Kranzle quadro 800 TST, quadro 1200 TST, quadro 1000 TS, quadro 1200 TS, quadro 1000 TST Operating Manual

Page 1

O p e r a t i n g m a n u a l

High Pressure Cleaners

Read and conform safety instructions

before use !

- GB -

Page 2

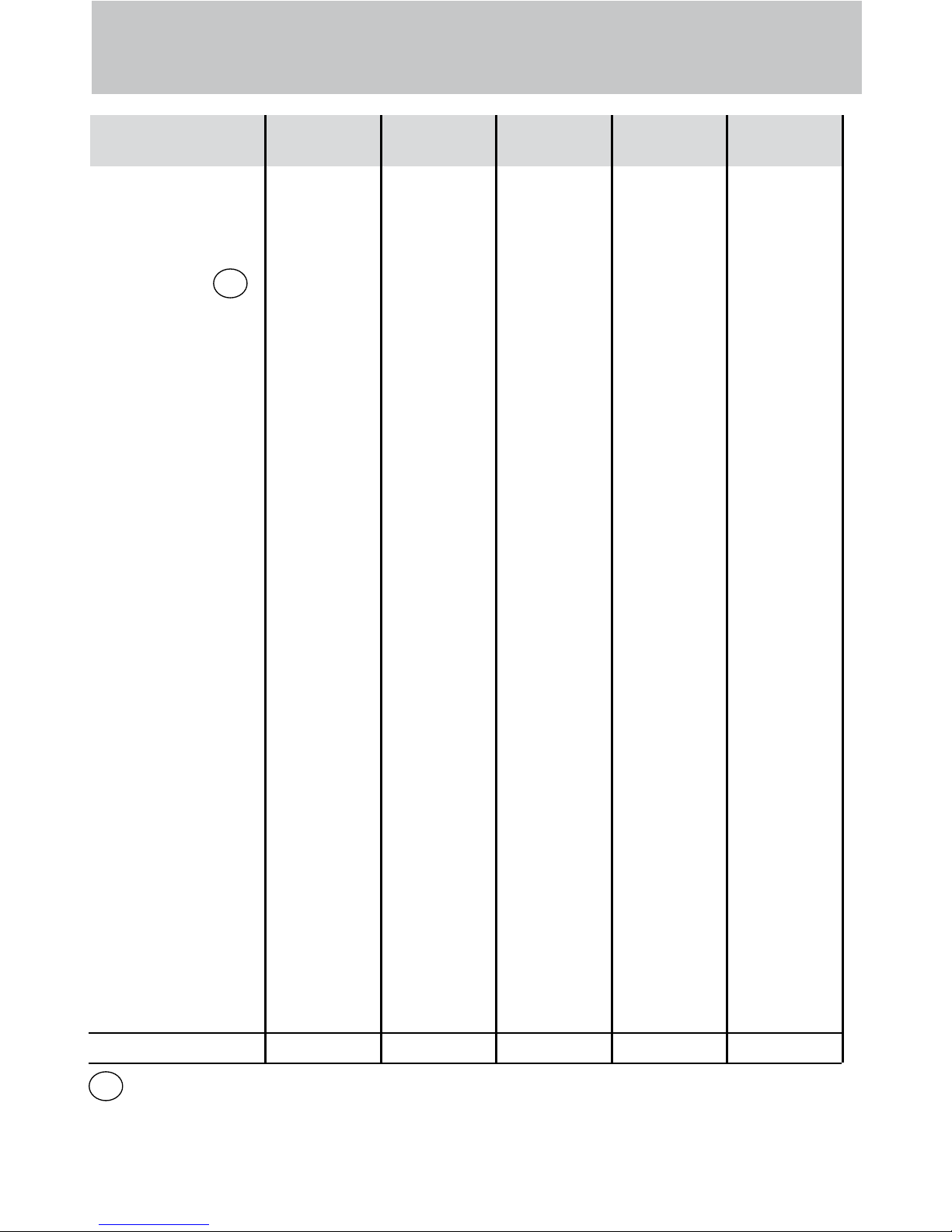

30 - 180 bar

200 bar

21 l/min

19 l/min

2507

08

16 l

max. 60 °C

2,5 m

yes

20 m

400 V/50 Hz

12 A

1400 U/min

P1: 7,5 kW

P2: 5,5 kW

89 kg

770 x 570 x

990

89 dB (A)

91 dB (A)

91 dB (A)

2,2 m/s²

ap. 22 N

40.422

2

Operating pressure,

steplessly adjustable

Perm. overpressure

Water output

at 0 bar

at nominal pressure

Nozzle size

(Flat jet)

(Turbokiller)

Volume

Water tank

Max. inlet water temperature to water tank

Direct suction height

Hose drum

High pressure hose

Electrical ratings

Motor speed adjustm.

Connect. wattage inp.

output.

Weight (incl. accessories

with empty water tank

Dimensions including

handle L x W x H in mm

Sound level acc. to

45 635 (rel. to

working place)

with Turbokiller

Guaranteed sound

level LWA

Vibrations at lance

Recoil at lance

Order n°.

30 - 220 bar

250 bar

17,5 l/min

15,6 l/min

2505

055

16 l

max. 60 °C

2,5 m

yes

20 m

400 V/50 Hz

12 A

1400 U/min

P1: 7,5 kW

P2: 5,5 kW

89 kg

770 x 570 x

990

89 dB (A)

91 dB (A)

91 dB (A)

2,2 m/s²

ap. 20 N

40.421

quadro

1000 TST

Technical

data

quadro

1200 TST

Technical data

30 - 250 bar

270 bar

15 l/min

13,5 l/min

2504

04

16 l

max. 60 °C

2,5 m

yes

20 m

400 V/50 Hz

12 A

1400 U/min

P1: 7,5 kW

P2: 5,5 kW

89 kg

770 x 570 x

990

89 dB (A)

91 dB (A)

91 dB (A)

2,2 m/s²

ap. 20 N

40.423

quadro

800 TST

Permissible tolerance for gures ± 5 % in acc. with VDMA uniform sheet 24411

*1

Min. water quantity to be supplied to the high pressure cleaner!

(2-8 bar admission pressure)

30 - 180 bar

200 bar

21 l/min

19 l/min

2507

16 l

max. 60 °C

2,5 m

no

10 m

400 V/50 Hz

12 A

1400 U/min

P1: 7,5 kW

P2: 5,5 kW

82 kg

770 x 570 x

990

89 dB (A)

91 dB (A)

91 dB (A)

2,2 m/s²

ap. 22 N

40.422 1

30 - 220 bar

250 bar

17,5 l/min

15,6 l/min

2505

16 l

max. 60 °C

2,5 m

no

10 m

400 V/50 Hz

12 A

1400 U/min

P1: 7,5 kW

P2: 5,5 kW

82 kg

770 x 570 x

990

89 dB (A)

91 dB (A)

91 dB (A)

2,2 m/s²

ap. 20 N

40.421 1

quadro

1000 TS

quadro

1200 TS

*1

Page 3

Dear customer

We would like to congratulate you on your new high pressure cleaner with integrated water tank and to thank you for the purchase.

To ease your introduction to the use of the cleaner, we have provided the following

pages of explanations, tips and hints, which we ask you to read before using for

the rst time.

The equipment will assist you professionally in all cleaning tasks, e.g.:

- facades

- agstones

- terraces

- vehicles of all types

- containers

- machines etc.

- barrels and containers

- channels

Description

Contents Side

Technical data .................................................... 2

Construction and components ................................4

Water system ..........................................................5

Detergent / caring system .......................................5

Lance and spay gun ................................................5

High pressure hose and spray device .....................6

Unloader valve - safety valve ..................................6

Delayed motor cut-out .............................................7

Safety cut-out ..........................................................7

Setting up / Location ...............................................7

Electrical connection ...............................................8

Brake .......................................................................9

Brief operating instructions......................................9

This is what you’ve purchased ...............................10

How to assemble and furnish your HP cleaner ......11

Preparation for use.................................................12

External suction......................................................13

When using detergents ..........................................14

To shut down the pump / Frost protection ..............14

Safety notes „This is prohibited !“...........................15

Additional accessories ...........................................18

Small repairs ..........................................................20

Spare parts lists .....................................................22

General rules..........................................................39

Inspection report ....................................................40

Declaration of conformity .......................................43

3

Page 4

1

2

3

4

5

8

9

6 Detergent valve

7 High pressure hose

8 Spray gun

9 Interchangeable lance with Turbokiller

10 Interchangeable lance with at jet

nozzle and nozzle protection

1 Water inlet connection with lter

2 Cover for water tank

3 High pressure pump

4 Press. gauge with glycerin lling

5 Unloader valve - safety valve

400 V / 50 Hz

Construction

The KRÄNZLE quadro 800 TST, 1000 TST and 1200 TST TST high pressure

cleaners are mobile machines with hose drum and 20m industrial hose. The

KRÄNZLE quadro 1000 TS und 1200 TS - high pressure cleaners are mobile machines without hose drum, however with 10m industrial hose. The schematic principle can be seen from the illustration.

Components

Description

10

7

6

4

Page 5

Water system

The water must be lead to the high pressure cleaner under pressure (2 – 8 bar

ad-mission pressure). A oat valve regulates the water inlet. Then, the water is

sucked by the high pressure pump from the water tank and supplied to the lance

under the set pressure. The high pressure jet is formed by the nozzle at the end of

the lance.

Description

6

5

Lance with spray gun

The machine can only be operated when the safety trigger is squeezed.

When the lever is squeezed, the spray gun opens. The liquid is then pumped to

the nozzle. The spray pressure increases and quickly reaches the selected operating pressure.

When the trigger is released, the trigger gun closes and any further spraying of

liquid from the lance is stopped and the manometer must show 0 bar.

The increase in pressure when the trigger gun is closed causes the unloader

valve-safety valve to open. The pump remains switched on and continues to pump

liquid through the pump at reduced pressure. When the spray gun is opened, the

unloader valve - safety valve closes and the pump ressumes spraying from the

lance with the selected operating pressure.

The spray gun is a safety device. Repairs should only be performed by qualied persons. Should replacement parts be required, use only components authorized by the manufacturer.

Detergent and caring system

The high pressure pump can also suck a detergent/caring agent and mix it with the high

pressure jet. The additive is sucked through the

pump and brought in with the set pressure.

Insert the detergent hose into the detergent container and open the detergent valve (6).

The detergent discharges with the water at the

high pressure nozzle.

Open the dosing valve, if the chemistry sieve is placed in a

liquid. Sucked air leads to destruction of the pump seals!!!

The rules concerning the environment, refuse and ground water

protection must be complied with!

Page 6

High pressure hose and spraying device

The high pressure hose and spraying device supplied with the machine are made

of high grade material. They are also optimized for the machine and marked as

required by the appropriate regulations.

If replacement parts are required, only such parts that are authorized

by the manufacturer and which bear the markings required by the

appropriate regulations may be used. The high pressure hose and

spraying device must be connected in a pressure-tight manner.

The high pressure hose may not be driven over, pulled excessively or

twisted. Hose lines are wear parts. Guarantee is accepted only for manufacturing errors, not for external damages.

Description

6

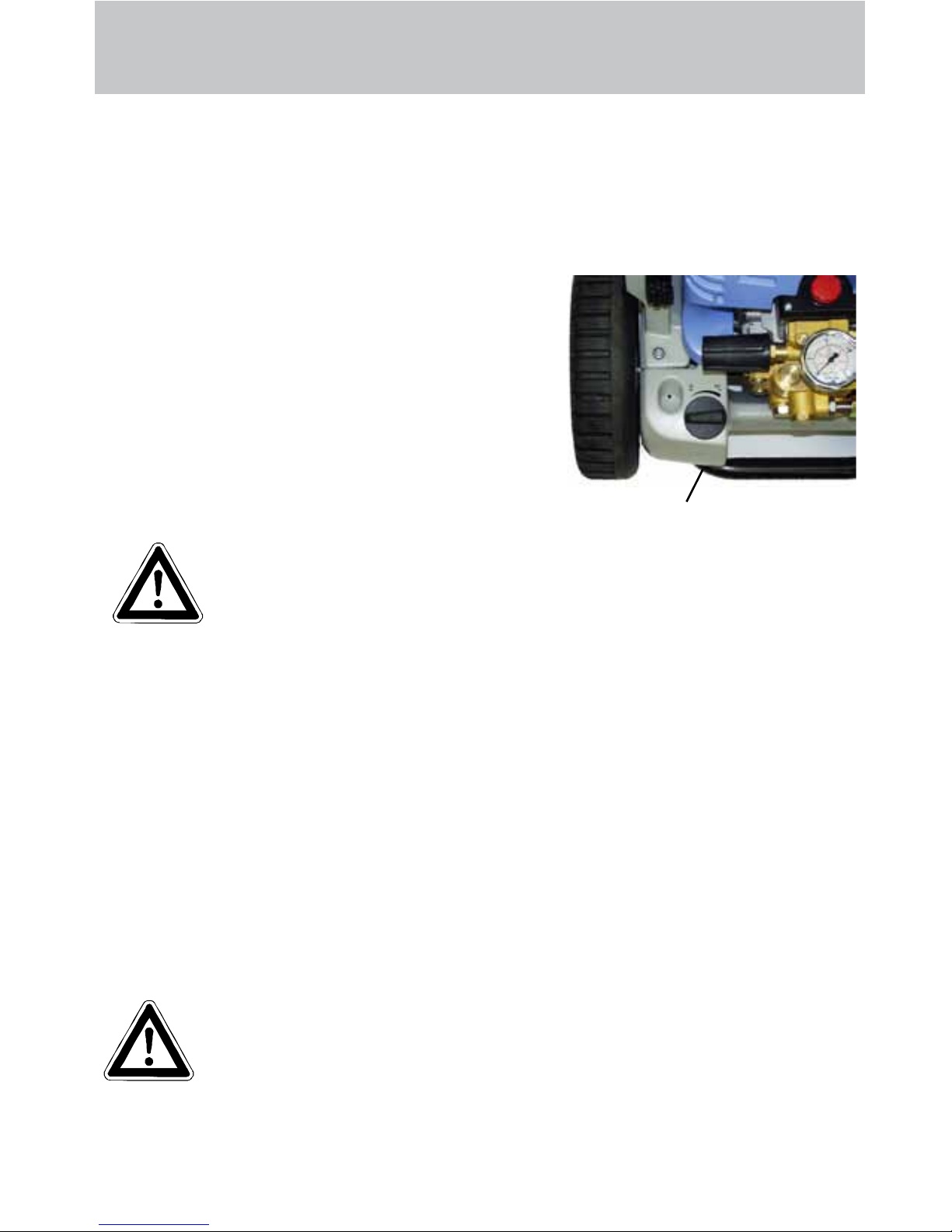

Unloader valve - safety valve

The unloader valve - safety valve protects the machine from a build up of excess

pressure, and is designed not to permit an excess pressure to be selected for

operation. The limit nut on the handle is sealed with a spray coating.

The operating pressure and spray rate can be steplessly adjusted by turning the

handle.

Replacements, repairs, new adjustments and sealing

should only be performed by qualied persons.

High pressure hose lines and spraying equipment must

not be repaired, but replaced by a new hose or spraying

equipment.

Page 7

7

Description

Delayed motor cut-out

Frequent, work-necessitated switching on and off of motors on

machines of this size puts a heavy load on the power network and

causes increased wear on internal electrical parts. Therefore the

motor of the new KRANZLE device only switches off 30 seconds after closing the

gun and then goes to stand still. By opening the gun, the device is started again.

Safety cut-out

If the device is accidentally not turned off after use or the pistol is not used for 20

minutes, the device automatically goes into the safety state via deactivating. By

operating the main switch again, the device is activated again.

When running your high pressure cleaner with hot water of 60° C

raised temperatures occur. Do not touch the machine without

safety gloves!

CAUTION !

Never suck in liquid containing solvents such as paint thinners, petrol,

oil or similar liquid matter. Pay attention to the instructions of

the manufacturers of the cleaning agents. The seals in the

machine are not resistant to solvents! The spray of solvents is inammable, explosive and poisonous.

CAUTION !

Neither set up and operate the machine in rooms where there is a risk

of re or explosion nor put it into puddles. Do not use the machine under

water. The device must not stand in the spray area of the high pressure jet.

Replacements and inspection work should only be performed by qualied persons when the machine is disconnected from the

power supply, i.e. the plug pulled out from the electrical

socket.

Setting up

Location

Page 8

Description

400 V / 50 Hz

Electrical connection

The machine is supplied with an electrical power cord with plug.

The mains plug must be tted to a standard grounded socket with a 30mA residual current operated device. The socket must be protected with a 16A delay

action fuse on the mains side.

KRÄNZLE quadro = 400 Volt / 50 Hz (phase-sequence not signicant)

When using an extension cable, this must have a grounded lead which is properly

connected to the socket. The conductors in the extension cable must have a minimum cross section of 1.5 mm². Plug connections must be of a spray-proof design

and may not be located on a wet oor.

CAUTION !

The use of extension cables which are too long may lead to malfunctions and

start up difculty.

When using a cable drum, always keep the cable wound as far as possible.

8

Page 9

9

Description

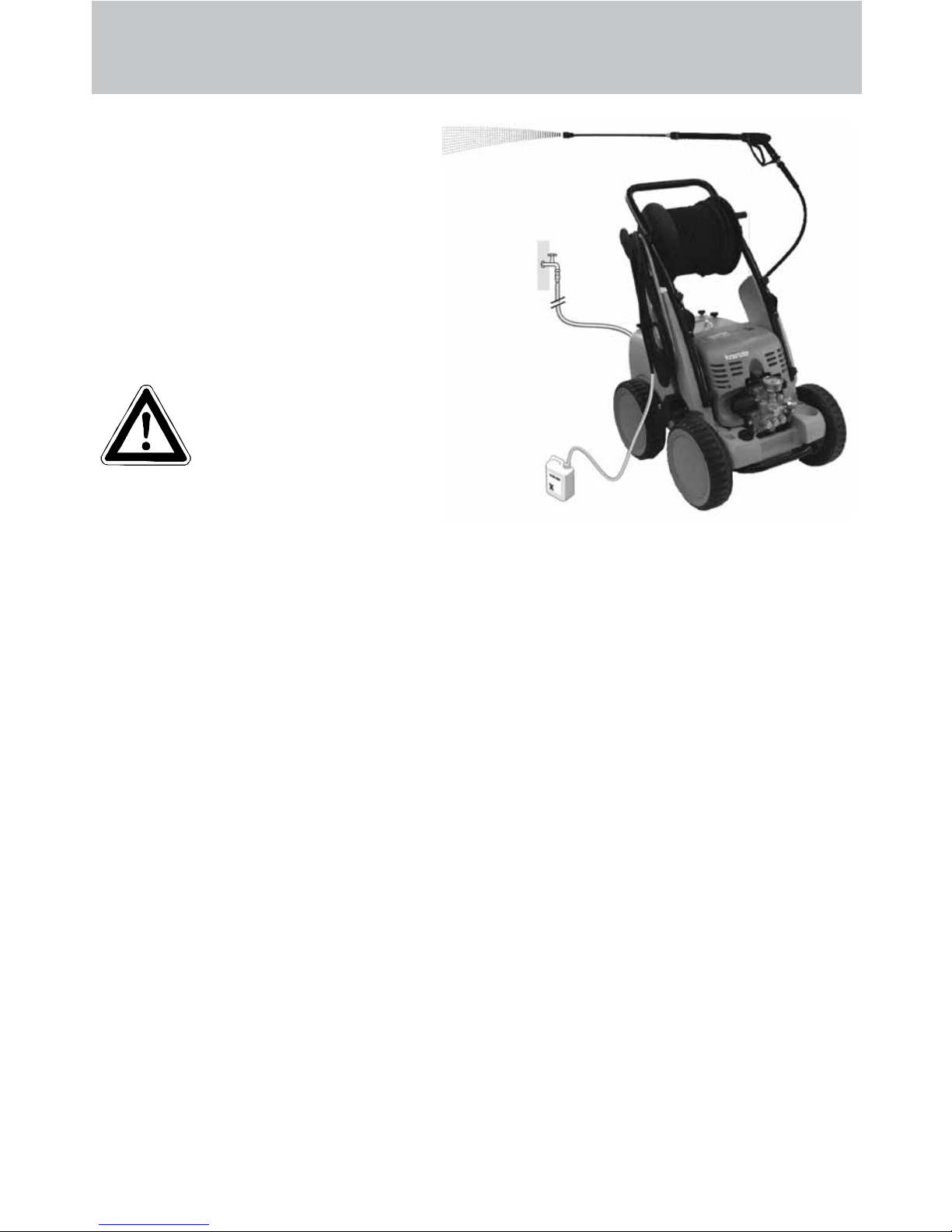

Brief operating instructions

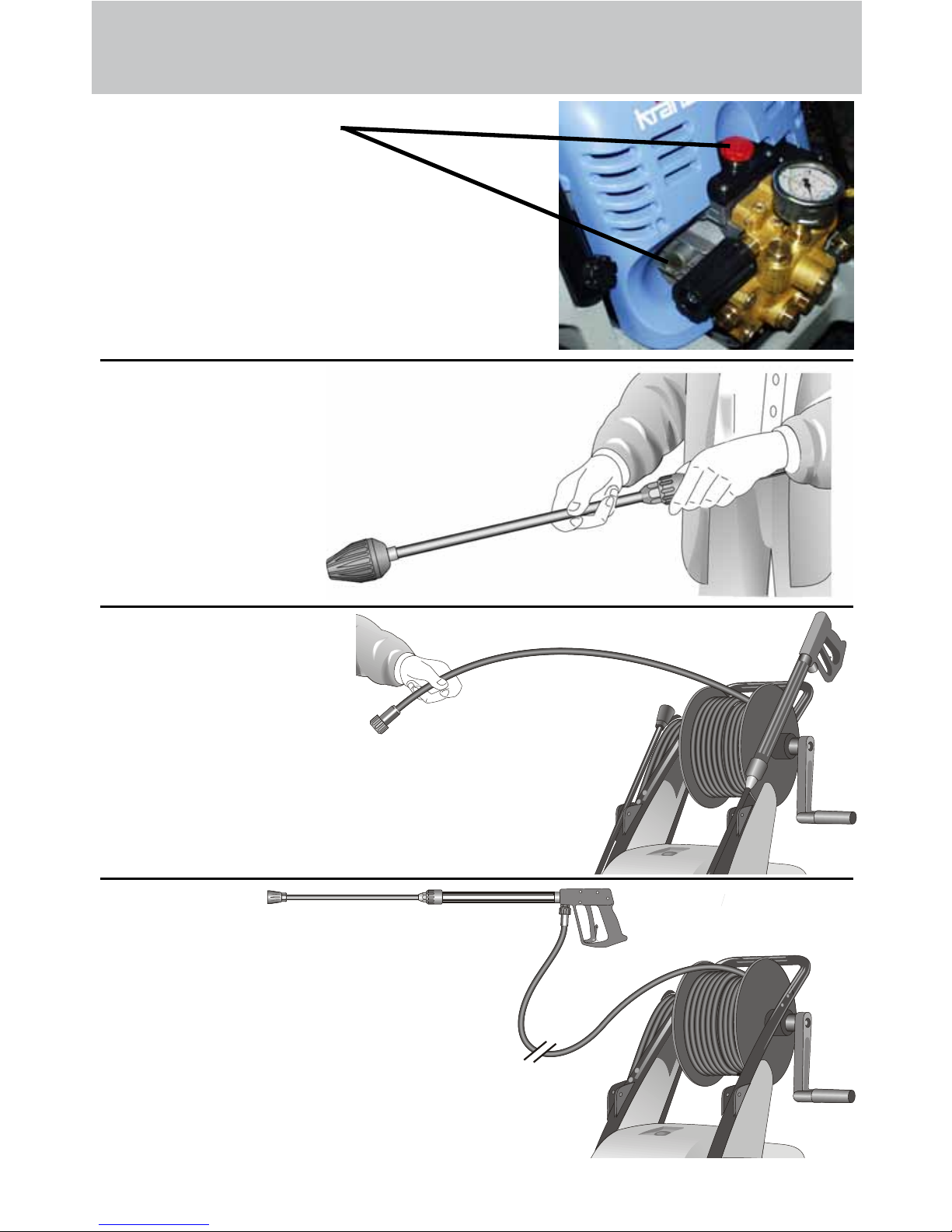

1. Connect high pressure hose with spray gun.

2. Connect to suitable water supply.

3. Connect current - (400 Volt three-phase current)

4. Switch on machine and start cleaning.

5. After having completed the cleaning process, put main switch in zero position and by opening the gun, reduce the pressure in the high pressure

hose.

Then, the high pressure hose can be rolled up

- Only use clean water ! Protect from frost !

CAUTION !

Please pay attention to the regulations of your waterworks company.

Because of the water tank, the device can be connected to any drinking water line

without worries.

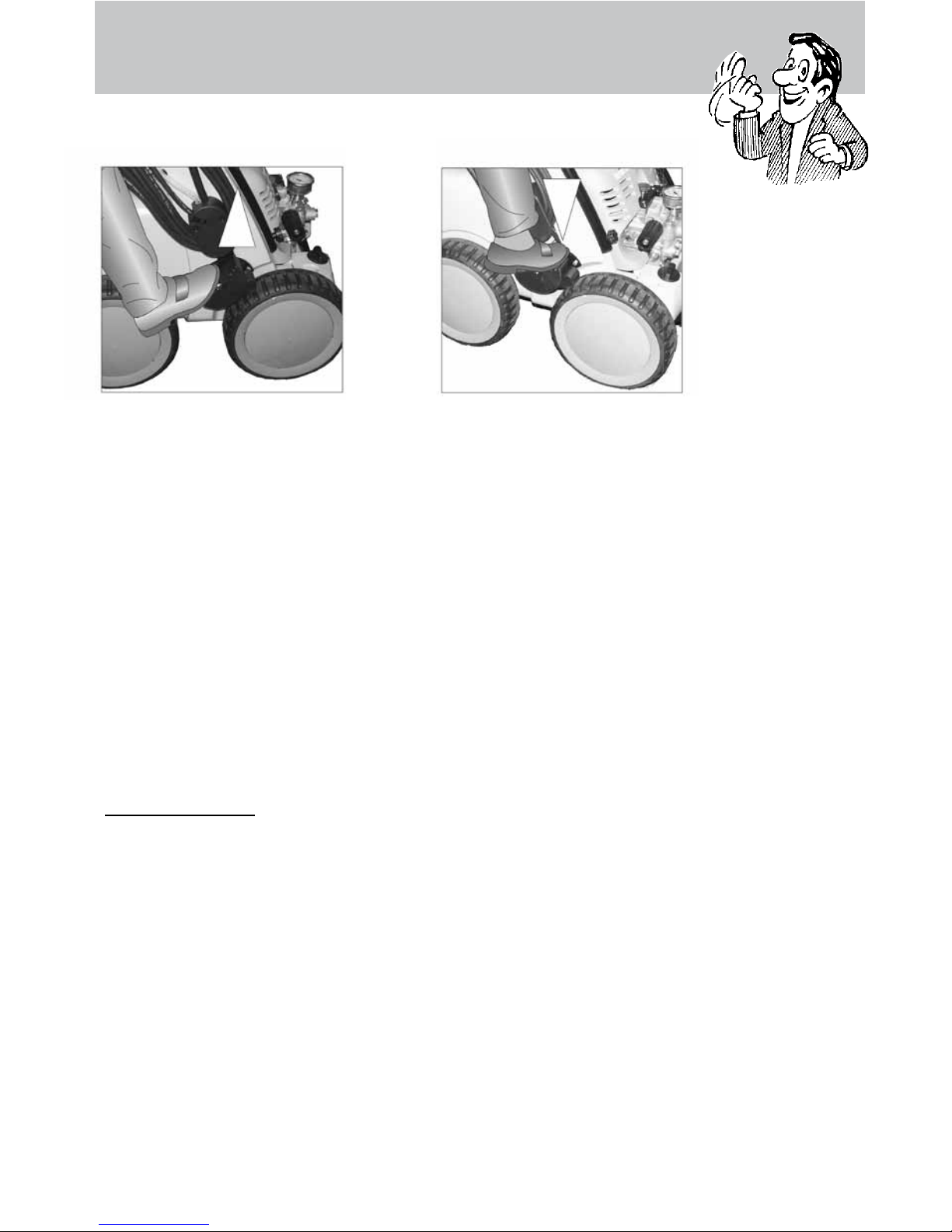

Brake not applied

Brake applied

Brake

Page 10

This is what you’ve purchased:

1. Turbokiller

Lance with nozzle

protection and high

pressure nozzle Flat jet 25°

2. Spray gun Starlet

with insulated grip an

screw connection

4. Operating

instructions

5. High pressure hose, 20 m NW 8

on hose drum

7. Water inlet part

(lter is already installed)

6. Crank for hose drum

10

R

3. KRÄNZLE - High pressure cleaners

quadro 800 TST, 1000 TST and quadro 1200 TST with hose drum

quadro 1000 TS and quadro 1200 TS without hose drum

Page 11

How to assemble and furnish your high pressure cleaner

Remove the screw from the drive shaft of the

hose drum. Unpack the crank and insert it onto

the hexagon head. Tighten the crank again with

the screw.

To check the oil level, loosen the oil

cover screw and take out the oil dip

stick. The oil level must be between

the two markings.

11

To control the high pressure cleaner

put

1. the foot against the tilt bases and

then pull the device

2. towards you.

Page 12

Preparation for use

1. Check oil level.

There are two

possibilities for checking the

oil level of the pump:

a) Oil must be visible in the viewing

window

b) The oil state must be between

the two markings on the oil

measuring rod.

3. Unroll hose without kinks and connect with handgun and pump. Use

max. 20 m HP hose.

4. Connection of high pressure

hose from device to lance

2. Connect the high pressure lance

or Turbokiller to the spray gun.

a

b

12

Page 13

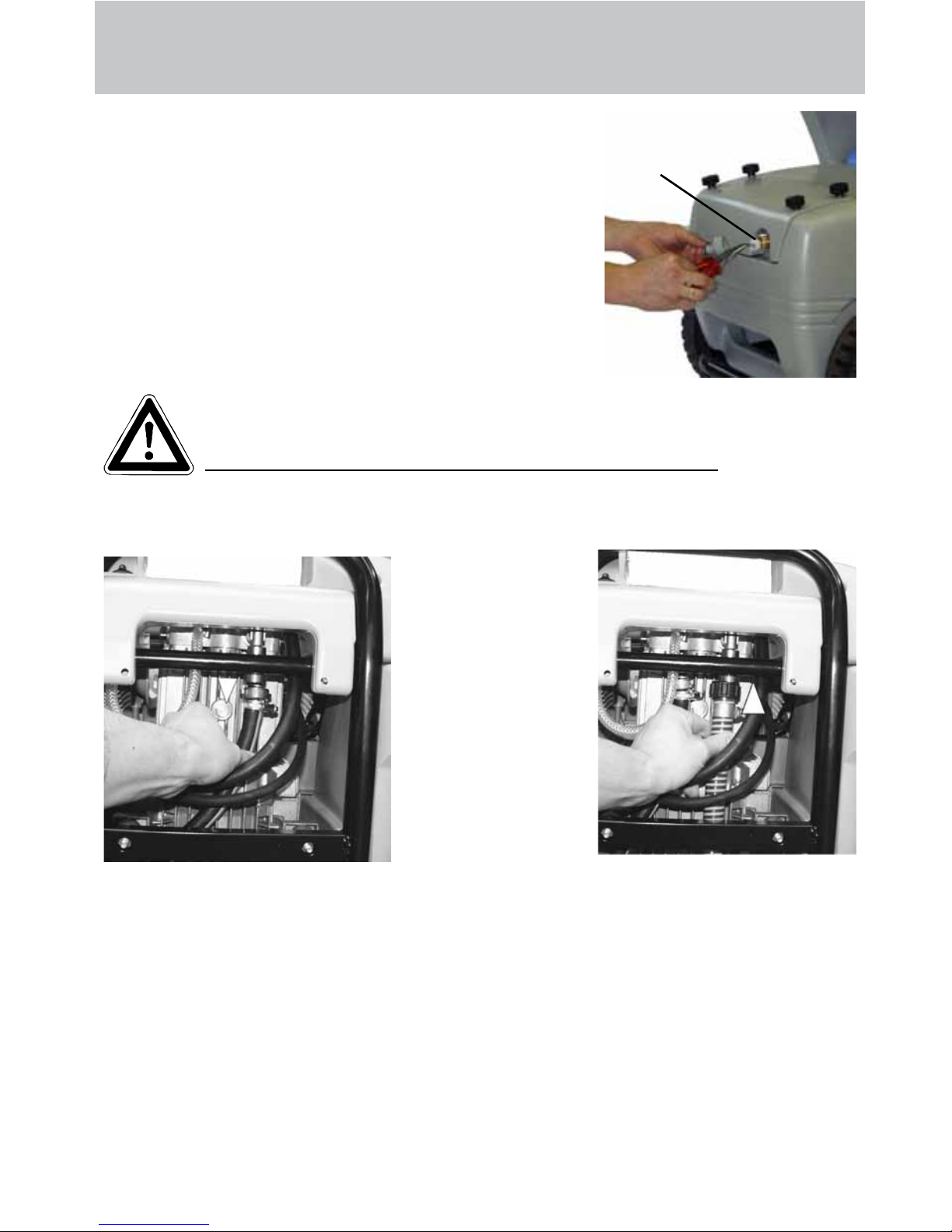

External suction

If water is to be sucked from an external container for the high pressure cleaner,

the connection hose

between the high

pressure pump and

the water tank must

be screwed off and

the suction hose

must be connected

directly to the pump.

Make sure that the

water is clean. Use

the Kränzle suction

hose with suction

lter. (Order N°. 15.038 3)

Maximum suction height 2.5 m, maximum water temperature for direct suction: 60°C

(see technical data on page 2)

Preparation for use

5. The machine must be connected to the water line

with cold water or up to 60° C warm water (see

page 2).

The hose cross section must be at least 3/4" =

16 mm (free passage). Filter 1 must always be

clean.

Please make sure that the lter is clean before

using your high pressure cleaner.

CAUTION !

When running your high pressure cleaner with hot water of 60° C raised temperatures occur.

Do not touch the pump without safety gloves!

13

1

Undercarriage

Undercarriage

Page 14

14

To shut down the pump

1. Switch off the machine. Device switch to „0“ position.

2. Cut off the water supply.

3. Open the spray gun briey until the pressure is released.

4. Apply the safety catch on the spray gun.

5. Remove the water hose and spray gun.

6. Pull the plug from the socket.

7. Winter: store the pump in rooms above 0°C.

8. Clean the water lter.

To shut down the pump:

Frost protection

Normally after operation, there is still some water in the device. Thus, you must take

special measures to protect the device from frost.

- Completely drain the device

For this purpose, separate the device from the water supply. Then, turn on the

main switch and open the gun. Now, the pump presses the remaining water from

the water tank and the pump. However, do not allow the device to operate without

water for longer than one minute.

- Fill the device with antifreeze agent

If the device is not operated for longer periods, especially over the winter, you

should pump an antifreeze agent through the device. For this purpose, ll the anti

freeze agent into the water box and turn on the device. Wait with opened gun,

until the agent comes from the nozzle.

However, the best way to protect the device from frost is

to store it at a frost-free location.

When using detergents:

Put chemistry sieve number 5 into the detergent container. Open the detergent valve, then

the detergent is sucked in. When closing the

detergent valve, the chemistry supply is automatically closed. Allow detergent to act and

then wash off. (see page 5).

Note that you must always comply

with the instructions provided by

the manufacturer of the detergent

(e.g. instructions concerning safety

clothing) and the water protection

regulations!

Page 15

Safety notes

As to the recoil see notice on page 2!

Apply the safety catch on

the spray gun after each use,

in order to prevent uninten-

tional spraying!

15

Page 16

16

This is prohibited !

Never direct the water jet at people or

animals !

Do not damage the

power cord or repair

it incorrectly !

Never pull the high

pressure hose if it

has formed kinks or

“nooses”!

Never pull the hose

over sharp edges !

Page 17

17

Never direct the water jet at the machine itself !

Never direct the

water jet at a power

socket !

Never allow children

to use the high pressure cleaner !

This is prohibited !

Page 18

Additional accessories for ...

(on demand)

Rotary scrubbing brush

Order No. 41.050 1

Drain and pipe cleaning hose

10 m - Order No. 41.058.1

15 m - Order No. 41.058

Environmental, refuse disposal and water protection

regulations must be observed when using the accessories!

18

Page 19

... further combination possibilities

Car cleaning, glass, caravan, boat etc.: rotary washing brush with 40 cm extension and

ST 30 nipple M22 x 1.5

Cleaning pipes, channels and drains: pipe

cleaning hose with KN nozzle and ST 30

nipple M22 x 1.5

Rotary point sprayer for extreme soiling:

Turbokiller with 40 cm extension and ST 30

nipple M22 x 1.5

Cleaning cars and all smooth surfaces:

brush with ST 30 nipple M22 x 1.5

19

Page 20

20

Small repairs ...

The nozzle is blocked!

No water but the gauge shows full pressure !

Rinse the hose through

rst.

You should now have a

powerful stream

of water,

but if you

only get a few

drops of water

from the

lance

remove the lance and clean

the nozzle.

Using the at spray lance you

only have to clean the front

nozzle.

Straighten a paper

clip and clean the nozzle.

Insert pointed object

into the hole and pull

the cap back!

Check visually whether the

nozzle is clean.

Now it works as well

as before.

Page 21

21

do it yourself !

Nozzle dirty or sticky!

Pressure gauge does not show full pressure

Water comes out in spurts.

If you do not use the high-pressure cleaner for some time the valves can stick

The high-pressure hose vibrates

Straighten a

paper clip...

When a valve is blocked,

the gauge

shows little

pressure or

no pressure

at all,

or the high

pressure

hose vibra-

tes!

Open the valve

with a socket

wrench...

and remove the

valve screw, the

valve and the

o-ring.

Replace the rubber o-ring.

and remove the

dirt from the valve

- the valve inside

must be closed.

Retighten the valve

screw

...and

repeat on all 6

valves.

Now it works

as well as

before!

Page 22

22

Complete Assembly

Page 23

23

quadro 800 TST - 1200 TST

Spare parts list KRÄNZLE quadro 800 TST - 1200 TST

Complete Assembly

No Description Qty. Ord.-No

No Description Qty. Ord.-No

24 Elastic-Stop-Mutter M8 4 41.410

25 Netzanschlusskabel 8 m 1 44.036

26 Schlauchtrommel kpl. 1 41.259 6

27 Chemiesaugschlauch (Gewebe) mit Filter 1 42.621

28 Gewebeschlauch 0,4m 1 42.622

29 Schlauchklemme 9 - 9 2 44.054

30 Gehäuse Waschmittelventil 1 44.145

31 O-Ring 5 x 1,5 (Viton) 1 44.150

32 O-Ring 28,24 x 2,62 1 44.149

33 Regulierkolben Chemieventil 1 44.147

34 Edelstahlfeder 1,8 x 15 x 15 1 44.148

35 Deckel für Chemieventil 1 44.146

36 Blechschraube 3,5 x 16 3 44.161

37 Blechschraube 3,5 x 19 2 44.162

38 Drehgriff Chemieventil mit Blendkappe 1 44.151

39.1 Lanze mit Flachstrahldüse für 800 TST 1 12.392-D2504

39.2 Lanze mit Flachstrahldüse für 1000 TST 1 12.392-D2505

39.3 Lanze mit Flachstrahldüse für 1200 TST 1 12.392-D2507

40 Starlett -Pistole mit Verlängerung 1 12.320 2

41.1 Turbo-Killer 04 bei quadro 800 TST 1 41.072

41.2 Turbo-Killer 055 bei quadro 1000 TST 1 41.072 4

41.3 Turbo-Killer 08 bei quadro 1200 TST 1 41.072 8

42 Hochdruckschlauch 20 m NW8 1 41.083

43 O-Ring 13 x 2,6 2 13.272

44 Verbindungsschlauch mit Winkel 1 42.625 1

45 Scheibe 8mm für Rad 4 44.246

46 Gewindestift M6x55 4 42.617 2

47 Rückschlagventil für Chemiesaugschl. 1 44.240

48 Chemieventil Kpl. Pos. 30-37 1 44.052

49 Wasserlter 1 42.633

Motor-Pumpe ohne Elektrik

1.1 für quadro 800 TST 1 42.622 1

1.2 für quadro 1000 TST 1 42.622 2

1.3 für quadro 1200 TST 1 42.622 3

1.4 für quadro 1000 TS 1 42.622 7

1.5 für quadro 1200 TS 1 42.622 8

2 Schubbügel 1 42.601

3 Sterngriffmutter M8 4 42.619

4 Stopfen 2 42.613

5 Wasserkasten 1 42.603

6 Lanzenablage 1 42.604

7 Kabelaufwicklung unten 1 42.611

8 Zugentlastung 1 43.431

9 Blechschraube 3,5 x 12 2 40.290

10 Kunststoffschraube 5,0 x 25 6 41.414

11 Scheibe 21 DIN125 12 40.207

12 Schraube M8x50 DIN912 2 42.620

13 Scheibe 8,4 DIN125 2 50.186

14 Kabelaufwicklung oben 1 42.612

15 Gummipuffer 25 x 25 4 44.227

16 Rad 4 44.017

17 Splint 5x28 DIN94 4 42.614

18 Radkappe 4 44.018

19.1 Frontplatte quadro 800 TST 1 42.609 1

19.2 Frontplatte quadro 1000 TST 1 42.609 2

19.3 Frontplatte quadro 1200 TST 1 42.609 3

20 Lanzenhalter 2 42.610

21 Blechschraube 3,5x16 DIN7981 4 44.161

22 Fahrgestell 1 42.602

23 Scheibe 8,4 DIN9021 4 41.409

Page 24

24

Brake

No Description Qty. Ord.-No

1 Grundplatte 1 42.615

2 Bremspedal 1 44.022

3 Bremshebel 1 44.023

4 Bremsklotz 1 44.024

5 Stift 6 x 50 1 44.035

6 Starlock-kappe 8 mm 1 44.165

7 Stift 6 x 40 1 44.035 1

8 Distanzring 2 42.626

9 Sechskantschraube M6x16 3 50.173

10 Unterlegscheibe DIN125-6,3 3 50.189

Spare parts list KRÄNZLE quadro 800 TST - 1200 TS

Brake

Page 25

25

Water inlet

No Description Qty. Ord.-No

Spare parts list KRÄNZLE quadro 800 TST - 1200 TS

Water inlet

1 Mutter R3/4“ 1 46.258

2 Revisionsdeckel 1 42.605

3 Sterngriffmutter M8 4 42.619

6 Dichtung für Schwimmerventil 1 46.261

7 Schwimmerventil 1 46.250

8 Gewindestift M6x40 4 42.617 1

9 Einströmschlauch 1 42.640

Page 26

26

Pump motor

Page 27

27

quadro 800 TST - 1200 TS

No Description Qty. Ord.-No

Spare parts list KRÄNZLE quadro 800 TST - 1200 TS

Pump motor

50 Motor compl. without switch 1 24.060

51 Schaltkasten kpl. Pos. 23 - 42 42.631

1 Stator 112 5,5kW 400V / 50Hz 1 40.540

2 A-Lager Flansch 1 40.530

3 Rotor 112 (400V / 50Hz) 1 40.531 5

4 Lüfterrad für BG 112 1 40.532

5 Lüfterhaube BG 112 1 40.533

6 V-Seal 1 40.545

7 Flachdichtung 1 43.030

10 Kegelrollenlager 31306 1 40.103

11 Öldichtung 35 x 47 x 7 1 40.080

12 Passfeder 8 x 7 x 28 1 40.459

13 Kugellager 6206 - 2Z 1 40.538

14 Innensechskantschraube M 6 x 30 4 43.037

19 Schraube M 4 x 12 4 41.489

20 Schelle für Lüfterrad 112 2 40.535

21 Schraube M 4 x 12 4 41.489

22 Erdungsschraube kpl. 1 43.038

23 Schalter 14,5 A Amazonas 1 41.111 6

24 Kunststoffschraube 4,0 x 16 6 43.417

25 Bock für Schalter 1 42.608

26 Kunststoffschraube 5,0 x 25 6 41.414

28 Kunststoffschraube 3,5 x 20 2 43.415

29 Lüsterklemme 5-pol. 1 43.326 1

30 Schütz 100-C12KN10 3x400V 50/60 Hz 1 46.005 1

31 Schaltkasten Unterteil 1 42.606

32 Schaltkasten Deckel 1 42.607

33 Steuerplatine Abschaltverz. 400V / 50Hz 1 42.563

34 Klemmrahmen mit Schalterabdichtung 1 43.453

36 Blechschraube 3,5 x 16 2 44.161

37 PG 16-Verschraubung 1 41.419 1

38 Dichtung für Schaltkastendeckel 1 42.607 1

39 Gegenmutter für PG9-Verschraubung 1 41.087 1

40 Gegenmutter für PG16-Verschraubung 1 44.119

41 PG 9 - Verschraubung 1 43.034

42 Überstromauslöser 3-polig 11,3-16A 1 42.641

Page 28

28

Transmission unit

Page 29

29

quadro 800 TST - 1200 TST

No Description Qty. Ord.-No

Spare parts list KRÄNZLE quadro 800 TST - 1200 TST

Pump transmission unit for AQ-Pump

1 Ölgehäuse 1 40.501

4 Innensechskantschraube M 8 x 30 6 41.036 1

5 Sicherungsscheibe 6 40.054

6 Flachdichtung 1 40.511

7 Öldichtung 20 x 30 x 7 3 40.044 1

9 Axial-Zylinderrollenlager AQ-Pumpe 1 40.524

11.1 Taumelscheibe AQ 9,5° 1 40.523-9,5

bei quadro 800 TST

11.2 Taumelscheibe AQ 10,8° 1 40.523-10,8

bei quadro 1000 TST + 1000 TS

11.3 Taumelscheibe AQ 12,75° 1 40.523-12,75

bei quadro 1200 TST + 1200 TS

12 Plungerfeder 3 40.506

13 Federdruckscheibe 3 40.510

14 Plunger 20 mm (lang) 3 40.505

15 Sprengring 3 40.048

16 O-Ring 14 x 2 1 43.445

18 Flachdichtung 1 41.019 3

19 Deckel ach für Ölgehäuse 1 41.023 1

20 Innensechskantschraube M 5 x 12 4 41.019 4

21 Ölmessstab AQ 1 40.463

22 Stützscheibe für Plungerfeder 3 40.513

23 O-Ring 13,94 x 2,62 1 42.167

24 Ölablassstopfen R 3/8“ 1 42.019

Ölgehäuse AQ kpl. ohne Taumelscheibe 40.514

Pos. 1, 4-7, 12-17, 22

Page 30

30

Unloader valve and pressure switch

Page 31

31

quadro 800 TST - 1200 TST

Spare parts list quadro 800 TST - 1200 TST

Unloader valve and pressure switch

No Description Qty. Ord.-No

No Description Qty. Ord.-No

Repair kits:

Repair kit 15.009 3

Pressure switch

1x Pos. 51, 1x Pos. 52, 1x Pos. 53,

3x Pos. 54, 1x Pos. 55, 1x Pos. 56,

1x Pos. 57, 1x Pos. 58, 1x Pos. 59

Pressure switch compl. No. 54 - 70 41.300 5

5 O-Ring 16 x 2 1 13.150

5.1 O-Ring 13,94 x 2,62 1 42.167

8 O-Ring 11 x 1,44 1 12.256

9 Edelstahlsitz 1 14.118

10 Sicherungsring 1 13.147

11 Edelstahlkugel 1 13.148

12 Edelstahlfeder 1 14.119

13 Verschlussschraube 1 14.113

14 Steuerkolben 1 14.134

15 Parbaks 16 mm 1 13.159

16 Parbaks 8 mm 1 14.123

17 Spanstift 1 14.148

18 Kolbenführung spezial 1 42.105

19 Kontermutter M 8 x 1 2 14.144

20 Ventilfeder rot bei quadro 800 1 14.125 1

20.1 Ventilfeder schwarz 1 14.125

bei quadro 1000 und 1200

21 Federdruckscheibe 1 14.126

22 Nadellager 1 14.146

23 Handrad 1 14.147

25 Elastic-Stop-Mutter M 8 x 1 1 14.152

26 Manometer 0-400 Bar 1 15.039 4

27 Aluminium-Dichtring 2 13.275

50 O-Ring 3,3 x 2,4 1 12.136

51 Führungsteil Steuerstößel 1 15.009 1

52 O-Ring 13 x 2,6 1 15.017

53 O-Ring 14 x 2 1 43.445

54 Parbaks 4 mm 2 12.136 2

55 Stützscheibe 2 15.015 1

56 Edelstahlfeder 1 15.016

57 Steuerstößel 1 15.010 2

58 Parbaks 7 mm 1 15.013

59 Stopfen M 10 x 1 (durchgebohrt) 1 13.385 1

60 Gehäuse Elektroschalter 1 15.007

61 Gummimanschette PG 9 1 15.020

62 Scheibe PG 9 1 15.021

63 Verschraubung PG 9 1 15.022

64 PVC-Kabel 2x 1,0 mm² 1 42.505

65 Blechschraube 2,8 x 16 6 15.024

66 Deckel Elektroschalter 1 15.008

67 O-Ring 44 x 2,5 1 15.023

68 Mikroschalter 1 44.262

69 Zylinderschraube M 4 x 20 2 15.025

70 Sechskant - Mutter M 4 2 15.026

72 Druckfeder 1 x 8,6 x 30 1 40.520

Page 32

32

Valve housing

Page 33

33

Spare parts list KRÄNZLE quadro 800 TST - 1200 TST

Valve housing for integrated AQ-pump

No Description Qty. Ord.-No

No Description Qty. Ord.-No

quadro 800 TST - 1200 TST

Repair kits:

Repair kit for sleeves 40.065 1

consisting of: 3x Pos. 13; 6x Pos. 14;

3x Pos. 15; 3x Pos. 16; 3x Pos. 18;

3x Pos. 20; 3x Pos. 23

Repair kit for sleeves without 40.517

brass parts consisting of:

3x Pos. 13; 6x Pos. 14; 3x Pos. 15;

3x Pos. 18; 3x Pos. 23

Repair kit valves 40.062 1

consisting of:

6x Pos. 2; 6x Pos. 3; 6x Pos. 4

1 Ventilgehäuse AQ mit integr. UL und 1 40.503 5

Druckschalter

2 O-Ring 18 x 2 6 40.016

3 Einlaß- / Auslaß- Ventil 6 42.024

4 O-Ring 21 x 2 6 42.025

5 Ventilstopfen 5 42.026

5.1 Ventilstopfen mit R 1/4“ IG 1 42.026 2

6 Sicherungsring 4 40.032

7 Innensechskantschraube M 12 x 45 4 40.504

8 Schlauchnippel R3/8“ x 6 1 42.634

9 Schlauchschelle 7 - 10 1 44.054

10 Chemiesaugschlauch mit Filter 1 42.621

11 Winkel 12L x 12L 1 42.630

13 Gewebemanschette 3 40.023

14 Backring 20 mm 6 40.025

15 O-Ring 31,42 x 2,62 3 40.508

16 Leckagering 20 x 36 x 13,3 3 40.509

17 Cu-Dichtring 21 x 28 x 1,5 2 42.039

18 Gummimanschette 3 40.512

19 Verschlussschraube R 1/2“ 2 42.032

20 Distanzring mit Abstützung 3 40.507

21 Aluminium-Dichtring bei quadro TS 2 13.275

22 Verschlussstopfen bei quadro TS 1 13.181

23 Druckring 20 mm 3 40.021

24 Zwischenring 20 mm 3 40.516

25 O-Ring 11 x 1,5 1 12.256

26 Edelstahlsitz Ø 7 1 14.118

27 Sprengring 1 13.147

28 Ausgangsteil Pumpe R1/4“ x 12 1 44.215

29 Dichtring 17 x 22 x 1,5 (Kupfer) 1 40.019

30 Stopfen 3/8“ 1 40.018

31 Dichtstopfen M 10 x 1 1 43.043

32 Dichtstopfen M 8 x 1 2 13.158

33 Ausgangsteil 1 40.522

für quadro 800, 1000, 1200 TST

33.1 Ausgangsteil M22x1,5 1 40.522 1

für quadro 1000, 1200 TS

34 Edelstahlkugel Ø10 1 12.122

35 Rückschlagfeder „K“ 1 14.120 1

37 O-Ring 18 x 2 1 43.446

40 Wassereingang R3/8“ AG 1 41.016

Page 34

34

Hose drum

Page 35

35

quadro 800 TST - 1200 TST

No Description Qty. Ord.-No

Spare parts list KRÄNZLE quadro 800 TST - 1200 TST

Hose drum

No Description Qty. Ord.-No

Hose drum compl. without hose 41.259 6

1 Seitenschale Schlauchführung 1 40.302

2 Seitenschale Wasserführung 1 40.301

3 Trommel Unterteil 1 40.304

4 Trommel Oberteil 1 40.303

5 Innensechskantschraube M 4 x 25 4 40.313

6 Lagerklotz mit Bremse 1 40.306

7 Lagerklotz links 1 40.305

8 Klemmstück 2 40.307

9 Kunststoffschraube 5,0 x 20 12 43.018

10 Antriebswelle 1 40.310

11 Welle Wasserführung 1 40.311

12 Elastic-Stop-Mutter M 4 4 40.111

13 Handkurbel klappbar 1 40.320 0

14 Verriegelungsbolzen 1 40.312

15 Scheibe MS 16 x 24 x 2 1 40.181

16 Wellensicherungsring 22 mm 2 40.117

17 Wellensicherungsring 16 mm 1 40.182

20 Parbaks 16 mm 2 13.159

21 Sicherungsscheibe 6 DIN6799 1 40.315

22 Schraube M 5 x 10 1 43.021

23 Drehgelenk 1 40.167

25 Distanzring 1 40.316

27 O-Ring 6,86 x 1,78 1 40.585

28 Anschlussstück 1 40.308

33 O-Ring 6 x 1,5 1 13.386

34 Stopfen M 10 x 1 1 13.385

40 Überwurfmutter 1 13.276 2

42 O-Ring 9,3 x 2,4 4 13.273

44 Verbindungsschlauch 1 42.624

45 Hochdruckschlauch NW 8 20 m 1 41.083

Page 36

36

Starlet II

No Description Qty. Ord.-No

Starlet-Gun with prolongation 12.320 2

Repair kit: „Starlet II“ 12.299

consisting of: 1x Position: 8, 9, 13-16, 24-26

1 Ventilkörper mit Handgriff 1 12.294

2 Schutzhülse 1 12.295

3 Abdeckschutz 1 12.296

4 Betätigungshebel grau 1 12.298 3

5 Sicherungshebel 1 12.149

6 Abschlussschraube M 16 x1 1 12.247

7 Stopfen 1 12.287

8 Gewindeführungshülse Ø3 R 1/4“ AG 1 12.250 1

9 Aufsteuerbolzen Ø3 1 12.284 1

10 Stift 1 12.148

11 Lagernadel 1 12.253

12 Edelstahlfeder 1 12.246

13 Edelstahlkugel 8,5 1 12.245

14 Edelstahlsitz Ø7 1 14.118

15 O-Ring 11 x 1,44 1 12.256

16 O-Ring 2,84 x 2,62 1 12.136 1

17 Blechschraube 3,9 x 8 4 12.297

18 Druckstück 1 12.252

19 Rohr kunststoffumspritzt bds. R 1/4“ AG 1 15.004 5

20 Überwurfmutter ST 30 M22 x 1,5 IG 1 13.276 1

21 Außen-Sechskant-Nippel R 1/4“ IG 1 13.277 1

22 O-Ring 9,3 x 2,4 1 13.273

23 Aluminium-Dichtring 4 13.275

24 O-Ring 15 x 1,5 1 12.129 1

25 Sicherungsring 1 12.258

26 Gleitschuh Ø3 1 12.289 1

51 Düsenschutz 1 26.002

52 Rohr 600 mm; bds. R1/4“ 1 12.385 2

53 ST 30 Nippel M 22 x 1,5 / R1/4“ m. ISK 1 13.370

54 Flachstrahldüse 2504 (bei quadro 800) 1 D2504

54.1 Flachstrahldüse 2505 (bei quadro 1000) 1 D2505

54.2 Flachstrahldüse 2507 (bei quadro 1200) 1 D2507

Page 37

37

Turbokiller

No Description Qty. Ord.-No

11 Sprühkörperschutz 1 41.528

12 Sprühkörper 1 41.529

13 O-Ring 6,88 x 1,68 1 41.521

14 Düsensitz 1 41.522

15 Düse 04 für quadro 800 1 41.532 0

15.1 Düse 055 für quadro 1000 1 41.532

15.2 Düse 08 für quadro 1200 1 41.537

16 Ring 1 41.533

17 Rotor 1 41.534

18 Stabilisator 1 41.524

19 O-Ring 41 x 1,78 1 41.538

20 Deckel 1 41.539

21 Deckelschutz 1 41.540

22 Rohr 500 mm lang; bds. R1/4“ 1 12.385 1

23 Nippel M22x1,5 x R1/4“ IG 1 13.370

Turbokiller 04 compl. with lance 41.072

Turbokiller 055 compl. with lance 41.072 4

Turbokiller 08 compl. with lance 41.072 8

Repair Kit Turbokiller 04 41.096 9

Repair Kit Turbokiller 055 41.097 1

Repair Kit Turbokiller 08 41.097 3

Spare parts list KRÄNZLE quadro 800 TST - 1200 TST

Turbokiller

Page 38

38

Wiring diagram

On-Off switch

with 14,5 Ampere

overload protection

Inlet line via

CEE 5x 16 A

400 V / 50 Hz

Pump motor

3x 400 V / 50 Hz

Pressure switch

Control plate with

Transformer 400 V / 50 Hz

Excess cur-

rent release

12 A

Page 39

39

Inspections

Accident prevention

The machine must be inspected according to the “Guidelines for Liquid Spray Devices” at least once every 12 months by a qualied person, to ensure that continued safe operation is guarateed.

The results of the inspection are to be recorded in writing.

This may be done in any form.

General rules

The machine is designed for accidents to be impossible if used correctly.

The operator is to be notied of the risk of injury from hot machine parts and the

high pressure water jet. The “Guidelines for Liquid Spray Devices” must be com-

plied with. (see pages 16 and 17)

Check the oil level at the oil dip stick prior to each use (see also page 11).

(Ensure horizontal position!)

Oil change:

The rst oil change should be carried out

after approximately 50 operating hours,

then every year or after 1000 operating

hours. If the oil turns grey or white, you

must certainly change the oil of your high

pressure pump.

Open the oil discharge screw at the bottom of the device over a collection resevoir.

Put the machine into a horizontal position

to drain the oil. The oil is to be caught in the

reservoir and disposed of in an approved

manner.

New Oil: 1,0 l Motor oil: 10/W60 SAE halfsynthetic oil

Page 40

40

for KRÄNZLE - High Pressure Cleaners

The high pressure cleaner must be inspected

by an expert every 12 months.

Appliance No.: Type of appliance:

The following must be checked:

1. Safety features

a) Manometer

b) Safety valve (pressure control)

c) Operating pressure

d) Cut out pressure (max. 10% above

operating pressure)

e) Low pressure with closed gun

2. General condition

a) High pressure hose

b) Cable, plug, switch (VDE)

c) Spray gun, spray accessories.

d) Motor

e) Oil level

Result of inspec-

tion:

Date of inspection:

Faults rectied,

Stamp and signature

Excerpt from the Guidelines for Liquid Spray Equipment (ZH 1/46) by the Central Ofce of the Professional Trade Association.

Inspection:

Liquid spray equipment should be inspected for safe operation by a qualied person whenever necessary, but no less than every 12 months. The maker’s or supplier’s instructions must be followed. The

inspection intervals may be extended if the equipment is not in active use.

The results of inspections must be recorded in writing and presented to the respective authorities on

demand. There is no set form for these records.

The information in the operating instructions are a part of

the inspection

Inspection report

Page 41

42

Guarantee

The guarantee is only valid for material and manufacturing errors.

Wearing does not fall within this gurantee.

The instructions in our operating manual must be complied with. The operating

instructions form part of the guarantee. The Guarantee is void if other parts are

used than genuine Kränzle accessory parts or genuine Kränzle spare parts.

For high-pressure cleaners sold to the user the guarantee period is 24 month.

For high-pressure cleaners sold for industrial use the guarantee period is 12

month. In the case of a guarantee please contact your dealer or authorized

seller delivering accessories and your purchase receipt. You can nd them in the

internet under www.kraenzle.com.

The guarantee is also void if the machine is used with exceeding the temperature

and speed limits, a voltage below the required rating, with less than the required

amount of water or with dirty water. Pressure gauge, nozzle, valves, sleeves, high

pressure hose and spray equipment are wear parts and are not covered by the

warranty.

Warranty

Page 42

Notes

42

Page 43

I. Kränzle GmbH

Elpke 97 . 33605 Bielefeld

High-pressure-cleaners

Hochdruckreiniger

Nettoyeurs à Haute Pression

R

We hereby declare,

that the high-pressure models:

(techn. documentation available from):

Nominal ow:

comply with the following guidelines and

specications and their amendments for

high-pressure cleaners:

Sound power level measured:

guaranteed:

Applied conformity evaluation

procedures:

Applied specications and

standards:

EC declaration of conformity

Bielefeld, den 29.02.12

Kränzle quadro 800/1200 TST

Kränzle quadro 1000/1200 TS

Manfred Bauer, Fa. Josef Kränzle

Rudolf-Diesel-Str. 20, 89257 Illertissen

K quadro 800 TST: 798 l/h

K quadro 1000 TST: 960 l/h

K quadro 1200 TST: 1140 l/h

Machine guideline 2006/42/EEC

Specication for electromagnetic

compatibility 2004/108/EEC

Outdoor noise directive 2005/88/EC,

Art. 13, High-pressure water jet machines

Appendix 3, part B, chapter 27

89 dB (A)

91 dB (A)

annex V, noise directive 2005/88/EC

EN 60 335-2-79 :2009

EN 55 014-1 :2006

EN 55 014-2 / A2:2008

EN 61 000-3-2 : 2006

EN 61 000-3-3 : 2008

Kränzle Josef

(Managing Director)

Page 44

Reprint only allowed with the authorization of .

As date of 29.02.2012

Order-N°.: 30.260 1

R

K r ä n z l e – w o r l d - w i d e :

Te c h n i c a l p e r f e c t i o n , t o p d e s i g n .

Loading...

Loading...