Krais K50-400, K50-600, K50-1250 Manual Instruction

MANUAL INSTRUCTION

Model P&P K50-400, P&P K50-600,

P&P K50-1250

READ SAFETY RECOMMENDATIONS BEFORE USE , THIS TOOL

PAGE 2

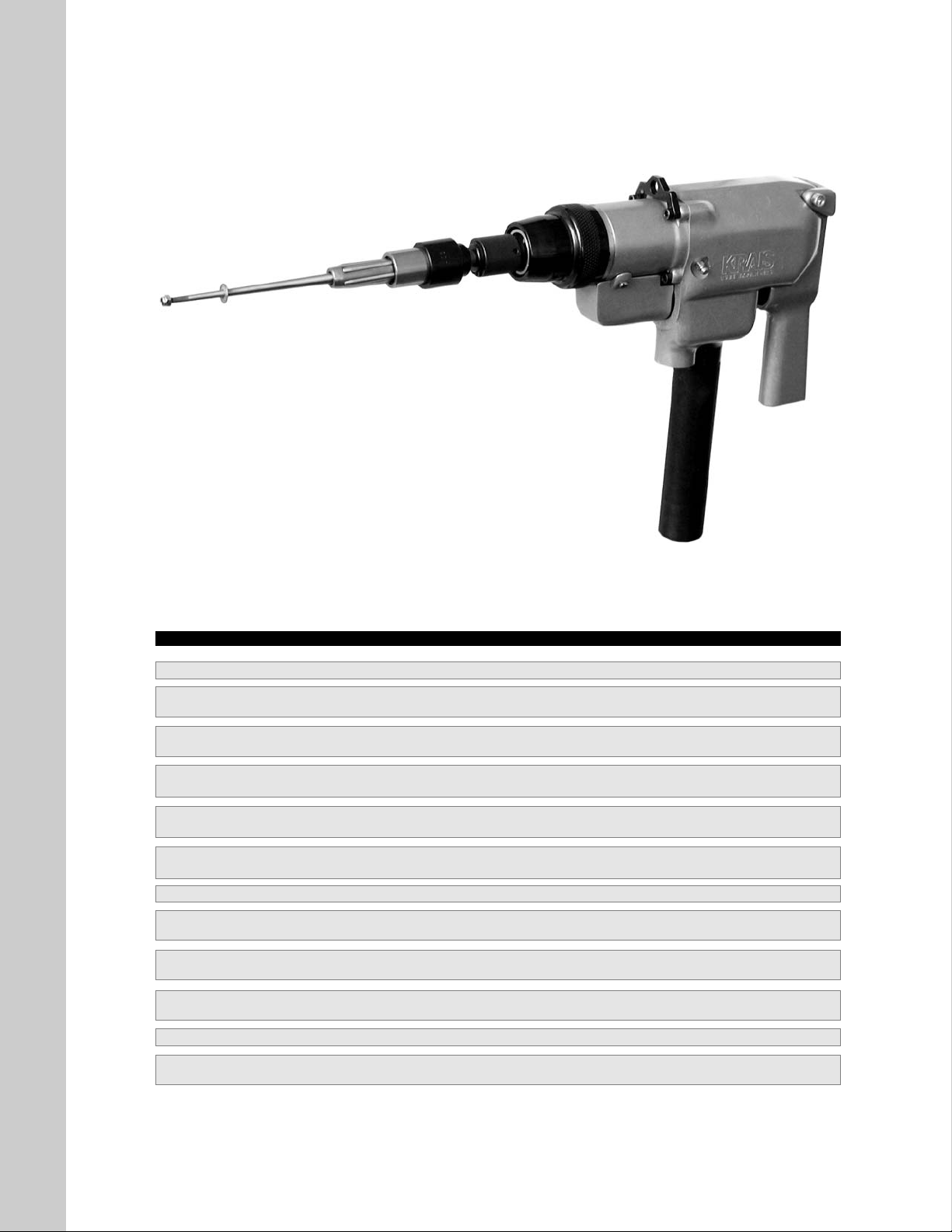

Model P&P K50-1250 P&P K50-600 P&P K50-400

Free speed 1250 rpm 600 rpm 400 rpm

Minimum torque

1,58 Nm 2,49 Nm 5,00 Nm

14 in.Lbs 22 in.Lbs 44,15 in.Lbs

Maximum torque

12,2 Nm 21,81 Nm 36,00 Nm

108 in.Lbs 193 in.Lbs 318 in.Lbs

Sound Pressure Level Lpa 83 dBa 83 dBa 83 dBa

Sound Power Level Lwa 94 dBa 94 dBa 94 dBa

Weight

4,76 kg 4,76 kg 4,76 kg

10,5 Lbs 10,5 Lbs 10,5 Lbs

Length

311 mm 311 mm 311 mm

12 1/4” 12 1/4” 12 1/4”

Side To Center Distance 1 7/16” (36.5mm) 1 7/16” (36.5mm) 1 7/16” (36.5mm)

Minimum Recommended Hose Diameter

3/8” (9.5 mm) 3/8” (9.5 mm) 3/8” (9.5 mm)

(maximum 25 Foot Length)

Air consumption

1700 l/min 1700 l/min 1700 l/min

60 cfm 60 cfm 60 cfm

Tube capacity

3/4” 1” 1 1/4”

19 mm 25,4 mm 31,7 mm

Square size 3/8” 3/8” 3/8”

Chucks

3/8” 3/8” 3/8”

opt. 1/2” opt. 1/2” opt. 1/2”

Tool Specifications

PAGE 3

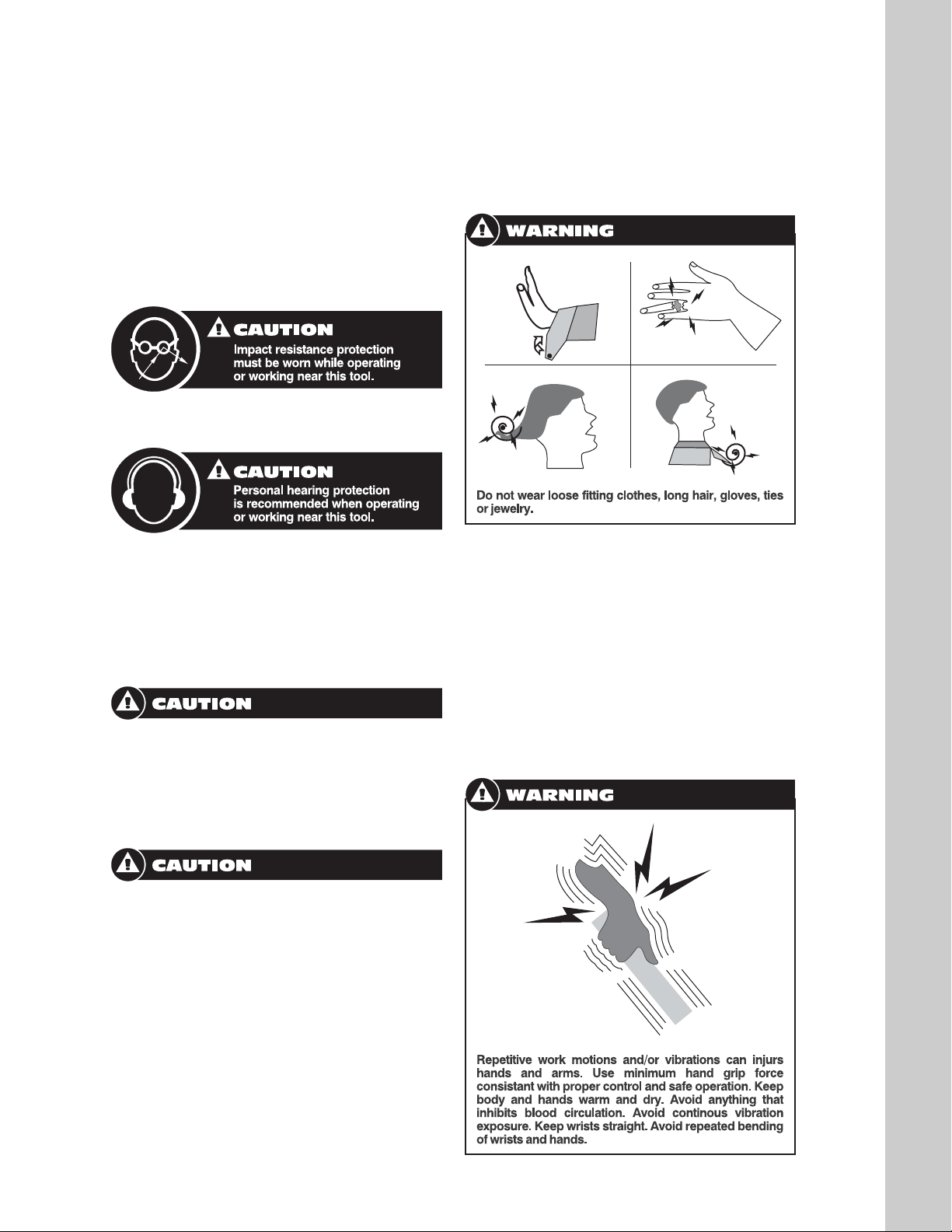

For your safety and the safety of others, read and

understand the safety recommendations and

operating instructions before operating this tool.

ALWAYS WEARPROTECTIVE EQUIPMENT

EYE AND FACE PROTECTION

HEARING PROTECTION

Hearing protectors are required in high noise

areas, 85 dBa or greater. The operation of other

tools and equipment the area, reflective surfaces, process noises and resonate structures,

can substantially contribute to and increase the

noise level in the area.

Moving components can entangle and enwrap.

And can result in serious injuries. Never wear

loose fitting clothes, gloves, ties or jewelry when

working with or near any power tool with an

exposed rotating shaft or spindle.

Tools with clutches can stall rather than shut-off

if adjusted over the maximum power output of

the tool, or if there is a drop in air pressure.

Operator must then resist the stall torque until

the throttle is released.

Higher torque pneumatic tools, inline and right

angle, are supplied with a torque reaction bar

designed to work with the torque of the tool it is

specified for. These bars can be braced against

the work or other suitable points to absorb and

relieve the operator of the torque reaction transmitted by the tool. Tool balance arms are also

available to absorb the torque reaction of the

tool while balancing the weight of the tool for

improved ergonomic applications.

Some individuals are susceptible to disorders of

the hands and arms when exposed to tasks, which

involve highly repetitive motions and/or vibrations.

Those individuals predisposed to vasculatory or circulatory problems may be particularly susceptible.

Cumulative trauma disorders such as carpal tunnel

syndrome and tendentious can be caused or

aggravated by repetitious, forceful exertions of the

hands and arms. These disorders develop gradually over periods of weeks, months, and years.

Safety Recommendations

TASKS SHOULD BE PERFORMED IN SUCH A

MANNER THAT THE WRISTS ARE MAINTAINED IN A NEUTRAL POSITION WHICH IS

NOT FLEXED, HYPEREXTENDED, OR TURNED

SIDE TO SIDE.

STRESSFUL POSTURES SHOULD BE AVOIDED AND CAN BE CONTROLLED THROUGH

TOOL SELECTION AND WORK LOCATION.

Any user suffering from prolonged symptoms of

tingling, numbness, blanching of the fingers, clumsiness or weakened grip, nocturnal pain in the

hand, or any other disorder of the shoulders, arms,

wrists, or fingers is advised to consult with a physician. If it is determined that the symptoms are job

related or aggravated by movements and postures dictated by the job design, it may be necessary for the employer to take steps to prevent further occurrences. These steps might include, but

are not limited to, repositioning the work piece or

redesigning the workstation, reassigning workers

to other jobs, rotating jobs, altering awork pace,

and/or changing the type of tool used so as to minimize stress on the operator. Some tasks may

require more than one type of tool to obtain the

optimum operator/tool/task relationship.

The following recommendations will help reduce or

moderate the effects of repetitive work motions:

uses a minimum handgrip force consistent with

proper control and safe operation;

keep wrists as straight as possible;

keep body and hands warm and dry.

Avoid anything that inhibits blood circulation

smoking tobacco;

cold temperatures;

certain drugs.

PAGE 4

Safety Recommendations - cont.

Avoid highly repetitive movements of the hands

and wrists, and continuous vibration exposure.

Use of this tool may produce hazardous fumes,

particles, and/or dust. To avoid adverse health

effects utilize adequate ventilation and/or a respirator. Read the material safety data sheet of any

materials involved in the tube expansion process.

This KRAIS product is designed to operate on minimum 90 psig (6.2 bar), maximum 125 psig (8.6)

air pressure. If the tool is properly sized and

applied, higher air pressure is unnecessary.

Excessive air pressure increases the loads and

stresses on the tool parts, mandrels, rolls and

cages and may result in premature wear and or

breakage. Installation of a filter-regulator-lubricator

in the air supply line ahead of the tool is required.

Before the tool is connected to the air supply,

check the throttle for proper operation (i.e., the

throttle moves freely and returns to the closed

"OFF" position when released). Clear the air hose of

accumulated dust and moisture. Be careful not to

endanger adjacent personnel. Before removing a

tool from service or changing sockets, make sure

the airline is shut off and drained of air. This will prevent the tool from operating if the throttle is accidentally engaged.

It is essential for safe operation that any operator of

OUR TOOLS uses good balance, sure footing, and

proper posture in anticipation of a torque reaction.

Ensure that the operator's hands will not be

wedged or pinched between the work and the tool

when operating.

NOTE: ANY USE OF THIS TOOL OTHER

THAN IT'S INTENDED PURPOSE COULD

CAUSE MAJOR DAMAGE TO THE TOOL AS

WELL AS POSE A RISK TO THE OPERATOR.

PAGE 5

Our tools are designed to operate at a minimum of 90 psi (6.2 bar) and a maximum of 125

psi (8.6 bar).

NOTE- using over 100 psi (6.8 bar) will cause

faster tool operation but will also lead to premature wear and or tool breakage of the expander

rolls and mandrel.

Fluctuation in air pressure has no effect on the

torque Control Unit, as this section is independent of the motor. A low air pressure situation

will result the tool operating slower, resulting in

longer rolling cycles.

LUBRICATIONS YOUR P&P K50 ALL

MODELS

We recommend that our Models P&P K50 are

Lubricator be used within our 15 ft supply line.

A quality grade S.A.E#10 or equivalent lubricating oil is recommended. With the P&P K50

motors running, set the lubricator to 5-10 drops

of oil per minute.

The gear section of your P&P K50 series' motor

is fitted with a pressure type grease fitting.

Approximately once four (4) weeks, pump two

(2) shots of grease into the unit using a hand

type grease gun.

CAUTION: DO NOT OVER LUBRICATE (see

above).

If excessive amount of grease are forced into

the gear section, the grease will ultimately work

its way into the motor section and will result in

sluggish tool operation.

Operating Instructions

To maintain efficient operation for continuous

use, these tools should be adjusted and serviced periodically. If accurate torque cannot be

maintained, check the shut-off trip as follows:

Remove two screws (80) holding valve cover

(79) in place. Remove cover to expose trip.

(During forward rotation the trip abuts valve (5A).

See page 10 for trip adjustment illustration.)

WARNING - REMOVE AIR SUPPLY FROM

TOOL PRIOR ANY DISASSEMBLY

Remove entire torque section as follows:

Remove 4 socket head cap screws (78). Using

tru-arc pliers, remove lock ring (162). Carefully

remove driving cam (61) and operating cam

(55). Care should be taken to prevent loss of the

balls contained in the units. Clean drive spindle

(52) and inspect for wear in the ball spline grooves. If spline is worn or dimpled, it should be

replaced. If spline and front bearing (47) show

no sign of wear, further disassembly of this unit

is unnecessary. Check follower (64) for excessive wear.

In reassembly, carefully position regulating

spring (54) on spring guide (46). Place operating

cam (55) on spindle, aligning grooves of the

spindle and grooves in the cam, Check condition of guide springs (58), place a spring in each

groove. Install five 5/32" (3.96mm) balls in each

groove. (Note: as these are extra precision

balls, no substitution should be made)

Place a small amount of grease on each angled

face of the operating cam, install inner ball retainer (57) and ball retainer (56). On each angled

face of the cam, place two of the larger balls

(60). Install driving cam (61). Do not dislodge the

balls from the helical faces. Install large lock

ring (62). The unit can then be handled in a normal manner.

To disassemble the motor package, hold the

end of the drive spider of the motor and pull

Service Instructions

Loading...

Loading...