Page 1

KRAMER ELECTRONIC S LTD.

USER MANUAL

MODEL:

FC-42

Component to HD-SDI

Converter

P/N: 2900-000384 Rev 3

Page 2

Page 3

FC-42 – Contents

i

Contents

1 Introduction 1

2 Getting Started 2

2.1 Achieving the Best Performance 2

2.2 Safety Instructions 3

2.3 Recycling Kramer Products 3

3 Overview 4

3.1 Defining the FC-42 Component to HD-SDI Converter 4

4 Installing in a Rack 7

5 Connecting the FC-42 8

5.1 Connecting to the FC-42 via RS-232 10

6 Using the FC-42 Component To HD-SDI Converter 11

6.1 Locking the Front Panel 11

6.2 Operating the FC-42 HD-SDI to Component Converter 11

7 Technical Specifications 13

8 Communication Protocol 14

Figures

Figure 1: FC-42 Component to HD-SDI Converter Front Panel 5

Figure 2: FC-42 Component to HD-SDI Converter Rear Panel 6

Figure 3: Connecting the FC-42 Component to HD-SDI Converter 9

Figure 4: Crossed Cable RS-232 Connection 10

Figure 5: Straight Cable RS-232 Connection with a Null Modem Adapter 10

Page 4

FC-42 - Introduction

1

1 Introduction

Welcome to Kramer Electronics! Since 1981, Kramer Electronics has been

providing a world of unique, creative, and affordable solutions to the vast range of

problems that confront video, audio, presentation, and broadcasting professionals

on a daily basis. In recent years, we have redesigned and upgraded most of our

line, making the best even better!

Our 1,000-plus different models now appear in 11 groups that are clearly defined

by function: GROUP 1: Distribution Amplifiers; GROUP 2: Switchers and Routers;

GROUP 3: Control Systems; GROUP 4: Format/Standards Converters; GROUP 5:

Range Extenders and Repeaters; GROUP 6: Specialty AV Products; GROUP 7:

Scan Converters and Scalers; GROUP 8: Cables and Connectors; GROUP 9:

Room Connectivity; GROUP 10: Accessories and Rack Adapters and GROUP 11:

Sierra Products.

Congratulations on purchasing your Kramer FC-42 Component to HD-SDI

Converter, which is ideal for the following typical applications:

Broadcast and production video studios

Postproduction and duplication studios

Non-linear editing

Page 5

2

FC-42 - Getting Started

Go to http://www.kramerelectronics.com to check for up-to-date

user manuals, application programs, and to check if firmware

upgrades are available (where appropriate).

This equipment is to be used only inside a building. It may only be

connected to other equipment that is installed inside a building.

i

!

2 Getting Started

We recommend that you:

Unpack the equipment carefully and save the original box and packaging

materials for possible future shipment

Review the contents of this user manual

2.1 Achieving the Best Performance

To achieve the best performance:

Use only good quality connection cables (we recommend Kramer high-

performance, high-resolution cables) to avoid interference, deterioration in

signal quality due to poor matching, and elevated noise levels (often

associated with low quality cables)

Do not secure the cables in tight bundles or roll the slack into tight coils

Avoid interference from neighboring electrical appliances that may adversely

influence signal quality

Position your Kramer FC-42 away from moisture, excessive sunlight and

dust

Page 6

FC-42 - Getting Started

3

Caution:

There are no operator serviceable parts inside the unit

Warning:

Use only the power cord that is supplied with the unit

Warning:

Do not open the unit. High voltages can cause

electrical shock! Servicing by qualified personnel only

Warning:

Disconnect the power and unplug the unit from the wall

before installing

!

2.2 Safety Instructions

2.3 Recycling Kramer Products

The Waste Electrical and Electronic Equipment (WEEE) Directive 2002/96/EC

aims to reduce the amount of WEEE sent for disposal to landfill or incineration by

requiring it to be collected and recycled. To comply with the WEEE Directive,

Kramer Electronics has made arrangements with the European Advanced

Recycling Network (EARN) and will cover any costs of treatment, recycling and

recovery of waste Kramer Electronics branded equipment on arrival at the EARN

facility. For details of Kramer’s recycling arrangements in your particular country

go to our recycling pages at http://www.kramerelectronics.com/support/recycling/.

Page 7

4

FC-42 - Overview

3 Overview

The Kramer FC-42 is a high performance converter for high definition (HD)

component video (Y, PB, PR). It converts the component video input

(Y, PB, PR) to HD-SDI on two BNC output connectors. The signal is also converted

to an RGB/HV signal on a 15-pin HD computer graphics video connector.

In addition, the FC-42 features:

HDTV compatibility

Multi-standard operation: SDI (SMPTE 259M and SMPTE 344M) & HD−SDI

(SMPTE 292M)

HD resolutions of 720p and 1080i (up to 60Hz) & 1080p (up to 30Hz)

Bi−level and tri−level sync input

No resolution conversion

ProcAmp control with memory for 16 setups

A test pattern generator with eight patterns

Control using the front panel with LCD display and RS−232

A worldwide power supply - 100−240V AC

Standard 19” rack mount size of 1U with included rack “ears”

3.1 Defining the FC-42 Component to HD-SDI Converter

This section defines the FC-42.

Page 8

FC-42 - Overview

5

FC-42 – Overview

5

#

Feature

Function

1

POWER Switch

Illuminated switch for turning the unit ON or OFF

2

SETUP / MENU LCD Display

Displays the setup and the menu

3

MENU Button

Press to open the menu (see Section 6.2)

4

ENTER Button

Press to load and save a set up, and to accept changes

5

Button

Press to decrease numerical values or select from several definitions

6

Button

Press to move up the menu list values

7

Button

Press to increase numerical values or select from several definitions

8

Button

Press to move down the menu list

9

LOCK Button

Press and hold for about 3 seconds to lock/unlock the front panel buttons

Figure 1: FC-42 Component to HD-SDI Converter Front Panel

Page 9

6

FC-42 - Overview

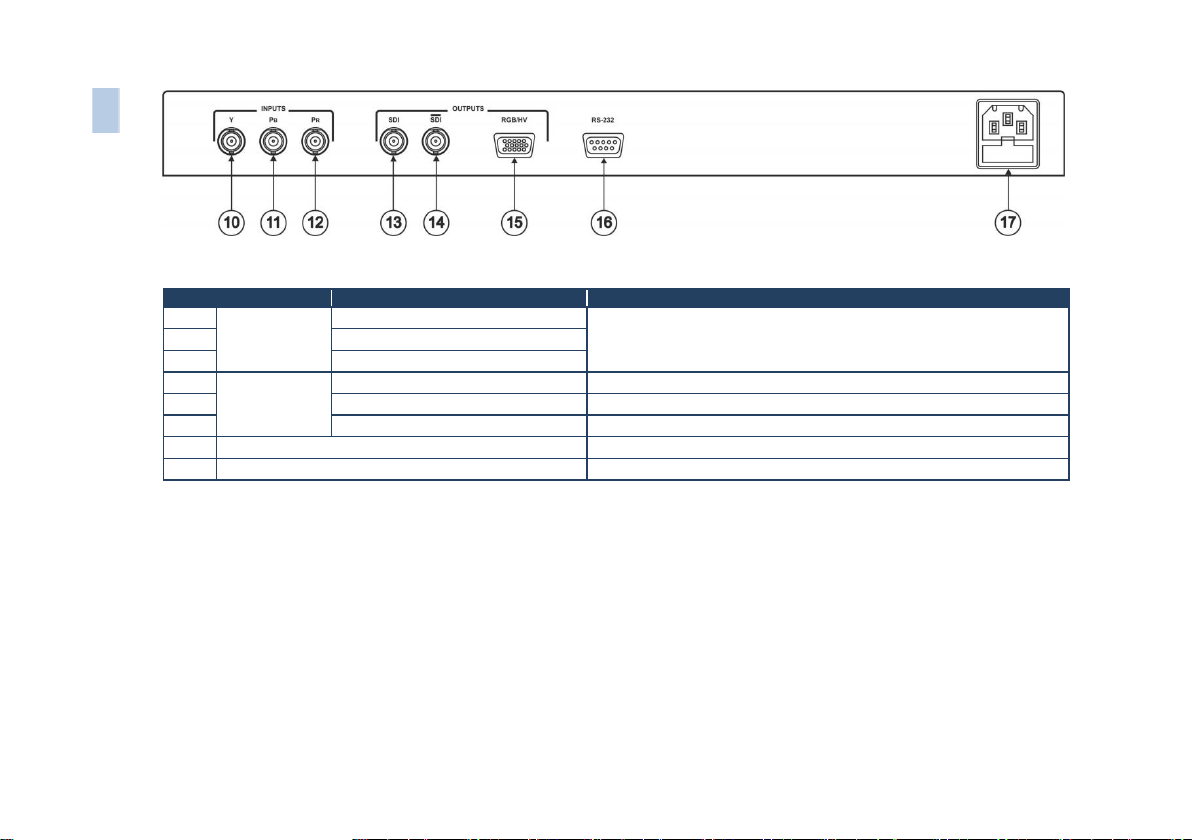

#

Feature

Function

10

INPUTS

Y BNC Connector

Connects to a component video source

11

PB BNC Connector

12

PR BNC Connector

13

OUTPUTS

SDI BNC Connector

Connects to an HD-SDI acceptor

14

SDI (bar) BNC Connector

Connects to an HD-SDI acceptor (reclocked and equalized)

15

RGB/HV 15-pin HD Connector

Connects to an RGB/HV acceptor

16

RS-232 9-pin D-sub Port

Connect to the PC or the remote controller

17

Power Connector with Fuse

AC connector, enabling power supply to the unit

6

FC-42 – Overview

Figure 2: FC-42 Component to HD-SDI Converter Rear Panel

Page 10

FC-42 - Installing in a Rack

7

4 Installing in a Rack

This section provides instructions for rack mounting the unit.

Page 11

8

FC-42 - Connecting the FC-42

Always switch off the power to each device before connecting it to your

FC-42. After connecting your FC-42, connect its power and then switch

on the power to each device.

i

5 Connecting the FC-42

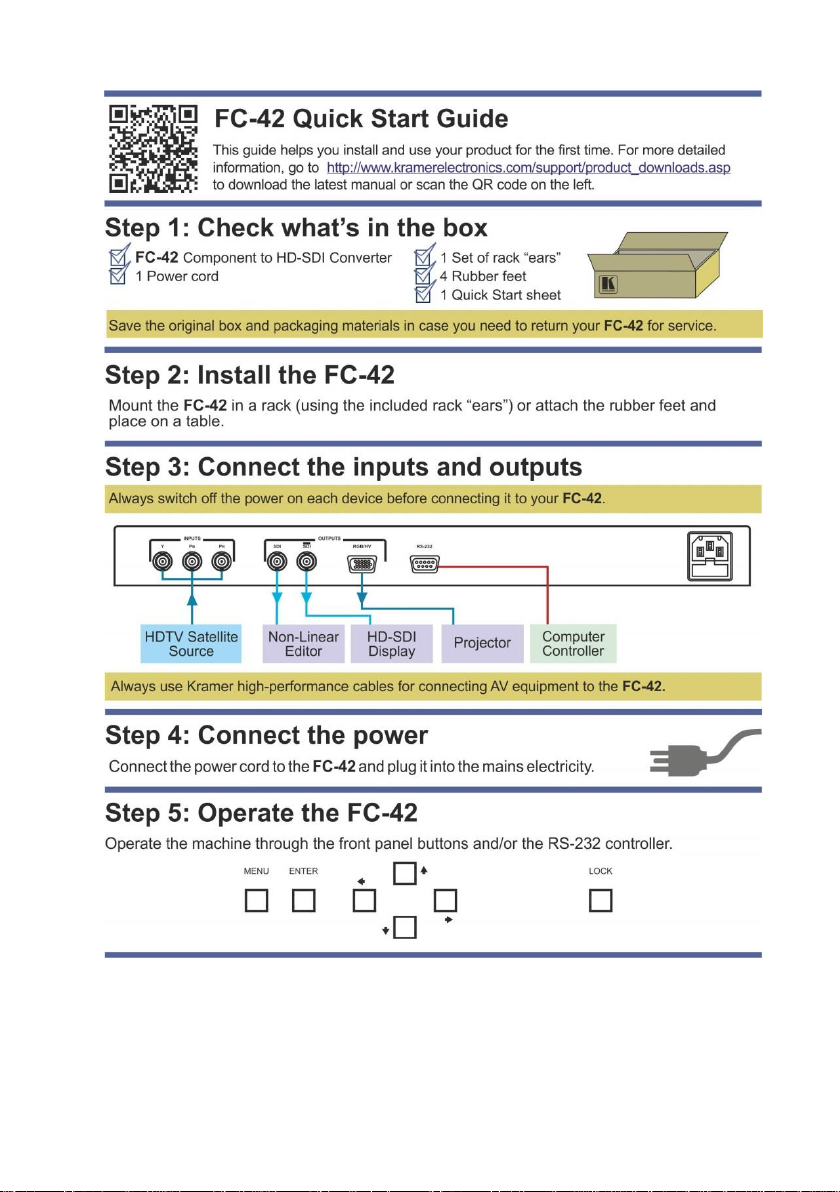

To connect the FC-42, as illustrated in the example in Figure 3, do the following:

1. Connect a component video source (for example, an HDTV Satellite receiver

source) to the Y, PB, PR INPUT BNC connectors.

2. Connect the OUTPUTS:

Connect the SDI BNC connector to an HD-SDI acceptor (for example,

a non-linear editor)

Connect the SDI BNC connector to an HD-SDI acceptor (for example,

an HD-SDI display)

Connect the RGB/HV 15-pin HD computer graphics video connector to

an RGBHV acceptor (for example, a projector)

3. Connect a PC or other controller, if required (see Section 5.1).

4. Connect the power cord (not shown in Figure 3).

Page 12

FC-42 - Connecting the FC-42

9

Figure 3: Connecting the FC-42 Component to HD-SDI Converter

Page 13

10

FC-42 - Connecting the FC-42

1

2

6

3

7

4

8

5

9

1

2

6

3

7

4

8

5

9

PC

1

2

6

3

7

4

8

5

9

to PC

Null-Modem

Adapter

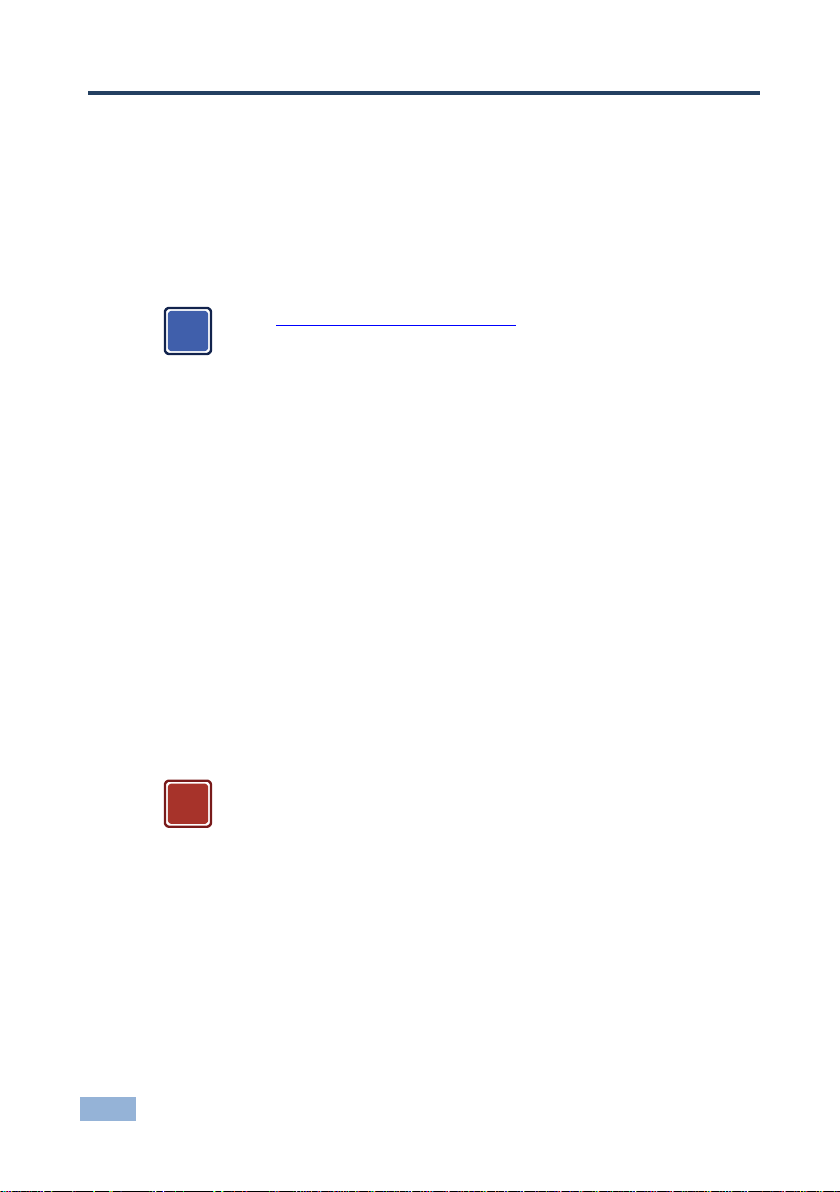

5.1 Connecting to the FC-42 via RS-232

You can connect to the unit via a crossed RS-232 connection, using for example,

a PC. A crossed cable or null-modem is required as shown in method A and B

respectively. If a shielded cable is used, connect the shield to pin 5.

Method A (Figure 4)—Connect the RS-232 9-pin D-sub port on the unit via a

crossed cable (only pin 2 to pin 3, pin 3 to pin 2, and pin 5 to pin 5 need be

connected) to the RS-232 9-pin D-sub port on the PC.

Note: There is no need to connect any other pins.

Figure 4: Crossed Cable RS-232 Connection

Hardware flow control is not required for this unit. In the rare case where a

controller requires hardware flow control, short pin 1 to 7 and 8, and pin 4 to 6 on

the controller side.

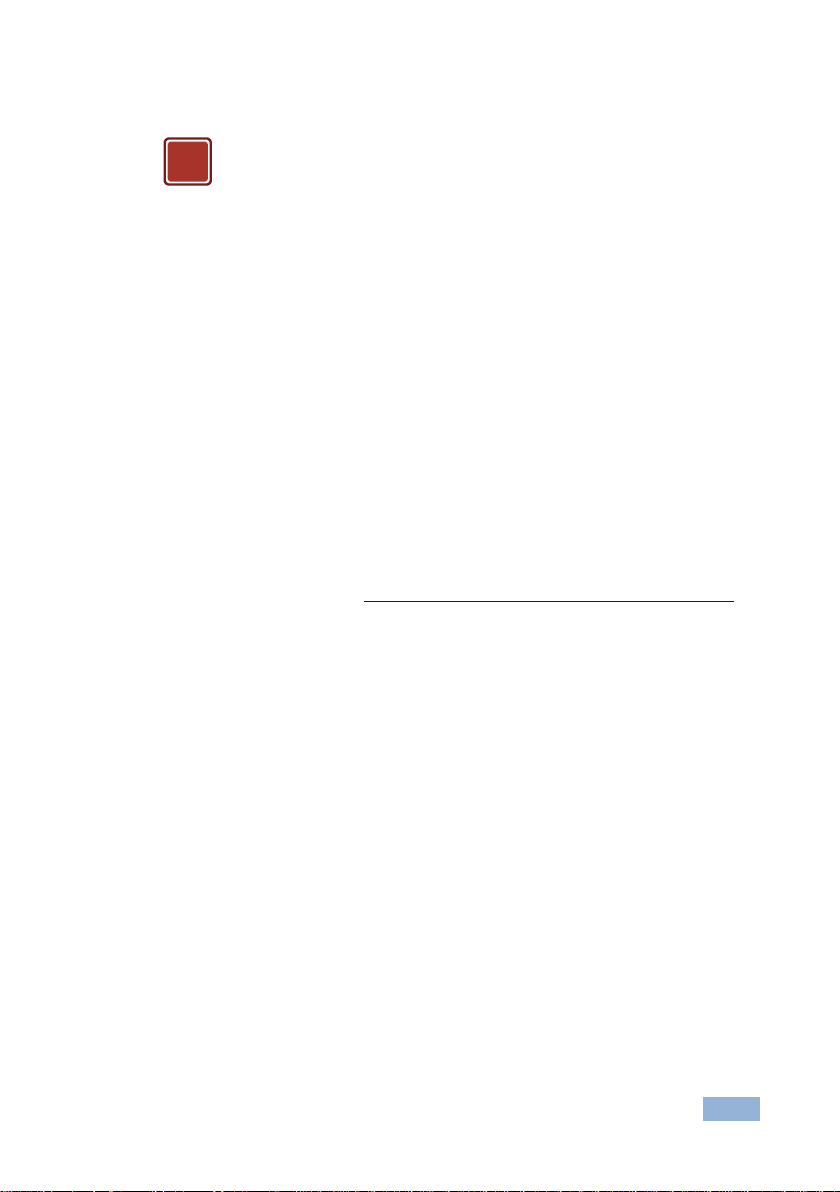

Method B (Figure 5)—Connect the RS-232 9-pin D-sub port on the unit via a

straight (flat) cable to the null-modem adapter, and connect the null-modem

adapter to the RS-232 9-pin D-sub port on the PC. The straight cable usually

contains all nine wires for a full connection of the D-sub connector. Because the

null-modem adapter (which already includes the flow control jumpering described

in Method A above) only requires pins 2, 3 and 5 to be connected, you are free to

decide whether to connect only these 3 pins or all 9 pins.

Figure 5: Straight Cable RS-232 Connection with a Null Modem Adapter

Page 14

FC-42 - Using the FC-42 Component To HD-SDI Converter

11

6 Using the FC-42 Component To HD-SDI

Converter

This section describes how to:

Lock/unlock the front panel button, see Section 6.1

Operate the FC-42, see Section 6.2

6.1 Locking the Front Panel

To prevent changing the settings accidentally or tampering with the unit via the

front panel buttons, lock your converter. Unlocking releases the protection

mechanism.

Even though the front panel is locked you can still operate via RS-232.

To lock the converter:

Press the LOCK button for more than three seconds, until the LOCK button

is illuminated

The front panel is locked. Pressing a button has no effect other than causing

the LOCK button to flash

Warning that you need to unlock to regain control via the front panel.

To unlock the converter:

Press the illuminated LOCK button for more than three seconds, until the

LOCK button is no longer illuminated

The front panel unlocks

6.2 Operating the FC-42 HD-SDI to Component Converter

The converter can save and load up to 16 setups via the converter menu. To use

the menu, press the:

MENU button to start or exit the menu

ENTER button to enter a submenu, load a setup, accept changes and reset

to the default settings

and buttons to scroll through the menu and sub-menus

Page 15

12

FC-42 - Using the FC-42 Component To HD-SDI Converter

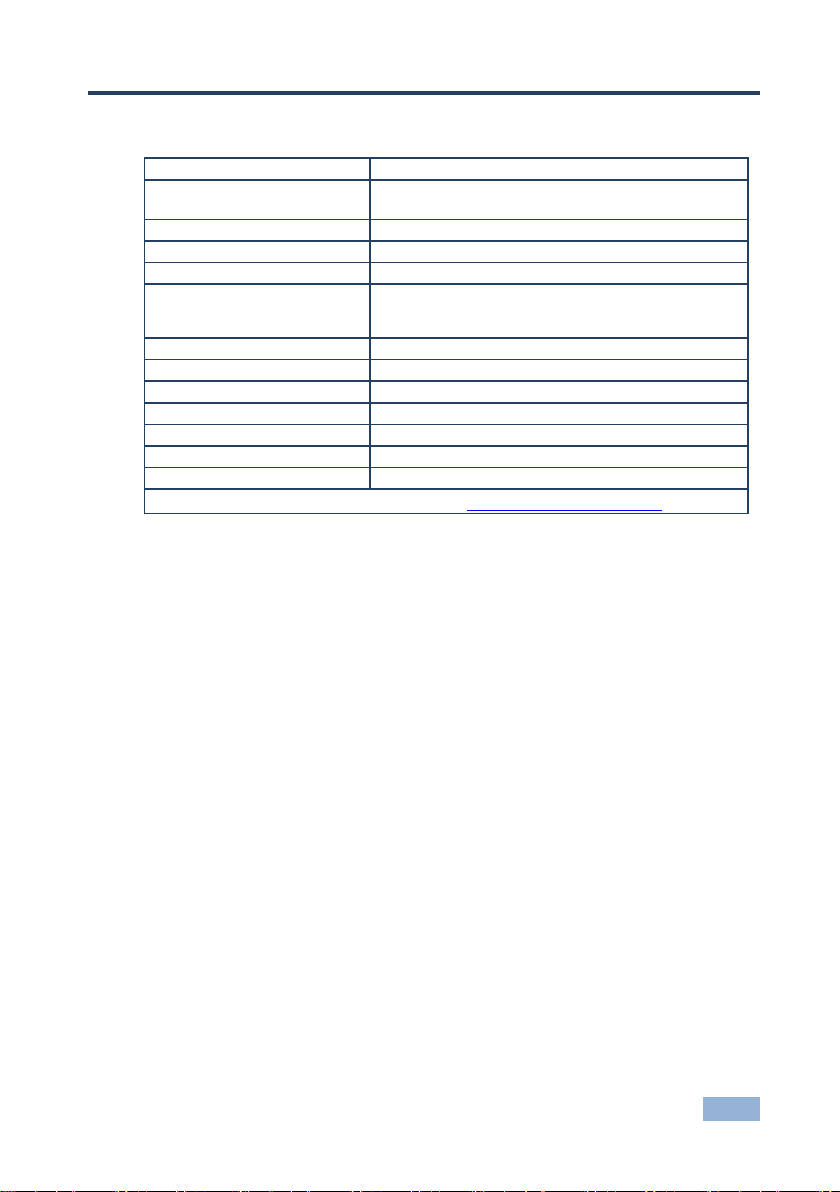

#

Menu Item

Submenu

Select

Notes

1

LOAD … SETUP

From 1 to 16

Refers to the setup

number (from 1 to 16)

2

SAVE SETTING AS

From 1 to 16

3

SET … STANDARD

SELECT MODE

AUTO, FORCED

4

SET … STANDARD

720p/59, 720p/50,

1080i/60, 1080i/59,

1080i/50,

1080p/30, 1080p/29,

1080p/25, 1080p/24,

1080p/23,

1080sf/30, 1080sf/29,

1080sf/25, 1080sf/24,

1080sf/23

5

SET … SYNC TYPE

BILEVEL, TRILEVEL

6

SET … IMAGE TUNING

(enter submenu)

1 FACTORY RESET

Sets all the image

tuning parameters to

zero

2 BLACK

From -32 to 31

3 Y-GAIN

From -64% to 63%

4 GAIN

From -64% to 63%

5 COLOR

From -64% to 63%

6 B-Y

From -64% to 63%

7 R-Y

From -64% to 63%

8 SHARPNESS

From 0 to 155%

In 5% steps

7

SET … Test signal

NO TEST SIGNAL

1 COLOR BARS 100%

2 Y-SWEEP 30MHZ

3 PULSE 2T AND BAR

4 Y RAMP

5 C-SWEEP 15MHZ

6 SPLIT BARS

7 GRID

8 GRID INVERSE

8

SET … Free run mode

BLACK SCREEN, BLUE

SCREEN

9

SET … Address of

machine

First, Second

and to increase or decrease numerical values or select from several

definitions of a setup

The converter automatically converts the input signal according to the setup

loaded from the menu. The setup is defined via the menu. To operate the

converter, press the MENU button to enter the menu, and load the desired setup

(from 1 to 16). The following table defines the menu items.

Page 16

FC-42 - Technical Specifications

13

INPUT:

1 component video - Y, PB, PR, on 3 BNC connectors

OUTPUTS:

2 SDI on BNC connectors

1 RGB/HV on a 15-pin HD connector

OUTPUT LEVEL:

800mVpp

RESOLUTION:

Up to 1080p

S/N RATIO:

49dB unweighted

CONTROLS:

Front panel buttons: MENU, ENTER, menu arrows,

LOCK;

rear panel: RS-232

POWER CONSUMPTION:

100-240V, 50/60Hz, 200mA Max. 12VA

OPERATING TEMPERATURE:

0° to +40°C (32° to 104°F)

STORAGE TEMPERATURE:

-40° to +70°C (-40° to 158°F)

HUMIDITY:

10% to 90%, RHL non-condensing

DIMENSIONS:

19" x 7" x 1U (W, D, H) rack mountable

WEIGHT:

2.6kg (5.7lbs) approx.

ACCESSORIES:

Power cord, null-modem adapter

Specifications are subject to change without notice at http://www.kramerelectronics.com

7 Technical Specifications

Page 17

14

FC-42 - Communication Protocol

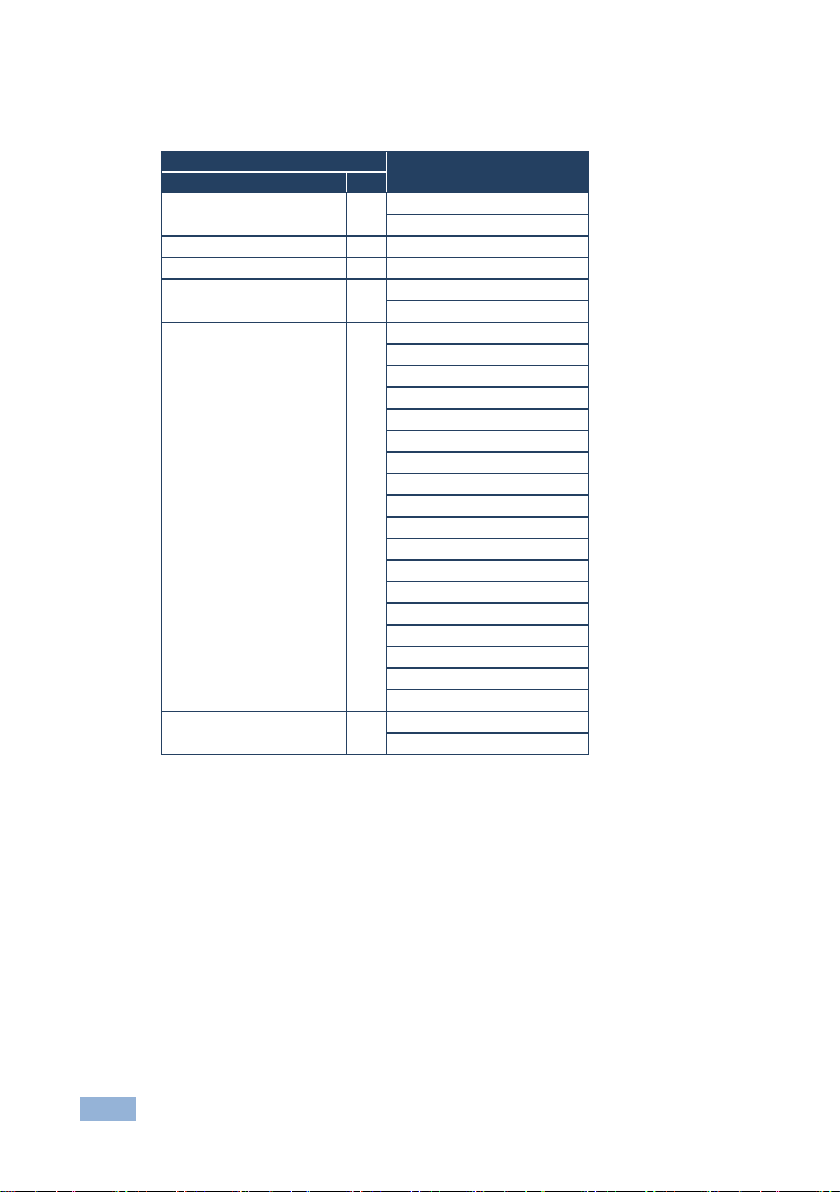

Instruction

Byte 1

Byte 2

Byte 3

Byte 4

Notes:

RESET

00

80

80

98+Machine

Addr

REPLY TO

RESET

40

80

80

98+Machine

Addr

READ LOCAL

PARAMETER

20

80+Parameter

Number

80

B8+Machine

Addr

REPLY TO READ

LOCAL

PARAMETER

60

80+Parameter

Number

80+Parameter

Data

B8+Machine

Addr

WRITE LOCAL

PARAMETER

21

80+Parameter

Number

80+Parameter

Data

B8+Machine

Addr

REPLY TO

WRITE LOCAL

PARAMETER

61

80+Parameter

Number

80+Parameter

Data

B8+Machine

Addr

1

READ GLOBAL

PARAMETER

20

80+Parameter

Number

80

98+Machine

Addr

REPLY TO READ

GLOBAL

PARAMETER

60

80+Parameter

Number

80+Parameter

Data

98+Machine

Addr

WRITE GLOBAL

PARAMETER

21

80+Parameter

Number

80+Parameter

Data

98+Machine

Addr

REPLY TO

WRITE GLOBAL

PARAMETER

61

80+Parameter

Number

80+Parameter

Data

98+Machine

Addr

1

SAVE

23

80 + Initial

Setup

Number

80+Destination

Setup Number

98+Machine

Addr 2 IDENTIFY

MACHINE

3D

81

80

98+Machine

Addr

3

IDENTIFY

FIRMWARE

VERS.

3D

83

80

98+Machine

Addr

4

8 Communication Protocol

The FC-42 is compatible with the protocol (ver 1.2) described below. For RS-232,

a null-modem connection between the FC-42 and controller is used. The default

data rate is 9600 baud, with no parity, 8 data bits and 1 stop bit. All the values

shown are hexadecimal.

Page 18

FC-42 - Communication Protocol

15

Local Parameter Number

Local Parameter Data

Description

#

Input Standard

01

0 - 720p/60

1 - 720p/59

2 - 720p/50

3 - 1080i/60

4 - 1080i/59

5 - 1080i/50

6 - 1080p/30

7 - 1080p/29

8 - 1080p/25

9 - 1080p/24

A - 1080p/23

B - 1080sf/30

C - 1080sf/29

D - 1080sf/25

E - 1080sf/24

F - 1080sf/23

Mode Input Standard

02

0 - Auto

1 - Forced

SYNC Type

04

0 - Bi-Level

1 - Tri-Level

Test Signal

05

0 - NO TEST SIGNAL

1 - COLOR BAR 100%

2 - Y-SWEEP 30 MHZ

3 - PULSE 2T AND BAR

4 - Y-RAMP

5 - C-SWEEP 15 MHZ

6 - RAINBOW

7 - GRID

8 - GRID INVERSE

Black

08

-32% - +31% (1% step)

Y-gain

09

-64% - +63% (1% step)

Gain

0A

-64% - +63% (1% step)

Color

0B

-64% - +63% (1% step)

B-Y

0C

-64% - +63% (1% step)

R-Y

0D

-64% - +63% (1% step)

Sharpness

0E

0% - +150% (10% step)

The following table defines the local parameter data:

Page 19

16

FC-42 - Communication Protocol

Global Parameter Number

Global Parameter Data

Description

#

Panel Lock

00

0 - Off (Default)

1 - On

Machine Address

01

0,1

Setup Number

02

0 - 15

Free Run Mode

03

0 - Black Screen (Default)

1 - Blue Screen

Input Standard

(Read Only)

(AUTO Mode Only)

08

0 - 720p/60

1 - 720p/59

2 - 720p/50

3 - 1080i/60

4 - 1080i/59

5 - 1080i/50

6 - 1080p/30

7 - 1080p/29

8 - 1080p/25

9 - 1080p/24

A - 1080p/23

B - 1080sf/30

C - 1080sf/29

D - 1080sf/25

E - 1080sf/24

F -1080sf/23

10 - Not Identified

11 - Not Identified

Presence of Input Signal

(Read Only)

09

0 - Input Signal is Present

1 - No Input Signal

The following table defines the global parameter data:

NOTE 1: These commands are sent by the unit also when Local / Global parameters are changed via the front panel or

as a result of execution of any other command.

NOTE 2: If it is necessary merely to save adjusted parameters in initial setup number (no setup number change), then

the value of byte3 must be equal to the value of byte2 - initial setup number.

NOTE 3: The reply to the Identify Machine command shows the machine name

- 1st byte: 0x7d

- 2nd byte: 0x80 + 0x00 (0 dec)

- 3rd byte: 0x80 + 0x29 (41 dec) - for the unit FC-42

- 4th byte: 0x98

NOTE 4: The reply to the Identify Firmware command shows the firmware version as

- 1st byte: 0x7d

- 2nd byte: 0x80 + the version number prior to decimal point

- 3rd byte: 0x80 + the version number following the decimal point

- 4th byte: 0x98

For example, for version 3.5, the reply would be 0x7d, 0x83, 0x85, 0x98.

Page 20

Page 21

For the latest information on our products and a list of Kramer distributors,

visit our Web site where updates to this user manual may be found.

We welcome your questions, comments, and feedback.

Web site: www.kramerelectronics.com

E-mail: info@kramerel.com

P/N:

2900-000384

Rev:

3

!

SAFETY WARNIN G

Disconnect the unit from the power

supply before opening and servicing

Loading...

Loading...