Page 1

Kramer Electronics, Ltd.

Preliminary

USER MANUAL

Model:

SP-10D

Digital Video Processor

Page 2

Contents

Contents

1 Introduction 1

2 Getting Started 1

2.1 Quick Start 2

3 Overview 3

4 Your SP-10D Digital Video Processor 4

5 Installing the SP-10D in a Rack 8

6 Connecting Your SP-10D Digital Video Processor 9

6.1 Connecting a PC 10

6.2 DIP-Switch Settings 11

7 Operating the SP-10D Digital Video Processor 12

7.1 Storing and Recalling Setups 14

7.2 Locking the Front Panel 14

8 Technical Specifications 15

9 Communication Protocol 16

Figures

Figure 1: SP-10D Digital Video Processor 5

Figure 2: Connecting the SP-10D Digital Video Processor 10

Figure 3: Crossed Cable RS-232 Connection 11

Figure 4: Straight Cable RS-232 Connection with a Null Modem Adapter 11

Tables

Table 1: Front Panel SP-10D Digital Video Processor 6

Table 2: Rear Panel SP-10D Digital Video Processor 7

Table 3: DIP-switch Settings 11

Table 4: Test Signals 12

Table 5: Technical Specifications of the SP-10D Digital Video Processor 15

Table 6: Protocol Definitions 16

i

Page 3

Introduction

1 Introduction

Welcome to Kramer Electronics! Since 1981, Kramer Electronics has been

providing a world of unique, creative, and affordable solution s to the vast

range of problems that confront the video, audio, presentation, and

broadcasting professional on a daily basis. In recent years, we have

redesigned and upgraded most of our line, making the best even better! Our

1,000-plus different models now appear in 11 groups

defined by function.

Thank you for purchasing your Kramer SP-10D Digital Video Processor.

This product is ideal for:

• Video broadcasting and editing studios

• All postproduction uses

• Presentation applications for multi-standard/multi-format sources

use

The package includes the following items:

• SP-10D Digital Video Processor

• Null-modem adapter

• Power cord

• This user manual

2

3

1

that are clearly

2 Getting Started

We recommend that you:

• Unpack the equipment carefully and save the original box and

packaging materials for possible future shipment

• Review the contents of this user manual

• Use Kramer high performance high-resolution cables

4

1 GROUP 1: Distribution Amplifiers; GROUP 2: Switchers and Matrix Switchers; GROUP 3: Control Systems;

GROUP 4: Format/Standards Converters; GROUP 5: Range Extenders and Repeaters; GROUP 6: Specialt y AV Products;

GROUP 7: Scan Converters and Scalers; GROUP 8: Cables and Connectors; GROUP 9: Room Connectivity;

GROUP 10: Accessories and Rack Adapters; GROUP 11: Sierra Products

2 We recommend that you use only the power cord supplied with this device

3 Download up-to-date Kramer user manuals from our Web site at http://www.kramerelectronics.com

4 The complete list of Kramer cables is on our Web site at http://www.kramerelectronics.com

1

Page 4

Getting Started

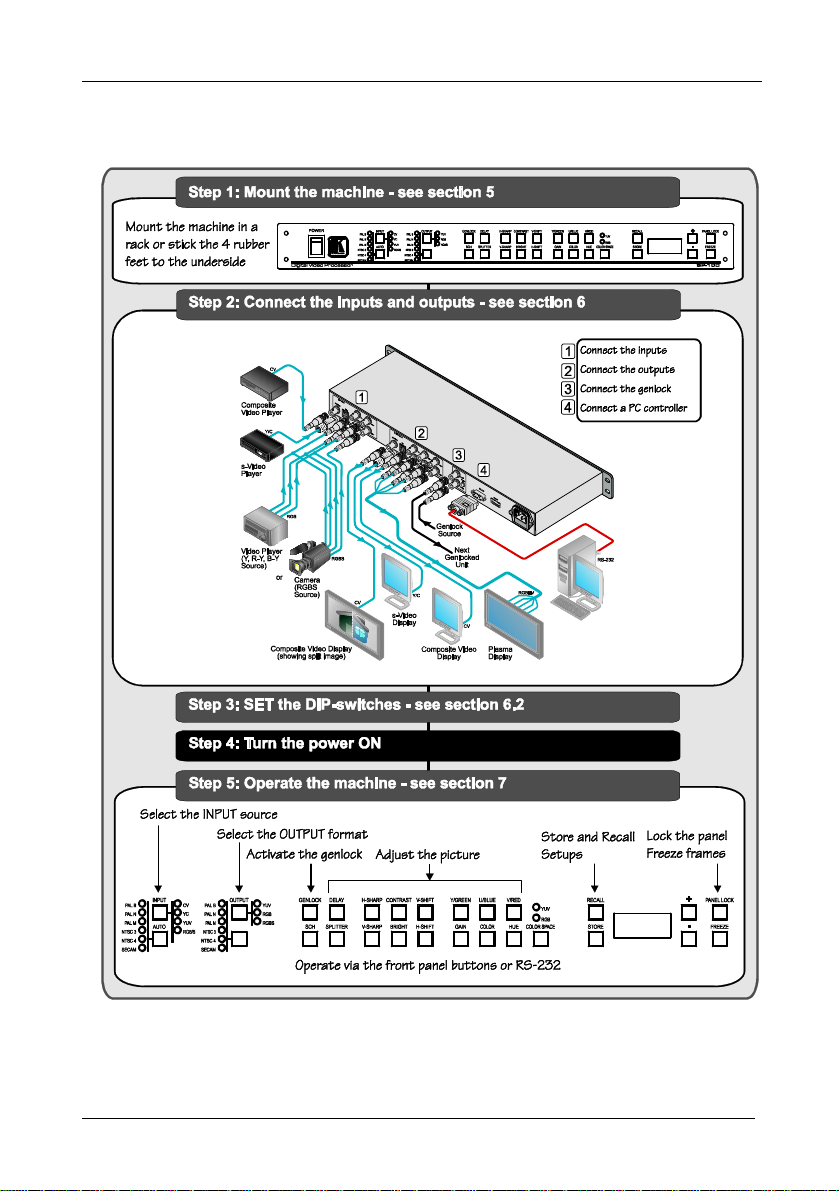

2.1 Quick Start

This quick start chart summarizes the basic setup and operation steps.

2

KRAMER: SIMPLE CREATIVE TECHNOLOGY

Page 5

Overview

3 Overview

The unique SP-10D is a multi-standard/multi-format broadcast quality

video processor – ProcAmp, TBC, format converter (for mixing different

types of equipment), and standards converter. It is a universal single-box

solution for all your video processing re q ui rements.

In particular, the SP-10D Digital Video Processor includes the following:

• Inputs: composite video, s-Video, component video (YUV or RGB/S),

and genlock

• Outputs

RGBS , RG B H V ) , “ b e f o r e/ a f t e r ” s p l i t -s c r e e n , a nd gen l o c k loop

• Video Standards

• ProcAmp functions: video gain, brightness, contrast, color, hue, and

sharpness (independent H and V)

• A full range of color control features in both YUV and RGB color

spaces

• Four-field memory for the highest picture quality

• Timing: genlocked to an external video reference with control of

H-delay and SCH phase. Alternatively, the unit can synthesize its own

timing to provide a full time-base-corrected (TBC) output

• Individual H and V Chroma – Luma delay

In addition, the SP-10D Digital Video Processor includes:

• 16 non-volatile memory setups that are available for saving the setting s

• Power-down save, picture freeze, and a screen splitter that provides

simultaneous "before and after" image comparison on one monitor

• Full 10-bit digital processing throughout, for the highest possible video

quality

1

: composite video, s-Video, component video (YUV, RGsB,

2

: PAL-B/D/G/H/I/M/N, NTSC-3.58/4.43, SECAM

3

Control the SP-10D:

• Using the front panel buttons and the 7-segment display

• Remotely, by RS-232 serial commands transmitted by a touch screen

system, PC, or other serial controller

1 All output formats are always available

2 The SP-10D can be used for conversion to any video standard. When transcoding between NTSC and PAL/SECAM, the

SP-10D uses a unique adaptive processing algorithm, which produces a high quality slow-motion picture, without blurre d

dynamic parts (something that commonly confuses many high-grade transcoders). The SP-10D processes "slow" scenes using

four TV fields, and portions of "fast" scenes using two TV fields. The SP-10D combines both methods for each TV frame

3 RGB and YUV inputs, RGB and YUV outputs, and independent control of RED, GREEN and BLUE; and Y, R-Y and B-Y

3

Page 6

Your SP-10D Digital Video Processor

To achieve the best performance:

• Connect only good quality connection cables, thus avoiding

interference, deterioration in signal quality due to poor matching,

and elevated noise levels (often associated with low quality cables)

• Avoid interference from neighboring electrical appliances that may

adversely influence signal quality and position your Kramer

SP-10D away from moisture, excessive sunlight and dust

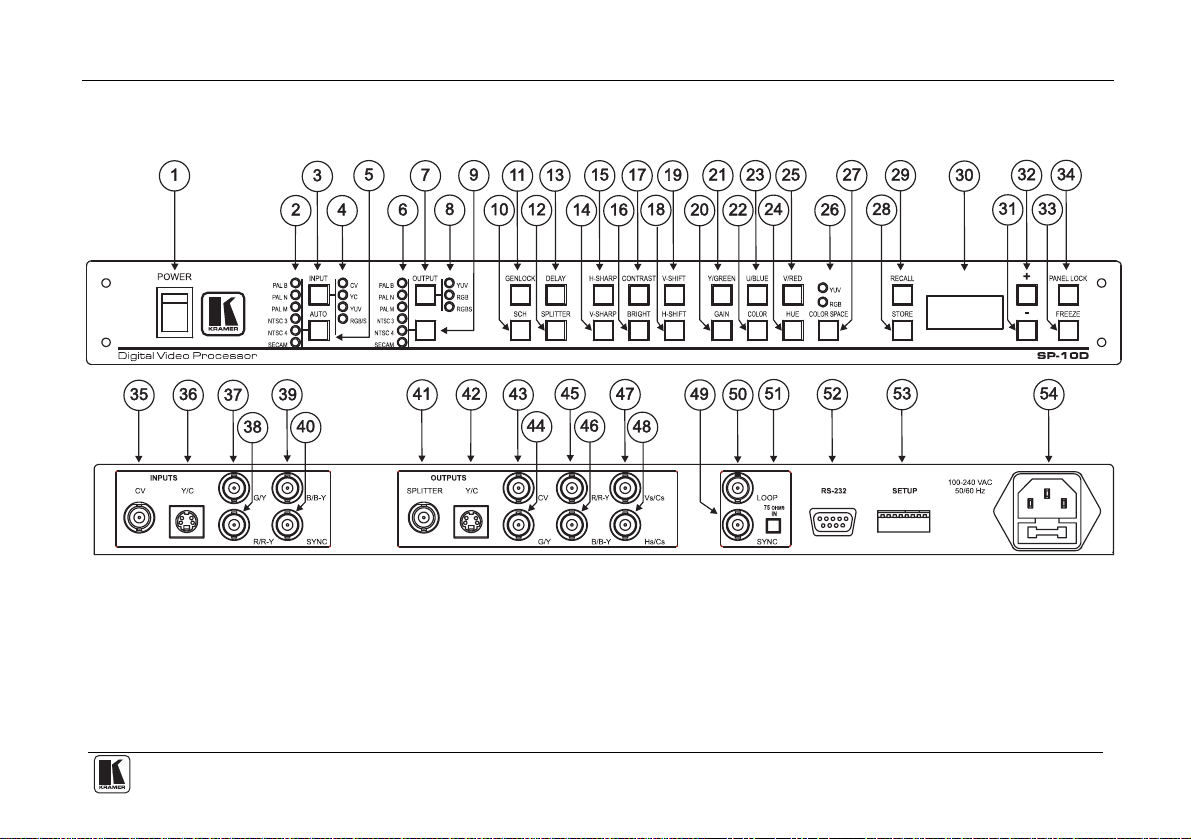

4 Your SP-10D Digital Video Processor

Figure 1, Table 1, and Table 2 define the SP-10D Digital Video Processor.

4

KRAMER: SIMPLE CREATIVE TECHNOLOGY

Page 7

Your SP-10D Digital Video Processor

Figure 1: SP-10D Digital Video Processor

5

Page 8

Your SP-10D Digital Video Processor

Table 1: Front Panel SP-10D Digital Video Processor

# Feature Function

1 POWER Switch Illuminated switch for turning the unit ON or OFF

2 INPUT STANDARD LEDs Cycle between PAL B, PAL N, PAL M, NTSC 3, NTSC 4, and

3 INPUT Selector Button Press to select the source, illuminating the appropriate LED

4 INPUT LEDs Cycle between the video sources: CV, YC, YUV, and RGB/S. The

5 AUTO Button Toggles between automatically recognizing the input standard

6 OUTPUT STANDARD LEDs Cycle between PAL B, PAL N, PAL M, NTSC 3, NTSC 4, and

7 (COMPONENT) OUTPUT

Button

8 COMPONENT OUTPUT LEDs Cycle between YUV, RGB, and RGBS. The corresponding LED

9 STANDARDS Button Selects the output video standard

10 SCH Button Press the SCH button and adjust the subcarrier to horizontal

11 GENLOCK Button Press to enable GENLOCK operation

12 SPLITTER Button Press the SPLITTER button and adjust the position of the

13 DELAY Button Press the DELAY

14 V-SHARP Button Press the V-SHARP button and adjust the vertical sharpness

15 H-SHARP Button Press the H-SHARP button and adjust the horizontal sharpness

16 BRIGHTNESS Button Press the BRIGHT button and adjust using the + and – buttons

17 CONTRAST Button Press the CONTRAST button and adjust using the + and – buttons

18 H-SHIFT Button Press the H-SHIFT button and adjust H-Chroma-Luma delay using

19 V-SHIFT Button Press the V-SHIFT button and adjust V-Chroma-Luma delay using

20 GAIN Button Press the VIDEO GAIN button and adjust using the +

21 Y/GREEN Button Press the Y

22 COLOR Button Press the COLOR

23 U/BLUE Button Press the U

1 Data delay problems, especially with long cables, occur when electronic signals travel via coaxial cable and the picture

shifts mainly in the horizontal axis (due to unequal delays between the sync signals and data). Center the picture by pressing

the DELAY button and adjust via the + and – buttons

2 To add brightness

3 To fade the picture in and out

4 For YUV

5 For RGB

6 When the COLOR SPACE button is selected

7 Pressing the + button enhances dull colors. Pressing the – button reduces distortion (snow)

SECAM. The corresponding LED lights

corresponding LED lights

(lighting the appropriate LED) and the manual selection mode

SECAM. The corresponding LED lights

Selects the component video output signal

lights

phase relative to the genlock source, using the + and – buttons

boundary between the edited image and the original image, using

the + and – buttons

1

button and adjust the H-delay of the output

signal relative to the genlock source, using the + and – buttons

using the + and – buttons

using the + and – buttons

the + and – buttons to enable horizontal shifting of the image

the + and – buttons to enable vertical shifting of the image

4

buttons

/GREEN5 button6 and adjust using the + and –

7

button and adjust using the + and – buttons

4

/BLUE5 button6 and adjust using the + and – buttons

2

and –3 buttons

6

KRAMER: SIMPLE CREATIVE TECHNOLOGY

Page 9

Your SP-10D Digital Video Processor

# Feature Function

24 HUE Button Press the HUE

25 V/RED Button Press the V

26 YUV/RGB LEDs Cycle between the different color spaces of color control: YUV and

27 COLOR SPACE Button Press to select the color space of the color control; if the COLOR

28 STORE Button Stores the current setup in the non-volatile memory

29 RECALL Button Recalls a setup from the non-volatile memory

30 7-segment Display Displays data when using a front panel button

31 - Button Press to decrease the level

32 + Button Press to increase the level

33 FREEZE Button Pauses the output video

34 PANEL LOCK Button Disengages the front panel buttons

RGB. The corresponding LED lights

SPACE button is not illuminated, color control is disabled

1

button and adjust using the + and – buttons

4

/RED5 button6 and adjust using the + and – buttons

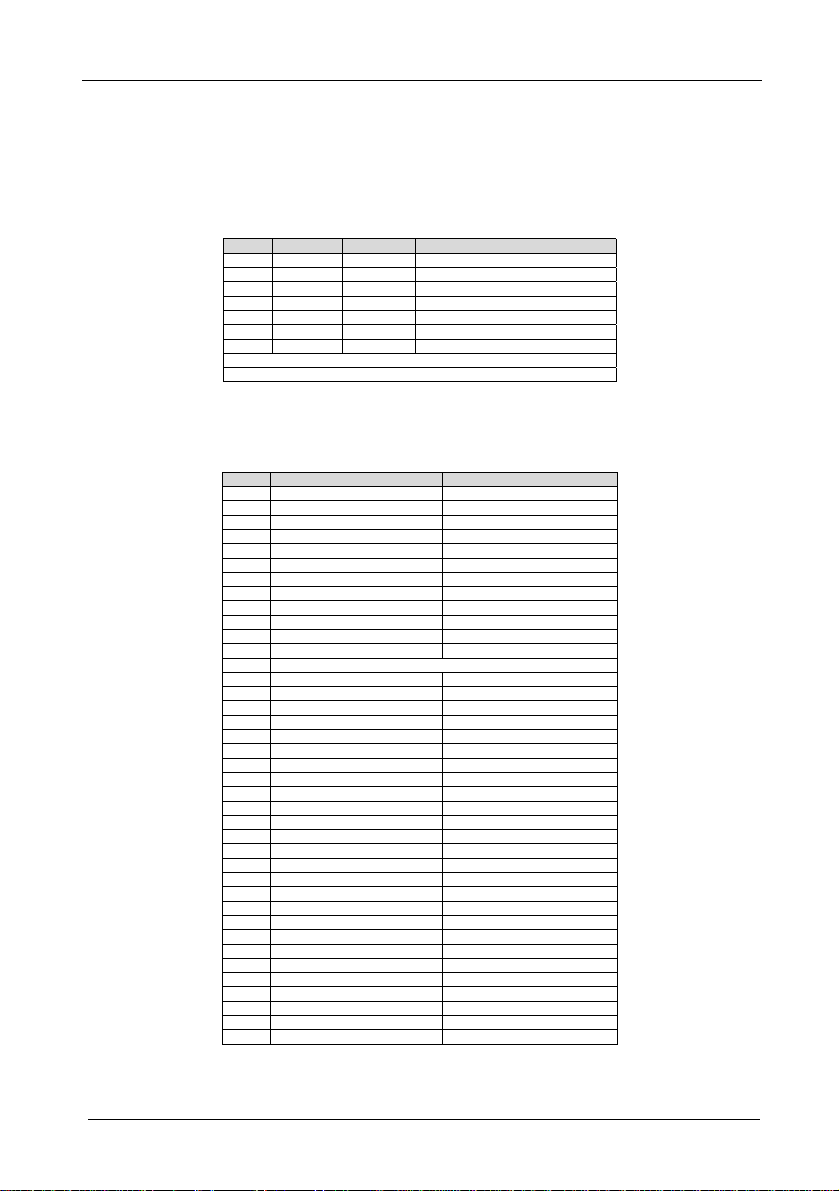

Table 2: Rear Panel SP-10D Digital Video Processor

# Feature Function

35

36 Y/C 4-pin Connector Connects to the s-Video source

37 G/Y BNC Connector Connects to the RGB (connect all 3 connectors: G,

38 R/R-Y BNC Connector

39 B/B-Y BNC Connector

40 SYNC BNC Connector Connects to the external video sync source

41

42 Y/C 4-pin Connector Connects to the s-Video (Y/C) acceptor

43 CV BNC Connector Connects to the composite video acceptor

44 G/Y BNC Connector Connects to the RGB (connect all 3 connectors:

45 R/R-Y BNC Connector

46 B/B-Y BNC Connector

47 Vs (vertical sync)/Cs

48 Hs (horizontal sync)/Cs

49 SYNC BNC Connector Connects to the genlock source

50 LOOP BNC Connector Connects to the next genlocked unit

51 75 OHMS IN Button

52 RS-232 Port Connects to the PC or the remote controller

53 SETUP DIP-switches DIP-switches setup (see section 6.2)

54 Power Connector with Fuse AC connector enabling power supply to the unit

CV BNC Connector Connects to the composite video source

B, and R), or YUV (connect all 3 connectors: Y,

INPUTS

SPLITTER BNC Connector Connects to the split image acceptor

OUTPUTS

3

BNC Connector

3

BNC Connector

B-Y, and R-Y), or RGBS (connect all 4 connectors:

G, B, R and S

G, B, and R), or YUV (connect all 3 connectors:

Y, B-Y, and R-Y), or RGBS (connect all 4

connectors: G, B, R and any Cs), or RGBHV

(connect all 5 connectors: G, B, R, Hs and Vs)

video acceptor

Press to terminate the genlock source (75Ω) or

release for looping

2

) video source

4

1 Available in all input and output formats and standards

2 Item 6 below

3 To use Cs (Composite Sync), set Dipswitch 2 ON (see Table 3

4 Push in to terminate the input. Release when the input extends to another unit

for details)

7

Page 10

Installing the SP-10D in a Rack

5 Installing the SP-10D in a Rack

This section provides instructions for rack mounting the 1U unit.

8

KRAMER: SIMPLE CREATIVE TECHNOLOGY

Page 11

Connecting Your SP-10D Digital Video Processor

6 Connecting Your SP-10D Digital Video Processor

You can use your SP-10D to convert composite video, s-Video, or component

video (YUV or RGB/S) signals to composite video, s-Video, and

1

component

video (YUV, RGsB, RGBS, RGBHV). The processing can be evaluated on a

“Before/after” split-screen.

2

To connect the SP-10D Digital Video Processor, do the following

:

1. Connect the following sources to the SP-10D:

• The composite video source (for example, a video player) to

the CV INPUT BNC connector

• The s-Video source (for example, an s-Video player) to the

Y/C INPUT 4-pin connector

2. Connect the component video IN PUT BNC connec tors , G /Y, B/B-Y, and

R/R-Y to either a YUV or an RGB vi deo sourc e, as follows:

• A video player source to G/Y, R/R-Y, and B/B-Y, or

• A camera (RGBS) source to G/Y, R/R-Y, B/B-Y and SYNC

3. Connect the following acceptors to the SP-10D:

• The SPLITTER OUTPUT BNC connector to a composite

video display

• The Y/C OUTPUT 4-pin connector to an s-Video display

• The CV OUTPUT BNC connector to a composite video

display

• The five BNC OUTPUTS connectors: G/Y, B/B-Y, R/R-Y,

Vs/Cs, and Hs/Cs to a video acceptor (for example, a plasma

display)

4. Connect the LOOP BNC connector to the next SP-10D genlocked unit (if

required) and release the Term button for looping

3

.

5. Connect a genlock source to th e SYNC BNC c onnector.

6. Connect a PC or other controller, if required (see section 6.1

7. Set the DIP-switches (see section 6.2

4

8. Connect the power cord

(not illustrated in Figure 2).

).

).

1 All output formats are always available. However, when only one output is required, connect that output of the SP-10D, a n d

leave the other outputs unconnected

2 Switch OFF the power on each device before connecting it to your SP-10D. After connec ting your SP-10D, switch on its

power and then switch on the power on each device

3 Pushed in terminates the input. Release when the input extends to another unit

4 We recommend that you use only the power cord that is supplied with this machine

9

Page 12

Connecting Your SP-10D Digital Video Processor

Figure 2: Connecting the SP-10D Digital Video Processor

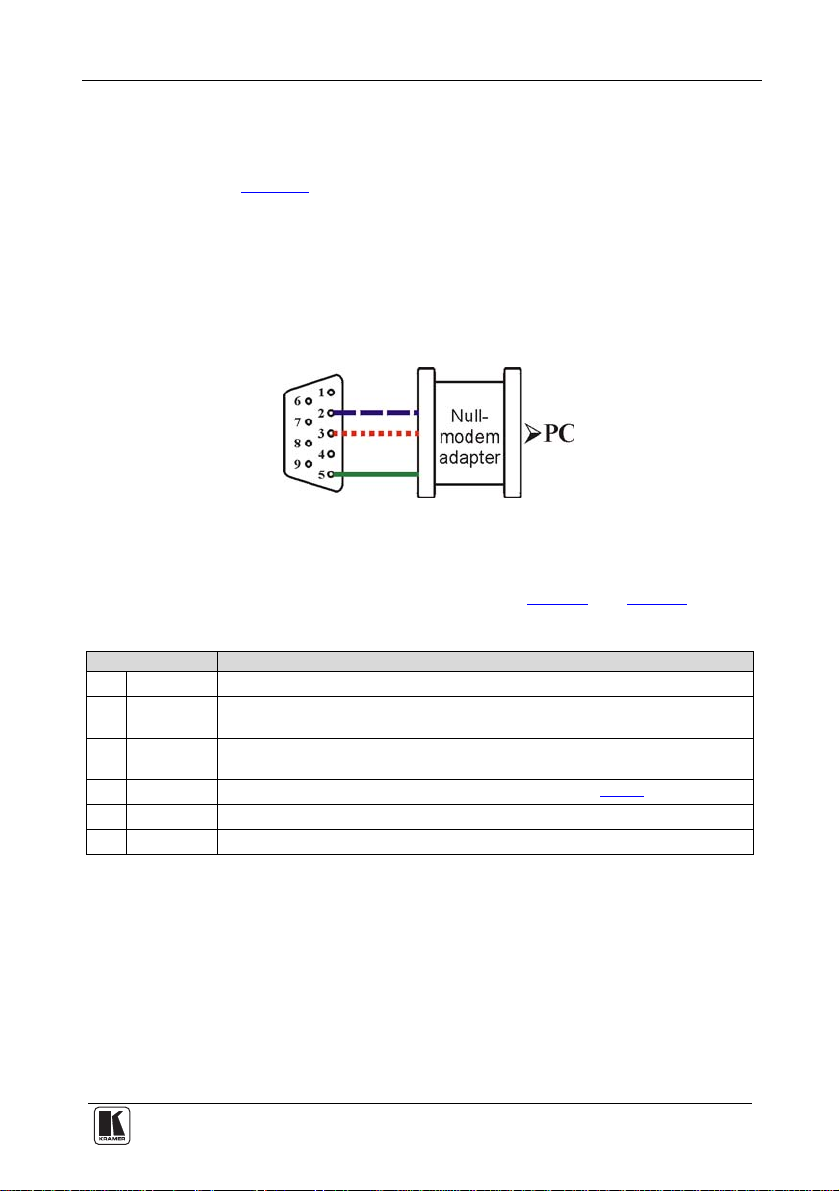

6.1 Connecting a PC

You can connect to the unit via a crossed RS-232 connection, using for

example, a PC. A crossed cable or null-modem is required as shown in

method A and B respectively. If a shielded cable is used, connect the shield

to pin 5.

Method A (Figure 3

)—Connect the RS-232 9-pin D-sub port on the unit via

a crossed cable (pin 2 to pin 3, pin 3 to pin 2, and pin 5 to pin 5) to the

RS-232 9-pin D-sub port on the PC.

Note: There is no need to connect any other pins.

Figure 3: Crossed Cable RS-232 Connection

10

KRAMER: SIMPLE CREATIVE TECHNOLOGY

Page 13

Connecting Your SP-10D Digital Video Processor

Hardware flow control is not required for this unit. In the rare case where a

controller requires hardware flow control, short pin 1 to 7 and 8, and pin 4

to 6 on the controller side.

Method B (Figure 4

)—Connect the RS-232 9-pin D-sub port on the unit via

a straight (flat) cable to the null-modem adapter, and connect the nullmodem adapter to the RS-232 9-pin D-sub port on the PC. The straight

cable usually contains all nine wires for a full connection of the D-sub

connector. Because the null-modem adapter (which already includes the

flow control jumpering described in Met ho d A a bove) only requires pins 2,

3 and 5 to be connected, you are free to decide whether to connect only

these 3 pins or all 9 pins.

Figure 4: Straight Cable RS-232 Connection with a Null Modem Adapter

6.2 DIP-Switch Settings

The SP-10D DIP-switch settings are defined in Table 3

Table 3: DIP-switch Settings

DIP-Switch Set as Follows:

1 Pedestal ON for pedestal of output signal (7.5 IRE offset selection for NTSC); OFF for no pedestal

2 HsVs/Cs ON for Composite Sync on outputs Hs/Cs and Vs/Cs; OFF for Horizontal Sync on

Hs/Cs, and Vertical Sync on Vs/Cs outputs

3 Secam VBI ON for insert identification signals occupying 9 lines of field-blanking period (only for

SECAM output standard) (bottle pulses); OFF for no insert (no bottle pulses)

4, 5, 6 Test Signals The status of these DIP-switches defines the test signal: see Table 4

7 AGC ON for enabling automatic gain control; OFF for disabling automatic gain control

8 ADDR For selecting one of two machine addresses (defining the machine address)

and Table 4:

11

Page 14

Operating the SP-10D Digital Video Processor

Table 4: Test Signals

VITS 330 (Modulated Staircase) – full field mode ON ON ON

No Signal1 OFF OFF OFF

Split 75% Bar Generator ON ON OFF

VITS 18 (Multiburst 5.8MHz) – full field mode ON OFF ON

Vertical 75% Bar Generator ON OFF OFF

Inverse Horizontal 75% Bar Generator OFF OFF ON

Horizontal 75% Bar Generator OFF ON OFF

VITS 17 (2T, 20T, 5 Step Staircase) – full field mode OFF ON ON

The SP-10D DIP 4 DIP 5 DIP 6

7 Operating the SP-10D Digital Video Processor

Operate your SP-10D Digital Video Processor via:

• The front panel buttons

• RS-232 serial commands transmitted by a touch screen system, PC,

or other serial controller

To operate the SP-10D using the front panel buttons, do the fol l owing:

1. Turn on the power and after it has completed its warm up sequence, press

the INPUT button to select the source—CV, YC, YUV, or RGB/S—that

you want to convert.

The appropriate INPUT LED lights (indicating selection and conversion

of that source).

2. When the AUTO button illuminates, the video standard corresponding to

the selected input is detected automatically.

The appropriate INPUT STANDARD LED li ghts: PAL B, PA L N, PAL

M, NTSC 3.58, NTSC 4.43 or SECAM

When the AUTO button does not illuminate—that is, the SP-10D is in

manual mode—select the desire d video sta ndard by pressi ng the AUTO

button to cycle between the vari ous video st andards.

3. Press the (Component) O UTPUT button to select the c omponent o utput

signal format: YUV, RGsB, or RGBS.

4. Press the STORE button twice to save the previous selection (power down

saving: optional).

5. Press the STANDARDS button to select the output standard of the

composite video signal.

The appropriate OUTPUT STANDARDS LED flashes as well as the

STORE button. However, the output standard is not altered.

2

.

1 This is the main mode; test signals are not available

2 For example, when the composite source is selected, the PAL B INPUT STANDARD LED lights

12

KRAMER: SIMPLE CREATIVE TECHNOLOGY

Page 15

Operating the SP-10D Digital Video Processor

6. Press the STORE button once.

For 5 seconds no output vide o signal is availabl e, and “rL” is displaye d in

the 7-segment display, indicating that the SP-10D is reloading.

After the reloading, the standard of the output video signal changes as well

as that of the “Before/after” split-screen.

7. Press the GENLOCK button to enable the genl ock function.

If the SYNC BNC connector

1

is connected to a genlock source, and the

standard of the signal on this input coincides with the standard of the output

video signal, the GENLOCK button illuminates. If not, the GENLOCK

button flashes.

2

8. Adjust the color

, brightness, contrast, hue, sharpness3, H-shift, V-shift4,

(Delay, SCH if required for genlock) a nd/or the video gain of the pict ure, as

follows:

5

• Press the appropriate button

The button illuminates, and flashes, and the 7-segment display

shows the current level (in digits)

The digit “0” corresponds to the normal level (“NORM”)

• Press the + button or – button once to gradually increase or

decrease the current level by one unit (the 7-segment display

shows the new level).

To increase or decrease the current level rapidly, press and

hold down the + button or – button, continuously

6

. To end the

rapid adjustment, release the + button or – button

Note, if you want to:

• Set the normal level (“NORM”) of the current level, press and

simultaneously hold down both the + button and – button.

The 7-segment display shows “0”

• Undo the adjustment, press the appropriate button one more

time. The appropriate button no longer flashes

• Save the result of the adjustment, press the STORE button

twice

1 Item 50 in Table 2

2 The SP-10D has a full range of color control features in both YUV and RGB color spaces with independent control of RED,

GREEN and BLUE; and Y, R-Y and B-Y

3 Using the V-SHARP and H-SHARP buttons

4 Using the V-SHIFT and H-SHIFT buttons

5 See the relevant items defined in Table 1

6 The 7-segment display starts to quickly scan the range. When it stops running, it has reached the maximum or minimum

setting

13

Page 16

Operating the SP-10D Digital Video Processor

• Store the result of the adjustment in another setup #, press the

STORE button once, select a setup # between 1 and 16 by

pressing the + and – buttons, and then press the STORE button

once again

If the adjustment is set such that the level setting is at its normal level

(“NORM”), the appropriate button no longer illuminates (otherwise this

button continues to illuminate in the main mode).

7.1 Storing and Recalling Setups

can store and recall up to 16 setups (or adjustments) in non-volatile

You

memory, using the STORE and RECALL buttons together with the + and –

buttons.

1

To store

a setup, do the following:

• Press the STORE button and then select a setup # between 1 and 16

by pressing the + and – buttons (the current settings are saved to

that setup #)

• Press the STORE button once again

To recall a setup, do the following:

• Press the RECALL button and then select the appropriate # (that

corresponds to the setup #) by pressing the + and – buttons (the

selected setup is recalled)

• Press the RECALL button once again

7.2 Locking the Front Panel

To

prevent changing the settings unintentionally or tampering with the front

panel, lock your SP-10D. Unlocking releases the protection mechanism.

To lock the SP-10D:

• Press the PANEL LOCK button (for about 2 seconds) until it

illuminates — freezing the front panel controls. Pressing a button

has no effect

and show the value of a ProcAmp setting if its button is pressed

2

, except to cause the PANEL LOCK button to flash3

4

1 Storing a new setup over a previous setup # replaces the previous setup #

2 Nevertheless, even though the front panel is locked you can still operate your PC control software

3 Warning that you need to unlock to regain control via the front panel

4 For example, if the HUE button is pressed when the panel is locked, then the 7-segment display illuminates the current

value of the HUE setting

14

KRAMER: SIMPLE CREATIVE TECHNOLOGY

Page 17

Technical Specifications

To unlock the SP-10D:

• Press the PANEL LOCK button (for about 2 seconds) until the

front panel controls unlock and the PANEL LOCK button no

longer illuminates

8 Technical Specifications

Table 5 includes the technical specifications:

Table 5: Technical Specifications1 of the SP-10D Digital Video Processor

INPUTS: 1 composite video: 1Vpp/75Ω on a BNC connector;

OUTPUTS: 1 composite video: 1Vpp/75Ω on a BNC connector;

VIDEO STANDARDS: PAL-B/D/G/H/I/M/N, NTSC-3.58/4.43, SECAM

DIGITAL RESOLUTION: 10 bits

BANDWIDTH (-3dB): 5MHz

DIFF. GAIN: 1%

DIFF. PHASE: 1Deg.

K-FACTOR: 0.4%

S/N RATIO: 60dB

LUMA NON-LINEARITY: 1%

CHROMA/LUMA DELAY: <15ns

MEMORY: Non-volatile memory for storage of 16 setups

CONTROLS: Front-panel and RS-232: contrast, brightness, video gain, color, hue, H/V

POWER SOURCE: Universal, 100-240V AC, 50/60Hz, 27VA

DIMENSIONS: 19” x 7” x 1U W, D, H, rack mountable

WEIGHT: 2.6kg (5.7lbs) approx.

ACCESSORIES: Power cord, null-modem adapter

1 YC: 1Vpp/75Ω (Y), 0.3Vpp/75Ω (C) on a 4-pin connector;

1 component: Y/R-Y/B-Y (or RGB/S) 1Vpp/0.7Vpp/0.7Vpp/75Ω on BNC

connectors;

1 SYNC (genlock): looped 75Ω/Hi-Z on BNC connectors

1 YC: 1Vpp/75Ω (Y), 0.3Vpp/75Ω (C) on a 4-pin connector;

1 component: Y/R-Y/B-Y (or RGB/S) 1Vpp/0.7Vpp/0.7Vpp/75Ω on BNC

connectors

sharpness, SCH phase, delay, H/V shift; R, G, B, R-Y, B-Y level; screen

splitter (process to bypass); freeze; panel lock

1 Specifications are subject to change without notice

15

Page 18

Communication Protocol

9 Communication Protocol

This protocol, which enables RS-2 3 2 c om muni cat i o n bet w een the SP-10D

and the PC, uses 4 bytes of information, and data is at 9600 baud.

Table 6: Protocol Definitions

First byte options

DEC HEX

1 128 80 RESET VIDEO

2 160 A0 READ PARAMETER

3 161 A1 WRITE PARAMETER

4 162 A2 RECALL

5 163 A3 STORE

6 189 BD IDENTIFY MACHINE

7 33 21 Set (for the rest of commands)

Second byte is the command type

Note:

1. When working in HEX, add 80 to the values in the table.

2. When working in DEC, add 128 to the values in the table.

3. All values in the table are in DEC.

Third byte is the parameter value

Byte 2 Comm and Description Byte 3 (parameter value)

0 INPUT FORMAT 0 - CV

1 - YC

2 - YUV

3 - RGB/S

4 - SDI

1 INPUT_STANDARD 0 - PAL B

1 - PAL N

2 - PAL M

3 - NT 3

4 - NT 4

5 - SEC

6 – AUTO

(READ 19 - INPUT_STANDARD_AUTO)

2 SPLITTER -100 - +100

3 SHARP_H 0 - 15

4 SHARP_V 0 - 15

5 CONTRAST -100 - +100

6 BRIGHTNESS -100 - +100

7 VIDEO_GAIN -100 - +100

8 H_SHIFT -16 - +15

9 V_SHIFT -1 - +1

10 Y -100 - +100

11 U 100 - +100

12 V 100 - +100

13 GREEN -100 - +100

14 BLUE -100 - +100

15 RED -100 - +100

16 COLOR -100 - +100

17 HUE -100 - +100

18 COLOR_SPACE 0 - OFF

1 - YUV

2 - RGB

19 INPUT_STANDARD_AUTO (READ ONLY)

0 - PAL B

1 - PAL N

2 - PAL M

3 - NT 3

4 - NT 4

5 - SEC

16

KRAMER: SIMPLE CREATIVE TECHNOLOGY

Page 19

Communication Protocol

Byte 2 Comm and Description Byte 3 (parameter value)

GLOBAL

20 OUTPUT FORMAT 0 - YUV

1 - RGB

2 - RGBS

21 OUTPUT_STANDARD 0 - PAL B

1 - PAL N

2 - PAL M

3 - NT 3

4 - NT 4

5 - SEC

22 GENLOCK 0 - OFF

1 - ON

23 PANEL_LOCK 0 - OFF

1 – ON

24 SCH -100 - +100

24 DELAY -100 - +100

26 FREEZE 0 - OFF

1 - ON

27 PROGRAM 0 - 15 (read only)

28 GENLOCK_STAT (Read only)

0 – No GENLOCK

Byte 4 is the machine address: can be 98 or 99 (in HEX).

First byte = I

Second byte=D

Third byte=E

MACHINE TO PC:

MACHINE POWER-UP

PC <- I = 34;D = 0;E = PROGRAMM NUMBER <- MACHINE (RECALL)

PRESS OF "RECALL"

PC <- I = 34;D = 0;E = PROGRAMM NUMBER <- MACHINE (RECALL)

PRESS OF "STORE"

PC <- I = 34;D = 0;E = PROGRAMM NUMBER <- MACHINE (RECALL)

CHANGE "OUTPUT_STANDARD"

PC <- I = 34;D = 0;E = PROGRAMM NUMBER <- MACHINE (RECALL)

CHANGING OTHER KEYS

PC <- I = 33;D = PARAMETER NUMBER; E = PARAMETER <- MACHINE (PARAMETER WRITE)

PC TO MACHINE:

RESET VIDEO

POWER-UP(PSEUDO)

PC -> I = 0;D = 0;E = 0 -> MACHINE

PC <- I = 0;D = 0;E = 0 <- MACHINE

DEFAULT

PC -> I = 0;D = 1;E = 0 -> MACHINE

WRITE EEPROM ALL PARAMETERS - DEFAULT (ALL PROGRAMS),RELOAD (RESTART)

PC <- I = 34;D = 0;E = PROGRAMM NUMBER <- MACHINE (RECALL)

PARAMETER READ

PC -> I = 32;D = PARAMETER NUMBER;E = 0 -> MACHINE

PC <- I = 32;D = PARAMETER NUMBER;E = PARAMETER <- PARAMETER

PARAMETER WRITE

PC -> I = 33;D = PARAMETER NUMBER;E = PARAMETER -> MACHINE

PC -< I = 33;D = PARAMETER NUMBER;E = PARAMETER <- MACHINE

WRITE OUTPUT_STANDARD

PC -> I = 33;D = 21;E = PARAMETER -> MACHINE MACHINE RELOAD (RESTART)

PC <- I = 34;D = 0;E = PROGRAMM NUMBER <- MACHINE (RECALL)

RECALL

PC -> I = 34;D = 0;E = PROGRAMM NUMBER -> MACHINE

PC <- I = 34;D = 0;E = PROGRAMM NUMBER <- MACHINE

PROGRAMM NUMBER - 0 = PROGRAMM 1

PROGRAMM NUMBER - 1 = PROGRAMM 2

PROGRAMM NUMBER - 15 = PROGRAMM 16

1 – GENLOCK

17

Page 20

Communication Protocol

STORE

PC -> I = 35;D = 0;E = PROGRAMM NUMBER -> MACHINE

PC <- I = 34;D = 0;E = PROGRAMM NUMBER <- MACHINE (RECALL)

IDENTIFY MACHINE

MACHINE NAME

PC -> I = 61;D = 1;E = 0 -> MACHINE

PC <- I = 61;D = MACHINE NAME HIGH;E = MACHINE NAME LOW <- MACHINE

SOFTWARE VERSION

PC -> I = 61;D = 3;E = 0 -> MACHINE

PC <- I = 61;D = SOFTWARE VERSION HIGH;E = SOFTW ARE VERSION LOW <- MACHINE

Examples:

1. Select CV input format:

H21 H80 H80 H98

Unit response:

H61 H80 H80 H98

2. Reset:

H80 H80 H80 H98

3. Recall set up 1:

HA2 H80 H80 H98

DEC: 162 128 128 152

4. Store set up 2:

HA3 H80 H81 H98

DEC: 162 128 129 152

18

KRAMER: SIMPLE CREATIVE TECHNOLOGY

Page 21

LIMITED WA RRANTY

Kramer El ec t ro ni cs (hereafter ) warran ts t his product free from defec ts i n m at erial and workmanship under the

following terms.

HOW LONG IS THE WARRANTY

Labor and parts are warranted for seven years from the date of the first customer purchase.

WHO IS PROTECTED?

Only the first purchase customer may enforce this warranty.

WHAT IS COVERED AND WHA T IS NOT COVERED

Except as below, this warr anty covers all defects in ma terial or workmanship in th is product. The following are not covered

by the warranty:

1. Any product which is not distributed by Kramer, or which is not purchased from an authorized Kramer dealer. If you are

uncertain as to whether a dealer is authorized, please contact Kramer at one of the agents listed in the Web site

www.kramerelectronics.com.

2. Any product, on which the serial number has been defaced, modified or removed, or on which the WARRANTY VOID

IF reattached, removed or otherwise interfered with.

TAMPERED sticker has been torn,

3. Damage, deteriorat ion or malfunc tion resu lting fr om:

i) Accident, misuse, abu se, negl ect, fire, wat er, ligh tning or other acts of nature

ii) Produ ct mo dific ation , or fa ilure to foll ow in struc tions s uppli ed wit h the produ ct

iii) Repair o r att empte d repa ir by a nyon e not au thor ized by Kram er

iv) Any shipme nt of th e produ ct (c laims m ust be pres ented to the ca rrier )

v) Removal or i nstallati on of the produc t

vi) Any other cause, w hich does n ot relate to a produ ct defe ct

vii) Cartons, equipment enclosures, cables or accessories used in conjunction with the product

WHAT WE WILL PA Y FOR AND WHAT WE WILL NOT PA Y FOR

We will pay labor and material expenses for covered i tems. W e will not pay for the following:

1. Removal or installations char ges.

2. Costs of initial technical adjustments (set-up), including adjustment of user controls or programming. These costs are the

responsi bility o f the Kram er deal er from wh om the pr oduct w as purcha sed.

3. Shipping charges.

HOW YOU CAN GET WARRANTY SERVICE

1. To obtain service on you product, you must take or ship it prepaid to any authorized Kramer service center.

2. Whenever warranty service is required, the original dated invoice (or a copy) must be presented as proof of warranty

coverage, and should be included in any shipment of the product. Please also include in any mailing a contact name,

company, address, and a description of the problem(s).

3. For the name of the nearest Kramer authorized service center, consult your authorized dealer.

LIMITATION OF IMPLIED WARRANTIES

All implied warranties, including warranties of merchantability and fitness for a particular purpose, are limited in duration to

the length of this warranty.

EXCLUSION OF DAMAGES

The liability of Kramer for any effective products is limited to the repair or replacem ent of the product at our option. Kramer shall

not be liabl e for:

1. Damage to other property caused by defects in this product, damages based upon inconvenience, loss of use of the product, loss

of time, c omme rcial lo ss; or :

2. Any other dam ages , whe ther inci den tal, c onseq uen tial o r o the rwise. Som e co untr ies m ay not allow lim itati ons o n how l ong an

implied warranty lasts and/or do not allow the ex clusion or limitation of incidental or consequential damages, so the above

limitati ons and e xclusio ns may no t apply to you.

This warra nty give s you spec ific le gal rights , and you m ay also have othe r rights, w hich vary from p lace to pl ace.

All products returned t o Kramer for service must have prior approval. This may be obtained from your dealer.

NOTE:

This equipment has been tested to determine compliance with the requ irements of:

EN-50081: "Electromagnetic compatibility (EMC);

Residential, commercial and light industry"

EN-50082: "Electromagnetic compatibility (EMC) gener ic immunity standard.

CFR-47: FCC* Rul es and Regulations:

CAUTION!

generic emission standard.

Part 1:

Part 1: Residential, commercial and light industry environment".

Part 15: “Radio frequency devices

Subpart B Unintentional radiators”

Servicing the machines can only be done by an authorized Kramer technician. Any user who makes changes or

modifications to the unit without the expressed approval of the manufacturer will vo id user authority to operate the

equipment.

Use the supplied DC power supply to feed power to the machine.

Please use recommended interconnection cables to connect the machine to o ther components.

* FCC and CE approved u sing STP cable (for twisted pai r products )

Kramer

19

Page 22

For the latest information on our products and a list of Kramer

distributors, visit our Web site: www.kramerelectronics.com,

where updates to this user manual may be found.

We wel

come your questions, comments and feedback.

Safety Warning:

Disconnect the unit from the power supply before

opening/servicing.

Caution

Kramer Electronics, Ltd.

Web site: www.kramerelectronics.com

E-mail: info@kramerel.com

P/N: 2900-000082 REV 3

Loading...

Loading...