Manual for

charging rectifier

type PRM1

SAFETY INSTRUCTIONS

Manual: 9-1718-A

P/n: 0001138

You must read this manual before installation, use or work on the product.

This product contains dangerous voltages that when touched can cause electric shock, burns

or death.

The product must be installed by qualified personnel and according to the installation

instructions. Service may only be performed by authorized service personnel. The equipment

housing may only be removed by authorised personnel when all power has been cut to the

equipment for at least five minutes. The protective covers and contact safety devices inside the

equipment may only be removed by authorised service personnel.

The power must always be disconnected in a safe way before starting any service/maintenance.

Warning for reverse voltage. Power is supplied from several sources.

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

2

We reserve the right to make changes to the content of this manual without prior notification.

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

3

CONTENTS

1 PRESENTATION .............................................................................................. 5

2 SAFETY INSTRUCTIONS ............................................................................... 6

3 TECHNICAL DATA ........................................................................................ 7

3.1 ELEKTRICAL DATA .............................................................................................................................. 7

3.1.1 Assortment .......................................................................................................................................... 7

3.1.2 Common electrical input data .......................................................................................................... 7

3.1.3 Common electrical output data ........................................................................................................ 7

3.1.4 Electrical data for rectifier module ................................................................................................... 8

3.2 ENVIRONMENTAL DATA .................................................................................................................. 8

3.3 MECHANICAL DATA .......................................................................................................................... 8

3.4 CONFORMITY WITH STANDARDS .................................................................................................. 9

4 FUNCTIONAL DESCRIPTION .................................................................... 10

4.1 GENERAL .............................................................................................................................................. 10

4.2 APPLICATION EXAMPLE ................................................................................................................. 10

4.3 LIKRIKTARMODULER ....................................................................................................................... 11

4.4 RACK FOR RECTIFIER MODULES AND OPERATOR PANEL ................................................... 11

4.5 TEST CONTACTS ................................................................................................................................. 11

4.6 I/O UNIT ................................................................................................................................................ 11

4.7 FUNCTIONS .......................................................................................................................................... 11

4.7.1 General ............................................................................................................................................... 11

4.7.2 Float charging ................................................................................................................................... 12

4.7.3 Equalization charging ...................................................................................................................... 12

4.7.4 Battery circuit test ............................................................................................................................. 12

5 OPERATION ................................................................................................... 13

5.1 GENERAL .............................................................................................................................................. 13

5.2 OPERATOR PANEL ............................................................................................................................. 13

5.3 RECTIFIER MODULES ........................................................................................................................ 13

5.4 MAINS SUPPLY .................................................................................................................................... 13

5.5 TEST CONTACTS ................................................................................................................................. 14

6 INSTALLATION INSTRUCTIONS ............................................................. 15

6.1 SAFETY INSTRUCTIONS ................................................................................................................... 15

6.2 GENERAL .............................................................................................................................................. 15

6.3 STORAGE AND PROTECTION ......................................................................................................... 15

6.4 MOUNTING .......................................................................................................................................... 15

6.4.1 General ............................................................................................................................................... 15

6.4.2 Rack .................................................................................................................................................... 15

6.4.2.1 I/O Unit ......................................................................................................................................... 15

6.5 ELECTRICAL INSTALLATION ......................................................................................................... 15

6.5.1 General ............................................................................................................................................... 15

6.5.2 Earthing ............................................................................................................................................. 16

6.5.3 Mains voltage .................................................................................................................................... 16

6.5.3.1 External fuse rating ..................................................................................................................... 16

6.5.3.2 Connection .................................................................................................................................... 16

6.5.4 Battery/Load ...................................................................................................................................... 16

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

4

6.5.5 Rectifier modules .............................................................................................................................. 17

6.5.6 I/O Unit .............................................................................................................................................. 17

6.5.6.1 General .......................................................................................................................................... 17

6.5.6.2 Communication cable ................................................................................................................. 17

6.5.6.3 Power supply ............................................................................................................................... 17

6.5.7 Operator panel .................................................................................................................................. 18

6.5.8 Test contacts ...................................................................................................................................... 18

7 STARTING UP ................................................................................................ 19

7.1 SAFETY INSTRUCTIONS ................................................................................................................... 19

7.2 PREPARATORY INSPECTION .......................................................................................................... 19

7.2.1 General ............................................................................................................................................... 19

7.3 POWERING UP ..................................................................................................................................... 19

7.3.1 DC ....................................................................................................................................................... 19

7.3.2 AC ....................................................................................................................................................... 19

7.4 CHECKING THE CHARGING VOLTAGE ...................................................................................... 19

7.5 CHECKING THE SETTINGS .............................................................................................................. 20

7.6 CHECKING THE OUTPUTS ............................................................................................................... 20

8 MAINTENANCE ............................................................................................ 21

8.1 ANNUAL INSPECTION...................................................................................................................... 21

8.1.1 General ............................................................................................................................................... 21

8.1.2 Checking the charging voltage ....................................................................................................... 21

8.1.3 Checking the cooling capacity ........................................................................................................ 21

9 FAULT TRACING .......................................................................................... 22

9.1 SAFETY INSTRUCTIONS ................................................................................................................... 22

9.2 FAULT TRACING FOLLOWING ALARM ....................................................................................... 22

9.3 OTHER FAULT TRACING.................................................................................................................. 22

Bilagor

A LAYOUT AND DIMENSION, PRM1

B CIRCUIT DIAGRAM, PRM1

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

1 PRESENTATION

PRM1 is a complete charge rectifier with built-in monitoring, intended for mounting in a 19”

rack.

The system is built on a modular basis for easy service and high flexibility. Its compact design

allows it to be used even in confined spaces. The clear display and well-arranged system of

menus of the monitoring unit make it easy and pleasant to work with. The rectifiers are of

“plug-in” type and can be connected in parallel to increase capacity and availability.

This description primarily deals with all installation, commissioning, service, maintenance

and technical data and is principally aimed at the personnel who are responsible for these

areas. An equivalent description of the parts of the equipment that relate to the monitoring

unit are detailed in the Manual for monitoring unit type PCM2.

Operation is handled primarily via the monitoring unit described in the Manual for monitoring

unit type PCM2. This is therefore chiefly aimed at the personnel that have the day to day

responsibility for the plant, but also to other personnel who have cause to work with the D.C.

system.

For a complete description, this manual is to be used together with the description for the

monitoring unit, Manual for monitoring unit type PCM2.

5

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

6

2 SAFETY INSTRUCTIONS

This product contains dangerous voltages that when touched can cause electric shock, burns

or death.

For safety reasons the concerned personnel are classified according to the following

requirements for specific skills.

Authorised service personnel:

• Have electrical training and adequate experience to avoid the dangers that electricity can

cause.

• Are certified to meet authority requirements for the work in question.

• Have linguistic skills that ensure that the content of this description cannot be

misunderstood.

• Have undergone a product-specific training programme for authorised service personnel

that are approved by KraftPowercon Sweden AB.

Qualified personnel:

• Have electrical training and adequate experience to avoid the dangers that electricity can

cause.

• Are certified to meet authority requirements for the work in question.

• Have linguistic skills that ensure that the content of this description cannot be

misunderstood.

Installation, service, maintenance and fault tracing may only be carried out by authorised

personnel and in accordance with the installation instructions.

The protective covers and contact safety devices inside the equipment may only be removed by

authorised service personnel.

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

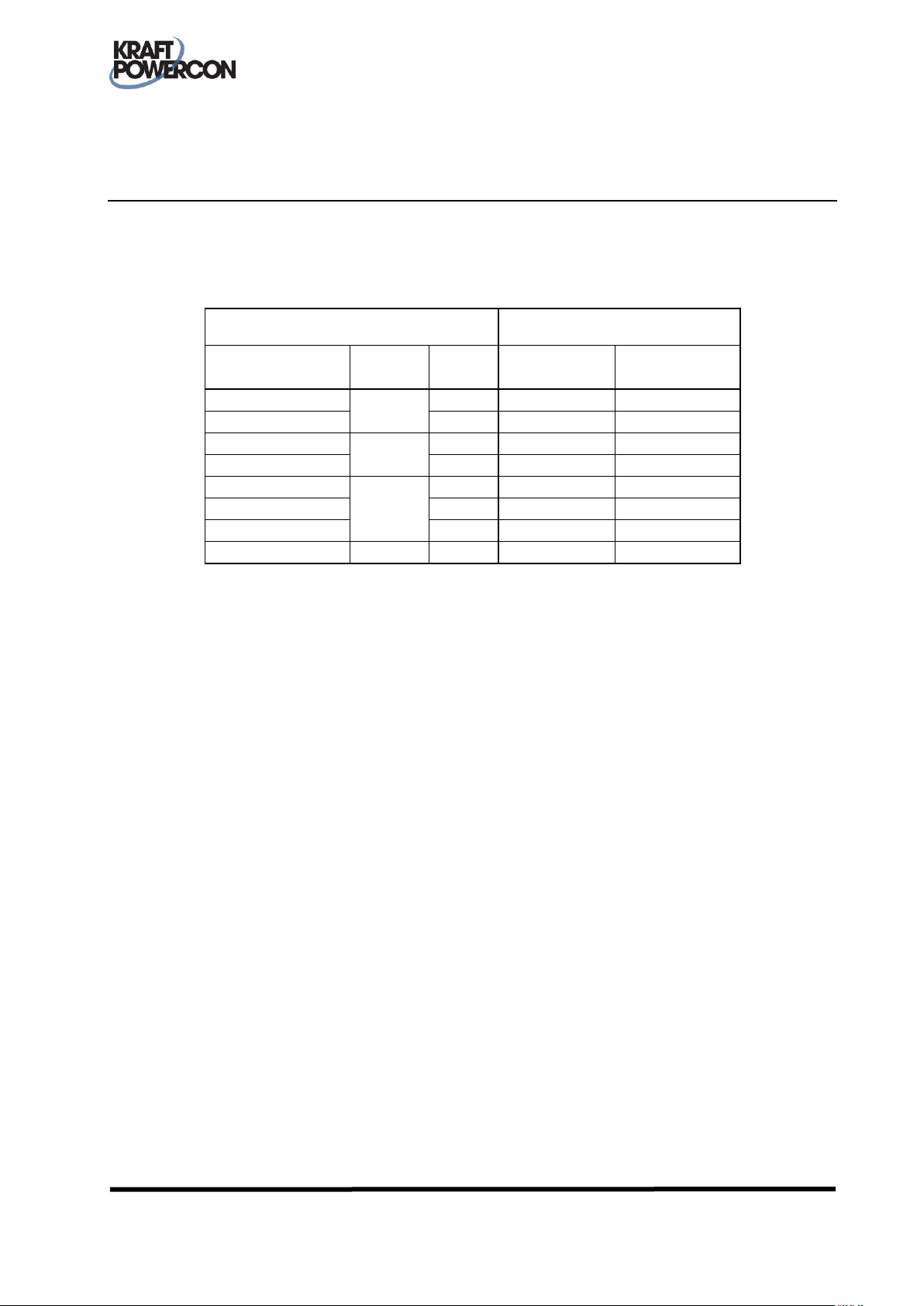

PRM1

Rectifier module

Model

designation

UNOM

IRATED

IRATED

Model

designation

(VDC)

(A)

(A)

PRM1 24/108

24

108

36

PCS 24/36

PRM1 24/210

210

70

PCS 24/70

PRM1 48/54

48

54

18

PCS 48/18

PRM1 48/150

150

50

PCS 48/50

PRM1 110/24

110

24

8

PCS 110/8

PRM1 110/48

48

16

PCS 110/16

PRM1 110/66

66

22

PCS 110/22

PRM1 220/30

220

30

10

PCS 220/10

3 TECHNICAL DATA

3.1 ELEKTRICAL DATA

3.1.1 Assortment

PRM1 can be equipped with up to three rectifier modules, depending on the model.

7

3.1.2 Common electrical input data

Rated voltage ............................................... 120*1/127*1/220/230/240 VAC 1- phase*2

Frequency ..................................................... 50/60 Hz

Power factor ................................................. > 0.99 at 230 VAC, full load

Connection ................................................... 6 mm2 screw terminal block per module

Other ............................................................. Mains switch and 2.5 m cable terminal rack included

*1

: Power derating below 190 VAC.

*2

: A single rectifier module is supplied from one phase, but several modules can each be

supplied from separate phases.

3.1.3 Common electrical output data

Voltage regulation (static) .......................... <±0.5 % of nominal output voltage

Voltage regulation (dynamic) .................... <±1 % within 3 seconds, 0-100 / 100-10 % load change

Current regulation....................................... <±1 % of rated current

Setting range, current limit ........................ 0 – 100 % of rated current

Ripple voltage .............................................. <0.1 %RMS

Ripple current .............................................. <0.1 % of rated current

Efficiency, typical ........................................ up to 92 %

Connection ................................................... For rated voltage:

24 V: 10 or 16 mm2 cable, 3 m included

48 V: 10 mm2 cable, 3 m included

110 V: 6 mm2 cable, 3 m included

220 V: 6 mm2 cable, 3 m included

*1

*1

: Depending on rectifier module

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

Model

designation,

rectifier

module

Output data

Input data

Power

loss*2

(W)

UNOM

Setting

range

IRATED

PMAX

Voltage

range

*3

Mains

power*1

Mains

current*1

(VDC)

(VDC)

(A)

(W)

(VAC)

(VA)

(Arms)

PCS 24/36

24

22 – 33

36

1000

90 - 290

1150

6

150

PCS 24/70

70

2000

90 - 290

2200

12

175

PCS 48/18

48

42 - 63

18

1000

90 - 290

1150

6

135

PCS 48/50

50

2700

90 - 290

2900

15

210

PCS 110/8

110

100 - 158

8

1000

90 - 290

1150

6

135

PCS 110/16

16

2000

90 - 290

2200

12

160

PCS 110/22

22

2700

90 - 290

2900

15

200

PCS 220/10

220

187 – 292

10

2475

90 - 290

2700

14

200

3.1.4 Electrical data for rectifier module

*1

: max at 195 VAC

*2

: typical at 230 VAC and full load

*3

: Power derating below 190 VAC.

8

3.2 ENVIRONMENTAL DATA

Class of enclosure ...................................................... IP20 as per EN 60529

Cooling........................................................................ Temperature controlled fans in rectifier

Ambient temperature (spec. data applies) ............. 0 to +40 °C

Storage temperature .................................................. -40 to +70 °C

Humidity .................................................................... <90 % RH, non-condensed

Altitude a.s.l ............................................................... <2000 m

Noise level, at 1m ...................................................... <50 dBA at 25 % last

3.3 MECHANICAL DATA

Version .....................................Rack for 19” frame

Placement ................................Indoors in dry, clean room

Mounting, rack .......................Mounted in 19” rack

Mounting, I/O-module ..........Mounted on 35 mm guide

Weight ......................................14 kg, fully equipped with 3 rectifier modules

Dimensions, rack ....................2 HU, 88.2/481.5/315 mm (h/w/d), see also dimension diagram

Dimensions, I/O-module .......117/224/66 mm (h/w/d), see also dimension diagram Appendix_A

Colour, rack .............................Colorless galvanized sheet

modules

rails or directly on

mounting plate

Appendix_A

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

3.4 CONFORMITY WITH STANDARDS

EN 60529 .............................. Encapsulation class IP20

EN 50178 .............................. LVD. Electronic equipment, including power electronics in electrical

power installations.

EN 61000-6-2 ....................... EMC. Immunity for industrial electronics

EN 61000-6-4 ....................... EMC. Emission from equipment in an industrial environment

9

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

4 FUNCTIONAL DESCRIPTION

4.1 GENERAL

PRM1 is a complete rectifier unit with

built-in monitoring, intended for

mounting in a 19” rack.

Most functions are handled by the monitoring unit and are described in the Manual for

monitoring unit PCM2. Only the functions that feature at a general rectifier level are described

here.

4.2 APPLICATION EXAMPLE

PRM1 is intended for integration in a complete DC system. An example of such is shown in the

simplified schematic below.

10

Figur 1 Applikationsexempel PRM1

1-3: Rectifier modules (T1-3), PRM1 9: I/O unit (K1), PRM1

5: Battery 10: Operator panel (P1), PRM1

6: Battery block 11: Alarm outputs

7-8: Distribution unit 12: Capacity test terminals

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

4.3 LIKRIKTARMODULER

The rectifier modules are of the “plug-in” type and can in principle be replaced during

operation. Depending on the model, up to three parallel modules can be fitted.

There are three indicator lamps on the front of the module:

AC OK - Green: Mains OK

Off: Mains power failure

WARNING -Yellow (permanent): Remote shutdown (standby) or

high temperature warning

Yellow (flashing): Communication fault

Off: Normal operation

ALARM - Off: OK

Red: Alarm (shutdown after DC overvoltage,

over temperature, fan error or internal fault)

11

4.4 RACK FOR RECTIFIER MODULES AND OPERATOR PANEL

The rack unit contains the operator panel and the rectifier modules.

The operator panel P1 is the unit used as the user interface. It is mounted modularly to the right

of the rectifier modules.

The rectifier modules (T1 – T3) are ”plug-in” modules.

4.5 TEST CONTACTS

There are short-circuit proof test contacts (X30) alongside the operator panel, for checking the

battery voltage. The test contacts accept 4 mm banana plugs.

4.6 I/O UNIT

The I/O unit contains connection terminals for the external connections required for the

monitoring unit.

4.7 FUNCTIONS

4.7.1 General

Only the most important functions are specified here. For more information, see the Manual for

monitoring unit PCM2.

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

4.7.2 Float charging

Float charging is the normal operating mode determined by the battery. The voltage level is to

be set according to the battery manufacturer’s instructions.

For more information, see the Manual for monitoring unit PCM2.

4.7.3 Equalization charging

Equalization charging means charging at an increased voltage level over a limited period. It is

used partly for the initial charge, and partly for equalizing cell voltages if spreading has

occurred.

For more information, see the Manual for monitoring unit PCM2.

WARNING! Generally, batteries of VR-type (vent regulated) should not be subject to equalization

charging. For some battery types equalization charging could even be harmful to the batteries. Always

follow the battery manufacturer’s instructions.

12

4.7.4 Battery circuit test

A battery circuit test is automatically carried out at optional intervals (normally once a day).

The test involves checking that the entire battery circuit, i.e. not only the battery block, is in

working order.

For more information, see the Manual for monitoring unit PCM2.

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

5 OPERATION

5.1 GENERAL

Most of the operation is associated with the monitoring unit. This is described in the Manual for

monitoring unit PCM2. Other operation is detailed in this section.

5.2 OPERATOR PANEL

The operator panel is the link between the equipment and the user. It is made up

of a display, a keypad and an LED. Operation is described in the Manual for

monitoring unit PCM2.

13

5.3 RECTIFIER MODULES

There are three indicator LEDs on the front of the rectifier

module with the following functions:

AC OK - Green: Mains OK

Off: Mains power failure

WARNING -Yellow (permanent): Remote shutdown (standby) or

high temperature warning

Yellow (flashing): Communication fault

Off: Normal operation

ALARM - Off: OK

Red: Alarm (shutdown after DC overvoltage,

over temperature, fan error or internal fault)

When the module gives an alarm you have the option of finding out the cause of the alarm in

detail via the operator panel menus, see the Manual for monitoring unit PCM2.

The modules are of the ”plug-in” type and can in principle be replaced during operation. For

more information, see the INSTALLATION INSTRUCTIONS section.

5.4 MAINS SUPPLY

PRM1 is supplied with a cable stump (phase, neutral, earth) per rectifier module. The rectifier

modules can therefore be supplied either from one common phase or from separate phases.

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

5.5 TEST CONTACTS

When measuring the battery voltage you should avoid measuring

directly on the battery poles, due to the risk of arcing in the event of a

possible short circuit. Instead, use the short-circuit protected test

contacts just below the operator panel.

The test contacts accept 4 mm insulated safety plugs, and also 4 mm

banana plugs. To avoid measurement errors, the voltmeter used

should have high internal resistance, 10 Mohm or better.

14

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

6 INSTALLATION INSTRUCTIONS

6.1 SAFETY INSTRUCTIONS

WARNING! This product contains dangerous voltages that when touched can cause electric shock,

burns or death. Protective earth must always be connected in a reliable way to avoid the risk of live parts

in the equipment in the event of faults. No live parts are permitted during installation. The product must

be installed by qualified personnel (see SAFETY INSTRUCTIONS section 2.)

WARNING! Check both before and after setting-up that the equipment does not have any mechanical

damage. Check that the equipment is designed for the existing rated voltage. Cables for input and output

power must be correctly dimensioned to avoid fire hazard.

6.2 GENERAL

15

Installation of parts belonging to the monitoring unit is not dealt with in this manual. For

complete installation instructions these instructions should therefore be used in combination

with the installation instructions included in the Manual for monitoring unit PCM2.

6.3 STORAGE AND PROTECTION

Storage is to be in a dry area and at a temperature within the -40 to +70 °C range.

6.4 MOUNTING

6.4.1 General

The equipment is intended for placement in a dry, clean environment that is free from

conductive dust. For EMC reasons, both rack and I/O unit must be placed within the same

metal enclosure and the supplied ferrite cores and mains filters are used as intended.

6.4.2 Rack

Mount the rack unit in a 19” rack frame. Make sure there is sufficient space for ventilation, see

Appendix A, DIMENSION DIAGRAM.

6.4.2.1 I/O Unit

The I/O unit is supplied with adapters for 35 mm guide rails. The unit can also be mounted

directly on a flat surface by removing the adapters first. Make sure that the distance between

the rack and I/O unit is sufficiently close for the supplied 2 m cable to reach.

6.5 ELECTRICAL INSTALLATION

6.5.1 General

The equipment is designed for permanent installation. Protective earth must be connected

before any other installation.

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

6.5.2 Earthing

Earth the rack using the 6 mm2 earthing wire connected to the back plane in the rack.

Earth the I/O unit via the 1.5 mm2 earthing wire connected to the unit’s cover.

6.5.3 Mains voltage

6.5.3.1 External fuse rating

The size of the external primary fuse is selected as follows:

1. Find the maximum mains current for the type of rectifier module in question from the

table in section Electrical data for rectifier module.

2. Multiply it by the number of rectifier modules.

3. Choose the next highest fuse rating.

NOTE: If you choose to feed the rectifier modules from different phases (see below), point 2

above must naturally be suitably modified.

6.5.3.2 Connection

16

Each rectifier module has its own wiring for

phase and neutral. It is therefore possible to

select between feeding the modules from

individual phases or to connect two or more

modules in parallel to the same phase. To

simplify this, the terminal blocks are fitted with

bipolar connection links that can be moved or

removed. At delivery, all mains inputs are

connected in parallel.

Note that since the PRM1 holds a maximum of

three modules, the fourth terminal is not

connected to any module.

Between the terminals is a mains filter that must be connected in order for the EMC properties

to apply.

The feeding network should be of TN-S type in order to avoid the risk of stray current.

6.5.4 Battery/Load

Check that the rectifier's rating plate shows a rated voltage that conforms with the battery's

nominal voltage.

WARNING! The rectifiers DC output has no internally fuse. Ensure that an external fuse is within the

circuit when connection against battery is performed.

Please note: Make sure to check the polarity before installation and commissioning.

Wrong polarity may cause damage to the rectifier module(s).

From DC rails on the back of the rack, the DC output cables, red for plus and blue for minus,

should be connected to a common mounting element in the battery central. For some models

with a slightly higher current, there are several cables for each pole that must then be connected

in parallel. For EMC reasons, the cables, depending on the model, are wrapped one or two turns

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

around a ferrite core. If they have to be replaced or extended, be sure to select cables that are

dimensioned to withstand the rectifier's rated current.

6.5.5 Rectifier modules

The rectifier modules are normally packed separately and are to be put in

place during the installation. The rack module slots should be equipped

with modules starting from the leftmost position and with spare slots to

the right.

The modules can in principle be replaced during operation. However, we

recommend disconnection of the mains supply first.

Loosen the two screws on the upper handle of the handle. It loosens a

handle that is angled downwards so that it can then pull out the module

from its place.

Conversely, a module is installed by gently pushing the module into

place and pushing it into the bottom. Then push the handle towards the

module and finally secure the handle with the two screws.

WARNING! Check carefully that the rectifier modules have the correct rated voltage.

17

6.5.6 I/O Unit

6.5.6.1 General

All the connections to the monitoring units are grouped in a unit called

the I/O unit. The connectors are pluggable, i.e. they can be removed for

better accessibility when installing. Only the connections that are made

between the rack unit and I/O unit via the supplied PRM1 wiring are

described here.

For other connections to the I/O unit, see Manual for monitoring unit

PCM2.

6.5.6.2 Communication cable

The supplied RJ45 cable (standard network cable) is already connected to the operator panel in

the rack at one end, the other end shall be connected to the I/O-unit connector X4. Note that

there are two physically identical connectors beside each other; X3 and X4. X4 is closest to the

short side of the unit.

6.5.6.3 Power supply

The power supply cable for the monitoring unit is supplied and is connected at one end to the

I/O-units screw terminal block X5 and is provided with a ferrite core for EMC reasons.

The second end is suitably connected to a fuse group in the battery central, cord no. 422 (from

X5:1) to minus and cable 423 (from X5:2) to plus.

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

6.5.7 Operator panel

The operator’s panel is already installed at delivery. The following

description is mainly intended for service in the future.

To loosen the operator panel, first loosen the two screws that hold

the carrier plate (see upper picture). On the back of the panel are two

cables that can now be disconnected. Then loosen the screws on the

back of the carrier plate holding the operator panel itself.

To mount the panel, the operator panel is fastened with screws from

the back of the carrier plate. Then connect the two cables. Finally,

attach the carrier plate to the rack with the two screws on the front.

6.5.8 Test contacts

The I/O unit’s connection terminal X7 has a contact for a short-circuit proof test contact, used to

measure the battery voltage. Use the enclosed cable to connect X7: 1 and X7: 6 marked 424 and

429 to the measurement terminal located just below the operator panel.

Use the enclosed cord to connect X7: 1 and X7: 6 marked 424 respectively 429 to the test contacts

located just to the right of the operator panel.

18

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

7 STARTING UP

7.1 SAFETY INSTRUCTIONS

WARNING! This product contains dangerous voltages that when touched can cause electric shock,

burns or death. All contact safety devices and plates must be fitted when operating.

7.2 PREPARATORY INSPECTION

7.2.1 General

Check that the equipment is free from damage, correctly fitted and that all the ventilation

openings are free from obstacles.

Check that all cable installations, electrical connections and protective earths are correctly

implemented.

Check that all protective covers are intact.

Check that the number of battery blocks is according to specification.

19

7.3 POWERING UP

7.3.1 DC

First connect the rectifier to the battery by, for example, connecting a fuse in the battery circuit.

Note that there is a connection current when the output capacitors of the rectifier modules are

charged. This can give rise to some sparking at the connection point.

After a few seconds, the operator panel display lights up and after a few more seconds, text

appears on the display. All measured values are initially zeroed. After about 10 seconds, the

measurements begin. Only after a total of about 30 seconds have passed, any alarms are

activated.

7.3.2 AC

Turn on mains breaker. The rectifier modules should now start up.

The battery now starts to charge, and if it was in a state of deep

discharge, the charging starts with rated current until the float charging

level is reached. Certain types of batteries require an initial equalizing

charging. Always follow the recommendations given by the battery manufacturer.

7.4 CHECKING THE CHARGING VOLTAGE

Check the settings of the monitoring unit to ensure that the voltage level for float charging and

equalizing charging conform to the battery manufacturer's specifications, see Manual for

monitoring unit PCM2.

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

When the battery is charged to a level where the ”High current” alarm is no longer active, you

should check that the actual output voltage conforms with the setting of the float charging

voltage, see section 8.1.1 Checking the charging voltage.

7.5 CHECKING THE SETTINGS

Each time the monitoring unit has been powered down, the built-in clock must be reset with the

current date and time, see the Manual for monitoring unit PCM2.

Check that the measurements on the display agree with the actual situation. Check that the

parameters for charging voltages, alarms and other parameters conform to the intended

functions, see the Manual for monitoring unit PCM2.

7.6 CHECKING THE OUTPUTS

The alarm outputs A-D and the output for fan control can be operated manually for simple and

smooth checking of external circuits, see the Manual for monitoring unit PCM2.

20

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

8 MAINTENANCE

8.1 ANNUAL INSPECTION

8.1.1 General

In addition to these instructions, you must observe the instructions for maintenance in the

Manual for monitoring unit PCM2 and the battery manufacturer's maintenance instructions.

8.1.2 Checking the charging voltage

Connect a voltmeter to the test contacts (see section Fel! Hittar inte referenskälla.).

Check that the rectifier's output voltage corresponds to the setting of the float charging level.

If the float charging voltage is temperature controlled, it is difficult to determine what the

expected output voltage should be. The solution is to temporarily shut down the temperature

control. You do this using the menu option Functions, battery temperature to specify that the

temperature sensor is not installed (see the Manual for monitoring unit PCM2, section Operation,

Functions). Do not forget If charge voltage is found to be in a state of non-conformance it is

therefore the voltage measurement that should be calibrated, see the instructions for

maintenance in the Manual for monitoring unit PCM2.to reset the parameter for the installed

temperature sensor following the completed measurement!

All control is based on measurement.

21

8.1.3 Checking the cooling capacity

Check that the rectifier modules’ ventilation vents are not clogged with dust or other

contaminants. Clean where necessary.

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

9 FAULT TRACING

9.1 SAFETY INSTRUCTIONS

WARNING! This product contains dangerous voltage that when touched can cause electric shock, burns

or death.

Service/maintenance work that involves working with removed contact protection devices may only be

carried out by authorised service personnel (see section 2 SAFETY INSTRUCTIONS).

WARNING! In the event of overvoltage, the electrolytic capacitors and varistors may explode. If work

must be done when the equipment is powered up and with exposed circuit boards, splinter protection

must therefore be used (protective goggles and screens).

9.2 FAULT TRACING FOLLOWING ALARM

22

Fault tracing in connection with alarm messages is described in the Manual for monitoring unit

PCM2.

9.3 OTHER FAULT TRACING

The type of faults that can be attributed to the rectifier in general are dealt with here. For faults

that relate to the monitoring unit see the Manual for monitoring unit PCM2.

The primary fuse trips when the rectifier is turned on

Cause 1: Incorrect type of mains fuse. Check that the mains fuse observes the specifications in

section 6.5.3 External fuse rating.

Cause 2: Internal rectifier module fault. Install one module at a time in order to identify the

module that is responsible for the problem. Replace the defective module.

The rectifier has no output, green indicator lamp “AC OK” is out

Cause 1: Mains voltage missing. Check that there is mains voltage to the mains input

terminals and that the mains breaker is closed.

Cause 2: Rectifier modules are not properly inserted.

The rectifier has no output, green indicator lamp ”AC OK” is lit, yellow indicator lamp

”WARNING” is lit and red indicator lamp ”ALARM” is off

Cause 1: Input ”EXT. FAULT” is used as external blocking and is in open state.

Cause 2: The rectifier module has been switched off due to overtemperature. Check that the

rectifier modules´ ventilation vents are not clogged with dust or other contaminants.

Clean where necessary. Check that the ambient temperature is within permitted

limits.

The rectifier has no output, green indicator lamp ”AC OK” is lit, yellow indicator lamp

”WARNING” and red indicator lamp ”ALARM” are off

Cause 1: Output fuses has tripped. Check that the output fuses are properly dimensioned to

handle the rectifier's rated current.

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

23

The rectifier module’s green indicator lamp ”AC OK” and red indicator lamp ”ALARM” are

lit

Cause 1: The rectifier module has been switched off due to overtemperature. Check that the

rectifier modules´ ventilation vents are not clogged with dust or other contaminants.

Clean where necessary. Check that the ambient temperature is within permitted

limits.

Cause 2: The rectifier module has been switched off due to fan error in the module. Replace

the fan or the entire rectifier module.

Cause 3: The rectifier module has been tripped by high output voltage, HVSD (High Voltage

Shut Down).Reset by removing power to the module, most simply by extracting the

module for a few seconds until all lamps are off, and then re-inserting it again. If the

fault reoccurs, the module may be faulty. Replace the rectifier module.

Cause 4: Other internal fault in the rectifier module. Replace the rectifier module.

The rectifier module's red indicator lamp “ALM” is lit

Cause 1: Unless the cause is obvious, e.g. see the alternatives above, you can show the status

of the rectifier module in detail via the display on the monitoring unit, see the

Manual for monitoring unit PCM2.

The rectifier output voltage is too low

Cause 1: The rectifier load is above its capacity (rated current). This is normal in connection

with recharging following deep discharge.

Cause 2: Battery circuit test in progress. This is a test that is normally executed automatically

once a day.

Cause 3: The requested charging voltage is close to or above the level of the parameter

Umaximum. The voltage will be limited 1% below this level. If higher voltage is desired,

the setting of the parameter Umaximum must be increased., see the Manual for monitoring

unit PCM2.

Cause 4: High temperature in the battery/battery compartment. Only applicable if the rectifier

controls the temperature of the float charging voltage. There is no fault with the

rectifier in this case. Look for the fault in the high temperature instead. Alternatively

the temperature sensor could be defective. Check whether the display is reporting

the correct battery temperature.

Cause 5: Incorrectly set float charging voltage level. Adjust the setting.

Cause 6: Incorrectly calibrated voltage measurement. Recalibrate the monitoring unit's

measurement of battery voltage.

The rectifier output voltage is too high

Cause 1: Equalizing charging in progress. This has either been initiated manually or

automatically following a power failure.

Cause 2: Low temperature in the battery/battery compartment. Only applicable if the rectifier

controls the temperature of the float charging voltage. There is no fault with the

rectifier in this case. Look for the fault in the low temperature instead. Alternatively

the temperature sensor could be defective. Check whether the display is reporting

the correct battery temperature.

Cause 3: Incorrectly set float charging voltage level. Adjust the setting.

Cause 4: Incorrectly calibrated voltage measurement. Recalibrate the monitoring unit's

measurement of battery voltage.

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

Date

Sign

Revision

Rev.

Drawing No.

This page

Date

Approved

Drawn

Design

Rev

F

E

D

C

B

A

1

2

3

4

5

6

7

8

Next page

Document type

ALARM

PCM2

OK

-Q1

-X11

[L]

-X11

[N]

-R1

Charging rectifier system type PRM1

for rectifier modules type PCS

2018-02-20

12062

A

MP

MP

1

-

Layout drawing

PRM1

KeBe

224

117

46

66*

* When mounted on

NS 35/7,5 bar

I/O unit, front view

I/O unit, side view

76.2

88.2

465

481.5

Rectifier subrack, front view

Rectifier subrack, side view

315

Air flow

Front

80

Minimum free

space for air flow

Mains breaker and terminals

Appendix A

LAYOUT AND DIMENSION, PRM1

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

Appendix B

CIRCUIT DIAGRAM, PRM1

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

Loading...

Loading...