 17

Hauptschalter

Main Switch

71139 6

8 Storage bin for spray gun and pipe

9 Brake

10 Storage bin for accessories

11 Fuel tank

12 Filler aperture for fuel

13 High pressure outlet

14 Fuel drainage screw

Hauptschalter

Pressur e

150

150

100

100

200

200

50

50

bar

bar

250

250

0

Wassertemperatur

Water temperature

50

40

30

20

10

0

70 80

60

°C

0

90

Zu Auf

100

off0on

110

120

130

140

150

Hauptschalter

Cleaning liquid

11

14

18.1

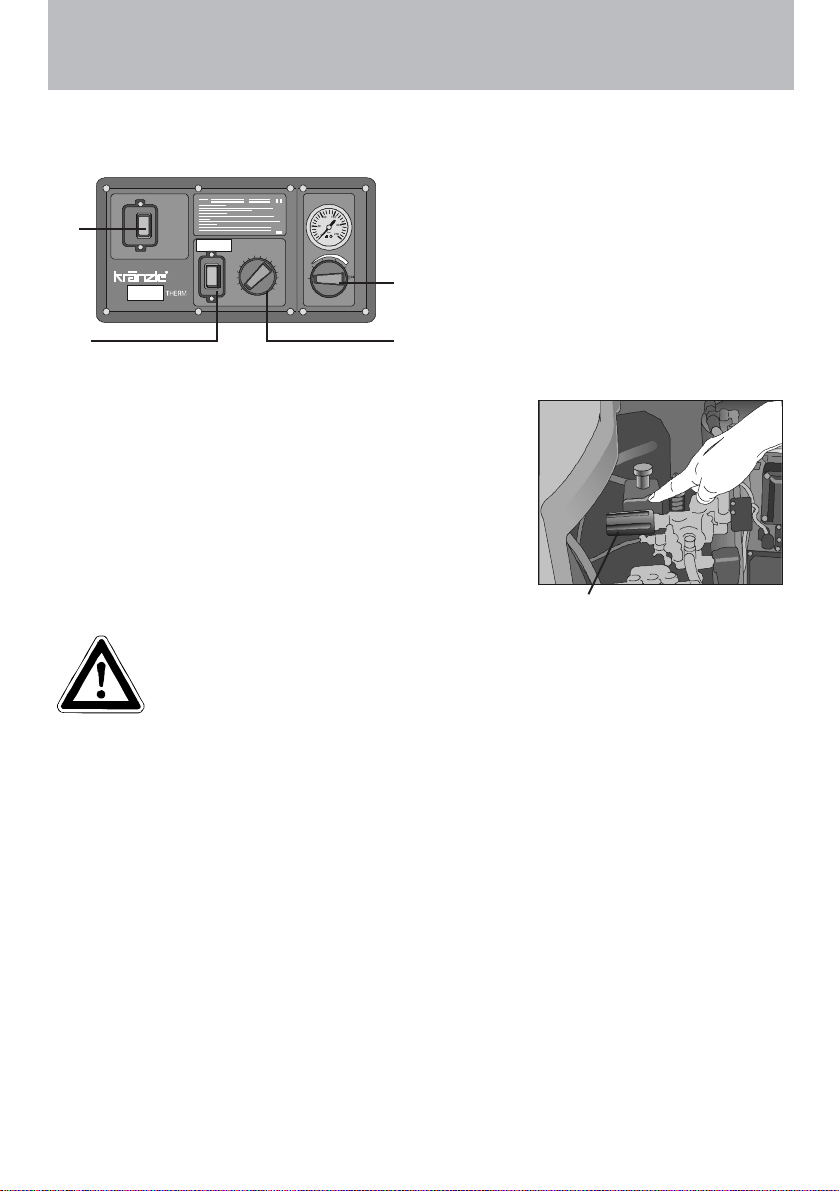

15 Master switch (appliance On- Off)

16 Brief operating instructions

17 Manometer

1918

18 Thermostat

18.1 (Burner ON- OFF) ignition

19 Detergent dispensing valve

3

Page 4

Description

Water system

The water flows into a tank.

A float valve regulates the water intake.

The water is then directed to the safety spray pipe

under pressure from the high pressure pump.

The high pressure spray is formed through the nozzle

on the spray pipe.

Detergent and caring system

The high pressure pump can also suck a detergent/caring agent and mix it with the

high pressure jet. - The detergent must have the ph-value 7-9 neutral.

Only open the dosing valve, if the chemistry sieve is placed in a

liquid.

The rules concerning the environment, refuse and ground water

protection must be complied with!

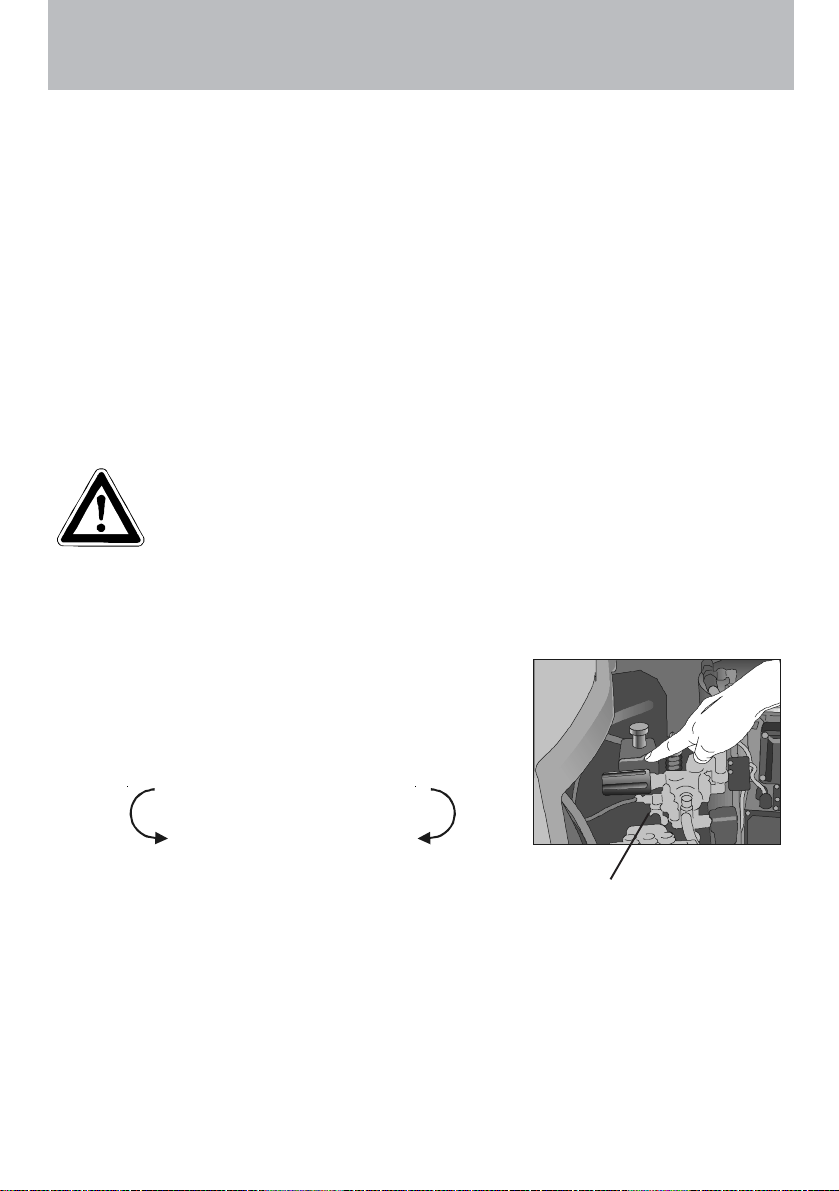

Pressure control and safety facilities

The pressure control valve allows full adjustment of the

quantity and pressure of the water.

The safety valve protects the machine from excessive

pressure and cannot be adjusted beyond the admissible

operating pressure. The setting nuts are sealed with

lacquer.

As an additional safety feature against overheating of the

combustion chamber a temperature sensor is installed in

the chimney. This sensor switches off the burner motor,

the ignition transformer and the solenoid valve as soon as

the exhaust gas temperature exceeds 250° C.

You find the unlocking button for the excess

temperature release on the console fixed to the

combustion chamber below the ignition transformer.

The machine has to rest for approx. 15 minutes before

it is allowed to press the unlocking button. If the

excess temperature sensor switches the machine off

repeatedly please call the technical service.

Replacements, repairs, new adjustments and sealing operations

may only be performed by trained personnel.

4

Page 5

Description

Motor protection switch

The pump motor is protected from overload by a motor

protecting switch. In case of an overload the motor is

switched off by the motor protecting switch. In case the

blue button is not set to „automatic resetting“, it has to

be pushed in again by hand. In case of a repeated

switching off of the motor by the motor protecting switch

the cause of the malfunction has to be removed.

Replacement and inspection work may

only be performed by trained personnel.

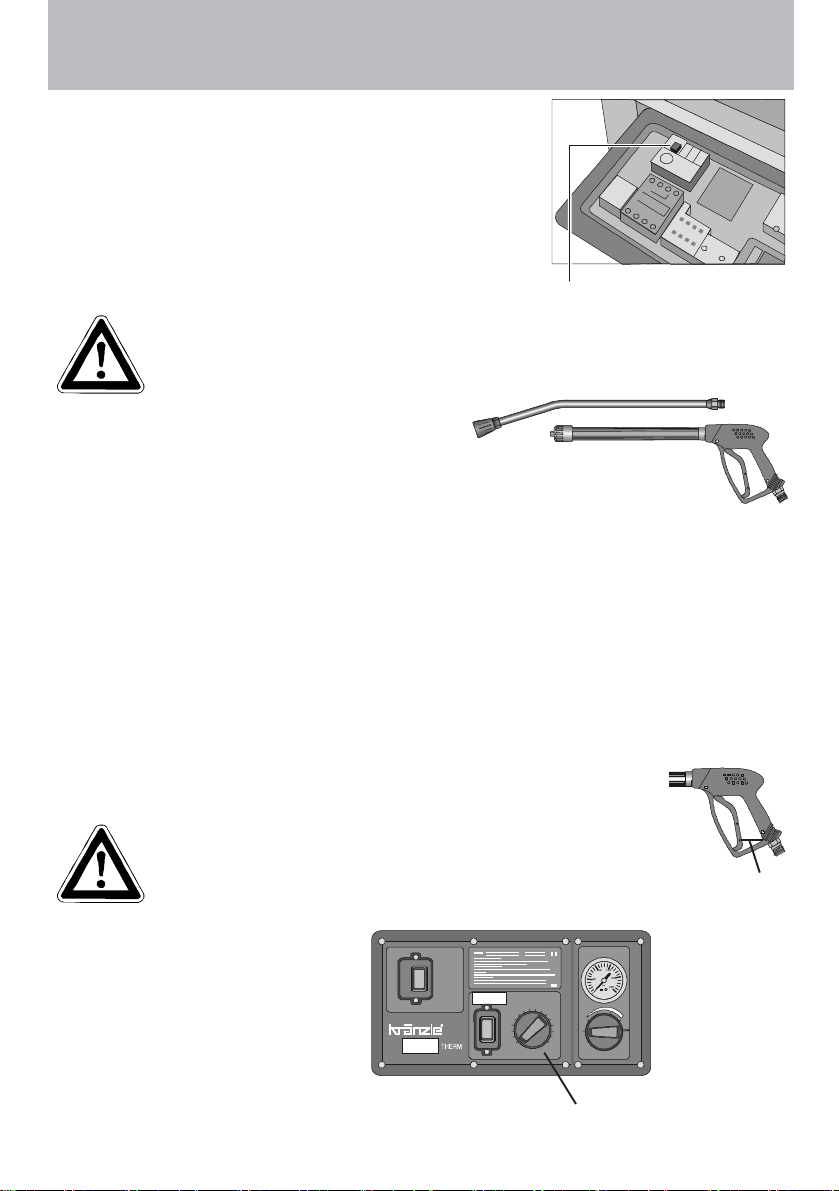

Spray pipe with spray gun

The spray gun only allows the machine to be

operated when the safety trigger is pulled.

The spray gun can be used when the safety trigger is pulled. The liquid is

then pumped up to the nozzle. Spray pressure builds up and quickly reaches the

selected operating pressure.

When the trigger is released the gun is closed, which prevents any further liquid

from coming out of the spray pipe.

The recoil resulting from the gun being closed opens the pressure control valve in

the machine. The pump remains switched on and pumps the circuit with reduced

overpressure. When the gun is opened (trigger pressed) the pressure control valve

closes and the pump starts to operate again at the selected pressure.

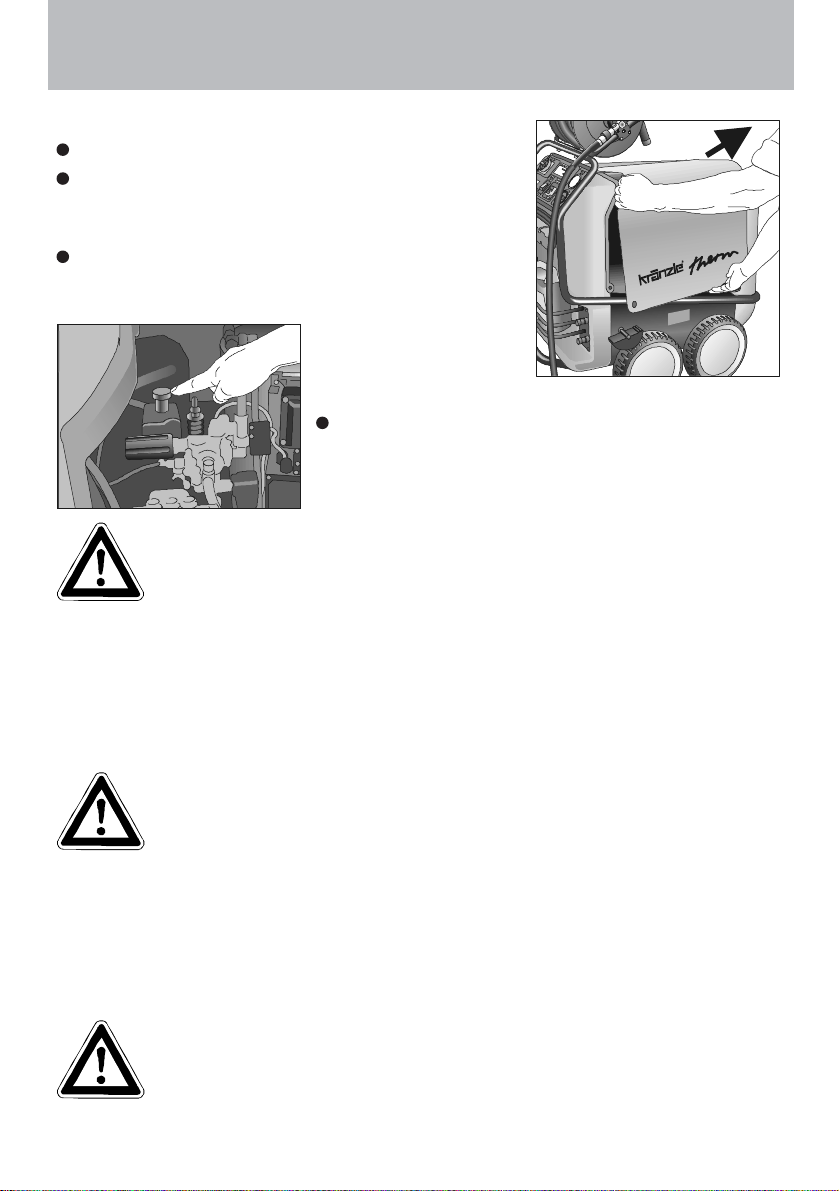

After completing work with your Kränzle therm, or if work is interrupted, the

safety catch (1) must be applied. This makes it impossible to press

the trigger by accident.

Blue button in the

unfolded control panel

The spray gun is a safety device. Repairs may only be

performed by trained personnel. If spare parts are

required, use only those approved by the maker.

Thermostat

The thermostat with rotary control

switch controls the temperature

of the spray water.

Hauptschalter

Main Switch

Wassertemperatur

Water temperature

50

40

30

20

10

0

1

Hauptschalter

Pressure

150

150

100

100

200

200

50

50

bar

bar

250

250

0

70 80

60

°C

0

90

Zu Auf

100

off0on

110

120

130

140

150

Hauptschalter

Cleaning liquid

Thermostat with

rotary control switch

5

Page 6

Safety Information

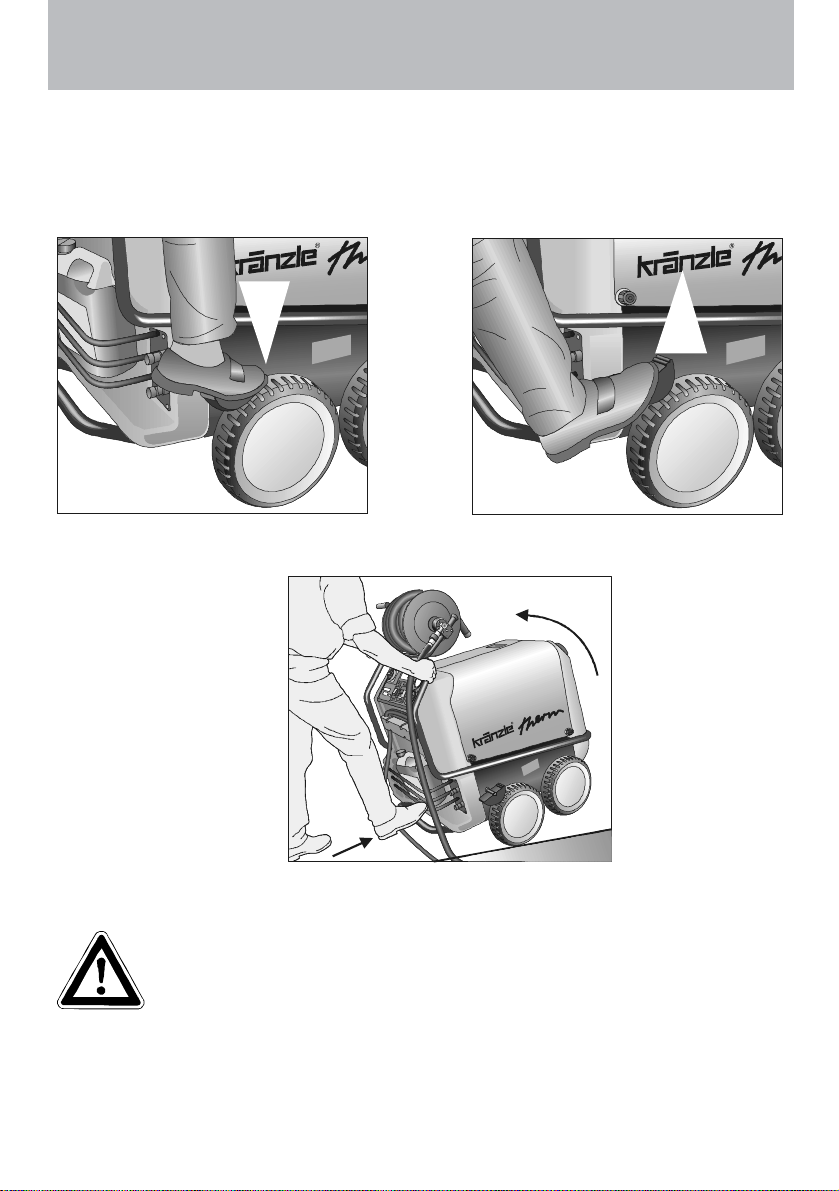

Brake

The Kränzle therm is fitted with a brake that prevents the machine from rolling away

on flat ground.

Always apply the brakes firmly when working with the machine !!!

Brake applied

If you want to move the

high pressure cleaner

into another direction,

first slightly tilt back the

machine by pressing the

foot rest and pulling the

pushbar at the same

time.

Brake not applied

Now you can

move the cleaner

into the desired

direction.

Safety Information

CAUTION !!!

For safety reasons always put the master switch into the „0“

position (=power switch-off) after completion of work.

When starting the cleaning process do not aim the high pressure jet at the

object to be cleaned for at least 30 seconds.

It is possible, that the water contents in the combustion chamber (approx. 5 litres) has

changed colour due to the resting time.

6

Page 7

Description

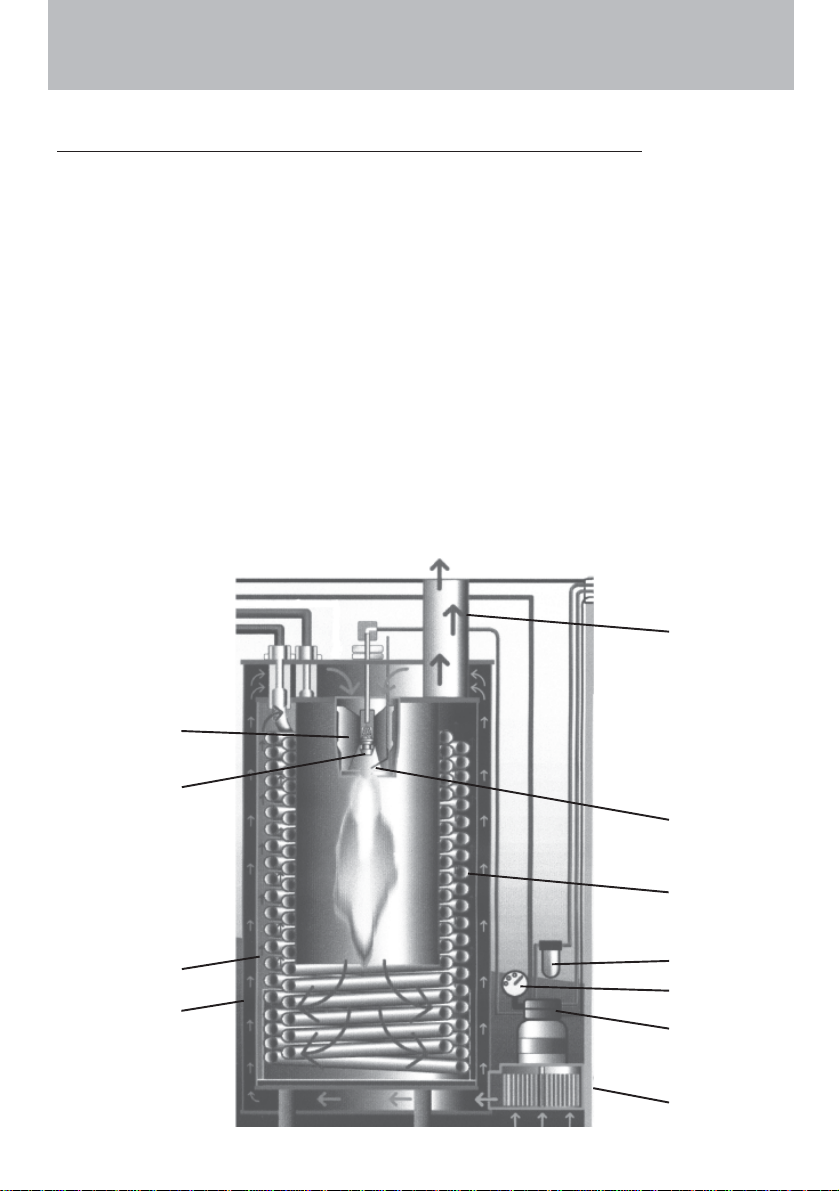

Heat exchanger

Heating coil: 34 m long - Content: 5 l of water – Heating capacity: 70 k W

The heat exchanger is heated by a high pressure fan heater.

A ventilator (1) draws in the cold, fresh air from the bottom end of the machine and forces

it upwards between the outer mantle (2) and the inner mantle (3). In the process, the

fresh air is pre-heated and the outer mantle of the heat exchanger is cooled.

The pre-heated air is pressed through a mixing unit (4). Here finely atomised fuel is

injected via a nozzle (5) and mixed with the air. The electrodes (6) located below then

ignite the fuel-air mixture.

The flame burns from top to bottom, turns round and the hot gas flows past the heating

coil (7) on its way back up. The burned gases collect in the exhaust chamber and are

emitted from the chimney (8).

The water is forced through a heating coil by the high pressure pump. Hot air flows

around the coil, as described above.

The fuel pump (9) draws the oil through a filter (10) and pumps it to the injector nozzle (5).

The surplus quantity of fuel flows straight back into the tank. The oil pressure (approx. 10

bar) is shown on the fuel manometer (11).

8

4

5

6

7

3

2

10

11

9

1

7

Page 8

Safety Information

Safety Information

Important!!!

The machine must be disconnected from the power supply when

servicing work is being carried out. The master switch should be

in position "0" and the plug out of the socket.

Do not use the cleaner if electrical connections or other safetyrelevant parts (e.g. o verpressure valve, high pressure hose,

spraying equipment etc.) are damaged.

The machine may only be used by persons who have received

the necessary training.

Never operate the machine without supervision.

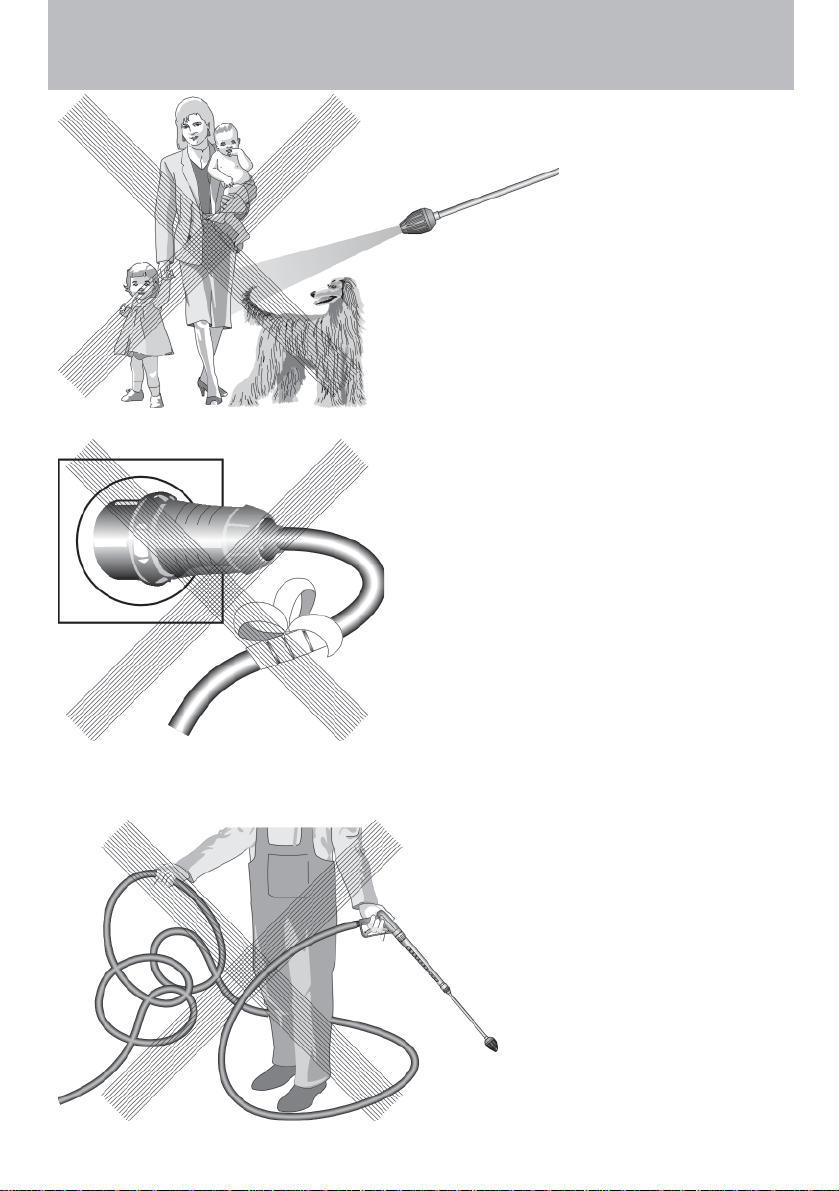

The water spray can be dangerous. It should never be directed at people, animals,

electrical apparatus or the machine itself.

Never direct the spray at power sockets.

Parts of the machine interior and parts of the gun and lance become hot when hot

water is used. Leave the cover of the machine closed when using the machine and do

not touch the metallic parts of the gun and lance.

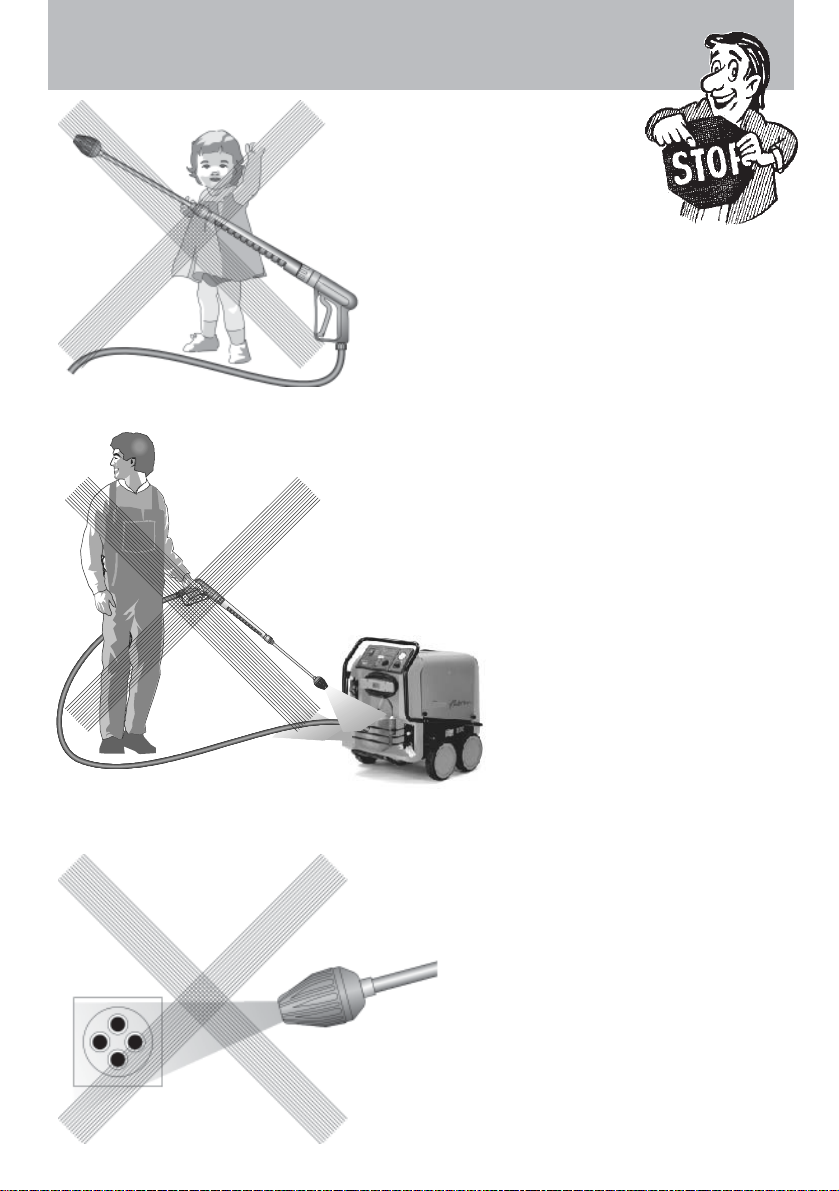

Children must not use high pressure cleaning equipment.

Do not damage the cable or repair it incorrectly.

Do not pull the high pressure hose if there are kinks or loops in it. Make sure that the

hose is not damaged on sharp edges.

Persons operating the machine should wear the necessary protective clothing, ie, waterproof clothing, rubber boots, safety goggles, headwear etc. It is prohibited to use the

machine in close vicinity to people lacking suitable protective clothing.

The high pressure spray can generate a high level of noise. If noise exceeds the

maximum allowed levels, users and others in the vicinity must wear suitable ear protection.

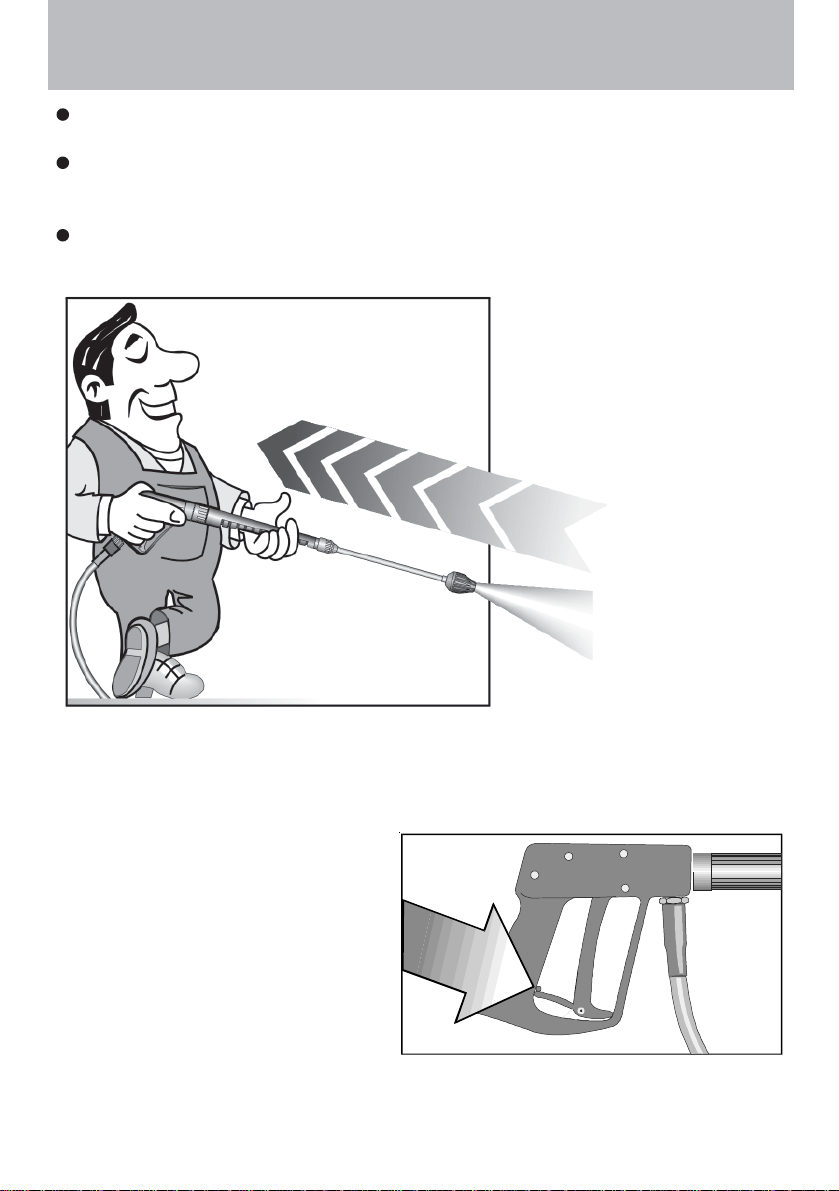

The high pressure spray causes recoil and additional twisting movement if the gun is

angled. The gun must therefore be held firmly with both hands. (see page 2)

Do not close off the exhaust aperture on the topside of the machine. Do not bend over

this aperture and do not put your hands inside it. Exhaust gases are very hot!

Do not clamp down the trigger of the gun. Apply the safety catch after use, in order to

prevent accidental spraying.

Do not spray against matter containing asbestos or other hazardous substances.

Never spray liquids containing solvents, such as paint thinner, petrol, oil, or anythng

similar. Note the specifications of the additive makers! The seals in the machine are

not resistant to solvents. The spray vapour of solvents is highly inflammable, explosive

and poisonous.

8

Page 9

Safety Information

The machine may not be set up and used in rooms where there is a danger of fire or

explosion. The machine may not be used under water.

Air is required for combustion, and exhaust fumes are generated. If the machine is used

in closed rooms, make sure that the exhaust fumes can escape and that there is

adequate ventilation.

Use light heating oil EL (DIN 51 603) or Diesel (DIN EN 590) only. The use of other fuel

is perilous and may even cause an explosion.

As to the recoil see notice on page 2!

Apply the safety catch on the

spray gun after each use, in

order to prevent uninten-

tional spraying!

9

Page 10

This is prohibited!

Never direct the

water jet at people

or animals!

Do not damage the

power cable or

repair it incorrectly!

10

Never pull the high

pressure hose if it

has formed kinks or

“nooses”!

Never pull the hose

over sharp edges!

Page 11

This is prohibited!

Never allow

children to use the

high pressure

cleaner!

Never direct the

water jet at the

machine itself!

Never direct the

water jet at a

power socket!

11

Page 12

Commissioning

Electrical connection

The voltage given on the specification plate must match the mains voltage.

The machine is supplied with a power cable and plug.

The plug must be connected to a properly installed electrical socket with

earthing and have a 30 mA FI residual current circuit breaker . The socket

must have a neutral 16A fuse on the mains side.

If an extension cable is used, it must have an earth line that is properly connected to the

plug connections. The lines in the extension cable must have a cross section of at least

1,5 mm². The plug connections must be of spray protected design and may not lie on a

wet surface. (If the extension cable is longer than 10 m the minimum cross section is

2,5 mm²)

Important!

Extension cables that are too long cause a drop in the voltage and thus

interruptions in operation. If you are using a cable drum, the cable must

always be fully unwound.

Brief operating instructions

To be found on the machine.

1. Connect the high pressure hose with the spray gun and lance to the machine.

2. Connect the water supply and turn on the tap.

3. Connect to the electrical supply.

4. Switch on the machine with the spray gun open and start the washing procedure.

If the system has to be de-aerated (machine vibrates), open and close the gun

several times.

5. When using the machine as a cold water high pressure cleaner:

ignition "OFF" - Set thermostat with rotary control switch to 0 °C.

6. When using the machine as a hot water high pressure cleaner:

ignition "ON" - Set thermostat with rotary control switch to min. 40 °C

7. When using the machine as a hot water high pressure cleaner:

preselect the water temperature with thermostat to min. 40° C

High pressure hose and spray equipment

The high pressure hose and spray equipment supplied with the machine are made of

high quality material specially adapted for the operating conditions of the machine, and

are properly marked.

If spare parts are required, only properly marked components approved by

the maker should be used. High pressure hoses and spray equipment

must be connected so that they are pressure-tight. The high pressure

hoses should not be driven over, pulled excessively or twisted. Do not pull

the hose over sharp edges, since this will invalidate the warranty.

12

Page 13

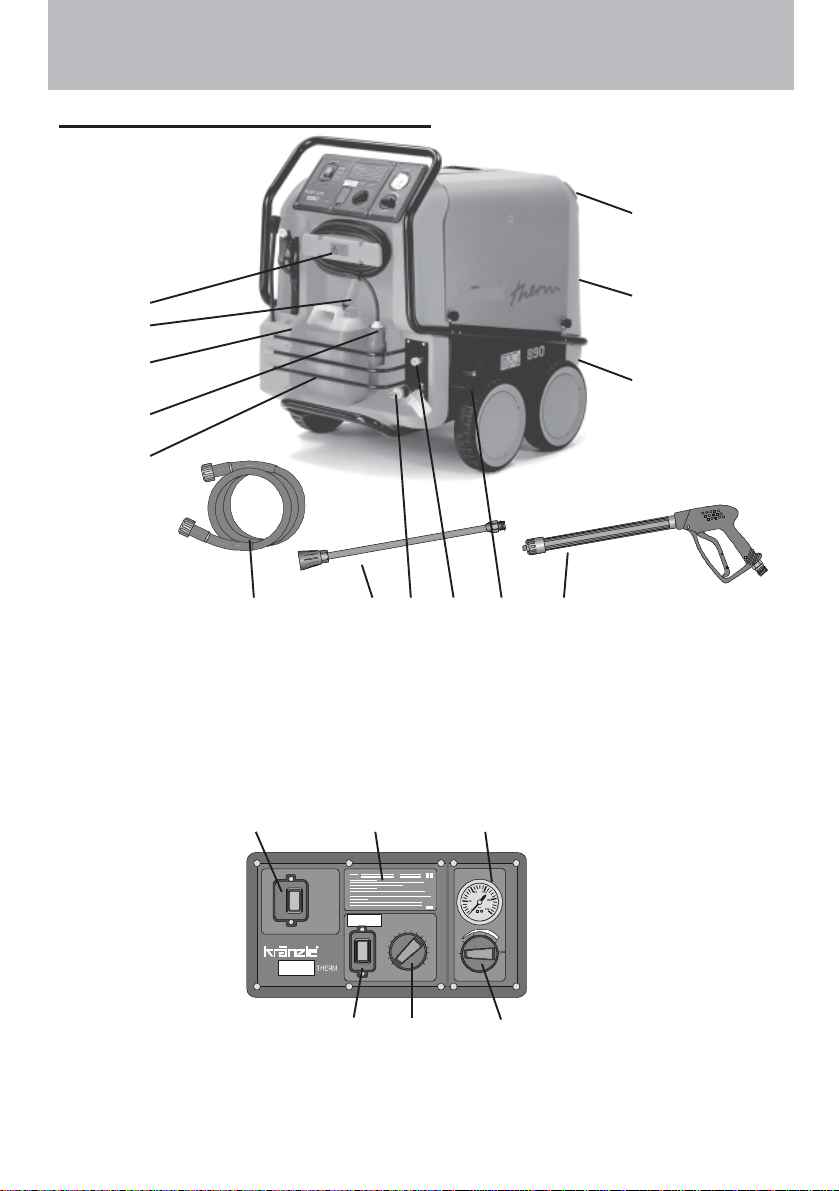

Commissioning

Commissioning

Secure the machine by applying the brake.

Open the right cover of the machine (without

chimney) and check the oil level of the high

pressure pump.

Do not start the machine if there is no oil on the

dipstick. Fill oil if necessary.

Fill the fuel tank with light heating oil prior to

use.

Use EL heating oil (DIN 51603) or diesel fuel only

Unsuitable fuels, such as petrol, may not be used (danger of

explosion)

Water connection

Connect the machine to a water tap using a hose of at least 1/2" and turn on the tap.

The water tank in the machine fills up. When the tank is full, the built-in float valve

closes the water inlet.

Use clean water only!

Follow the instructions of the local water supply utility .

Connection of the machine to drinking water mains must be in

accordance with EN 61 770.

High pressure connection

Connect the high pressure hose to the handgun.

Unwind the hose so that it is free of loops and connect it to the handgun and the

machine.

Check that all screw-type connections are pressure-tight. Leaks

from gun, high pressure hose or hose drum must be eliminated

immediately. Leakage leads to increased wear.

13

Page 14

Commissioning

Electrical connection

- Check that the master switch (1) is off (position "0").

Connect the power cable to a properly

installed electrical socket with earthing

and a 30 mA FI fault current safety

switch. The socket must have neutral 16A

fusing on the mains side.

3

2

1

1A

Hauptschalter

Main Switch

Wassertemperatur

Water temperature

50

40

30

20

10

0

Hauptschalter

Pressur e

150

150

100

100

200

200

50

50

bar

bar

250

250

0

70 80

60

°C

0

90

Zu Auf

100

off0on

110

120

130

140

150

Hauptschalter

Cleaning liquid

- Switch off the ignition. Rocker switch (1A) to „0“.

- Set the pressure control (4) valve to maximum

pressure (see on page 12) and close the detergent

valve (3).

- Open the gun and switch the master switch on.

The high pressure pump now presses the air out of the

lines, and after a short time the high pressure spray

forms and the operating pressure is reached.

(Open and close the gun repeatedly)

The machine is fitted with a Total-StopSystem. If the gun is closed for longer

than approx. 20 seconds, the machine switches off automatically,

after 20 minutes the machine moves to safety switch off and you

must use the main switch to turn it back on.

The machine restarts automatically when the gun is operated,

provided that the master switch is on.

4

Usage as a cold water high pressure cleaner

- Leave the ignition "OFF". Rocker switch (1A) to „0“.

- Start cleaning

Usage as a hot water high pressure cleaner

- Set the target temperature on the thermostat to min. 40 °C and than switch the

ignition "ON" (rocker switch).The oil burner starts to work. The water is heated up

and kept at the temperature you have set.

Steam level

To reach the steam level, i.e. over 90 ° C water temperature, open the right cover on

the housing (see page 13) and adjust the pressure or water quantity on the hand

wheel (4) downward and use the thermostat with rotary switch to select the

temperature up to a maximum of 150 °. In the case of machines with hose drums,

the high pressure hose must always be unwound completely.

14

Page 15

Decommissioning

Usage with detergents

- The detergent must have the ph-value 7-9 neutral.

- Wait until the pump has pressed the air out of the lines

- Put the chemical filter into a container with detergent

- Open the detergent valve.

The pump now draws detergent in and mixes it with the high pressure spray.

- Set the desired concentration of detergent.

- At the end of the working procedure with detergent reset the rotary button to „O“.

- When the high pressure cleaner is operated with open chemistry valve

without chemicals, the pump sucks in air. Damages caused to the pump as

a result are not covered by the guarantee.

Comply with additive manufacturers’ instructions (e.g. protective

equipment and waste water regulations). Use only additives

approved for use with high pressure cleaners. Using other additives

impairs the safety of the machine.

In the interests of the environment and to keep expenditure down,

we recommend sparing use of detergent. Please observe the

recommendations of the detergent manufacturer.

After using detergents, rinse the machine for approx. 2 minutes by

pressing the trigger of the spray gun.

Adjusting the pressure

Use the pressure control valve (4) directly on the

pump head to adjust the pressure.

turn left:

min.

Decommissioning

- Switch off the master switch (position "0").

- Pull the plug out of the power socket.

- Turn off the water supply.

- Open the gun until the pressure is gone.

- Lock the gun.

- Disconnect the water hose.

- Slacken the connections of the high pressure hose and gun and unscrew the high

pressure hose from the machine (appliances without hose drum).

turn right:

max.

4

15

Page 16

Care and Maintenance

Anti-Freeze Protection

The machine is normally still partially filled with water after work has been completed. It

is therefore necessary to take special precautions to protect the machine from frost.

- Completely empty the machine of water.

Disconnect the machine from the water supply and switch off the ignition.

Switch on the master switch and open the gun. The pump now presses the

remaining water out of the heating coil. Do not allow the machine to run for

longer than a miniute without water.

- Fill the machine with anti-freeze

If the machine is not in use for lengthy periods of time, it is advisable to

pump anti-freeze into the machine, especially in winter.

freeze agent into the water box and turn on the machine without ignition (rocker

switch to „0“). Wait with opened gun, until the agent comes from the nozzle.

However, the best protection against frost is to keep

the machine in a place that is safe from frost.

Care and Maintenance

Care and maintenance is required to keep the machine in good working order, and

to allow you to enjoy the machine for as long as possible.

IMPORTANT!!!

Always remove the plug before working on the machine!

For this purpose, fill the anti-

What to do!

- Weekly, or after approx. 40 hours of operation

Check the oil level of the high pressure pump.

Loosen the red oil stopper on the high pressure pump and pull out the oil

measuring rod.

If the oil level is too low, add oil until the oil level is between the two markings on

the oil measuring rod.

Change the oil if it has a grey or whitish appearance. The oil should be

disposed of responsibly.

Check the filter in front of the float valve in the water tank and the fuel filter

in front of the solenoid valve. Clean the filters if necessary.

- Yearly, or after approx. 500 hours of operation

Desulphurise and decarbonize the heating coil.

Check the oil burner and ignition system

Clean the oil nozzle, oil filter, soenoid valve and filter, clean and adjust the

ignition transformer, ignition cable and ignition electrodes and replace defective parts

Changing the oil

16

Page 17

Care and Maintenance

Changing the oil

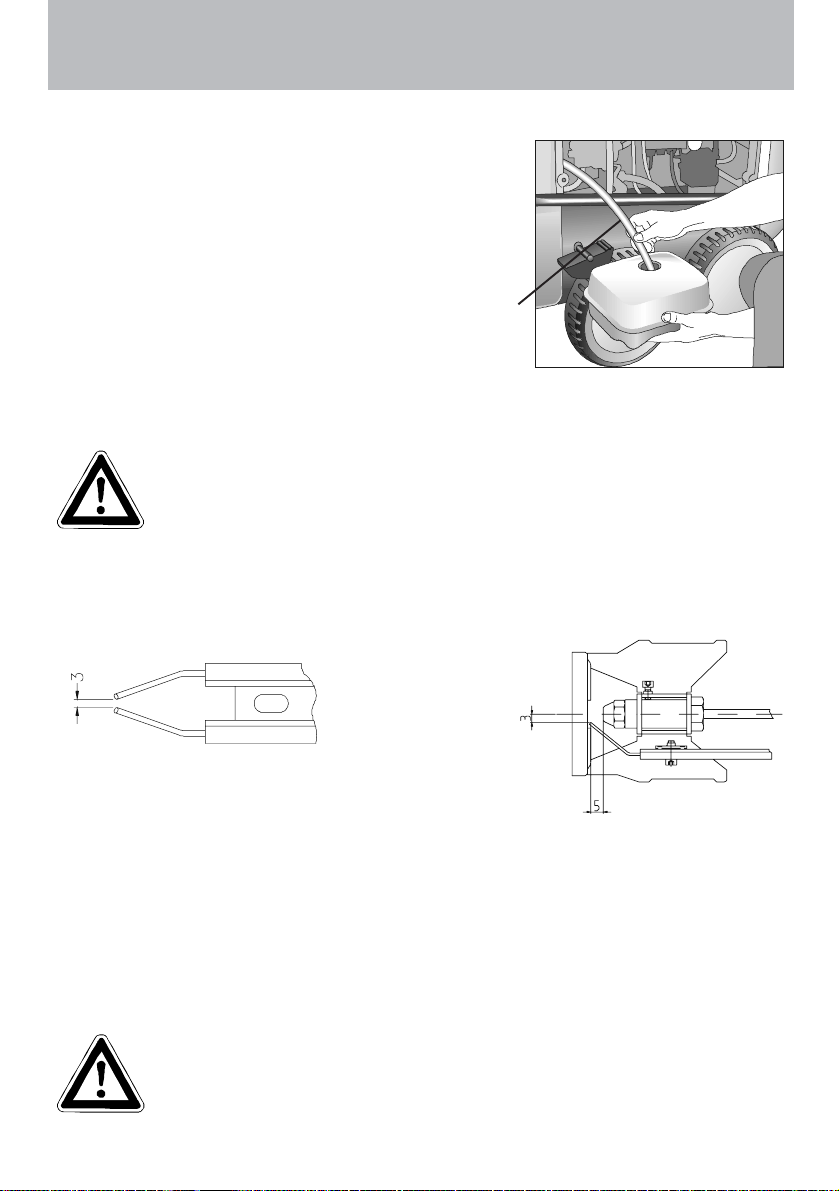

To do this, take the oil drainage hose (1)

connected to the oil drain screw, from the inside

of the machine and open the red oil filler cap on

the top side of the black oil reservoir. Open the

cap at the end of the hose. Drain off the oil into

an oil pan and dispose of it responsibly. Close

the end of the hose.

Refill with oil as described above.

Oil leakage

If oil leaks out, go to the nearest customer service immediately (dealer). (Environmental damages, transmission damages, loss of guarantee.)

Type of oil: Formula RS of Castrol - Quantity: 1.0 l

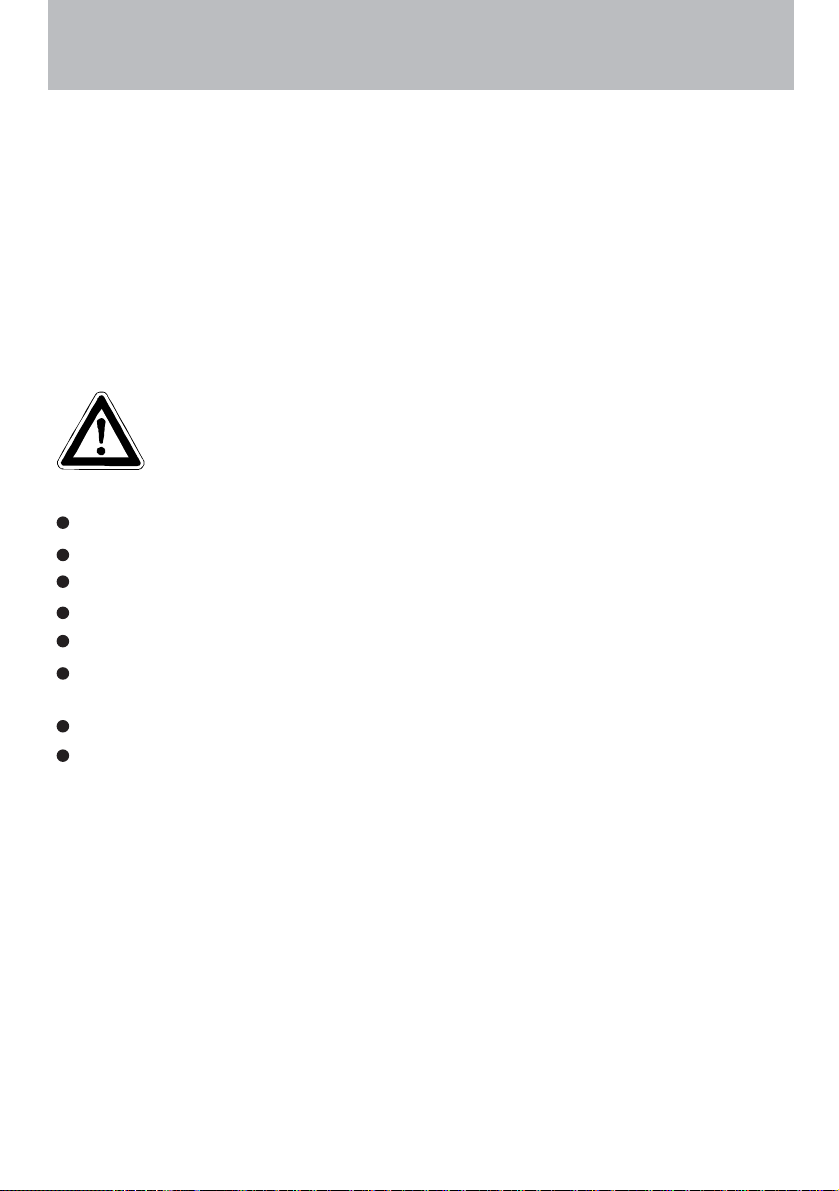

Adjusting ignition electrodes

For a smooth ignition, the setting of the ignition electrode must be controlled

regularly.

1

Check distance in mm

Fuel System

Your fuel may contain particles of dirt, or impurities or water may get into the tank

during refuelling. Check the tank for impurities on a regular basis. Clean the tank

when necessary

Empty the fuel tank using the drainage screw at the bottom of the tank. Clean the

tank and fuel lines. Clean tank and fuel lines carefully and check to see whether

there are water droplets on the inside of the tank, because these must be removed.

Detergent and dirty fuel must be disposed of responsibly.

17

Page 18

Care and Maintenance

Decalcifying the heating coil

Calcified machines use an unnecessary amount of energy because the water can only

be heated slowly and the excess pressure valve feeds a part of the water back into the

pump circuit.

Calcified machines can be recognised by increased pipeline resistance.

Check pipeline resistance by disconnecting the high pressure lance from the gun

and switching the machine on. A full jet of water emerges from the gun. The

machine must be decalcified if the pressure shown on the manometer is greater

than 25 bar.

Decalcifiers are caustic!

Observe the instructions for usage and accident prevention. Wear

protective clothing to prevent the decalcifying agent from

contacting your skin, eyes and clothing (eg, gloves, safety mask

etc.)

Proceed as follows to decalcify the machine:

Unscrew the high pressure hose from the machine and decalcify it separately.

Put the detergent suction hose into a container of decalcifying solution.

Set the dispenser valve to the maximum concentration.

Switch on the machine.

Hold the gun in a separate container and press the trigger.

Wait for about a minute until the decalcifier comes out of the gun

(recognisable by its whitish colour).

Switch off the machine and allow the solution to act for about 15-20 minutes.

Switch the machine back on and rinse it through with clear water for about 2

minutes.

Now check whether pipeline resistance is back to an acceptable level. Repeat the

decalcifying process if the pressure without the high pressure lance is still above 25

bar.

18

Page 19

Care and Maintenance

Rules, directives, inspections

Inspections performed by Kränzle

- measurement of earth line resistance

- measurement of voltage and current

- inspection of tension consistency with +/- 1530 V

- pressure check of heating element at 300 bar

- visual and functional check as per the inspection sheet provided

- exhaust fume analysis (see test strips provided)

Guidelines for liquid sprayers

The machine conforms with the "Guidelines for liquid sprayers". These

guidelines are issued by the organisation of trade associations and may be

obtained from Carl Heymann-Verlag KG, Luxemburger Str. 49, 50939 Köln.

These guidelines specify that this machine is to be inspected by qualified

personnel whenever necessary, but no less than once every 12 months.

These inspections must be recorded in the inspection log at the end of this

manual.

Pressure container and steam boiler directives

Kränzle high pressure cleaning equipment conforms to the pressure container

and steam boiler directive. No construction approval, notification of licence and

takeover inspection are required. The water capacity is less than 10l.

Duties of owner

The owner is to ensure before the sprayer is used that all safety-relevant

components are in a serviceable condition. (e.g., safety valves, hose and electric

cables, spray equipment etc).

Emission control legislation

With stationary installation, the emission levels of the machine must be checked

once a year by a qualified organisation or person according to German law.

The first inspection must be carried out four weeks after the machine is

commissioned. The owner is responsible for having the inspection performed.

19

Page 20

Description of function - Troubleshooting

IMPORTANT!!!

Always remove the plug before working on the machine!

Hauptsc ha lt er

Main Switc h

1

1A

40

30

20

10

Wassertemperatur

Water te mp er at ure

60

50

0

3

Hauptschalter

Pressure

150

150

100

100

200

200

50

50

bar

bar

250

250

0

0

70

80

90

Zu Auf

off0on

100

110

120

130

140

150

Haupts cha lt er

°C

Cleaning liquid

1 Master switch

1A Ignition “ON/OFF

2 Thermostat with rotary switch

3 Brief operating instructions

2

17 18

13

12

6

4

7

8

5

11

14

10

15

16

20

22

19

9

21

4 Hand wheel for pressure adjustment

5 High pressure pump

6 Pressure switch black (start solenoid

valve)

7 Pressure switch red (start pump)

8 Safety valve

9 Motor for ventilator and fuel pump

10 Solenoid valve (Fuel)

11 Terminal box

12 Ignition transformer

20

13 Thermosensor water

14 Excess temperature release

15 Fuel manometer

16 Fuel pump

17 Ignition electrodes

18 Thermosensor exhaust gas

19 Fuel tank

20 Ball cock fuel

21 Ventilator

22 Fuel filter

Page 21

Description of function - Troubleshooting

Cold water mode

1. Connect to water supply and determine whether the water tank fills up completely

and the float valve stops.

2. Ignition (switch 1A) to OFF.

3. Main switch to ON.

4. Open high pressure gun. The pump sucks water from the water tank and moves

the water through the heating coil to the lance, the pressure is increased.

After you close the gun, press the red pressure switch (7). The 20-Second-Stop

system is activated, i.e. after closing the gun, the pump motor is turned off after 20

seconds. When you open the gun the motor starts again.

If the gun stays closed for more than 20 minutes, the safety switch off is activated

and the machine is turned off completely, i.e. if you want to use the machine you

must first turn it OFF and then ON with the main switch.

A TTENTION!!

If the pressure is not built up immediately , there is still air

in the pump. Open and close the gun repeatedly to press

the air from the machine.

Hot water mode

Start the machine just like in cold water mode and then turn the rocker switch for the

burner to ON. Then, turn the rotary switch on the thermostat, (2) located on the front,

to the desired temperature (at least 40 °C) in order to activate the burner, i.e., that fuel

is injected.

The manometer (15) on the fuel pump shows approx. 10 bars. If this display is missing, check whether

1. there is heating oil in the tank

2. the fuse in the terminal box ( 11 ) for the motor ( 9 ) has blown.

3. the fuel sieve (22) or the fuel sieve in the pump (16) is dirty.

4. the ball cock (20) is closed.

5. the fuel pump does no operate smoothly or is blocked.

6. the ventilator jams.

The thermostat grants permission to open the solenoid valve; after opening the gun,

the burner starts. If the solenoid valve is open, the fuel pressure is approx. 10 bars.

The burner starts and heats the water to the temperature preset by you. When the

temperature is reached, the burner turns off. If the temperature drops again, the

burner switches back on automatically, so that you continuously have the desired

temperature.

21

Page 22

Description of function - Troubleshooting

The thermostat with rotary switch is controlled by a thermosensor, mounted to the

outlet of the heating coil.

In the electro distributor box (11) mounted to the combustion unit, there is a fuse,

which protects the motor (9) for the fuel pump and ventilator. If the motor is overloaded,

the fuse blows. This can happen when the fuel pump is blocked or does not work

freely, when the ventilator is blocked or does not operate freely or when there is an

electrical problem.

There is a thermosensor (18) in the waste gas tube, which controls an excess

temperature relay with trigger function (4), i.e. when the exhaust gas temperature in

the chimney increases above 230 °C, this relay triggers. To activate it again, you must

wait until the combustion unit has cooled, i.e. approximately 15 minutes. Then, you

can press the button under the cover (14) again. The excess temperature relay can

trigger when the machine is operated over a longer period in the highest steam level, or

when there is lots of soot on the heating coil due to poor combustion, or when the

inside of the heating coil is calcified, so that there is no ventilation (cooling).

As further safety function, the burner is also switched off, when the water

temperature exceeds 147 °C.

1

Hauptsc ha lt er

Main Switch

30

20

10

Wassertemperatur

50

40

0

Water te mpe r atur e

60

3

Hauptschalter

Pressure

150

150

100

100

200

200

50

50

bar

bar

250

250

0

0

70 80

90

Zu Auf

off0on

100

110

120

130

140

150

Haupts cha lt er

°C

Cleaning liquid

1A

2

1 Master switch

1A Ignition “ON/OFF

2 Thermostat with rotary switch

3 Brief operat. instruction

4 Hand wheel for pressure

adjustment

5 High pressure pump

6 Pressure switch black

7 Pressure switch red

8 Safety valve

9 Motor for ventilator and fuel

pump

10 Solenoid valve (Fuel)

11 Terminal box

12 Ignition transformer

13 Thermosensor water

14 Excess temperature release

15 Fuel manometer

16 Fuel pump

17 Ignition electrodes

18 Thermosensor exhaust gas

19 Fuel tank

20 Ball cock fuel

21 Ventilator

22 Fuel filter

22

17

18

13

12

6

7

4

8

5

11

14

10

15

16

20

22

19

9

21

Page 23

Troubleshooting

IMPORTANT!!!

Always remove the plug before working on the machine!

Malfunction Cause of malfunction / Trouble shooting

Water supply

Water tank runs over.

Water tank does not fill

completely.

Pump does not suck.

Test: check water and chemical

system for tightness.

High-pressure pump

Pump makes lots of noise.

Operating pressure is not

reached.

Water drops from the pump.

Oil drops from the transmission.

Pressure is too low

Machine does not switch off

Test: Disconnect pressure switch

(red) bridge on the panel

between terminal 5 + 6

Float valve is dirty.

Float valve is defect.

Water filter is dirty.

Check water inlet quantity.

Valves stick or are dirty.

Suction hose leaks.

Chemistry valve is open or leaks.

Check hose clips (connections).

High-pressure nozzle is clogged.

Connect water inlet directly to the pump (2-4 bar

pre-pressure).

Pump sucks air. Check suction connections.

Check high-pressure nozzle.

Check valves.

Check O-rings under valves.

Check sleeves.

Manometer is defect.

Unloader: check stainless steel seat and ball.

Check seals on the control piston.

Replace sleeves in the pump.

Replace O-rings.

Check oil seals (replace).

Check plunger and plunger guides.

Check water supply, since water deficiency or air

suction can cause damage to seals and O-rings

(chemistry valve leaks?).

Worn high pressure nozzle

Stainless steel seat, ball, O-ring in unloader is dirty

or defect.

Manometer is defect

Check return body and O-ring in unloader of the

valve housing.

Check pressure switch (red).

Check micro switch.

Check cable connections.

Board is defect.

23

Page 24

Troubleshooting

Malfunction Cause of malfunction / Trouble shooting

Machine does not start

Heating (burner)

Fuel pump/blower operates, but

burner does not heat.

Fuel pump/blower does not operate.

- Pump makes lots of noise

- Fuel operating pressure has not been

reached

Coupling between burner motor and

fuel pump is broken

Sole noid valve on the fuel pump

does no t op en

Test: Pressure switch (black)

Bridge in terminal box between

terminal 3 +4

Test: Connect solenoid valve 230 V

externally

Oil pressure on the fuel pump is

too low

too high

Check electricity supply.

Check main switch.

Check cable connections.

Check board.

Check pressure switch.

Switch off by overcurrent release.

Set water temperature is reached.

Increase temperature on thermostat with rotary

control switch.

Open gun, until temperature drops.

Fuel tank is empty.

Fuel filter is dirty.

Fuel nozzle is dirty.

Float switch in fuel tank is defect.

Blower/fuel pump motor is defect.

Check electrical equipment.

Check fuse in terminal box.

Coupling between burner motor and fuel pump is

defect.

Water in fuel tank.

Dirt or rust in the fuel pump.

Clean tank.

Replace fuel pump.

Check pressure switch (black).

Solenoid valve is defect or dirty.

Clean filter, clean supply line, clean fuel pump.

Setting is wrong.

Clean fuel nozzle, or replace it.

24

Page 25

Troubleshooting

Malfunction Cause of malfunction / Trouble shoooting

Ignition does not function

Ventilator does not operate

Check ignition cable.

Charring of plug-in contacts by moisture.

Cable is broken

Check ignition transformer connections.

Transformer is defect

Ignition electrode has been falsely set or burnt up.

Burning

Smoke during operation

Smoke after switching off

Spray gun -

High-pressure hose

Gun drips

High pressure hose drips

Nozzle is clogged

Sucking detergent

Detergent is not sucked

Blower-/fuel pump motor is defect.

Check electrical equipment.

Check fuse in terminal box.

Coupling between burner motor and fuel pump is

defect.

Fuel is dirty.

Nozzle or nozzle stock leaks.

Water in tank.

Check for leakages.

Replace seals.

Replace O-ring under screwed connection.

Manometer indicates pressure, but no water comes

out of HP-hose – clean nozzle.

Pump sucks air.

Check hose clips.

Test:

Connect water line to the pump.

Water inlet: 2 - 4 bar pre-pressure. No water must

come from the detergent hose.

25

Page 26

Guarantee

A

Warranty

This warranty covers material and/or workmanship related defects only and does not

extend to ordinary wear.

Machine must be operated according to enclosed operating instructions which are part of

present warranty conditions.

ll products sold directly to private customers are warrantied for a period of 24 months,

whereas the warranty period for industrial purchases is limited to 12 months.

In case of any warranty claims, please have your HP cleaner together with accessories

and your purchase document ready and contact your nearest dealer or authorized service

point which can also be looked up in the internet at www.kraenzle.com

Warranty is void in case of attempts to modify any of the safety devices or in the event of

exceeding temperature or rpm limits - this also applies to undervoltage, low water and/or

polluted water. Gauge, nozzle, valves, sealing gaskets, high pressure hose and spray

equipment are considered wear parts and do not fall under this warranty.

.

26

Page 27

A1 Ignition transformer

B1 Thermostat

F1 Fuse 3.15 timelag

K3 Motor contactor

M1 Motor, HP pump

M2 Burner motor

Q1

Q1 Master switch

Q2 Burner switch

S1 Excess temperature release

Circuit diagramme

S2 Pressure switch delayed motor cut-out

Q2

K3

with delayed

motor cut-out

Control board

S3 Pressure switch burner release

S4 Float switch (Fuel)

S5 Waterflow detector

Y1 Fuel valve

CEE 4x16A

400V/50Hz

27

F1

S1

S3

Y1

M1

B1

S5

Y1

B1

S4

Control board

Burner console

S2

Anti-interference

device

A1

M2

Page 28

28

4-pole control

line 4x1,0 mm²

Screening unit

Pressure switch

burner release

(black)

Terminal box

Control

board

Terminal box terminal plan

Solenoid

valve (Fuel)

Float switch

(Fuel)

Ignation

transformator

Burner motor

Waterflow

detector

Page 29

Differential

pressure switch

(red)

Cockpit terminal plan

Pump

Start - Stop

29

with delayed

motor cut-out

Control board

B1 Thermostat

7-pole control

line 4x1,0 mm²

Motor contactor

Overcurrent

relaese

Earth cable

Machine frame

Master switch

Mains connection cable

Three-Phase motor

High pressure pump

Page 30

Complete Assembly

30

Page 31

Kränzle therm 890 / 1160

Spare parts list KRÄNZLE therm

Complete assembly

No. Description Qty. Order No.

1 Cockpit 1 44.006

2 Brennstofftank 1 44.004

3 Wassertank 1 44.009

4 Kabelaufwicklung 1 44.007

5 Lanzenköcher 1 44.008

6 Haube rechts 1 44.032

7 Haube links 1 44.031

8 Rad 4 44.017

9 Radkappe 4 44.018

10 Bremspedal 1 44.022

11 Bremshebel 1 44.023

12 Bremsklotz 1 44.024

13 Tankdeckel 1 44.005

14 Fahrgestell 1 44.001

15 Frontbügel 1 44.002

16 Schubbügel 1 44.003

17 Reeling 1 44.016

18 Top-Strebe 1 44.019

19 Starlock-kappe 20 mm 4 40.142

20 O-Ring 70 x 5 1 44.020

21 Innensechskantschraube M 8 x 12 4 40.122

22 Innensechskantschraube M 8 x 35 2 41.510

23 Unterlegschiebe 8,4 DIN 9021 4 41.409

24 Schraube 3,9 x 16 4 12.150

25 Stift 6 x 50 1 44.035

26 Starlock-kappe 8 mm 1 44.165

27 Schloßschraube M 8 x 35 2 41.408

28 Ablaßschraube Brennstofftank 1 44.004 1

29 Stift 6 x 40 1 44.035 1

30 Elastic-Stop-Mutter M 8 2 41.410

31 Dichtung für Ablaßschraube 1 41.047 1

32 Netzanschlußleitung mit Stecker 1 44.036

33 Kunststoffschraube 6 x 30 12 43.423 1

35 Scheibe 4 44.034

36 Sterngriff 4 50.168 1

37 bei Gerät ohne Schlauchtrommel

37.1 bei Gerät mit Schlauchtrommel

38 O-Ring 9,3 x 2,4 Viton 2 13.273 1

39 Starlett -Pistole mit Verlängerung 1 12.320 2

40 Lanze mit Flachstrahldüse 25045 (bei therm 890) 1 12.392-D25045

40.1 Lanze mit Flachstrahldüse 2507 (bei therm 1160) 1 12.392-D25070

8,0m, 4x 1,5 mm², H07RNF

Hochdruckschlauch NW 8 10 m 1 41.081 3

Hochdruckschlauch NW 8 20 m 1 41.083 3

31

52524

Page 32

Electronics switchbox

32

Page 33

Kränzle therm 890 / 1160

Spare parts list KRÄNZLE therm

Electronics switchbox

No Description Qty. Ord.-No

1 Frontplatte Elektrik 1 44.158 1

2 Frontplatte Manometer 1 44.043

3 Gummidichtung Elektrik 1 44.044

4 Kabeldurchführungsplatte 1 44.045

5 Hauptschalter 2 41.111 6

6 Dichtung für Thermostat 1 44.156

7 Klemme Wago 2,5 mm² 1 44.047

7.1 Erdungsklemme Wago 2,5 mm² 1 44.048

8 Manometer 1 15.039 1

9 Klemmbügel für Manometer 1 44.049

11 Drehgriff Thermostat 1 44.153

12 Thermostat drehbar 0-150°C 1 44.167

13 Gewindeschneidschraube M 2,5 x 8 1 44.168

14 Klemmsockel mit Sicherung 3,15 A träge 1 44.166

14.1 Feinsicherung 3,15 A träge 1 44.166 3

17 Klemmrahmen mit Schalterabdichtung 1 41.110 5

18 Klemmrahmen mit Schalterabdichtung 1 43.453

19 Kunststoffschraube 3,5 x 9,5 4 41.088

20 Schraube M 5 x 10 10 43.021

21 Kunststoffschraube 4,8 x 16 6 40.282

22 PG-Verschraubung PG 11 3 41.419

23 PG-Verschraubung PG 9 1 41.087

24 PG-Verschraubung PG 16 2 41.419 1

25 O-Ring 28,24 x 2,62 1 44.149

26 Schlauchklemme 9 - 9 2 44.054

27 Kunststoffschlauch für Waschmittelansaugung 1 44.055

28 Kunststoffschlauch mit Filter und Rückschlagv. 1 44.056 1

29 Schütz 100-C12KN10 400 Volt 50/60 Hz 1 46.005 1

30 Überstromauslöser 3-polig 12,0 A 1 46.040 1

31 Hutschiene 125 mm lang 1 44.125

32 Kabelhalteschiene 1 44.155

33 Blechschraube 3,9 x 9,5 11 41.636

34 Rückschlagventil für Waschmittelansaugung 1 44.240 1

35 Schraube M 4 x 12 2 41.489

36 Anschlußmuffe Manometer 1 44.136

37 Druckmeßleitung 1 44.102

38 Blechschraube 3,5 x 19 2 44.162

39 Blechschraube 3,5 x 16 3 44.161

40 Drehgriff Chemieventil mit Blendkappe 1 44.151

41 Regulierkolben Chemieventil 1 44.147

42 Edelstahlfeder 1,8 x 15 x 15 1 44.148

43 Deckel für Chemieventil 1 44.146

44 Gehäuse Waschmittelventil 1 44.145

45 O-Ring 5 x 1,5 (Viton) 1 44.150

46 Klemmrahmen für Platine Nachlaufverzögerung 1 44.194

47 Platine Nachlaufverzögerung 400 V / 50/60 Hz 1 42.503

47.1 Platine Nachlaufverzögerung 230 V / 50/60 Hz 1 42.504

48 Halterung Überstromauslöser 1 44.259

49 Verschluß für Halterung 1 44.260

Chemical valve compl. Pos. 25-27, 39-45 44.052

33

Page 34

Water supply

34

No Description Qty. Ord.-No

1 Wassertank 1 44.009

2 Schwimmerventil 1 46.250 5

5 Anschlußstück R 3/8" IG 1 41.423

7 Einströmschlauch 1 44.027

9 O-Ring 13 x 2,6 1 13.272

10 Schlauchtülle 1 44.126

11 Überwurfmutter 1 41.047

12 Schlauchschelle 12 - 22 2 44.054 2

13 Wassereingangsschlauch 1 44.028

14 Schlauchtülle R3/8" x 13 1 44.029

16 Ermetorohr 12 mm 1 44.030

17 Ermetomutter 12 mm 2 40.075

18 Klemmhülse 12 mm 2 40.074

19 Ermetoverschraubung 12 L x 12 L 1 44.060

20 Wasserausgangsteil 1 44.061

21 O-Ring 1 41.047 3

22 Steckkupplung 1 41.047 2

23 Gummidichtung 1 41.047 1

24 Wasserfilter 1 41.046 2

Plug-in connection compl. Pos. 21-23 41.047 4

Page 35

Fuel supply

No Description Qty. Ord.-No

1 Deckel Brennstoffversorgung 1 44.011

2 Flansch mit Brennstoffleitungen 1 44.010

3 Gummidichtung 1 44.012

5 Schwimmerschalter 1 44.014

8 Rücklaufschlauch 1 44.015

9 Schlauchschelle 7 - 11 2 44.054

10 Einschraubwinkelverschraubung 1/4" x 6 1 44.062

11 Schraube 5,0 x 25 3 41.414 1

15 Kugelhahn 1 44.203

16 Anschlußteil Brennstofffilter 2 44.214

17 Gummidichtung 3/4" 2 41.047 1

18 Filtergrundkörper 1 13.301

19 Gummidichtung 1 13.303

20 Siebkörper Brennstofffilter 1 44.213

21 Filterbecher 1 13.302

22 Einschraubwinkel R1/4" AG x 10L 2 40.121 1

23 Brennstoffpumpe mit Magnetventil 1 44.073

24 Brennstoffmanometer 0-15 bar R1/8" 1 44.082

25 Magnet für Magnetventil 1 44.251 1

26 Magnetventil 1 44.251

27 Abstandsrohr 128 mm 1 44.084

28 Schlauchtülle 1/4" x 6 1 44.053

29 Winkeleinschraubverschraubung 1/8" x 6 1 44.110 1

30 Winkeleinschraubverschraubung 1/4“ AG x 1/4“ IG 1 40.121

31 Doppelnippel 1/4“ x 1/4“ 1 44.251 2

Fuel filter compl. Pos. 15 - 21 44.083

Fuel pump compl. Pos. 22-26, 28-31 44.073 1

29999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999

35

29

Page 36

Combustion chamber

36

Page 37

Kränzle therm 890 / 1160

Spare parts list KRÄNZLE therm

Combustion chamber

No Description Qty. Ord.-No

3 Deckel Düsenstock 1 44.079

5 Ablaufgarnitur 1 44.204

6 Ermetowinkel 2x R1/4" IG 2 44.127 1

7 Ringmutter M 8 DIN 582 3 44.115

8 Federring A 8 5 44.222

9 Edelstahlmutter M 8 2 14.127 2

10 Tiefenanschlag 1 44.088

11 Brennstoffleitung „Düsenstock“ 137 mm 1 44.089

12 Winkelverschraubung 6L x 6L 1 44.106

13 Brennstoffleitung Pumpe 1 44.108

14 Edelstahlschraube M 6 x 10 3 44.177

16 Blechschraube 6,3 x 13 7 44.109

17 Unterlegscheibe A 10,5 DIN 9021 3 50.182

18 Sechskantschraube M 10 x 20 DIN 933 3 44.116

20 Gebläsestutzen 1 44.068

21 Gebläsegehäuse 1 44.069

22 Lüfterrad 1 44.071

23 Gebläsedeckel 1 44.070 1

24 Brennermotor 220 V / 50 Hz 1 44.072

25 Steckkupplung 1 44.085

29 Zyl.schraube mit ISK M 5 x 12 DIN 912 1 40.134

30 Schraube 5,0 x 25 9 41.414 1

31 Unterlegscheibe 4,3 4 44.059

32 Senkschraube M 4 x 8 4 44.091

33 Gewindestift M 6 x 8 DIN 914 7 44.090

40 Hydrospeicher 1 44.140

41 Anschlussmuffe für Hydrospeicher 1 44.140 1

42 Einstellbare T-Verschraubung 1 44.141

43 Einschraubwinkelverschr. 3/8" x 12L 2 44.092

44 Hochdruckschlauch 1 44.093

45 Fühleraufnahme 1 44.170

46 Dichtring 1 14.149

47 Einschraub-T R3/8" x 2x 12 mm 1 44.173

48 Schneidring 12 mm 1 40.074

49 Überwurfmutter f. Ermeto 12 mm 1 40.075

50 Ermetorohr 1 44.030

51 Abschlussring 2 44.086

52 Gewindestift M 6 x 8 DIN 914 7 44.090

53 Blechschraube 4,8 x 13 4 44.112

54 Fühler Muffe 1 44.171

55 Mutter 1 44.172

Blower-fuel pump unit 44.244

consisting of items: Pos. 21 - 33

37

Page 38

Combustion chamber

38

Page 39

Kränzle therm 890 / 1160

Spare parts list KRÄNZLE therm

Combustion chamber

No Description Qty. Ord.-No

1 Außenmantel mit Grundplatte 1 44.063

3 Innenmantel mit Bodenplatte 1 44.064 1

5 Innendeckel 1 44.065

6 Außendeckel 1 44.066

7 Brennstoffdüse 60° B 1,50 gph bei 890 1 44.077

7.1 Brennstoffdüse 60° B 1,75 gph bei 1160 1 44.077 4

8 Blockelektrode 1 44.080

9 Düsenstock Ø 25 mm, 6 Schlitze 1 44.076 4

10 Düsenhalter 1 44.078

11 Edelstahlschraube M 6 x 10 3 44.177

12 Klemmblech für Elektrode 1 44.076 1

13 Zyl.schraube mit ISK M 5 x 15 DIN6912 1 44.076 2

14 Einstellbare T-Verschraubung 1 44.141

15 Abschlußhülse 2 44.081

16 Gewindestift M 6 x 8 DIN 914 2 44.090

17 Fühler Muffe 1 44.171

18 Mutter 1 44.172

19 Edelstahlmutter M 8 7 14.127 2

20 Federring A 8 7 44.222

25 Heizschlange 1 44.226

26 Flammprallplatte Edelstahl 1 44.224

27 Isolationsplatte 1 44.223

Heating coil with inner mantle 1 44.064

Combustion chamber compl. for therm 890 44.099-890

Combustion chamber compl. for therm 1160 44.099-1160

39

3333

Page 40

Unloader and pressure switch

No. Description Qty. Order No.

Valve housing compl. with pressure switch mech., 40.515 1

Pos. 5-59, 73, 74

Guide piston compl. w. hand wheel 44.209

Pos. 5, 14-25

Pressure switch (black) compl. with cable 0,59 m 44.120

Pos. 26, 27,52, 54, 55, 56, 60 - 74

Pressure switch (red) compl. with cable 0,49 m 44.120 1

Pos. 51 - 74

Output piece for red switch, compl. 15.009 3

Pos. 51 -59

Output piece for black switch, comp. 15.011 1

Pos. 26, 27, 52, 54-56, 73, 74

40

Page 41

Kränzle therm 890 / 1160

No. Description Qty. Order No.

5 O-Ring 16 x 2 2 13.150

8 O-Ring 11 x 1,44 1 12.256

9 Edelstahlsitz 1 14.118

10 Sicherungsring 1 13.147

11 Edelstahlkugel 8,5 mm 1 13.148

12 Edelstahlfeder 1 14.119

13 Verschlussschraube 1 14.113

14 Steuerkolben 1 14.134

15 Parbaks 16 mm 1 13.159

16 Parbaks 8 mm 1 14.123

17 Spannstift 1 14.148

18 Kolbenführung spezial 1 42.105

19 Mutter M 8 x 1 2 14.144

20 Ventilfeder schwarz 1 14.125

21 Federdruckscheibe 1 14.126

22 Nadellager 1 14.146

23 Handrad 1 14.147

25 Elastic-Stop-Mutter 1 14.152

26 Parbaks 7 mm 1 15.013

27 Ausgangsteil R1/4" AG 1 15.011

50 O-Ring 5 x 1,5 1 15.014

51 Führungsteil Steuerstößel 1 15.009 1

52 O-Ring 12,3 x 2,4 2 15.017

53 O-Ring 14 x 2 1 43.445

54 O-Ring 3,3 x 2,4 4 12.136

55 Stützscheibe dm 5 1 15.015

55.1 Stützscheibe dm 4 2 15.015 1

56 Edelstahlfeder 2 15.016

57 Steuerstößel lang 1 15.010 2

58 Parbaks 1 15.013

59 Stopfen M10x1 (durchgebohrt) 1 13.385 1

60 Gehäuse Elektroschalter (schwarz) 2 15.007

60.1 Gehäuse Elektroschalter (rot) 1 15.007 1

61 Gummimanschette PG 9 2 15.020

62 Scheibe PG 9 2 15.021

63 Verschraubung PG 9 2 15.022

64 Kabel 3 x 1,0 mm² 0,59 m 1 44.131

64.1 Kabel 3 x 1,0 mm² 0,49 m 1 44.131 1

65 Blechschraube 2,9 x 16 12 15.024

66 Deckel Elektroschalter (schwarz) 1 15.008

66.1 Deckel Elektroschalter (rot) 1 15.008 1

67 O-Ring 44 x 2,5 2 15.023

68 Mikroschalter 2 15.018

69 Zylinderschraube M 4 x 20 4 15.025

70 Sechskant-Mutter M 4 4 15.026

73 Grundteil Elektroschalter 1 15.009

72 Druckfeder 1 x 8,6 x 30 1 40.520

74 Steuerkolben 1 15.010

41

Page 42

42

Terminal box and transformer

No. Description Qty. Order No.

1 Konsole mit integr. Klemmkasten 1 44.067 1

2 Transformator 230 V / 50 Hz 1 44.074

3 Kunststoffschraube 4,0 x 25 8 43.425

4 Deckel für Klemmkasten 1 44.075 2

6 Hutschiene für Verteilerkasten 1 44.125

7 Durchgangsklemme grau 18 44.047

8 Durchgangsklemme grün/gelb 3 44.048

9 Querbrücker 24 A 6 44.047 1

10 Entstörkondensator 1 44.124

11 Blechschraube 3,9 x 9,5 7 12.172

14 Kunststoffschraube 4 x 60 4 43.420

18 Zündkabel mit Stecker 1 44.114

19 PG-Verschraubung PG 16 2 41.419 1

20 PG-Verschraubung PG 11 5 41.419

21 Steuerplatine für Ölabschaltung 230V/50/60Hz 1 44.302

22 Haltesockel für Entstörglied 1 44.178

23 Abdeckplatte für Durchgangsklemme 1 44.047 2

24 Abdeckplatte für Sicherungsklemme 1 44.166 1

25 Halteklemme für Feinsicherung 1 44.166

25.1 Feinsicherung 3,15 A träge 1 44.166 3

26 Abdeckkappe Überstromauslöser 1 44.154

27 Schraube M 4 x 12 2 41.489

28 Dichtung für Übertemperaturauslöser 1 44.157

29 Übertemperaturauslöser 2 44.169

30 Deckel für Übertemperaturauslöser 2 44.182

31 Dichtung für Deckel Übertemperaturauslöser 1 44.182 1

32 Dichtung für Deckel Klemmkasten 1 44.075 3

Terminal box and transformer compl. 44.245

consisting of: Pos. 1 - 32, incl. pressure switch

Page 43

Kränzle therm 890 / 1160

No. Description Qty. Order No.

1 Aggregathalterung 1 44.013

2 Schwingmetall 30 x 30 4 44.227

4 Elastic-Stop-Mutter M 8 4 41.410

5 Unterlegscheibe 8,4 DIN 9021 7 41.409

6 Innensechskantschraube M 8 x 35 3 43.059

11 Schlauchschelle 10 - 16 1 41.046 3

14 O-Ring 13 x 2,6 1 13.272

17 By-Pass- Schlauch 1 44.097

18 Hochdruckschlauch 1 44.093

19 Druckmessleitung 1 44.102

27 Sauganschluß 3/8" AG x 3/4" AG 1 41.016

28 Schlauchtülle 9,0 für therm 890 1 44.126 1

28.1 Schlauchtülle 11,3 für therm 1160 1 44.126 2

33 Schlauchverschraubung 3/4" x 19 1 44.122

34 Schlauchschelle 20 - 32 2 44.054 1

35 Gummidämpfer 15 x 15 2 43.419

36 Ansaugschlauch 1 44.096

37 Saugglocke mit Sieb 1 15.038 5

Suction hose compl. for therm 890 44.096 2

Pos. 14, 28, 33, 34, 36, 37

Suction hose compl. for therm 1160 44.096 3

Pos. 14, 28, 33, 34, 36, 37

Motor-Pump compl. for therm 890 44.219 2

Motor-Pump compl. for therm 1160 44.219 3

43

Page 44

Safety valve for heating coil

Safety valve for

(Adjustment must be approx. 15%

No. Description Qty. Order No.

1 Ventilkörper 1 14.145

4 Ermetoverschraubung R 3/8" x 12 mm 1 40.076

5 Ausgangsteil 1 14.115 2

6 Ermetoverschraubung R1/4" x 6 mm 1 44.175

7 Stopfen R1/4" 1 13.387

8 O-Ring 1 13.275

9 Stopfen M 10 x 1 1 13.158

10 Spanstift 1 14.148

11 Steuerkolben 1 14.133

12 O-Ring 1 13.150

13 Kolbenführung 1 14.130

14 Parbaks 16 mm 1 13.159

15 Parbaks 8 mm 1 14.123

21 Ventilfeder 1 14.125

22 Federdruckscheibe 1 14.126

23 Sechskantmutter M 8 x 1 2 14.144

33 Schlauchtülle 1/4" x 6 1 44.053

34 Einschraubwinkel 1 40.121

35 O-Ring 11 x 1,44 1 12.256

36 Edelstahlsitz 1 14.118

37 Sprengring 1 13.147

38 Edelstahlkugel 8,5 mm 1 13.148

39 Edelstahlfeder 1 14.119

40 O-Ring 15 x 2 1 13.150

41 Eingangsstück R3/8" 1 13.136

42 O-Ring 1 13.150

43 Stopfen R3/8" 1 14.139

44 Dichtring 1 14.149

45 Dichtring 2 13.275

heating coil

above the operating pressure)

44

Guide piston compl. Pos. 10-15; 21-23 14.110 1

Safety valve compl. Pos. 1-45 44.205

Page 45

Waterflow detector

No. Description Qty. Order No.

38 Hochdruckschlauch 260 mm 1 44.093 1

39 Winkelverschraubung 12L x 12L 1 42.630

41 Grundkörper Strömungswächter 1 12.601

42 Strömungskörper 1 12.602

43 Abdeckung 1 12.603

44 Schraube M 4 x 10 4 43.470

45 Eingangsteil 3/8“ x 12 mit Mutter und Schneidring 1 12.604

46 Magnetschalter 1 40.594

Waterflow detector compl. Pos. 41 - 46 12.600 1

45

Page 46

V alve housing

No. Description Qty. Order No.

1 Ventilgehäuse 1 40.503 4

2 O-Ring 18 x 2 6 40.016

3 Ein- / Auslaßventil 6 42.024

4 O-Ring 21 x 2 6 42.025

5 Ventilstopfen 5 42.026

5.1 Ventilstopfen mit R 1/4" IG 1 42.026 2

6 Sicherungsring 4 40.032

7 Innensechskantschraube M 12 x 45 4 40.504

8 Saugzapfen Chemie 1 44.189

9 Schlauchschelle 10 - 16 1 41.046 3

10 Saugschlauch Reinigungsmittel 1 44.055

13 Gewebemanschette 20 mm 3 40.023

14 Backring 20 mm 6 40.025

15 O-Ring 31,42 x 2,62 3 40.508

16 Leckagering 20 mm 3 40.509

17 Cu-Dichtring 21 x 28 x 1,5 2 42.039

18 Manschette 20 mm 3 40.512

19 Verschlußschraube R 1/2" 2 42.032

20 Distanzring mit Abstützung 3 40.507

23 Druckring 20 mm 3 40.021

24 Zwischenring 20 mm 3 40.516

25 Rückschlagkörper 1 14.122

26 O-Ring 6 x 3 1 14.121

28 Ausgangsteil Pumpe R1/4" x 12 1 44.215

29 Dichtring 1 40.019

30 Stopfen 3/8" 1 40.018

32 Dichtstopfen 2 13.158

33 Ausgangsteil 1 42.161

34 Rückschlagfeder 1 14.120

37 O-Ring 18 x 2 1 43.446

46

Valve housing compl. w/o press. gauge 40.515 1

Repair kit valves 40.062 1

Repair kit sleeves 40.517

Page 47

Transmission unit (pump)

No. Description Qty. Order No.

1 Ölgehäuse mit Öldichtungen 1 40.501

4 Innensechskantschraube M 8 x 25 6 40.053

5 Sicherungsscheibe 6 40.054

6 Flachdichtung 1 40.511

7 Öldichtung 20 x 38 x 7 3 40.044 1

8 Wellenscheibe 1 40.043

9 Axial-Rollenkäfig 1 40.040

10 AS-Scheibe 1 40.041

11 Swash plate 9,5° for 890 1 40.042 1-9,5

11.1 Swash plate 12° for 1160 1 40.042 1-12,0

12 Plungerfeder 3 40.506

13 Federdruckscheibe 3 40.510

14 Plunger 20 mm (lang) 3 40.505

15 Sprengring 3 40.048

16 O-Ring 14 x 2 2 43.445

17 Verschlußschraube M 18 x 1,5 1 41.011

18 Flachdichtung 1 41.019 3

19 Deckel 1 40.518

20 Innensechskantschraube M 5 x 12 4 41.019 4

21 Ölmeßstab 1 42.520

22 Stützscheibe für Plungerfeder 3 40.513

23 Einschraubwinkel 3/8" x 3/8" 1 44.127

24 Ölablasschlauch 1 44.128 1

25 Kupferring 3 14.149

26 Verschlußkappe 1 44.130

Oil housing AQ compl. 40.501 1

Pos. 1, 4, 5, 6, 12-17, 22.

47

Page 48

Pump motor

No. Description Qty. Order No.

1 Stator 112 5,5 kW 400V / 50Hz 1 40.540

2 A-Lager Flansch 1 40.530

3 Rotor 112 400V / 50Hz 1 40.531

4 Lüfterrad BG112 1 40.532

5 Lüfterhaube BG 112 1 40.533

6 Klemmkasten 1 40.534

7 Flachdichtung 1 43.030

8 Lüsterklemme 2,5 mm² 4-polig 1 43.031 1

9 PG-Verschraubung PG 13,5 1 40.539

10 Kegelrollenlager 31306 1 40.103

11 Öldichtung 35 x 47 x 7 1 40.080

12 Paßfeder 8 x 7 x 32 1 40.104

13 Kugellager 6206 - 2Z 1 40.538

14 Innensechskantschraube M 6 x 30 4 43.037

15 Toleranzhülse 1 40.544 1

16 Blechschraube 2,9 x 16 1 43.036

19 Schraube M 4 x 12 4 41.489

20 Schelle für Lüfterrad BG112 2 40.535

21 Schraube M 4 x 12 4 41.489

22 Erdungsschraube kpl. 1 43.038

Motor compl. 5.5 kW, 400V 3~ 50Hz 24.060

48

Page 49

Fuel pump

No. Description Qty. Order No.

22 Einschraubwinkel R1/4" AG x 10L 2 40.121 1

23 Brennstoffpumpe mit Magnetventil 1 44.073

24 Brennstoffmanometer 0-15 bar R1/8" 1 44.082

25 Magnet für Magnetventil 1 44.251 1

26 Magnetventil 1 44.251

28 Schlauchtülle 1/4" x 6 1 44.053

29 Winkeleinschraubverschraubung 1/8" x 6 1 44.110 1

30 Winkeleinschraubverschraubung 1/4“ AG x 1/4“ IG 1 40.121

31 Doppelnippel 1/4“ x 1/4“ 1 44.251 2

Fuel pump compl. Pos. 22-26, 28-31 44.073 1

49

Page 50

Hose drum

(Special accessory)

Upgrade kit: 44.152

50

Page 51

Spare parts list KRÄNZLE therm

Hose drum

No. Description Qty. Order No.

1 Seitenschale Schlauchführung 1 40.302

2 Seitenschale Wasserführung 1 40.301

3 Trommel Unterteil 1 40.304

4 Trommel Oberteil 1 40.303

5 Innensechskantschraube M 4 x 25 4 40.313

6 Lagerklotz mit Bremse 1 40.306

7 Lagerklotz links 1 40.305

8 Klemmstück 2 40.307

9 Kunststoffschraube 5,0 x 20 12 43.018

10 Antriebswelle 1 40.310

11 Welle Wasserführung 1 40.311

12 Elastic-Stop-Mutter M 4 4 40.111

13 Handkurbel klappbar 1 40.309 9

14 Verriegelungsbolzen 1 40.312

15 Scheibe MS 16 x 24 x 2 1 40.181

16 Wellensicherungsring 22 mm 2 40.117

17 Wellensicherungsring 16 mm 1 40.182

20 Parbaks 16 mm 2 13.159

21 Sicherungsscheibe 6 DIN6799 1 40.315

22 Schraube M 5 x 10 1 43.021

23 Drehgelenk 1 40.167

25 Distanzring 1 40.316

27 O-Ring 6,86 x 1,78 1 40.585

28 Anschlußstück 1 40.308

33 O-Ring 6 x 1,5 1 13.386

34 Stopfen M 10 x 1 1 13.385

No. Description Qty. Order No.

Kränzle therm 890 / 1160

35 Haltebügel 1 44.143

36 Gummistopfen 2 40.208 1

37 Schloßschraube M 8 x 40 2 44.159

38 Elastic-Stop-Mutter M 8 2 41.410

40 Überwurfmutter 1 13.276 2

42 O-Ring 9,3 x 2,4 4 13.273

44 Verbindungsschlauch NW 8 1 m 1 44.160

45 Hochdruckschlauch NW 8 20 m 1 41.083 3

51 Kurbelarm 1 40.309 1

52 Hülse 1 40.309 2

53 Druckfeder 1 40.309 3

54 Bolzen 1 40.309 4

55 Griff mit Kappe und Gleitscheibe 1 40.309 5

56 Spannstift 4 x 28 1 40.309 6

57 Flachsprengring SW18 1 40.309 8

Hose drum compl. 41.259

without hose, without bracket

Bracket compl. 44.143 1

consisting of: Pos. 35 - 38

Crank compl. 40.309 9

consisting of: Pos. 51 - 57

51

Page 52

Gun

No. Description Qty. Order No.

1 Ventilkörper mit Handgriff 1 12.294

2 Schutzhülse 1 12.295

3 Abdeckschutz 1 12.296

4 Betätigungshebel 1 12.298

5 Sicherungshebel 1 12.149

6 Abschlußschraube M 16 x1 1 12.247

7 Stopfen 1 12.287

8 Gewindeführungshülse R 1/4" AG 1 12.250

9 Aufsteuerbolzen 1 12.284

10 Stift 1 12.148

11 Lagernadel 1 12.253

12 Edelstahlfeder 1 12.246

13 Edelstahlkugel 1 12.245

14 Edelstahlsitz 1 13.146

15 O-Ring 11 x 1,44 1 12.256

16 O-Ring 3,3 x 2,4 1 12.136

17 Blechschraube 3,9 x 8 4 12.297

18 Druckstück 1 12.252

19 Rohr kunststoffumspritzt bds. R 1/4" AG 1 15.004 5

20 Überwurfmutter ST 30 M22 x 1,5 IG 1 13.276 1

21 Außen-Sechskant-Nippel R 1/4" IG 1 13.277 1

22 O-Ring 9,3 x 2,4 1 13.273

23 Aluminium-Dichtring 4 13.275

24 O-Ring 15 x 1,5 1 12.129 1

25 Sicherungsring 1 12.258

51 Düsenschutz 1 26.002

52 Rohr 500 mm; bds. R1/4" 1 12.385 1

53 ST 30 Nippel M 22 x 1,5 / R1/4" m. ISK 1 13.370

54 Flat jet nozzle 25045 (therm 890) 1 D25045

54.1 Flat jet nozzle 2507 (therm 1160) 1 D2507

Starlet-Gun compl. with prolongation Pos. 1-24 12.320 2

Rep.-kit "Starlet II" 12.299

52

consisting of 1x Position: 13, 9, 10, 15, 14

Page 53

EEEEEE

Water intake filter

No. Description Qty. Order No.

1 Filtergrundkörper 1 13.301

2 Filterbecher 1 13.302

3 Siebkörper 1 13.304

4 Gummidichtung 1 13.303

5 Gummidichtung 3/4" 2 41.047 1

6 Eingangsteil beids. 3/4" AG 1 13.305

7 Anschlußteil 1 13.306

8 O-Ring 14 x 2 1 43.445

9 Tülle 1 13.307

10 O-Ring 13 x 2,6 1 13.272

11 Überwurfmutter 1 41.047

Filter complete 13.300 3

Pos. 1 - 11

47 474747

53

Page 54

High

pressure

connection

Pipeline plan

Detergent

Water inlet

Safety valve

S 250

Heating chamber

Safety valve, number

5 must be set approx.

15 % higher than the

unloader valve on the

HP pump

1 Float valve, water inlet 5 Safety valve for heating coil

2 Water tank 6 Excess pressure line, safety valve

3 Control valve, detergent 7 Fuel pump with solenoid valve

4 High pressure pump 8 Fuel filter

with integrated unloader valve 9 Fuel tank

54

Page 55

High-pressure-cleaners

Hochdruckreiniger

Nettoyeurs À Haute Pression

I. Kränzle GmbH

Elpke 97 . 33605 Bielefeld

EC declaration of confor mity

We hereby declare,

that the high-pressure models:

(techn. documentation available from):

comply with the following guidelines and

specifications and their amendments for

high-pressure cleaners:

Sound power level measured:

guaranteed:

Applied specifications and

standards:

Bielefeld, den 08.09.05

Kränzle therm 890

Kränzle therm 1160

Manfred Bauer, Fa. Josef Kränzle

Rudolf-Diesel-Str . 20, 89257 Illertissen

Machine guideline 89/392/EEC

Low voltage guideline 73/23 EEC

Specification for electromagnetic

compatibility 89/336 EEC

Outdoor noise directive 2000/14/EC,

Art. 13, High-pressure water jet machines

Appendix 3, part B, chapter 27

89 dB (A)

91 dB (A)

EN 60 335-2-79 / A1:2001

EN 55 014-1 / A2:2002

EN 55 014-2 / A1:2001

EN 61 000-3-2 / A14:2000

EN 61 000-3-3 / A1:2001

(Managing Director)

55

Page 56

Inspection sheet

Customer:____________________

Mixing unit:

Number of slots: 6

Bore diam.: 25mm

All lines connected

Hose clamps tight

Screws all installed and tightened

Ignition cable plugged in

Visual check carried out

Brake function checked

Leak test:

Water tank filled and checked

Water inlet checked for tightness

Float valve function checked

Machine checked for tightness under pressure

Electrical check:

Earth line checked

Current intake

Operating pressure:

Switch-off pressure:

Steam phase checked

Chemical valve checked

Start/Stop automatic and

re-run delay checked

56

Page 57

Kränzle therm 890 / 1160

Burner nozzle checked:

Thermostat function checked

Burner function checked:

Water temperature reached: °C

Fuel pressure: bar

Measured smoke

spot number:

Result of flue gas analysis:

8 8,5 9 9,5 10 10,5 11,511 12

0123

70 72 74 76 78 80 82 84 86 88 90

Safety equipment sealed with lacquer:

Name of inspector:_____________________

Date: _____________________

Signature: _____________________

57

Page 58

Inspection report for HP cleaners

Inspection report on annually carried out Labour Safety Inspection (UVV) according

to the Guidelines for Liquid Spray Equipment. (This inspection sheet serves as proof

for the completion of the retest and must be kept carefully!)

Owner: _____________________ Type: therm 890/1 160 Built: ________

Address: _____________________ Serial no.: _______________________

_____________________ Rep.-order-no.: ___________________

ko

:noitcepsnifoepocS

)dnahno(etalpepyT

)dnahno(launamgnitarepO

ecived-,gnirevocevitcetorP

)ssenthgit(enilerusserP

f(eguagerusserP

)noitcnu

)ssenthgit(evlavtaolF

)gnikram(ecivedgniyarpS

rotcennoc/esoh-PH

)gnikram,egamad(

snepoevlavytefaS

riovresererusserP

)ssenthgit(enilliognitaeH

dioneloS

hctiws-ffO/nO

)noitcnuf(

desU

)noitcnuf(evlav

)noitcnuf(tatsomrehT

)noitcnuf(rellortnocwolF

)egamad(elbacrewoP

)egamad(gulprewoP

cudnocevitcetorP

ecivedytefasytitnauqretaW

slacimehc

slacimehcdewollA

seyon

%02/%01ta

erusserpgnitarepofognideecxe

)detcennoc(rot

)noitcnuf(hctiwSffOycnegremE

-riaper

de

v-²OC

uG

:atadnoitcepsnI

elzzonerusserp-hgiH

rab............erusserpgnitarepO

.erusserpffo-gnittuC

rab............

elacshcarahcaBot

²OC%...................eula

%.............gnitarycneiciffE

:eulav

noitalusnI

:tnerrucegakaeL

dekcoln

/dedeecxeton.tsiserrotcudnoC

Inspection result (tick):

The appliance was checked by an

expert according to the Guidelines for

Liquid Spray Equipment, the defects

found have been rectified so that the

Labour Safety can be confirmed.

The appliance was checked by an

expert according to the Guidelines for

Liquid Spray Equipment. The Labour

Safety cannot be confirmed unless the

defects found are rectified by repair or

replacement of the faulty parts.

.mreted

tes

eulav

.cca...................rebmuntopsekomS

eulav

The next retest according to the Guidelines

for Liquid Spray Equipment has to be carried

out by:

Month: __________ Year: _____________

R

58

Place, Date: ___________________

Signature: _____________________

- Test Stamp Mark: Order Number UVV200106

Page 59

Inspection report for HP cleaners

Inspection report on annually carried out Labour Safety Inspection (UVV) according

to the Guidelines for Liquid Spray Equipment. (This inspection sheet serves as proof

for the completion of the retest and must be kept carefully!)

Owner: _____________________ Type: therm 890/1 160 Built: ________

Address: _____________________ Serial no.: _______________________

_____________________ Rep.-order-no.: ___________________

ko

:noitcepsnifoepocS

)dnahno(etalpepyT

)dnahno(launamgnitarepO

ecived-,gnirevocevitcetorP

)ssenthgit(enilerusserP

)noitcnu

f(eguagerusserP

)ssenthgit(evlavtaolF

)gnikram(ecivedgniyarpS

rotcennoc/esoh-PH

)gnikram,egamad(

snepoevlavytefaS

riovresererusserP

)ssenthgit(enilliognitaeH

)noitcnuf(evlavdioneloS

)noitcnuf(tatsomrehT

)noitcnuf(rellortnocwolF

)egamad(elbacrewoP

)egamad(gulprewoP

cudnocevitcetorP

hctiws-ffO/nO

)noitcnuf(

desU

slacimehc

ecivedytefasytitnauqretaW

slacimehcdewollA

seyon

%02/%01ta

erusserpgnitarepofognideecxe

)detcennoc(rot

)noitcnuf(hctiwSffOycnegremE

-riaper

de

v-²OC

uG

:atadnoitcepsnI

elzzonerusserp-hgiH

rab............erusserpgnitarepO

.erusserpffo-gnittuC

rab............

elacshcarahcaBot

²OC%...................eula

%.............gnitarycneiciffE

:eulav

noitalusnI

:tnerrucegakaeL

dekcoln

/dedeecxeton.tsiserrotcudnoC

Inspection result (tick):

The appliance was checked by an

expert according to the Guidelines for

Liquid Spray Equipment, the defects

found have been rectified so that the

Labour Safety can be confirmed.

The appliance was checked by an

expert according to the Guidelines for

Liquid Spray Equipment. The Labour

Safety cannot be confirmed unless the

defects found are rectified by repair or

replacement of the faulty parts.

.mreted

tes

eulav

.cca...................rebmuntopsekomS

eulav

The next retest according to the Guidelines

for Liquid Spray Equipment has to be carried

out by:

Month: __________ Year: _____________

Place, Date: ___________________

Signature: _____________________

59

Page 60

Best.-Nr.: 30.234 1

Reprint only allowed with the authorization of .

As date of 08. 09. 2005

R

Loading...

Loading...