Kranzle therm 601 E-ST 18, therm 891 E-ST 48, therm 601 E-ST 24, therm 601 E-ST 36, therm 871 E-ST 48 Operating Manual

Page 1

www.kraenzle.com

therm 601 E-ST 18

therm 601 E-ST 24

therm 601 E-ST 36

therm 871 E-ST 48

therm 891 E-ST 48

Operating manual

High pressure cleaner

- GB -

Read and conform safety instructions before use!

Keep instructions in a safe place for later use and

pass them on to any future user.

Page 2

Contents

Contents ................................................................................................................ 2

Overview ’This is what you have purchased’ ................................................................. 4

Description of appliance ................................................................................................ 5

Technical data .............................................................................................................. 6

General rules ................................................................................................................ 8

Safety precautions – accident prevention ................................................................. 8

Water connection – electrical connection ......................................................................11

Putting into operation ................................................................................................ 12

Usage as a cold water high pressure cleaner ....................................... 13

Usage as a hot water high pressure cleanerr ........................................ 13

Kränzle- technology ................................................................................................... 14

Water and cleaning system ................................................................... 14

Lance and spray gun ............................................................................. 14

Total stop system ................................................................................... 14

High pressure hose and spray device ................................................... 15

Pressure control valve – safety valve .................................................... 15

Thermostat ............................................................................................ 16

Electric heating ...................................................................................... 18

Suction of detergents ................................................................................................... 19

Decommissioning - frost protection .............................................................................. 20

Care and Maintenance (weekly/yearly) ...................................................................... 22

Changing the oil .................................................................................... 21

Decalcifying the continuous-flow heater ................................................ 22

Particular rules, directives and inspections .................................................................. 23

Troubleshooting ......................................................................................................... 24

Small repairs – do it yourself ...................................................................................... 26

2

Page 3

3

Page

Spare parts lists .........................................................................................................28

Water inlet .............................................................................................28

Water supply ..........................................................................................29

Heating module 18/24 kW .....................................................................30

Heating module 36/48 kW .....................................................................31

Electric module 18/24 kW ......................................................................32

Electric module 36/48 kW ......................................................................34

Engine bearing ......................................................................................36

Unloader valve and pressure switch ......................................................38

Pump .....................................................................................................42

Pump motor ...........................................................................................46

Valve housing ........................................................................................48

Electronics switchbox ............................................................................50

Safety valve ...........................................................................................52

Flow monitoring device ..........................................................................53

Gun 'Starlet' ...........................................................................................54

Pipeline plan ..............................................................................................................55

Wiring diagram 18/24 kW.............................................................................................56

Wiring diagram 36/48 kWl ............................................................................................57

Inspection reports- attestation form .............................................................................58

EG – Declaration of Conformity ...................................................................................68

Guarantee ..............................................................................................................59

Page 4

4

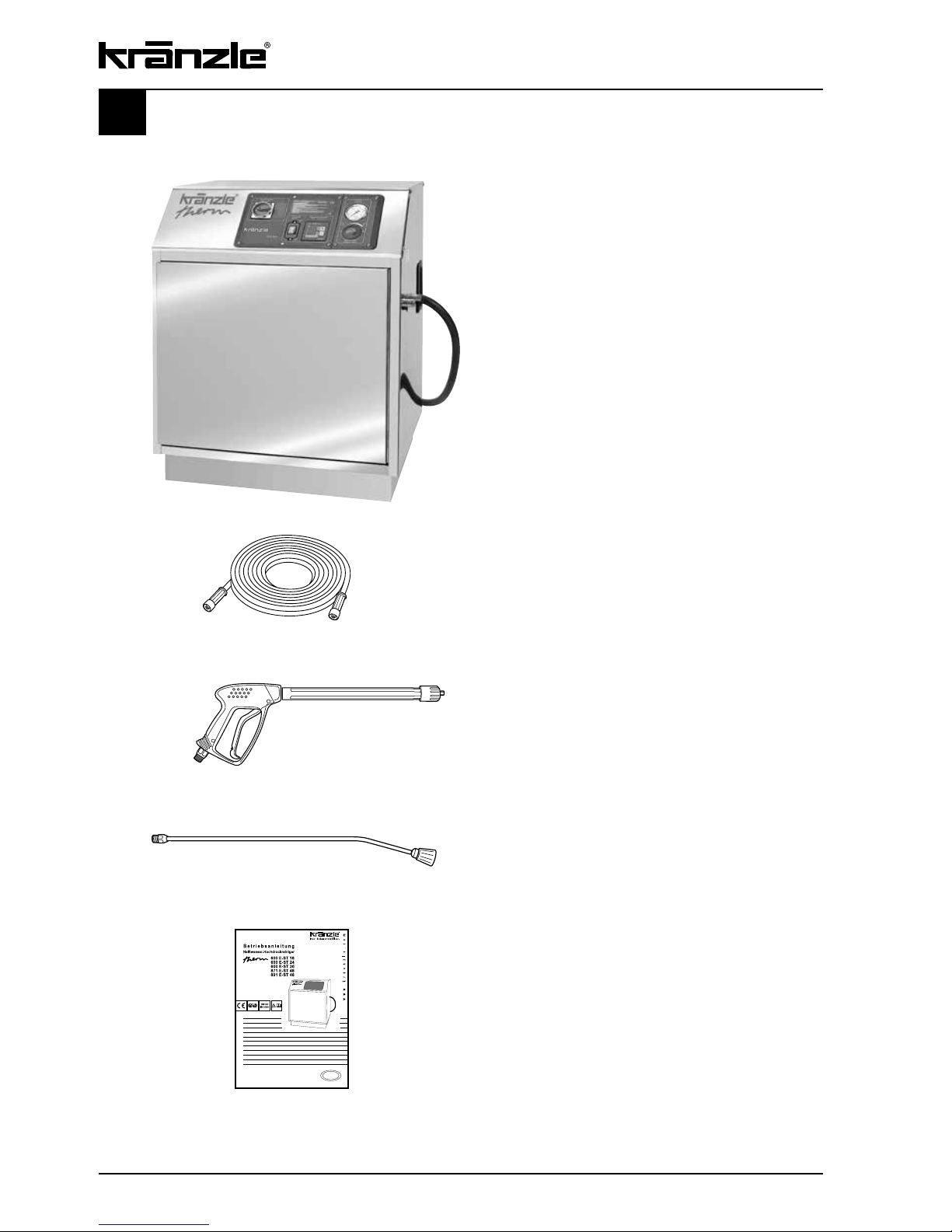

This is what you have purchased

1.

Kränzle hot water high-pressure cleaners

therm E-ST, electrically heated

2.

Steel-fabric high-pressure

hose, 10 m, NW 8

3.

Safety spray gun with insulated

handle and screw connection

4.

Spray lance

5.

Operating manual

Page 5

5

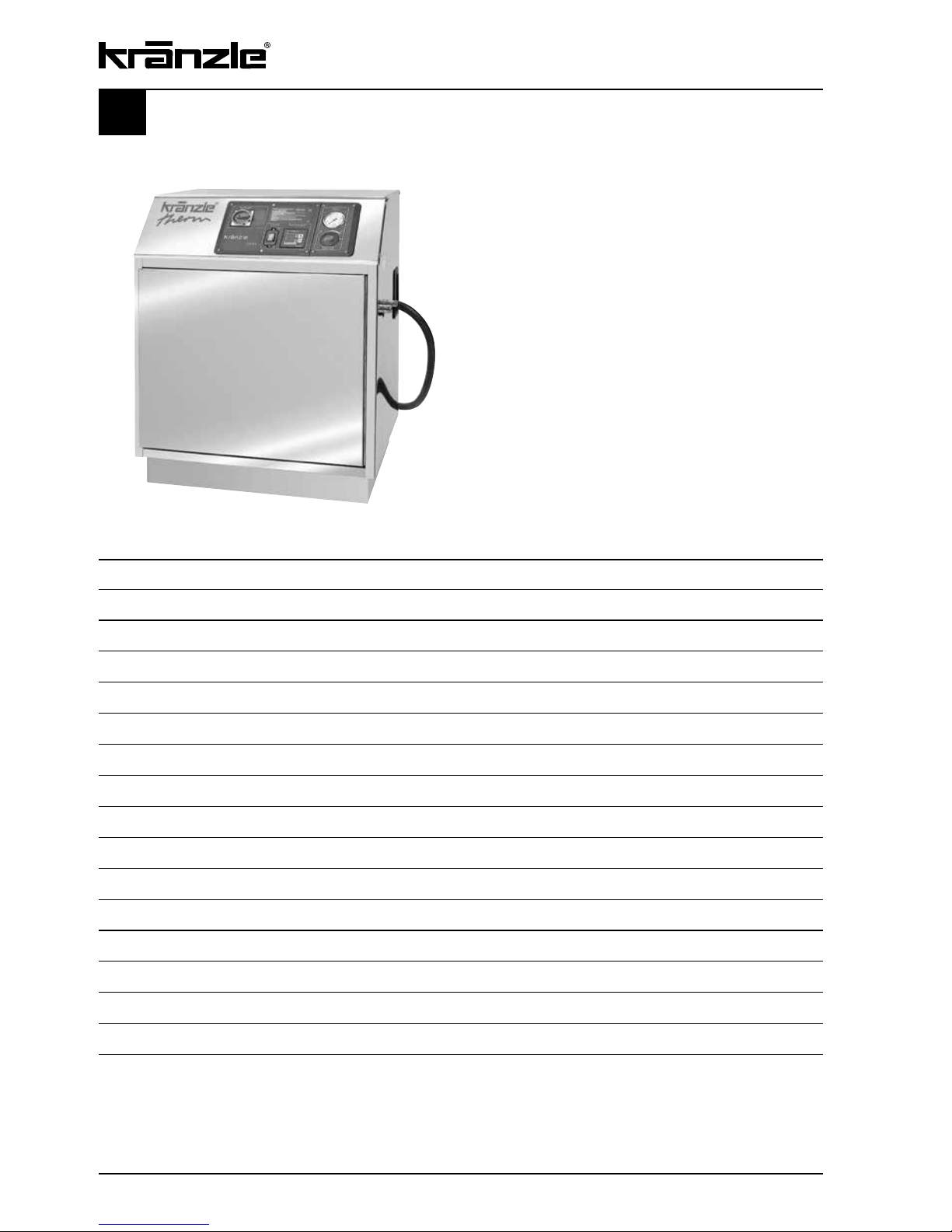

Operating panel

Water inlet with filter

High-pressure outlet

3 m power lead (without plug)

Front door, lockable

Stainless steel housing

Description of appliance - Kränzle therm E-ST

Master switch (appliance ON-OFF)

Heating switch (burner ON/OFF)

Brief operating instructions

Pressure gauge – high pressure

Digital thermostat for adjusting

water temperature

Detergent switch (ON-OFF)

Page 6

6

Technical data

Operating pressure, continuously adjustable

30 - 100 bar

(nozzle 25045)

30 - 100 bar

(nozzle 25045)

Operating pressure, continuously adjustable

30 - 160 bar

(nozzle 2503)

30 - 160 bar (nozzle 2503)

Admissible overpressure, nozzle size 25045 120 bar 120 bar

Admissible overpressure, nozzle size 2503 170 bar 170 bar

Water output 180 - 600 l/h 180 - 600 l/h

Maximum hot water discharge 60 °C at 32 bar 72 °C at 32 bar

Sucked in water is heated by 26 °C with 10 l/min by 26 °C with 10 l/min

Maximum water inlet temperature 60 °C 60 °C

Steel fabric high-pressure hose 10 m 10 m

Connected load 400 V, 32,6 A, 50 Hz 400 V, 41,2 A, 50 Hz

Wattage 20,6 kW 26,6 kW

Heating output 18 kW 24 kW

Fuse 50 A 63 A

Protection type IP 54 IP 54

Weight 220 kg 220 kg

Dimensions in mm (W x D x H) 800 x 650 x 950 800 x 650 x 950

Order No. 41.358 5 41.358 6

therm 601 E-ST 18 therm 601 E-ST 24

Page 7

7

30 - 100 bar (nozzle 25045) 30 - 170 bar (nozzle 2505) 30 - 220 bar (nozzle 2505)

30 - 160 bar (nozzle 2503)

120 bar

170 bar

180 - 600 l/h 180 - 870 l/h 180 - 900 l/h

80 °C at 32 bar 80 °C at 32 bar 80 °C at 32 bar

by 50 °C with 10 l/min by 46 °C with 14 l/min by 46 °C with 15 l/min

60 °C 60 °C 60 °C

10 m 10 m 10 m

400 V, 58,6 A, 50 Hz 400 V, 80 A, 50 Hz 400 V, 80 A, 50 Hz

38,6 kW 53,5 kW 53,5 kW

36 kW 48 kW 48 kW

80 A 80 A 80 A

IP 54 IP 54 IP 54

220 kg 220 kg 220 kg

800 x 650 x 950 800 x 650 x 950 800 x 650 x 950

41.358 7 41.358 9 41.358 8

Permissible tolerance for figures ± 5 % in acc. with VDMA uniform sheet 24411

therm 601 E-ST 36 therm 871 E-ST 48 therm 891 E-ST 48

Page 8

Range of application

This machine may only be used for cleaning facades, vehicles, containers, pavement

slabs, stables, machines and similar objects.

Inspections

The machine must be inspected according to the “Guidelines for Liquid Spray Devices” at

least once every 12 months by a qualified person, to ensure that continued safe

operation is guaranteed. The results of the inspection are to be recorded in writing. This

may be done in any form. For inspection reports see pages 48/49.

High-pressure cleaners used for commercial purposes have to be

checked by a qualified person at least every 12 months!

Accident prevention

The machine is designed for accidents to be impossible (if used according to these

instructions). Please read safety notes included in these instructions carefully before using

the machine and act correspondingly. Operating staff has to be instructed according to

this manual. The “Guidelines for Liquid Spray Devices” must be complied with.

Setting up - Location

Neither set up and operate the machine in rooms where there is a risk

of fire or explosion nor put it into puddles. It is prohibited to use the

machine under water.

Do not jam the trigger of the gun during operation!

When carrying through service and maitenance tasks the machine has

to be cut off the power supply system. Put main switch to "0" and pull

plug out of socket

.

Never operate the machine if cables or other safety-relevant parts (e.g.

excess pressure valve, high-pressure hose, spraying devices, etc.) are

defective.

8

General rules

Safety notes

Page 9

9

Safety notes

Never operate the machine without supervision. The machine may only

be operated by persons who have been instructed accordingly.

Some parts inside the machine, all water conducting components and all

metal parts of gun and lance are hot during hot water operation. Keep all

hoods and protective covers closed during operation and never touch

any metal parts of gun or lance.

Persons operating the machine should wear the necessary protective

clothing, i.e. waterproof clothing, rubber boots, safety goggles, headwear

etc. It is prohibited to use the machine in close vicinity to people lacking

suitable protective clothing.

The high pressure spray can generate a high level of noise. If noise

exceeds the maximum allowed levels, users and others in the vicinity

must wear suitable ear protection

.

Do not spray against matter containing asbestos or other hazardous

substances.

For safety reasons always switch the main switch to "0"- postion after

having finished the cleaning task (disconnection from power supply).

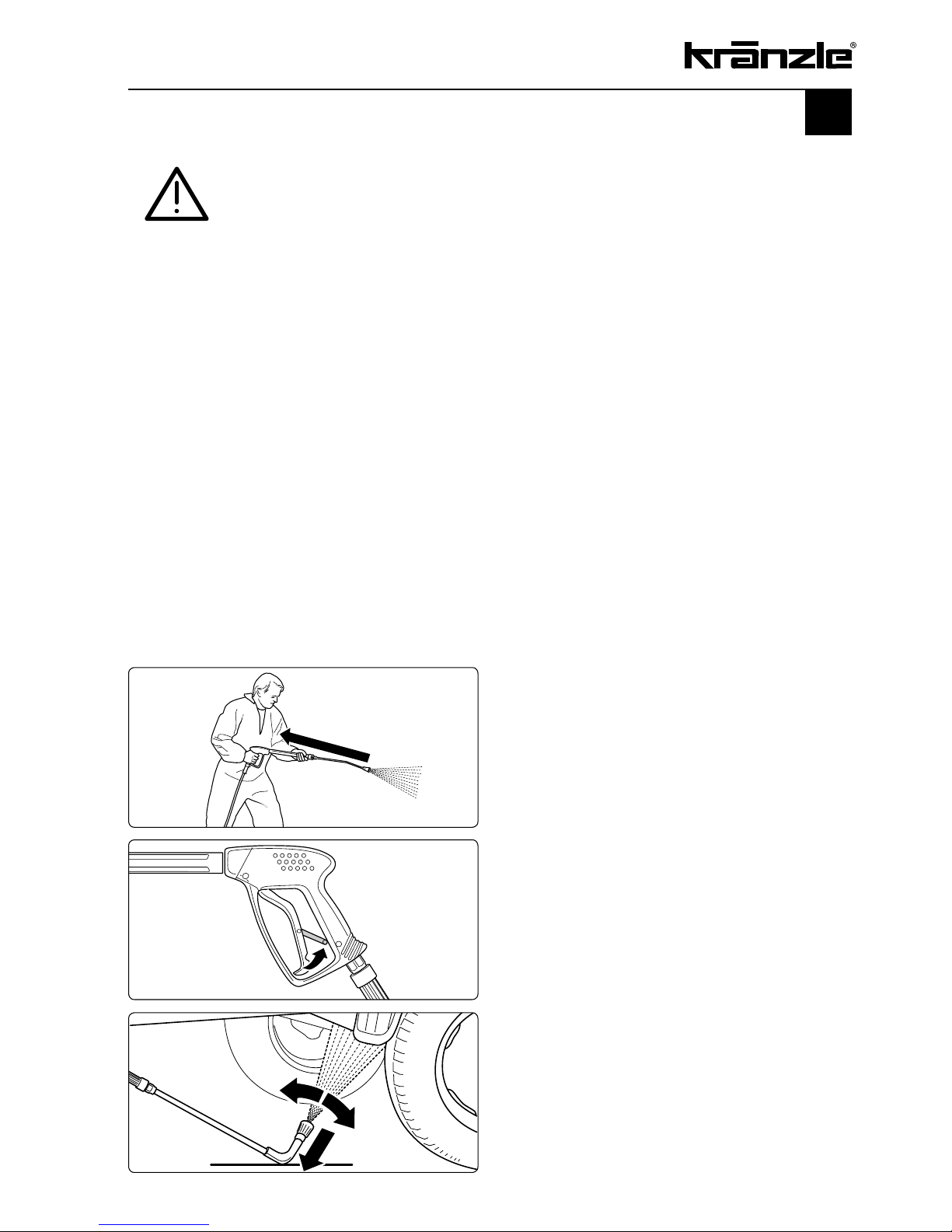

Bear in mind that during cleaning tasks

with a high-pressure water jet a significant

recoil at the lance arises.

Additionally angled lances produce a

clearly perceivable amount of torque.

Apply the safety catch on the spray gun

after each use, in order to prevent

unintentional spraying!

Always aim the underbody lance! Bear in

mind when using a curved or angled

spraying lance that there is a significant

amount of torque in the recoil!

Page 10

10

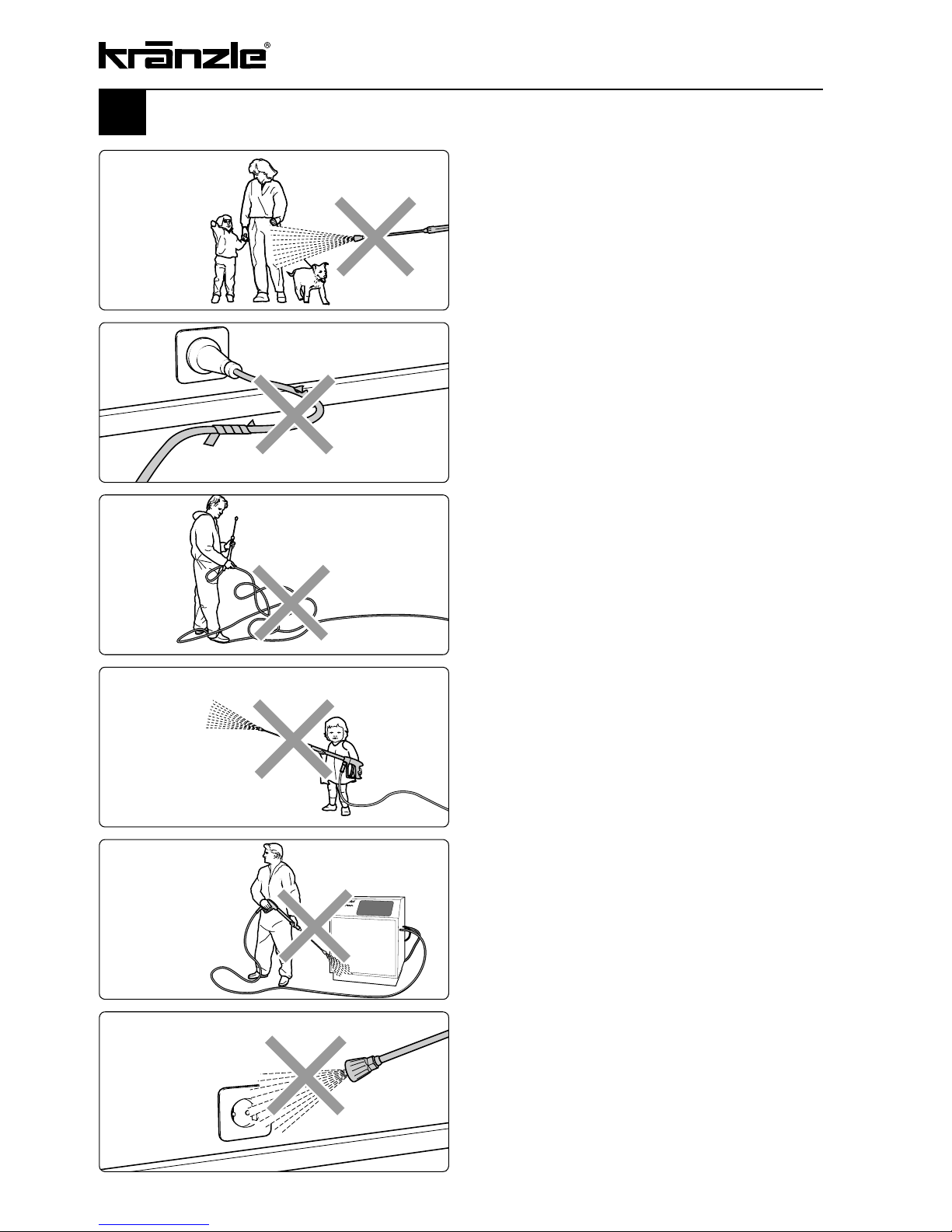

Safety notes - This is prohibited!

Never allow children to use the high

pressure cleaner!

Never direct the water jet at the

machine itself!

The machine may not be placed within

reach of the water jet spray mist!

Never direct the water jet at a power

socket!

Never direct the water jet at people

or animals!

Only use power cables which are in

perfect working order! Do not damage

the power cable or repair it incorrectly!

Never pull the high pressure hose if

it has formed kinks or “nooses”!

Never pull the hose over sharp edges!

Page 11

11

Connection to water supply

Please pay attention to the regulations of your waterworks company! In accordance

with DIN EN 61770, the machine may not be directly connected to the public drinking

water supply lines. A brief connection however is permissible according to DVGW

(German Association for Gas and Water Affairs) if a tube ventilator with check valve

(Kränzle Order-No. 41.016 4) is built into the water supply. Also indirect connection to

the public drinking water supply lines is permissible by way of free emission in

accordance with EN 61 770; e.g. by using a reservoir with a float valve. Direct

connection to a non-drinking water supply line is permissible.

Electrical connection

The voltage given on the specification plate must match the mains

voltage.

The machine is supplied with power cable without plug. The plug has to be equipped with a safety earth terminal and a 30 mA residual-current circuit breaker.

The mains connection has to be fused with a time-delay fuse according to the

specifications on page 6/7.

If an extension cable is used, it must have an earth line that is properly connected to the

plug connections. The conductors in the extension cable must have the following minimum cross section:

at 18 kW - 6 mm

2

at 24 kW - 10 mm

2

at 36 kW - 16 mm

2

at 48 kW - 25 mm

2

Extension cables that are too long cause a drop in voltage and thus

malfunctions. If you are using a cable drum, the cable must always

be fully unwound.

Page 12

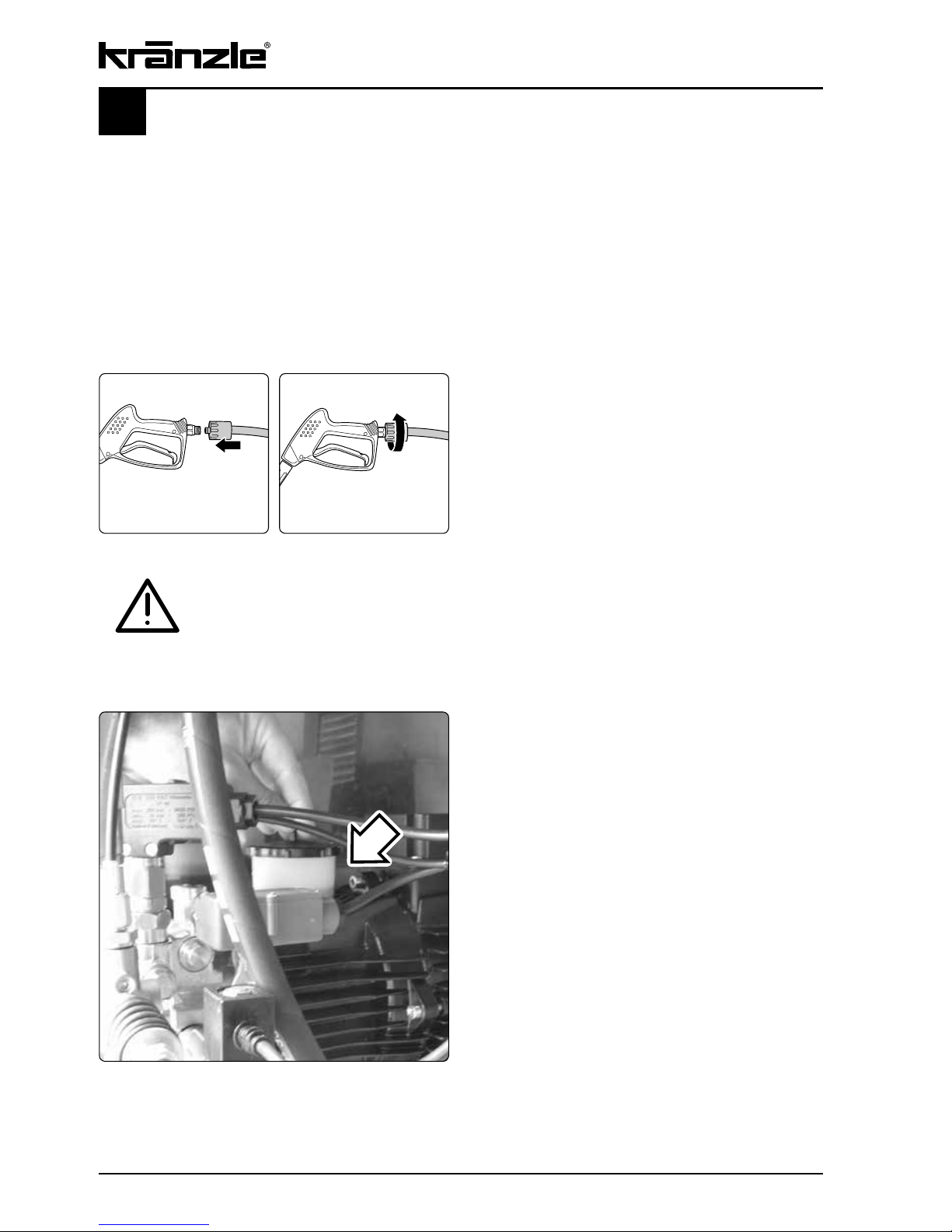

1.

Connect to power circuit. Make sure that the main switch is in "OFF" position.

2.

Connect machine to water mains (2 - 8 bar pre-pressure). Inside diameter of hose

minimum 1/2 ". The water storage tank fills with water. The float valve shuts the water

intake as soon as the tank is full.

3.

Fasten high-pressure hose to appliance

4.

Push on HP hose to gun.

5.

Screw together HP hose and gun

pressure-tightly.

12

Putting into operation

6.

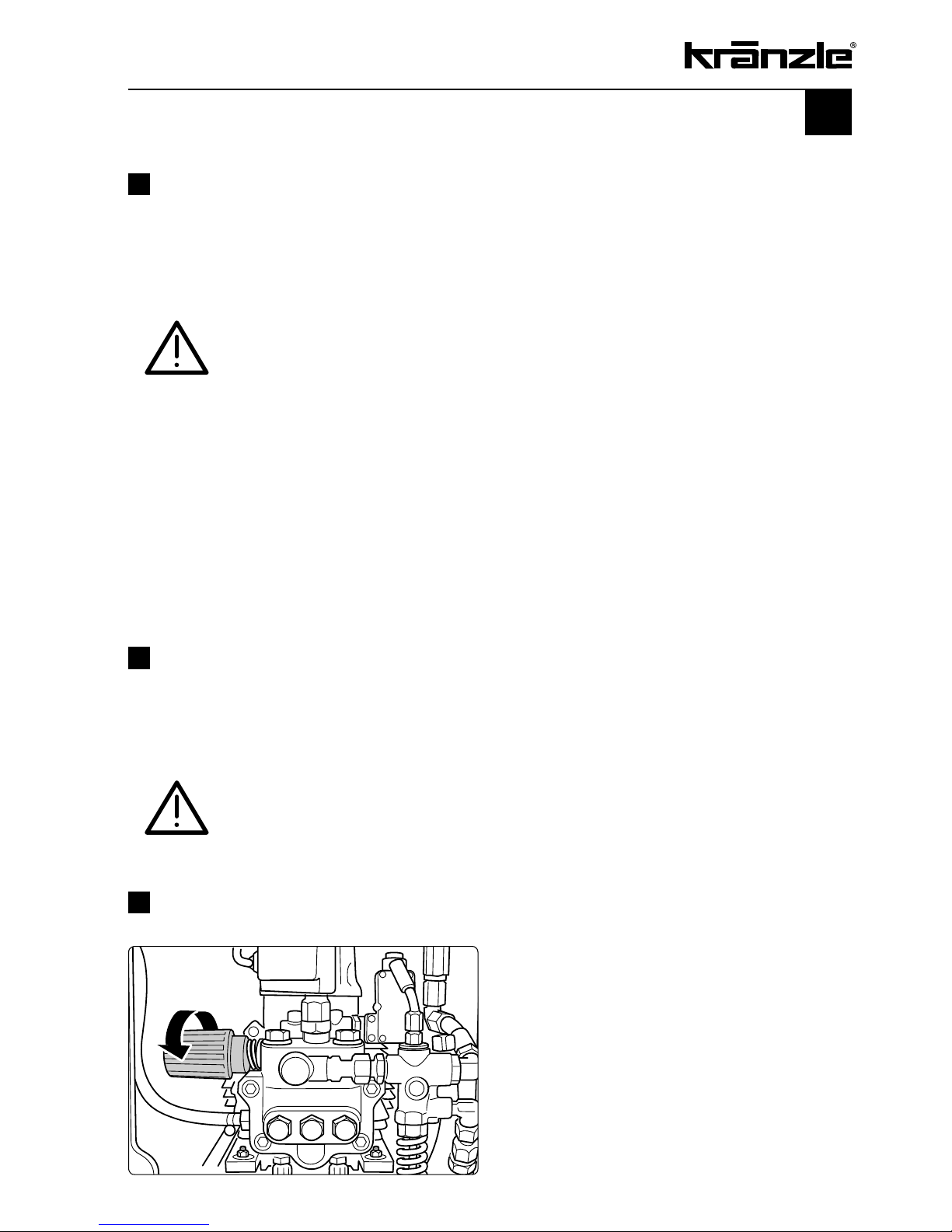

Always check oil level prior to

operation! Open the HP cleaner.

Do not start the machine if the oil level is not

between the two markings on the oil-level

glass. Refill with oil if necessary.

See page 23.

Take care that all screw connections are pressure-tight. A leakage

of gun, high-pressure hose or hose drum has to be repaired at once.

Leakages lead to an increased wear and guarantee is void if

consequential damages occur.

Page 13

1.

Ignition switch to -OFF- position

Detergent valve must be closed!

(Switch in left end stop position)

2.

Switch on main switch with disengaged

spray gun. Vent high-pressure cleaner: Pull

and release trigger of spray gun various

times.

Start cleaning task.

Usage as a cold water high-pressure cleaner

1.

a) Temperature mode: Set required tem-

perature at the thermostat.

(Min. temperature 40 °C)

b) Percentage mode: Set percentage

value for heating output.

2.

Switch on main switch with disengaged

spray gun. Vent high-pressure cleaner:

Pull and release trigger of spray gun

various times.

Detergent valve must be closed!

(Switch in left end stop position)

3.

Start ignition. The water is heated up

and constantly kept at the set

temperature.

Start cleaning task.

Usage as a hot water high pressure cleaner

13

Page 14

14

Water and cleaning system

The water is fed to the high-pressure cleaner under pressure (2-8 bar pre-pressure).

A float valve regulates the water flow in the storage tank. Then the water is sucked

directly from the storage tank by the high-pressure pump and forced with the adusted

pressure through the heat exchanger to the safety spray lance. The high pressure jet

is formed by the nozzle at the end of the safety lance.

Environmental, refuse disposal and water protection regulations

must be observed!

Kränzle technology

Lance with trigger gun

The machine can only be operated when the safety trigger is squeezed. When the lever

is squeezed, the spray gun opens. The liquid is then pumped to the nozzle. The spray

pressure increases and quickly reaches the selected operating pressure. When the

trigger is released, the trigger gun closes and any further spraying of liquid from the

lance is stopped. The motor stops.

When actuating the gun once more the pressure control valve - safety valve closes and

the motor is started again. The pump resumes feeding water to the spraying lance with

the selected operating pressure. When the gun is closed, the water hammer opens the

pressure control valve - safety valve and the motor is switched off by the pressure

switch.

The trigger gun is a safety device. Repairs should only be performed

by qualified persons. Should replacement parts be required, use only

components authorized by the manufacturer.

Total stop system

The machine is fitted with a Total-Stop-System. If the gun is closed for longer than

approx. 20 seconds, the machine switches off automatically, after 20 minutes the

machine moves to safety switch off and you must use the main switch to turn it back on.

The machine restarts automatically when the gun is operated, provided that the master

switch is on.

Page 15

15

High pressure hose and spraying device

The high pressure hose and spraying device supplied with the machine are made of high

grade material, they are also optimized for the machine and marked as required by the

appropriate regulations.

If replacement parts are required, only such parts that are authorized

by the manufacturer and which bear the markings required by the

appropriate regulations may be used.

The high pressure hose and spray device must be connected in a

pressure-tight manner.

The high pressure hose may not be driven over, pulled excessively, or

twisted. The hose may under no circumstances be pulled over sharp

edges, since otherwise the guarantee is automatically void.

Hoses are wearing parts. The guarantee only covers defects of

fabrication no external damages whatsoever.

Defective high-pressure hoses and spraying devices may not be

repaired. They always have to be replaced.

Pressure control valve-safety valve

The pressure control valve allows full adjustment of water quantity and pressure. The

safety valve protects the machine from excessive pressure and cannot be adjusted

beyond the admissible operating pressure. The setting nuts are sealed with lacquer

.

Replacements, repairs, new adjustments and sealing operations may

only be performed by trained personnel.

Adjustment of pressure, quantity and temperature

The operating pressure, the water

flow and correspondingly the water

temperature ist controlled by the

pressure control valve.

A right-hand turn increases the

pressure, a left-hand turn decreases

the pressure.

Page 16

16

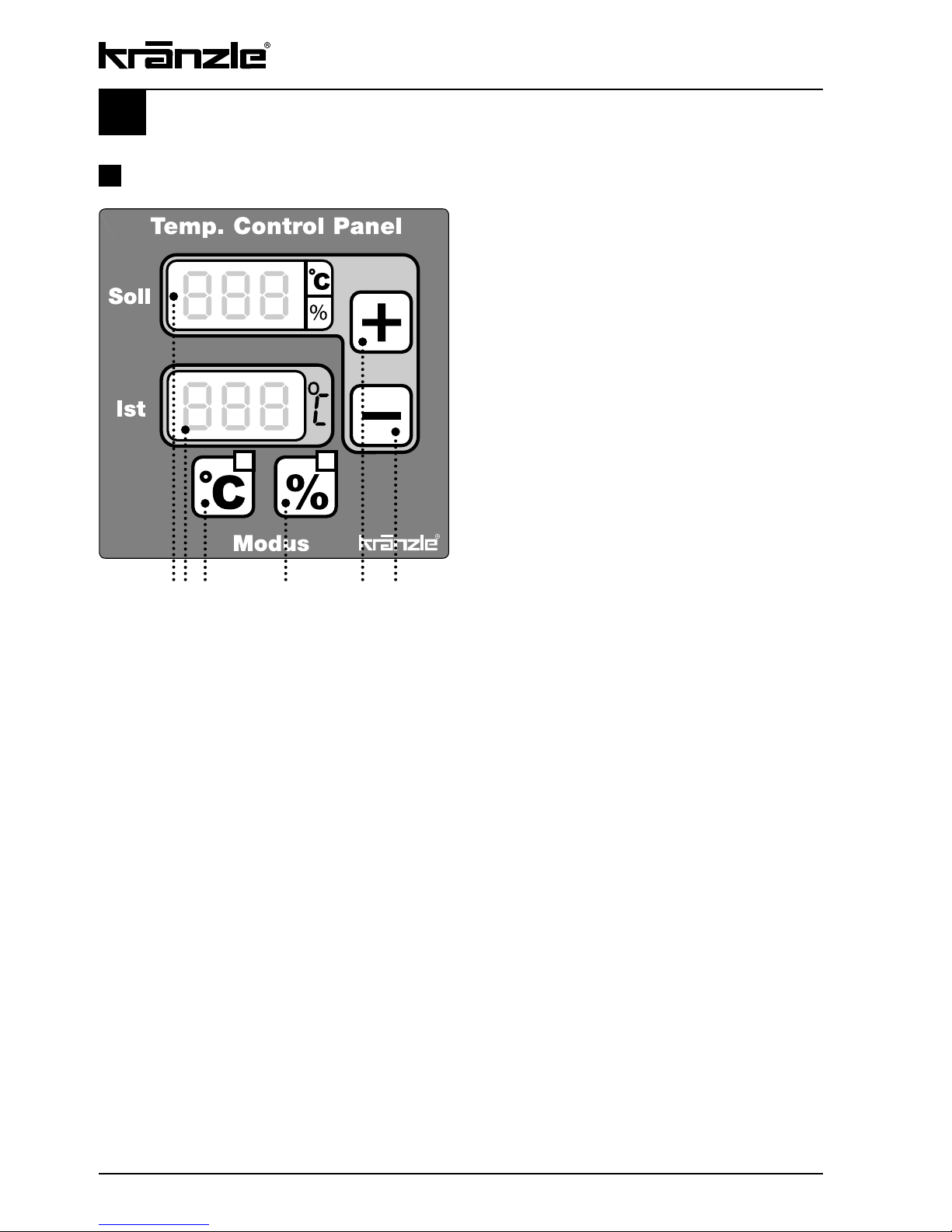

Kränzle technology

The thermostat controls the spray water

temperature.

After you switch on the device, "888"

appears in both displays for approx. 1

second as a test of the functioning of the

displays.

Thermostat

12 3 4 5 6

The thermostat has two operating modes:

1. Temperature mode

This mode is always activated when the unit is switched on or can be selected using

the "°C°" button (Pos. 3). The red LED above the "°C" button and next to the set

temperature display lights up. The desired "Set" temperature is set using the two buttons

(+/-, Pos. 5+6) and can be read in the upper display (Pos. 1). If you press the button for

a longer time, the set temperature is quickly adjusted in 5°C increments.

The last set value set is also stored after the unit is switched off and is available again

immediately after switching back on.

The current spray temperature can be read from the bottom display (Pos. 2).

2. Percentage mode

This mode is activated by pressing the "%" button (Pos. 4). The yellow LED above the

"%" button and next to the set temperature display ashes.

In the temperature control system in conventional high pressure cleaners, and in

temperature mode for this unit, the water temperature is measured at the outlet of the

heater, and the heater is switched on an off according to the temperature desired by the

user. Due to the large amount of water in the heating coil, it takes a long time until the

temperature sensor registers that the burner has switched on and the desired temperature

has been reached. This means that the temperature increases far above the desired value

or falls far below the desired value.

Page 17

17

Thermostat - Percentage mode

The innovative new percentage mode now lets the user specify the switching duration

of the heater in percent using the "+" and "-" buttons (Pos. 5+6) (100% being the max.

temperature) rather than setting the desired temperature. Now the result of the setting

must be checked by using the "Actual" temperature display. If the desired temperature has

not yet been reached, the percentage must be increased.

By setting percentages of the heating duration, the temperature of the high pressure jet is

kept constant in a very narrow range.

The last value set is also saved after the unit is switched off in percent mode.

Operating hour meter

The cleaner is equipped with an operating hour meter.

If during normal operation the momentary operating mode button ( "°C" or "%" ) is actuated for

more then 2 seconds, the operating time of the pump is displayed for 5 seconds and afterwards the

combustion time for 5 seconds as well. Thereafter the display shows the original values again.

As long as the operating hours are displayed no further inputs on the monitor are possible.

The operating time is displayed in hours [ h ] either in the “TARGET” or in the „ACTUAL“

window. The 1000 and 100 hours are displayed in the „TARGET“ window and the 10, 1 and

1/10 hours in the “ACTUAL” window:

Pump operating time: Target-Display: P 9 9 Actual-Display: 9 9. 9 for 9 999.9h

Combustion time: Target-Display: F 9 9 Actual-Display: 9 9. 9 for 9 999.9h

e.g.: F00 27.3 = Cumbustion time 27 hours and 18 minutes

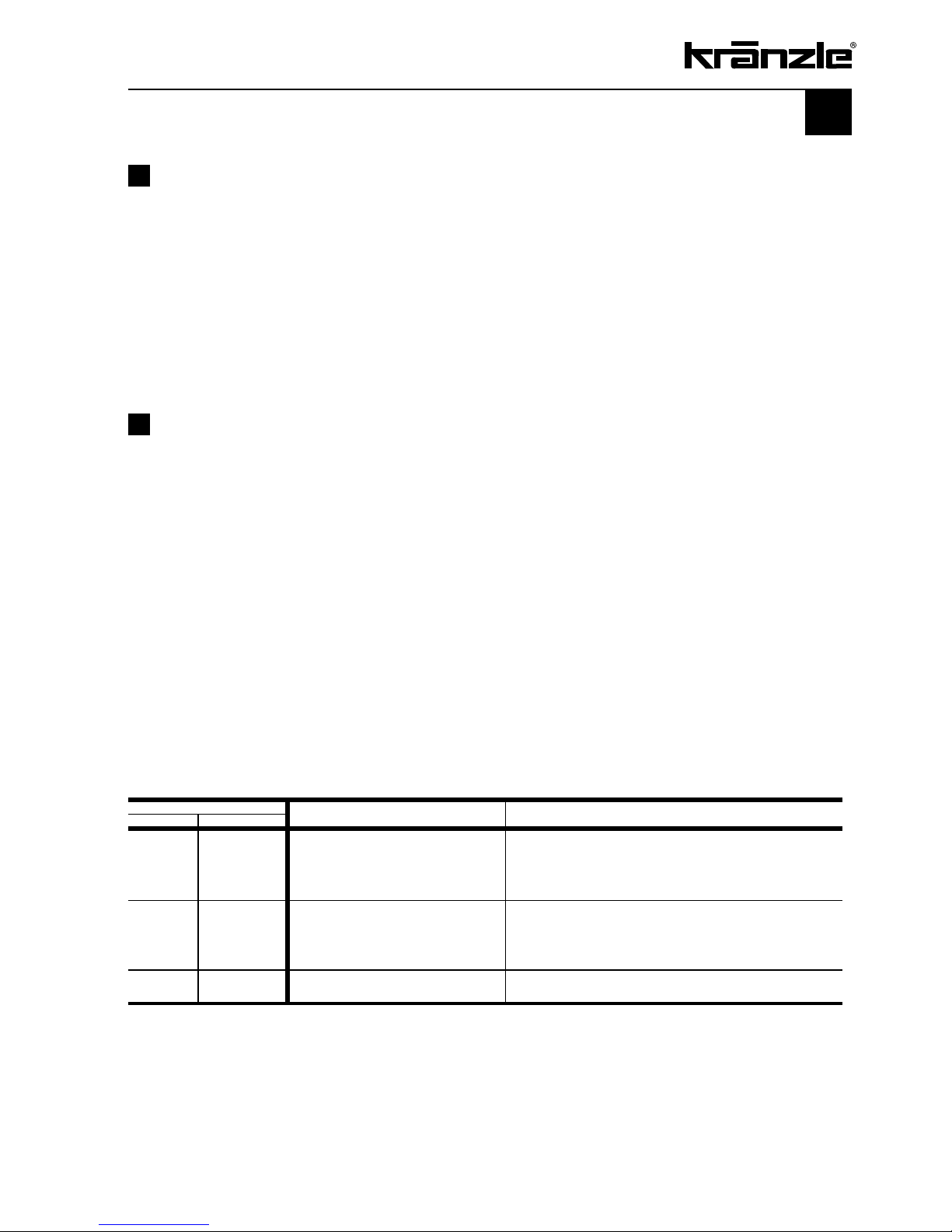

Displayed malfunctions

Display as follows

Cause Action

SOLL IST

Err OFF

Water temperature at

heating chamber outlet

above 147 °C

Operate appliance without heating „Heating

OFF“ until the temperature has dropped

below 147°C. Switch main switch „OFF“ and

then back „ON“ again

AUS

(OFF)

E7

Appliance has not been

operated for more than 20

minutes

-> Safety cut-off

Switch main switch „OFF“ and then back

„ON“ again.

Err E2

Temperature sensor

defective

Replace temperature sensor

Page 18

18

Kränzle technology

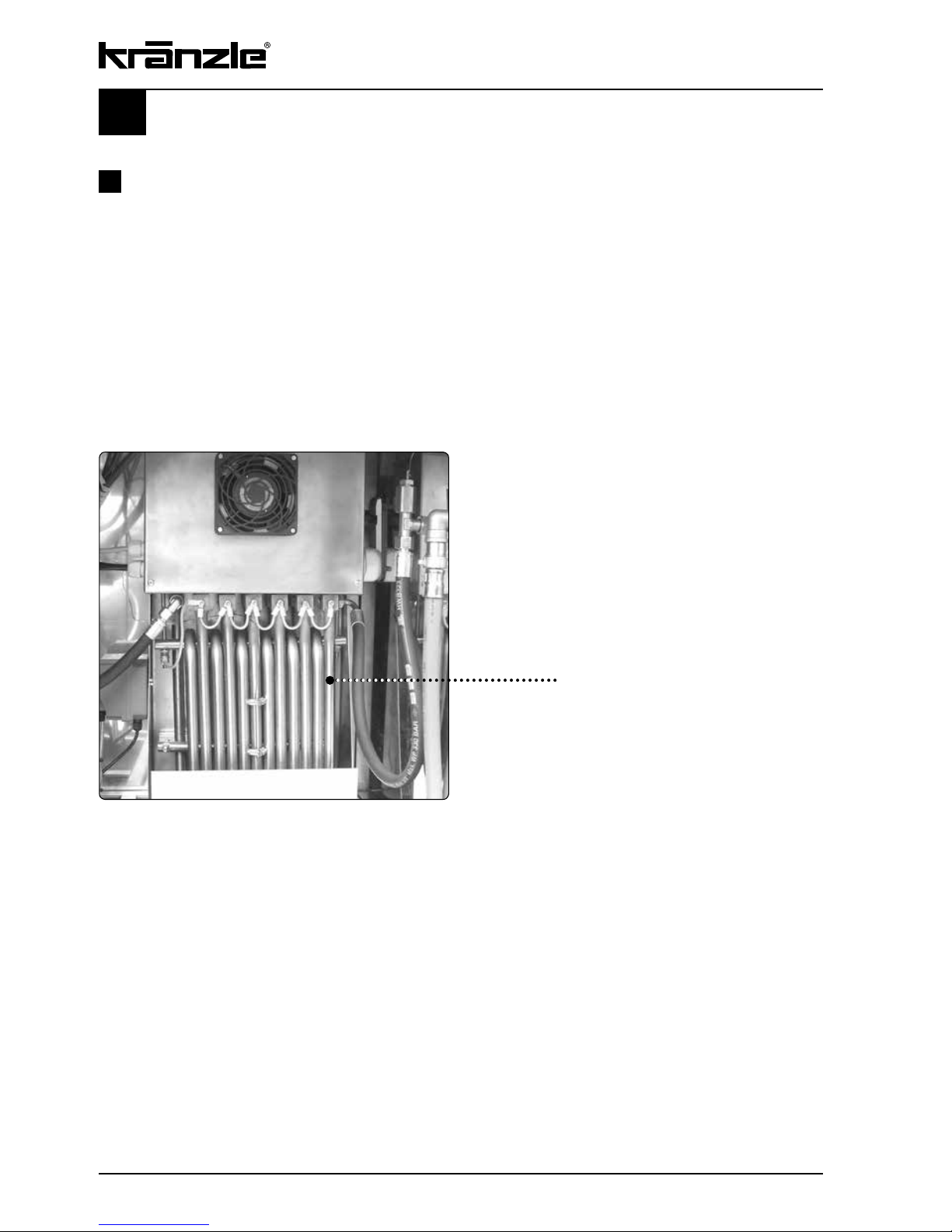

Electric heating 18, 24, 36, 48 kW

The flow heaters are connected in series in modular design according to machine type

and kW output.

For water temperature at max. water output we refer to the table on pages 6/7, second

column „Heating of sucked in water“.

To be able to reach the maximum hot water output temperature it might be necessary to

reduce the operating pressure, thus reducing the water output in l/min at the same time

(see page 15).

For the temperature values we refer once more to the table on page 6/7, see „max. hot

water output“.

Flow heater

Page 19

Detergent supply from the suction side:

Detergent injection on the pressur side, as you probably know it from other HP cleaners,

consume approx. 30 % of the cleaning energy, no matter if they are used or not. Due to the

water tank fitted to the Kränzle therm cleaners it is now possible to directly suck the

detergent into the pump thus reducing output loss and increasing the efficency

considerably.

The detergents are applied without having to reduce the working

pressure.

Only open the dosing valve, if the detergent sieve is placed in a

liquid. Sucked air leads to destruction of the pump seals! No

guarantee!

Keep detergent-ph-value neutral 7 - 9!

Observe specifications of detergent manufacturer!

e.g.: protective equipment, rules for waste water treatment etc.

Never suck in liquids containing solvents like varnish solvents,

petrol, oil or similar liquid! Observe specifications of detergent

manufacturers

!

Seals inside the appliance are no resistant against solvents! The spray

mist of solvents is highly inflammable, explosive and poisonous.

19

Suction of detergents

1.

Place detergent filter into detergent

container.

2.

Dosing of detergent is done by turning

the detergent valve.

3.

By closing the detergent valve the

supply of detergent is stopped.

4.

After having used detergents rinse the

appliance with open spray gun and clean

water for at least 2 minutes.

Page 20

20

Decommissioning - frost protection

1. Switch off the machine - main switch to „0“- position

2. Cut off the water supply

3. Open the spray gun briefly until the pressure is released

4. Apply the safety catch on the spray gun

5. Remove the water hose and spray gun

6. Drain the pump: switch on the motor for approx. 20 seconds

7. Pull the plug from the socket

8. Clean HP hose and stow away

9. Clean water filter

Frost protection

The machine is normally still partially filled with water after work has been completed.

In case the high-pressure cleaner is exposed to frost:

To protect the appliance from frost, completely empty it of water:

Disconnect the machine from the water supply and switch off the ignition. Switch on the

master switch and open the gun. The pump now presses the remaining water out of the

water tank, the pump and the continuous-flow heater.

Do not allow the machine to run for longer than a minute without water.

If the machine is not in use for lengthy frosty periods of time, it is advisable to pump

anti-freeze into the machine: For this purpose, fill the antifreeze agent into the water

tank and switch on the machine without ignition. Wait with opened gun, until the agent

comes from the nozzle.

However, the best protection against frost is to keep the machine in a place that is

safe from frost.

Page 21

21

Change the oil:

First oil change after approximately

50 operating hours. Thereafter the oil

should be changed every 500 operating

hours or yearly.

Take the oil drainage hose, which is

connected to the oil drainage screw from the

inside of the appliance.

Open the red oil ller plug at the top side of

the black oil housing.

Open the cap at the end of the hose. Drain

off the oil into an oil pan and dispose of it

responsibly. Close the end of the hose. Rell

with new oil.

Weekly, or after approx. 40 hours of operation:

- Check the oil level of the high pressure pump. If the oil level is too low, add oil until

the oil level is between the two markings on the oil measuring rod.

Change the oil if it has a grey or whitish appearance. The oil should be

disposed of responsibly.

- Check the water filter in front of the float valve in the water tank and the fuel filter

in front of the solenoid valve. Clean the filters if necessary.

Yearly, or after approx. 500 hours of operation:

- Desulphurise and decarbonize the continuous-flow heater.

- Change the oil

Oil leakage: If oil leaks out, go to the nearest customer service

(dealer) immediately. (Environmental damages, transmission

damages)

In case of increased humidity or fluctuations in temperature

development of condensed water is possible; if the oil turns grey,

you must change it at once.

Care and Maintenance

The machine must be disconnected from the power supply when

servicing work is being carried out. The main switch should be in

position "0" and the plug out of the socket.

Page 22

22

Decalcifying the continuous-flow heater:

Calcified machines use an unnecessary amount of energy because the water can only

be heated slowly and the excess pressure valve feeds a part of the water back into the

pump circuit.

Calcified machines can be recognised by increased pipeline resistance.

Check pipeline resistance by disconnecting the high pressure lance from the gun and

switching the machine on. A full jet of water emerges from the gun. The machine must be

decalcified if the pressure shown on the manometer is greater than 25 bar.

Proceed as follows to decalcify the machine:

1.

Unscrew the high pressure hose from the machine and decalcify it separately.

2.

Put the detergent suction hose into a container of decalcifying solution.

3.

Set the detergent valve to the maximum concentration.

4.

Switch on the machine.

5.

Hold the gun in a separate container and press the trigger.

6.

Wait for about a minute until the decalcifier comes out of the gun

(recognisable by its whitish colour)

7.

Switch off the machine and allow the solution to act for about 15-20 minutes.

8.

Switch the machine back on and rinse with clear water for about 2 minutes.

9.

Now check whether pipeline resistance is back to an acceptable level.

Repeat the decalcifying process if the pressure without the high pressure lance is

still above 25 bars.

Decalcifiers are caustic!

Observe the instructions for usage and accident prevention. Wear

protective clothing to prevent the decalcifying agent from contacting

your skin, eyes and clothing (e.g. gloves, safety mask etc.)

Page 23

23

Particular rules, directives and

inspections

Inspections performed by Kränzle

- measurement of earth line resistance

- measurement of voltage and current

- inspection of tension consistency with +/- 1530 V

- pressure check of the heating units at 300 bar

- visual and functional check as per the inspection sheet provided

Guidelines for liquid sprayers

The machine conforms with the "Guidelines for liquid sprayers". These guidelines are

issued by the organisation of trade associations and may be obtained from Carl

Heymann-Verlag KG, Luxemburger Str. 49, 50939 Köln. These guidelines specify that

this machine is to be inspected by qualified personnel whenever necessary, but no less

than once every 12 months. These inspections must be recorded in the inspection log at

the end of this manual.

Pressure container and steam boiler directives

Kränzle high pressure cleaning equipment conforms to the pressure container and

steam boiler directive. No construction approval, notification of licence and takeover

inspection are required. The water capacity is less than 5 l.

Duties of owner

The owner is to ensure that all safety-relevant components are in a serviceable condition

before the sprayer is used. (e.g., safety valves, hose and electric cables, spray

equipment etc).

Page 24

24

Troubleshooting

Malfunction

Water supply

Water tank runs over.

Water tank does not fill completely.

Pump does not suck.

Test: check water and chemical

system for tightness.

High-pressure pump

Pump makes loud noises.

Operating pressure is not reached.

Water drops from the pump.

Oil drops from the transmission.

Pressure is too low.

Machine does not switch off

Test: Bridge pressure switch (red)

Appliance does not start or

stopps during operation

Cause of malfunction / remedy

Float valve is dirty or defect.

Float valve is defect. Water filter is dirty. Insufficient

water inlet quantity.

Valves stick or are dirty. Suction hose leaks.

Chemistry valve is open or leaks. Check hose clips

(connections). High-pressure nozzle is clogged.

Connect water inlet directly to the pump (2-8 bar

pre-pressure). Disconnect suction lines below the

pump

Pump sucks air. Check suction connections.

Check high-pressure nozzle. Check valves. Check

O-rings under valves. Check sleeves. Manometer

is defect. Unloader: check stainless steel seat and

ball. Check seals on the control piston.

Replace sleeves in the pump.

Replace O-rings.

Check oil seals (replace). Check plunger and plunger guides. Check water supply, since water deficiency or air suction can cause damage to seals and

O-rings (chemistry valve leaks?)

Worn high pressure nozzle. Stainless steel seat,

ball, O-ring in unloader is dirty or defect.

Manometer is defect.

Check return body and O-ring in unloader of the

valve housing.

Check pressure switch (red). Check micro switch.

Check cable connections. Board is defect.

Check electricity supply. Check main switch.

Check cable connections. Check board.

Check pressure switch. Switch off by overcurrent

release.

Page 25

25

Malfunction

Machine does not start

Electrical heating elements

Insufficient water temperature.

Leakage

Gun drips. High pressure hose drips.

Manometer indicates pressure, but no

water comes out of HP-hose.

Sucking detergent

Control knob leaking.

Detergent is not sucked.

Cause of malfunction / remedy

Check electricity supply.

Check main switch.

Check cable connections.

Board defective.

Check pressure switch.

Switch off by overcurrent release.

Check electricity:

- ON-OFF - Switch

- Contactor

- Flow monitoring device

Clean nozzle. Replace seals.

Replace O-ring below screwed connection.

Clean nozzle.

Replace seals.

Pump sucks air. Check hose clips.

Test: Connect water line to the pump.

Water inlet: 2 - 8 bar pre-pressure. No water must

come from the detergent hose.

Page 26

26

Small repairs

do it yourself

No water from the nozzle but the gauge

shows full pressure: Most likely the nozzle

is blocked.

(Inside the pressure gauge there is no water but a

filling with glycol to damp the vibration of the pointer.)

Proceeding:

Switch off the cleaner. Pull plug from the

socket. Operate gun seveal times to decrease the

pressure. First unscrew gun and lance, then rinse hose

from any residues. Check water inlet filter for soiling. If the

problem still exists, take wire (paper clip) and push

cautiously through nozzle opening. If this procedure is not

successful, the nozzle has to be dismantled and cleaned

(from the backside) or even replaced, if necessary.

Pressure gauge shows little

pressure, the water from the nozzle comes in

squirts, the high-pressure hose vibrates.

Most likely the valves are soiled.

Proceeding:

Unscrew all 6 valves, one after the other

(hexagonal brass screws, 3 in a row,

vertically and horizontally)

Take out valve body (with green or red plastic

coating) and O-ring by means of needle nose

pliers. Check O-ring for damage. In case of a

damage the O-ring has to be replaced.

Take a wire (paper clip) and clean valves under

running water. Also clean valve seating inside the

pump.

Do not forget the O-ring during reassembly!

Page 27

27

The pressure gauge shows full

pressure although the gun has been

closed. The pressure switch valve

switches constantly.

Possible cause no.1: Leakage

Having closed th gun, the HP cleaner must shut

down and the pressure gauge must show „0“

bar. If the pressure gauge still shows full pressure and the motor constantly switches on and

off, the possible reason for this can be a leakage

of the pump, the HP hose or the lance.

Proceeding:

Check the connections from the HP cleaner to

the the HP hose, from the hose to the gun and

also the connection between lance and gun for

tightness. Switch off the cleaner. Shortly press

the trigger of the gun to decrease the pressure.

Unscrew HP hose, gun and lance and check the

O-rings. If the O-rings are damaged they have to

be replaced.

In case of a leakage there is no guarantee for

possible consequential damages.

Possible cause no. 2:

The non-return valve is soiled or

defective

Proceeding:

Unscrew pump outlet.

Take out non-return valve body and check for

soiling or damage of the O-ring.

Replace non-return valve if necessary.

There is no guarantee if the pump is

damaged by defective O-rings due to air

induction or lack of water (cavitation).

Page 28

Ersatzteilliste

28

7

10

10

9

9

11

16

1

6

6

4

10

8

12

10

5

8

9

17

2

3

20

14

8

15

18

19

9

8

21

Page 29

29

Kränzle therm E-ST - Gehäuse

Position Bezeichnung Stck. Art.-Nr.

1 Seitenblech links 1 47.111

2 Deckel 1 47.113

3 Rückwand 1 47.114

4 Seitenblech rechts 1 47.112

5 Frontblech 1 47.115

6 Wetterschutzgitter 3 47.100 2

7 Lüfter 1 47.104

8 Kreuzschlitzschraube M4 x 10 22 43.470

9 Zahnscheibe Ø 4,3 mm 22 43.471

10 Mutter M5 24 44.113 1

11 Schließzylinder 1 47.116

12 Winkel mit Bolzen 2 47.117

13 Sauganschluß Wassereing. 3/4“AG x 1/2“AG 1 41.016 1

14 HD-Ausgang 1 13.368

15 Kantenschutz 1 47.119

16 Innensechskantschraube M5 x 10 4 43.021

17 Kreuzschlitzschraube M6 x 12 11 43.421

18 Fuß 4 47.118

19 Lüftergitter 1 47.104 1

20 Winkel ½“ 1 42.764

21 Sauganschluß Wassereing. ¾“AG x ½“ AG 1 41.016 1

32.3 Netzanschlußkabel 4 x10 mm² 1 44.610 1

Page 30

12

25

24

23

26

24

23

9

8

7

6

5

4

2

3

10

11

13

14

15

16

18

17

1

20

21

22

27

28

24

23

24

23

29

19

30

Ersatzteilliste

30

Page 31

31

Kränzle therm E-ST - Wasserversorgung

Position Bezeichnung Stck. Art.-Nr.

1 Rahmen 1 47.120

2 Hauptschalter 63A für 601-18/24/36 1 44.622

2.1 Hauptschalter 100A für 871 48; 891 48 1 44.623

3 Anschlußkabel 4x6 mm² 18KW 1 44.6101

4 Ermetomutter M18x1,5 1 40.075

5 Temperaturfühler 1 44.954 1

6 Nippel 3/8“ auf M22AG 1 13.369

7 Kupferdichtring 17,3 x 1,3 1 14.149

8 Ermetoverschraubung T-Stück gelb verzinkt 1 44.173

9 Hochdruckschlauch 1 44.702

10 Chemieschlauch 1 47.121

11 Deckel für Reinigungsmittelbehälter 1 47.110 1

12 Reinigungsmittelbehälter 1 47.110

13 Winkel 3/8 16 x 3/8 16 1 44.138

14 Wasserschlauch Eingang 1 12.353

15 Mutter für Schwimmerventil 1 46.258

16 Wassertank 1 44.009

17 Einströmschlauch 1 44.027

18 Schwimmerventil 1 44.025

19 Doppelnippel ½“

20 Verschlusskappe 1 44.130

21 Kupferring 3 14.149

22 Ölablassschlauch 1 44.128 1

23 Selbstsichernde Mutter M8 7 41.410

24 Unterlegscheibe 8,4 DIN 9021 8 41.409

25 Aggregathalterung 1 44.013

26 Schwingmetall 30 x 30 4 44.227

27 Einschraubwinkel 3/8“ x 3/8“ 1 44.127

28 Eingangstück R3/8“ IG für UL250 1 13.136

29 Sechskantschraube M8 x 35 1 40.153

Position Bezeichnung Stck. Art.-Nr.

Page 32

48

45

46

47

49

30

30

1

38

37

39

40

36

7

40

36

6

5

4

3

34

35

34

36

40

9

10

11

12

34

13

38

37

38

14

17

43

40

16

15

19

20

21

44

24

25

38

39

38

39

28

37

29

18

2

31

33

34

35

27

35

42

37

38

26

8

35

39

39

22

41

31

32

Ersatzteilliste

32

49 Temperaturfühler 1 44.954 1

Position Bezeichnung Stck. Art.-Nr.Position Bezeichnung Stck. Art.-Nr.

Page 33

33

Kränzle therm E-ST 18/24 kW Heiz- und Elektromodul

Position Bezeichnung Stck. Art.-Nr.

1 Heizungsgehäuse VA 1 44.746

2 Chemiepumpe 1 15.038 7

3 Kabelkanal 1 44.749

4 Thermostat 0 – 90 Grad 1 44.619

5 Moosgummidichtung 1 44.755 1

6 Andrückblech 1 44.754 1

7 Verdrahtungsbrücke 3 44.714

8 Deckel für Heizungsgehäuse VA 1 44.750

9 Lüfter 1 44.626

10 Leitungsschutzschalter AEG B32 bei 18/36 kW 1 44.616

10.1 Leitungsschutzschalter AEG B40 bei 24 kW 1 44.616 1

11 Schütz DIL M32 230V 50Hz 1 44.621 1

12 Sicherungsautomaten 16A 1 44.617

13 Hutschiene 1 44.751

14 Usit-Ring 1 12.387

15 Ermetoverschraubung Winkel 2 44.865

16 Eingangsteil 1 44.394

17 Zentrierblech 3 Heizstäbe 1 44.756

18 Elektroheizstäbe 1x6KW bei 18 kW 1 44.600

18 Elektroheizstäbe 1x8kW bei 24kW 1 44.601

18 Elektroheizstäbe 3x6KW bei 18 kW 1 44.602

18 Elektroheizstäbe 3x8kW bei 24kW 1 44.603

19 Ausgangsteil Pumpe 1 44.215

20 Ermeto T-Stück 1 44.869

21 Hochdruckschlauch 1 44.702

22 Fernauslöser 1 44.618

23 Zahnscheibe Ø 4,3mm 11 43.471

24 Usit-Ring 16,7 x 24 x 1,5 1 12.129

25 Hydrospeicher 1 44.140

26 Unteres Halterohr 1 44.752

27 Gewindestange Edelstahl M8 2 44.624 1

28 Obere Halterohr 1 44.753

29 Abstandsrohr 1 44.625

30 Schlauchschelle SGS 20-32/9 2 44.054 1

31 PG 13,5 2 44.663

32 PG 9 1 43.034

33 Schraube M8 x 70 2 44.621

34 Kreuzschlitz M4 x 10 15 43.470

35 Unterlegscheibe Ø 4,3 mm 25 43.472

36 Federring Ø 4,3 mm 9

37 Mutter M8 Niedrigbauform 10 14.127 2

38 Federring DIN 128 – A8 10 44.222

39 Unterlegscheibe Ø 8,4 mm 10 41.409

40 Mutter M4 Niedrigbauform 24 44.755

41 PE Klemme 1 44.048

42 Keramikhülse 6 44.756

43 Schraube M8 x 35 2 40.135

44 Anschlußmuffe für Hydrospeicher 1 44.140 1

45 Hauptschalter 63 A 1 44.622

46 PG 29 Verschraubung 1

47 PG 36/29 Reduzierung 1

48 PG 36 Mutter 1

Position Bezeichnung Stck. Art.-Nr.

Page 34

22

49

30

30

45

46

48

1

38

37

39

40

36

7

40

36

6

5

4

3

34

35

34

36

40

9

10

11

12

34

13

38

37

38

14

43

40

16

15

19

20

21

44

24

25

37

38

39

38

39

28

37

29

18

2

31

33

34

35

27

35

42

37

38

26

8

35

39

39

22

41

31

32

11

18

Ersatzteilliste

34

Page 35

35

Kränzle therm E-ST 36/48 kW Heiz- und Elektromodul

Position Bezeichnung Stck. Art.-Nr.

1 Heizungsgehäuse VA 1 44.746

2 Chemiepumpe 1 15.038 7

3 Kabelkanal 1 44.749

4 Thermostat 0 – 90 Grad 1 44.619

5 Moosgummidichtung 1 44.755 1

6 Andrückblech 1 44.754 1

7 Verdrahtungsbrücke 6 44.714

8 Deckel für Heizungsgehäuse VA 1 44.750

9 Lüfter 1 44.626

10 Leitungsschutzschalter AEG B32 bei 18/36 KW 2 44.616

10.1 Leitungsschutzschalter AEG B40 bei 48kW 2 44.616 1

11 Schütz DIL M32 230V 50Hz 2 44.621 1

12 Sicherungsautomaten 16A 1 44.617

13 Hutschiene 1 44.751

14 Usit-Ring 1 12.387

15 Ermetoverschraubung Winkel 2 44.865

16 Eingangsteil 1 44.394

17 Zentrierblech 6 Heizstäbe 1

18 Elektroheizstäbe 36kW 6 x 6 1 44.604

18 Elektroheizstäbe 48kW 6 x 8 1 44.605

19 Ausgangsteil Pumpe 1 44.215

20 Ermetoverschraubung T-Stück 2xErmeto; 1xMutter 1 44.869

21 Hochdruckschlauch 1 44.702

22 Fernauslöser 2 44.618

23 Zahnscheibe Ø4,3mm 11 43.471

24 Usit-Ring 16,7 x 24 x 1,5 1 12.129

25 Hydrospeicher 1 44.140

26 Unteres Halterohr 1 44.607

27 Gewindestange Edelstahl M8 2 44.624 1

28 Obere Halterohr 1 44.625 1

29 Abstandsrohr 1 44.625

30 Schlauchschelle SGS 20-32/9 2 44.054 1

31 PG 13,5 2 44.663

32 PG 9 1 43.034

33 Schraube M8 x 70 2 44.621

34 Kreuzschlitz M4 x 10 15 43.470

35 Unterlegscheibe Ø 4,3 mm 46 43.472

36 Federring Ø 4,3 mm 18

37 Mutter M8 Niedrigbauform 10 14.127 2

38 Federring DIN 128 – A8 10 44.222

39 Unterlegscheibe Ø 8,4 mm 10 41.409

40 Mutter M4 Niedrigbauform 39 44.755

41 PE Klemme 1 44.048

42 Keramikhülse 12 44.756

43 Schraube M8 x 35 3 40.135

44 Anschlußmuffe für Hydrospeicher 1 44.140 1

45 Hauptschalter 100 A 1 44.623

46 PG36 Verschraubung 1

48 PG36 Mutter 1

49 Temperaturfühler 1 44.954 1

Position Bezeichnung Stck. Art.-Nr.

Page 36

1

9

10

11

27

60

37

40

48

61

36

32

44

43

29

42

31

12

3

38

28

26

41

73

4

2

53

58

57

56

55

54

51

52

50

59

45

47

46

71

72

53

32

8

13

25

22

21 20

23

24

70

17

14

19

18

5

15

16

Ersatzteilliste

36

61 Magnetspule 1 44.251 1

70 Steuerkolben kpl. mit Handrad 44.209

71 Rep. Satz Druckschaltermechanik

72 Druckschalter ohne Mechanik 44.389

73 Druckschalter schwarz komplett 12.632

Page 37

Kränzle therm 601 und 871 E-ST Unloader und Druckschalter

37

Position Bezeichnung Stck. Art.-Nr.

1 Ventilgehäuse AM-Pumpe 1 40.451

2 O-Ring 15 x 2 6 41.716

3 Ventile für APG-Pumpe 6 41.715 1

4 O-Ring 15 x 2 6 13.150

8 Verbindungsstück 1/8“ IG x 1/8“ IG 1

9 Dichtring 1 40.019

10 Stopfen 1 40.018 1

11 Doppelnippel 1 44.251 2

12 Magnetventil 1 44.251

13 Schlaucheinbindung NW 4,8 1 12.032 A

14 Steuerkolben 1 14.134

15 Parbaks 16 mm 1 13.159

16 Parbaks 8 mm 1 14.123

17 Spannstift 1 14.148

18 Kolbenführung spezial 1 42.105

19 Mutter M 8 x 1 2 14.144

20 Ventilfeder schwarz 1 14.125

21 Federdruckscheibe 1 14.126

22 Nadellager 1 14.146

23 Handrad AM-Pumpe 1 40.457

24 Kappe Handrad AM-Pumpe 1 40.458

25 Sicherungsmutter M8 x 1 1 14.152

26 Edelstahlsitz 1 14.118

27 Sprengring 1,3 x 15,5 1 13.147

28 O-Ring 11 x 1,44 1 12.256

29 Überwurfmutter PG11 2 15.203

31 Ventilstopfen 4 42.026

32 Ventilstopfen mit R1/4“ IG 2 42.102

36 Chemieschlauch 1

37 Edelstahlkugel 8,5 mm 1 13.148

38 Edelstahlfeder 1 14.119

40 O-Ring 13,94 x 2,62 1 42.167

41 Druckschalter Blindstopfen 1 44.551

42 Gehäuse Elektroschalter schwarz 1 15.007

43 Mikroschalter 2 44.262

44 Deckel Elektroschalter (sw) 2 15.008

45 O-Ring 44 x 2,5 2 15.023

46 Blechschraube 2,9 x 19 12 15.024

47 Sechskant-Mutter M4 4 15.026

48 Zylinderschraube M4 x 20 4 15.025

50 O-Ring 3,3 x 2,4 2 12.136

51 Führungsteil Steuerstößel 2 15.009 1

52 O-Ring 13 x 2,6 2 15.017

53 O-Ring 14 x 2 2 43.445

54 Parbaks 4 mm 2 12.136 2

55 Stützscheibe 2 15.015 1

56 Edelstahlfeder 2 15.016

57 Steuerstößel 2 15.010

58 Parbaks 7 mm 1 15.013

59 Stopfen M 10 x 1 (durchgebohrt) 2 13.385 1

60 Verschlussschraube 1 14.113

Page 38

24

36

12

8

13

1

9

10

11

27

37

40

48

32

44

43

29

42

31

17

14

22

21 20

19

18

5

15

16

2325

3

38

28

26

73

4

2

53

58

57

56

55

54

51

52

50

59

45

47

46

71

72

70

50

53

58

57.1

56

55

54

51

52

59

54

55

71

74

29

48

44.1

43

42.1

45

47

46

71

Ersatzteilliste

38

57.1 Steuerstößel lang 1 15.010 2

58 Parbaks 7 mm 3 15.013

59 Stopfen M 10 x 1 (durchgebohrt) 2 13.385 1

70 Steuerkolben kpl. mit Handrad 44.209

71 Rep. Satz Druckschaltermechanik

72 Druckschalter ohne Mechanik 44.389

73 Druckschalter schwarz komplett 12.632

74 Druckschalter ohne Mechanik rot

Page 39

Kränzle therm 891 E-ST 48 Unloader und Druckschalter

39

Position Bezeichnung Stck. Art.-Nr.

1 Ventilgehäuse AQ-Pumpe 1 40.503 4

2 O-Ring 18 x 2 6 40.016

3 Ein/Auslaßventil 6 42.029

4 O-Ring 21 x 2 6 42.025

5 O-Ring 16 x 2 1 13.150

9 Kupfer Dichtring 21 x 28 x 1,5 1 42.039

8 Verbinder 1/8“ IG x 1/8“ IG 1

10 Nippel 1

11 Doppelnippel 1 44.251 2

12 Magnetventilkörper 1 44.251

13 Schlaucheinbindung NW4,8 1 12.032 A

14 Steuerkolben 1 14.134

15 Parbaks 16 mm 1 13.159

16 Parbaks 8 mm 1 14.123

17 Spannstift 1 14.148

18 Kolbenführung Spezial 1 42.105

19 Mutter M 8 x 1 2 14.144

20 Ventilfeder schwarz 1 14.125

21 Federdruckscheibe 1 14.126

22 Nadellager 1 14.146

23 Handrad AQ-Pumpe 1 14.147

24 Magnetspule 1 44.251 1

25 Sicherungsmutter M8 x 1 1 14.152

26 Edelstahlsitz 1 14.118

27 Sprengring 1,3 x 15,5 1 13.147

28 O-Ring 11 x 1,44 1 12.256

29 Überwurfmutter PG 11 3 15.203

31 Ventilstopfen 4 42.026

32 Ventilstopfen mit R1/4“ IG 2 42.026 2

36 Chemieschlauch 1

37 Edelstahlkugel 8,5 mm 1 13.148

38 Edelstahlfeder 1 14.119

40 O-Ring 13,94 x 2,62 1 42.167

41 Druckschalter Blindstopfen 1 14.113

42 Gehäuse Elektroschalter schwarz 1 15.007

42.1 Gehäuse Elektroschalter rot 1 15.007 1

43 Mikroschalter 3 44.262

44 Deckel Elektroschalter (sw) 2 15.008

44.1 Deckel Elektroschalter (rot) 1 15.008 1

45 O-Ring 44 x 2,5 3 15.023

46 Blechschraube 2,9 x 19 18 15.024

47 Sechskant-Mutter M4 6 15.026

48 Zylinderschraube M4 x 20 6 15.025

49 Druckfeder 1 x 8,6 x 30 1 40.520

50 O-Ring 3,3 x 2,4 3 12.136

51 Führungsteil Steuerstößel 3 15.009 1

52 O-Ring 13 x 2,6 3 15.017

53 O-Ring 14 x 2 3 43.445

54 Parbaks 4 mm 4 12.136 2

55 Stützscheibe 4 15.015 1

56 Edelstahlfeder 3 15.016

57 Steuerstößel 2 15.010

Page 40

40

13

14

15

16

23

18

24

14

20

23

27

9

2

12

8

11

35

26

33

34

37

1

25

10

3

Ersatzteilliste -

Ventilgehäuse

Kränzle therm 601 E-ST 18/24/36,

Kränzle therm 871 E-ST 48

Position Bezeichnung Stck. Art.-Nr.

1 Dichtring 17 x 22 x 1,5 (Kupfer) 1 40.019

2 Stopfen 3/8“ 1 40.018

3 Ansaugschlauch mit Nippel R 1/4“ 2 44.096 4

8 Dichtstopfen M10 x 1 2 43.043

9 Dichtstopfen M8 x 1 2 13.158

10 Sicherungsring 4 40.032

11 Innensechskantschraube M12 x 45 4 40.504

12 Ausgangsteil Pumpe R 1/4“ x 12 1 44.215

13 Gewebemanschette 20 mm 3 40.023

14 Backring 20 mm 6 40.025

15 O-Ring 31,42 x 2,62 3 40.508

16 Leckagering 20 mm 3 40.509

18 Manschette 20 mm 3 40.512

20 Distanzring mit Abstützung 3 40.507

23 Druckring 20 mm 6 40.021

24 Zwischenring 20 mm 3 40.516

25 O-ring 11 x 1,5 1 12.256

26 Edelstahlsitz Ø 7 mm 1 14.118

27 Sprengring 1 13.147

33 Ausgangsteil 1 40.522

34 Edelstahlkugel 1 12.122

35 Rückschlagfeder „K“ 1 14.120 1

37 O-Ring 18 x 2 1 43.446

Page 41

1 Dichtring 17 x 22 x 1,5 (Kupfer) 1 40.019

2 Stopfen 3/8“ 1 40.018

8 Dichtstopfen M10 x 1 2 43.043

9 Dichtstopfen M8 x 1 2 13.158

10 Sicherungsring 4 40.032

11 Innensechskantschraube M12 x 45 4 40.504

12 Ausgangsteil Pumpe R 1/4“ x 12 1 44.215

13 Gewebemanschette 20 mm 3 40.023

14 Backring 20 mm 6 40.025

15 O-Ring 31,42 x 2,62 3 40.508

16 Leckagering 20 mm 3 40.509

18 Manschette 20 mm 3 40.512

20 Distanzring mit Abstützung 3 40.507

23 Druckring 20 mm 6 40.021

24 Zwischenring 20 mm 3 40.516

25 O-ring 11 x 1,5 1 12.256

26 Edelstahlsitz Ø 7 mm 1 14.118

27 Sprengring 1 13.147

33 Ausgangsteil 1 40.522

34 Edelstahlkugel 1 12.122

35 Rückschlagfeder „K“ 1 14.120 1

37 O-Ring 18 x 2 1 43.446

38 Kupfer-Dichtring 17 x 22 x 1,5 2 40.019

39 Sauganschluss 3/8“ AG x 3/4“ AG 1 41.016

40 O-Ring 13 x 2,6 1 13.272

41 Ansaugschlauch 1 44.096 2

42 Verschlußstopfen 1 40.051

Pos. Bezeichnung Stck. Art.-Nr.

41

Ersatzteilliste -

Ventilgehäuse

Kränzle therm 891 ES-T 48

42

38

13

14

15

16

23

18

24

14

20

23

27

9

2

12

8

11

35

26

33

34

37

1

25

10

41

40

39

38

Page 42

12

13 14

15

20

19

18

17

7

1

4

5

6

8

9

10

11

21

16

Position Bezeichnung Stck. Art.-Nr.

Ersatzteilliste -

Pumpenantrieb

Kränzle therm 601 E-ST 18/24/36,

therm 871 E-ST 48

1 Ölgehäuse mit Öldichtungen 1 40.452

4 Innensechskantschraube M 8 x 25 6 40.053

5 Sicherungsscheibe 6 40.054

6 Flachdichtung 1 40.511

7 Öldichtung 18 x 28 x 7 3 41.031

8 Wellenscheibe 1 40.043

9 Axial-Rollenkäg 1 40.040

10 AS-Scheibe 1 40.041

11 Taumelscheibe 10,8° für 871 1 40.460-10,8

11.1 Taumelscheibe 7,66° für 601 1 40.460-7,66

12 Plungerfeder 3 40.506

13 Federdruckscheibe 3 40.454

14 Plunger 18 mm (AM-Pumpe) 3 40.455

15 Sprengring 3 41.035

16 O-Ring 14 x 2 2 43.445

17 Verschlussschraube M 18 x 1,5 1 41.011

18 Flachdichtung 1 41.019 3

19 Deckel 1 41.023 1

20 Innensechskantschraube M 5 x 12 4 41.019 4

21 Ölmessstab (AM-Pumpe) 1 40.461

Ölgehäuse AM kpl. 40.452 1

Pos. 1, 4-7, 12-17

42

Page 43

1 Ölgehäuse 1 40.501

4 Innensechskantschraube M 8 x 30 6 41.036 1

5 Sicherungsscheibe 6 40.054

6 Flachdichtung 1 40.511

7 Öldichtung 20 x 30 x 7 3 40.044 1

9 Axial-Zylinderrollenlager AQ-Pumpe 1 40.524

11 Taumelscheibe 10,8° 1 40.523-10,8

12 Plungerfeder 3 40.506

13 Federdruckscheibe 3 40.510

14 Plunger 20 mm (lang) 3 40.505

15 Sprengring 3 40.048

16 O-Ring 14 x 2 1 43.445

18 Flachdichtung 1 41.019 3

19 Deckel 1 41.023 1

20 Innensechskantschraube M 5 x 12 4 41.019 4

21 Ölmessstab 1 40.461

22 Stützscheibe für Plungerfeder 3 40.513

26 Einschraubwinkel 3/8“ x 3/8“ 1 44.127

Ölgehäuse AQ kpl. 40.514

Pos. 1, 4-7, 12-17, 22

Position Bezeichnung Stck. Art.-Nr.

43

Ersatzteilliste -

Pumpenantrieb

Kränzle therm 891 ES-T 48

21

12 13 14 15

20

19

18

7

1

4

5

6

22

16

9

11

Page 44

Position Bezeichnung Stck. Art.-Nr.

1 Stator BG100 2,3kW 230V / 50Hz 1 40.720

Stator BG100 4,8kW 400V 7 50Hz 1 40.710

2 A-Lager Flansch 1 40.700

3 Rotor BG100 230V / 50Hz 1 40.703 1

Rotor BG 100 400V / 50Hz 1 40.703

4 Lüfterrad BG100 1 40.702

5 Lüfterhaube BG 100 1 40.701

6 Klemmkasten 1 40.534

7 Flachdichtung 1 43.030

8 Lüsterklemme 2,5 mm² 4-polig 1 43.031 1

9 PG-Verschraubung PG 13,5 1 40.539

10 Schrägkugellager 7306 1 40.704

11 Öldichtung 35 x 47 x 7 1 40.080

12 Passfeder 8 x 7 x 28 1 40.459

13 Kugellager 6206 - 2Z 1 40.538

14 Innensechskantschraube M 6 x 30 4 43.037

15 Toleranzhülse 1 40.544 1

16 Blechschraube 2,9 x 16 1 43.036

17 V-Seal 1 40.545

19 Schraube M 4 x 12 4 41.489

20 Schelle für Lüfterrad BG100 2 40.535

21 Schraube M 4 x 12 4 41.489

22 Erdungsschraube kpl. 1 43.038

44

12

133

194 20

17

5

1

2

6

7

89

10 11

14

1621

22

Ersatzteilliste -

Motor

Kränzle therm 601 E-ST 18/24/36,

therm 871 E-ST 48

Page 45

45

Ersatzteilliste -

Motor

Kränzle therm 891 E-ST 48

1 Stator 112 5,5 kW 400V / 50Hz 1 40.540

2 A-Lager Flansch 1 40.530

3 Rotor 112 400V / 50Hz 1 40.531 5

4 Lüfterrad BG112 1 40.532

5 Lüfterhaube BG 112 1 40.533

6 Klemmkasten 1 40.534

7 Flachdichtung 1 43.030

8 Lüsterklemme 2,5 mm² 4-polig 1 43.031 1

9 PG-Verschraubung PG 13,5 1 40.539

10 Kegelrollenlager 31306 1 40.103

11 Öldichtung 35 x 47 x 7 1 40.080

12 Passfeder 8 x 7 x 28 1 40.459

13 Kugellager 6206 - 2Z 1 40.538

14 Innensechskantschraube M 6 x 30 4 43.037

15 Toleranzhülse 1 40.544 1

16 Blechschraube 2,9 x 16 1 43.036

17 V-Seal 1 40.545

19 Schraube M 4 x 12 4 41.489

20 Schelle für Lüfterrad BG112 2 40.535

21 Schraube M 4 x 12 4 41.489

22 Erdungsschraube kpl. 1 43.038

Position Bezeichnung Stck. Art.-Nr.

12

133

194 20

17

5

1

2

6

7

89

10 11

14

1621

22

Page 46

46

61

15

3

2

7

23

10

34

4

38

40

5

14

9

6

42

39

41

35

1

12

13

21

22

11

45

46

37

36

60

59

56

57

58

53

52

51

50

55

54

Ersatzteilliste

Page 47

Kränzle therm E-ST

Ventilgehäuse und Sicherheitsventil

47

Position Bezeichnung Stck. Art.-Nr.

1 Ventilkörper 1 14.145

2 Einschraubwinkel 1 40.1213

3 Schlauchtülle 1/4“ x 6 1 44.053

4 Ermetoverschraubung R 3/8“ x 12 mm 1 40.076

5 Ausgangsstück „K“ R3/8“ IG 1 14.115 1

6 Ermetoverschraubung R3/8“ 12mm 1 44.365

7 Chemieschlauch 1 44.104

9 Stopfen M 10 x 1 1 13.275

10 Spanstift 1 14.148

11 Steuerkolben 1 14.133

12 O-Ring 1 13.150

13 Kolbenführung 1 14.130

14 Parbaks 16 mm 1 13.159

15 Parbaks 8 mm 1 14.123

21 Ventilfeder 1 14.125

22 Federdruckscheibe 1 14.126

23 Sechskantmutter M 8 x 1 2 14.144

34 Stopfen R1/4“ 1 13.387

35 O-Ring 11 x 1,44 1 12.256

36 Edelstahlsitz 1 14.118

37 Sprengring 1 13.147

38 Edelstahlkugel 8,5 mm 1 13.148

39 Edelstahlfeder 1 14.119

40 O-Ring 15 x 2 1 13.150

41 Eingangsstück R3/8“ 1 13.136

42 O-Ring 1 13.150

45 Winkelverschraubung 1 44.062

46 Druckmessleitung 1 44.102 1

50 Eingangsteil M18 x 1,5“ x 12L 1 44.364

51 Magnetschalter 1 40.564 2

52 Abdeckung 1 12.603

53 Schraube M 4 x 8 4 44.216

54 Hochdruckschlauch 1 44.702 1

55 Ausgangsteil 1/4“ 1 44.394

56 O-Ring 14 x2 1 43.445

57 Druckfeder Strömungswächter 1 14.217

58 Strömungskörper mit Zapfen für Feder 1 14.218

59 Anschlagstopfen mit Zapfen und Strömungswächter 1 14.219

60 Strömungskörper incl. Stopfen und Feder 1 14.218

61 Druckschalter kpl Rot 1 44.389 1

Steuerkolben kpl. Pos. 10-15; 21-23 14.110 1

Sicherheitsventli kpl. Pos. 1-45 44.205

Page 48

14

2

10

12

23

30

22

21

1

4

39

3

39

5

5

6

7

31

Position Bezeichnung Stck. Art.-Nr.

1 Frontplatte Elektrik 891 1 44.042

2 Frontplatte Manometer 1 44.043

3 Bedienteil 1 44.257

4 Manometer 601 – 871 250bar 1 15.039 1

4.1 Manometer 891 400bar 1 15.039 4

5 Schraube M 5 x 14 10 40.536

6 Unterlegscheibe Ø 5,3 mm 4 40.135

7 Mutter M 5 4 44.113 1

10 Sicherungsmutter M 4 4 40.111

12 Klemmrahmen mit Schalterabdichtung 1 41.110 5

14 Kunststoffschraube 3,5 x 9,5 2 41.088

21 Klemmbügel für Manometer 1 44.049

22 Hauptschalter 1 40.046

23 Heizungsschalter 1 41.111 6

30 Anschlussmuffe Manometer 1 44.136

31 Druckmeßleitung 1 44.102 1

39 Chemieschalter kpl. 1 44.620

48

Ersatzteilliste -

Konsole

Kränzle therm 601 E-ST 18/24/36,

therm 871 E-ST 48; therm 891 E-ST 48

Page 49

3

9

4

9

5

7

1

2

4

8

8

10

Ersatzteilliste -

Konsole

Kränzle therm 601 E-ST 18/24/36,

therm 871 E-ST 48; therm 891 E-ST 48 kW

Position Bezeichnung Stck. Art.-Nr.

1 Schütz 400V 1 46.005 1

2 Gummidichtung Elektrik 1 44.044

3 Steuerplatine 1 44.255

4 Klemme Wago 2,5mm² 10 44.047

5 Hutschiene 50 mm 2 44.125 1

7 Hutschiene 30 mm 1 44.125 2

8 Erdungsklemme Wago 2,5mm² 3 44.048

9 Blechschraube 3,9 x 9,5 10 41.636

10 Überstromauslöser 12,5A 601-871 1 42.641 2

10.1 Überstromauslöser 16A 891 1 42.641

49

Page 50

3

4

5

2

9

20

17

15

11

1

6

14

15

18

19

13

3

12

8

7

10

21

18

19

16

22

Position Bezeichnung Stck. Art.-Nr.

1 Konsolenblech 1 47.122

2 Schaltkasten 1 47.123

3 PG 16 Verschraubung 4 40.145

4 Verschraubung M20 2

5 PG 9 Verschraubung (3-teilig) 1 43.034

6 Leistungsrelais 1 41.438 1

7 Klemme Wago 2,5 mm² 6 44.047

8 Erdungsklemme Wago 2,5mm² 2 44.048

9 Klemme Wago 2,5 mm² 11 44.047

10 Kabelkanal 1

12 Gegenmutter für M20 Verschraubung 2

13 Federring M20 1

14 Mutter M6 1 14.127 1

15 Kreuzschlitzschraube M4 x 12 6 41.489

16 Sicherung 1 44.166

17 Klemmschiene 125mm 1 44.125

18 Mutter M4 6 12.138

19 Zahnscheibe Ø 3,2mm 4

20 Sechskantschraube M6 x 20 1

21 Gegenmutter für PG 16 Verschraubung 4 44.119

22 Unterlegscheibe Ø 6,4 2 50.189

50

Ersatzteilliste -

Konsolengehäuse

Kränzle therm 601 E-ST 18/24/36,

therm 871 E-ST 48; therm 891 E-ST 48kW

Page 51

1 Ventilkörper mit Handgriff 1 12.294

2 Schutzhülse 1 12.295

3 Abdeckschutz 1 12.296

4 Betätigungshebel grau 1 12.298 3

5 Sicherungshebel 1 12.149

6 Abschlussschraube M 16 x1 1 12.247

7 Stopfen 1 12.287

8 Gewindeführungshülse Ø3 R 1/4“ AG 1 12.250 1

9 Aufsteuerbolzen Ø3 1 12.284 1

10 Stift 1 12.148

11 Lagernadel 1 12.253

12 Edelstahlfeder 1 12.246

13 Edelstahlkugel 8,5 1 12.245

14 Edelstahlsitz Ø7 1 14.118

15 O-Ring 11 x 1,44 1 12.256

16 O-Ring 2,84 x 2,62 1 12.136 1

17 Blechschraube 3,9 x 8,5 4 41.079

18 Druckstück 1 12.252

19 Rohr kunststoffumspritzt bds. R 1/4“ AG 1 15.004 5

20 Überwurfmutter ST 30 M22 x 1,5 IG 1 13.276 1

21 Außen-Sechskant-Nippel R 1/4“ IG 1 13.277 1

22 O-Ring 9,3 x 2,4 1 13.273

23 Aluminium-Dichtring 4 13.275

24 O-Ring 15 x 1,5 1 12.129 1

25 Sicherungsring 1 12.258

26 Gleitschuh Ø3 1 12.289 1

51 Düsenschutz 1 26.002

52 Rohr 600 mm; bds. R1/4“ 1 12.385 2

53 ST 30 Nippel M 22 x 1,5 / R1/4” m. ISK 1 13.370

54 Flachstrahldüse 2504 (bei quadro 800) 1 D2504

54.1 Flachstrahldüse 2505 (bei quadro 1000) 1 D2505

54.2 Flachstrahldüse 2507 (bei quadro 1200) 1 D2507

Ersatzteilliste

Kränzle E-ST

Pistole 'Starlet'

Position Bezeichnung Stck. Art.-Nr.

51

-12

53

22

21

20

23

19

23

54

51

52

1

2

3

4

5

6

8

16

10

11

12

7

13

14

15

9

17

18

25

24

26

Page 52

Pipeline plan

1 Float valve, water inlet

2 Water tank

3 Control valve, detergent

4 High pressure pump with integrated unloader valve

5 Safety valve for heating coil

6 Excess pressure line, safety valve

7 Flow monitoring device

8 Heating elements

Safety valve, number 5 must be set approx. 15 % higher than

the unloader valve on the HP pump

52

Page 53

Kränzle therm E-ST

Wiring diagram 18 / 24 kW

53

Page 54

Kränzle therm E-ST

Wiring diagram 36 / 48 kW

54

Page 55

Inspection report for HP cleaners

Type plate (on hand)

Operating manual (on hand)

Protective covering, -device

Pressure line (tightness)

Pressure gauge (function)

Float valve (tightness)

Spraying device (marking)

HP-hose/ connector (damage, marking)

Safety valve opens at 10% / 20% excess

Pressure reservoir

Heating oil line (tightness)

Solenoid valve (function)

Thermostat (function)

Flow controller (function)

Power cable (damage)

Power plug (damage)

Protective conductor (connected)

Emergency Off Switch (function)

On/Off-switch

Water quantity safety device (function)

Used chemicals

Allowed chemicals

Inspection report on annually carried out Labour Safety Inspection (UVV) according to the

Guidelines for Liquid Spray Equipment. (This inspection sheet serves as proof for the completion of

the retest and must be kept carefully!) Kränzle-Test Stamp Mark: Order Number UVV200106

Scope of inspection:

ok yes no repaired

Inspection data

determ. value set value

Owner:

Address:

Type therm:

Serial no.:

Rep.-order-no.:

The appliance was checked by an expert according to the Guidelines for Liquid Spray

Equipment, the defects found have been rectified so that the Labour Safety can be confirmed

.

The appliance was checked by an expert according to the Guidelines for Liquid Spray

Equipment. The Labour Safety cannot be confirmed unless the defects found are rectified by

repair or replacement of the faulty parts

.

The next retest according to the Guidelines for Liquid Spray Equipment has to be carried out

by:

Month Year

Place, Date Signature

Inspection result (tick)

High-pressure nozzle

Operating pressure ................bar

Cutting-off pressure................bar

Efficiency rating......................%

Conductor resist. not exceeded / value:

Insulation

Leakage current:

Gun locked

55

Page 56

Inspection report for HP cleaners

Type plate (on hand)

Operating manual (on hand)

Protective covering, -device

Pressure line (tightness)

Pressure gauge (function)

Float valve (tightness)

Spraying device (marking)

HP-hose/ connector (damage, marking)

Safety valve opens at 10% / 20% excess

Pressure reservoir

Heating oil line (tightness)

Solenoid valve (function)

Thermostat (function)

Flow controller (function)

Power cable (damage)

Power plug (damage)

Protective conductor (connected)

Emergency Off Switch (function)

On/Off-switch

Water quantity safety device (function)

Used chemicals

Allowed chemicals

Inspection report on annually carried out Labour Safety Inspection (UVV) according to the

Guidelines for Liquid Spray Equipment. (This inspection sheet serves as proof for the completion of

the retest and must be kept carefully!) Kränzle-Test Stamp Mark: Order Number UVV200106

Scope of inspection:

ok yes no repaired

Inspection data

determ. value set value

Owner:

Address:

Type therm:

Serial no.:

Rep.-order-no.:

The appliance was checked by an expert according to the Guidelines for Liquid Spray

Equipment, the defects found have been rectified so that the Labour Safety can be confirmed

.

The appliance was checked by an expert according to the Guidelines for Liquid Spray

Equipment. The Labour Safety cannot be confirmed unless the defects found are rectified by

repair or replacement of the faulty parts

.

The next retest according to the Guidelines for Liquid Spray Equipment has to be carried out

by:

Month Year

Place, Date Signature

Inspection result (tick)

High-pressure nozzle

Operating pressure ................bar

Cutting-off pressure................bar

Efficiency rating......................%

Conductor resist. not exceeded / value:

Insulation

Leakage current:

Gun locked

56

Page 57

Inspection report for HP cleaners

Type plate (on hand)

Operating manual (on hand)

Protective covering, -device

Pressure line (tightness)

Pressure gauge (function)

Float valve (tightness)

Spraying device (marking)

HP-hose/ connector (damage, marking)

Safety valve opens at 10% / 20% excess

Pressure reservoir

Heating oil line (tightness)

Solenoid valve (function)

Thermostat (function)

Flow controller (function)

Power cable (damage)

Power plug (damage)

Protective conductor (connected)

Emergency Off Switch (function)

On/Off-switch

Water quantity safety device (function)

Used chemicals

Allowed chemicals

Inspection report on annually carried out Labour Safety Inspection (UVV) according to the

Guidelines for Liquid Spray Equipment. (This inspection sheet serves as proof for the completion of

the retest and must be kept carefully!) Kränzle-Test Stamp Mark: Order Number UVV200106

Scope of inspection:

ok yes no repaired

Inspection data

determ. value set value

Owner:

Address:

Type therm:

Serial no.:

Rep.-order-no.:

The appliance was checked by an expert according to the Guidelines for Liquid Spray

Equipment, the defects found have been rectified so that the Labour Safety can be confirmed

.

The appliance was checked by an expert according to the Guidelines for Liquid Spray

Equipment. The Labour Safety cannot be confirmed unless the defects found are rectified by

repair or replacement of the faulty parts

.

The next retest according to the Guidelines for Liquid Spray Equipment has to be carried out

by:

Month Year

Place, Date Signature

Inspection result (tick)

High-pressure nozzle

Operating pressure ................bar

Cutting-off pressure................bar

Efficiency rating......................%

Conductor resist. not exceeded / value:

Insulation

Leakage current:

Gun locked

57

Page 58

Kränzle therm 601 E-ST 18, 601 E-ST 24,

601 E-ST 36, 871 E-ST 48, 891 E-ST48

Manfred Bauer, Fa. Josef Kränzle

Rudolf-Diesel-Str. 20, 89257 Illertissen

machinery directive 2006/42/EEC,

EMV-directive 2004/108/EEC,

EN 60 335-2-79 :2009

EN 55 014-1 :2006

EN 55 014-2 / A2:2008

EN 61 000-3-2 : 2006

EN 61 000-3-3 : 2008

58

EC declaration of conformity

Hereby we declare that,

technical specifications available from:

comply with the following guidelines

and their amendments for high-pressure

cleaners:

Applied specifications and standards:

I. Kränzle GmbH

Elpke 97

D - 33605 Bielefeld

Bielefeld, 19.04.2012

Kränzle Josef

(Managing director)

Page 59

Guarantee

The guarantee is only valid for material and manufacturing errors.

Wearing does not fall within this gurantee.

The instructions in our operating manual must be complied with..

The operating instructions form part of the guarantee.

T

he guarantee period is 12 month from date of purchase.

In the case of a guarantee please contact your dealer or authorized seller delivering

accessories and your purchase receipt. You can fin them in the internet under

www.kraenzle.com.

The guarantee is also void if the machine is used with exceeding the temperature and

speed limits, a voltage below the required rating, with less than the required amount of

water or with dirty water.

Pressure gauge, nozzle, valves, sleeves, high pressure hose and spray equipment are

wear parts and are not covered by the warranty.

59

Page 60

www.kraenzle.com

Made

in

Germany

As date of 21.07.2014, Order no. 30.244 1

Subject to technical modifications.

Ingrid Kränzle GmbH

Elpke 97

33605 Bielefeld (Germany)

Telefon: +49 (0) 521 / 9 26 26-0

Telefax: +49 (0) 521 / 9 26 26-40

info@kraenzle.com

Loading...

Loading...