Kranzle bully 980 TS, bully 980 TST, bully 1180 TS, bully 1180 TST, bully 1000 TST Operating Manual

Page 1

EN

Operating manual

High-pressure cleaner

bully 980 TS

bully 980 TST

bully 1180 TS

bully 1180 TST

bully 1000 TST

www.kraenzle.com

Page 2

Operating manual

High-pressure cleaner

bully 980 TS

bully 980 TST

bully 1180 TS

bully 1180 TST

bully 1000 TST

EN

Operating manual!

This manual is a translation of the original manual.

instructions before use! Technical data will be found in the Spare parts list.

Please be aware that the spare part list is part of the operating manual.

Keep both leaflets for later use or any subsequent owners.

2 3

Read and conform safety

Page 3

Contents Explanatory symbols

Dear customer:

We would like to congratulate you on the purchase of your new high pressure

cleaner and thank you for your confidence in our products!

Your choice has fallen on an absolute quality product!

Kränzle high pressure cleaners are characterized by their convenient and compact

design as well as their high suitability for everyday use.

Highest precision and dimensional accuracy in addition to a technology package

consisting of a multitude of details mark the dierence when it comes to

performance, safety and durability.

In order to facilitate handling of the high pressure cleaner, the following pages are

intended to further explain its use. The illustrations may be subject to deviation

depending on the type of equipment or accessory of high pressure cleaner

purchased by you.

Contents ........................................................................................... 4

Explanatory symbols .................................................................

Safety notes ................................................................................... 6

Description of high pressure cleaner ................................. 1

General rules .................................................................................. 1

Functional details ........................................................................ 1

Putting into operation ..............................................................

Direct suction ...............................................................................

Taking out of operation ............................................................

Small repairs - do it yourself ................................................... 26

Kränzle accessories ..................................................................... 30

EU Declaration of Conformity ................................................

Warranty ......................................................................................... 33

Inspection reports ....................................................................... 34

Explanatory symbols used in the operating manual

Failure to observe this note may entail

environmental damage.

Note on the use of the high pressure cleaner that failure to

adhere to the instructions may cause excessive wear or total

breakdown of the bully-series.

Warning!

Failure to observe this note may result in serious injuries!

Explanatory symbols affixed to the high-pressure cleaner

In case of improper use, the high pressure jets can be

very dangerous. Do not direct high pressure jet at persons,

animals or active electrical equipment or the high-pressure

cleaner itself.

The high-pressure cleaner may not be connected directly

to the public drinking water supply network.

Risk of burns due to hot surfaces!

Products marked with this symbol may contain constituents

posing a risk to health or the environment if incorrectly disposed of. These products must never be disposed of as

household waste.

Explanatory symbols affixed on the packaging

This symbol denotes recyclable packaging materials

which must not be disposed of as household waste.

Information on proper disposal will be gathered from

the recycling directives issued by your local authority.

4 5

Page 4

Safety notes

Safety notes - This is prohibited!

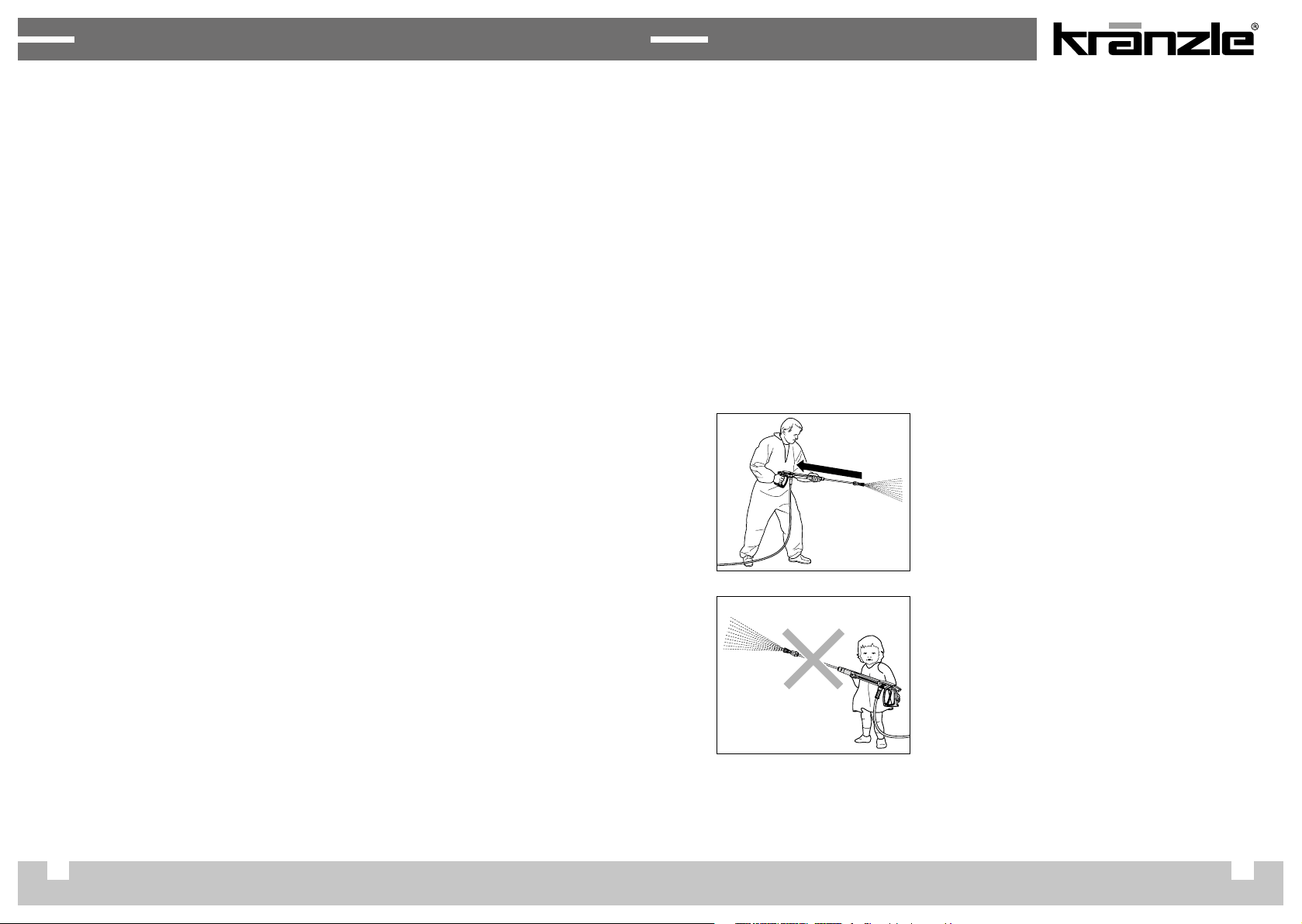

User operating the high-pressure cleaner should wear the necessary protective

clothing, i.e. waterproof clothing, rubber boots, safety goggles, ear protection

headwear etc. It is prohibited to use the high-pressure cleaner in close vicinity

to people lacking suitable protective clothing.

Use of high-pressure cleaners may result in aerosols being generated. An aerosol

is a mixture of floating solid or liquid particles in a gas. Inhaling aerosol particles may cause damage to health. Employers are under obligation to carry out

a hazards assessment in order to determine the necessary protective measures

to prevent inhalation of aerosols as governed by the surface due to be cleaned

in each case. Respiratory masks, Class FFP 2 or higher, are suitable for protection

against aqueous aerosols.

Whenever the high-pressure cleaner is left unattended, the mains disconnect

switch must always be switched off.

Do not spray against matter containing asbestos or other hazardous substances!

Never spray flammable liquids or liquids containing solvents such as paint thinners,

petrol, oil or similar liquids! Explosion hazard due to spraying such materials!

Due to the high pressure jet, damage may occur on the objects to be cleaned,

e.g. car tires; therefore, a minimum distance of 30 cm is to be kept!

Prior to putting the high-pressure cleaners into operation, check its components

(High pressure hose, power supply cables, safety trigger gun) for any damage.

Replace defect or damaged components!

Replacement of the power supply cables is only permitted by use of an original

power supply cable of the manufacturer and must be performed by a qualified

electrician.

Safety devices serve to protect the user and must never be de-activated or their

function bypassed.

The high-pressure cleaner is to be properly used. The user is required to adhere

to local requirements and to watch out for the persons in the danger zone!

If used in elevated positions where there is a risk of the unit falling to the ground,

it must be secured against rolling away or tipping over.

The high-pressure cleaner is not designed for use by persons with restricted physical,

sensory or mental abilities (including children)!

When using high pressure water for cleaning,

make sure that there is a clearly noticeable recoil

effect on the lance. Therefore ensure a firm

footing (see technical data).

Only use high-pressure hoses, couplings and fittings recommended by Kränzle.

Only these accessories ensure safety of the equipment.

If use is made of an extension cable, this must be suitable for outdoor use. In

addition care needs to be taken to ensure that the cable is kept dry and that it is

situated above the ground. We recommend the use of a cable drum capable of

keeping the socket at least 60 mm above the ground.

6 7

Never allow children or untrained persons to

use the high pressure cleaner or to play with it!

Children must be kept under supervision to

prevent them from playing with the equipment.

Page 5

Safety notes - This is prohibited!

Safety notes - This is prohibited!

Never direct the high pressure jet at the high

pressure cleaner itself! The high pressure cleaner

may not be placed within reach of the high

pressure jet spray mist!

Never direct the high pressure jet at power sockets

or any other electrical installations! Within the

working area, all live parts are to be protected

from both water jet and spray mist.

Always pay attention to the underbody lance

resting on the surface! Bear in mind when using

a curved or angled spraying lance that there is

a significant amount of torque in the recoil!

(The underbody lance is available as

optional accessory).

Never direct the high pressure jet at people or

animals! Never direct the high pressure jet at

yourself or other persons, not even to clean

clothing or shoes.

Only use a power supply cable in perfect working

order! Do not damage or improperly repair the

power cable (tearing, squeezing, running over, ...).

Never pull the high pressure hose if it has formed

kinks or “nooses”! Never pull the high pressure

hose over sharp edges!

Apply the safety catch on the safety trigger gun

after each use in order to prevent

unintentional spraying!

8 9

Page 6

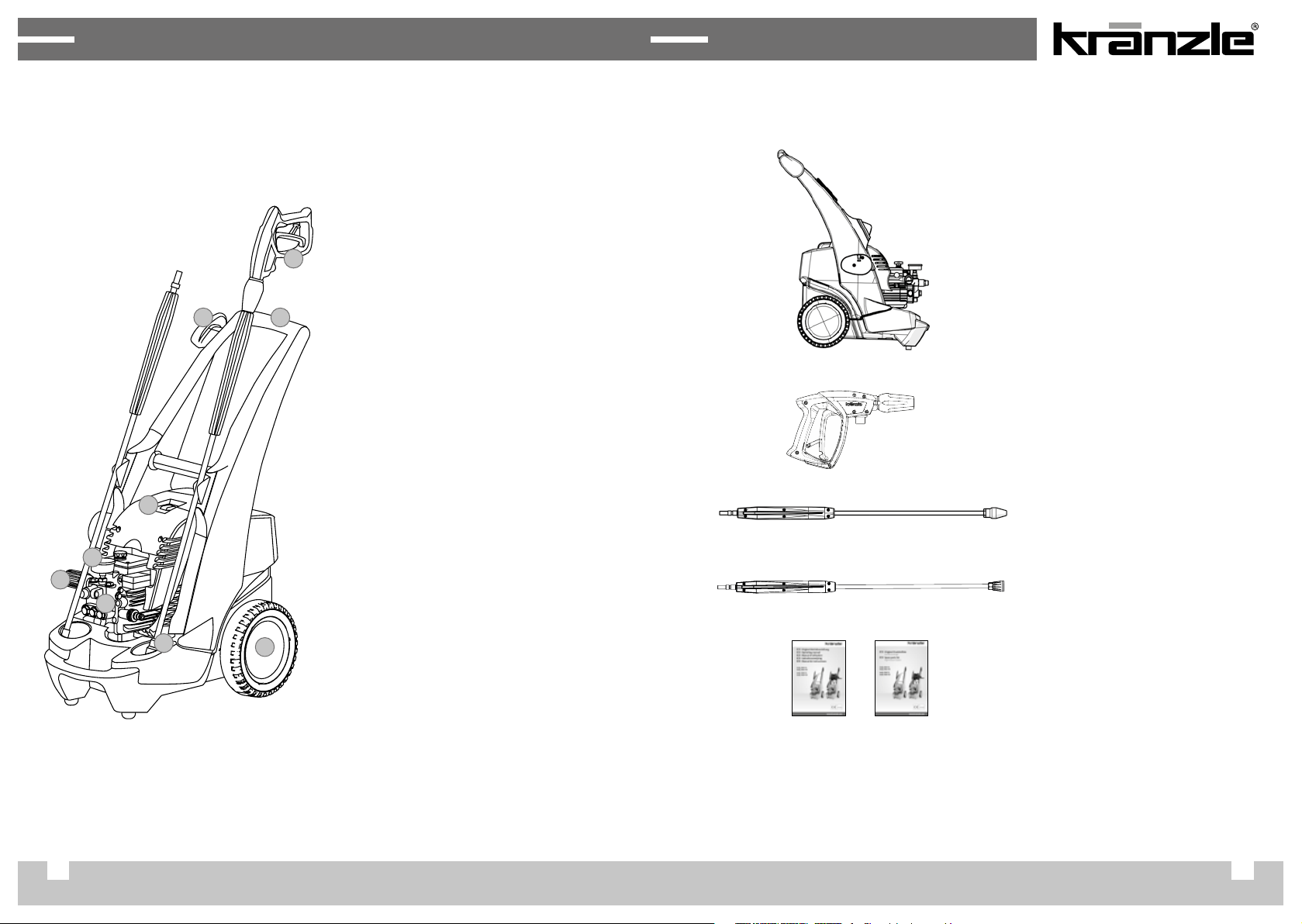

Description of high pressure cleaner

Description of high pressure cleaner

Design: bully-series without hose drum

The bully 90 TS and bully 110 TS is a mobile high pressure cleaner with an

advanced arrangement system. Please see construction scheme for more details.

1. Ergonomically shaped handle

2. Pump head made of special brass

3. Storage for safety trigger gun

with lance

4. Safety trigger gun

5. Large stainless steel

pressure gauge

6. On/O switch

7. Integrated trolley takes steps

and rough ground in its stride

8. Infinitely variable pressure

and quantity regulation

9. Cable reel for the power

supply cable

This is what you have purchased: bully-series without hose drum

1. Kränzle high pressure cleaner

bully 980 TS

bully 1180 TS

2. Trigger gun with safety catch,

short design with quick release

coupling

3. Dirtkiller lance

with quick release coupling

4. Stainless steel lance with flat jet

nozzle and quick release coupling

5. Operating manual

Spare parts list

10 11

Page 7

Description of high pressure cleaner

Description of high pressure cleaner

Design: bully-series with hose drum

The bully 90 TST, bully 110 TST and bully 1000 TST is a mobile high pressure

cleaner with an advanced arrangement system. Please see construction scheme

for more details.

1

1. Ergonomically shaped handle

2. Pump head made of special brass

3. Storage for safety trigger gun

with lance

4. Safety trigger gun

5. Large stainless steel

pressure gauge

6. On/O switch

7. Integrated trolley takes steps

and rough ground in its stride

8. Infinitely variable pressure

and quantity regulation

9. Cable reel for the power

supply cable

This is what you have purchased: bully-series with hose drum

1. Kränzle high pressure cleaner

bully 980 TST

bully 1180 TST

bully 1000 TST

2. Trigger gun with safety catch,

short design with quick release

coupling

3. Dirtkiller lance

with quick release coupling

4. Stainless steel lance with flat jet

nozzle and quick release coupling

5. Operating manual

Spare parts list

10. Hose drum with 15 m

steel weave high pressure hose

12 13

Page 8

General rules

Intended use

This high pressure cleaner is to be used solely for high pressure water jet cleaning

applications without detergents or low-pressure cleaning work with detergents

(e.g. with a foam injector or washing brush).

Environmental, refuse disposal and water protection regulations

must be observed!

Inspections

The high pressure cleaner must be inspected according to the “Guidelines for

Liquid Spray Devices” at least once every 12 months by a qualified person, to

ensure that continued safe operation is guaranteed. The results of the inspection

are to be recorded in writing (see Inspection reports).

High pressure cleaners used for commercial purposes have

to be checked by a qualified person at least every 12 months!

Accident prevention

The high pressure cleaner is designed for accidents to be impossible if used

correctly. The user is to be notified of the risk of injury from hot machine parts

and the high pressure jet. The “Guidelines for Liquid Spray Devices” must be

complied with.

Oil change

The first oil change should be carried out

after approximately 50 operating hours,

then every year or after 250 operating

hours. If the oil turns grey or white, you

must change the oil. In case of exchanging

oil being required, the oil drain screw must

be opened above a container and the high

pressure cleaner be emptied. The oil is to be

caught in the reservoir and disposed of in an

approved manner.

New oil: 1. l

Kränzle high-performance transmission oil (Item no.: 400932)

or Motor oil 10W40.

Oil leakage

If oil leaks contact your nearest after-sales service (dealer) at once.

(environmental damage, damage to the transmission).

In case of increased humidity or fluctuations in temperature

development of condensed water is possible. If the oil turns grey

or white, you must change it.

14 15

Page 9

Functional details

Functional details

Please note: Lack of water

Lack of water occurs more often than you

probably believe. The more powerful a high

pressure cleaner is the greater is the danger

that a lack of water occurs. If there is only

an insucient amount of water available,

cavitation (water-gas mixture) arises inside

the high pressure pump, which is normally

noticed too late or even not at all. The high

pressure pump will be destroyed. Please

check the available quantity of water by filling a bucket with liter scale for one minute.

Required minimum quantity of water (see technical data).

If the metered quantity of water is too small, you have to use a different water connection, guaranteeing the necessary output. Lack of

water leads to an accelerated wear of the joints (no warranty).

Never let the high pressure pump run dry for more than 60 seconds.

Water supply

Please pay attention to the regulations of your waterworks company! In accordance with DIN EN 61770, the high pressure cleaner

may not be directly connected to the public drinking water supply

lines. A brief connection however is permissible according to DVGW

(German Association for Gas and Water Aairs) if a non-return valve with tube ventilator (Kränzle order no. 41.016 4) is built into the

water supply. Once the water has passed through the non-return

valve it is no longer considered as drinking water. Also indirect

connection to the public drinking water supply lines is permissible

by way of free emission in accordance with EN 61 770; e.g. by using

a reservoir with a float valve. Direct connection to a non-drinking

water supply line is permissible.

Insucient quantity of electricity

If there are too many collectors in your

proximity connected to the network at the

same time, the available voltage and the

current intensity may decline. Consequently

the motor of the high pressure cleaner does

not start or even blows. The power supply

may also be insucient if the power supply

cable is too long or too thin. If extension

cables are too long, this may lead to a voltage drop causing malfunctions or start-up

diculties.

Check the line fusing and have the voltage and the available current intensity checked by an expert in case of uncertainty (see technical data).

Electrical connection

The high pressure cleaner is supplied with a 5 meters long power supply cable.

The mains plug must be fitted to a standard grounded socket with a 30 mA

residual current operated device. Connection up to the mains must be carried

out by a properly trained electrician and must comply with the requirements of

IEC60364-1. The socket must be protected with a 16 A fuse on the mains side.

When using an extension cable, this must have an earthed lead which is properly

connected to the socket. The conductors in the extension cable must have a minimum cross section of 1.5 mm². Plug connections must be of a spray-proof design,

and may not be located on a wet floor. For extension cables of more than 10 m in

length, the minimum cross-section must be 2.5 mm²! When using a cable drum,

the power supply cable always must be unwound all the way.

16 17

Page 10

Functional details

Functional details

Water and cleaning system

Water can be connected at mains pressure to the high pressure pump. The water

is then forced under pressure by the high pressure pump to the lance. The high

pressure jet is formed by the nozzle at the end of the lance.

Environmental, refuse disposal and water protection regulations

must be observed!

Safety jet pipe with safety trigger gun

The high pressure cleaner can only be operated when the trigger of the safety

deactivation trigger gun‘s trigger is actuated. When the trigger is pulled, the

safety trigger gun opens. The liquid is then transported to the nozzle. The spray

pressure increases and quickly reaches the operating pressure. When the trigger is

released, the safety trigger gun closes and any further spraying of liquid from the

safety jet pipe is prevented. The stainless steel pressure gauge must show 0 bar.

The increase in pressure when the safety trigger gun is closed causes the pressure control valve-safety valve to open. The motor is switched o by the pressure

switch. When thesafety trigger gun is opened, the pressure control valve - safety

valve closes, the motor is started and the high pressure pump resumes pressure

spraying from the safety jet pipe with the selected operating pressure.

The safety trigger gun is a safety device. Repairs should only be performed by qualified persons. Should replacement parts be required, use

only components authorized by the manufacturer.

Motor protection switch

Motor is protected against overload by means of a motor protection switch.

In case of motor overload or blocking, the motor of the high pressure cleaner

switches o automatically. If motor tends to switch o repeatedly, make sure to

detect appears. Make sure to detect and remedy the cause of the failure.

Replacements and inspection work should only be performed by qualified

persons when the high pressure cleaner is disconnected from the power

supply, i.e. with plug pulled out from the electrical socket.

Totalstop system

The small quadro series is equipped with a total stop system. After water connection and high pressure hose connection you switch the high pressure cleaner at the

main switch to "ON", a red signal ligths up. If the main switch is switched on, the

motor is started via a pressure switch when opening the safety trigger gun. When

closing the safety trigger gun the motor is switched o immediately. The high

pressure cleaner remains on standby until the main switch is switched "OFF". After

that, the red lights stops.

High pressure hose and spray device

The high pressure hose and spray device which are part of the bully-series

equipment, are made of high quality material and engineered to conform with the

operating conditions of the high pressure cleaner and are duly labeled.

Pressure control valve - safety valve

The pressure control valve - safety valve protects the high pressure cleaner from

a build up of excess pressure, and is designed not to permit an excess pressure

to be selected for operation. The limit nut on the handle is sealed with a spray

coating. The operating pressure and spray rate can be steplessly adjusted by

turning the handle.

Replacements, repairs, new adjustments and sealing should only

be performed by qualified persons.

18 19

If replacement parts are required, only such parts that are authorized by

the manufacturer may be used. The warranty is automatically void if spare

parts of third-party providers are used! The high pressure hose and spray

device must be connected in a pressure-tight manner (without leakage).

The high pressure hose may not be driven over, pulled excessively, or twisted. The high pressure hose may under no circumstances be pulled over

sharp edges. Defective high pressure hoses must not be repaired (acc. to

DIN 20022) but have to be replaced by new hoses approved by the manufacturer.

Prior to putting the high pressure cleaner into operation make sure

that all safety instructions be observed.

Page 11

Putting into operation

Putting into operation

1. Move high pressure cleaner to the job

site. The bully-series is a movable high

pressure cleaner with sturdy trolleys

ideally suited for dicult terrain and

stairs.

It is imperative that safety instructions be observed during

use of the high pressure cleaner.

Neither set up or operate the bully-series in rooms where there is a

risk of fire or explosion nor put it into puddles. Do not use the high

pressure cleaner under water. If, none the less, the high pressure

cleaner is operated in a hazardous area, the applicable safety

regulations are to be observed.

2. Unwind high pressure hose straight and

without nooses. For high pressure cleaners with hose drum, however, it must

be uncoiled completely. (When extending

the high-pressure hose please consider

the maximum length of 20 m!)

3. Without hose drum:

For high pressure cleaners without hose

drum the high pressure hose included in

the scope of the delivery must be screwed

with the pump outlet in a tight and pressure tight manner.

4. Tightly screw together high-pressure

hose and safety trigger gun.

5. First pull back the retaining sleeve

of the safety trigger gun, then insert

lance into the plug coupling connection

of the safety trigger gun.

6. After insertion of the lance, release

retaining sleeve and make sure that

the lance is in a secure position.

Grease quick release nipple regularly

using acid-free grease.

Prior to insertion, check plug coupling connection of lance for cleanliness (sand, dirt ..) and use clear water to clean, if necessary.

Impurities may damage the sealing in the plug coupling.

20 21

Page 12

Putting into operation

Putting into operation

7. Check water inlet filter for cleanliness

prior to putting the high pressure

cleaner into operation.

Manually unscrew plug-in coupling.

Take out the water inlet filter using

needle nose pliers and thoroughly

rinse it with clear water and clean

it with the other parts.

Check the water inlet sieve for damage. Do not operate the

high pressure cleaner without or with a damaged filter.

8.

Connect water hose to water inlet (minimum requirements; 5 m hose length,

cross-section ¾", 10 bar).

sure cleaner may be connected to a

water mains (1-10 bar pre-pressure)

with either cold or hot water (up to

60 °C). The bully series provides the

opportunity of sucking in water out

of a container (see direct suction).

Be careful when using hot water!

When running your high pressure cleaner with hot water of 60 °C raised

temperatures occur. Do not touch the metal parts of the high pressure

cleaner without safety gloves!

The high pres-

10. Connect to circuit (see technical data).

Do not touch the mains plug or any live parts with wet or moist hands.

11. Switch on high pressure cleaner with

opened safety trigger gun. Bleeding

of the high pressure cleaner: Pull and

release trigger of safety trigger gun

several times. Start cleaning task.

12. When using the filth killer lance make

sure that lance points downward when

starting.

13. Adjust operating pressureinfinitely

using the rotary handle. The maximum

pressure is factory-set.

9. Each time check oil level at the oil

dipstick prior to putting the high

pressure cleaner into operation.

(Take care that cleaner is in horizontal

position!) Oil level must reach until the

upper edge of marking "OK“.

22 23

14. The bully-series units are equipped

with a support for the safety trigger

gun with lance during breaks.

Page 13

Direct suction

Taking out of operation

Direct water extraction

Due to the suction capacity of its high pressure pump (up to 2.5 m suction height,

max. hose length 3 m) this high pressure cleaner can suck in water for cleaning

purposes from separate containers or ponds.

1. Mount suction hose with suction filter

(Item.-no. 15.03 3).

2. Put filled suction hose into the waterfilled container and start the cleaning

job. Use clean water only! Never suck

in water containing chlorine! Do not

suction air!

Prior to starting the first suction the high pressure pump and the

suction hose has to be filled with water!

Note

Depending on the water quality it may occur after a prolonged standstill

that the valves get sticky. Consequently the high pressure cleaner cannot

properly suck in water from a container. In this case connect a hose with

pressurized water to the pump inlet. Having started the high pressure

cleaner the pressurized water opens the valves and the machine resumes

sucking in water from the container. Now you can carry on with your

cleaning task as usual.

1. Switch o the high pressure cleaner

2. Cut o the water supply

3. Open the safety trigger gun catch briefly until the pressure is released

4. Apply safety catch on the trigger gun

5. Remove high pressure hose and safety trigger gun

6. Emptying high pressure pump: Hold high pressure hose and switch

motor on until water jet stops escaping at the outlet.

7. Pull the plug from the socket

8. Clean high pressure hose and wind up without loops

9. Clean and wind up the power supply cable

10. Clean the water inlet sieve

11. Store high pressure cleaners in frost-free rooms in winter

Frost protection

For protecting the high-pressure cleaner against frost please empty it completely.

Separate high-pressure cleaner from water supply and switch it on.

the trigger gun the high-pressure pump presses water out of the high-pressure

cleaner. However, do not allow the device to operate without water for more

than one minute.

By opening

Due to their small base, the compact and

mobile Kränzle high pressure cleaners are

easy to store.

24 25

Page 14

Small repairs - do it yourself

Small repairs - do it yourself

Problem

No water from nozzle although the high pressure cleaner is running.

The stainless steel pressure gauge shows full pressure.

Cause

Most likely the nozzle is blocked.

The stainless steel pressure gauge shows

full pressure, but from the nozzle comes

only little water or no water at all.

(Inside the stainless steel pressure gauge is

no water but a filling with glycerin to damp

the vibration of the pointer.)

Proceeding:

Switch o the high pressure cleaner. Pull

plug from the socket. Operate safety trigger

gun catch several times to decrease the

pressure.

Unscrew safety trigger gun and lance first,

then rinse high pressure hose to remove

possible soiling.

Check water inlet filter for soiling.

If the problem still exists, take wire (paper

clip) and push through nozzle opening. If

this procedure is not successful, the nozzle

has to be replaced.

Problem

Irregular jet from nozzle.

The stainless steel pressure gauge shows low pressure.

Cause

Most likely the valves are soiled or sticky.

The stainless steel pressure gauge shows

low pressure despite fully turned up pressure regulation. The water from the lance

comes in squirts. The high pressure hose

vibrates.

(Inside the stainless steel pressure gauge is

no water but a filling with glycerin to damp

the vibration of the pointer.)

Proceeding:

Unscrew all 6 valves, one after the other

(hexagonal brass screws, 3 in a row,

vertically and horizontally)

Take out valve body and O-ring by means

of needle nose pliers. Check O-ring for

damage. In case of a damage the O-ring

has to be replaced.

Take a wire (paper clip) and clean valves

under running water.

Do not forget the O-ring during reassembly!

Pull plug from socket prior to starting any repair work!

26 27

Page 15

Small repairs - do it yourself

Small repairs - do it yourself

Small repairs - do it yourself

Small repairs - do it yourself

Problem

After closing the safety trigger gun the high pressure cleaner

keeps switching on and o.

The stainless steel pressure gauge continuously displays full pressure.

Possible cause No. 1

Leckage.

Having closed the trigger gun with safety catch, the high pressure cleaner must

shut down and the stainless steel pressure

gauge must show „0“ bar. If not shut down

and the stainless steel pressure gauge continuously shows full pressure, this could be

due to leakage at the high pressure pump,

at the pressure switch, at the high pressure

hose or at the trigger gun with safety catch.

Proceeding:

Check connections from the high pressure

cleaner to the high pressure hose and from

the high pressure hose to the safety trigger

gun and also the connection between lance

and safety trigger gun for tightness.

Problem

After closing the safety trigger gun the high pressure cleaner

keeps switching on and o.

The stainless steel pressure gauge continuously displays full pressure.

Possible cause No. 2

The non-return valve is defective.

Proceeding:

Switch o the high pressure cleaner and

pull plug from socket. Stop water supply.

Operate safety trigger gun catch several

times to decrease the pressure.

Unscrew pump outlet.

Remove check body and check O-Ring for

soiling or damage. Also check seal seat inside pump housing for soiling or damage.

Switch o the high pressure cleaner. Shortly

press the trigger of the safety trigger gun

to decrease the high pressure cleaner.

Unscrew high pressure hose, safety trigger

gun and lance and check the O-rings. If

the O-rings are damaged they have to be

replaced.

There is no guarantee if the high pressure pump is damaged by

In case of a leakage there is no guarantee for possible

consequential damages.

28 29

defective O-rings due to air induction or lack of water (cavitation).

If sealing rings are defective replace

O-rings at once.

Page 16

Kränzle accessories

Adapter for accessories

with screw connections

with quick release nipple

For item no. 12.440 (fig. left)

400 mm extension

with grip plates

Item no.: 12440 (fig. left)

Item no.: 12441 (fig. right)

Rotating washing brush

400 mm

Stainless steel extension

Brush head ∅ 180 mm

Nozzle size 3.2 mm

* in combination wi th adapter only

Item no.: 410501

Kränzle accessories

Double lance

with ISO handle

with quick release nipple

Low pressure nozzle D3035

as standard

Item no.: 12133

Sludge suction cleaner

from stainless steel

max. suction height 3 m

Nozzle system D00045

Item no.: 41801

Underbody lance *

Stainless steel pipe

1000 mm extension

Nozzle system 4007

* in combination wi th adapter only

Item no.: 41075

The high pressure cleaner accessories are safety components!

Any warranty will be void if parts not authorised by Kränzle are used.

Please indicate the technical data of the high pressure cleaner

(device type) when placing your order.

Suction hose

with suction filter

with return valve

hose length 3 m

Item no.: 15033

30 31

Page 17

The warranty obligation of Josef Kränzle GmbH & Co. KG towards the dealer

from whom you have purchased this Kränzle high-pressure cleaner (= product)

applies to material faults only such as material and manufacturing defects.

Defects attributable to long and frequent use of the product, typically arising

due to the age of the high-pressure cleaner and intensity of its use are defined

as normal wear in respect of product components. Purchaser’s rights to assert

claims for such defects are ruled out. Parts subject to wear include in particular

the pressure gauge, nozzle, valves, sleeves, high-pressure hose and spray equipment.

The product is to be operated in conformity with this operating manual.

The operating manual is deemed to be part of the warranty provisions.

Any changes made to the safety devices of the product or instances of

maloperation – such as exceeding the temperature and speed limits,

undervoltage, insufficient water supply and sewage water, or failure to

use the product for the intended purpose – may result in damage occurring

to the product. Such damage is not deemed to constitute any material defect.

Should the use of accessories or spares other than original Kränzle component parts

und original Kränzle replacement parts be the cause of defects on our product,

this may lead to all warranty claims becoming null and void. Only the use of

original Kränzle replacement parts matching the relevant Kränzle high-pressure

cleaner provides adequate assurance for safe and trouble-free operation of the

Kränzle high-pressure cleaner.

With regard to legal warranty claims, the limitation periods of the respective

countries shall apply.

Where warranty claims apply to any other defects, please contact your

local dealer, presenting the accessories together with your purchase receipt,

or the nearest authorised service centre. This can also be found on the

internet under

EU Declaration of Conformity

Warranty

We here by declare that the design of

the high pressure cleaners:

Nominal flow:

technical specifications available from:

comply with the following guidelines

and their amendments for high

pressure cleaners:

Noise pressure level, typical:

Noise pressure level, guaranteed:

Applied conformity assessment

procedure:

Applied specifications and standards:

bully 980 TS / TST

bully 1180 TS / TST

bully 1000 TST

bully 980 TS / TST: 960 l/h

bully 1180 TS / TST: 1140 l/h

bully 1000 TST: 960 l/h

Fa. Josef Kränzle GmbH & Co. KG

Manfred Bauer

Rudolf-Diesel-Str. 20, 89257 Illertissen

Machinery Directive 2006/42/EC

EMC Directive 2014/30/EU

ROHS Directive 2011/65/EU

Outdoor Directive 2000/14/EC

89 dB (A)

91 dB (A)

Annex V, Outdoor Directive

2000/14/EC

EN 60335–1:2012/A13:2017

EN 60335–2–79:2012

EN 62233: 2008

EN 55014–1: 2006+A1: 2009+A2: 2011

EN 55014–2: 2015

EN 61000–3–2: 2014

EN 61000–3–3: 2013

32 33

Josef Kränzle GmbH & Co. KG

Rudolf-Diesel-Straße 20

89257 Illertissen (Germany)

Illertissen, 2019-04-05

Ludwig Kränzle

(Managing director)

www.kraenzle.com.

Page 18

Inspection reports

Inspection reports

High pressure cleaners for industrial use have to be checked by an expert every

12 months! Inspection report on annually carried out Labour Safety Inspection (UVV)

according to the Guidelines for Liquid Spray Equipment. (This inspection sheet serves

as proof for the completion of the retest and must be kept carefully!)

Kränzle-tes t seals: Item no.: UVV2001 06

Owner: .................................................................................

Address: ...............................................................................

.....................................................................................................

Scope of inspection o.k. yes no repaired

Type plate (on hand)

Operating manual (on hand)

Protective covering, Protective device

Pressure line (tightness)

Stainless steel pressure gauge (function)

Float valve (tightness)

Spraying device (marking)

High pressure hose / connector (damage, marking)

Safety valve opens at 10 % / 20 % exceeding

power supply cable (damage)

Protective conductor (connected)

On / O switch

Inspection data determined value set value

High pressure nozzle

Operating pressure ………………bar

Switch o pressure ……………..bar

protective conductor resistance not exceeded / value

Insulation

Leakage current

Safety trigger gun locked

Type: .......................................................................................

Serial no.: .............................................................................

Repair order no.: .............................................................

High pressure cleaners for industrial use have to be checked by an expert every

12 months! Inspection report on annually carried out Labour Safety Inspection (UVV)

according to the Guidelines for Liquid Spray Equipment. (This inspection sheet serves

as proof for the completion of the retest and must be kept carefully!)

Kränzle-tes t seals: Item no.: UVV2001 06

Owner: .................................................................................

Address: ...............................................................................

.....................................................................................................

Scope of inspection o.k. yes no repaired

Type plate (on hand)

Operating manual (on hand)

Protective covering, Protective device

Pressure line (tightness)

Stainless steel pressure gauge (function)

Float valve (tightness)

Spraying device (marking)

High pressure hose / connector (damage, marking)

Safety valve opens at 10 % / 20 % exceeding

power supply cable (damage)

Protective conductor (connected)

On / O switch

Inspection data determined value set value

High pressure nozzle

Operating pressure ………………bar

Switch o pressure ……………..bar

protective conductor resistance not exceeded / value

Insulation

Leakage current

Safety trigger gun locked

Type: .......................................................................................

Serial no.: .............................................................................

Repair order no.: .............................................................

Inspection result (check)

The high pressure cleaner was checked by an expert according to the Guidelines

for Liquid Spray Equipment, the defects found have been rectified so that the

Labour Safety can be confirmed.

The high pressure cleaner was checked by an expert according to the Guidelines

for Liquid Spray Equipment. The Labour Safety cannot be confirmed unless the

defects found are rectified by repair or replacement of the faulty parts.

The next retest according to the Guidelines for Liquid Spray Equipment has to be

carried out by: Month

................................................................... Year .......................................................................

Place, Date ..........................................................................Signature ...............................................................................

Inspection result (check)

The high pressure cleaner was checked by an expert according to the Guidelines

for Liquid Spray Equipment, the defects found have been rectified so that the

Labour Safety can be confirmed.

The high pressure cleaner was checked by an expert according to the Guidelines

for Liquid Spray Equipment. The Labour Safety cannot be confirmed unless the

defects found are rectified by repair or replacement of the faulty parts.

The next retest according to the Guidelines for Liquid Spray Equipment has to be

carried out by: Month

................................................................... Year .......................................................................

Place, Date ..........................................................................Signature ...............................................................................

34 35

Page 19

Josef Kränzle GmbH & Co. KG

Rudolf-Diesel-Straße 20

89257 Illertissen (Germany)

Made

in

Germany

sales@kraenzle.com

© Kränzle 22.05. 2019 / Ord. no.: 306060 / Subjec t to technical modifi cations and errors.

www.kraenzle.com

Loading...

Loading...