Kranzle Therm 870-1, therm 635-1, therm 875-1, therm 895-1, therm 1165-1 Operating Manual

...Page 1

DIN EN

ISO 9001

Operating manual

Hot Water High-Pressure Cleaners

Read and conform safety instructions before use!

- GB -

Page 2

2

therm 870-1

Operating pressure,

continuously adjustable

30 - 170 bar

Admissible overpressure 190 bar

Water output Qmax 870 l/h

Nozzle size, flat jet nozzle

D25045

Hot water output temperature (water supply 12 °C)

max. 80 °C

Steam level max. 140 °C

Heating oil jet - Oil pressure

1,5 Gph-10 bar

Heating oil consumption

at max. heating output

5,3 kg/h = 6,3 l/h

Heating output 55 kW

Exhaust gas mass flow 0,035 kg/s

Fuel tank 25 l

High pressure hose for

machines without hose

drum

10 m

High pressure hose for

machines with hose

drum

20 m

Connected load

400 V, 8,7 A, 50 Hz

Power input P 1 - 4,8 kW

Power output P 2 - 4,0 kW

Weight 220 kg

Dimensions without

reel, L x W x H in mm

1050 x 800 x

1000

Sound level acc. to DIN

45 635

86 dB (A)

Guaranteed sound level L

WA

89 dB (A)

Vibrations at lance ca. 21 N

Recoil at lance

2,2 m/s

2

Order No.

without hose drum

41.340

Order No.

with hose drum

41.340 1

Tecnical data

Permissible tolerance for figures ± 5 % in acc. with VDMA uniform sheet 24411

Page 3

Tecnical data ..........................................................................................................................2

Contents ..........................................................................................................................3

Overview “This is what you have purchased” ............................................................................4

Description of appliance ............................................................................................................5

General rules ..........................................................................................................................6

Safety precautions – accident prevention ..................................................................................7

That's what you have to observe ...........................................................................................9

Kränzle- technology ...............................................................................................................10

Water and cleaning system .............................................................................10

Lance and spray gun ...................................................................................... 11

High pressure hose and spray device ............................................................. 11

Total stop system ............................................................................................12

Pressure control valve – safety valve .............................................................12

Motor protecting switch ..................................................................................12

Thermostat ......................................................................................................12

Heat exchanger ...............................................................................................13

Commissioning ......................................................................................................................14

Usage as a cold water high pressure cleaner .................................................16

Usage as a hot water high pressure cleaner ..................................................17

Steam level .....................................................................................................17

When using detergents ...................................................................................18

Decommissioning - frost protection ..........................................................................................19

Care and Maintenance (weekly/yearly) ..................................................................................20

Changing the oil ..............................................................................................21

Decalcifying the heating coil ...........................................................................21

Fuel System ....................................................................................................22

Ignition electrodes ........................................................................................... 22

Particular rules, directives and inspections ..............................................................................23

Circuit diagramme ....................................................................................................................24

Troubleshooting .....................................................................................................................26

Pipeline plan ........................................................................................................................33

Inspections – inspection reports ..............................................................................................34

EG – Declaration of Conformity ............................................................................................... 36

Guarantee ........................................................................................................................37

Inspection sheet .......................................................................................................................38

3

Contents

Page

Page 4

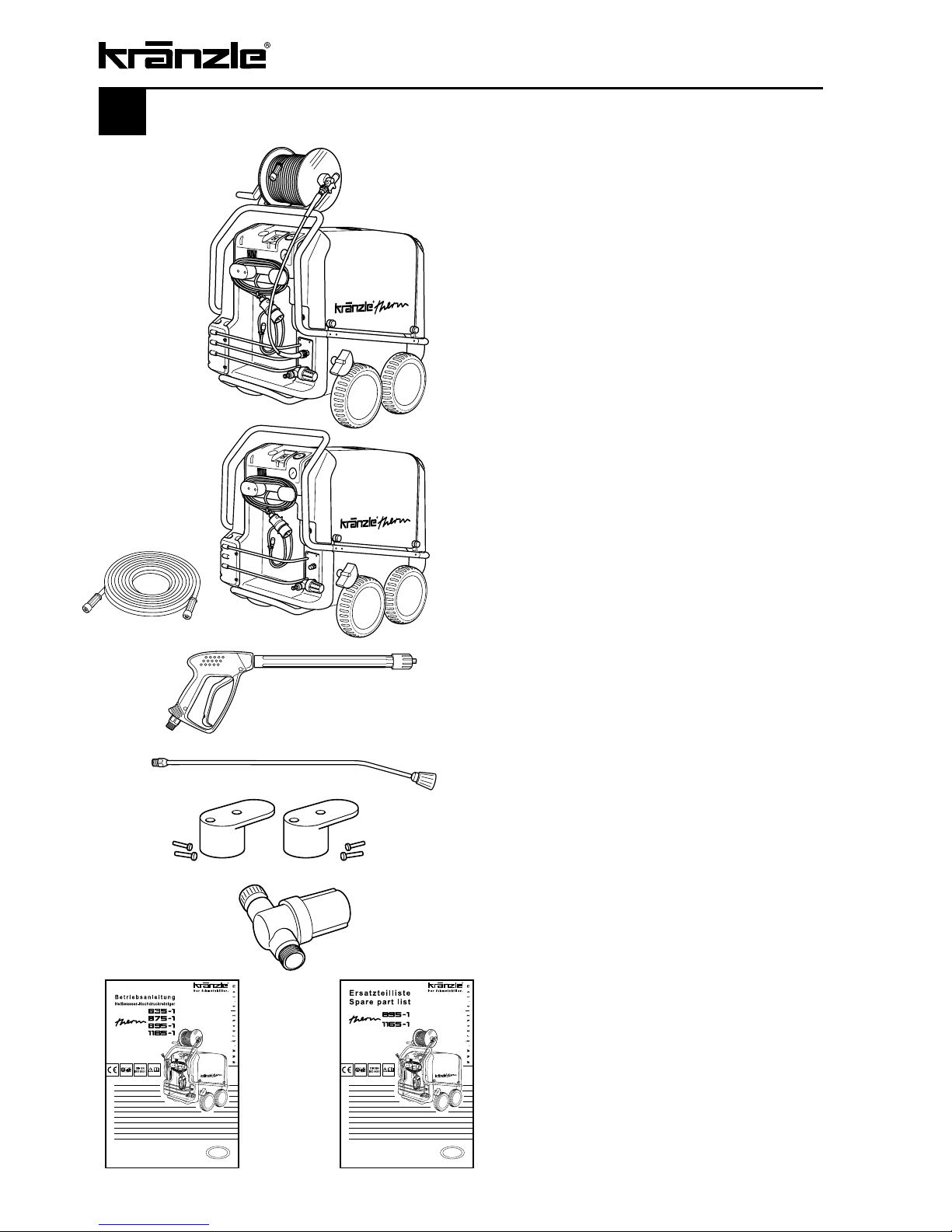

1.

Kränzle high-pressure cleaner therm

with hose drum and 20 m steel-weave

high-pressure hose NW 8

or

Kränzle high-pressure cleaner therm

without hose drum but with 10 m steel-

weave high-pressure hose NW 8

2.

Safety spray gun with insulated handle

and screw connection

6.

Operating manual + Spare parts list

4.

Holding devices for cable with screws

5.

Water intake filter

3.

Lance with flat-jet nozzle

+

4

This is what you have purchased

Page 5

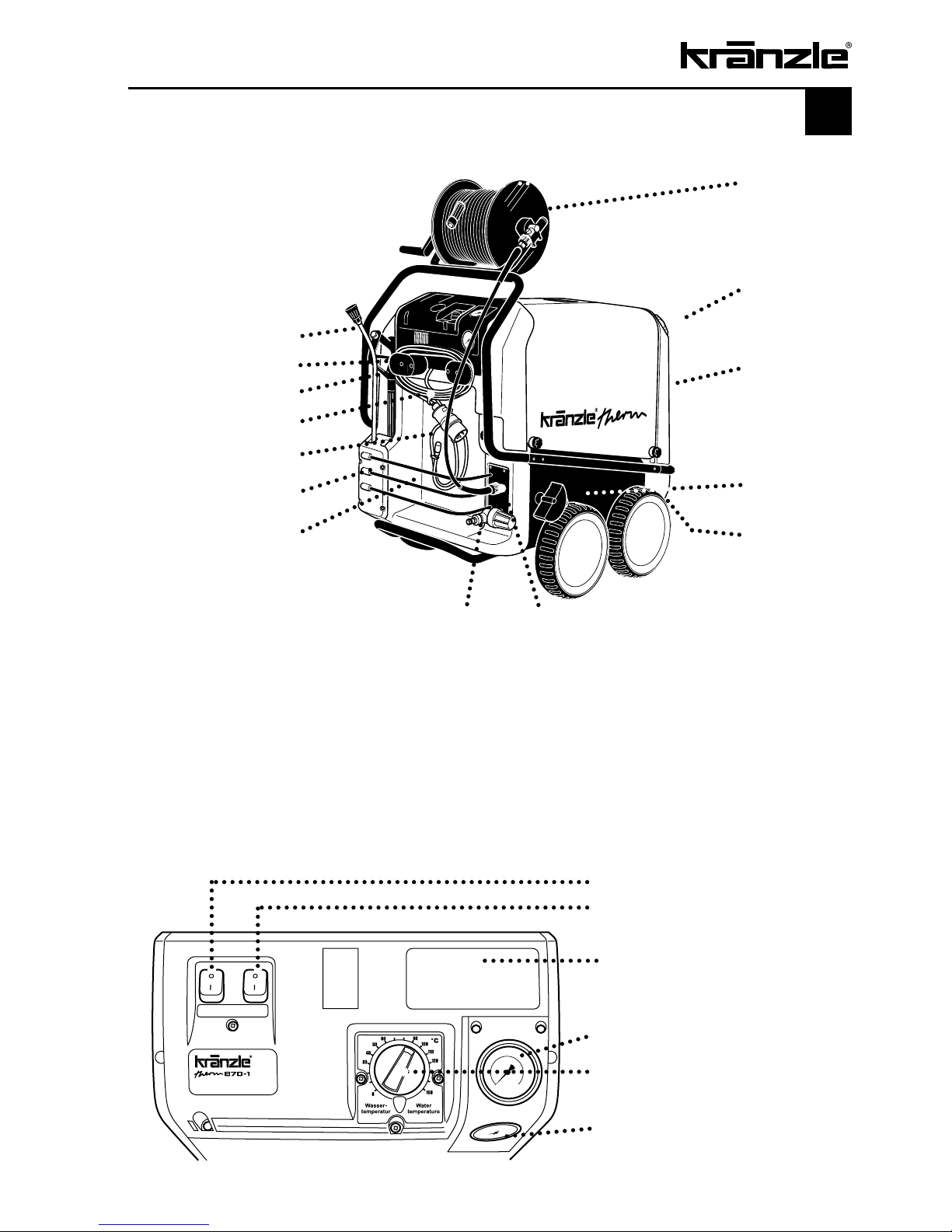

1 Waterinletconnectionwithlter

2 Power cable

3 Winder for cable

4 Suction hose for detergent

5 Hose drum (option)

6 Spray gun

7 Spray pipe attachment

5

Description of appliance

Master switch (appliance ON-OFF)

Heating switch (burner ON/OFF

)

Brief operating instructions

Pressure gauge – water pressure

Digital thermostat for adjusting

water temperature

Pressure gauge - fuel

8 Storage bin for spray gun and pipe

9 Brake

10 Storage bin for accessories

11 Fuel tank

12 Filler aperture for fuel

13 High pressure outlet

14 Fuel drainage screw

5

9

1

13

2

4

6

7

8

10

12

3

11

14

Page 6

Range of application

This machine may only be used for cleaning facades, vehicles, containers, pavement

slabs, stables, machines and smilar objects.

Inspections

The machine must be inspected according to the “Guidelines for Liquid Spray Devices”

at least once every 12 months by a qualified person, to ensure that continued safe

operation is guaranteed. The results of the inspection are to be recorded in writing. This

may be done in any form. For inspection reports see pages 34 - 35.

High-pressure cleaners used for commercial purposes have to be

checked by a qualified person at least every 12 months!

Accident prevention

The machine is designed for accidents to be impossible (if used according to these

instructions). Please read safety notes included in these instructions carefully before

using the machine and act correspondingly. Operating staff has to be instructed according to this manual. The “Guidelines for Liquid Spray Devices” must be complied with.

Setting up - Location

Neither set up and operate the machine in rooms where there is a risk

of fire or explosion nor put it into puddles. Do not use the machine

under water.

During the combustion process air is needed and exhaust gas emerges. If the

machine is operated in a confined space, precautions have to be taken to safely

exhaust the fumes. Furthermore a sufficient ventilation has to be provided for.

Never shut the exhaust gas outlet on top of the machine. Never stoop over this

aperture and never reach into it. Emerging gases are extremely hot!

Do not jam the trigger of the gun during operation!

When carrying through service and maitenance tasks the machine has to be cut off

the power supply system. Put main switch to "0" and pull plug out of socket.

Never operate the machine if cables or other safety-relevant parts (e.g. excess pressure valve, high-pressure hose, spraying devices, etc.) are defective.

6

General rules

Safety notes

Page 7

7

Safety notes

Never operate the machine without supervision.

The machine may only be operated by persons who have been instructed accordingly.

Some parts inside the machine, all water conducting components and all metal parts

of gun and lance are hot during hot water operation. Keep all hoods and protective

covers closed during operation and never touch any metal parts of gun or lance.

Persons operating the machine should wear the necessary protective clothing, i.e.

waterproof clothing, rubber boots, safety goggles, headwear etc. It is prohibited to

use the machine in close vicinity to people lacking suitable protective clothing.

The high pressure spray can generate a high level of noise. If noise exceeds the

maximum allowed levels, users and others in the vicinity must wear suitable ear

protection

.

Do not spray against matter containing asbestos or other hazardous substances.

Only use light heating oil EL (DIN 51 603) or diesel (DIN EN 590). The use of any other

fuel may be hazardous and dangerous (risk of explosion).

For safety reasons always switch the main switch to "0"- postion after having finished the cleaning task (disconnection from power supply).

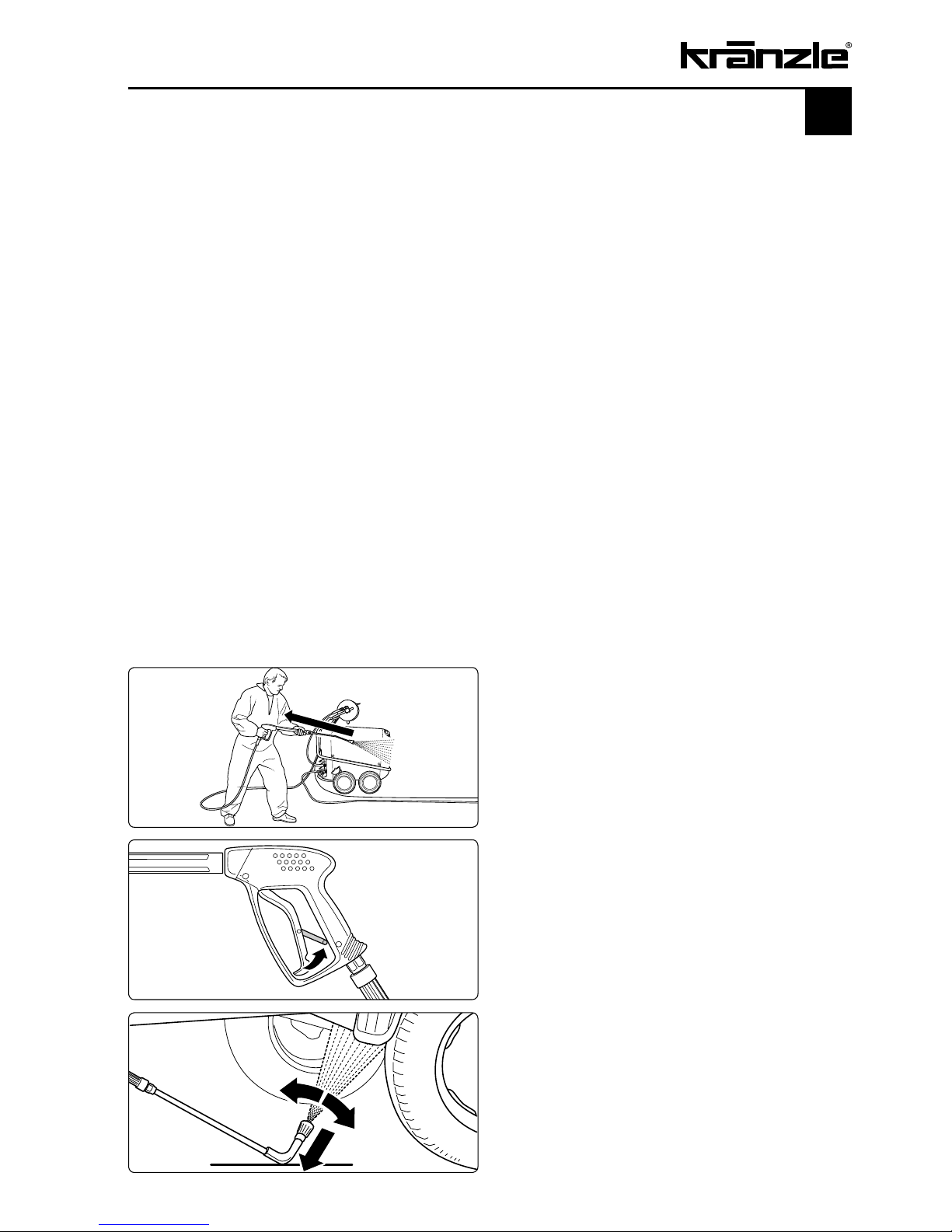

Bear in mind that during cleaning tasks

with a high-pressure water jet a significant

recoil at the lance arises (see technical

data on page 2).

Apply the safety catch on the spray gun

after each use, in order to prevent

unintentional spraying!

Always aim the underbody lance! Bear in

mind when using a curved or angled

spraying lance that there is a significant

amount of torque in the recoil!

Page 8

8

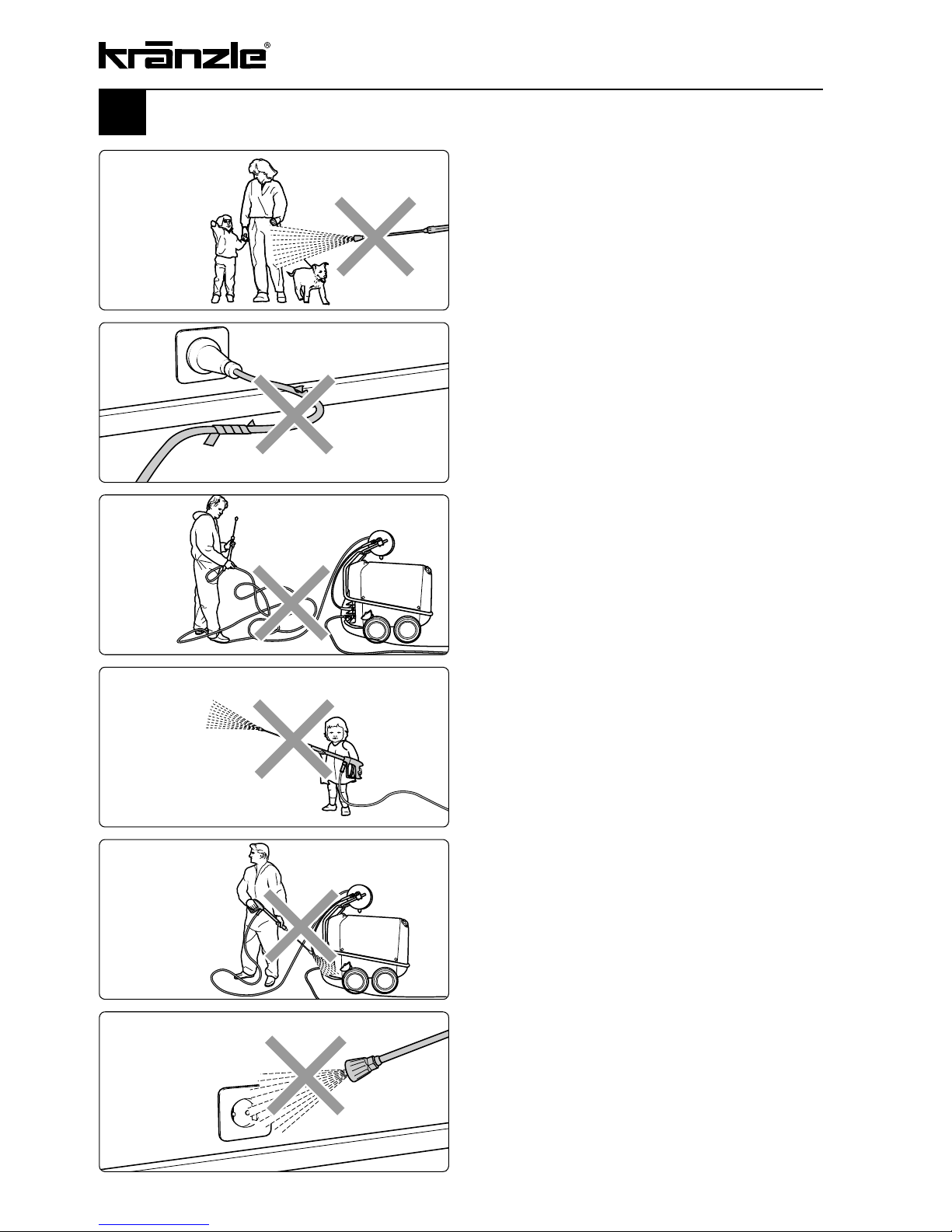

Safety notes - This is prohibited!

Never allow children to use the high

pressure cleaner!

Never direct the water jet at the

machine itself!

The machine may not be placed within

reach of the water jet spray mist!

Never direct the water jet at a power

socket!

Never direct the high-pressure water jet

towards the operator him-/herself or

towards other persons, not even for

cleaning clothing or shoes.

Never direct the water jet at animals!

Only use power cables which are in

perfect working order! Do not damage

the power cable or repair it incorrectly!

Never pull the high pressure hose if it

has formed kinks or “nooses”!

Never pull the hose over sharp edges!

Page 9

9

Please note - important!

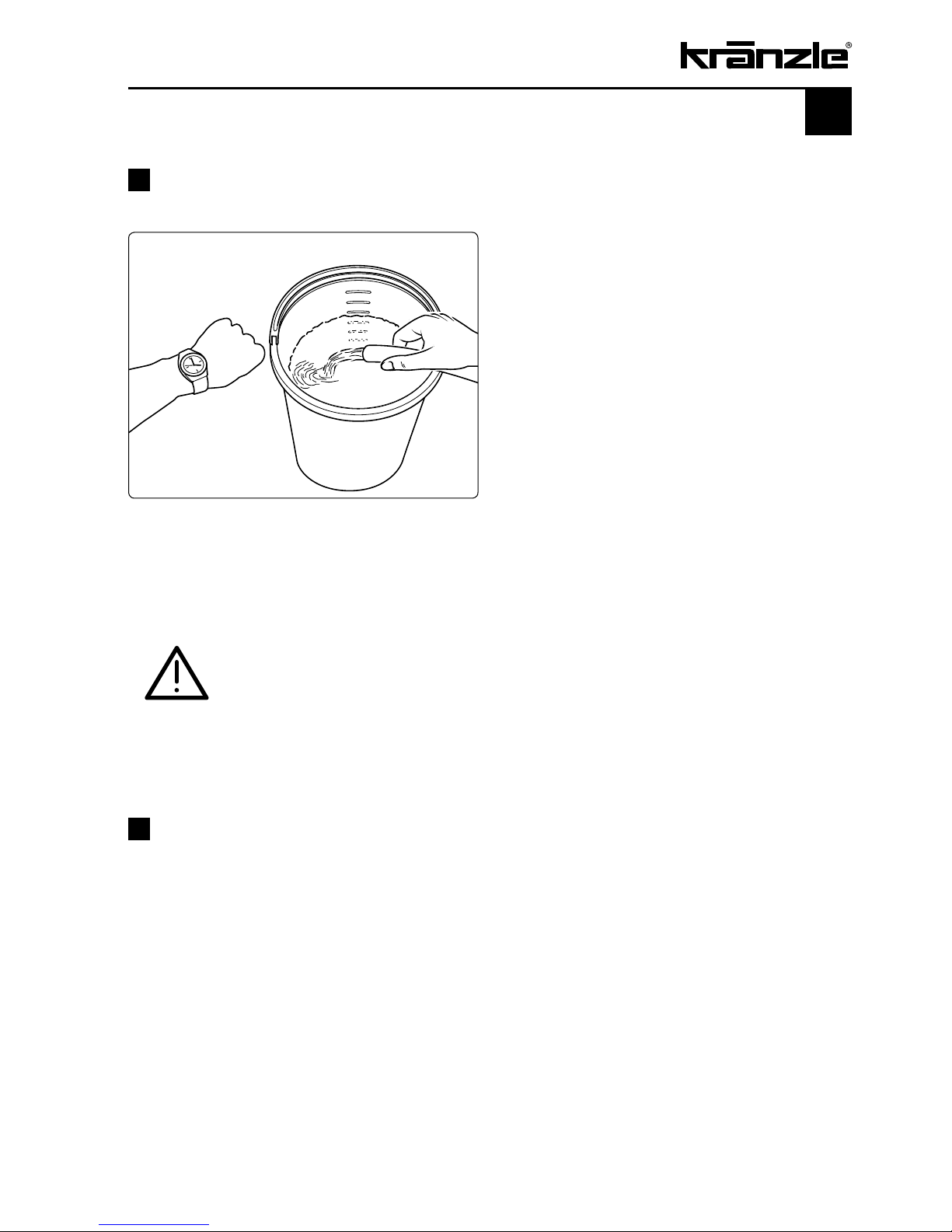

Lack of water

Lack of water occurs more often than you

probably believe. The more powerful a

high-cleaner is the greater is the danger

that a lack of water occurs. If there is only

an insufficient amount of water available,

cavitation arises inside the pump, which is

normally noticed too late or even not at all.

The pump will be destroyed!

Please check the available quantity of

water by filling a bucket with litre scale for

half a minute

.

Required minimum quantities: see technical data

If the metered quantity of water is too small, you have to use a

different water connection, guaranteeing the necessary output.

Lack of water leads to an accelerated wear of the joints (no

guarantee)

Connection to water supply

Please pay attention to the regulations of your waterworks company! In accordance

with DIN EN 61770, the machine may not be directly connected to the public drinking

water supply lines. A brief connection however is permissible according to DVGW

(German Association for Gas and Water Affairs) if a tube ventilator with check valve

(Kränzle Order-No. 41.016 4) is built into the water supply. Also indirect connection to

the public drinking water supply lines is permissible by way of free emission in

accordance with EN 61 770; e.g. by using a reservoir with a float valve.

Direct connection to a non-drinking water supply line is permissible.

Page 10

10

Please note - important!

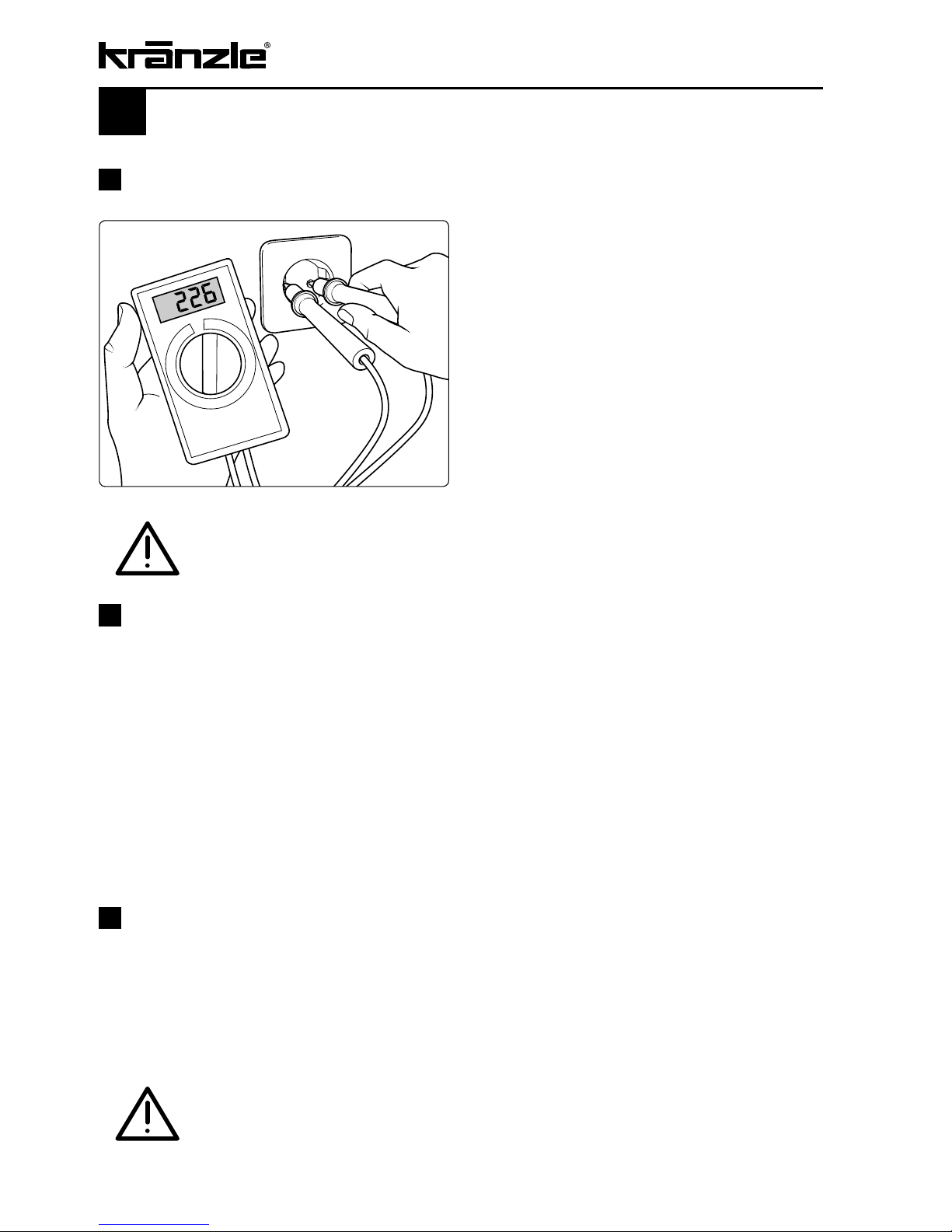

Insufficient quantity of electricity

If there are too many collectors in your

proximity connected to the network at the

same time, the available voltage and the

current intensity may decline.

Consequently the motor of the high-pressure cleaner does not start or even blows.

The power supply may also be insufficient

if the power cable is too long or too thin. If

extension cables are too long, this may

lead to a voltage drop causing

malfunctions or start-up difficulties

Electrical connection

The machine is supplied with an electrical power cable with plug. The mains plug must

be fitted to a standard grounded socket with a 30 mA residual current operated device.

The socket must be protected with a 16A delay action fuse on the mains side. When

using an extension cable, this must have an earthed lead which is properly connected to

the socket. The conductors in the extension cable must have a minimum cross section of

1.5 mm². Plug connections must be of a spray-proof design, and may not be located on

a wet floor. With extension cables of more than 10 m the minimum cross section must

be 2.5 mm! When using a cable drum, always keep the cable wound as far as possible

.

Check the line fusing and have the voltage and the available current

intensity checked by an expert in case of uncertainty.

Water and Cleaning System

The water is fed to the high-pressure cleaner under pressure (2-8 bar pre-pressure). A

float valve regulates the water flow in the storage tank. Then the water is sucked directly

from the storage tank by the high-pressure pump and forced with the adusted pressure

through the heat exchanger to the safety spray lance. The high pressure jet is formed by

the nozzle at the end of the safety lance.

Environmental, refuse disposal and water protection regulations

must be observed!

Kränzle technology

Page 11

11

Kränzle technology

Lance with trigger gun

The machine can only be operated when the safety trigger is squeezed. When the lever

is squeezed, the spray gun opens. The liquid is then pumped to the nozzle. The spray

pressure increases and quickly reaches the selected operating pressure. When the trigger is released, the trigger gun closes and any further spraying of liquid from the lance is

stopped. The motor stops.

When actuating the gun once more the pressure control valve - safety valve closes and

the motor is started again. The pump resumes feeding water to the spraying lance with

the selected operating pressure. When the gun is closed, the water hammer opens the

pressure control valve - safety valve and the motor is switched off by the pressure

switch.

The trigger gun is a safety device. Repairs should only be performed

by qualified persons. Should replacement parts be required, use only

components authorized by the manufacturer.

High pressure hose and spraying device

The high pressure hose and spraying device supplied with the machine are made of high

grade material, they are also optimized for the machine and marked as required by the

appropriate regulations.

If replacement parts are required, only such parts that are authorized by the manufacturer and which bear the markings required by the appropriate regulations may be used.

The high pressure hose and spray device must be connected in a pressure-tight

manner.

The high pressure hose may not be driven over, pulled excessively, or twisted. The

hose may under no circumstances be pulled over sharp edges, since otherwise the

guarantee is automatically void.

Hoses are wearing parts. The guarantee only covers defects of fabrication no

external damages whatsoever.

Defective high-pressure hoses and spraying devices may not be repaired. They

always have to be replaced.

Page 12

12

Kränzle technology

Pressure control valve-safety valve

The pressure control valve allows full adjustment of the quantity and pressure of the

water. The safety valve protects the machine from excessive pressure and cannot be

adjusted beyond the admissible operating pressure. The setting nuts are sealed with

lacquer.

Replacements, repairs, new adjustments and sealing operations may

only be performed by trained personnel.

Motor protection switch

The pump motor is protected from overload by a motor protection switch, which cuts out

the motor in the event of overload. To start the motor again the main switch has to be

switched off and then on again. However should the switch trip frequently, the cause of

the malfunction should be located and rectified.

Replacements and inspection work should only be performed by

qualified persons when the machine is disconnected from the power

supply, i.e. with plug pulled out from the electrical socket.

Total stop system

The machine is fitted with a Total-Stop-System. If the gun is closed for longer than

approx. 20 seconds, the machine switches off automatically, after 20 minutes the

machine moves to safety switch off and you must use the main switch to turn it back on.

The machine restarts automatically when the gun is operated, provided that the master

switch is on.

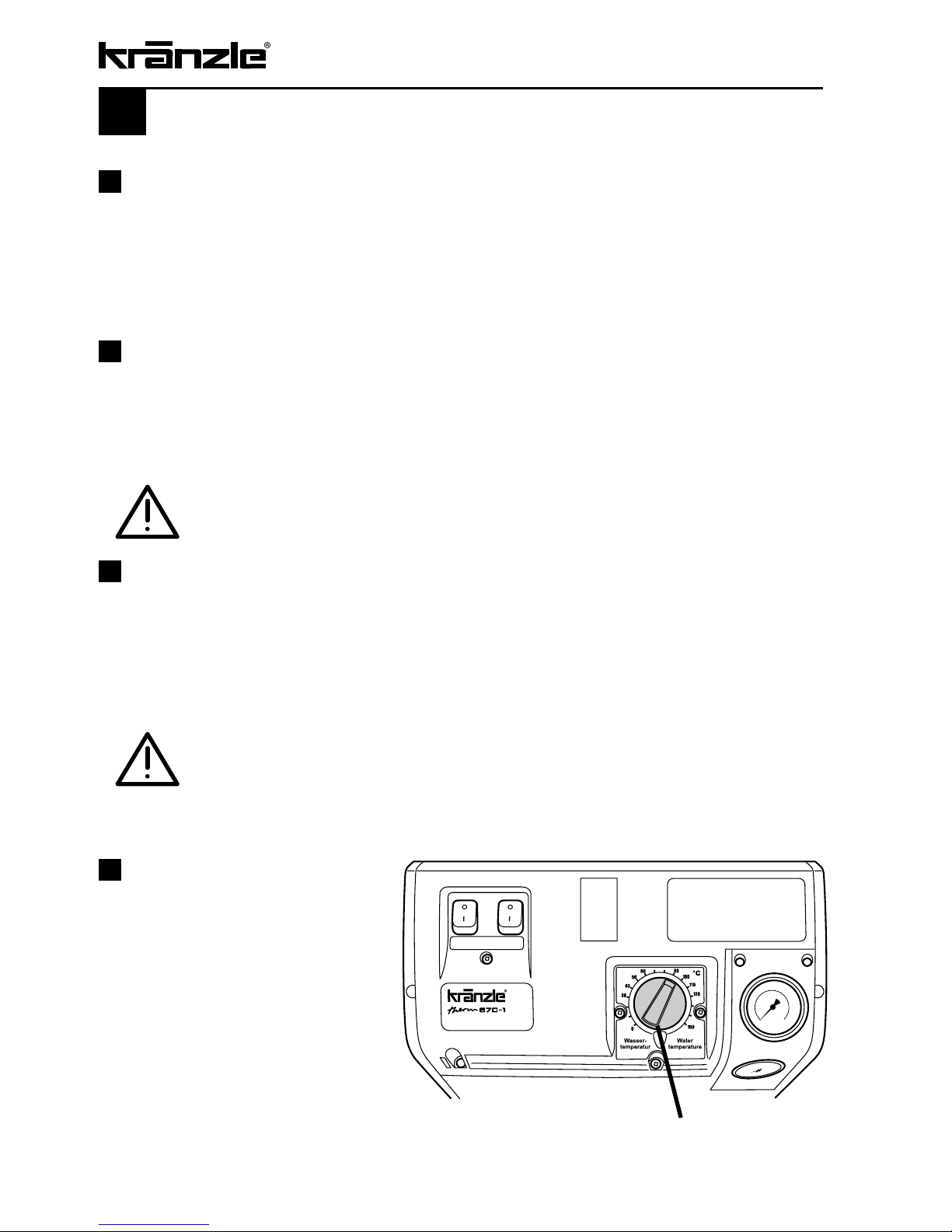

Thermostat

The thermostat with rotary control

switch controls the temperature

of the spray water.

Use the rotary control switch to

adjust the desired water

temperature.

Thermostat with

rotary control switch

Page 13

13

Heat exchanger

The water is forced through a heating coil by the high pressure pump. Heating coil: 38 m

long - Content: 5 l of water - Heating capacity: max. 90 kW

The fuel pump draws the oil from the tank through a filter and pumps it to the injector

nozzle. The oil pressure is shown on the fuel manometer.

The heat exchanger is heated by a high pressure fan heater.

A ventilator draws in the cold, fresh air from the bottom end of the machine and forces it

upwards between the outer mantle and the inner mantle. In the process, the fresh air is

pre-heated and the outer mantle of the heat exchanger is cooled.

The pre-heated air is pressed through a mixing unit. Here finely atomized fuel is injected

via a nozzle and mixed with the air. The electrodes located below then ignite the fuel-air

mixture.

The flame burns from top to bottom, turns round and the hot gas flows past the heating

coil on its way back up. The burned gases collect in the exhaust chamber and are emit-

ted from the chimney.

Chimney

Mixing unit

Nozzle

Electrodes

Inner cladding

Outer cladding

Oil filter

Fuel manometer

Fuel pump

Heating coil

Fan

Page 14

14

Commissioning

3.

Fill fuel tank with fuel. (Light heating oil

EL DIN 51 603 or diesel fuel)

Max. quantity 25 litres.

4

. Check water inlet filter for

cleanliness prior to putting the

machine into operation! Unscrew

glass body of the inlet filter and check

if metal sieve is soiled.

5.

Each time check oil!

Do not start the machine if there is no oil

visible in the sight glass. Refill with oil if

necessary. See page 20

1.

Install holding devices for power cable.

2.

Install water inlet filter.

6.

Release fixing brake.

Page 15

15

8.

Steering the machine: To change

direction tilt machine by pressing a foot

against the footrest and pull the handle

at the same time. Then turn machine

into desired direction.

9.

Connect machine to water mains

(2 - 8 bar pre-pressure).

Inside diameter of hose minimum

1/2 ". The water storage tank is filled

with water. The float valve shuts

the water intake as soon as the tank is

full.

10.

Connect to power circuit

. Make sure

that the main switch is on the "OFF"

position.

T

he socket must be protected with a

16A delay action fuse on the mains

side

.

7.

Move machine to job site.

Kränzle-therm appliances are movable

machines with a sturdy chassis.

11.

Release fixation of hose drum.

12.

Unwind HP hose from hose drum

without kinks and nooses.

Open gun before reeling up or

unreeling the hose in order to bleed

pressure from hose.

Page 16

16

Commissioning

13.

Push on HP hose to gun.

14.

Screw together HP hose and gun

pressure-tightly.

Take care that all screw connections are pressure-tight. A leakage of

gun, high-pressure hose or hose drum has to be repaired at once.

Leakages lead to an increased wear and to a possible malfunction of

the delayed motor cut-out.

1.

Ignition switch to -OFF- position

Usage as a cold water high-pressure cleaner

When starting the cleaning process do

not aim the water jet towards the object

you want to clean for at least 30 seconds.

Maybe the water inside the combustion

chamber has changed colour due to the rest

time.

Start cleaning process.

2.

Switch on main switch with disen gaged spray gun. Vent high-pressure

cleaner: Pull and release trigger of

spray gun various times.

Detergent valve must be closed!

(Turn knob to extreme right position

"close")

Page 17

17

During high-pressure operation (above 30 bars) the temperature

may not exceed 90 °C.

Steam level (90 °C - 150 °C)

During steam operation the pressure may not exceed 30 bar!

To reach the steam level (above 90 °C water temperature) adjust the

pressure below 30 bar and choose by means of the thermostat the

desired temperature of up to max. 150 °C.

In the case of machines with hose drums, the high pressure hose

must always be unwound completely.

Usage as a hot water high pressure cleaner

Start cleaning.

4.

Start ignition. The water is heated up

and constantly kept at the set

temperature.

3.

Switch on main switch with disen gaged

spray gun. Vent high-pressure cleaner:

Pull and release trigger of spray gun

various times.

Detergent valve must be closed!

(Turn knob to extreme right position

"close")

Method same as with cold water

high-pressure cleaner, then ...

1.

Set desired temperature at

the thermostat.

(Min. temperature 40 °C)

2.

Engage fixing brake before starting the

cleaning process!

Page 18

18

Suction of detergents

with detergent supply from the suction side:

Detergent injection on the pressur side, as you probably know it from other HP cleaners,

consume approx. 30 % of the cleaning energy, no matter if they are used or not. Due to the

water tank fitted to the Kränzle therm cleaners it is now possible to directly suck the

detergent into the pump thus reducing output loss and increasing the efficency considerably.

The detergents are applied without having to reduce the working pressure

.

1.

Place detergent filter into detergent

container

.

2.

Dosing of detergent is done by turning

the detergent valve

.

3.

By closing the detergent valve the supply of

detergent is stopped

.

4.

After having used detergents rinse the

appliance with open spray gun and clear

water for at least 2 minutes.

Only open the dosing valve, if the detergent sieve is placed in a liquid.

Sucked air leads to destruction of the pump seals! No guarantee!

Keep detergent-ph-value neutral 7 - 9!

Observe specifications of detergent manufacturer!

e.g.: protective equipment, rules for waste water treatment etc.

Never suck in liquids containing solvents like varnish solvents, petrol,

oil or similar liquid! Observe specifications of detergent manufacturers

!

Seals inside the appliance are no resistant against solvents! The spray

mist of solvents is highly inflammable, explosive and poisonous.

Page 19

19

Decommissioning - frost protection

01. Switch off the machine - main switch to „0“- position

02. Cut off the water supply

03. Open the spray gun briefly until the pressure is released

04. Apply the safety catch on the spray gun

05. Remove the water hose and spray gun

06. Drain the pump: switch on the motor for approx. 20 seconds

07. Pull the plug from the socket

08. Clean HP hose and wind up; fix drum

09. Clean power cable and wind up

10. Clean water filter

Frost protection

The machine is normally still partially filled with water after work has been completed.

To protect the appliance from frost, completely empty it of water:

Disconnect the machine from the water supply and switch off the ignition. Switch on the

master switch and open the gun. The pump now presses the remaining water out of the

water tank, the pump and the heating coil.

Do not allow the machine to run for longer than a minute without water.

If the machine is not in use for lengthy frosty periods of time, it is advisable to pump

anti-freeze into the machine: For this purpose, fill the antifreeze agent into the water

tank and switch on the machine without ignition. Wait with opened gun, until the agent

comes from the nozzle.

However, the best protection against frost is to keep the machine in a place that is

safe from frost.

Page 20

20

Weekly, or after approx. 40 hours of operation:

- Check the oil level of the high pressure pump. If the oil level is too low, add oil until

the oil level is between the two markings on the oil measuring rod.

Change the oil if it has a grey or whitish appearance. The oil should be

disposed of responsibly.

- Check the water filter in front of the float valve in the water tank and the fuel filter

in front of the solenoid valve. Clean the filters if necessary.

Yearly, or after approx. 500 hours of operation:

- Desulphurise and decarbonize the heating coil.

- Check heating coil for calcification, decalcify if necessary.

- Check the oil burner and ignition system.

- Clean the oil nozzle, oil filter, solenoid valve and filter, clean and adjust the ignition

transformer, ignition cable and ignition electrodes and replace defective parts.

- Change the oil

Oil leakage: If oil leaks out, go to the nearest customer service (dealer) immediately. (Environmental damages, transmission damages,

loss of guarantee.)

In case of increased humidity or fluctuations in temperature development of condensed water is possible; if the oil turns grey, you must

change it.

Care and Maintenance

The machine must be disconnected from the power supply when servicing work is being carried out. The main switch should be in

position "0" and the plug out of the socket.

Page 21

21

Changing the oil:

First oil change after approximately

50 operating hours. Thereafter the oil

should be changed every 500 operating

hours or yearly.

Take the oil drainage hose, which is

connected to the oil drainage screw from the

inside of the appliance.

Opentheredoilllerplugatthetopsideofthe

black oil housing.

Open the cap at the end of the hose.

Drain off the oil into an oil pan and dispose of it responsibly. Close the end of the

hose.Rellwithnewoil.

Decalcifying the heating coil:

Calcified machines use an unnecessary amount of energy because the water can only

be heated slowly and the excess pressure valve feeds a part of the water back into the

pump circuit.

Calcified machines can be recognised by increased pipeline resistance.

Check pipeline resistance by disconnecting the high pressure lance from the gun and

switching the machine on. A full jet of water emerges from the gun. The machine must be

decalcified if the pressure shown on the manometer is greater than 25 bar.

Proceed as follows to decalcify the machine:

1. Unscrew the high pressure hose from the machine and decalcify it separately.

2. Put the detergent suction hose into a container of decalcifying solution.

3. Set the dispenser valve to the maximum concentration.

4. Switch on the machine.

Page 22

22

5. Hold the gun in a separate container and press the trigger.

6. Wait for about a minute until the decalcifier comes out of the gun

(recognisable by its whitish colour)

7. Switch off the machine and allow the solution to act for about 15-20 minutes.

8. Switch the machine back on and rinse it through with clear water for about 2

minutes.

9. Now check whether pipeline resistance is back to an acceptable level.

Repeat the decalcifying process if the pressure without the high pressure lance is

still above 25 bars.

Decalcifiers are caustic!

Observe the instructions for usage and accident prevention. Wear

protective clothing to prevent the decalcifying agent from contacting

your skin, eyes and clothing (e.g. gloves, safety mask etc.)

Detergent and dirty fuel must be disposed of responsibly.

Adjusting ignition electrodes:

For a smooth ignition, the setting of the ignition electrode must be controlled regularly

(after 500 operating hours at the latest).

Care and Maintenance

Fuel System:

Your fuel may contain particles of dirt, or impurities or water may get into the tank during

refuelling. To protect the fuel pump the machine is equipped with a fuel filter. Check this

filter regularly for impurities and clean if necessary.

Check the tank for impurities on a regular basis. Clean the tank when necessary. Empty

the fuel tank using the drainage screw at the bottom of the tank. Clean tank and fuel

pipes thoroughly. Screw drainage screw back in.

Page 23

23

Particular rules, directives and

inspections

Inspections performed by Kränzle

- measurement of earth line resistance

- measurement of voltage and current

- inspection of tension consistency with +/- 1530 V

- pressure check of heating coil at 300 bar

- visual and functional check as per the inspection sheet provided

- exhaust fume analysis (see test strips provided)

Guidelines for liquid sprayers

The machine conforms with the "Guidelines for liquid sprayers". These guidelines are

issued by the organisation of trade associations and may be obtained from Carl

Heymann-Verlag KG, Luxemburger Str. 49, 50939 Köln. These guidelines specify that

this machine is to be inspected by qualified personnel whenever necessary, but no less

than once every 12 months. These inspections must be recorded in the inspection log at

the end of this manual.

Pressure container and steam boiler directives

Kränzle high pressure cleaning equipment conforms to the pressure container and steam

boiler directive. No construction approval, notification of licence and takeover inspection

are required. The water capacity is less than 10 l.

Duties of owner

The owner is to ensure that all safety-relevant components are in a serviceable

condition before the sprayer is used. (e.g., safety valves, hose and electric cables, spray

equipment etc).

Emission control legislation

With stationary installation, the emission levels of the machine must be checked once a

year by a qualified organisation or person according to German law. The first inspection

must be carried out four weeks after the machine is commissioned. The owner is responsible for having the inspection performed.

Page 24

24

Circuit diagramme 400 V, 50 HZ

Connection via

CEE 4 x 16 A

380 V, 50 Hz

+ MP

Master switch

Switch

Heating

Three-Phase motor

High pressure pump

Burner

motor

Ignition

trans-

former

Fuel valve

Thermostat with

rotary control switch

Excess

current actua-

tor 15 A

Sensor

Excess temp.

F1

F2

Pressure switch

Burner release

Flow controller

Burner release

Pressure switch

Motor Start/Stop

Sensor

Water temperature

Photo cell

Flame monitoring

Float switch

Lack of fuel

Page 25

25

Notes

Page 26

Malfunction

Water supply

Water tank runs over.

Water tank does not fill completely.

Pump does not suck.

Test: check water and chemical

system for tightness.

High-pressure pump

Pump makes loud noises. Operating

pressure is not reached.

Water drops from the pump.

Oil drops from the transmission.

Pressure is too low.

Machine does not switch off

Test: Bridge pressure switch (red)

Appliance does not start or

stopps during operation

Cause of malfunction / remedy

Float valve is dirty or defect.

Float valve is defect. Water filter is dirty.

Insufficient water inlet quantity.

Valves stick or are dirty. Suction hose leaks.

Chemistry valve is open or leaks. Check hose

clips (connections).

High-pressure nozzle is clogged.

Connect water inlet directly to the pump (2-4 bar

pre-pressure). Disconnect suction lines below

the pump

Pump sucks air. Check suction connections.

Check high-pressure nozzle. Check valves. Check

O-rings under valves. Check sleeves. Manometer

is defect. Unloader: check stainless steel seat and

ball. Check seals on the control piston.

Replace sleeves in the pump.

Replace O-rings.

Check oil seals (replace). Check plunger and

plunger guides. Check water supply, since water

deficiency or air suction can cause damage to

seals and O-rings (chemistry valve leaks?)

Worn high pressure nozzle. Stainless steel seat,

ball, O-ring in unloader is dirty or defect.

Manometer is defect.

Check return body and O-ring in unloader of the

valve housing.

Check pressure switch (red). Check micro

switch.

Check cable connections. Board is defect.

Check electricity supply. Check main switch.

Check cable connections. Check board.

Check pressure switch. Switch off by overcurrent

release.

26

Troubleshooting

Page 27

27

Troubleshooting

Excess temperature release

As an additional safety device the appliance is equipped

with an excess temperature sensor inside the chimney. Should

the safety devices as e.g. the float monitoring device be defectice and the burner continues to heat although the heating coil

does not conduct away heat a destruction of the heating coil

would be inevitable. As soon as the temperature inside the

chimney exceeds 260 °C the excess temperature release triggers and cuts out the appliance.

The display of the excess temperature release is located on the

back of the switchbox inside the appliance.

RED: Excess temperature released, let appliance cool down, no hot water operation possible

YELLOW: Appliance cooled down, activation of hot water opertion possible by pressing

the RESET-button

ATTENTION !!!

Immediately contact service in case of recurrence

Heißwasserbetrieb erst

nach Abkühlung möglich.

Hot-water operation only possible

after cooling down phase.

Gerät abgekühlt , Heißwa sserbetrieb

nach RESET w ieder mö glich.

Machin e cooled down, hot-water

operat ion possi ble afte r RESET.

Überhitzung / Overheating

R

Page 28

28

Troubleshooting

Hot water mode

The fuel manometer shows the fuel pressure.

If no pressure is shown, check if

- there is heating oil in the tank.

- the fuse in the electric box (below the operating panel) for the motor has blown.

- the fuel sieve or the fuel sieve in the pump is dirty.

- the fuel pump does no operate smoothly or is blocked.

- the ventilator jams.

The thermostat grants permission to open the solenoid valve. The burner starts and

heats the water to the temperature preset by you. As soon as the temperature is reached

the burner switches off.

If the temperature drops again, the burner switches on automatically, so that the desired

temperature is constantly kept.

The thermostat is controlled by a thermosensor, mounted to the outlet of the heating coil.

In the electro distributor box (below the operating panel), there is a fuse (Circuit diagramme, F1) on the PCB which protects the motor for fuel pump and ventilator. If the motor is

overloaded, the fuse blows. This can happen when the fuel pump is blocked or does not

work freely, when the ventilator is blocked or does not operate freely or when there is an

electrical problem.

A second fuse (Circuit diagramme, F2) on the PCB triggers, if the ignition transformer is

faulty.

The transformer on the PCB is protected by two fuses (32 mA, 630 mA).

To avoid an overheating of the combustion chamber, a flow monitoring device is installed

between high-pressure pump and combustion chamber, which only permits fuel injection

if water is running through the heating coil at the same time.

Page 29

Malfunction

Heating (burner)

Fuel pump/blower operates, but

burner does not heat.

Fuel pump/blower does not operate.

- Pump makes loud noises

Fuel operating press. is not reached

Smoke during operation.

Smoke after switching off.

Solenoid valve on the fuel pump

does not open

Test: Pressure switch (black)

Bridge in terminal box between

terminal 3 +4

Test: Connect solenoid valve 230 V

externally.

Oil pressure on the fuel pump is

too low/too high.

Ignition does not function.

Ventilator does not operate.

Leakage

Gun drips. High pressure hose drips.

Manometer shows pressure

but no water comes out.

Sucking detergent

Detergent is not sucked.

Cause of malfunction / remedy

Set water temperature is reached. Increase

temperature on thermostat with rotary control

switch. Open gun, until temperature drops. Fuel

tank is empty. Fuel filter is dirty. Fuel nozzle is dirty.

Coupling between burner motor and fuel pump is

defect. Blower/fuel pump motor is defect. Check

electrical equipment. Check fuse in electric box.

Water in fuel tank.

Dirt or rust in the fuel pump. Clean tank.

Replace fuel pump.

Fuel is dirty. Nozzle or nozzle stock leaks.

Water in tank.

Check pressure switch (black). Solenoid valve is

defect or dirty. Clean filter, clean supply line,

clean

fuel pump. Setting is wrong. Clean fuel nozzle,

or replace it.

Check ignition cable. Charring of plug-in contacts

by moisture. Cable is broken. Check ignition

transformer connections. Transformer is defect

Ignition electrode has been falsely set or burnt up.

Blower-/fuel pump motor is defect. Check electrical equipment. Check fuse in terminal box.

Coupling between burner motor and fuel pump is

defect.

Clean nozzle. Replace seals.

Replace O-ring under screwed connection.

Clean nozzle.

Pump sucks air. Check hose clips.

Test: Connect water line to the pump.

Water inlet: 2 - 8 bar pre-pressure. No water

must come from the detergent hose.

29

Troubleshooting

Page 30

30

Small repairs

do it yourself

No water from the nozzle but the

gauge shows full pressure: Most likely

the nozzle is blocked.

(Inside the pressure gauge there is no water but a

filling with glycerin to damp the vibration of the pointer.)

Proceeding

:

Switch off the cleaner. Pull plug from the socket.

Operate gun seveal times to decrease the pressure.

First unscrew gun and lance, then rinse hose from

any residues.

Check water inlet filter for soiling. If the problem still

exists, take wire (paper clip) and push cautiously

through nozzle opening.

If this procedure is not successful, the nozzle has to

be dismantled and cleaned (from the backside) or

even replaced, if necessary.

Page 31

31

The pressure gauge shows full

pressure although the gun has been

closed. The pressure switch valve

switches constantly.

Possible cause no.1: Leakage

Having closed th gun, the HP cleaner must shut

down and the pressure gauge must show „0“

bar. If the pressure gauge still shows full pressure and the motor constantly switches on and

off, the possible reason for this can be a leakage of the pump, the HP hose or the lance.

Proceeding:

Check the connections from the HP cleaner to

the the HP hose, from the hose to the gun and

also the connection between lance and gun for

tightness. Switch off the cleaner. Shortly press

the trigger of the gun to decrease the pressure.

Unscrew HP hose, gun and lance and check

the O-rings. If the O-rings are damaged they

have to be replaced.

In case of a leakage there is no guarantee

for possible consequential damages.

Possible cause no. 2:

The non-return valve is soiled or

defective

Proceeding:

Unscrew pump outlet.

Take out non-return valve body and check for

soiling or damage of the O-ring.

Replace non-return valve if necessary.

There is no guarantee if the pump is

damaged by defective O-rings due to air

induction or lack of water (cavitation).

Page 32

32

Small repairs

do it yourself

Pressure gauge shows little

pressure, the water from the nozzle

comes in squirts

,

The high-pressure hose vibrates.

Most likely the valves are soiled

.

Proceeding

:

Unscrew all 6 valves, one after the other

(hexagonal brass screws, 3 in a row,

vertically and horizontally)

Take out valve body (with green or red plastic

coating) and O-ring by means of needle nose

pliers. Check O-ring for damage. In case of a

damage the O-ring has to be replaced.

Take a wire (paper clip) and clean valves under

running water. Also clean valve seating inside

the pump.

Do not forget the O-ring during reassembly!

Page 33

33

Pipeline plan

1 Float valve, water inlet

2 Water tank

3 Control valve detergent

4 High pressure pump with integrated unloader valve

5 Flow-Safety-Block with integrated

safety valve for heating coil and flow monitoring device

6 By-Pass line

7 Fuel pump with solenoid valve

8 Fuel filter

9 Fuel tank

Detergent

High pressure

connection

Water inlet

Safety valve, number 5 must be set approx. 15 % higher than

the unloader valve on the HP pump.

Page 34

34

Inspection report for HP cleaners

Type plate (on hand)

Operating manual (on hand)

Protective covering, -device

Pressure line (tightness)

Pressure gauge (function)

Float valve (tightness)

Spraying device (marking)

HP-hose/ connector (damage, marking)

Safety valve opens at 10% / 20% excess

Pressure reservoir

Heating oil line (tightness)

Solenoid valve (function)

Thermostat (function)

Flow controller (function)

Power cable (damage)

Power plug (damage)

Protective conductor (connected)

Emergency Off Switch (function)

On/Off-switch

Water quantity safety device (function)

Used chemicals

Allowed chemicals

High-pressure nozzle

Operating pressure ............bar

Cutting-off pressure.............bar

Smoke spot number...........acc. to Bacharach scale

CO²-value...................% CO²

Efficiency rating.............%

Conductor resist. not exceeded / value:

Insulation

Leakage current:

Gun locked

Inspection report on annually carried out Labour Safety Inspection (UVV) according to the

Guidelines for Liquid Spray Equipment. (This inspection sheet serves as proof for the completion of

the retest and must be kept carefully!) Kränzle-Test Stamp Mark: Order Number UVV200106

Scope of inspection:

ok yes no repaired

Inspection data

determ. value set value

Owner:

Address:

Type therm:

Serial no.:

Rep.-order-no.:

The appliance was checked by an expert according to the Guidelines for Liquid Spray

Equipment, the defects found have been rectified so that the Labour Safety can be confirmed

.

The appliance was checked by an expert according to the Guidelines for Liquid Spray

Equipment. The Labour Safety cannot be confirmed unless the defects found are rectified by

repair or replacement of the faulty parts

.

The next retest according to the Guidelines for Liquid Spray Equipment has to be carried out

by:

Month Year

Place, Date Signature

Inspection result (tick)

Page 35

35

Inspection report for HP cleaners

Type plate (on hand)

Operating manual (on hand)

Protective covering, -device

Pressure line (tightness)

Pressure gauge (function)

Float valve (tightness)

Spraying device (marking)

HP-hose/ connector (damage, marking)

Safety valve opens at 10% / 20% excess

Pressure reservoir

Heating oil line (tightness)

Solenoid valve (function)

Thermostat (function)

Flow controller (function)

Power cable (damage)

Power plug (damage)

Protective conductor (connected)

Emergency Off Switch (function)

On/Off-switch

Water quantity safety device (function)

Used chemicals

Allowed chemicals

High-pressure nozzle

Operating pressure ............bar

Cutting-off pressure.............bar

Smoke spot number...........acc. to Bacharach scale

CO²-value...................% CO²

Efficiency rating.............%

Conductor resist. not exceeded / value:

Insulation

Leakage current:

Gun locked

Inspection report on annually carried out Labour Safety Inspection (UVV) according to the

Guidelines for Liquid Spray Equipment. (This inspection sheet serves as proof for the completion of

the retest and must be kept carefully!) Kränzle-Test Stamp Mark: Order Number UVV200106

Scope of inspection:

ok yes no repaired

Inspection data

determ. value set value

Owner:

Address:

Type therm:

Serial no.:

Rep.-order-no.:

The appliance was checked by an expert according to the Guidelines for Liquid Spray

Equipment, the defects found have been rectified so that the Labour Safety can be confirmed

.

The appliance was checked by an expert according to the Guidelines for Liquid Spray

Equipment. The Labour Safety cannot be confirmed unless the defects found are rectified by

repair or replacement of the faulty parts

.

The next retest according to the Guidelines for Liquid Spray Equipment has to be carried out

by:

Month Year

Place, Date Signature

Inspection result (tick)

Page 36

Kränzle therm 870-1

Manfred Bauer, Fa. Josef Kränzle

Rudolf-Diesel-Str. 20, 89257 Illertissen

machinery directive 89/392/EEC,

low-voltage directive 73/23 EEC,

EMV-directive 89/336 EEC,

noise directive 2000/14/EC, Art. 13,

HP water spraying machines

annex 3, part B, chapter 27

86 dB (A)

89 dB (A)

EN 60 335-2-79:2004

EN 55 014-1 / A2:2002

EN 55 014-2 / A1:2001

EN 61 000-3-2 / A14:2000

EN 61 000-3-3 / A1:2001

36

EC declaration of conformity

Hereby we declare that:

technical specifications available from:

comply with the following guidelines

and their amendments for high-pressure

cleaners:

Sound level measured:

Sound level guaranteed:

Applied specifications and standards

I. Kränzle GmbH

Elpke 97

D - 33605 Bielefeld

Bielefeld, den 08.09.2005

Droitsch

(Managing director)

Page 37

Guarantee

The guarantee is only valid for material and manufacturing errors.

Wearing does not fall within this gurantee.

The instructions in our operating manual must be complied with..

The operating instructions form part of the guarantee.

T

he guarantee period is 12 month from date of purchase.

In the case of a guarantee please contact your dealer or authorized seller delivering

accessories and your purchase receipt. You can fin them in the internet under

www.kraenzle.com.

The guarantee is also void if the machine is used with exceeding the temperature and

speed limits, a voltage below the required rating, with less than the required amount of

water or with dirty water.

Pressure gauge, nozzle, valves, sleeves, high pressure hose and spray equipment are

wear parts and are not covered by the warranty.

37

Page 38

38

Inspection sheet Kränzle therm

All lines connected

Hose clamps tight

Screws all installed and tightened

Ignition cable plugged in

Visual check carried out

Brake function checked

Leak test

Water tank filled and checked

Water inlet checked for tightness

Float valve function checked

Machine checked for tightness under pressure

Electrical check

Earth line checked

Current intake

Operating pressure

Switch-off pressure

Customer

Page 39

Steam phase checked

Chemical valve checked

Start/Stop automatic and re-run

delay checked

Fuel shortage switch checked

Thermostat function checked

Burner function checked

Water inlet temperature

Water outlet temperature

Fuel pressure bar

Measured smoke spot number

39

70072174

9

2

76

9,5 10

10,51111,5

12

3

78 80 82 84 86 88 90

°C

bar

12,5

13

13,5

14

Safety equipment sealed with lacquer

The appliance fulfills all requirements according

to this inspection sheet

Name of inspector

Date

Signature

Result of flue gas analysis

5 6 7 8 9 10 11 12 13 14 15

°C

Page 40

Kränzle - world-wide:

Technical perfection at its best.

I. Kränzle GmbH

Elpke 97

D - 33605 Bielefeld

Reprint only allowed with the authorization of Kränzle.

As of 08-07-2008

Subject to technical modifications. Order no. 30.768 0

Loading...

Loading...