Page 1

Kramer Electronics, Ltd.

Preliminary

USER MANUAL

Model:

7408

SDI to Analog Converter

Page 2

Contents

Contents

1 Introduction 1

2 Getting Started 1

2.1 Quick Start 2

3 Overview 3

4 Your 7408 SDI to Analog Converter 3

5 Using Your 7408 SDI to Analog Converter 5

5.1 Connecting Your 7408 SDI to Analog Converter 5

5.2 Connecting to the 7408 via RS-232 6

5.3 Setting the DIP-Switches 7

6 Technical Specifications 8

7 Communication Protocol (Ver 0.1) 9

Figures

Figure 1: 7408 SDI to Analog Converter 4

Figure 2: Connecting a 7408 SDI to Analog Converter 6

Figure 3: Crossed Cable RS-232 Connection 6

Figure 4: Straight Cable RS-232 Connection with a Null-Modem Adapter 7

Tables

Table 1: 7408 SDI to Analog Converter 4

Table 2: Setting the DIP-switches 7

Table 3: DIP-Switch Settings (AUTO, PAL, and NTSC) 8

Table 4: Technical Specifications of the 7408 SDI to Analog Converter 8

Table 5: Structure of the Protocol 9

Table 6: Instruction Set for the 7408 9

i

Page 3

Introduction

1 Introduction

Welcome to Kramer Electronics! Since 1981, Kramer Electronics has been

providing a world of unique, creative, and affordable solution s to the vast

range of problems that confront the video, audio, presentation, and

broadcasting professional on a daily basis. In recent years, we have

redesigned and upgraded most of our line, making the best even better! Our

1,000-plus different models now appear in 11 groups

1

that are clearly

defined by function.

Thank you for purchasing your Kramer DigiTOOLS 7408 SDI to Analog

Converter, which is ideal for broadcast and production video studios,

postproduction and duplication studios, and non-linear editing. The package

includes the following items:

• 7408 SDI to Analog Converter

• Power supply

• Null-modem adapter

®

• Windows

• This user manual

-based Kramer control software

2

2 Getting Started

We recommend that you:

• Unpack the equipment carefully and save the original box and

packaging materials for possible future shipment

• Review the contents of this user manual

• Use Kramer high performance high-resolution cables

3

1 GROUP 1: Distribution Amplifiers; GROUP 2: Switchers and Matrix Switchers; GROUP 3: Control Systems;

GROUP 4: Format/Standards Converters; GROUP 5: Range Extenders and Repeaters; GROUP 6: Specialt y AV Products;

GROUP 7: Scan Converters and Scalers; GROUP 8: Cables and Connectors; GROUP 9: Room Connectivity;

GROUP 10: Accessories and Rack Adapters; GROUP 11: Sierra Products

2 Download up-to-date Kramer user manuals from our Web site at http://www.kramerelectronics.com

3 The complete list of Kramer cables is on our Web site at http://www.kramerelectronics.com

1

Page 4

Getting Started

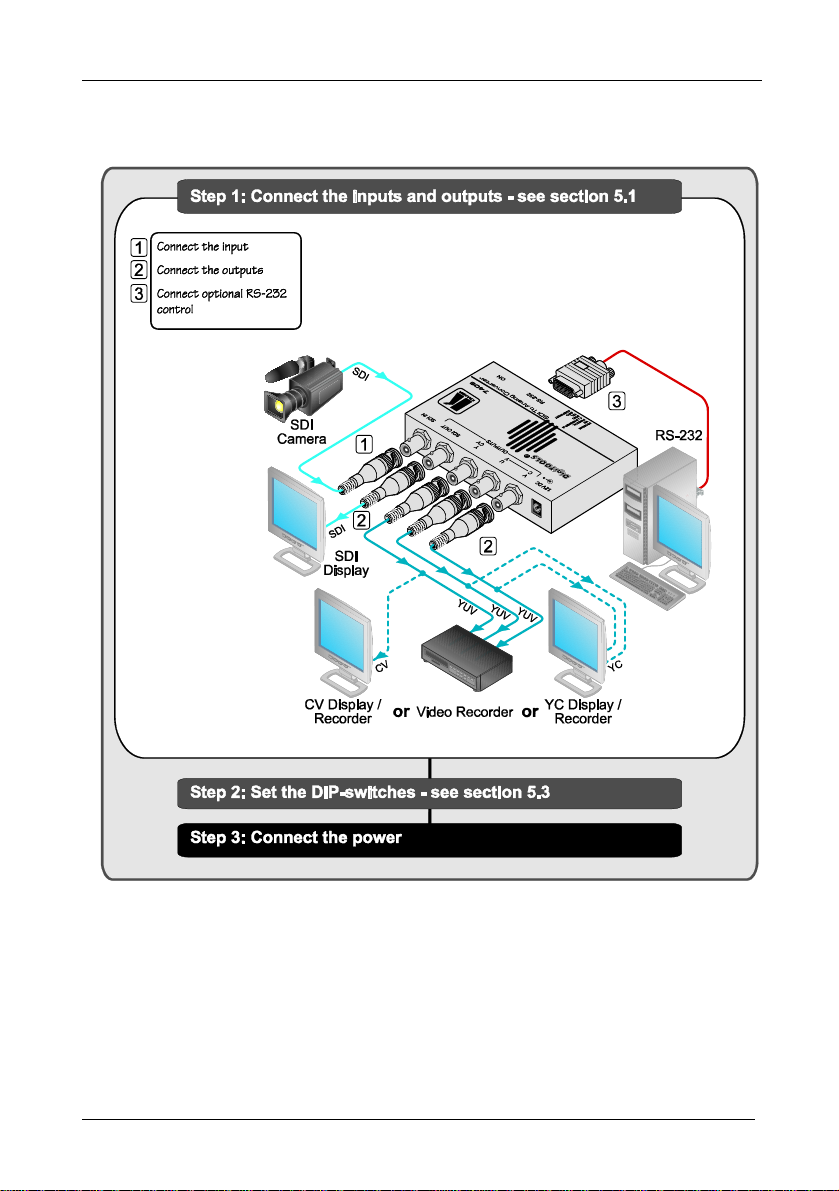

2.1 Quick Start

This quick start chart summarizes the basic setup and operation steps.

2

KRAMER: SIMPLE CREATIVE TECHNOLOGY

Page 5

Overview

3 Overview

The Kramer DigiTOOLS 7408 SDI to Analog Converter is a high quality,

full 10-bit SDI to Analog video converter in a Kramer Tool housing. The

7408 SDI to Analog Converter is a multi-standard unit, converting 525-line

SDI to NTSC or NTSC4.43, and 625-line SDI to PAL-B/D/G/H/I/N.

The 7408 features:

• Reclocked and equalized SDI output (loop)

• 4 times digital over sampling to minimize digital artifacts

• Output configuration to Composite Video and s-Video (Y/C), or

component video (YUV)

• User-friendly Windows PC software, provided for ProcAmp

control via RS-232 for adjusting parameters such as contrast, hue,

saturation and sharpness

• NTSC encoding with or without a 7.5IRE setup

• A perforated cover to prevent overheating

To achieve the best performance:

• Connect only good quality connection cables, thus avoiding

interference, deterioration in signal quality due to poor matching,

and elevated noise levels (often associated with low-quality cables)

• Avoid interference from neighboring electrical appliances that may

adversely influence signal quality and position your Kramer 7408

away from moisture, excessive sunlight and dust

4 Your 7408 SDI to Analog Converter

Figure 1 and Table 1 define the 7408 SDI to Analog Converter:

3

Page 6

Your 7408 SDI to Analog Converter

COMPONENT

AUTO

PAL

NTSC

4xOS

PEDEST AL

VBI

PROGRAM

Figure 1: 7408 SDI to Analog Converter

Table 1: 7408 SDI to Analog Converter

# Feature Function

1

12V DC

2

V / C BNC connector

3

U / Y BNC connector

4

Y / CV

5 SDI OUT BNC Connector Connects to the reclocked and equalized SDI acceptor

6 SDI IN BNC Connector Connects to the SDI source

7

ON LED

8 RS-232 Port Connects to the PC or the remote controller

9 DIP-switches To setup the unit (see section 5.2)

+12V DC connector for powering the unit

Connect to: component video or composite video and/or s-Video

acceptors (according to DIP-switch selection − see Table 3

Illuminates when receiving power

)

4

KRAMER: SIMPLE CREATIVE TECHNOLOGY

Page 7

Using Your 7408 SDI to Analog Converter

5 Using Your 7408 SDI to Analog Converter

You can use your 7408 SDI to Analog Converter to convert SDI video to

professional analog video: composite video and s-Video, or component

video (as the example in Figure 2

5.1 Connecting Your 7408 SDI to Analog Converter

T

o connect the 7408, do the following

1. Connect the SDI source (for example, a digital camera) to the SDI

IN BNC connector. You m ay also connect t he SDI OUT B NC

connector to an SDI acceptor (such as an SDI monitor).

2. Connect the following:

An s-video acceptor (such as an s-video monitor) to the C−Y

output BNC connectors; and/or,

A composite video acceptor, such as a composite video monitor

to the CV output BNC connector; or,

A component video acceptor, such as a VCR, to the YUV BNC

connectors

3. Connect a PC (if required) to the RS-232 port (see section 5.2

4. Set the DIP-switches, as section 5.2

5. Connect the 12V DC power adapter to the power socket and

connect the adapter to the mains electricity.

illustrates).

1

:

describes.

).

Warning:

Do not cover the 7408

1 Switch OFF the power on each device before connecting it to your 7408. After connecting your 7408, switch on its power

and then switch on the power on each device

5

Page 8

Using Your 7408 SDI to Analog Converter

Figure 2: Connecting a 7408 SDI to Analog Converter

5.2 Connecting to the 7408 via RS-232

You can connect to the unit via a crossed RS-232 connection, using for

example, a PC. A crossed cable or null-modem is required as shown in

method A and B respectively. If a shielded cable is used, connect the shield

to pin 5.

Method A (Figure 3

)—Connect the RS-232 9-pin D-sub port on the unit via

a crossed cable (only pin 2 to pin 3, pin 3 to pin 2, and pin 5 to pi n 5 need

be connected) to the RS-232 9-pin D-sub port on the PC.

Note: There is no need to connect any other pins.

Figure 3: Crossed Cable RS-232 Connection

6

KRAMER: SIMPLE CREATIVE TECHNOLOGY

Page 9

Using Your 7408 SDI to Analog Converter

Hardware flow control is not required for this unit. In the rare case where a

controller requires hardware flow control, short pin 1 to 7 and 8, and pin 4

to 6 on the controller side.

Method B (Figure 4

)—Connect the RS-232 9-pin D-sub port on the unit via

a straight (flat) cable to the null-modem adapter, and connect the nullmodem adapter to the RS-232 9-pin D-sub port on the PC. The straight

cable usually contains all nine wires for a full connection of the D-sub

connector. Because the null-modem adapter (which already includes the

flow control jumpering described in Met ho d A a bove) only requires pins 2,

3 and 5 to be connected, you are free to decide whether to connect only

these 3 pins or all 9 pins.

Figure 4: Straight Cable RS-232 Connection with a Null-Modem Adapter

5.3 Setting the DIP-Switches

Configure the 7408 unit by setting the DIP-switches, as Table 2

Table 2: Setting the DIP-switches

DIPS Function Description

1 PROGRAM ON f or upgrading firmware; otherwise OFF

2 VBI ON to enable Vertical Interval Blanking; OFF to disable

3 PEDESTAL1 ON for pedestal (7.5 IRE offset selection for NTSC); OFF for no pedestal

4 4XOS2 ON to enable oversampling3; OFF to disable oversampling

5 NTSC ON for NTSC 3.58 (see Table 3)

6 PAL ON for PAL (see Table 3)

7 AUTO ON for multi-standard; OFF for user selected (fixed) standard (see Table 3)

8 COMPONENT ON for component video; OFF for composite video and/or s-video

defines:

1 NTSC offsets the black level within the active video signal by 7.5 IRE when selected

2 4xOS is 4 x Oversample

3 When this method is used, the noise figure is improved

7

Page 10

Technical Specifications

Table 3: DIP-Switch Settings (AUTO, PAL, and NTSC)

AUTO PAL NTSC 7408 Output Standard

OFF OFF OFF NTSC 4.43

OFF OFF ON NTSC 3.58

OFF ON OFF PAL-B

OFF ON ON PAL-N

ON OFF OFF PAL-N for 625 line SDI input; NTSC 4.43 for 525 line SDI input

ON OFF ON PAL-N for 625 line SDI input; NTSC 3.58 for 525 line SDI input

ON ON OFF PAL-B for 625 line SDI input; NTSC 4.43 for 525 line SDI input

ON ON ON PAL-B for 625 line SDI input; NTSC 3.58 for 525 line SDI input

6 Technical Specifications

Table 4 includes the technical specifications:

Table 4: Technical Specifications1 of the 7408 SDI to Analog Converter

INPUT: 1 SDI: SMPTE-259M, ITU-R BT.601 on a BNC connector

OUTPUTS: 1 reclocked SDI: SMPTE-259M, ITU-R BT.601 on a BNC connector;

BANDWIDTH (-3dB): 5.7MHz

DIFF. GAIN: <1%

DIFF. PHASE: <1Deg

K-FACTOR: 0.5%

S/N RATIO: >70dB (flat field)

DIGITAL RESOLUTION: 10 bit

LUMA NON-LINEARITY: 0.9%

CHROMA/LUMA DELAY: <15nsec

POWER SOURCE: 12V DC, 320mA

DIMENSIONS: 12cm x 7.5cm x 2.5cm (4.7" x 2.95" x 0.98") W, D, H

WEIGHT: 0.3kg (0.66lbs)

ACCESSORIES: Power supply, null-modem adapter

OPTIONS: RK-3T 19" rack adapter

1 composite video: 1Vpp/75Ω on a BNC connector;

1 s-Video: 1Vpp, 0.3Vpp/75Ω on two BNC connectors;

1 component video (Y, U and V) on three BNC connectors

1 Specifications are subject to change without notice

8

KRAMER: SIMPLE CREATIVE TECHNOLOGY

Page 11

Communication Protocol (Ver 0.1)

7 Communication Protocol (Ver 0.1)

RS-232 communication between the 7408 and the PC is done using the f ollowing protocol. The protocol uses four b ytes of

information, and data is at 9600 baud, no parity, 8 data bits and 1 stop bit. The controller and machine should be connected

via a null-modem connection, that is, if using a DB-9 port, connect as follows:

Connect pin 5 of the PC to pin 5 of the machine

Cross pins 2 and 3, i.e., connect pin 2 of the PC to pin 3 of the machine, and connect pin 3 of the PC to pin 2 of the machine

On the PC side, short pins 4 and 6

On the PC side, short pins 1, 7 and 8

Table 5: Structure of the Protocol

MSB

0 TO PC I5 I4 I3 I2 I1 I0

7 6 5 4 3 2 1 0

1st byte

1 D6 D5 D4 D3 D2 D1 D0

7 6 5 4 3 2 1 0

2nd byte

1 E6 E5 E4 E3 E2 E1 E0

7 6 5 4 3 2 1 0

3rd byte

1 E7 D7 0 1 1 1 0

7 6 5 4 3 2 1 0

4th byte1

Note that the MSB’s of the DATA (D7) and the EXTENDED DATA (E7) are in the fourth byte. Terminology:

TO PC is the “DESTINATION BIT”

I4..I0 is the “INSTRUCTION”

D7..D0 is the “DATA”

E7..E0 is the “EXTENDED DATA”

The destination bit, TO PC, is 0 when sending from the PC to the machine, or 1 when sending from the machine to the PC.

INSTRUCTION

DATA

EXTENDED DATA

MSB’s ADDR

Table 6: Instruction Set for the 7408

INSTRUCTION I7 I6 I5 I4 I3 I2 I1 I0

Dec Hex

0 0 Reset 0 0 0 0 0 0 0 0

3 3 Store machine settings 0 0 0 0 0 0 1 1

4 4 Recall machine settings 0 0 0 0 0 1 0 0

5 5 Set Video Parameter 0 0 0 0 0 1 0 1

6 6 Request Video Parameter 0 0 0 0 0 1 1 0

7 7 Read video encoder data 0 0 0 0 0 1 1 1

8 8 Write video encoder data 0 0 0 0 1 0 0 0

10 A Write EEPROM data 0 0 0 0 1 0 1 0

11 B Read EEPROM data 0 0 0 0 1 0 1 1

12 C Write I²C 0 0 0 0 1 1 0 0

13 D Read I²C 0 0 0 0 1 1 0 1

14 E Read video standard 0 0 0 0 1 1 1 0

15 F Is setup defined? 0 0 0 0 1 1 1 1

16 10 Error 0 0 0 1 0 0 0 0

30 1E Lock Front Panel 0 0 0 1 1 1 1 0

31 1F Request Bar 0 0 0 1 1 1 1 1

57 39 Enable “Power-down save” 0 0 1 1 1 0 0 1

61 3D Identify machine 0 0 1 1 1 1 0 1

LSB

1 Note that the MSB’s of the DATA (D7) and the EXTENDED DATA (E7) are in the fourth byte

9

Page 12

Communication Protocol (Ver 0.1)

DESCRIPTION OF INSTRUCTIONS

INSTRUCTION 0 – RESET

DATA=0: initialize the machine.

When the machine is initialized, it will send the RESET code (DATA = 0). If the machine receives this code, it will reset to

its “power-up” state.

DATA=1: configure the machine to its factory default state.

When the machine receives this code, all programmable parameters will be reset to their factory-default values.

EXTENDED DATA - set as 0.

INSTRUCTION 3 – STORE MACHINE SETTINGS

DATA = setup# (1 to 10) where present values of machine settings are saved.

EXTENDED DATA - set as 0.

- When the machine receives this instruction, its present settings (video parameters) are saved in non-volatile memory. The

machine replies by sending the same 4 bytes (except for the Destination Bit) back to the PC.

- When the user saves the machine settings using the front-panel buttons, then this instruction is sent to the PC.

INSTRUCTION 4 – RECALL MACHINE SETTINGS

DATA = setup# (1 to 10) of machine settings which are to recalled.

EXTENDED DATA - set as 0.

- When the machine receives this instruction, it recalls the settings which were previously saved in the setup#. The machine

replies by sending the same 4 bytes (except for the Destination Bit) back to the PC.

- When the user recalls a setup using the front-panel buttons, then this instruction is sent to the PC.

INSTRUCTION 5dec – SET VIDEO PARAMETER

DATA = Video parameter #, defined as follows:

1 = Brightness

2 = Contrast

3 = Hue

4 = Sharpness

5 = Colour saturation

6 = R-Y saturation

7 = B-Y saturation

EXTENDED DATA - value for selected video parameter .

- When the machine receives this instruction, then, if valid, the selected video parameter is set and the machine replies by

sending the same 4 bytes (except for the Destination Bit) back to the PC.

- When the user changes video parameters using the front-panel buttons, then this instruction is sent to the PC.

Note that the video parameter values range from 0 (minimum) up to 255dec ( maximum), and do not necessarily correspond

with the number displayed on the panel of the 7408. If a value outside the legal range of a particular parameter is sent, the

error code will be returned.

INSTRUCTION 6 – REQUEST VIDEO PARAMETER

For sending to machine, DATA = VIDEO parameter #, defined as in INSTRUCTION 5; EXTENDED DATA=0;

When replying DATA = VIDEO parameter #, defined as in INSTRUCTION 5; EXTENDED DATA- value for selected

VIDEO parameter.

INSTRUCTION 7 – READ VIDEO ENCODER DATA

For sending to machine, DATA = VIDEO ENCODER sub-address which is to be read.

When replying:- DATA = VIDEO ENCODER sub-address; EXTENDED DATA = requested data.

The PC sends this instruction to the machine. The machine replies by sending back the data assigned to this sub-address.

INSTRUCTION 8 – WRITE VIDEO ENCODER DATA

DATA = VIDEO ENCODER sub-address; EXTENDED DATA = data to be written to this sub-address.

The PC sends data directly to the encoder. The machine implements this new value, and replies by sending the same 4 b ytes

(except for the Destination Bit) back to the PC.

CAUTION – this function was designated for development and testing purposes. Imprope r use of this function may cause

erratic behaviour of the machine.

INSTRUCTION 10dec – WRITE EEPROM DATA

DATA = EEPROM sub-address; EXTENDED DATA = data to be written to this sub-address.

The PC sends data directly to the EEPROM. The EEPROM stores this new value, and repl ies by sending the same data ba ck

to the PC.

10

KRAMER: SIMPLE CREATIVE TECHNOLOGY

Page 13

Communication Protocol (Ver 0.1)

CAUTION – this function was designated for development and testing purposes. Imprope r use of this function may cause

erratic behaviour of the machine.

INSTRUCTION 11dec – READ EEPROM DATA

For sending to machine, DATA = EEPROM sub-address which is to be read.

When replying:- DATA = EEPROM sub-address; EXTENDED DATA = requested data.

The PC sends this instruction to the machine. The machine replies by sending back the data stored in this sub-address.

INSTRUCTION 12dec – WRITE I²C

DATA = I²C sub-address; EXTENDED DATA = data to be written to this sub-address. The PC sends I²C data (to the I²C

address which was last accessed via INSTRUCTION 13). The machine replies by sending the same data back to the PC.

CAUTION – this function was designated for development and testing purposes. Imprope r use of this function may cause

erratic behavior of the machine.

INSTRUCTION 13dec – READ I²C

For sending to machine, DATA = I²C address; EXTENDED DATA = sub-address. When replying:- DATA = sub-address ;

EXTENDED DATA = data read.

The PC sends this instruction to the machine. The machine replies by sending back the data of this address and sub-address.

INSTRUCTION 14dec – READ VIDEO STANDARD

For sending to machine, set DATA = EXTENDED DATA = 0.

When replying:- DATA = 0; EXTENDED DATA = VIDEO STANDARD.

The PC sends this instruction to the machine. The machine replies by sending back the video standard, defined as follows:

0 = NTSC4.43

1 = NTSC

2 = PAL

3 = PAL-N

64dec (40hex)= Invalid or no input detected

Note that when the DIP-switches are set for a fixed standard, the 7408 will reply by sending the code for the fixed standard.

INSTRUCTION 16dec – ERROR

If the machine receives an invalid instruction, it replies by sending this error code.

INSTRUCTION 30dec – LOCK FRONT PANEL

DATA = 0: panel is unlocked.

DATA = 1: panel is locked.

EXTENDED DATA - set as 0.

- When the machine receives this instruction, it will lock or unlock the panel for contr ol via the front-panel pushbutton

switches (RS-232 control is unaffected).

- When the user changes the lock status using the front-panel button, then this instruction is sent to the PC.

INSTRUCTION 31dec – REQUEST BAR

For sending DATA = EXTENDED DATA = 0

When replying EXTENDED DATA = 1, if Bar

INSTRUCTION 57dec – ENABLE “POWER-DOWN SAVE”

DATA = 0 disables power-down saving; DATA = 1 enables saving. EXTENDED DATA - set to 0.

The PC sends this instruction to the machine. The power-down option is enabled or disabled according to the valu e of DATA.

If the power-down option is enabled, then the machine will “remember” its state before being turned off, and revert to thi s

state when turned on again. Note that whenever the machine is turned on, the power-down save option is enabled.

INSTRUCTION 61dec – IDENTIFY MACHINE

For sending, DATA = 1 to request machine name; DATA = 3 to request software version n umber. EXTENDED DATA - se t

to 0.

The PC sends this instruction to the machine. The machine relies as follows:

If the machine name is requested, the machine replies with DATA = 40 (hex), and EXTENDED DATA = 45 (hex).

If the software version is requested, the machine replies with DATA as the version number before the decimal point, and

EXTENDED DATA is the value following the decimal point. For example, for version 3.4, the machine replies with DATA =

03 (hex), and EXTENDED DATA = 04 (hex).

11

Page 14

LIMITED WARRANTY

Kramer Electronics (hereafter ) warrants this product free from defects in material and workmanship under the

following terms.

HOW LO NG IS THE W ARR ANTY

Labor and parts are warranted for three years from the date of the first cus tomer purchase.

WHO IS PROTEC TED?

Only the first purchase customer may enforce this warranty.

WHAT IS COVERED AND WHAT IS NO T COVERED

Except as below, this warranty covers all defects in material or workmanship in this product. The following are not covered

by the warranty:

1. Any product which is not distributed by Kramer, or which is not purchased from an authorized Kramer dealer. If you are

uncertain as to whether a dealer is authorized, please contact Kramer at one of the agents listed in the Web site

www.kramerelectronics.com.

2. Any product, on which the serial number has been defaced, modified or removed, or on which the WARRANTY VOID

IF reattached, removed or otherwise interfered with.

TAMPERED sticker has been torn,

3. Damage, deterioration or malfunction resulting from:

i) Accident, m isuse, a buse, n eglec t, fire, wat er, l ightnin g or oth er acts of nature

ii) Product mo dificati on, or f ailure to foll ow instru ction s suppli ed with t he produ ct

iii) Repair o r attemp ted repa ir by an yone n ot author ized by Kramer

iv) Any ship ment o f th e pro duct (c laim s must be pre sente d to the car rier )

v) Removal or inst allati on of th e produ ct

vi) Any other ca use, w hich doe s not rel ate to a pr oduct d efec t

vii)Cartons, eq uipmen t enclos ures , cables o r acces sories used in conjunc tion wi th the p roduct

WHAT WE WILL PA Y FOR AND WHAT WE WILL NOT PA Y FOR

W e will p ay labor a nd mat erial ex penses for cov ered i tems. We will not pay for the f ollowin g:

1. Removal or installations charges.

2. Costs of initial technical adjustments (set-up), including adjustment of user controls or programming. These costs are the

respon sibili ty of the Krame r deale r from wh om the produ ct was pu rchas ed.

3. Shipping charges .

HOW YOU CA N GE T WARRANT Y SERV ICE

1. To obtain service on you product, you must take or ship it prepaid to any authorized Kramer service center.

2. Whenever warranty service is required, the original dated invoice (or a copy) mus t be presented as proof of warranty

coverage, and should be included in any shipment of the product. Please also include in any mailing a contact name,

company, address, and a description of the problem(s).

3. For t he name of the nearest Kramer authorized service center, consult your authorized dealer.

LIMITATION OF IMPLIED W ARRANTIES

All implied warranties, including warranties of merchantability and fi tn ess for a particular purpose, are limited in duration to

the length of this warranty.

EXCLUSION OF DAMAGES

The liability of Kramer for any effective products is limited to the repair or replacement of the product at our option. Kramer shall

not be liable for:

1. Damage to other p roperty caused b y defect s in this product , damage s based upon i nconven ience, loss of use of the pr oduct, loss

of time, commercial loss ; or:

2. Any other dam ages , whet her i ncide ntal, co nseque nti al or othe rwise . Som e co untri es ma y n ot all ow li mita tion s on ho w lo ng a n

implied warr anty lasts and/or do not allow the excl usion or limitation of incidental or conseque ntial damages, so the above

limitati ons and exclus ions ma y not app ly to you.

This warranty gives you specific legal rights, and you may also have other rights, which vary from place to place.

NOTE:

All pr oduc ts return ed to Kra mer fo r servi ce mus t have pri or appr oval. This ma y be obt ained fr om you r deale r.

This equipment has bee n tested to determine com pliance with the requiremen ts of:

EN-50081: "Electromagnetic compatibility (EMC);

Residential, commercial and l ight industry"

EN-50082: "Electromagnetic compatibility (EMC) generic immunity standard.

CFR-47: FCC* Rules and R e gulation s:

CAUTIO N!

generic emiss ion stand ard.

Part 1:

Part 1: Residential, commer cial and light industry enviro nment".

Part 15: “Radio frequency devices

Subpart B Unintentional radiators”

Servicing the machines can only be done by an authorized Kramer technician. Any user who makes changes or

modifications to the unit without the expressed approval of the manufacturer will void user authority to operate the

equipment.

Use the supplied DC power supply to feed power to the machine.

Please use recommended interconnection cables to connect the machine to other components.

* FCC and CE app roved usi ng STP cable ( for twi sted pair p roduc ts)

Kramer

12

KRAMER: SIMPLE CREATIVE TECHNOLOGY

Page 15

For the latest information on our products and a list of Kramer

distributors, visit our Web site:

www.kramerelectronics.com

where updates to this user manual may be found.

We welcome your questions, comments and feedback.

Safety Warning:

Disconnect the unit from the power supply before

opening/servicing.

Caution

Kramer Electronics, Ltd.

Web site: www.kramerelectronics.com

E-mail: info@kramerel.com

P/N: 2900-000019 REV 2

Loading...

Loading...